Page 1

1 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies Corporation

CDX-135Z

Wireless Smoke/CO Detector with Heat and

Freeze Sensor Installation Manual

Attention: Please take a few minutes to thoroughly read this guide which should be

saved for future reference.

The CDX-135Z wireless smoke and carbon monoxide detector with heat and freeze

sensor is compatible with the following Interlogix learn mode panels: Simon®XT, Simon

XTI, Concord®4 (firmware version 4.7 or higher), Advisor®One and UltraSync

Description

The Interlogix CDX-135Z supervised photoelectric smoke and carbon monoxide (CO)

detector with heat and freeze sensors is a self-diagnostic Learn Mode wireless sensor

with wireless interconnection, 10-yr sealed battery and sensor life, built-in sounder,

diagnostic/status LED, integrated fixed temperature and rate-of-rise heat sensor and a

pre-freeze condition sensor.

The CDX-135Z uses a 319.5MHz transmitter for communication to the control panel

and a 915MHz transmitter for interconnection communication between networked

detectors. Up to 24 detectors can be a part of the same interconnected network. The

dual transmitter design ensures interconnection integrity is maintained independent of

control panel status. Because of this unique design the CDX-135Z is multi listed to UL

217, UL268, UL2034 and UL2075 requirements.

The combination alarm combines the detection capabilities of a photoelectric sensor

with that of an electrochemical sensor, which is used to detect CO. The highly accurate

electrochemical CO sensor uses sophisticated onboard microprocessor to effectively

Page 2

2 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies Corporation

track CO level over time. The detector has a test feature that allows for testing with real

CO gas.

The CDX-135Z uses a 10-year sealed-in lithium battery ensuring continuous operation

over the 10 year life of the detector. This eliminates worry about battery removal or

unauthorized deactivation of alarm. The self-activation feature activates the detector

when attached to the mounting bracket. At the end of detector life, the unit will chirp

and send communication back to control panel, indicating the detector is in need of

replacement.

WARNING: After ten years from initial power up, this alarm will beep two times

every 30 seconds to indicate that it is time to replace the detector. Replace the alarm

immediately. It will not detect CO in this condition.

To help identify the date to replace the unit, a label has been affixed to the side of the

alarm. Write the "Install date" in the space provided, and then write in the "Replace by"

date (10 years from initial power up) in permanent marker on the label prior to installing

the unit.

Two labels have been provided at the back of this installation manual that have

important information on what to do in case of a CO alarm. Place one label next to the

alarm after it is mounted, and one near a fresh air source such as a door or window.

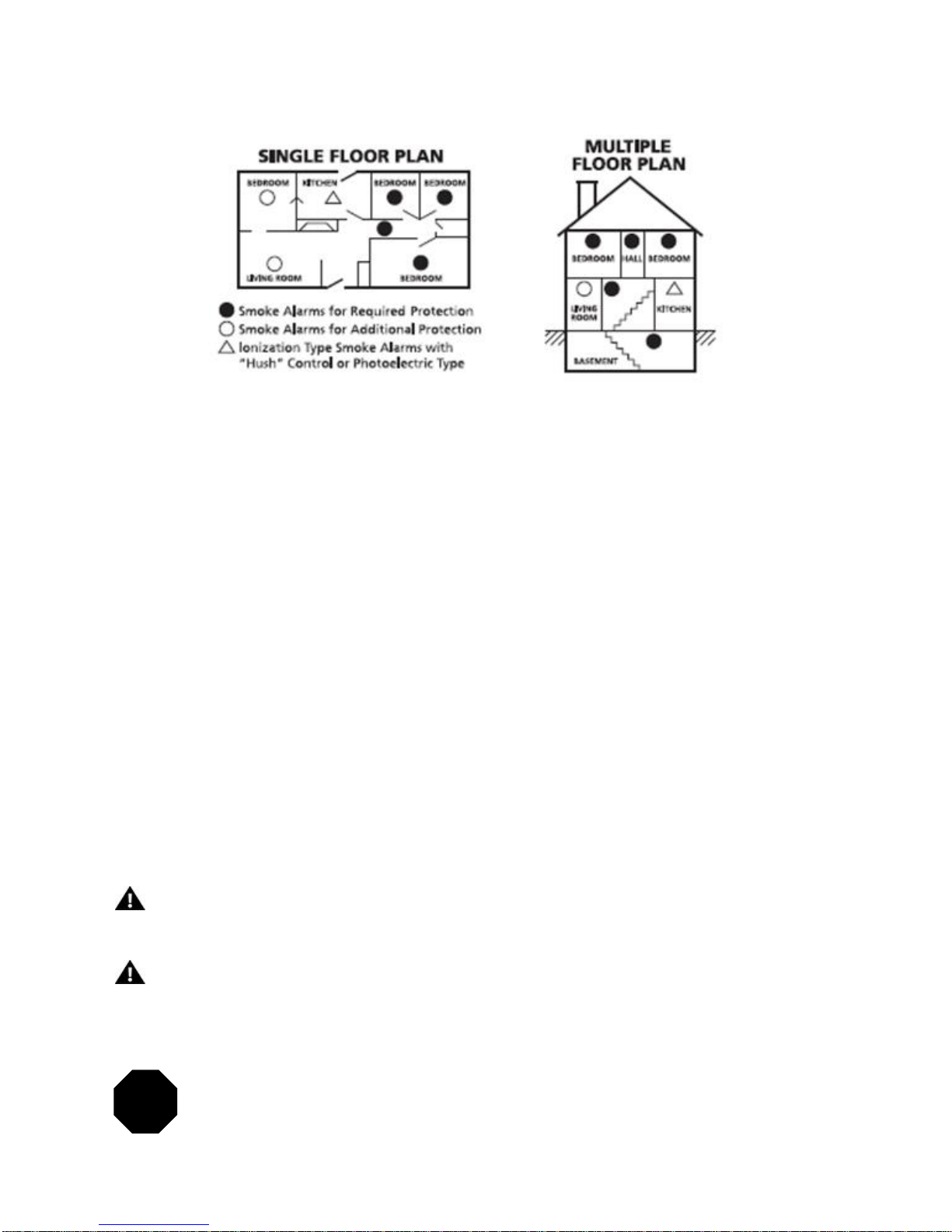

Recommended Locations for Detectors

• Locate detectors in all sleeping areas. Try to monitor the exit path as the bedrooms

are usually farthest from the exit. If more than one sleeping area exists, locate

additional detectors in each sleeping area.

• Locate additional detectors to monitor any stairway as stairways act like chimneys

for smoke and heat.

• Locate at least one detector on every floor level.

• Locate a detector in every bedroom.

• When mounting a detector on the ceiling, locate it at a minimum of 4” (10 cm) from

the side wall.

• When mounting the detector on the wall, use an inside wall with the top edge of the

alarm at a minimum of 4” (10 cm) and a maximum of 12” (30.5 cm) below the

ceiling.

Page 3

3 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies Corporation

Figure 1

Figure 2

Locations to Avoid

• In the garage. Products of combustion are present when you start your automobile.

• Normal cooking may cause nuisance alarms. If a kitchen detector is desired, it

should have an alarm silence feature or be a photoelectric type.

• In an area where the temperature may fall below 32ºF (0C) or rise above 100ºF

(37.8C), such as garages and unfinished attics.

• Detectors should not be installed within 3 ft (.9m) of the door to a bathroom

containing a tub or shower, forced air supply ducts used for heating or cooling,

ceiling or whole house ventilating fans, or other high air flow areas.

• Do not install near vents, flues, chimneys or any forced/unforced air ventilation

openings.

• Do not install near fans, doors, windows or areas directly exposed to the weather.

This model is powered by a non-replaceable, long life sealed lithium battery system,

and includes SMART HUSHTM control to temporarily silence nuisance alarms.

INSTALLATION / ACTIVATION / ENROLLMENT

WARNING: THIS DETECTOR SHOULD BE INSTALLED BY A CERTIFIED

TECHNICIAN.

WARNING: FAILURE TO PROPERLY INSTALL AND ACTIVATE THIS

DETECTOR WILL PREVENT PROPER OPERATION AND RESPONSE TO

HAZARDS.

If you are installing detectors and will use the wireless interconnect function,

proceed to the next section "WIRELESS INTERCONNECT". If you are not

using the wireless interconnect function, then proceed with the following two

steps.

STOP

Page 4

4 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies Corporation

1. After selecting the proper location for the detector, attach the mounting bracket

(trim plate) to the wall or ceiling. To ensure aesthetic alignment of the detector with

the hallway, or wall, the "A" line on the mounting bracket (trim plate) must be

parallel with the hallway when ceiling mounted, or horizontal when wall mounted.

2. Install the detector fully on the mounting bracket (trim plate) by rotating the

detector in a clockwise direction.

NOTE: Installing the detector on the mounting bracket (trim plate) will automatically

activate the battery. The power up sequence is indicated by the LED ring slowly

blinking GREEN one time.

NOTE: Detectors will emit a series of slow RED LED blinks as the unit searches

for a wireless network. If you are intending to use the detectors without the

wireless interconnect function, ignore these notifications, and the wireless

interconnect function will eventually turn off (~15 minutes OR to immediately close

the network, push the Test/Hush button until two beeps are heard (approximately 4

seconds) and then release the button.

• Network closed sound on each detector confirms network has been

closed. GREEN LED flashes once every 60 seconds to indicate normal

operation.

NOTE: The battery activation is a one-time feature. After activation, the battery

cannot be turned off, and can only be discharged at the end of unit life. If the

detector is removed from the mounting plate, the battery will remain active. See

Permanently Disable Detector / Discharge Battery section to de-energize the

detector.

WIRELESS INTERCONNECT

A maximum of 24 compatible devices may be interconnected in a multiple station

arrangement. The interconnect system should not exceed the NFPA interconnect limit

of 12 smoke detectors and/or 18 detectors total (smoke, CO, smoke/CO combination,

heat, etc.).

WIRELESS INTERCONNECT MODEL COMPATIBILITY

The following Interlogix model can be interconnected using wireless interconnect:

• SDX-135Z

• Maximum distance between wireless interconnect models is 300 feet in open air.

Set up a Wireless Detector Network (Wireless Interconnect)

Creating a wireless interconnect network is a simple process, with intelligent “selfenrollment” features.

1. Remove all wireless detectors from their packaging (suggest using a table and

activating all detectors in a group).

Page 5

5 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies Corporation

2. Power on all detectors by attaching the detectors onto the mounting bracket (trim

plate) to activate the battery, or by carefully turning the activation wheel with a

screwdriver. See Figure 3.

Figure 3

• The GREEN LED will fade on and off once, then the RED LED will begin

fading on/off every 3 seconds.

NOTE: If no further steps are taken within 15 minutes of initial power up, the

wireless function will turn off. The unit will then perform as a standard single station

detector.

NOTE: At any time during wireless setup, if you have a problem, reset the unit's

wireless settings as described in section “Resetting a Detector’s Wireless Settings”

3. Push and hold the Test/Hush button on any one detector until two beeps are heard

(approximately 4 seconds) and then release the button. This detector will

automatically create a new wireless network.

• A brief series of quick GREEN LED blinks will occur and then the GREEN LED

will fade on/off every second on the button-pushed detector (network creator).

4. Wait for the other wireless detectors to join the wireless network.

• A brief series of quick GREEN LED blinks will occur and then the GREEN LED

will fade on/off approximately every 3 seconds.

NOTE: At this point, you can push/release the test button once on any detector,

and the RED LED will flash the number of enrolled detectors.

5. Wait for the network setup to timeout (approximately 15 minutes), OR to

immediately close the network, push the Test/Hush button until two beeps are

heard (approximately 4 seconds) and then release the button.

• Network closed sound on each detector confirms network has been closed.

GREEN LED flashes once every 60 seconds to indicate normal operation.

6. After selecting the proper location for your detector, attach the mounting bracket to

the wall or ceiling. To ensure aesthetic alignment of the detector with the hallway,

Page 6

6 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies Corporation

or wall, the "A" line on the mounting bracket must be parallel with the hallway when

ceiling mounted, or horizontal when wall mounted.

• Install the detector fully on the mounting bracket (trim plate) by rotating the

detector in a clockwise direction. NOTE: The detector will mount to the bracket

in 4 positions (every 90 degrees).

7. The detector is now activated. After installation / activation, test your alarm as

described in Operation and Testing section.

Adding Detectors to an Existing Wireless Interconnected Network

For various reasons, you might want to add additional detectors to your existing

wireless interconnection network.

1. Remove the new detector from its packaging.

2. Place and hold a magnet for four seconds on the cover of an existing detector in

the network at the designated location per figure 4. The detector will beep once

when the magnet is detected, then the detector will beep twice and the button will

start flashing the RED LED rapidly to indicate the proper mode has been entered

to reset the wireless interconnect settings.

3. Push and hold the test button on any existing detector until two beeps are heard

(approximately four seconds), and then release the button.

• The button-pushed detector will cause the GREEN LED to fade on/off on each

existing detector to signal that the wireless interconnection network has been

opened.

NOTE: From this point, you have fifteen (15) minutes to power up the new

detector.

3. Power up the new wireless unit by twisting the detector onto the mounting bracket

(trim plate) to activate the battery, or by carefully turning the activation wheel with a

screwdriver. See Figure 3.

• The new unit's RED LED will fade on/off every three seconds as it searches

for the network.

• A slow GREEN LED fading on/off confirms the new unit has found and joined

the existing wireless interconnection network.

4. Wait fifteen (15) minutes for the network setup to timeout, OR to immediately close

the network, push and hold the test button until two beeps are heard

(approximately four seconds), and then release the button.

• GREEN LED flashes once every 60 seconds on the new detector to indicate

normal operation.

5. After selecting the proper location for your detector, attach the mounting bracket to

the wall or ceiling. To ensure aesthetic alignment of the detector with the hallway,

or wall, the "A" line on the mounting bracket must be parallel with the hallway when

ceiling mounted or horizontal when wall mounted.

Page 7

7 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies Corporation

• Install the detector fully on the mounting bracket (trim plate) by rotating the

detector in a clockwise direction. NOTE: The detector will mount to the bracket

in four positions (every 90 degrees).

6. The detector is now activated. After installation / activation, test your alarm as

described in Operation and Testing section.

Resetting a Detector’s Wireless Interconnect Settings

If you experience a delay or problem during wireless interconnection setup, you might

need to start over as if the detector is first removed from its packaging. Also, this "outof-box" mode can be used to attempt to reset/clear a network error condition.

1. Place and hold a magnet for 4 seconds on the cover at the designated location per

Figure 4. The detector will chirp once when the magnet is detected, then the

detector will chirp twice and the button will start flashing the RED LED rapidly to

indicate the proper mode has been entered to reset the wireless settings.

Figure 4

2. Press and hold the Test/Hush button for approximately eight seconds while the

RED LED is rapidly flashing. After four seconds, two beeps will occur (do not

release the button). After eight seconds, three beeps will occur. The button can

now be released.

3. Observe two cycles of RED LED on/off, one cycle of GREEN LED on/off

4. The RED LED will begin fading on/off every three seconds.

5. If no further steps are taken within 15 minutes of resetting the detector to "Out-ofBox" mode, the RED LED will fade on/off for approximately 30-40 seconds, and the

interconnect function will turn off. The detector will then perform as a standard

standalone alarm.

Page 8

8 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies Corporation

Enrolling a Detector with a Panel

The following section provides a general guideline for programming (enrolling) the unit

into control panel memory. Refer to the panel documentation for complete

programming details.

1. Set the control panel to into installer programming mode

2. When requested to broadcast a signal from the detector to the panel, remove the

detector from the mounting bracket (trim plate). A tamper message will be

transmitted for smoke, CO, and freeze devices.

3. After waiting approximately 1 minute, reinstall the detector on the mounting bracket

(trim plate). The unit will start chirping rapidly if not re-installed on the trim plate

after 3 minutes.

4. Exit from installer programming mode

NOTE: Each enrollment type (smoke, CO and Freeze) is programmed with a unique

TX ID when manufactured. Labels included on the outside and inside of the packaging

provide these IDs. The unique ID is enrolled into the control panel at the time of

installation. Use these IDs where appropriate in the specific panel being used

enrollment instructions.

Verify programming and unit-to-panel communication

Before mounting, verify that the desired unit location provides good RF communication

to the panel.

To verify programming and RF communication

1. Put the panel into Dealer Sensor Test mode (refer to the specific panel installation

instructions)

2. Take the detector to the desired mounting location.

3. Press and release the Test button. A quick beep will confirm the button has been

pushed.

4. Listen for the appropriate response from system sirens to determine signal integrity

from the unit to the panel (refer to the specific panel installation instructions)

5. Exit from Dealer Sensor Test mode.

Operation and Testing

OPERATION

The smoke alarm takes precedence when both smoke and carbon monoxide are

present.

Smoke/heat alarm pattern is three long beeps, 1.5 seconds pause, three long

beeps, repeating

Page 9

9 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies Corporation

Carbon monoxide alarm pattern is four quick beeps repeating every 5 seconds

WARNING: CARBON MONOXIDE ALARM ACTIVATION INDICATES THE

PRESENCE OF CARBON MONOXIDE (CO) AT HIGH CONCENTRATIONS WHICH

CAN KILL YOU.

If the CO condition that caused the alarm in the first place continues, the initiating alarm

unit will reactivate in alarm mode. If the unit goes into alarm mode again within six

minutes, it is sensing high levels of CO which can quickly become a dangerous

situation.

If the CO alarm reactivates within a 24 hour period, call a qualified appliance technician

to investigate sources of CO from fuel burning equipment and appliances, and to

inspect for proper operation of equipment.

If problems are identified during this inspection, have the equipment serviced

immediately. Note any combustion equipment not inspected by the technician and

consult the manufacturer’s instructions, or contact the manufacturer directly for more

information about CO safety and the equipment. Make sure that motor vehicles are not,

or have not been, operating in a garage attached or adjacent to the residence.

The detector is operating once it is activated and testing is complete. When products of

combustion (smoke or CO) are sensed, the unit sounds a loud 85dB alarm. See

Detector Visual and Audible Indicators table. In high levels of CO, the unit will go into

alarm in a shorter period of time than at low levels of CO.

The CO sensor meets the alarm response time as follows:

At 70 PPM, the unit must alarm within 60-240 minutes.

At 150 PPM, the unit must alarm within 10-50 minutes.

At 400 PPM, the unit must alarm within 4-15 minutes.

TESTING (PUSH TO TEST BUTTON)

Test your detector every three months by pressing and releasing the test button

quickly. A quick beep will confirm the button has been pushed.

See Detector Visual and Audible Indicators table. The alarm will sound if the electronic

circuitry, horn, speaker, and battery are working. If the alarm does not sound, the

detector must be replaced.

WARNING: DUE TO THE LOUDNESS (85+ DECIBELS) OF THE ALARM,

ALWAYS STAND AN ARM’S LENGTH (ABOUT 2.5 FT. (0.7M) AWAY FROM THE

UNIT OR USE EAR PROTECTION WHEN TESTING.

Weekly testing is required to ensure proper operation. Erratic or low volume sound (or

no sound) coming from your detector may indicate a defective alarm and it should be

Page 10

10 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

returned for service. See Permanently Disable Detector/Discharge Battery section to

determine how to prepare the unit for shipment or disposal.

WARNING: DO NOT USE AN OPEN FLAME TO TEST YOUR DETECTOR.

YOU COULD DAMAGE THE DETECTOR OR IGNITE COMBUSTIBLE MATERIALS

AND START A STRUCTURE FIRE.

FUNCTIONAL SMOKE TEST

The smoke test verifies that the unit activates when detecting smoke, that the

transmitted signal is received by the receiver/panel, and that the panel reports the

alarm to the central monitoring station. The smoke test should be performed annually.

A canned smoke testing agent must be used for the functional smoke test

NOTE: Use Interlogix brand of Smoke! In A Can part number SM-200.

1. Wait at least 90 seconds after installation to test the smoke detector.

2. Make sure the GREEN LED is flashing for normal operation (one GREEN LED

blink every 60 seconds).

3. From a distance of 2 - 4 feet (0.6 – 1.2m), aim spray for 1 – 2 seconds at the vents

or side of the detector.

4. The alarm will sound within 1 – 10 seconds if the detector functions properly.

5. Press the Test/Hush button to quiet the sounder.

6. Contact the central monitoring station to verify they received the alarm report.

7. Alert the central monitoring station when you are finished testing.

NOTE: An alternative method for performing a functional smoke test in the field is to

hold a smoldering punk or cotton wick close to the detector and direct the smoke into

the vent openings until an alarm is indicated.

CO INSPECTION AND FUNCTIONAL GAS TEST

A canned CO testing agent must be used for the CO functional gas test. Contact a local

supplier for canned CO gas – Solo C6

TM

CO Detector Tester.

NOTE: Cans of Solo C6TM CO Detector Tester can be sourced from the manufacturer

per the following contact information:

Product Code: Solo C6-024

SDi, 1345 Campus Parkway, Suite A18, Wall Township, NJ 07753 USA

Tel: (732) 751-9266, Fax: (732) 751-9241

Email: sales@sdifire.com, Web: www.sdifire.com

1. Wait at least 20 minutes after installation to test the CO detector.

Page 11

11 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

2. Make sure the GREEN LED is flashing for normal operation (one GREEN LED

blink every 60 seconds).

3. Set the control panel to sensor test mode

4. To expedite testing, by-pass the CO accumulator circuit by placing the detector in

“System Test Mode”. Start System Test mode by placing magnet next to reed

switch (Figure 4) and hold it for four seconds until unit chirps twice and the RED

LED begins blinking rapidly.

5. Remove the magnet away from the reed switch.

6. Within 10 second after the magnet is removed press and release Test Button then

within 2 seconds:

7. Press and hold the Test/Hush button until the unit beeps three times

(approximately 8 seconds), and then release the button. The unit will enter the

functional CO Gas test mode within 5 seconds. The GREEN LED will blink

periodically (1 second rate) indicating that the alarm is in functional test mode.

8. Apply UL approved CO test agent to the testing port (Figure 5). When CO is

detected, the unit will activate a CO alarm.

Figure 5

9. To exit functional gas test mode:

a. Press and release the Test button or wait for a two minute timeout.

b. The alarm will reset and then return to normal operating mode.

10. At the control panel, exit sensor test mode.

SMOKE/CO DETECTOR MEMORY

If a detector experiences a smoke or CO alarm event, and then stops alarming, the unit

will give a visual (LED) indicator that a previous alarm has occurred within the last hour.

See the Detector Visual and Audible Indicators table.

Page 12

12 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

AMBIENT LIGHT SENSING

In low light ambient conditions, the GREEN LED will reduce in brightness and intensity.

This detector samples the ambient light conditions of its location and, if possible,

determines a Night/Day cycle. A valid Night/Day cycle will delay the conditions that

require that the detector be replaced (Low Battery or end of Unit Life) or Network Error

chirps at night until the next Day cycle begins. Once the unit goes into End of Unit Life

or Network Error, the chirps can only be silenced by pressing the Test/Hush button.

After 7 days of End of Unit Life chirps, the chirps can no longer be silenced by pressing

the Test/Hush button. Low Battery chirps cannot be silenced. See Troubleshooting

Guide.

WARNING: REPLACE DETECTOR AS SOON AS POSSIBLE WHEN AN END

OF UNIT LIFE OR LOW BATTERY MODE.

If the detector cannot determine a valid Night/Day cycle because the detector is located

in either a constantly dark or lighted location, Low Battery, End of Unit Life, and

Network Error chirps will not be inhibited. If the unit is moved to a location that is not

constantly dark or lighted, it will determine a Night/Day cycle because the unit

continuously samples ambient light conditions.

Detector Visual and Audible Indicators

Operational Mode

Visual Indication

Audible

Indication

Action:

Normal Operation

One GREEN LED

blink every 60

seconds.

None

None

Carbon Monoxide

(CO) Alarm

On all alarming

detectors, the

RED LED blinks

per a Temporal

T4 Pattern

Temporal T4

alarm pattern is

alarm pattern is

four quick blinks

repeating every 5

seconds

On the detector

initiating the CO

Alarm only, the

GREEN LED will

blink every

second.

Alarm per

Temporal T4

Pattern

Temporal T4

alarm pattern is

four quick beeps

repeating every 5

seconds.

Carbon Monoxide has been

detected. Follow the

instructions at the beginning of

this User Guide under the

section "What to do when the

alarm sounds, CO alarm

activation"

Page 13

13 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

Operational Mode

Visual Indication

Audible

Indication

Action:

Smoke/Heat (Fire)

Alarm

On all alarming

detectors, the

RED LED blinks

per a Temporal

T3 Pattern

Temporal T3

alarm pattern is

three long blinks,

1.5 second pause,

three long blinks,

repeating.

On the detector

initiating the

Smoke/Heat

Alarm only, the

GREEN LED will

blink every

second.

Alarm per

Temporal T3

Pattern

Temporal T3

alarm pattern is

three long beeps,

1.5 second pause,

three long beeps,

repeating.

Smoke/fire has been detected.

Follow the instructions at the

beginning of this User Guide

under the section "What to do

when the alarm sounds,

Smoke/Heat alarm activation"

Freeze Warning

One RED LED

blink every 20

seconds.

None

None. Flashing continues

while condition exists.

Tamper Condition

One RED LED

blink every 30

seconds.

Detector chirps

once when

tamper condition

is first sensed,

then the detector

will chirp every 30

seconds after a 3

minute delay.

Reattach detector to its trim

plate, otherwise flashing and

chirping will continue while

condition exists.

Fault Mode/Fatal

Error

One AMBER LED

blink every 5

seconds.

Detector chirps

every 30 seconds.

Flashing/chirping continues

while condition exists.

Remove detector from service.

If fatal error cannot be cleared,

permanently discharge and

decommission the detector.

System Test Mode

Rapidly flashing

RED LED for 10

seconds duration

1 detector chirp

when magnet

detected, 2

detector chirps

when System

Test mode

enabled

Hold magnet next to button for

4 seconds as described in

User Guide.

Local Detector Test

(button press when

no alarm condition

is present)

Flashes RED,

AMBER, GREEN,

then current

protocol

Temporal T3 and

T4 patterns

Allow completion of test or

perform button press to cancel

before end of countdown return to normal operation

Page 14

14 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

Operational Mode

Visual Indication

Audible

Indication

Action:

System Detector

Test (button press

in System Mode

when no alarm

condition is

present)

Flashes RED,

AMBER, GREEN,

then current

protocol on each

detector in the

network

Temporal T3 and

T4 patterns

Allow completion of test or

perform button press to cancel

before end of countdown return to normal operation

Smoke/Heat or CO

Alarm Memory

(detector has

experienced an

alarm event within

the last hour)

Alternating

flashing RED and

AMBER LEDs. 1

second RED/1

second AMBER/8

seconds OFF,

repeating for 1hour

None

Press test button to clear

alarm memory, or allow 1 hour

time out to return to normal

operation. Note - pressing the

test button will

Alarm Nuisance and Hush

This detector is designed to minimize nuisance alarms. Cigarette smoke will not

normally cause the unit to alarm, unless the smoke is blown directly into the detector.

Combustion particles from cooking may set off the alarm if it is located too close to a

cooking appliance. Large quantities of combustible particles are generated from spills

or when broiling. Using the fan on a range hood which vents to the outside (nonrecirculating type) will also help prevent nuisance alarms from occurring by removing

these combustible products from the kitchen.

If the source of a smoke alarm (3 long beeps) is immediately known, you can use the

Hush feature to silence the alarm for approximately 8 - 10 minutes. If no fire is present,

check to see if one of the reasons listed in "Locations to avoid" may have caused the

alarm. If a fire is discovered, get out and call the fire department.

SMART HUSHTM CONTROL AND LOCATE FEATURE

HUSH

The SMART HUSHTM control is extremely useful in a kitchen area or other area prone

to nuisance alarms. The SMART HUSHTM feature has the capability of temporarily

desensitizing the detectors(s) for approximately 8 - 10 minutes. This feature is to be

used only when a known alarm condition, such as smoke from cooking, activates an

alarm. Pushing the Test/Hush button on any initiating detector (GREEN LED flashing

every second), will silence that unit if smoke is not too dense. (In an interconnected

system, all compatible units will also silence.) The smoke alarm will automatically reset

after approximately 8-10 minutes and sound the alarm if particles of combustion are still

present.

Page 15

15 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

LOCATE

This wireless model includes a feature to help you locate the initiating detector(s) in a

wireless interconnect system. During a known smoke alarm event, pushing the

Test/Hush button on any non-initiating detector will silence ALL wireless units EXCEPT

the initiating detectors(s) for two minutes.

After two minutes, all units will resume interconnect alarm if the initiating detector has

not been located and silenced.

NOTE: Depending on detector locations and the location of the smoke source, it is

possible for more than one detector to detect the smoke source and become an

"initiating" alarm unit.

WARNING: THE LOCATE FEATURE CAN BE USED FOR CO ALARM EVENTS

ALSO, BUT IT IS IMPOSSIBLE TO DETERMINE THE SOURCE OF A CO ALARM

USING SIGHT OR SMELL. ALWAYS CONSIDER A CO ALARM EVENT AS

DANGEROUS, AND REMEMBER TO FOLLOW THE STEPS OUTLINED IN THIS

INSTALLATION MANUAL, "WHAT TO DO WHEN THE ALARM SOUNDS, CO

ALARM ACTIVATION".

NOTE: Hush and Locate features are dependent on the type of models enrolled in the

wireless interconnect system. Non-wireless models cannot be enrolled in the wireless

interconnect system and therefore cannot receive the wireless Locate feature; they will

continue to alarm until the initiating unit is Hushed or the Smoke/CO condition clears.

NOTE: The SMART HUSHTM feature and Locate feature can be used repeatedly until

the air has been cleared of the condition causing the alarm.

NOTE: Dense smoke will override the SMART HUSHTM feature and sound a

continuous alarm.

Caution: Before using the alarm SMART HUSH

TM

feature, identify the source

of the smoke and be certain safe conditions exist.

Battery

NOTE: This detector is powered by a non-replaceable, sealed lithium battery system.

No battery installation or replacement is necessary for the life of the detector.

NOTE: Constant exposure to high or low humidity or temperatures may reduce battery

life.

WARNING: DO NOT ATTEMPT TO OPEN THE DETECTOR FOR ANY

REASON! DO NOT TRY TO REPAIR THE DETECTOR YOURSELF. NO

SERVICEABLE PARTS INCLUDED.

Page 16

16 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

LOW BATTERY

This detector is equipped with a low battery monitor circuit. If the battery capacity can

no longer provide adequate power for all alarm functions, the low battery condition will

occur. See Troubleshooting Guide.

The detector battery must be discharged and the detector must be replaced within 7

days of the first occurrence of the “Low Battery Warning” to provide continuous alarm

protection. Reference the "Permanently Disable Detector/Discharge Battery" section

below for battery discharging instructions.

Permanently Disable Detector/Discharge Battery

WARNING: DISCHARGING THE DETECTOR BATTERY IS PERMANENT.

ONCE THE DETECTOR BATTERY HAS BEEN DISCHARGED, IT CANNOT BE

REACTIVATED!

ONCE DISCHARGED, THE DETECTOR WILL NO LONGER DETECT

SMOKE OR CO.

ONCE THE DETECTOR BATTERY IS DISCHARGED, THE BATTERY IS

DEPLETED AND THE ALARM WILL NO LONGER FUNCTION.

ONCE THE DETECTOR BATTERY HAS BEEN DISCHARGED, THE

DETECTOR CANNOT BE MOUNTED ONTO THE MOUNTING PLATE OR

REACTIVATED.

WARNING: FAILURE TO DISCHARGE ALARM BATTERY AS INSTRUCTED

PRIOR TO DISPOSAL MAY CREATE POTENTIAL FOR LITHIUM BATTERY

RELATED FIRE OR HAZARD.

To Permanently Disable Detector / Discharge Battery:

1. Rotate the detector counterclockwise to remove it from the mounting plate.

2. Push in the dashed area with a screwdriver to break tab.

Page 17

17 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

Figure 6

3. After the tab is broken, use the screwdriver to turn the slotted arrow to the

"Permanently Disable Detector/Discharge Battery" location. This will disable the

detector, stop the low battery or end of unit life “chirps” and render the detector

safe for disposal by draining the battery. Reference FIGURE 6.

Troubleshooting Guide

Trouble Condition

Visual Indication

Audible

Indication

Action:

Fault Mode/Fatal

Error

One AMBER LED

blink every 5

seconds.

Detector chirps

every 30 seconds.

1. Push the Test/Hush button

once to attempt to reset the

detector.

The RED LED will blink out an

Error Code (number of blinks)

when the Test/Hush button is

pushed/released once. Report

the number of blinks to

Customer Service, if needed.

2. Clean your detector. See

Section 12, "Cleaning Your

Detector" for instructions.

Network Error

One AMBER LED

blink every 5

seconds.

Detector chirps

every 30 seconds.

1. Push the Test/Hush button

once to silence the audible

indication for 24 hours at a

time.

The RED LED will blink out an

Error Code (number fo blinks)

when the Test/Hush button is

pushed/released once. Report

the number of blinks to

Customer Service, if needed.

2. Following instructions in

Section 4.3, "Resetting a

Detector’s Wireless Settings",

then attempt to rejoin the

network by following the

instructions in Section 4.2,

"Adding Another Detector to

an Existing Wireless Network

Between Detectors (Wireless

Interconnect)".

*If the error persists, remove,

discharge, and replace the

detector as soon as possible.

Page 18

18 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

Trouble Condition

Visual Indication

Audible

Indication

Action:

Low Battery

One AMBER LED

blink every 5

seconds.

Detector chirps

every 60 seconds.

1. Push the Test/Hush button

once to silence the audible

indication for 24 hours at a

time.

Remove, discharge, then

dispose of detector. Replace

as soon as possible.

End of Detector Life

One AMBER LED

blink every 5

seconds.

Double detector

chirp every 30

seconds.

The RED LED will blink out an

Error Code of 9 blinks. Start of

EOL will be delayed if Night

Detect is active.

Hush (for Low

Battery, Network

Error, End of Life)

One AMBER LED

blink every 5

seconds.

Chirp temporarily

silenced for 24

hours.

Push the Test/Hush button to

initiate Hush.

Sensor Cleanliness

Level (Clean-Me

Indication)

AMBER LED

Clean-Me blink

sequnce after

TESTING (PUSH

TO TEST

BUTTON)

temporal pattern

per Section 5,

"Operation and

Testing"

None

1. Push the Test/Hush button

to initiate detector test.

Following the temporal

patterns, the AMBER LED will

blink the cleanliness status of

the detector:

0-1: Unserviceable fault;

remove, discharge, and

replace the detector.

2-3: Insensitive; requires

cleaning per Section 12,

"Cleaning Your Detector"

4-7: Normal Sensitivity

8-9: Too sensitive, requires

cleaning per Section 12,

"Cleaning Your Detector".

Alarm Fault - # of LED Blinks (short duration blinks)

CO Sensor Test - 2

CO Sensor Short - 4

CO Calibration - 6

Push to Test - 7

Memory - 8

Life Expiration - 9

Smoke Chamber - 10

Interconnect Supervision - 13

Smoke Drift Compensation - 14

Wireless Faults - # of LED Blinks (long duration blinks)

Fault Coordinator - 2

Fault RFD - 3

CCI Supervision - 4

RFD Check In - 5

RFD Time Sync - 6

Page 19

19 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

General Carbon Monoxide (CO) Information

Carbon monoxide (CO) is a colorless, odorless, and tasteless poison gas that can be

fatal when inhaled. CO inhibits the blood's capacity to carry oxygen.

POSSIBLE SOURCES OF CARBON MONOXIDE

Inside your home, appliances used for heating and cooking are the most likely sources

of CO. Vehicles running in attached garages can also produce dangerous levels of CO.

CO can be produced when burning any fossil fuel: gasoline, diesel, propane, natural

gas, oil and wood. It can be produced by any fuel-burning appliance that is

malfunctioning, improperly installed, or not ventilated correctly, such as:

Furnaces/boilers, gas ranges/stoves, gas clothes dryers, water heaters, portable fuel

burning space heaters, fireplaces, wood-burning stoves and certain swimming pool

heaters. Blocked chimneys or flues, back drafting and changes in air pressure,

corroded or disconnected vent pipes, or a loose or cracked furnace heat exchanger can

also release CO into your building. Vehicles and other combustion engines running in

an attached garage and using a charcoal/gas grill or hibachi in an enclosed area are all

possible sources of CO.

The following conditions can result in transient CO situations:

Excessive spillage or reverse venting of fuel-burning appliances caused by outdoor

ambient conditions such as: Wind direction and/or velocity, including high gusts of wind,

heavy air in the vent pipes (cold/humid air with extended periods between cycles),

negative pressure differential resulting from the use of exhaust fans, simultaneous

operation of several fuel-burning appliances competing for limited internal air, vent pipe

connections vibrating loose from clothes dryers, furnaces/boilers, or water heaters,

obstructions in, or unconventional, vent pipe designs which can amplify the above

situations, extended operation of unvented fuel-burning devices (range, oven, fireplace,

etc.), temperature inversions which can trap exhaust gases near the ground, car idling

in an open or closed attached garage, or near a home.

CO SAFETY TIPS

Every year, have the heating system, vents, chimney and flue inspected and cleaned

by a qualified technician. Always install appliances according to manufacturer’s

instructions and adhere to local building codes. Most appliances should be installed by

professionals and inspected after installation. Regularly examine vents and chimneys

for improper connections, visible rust, or stains, and check for cracks in furnace heat

exchangers. Verify that the color of flame is blue on pilot lights and burners. A AMBER

or orange flame is a sign that the fuel is not burning completely and may be releasing

CO. Teach all household members what the alarm sounds like and how to respond.

Fire Departments, most utility companies and HVAC contractors will perform CO

inspections, some may charge for this service. It’s advisable to inquire about any

applicable fees prior to having the service performed. Interlogix will not pay for, or

reimburse the owner or user of this product, for any repair or dispatch calls related to

the alarm sounding.

Page 20

20 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

SYMPTOMS OF CO POISONING

Initial carbon monoxide poisoning symptoms are similar to the flu with no fever and can

include dizziness, severe headaches, nausea, vomiting and disorientation. Everyone is

susceptible but experts agree that unborn babies, pregnant women, senior citizens and

people with heart or respiratory problems are especially vulnerable. If symptoms of

carbon monoxide poisoning are experienced seek medical attention immediately. CO

poisoning can be determined by a carboxyhemoglobin test.

The following symptoms are related to CARBON MONOXIDE POISONING and should

be discussed with ALL members of the household:

1. Mild Exposure: Slight headache, nausea, vomiting, fatigue (often described as

“Flu-like” symptoms).

2. Medium Exposure: Severe throbbing headache, drowsiness, confusion, fast heart

rate.

3. Extreme Exposure: Unconsciousness, convulsions, cardio respiratory failure and

death.

The above levels of exposure relate to healthy adults. Levels differ for those at high

risk. Exposure to high levels of carbon monoxide can be fatal or cause permanent

damage and disabilities. Many cases of reported carbon monoxide poisoning indicate

that while victims are aware they are not feeling well, they become so disoriented they

are unable to save themselves by either exiting the building, or calling for assistance.

Also, young children and household pets may be the first affected. Familiarization with

the effects of each level is important.

Cleaning Your Detector

YOUR DETECTOR SHOULD BE CLEANED AT LEAST ONCE A YEAR

You can clean the detector by using a vacuum cleaner hose and vacuuming through

the openings around the perimeter of the detector. The outside of the detector can be

wiped with a damp cloth. Use only water to dampen the cloth, use of detergents or

cleaners could damage the detector.

If the detector is in fault mode and the RED LED is blinking a fault code of 10 flashes

(after a Test/Hush button push), the detector may be in need of cleaning. After

cleaning, press the Test/Hush button. If the fault does not clear, the alarm needs to be

replaced.

• Never use detergent or other solvents to clean the detector.

• Avoid spraying air freshener, hair spray, or other aerosols near the detector.

• Do not paint the detector. Paint will seal the vents and interfere with the sensor’s

ability to detect smoke and CO.

Page 21

21 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

• Never attempt to disassemble the detector to clean inside. This action will void

your warranty.

• The following substances can affect the CO sensor and may cause false readings

and damage to the sensor: Methane, propane, isobutane, iso-propanol, ethyl

acetate, hydrogen sulfide, sulfide dioxides, alcohol based products, paints, thinner,

solvents, adhesives, hair spray, after shave, perfume, and some cleaning agents.

• Move the detector and place in another location prior to performing any of the

following:

- Staining or stripping wood floors or furniture

- Painting

- Wall papering

- Using adhesives

Storing the detector in a plastic bag during any of the above projects will protect the

sensors from damage. When household cleaning supplies or similar contaminates are

used, the area must be well ventilated.

WARNING: REINSTALL THE DETECTOR AS SOON AS POSSIBLE TO

ASSURE CONTINUOUS PROTECTION.

Good Safety Habits

NFPA (NATIONAL FIRE PROTECTION ASSOCIATION)

The National Fire Protection Association’s Standard 72, reads as follows:

Where required by other governing laws, codes, or standards for a specific type of

occupancy, approved single and multiple-station smoke alarms shall be installed as

follows:

(1) In all sleeping rooms and guest rooms

(2) Outside of each separate dwelling unit sleeping area, within 21 ft (6.4 m) of any

door to a sleeping room, with the distance measured along a path of travel

(3) On every level of a dwelling unit, including basements

(4) On every level of a residential board and care occupancy (small facility), including

basements and excluding crawl spaces and unfinished attics

(5) In the living area(s) of a guest suite

(6) In the living area(s) of a residential board and care occupancy (small facility)

SMOKE DETECTION – ARE MORE SMOKE DETECTORS DESIREABLE?

The required number of smoke detectors might not provide reliable early warning

protection for those areas separated by a door from the areas protected by the required

smoke alarms. For this reason, it is recommended that the householder consider the

use of additional smoke detectors for those areas for increased protection. The

Page 22

22 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

additional areas include the basement, bedrooms, dining room, furnace room, utility

room, and hallways not protected by the required smoke detectors. The installation of

smoke detectors in attics (finished or unfinished), garages, or within 6’ of a heating or

cooking appliance is not normally recommended, as these locations occasionally

experience conditions that can result in improper operation.

CALIFORNIA STATE FIRE MARSHALL

Early warning fire detection is best achieved by the installation of fire detection

equipment in all rooms and areas of the household as follows: A smoke detector

installed in each separate sleeping area (in the vicinity, but outside the bedrooms), heat

or smoke detectors in the living rooms, dining rooms, bedrooms, kitchens, hallways,

attics, furnace rooms, closets, utility and storage rooms, basements and attached

garages.

WARNING: ANY CHANGES OR MODIFICATIONS MADE TO THIS PRODUCT

NOT EXPRESSLY AUTHORIZED BY THE MANUFACTURER COULD VOID THE

USER’S RIGHT TO OPERATE THIS DEVICE.

CONTACT INFORMATION

For contact information, visit us online at www.interlogix.com.

For technical support, see www.interlogix.com/support

COPYRIGHT

Copyright © 2017 United Technologies Corporation. All rights reserved.

TRADEMARKS

Interlogix is a registered trademark of United Technologies Corporation. Interlogix is part

of UTC Climate, Controls & Security, a unit of United Technologies Corporation.

PLACED ON THE MARKET BY:

UTC Fire & Security Americas Corporation, Inc.

3211 Progress Drive, Lincolnton, NC, 28092, USA

Made in China

Page 23

23 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

Specifications

Power

3V DC non-replaceable sealed lithium

batteries

Smoke sensor

Photoelectric

CO sensor

Electrochemical

Temperature sensor

NTC Thermistor

Battery life

10 years

Detector life

10 years

Audible alarm

Smoke/heat

CO

85dB at 10’ @ 3.2±0.5 KHz pulsing alarm

Temporal T3 pattern

Temporal T4 pattern

Dimensions

Ø 5.6 ± 0.01in. x 2.3 ± 0.04in.

(Ø142.3 ± 0.3mm x 59.0 ± 1.0mm)

Smoke Sensitivity

0.97 to 3.67 %/ft. obscuration

CO Alarm Response

Time

70 PPM: 60 – 240 minutes

150 PPM: 10 – 50 minutes

400 PPM: 4 – 15 minutes

Rate-of-Rise (ROR)

heat detection

15°F/min (8.3C/min) monitoring above 85°F

(29.4C)

Fixed temperature heat

detection

135°F (57.2C) ± 5°F (2.8C)

Freeze warning

41°F (5C) ± 5°F (2.8C)

Storage temperature

-4 to 140oF (-20 to 60C)

Operating environment

Temperature

Relative humidity

32 to 100oF (0 to 37.8C)

0 to 95% noncondensing

Regulatory

Listings

UL217, UL268, UL2034, UL2075 CAN/ULCS531, CSFM, FCC, IC

Page 24

24 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

Product Ordering

Model

Description

CDX-135Z

Wireless Interconnected Combination Smoke and Carbon

Monoxide Detector with Heat and Freeze Sensor, Sounder, UL

217, UL 268, UL 2034, UL 2075, ULC S531

Accessories

SM-200

Smoke! In A Can (canned smoke) for functional testing of smoke

detectors

SM-EXT1

Extension tube for Smoke! In A Can

Regulatory Information

This device complies with FCC Part 15 and Industry Canada license exempt RSS

standard(s). Operation is subject to the following two conditions: (1) this device may not

cause interference, and (2) this device must accept any interference, including

interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux

appareils radio exempts de licence. L'exploitation est autorisée aux deux conditions

suivantes: (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de

l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d'en compromettre le fonctionnement.

RF EXPOSURE

All transmitters regulated by IC must comply with RF exposure requirements listed in

RSS-102 - Radio Frequency (RF) Exposure Compliance of Radiocommunication

Apparatus (All Frequency Bands). Currently this device is approved for use for when 20

cm can be maintained between the antenna and users. Specific Absorption Rate

(SAR) evaluation is required if the separation distance between the user and/or

bystander and the antenna and/or radiating element of the device is less than or equal

to 20 cm. Exceptions are listed in RSS-102. Note that integration < 20 cm will require

further certification with IC such as a Multiple listing and Class IV Permissive Change

application.

Tous les émetteurs régulés par Industrie Canada doivent ętre conformes à la notice

RSS-102 d'Industrie Canada concernant la Conformité des appareils de

radiocommunication aux limites d'exposition humaine aux radiofréquences (toutes

bandes de fréquences). Ce produit est ainsi approuvé pour une utilisation d'au moins

20 cm entre l'antenne et toute personne à proximité. Une évaluation du Débit

d'Absorption Spécifique (DAS) est requise si cette distance de séparation est inférieure

ou égale à 20 cm. Des exceptions sont toutefois répertoriés dans la notice RSS-102.

Mais il est souligné que l'utilisation d'un dispositif à moins de 20 cm nécessite une

Page 25

25 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

certification supplémentaire avec Industrie Canada, comme un complément

d'information et l'application à la notice de Changement Permissif de Classe IV.

If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by UTC Fire and Security could void

the user’s authority to operate the equipment.

FCC: SAK25609702

IC: 7145A-25609702

Page 26

26 P/N 466-5307 • REV A • ISS 15MAR17 ©2017 United Technologies

Corporation

Alarm Procedure

For questions concerning this

detector

please contact Product

Support at 1-855-286-8889. Our internet address is

www.interlogix.com/support.

For your

convenience,

write down the following

information. If you call

Product

Support, these are the first

questions

you will be asked.

Alarm

Model Number:

(located on back of detector)

Date

Code:

(located on back of

detector)

The National Fire Protection Association

(NFPA)

and the manufacturer recommend replacing

this

alarm ten years from the date code.

Date of Purchase:

Where Purchased:

WHAT TO DO WHEN THE ALARM SOUNDS

Smoke/heat alarm pattern is three long

beeps, 1.5 second pause, three long beeps,

repeating.

Carbon monoxide (CO) alarm pattern is four

quick beeps repeating every 5 seconds.

Loading...

Loading...