Intergas XTREME 24, XTREME 30, XTREME 36 Installation Manual

INSTALLATION MANUAL

High Eiciency Wall-Mounted Gas Boiler

Read this installation manual thoroughly before the installation and use of the

boiler. Follow all indicated instructions. This installation manual must remain

with the boiler.

XTREME 24

XTREME 30

XTREME 36

G.C. 47-291-10

G.C. 47-291-11

G.C. 47-291-12

2

1 Preface 5

1.1 Regulation ....................................................................................................................5

1.2 Warnings .....................................................................................................................5

1.3 Manual handling ..............................................................................................................5

1.4 Pictograms ...................................................................................................................6

1.5 Warnings on the box ...........................................................................................................6

1.6 Abbreviations .................................................................................................................6

2 Safety regulations 7

2.1 General .......................................................................................................................7

2.2 The installation ...............................................................................................................7

3 General boiler information 8

3.1 General .......................................................................................................................8

3.1.1 ErP label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.2 Gas category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Data plate ....................................................................................................................9

3.2 Operation ....................................................................................................................9

3.4 Control panel ................................................................................................................10

3.5 Operational modes ...........................................................................................................10

4 Main components 11

4.1 Standard scope of delivery ....................................................................................................12

4.2 Accessories ..................................................................................................................13

4 Installer important points 14

5 Installation 15

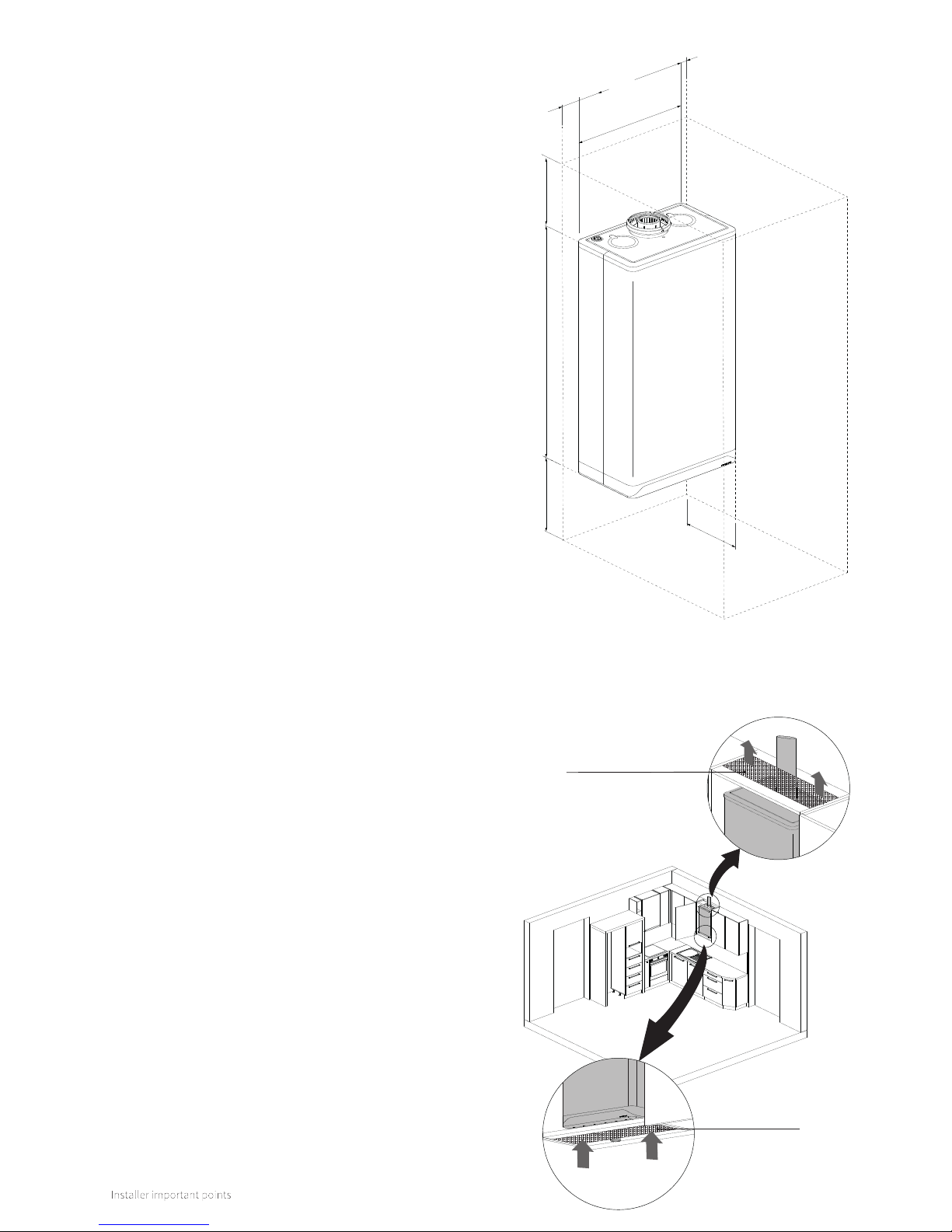

5.1 Overall dimensions of boiler + assembly bracket ...............................................................................15

5.1.1 Installing the wall bracket and assembly bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.2 Installation location ..........................................................................................................16

5.2.1 Installation in a kitchen cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

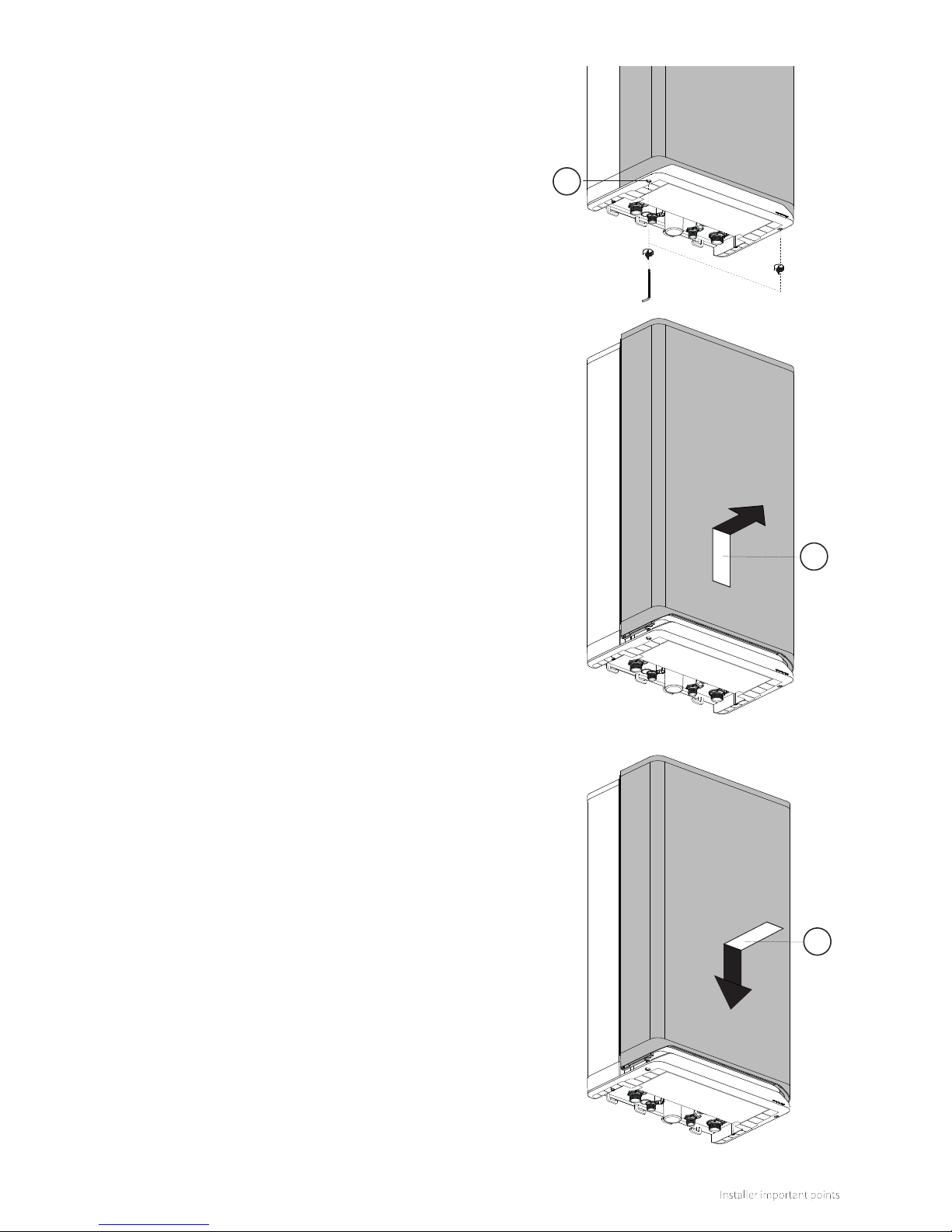

5.2.2 Removing/installing the front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

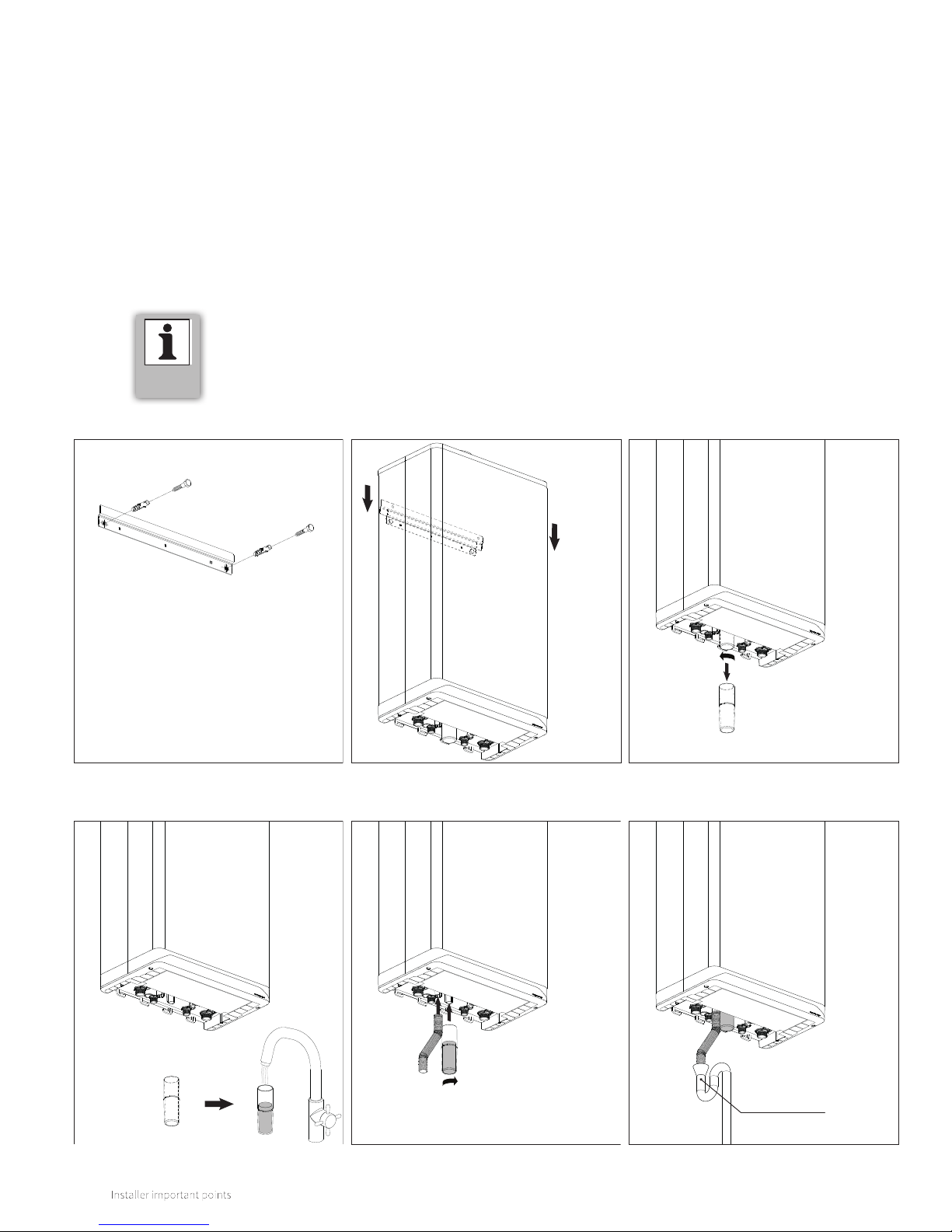

5.3 Installing the boiler ...........................................................................................................18

6 Connection 19

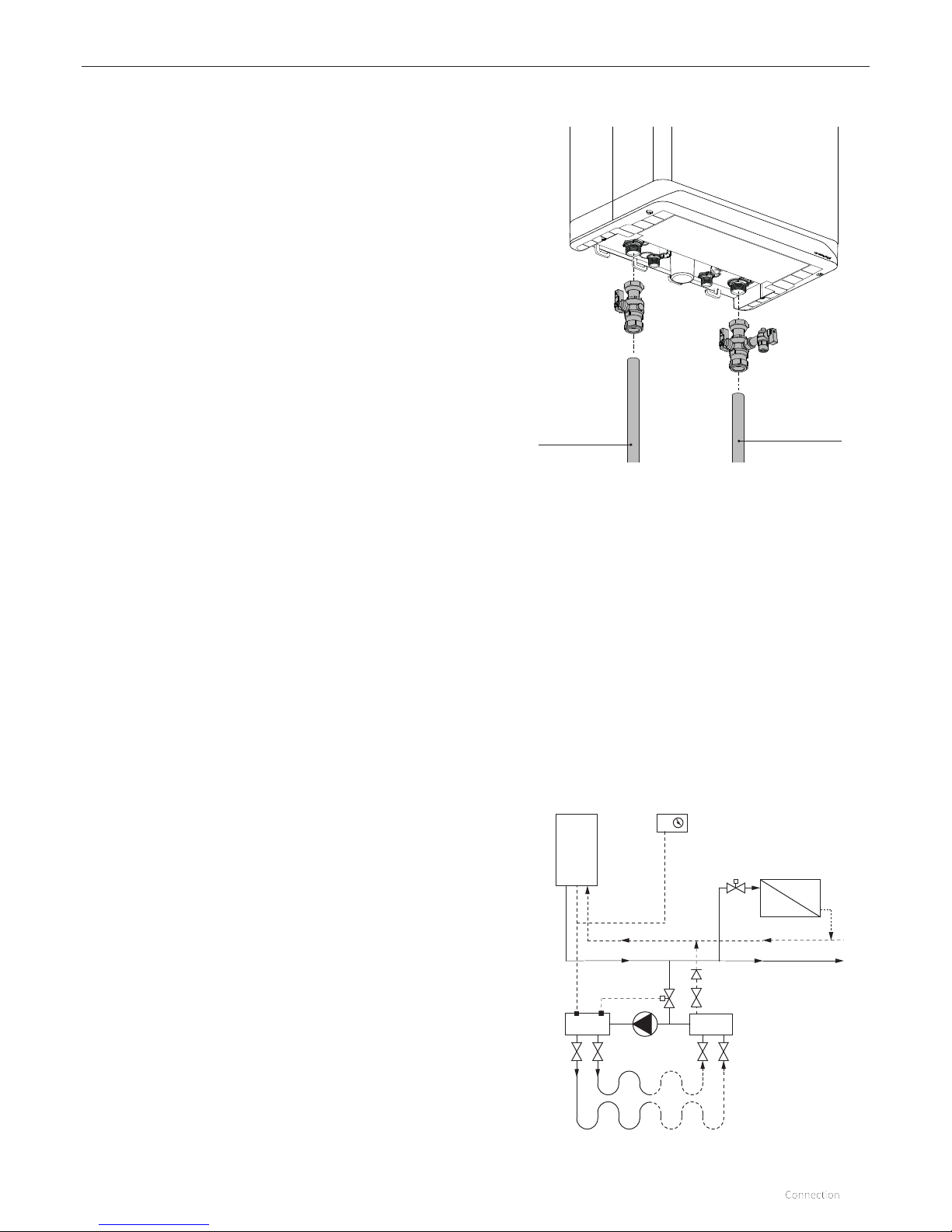

6.1 Connecting the central heating system ........................................................................................19

6.1.1 Expansion vessel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6.1.2 Thermostatic radiator valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1.3 Floor heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6.1.4 LT/HT zone system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

6.1.5 Division of central heating system in groups with extra heat source 21

CONTENTS

Benchmark places responsibilities on both manufacturers and installers. The purpose is to ensure that customers are provided

with the correct equipment for their needs, that it is installed, commissioned and serviced in accordance with the manufacturer’s

instructions by competent persons and that it meets the requirements of the appropriate Building Regulations. The Benchmark

Checklist can be used to demonstrate compliance with Building Regulations and should be provided to the customer for future

reference. Please read the Benchmark Checklist carefully, page , and complete all sections, as required by law, relevant to the

appliance and installation. Failure to install and commission according to the manufacturer’s instructions and complete the

Benchmark Commissioning Checklist will invalidate the warranty for the Gas Boiler installation. The details within the Checklist

will be required in the event of any warranty work. On completion the Checklist must be le with the end user. The relevant

sections of the Service Record, page , must be completed on each subsequent Service visit.

Installers are required to carry out installation, commissioning and servicing work in accordance with the Benchmark Code of

Practice which is available from the Heating and Hotwater Industry Council who manage and promote the scheme. Visit www.

centralheating.co.uk for more information.

3

6.2 Connection of domestic hot water ............................................................................................22

6.2.1 DHW circuit resistance graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

6.2.2 Boiler with heat pump boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6.2.3 Boiler with Pre-Heated Solar Boiler) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

6.3 Electrical connection .........................................................................................................25

6.4 Gas connection ..............................................................................................................25

6.5 Connecting room thermostat .................................................................................................26

6.5.1 Connecting Modulating OpenTherm thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.5.2 Connecting on/o room thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.5.3 Connecting 230V room thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.5.4 Connecting outdoor sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

6.5.5 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.5.6 Connecting boiler sensor/thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.5.7 PC interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.5.8 Comfort Touch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.6 Flue and air supply duct ......................................................................................................29

6.6.1 Dra, materials and insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

6.7 Pipeline lengths ..............................................................................................................30

6.7.1 Replacement lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

6.7.2 Example calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.8 General layout of the flue .....................................................................................................31

6.8.1 Wall terminal with twin-pipe horizontal terminal C13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.8.2 Façade combi-pipe horizontal terminal C13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.8.3 Roof terminal with combi-pipe vertical terminal and twin-pipe vertical terminal C33 34

6.8.4 Roof terminal and air supply duct from the façade C53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6.8.5 Clamping the flue system (parallel and concentric) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

7 Operation 38

7.1 Using the control panel .......................................................................................................38

7.2 Preparation activities .........................................................................................................38

7.2.1 Filling and venting central heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

7.2.2 Domestic hot tap water facility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

7.2.3 Gas supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.3 Commissioning procedure ....................................................................................................40

7.4 Clock function ...............................................................................................................41

7.5 Shutting down the boiler .....................................................................................................42

8 Settings and adjustments 43

8.1 Structure of the settings ......................................................................................................43

8.1.1 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

8.1.2 Domestic hot water menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

8.1.3 Central heating menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

8.1.4 RF menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.1.5 Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.2 Setting and adjusting the clock functions ......................................................................................49

8.2.1 Setting the clock program on CH operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

8.2.2 Setting the clock program on DHW operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.3 Parameters ..................................................................................................................52

8.4 Switching DHW comfort function on and o. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

8.5 Adjusting maximum central heating output ....................................................................................53

8.6 Adjusting pump capacity .....................................................................................................53

8.7 Weather-dependent control ..................................................................................................54

8.8 Conversion to another gas type ...............................................................................................55

8.9 Gas/air control ...............................................................................................................56

8.10 Inspection of gas air control ...................................................................................................57

8.10.1 Measuring flue gas at maximum output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.10.2 Measuring flue gas at minimum output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

8.10.3 Minimum output correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

9 Faults 63

9.1 Fault codes ..................................................................................................................63

9.2 Other faults ..................................................................................................................65

9.2.1 No heat (central heating) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

9.2.2 Central heating does not reach the correct temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.2.3 Central heating system remains too warm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.2.4 No domestic hot water (DHW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

9.2.5 Domestic hot tap water does not reach the correct temperature 66

9.2.6 Burner ignites loudly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

9.2.7 Burner resonates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4

10 Maintenance 68

10.1 Disassembly .................................................................................................................68

10.2 Cleaning .....................................................................................................................68

10.3 Installation ..................................................................................................................69

10.4 Checklist ....................................................................................................................70

11 Technical specifications 71

11.1 Electrical schematic ..........................................................................................................72

11.2 Product card according to CELEX-32013R0811, Appendix IV .....................................................................74

11.3 NTC resistances ..............................................................................................................74

12 Guarantee provisions and CE declaration 75

13 Gas boiler system commissioning checklist 76

14 Service record 77

To be completed at each annual service, not subsequent.

To be completed at each annual service, not subsequent.

5

1 PREFACE

The manufacturer Intergas Heating Ltd accepts no liability

whatsoever for damage or injury caused by failure to adhere

(strictly) to the safety regulations and instructions, or

carelessness during installation of the Intergas Boiler wall

mounted gas fired boiler and any associated accessories

Intergas Heating Ltd continuously developing ways to

guarantee the quality of its products and to improve them

where necessary. In so doing it reserves the right to modify at

any time the features named in this document.

Read and observe all safety instructions in this instruction

manual to prevent unsafe situations, fire, explosion, damage to

property or personal injury.

1.1 Regulation

1.2 Warnings

1.3 Manual handling

The Intergas combination boiler meets the requirements of Statutory Instrument 'The

Boiler (Eiciency) Regulations' and is deemed to meet the requirements of:

► Low Voltage Directive (2014/35/EC)

► Gas Appliances Regulation (2016/426/EC)

► Boiler Eiciency Directive for new oil- and gas-fired central heating boilers (92/42/EC)

► EMC Directive (2014/30/EC)

► RED Directive (2014/53/EU)

► Ecodesign (2009/125/EG)

► Energy labelling 2010/30/EU

Intergas declares that the materials used in the manufacturing of this appliance are

nonhazardous and that no substances harmful to health are contained within the

appliance.

Intergas accepts no responsibility for the unsatisfactory

performance of the appliance or flue arising from the failure

to comply with the installation and user instructions. Incorrect

installation could invalidate your guarantee and may lead to

prosecution.

The appliance cannot be removed from the orginal place of

installation and transferred to another site or re-sold without prior

consent from Intergas to re-register the appliance with Intergas in

order to maintain the warranty.

The boiler must be installed in accordance with these instructions

and the regulations currently in force. Read these instructions

carefully before installing or using the appliance. It is the installers

responsibility that the installation conforms to the current

legislation and Standard Codes of Practice.

When moving the boiler always keep your back straight, bend

your knees, don’t twist, move your feet. Avoid bending forwards or

sideways and keep the load as close to your body as

possible. Where possible transport the boiler using a suitable

trolley, sack truck or get some assistance. Grip the boiler firmly and

before liing establish where the weight is concentrated to

determine the centre of gravity, repositioning yourself if necessary.

6

1.6 Abbreviations

► DHW: Domestic hot water

► CH: Central heating

► CW: Comfort domestic hot water

► HE: High eiciency

► PHS: Pre Heated Solar water.

► LT: Low temperature (zone).

► HT: High temperature (zone)

► OT: OpenTherm

► RF: Radio frequency

► PC: Personal computer

► NTC: Sensor (Negative temperature coeicient)

► PP: Polypropylene

► CAC: Combination air supply duct and combustible

gas flue system (chimney system)

1.4 Pictograms

CAREFUL / IMPORTANT

Procedures which, if these are not performed

with the required caution, can damage the

product, the surrounding or the environment or

may result in personal injury.

COMMENT

Procedures and/or instructions which, if they

are not followed, can negatively aect the

operation of the boiler.

The following pictograms are used in this installation manual:

1.5 Warnings on the box

SEE

Reference to other manuals

INSTRUCTION (THIS SIDE UP)

Store the appliance upright as indicated on the

box.

INSTRUCTION (FRAGILE)

This is a fragile piece of equipment: Please be

very careful not to drop.

MAX 3 MAX2

INSTRUCTION (FRAGILE)

This is a fragile piece of equipment: Please

provide a dry storage for the appliance.

INSTRUCTIE (STACK)

No more than three boxes should be stacked on

top of each other.

7

A gas leak could potentially cause an

explosion. If you smell gas, observe the

following rules:

► Prevent flames or sparks:

- Do not smoke, use a lighter or strike

matches.

- Do not operate any electrical switches

or unplug any equipment.

- Do not use the telephone or ring

doorbells.

► Turn o the gas at the meter or regulator.

► Open windows and doors.

► Warn your neighbors and leave the

building

► Prevent anyone from entering the

building.

► Call the National Gas Emergency Service

on 0800 111 999.

L.P.G. boilers: Call the supplier’s number

on the side of the gas tank

It is law that all gas appliances are installed and serviced by a Gas Safe registered

competent engineer if in any doubt please check with Gas Safe (0800 408 5500)

and in accordance with the following recommendations:

► Current Gas Safety (Installation and Use) Regulations

► All current building regulations

► Building Standards (Scotland) Consolidated

► This appliance must be installed in accordance with the Gas (Safety and Use)

Regulations, current Building Regulations, Building Standards (Scotland),

I.S.813 Installation of Gas Appliances (Ireland), IEE Wiring Regulations (BS

7671), Health and Safety Document No. 635 (Electricity at Work Regulations)

and Local Water Authority Bye Laws

► UK Water Regulations and Bye Laws

► Health & Safety

2.1 General

2.2 The installation

The installation must comply with the following British Standards codes of practice:

► BS 5440: Flues and Ventilation for gas appliances of rated input not exceeding 70kW

(Part 1 Flues)

► BS 5440: Flues and Ventilation for gas appliances of rated input not exceeding 70kW

(Part 2 Air Supply)

► BS 5546: 2000 Installation of gas hot water supplies for domestic purposes.

► BS 5549: 1990 Forced circulation hot water systems

► BS 6700: 1997 Design, Installation, testing and maintenance of services supplying hot

water

► BS 6798: 2000 Specification for installation of gas fired hot water boilers of rated input

not exceeding 70kW

► BS 6891: 1998 Installation of low pressure gas pipe-work installations up to 35mm (RI)

► BS 7593: 1992 Code of practice for treatment of water in heating systems

► BS 7671: 2001 Requirements for electrical installations, IEE Wiring regulations

Reference should also be made to:

► Guide to condensing boiler installation assessment procedures for dwellings

► The institute of Gas Engineers document IGE/UP/7 for timber frame dwellings

2 SAFETY REGULATIONS

Safety precautions If you smell gas

8

3 GENERAL BOILER INFORMATION

The Intergas Xtreme wall-mounted gas boiler is a closed unit. The boiler is

intended solely to provide heat for the water in a central heating system

and domestic hot water installation for household use.

The Intergas Xtreme meets the European directives and additional national

regulations that are indicated by CE marking. The associated conformity

declaration can be requested from Intergas Heating Ltd (also see §12)

The Intergas Xtreme meets the electrical protection class IPX4D.

The boiler can be connected to stainless steel or plastic (PPT120)

combination throughputs that have a CE label.

3.1 General

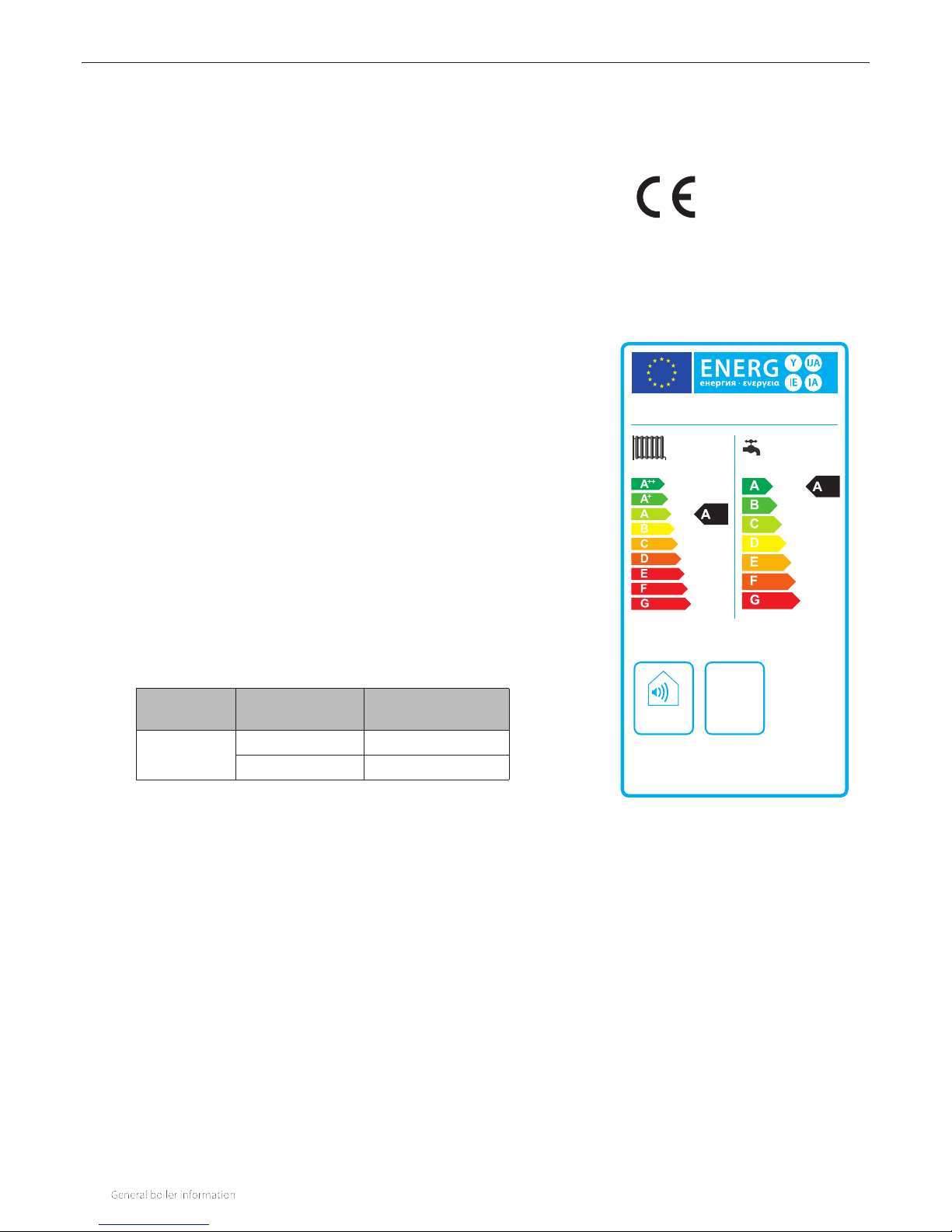

3.1.1 ErP label

3.1.2 Gas category

Gas category Gas type Gas inlet pressure

(mbar)

II

2H3P

Natural gas (G20) 20

LPG (G31) 37

The Intergas Xtreme is factory-set for H-gas, G20. The boiler

may optionally be converted to another gas type using a

conversion set (see §8.8).

Based on the European ErP Directive (Energy related Products) all newly

produced gas fired boilers have to meet minimum standards regarding

energy performance.

The Intergas Xtreme carries an European energy label containing specific

information regarding energy eiciency class (CH and DHW), noise level

en maximum power.

The Intergas Xtreme carries label A for both CH and DHW.

In addition the Intergas Xtreme meets the following DWH capacity profile:

► Xtreme 24 : L

► Xtreme 30 : XL

► Xtreme 36 : XXL

The extensive product fiche can be found in §11.2.

Xtreme -Intergas Heating Ltd

dB

--

--

kW

2015 811/2013

9

Identification of the product

You will find the unit details on the data plate on the bottom

of the unit. The data plate contains, beside the supplier

information and the boiler specification (boiler type and model

name), the following information:

3.3 Data plate

3.2 Operation

The Intergas Xtreme is a modulating high eiciency boiler. This means

that the capacity is adjusted according to the desired heating capacity.

Two separate copper circuits are integrated in the aluminium heat

exchanger.

In addition, the Intergas Xtremehas a second heat exchanger (heat

recovery unit). This second heat exchanger is integrated in the flue of the

boiler so that the eiciency of domestic hot water is increased further.

The residual heat of the flue gases of the central heating use is also used

to preheat the domestic hot water.

By applying this technology, less energy is required to bring the water to

the correct temperature and an extremely high eiciency is achieved.

The boiler has a burner controller which, with each heat demand of the

heater or the domestic hot water facility, controls the pump (only during

heat demand of the heater) and the fan, opens the gas valve, ignites the

burner and continuously monitors and regulates the flame, depending

on the requested capacity.

****

-yymm

****

Production code-Serial no.

YY = year of production,

mm = month of production

PIN

Product Information Number

Data related to Domestic Hot Water

Data related to Central Heating

Information regarding electrical power supply

(Voltage, mains frequency, elmax, IP-class)

PMS

Permissible overpressure in CH circuit in bar

PWS

Permissible overpressure in DHW circuit in bar

Qn HS

Input related to gross caloric value in kilowatts

Qn Hi

Input related to net caloric value in kilowatts

Pn

Output in kilowatts

BE, CH, DE, ES,

FR, GB, IE, IT, MT

Countries of Destination (EN 437)

I2E(s), I2H,

IIELL3P, II2H3P,

II2Esi3P

Approved unit categories (EN 437)

G20-20 mbar

G25-25 mbar

Gas group and gas connection pressure as set

at the factory (EN 437)

B23, ......C93(x)

Approved flue gas category (EN 15502)

Tmax

Maximum flow temperature in °C

IPX4D

Electrical protection class

10

The boiler has a number of operational modes:

The boiler is switched o.

The boiler is out of order but is connected to the mains voltage.

In this mode, the display view is characterized by:

► Showing the power LED [ ].

► Showing the pressure in the central heating system (in bar)

on the le display [ ].

► Showing a line on the right display [ ].

The boiler is switched on and is ready for a heat demand.

The boiler is switched on and is ready to answer a request for

either domestic hot water or hot central heating water.

In this mode, the display view is characterized by:

► Showing the power LED [ ]. All other symbols and values

are not displayed.

3.4 Control panel

The boiler has a fully integrated touch screen control panel

that displays information about the operational mode of the

boiler. Symbols (buttons), numbers, points and/or letters are

displayed.

The buttons light up so that they can be operated.

For extensive control options, see §8.

3.5 Operational modes

Boiler is switched o

(mains voltage is present, however)

Boiler is switched on

(ready for heat demand)

The boiler is in operation and is supplying domestic hot

water.

The boiler is in operation and is supplying domestic hot water

to one of the tap points. The display view is characterized by:

► Showing the power LED [ ].

► Showing the flame. The burner is switched on [ ].

► Showing the tap symbol [ ].

The boiler is in operation and is supplying central heating

water.

The boiler is in operation and is supplying central heating

water. The display view is characterized by:

► Showing the power LED [ ].

► Showing the flame. The burner is switched on [ ].

► Showing the radiator symbol [ ].

Boiler is in operation (domestic hot water)

Boiler is in operation (central heating water)

COMMENT

► Only use your fingers to operate the

touch screen

11

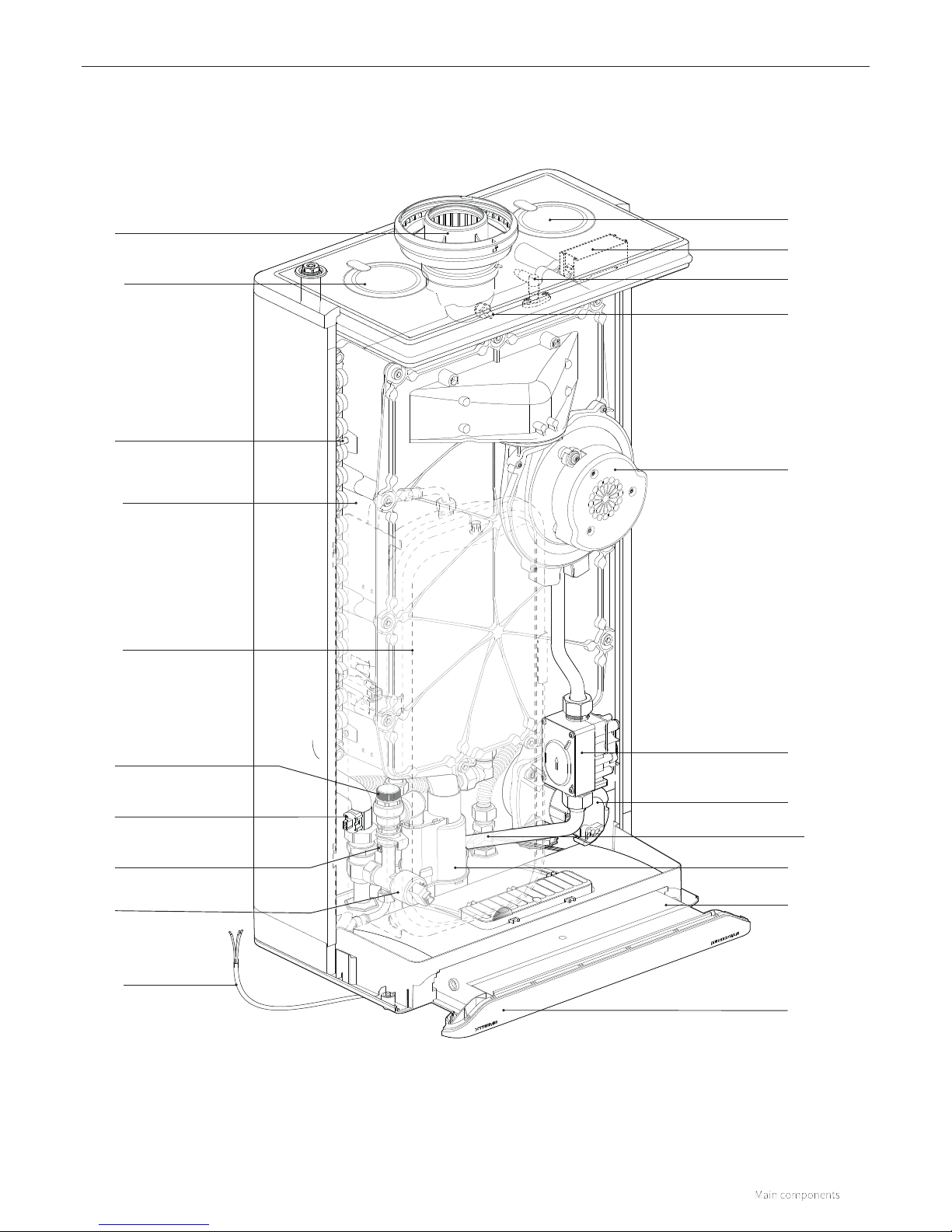

4 MAIN COMPONENTS

Flue adapter

Air supply duct

(not to be removed)

Ignition pin

Ignition unit

Air supply duct

(not to be removed)

Flue sensor

Fan

Gas valve

Pump

Flow sensor

Siphon base

Burner controller

with control panel

Control panel and

readout

Heat exchanger sensor

Heat exchanger

Expansion vessel

shown in broken lines

Domestic hot water sensor

Pressure relief valve

Central heating

flow sensor

Central heating

pressure sensor

Mains lead 230 V

AC without plug

(stripped)

12

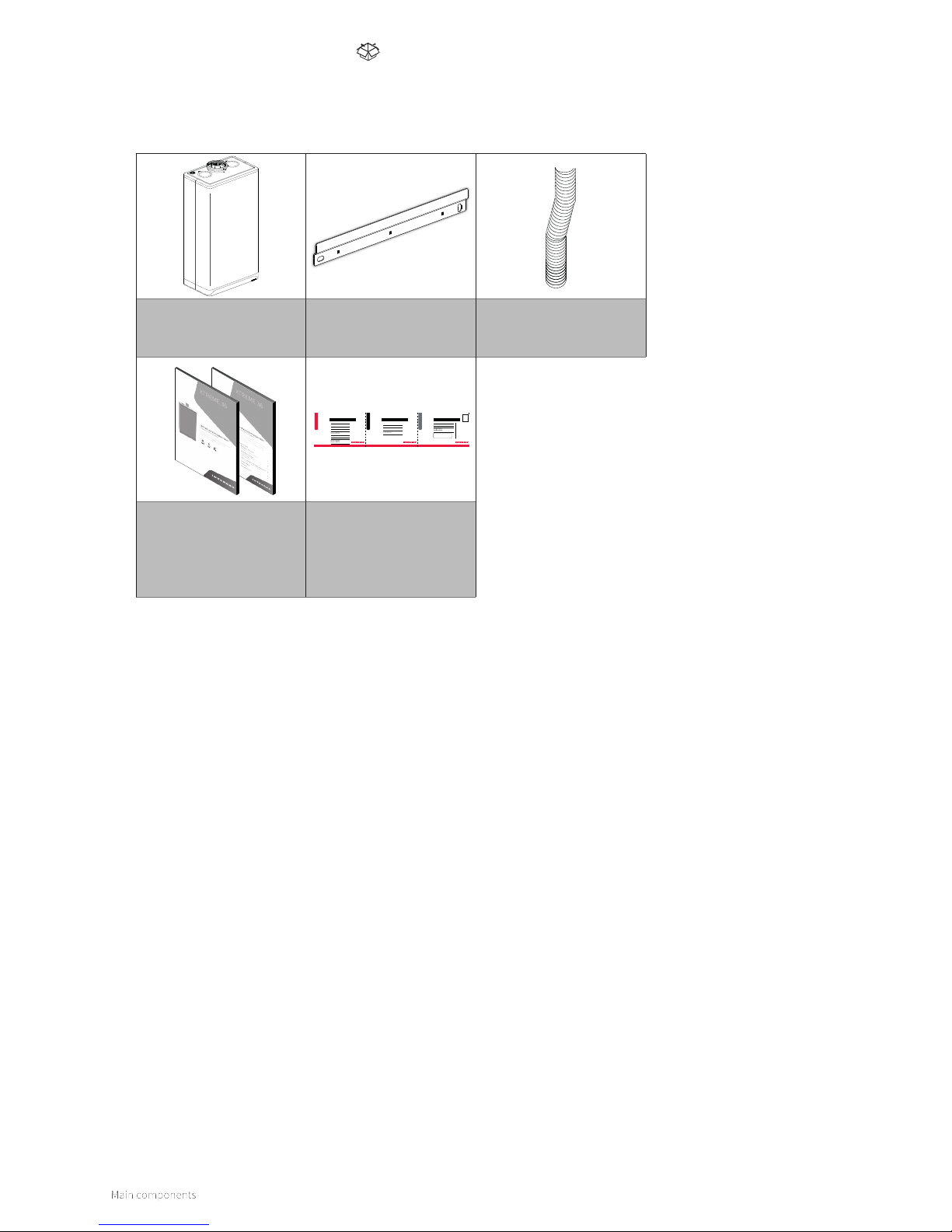

4.1 Standard scope of delivery

Boiler Wall bracket Flexible condensate hose

Garantiebewijs Intergas HR-ketel

Garantiebewijs Intergas HR-ketel Garantiebewijs Intergas HR-ketel

Datum installatie:

Volgens geldende voorschriften

geïnstalleerd door:

Naam installateur:

Adres:

Postcode:

Woonplaats:

Naam koper:

Adres:

Postcode:

Woonplaats:

Het garantiebewijs is slechts geldig, indien de aan het garantiebewijs gehechte

antwoordkaart binnen 8 dagen na de installatie wordt ingezonden. Deze kaart

moet volledig en duidelijk worden ingevuld en voorzien zijn van de handtekening

van koper en installateur. Door ondertekening van deze kaart verklaart koper

zich akkoord met de staat van de ketel bij aflevering.

Het garantiebewijs is slechts geldig, indien de aan het garantiebewijs gehechte

antwoordkaart binnen 8 dagen na de installatie wordt ingezonden. Deze kaart

moet volledig en duidelijk worden

ingevuld en voorzien zijn van de handtekening

van koper en installateur. Door ondertekening van deze kaart verklaart koper

zich akkoord met de staat van de ketel bij aflevering.

Voor de ‘Garantiebepalingen

Intergas HR-ketels’ verwijzen

wij u naar onze website:

www.intergasverwarming.nl

of naar het bij uw HR-ketel

bijgevoegde installatievoorschrift.

Op uw verzoek sturen wij u

graag een exemplaar toe.

Datum installatie:

Naam koper:

Adres:

Postcode:

Woonplaats:

Installateur

>>Betrouwbaar in warmte >>Betrouwbaar in warmte >>Betrouwbaar in warmte

Type/Serienr.

Intergas Verwarming BV

Antwoordnummer 5

7740 VB COEVORDEN

Datum installatie:

Naam koper:

Adres:

Postcode:

Woonplaats:

Type/Serienr. Type/Serienr.

Postzegel

niet nodig

voor klant

voor fabrikant

12345678910

12345678910

12345678910

voor installateur

Installation and operation

instruction

Guarantee card

Check whether the package is undamaged. Unpack the boiler

and check whether all components are present. Also check

for any damages to the boiler or accessories and, if present,

immediately notify the supplier.

13

Item no 090347

Post-Heating Solar Boiler

conversion set

Item no 842177

Thermostatic mixing valve

Item no 203207

Outdoor sensor

Item no 093697

LT/HT two-way valve set

Item no 093707

LT/HT three-way valve set

Item no 081286

Extension L=100 incl.

wall bracket (for plume

management kit)

Item no 084661

Bend 45°

Item no 084660

Bend 90°

Item no 081295

Deflector kit

Item no 087910

Weather slate (steep roof)

Item no 087372

Weather slate (flat roof)

Item no 089975

Extension L=100

incl. wall bracket

Item no 081298

Horizontal telescopic

oset wall terminal

1

Item no 082980

Horizontal straight wall

terminal extended

1

Item no 081297

Horizontal telescopic wall

terminal

1

Item no 0821973

Vertical roof terminal

(incl. boiler adapter 60/100)

Item no 081294

Plume management kit

Item no 081284

Elbow 90° (for plume

management kit)

Item no 081285

Elbow 60° (for plume

management kit)

4.2 Accessories

Original Intergas accessories can be ordered separately at

the regular wholesaler. Instructions about the correct way to

assemble and use these accessories are provided upon order

and are therefore not included in this installation manual.

1

Only to be used in combination with the base adapter on the boiler

14

4 INSTALLER IMPORTANT POINTS

Please read all instructions before fitting this appliance

► The installer shall instruct the user on the operation of the boiler, safety devices contained within

the boiler and on the location of the filling loop and how to re-pressurise the system if the water

pressure falls.

► The installer should hand over the installation and user instructions upon completion with the

completed Benchmark Commissioning Checklist.

► The service engineer must complete the service record on the Benchmark Checklist aer each

service.

► It is required under Gas Safe Regulations for the installation to be notified to and registered with

Gas Safe, Intergas and Building Control (Gas Safe Notifcation).

► Before proceeding to commission the boiler check the gas inlet pressure is 20mbar (NG) or

37mbar for Propane.

► Combustion analysis with a correctly calibrated and certificated analyser is essential for safe

commissioning of the boiler.

► A pressure reducing valve set to 3.5 bar must be fitted if supply mains pressure is above 4 bar.

► In hard water areas where the PH is 200ppm or above, appropriate protection actions must be

taken in accordance with BS 7593 in line with building regulations Part L.

See also Guarantee Provisions on page 75, point 4.

► The user should be instructed to keep the instructions in a safe place for servicing and future

reference.

► It is important to keep the boiler clear of dust during the installation. In particular, do not allow

debris to enter the flue connection at the top.

► Before fitting the boiler ensure that the pipe work that you are installing is connected to the

appropriate connections on the boiler.

It is important to thoroughly flush the water circuits, aer isolating the boiler, in order to remove

any fluxes and debris from them. This should be done particularly where boilers are being fitted to

existing radiator circuits (please refer to current Standard Codes of Practice).

► Intergas recommend water treatment in accordance with the Benchmark Guidance on Water

Treatment in Central Heating Systems, we recommend the use of FERNOX, SENTINEL or ADEY

inhibitors. It is most important that correct concentration of water treatment is maintained

for the life of the boiler, a water sample is required on installation and to be verified by the

aforementioned manufacturers should we attend a warranty call a water sample may be required

to keep the warranty valid. (BS 7593:2006)

► This boiler has been factory set but adjustment may be required to the heating input in order to

match the individual heating demand. This can be done by changing parameter P010 (= max.

power CH) or parameter P070 (= max. power domestic water).

► Please do not use the pressure relief valve as a means of flushing the system.

► Remember that aer hot water draw of a possible delay may occur before the heating system will

fire up.

► All fluxes, residues and cleaner must be flushed from pipe-work and radiators prior to

commissioning.

► External expansion vessels are best connected water side downwards to allow correct draining/

cleaning of system and to prolong the life of the vessel diaphragm.

► Note: an anti-cycle delay time can be set up to a maximum of 15 minutes by adjusting parameter

P036 as described in §8.3.

► If you experience any problems please refer to the installation and commissioning guidelines

within the boiler instruction manual. If necessary, please contact Intergas Heating Ltd).

15

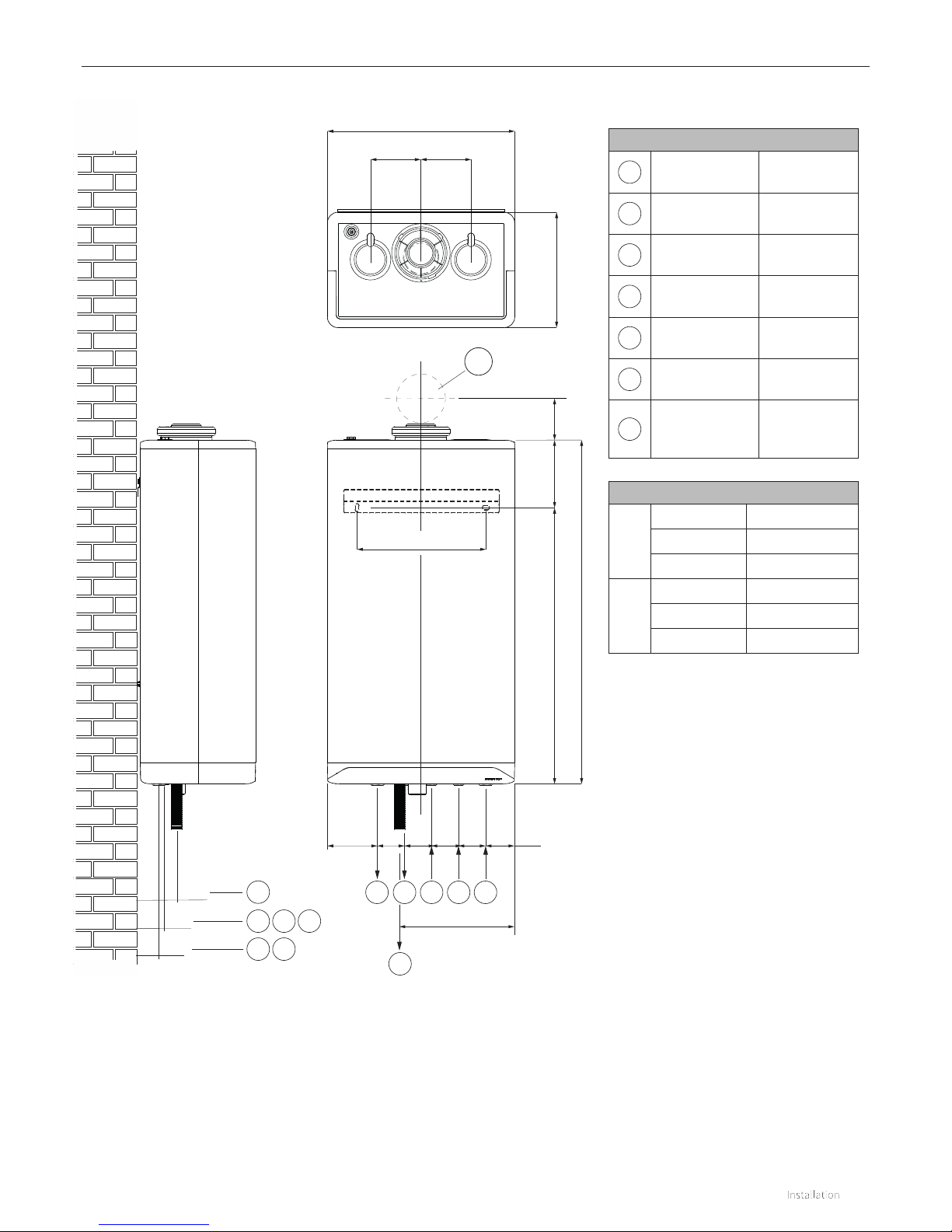

450

277

120

120

6565120 6565 70

275

148 98h

H

=320=

50

65

95

Connections

A

Central heating

flow

3/4"

B

Central heating

return

3/4"

C

Gas flow 1/2"

D

Domestic hot

water - cold

1/2"

E

Domestic hot

water - hot

1/2"

F

Condensation

drain

Ødn25

Z

Flue pipe / Air

supply

Ø60/100

(concentric,

wall terminal )

5 INSTALLATION

A

E C D

B

F

A B

D E

F

Z

C

5.1 Overall dimensions of boiler + assembly bracket

5.1.1 Installing the wall bracket and assembly bracket

Using the corresponding fasteners, attach the wall bracket and

the assembly bracket horizontally to the wall. Refer to the drill

pattern in §5.1 or refer to the installation instructions supplied

with the assembly bracket.

Overall dimensions

h =

650 mm Xtreme 24

650 mm Xtreme 30

710 mm Xtreme 36

H =

766 mm Xtreme 24

766 mm Xtreme 30

826 mm Xtreme 36

16

5.2.1 Installation in a kitchen cabinet

The boiler can be placed between two kitchen cabinets or

inside one cabinet. Make sure, however, that there is suicient

ventilation below and above the boiler. If the boiler is placed

inside a cabinet, ventilation openings of at least 50cm2 must

be created above as well as below.

The boiler must be installed on a wall that has suicient

strength to be able to bear the boiler filled with water.

There must be a Earthed fuse spur available at a maximum

distance of one (1) metre from the boiler. The condenstate

must be connected from the boiler and drain away to the

sewer.

To prevent freezing of the condensation drain piping, the boiler

must be installed in a frost-free area.

Make sure the boiler is easily accessible by ensuring that there

is suicient free space surrounding the boiler. This facilitates

the maintenance of the boiler, amongst other things.

5.2 Installation location

at least 50cm

2

at least 50cm

2

min. 200

H

min. 250

min. 50

277

450

min. 10

17

5.2.2 Removing/installing the front panel

► The front panel of the boiler must be removed to perform

various maintenance activities. Do this as follows:

► Unscrew both (lossless) socket screws (1) under the boiler

by using a 5mm socket wrench.

► Slide the front panel (2) upward and then remove it by

pulling it towards you.

1

2

Replace front panel

To replace the front panel, proceed as follows:

► Position the front panel (3) against the boiler and slide

it downwards until it is properly connected to the

boiler.

► Screw tight both socket screws under the boiler using

a 5mm socket spanner.

3

18

5.3 Installing the boiler

1. Install the wall bracket.

2. Place the boiler: Slide the boiler from the top down, over the

wall bracket.

3. Remove the siphon cup.

4. You must fill the siphon cup just over half full with water.

5. Replace the cup. Install the flexible hose on the spout of the

siphon.

6. Connect the flexible hose of the siphon to a 19 mm solvent

weld pipe. To minimize the risk of freezing the condensate

pipe should be connected internally and terminate to an

internal sol stack (ref.: TB115 Gas Safe & HHIC).

7. Install the air supply duct and the flue (see §6.6).

COMMENT

► The Intergas Xtremehas a boiler-specific

siphon cup. Ensure that the proper

version is ordered upon replacement.

(Item no 510054)

1. Assemble wall bracket

4. Fill siphon cup 5. Replace siphon cup in position and

attach flexible hose

6. Connect the flexible hose to the

sewer via an open connection.

2. Place boiler 3. Remove siphon cup

Open connection

to sewer

19

6.1.2 Thermostatic radiator valves

6.1.1 Expansion vessel

► Flush the central heating system thoroughly.

► Fit the flow and return pipes to the isolation valves.

► All pipes must be fitted unstressed in order to prevent pipes

from ticking.

► Existing connections must not be twisted, in order to avoid

leakages.

The CH system should be equipped with:

► A drain tap in the return pipe immediately below the

appliance.

► A drain tap at the lowest point(s) of the installation.

► A non return valve, if pipes run upwards at a short

distance from the appliance. This avoids the occurrence of

thermosyphon eect during DHW operation mode.

If all radiators have thermostatic radiator valves or valves that

can be closed to separate the flow completely from the return,

a minimum amount of water circulation must be ensured by

the installation of bypass piping, for example (also see §8.5).

The appliance is fitted with a expansion vessel adequate for a

system with a water volume not exceeding 100 litres, typically 8

radiators. For larger volume systems, an additional expansion

vessel must be fitted. Contact Intergas for advice in these cases.

6 CONNECTION

6.1.3 Floor heating

Floor heating with pump

For eective operation of the DHW supply any undesired

circulation through the appliance as a result of a second pump

in the CH circuit must be avoided.

Connect the floor heating system in a hydraulically neutral

manner to the appliance, or equip the CH circuit with an

electric shut-o valve or check valve to prevent flow

through the appliance when there is no CH request for heat.

Make sure there is a minimum of water circulation; see §8.5.

Underfloor heating connection diagram

A. Boiler

B. Central heating pump

C. Thermostatic control valve

D. Spring-operated non-return valve

E. Electric shut-o valve 230V~

F. Radiators

G. Room/clock thermostat

H. Maximum thermostat

A

G

H

F

C

B

C

E

D

6.1 Connecting the central heating system

Return pipe

Flow piping

20

6.1.4 LT/HT zone system

The central heating system can be divided into two groups,

each with a dierent heating temperature, for example a hightemperature zone (HT) with radiators and a low-temperature

zone (LT) with underfloor heating system without its own

circulation pump.

Both zones must have their own room thermostat. LT/HR

zone control is activated by the adjustment of a number of

parameters.

There are two dierent installation sets available for installing

the LT/HT zone system:

► Installation set with two-way valve (item no 093697).

► Installation set with three-way valve (item no 093707).

Operational principle

The valve divides the heat over both zones. Both zones have

their own room thermostat and are alternately (time-limited)

heated through switching over the valve.

IMPORTANT

► Ensure that the external pump pressure

of the central heating pump in the boiler

is taken into consideration during the

design phase of the underfloor heating.

► If the radiators in the HT zone have

thermostatic radiator valves, this zone

must have a bypass valve.

21

Operational principle

If the room thermostat switches o the boiler because another

heat source is heating the room, it is possible that the other

rooms will cool down.

This can be prevented by dividing the central heating system

into two groups. The group with the external heat source (Z2)

can be closed o from the main circuit with an electric shut-o

valve. Both groups have their own room thermostat.

Note: This ‘external heat source’ control can only be applied if

no external boiler must be heated.

Installation manual

► Place the shut-o valve (B) according to the connection

diagram.

If an OpenTherm or an on/o thermostat is used:

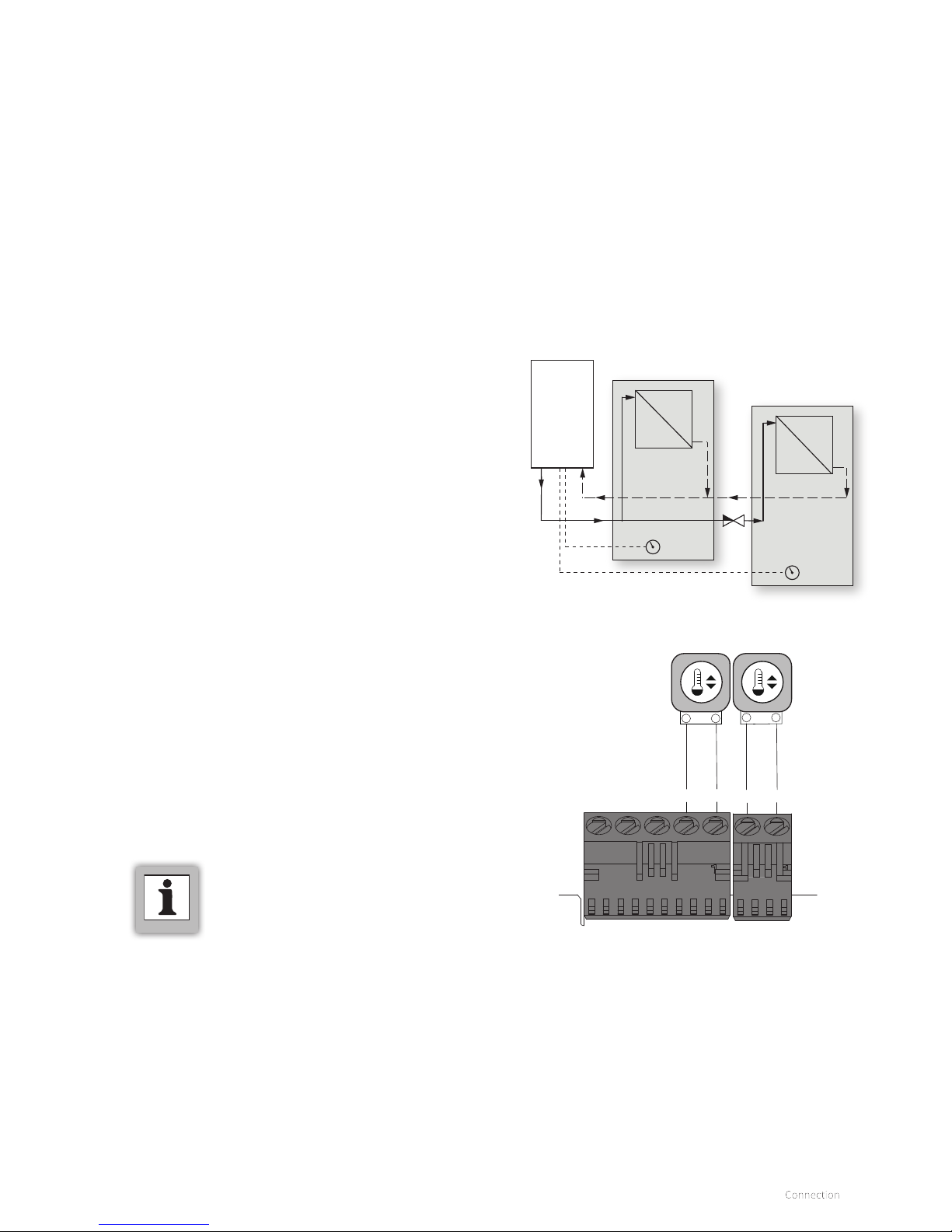

6.1.5 Division of central heating system in groups with extra heat source

Connection diagram ‘external heat source’

control

A. Boiler

B. Electric shut-o valve 230V~

C. Radiators

T1. Room thermostat Group 1

T2. Room thermostat Group 2

Z1. Group 1

Z2. Group 2

A

Z1

B

C

T

1

Z2

C

T

2

COMMENT

► All types of thermostats (OpenTherm, on/

o or RF) can be used in both groups.

12

X13 X12

12

12

12

T2 T1

► Connect the room thermostat of Group 1 (T1) to Connector

X12 1/2.

► Connect the room thermostat of Group 2 (T2) to Connector

X13 1/2.

► Change parameter P081 (see §8.3).

If an RF thermostat is used:

► Connect the RF thermostat using the RF menu; see §7.1.4.

The RF thermostat can only be used for Group 2.

► Change parameter P081 (see §8.3).

Connect thermostats Groups 1 and 2

22

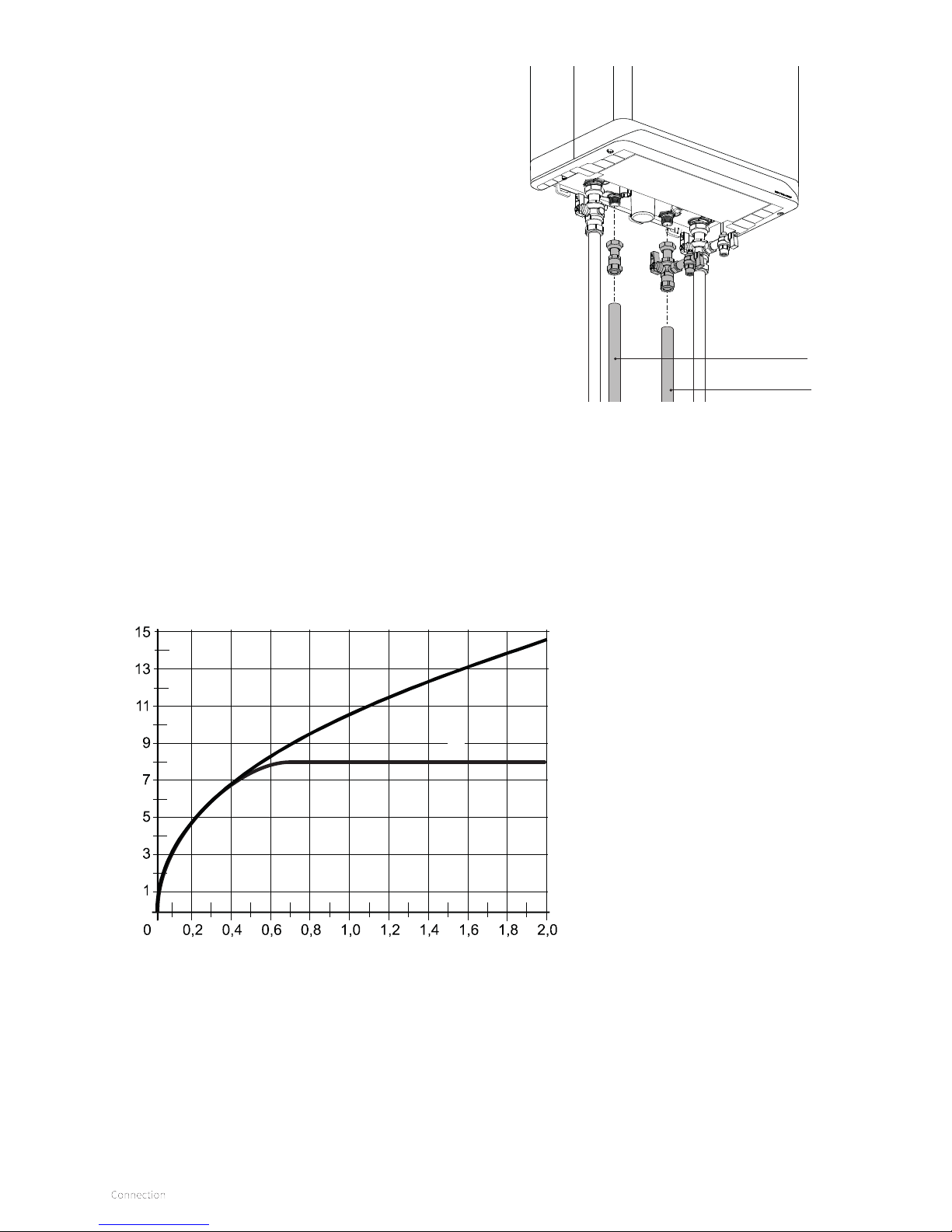

6.2.1 DHW circuit resistance graph

► Flush the installation thoroughly to clean (please refer to

current Standard Codes of Practice).

► Fit the cold and hot water pipes into the shut o valve and

the elbow.

► Existing connections must not be twisted, in order to avoid

leakages. Make sure the compression fittings are tightened

thoroughly to prevent leakage.

Comments

► The specific pipeline length with a piping diameter of

12/10mm or 15/13mm is 30 meters and 17.7 meters,

respectively.

► If the boiler is only used for the domestic hot water facility,

the heating function can be switched o. Parameter P001

must then be changed from 0 to 2. In this case, the central

heating system does not need to be connected or filled.

► If the boiler is out of order and disconnected from the

electricity network during the winter months, the water

must be drained to prevent freezing. Disconnect the

domestic hot water connections immediately directly under

the boiler.

► The Xtreme 24 is equipped with a flow restrictor with a

nominal value of 8l/min. The Xtreme 30 and Xtreme 36 do

not have this feature. If desired, this can be ordered from

Intergas as an option.

The Xtreme 36 allows larger volume flows with high water

pressures; to ensure an exhaust temperature of 55°C, the

DHW facility has to be set at 9 l/min.

6.2 Connection of domestic hot water

Cold water pipe

Water supply system (bar)

Domestic hot water

piping

Flow rate (l/min)

B, C

A

A. Xtreme 24

B. Xtreme 30

C. Xtreme 36

23

A

B

C

D

E

F

A. Heat pump

B. Boiler

C. Switch valve

D. Cold water inlet

E. DHW temperature of heat pump

F. DHW temperature of domestic hot water

Connection diagram of boiler with heat pump boiler

Installation:

The combination must be connected according to the

connection diagram. The following points are important to

guarantee a correct operation of the combination.

Thermostatic switch valve:

The thermostatic switch valve used is a modified valve that

meets the specific requirements to which the combination

heat pump boiler and Intergas Xtremeare subject. For the

correct operation of the combination, the switch valve has a

fixed temperature setting. The thermostatic switch valve can be

ordered from Intergas (item no: 065127).

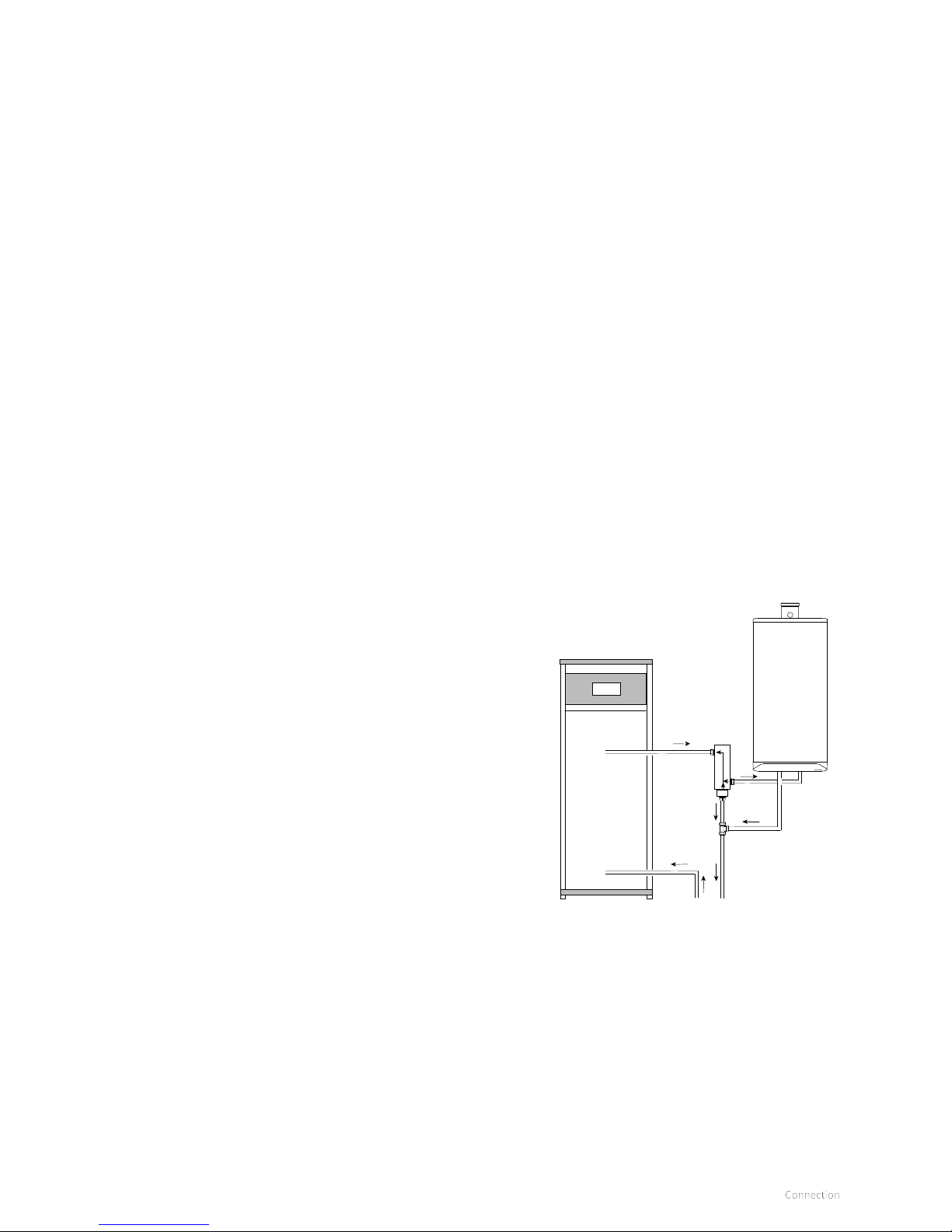

6.2.2 Boiler with heat pump boiler

The boiler is suitable for use in combination with a heat pump

boiler.

If the exhaust temperature of a heat pump boiler is lower than

55°C, the Intergas Xtrememakes sure that the domestic hot

water from the heat pump boiler is post-heated under HE

conditions.

Operational principle:

The domestic hot water connection of the heat pump boiler

is connected to the mix input of the thermostatic switch valve

(see the principle diagram). If the DHW temperature of the

boiler is higher than the set temperature of the switch valve,

the heat pump boiler will be tapped. Because the switch valve

is not fully closing, a small amount will also run through the

Intergas Xtreme(about 10% of the total flow).

As soon as the exhaust temperature of the heat pump boiler

becomes lower than the set temperature of the switch valve,

the flow through the Intergas Xtremewill increase. If the flow

becomes greater than the domestic hot water threshold of

the Intergas Xtreme, the boiler will start domestic hot water

demand.

When the exhaust temperature of the heat pump boiler has

become lower than the set temperature of the switch valve

minus 12K, almost the entire domestic hot water flow goes

through the Intergas Xtreme. The small leakage flow is now

taken from the heat pump boiler. Aer the entire switching of

the switch valve, the domestic hot water flow will be limited by

the Intergas Xtreme.

24

Domestic hot water inlet pressure:

For a flow volume of 20 litres per minute, the initial pressure

must be a minimum of 2.3 bar. The allowed domestic hot

water operational pressure for the combination may be a

maximum of 6 bar. A safety group (6 bar) must be installed for

this purpose.

Maximum flow volume:

If the domestic hot water flow is greater than 20 litres per

minute, the Intergas Xtremewill start domestic hot water

demand, regardless of the exhaust temperature of the heat

pump boiler.

Maximum temperature setting of the heat pump boiler:

The temperature of the heat pump boiler may not be set higher

than 60°C.

Position of thermostatic switch valve:

To prevent the thermostatic switch valve being influenced too

much by the surrounding air, this valve must be placed in a

vertical position and as close as possible to the domestic hot

water connection of the boiler (maximum distance of 100mm).

This prevents the boiler operating with each tap request.

Influence of water flows:

To prevent the flow being influenced by the Intergas

Xtremeduring the switching of the valve, the domestic hot

water ‘out’ pipeline of the combination must run straight (see

connection diagram [F]).

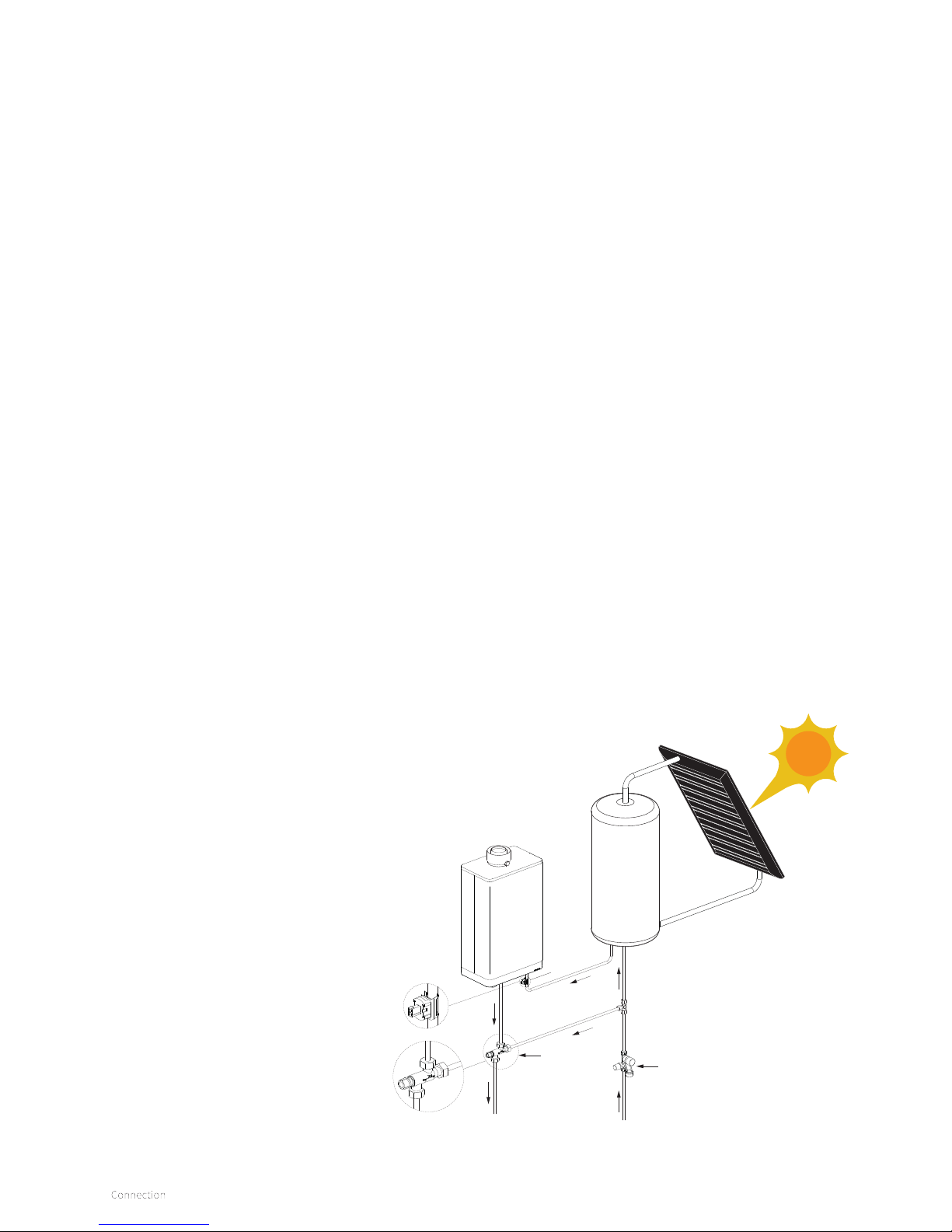

6.2.3 Boiler with Pre-Heated Solar Boiler)

A connection set and a thermostatic mixing valve are available

to order for this purpose.

Comment:

The cold water sensor must be connected to Connector X13

4/5. When combined with a solar energy system, a thermostatic

mixing valve, set at 62.5°C, must always be placed aer the

boiler.

► Pre-heated Solar boiler conversion set item no 090347

► Thermostatic mixing valve item no 842177

C

C

H

D

B

A

C

E

G

F

I

ART.NR.

842177

A

Connection diagram:

A. Boiler

B. Solar boiler

C. Cold water

D. Safety group

E. T max. 85°C

F. Domestic hot water

G. Thermostatic mixing valve 35°C-65°C

(set at 62.5°C)

H. Domestic hot water mixed

I. Cold water sensor

Loading...

Loading...