Xclusive 24

G.C. 47-291-13

Xclusive 30

G.C. 47-291-14

Xclusive 36

G.C. 47-291-15

INSTALLATION MANUAL

High Eiciency Wall-Mounted Gas Boiler

Read this installation manual thoroughly before the installation and use of the

boiler. Follow all indicated instructions. This installation manual must remain

with the boiler.

Smart Opentherm™

Benchmark places responsibilities on both manufacturers and installers. The purpose is to ensure that customers are provided

with the correct equipment for their needs, that it is installed, commissioned and serviced in accordance with the manufacturer’s

instructions by competent persons and that it meets the requirements of the appropriate Building Regulations. The Benchmark

Checklist can be used to demonstrate compliance with Building Regulations and should be provided to the customer for future

reference. Please read the Benchmark Checklist carefully, page 90 , and complete all sections, as required by law, relevant to

the appliance and installation. Failure to install and commission according to the manufacturer’s instructions and complete the

Benchmark Commissioning Checklist will invalidate the warranty for the Gas Boiler installation. The details within the Checklist will

be required in the event of any warranty work. On completion the Checklist must be le with the end user. The relevant sections of

the Service Record, pages 91 & 92, must be completed on each subsequent Service visit.

Installers are required to carry out installation, commissioning and servicing work in accordance with the Benchmark Code of

Practice which is available from the Heating and Hotwater Industry Council who manage and promote the scheme. Visit www.

centralheating.co.uk for more information.

CONTENTS

1 Preface 5

1.1 Regulation ....................................................................................................................5

1.2 Warnings .....................................................................................................................5

1.3 Manual handling ..............................................................................................................5

1.4 Pictograms ...................................................................................................................6

1.5 Warnings on the box ...........................................................................................................6

1.6 Abbreviations .................................................................................................................6

2 Safety regulations 7

2.1 General .......................................................................................................................7

2.2 The installation ...............................................................................................................7

3 General boiler information 8

3.1 General .......................................................................................................................8

3.1.1 ErP label ......................................................................................................................8

3.1.2 Gas category ..................................................................................................................8

3.2 Operation ....................................................................................................................9

3.3 Data plate ....................................................................................................................9

3.4 Control panel ................................................................................................................10

3.5 Operational modes ...........................................................................................................10

4 Main components 11

4.1 Standard scope of delivery ....................................................................................................12

4.2 Accessories ..................................................................................................................13

5 Installer important points 14

6 Installation 15

6.1 Overall dimensions of boiler including the wall bracket .........................................................................15

6.1.1 Mounting the wall bracket ....................................................................................................15

6.2 Installation location ..........................................................................................................16

6.2.1 Installation within a kitchen area or wall cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.2.2 Removing/installing the front panel ...........................................................................................17

6.3 Installing the boiler ...........................................................................................................18

7 Connection 19

7.1 Connecting to the central heating system circuit ...............................................................................19

7.1.1 Expansion vessel .............................................................................................................19

7.1.2 Thermostatic radiator valves ..................................................................................................20

7.1.3 Underfloor heating ...........................................................................................................20

7.1.4 X-Plan zone Hydraulic diagram ................................................................................................22

7.1.5 X-Plan wiring diagram (Unvented cylinder option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1.6 S-Plan zone hydraulic diagram ................................................................................................24

7.1.7 S-Plan wiring diagram ........................................................................................................25

7.1.8 S-Plan wiring diagram (With outside weather compensation kit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

2

7.1.9 Y-Plan zone hydraulic diagram ................................................................................................27

7.1.10 Y-Plan wiring diagram ........................................................................................................28

7.2 Connection of domestic hot water ............................................................................................29

7.2.1 DHW circuit resistance graph ..................................................................................................29

7.2.2 Boiler with heat pump boiler ..................................................................................................30

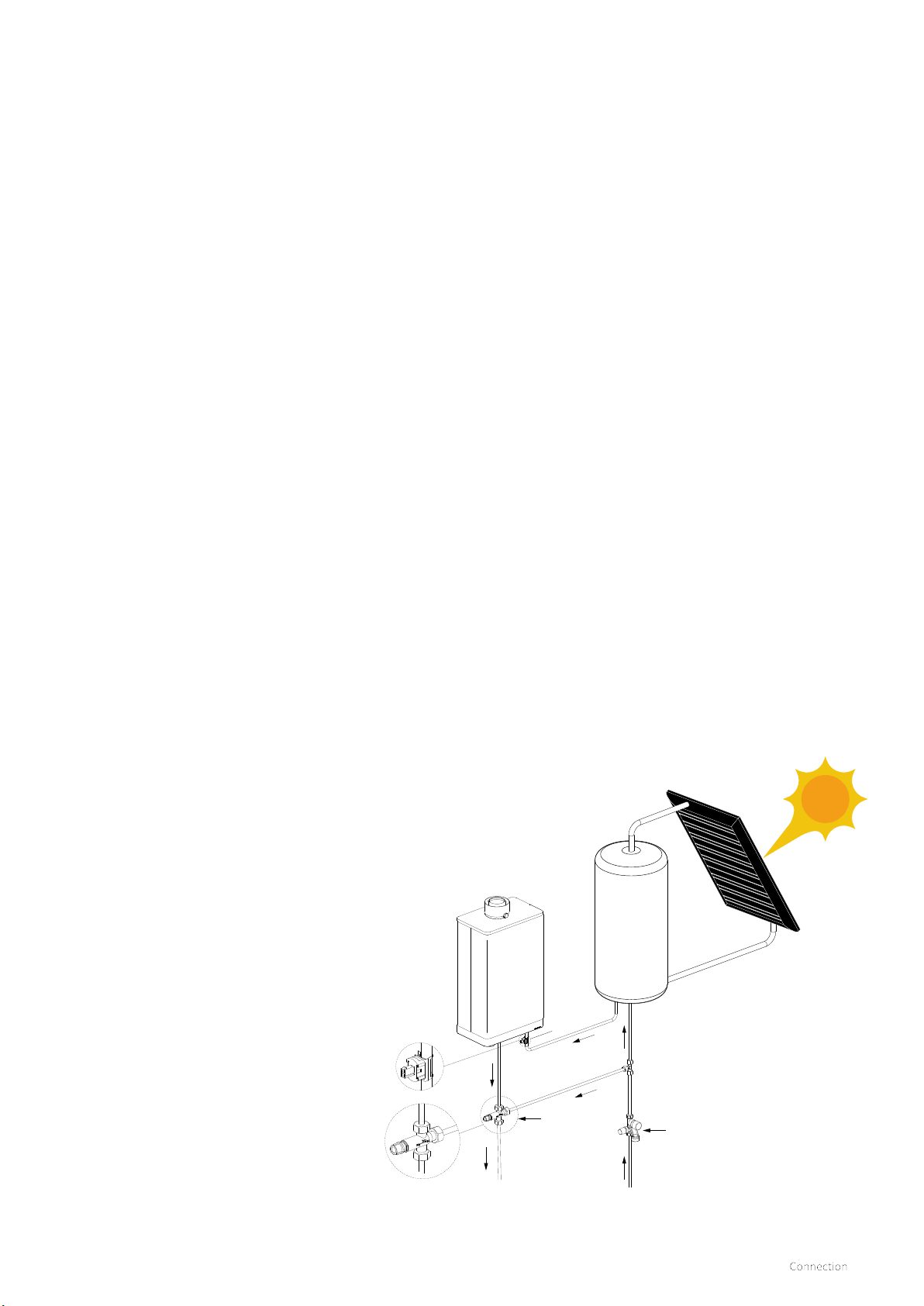

7.2.3 Boiler with Pre-Heated Solar Boiler) ...........................................................................................31

7.3 Electrical connection .........................................................................................................32

7.4 Gas connection ..............................................................................................................32

7.5 Connecting room thermostat .................................................................................................33

7.5.1 Connecting Modulating OpenTherm thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.5.2 Connecting on/o volt free TPI room thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.5.3 Connecting 230V room thermostat ............................................................................................33

7.5.4 Connecting outdoor sensor ...................................................................................................34

7.5.5 Frost protection ..............................................................................................................34

7.5.6 Connecting boiler sensor/thermostat ..........................................................................................35

7.5.7 PC interface .................................................................................................................35

7.5.8 Comfort Touch ...............................................................................................................35

7.6 Flue and air supply duct ......................................................................................................36

7.6.1 Flue, materials and compounds ...............................................................................................36

7.7 Pipeline lengths ..............................................................................................................37

7.7.1 Replacement lengths .........................................................................................................37

7.7.2 Example calculation ..........................................................................................................37

7.8 General layout of the flue .....................................................................................................38

7.8.1 Horizontal wall terminal 60/100mm C13 .......................................................................................39

7.8.2 Flue terminal positions 60/100mm C13 ........................................................................................40

7.8.3 PMK terminal positions 60mm ................................................................................................41

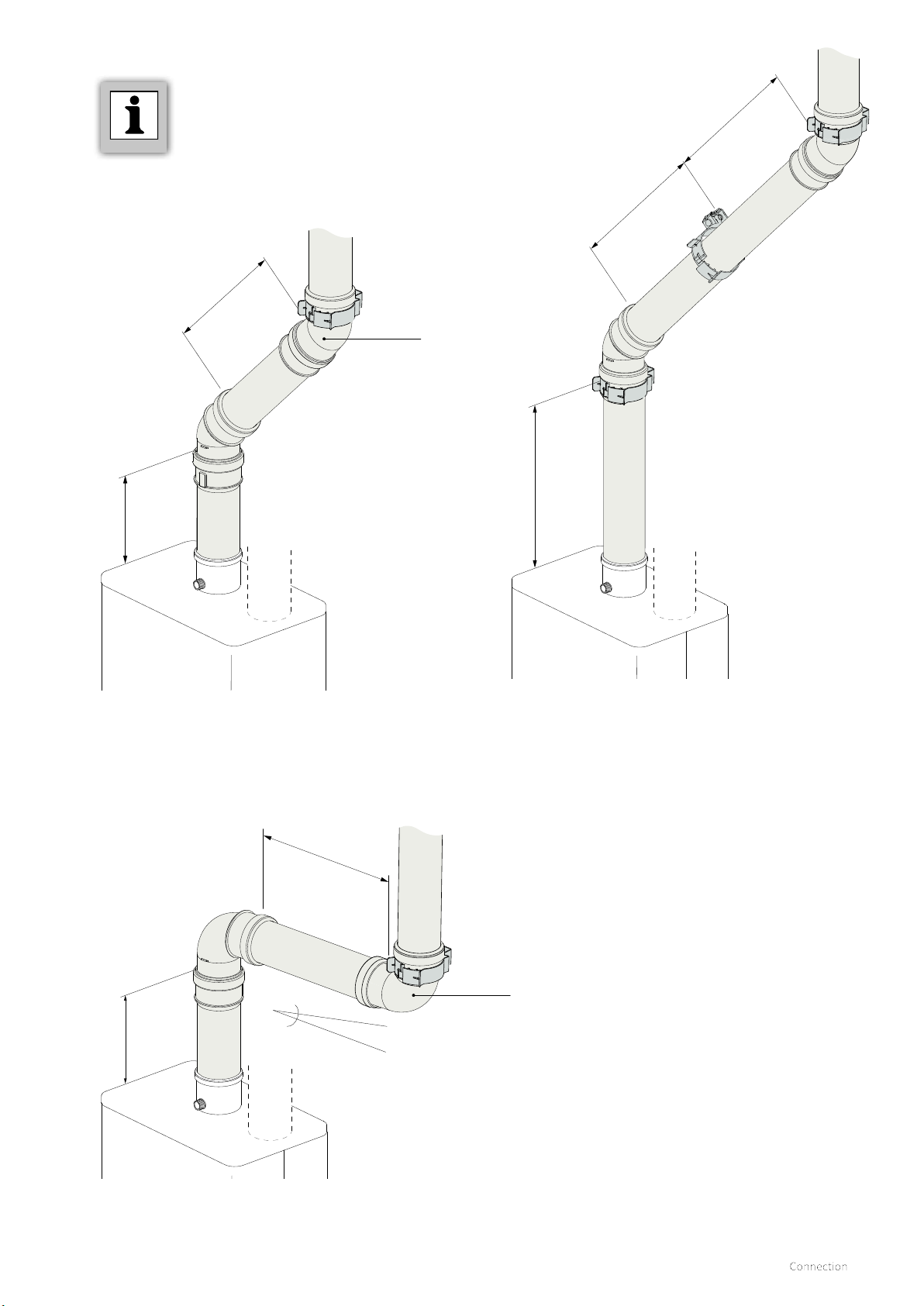

7.8.2 Vertical roof terminal for twin-pipe 80mm flue system C33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

7.8.3 Vertical roof terminal and air supply duct from the facade C53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

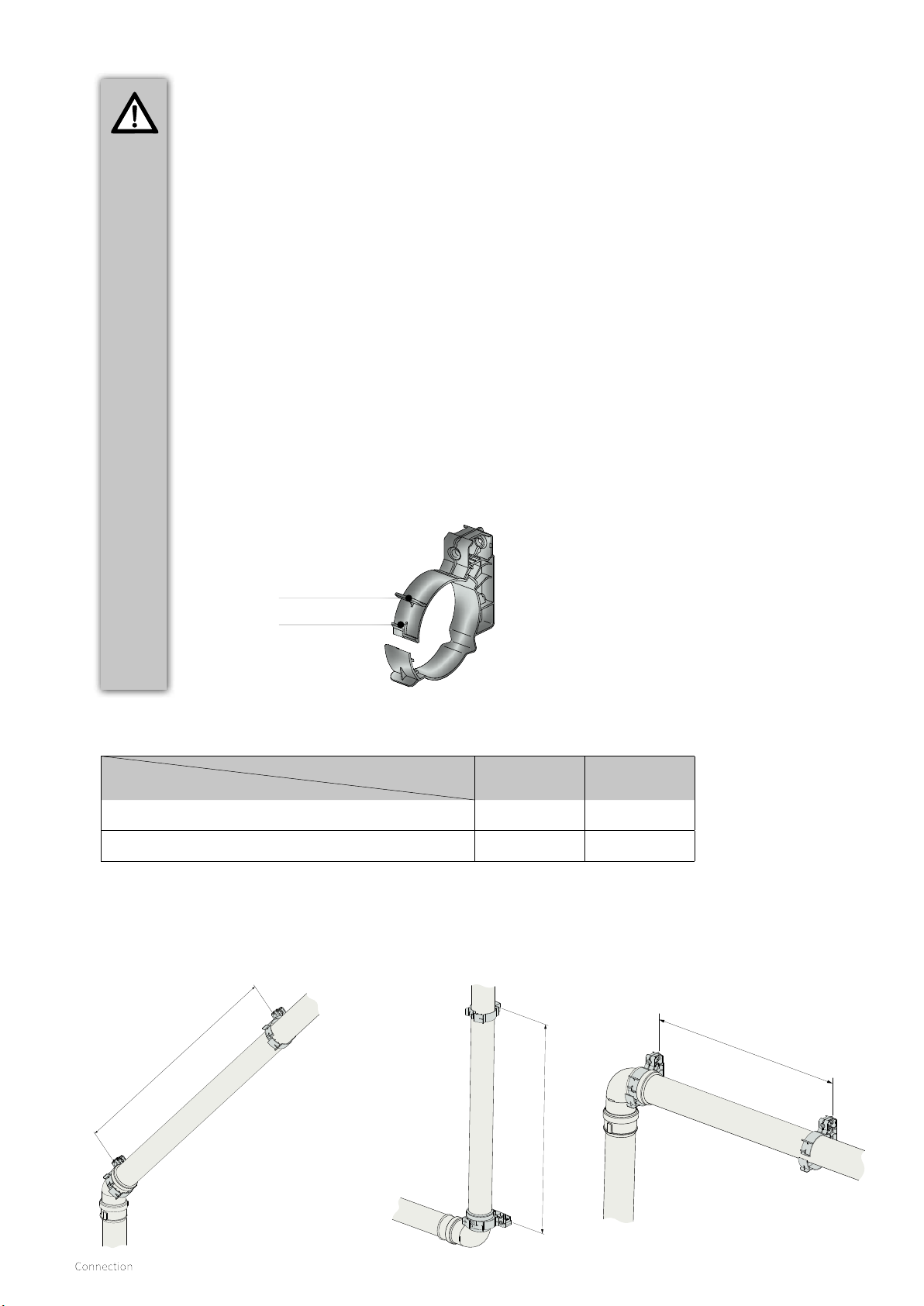

7.8.4 Clamping the flue system (twin and concentric) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

7.8.7 Twin flue terminal positions ..................................................................................................46

8 Operation 47

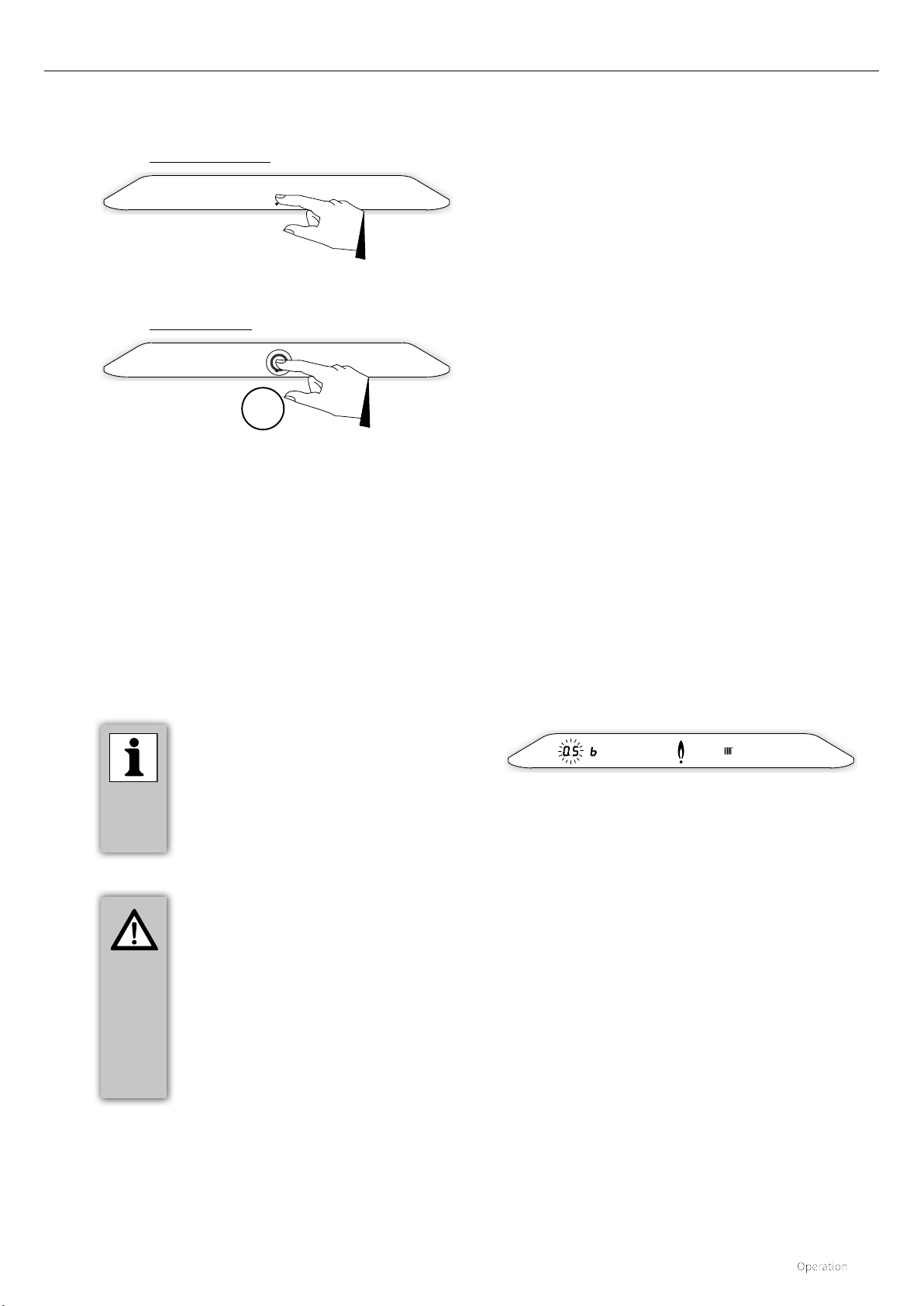

8.1 Using the control panel .......................................................................................................47

8.2 Boiler preparation ............................................................................................................47

8.2.1 Filling and venting the central heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

8.2.2 Domestic hot water facility ....................................................................................................48

8.2.3 Gas supply ...................................................................................................................48

8.3 Commissioning procedure ....................................................................................................49

8.4 Clock function ...............................................................................................................50

8.5 Shutting down the boiler .....................................................................................................51

9 Settings and adjustments 52

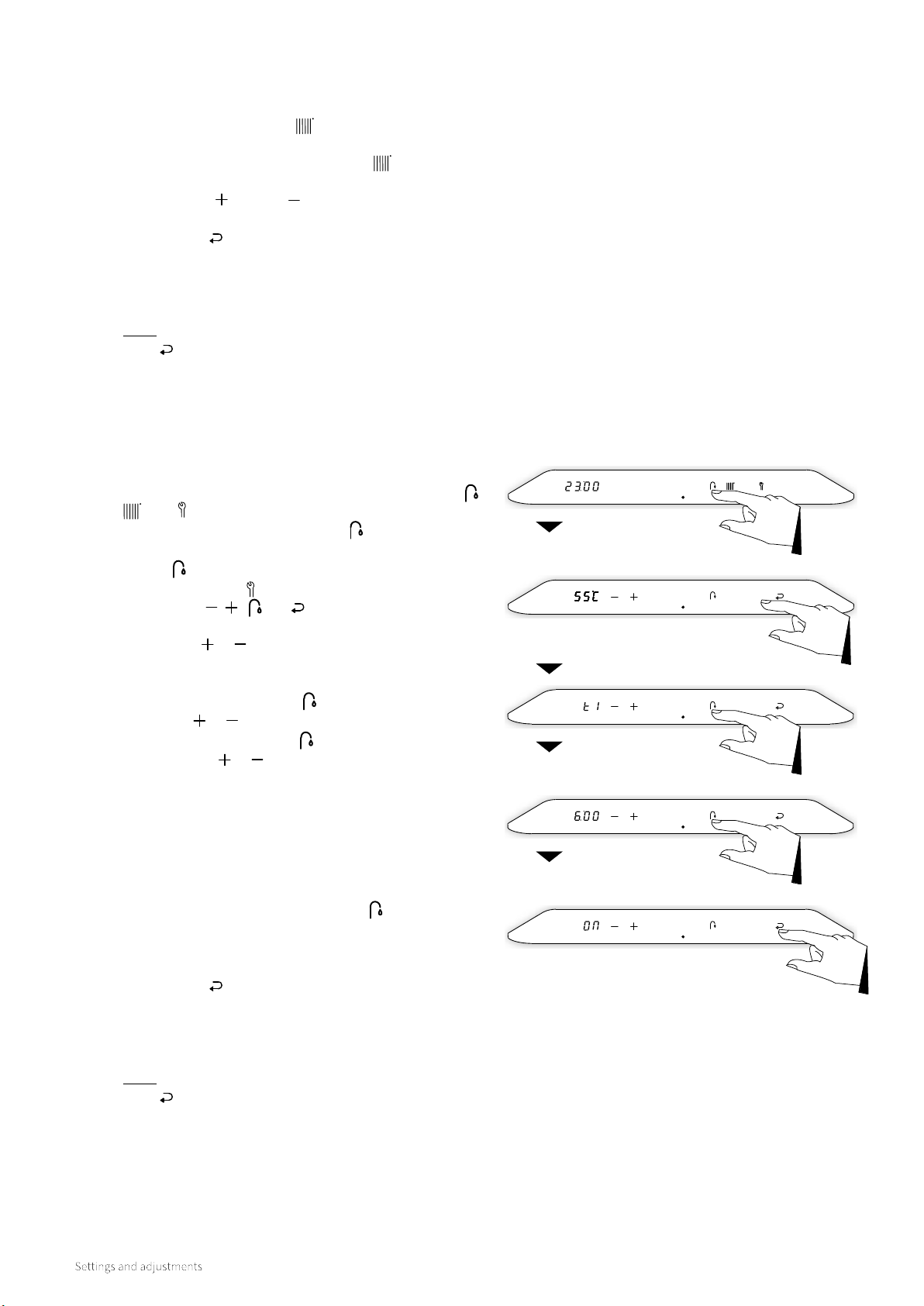

9.1 Navigate the settings .........................................................................................................52

9.1.1 Main menu ..................................................................................................................52

9.1.2 Domestic hot water menu ....................................................................................................53

9.1.3 Central heating menu ........................................................................................................54

9.1.4 RF menu .....................................................................................................................54

9.1.5 Service menu ................................................................................................................56

9.1.6 Info menu ...................................................................................................................58

9.2 Setting and adjusting the clock functions ......................................................................................59

9.2.1 Programming the CH on / o times ............................................................................................59

9.2.2 Programming the DHW pre-heat on / o times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.3 Parameters ..................................................................................................................62

9.4 Switching DHW comfort function on and o. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

9.5 Adjusting the maximum central heating output ................................................................................63

9.6 Adjusting pump capacity .....................................................................................................63

9.7 Outside weather compensation ...............................................................................................64

9.8 Conversion to another gas type ...............................................................................................65

9.9 Gas/air control ...............................................................................................................66

9.10 Inspection of the gas air control valve .........................................................................................67

9.10.1 Measuring the flue gas at maximum output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.10.2 Measuring the flue gas at minimum output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

9.10.3 Minimum output correction ...................................................................................................70

10 Faults 71

10.1 Fault codes ..................................................................................................................71

10.2 Other faults ..................................................................................................................73

10.2.1 No heat (central heating) .....................................................................................................73

10.2.2 Central heating does not reach the correct temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.2.3 Central heating system remains too warm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.2.4 No domestic hot water (DHW) .................................................................................................74

3

10.2.5 Domestic hot tap water does not reach the correct temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

10.2.6 Burner ignites loudly .........................................................................................................74

10.2.7 Burner resonates .............................................................................................................75

10.3 Notifications .................................................................................................................75

11 Maintenance 76

11.1 Annual service procedure .....................................................................................................76

11.2 Annual service continued (syphon maintenance). ..............................................................................76

11.3 Annual service continued (internal maintenance) ..............................................................................78

11.3.1 Annual service continued (cleaning) ...........................................................................................78

11.4 Annual service (re-assemble) ..................................................................................................79

11.5 Annual service checklist ......................................................................................................80

12 Technical specifications 81

12.1 Electrical schematic ..........................................................................................................82

12.2 Product Fiche according to CELEX-32013R0811, Appendix IV ....................................................................84

12.3 NTC resistances ..............................................................................................................84

13 Spares short list 85

15 Benchmark Commissioning & Warranty Validation Service record 87

To be completed at each annual service, not subsequent.

4

1 PREFACE

The manufacturer Intergas Heating Ltd accepts no liability whatsoever for damage or

injury caused by failure to adhere (strictly) to the safety regulations and instructions,

or carelessness during installation of the Intergas wall mounted gas fired boiler and

any associated accessories

Intergas Heating Ltd are continuously developing ways to guarantee the quality of its

products and to improve them where necessary. In so doing we (Intergas Heating Ltd.)

reserve the right to modify at any time the features named within this document.

Read and observe all safety instructions within this instruction manual to prevent

unsafe situations, fire, explosion, damage to property or personal injury.

1.1 Regulation

The Intergas combination boiler meets the requirements of Statutory Instrument ‘The

Boiler (Eiciency) Regulations’ and is deemed to meet the requirements of:

► Low Voltage Directive (2014/35/EU)

► Gas Appliances Regulation (EU) 2016/426

► Boiler Eiciency Directive (92/42/EEC)

► EMC Directive (2014/30/EU)

► RED Directive (2014/53/EU)

► Ecodesign (2009/125/EC)

► Energy labelling Regulation (EU) 2017/1369

Intergas declares that the materials used in the manufacturing of this appliance are

non hazardous and that no substances harmful to health are contained within the

appliance.

1.2 Warnings

Intergas accepts no responsibility for the unsatisfactory performance of the appliance

or flue arising from the failure to comply with this installation manual. Incorrect

installation could invalidate your guarantee and may lead to prosecution.

The appliance cannot be removed from the original place of installation and transferred

to another site or re-sold without prior consent from Intergas. You must re-register the

appliance with Intergas in order to maintain any remaining warranty.

The boiler must be installed by a competent Gas Safe registered

engineer and in accordance with these instructions, It is the installers responsibility to

ensure that the installation conforms to the current legislation and Standard Codes of

Practice.

Please read these instructions carefully before installing or using the

appliance.

1.3 Manual handling

When moving the boiler always keep your back straight, bend your knees, don’t twist,

move your feet. Avoid bending forwards or sideways and keep the load as close to

your body as possible. Where possible transport the boiler using a suitable trolley, sack

truck or get some assistance. Grip the boiler firmly and before liing establish where

the weight is concentrated to determine the centre of gravity, repositioning yourself if

necessary.

5

1.4 Pictograms

The following pictograms are used within this installation manual:

CAREFUL / IMPORTANT

Procedures which, if these are not performed

with the required caution, can damage the

product, the surrounding or the environment or

may result in personal injury.

COMMENT

Procedures and/or instructions which, if they

are not followed, can negatively aect the

operation of the boiler.

SEE

Reference to other manuals

1.5 Warnings on the box

INSTRUCTION (THIS SIDE UP)

Store the appliance upright as indicated on the

box.

INSTRUCTION (FRAGILE)

This is a fragile piece of equipment: Please

handle with care do not to drop.

INSTRUCTION (FRAGILE)

This is a fragile piece of equipment: Please

provide dry storage for the appliance.

INSTRUCTION (STACK)

MAX 3 MAX2

No more than three boxes should be stacked on

top of each other.

1.6 Abbreviations

► DHW: Domestic hot water

► CH: Central heating

► CW: Comfort domestic hot water

► HE: High eiciency

► PHS: Pre Heated Solar water.

► LT: Low temperature (zone).

► HT: High temperature (zone)

► OT: OpenTherm

► RF: Radio frequency

► PC: Personal computer

► NTC: Sensor (Negative temperature coeicient)

► PP: Polypropylene

► CAC: Combination air supply duct and combustible

gas flue system (concentric chimney system)

6

2 SAFETY REGULATIONS

Safety precautions If you smell gas

A gas leak could potentially cause an

explosion. If you smell gas, observe the

following rules:

► Prevent flames or sparks:

- Do not smoke, use a lighter or strike

matches.

- Do not operate any electrical switches or

unplug any equipment.

- Do not use the telephone or ring

doorbells.

► Turn o the gas at the meter or regulator.

► Open windows and doors.

► Warn your neighbors and leave the building

► Prevent anyone from entering the building.

► Call the National Gas Emergency Service on

0800 111 999 (From a location away from

the gas leak).

L.P.G. boilers: Call the supplier’s number on

the side of the gas tank or cylinder.

2.1 General

Depending on the year of construction, an Intergas HR boiler may contain part(s)

in which ceramic fibers are used. Always use the recommended personal

protective equipment when working with ceramic fibers.

It is law that all gas appliances are installed and serviced by a Gas Safe registered

competent engineer, if in any doubt please check with Gas Safe (0800 408 5500)

and in accordance with the following recommendations:

► Current Gas Safety (Installation and Use) Regulations

► All current building regulations

► Building Standards (Scotland) Consolidated

► I.S.813 Installation of Gas Appliances (Ireland)

► IET Wiring Regulations (BS 7671)

► Health and Safety Document (Electricity at Work Regulations)

► UK Water fittings Regulations and Byelaws

► Health & Safety Regulations

2.2 The installation

The installation must comply with the following British Standards codes of practice:

► BS 5440: Flueing and Ventilation for gas appliances of rated input not exceeding 70kW (Part 1 Flues)

► BS 5440: Flueing and Ventilation for gas appliances of rated input not exceeding 70kW (Part 2 Air Supply)

► BS 5546: 2010 Specification for installation and maintenance of gas-fired water-heating appliances of a

rated input not exceeding 70Kw net.

► BS EN 12828:2012+A1:2014 Heating systems in buildings. Design for water-based heating systems

► BS EN 806-1:2000 Specifications for installations inside buildings conveying water for human consumption.

General (802-2 Design, 806-3 Pipe sizing, 806-4 Installation, 806-5 Operation and maintenance).

► BS 6798: 2014 Specification for selection, installation, inspection, commissioning, servicing and

maintenance of gas-fired boilers of rated input not exceeding 70kW net

► BS 6891: 2015+A1:2019 Specification for the Installation and maintenance of low pressure gas installation

pipework of up to 35mm (R1 1/4) on premises

► BS 7593: 2019 Code of practice for the preparation, commissioning and maintenance of domestic central

heating and cooling water in systems

► BS 7671: 2018 Requirements for electrical installations, IET Wiring regulations

► BS 5955-8:2001 Plastic pipework (thermoplastics materials). Specification for the installation of

thermoplastic pipes and associated fittings for use in domestic hot and cold services and heating systems

in buildings.

Reference should also be made to:

► Guide to condensing boiler installation assessment procedures for dwellings (SBSA)

► The institute of Gas Engineers document & managers IGE/UP/7 Gas installations in timber frame and light

steel framed buildings.

7

3 GENERAL BOILER INFORMATION

3.1 General

The Intergas Xclusive wall-mounted gas boiler is a room sealed unit. The

boiler is intended solely to provide heat for the water in a central heating

system and domestic hot water installation and is for domestic use only.

The Intergas Xclusive meets the European directives and additional national

regulations that are indicated by CE marking. The associated conformity

declaration can be requested from Intergas Heating Ltd (also see §14)

The Intergas Xclusive meets the electrical protection class IPX4D.

3.1.1 ErP label

Based on the European ErP Directive (Energy related Products) all newly

produced gas fired boilers have to meet minimum standards regarding

energy performance.

The Intergas Xclusive carries an European energy label containing specific

information regarding energy eiciency class (CH and DHW), noise level

and maximum power.

Intergas Heang Ltd Xclusive --

XL

The Intergas Xclusive carries label A for both CH and DHW.

In addition the Intergas Xclusive meets the following DHW capacity profile:

► Xclusive 24 : L

► Xclusive 30 : XL

► Xclusive 36 : XL

The extensive product fiche can be found in §12.2.

3.1.2 Gas category

Gas category Gas type Gas inlet pressure

II

2H3P

The Intergas Xclusive is factory-set for H-gas, G20. The boiler

may optionally be converted to another gas type (as in §3.1.2)

using a conversion set (see §9.8).

(mbar)

Natural gas (G20) 20

LPG (G31) 37

--

kW

+

A

A

B

C

D

E

F

A

+++

A

++

A

+

A

A

B

C

D

--

2019 811/2013

A

dB

8

3.2 Operation

The Intergas Xclusive is a modulating high eiciency boiler. This means

that the output is adjusted according to the desired heating capacity.

Two separate copper circuits are infused within the aluminium

Bithermic heat exchanger.

The boiler has a printed circuit board with microprocessor control, this

allows constant calculations to take place during any demand for either

heating or hot water, these calculations are based on many factors and

measuring points within the boiler.

The microprocessor manages and takes control of the modulating

output, ensuring optimum eiciency is maintained at all times during

production.

3.3 Data plate

Identification of the product

You will find the unit details on the data plate on the bottom

of the boiler. The data plate contains, important information

and the boiler specification (boiler type and model name), and

the serial number:

******

-yymm

PIN

PMS

PWS

Qn HS

Qn Hi

Pn

BE, CH, DE, ES,

FR, GB, IE, IT, MT

I2E(s), I2H,

IIELL3P, II2H3P,

II2Esi3P

G20-20 mbar

G31-37 mbar

B23, ......C93(x)

Tmax

IPX4D

******

Production code - Serial number

YY = year of production,

mm = month of production

Product Information Number

Data related to Domestic Hot Water

Data related to Central Heating

Information regarding electrical power supply

(Voltage, mains frequency, elmax, IP-class)

Permissible overpressure in CH circuit in bar

Permissible overpressure in DHW circuit in bar

Input related to gross caloric value in kilowatts

Input related to net caloric value in kilowatts

Output in kilowatts

Countries of Destination (EN 437)

Approved unit categories (EN 437)

Gas group and gas connection pressure as set

at the factory (EN 437)

Approved flue gas category (EN 15502)

Maximum flow temperature in °C

Electrical protection class

9

3.4 Control panel

The boiler has a fully integrated touch screen control panel

that also displays information about the operational status,

temperature settings, demand symbols and fault codes.

The display has multiple functions and options please refer to

section §9 for further detail.

COMMENT

► The touch screen is very sensitive only

use a finger tip and not any sharp objects.

3.5 Operational modes

The boiler has a number of operational modes:

The boiler is switched o.

The boiler is switched o but is connected to the mains power.

In this mode, the display view is characterised by:

► Displaying the power LED [

► Displays the pressure within the central heating system on

le hand side [ ].

► Displaying a line on the right display [ ].

Boiler is switched o

(mains voltage is present)

].

The boiler is switched on and is ready for a heat demand.

The boiler is switched on and is ready to answer a request for

either domestic hot water or hot central heating water.

In this mode, the display view is characterised by:

► Displaying the power LED [

]. All other symbols and values

are not displayed.

The boiler is operating and producing domestic hot

water.

The boiler is operating and supplying domestic hot water to a

tap or shower etc. The display view is characterised by:

► Displaying the power LED [ ].

► Displaying the flame i.e. burner is switched on [ ].

► Displaying the tap symbol [ ].

The boiler is operating and producing central heating

water.

The boiler is operating and supplying central heating water.

The display view is characterised by:

► Displaying the power LED [ ].

► Displaying the flame i.e. burner is switched on [ ].

► Displaying the radiator symbol [ ].

Boiler is switched on

(ready for heat demand)

Boiler is in operation (domestic hot water)

Boiler is in operation (central heating water)

10

4 MAIN COMPONENTS

Flue appliance adapter

Air supply duct

(for 80mm twin flue only)

NTC Heat exchanger

sensor (S0)

Air supply duct

(for 80mm twin flue only)

Ignition module

Ignition electrode

vNTC Flue gas sensor (S5)

Fan assembly

Heat exchanger

Expansion vessel

shown as silhouette

3bar Pressure relief valve

NTC Central heating

flow sensor (S1)

NTC Domestic hot

water sensor (S3)

Central heating

low pressure sensor

24V DC Gas valve

Heating Modulating Pump

Flow turbine sensor

Condense syphon

Printed circuit board and

housing

Mains lead 230 V

AC (bare)

Touch screen fascia panel

11

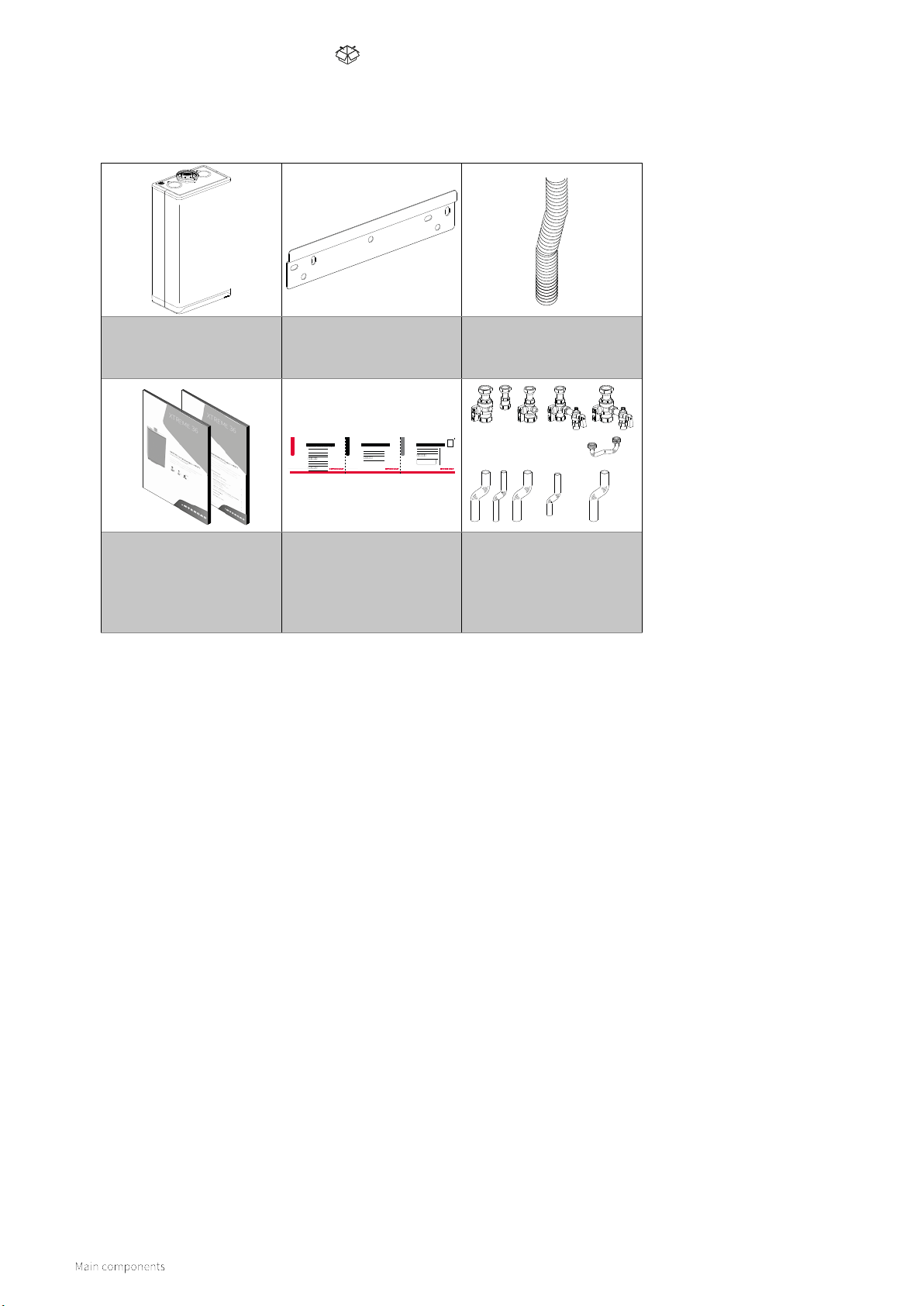

4.1 Standard scope of delivery

>>Betrouwbaar in warmte >>Betrouwbaar in warmte >>Betrouwbaar in warmte

Check whether the package is undamaged. Unpack the boiler

and check whether all components are present. Also check

for any damages to the boiler or accessories and, if present,

immediately notify the supplier.

Boiler Wall bracket & fixings Flexible condensate hose

Installation and operation

instruction

Garantiebewijs Intergas HR-ketel Garantiebewijs Intergas HR-ketel

Type/Serienr.

Datum installatie:

Volgens geldende voorschriften

geïnstalleerd door:

voor klant

Naam installateur:

Adres:

Postcode:

Woonplaats:

Naam koper:

Adres:

Postcode:

Woonplaats:

12345678910

Type/Serienr. Type/Serienr.

Voor de ‘Garantiebepalingen

Intergas HR-ketels’ verwijzen

Datum installatie:

wij u naar onze website:

Naam koper:

www.intergasverwarming.nl

voor installateur

of naar het bij uw HR-ketel

Adres:

bijgevoegde installatievoorschrift.

Postcode:

Op uw verzoek sturen wij u

graag een exemplaar toe.

Woonplaats:

Het garantiebewijs is slechts geldig, indien de aan het garantiebewijs gehechte

antwoordkaart binnen 8 dagen na de installatie wordt ingezonden. Deze kaart

moet volledig en duidelijk worden

van koper en installateur. Door ondertekening van deze kaart verklaart koper

zich akkoord met de staat van de ketel bij aflevering.

12345678910

ingevuld en voorzien zijn van de handtekening

Garantiebewijs Intergas HR-ketel

Datum installatie:

Naam koper:

Adres:

voor fabrikant

Postcode:

Woonplaats:

Installateur

Het garantiebewijs is slechts geldig, indien de aan het garantiebewijs gehechte

antwoordkaart binnen 8 dagen na de installatie wordt ingezonden. Deze kaart

moet volledig en duidelijk worden ingevuld en voorzien zijn van de handtekening

van koper en installateur. Door ondertekening van deze kaart verklaart koper

1234567891 0

zich akkoord met de staat van de ketel bij aflevering.

Postzegel

niet nodig

Intergas Verwarming BV

Antwoordnummer 5

7740 VB COEVORDEN

Guarantee card Connection set

12

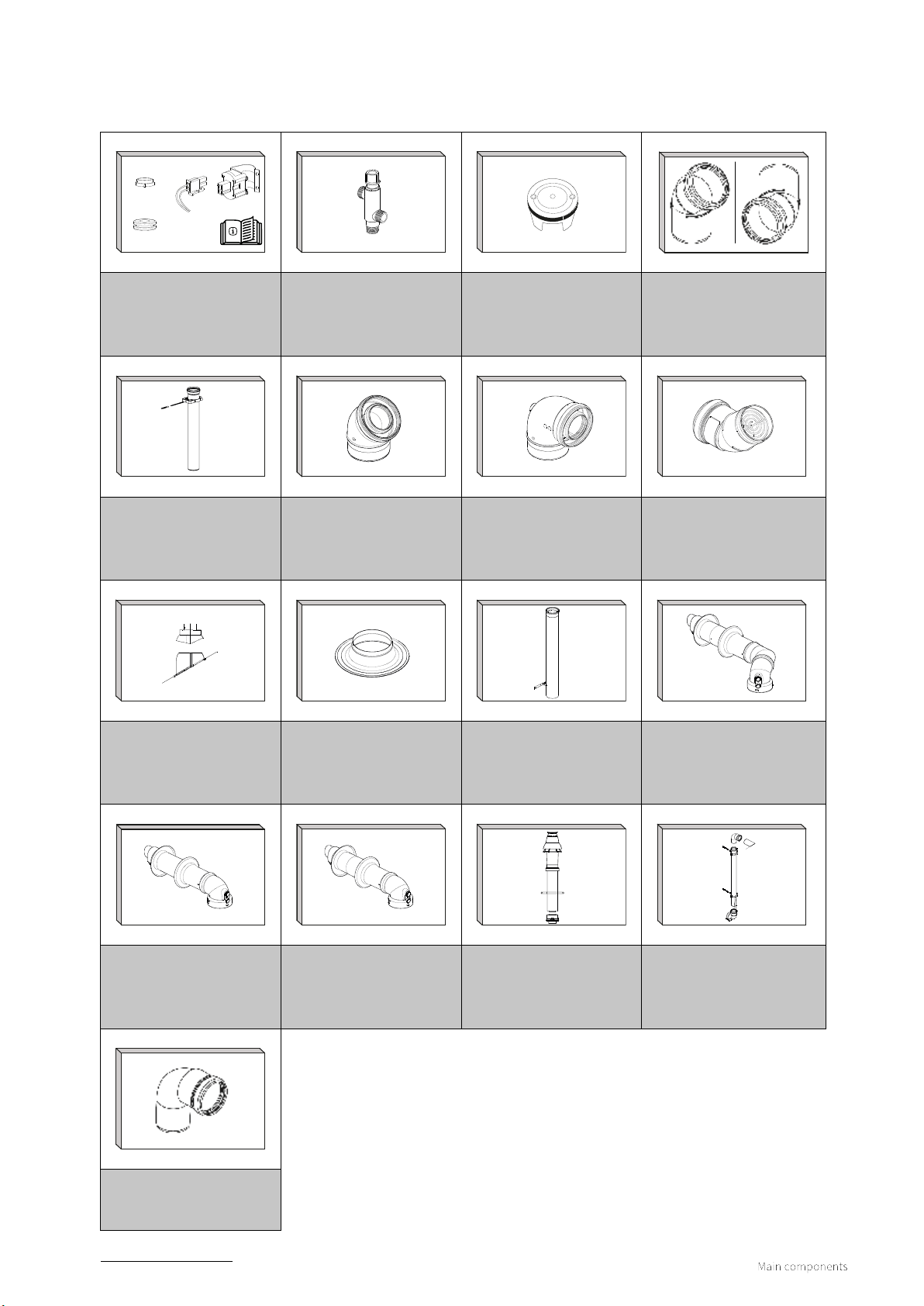

4.2 Accessories

Original Intergas accessories can be ordered separately at your local stockist.

Instructions about the correct way to assemble and use these accessories are provided

with the product ordered and are therefore not included within this installation manual.

Item no 090347

Post-Heating Solar Boiler

conversion set

Item no 081286

Extension L=1000mm inc.

wall bracket (for plume

management kit)

Item no 087910

60/100 flue weather slate

(pitched roof)

Item no 842177

Thermostatic mixing valve

Item no 084661

Bend 45°

Item no 087372

60/100 flue weather slate

(flat roof)

Item no 203207

Outdoor sensor (For

use with weather

compensation)

Item no 084660

Bend 90°

Item no 082975

60/100 extension

L=1000mm

inc. wall bracket

Item no 081285

Elbow 60° (2 per box) (for

plume management kit)

Item no 081295

Plume terminal bend

Item no 081298

Horizontal telescopic oset

wall terminal

1

Item no 082980

Horizontal non telescopic

straight wall terminal

1

Item no 081297

Horizontal telescopic wall

terminal

1

Vertical roof terminal

(inc. boiler adapter

Item no 081284

Elbow 90° (for plume

management kit)

1

Only to be used in combination with the base adapter on the boiler

Item no 0821973

60/100)

Item no 081294

Plume management kit

(inc. 2x wall brackets)

13

5 INSTALLER IMPORTANT POINTS

Please read all instructions before fitting this appliance

► The installer must instruct the user on the operation of the boiler, fault code diagnosis and how to reset

the boiler, location of the filling loop and how to re-pressurise the system if the water pressure drops to

below 0.5 bar.

► The installer must hand over these installation and user instructions ensuring the Benchmark

Commissioning Checklist has been completed correctly.

► The attending engineer must complete the service record on the Benchmark Checklist aer each

service and/or replacing any parts within the boiler.

► It is required under Gas Safe Regulations for the installation to be notified and to register the

installation with Gas Safe, and Building Control (Gas Safe Notification).

► You must register the boiler with Intergas heating ltd within 30 days of the installation to validate any

warranty supplied with the boiler, via post, website or MiReg if you are the installer.

► When commissioning the boiler, check the gas inlet working pressure is 20mbar (NG) or 37mbar for

(LPG) on P1 of the boiler gas valve. (Min 17mB (NG) 30mB (LPG) with all connected appliances operating

at full rate).

► Combustion analysis with a correctly calibrated and certificated electronic analyser is essential for safe

commissioning of the boiler, this must be documented within the Benchmark commissioning checklist.

► A pressure reducing valve set to 3.5 bar must be fitted if the mains water supply pressure is above 5 bar,

this should be located no closer than 3 metres proximity to the boiler for expansion purposes.

► In areas where the water hardness is 200ppm or above, appropriate protection must be taken in

accordance with BS 7593 & in line with building regulations Part L. (See Warranty Provisions on page 88,

point 15).

Intergas recommend Hydroflow HS38a wired into the boiler or HS38b which can be powered

separately.

► The end user / home owner should be advised to keep this installation manual in a safe place,

preferably near the appliance for servicing and future reference, it is a legal requirement that any

attending engineer can check the validity of the Benchmark commissioning checklist (Benchmark

certificate).

► It is important to protect the boiler during the installation. In particular, do not allow any dust or debris

to enter the flue connection at the top of the appliance.

► Before operating the boiler please ensure that the copper pipework you are installing is connected

to the appropriate tappings on the boiler. (Plastic pipework where appropriate must be a minimum

distance of 1000mm away from the boiler connections as per BS 5955-2008).

► It is important to chemically treat and thoroughly flush the heating circuits, prior to commissioning

the boiler, in order to remove any residue fluxes and debris from within them, (please isolate the

appliance). The system flush must be carried out to BS 7593:2019 and an appropriate inhibitor added

to the correct dosage, dependant on the system capacity, as indicated on the product used.

► Intergas recommend water treatment in accordance with the Benchmark Guidance on Water Treatment

in Central Heating Systems, we recommend the use of FERNOX, SENTINEL or ADEY inhibitors. It is most

important that correct concentration of water treatment is maintained for the life of the boiler, a water

sample is required upon installation and to be verified by the aforementioned manufacturers should

we attend a warranty call a water sample may be required to keep the warranty valid. (BS 7593:2019)

► As per BS 7593:2019 Intergas recommend the fitting of an approved magnetic type filter to the

heating return pipe under the boiler (Intergas Nickel plated brass system filter recommended).

► This boiler has been factory set but adjustment may be required to the heating output in order to

match the individual heating demand. This can be done by changing parameter P010 (= max. power

CH) or parameter P070 (= max. power domestic water). See §9.1.5 "To modify a parameter".

► Please do not use the pressure relief valve as a means of flushing, draining the boiler or system.

► Aer domestic hot water production a preset time delay will occur this is designed to prevent the boiler

from cycling thus enhancing the overall eiciency further.

Note: an anti-cycle delay time can be set up to a maximum of 15 minutes by adjusting parameter P036

as described in §8.3.

► When required an external expansion vessels should be inverted with the water side facing downwards

and connected to the heating return (not the flow side) this will allow correct draining of system and

help prolong the life of the vessel diaphragm. (precharge air pressure should be set as per the internal

vessel of the boiler i.e. 0.75bar +/- 0.2bar).

► If you experience any problems please refer to the installation and commissioning guidelines within the

boiler instruction manual. (If necessary, please contact Intergas Heating Ltd).

14

6 INSTALLATION

Z

6.1 Overall dimensions of boiler including the wall bracket

450

120

100

246

160

120

Z

=320=

Connections

277

98h

Central heating

A

flow

Central heating

B

return

C

Gas flow

Domestic cold

D

water - Inlet

Domestic hot

E

water - Outlet

Condense

F

syphon outlet

Flue / Chimney

appliance

connection

22mm with isolation

valve fitted

22mm with isolation

valve fitted

22mm with isolation

valve fitted

15mm with isolation

valve fitted

15mm with isolation

valve fitted

Ødn25

Ø60/100

(concentric, wall

terminal )

148

h =

H =

Overall dimensions

618 mm

618 mm

Xclusive 24

Xclusive 30

678 mm Xclusive 36

766 mm Xclusive 24

95

65

50

F

A B

D E

6.1.1 Mounting the wall bracket

Due to the size and weight of the appliance it is not

recommended to install the boiler on a stud wall as this may

also cause noise issues.

H

766 mm Xclusive 30

826 mm Xclusive 36

6565120 6565 70

A

E C D

C

F

B

275

Refer to the installation dimensions and clearances on the

boiler template supplied with this appliance.

15

6.2 Installation location

The boiler must be installed on a solid brick wall that has

suicient strength to be able to withstand the weight of the

boiler when filled with water (see Technical data).

The appliance must be connected to a 3 amp fused spur within

one (1) meter of the boiler. The condense discharge from the

boiler must be connected to an internal drain or waste system

where possible to prevent freezing during any adverse weather

conditions.

Any unheated area's i.e. a lo space or garage must be treated

as external and therefore adequate frost protection measures

must be taken for the boiler and any pipework etc. (see §6.3)

Make sure the boiler is easily accessible by ensuring that the

adjacent clearances are adhered to.

Further dimensions

*D =

600 mm Xclusive 24,30,36

* 5mm clearance from a closing door

600mm for servicing clearnances

min. 10

min. 50

450

min. 200

H

H =

766 mm Xclusive 24

766 mm Xclusive 30

826 mm Xclusive 36

6.2.1 Installation within a kitchen area or wall cabinet

The boiler can be installed between two kitchen wall units or

inside a cabinet that is of suicient size.

There must be suicient ventilation above and below the

boiler for cooling purposes (as per the adjacent diagram). Any

decor panels or grills used to aid ventilation must be removable

for servicing and maintenance purposes.

CAREFUL

► The appliance must not be installed

above any heat source as this will

invalidate any warranty supplied with

the boiler.

min. 250

Minimum dimension 50cm

277

*D

2

Minimum dimension 50cm

16

2

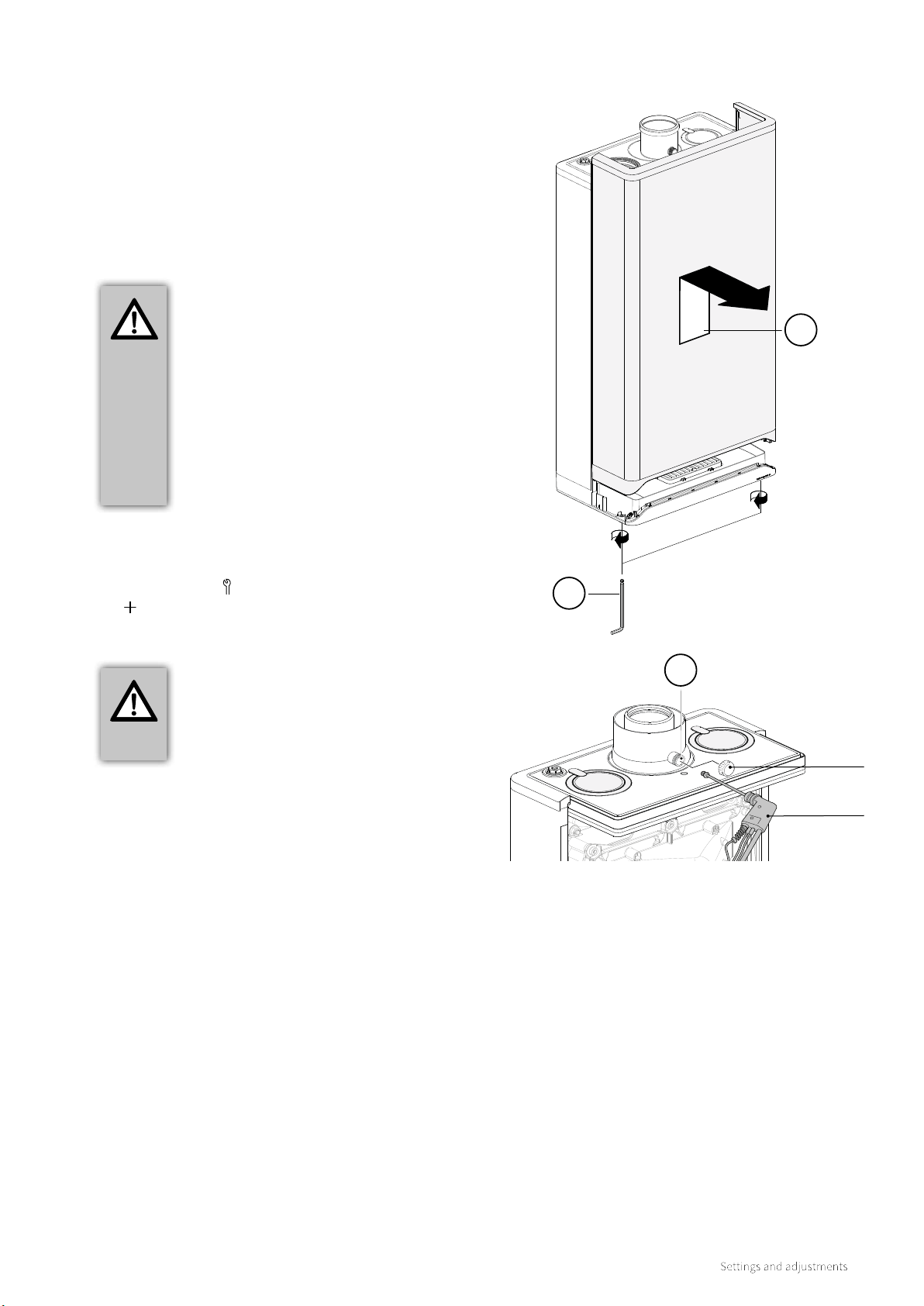

6.2.2 Removing/installing the front panel

► The front cover of the boiler must be removed to perform

various maintenance activities however you must be a

competent Gas Safe registered engineer before carrying out

the following procedure!

► Loosen both screws (1) under the boiler by using a 5 mm

allen key. (They are captive and therefore will not drop out

of the lower housing).

► Slide the front cover (2) upward and then remove it by

pulling it towards you.

COMMENT

► The front cover has a rubber seal around

the inner edge sometimes making it

very sti to slide o so please ensure the

boiler is secured to the wall correctly

before attempting this procedure!

1

Replacing the room sealed front cover.

To replace the front panel, proceed as follows:

► Position the front panel (3) against the boiler and slide

it downwards until it is correctly connected to the

lower fascia panel.

► Hand tighten screws under the boiler using a 5 mm

allen key (do not over tighten).

CAREFUL

► This is a room sealed cover and therefore

extremely important that it is fitted

correctly, failure to do so could lead to

products of combustion entering the

room / environment where it is situated.

2

3

17

6.3 Installing the boiler

1. Attach the wall bracket.

2. Li the boiler (2 person li) and slide it down onto the wall bracket.

3. Remove the syphon cup.

4. You must fill the syphon cup just over half full with water.

5. Replace the cup and install the supplied black flexible hose onto boiler

outlet union.

6. Connect the flexible hose to a 22 mm O.D solvent weld pipe. To minimize

the risk of freezing the condensate pipe should be connected internally

and terminate to an internal soil stack, (ref.: TB115 Gas Safe & HHIC).

7. Install the flue system (see §7.6).

8. Install the required pipework as per the following sections.

9. Should the condensate be terminated to an external soil pipe, drain,

rainwater system or soakaway we only recommend the Condensate PRO

system which is available from our normal stockists or heating supplies.

https://condensatepro.co.uk

COMMENT

► The Intergas Xclusivehas a boiler-

specific siphon cup. Ensure that

the correct version is ordered upon

replacement. (Item no 510054)

1. Mount the wall bracket (ensure its level)

4. Fill the condense syphon cup 5. Replace the condense syphon cup

18

2. Hang the boiler onto the wall bracket 3. Twist and pull to remove the condense

and attach the supplied flexible hose

syphon cup

Open connection

to waste system

6. Connect the flexible hose to the waste

system via a tundish or similar.

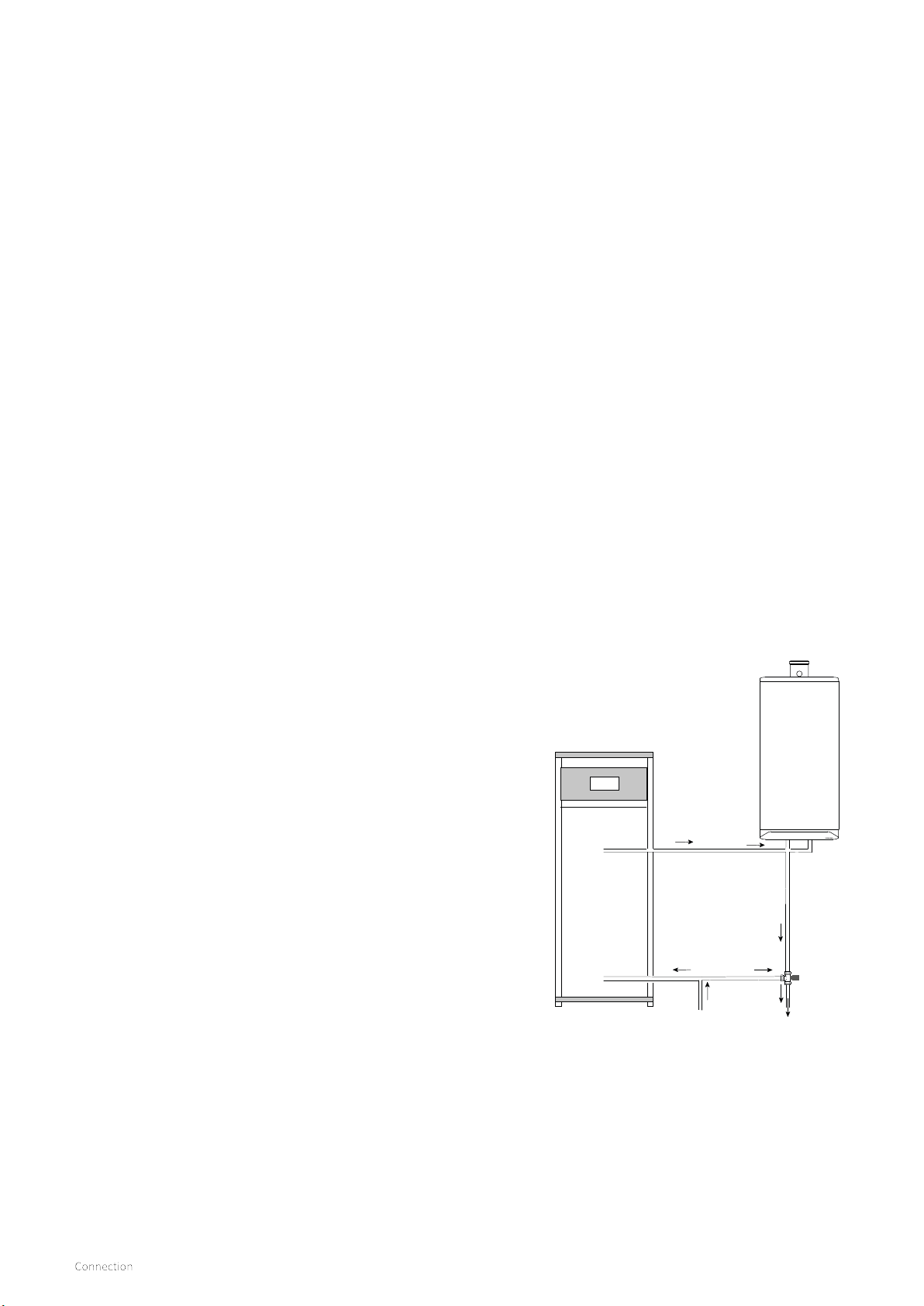

7 CONNECTION

7.1 Connecting to the central heating system circuit

► Flush the central heating system thoroughly as per

BS7593:2019.

► Fit the flow and return pipes to the isolation valves using the

supplied 3/4" fibre washers, noting that the filling link valve

attaches to the return side as per the adjacent drawing.

► The pipework must be correctly supported with full wrap

over type clips / brackets.

► Do not over tighten the connections onto the boiler as

this can cause stress damage and possible internal boiler

leakage.

The CH system should include the following:

► As per BS 7593:2019 a magnetic type filter such as the

Intergas system filter, should be fitted onto the return

pipework as shown in the adjacent diagram.

► When installing the Intergas system filter, the supplied

spigot valve should be fitted to the bottom union to enable

combined isolation with the boiler return valve.

► The drain / dosing valve at the bottom of the filter housing

facilitates the easy draining of the appliance, with the spigot

valve and heating flow valve both closed at the same time.

► A drain tap at the lowest point(s) of the installation.

► A full bore spring loaded single check valve, in the

return pipework nextto the boiler whenever the pipework

rises above the appliance. This prevents the occurrence

of thermosyphoning (radiators getting warm) during DHW

production.

Preformed flow pipe

Preformed return pipe

7.1.1 Expansion vessel

The appliance is fitted with a expansion vessel adequate for a typical

heating system with 8 radiators installed. For larger volume systems,

an additional expansion vessel must be fitted. Refer to the below

table or contact Intergas for further advice in these cases.

SAFETY VALVE

SETTING (bar)

VESSEL CHARGE

PRESSURE (bar)

INITIAL SYSTEM

PRESSURE (bar)

TOTAL WATER

CONTENT of SYSTEM

LITRES

25

50

75

100

125

150

175

200

For syst. volumes other than those

given above, mult. the syst. volume

by the factor across

Intergas system filter.

3.0

0.75 1.0 1.5

1.0 1.5 2.0 1.5 2.0 2.0

EXPANSION VESSEL VOLUME (litres)

3.5 6.5 13.7 4.7 10.3 8.3

7.0 12.9 27.5 9.5 20.6 16.5

10.5 19.4 41.3 14.2 30.9 24.8

14.0 25.9 55.1 19.0 41.2 33.1

17.5 32.4 68.9 23.7 51.5 41.3

21.0 38.8 82.6 28.5 61.8 49.6

24.5 45.3 96.4 33.2 72.1 57.9

28.0 51.8 110.2 38.0 82.4 66.2

0.140 0.259 0.551 0.190 0.412 0.33

Spigot isolation

valve

Drain/Dosing

valve.

19

7.1.2 Thermostatic radiator valves

If the radiators have thermostatic radiator valves or valves that

can be closed to isolate the flow completely from the return, a

minimum amount of water circulation (6ltrs/min *) must be

maintained by installing a manual fixed bypass as this will not

interfere with the pump modulation, (* also see §9.5).

7.1.3 Underfloor heating

Underfloor heating with pump

For eective operation of the DHW supply any undesired

circulation through the appliance as a result of a second pump

in the CH circuit must be avoided.

Connect the underfloor heating system in a hydraulically

neutral manner to the appliance, or install the CH circuit with

an normally open zone valve ( I ) to prevent flow through the

appliance heat exchanger when there is no CH demmand.

see §9.5. for minimum permissible water circu lation through

the boiler heat exchanger.

Underfloor heating connection diagram

A. Boiler

B. Under floor circulation pump

C. Thermostatic mixing valve

D. Spring-operated non-return valve

E. Normally closed 230V~ zone valve (Radiators)

. Normally closed 230V~ zone valve (Under floor)

E

1

F. Radiators (Fitted with TRV's except room stat location)

G. Programmable room thermostat

H. Limit thermostat

I. Normally open 230V~ zone valve (powered via X4 terminal 3)

G

A

F

I

C

H

D

E

E1

B

20

Underfloor option wiring diagram

230Vac 3amp

Switched

Fused Spur

L N

Wiring centre

Time control to

Heating circuit

L

N

HTG on

Orange & Grey

wires from underfloor

Zone are not required.

Isolate and make safe.

(If applicable cables not always

supplied with this valve model)

1 2

NEUTRAL

EARTH

GREY (P/LIVE)

Room thermostat

2

1

3

3 4 5 6 7 8 9 10

EARTH

M/V SWITCHED LIVE

Zone Valve

FLOW TO

UNDER FLOOR

V4043B

(normally open)

OpenTherm

Heating Control

Zone Valve

Heating

(normally closed)

M/V SWITCHED LIVE

SWITCHED LIVE

Parameter P081

must adjusted to

value '1'

Switched Live from

NEUTRAL

underfloor heating

SWITCHED LIVE

controls to X3 Pin 2

S/L FROM BOILER

123

V4043H

X15

(24V=)

X13

X14

(24V =)

X12

(24V =)

X11

(24V =)

N/A

X10

(24V =)

N/A

24V=

(230V ~)

230V

X8

X5

(230V ~)

X4

(230V ~)

F1 (3,15 AT)

X3

(230V ~)

FUSE

X2

(230V ~)

X1

(230V ~)

21

7.1.4 X-Plan zone Hydraulic diagram

Key to Hydraulic & Wiring diagrams

A. Honeywell V4043H DHW Zone valve (Normally closed)

B. Honeywell V4043B Heating Zone valve (Normally open)

C. OpenTherm room thermostat (or programmable OT type if

not using the boiler intergral timer option for the heating

D. Cylinder overheat thermostat (manual reset)

E. Cylinder NTC sensor (art. no. 065117)

F. Pressure relief valve (3 Bar)

G. T/P safety (8 Bar)

H. Expansion vessel (potable)

C

Built in 6 ltr

expansion vessel

Stainless steel unvented cylinder (≥30 kW coil)

(storage capacity to be established by the installer)

D

E

m

A

ErP modulating

pump

Additional expansion

vessel option see §7.1.1

m

B

22

7.1.5 X-Plan wiring diagram (Unvented cylinder option)

Comments

► The unvented cylinder must comply with G3 regulations regarding

the safety controls which are normally supplied as a kit with the

vessel.

► The over heat protection (with manual reset) is wired through our

OpenTherm circuit to prevent the boiler from creating a hot water

demand should this safety control operate.

► For rapid recovery a 30 kW rated coil or greater is recommended

(this should be specified when ordering your vessel).

Parameter P001 change to option 1

Parameter P081 change to option 3

Parameter P070 adjust output to cylinder coil rating (% of kW)

230v to Overheat thermostat

L N

230Vac 3amp

Switched

Cylinder O/H Stat

Manual reset

Fused Spur

D

EARTH

Zone Valve

D H W

V4043H

(normally closed)

A

Hot Water Timer (option)

(Volt free switching)

L

N

o

on

C

1 2

E

NTC

Cylinder

Sensor

S/L to HTG M/V

GREY (LIVE)

Wiring Centre

3 4 5 6 7 8 9 10

EARTH

S/L to M/

B

Zone Valve

C/HEATING

V4043B

(normally open)

C

BLUE (neutral)

DHW S/L to M/V

Orange & grey wires from

heating zone are not

required, please isolate &

make them safe.

(if applicable cables not always

supplied with this valve model)

Note:

BLUE (neutral)

BLUE (neutral)

DHW S/L

The zone valve B closes when a

demand for DHW is created giving

priority to recover the cylinder.

X15

(24V=)

12

OpenTherm

Heating Control

1

2

45

3

X13

X14

(24V =)

12 123

X12

(24V =)

X11

(24V =)

N/A

X10

(24V =)

N/A

24V=

(230V ~)

230V

X8

X5

(230V ~)

X4

(230V ~)

F1 (3,15 AT)

X3

(230V ~)

FUSE

X2

(230V ~)

X1

(230V ~)

23

7.1.6 S-Plan zone hydraulic diagram

Key to Hydraulic & Wiring diagrams

A. Honeywell V4043H DHW Zone valve (Normally closed)

B. Honeywell V4043H Heating Zone valve (Normally closed)

C. Twin channel Programmer

D. Cylinder overheat thermostat (manual reset)

E. Pressure relief valve (3 Bar)

F. T/P safety (8 Bar)

G. Expansion vessel (potable)

H. System By-pass (Should be 3 meters from boiler connections)

See §9.5 for minimum permissible water circulation through the

boiler heat exchanger.

► To alter the boiler from a combi to a system boiler please see

section §9.1.5 & §9.3

Parameter P001 change to "option 3"

Parameter P010 change to required system output %

(example 30kW set P010 to 50(%) = 15kW output)

C

Built in 6 ltr

expansion vessel

Stainless steel unvented cylinder

(storage capacity to be established by the installer

F

G

D

m

A

ErP modulating

pump

E

Additional expansion

vessel option see §7.1.1

H

CH circuit

24

m

B

7.1.7 S-Plan wiring diagram

230Vac 3amp

Switched

Fused Spur

L N

LIVE SUPPLY

Wiring Centre

Twin channel

Programmer

L

N

HTG on

DHW on

1 2

NEUTRAL

EARTH

M/V/S/L

3

Cylinder

thermostat

1

C

Room

thermostat

2

1

P/LIVE

3 4 5 6 7 8 9 10

M/V/S/L

HTG S/L

DHW S/L

P/LINE

Zone Valve

EARTH

NEUTRAL

C/HEATING

V4043H

(normally closed)

Zone Valve

D H W

V4043H

(normally closed)

S/L TO BOILER (DHW)

S/L TO BOILER (HTG)

S/LIVE (BOILER)

23 1

X15

(24V=)

X14

X13

(24V =)

X12

(24V =)

X11

(24V =)

N/A

X10

(24V =)

N/A

24V=

(230V ~)

230V

X8

X5

(230V ~)

X4

(230V ~)

F1 (3,15 AT)

X3

(230V ~)

FUSE

Note:With all wiring diagrams when using a digital type room thermostat the Neutral wire from the

wiring centre (2) to room thermostat (2) will not be required.

X2

(230V ~)

X1

(230V ~)

25

7.1.8 S-Plan wiring diagram (With outside weather compensation kit)

230Vac 3amp

Switched

Fused Spur

L N

LIVE SUPPLY

Wiring Centre

Twin channel

Programmer

L

N

HTG on

DHW on

1 2

BLUE

NEUTRAL

EARTH

M/V S/L

3

Cylinder

thermostat

1

C

Room

thermostat

2

1

P/LIVE

3 4 5 6 7 8 9 10

M/V S/L

HTG S/L

DHW S/L

P/LIVE

Zone Valve

G/YELLOW

C/HEATING

V4043H

Zone Valve

S/LIVE (DHW)

S/LIVE (HTG)

S/LIVE (BOILER)

D H W

V4043H

Relay Coil

N/C COM

50051W

Outdoor Sensor S6

23 1234345 1

X15

(24V=)

X14

X13

(24V =)

X12

(24V =)

X11

(24V =)

N/A

X10

(24V =)

N/A

24V=

(230V ~)

230V

X8

X5

(230V ~)

X4

(230V ~)

F1 (3,15 AT)

X3

(230V ~)

FUSE

Note:With all wiring diagrams when using a digital type room thermostat the Neutral wire from the

wiring centre (2) to room thermostat (2) will not be required.

X2

(230V ~)

X1

(230V ~)

26

7.1.9 Y-Plan zone hydraulic diagram

Key to Hydraulic & Wiring diagrams

A. Room thermostat

B. Twin channel programmer

C. Cylinder thermostat

D. Boiler pressure reflief valve (3 Bar)

E. Hot water draw o (Gravity)

F. Mid position zone valve

G. Cold feed and expansion tank

H. System By-pass (Should be 3 meters from boiler connections)

► To alter the boiler from a combi to a system boiler please see

section §9.1.5 & §9.3

Parameter P001 change to "option 3"

Parameter P010 change to required system output %

See §9.5 for minimum permissible water circulation through the boiler

heat exchanger.

G

A

D

Built in 6 ltr

expansion

vessel

ErP

modulating

pump

H

B

E

C

Open vented cylinder

(storage capacity to be established by

the installer

AB

A

B

m

F

CH circuit

27

7.1.10 Y-Plan wiring diagram

230Vac 3amp

Switched

Fused Spur

L N

NEUTRAL

thermostat

Room

2

1

EARTH

3

M/V S/L

Cylinder

thermostat

1

C

2

S/L to BOILER

LIVE

Mid position

Zone Valve

V4073A

Twin channel

Programmer

L

N

HTG on

DHW on

DHW o

X15

(24V=)

Wiring Centre

X13

X14

(24V =)

LIVE

SUPPLY

X12

(24V =)

1 2

X11

(24V =)

N/A

3 4 5 6 7 8 9 10

NEUTRAL

X10

(24V =)

N/A

HTG S/L

24V=

DHW S/L

X8

(230V ~)

230V

LIVE

X5

(230V ~)

X4

(230V ~)

F1 (3,15 AT)

S/L LIVE to BOILER

23 1

X3

(230V ~)

FUSE

X2

(230V ~)

X1

(230V ~)

Note:With all wiring diagrams when using a digital type room thermostat the Neutral wire from the

wiring centre (2) to room thermostat (2) will not be required.

28

7.2 Connection of domestic hot water

B, C

► Flush the pipework thoroughly to clean any debris or

residue remaining from the installation (please refer to

current Standard Codes of Practice).

► Using the supplied isolation valve, fibre washer and std

15mm copper tail connect the mains inlet cold water.

► Using the supplied swivel union, fibre washer and Long

15mm copper tail connect the domestic hot water outlet.

► Do not over tighten the connections onto the boiler as

this can cause stress damage and possible internal boiler

leakage.

Comments

► The pipework should be kept to the minimum lengths

possible and where possible long radius or formed bends to

facilitate reduced frictional losses or high resistance circuits.

► The appliance has built-in frost protection, however this

will not protect the entire system, as that will require an

external frost protection kit. (The power & Gas supply

must be switched on for the frost protection to operate at

approximately 5°C to 15°C).

► The Xtreme 24 is equipped with a flow restrictor with a

nominal value of 8 l/min. The Xtreme 30 and Xtreme 36 do

not have this feature.

► The Xtreme 36 & 30 have increased flow rates due to their

increased outputs, so a flow limiter is not normally required.

► Where the mains water is 5 bar or greater then a 3 bar

pressure reducing valve must be fitted no closer in proximity

to the boiler than 3 metres (for expansion purposes).

► In hard water areas of 200ppm or above a scale reducer

must be installed on the mains cold water inlet, Intergas

recommend the Hydroflow HS38 powered via X4

connections 1 & 2.

Domestic hot water

oultet pipework (long)

Mains cold water

inlet pipework (std)

7.2.1 DHW circuit resistance graph

20

18

16

14

12

10

8

6

Flow rate (l/min)

4

2

0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1,0 1,1 1,2 1,3 1,4 1,5

0

Water supply system (bar)

(dependant on fittings used and water circuit lengths)

A. Xclusive 24

B. Xclusive 30

C. Xclusive 36

A

29

7.2.2 Boiler with heat pump boiler

The boiler is suitable for use in combination with a heat pump

unit.

If the outlet temperature of a heat pump boiler is lower than

55°C, then the Intergas Xclusive will create a demand to

increase this depending on the boilers target temperature

setting.

Operational principle:

The domestic hot water outlet connection of the heat pump

unit is connected to the input of the thermostatic mixing valve

(see the adjacent diagram). If the DHW temperature of the

boiler is higher than the set temperature of the mixing valve,

the heat pump boiler will be stopped. (The mixing valve does

not fully close, a small amount (approximately 10%) will

always pass through the Intergas Xclusive.

As soon as the outlet temperature of the heat pump unit

becomes lower than the set temperature of the mixing valve,

the flow through the Intergas Xclusive will increase. If the flow

becomes suicient > 2.5lts/min then the Intergas Xclusive boiler

will start producing domestic hot water.

When the outlet temperature of the heat pump unit has

become lower than the set temperature of the mixing valve

< 12°C, almost the entire domestic hot water flow diverts

through the Intergas Xclusive. This time approximately 10% of

the flow is now taken from the heat pump unit.

The domestic hot water flow rate will be limited to the

maximum possible through the Intergas Xclusive (see §7.2.1).

Connection diagram for Xclusive boiler with heat pump unit

A. Heat pump unit

B. Xclusive Boiler

C. Mixing valve (Set to 55°C) max 60°C

D. Mains cold water inlet (service valve required)

E. DHW outlet from heat pump unit

F. DHW outlet (mixed supply) for consumer

Installation:

The combination must be configured according to the adjacent

connection diagram. The following points are important to

guarantee a correct operation of the combination.

Thermostatic mixing valve (switched):

The thermostatic switch valve used is a modified valve that

meets the specific requirements to which the combination heat

pump boiler and Intergas Xclusiveare subject. For the correct

operation of the combination, the switch valve has a fixed

maximum temperature setting.

B

E

A

D

C

F

30

Domestic hot water inlet pressure:

For a flow volume of 15 litres per minute, the initial pressure

must be a minimum of 2.3 bar. The maximum static domestic

hot water pressure for the Xclusive is 5 bar. A pressure

reducing valve (set to 3 bar) must be installed to prevent

excessive build up, it must be located no closer in proximity to

the boiler than 3 meters (for expension purposes).

Maximum flow volume:

If the domestic hot water flow is greater than 20 litres per

minute, the Intergas Xclusive will start a domestic hot water

demand, regardless of the outlet temperature of the heat

pump unit.

Maximum temperature setting of the heat pump boiler:

The outlet temperature of the heat pump unit must not be set

higher than 60°C.

Position of thermostatic mixing valve:

To prevent the thermostatic mixing valve being influenced too

much by the surrounding air temperature, the valve must be

placed in a position and as close as possible to the domestic

hot water connection of the boiler (maximum distance of

500mm). This prevents the boiler from igniting every time an

outlet tap or shower is operated.

Influence of water flow:

To prevent the flow by the Intergas Xclusivebeing influenced

during operation of the valve, the domestic hot water ‘out’

pipework of the combination must run straight (see connection

diagram [F]).

7.2.3 Boiler with Pre-Heated Solar Boiler)

A connection set and a thermostatic mixing valve are available

to order for this purpose.

Comment:

The NTC cold water sensor must be wired to Connection X13

4/5. When combined with a solar energy system, a thermostatic

mixing valve, set at 55°C (max 60°C), must always be installed

aer the boiler for safety reasons.

► Pre-heated Solar boiler conversion set item no 090347

► Thermostatic mixing valve item no 842177

Connection diagram:

A. Intergas Xclusive boiler

B. Solar thermal store

C. Mains cold water inlet

D. Safety group (pressure reducing &

pressure relief valve)

E. Hot out to cold inlet max. 85°C

F. Domestic hot water outlet

G. Thermostatic mixing valve 35°C-65°C

(set at 55°C) TMV3

H. Domestic hot water mixed outlet

I. Inlet water NTC sensor

Thermostatic

mixing valve

B

A

A

I

F

G

H

C

E

C

D

C

31

7.3 Electrical connection

CAREFUL

► A fused spur must be located no more

than 1 metre from the appliance.

► For installation within a moisture bound

area i.e a bathroom or kitchen then

please consult the current electrical

regulations for safe separation distances.

► When working on the electrical circuit

always isolate the 230v supply.

► Should the mains power cord be

replaced, this must be ordered directly

from Intergas.

To gain access to the electrical connections or PCB:

► Remove the front panel (see §6.2.2) and pull the PCB

housing forward; then tilt it downwards.

► Consult the electrical schematic in §12.1 for all boiler

connections.

CAREFUL

► The Xclusive complies with IPX4D water

ingress protection. Any cables routed

through the PCB housing must have

grommets or glands fitted to ensure this

integrity is maintained.

► Aer the desired connections have been made, slide the

PCB housing back into the boiler (until the le and right

safety clips are locked) then replace the front room sealed

cover on the boiler; see §6.2.2.

► Aer making the desired connections re-establish the power

supply to the boiler.

7.4 Gas connection

► Using the supplied gas isolation valve & fibre washer

connect the preformed gas pipe to the installation supply

pipework and fully tighten.

► Ensure that the gas pipework is correctly supported with

wrap over type clips.

► Open the main gas valve and boiler isolation valve then

purge the system of air.

► Carry out a full tightness test checking all connections for

any leakage (any leaks must be rectified before proceeding).

CAREFUL

► Before starting any work on the boiler,

► The boiler is intended exclusively to be

► When pollution in the gas is to be

always close the gas isolation valve.

installed on a domestic gas supply with a

meter that includes an ECV and pressure

governor.

expected a gas filter must be placed

in the gas installation pipework to the

boiler.

Gas isolation

valve

22 mm preformed

gas pipe

32

7.5 Connecting room thermostat

X13

The boiler is suitable for connection to the following room

thermostats:

► OpenTherm (OT) thermostat/Intergas Comfort Touch

► On/o thermostat (TPI)

► RF thermostat; see §9.1.4.

7.5.1 Connecting Modulating OpenTherm thermostat

The boiler is supplied with an OpenTherm connection X13 1/2 .

This allows the connection of the Intergas Comfort Touch as

well as other modulating OpenTherm thermostats without

any additional modifications. The Xclusive is also suitable for

OpenTherm Smart Power.

► Position the thermostat in a room that functions as a

reference point (in general, the living room or hall).

► Remove the link and connect the modulating thermostat to

terminals 1/2 X13 (also see §12.1); the polarity of the wires

is not important in this situation.

If you would like to make use of the *domestic hot water on/

o switch function of the OpenTherm thermostat, the DHW

comfort function must be set to ‘eco’ or ‘on’ (see §9.1.2) and

parameter P074 must be set to 0.

On

O

12

Remove the yellow link

wire prior to connecting

the room thermostat

2 1

*Dependant on model type and availability for further

information, consult the manufacturers instructions for the OT

room thermostat installed.

7.5.2 Connecting on/o volt free TPI room thermostat

The boiler is suitable for connection to a 2-wire on/o room

thermostat.

► Position the thermostat in the room that functions as a

reference point (in general, the living room or hall).

► Remove the link and connect the TPI room thermostat to

Connector 1/2 X13 (also see §12.1); the polarity of the wires

is not important in this situation.

► If both OpenTherm and on/o TPI

thermostats are connected, the on/o

TPI thermostat will have priority over the

OpenTherm thermostat.

7.5.3 Connecting 230V room thermostat

This should be wired to connector X3 1/2.

Connecting Intergas Comfort Touch,

OpenTherm and/or on/o volt free TPI

room thermostat

On

O

12

LS

► Position the thermostat in the room that functions as a

reference point (in general, the living room or hall).

► Connect the 2-wire room thermostat to terminals 1/2

X3 (also see §12.1); the polarity is not important in this

situation however terminal 1 (L) is the supply from the PCB

90 to 230v ac, terminal 2 (S) is the demand signal from the

room thermostat to the boiler.

IMPORTANT (HIGH VOLTAGE)

► Isolate the appliance from the electrical

supply before connecting the thermostat.

12

X4 X3 (230V)

Connecting 230V room thermostat

33

7.5.4 Connecting outdoor sensor

The boiler has the facility to operate with an Intergas outdoor

weather sensor, part number 203207. The outdoor sensor must

be used in combination with an on/o or OpenTherm room

thermostat.

In principle, any on/o or OpenTherm room thermostat can

be combined with an Intergas outdoor weather sensor.

With an on/o thermostat, the boiler will adjust the flow

temperature according to the room target temperature.

With an OpenTherm thermostat, the flow temperature is

controlled via the actual internal & external temperatures, this

modulates the burner using load control to give a more precise

output from the boiler saving energy.

► Connect the outdoor sensor to Connector X13 terminals 3/4

(also see §12.1).

For the heating line graph, see §9.7 Outside weather

compensation.

7.5.5 Frost protection

► To prevent freezing of the condensate pipework and the

boiler, it must be installed in a frost-free area..

► The boiler is equipped with a frost protection system.

Should the temperature of the water within the heat

exchanger drop below 5 °C, the pump will run and if

required it will ignite the burner until the temperature of the

water is up to approximately 15 °C.

4

3

Outdoor weather sensor

part number. 203207

34

X13 X12

Connecting outdoor sensor

1212

12

On

O

Comment

With the on/o TPI room thermostat fitted as per §7.5.2 you

must locate the frost stat in an area that will be subject to the

coldest conditions, ideally a radiator fitted within the

frost-sensitive area must be open on both lock shield & wheel

head valves.

► The ideal place to site a frost thermostat is the coldest area

within the property (for example, a garage or roof space).

► Connect the frost thermostat in parallel with an on/o

room thermostat or RF thermostat onto Connector X13 1/2

(also see §12.1).

CAREFUL

► With the use of an OpenTherm

thermostat, a frost thermostat must not

be connected in parallel on Connector

X13. In this situation, connect the

OpenTherm thermostat to Connector X13

and the frost thermostat to Connector

X12.

If the (external) frost thermostat is used for the installation

and it is connected to the boiler as shown, it will not be active

when the boiler is switched o or the power removed.

X13 X12

Frost thermostat and on/o thermostat

parallel connection

12

12

X13 X12