Page 1

Glassbreak

5150 Series

Sensors

Shock Sensors

Sentrol On-the-Glass Shoc k Sensors

❒ 5150–W ❒ 5150–M

X

❒ 5150C–W ❒ 5150C–M

Quantity 5

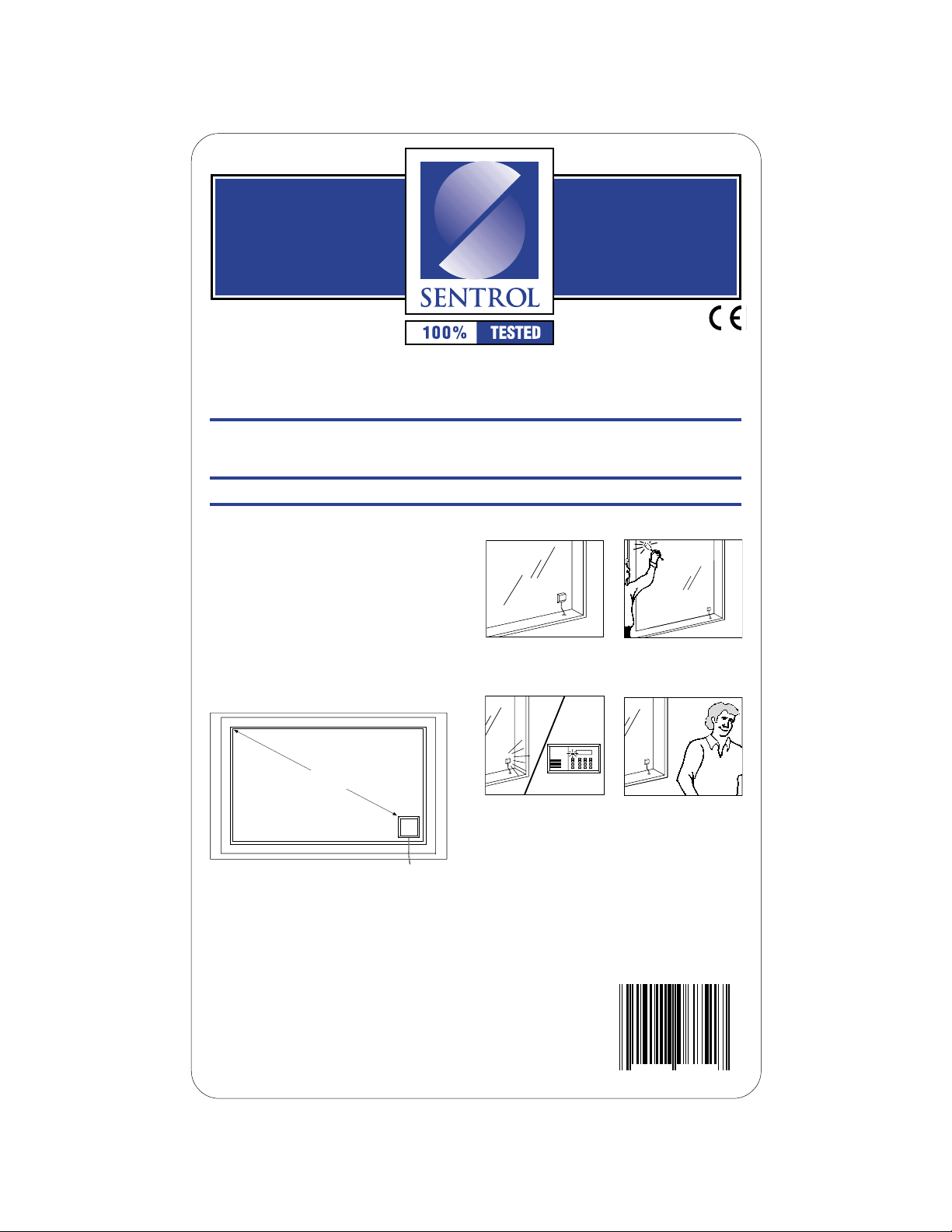

Easy Installation and Range Verification

• Mount directly on the glass

• Two wire, self powered, solid state

• Easy mounting with specially

formulated 3M™ adhesive tape

Applications

The 5150 is rated for all types of glass, without

adjustment. The sensor is rated for plate, wired,

tempered and laminated glass up to 1/4".

Mount sensor 1" from the

frame

Strike far opposite

corner of glass with

screwdriver handle

10'

Maximum Coverage

Shock sensors are intrusion detection devices

designed to detect a glass break big enough to

reach, crawl, or walk through. Shock sensors aren’t

rated to detect cracks, bullet holes and other small

holes, removing windows, or entry via glass cutting

without breakage. All Glassbreak sensors should be

Protected under patent 4,745,398 re. 33,807 and other patents

SENTROL , inc

503-692-4052

From U.S. and Canada: 800-547-2556

Sensor trips at panel or

keypad verifying range

for entire glass area

backed up by interior protection.

Laminated Glass will reduce the specified range.

Test carefully to ensure maximum detection. Armor

coated glass and plexiglass will reduce specified

range by 50%, from a 10' radius to a 5' radius.

This shock sensor is self powered and therefore will

not effect battery life for wireless transmitters.

Walk away with confidence

5150-W

0

46188 06851

7

Page 2

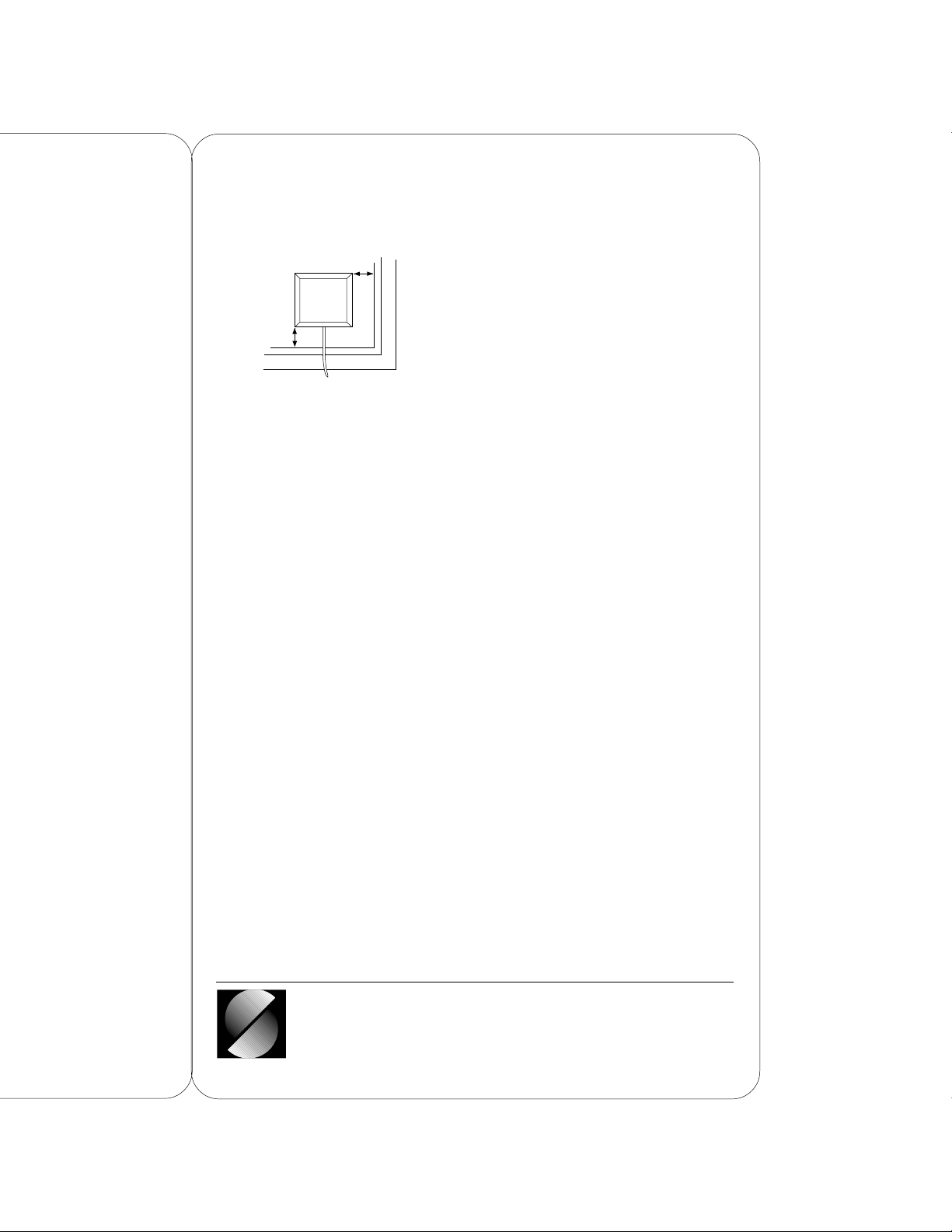

Step 1 — Mounting

To maximize range, mount the 5150 Series shock

sensor approximately 1" out from any side of the

frame.

1"

1"

Sensors mount with industrial grade acrylic tape

specifically formulated to resist the effects of

sunlight and extreme temperature changes after

application.

For best adhesion:

• Glass must be clean and dry. With a clean

cloth, apply a 50/50 solution of isopropyl

alcohol and water to remove residue.

• The ideal mounting temperature is 70° to

100°F (21° to 38°C). Application at glass

temperatures below 50°F (10°C) is not

recommended because the adhesive may

become too firm to adhere readily. Once the

tape is applied, however, low temperatures

do not effect bonding.

• Bond strength depends on how much

surface contact develops. Press the sensor

firmly to the glass. Firm application pressure

develops better adhesion and thus improves

the bond.

Step 2 — Wiring

The 5150 is a two wire device. It draws no power

from the loop. The sensor generates its own power

by converting the shock energy of the break into

electricity using a piezo transducer.

All 5150 Series shock sensors are non-polarity

sensitive. The alarm output operates without respect

to polarity and wires directly into the closed loop.

When wiring multiple sensors in series, be aware

that resistance is additive. The value of the end-ofline resistor may have to be adjusted when a large

quantity of sensors are in series. Sentrol

recommends a maximum of 10 sensors in series.

The 5150 does not require a processor. Do not wire

the sensor into fast response loops—false alarms

will result.

Step 3 — Testing

The 5150 sensor is tested by rapping the glass with

the handle of a large screwdriver. Test at likely

points of attack — near door and window latches

and the lower points where it can be kicked in. This

is an accurate test of the sensor since the energy

output from a glass break is typically at least 50%

more that the energy output from the hardest rap

test. In Sentrol’s experience, a screwdriver handle

rap provides an excellent test of sensor operation

with little risk of damaging the glass.

Connect an ohmmeter across the sensor leads.

Resistance is typically 14 ohms (13–24 ohms is

acceptable and within specification). Resistance

should increase to one Meg ohm as the sensor is

tripped from the shock generated by the rap. Hold

there for 1 to 10 seconds.

To ensure proper operation and detection, test the

sensor at least once a year.

Specifications

Resistance: Typical (normally closed) .......................................................................... 24 ohms maximum

Alarm (open) ......................................................................................... 1 Meg ohm minimum

Time open on alarm .................................................................................... 1–10 seconds (5 sec. Nominal)

Maximum loop voltage .................................................................................................................... 15 V DC

Maximum loop current ...................................................................................................................... 15 mA

Power consumption .............................................................................................. Self-generating on alarm

Lightning suppression ............................................................................................ 400 W for 1 msec pulse

Temperature ....................................................................................................... 0° to 120°F (-18° to 50°C)

Sensitivity ................................................................................................................................... Factory set

Mounting method .................................................................................................. Field proven acrylic tape

Size .................................................................................................................... 1.25" W x 1.25" L x 0.37" D

Lead ..................................................................................................................... 22 gauge, 2 wire zip cord

Colors .................................................................................................................... White, Mahogany brown

SENTROL, inc

corporate headquarters

12345 SW Leveton Dr., Tualatin, OR 97062

Tel.: 503.692.4052 Fax: 503.691.7566

http://www.sentrol.com

U.S. & Canada: 800.547.2556

Technical Service: 800.648.7424

Faxback: 800.483.2495

Sentrol, Inc. reserves the right to change

specifications without notice.

©

1996 Sentrol, Inc.

G-2718-01096

13462 Rev B

Loading...

Loading...