Page 1

4-Zone Mouse Senso

r

Integration Guide

Interlink Electronics

®

FSR

4-Zone Mouse Sensor and USB Interface Chip

Force Sensing Resistors®

Integration Guide

Document P/N: EIG-10003 Rev. A

Interlink Electronics and the six dot logo are registered trademarks of Interlink Electronics, Inc.

www.interlinkelectronics.com

Page 2

4-Zone Mouse Senso

r

Integration Guide

Table of Contents

1.0

Introduction.................................................................................................................... 1

2.0 Scope ................................................................................................................................ 1

3.0 Theory of Operation .................................................................................................... 2

4.0 Mounting .......................................................................................................................... 4

5.0 Connection ..................................................................................................................... 6

6.0 Actuator ........................................................................................................................... 9

7.0 USB Information ......................................................................................................... 10

7.1 Device PID and VID ............................................................................................. 10

7.2 Data Packet ......................................................................................................... 10

7.3 USB Suspend Mode ............................................................................................ 10

8.0 Electrical Specifications ......................................................................................... 11

8.1 Controller Chip ..................................................................................................... 11

8.2 Clock Signal ......................................................................................................... 11

8.3 Operating Current ................................................................................................ 11

8.4 Mouse Speed Configuration ................................................................................ 11

9.0 Controller Chip Example Bill of Materials ......................................................... 13

10.0 Orderable Part Numbers .......................................................................................... 14

11.0 Intellectual Property & Other Legal Matters .................................................... 14

12.0 Contact Interlink Electronics ................................................................................ 15

www.interlinkelectronics.com

Page 3

4-Zone Mouse Senso

r

Integration Guide

1.0 Introduction

The 4-zone Force Sensing Resistor (FSR) paired with a suitable actuator can be implemented as

a finger-actuated "mouse" pointing module. This pointing module provides accurate 360-degree

mouse control. Users control direction by applying pressure in the direction of the desired

movement and adjust speed by altering the amount of pressure on the device.

The purpose of this document is to guide users through the successful integration of a USB

controller chip (microprocessor) and the Interlink Electronics 4-zone FSR.

2.0 Scope

This Integration Guide provides the OEM integrator with all of the necessary technical information

to successfully integrate the Interlink Electronics 4-zone FSR and USB microcontroller chip into

products such as:

NEMA-rated industrial pointing devices

industrial keyboards

military computers

Sensor and chip part numbers are detailed in section 10.

www.interlinkelectronics.com

1

Page 4

4-Zone Mouse Senso

r

Integration Guide

3.0 Theory of Operation

The most basic FSR consists of two membranes separated by a thin air gap. The air gap is

maintained by a spacer around the edges and by the rigidity of the two membranes. One of the

membranes has two sets fingers which are interdigitated and electrically distinct; each set

connects to one trace on the tail. The other membrane is coated with FSR ink. When the two

layers are pressed together, the FSR ink shorts the two traces together with a resistance that

depends on applied force.

Figure 1: Exploded view of a standa rd single-zone FSR

www.interlinkelectronics.com

2

Page 5

4-Zone Mouse Senso

r

Integration Guide

The 4-zone FSR is simply a combination of four basic FSRs arranged in a North, South, East,

West pattern. Each zone interpenetrates into the two zones on either side of it. This overlapping

of the zones allows us to determine how much force is in each zone relative to the others. Once

the relative force in each zone is known, the direction and speed of the mouse pointer can be

determined.

Figure 2: Exploded view of 4-zone FSR

www.interlinkelectronics.com

3

Page 6

4-Zone Mouse Senso

r

Integration Guide

4.0 Mounting

Mechanical installation of the 4-zone FSR has a few critical features that must be considered for

mounting.

To ensure proper registration of the sensor, crop marks made in the copper layer should be

included in the PCB layout. Sufficient registration accuracy is achievable by placing the FSR by

eye using the crop marks.

Figure 3: PCB copper layer showing crop mark locations and size/location of pads.

(All dimensions in millimeters)

www.interlinkelectronics.com

4

Page 7

4-Zone Mouse Senso

r

Integration Guide

Copper traces should not be routed underneath the sensor; they will interfere with its proper

operation. If traces must be routed towards the sensor, vias should be used to bring the traces to

another layer of the board before the sensor’s active area is reached. Interlink recommen ds that

the vias do not extend more than 1.27mm from the bottom of the pads. (See Figure 3)

Figure 4: 4-zone FSR showing overall dimensions, center of part, and size/location of contacts.

(All dimensions in millimeters)

www.interlinkelectronics.com

5

Page 8

4-Zone Mouse Senso

r

Integration Guide

Heat generated during the soldering of components can damage the FSR. Therefore, the sensor

should not be mounted until PCB assembly is complete. When laminating the FSR to the PCB, be

sure to use a hard roller or other depression tool to ensure proper bonding of the sensor’s

pressure-sensitive adhesive and the removal of any air bubbles.

Figure 5: 4-zone FSR pinout reference. Sensor is shown with silver contacts facing away.

5.0 Connection

The 4-zone FSR is connected to the PCB with either a pressure-sensitive z-axis conductive

adhesive or a heat-bonded z-axis conductive adhesive. Both methods of adhesion are meant to

provide an electrical, not mechanical bond; therefore, a mechanical means of applying constant

pressure to the joint should be incorporated into the mounting of the 4-zone FSR. This will

prevent the delamination of the adhesive, which can lead to an open circuit and failure of the

module.

Recommended Conductive Adhesives:

3M 9703/9705 Anisotropic Electrically Conductive Adhesive Transfer Tape

3M 7303 Heat-Bondable Anisotropic Electrically Conductive Adhesive Film

www.interlinkelectronics.com

6

Page 9

4-Zone Mouse Senso

r

Integration Guide

Constant pressure on the sensor contacts can be applied in a couple different ways. One method

is to use the module’s case or housing to apply pressure to the joint through a piece of rubber.

The rubber is used to take up tolerances in the design and can be made as an extension of the

actuator (See Figure 4). This design can provide a long-lasting high-quality conn ection and is

appropriate for most designs.

Figure 6: Cross section view showing constant pressure being applied to the sensor contacts by the

module's case through an extension of the rubber actuator

www.interlinkelectronics.com

7

Page 10

4-Zone Mouse Senso

r

Integration Guide

Another connection method is to use a screw-down metal clamp to apply pressure to the sensor

contacts through a piece of rubber. Again, the rubber is used to take up tolerances in the design.

This is the most robust connection method and is appropriate for military applic ations.

Figure 7: Exploded view of screw-down metal clamp assembly

www.interlinkelectronics.com

8

Page 11

4-Zone Mouse Senso

r

Integration Guide

6.0 Actuator

An actuator must be used to achieve the best pointing results with the 4-zone FSR. There are

certain features on the actuator that are of special importance and extra care should be taken

when designing them.

Proper alignment of the actuator over the sensor is essential for implementing a successful

pointing device. Section 4 shows that the 4-zone FSR is registered to crop marks on the PCB;

therefore, a registration system designed to align the actuator to the PCB should adequately

ensure the correct alignment of the actuator to the 4-zone FSR.

To avoid preloading of the sensor, there must be a skirt surrounding the actuator. The skirt’s job

is to keep the actuator a minimum distance away from the sensor surface when not in use.

However, the skirt cannot be made too tall or the module’s actuation force will be adversely

affected. Other design elements that should be paid close attention to are the actuator diameter

and spherical radius.

Figure 8: Cross section view of actuator. (All dimensions in millimeters)

The actuator design is vital to the correct operation of the 4-zone FSR. Interlink Electronics

encourages customers to visit our website to download detailed CAD models of the rubber

actuator. www.interlinkelectronics.com/support

www.interlinkelectronics.com

9

Page 12

r

7.0 USB Information

Communication to the microprocessor is done via USB and:

Uses the low speed USB standard

Is compatible with any USB 1.1 or 2.0 host

Enumerates as HID device

The microprocessor reports data to the host at a rate of 50 reports/sec.

7.1 Device PID and VID

This IC’s Product ID (PID): 0x0002

Interlink’s Vendor ID (VID): 0x214A

7.2 Data Packet

The data packet from the chip is organized as:

Byte 0

o Bit 0 is the Left Button status

o Bit 1 is the Right Button status

o Bit 2 is the Middle button status

Byte 1 reports the X direction. The values range from -127 to +127 counts.

Byte 2 reports the Y direction. The values range from -127 to +127 counts.

4-Zone Mouse Senso

Integration Guide

7.3 USB Suspend Mode

The chip will not respond to a “suspend” command from the host. It will always stay active

with the current consumption as described in section 8.3.

Note: This device will not wake the host from suspend mode.

www.interlinkelectronics.com

10

Page 13

4-Zone Mouse Senso

r

Integration Guide

8.0 Electrical Specifications

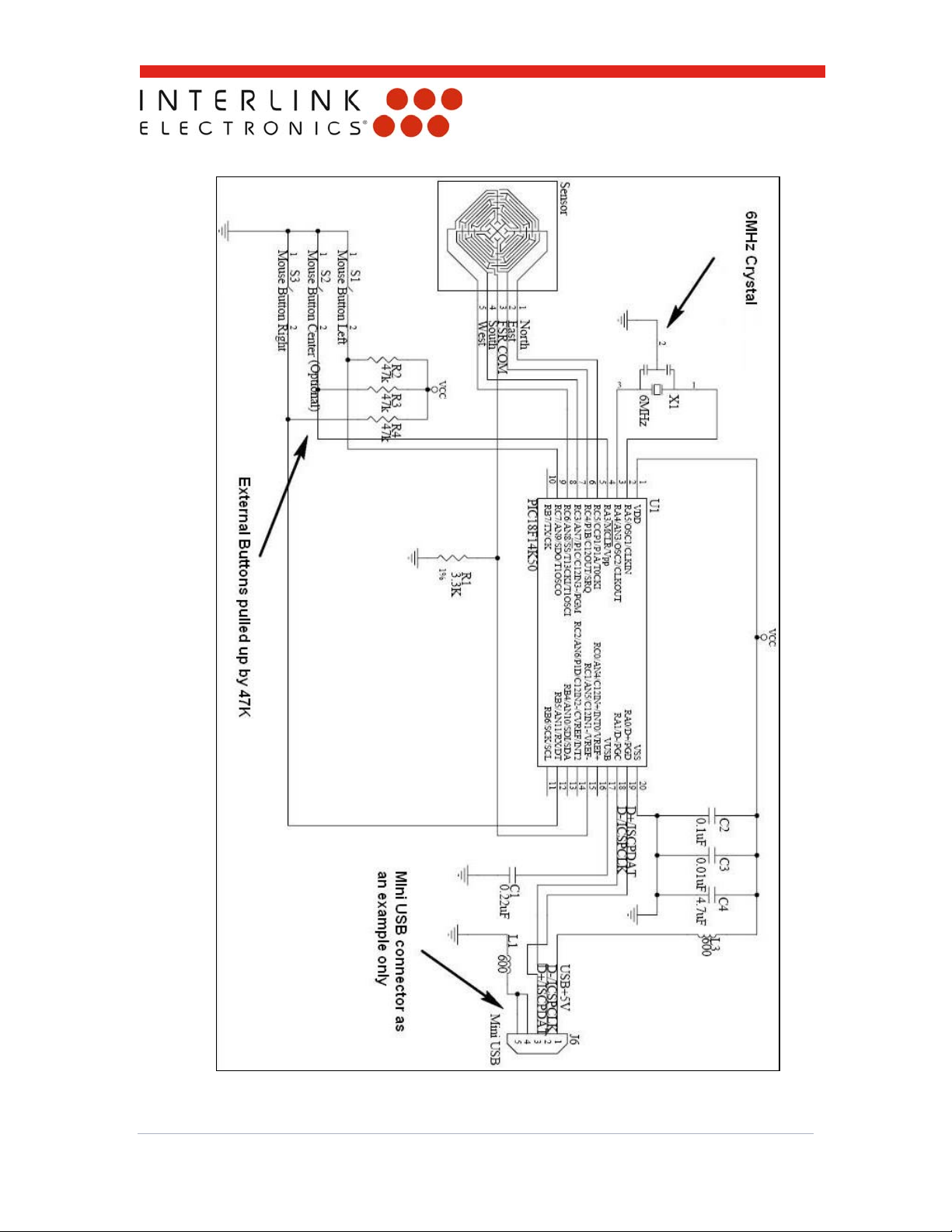

8.1 Controller Chip

The controller chip used in this schematic is microchip PIC18F14K50. This IC, when

combined with Interlink’s proprietary FW, forms the controller engine for this sensor type.

8.2 Clock Signal

The default setting for a clock signal comes from a 6MHz crystal. To meet your needs,

Interlink can supply another version of this chip that will work with a direct clock signal.

8.3 Operating Current

Under normal operation, the device draws between 10mA to 12mA. This current draw is

typical of a full assembly (chip, sensor, etc).

8.4 Mouse Speed Configuration

Mouse speed can be configured by the user. R1 is the controlling factor for this. The

default value that is recommended by Interlink is 3.3K. If desired, the user can change

R1 values to slow down or speed up the mouse. In order to achieve a higher speed, the R1

value must be increased. Interlink recommends that the user should not exceed the limits

of 1K to 10K. (See Figure 8)

www.interlinkelectronics.com

11

Page 14

r

4-Zone Mouse Senso

Integration Guide

Figure 9: Recommended schematics for the controller chip

www.interlinkelectronics.com

12

Page 15

4-Zone Mouse Senso

r

Integration Guide

9.0 Controller Chip Example Bill of Materials

Used Part Type Designator Description

1 0.01uF C3 CAP,CER,0.01UF,10%,50V,0603

1 0.1uF C2 CAP,CER,0.1UF,10%,25V,0603

1 0.22uF C1 CAP,CER,0.22UF,5%,16V,0603

1 4.7uF C4 CAP,CER,4.7UF,10%,6.3V,0603

2 600 L1 L3

1 3.3K R1

3 47k R2 R3 R4

1 PIC18F14K50 U1

1 6MHz X1

3 No Momentary S1, S2, S3

Ferrite Chip, 600 Ohm, 500mA,

0805,SMD

Resistor, 3.3K OHM, Metal Film, 0402,

1%, 100ppm

Resistor, 47K OHM, Metal Film, 0402,

1%, 100ppm

MCU, PIC18F14K50, SSOP20

With Interlinks FW

Ceramic Resonator, 6MHz, SMD,

w/caps

Tactile & Jog Switches SPST-NO

200g Force GW SMD

Table 1: Controller chip example bill of materials

www.interlinkelectronics.com

13

Page 16

r

10.0 Orderable Part Numbers

Hardware Development Kit (54-00016)

o QTY 1 MicroModule Demo with USB Cable

1

o QTY 5 Programmed Microchip PIC18F14K50 microprocessors

o QTY 5 4-Zone Mouse Sensor, Square

o QTY 5 4-Zone Mouse Sensor, Square with Conductive Adhesive

o QTY 5 4-Zone Mouse Sensor, Square with tail and solder tabs

o QTY 1 USB Flash Drive with Product Literature

4 Zone Mouse Sensor and USB Interface Chip Datasheet

4 Zone Mouse Sensor and USB Interface Chip Integration Guide

Programmed Microprocessor, PIC18F14K50, Tape & Reel (54-00005)

4-Zone Mouse Sensor, Square (34-00002)

2

4-Zone Mouse Senso

Integration Guide

4-Zone Mouse Sensor, Square with Conductive Adhesive (30-79069)

4-Zone USB High Temperature Microprocessor (24-00178)

11.0 Intellectual Property & Other Legal Matters

Interlink Electronics holds several domestic and international patents for its Force Sensing Resistor

technology. FSR and Force Sensing Resistor are company trademarks. All other trademarks are

the property of their respective owners.

The product information contained in this document provides general information and guidelines

only and must not be used as an implied contract with Interlink Electronics. Acknowledging our

policy of continual product development, we reserve the right to change, without notice, any detail

in this publication. Since Interlink Electronics has no control over the conditions and method of use

of our products, we suggest that any potential user confirm their suitability for their own application.

1

Microprocessors covered here are capable of measuring any of the 4 Zone FSR’s offered by

Interlink Electronics.

2

Sensors provided with tail extension and solder tabs for ease of connection during hardware

development.

www.interlinkelectronics.com

14

Page 17

r

12.0 Contact Interlink Electronics

United States

Corporate Office

Interlink Electronics, Inc.

546 Flynn Road

Camarillo, CA 93012, USA

Phone: +1-805-484-8855

Fax: +1-805-484-9457

Web: www.interlinkelectronics.com

Sales and support: sales@interlinkelectronics.com

Japan

Japan Sales Office

Kannai-Keihin Bldg. 10F/1004

2-4-2 Ougi-cyo, Naka-ku

Yokohama-shi, Kanagawa-ken 231-0027

Japan

Phone: +81-45-263-6500

Fax: +81-45-263-6501

Web: www.interlinkelec.co.jp

4-Zone Mouse Senso

Integration Guide

www.interlinkelectronics.com

15

Loading...

Loading...