Model 94x, 97x Proximity Reader

Installation Manual

Copyright Copyright © 2008, GE Security Inc. All rights reserved.

This document may not be copied or otherwise reproduced, in whole or in part,

except as specifically permitted under US and international copyright law,

without the prior written consent from GE.

Document number/460157001P (January 2008).

Disclaimer THE INFORMATION IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT

Trademarks

and patents

Intended use Use this product only for the purpose it was designed for; refer to the data sheet

compliance

Regulatory

NOTICE. GE ASSUMES NO RESPONSIBILITY FOR INACCURACIES OR OMISSIONS

AND SPECIFICALLY DISCLAIMS ANY LIABILITIES, LOSSES, OR RISKS, PERSONAL OR

OTHERWISE, INCURRED AS A CONSEQUENCE, DIRECTLY OR INDIRECTLY, OF THE

USE OR APPLICATION OF ANY OF THE CONTENTS OF THIS DOCUMENT. FOR THE

LATEST DOCUMENTATION, CONTACT YOUR LOCAL SUPPLIER OR VISIT US ONLINE

AT WWW.GESECURITY.COM.

This publication may contain examples of screen captures and reports used in

daily operations. Examples may include fictitious names of individuals and

companies. Any similarity to names and addresses of actual businesses or

persons is entirely coincidental.

GE and the GE monogram are registered trademarks of General Electric.

Model 94x/97x Proximity Reader product and logo are trademarks of

GE Security.

Other trade names used in this document may be trademarks or registered

trademarks of the manufacturers or vendors of the respective products.

and user documentation. For the latest product information, contact your local

supplier or visit us online at www.gesecurity.com.

FCC

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio communications.

You are cautioned that any changes or modifications not expressly approved

by the party responsible for compliance could void the user's authority to

operate the equipment .

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Radio interference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Electrostatic discharge (ESD) precaution. . . . . . . . . . . . . . . . . . . . . . . . .2

Product features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mounting the reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Back-to-back readers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

External tamper feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mounting diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Configuring the reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Switch settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Selecting reader power level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Selecting operating mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Selecting beeper sound level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Connecting the reader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Wiring diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Testing the reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Troubleshooting the reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

All installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Unsupervised modes only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Supervised modes only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Regulatory approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

UL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

CE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

i

Model 94x/97x Proximity Reader

ii

Installation Manual

Figures

Figure 1. Recommended Additional Mounting Instructions

Figure 2. Model 940 Reader - Gang Box Mounting.........................12

Figure 3. Model 940 Reader - Direct Wall Mounting.......................13

Figure 4. Model 941 Reader - Gang Box Mounting.........................14

Figure 5. Model 941 Reader - Direct Wall Mounting.......................15

Figure 6. Model 970/972 Reader - Gang Box Mounting...............16

Figure 7. Model 970/972 Reader - Direct Wall Mounting.............17

Figure 8. Model 971/973 Reader - Gang Box Mounting...............18

Figure 9. Model 971/973 Reader - Direct Wall Mounting.............19

Figure 10. Model 94x/97x Reader, J1 Connector and DIP

Figure 11. (PCB Assembly P/N 100079001 manufactured |

Figure 12. Wiring Diagram, Model 94x/97x

Figure 13. Wiring Diagram, Model 94x/97x

Figure 14. Wiring Diagram, Model 94x/97x

Figure 15. Typical Installation (Internal to the microcontroller)

Figure 16. Typical Installation (External to the microcontroller)

for External Tamper Switch Activation..............................11

Switch Locations (PCB Assembly P/N 100079002

manufactured 12/02 or later)................................................22

prior to 12/02)................................................................................23

Supervised F/2F Mode...............................................................30

Unsupervised F/2F Mode.........................................................32

Unsupervised Wiegand Mode ..............................................34

Using Shielded Cable/Drain Wire......................................... 46

Using Shielded Cable/Drain Wire......................................... 46

Introduction 1

Introduction

This manual is an installation guide for the GE Models 940, 941,

970, 971, 972, and 973 proximi ty rea ders. Thr oughout this g uide,

the abbreviation 94x represents reader models 940 and 941. The

abbreviation 97x represents reader models 970, 971, 972, and

973.

The 94x and 97x readers while similar in functionality offer a

variety of features making them suitable for different

applications. The 94x and 97x readers are designed to mount on

standard U.S. gang boxes. The 94x readers are single-gang box

size. The 97x readers are sized for larger dual gang box

installation, offer greater badge read range, and a keypad option.

Models 940 and 970 give t he greatest all-around b adge read rang e

for their respective sizes, making th em ideal for most

installations.

Models 941 and 971 are tuned for ins ta ll at ion on meta l mounting

plates. The standar d metal mounti ng plate shie lds t he re ader from

the effects of a metal wall, which would otherwise dramatically

reduce the read ra nge. The opt ional back- to-ba ck me tal mounting

plate shields the reade r from the ef fects of a metal wall and makes

the reader unidirectional; ideal for direct back-to-back reader

installations.

Models 972 and 973 are dual gang size readers, identical to the

970 and 971 respective ly, except f or their built-i n twelve-po sition

keypad. This feature makes these readers ideal for installations

requiring keypad PIN entry in addition to a valid badge read.

Model 94x/97x Proximity Reader

2

Installation Manual

Safety

Radio interference

WARNING: This is an FCC Class A product. In a domestic

environment, this product may cause radio

interference, in which case, the user may be

required to take adequate measures.

Electrostatic discharge (ESD) precaution

WARNING: Circuit board components are vulnerable to damage

by electrostatic discharge (ESD). ESD can cause

immediate or subtle damage to sensitive electronic

parts. An electrostatic charge can build up on the

human body and then discharge when you touch a

board. A discharge can be produced when walking

across a carpet and touching a board, for example.

Before handling any board, make sure you dissipate

your body’s charge by touching ground. This

discharges any static electricity build-up.

Product features 3

Product features

The GE Model 94x/97x Reader offers:

• Intelligent bidirectional communication between the

reader and microcontroller, which can be accomplished

up to 5,500 feet.

TM

• The ability to read all I SO ProxLite

Entrée badges and key tags.

• Field changeable DIP switches allow all 94x and 97x

readers to operate in one of four distinct operating

modes: Wiegand (4001), F/2F, Supervised, and Silent

Supervised.

• Rugged, weather-resistant, molded ABS construction

with integral backplate.

• Standard 12V operation.

• A clear, logical user interface with three LEDs and a

switch selectable beeper with volume control.

• Built-in tamper alarm also detects removal from wall.

• External tamper alarm option.

• Tactile keypad (Models 972 and 973 only) for Personal

Identification Number (PIN) input.

, ProxLite, and

Model 94x/97x Proximity Reader

4

Installation Manual

System requirements

Host software

Microcontrollers • Micro/2

Microcontroller

firmware

Badge and keytag

formats

• Secure Perfect

•Picture Perfect

•Micro/4

•Micro/5-PX with 2RP or 8RP

• Micro/5-PXN with 2RP or 8RP

• M5PXNplus with 2RP or 8RP

• Micro/PX-2000

• Micro/PXN-2000

• M2000PXNplus

• M3000PXNplus with 2RP or 8RP

• For Micro/2 and Micro/4:

Secure Perfect: Version 5 or later

Picture Perfect: Version 1.7.0 or later

• For Micro/5-PX, Micro/5-PXN, Micro/PX-2000

and Micro/PXN-2000:

Secure Perfect: 3.1.0.6 or later

Picture Perfect: 1.7.0 or later

•ISO ProxLite

•ProxLite

•Entrée

•Proximity Perfect

®

Edition 3.0 or later

™

1.7 or later

Note: Proximity Perfect cards are obsolete

however they are supported by the Model

94x/97x readers.

Technical specifications 5

Technical specifications

For UL compliant installation notes, refer to “UL” on page 44.

Operating

temperature range

Relative humidity 5% to 95% (non-condensing)

Physical dimensions

Model 94x

Model 97x

Index of protection IP55

Color Light gray and black

Power supply Nominal 12VDC, 75mA, 150mA or 200mA

Cable specifications Belden 8725 or equivalent, 20 AWG minimum,

Maximum cabling

distance

Read range Determined by the reader’s power level setting and

a

-31 F (-35 C) to +151 F (+66 C)

(HxWxD)

4.75" (121 mm) x 2.9" (74 mm) x 0.90" (23 mm)

4.75" (121 mm) x 5.5" (140 mm) x 0.90" (23 mm)

dependent on the power setting selected.

See Table 1 “Power level switch settings,” on page 24

shielded pairs

The maximum cable distance between the reader

and the microcontroller is influenced by a number of

factors including wire gauge and reader power level

setting. See Table 3 “Cable distances,” on page 25.

other environmental conditions. See Table 2 “Read

range by model number,” on page 24.

Pinouts The reader is supplied with a ten-wire cable. On one

end is a keyed connector that mates with the J1

connector on the back of the reader. The other ends

are stripped ready for connection to the field wiring

using a terminal block or in-line splice connectors.

a. The reader will work well with unshielded cable in most environments. No

company, including GE, can guarantee that data will be reliably transmitted

over long distances on unshielded cable in every installation.

Model 94x/97x Proximity Reader

6

Installation Manual

Parts list

• Model 940 Reader (single-gang) gray

• Model 940 Reader (single-gang) black

• Model 941 Reader (single-gang metal mount) gray

• Model 941 Reader (single-gang metal-mount) black

• Model 970 Reader (dual-gang) gray

• Model 970 Reader (dual-gang) black

• Model 971 Reader (dual-gang metal-mount) gray

• Model 971 Reader (dual-gang metal-mount) black

• Model 972 Reader (dual-gang with keypad) gray

• Model 972 Reader (dual-gang with keypad) black

• Model 973 Reader (dual-gang metal mount w/keypad) gray

• Model 973 Reader (dual-gang metal mount w/keypad) black

• Optional Tamper Key Tool

• 94x Plas tic Backpla te (gray)

• 94x Plastic Backplate (black)

• 97x Plas tic Backpla te (gray)

• 97x Plastic Backplate (black)

• Standard 941 Metal Mounting Plate (gray)

• Standard 941 Metal Mounting Plate (black)

• Standard 971/973 Metal Mounting Plate (gray)

• Standard 971/973 Metal Mounting Plate (black)

• Optional Back-to-Back 941 Metal Mounting Plate (gray)

• Optional Back-to-Back 971/973 Metal Mounting Plate

(black)

• 94x Weather-resistant Gasket

• 97x Weather-resistant Gasket

•Reader Cable

Refer to the GE Product Catalog for part numbers and ordering

information.

Installation overview 7

Installation overview

The following steps are g eneral inst ructi ons fo r in stalli ng the 94x/

97x reader. Each step is explained in further detail in the sections

that follow.

1. Mount the reader backplate.

Refer to “Mounting the reader” on page 8.

2. Configure the reader.

Refer to “Configuring the reader” on page 20.

3. Connect the reader.

Refer to “Connecting the reader” on page 28.

4. Test the reader.

Refer to “Testing the reader” on page 36.

Model 94x/97x Proximity Reader

8

Installation Manual

Mounting the reader

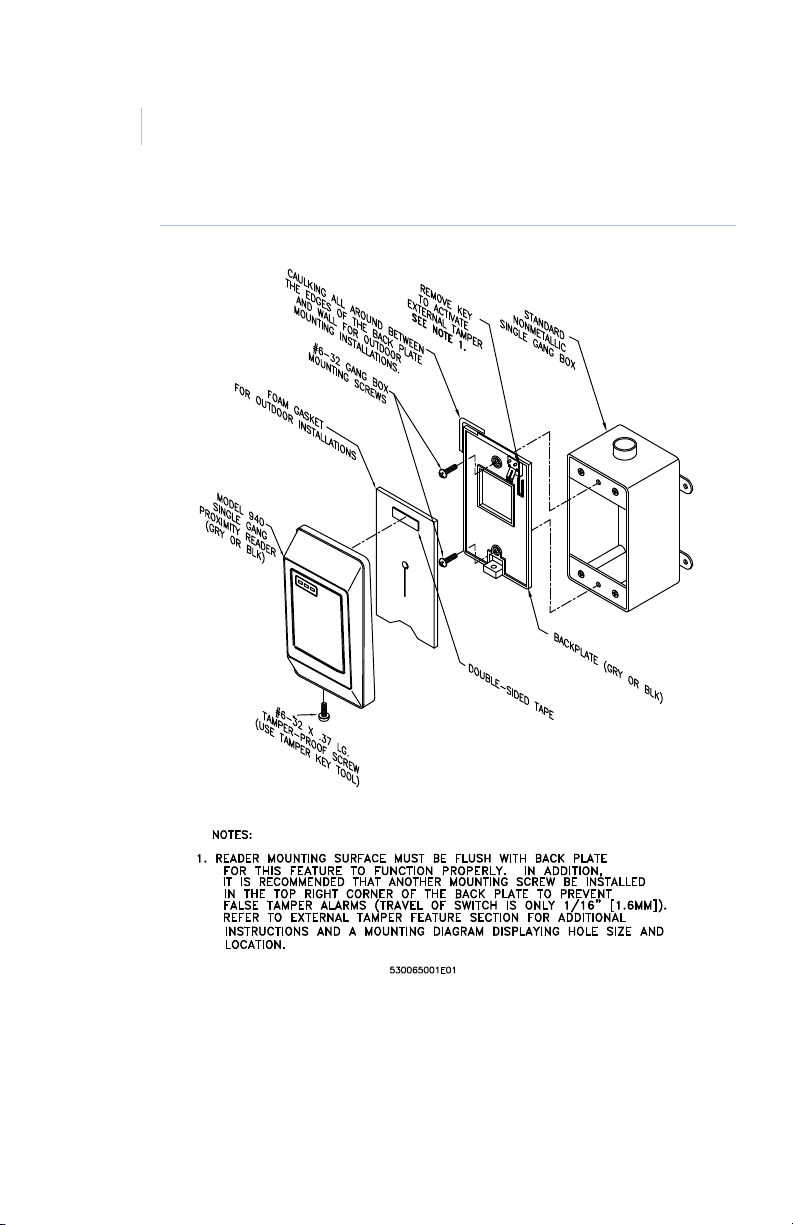

The reader comes with a back plate suitable for mount ing directly

onto standard U.S. electrical gang boxes (Model 94x onto singlegang box and Model 97x onto dual-gang box). The reader may

also be mounted directly onto a hollow wall.

Important:

• Readers should not be mounted within three feet of a

computer terminal. Some terminals radiate electrical

noise that may reduce the effective maximum read range.

• Never mount Models 940, 970 or 972 on or near metal.

Metal effects the tuning of the reader and may severely

degrade its performance, decreasing read range and

increasing current draw.

• Models 941, 971 and 973 are factory tuned to work with

a metal back and must be mounted with the metal

mounting plate to operate correctly.

• A gasket is supplied with the reader to form a weatherresistant seal between the mounting surface and the

inside of the reader for outdoor installations. The gasket

should be located on the inside surface of the reader’s

plastic backplate. For outdoor installations, where the

reader is mounted in direct exposu re to weather , a b ead of

silicone caulking should be applied between the reader

and the wall to prevent water from entering the back of

the reader.

Mounting the reader 9

Back-to-back readers

Models 941, 971 and 973 Readers are suitable for back-to-back

installation (to provide in/out access control). Using the standard

metal mounting plates, the two readers should be mounted with

their centers offset by at least 10 inches to provide interferencefree operation. Using the optional back-to-back metal mounting

plates allows the two readers to be mounted directly opposite

each other on a 4-inch thick wall.

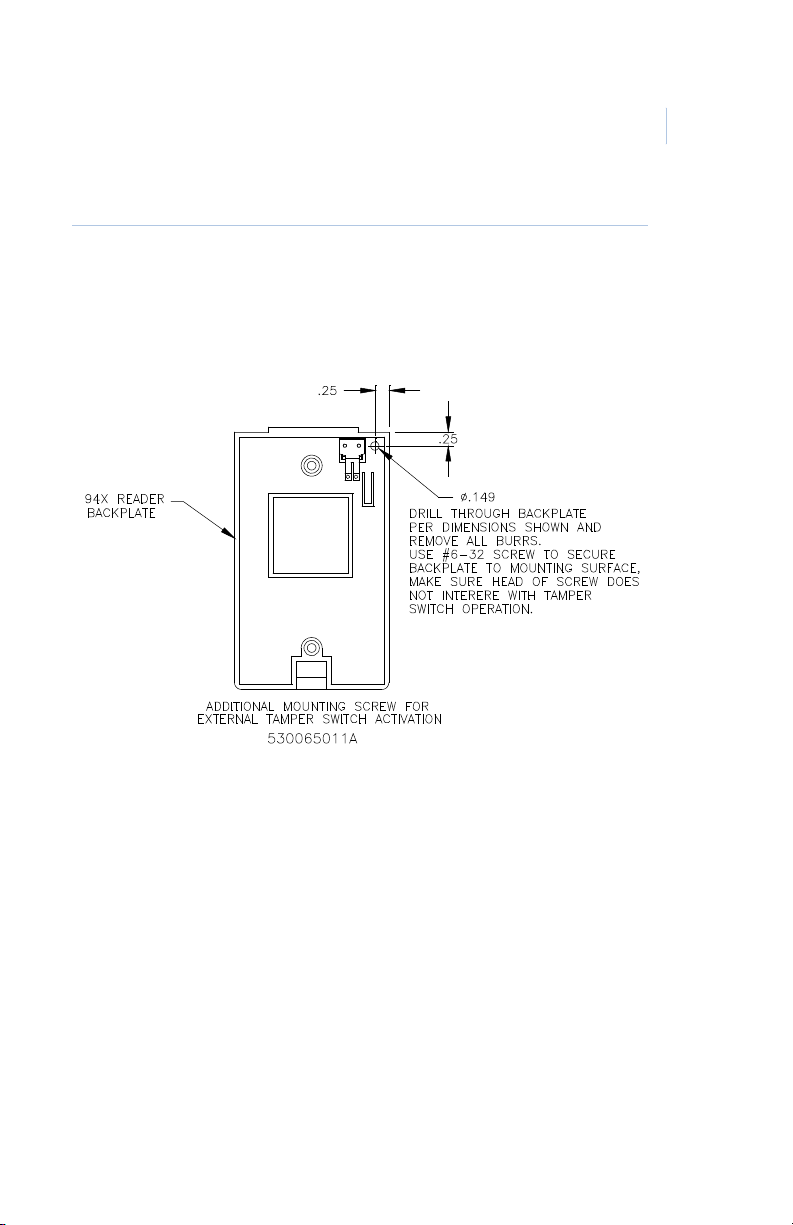

External tamper feature

The Model 94x/97x Readers are also equipped with an external

tamper feature. This feature can be activ ated by removi ng the key

on the backplate prior to mounting.

Model 94x only: Apply the mounting method as shown in

Figure 1, Recommended Addit ion al Mounti ng Instructions for

External Tamper Switch Activation to mounting instructions in

Figure 2, "Model 940 Reader - Gang Box Mounting" Figure 3,

"Model 940 Reader - Direct Wall Mounting" Figure 4, "Model

941 Reader - Gang Box Mounting" and Figure 5, "Model 941

Reader - Direct Wall Mounting" if you are using the external

tamper feature.

Note: In order for this feature to work properly, the reader mounting

surface must be flush with the backplate.

Model 94x/97x Proximity Reader

10

Installation Manual

Mounting diagrams

The figures listed below begin on the next page. Refer to the

appropriate figure for the type of reader you are mounting.

• Figure 1, Recommended Additional Mounting

Instructions for External Tamper Switch Activation

• Figure 2, “Model 9 40 Reader - Gang Box Mounti ng,” on

page 12.

• Figure 3, “Model 940 Reader - Direct Wall Mounting,”

on page 13.

• Figure 4, “Model 9 41 Reader - Gang Box Mounti ng,” on

page 14.

• Figure 5, “Model 941 Reader - Direct Wall Mounting,”

on page 15.

• Figure 6, “Model 970/972 Reader - Gang Box

Mounting,” on page 16.

• Figure 7, “Model 970/972 Reader - Direct Wall

Mounting,” on page 17.

• Figure 8, “Model 971/973 Reader - Gang Box

Mounting,” on page 18.

• Figure 9, “Model 971/973 Reader - Direct Wall

Mounting,” on page 19.

Mounting the reader 11

Figure 1. Recommended Additional Mounting Instructions for External Tamper Switch

Activation

Model 94x/97x Proximity Reader

12

Installation Manual

Figure 2. Model 940 Reader - Gang Box Mounting

Figure 3. Model 940 Reader - Direct Wall Mounting

Mounting the reader 13

Model 94x/97x Proximity Reader

14

Installation Manual

Figure 4. Model 941 Reader - Gang Box Mounting

Figure 5. Model 941 Reader - Direct Wall Mounting

Mounting the reader 15

Model 94x/97x Proximity Reader

16

Installation Manual

Figure 6. Model 970/972 Reader - Gang Box Mounting

Figure 7. Model 970/972 Reader - Direct Wall Mounting

Mounting the reader 17

Model 94x/97x Proximity Reader

18

Installation Manual

Figure 8. Model 971/973 Reader - Gang Box Mounting

Figure 9. Model 971/973 Reader - Direct Wall Mounting

Mounting the reader 19

Model 94x/97x Proximity Reader

20

Installation Manual

Configuring the reader

Switch settings

T w o banks of f our DIP swi tches l ocate d on the bac k of the r eader

are used to select the reader power level, operating mode, and

beeper sound level. Please note that the location and orientation

of switch block SW2 have changed for readers manufactured

after December , 2002 as il lustrat ed in Figure 10, “Model 94x/97x

Reader, J1 Connector and DIP Switch Locations (PCB Assembly

P/N 100079002 manufactured 12/02 or later),” on page 22.

CAUTION: Power should be removed from the reader while switch

Selecting reader power level

settings are changed.

The reader’s power requirement is selected using four DIP

switches. The optimum power level will vary with each

installation. Higher power levels give improved read range for

badges, while lower power levels allow greater cabling distance

between the reader and the microcontroller. A detailed

explanation is provid ed below. The figures on the next page show

the location of the DIP switches. Th e tables that follow the

figures give the switch settings along with the read ranges and

cable distances.

Explanation of Read Range/Cable Distance/Power Level:

Maximum badge read range is determined by the distance at

which the field transmitted by the reader is just strong enough to

wake up the badge. Therefore, the higher the reader’s

transmission power, the greater the badge read range will be. The

trade-off for increased read range is a decrease in the maximum

cabling distance between the reader and the microcontroller. The

Configuring the reader 21

trade-off between read range and cabling distance is common to

all proximity badge readers. The power selection switches on the

94x/97x readers allow the optimum power setting to be selected

to suit individual installations.

For example: On the high power setting, giving the greatest

badge read range, the reader typically requires 200mA of supply

current from the microcontroller. If there is 1,000 feet of 22AWG cable between the reader and the microcontroller, the total

reader power and power re turn path is 2,000 fe et. Since 22-AWG

cable has a typical resistance of 16 ohms per 1,000 feet, the total

resistance in the reader’s power and pow er return wire is 32

ohms. By Ohms Law (V=IR), it follows that the total voltage

dropped in the reader power and power return wires will be 6.4V

(6.4V = 200mA x 32 Ohms). Therefore, the reader sup ply voltage

will drop from 12V at the microcontr oller t o 5.6V (12V - 6.4 V) at

the reader. Such a supply voltage is too low for the reader to

function reliably.

If the low power setting is selected, the badge read range is

reduced. However, the reader now typically requires only 75mA

of supply current; therefore, the voltage drop in the power and

power return wires is much less. In this case, the reader supply

voltage will only be reduced to 9.6V; high enough for reliable

operation.

Model 94x/97x Proximity Reader

1

2

3

4

OFF

ON

SW2

22

Installation Manual

Figure 10. Model 94x/97x Reader, J1 Connector and DIP Switch Locations

(PCB Assembly P/N 100079002 manufactured 12/02 or later)

Configuring the reader 23

4

3

2

1

ON

OFF

SW2

Figure 11. (PCB Assembly P/N 100079001 manufactured prior to 12/02)

CAUTION: Power should be removed from the reader while switch

settings are changed.

Model 94x/97x Proximity Reader

24

Installation Manual

The table below shows the switch settings for each of the three

power levels.

Table 1. Power level switch settings

Power Level Switch 1 Switch 2 Switch 3 Switch 4

LOW OFF ON ON OFF

MEDIUM ON OFF OFF ON

HIGH ON ON ON ON

The table below gives the read ranges for each of the readers

based on the power level settings. All read ranges are typical

maximums.

Table 2. Read range by model number

Power level 97x 94x

LOW 5 in

127 mm

MEDIUM 6 in

152 mm

HIGH 7 in

178 mm

in = inches

mm = millimeters

4 in

102 mm

5 in

127 mm

6 in

152 mm

Configuring the reader 25

The table below gives the maximum cabling distances between

the reader and the microcontroller for each of the three power

levels.

Table 3. Cable distances

Power

level

LOW 5500 ft

MEDIUM 2200 ft

HIGH 600 ft

13.6 Volts (see Note 1) 12 Volts (see Note 1)

18 AWG 22 AWG 18 AWG 22 AWG

1676 m

671 m

183 m

Note:

1 Reader supply voltage measured at microcontroller:

13.6V is nominal when line powered, 12V is nominal

when battery powered.

2 Not recommended for 12V, battery-backed installations.

3 All cable distances are typical maximums.

4 Readers powered by a local 12 VDC power supply will

have a maximum cable distance of 5,500 feet (1676 m) of

22-AWG telephone wire for all power level settings.

2000 ft

610 m

900 ft

274 m

250 ft

76 m

3500 ft

1067 m

1100 ft

335 m

See Note 2 See Note 2

1500 ft

457 m

450 ft

137 m

Model 94x/97x Proximity Reader

26

Installation Manual

Selecting operating mode

Field changeable DIP switches allow all 94x and 97x readers to

operate in one of four distin ct opera ti ng modes : Wiegand (4001),

F/2F, Supervised, and Silent Supervised.

In the unsupervised modes, the reader communicates with the

microcontroller over a unidirectional Wiegand or F/2F data link

that carries badge data only.

In the supervised modes, the reader communicates with the

microcontroller over a bidirectional F/2F data link, that carries

badge data, supervision messages, exit request and door switch

status, and microcontroller acknowledgments and commands.

Silent Supervised mode

is ideal for inst allati ons where no aud ible

or visual indication of communication loss with the

microcontroller is desired at the reader.

The table below shows the DIP switch settings for each of the

four operating modes.

Table 4. Operating mode DIP switch settings

Operating mode Switch 5 Switch 6

Wiegand

F/2F

Supervised F/2Fb

Silent supervised F/2Fb

a. ProxLite badge data is sent using 40-bit (4001) Wiegand format . Keyboard

b. All ProxLite badge data is sent using a 12-digit F/2F format .

a

b

information is sent using 8-bit Wiegand format .

OFF OFF

ON OFF

OFF ON

ON ON

Configuring the reader 27

Selecting beeper sound level

The table below shows the DIP switch settings for the three

beeper sound levels.

Table 5. Beeper sound level DIP switch settings

Beeper sound level Switch 7 Switch 8

Normal ON ON

Low ON OFF

Off OFF ON

Model 94x/97x Proximity Reader

28

Installation Manual

Connecting the reader

For pinout and wiring information, refer to the following:

• Pinouts on page 28

• Wiring diagrams on page 29

Note: To maintain CE compliance, shielded cable and connections must

be used as shown in the section, “CE/FCC compliance” on page 46.

Pinouts

The table below shows the pinouts for connecting the reader to

the microcontroller. Connector J1, pin 1 is to the right as you

view the connector from behind the reader. See Figure 10 on

page 22 and Figure 11 on page 23.

Table 6. Pinouts

Connector: J1

Pin number

Signal Pigtail Wire Color

1+12 VDC Red

2 Ground Black

3 Red LED External Drive Blue

4 Green LED External Drive Brown

5 Yellow LED External Drive Orange

6 Reader Data 0 Green

7 Reader Data 1 White

8 Beeper External Drive Violet

9Keying Pin

10 Door DI (Door Contact Switch) Yellow

11 Exit DI (Exit Request Button) Gray

Connecting the reader 29

Wiring diagrams

See the wiring diagrams that follow for details on connecting the

reader to the microcontroller based on the mode of the reader.

• Figure 12, “Wiring diagram, Model 94x/97x Supervised

F/2F Mode,” on page 30.

• Figure 13, “Wiring diagram, Model 94x/97x

Unsupervised F/2F Mode,” on page 32.

• Figure 14, “Wiring diagram, Model 94x/97x

Unsupervised Wiegand Mode,” on page 34.

Model 94x/97x Proximity Reader

30

Installation Manual

Figure 12. Wiring diagram, Model 94x/97x Supervised F/2F Mode

Connecting the reader 31

Note: (Unless otherwise specified):

1 For Micro/2/4/5 only: a 470 ohm, 1/2W, pull-up resistor is required between +12 VDC and

READER DATA 1. The pull-up resistor should be installed at the microcontroller’s terminal block.

Resistors are supplied with the reader.

2 Shielded cable is recommended in electrically noisy environments.

3 If using shielded cable, connect all shields together at the microcontroller end. Connect to the

ground stud in the lower left corner of Micro/2/4/5 cabinets using 14-AWG wire. No shield

connections at the reader.

4 If using a local power supply, do not connect +12V line from the microcontroller to the reader.

However, the negative side of the power supply must be connected to the microcontroller

(pin 2 on the reader port). Keep the wiring from power supply to reader less than 50 feet.

5 Switching the external indicator drives to GND activates the indicator. High impedance or +12V

deactivates indicators. These drives may also be connected to user supplied, external

indicating circuitry.

6 Refer to the appropriate system manual to determine whether this connection is required for

door switch operation.

7 Blocking diodes may be 1N5817 or GE part number 521224001 (included with reader). The

diode must be installed in a secure location, not accessible through the reader removal.

8 Protection diodes may be 1N4002, 1N4003, or 1N4004 (installer supplied) for the door strike

assembly.

9 Fuse, power supply, door strike, and relay are provided by the installer.

10 If the door contact switch is not used, link reader pin 10 to pin 2.

11 Request to exit (REX) terminals on the reader are not to be connected for UL listed installations.

Model 94x/97x Proximity Reader

32

Installation Manual

Figure 13. Wiring diagram, Model 94x/97x Unsupervised F/2F Mode

Connecting the reader 33

Note: (Unless otherwise specified):

1 For Micro/2/4/5 only: a 470 ohm, 1/2W, pull-up resistor is required between +12 VDC and

READER DATA 1. The pull-up resistor should be installed at the microcontroller’s terminal

block. Resistors are supplied with the reader.

2 Shielded cable is recommended in electrically noisy environments.

3 If using shielded cable, connect all shields together at the microcontroller end. Connect to

the ground stud in the lower left corner of Micro/2/4/5 cabinets using 14-AWG wire. No

shield connections at the reader.

4 If using a local power supply, do not connect +12V line from the microcontroller to the

reader. However, the negative side of the power supply must be connected to the

microcontroller (pin 2 on the reader port). Keep the wiring from power supply to reader less

than 50 feet.

5 Switching the external indicator drives to GND activates the indicator. High impedance or

+12V deactivates indicators. These drives may also be connected to user supplied, external

indicator driving circuitry.

6 Refer to the appropriate system manual for specific wiring details.

7 Blocking diodes may be 1N5817 or GE part number 521224001 (included with reader). The

diode must be installed in a secure location, not accessible through the reader removal.

8 Protection diodes may be 1N4002, 1N4003, or 1N4004 (installer supplied) for the door

strike assembly.

9 Fuse, power supply, door strike, and relay are provided by the installer.

10 Request to exit (REX) terminals on the reader are not to be connected for UL listed

installations.

Model 94x/97x Proximity Reader

34

Installation Manual

Figure 14. Wiring diagram, Model 94x/97x Unsupervised Wiegand Mode

Connecting the reader 35

Note: (Unless otherwise specified):

1 For Micro/2/4/5 only: two 470 ohm, 1/2W, pull-up resistors are required; one between +12

VDC and READER DATA 1, the other between +12 VDC and READER DATA 0. The pull-up

resistors should be installed at the microcontroller’s terminal block. Resistors are supplied

with the reader.

2 Shielded cable is required. Belden 8725 wire is recommended. Do not pair DATA 1 and DATA 0.

3 If using shielded cable, connect all shields together at the microcontroller end. Connect to the

ground stud in the lower left corner of Micro/2/4/5 cabinets using 14-AWG wire. No shield

connections at the reader.

4 If using a local power supply, do not connect +12V line from the microcontroller to the reader.

However, the negative side of the power supply must be connected to the microcontroller

(pin 2 on the reader port). Keep the wiring from power supply to reader less than 50 feet.

5 Switching the external indicator drives to GND activates the indicator. High impedance or

+12V deactivates indicators. These drives may also be connected to user supplied, external

indicator driving circuitry.

6 Refer to the appropriate system manual for specific wiring details.

7 Blocking diodes may be 1N5817 or GE part number 521224001 (included with reader). The

diode must be installed in a secure location, not accessible through the reader removal.

8 Protection diodes may be 1N4002, 1N4003, or 1N4004 (installer supplied) for the door strike

assembly.

9 Fuse, power supply, door strike, and relay are provided by the installer.

10 Request to exit (REX) terminals on the reader are not to be connected for UL listed

installations.

Model 94x/97x Proximity Reader

36

Installation Manual

Testing the reader

Follow the steps below to verify that the reader is working

correctly.

1. Check all cabling and electrical connections from the

reader to the microcontroller. Refer to the wiring

diagrams on page 30, page 32, and page 34.

2. Verify that the microcontroller is properly configured.

Refer to the appropriate GE microcontroller manual.

3. Verify that the reader switches are properly set for the

power setting, cabling type, distance, and desired mode

of operation. See “Switch settings” on page 20.

4. Apply power to the reader and verify that the yellow

LED is on. You may want to use a multimeter to test the

voltage at the reader’s pigtail connector J1, using ground

(pin 2) as a reference. The power pin (pin 1), data lines

(pins 6 and 7) and door DO (pin 4) should all read

approximately 12V.

5. Check that the proper version of firmware is installed in

the microcontroller. Refer to the appropriate

microcontroller manual.

6. Close the tamper swit ch by joining the reader and

backplate.

Note: If external tamper is activated, make sure the reader

backplate mounting surface is flush with backplate.

When all wires are connected to the reader, ensure that

the supervision function is operating properly (if a

supervised mode is sel ected ), by ver ifyin g that t he reade r

is not sounding a short triple beep every 30 seconds, and

the red LED is not flashing slowly (every 2 seconds). If

Testing the reader 37

such an alarm is present, refer to the troubleshooting

guide at the end of this manual.

Note: In silent supervised mode, no indication of loss of

supervision is provided, except badges will not be read.

7. Select a known good ProxLite test badge. Be sure the

badge is properly entered in the host syste m, and the

micro badge data format matches the rea der. If the reader

is used with a keypad (Models 972 and 973 only) , assi gn

a proper PIN.

8. Check that the door is secure. Present the badge to the

reader. Observe that the reader beeps briefly and the

yellow LED blinks off.

9. If the reader is used with a keypad (Models 972 and 973

only), enter a PIN. Refer to the host manual for

instructions on entering the PIN. Observe that the green

LED turns on indicating a valid access has been granted

by the host.

10. Open the door. This verifies that the door strike operates

correctly.

Model 94x/97x Proximity Reader

38

Installation Manual

Troubleshooting the reader

If the operation of a component is in doubt, substitute a known

good component and retry the system. Always verify wiring

against wiring diagrams before powering up the system.

The troubleshooti ng guide is divided int o thre e sect ions. The firs t

section is applicable to all installations, the second section

provides additional diagnosis for unsupervised readers, and the

last section provides additional diagnosis for supervised readers.

All installations

All LEDs are on and the beeper is on (if enabled): Usually, an

indication that the rea der’s vol tage is too low. This may be caused

if the wrong reader voltage is selected at the microcontroller or

the cable is too long between the reader and the microcontroller.

1. Measure the reade r supp ly volta ge at the mi crocont roll er.

It should read between 12 and 15 VDC. If the voltage is

correct, continue to step 2 below. If the voltage is

incorrect, refe r to the ap propriat e micro controll er manual

and correct the voltage.

2. Set the reader to low power mode if the cable distance is

too long (See Table 1 “Power level switch settings,” on

page 24). This may correct the problem.

3. If the problem is still present, while in low power mode,

measure the voltage betwe en J1 p in 1 (power) and J1 pin

2 (ground). This voltage should be greater than 8 VDC

and less than or equal to the reader supply voltage. If the

voltage is too low, correct the wiring. If the voltage is

correct, replace the reader.

Troubleshooting the reader 39

None of the LEDs are on: Check that the beeper is enabled (See

Table 5 “Beeper sound level DIP switch settings,” on page 27),

then present a known good ProxLite test badge to the reader

while listening for the beeper.

If the beeper sounds, the reader is faulty and should be replaced.

If the beeper does not sound, check the power connections to the

reader and check the reader supply voltage at connector J1 pin 1.

The green LED is always on: The green LED indicates that the

door strike is open. It is controlled by the input on connector J1

pin 4.

1. Disconnect the wire on J1 pin 4. If the green LED stays

on, the reader is faulty and should be replaced. If the

green LED goes of f the n the pro blem is mos t likel y not in

the reader.

2. Reconnect the wire on J1 pin 4 and measure the voltage

at J1 pin 4. Low voltage turns on the green LED. If the

voltage is low, check to see if the host system is turning

on the door strike.

The beeper doesn’t sound and the yellow LED doesn’t blink

when a badge is presented to the reader OR the badge read

range is very poor:

When the beeper sounds and t he y ell ow LED

blinks off, it indicates that a badge has been read and its data sent

to the microcontroller.

Note: The beeper will not sound if it has been disabled. (See Table 5

“Beeper sound level DIP switch settings,” on page 27

.)

1. Models 941, 971 and 9 73: Check that th e metal b ackplate

is installed correctly. See the appropriate installation

drawing in this manual for details.

All other models: Be sure they are not mounted on or

near a metal w all or large metal object.

Model 94x/97x Proximity Reader

40

Installation Manual

2. Check that the reader is not mounted within 3 feet

(1 meter) of a computer terminal or within 10 inches

(250 mm) of another proximity reader. The only

exception to this 10-inch (250 mm) limit is for 941, 971,

and 973 readers inst alled wi th th e optiona l, back-t o-back,

metal mounting plates.

3. Present a test ba dge ( kno wn to be working) to the reader.

If the beeper and yellow LED still fail to indicate a valid

badge read and se nd, re place th e rea der wit h a r eader that

you know is working correctly. If this corrects the

problem, the original reader is faulty and should be

replaced. If this does not correct the problem, the badge

is probably defective.

The door does not open and the green LED does not turn on

when a badge is presented:

1. Verify that the badge an d reade r are proper ly ent ered i nto

the system.

2. Verify that the door strike and the green LED are wired

correctly. Since the green LED and the door strike are

separate indicators, this problem is not an indication of a

defective reader.

The green LED does not turn on, but the door strike unlocks

the door when a valid badge is presented:

1. Verify that the door DO is wired correctly. Refer to the

appropriate wiring diagram.

2. Disconnect the wire from J1 pin 4 (green LED) and

connect J1 pin 4 to J1 pin 2 (gro und). If the gree n LED is

now on, the reader is good and the connection to the

reader is defective. If the green LED does not turn on,

replace the reader.

Troubleshooting the reader 41

Green LED turns on but the door does not open: Verify correct

door strike wiring and operation. The reader is functioning

properly.

The beeper is always on and/or the yellow LED is off: The

yellow LED blinks off and the beeper sounds while a key is

pressed (Models 972 and 973 only), as long as the reader DIP

switches are not set to disable the beeper.

False or intermittent tamper alarm s: Ver ify that the reader

mounting surface is flush with the backplate. If you continue to

experience proble ms with tamper operatio n, clean the contacts on

the PC board as well as the contact fingers on the backplate.

Unsupervised modes only

The reader sounds a short triple beep every 30 seconds and the

red LED flashes quickly (every 400 ms):

violation. Verify that the r eader hous ing is prope rly secur ed to the

backplate. If an external tamper is used, review the appropriate

recommended mounting instructions. If the reader is secure and

mounted properly, then the reader is faulty and should be

replaced.

Indicates a tamper

Supervised modes only

Reader sounds a short triple beep every 30 seconds and the red

LED flashes slowly (every 2 seconds):

communication with the microcontroller.

1. Check the reader to microcontroller wiring. Refer to the

appropriate instal lation drawing. Verify that the AUX DO

is jumpered to the READER DATA 1 on the

microcontroller.

The reader has lost

Model 94x/97x Proximity Reader

42

Installation Manual

2. Verify that the correct pull-up resistor is installed on the

microcontroller. See Figure 12, “W iri ng diagram, Model

94x/97x Supervised F/2F Mode,” on page 30.

3. Verify that the microcontroller has the correct firmware

for a supervised reader. Refer to the manual that came

with your microcontroller for instructions.

4. Try the reader on a different reader input of the

microcontroller. If this corrects the problem, then the

microcontroller is probably causing the problem.

5. Replace the reader with one you know is working

correctly. If this corrects the problem, then the reader is

probably faulty and should be replaced.

6. If none of the above steps have identified the problem,

there may be a significant noise source present in the

installation that is interfering with the reader-tomicrocontroller communications. If this is the case, use

shielded wire for reader-to-microcontroller connections.

The beeper sounds and the yellow LED blinks off more than

once when a valid badge is presented:

The beeper sounds and

the yellow LED blinks off every time badge data is sent to the

microcontroller. When a badge is presented to the reader, data is

transmitted from the badge to the reader. The reader interprets

and checks the data received to make sure it has not been

corrupted. The reader then sends the data to the microcontroller

and waits approximately 1/3 of a second for the microcontroller

to acknowledge re ceipt. If no ackn owledge is receiv ed during this

time, the reader resends the data causing the beeper to sound

again and the LED to blink off. After the third unacknowledged

attempt, the reader stops trying and indicates a communications

error. This feature is useful in troubleshooting marginal

installations where a high level of electrical noise may cause the

reader to mak e multiple at tempts at communications.

Troubleshooting the reader 43

1. If multiple beeps occu r regularly, refer to the i nstallation

drawings to verify that the correct pull-up resistor has

been added to the microcontroller.

2. Replace the reader with one you know is working

correctly. If this solves the problem, t he o rigin al rea der i s

probably faulty and should be replaced. If the problem

persists, use shielded cable between the microcontroller

and the reader.

The reader sounds a short triple beep every 30 seconds and the

red LED flashes quickly (every 400 ms):

Indicates a tamper

violation. Verify that the r eader hous ing is prope rly secur ed to the

backplate. If an external tamper is used, review the appropriate

recommended mounting instructions. If the reader is secure and

mounted properly, then the reader is faulty and should be

replaced.

The beeper and/or red LED are always on: The microcontroller

may command the reader to turn on the red LED and the beeper

as long as the reader DIP switches are not set to disable the

beeper. If the door status switch input at J1 pin 10 is not tied to

ground, the reader informs the system that the door is open. The

system may then activate the alarm at the reader. If this is not the

problem, then the system software probably told the reader to

activate its alarm. Refer to the appropriate system manual for

conditions that cause the software to activate the alarm. If it

appears that no such system command is active, replace the

reader with one you know works correctly. If this solves the

problem, the original reader is faulty and should be replaced.

The green LED flashes quickly (every 400 ms): This indicates

that the microcontroller has requested a PIN entry on a Model

972 or 973 Reader with a keypad. For all other models, chec k the

reader configuration on your system to be sure a keypad reader

was not selected.

Model 94x/97x Proximity Reader

UL Listed Installations

44

Installation Manual

Regulatory approvals

UL

Specifications for UL compliance are shown below:

• Operating Temperature Range: +32 F (+0 C) to +120 F

(+49 C)

• Relative H umidity: 85%

• The Model 94x/97x readers were evaluated by UL for

indoor use only.

CE

Manufacturers

Declaration of Conformity

For

Product Identification:

Model/type: 430084001/2, 430084501/502 BOM revision level:940=Q; 941=P

(Model 94X) 970=Q, 971=P, 972=Q,

430085001/2, 430085501/502, 973=P

430088001/2, 430088501/502

(Model 97X)

Category (description): Proximity Reader

Brand: GE Security

Manufacturer: GE Security B.V. GE Security GE Security

Kelvinstraat 7 1510 Tate Blvd Suite 100

6003 DH Weert Hickory, NC 28511 791 Park of Commerce Blvd.

The Netherlands USA Boca Raton, Florida 33487

USA

EU Representative: GE Security B.V.

Kelvinstraat 7

6003 DH Weert

The Netherlands

Equipment class identifier (RF products falling under the scope of R&TTE)

Means of Conformity:

We declare under our sole responsibility that this product is in conformity with Directive 93/68/EEC

(Marking) and/or complies with the essential requirements and all other relevant provisions of the

1999/5/EC (R&TTE) based on test results using (non)harmonized standards in accordance with the

Directives mentioned.

Concerning R&TTE

EMC Safety Radio

A sample of the

product has been

tested by:

PSE

12955 Bellamy

Brothers Blvd.

Dade City, FL 33525

PSE

12955 Bellamy

Brothers Blvd.

Dade City, FL 33525

PSE

12955 Bellamy

Brothers Blvd.

Dade City, FL 33525

Test report reference 07F256I 02P351/ 02P352 02F351C/ 02F352C

Applied standards EN50130-4(1995)

+A1(1998) +A2(2003)

EN60950-1 (2001) EN300-330 v1.3.1

(2001/2006)

Not Applicable None (class 1 product) (class 2 product)

x

Regulatory approvals 45

Model 94x/97x Proximity Reader

O

46

Installation Manual

CE/FCC compliance

To make the Model 94x/97x reader installation CE and FCC

compliant, the cable connecting the reader to the microcontroller

must have its shield g rounded at the microc ontrolle r , accor ding to

one of the methods specified in the figures below.

Note: Do not make shielded connections at the reader.

Figure 15. Typical installation (Internal to the micro)

Using shielded cable/drain wire

Figure 16. Typical installation (External to the micro)

Using shielded cable/drain wire

Transition

Series

i

GE

Security

U.S.

T 888 GE SECURITY (1 888 437 3287)

F 561 998 6224

Asia

T 852 2907 8108

F 852 2142 5063

Australia

T 61 3 9259 4700

F 61 3 9259 4799

Europe

T 32 2 725 11 20

F 32 2 721 86-13

Latin America

T 305 593 4301

F 305 267 4300

www.gesecurity.com

© 2008 General Electric Company

All Rights Reserved.

460157001P/01-08

Loading...

Loading...