BYOS 1

™

SLIDE SYSTEM

(BUILD YOUR O W N S L I D E )

Assembly & Installation Instructions

Visit

int

er

-fab.com to view our installation help video.

(Video does NOT replace installation instructions.)

I

M

WARNING

The installation of this product should be done only by a licensed and professional installer. Installation should

be done strictly in conformance with all local building codes, electrical codes and other building and safety laws

and regulations. Among other things, your installer should carefully analyze the need to bond the product

prevent an electrical hazard. Failure to properly install this product could result in a dangerous condition,

including but not limited to electrical or structural hazards. Inter-Fab, Inc. disclaims all liability arising from the

installation and the user assumes all risk associated with the installation.

IN TE R- FA B, IN C. 30 50 S . A LVE RN ON WAY • TU CS ON , A Z 8 57 13

52 0. 79 0. 70 40 • 8 00 .7 37 .5 38 6 • F AX 52 0. 79 0. 71 27 • in te r - fa b. co m

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

PORTANT INSTALLATION INFORMATION

to

B Y O S 1 L I A B I L I T Y D I S C L A I M E R

IMPORTANT NOTICES

LIABILITY DISCLAIMER: This BYOS product provides the customer the opportunity to

design a one-of-a-kind slide, unique to the customer’s preferences. When purchasing this

BYOS product, the customer acknowledges and agrees that he or she has designed and

created the specifications for this product. S.R.Smith makes no claims, representations

or warranties, whether expressed or implied, regarding this design of this product, or

this product’s safety, relability, durability, or performance. In no event shall S.R.Smith

be liable for any direct, indirect, punitive, incidental, special, or consequential damages

arizing out of or connected with the use or misuse of this product.

Inter-Fab recommends that you read the BYOS 1 Installation Manual in its entirety before attempting

an installation.

• It is highly recommended that provision be made for future maintenance and/or removal of the

slide from the substrate, if necessary. Do not fully encase the slide in concrete or pernanently

fixed structure/material.

• Do not construct objects or formations along or over the slide pathyway that obstruct the

pathway for sliders or cause potential harm to the head, arms or legs.

• Minimum recommended head clearance above the slide pathway is 7 feet.

• Minimum BYOS 1 water envelope is 7’ wide (centered on slide) x 13.5’ long x 4.5’ deep

• The exit section must be installed with the correct alighnmenet to the pool edge with a

minimum overhang of 3” and should be supported at the fiberglass landing plate.

• Zoom Flume™ water delivery system requires a 1” PVC flex hose. For best performance,

the recommended water flow at the slide is 20-40 GPM, connecting a ball valve in line is

recommended for water flow adjustment. NOTE: Connect the Zoom Flume™ water

delivery system to water source and test for leaks or defects prior to final assembly/

installation.

• See page 16 of installation manual for BYOS 1 Care and Maintenance.

WARNING

FAILURE TO INSTALL BYOS 1 PRODUCTS SO THAT THE ENTRY SECTION SUPPORT

•

FRAME IS LEVEL, WILL CAUSE THE DESIGN TO EXCEED THE RECOMMENDED

ANGLE OF DESCENT AND MAY RESULT IN PERSONAL INJURY AND/OR PROPERTY

DAMAGE. NO INSTALLED BYOS 1 SLIDE SHOULD EXCEED A 20 DEGREE SLOPE.

• FAILURE TO INSTALL THE BYOS 1 SLIDE ANCHOR SYSTEM TO THE MINIMUM

DEPTH SPECIFIED IN THE INSTALLATION INSTRUCTIONS OR ALTERATION OF THE

BYOS 1 SLIDE ANCHOR SYSTEM WILL CAUSE STRUCTURAL INSTABILITY AND MAY

RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE.

.

• DO NOT DRILL INTO OR THROUGH ANY BYOS SLIDE SECTION OR ANCHOR OR

OTHERWISE MODIFY. IT WILL WEAKEN THE PART AND VOID THE WARRANTY.

3050 S. Alvernon Way • Tucson, AZ 85713

520.790.7040 • 800.737.5386 • Fax 520.790.7127 • inter-fab.com

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

i

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

TABLE OF CONTENTS:

BYOS Liability Disclaimer ...........................................................i

Intended Use Instructions ........................................................2

Water Safety Envelope.............................................................3

Slide Placement......................................................................4

Getting Started.......................................................................5

Tools Required........................................................................6

Step 1: Preparing Site.............................................................6

Step 2: Flume Assembly .......................................................6-7

Step 3: Entry Section Anchor Assembly ..................................8-9

Step 4: Variable 15˚ and 30˚ Anchor Information......................10

Step 5: Move the Slide ..........................................................10

Step 6: Excavate the Holes ....................................................11

Step 7: Reset Slide in Position................................................11

Step 8: Final Slide Position ................................................12-14

Step 9: Pour Concrete Piers ..................................................14

Step 10: Connect Water Supply .............................................14

Flume & Anchor Support Hardware.........................................15

Slide Care & Maintenance......................................................16

Page for Notes.....................................................................17

Inter-Fab Limited Warranty.....................................................18

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

1

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

INTENDED USE

WARNING

1. Everyone who uses this slide must know, understand and follow these instructions

2. The ANSI/APSP/ICC-5 2011 standard for above ground pools prohibits the use of slides or diving boards

on above ground pools.

3. This slide is designed for residential inground pool use ONLY. This slide may not be used on any above

ground pool. Such use of this slide may result in serious injury or death.

4. This slide should never be installed on above ground pools, ponds, floating docks or platforms, boat docks

or houseboats or any natural body of water.

5. This slide should never be installed on any commercial, public or semi-public pool.

6. Be familiar with the shape and depth of the pool before you slide. This slide should only be used with the

proper water safety envelope, as described in Diagrams A, B & C on page 3 and in accordance with the

slide positioning diagrams on page 4.

7. Because the slide may only be used in water 4.5’ deep or greater, all slide users must be able to swim

in deep water.

8. Weight limit for this slide is 250 pounds, no slider weighing more than 250 pounds may use this slide.

9. The surface of the slide is very slippery when wet; USE CAUTION when entering the slide and when

transitioning from standing to sitting.

10. Slide in a feet first sitting position ONLY.

11. IMPORTANT: sliding headfirst is prohibited: serious spinal injury resulting in paralysis or death can result.

12. Maintain adult supervision at all times.

13. Only one person at a time is allowed on the slide.

14. Be sure the water delivery system is on and lubricating the slide prior to use.

15. Collision with another swimmer or a diver can result in serious injury or death for one or both persons:

Before sliding, always make sure that the path in front of the slide is free from any (including submerged)

obstructions including other people or objects in the pool such as rafts, inner tubes etc. When a diving

board is also present, make sure you do not use the slide while someone is on or using a diving board.

Take turns.

16. No roughhousing or horseplay should be allowed on the slide at any time.

17. Do not stand, jump or dive from any part of the slide.

18. Do not slide on objects such as rafts or inner tubes. doing so greatly increases your risk of injury.

19. Do not slide through or at objects such as rafts or inner tubes, doing so greatly increases your risk of

injury.

20. Do not use this slide if physically impaired or handicapped without your doctor’s permission.

21. Do not use this slide with a history of heart conditions, seizures, back problems, fainting or fear of

heights.

22. Do NOT use this slide if you are pregnant

23. Do not drink alcohol and use this slide.

24. Don’t take chances, inspect the slide at least once a year (see the slide inspection list on page 16, do

not use the slide if any part becomes loose, damaged, weakened or broken. If necessary, before using

the slide again, have it inspected and repaired by a competent professional familiar with pool slides.

.

INSTRUCTIONS

WARNING: SERIOUS INJURY OR DEATH CAN RESULT FROM THE

IMPROPER INSTALLATION OR USE OF THIS SLIDE.

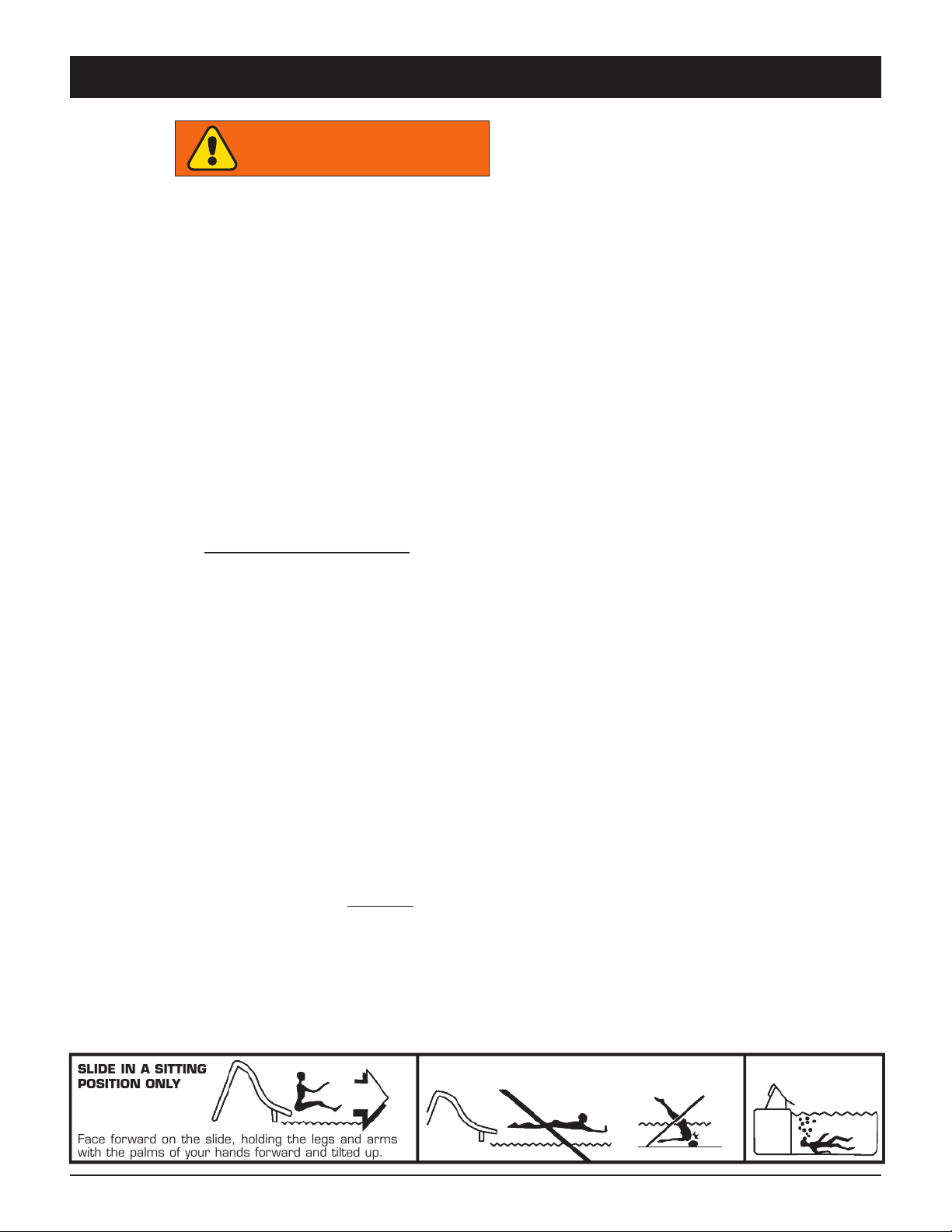

SLIDE IN A SITTING

POSITION ONLY

Face forward on the slide, holding the legs and arms

with the palms of your hands forward and tilted up.

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

DO NOT SLIDE HEAD FIRST

2

SERIOUS INJURY

CAN RESULT

DEEP WATER

SWIMMERS

ONLY

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

WATER SAFETY ENVELOPE

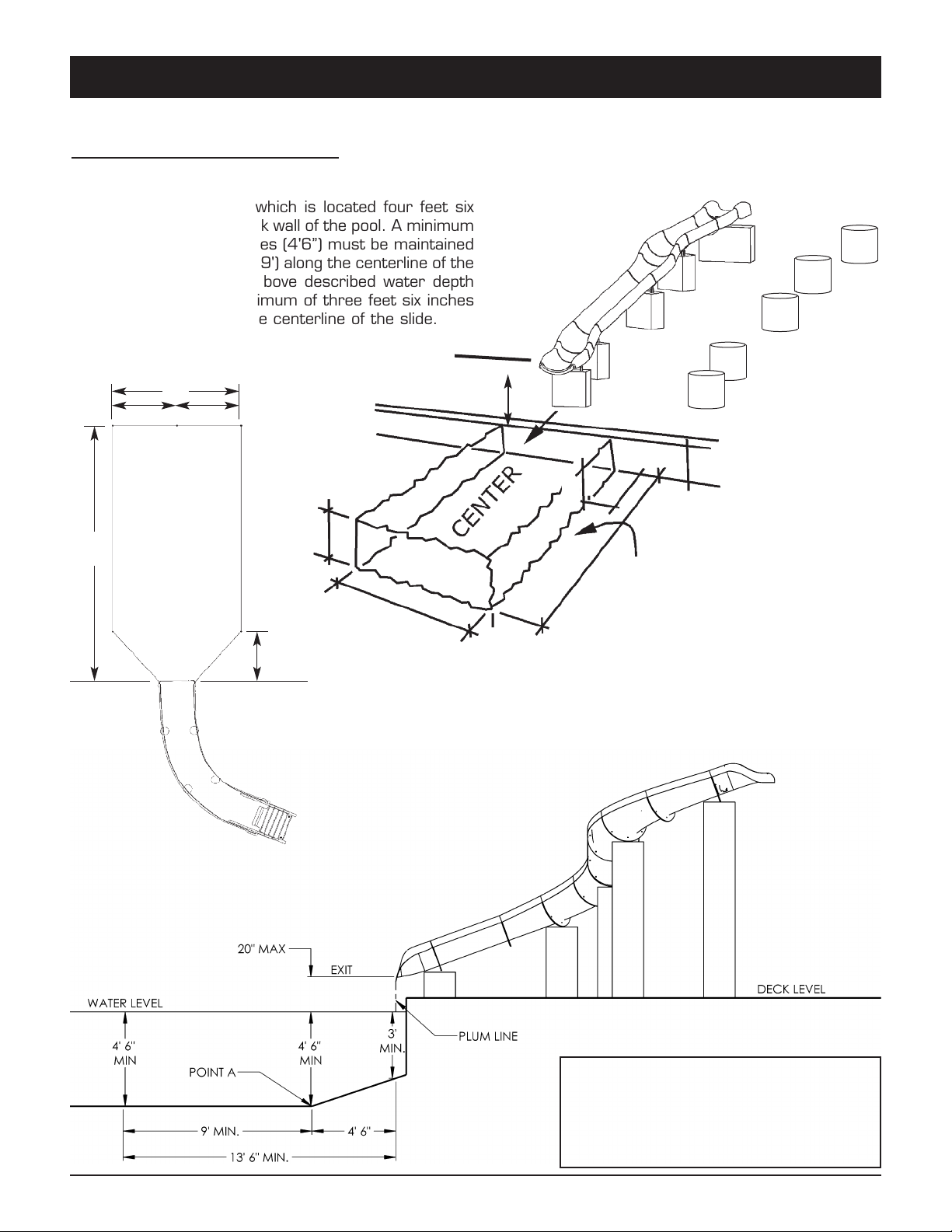

A minimum water depth of three feet (3') under the exit

f the slide which increases to a depth of four feet six

o

inches (4'6”) at point A which is located four feet six

inches (4'6") from the back wall of the pool. A minimum

depth of four feet six inches (4'6”) must be maintained

at a distance of nine feet (9') along the centerline of the

slide from point A. The above described water depth

profile shall extend a minimum of three feet six inches

(3'6") on either side of the centerline of the slide.

(See Diagrams A, B & C)

7'

3'6"3'6"

13'6"

C/L

4’6”

:

2

0

7’

DIAGRAM A

(NOT TO SCALE)

OR

”

M

a

x

”

6

’

4

4’6”

”

6

’

3

WATER SAFETY

1

3’

ENVELOPE

2'6"

DIAGRAM B

(NOT TO SCALE)

Minimum Slide

Clearance Area

DIAGRAM C

(NOT TO SCALE)

Minimum Water Safety Envelope

ALL SLIDES SHOULD

BE BONDED

Check your local electrical

code requirements.

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

3

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

SLIDE PLACEMENT

If the slide meets the pool edge at an angle, then the outside curve “Pivot A” has to be at

the pool edge. Refer to Diagram D & E below.

” MINIMUM

3” MINIMUM

OVERHANG

3

OVERHANG

DIAGRAM D

(NOT TO SCALE)

DIAGRAM E

(NOT TO SCALE)

If the slide meets the pool edge straight on, then the end of the exit section should be parallel

with the pool edge. Refer to the Diagram F below.

3” MINIMUM

OVERHANG

DIAGRAM F

(NOT TO SCALE)

NOTE: The exit point of the flume can be no higher than 20” above the water.

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

4

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

GETTING STARTED

Inter-Fab has provided you with a slide system which matches the pathway and spatial

requirements you provided to us as closely as possible. It is important to note however,

that Inter-Fab does not approve or accept liability for BYOS designs. All designs should be

checked by a licensed Civil or Structural Engineer in your state, and when necessary,

inspected/approved by the applicable local governing agency.

Inter-Fab recommends that you read these instructions and helpful hints in their entirety

before attempting an installation.

IMPORTANT NOTICES:

• It is highly recommended that provision be made for future removal of the slide from

the substrate, if necessary.

• The sizes of the concrete piers for the anchor supports specified herein are minimum

measurements required for the BYOS, and may need to be increased due to local

weather, soil conditions, frost line and/or local building codes.

• For best performance, the recommended water flow at the slide is 30 GPM.

• Zoom Flume water delivery system requires a 1” flexible PVC hose. NOTE: A ball valve

in line is recommended for water flow adjustment.

• Do not construct objects or formations along or over the slide pathway that obstruct

the pathway for sliders or cause potential harm to the head, arms or legs. Minimum

recommended head clearance above the slide pathway is 7 feet.

• Minimum BYOS water envelope is 7’ wide (centered on slide) x 13.5’ long x 4.5’ deep.

• The exit section must be installed with the correct alignment to the pool edge and should

be supported at the fiberglass landing plate. Do not exceed 20” above the water.

• The surface of the slide is very slippery when wet, use caution when entering the slide.

Seating assist rails are recommended for the transition from standing to sitting.

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

5

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

LIST OF REQUIRED TOOLS

Tools required for assembly and installation of BYOS slide:

1. 3/8" Drive Ratchet

2. 3/4” Socket

3. 3/4" Box End Ratchet Wrench

4. 9/16" Socket

5. 9/16" Box End Ratchet Wrench

6. Torque Wrench

7. Angle Finder

8. Tape Measure

9. 48” Level

ASSEMBLY AND INSTALLATION INSTRUCTIONS

STEP ONE: Preparing site area for BYOS slide system.

First, Level the hill substrate to the approximate final grade.

EXIT SECTION

TIP:

• The exit section should be supported at the fiberglass

landing plate. (Fig. 1) The exit plate can simply rest

upon the substrate or be drilled from the side and

bolted to a bracket. (not supplied)

NOTE: Build the support for the exit landing in

the correct orientation and at the correct

height prior to setting the fully assembled slide

in place. The exit point of the flume can be no

higher than 20” above the water.

STEP TWO: Flume assembly.

Starting with the exit section, assemble the slide on the

ground, right side up along actual pathway where the slide will

reside. (Be careful not to scratch the slide) Attach the exit

section anchor support, followed by the next flume section in

the correct order of the slide pathway. To help identify the

flume sections for the correct order of assembly, there are

stickers attached at each flange end of each flume section.

For example, attach the letter A end of the exit section to the

letter A end of the next flume section of your custom BYOS

slide. (Fig. 2 - sample only) Attach the anchor supports in

the specified locations as you build uphill and away from the

pool. Stickers are attached to the side of the flange connection

that the anchor support will connect to.

Landing Plate

Fig. 1

Fig. 2

F’s

E’s

D’s

C’s

B’s

A’s

NOTE: Anchor support locations are noted on a separate sheet (included) that is

specific to your exact slide design. There are stickers attached to the correct flume

piece to indicate which side of the flange you need to connect the anchor support to.

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

6

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

STEP TWO: Flume assembly - CONTINUED

TIPS:

• Be careful not to allow dirt to get into the water delivery system on the entry section.

• Gasket end of each flume section goes uphill.

• The Entry Section Support bolts to the inside of the Entry Section. There are

four 3/8” bolts, 2 on each side.

• Anchor supports attach to the down slope side of the flange. (Fig. 3)

• Each flange has 7 bolts. Five bolts are 3/8” (Fig. 3 positions 1, 4, 5, 6, 7) and

two bolts are 1/2” (Fig. 3 positions 2,3). The anchor supports (where required)

attach to the 1/2” bolts. Use Anti-Seize (in BYOS-101 Combo Kit) on all bolts.

• Insert bolts in this order: bolt, flat washer, flanges, flat washer, lock washer, nut.

On flanges that require anchor supports insert bolts in this order: bolt, flat

washer, flanges, anchor support, flat washer, lock washer, and nut.

• Insert and hand tighten all the flange bolts. Then, utilizing a torque wrench,

tighten each nut to approximately half of the maximum 25 ft. lbs. Tighten the

bolts in an alternating fashion working from left to right starting with the center

bolt, then tighten the two 1/2” bolts, working your way up the flange (Fig. 3).

Repeat this same tightening process until the specified 25 ft lbs is reached on

each bolt. Do not over tighten. Using greater force may fracture the fiberglass.

Tightening the bolts in this sequence is necessary to compress the gasket evenly.

7

6

2

1

3

5

4

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

Fig. 3

7

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

STEP THREE: Entry section anchor assembly.

The BYOS ESA COMBO Entry Section Anchor consists of 1 upright, 1 right support arm and

1 left support arm. The assembly is attached to the BYOS Entry Section with the hardware

kit BYOS-101 COMBO. (Fig. 4)

Carefully turn the BYOS Entry Section upside down (on cardboard) and set the anchor

upright into position as shown in Fig. 5.

Using 4 each 3/8”x1” bolts, attach the anchor to the entry section. Use a flat washer on

each side of the part and anchor. Pass the bolt through from the outside of part toward

the underside and add a lock washer and a nut to each bolt. Hand tighten only. (Fig. 6)

Attach right and left arms as shown in Fig. 7 and 8. The arms are attached at this point

only to the anchor upright using 2 each 3/8”x1” bolts with flat washers, lock washers and

nuts. Hand tighten only. NOTE: The other end of the right and left arms will attach to

flume flanges when connecting the next BYOS section during the slide assembly.

NOTE: Right and Left arms attach to the inside of the ESA COMBO uprights.

Fig. 4 Fig. 5 Fig. 6

Fig. 7 Fig. 8

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

8

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

STEP THREE: Entry section anchor assembly - CONTINUED

The BYOS ESA COMBO must have a minimum concrete embedment depth as shown in Fig. 9.

The maximum gap between bottom on BYOS entry section and concrete is 12”. Anchor may

be mounted in ground or with minimum 18” diameter tube.

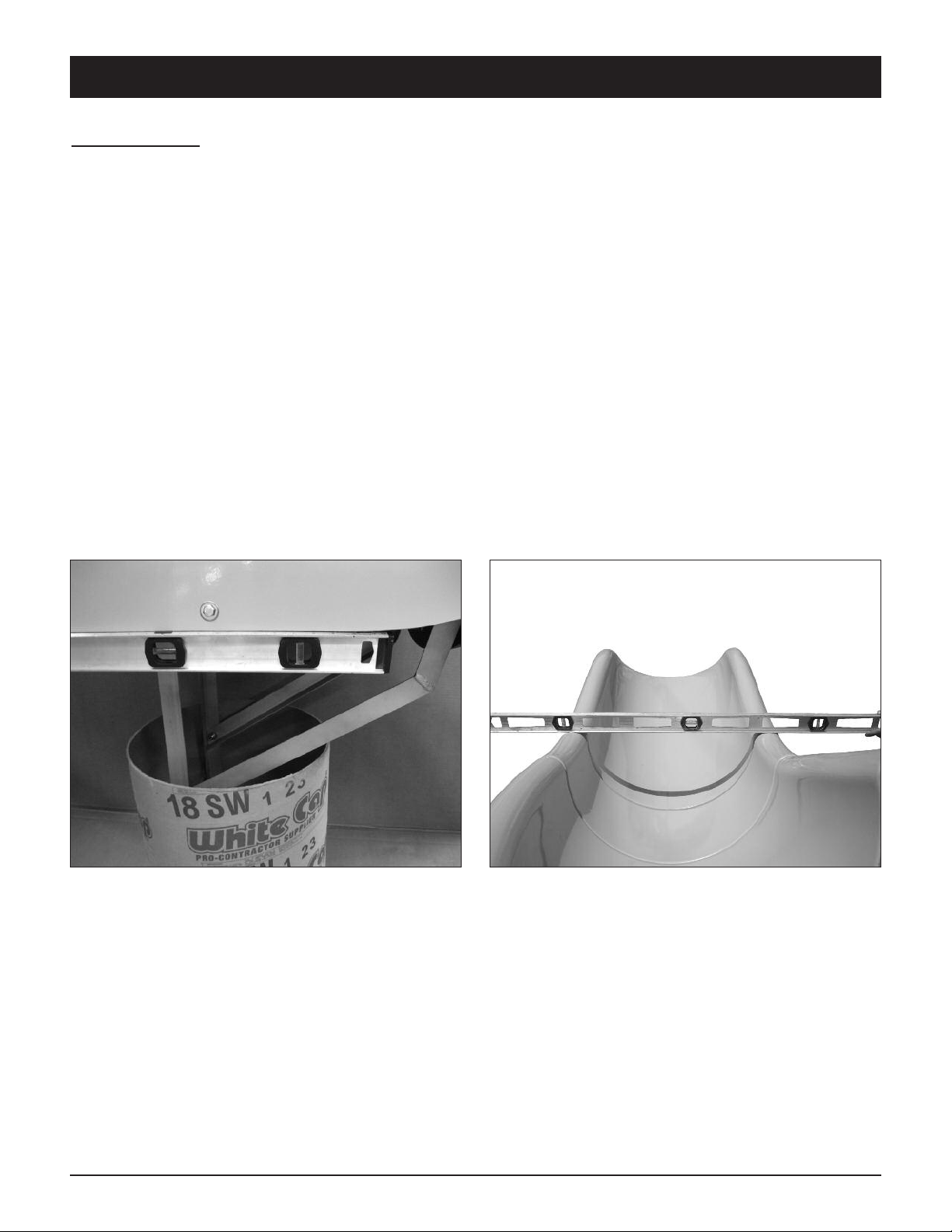

When oriented correctly, the bottom of the entry section will be level as shown in Fig. 10.

When attaching the first BYOS section to the Entry Section, the anchor right and left arms

will be attached as shown in Fig. 11 and 12.

NOTE: When slide is assembled and leveled as per instructions, the bolts on the

anchors may be tightened.

TIP: Once all the flume sections are assembled and the flange bolts are correctly tightened,

do a water test with a garden hose to ensure there are no flume to flume leaks.

Fig. 9 Fig. 10

Fig. 11 Fig. 12

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

9

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

STEP FOUR: Variable 15˚ and 30˚ Anchor information.

The following information is for the BYOS 15A LONG and the BYOS 30A LONG Anchors and

should be reviewed before proceeding onto the next step. Our 15˚ and 30˚ anchors have

been modified to allow easier use with concrete tube forms.

We have lengthened our BYOS flume anchors to allow room for concrete chutes when using

concrete tube forms in a BYOS installation. This improved anchor design will provide more

flexibility in installation options and make your BYOS installations even easier. (Fig. 13)

8”

32”

Maximum Concrete

Embedment Depth

M

inimum Co

Emb

e

dme

nc

nt De

re

pth

te

20”

4”

Fig. 13

STEP FIVE: Move the slide.

Once the entire slide is assembled and resting on the anchor supports in its correct horizontal

position on the pathway, use spray paint to carefully mark the location of the anchor supports.

Next, with sufficient manpower, gently move the assembled slide (if possible) approximately

3 feet to one side.

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

10

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

STEP SIX: Excavate the holes.

Pier holes for the flume anchor supports (Straight, 15° and 30°) should be a minimum of

12” long, 24” wide and 24” deep, or minimum 18” diameter tube.

The hole for the entry section anchor support should be a minimum of 12” long, 24” wide and

24” deep, or minimum 18” tube.

WARNING

The above specified sizes for the concrete piers represent a minimum

and should be increased due to local weather, soil conditions, frost

line and/or local building codes. Anchor supports shall be bonded.

Refer to your local building/electrical code requirements.

STEP SEVEN: Reset the BYOS in position.

Ensure sufficient blocking material is on hand, then utilizing sufficient manpower; lift the

assembled slide back into its correct horizontal and vertical position and block in place.

At this point, the anchor supports should be directly over, centered and within the holes for

the piers or tubes, adjust hole location as necessary at this time. The top rebar cross member

will be approximately 4” below final concrete grade for maximum anchor embedment depth.

Minimum anchor embedment depth will have the middle rebar cross member approximately

4” below final concrete grade. (See Fig. 13) NOTE: It is essential that the vertical portions

of the anchors are plumb.

Anchor supports shall be bonded. Refer to your local building/electrical code requirements.

With the exception of the exit section landing plate (Fig. 1), make sure that a minimum 3 inch

clearance is maintained between any portion of the underside of the slide (including the

flanges) and the substrate. Based on the slider’s weight and velocity the slide can move

slightly both vertically and horizontally. If the slide rubs upon the substrate due to this motion

a wear spot and/or leak can develop.

Fig. 14

24”

24”

12”

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

24”

24”

12”

ENTRY SUPPORT

24” x 24” x 12”

OR

18” Tube at 24” Depth

FLUME SUPPORTS

24” x 24” x 12”

OR

18” Tube at 24” Depth

11

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

STEP EIGHT: Final slide position.

It is essential that the slide be in its correct horizontal and vertical position prior to pouring

concrete; and since the pool cannot be moved, start checking position with the exit section

first. Starting with and then ensuring that the exit section is installed correctly is absolutely

necessary for a successful installation.

The exit section must meet the pool edge at the correct elevation, in the correct orientation

and be level in both axes. (Fig. 15 & Fig. 16) When determining level position for the exit

section please note that the exit section starts with a 15° up slope, which then makes a

gradual transition to level point toward the exit point. Check for level position only as illustrated

below.

Fig. 15 Fig. 16

Utilize an angle finder along the centerline of the flume ensure the flume is at the correct angle.

Check the angle along the centerline of the flume only. (Fig. 17) Do not check angle on up

or down wedge as the slope transitions through them.

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

Fig. 17

12

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

STEP EIGHT: Final slide position - CONTINUED

When checking for the correct flume angle keep the below in mind:

• Each slide section is identified on the underside.

• The exit section starts at 15° on the up slope end which then makes a gradual

transition to level toward the exit point.

• The up and down wedges are 15°, but transition in slope and cannot be checked

for slope

• The curved sections are either 15° or 30°

• The 2.5’ and 5’ straight sections do not have a slope, but slope relative to the

section above such as: flat (0°), 15° or 30°

• The entry section seating area is almost flat, however, for proper drainage it

incorporates a slight downhill slope which transitions to a full 15°. To ensure

correct placement of the entry section the trim line along the bottom edge of

the outside wall was made level. If properly installed the bottom edge of the outside

wall of the entry section will be level. (Fig. 18)

ENTRY SECTION

Fig. 18 Fig. 19

The sides of the flumes should be checked for level as well. The only place along the flume

where level positions can be determined is at the flange/gasket locations. Place level across

the flume at the flume joint as illustrated. (Fig. 19) Check each flange location for level position,

adjust as necessary.

TIPS FOR SETTING THE SLIDE IN FINAL POSITION:

• It may take a series of adjustments to get the slide in its correct position.

• At this point the entire slide should be assembled, anchor supports attached

and all bolts correctly tighten. The slide should be blocked up in its approximate

horizontal and vertical position.

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

13

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

STEP EIGHT: Final slide position - CONTINUED

TIPS FOR SETTING THE SLIDE IN FINAL POSITION - CONTINUED

• Now, place the exit section in its correct horizontal and vertical position relative

to the pool edge by adjusting the blocks.

• Then, start at the top of the slide and work down using an angle finder along

the center of the flume, adjust the blocks to achieve the correct angle for the

flume.

• Once the angle for the flume is set correctly, re-check the position of the exit

section for alignment and height above water, adjust as necessary.

• Then, start at the top of the slide and work down, adjust the blocking materials

to level the flume from side to side.

• Once the flume is level from side to side, re-check the position of exit section

for alignment and height above water, adjust as necessary.

• Repeat this process until the entire slide is correctly positioned.

STEP NINE:

Once the correct horizontal and vertical position of the slide has been established and verified,

pour the concrete around anchor supports and allow to cure.

Pour concrete piers.

STEP TEN: Connect water supply system.

The BYOS™ slide can be plumbed with 1” Flex PVC.

Glue and slip the pipe into the 1” female fitting on the underside of the Entry section. (Fig. 20)

Use PVC primer and glue (not included) as required.

A ball valve is recommended to adjust water flow.

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

Fig. 20

14

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

BYOS™ FLUME & ANCHOR SUPPORT HARDWARE

Seating Support

Anchor

Seating Support

Anchor Support Arms

15˚ Support

Anchor

30˚ Support

Anchor

The entry support anchor comes with a part specific hardware kit. Use hardware set BYOS101 COMBO.

The 15˚ and 30˚ support anchors all attach to flume sections using the two larger bolts in

positions 2 and 3 shown below. (Fig. 21) Use hardware set BYOS-102.

BYOS-101 COMBO – ENTRY SECTION ANCHOR SUPPORT HARDWARE

QTY PART NUMBER COMPONENT DESCRIPTION

6 H-SS 3/8 LOC WA 3/8" Lock Washer Stainless Steel

12 H-SS 3/8 FLT WA 3/8" MS 815 Flat Washer Stainless Steel

6 H-SS 3/8 F NUT 3/8" Hex Nut Stainless Steel

6 H-SS 3/8X1 HB 3/8"-16X1” Hex Bolt Stainless Steel

BYOS-102 – FLUME TO FLUME CONNECTION HARDWARE

QTY PART NUMBER COMPONENT DESCRIPTION

2 H-SS 1/2 LOC WA 1/2" Split Lock Washer Stainless Steel

2 H-SS 1/2 H NUT 1/2"-13 Hex Finish Nut Stainless Steel

4 H-SS 1/2 F WASH 1/2" USS Flat Washer Stainless Steel

2 H-SS 1/2-13 x 2 1/2"-13 x 2 Hex Bolt Stainless Steel

5 H-SS 3/8 LOC WA 3/8" Lock Washer Stainless Steel

10 H-SS 3/8 FLT WA 3/8" MS 815 Flat Washer Stainless Steel

5 H-SS 3/8 F NUT 3/8"-16 Hex Nut Stainless Steel

5 H-SS 3/8-16 3/8"-16 x 1-1/2 Hex Bolt Stainless Steel

6

4

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

2

1

TIP: When attaching an anchor support

to a flange, insert bolts in this order:

bolt

flat washer

flanges

anchor support

7

3

5

flat washer

lock washer

nut

NOTE: Use Anti-Seize on all bolts!

Fig. 21

15

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

BYOS™ SLIDE CARE & MAINTENANCE:

Your BYOS slide requires periodic maintenance to keep it looking like new and protected

from the elements.

• Wash slide monthly or more frequently if needed using a mild soap and soft cloth. Keep

cleaning materials from entering pool.

• Do not use abrasive cleaners, bleaches, chlorines, high alkaline or strong

acidic cleaners.

• Do not use steel wool, wire brushes, metal scrapers, Scotchbrite or other

abrasive sponge pads.

• Keeping your slide’s gel coat finish coated with wax - starting when the slide is new is the best way to prolong its life.

• Choose a wax intended for use on gel coat surfaces. Preferably one designed

for use in a Marine environment.

• Test product on small inconspicuous section of slide prior to full application.

• While application instructions will vary between brands of wax, in general

you apply the wax with a cloth or foam pad using circular motion. Once wax

dries to a haze, buff the excess with a soft dry cloth.

• Routine waxing (at least twice a year) will maintain the smooth reflective

surface of your slide.

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

16

I N S T A L L A T I O N I N S T R U C T I O N S B Y O S 1 S L I D E

NOTES:

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

17

I N T E R - F A B L I M I T E D W A R R A N T Y

Y

ou

Y

ild

u

B

ar

G

fac

te

x

t.

s

i

m

ny

e

r

cts o

av

tory

d

n

te

n

I

war

e

r

s not e

oe

al d

ic

met

uipm

q

rra

a

v

e

es

s

l inc

e

h

s

d

e

od

oid

s

ed by t

over

c

s

i

at

h

W

d

an

s

al

i

r

ate

m

n

i

e

d

an

e

as

ch

ur

p

n

e

pm

ui

q

e

e

th

of

h

T

.

d

e

i

f

ci

e

p

s

as

ove

c

ot

n

s

i

at

h

W

anty is not e

• This war

• This war

• Re

and

o

c

oe

d

stresses. Th

o

n

n the

• I

all war

• S.R.Smith shall not b

ny

a

har

c

r

anty d

r

to BYOS Slid

r

e

f

ar, che

te

o

ion

s

rro

ov

c

not

s

ted to

i

m

i

t l

nt that pr

e

v

e

antie

r

her expen

t

o

s, or

ge

f

tr

a

e

s w

i

a

s ar

Ow

r

den

iv

R

war

s

i

wor

to

-Fab

r

an

r

by

nfor

ar

C

am

allic

e

ty a

n

f Go

ucts ar

e

r

e

uc

ur

n

R

R

er

an

r

kman

or

e

th

agr

ate

l

e

r

ty

s

i

h

t

ab

ce

nd

te

x

and

e

, d

age

s

t

par

nt that

do

so

l

i

d, m

.

d

sponsib

e

l

as

h

in conne

d

e

r

IMIT

L

1

lide

S

er

S

ide

lides

S

n

u

e

On

te

n

I

y?

t

for

p

i

h

s

e

r

al

n

gi

i

e

r

to

s

e

e

y

l

on

s

t

an

r

ar

w

y any party othe

b

le

yond

e

b

d

n

a

has

es n

se o

le

o

s

nance

ation, m

ny

a

e

b

t i

o

r a

d

e

r

or

f

ime,

t

f

c

Mainte

iscolor

,

su

alte

e

s

o

D WARRAN

E

OS

Y

B

(

lides

S

ies

A

9

1

(

ear

Y

)

1

(

war

.

c

n

I

,

Fab

-

r

od

i

r

pe

a

.

r

e

own

l

tai

p

e

r

or

r

pai

cts

fe

e

d

to

?

y

iod

r

pe

the

uctions for

instr

isuse

phy

er

h

t

o

d

ifie

mod

n

e

de da

u

cl

n

dent o

cci

se, a

bu

e

air

p

e

r

or

ost of

c

the

nven

o

c

in

tion with the

u

B

,

)

1

R

G

(

B

9

1

/

it

im

L

ts

an

r

mon

12

of

war

s

i

h

T

at

,

e

ac

l

mate

n

i

than the

r

12 months.

of

ing

, fad

mage

da

l

a

ic

s

has

or

e o

g

a

m

r n

y anyone

b

d

ov

m

e

r

e,

ienc

mov

e

r

Y

ild

G

/

7

S

A

3

2

/

W

ed

pr

l

al

s

th

ty

an

r

ol

s

ts

i

an

s

al

i

r

or

gular

e

r

of m

a

n

e

e

b

re resu

u

l

i

r fa

en

g

i

l

eg

without the

r

al or

iden

inc

r

al or

ou

R

/

ar

od

T

.

s

i

e

d

iginal r

ate

re

sub

ce, fi

p

e

t

e

Ow

r

1

S

A

4

2

an

r

ts

uc

s

i

h

con

cr

s

i

d

wor

mainte

ials, m

r

t

no

cte

e

j

re, i

lace

l expen

a

e

lac

p

T

n

G

/

0

4

2

/

y

t

man

t

i

an

r

war

e

g

n

ti

,

on

ti

e

an

km

tail owne

e

nanc

icr

ded

u

cl

in

to

d

fro

ng

ti

l

m

p

nt of any d

e

m

es

s

nt of

e

m

lide

S

S

R

B

uf

ty

t

n

an

h

s

ab

ro

p

ior

r

,

ob

t

2

)

5

1

9

2

/

e

tur

ac

gi

e

b

upon

od

pr

y

.

p

i

.

r

and

e

iolog

h

t

in

e

usiv

ther ca

o

m

er i

p

itte

wr

ephon

el

such p

2

OS

Y

B

(

d

an

,

)

A

f

e

e

fr

e

b

to

s

d

e

th

om

r

f

s

n

us

r

ope

pr

e

th

s

l

fai

at

th

uct

aning. Nor

le

c

ical staining and

T

y.

t

n

warra

is

en

r

e

r

l

l

c

e c

od

a

tiv

u

ti

pr

a

uc

o

ses,

n

o

ov

p

e

s

ll

t.

o

al of

r

la

,

inc

r i

od

physical

sta

n

n ap

f

e

,

)

d

om

r

of

ate

an

e

pe

to

al we

m

r

warran

his

n

ro

vi

ing, b

lud

ce da

nte

I

uct, nor

mat

,

r

bo

e

d

ust or

men

m

r

r

e

f

e

r

c

for

a

Fab

-

eria

ar

c

tai

g

f

ar

ta

o

ts

m

t

ut

e.

l

e

y

l

,

r

l

IMPOR

(G

Int

sy

G

discl

fo

Op

How to make a warranty claim

Visit www.interfab.com and click on the

form and inc

T

ional Sup

t

e

ide

nsu

S

ity

e

p

re

re

rie

em.

arden Ride Slide O

ab rec

F

er-

m

e

st

n

arde

aims any

r resolution of any iss

onal Support Syst

ti

ommends t

p

l

he

o

t

l

S

Ride

iabil

l

lude all required doc

anyone inst

hat

r

prope

ide

sl

s

ting

l

su

ari

ues

Syst

ort

p

al

inst

instal

s

rom su

f

ng as a result of installations not utilizing the Garden Ride Slide

si

:

umentation.

RIDE

N

ARDE

G

OR

F

E

OT

N

T

AN

3050 S. ALVERNON WAY • TUCSON, AZ 85713

520.790.7040 • 800.737.5386 • FAX 520.790.7127 • INTER-FAB.COM

BYOS-IM Rev. 08/15 (SBK-BYOS INSTAL)

cau

ste

y

instal

st

arat

p

se

m

and anchor sy

w

not

Optional

l

l

pport

his anc

se t

arrant

ook sol

h is sold sep

hor and su

to the

y

l

e

S

damag

pport

u

S

e

rs a su

e

off

Inc.

ab,

r-F

e

Int

:

S

IDE

L

S

arden Ride Slide Series whic

he G

or t

em) f

alling a G

ion

at

l

w

d

e

l

ch instal

“File a Warranty Claim” link. You must fill out all required fields in the

arden Ride Slide Series slide u

doe

ab

r-F

e

Int

.

ide

sl

he

t

of

Ride

n

arde

G

the

t

ithou

ow

pool

he

ations.

l

T

18

S

ne

l

s

ide

r shal

e

ely

ort

p

d

and

m

.

o

t

r

e

l

Loading...

Loading...