Intergas Compact HRE 18 OV, Compact HRE 24 OV, Compact HRE 30 OV, 18 OV, 24 OV Operating Instructions Manual

...

1

Compact HRE

18 OV

24 OV

30 OV

Operating Instructions

Installation of the appliance may only be carried out by an installer/competent person.

Please ask your installer to instruct you on how to fill and bleed the appliance and the

installation and on their operation. Strictly abide by all the instructions and warnings.

Always use the appliance in accordance with the Operating Instructions. It is forbidden to

interfere with a sealed component.

CONTENTS

1 Operation of the appliance 2

1.1 Operation of the central heating ................................................................. 2

1.2 Operation of domestic hot water supply (in combination with an indirectly

heated hot water storage cylinder ............................................................. 2

2 Operation and display read-out 2

2.1 Operating mode on the service display ...................................................... 3

2.2 Changing the settings of the various functions ........................................... 3

3 Start-up 3

4 Faults 4

5 Maintenance 4

© 2011 Intergas Heating Ltd Subject to change.

2

Intergas Heating Ltd is a licensed member of the Benchmark Scheme which aims to improve the standards of installation and commissioning of domestic

heating and hot water systems in the UK and to encourage regular servicing to optimise safety, efficiency and performance. Benchmark is managed and

promoted by the Heating and Hotwater Industry Council. For more information visit www.centralheating.co.uk. Please ensure that the installer has fully

completed the Benchmark Checklist on the inside back pages of the installation instructions supplied with the product and that you have signed it to say that

you have received a full and clear explanation of its operation. The installer is legally required to complete a commissioning checklist as a means of

complying with the appropriate Building Regulations (England and Wales). All Installations must be notified to Local Aerea Building Control either directly or

through a Competent Persons Scheme. A Building Regulations Compliance Certificate will then be issued to the customer who should, on receipt, write the

Notification Number on the Benchmark Checklist. This product should be serviced regularly to optimise its safety, efficiency and performance. The service

engineer should complete the relevant Service Record on the Benchmark Checklist after each service. The Benchmark cheklist may be required in the

event of any warrranty work and as supporting documentation relating to home improvements in the optional documents section of the Home Information

Pack.

1 OPERATION OF THE APPLIANCE

The purpose of the Intergas Compact HRE OV wall mounted gas fired boiler is to heat water and to supply it to the central heating (CH)

system and when an indirectly heated domestic hot water storage cylinder is installed, apply heat to the domestic hot water (DHW)

installation. The Intergas Compact HRE OV boiler is designed for use in open vent systems with a header tank.

The appliance is fitted with a modulating control. This means that the power is adjusted in line with the required heat. The boiler

controller responds to each call for heat from the heating or the DHW system by igniting the burner and monitoring the flame.

1.1 Operation of the central heating

The call for heat arises as a result of the room temperature being lower than the temperature set on the room thermostat. The central

heating temperature control modulates on the basis of the set central heating supply temperature. This means that when the desired CH

supply temperature is approached the appliance adjusts the power. The pump for the CH has a post purge period of 1 minute. The post

purge period may be changed if desired. The pump runs automatically for 10 seconds once every 24 hours to prevent blocking.

1.2 Operation of domestic hot water supply

By connecting the Compact HRE OV to a DHW storage tank the DHW circuit can be heated. The built-in regulation ensures that the

DHW demand takes preference over a CH demand. During delivery of hot tap water no heat is supplied by the appliance to the central

heating system.

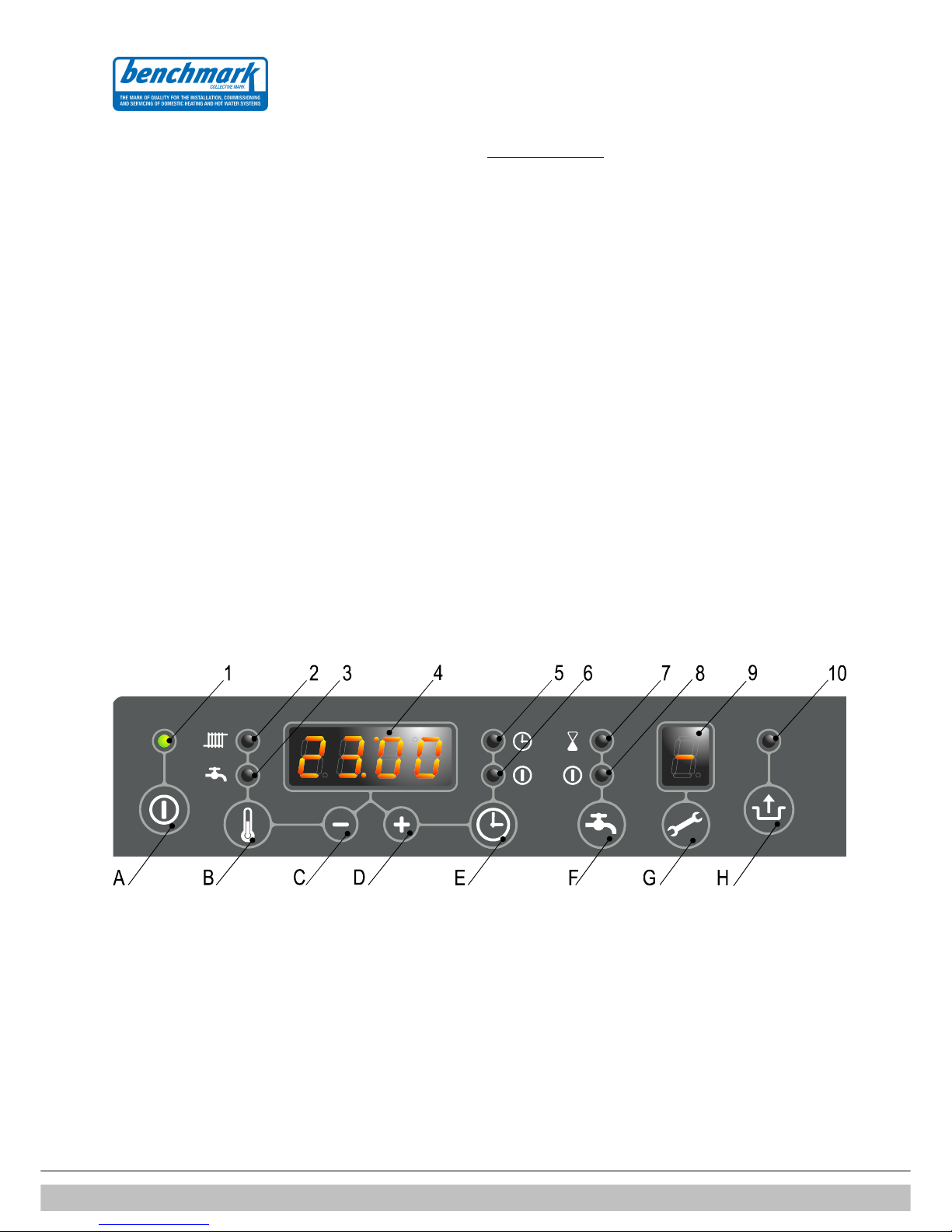

2 OPERATION AND DISPLAY READ-OUT

Read-out Operat

ion

1

On / off

A On / Off button

2

CH operation or setting maximum CH temperature

B DHW / CH button, for setting desired temperature

3

DHW operation or setting DHW temperature

C - button

4

Desired temperature of CH or DHW in °C / Fault code/ Time

D + button

5

Clock “on” CH enabled

E Clock function setting

6

Clock “off” CH disabled

F DHW comfort function off/eco/on (

not applicable for Compact HRE OV

)

7

DHW comfort function eco (

not applicable for Compact HRE OV)

G Service button

8

DHW comfort function on ((

not applicable for Compact HRE OV)

H Reset button

9

Operating code

10

Flashes to indicate fault

3

2.1 Operating mode on the service display:

—

Off (appliance frost protection active)

3

Ventilate

Wait mode

4

Ignite

0

CH pump post run

5

CH mode

1

Desired temperature reached

6

DHW mode

2

Self test

7

Heat up appliance on (not applicable for Compact HRE OV)

Note

When the red LED above the reset key flashes a fault has occurred. A fault code will then appear on the temperature/clock display.

2.2 Changing the settings of the various functions

Keeping the key pressed for 2 seconds takes you to the user settings menu (LED at and the display starts to flash).

Then each time you press the key a different function LED will start to flash. The value of the function can be set using the

and keys. The value set is displayed on the display.

• The reset key closes the settings menu and stores the changes.

• If no key is pressed for 30 seconds, the settings menu is automatically closed and the changes are stored.

• The on/off key closes the settings menu without storing the changes.

• The button restores the default setting for the switch moments (hold for 5 seconds).

• By pressing the or keys the clock can be set and the switch moments can be defined.

• By pressing the button 2 time blocks can be programmed in which the CH is on (switch moments 1 to 4).

• By pressing the button the new times will be stored in the boiler controller. In the display appears [P] for a short period.

• Pressing the button for less than 1 second the following additional functions can be activated:

1. t-on (temporary on), the boiler will respond on every CH demand from the room thermostat until the next switch moment.

2. c-on (continuous on), the boiler will respond on every CH demand from the room thermostat without any time limit.

3. OFF, the boiler will not respond on any CH demand from the room thermostat.

The maximum CH supply temperature. Can be set between 30°C and 90°C (standard setting 80°C).

Low setting for moderately cold weather, high setting for colder weather.

DHW temperature.

The temperature in the DHW storage cylinder can be set, if it is connected to an external sensor,

between 40°C and 65°C (standard setting 60°C). To prevent the growth of legionella it is advised not to set the DHW

temperature below 60°C.

All other alterations of settings of the boiler may only be carried out by your installer.

3 START-UP

Once the appliance has been connected to water, gas and electricity supplies and

checked by an authorised installer, the appliance can be started.

Please check the following points:

• The heating system feed tank and system must be filled and bled with the manual bleed screws on the radiators.

• The appliance must be switched off (Horizontal dash on service display, other LEDs off).

• Never switch the appliance on if the appliance, the CH system and heating system feed tank have not been completely

filled and bled.

• The room thermostat must be set below the temperature in the room.

• The gas tap must be open.

• Switch the appliance on with the on/off key in the display (The LED lights up, and the service display goes out).

• Set the clock and the switch moments. If the boiler is in a time block that CH is not active the boiler must be set in c-on (see §2.2).

• Set the room thermostat higher than the actual room temperature. The appliance will fire for purposes of the CH system.

4 FAULTS

If the following simple appliance faults occur, they can be resolved as follows. In the case of repeated occurrence or other faults

always notify your installer.

1. The CH system does not heat up or does not become sufficiently warm:

• Increase the temperature setting at the room thermostat.

• Open the radiator valves.

• Increase the CH water temperature setting using the and the and key on the operating panel (see §2).

• Bleed the appliance and installation and check the CH water pressure.

2. The domestic hot water supply does not become hot or hot enough (only when an indirectly heated DHW cylinder

is applied):

• Open the domestic hot water tap further.

• Set the domestic hot water temperature higher using the

and the and key on the operating panel (see §2).

4

3. The fault LED above the reset key is flashing. The following codes are indicated on the display (4):

• 1 The appliance becomes too hot, there is insufficient flow. Open the radiator valves, bleed the appliance and

installation.

• 4 The burner does not light. Consult your installer.

After rectifying the fault press the reset button and the appliance will start up again. For the meaning of the other operating and

fault codes please refer to the installation instructions.

Frost protection

To prevent freezing of the condensate drain, the appliance should be installed in a frost-free room.

The appliance is equipped with frost protection which, as long as mains current is present, switches on the external

CH pump and if necessary the burner when the heat exchanger temperature falls too far.

Note

If an internal or external frost thermostat has been installed in the system and connected to the appliance, it is not active when the appliance

has been switched off at the operating panel ( - on service display).

5 MAINTENANCE

The appliance can be cleaned with a damp cloth. Do not use aggressive or abrasive cleaning agents or solvents.

The appliance and the installation should be checked and where necessary cleaned annually by a registered

installer. The same applies to the flue pipe and air supply pipe.

If you smell gas or are worried about gas safety please call the National Gas Emergency Service at 0800 111 999.

For more details visit the website of the National Grid www.nationalgrid.com/uk/Gas/Safety/Emergency.

Always use a Gas Safe registered engineer to fit, fix or service your gas appliance. To find or check an engineer call Gas Safe

Register’s free helpline on 0800 408 5500 or visit www.GasSafeRegister.co.uk.

Intergas boilers are manufactured in a Kiwa ISO 9001 certified production faccility.

Intergas Heating Ltd

883.257-04

Intergas Heating Limited Telephone: 01527 888000

Building 94, Bay 1 Vantage Point Fax : 01384 279480

The Pensnett Estate info@intergasheating.co.uk

Kingswinford www.intergasheating.co.uk

West Midlands

DY6 7FS

Loading...

Loading...