Page 1

USER MANUAL // TAZER

Page 2

table of contents //

Introduction / Registration 2

Unboxing 4

Get Charged / Build 5

Connect the System . 7

Suspension Setup 8

Frame Features / Component Spec 10

Geometry 11

Exploded View an d B.O.M. 12

Torque Chart 15

Unique Identi ers 16

About the Batter y 17

Installing / Removing B attery 20

Turning the Power On / Off 22

Cycle Computer Di splay and Setting 23

Assist and Shif t Switches 24

Maintenance 26

Troubleshooting 28

E-bike Declaration of Conformity 30

At Intense, we have one goal -

to provide the ride of your life //

Our team of designer s, engineers and pro duct experts ar e focused on

one thing every day: your ex perience on the bike. We build bikes that

are as thrilling to lo ok at as they are to ride, and we bui ld them for the

select few of you who unde rstand the difference and ref use to settle for

anything else. From the e arly days of Intense, when founder Jeff S teber

worked alone in his gara ge to today, where a crew of talented people wo rk

in a Temecula, CA factory, Intense has b een a brand built on passion by

forward thinker s who, even today, love nothing more than to throw a leg

over a sweet bike and head out for a ri p. We’re so glad you’ve joined us.

Welcome to Intense, enjoy yo ur experience.

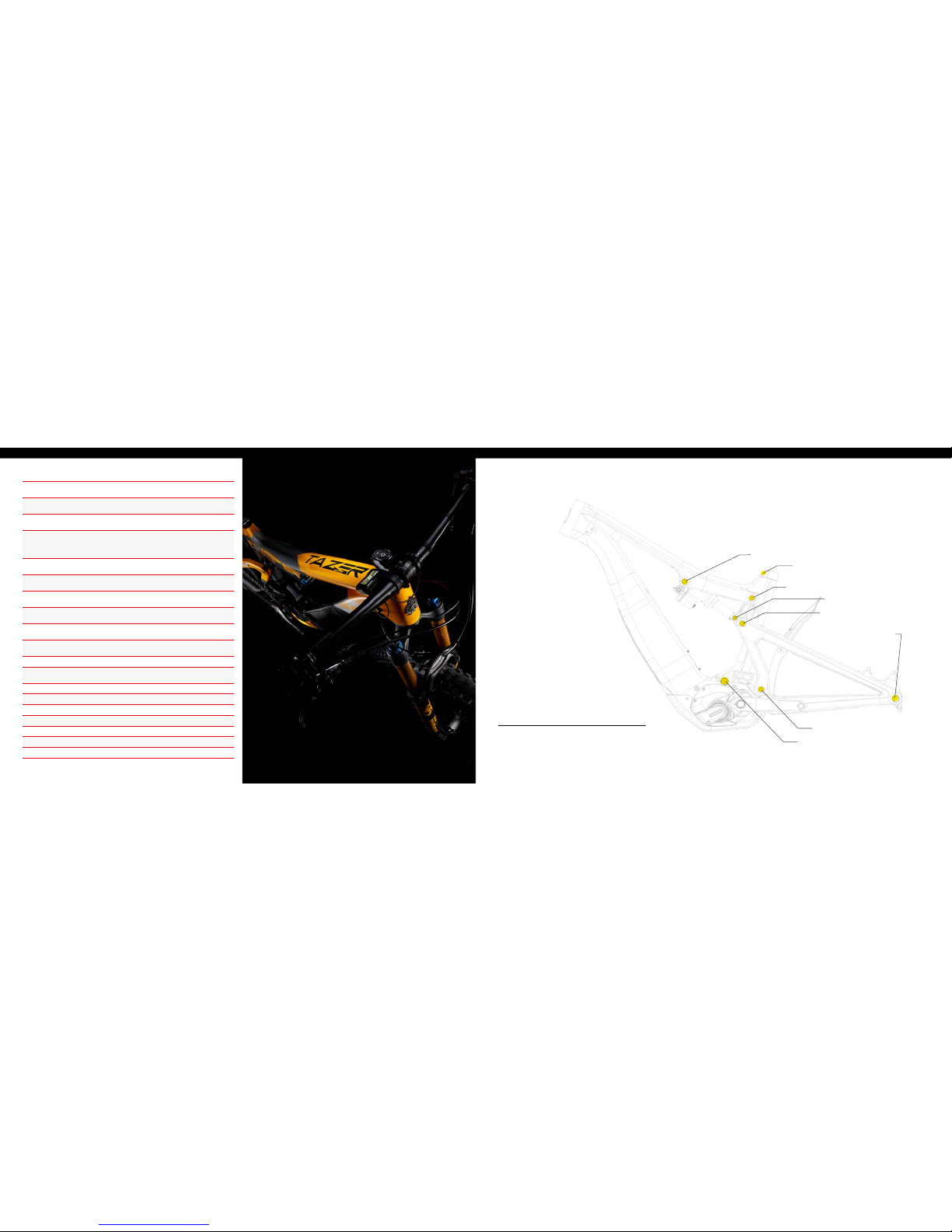

the tazer //

More than an eBike, thin k of the Taze r as an Intense bike that happens

to have an E-assist featur e. Built with aggress ive trail geometr y, Jeff

Steber tuned kinema tics and 29”/27.5” front and rea r wheel sizes, this

bike delivers a unique ri de for an eMTB that won’t feel cumber some and

has a seamless pedal -to-power transition.

#NOSHUTTLEREQUIRED

register your bike //

www.intensecycles.com/warranty-card/

technica l assistance

techcenter@intensecycles.com

951 -30 7-92 11

Welcome to

th e fam i ly

2 // tazer user manual INTENSE CYCLES // 3

Page 3

4 // tazer user manual INTENSE CYCLES // 5

setup

Preface //

Before you can get out th ere and rip up the trail s,

we need to get your bike unpacked and b uilt up.

This is a good chanc e for you to become fami liar

with your bike and to ensure th e performance and

ride character istics of the Tazer is optimised for you .

Tools needed

• sho ck pump

• small r uler or measuring device

• torque wrench

• I ntense Carbon Paste

Unboxing your tazer //

Careful attentio n has been given to the packaging of your Intense Tazer

to not only ensure that it ar rives safely and und amaged, but also that

you are able to re-us e the packaging for situations in whi ch you need to

safely transpor t your bike.

1. Rest the box on the ground or stable surface

with the top side facing up.

2. Pull the aps and open the top l id.

3. Remove the INTEN SE accessory box, which contains

your user manual, torque wrench, and shock pump.

4. Everything in the box is numbere d. Remov e the in serts

in chrono logical order taking care n ot to rip or tear th e

cardbard s o that th ey can b e reused in the future .

5. After removing the h andleba r and contro l protector (#7), raise the

dropper post by activating the trigger located on the handlebar.

6. Mount the frame onto a bike stand using the seatpost as your

clamp ing surface. WARNING: Do not clamp onto any of the carbon

surfaces of the frame as this could severely damage the frame.

7. Co ntinue by remov ing the remainin g protectors from the bike.

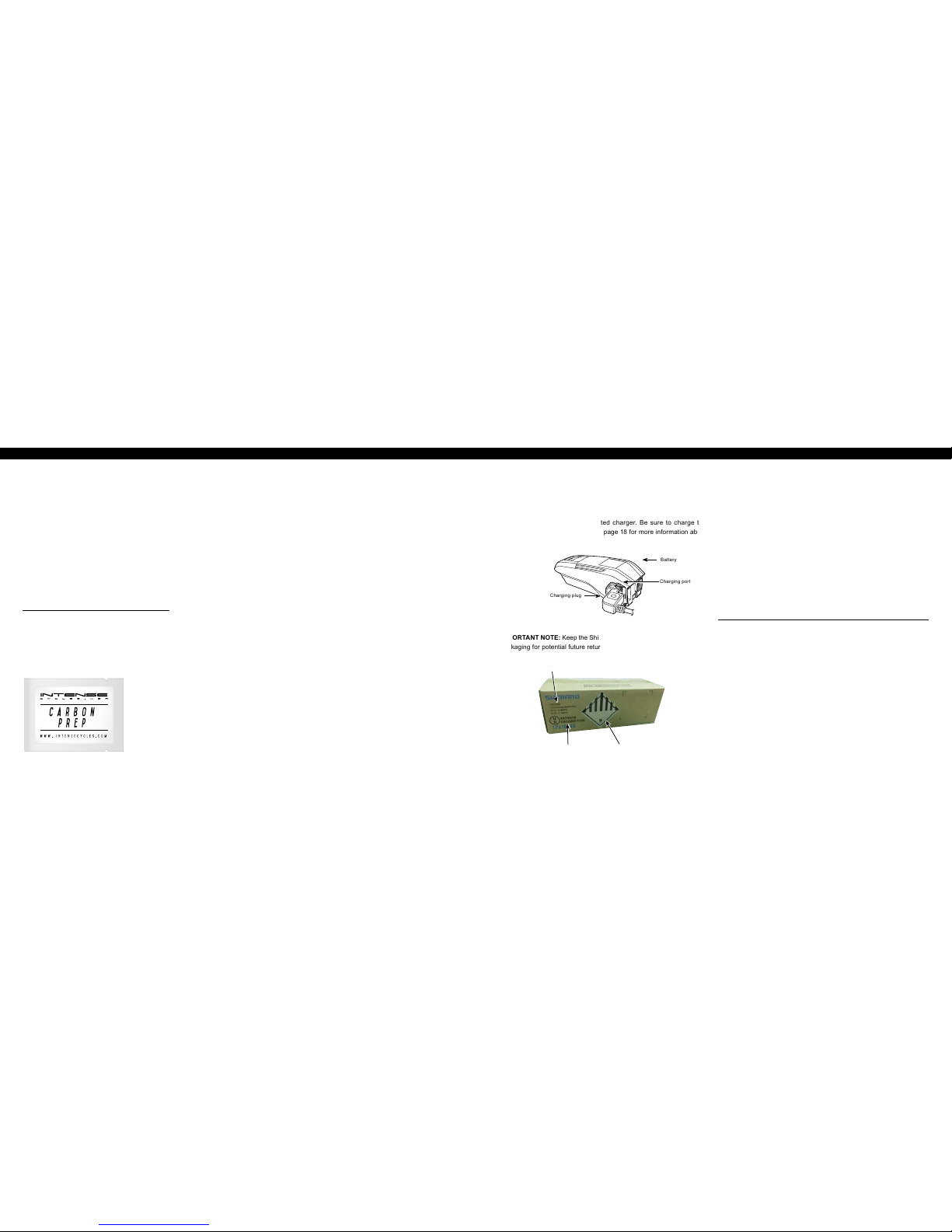

Get charged //

The battery is no t fully charged at the time of pur chase, so before you start

building your Tazer, take a moment to unpack and c harge the supplied

Shimano batter y using its dedicated c harger. Be sure to charge the

battery until it i s fully charged. See page 18 for more informat ion about

charging the battery.

Charging plug

Battery

Charging port

IMPORTANT NOTE: Keep the Shimano battery box and original internal

packaging for potential future returns to Shimano.

packaging identifiers

1. Frame spacer

2. Wheel stabil izer (fro nt wheel)

3. Wheel stabil izer (rear wheel)

4. Rear wheel cover

5. Front wheel cover

6. Cassette cover

7. Handlebar and

contro l protector

8. Fork cover

9. Downtube / toptube protector

building your tazer //

Once all the protec tors have been removed from the bike, we can beg in

the process of mou nting the components onto the frame.

Handlebar Installation

1. Spin the stem around so that the faceplate is facing forward.

2. Using a 4 mm allen key, remove the faceplate from the stem.

3. Making sure that all the cables are oriented properly, place

the handlebar into the stem and reinstall the facep late.

With the handlebar centered, torque the faceplate bolts to

6 Nm / 54 in-lbs. NOTE: Take your time when installing the

faceplate bolts to prevent any type of cross threading.

p r o t i p

When installing th e faceplate, always tight en the stem bolts in a cro ss

pattern (top left – bo ttom right, bottom left – Top right).

Mounting the Derailleur

1. Using a knife or scissors, carefully remove the bubble wrap

and z ipties fro m the rear d erailleur, ch ain, and B-s crew.

2. With a 5mm allen key, mount the rear derailleur onto the

derailleur han ger being care ful to avoid cross threading .

3. Using a torque wrench, tighten the derailleur

bolt to 8-10 Nm / 70-90 in-lbs.

UN number

Hazardous goods labelPackaging code

Page 4

6 // tazer user manual INTENSE CYCLES // 7

Installing the rear wheel

1. Remove the brake pad sp acers from the rear brake. Be sure

to keep this in a safe spot so it c an be reused in the future.

2. Remove the rear axle.

3. Grab the rear wheel and c arefully remove the disc

guard. Check the disc gu ard to make sure the end

cap is not accident ally removed with the guard.

4. Pull the derailleur back an d slide the rear wheel

into the rear triangl e of the bike, setting the chain

on the smallest gear of t he cassette.

5. From the non-drive sid e, slide the axle through the dropo ut and

wheel assembly, threading i t by hand in a clockwise directio n.

6. Using a 5mm allen key from the dr ive side, tighten the axle in

a counter clock wise direction. Torque to 11 Nm / 100 in-lbs.

7. From t he non-drive side, tighten the c one spacer with

a 5mm allen key. Torque to 14 Nm / 125 in-lbs.

Installing the front wheel

1. Grab the front w heel and carefully remove the disc guard.

2. Remove the front axle as well as t he pad spacer from the front

brake. Be sure to keep the pad spac er in a safe spot for future use.

3. With the rotor side of the wh eel on the non-drive side

of the bike, line the brake cali per up with the disc rotor

carefuly sliding th e front wheel between the fork le gs.

4. Slide the axle through t he fork dropout and wheel assemb ly

and tighten by turning in a c lockwise direction. NOT E: To

prevent accidental opening of the quick release lever while

riding, always lock t he lever in an upward direction (paralle l

to the fork leg) or horizo ntally towards the rear of the bike.

Quick Component Check

All INTENSE bicyc les are delivered " Ride Ready", meaning you c an

expect the bikes to com e with the brakes and dr ivetrain all proper ly

adjusted. However, to ensure that nothing happened during shipping,

we recommend that you c heck that all the c omponents are oper ating

correctly bef ore heading out to the trail.

1. One wheel at a time, sp in the wheels to make sure there

is no rotor rub from th e brake pads. Give the brakes a

squeeze to make sure every thing feels alright.

2. Check that the derailleu r is adjusted properly by

running up and down th e gears making sure that

everything is functioning nice and smoothly.

setting preload on the h eadset

and tightening the stem

1. Remove the bike from the st and and place it onto the ground.

2. Check that front wheel is i nline with the stem.

PRO TIP: You can line up the back of the ha ndlebar with

the front of the fork c rown to help with alignment.

3. Set the preload on the heads et by tightening

the bolt in the center c ap.

4. Tighten stem bolts with 5m m allen key

and torque to 8 Nm / 70 in-l bs.

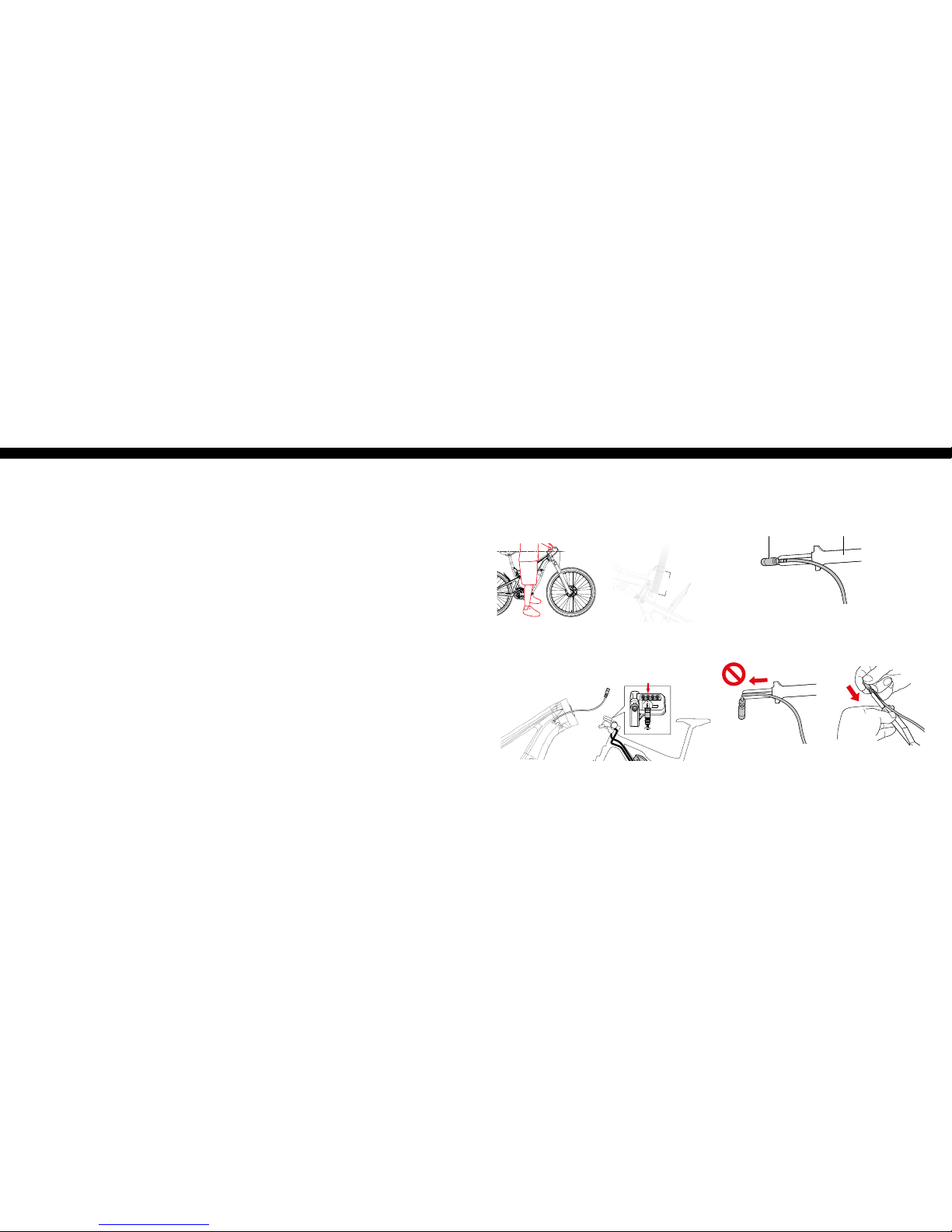

connecting the system //

Now that your bike is built, we n eed to plug the electric wire that c an be

found coming out of th e down tube (drive side) into the back of the cycling

computer as shown be low.

seat po st

When insertin g the seat post, apply a li beral coat carb on paste and

gently slide it into the se at tube. With a minimum se at post insertio n of

4" (100mm), tighten seat post clamp to 5 Nm / 4 5 in-lbs. NOTE: Over

tightening the seat po st clamp will inhibit the movement of the sea t post

and potentially damag e seat post and/or seat tube.

connecting the electric wire

Use the Shimano original tool (TL-EW02) for installation and removal of

the electric wi re. Set so that the projec tion on the conne ctor is aligned

with the groove on the nar row end of the tool.

When installing th e electric wire, do n ot forcibly bend the c onnector. It

may result in a poor cont act. When connecting the elec tric wire, push it

in until it clicks in plac e.

Connector

Shimano Installation Tool

(TL- EW02 )

min. seat height

4”

(100m m)

Page 5

8 // tazer user manual INTENSE CYCLES // 9

Travel

155 mm (6.1")

Shock Stroke

55 mm (2.15")

Shock Sag

30% when sitt ing on the bike

Fork Sag

20% when sitti ng on the bike

Shock

Fox Float DPX2 Sho ck 185 x 55 mm

RIDER WEIG HT

(LBS/KG S)

Air Pressure

(PSI)

REBOUND

(clicks out fr om fully close d)

Closed is Clockwise

Open is Counter Clockwise

Low Speed

Compression

100 lbs/ 45 kgs

130 11

10 Clicks Out

110 lbs/ 50 kgs

145 10

120 lbs/ 54 kgs

160 9

130 lbs/ 59 kgs

175 9

140 lbs/ 63 .5 kgs

190 8

150/ 68 kgs

205 8

8 Clicks Out

160/ 73 kgs

220 7

170/ 77 kgs

235 7

180/ 82 kgs

250 6

190/ 86 kgs

265 6

200/ 91 kgs

280 5

6 Clicks Out

210/ 95 kgs

295 5

220/ 100 kgs

310 4

230/ 104 kgs

325 3

240/ 109 kgs

340 2

250/ 113 kgs

350 2

shock setup //

Proper set u p and tuning can vary fro m sh ock to shock. Please c onsult

the Fox manual included w ith your bike for complete i nformation abou t

set up, tuning and general maintenance or visit www.foxracingshox.com

setting the sag //

1. Remove fork and shoc k air caps and be sure you have a

shock pump and a small r uler or measuring device handy.

2. Go ahead and hop on the bike. Be sur e to place

all your weight on the seat w ith the dropper in the

up position and both h ands on the grips.

3. Give the bike 5-6 mo derate bounces and

sit back down on the sad dle.

4. Now have your friend slide bot h the rear shock and the front fork

o-rings dow n against the seal lip of the damper bodys (I mage #1).

5. Step off the bike nice and easy. Be sure to n ot compress

the suspension af ter the o-rings have been set.

P r o T i p

Here is where having a fr iend helps. Have them st raddle the front

wheel and pull the hand le bars in a upward direction as to not allow th e

suspension to comp ress as you get off (Image #4).

6. Using your measuring devic e, measure the gap between

the suspension seal l ip and the o-ring. Using the ch art

on the following pag e will tell you if you need more air

pressure or less air p ressure (Images #2, #3).

7. Adju st air pressure with your shock pump ac cordingly (Image #5).

8. Re-visit steps 2-6 unt il your desired sag

measurement have been reached.

9. Install valve caps.

20%

(30mm)

While suspension

is compressed on

fork or rear sho ck,

slide o-ri ng down

against the sea l lip

of damper body.

Release compression.

Measure gap fro m

o-ring to se al lip.

4

21

3 5

cm 1 2 3 4 5 6 7 8 9 10

30%

(16.5m m)

FOX FLOAT dpx2

185 x 55mm

NOTE:

• FLOAT DPX2 shocks have a maximum

pressure of 35 0psi (24.1 bar).

• Max rider weight for the DPX 2 shock on

the Tazer is 250 lbs / 113 kg based on

30% sag require ment and DPX2 shoc k

max air pressu re of 350 psi.

• Max rider weight for TAZER f rame

is 300 lbs / 136 kg.

• Please contact the Inten se Cycles Tech

Center for shoc k tment options.

Page 6

10 // tazer user manual INTENSE CYCLES // 1 1

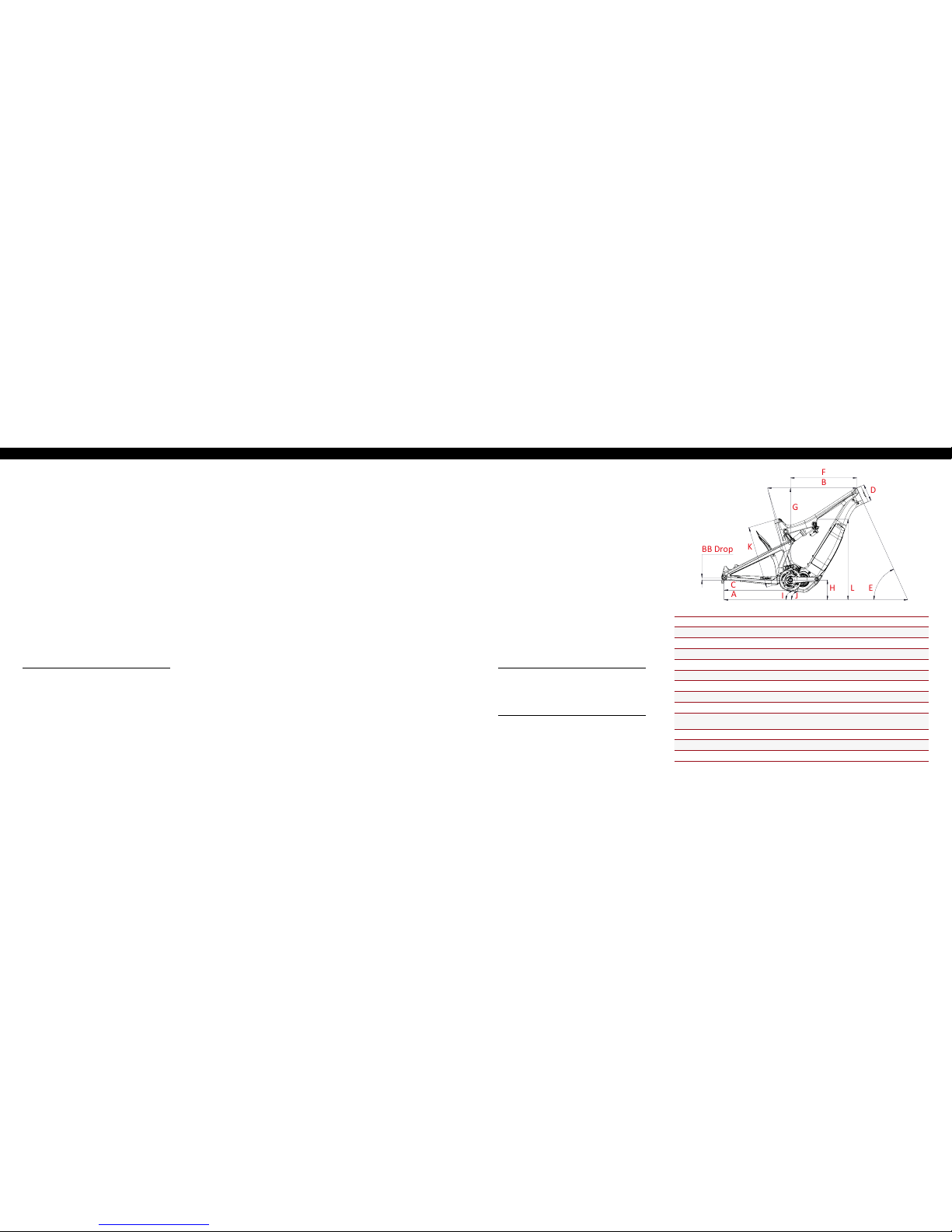

Geometry //

A

B

BB Drop

C

F

E

D

G

H

L

K

I

J

GEOMETRY NOTE

Geometry taken at top out with 567mm axle to

crown length and 51mm fork of fset.

Component spe c NOTE

The Tazer is designed around th e use of a single

chain ring only. Use of a doubl e or triple ring set will

not allow proper cle arance with the frame.

Frame Features //

• Rear Travel: 155mm / 6.1

inches with metri c 185 x 55

stroke shock

• 29” Front Wh eel size, 27. 5” x

2.80” Plus Rear Wh eel size

• Progressive Shock Curve

• Integrated 148 x 12mm

dropouts

• Internal Cable Routing

• Flack Guard: Downtube,

Chainstay, Seatstay and

Seattube protection

• Molded: Rear Fender

• Tapered Head Tube

• Replaceable Grease Zerk on

back of Lower Link

• Max Bea rings and Dedicated

Frame Hardware

• Molded Skid plate

• Removable Battery

Component Spec //

• Fork: Acc epts 1.125” straig ht

steer or 1.125”/1.5” tapered

steer, 160mm travel/ 6.3

inches, 567mm A xle to Crown,

51mm O ffse t

• Shock : 185mm x 55mm Metric

Shock, Trunnion with 20 mm x

8mm Reducers on sho ck

• Seat po st: 31.6mm

• Headset: Z ero Stack 49mm

Upper/ 56mm Lower

• Rear A xle: BOOST 148 x 12mm

• Brake Mount : Post Mount for

200mm rotor

• Shimano E8 000 Motor

• Shimano E8 010 Battery

SMALL MEDIUM LARGE

A

Wheel Base: 1199.4 mm/ 47.2” 123 0 mm/ 48.4” 1260 mm/ 49.6”

B

Top Tub e Len gth: 577 mm/ 22.7” 605 mm/ 23 .8” 633.4 mm/ 25”

C

Chain Stay Length: 450 mm/ 17.7” 450 mm/ 17.7” 4 50 mm/ 17.7”

D

Head Tube Length: 10 0 mm/ 3.94” 115 mm/ 4. 5” 125 mm/ 4.9”

E

Head Tube Angle: 64.9˚ 64.9˚ 64.9˚

F

Reach: 425 mm/ 16.7 ” 450 mm/ 17.7” 475 mm/ 18.7”

G

Stack: 610 m m/ 24” 623 mm / 24.54” 632 mm/ 24. 9”

H

BB Height: 347 mm/ 13.65” 347 mm/ 13.65 ” 347 mm/ 13.65”

BB Drop 12 mm/ 0.47” 12 mm/ 0.47” 12 mm/ 0.47”

I

Seat Tube Angle

(Effective):

75.4˚ 75.4˚ 75.4˚

J

Seat Tube Angle (Actual): 72.9˚ 72.9˚ 72.9˚

K

Seat Tube Length: 394 m m/ 15.5” 419 mm/ 16.5” 445 mm/ 17.5”

L

Standover Height: 806 mm/ 31.7” 814.1 mm/ 32” 8 22 mm/ 32.4”

getting to

know your

tazer

W A R N I N G

Use the supplied key to remove t he battery from the

frame to perform battery swap or for charging. Do

not move or alter the batte ry frame mounts from th eir

factory posit ion in the downtube as this could r esult

in subpar perfor mance, may lead to battery and or

frame damage and is not c overed under warranty.

Please contact Intense Cycles Tech Center if you

have any questions relatin g to the battery mounts.

Page 7

12 // tazer user manual INTENSE CYCLES // 1 3

exploded view and b.o.m. //

52

15

45

24

28

54

47

15

26

36

20

41

44

3

12

14

10

44

3

3

8

6

2

56

55

22

23

43

5

46

37

11

39

1

4

17

7

9

38

13

23

23

44

3

19

9

38

44

38

9

43

46

17

4

28

28

25

45

16

16

42

34

40

49

48

29

57

50

42

42 21

27

21

22

18

18

32

33

30

31

Foam in Door Latch

53

9

38

51

35

(continued on next page)

ITEM

NO.

ITEM

PART

NUMBER

DESCRIPTION Q TY. TORQUE SPEC.

1

Bearing Spacer 130754 Lower Link Bearing Spacer 1 N/A

2

Rear Axle 130757

Axle Rear

148 x 12mm Boost

1

11 Nm /

100 in-lb s

3

Bearing Cap 130765

Upper Link Bear ing Cap,

24mm

4 N/A

4

Bearing Cap 130778 Lower Link Bea ring Cap, 28mm 2 N/A

5

Pivot Bolt 130785 Lower Link Pi vot Bolt 1

20 Nm /

175 in-lbs

6

Hanger 13 0790 Derailleur Hanger, Forged 1 N/A

7

Pivot Bolt 130795

Lower Link Expa nder Bolt

(Lower Pivot)

1

7 Nm /

60 in-lbs

8

Hanger Bolt 130798 Derailleur Hanger Bolt 1

11 Nm /

100 in-lb s

9

Cone Adjuster 13080 7

Cone Adjuster,

8.3 mm Height

4 N/A

10

Bearing Spacer 130847

Upper Link Bear ing Spacer

(Upper Pivot)

1 N/A

11

Lower Link 13 0848 Forged Lower Link Tazer, Blk 1 N/A

12

Forged Top Link 13084 9 Forged Top Link Tazer, Blk 1 N/A

13

Axle Lower 130850 Axle Lower Pi vot Tazer 1

20 Nm /

175 in-lbs

14

Bearing Spacer 1308 51

Upper Link Bear ing Spacer

(Lower Pivot)

1 N/A

15

Bearing Spacer 130852

Shock Mount Be aring

Spacer (Trunio n Pivot)

2 N/A

16

Shock Bolt 130853 Trunion Pivot Shock Bolt 2

16 Nm /

140 in-l bs

17

Bearing Spacer 130860

Lower Link Bear ing Spacer

(Upper Pivot)

2 N/A

18

Drive Unit Bolt 13 0862

Drive Unit Bolt M 8 x 18 with

T40 Br oach

4

10 Nm /

88 in-lbs

19

Pivot Bolt 130863

Upper Link Exp ander Bolt

(Upper Pivot)

1

7 Nm /

60 in-lbs

ITEM

NO.

ITEM

PART

NUMBER

DESCRIPTION Q TY. TORQUE SPEC.

20

Pivot Bolt 130864

Upper Link Exp ander Bolt

(Lower Pivot)

1

7 Nm /

60 in-lbs

21

Skidplate

Spacer

130867 Skidplate Spac er 2 N/A

22

FHCS M8 x 30 130868

Drive Unit/ Skid Plate Bolt

M8 x 1.25 x 30 mm

2

10 Nm /

88 in-lbs

23

Plug 140 038 Lower Link Pivot Plug 3 N/A

24

Cable Guide

Plug

140039 Cable Guide Plug, So lid 1 N/A

25

Cable Guide

Plug

140040 Guide Cable P lug, 5mm ID 1 N/A

26

Battery Door 140050 Battery Door 1 N/A

27

Skid Plate 1400 51 Skid Plate 1 N/A

28

Cable Guide

Plug

140052 Guide Cab le Plug, 4mm ID 3

29

Rear Fender 140054 Rear Fender 1 N/A

30

Battery Pul l

Strap

140055 Battery Pull St rap 1 N /A

31

Foam Pad 140056 Battery Do or Foam Pad 1 N/A

32

Gasket 140057 Bat tery Door Gasket 1 N/A

33

Foam Pad 140058

Battery Co mpartment

Foam Pad

1 N/A

34

Battery Cha rge

Window

140059 Battery Charge Window 1 N/A

35

Grommet 1400 60

Speed Sensor Wire

Grommet

1 N/A

36

Seat Clamp 340342 Bolt-on Seat Clamp 1 N/A

37

Zerk Fitting 401011 M6 x 1.0 1

5 Nm /

40 in-lbs

38

SHCS M6 x 2 2 410009

Cone Adjuster B olt, Socket

Head, M6 x 22

4

14 Nm /

125 in-lbs

Page 8

14 // tazer user manual INTENSE CYCLES // 1 5

ITEM

NO.

ITEM

PART

NUMBER

DESCRIPTION Q TY. TORQUE SPEC.

39

BHCS M5 X 12 410010

Skid Plate Bolt , Button

Head, M5 X 12

2

6 Nm /

54 in-lbs

40

SHCS M8 x 35 4100 45 Sh ock Bolt, M8 x 35 Steel 1

16 Nm /

140 in-l bs

41

SHCS M6 x 18 410 048

Seat Clamp Bolt , Socket

Head, M6 x 18

1

5 Nm /

45 in-lbs

42

M5 x 11 4100 68

Fender / Skidpla te Bolt, Low

prole Socket Head, M5 x 11

5

1 Nm/9 in -lbs

(Fender)

2 Nm/18 in-lbs

(Skidplate)

43

Bearing 7902 430007

15 x 28 x 7 2RS

MAX Angular Contact Bearing

2 N/A

44

Bearing 6802 430008

15 x 24 x 5 2RS

MAX Radial Bearing

4 N/A

45

Bearing 6800 430011

10 x 19 x 5 2RS

MAX Radial Bearing

2 N/A

46

Bearing 3802 430014

15 x 24 x 7,

Double Row Radia l Bearing

2 N/A

47

Flack Guard

Downtube

500301

Flack Guard Tazer

Downtube

1 N/A

48

Flack Guard CS 5003 02

Flack Guard Tazer

Chainstay

1 N/A

49

Flack Guard 500303 Fla ck Guard Tazer Seatstay 1 N /A

50

Flack Guard 500304

Flack Guard Tazer

Seat Tube Protector

1 N/A

51

Flack Guard 500305 Flack Guar d Tazer RT Strut 1 N/A

52

Head Badge 500335 H ead Badge Flame Logo 1 N/A

53

Rear Shock 185 x 55, Trunnion 1 N/A

54

Battery Shimano E8010 1 N/A

55

Front Triangle Carbon, 3 Sizes 1 N/A

56

Motor Shimano E8000 1 N/A

57

Rear Triangle Ca rbon, 1 Size 1 N/A

16 Nm / 140 in-lbs

5 Nm / 45 in-lbs

16 Nm / 140 in-lbs

M8 HEX 7 Nm / 60 in -lbs

M5 HEX 14 Nm / 125 in-l bs

20 Nm / 175 in-lbs

M8 HEX 7 Nm / 60 in -lbs

M5 HEX 14 Nm / 125 in-l bs

M8 HEX 7 Nm / 60 in -lbs

M5 HEX 14 Nm / 125 in-l bs

Derailleur Ca p: 11 Nm / 100 in-lbs

Axle (non- drive side): 11 Nm / 100 in-lbs

Adjuster cone (no n-drive side): M5 H EX

14 Nm / 125 in-lbs

torque specifications //

Achieving proper torque is vital to ensuring the safe performance and function

of the tazer frame. Failu re to do so could result in sub- optimal performance

of your frame as well as prem ature wea r and tear of individual parts.

additional reference

In addition to this ch art, torque values are laser etched

onto corresponding hardware for your reference.

Page 9

about the battery //

16 // tazer user manual INTENSE CYCLES // 1 7

DANGER

Use the Shimano specied c harger and observe the specied charging

conditio ns when charging the sp ecied batter y. Not doing so may cause

overheating, bursti ng, or ignition of the battery.

CAUTION

• W hen removing the battery cha rger power plug from the outlet or the

charging plug fro m the battery, do not pull it out by the cord.

• Whe n charging the battery wh ile it is mounted on the bicycle, be c areful

not to trip over the charg er cord or get anything caugh t on it. This may

lead to injury or c ause the bicycle to fall over, damaging the co mponents.

RIDING THE BICYCLE

1. Turn on the power.

a. You cannot use the battery immed iately after shipment.

Refer to ”CHARGIN G THE BATTERY”

b. Do not place your feet on the pe dals when turning

the power on. A system erro r may result.

c. Power cannot be turne d on while charging.

2. Sel ect your preferred assist mode.

3. As sistance will start when th e pedals start turning.

4. Chan ge the assist mode in accordanc e with the riding conditions .

5. Turn the power of f when parking the bicycle.

a. Do not place your feet on the peda ls when turning

the power off. A system er ror may result.

Intense bicycle identification //

It’s important to kee p track of your Tazer’s serial number as well as the

serial numbers of its important components for warranty and replacement

purposes. Inclu ded in your ACCESSORY KIT is a serial nu mber sheet so

this information c an easily be tracked and stored in a safe plac e.

REgistering / replacing

your abus battery key

Worried about losi ng your key or need to order a spare? No wor ries.

However, to successfully or der a replacement, you’re going to need a f ew

bits of information s o, before its too late, do yourself a favor an d document

and register the unique identiers of your key.

key type : wafer

key code:

key profil e:

To order your new key, head over

to https://mobilesecurity.abus.com

and click "Order Key " or visit your

local ABUS deal er for help.

key code

key

prole

Handling and char ging the battery

• Cha rging can be carried ou t at any time regardless of the amount o f

charge remaining, b ut you should charge the batter y until it is fully charged

• B e sure to use the dedicated charger wh en recharging the battery.

• T he battery is not fully charge d at the time of purchase. Before

riding, be sure to char ge the battery until it is fully charge d.

• If t he battery has become f ully spent, charge it as soon as po ssible. If you

leave the battery w ithout charging, it will cau se the battery to deterior ate.

• I f the bicycle will not be ridden over an ex tended period of time,

store it away with approxim ately 70% battery capacity remaining. In

addition, take care n ot to let the battery become co mpletely empty

by charging it every 6 mo nths.

• T he use of a genuine Shimano batter y is recommended. Connect

to E-TUBE PROJECT and click [C onnection check] to conr m

whether the batter y in use is a genuine Shimano batter y. If using a

battery from a nother manufacturer, make sure to carefully re ad the

instruction manual for the battery before use.

Page 10

18 // tazer user manual INTENSE CYCLES // 1 9

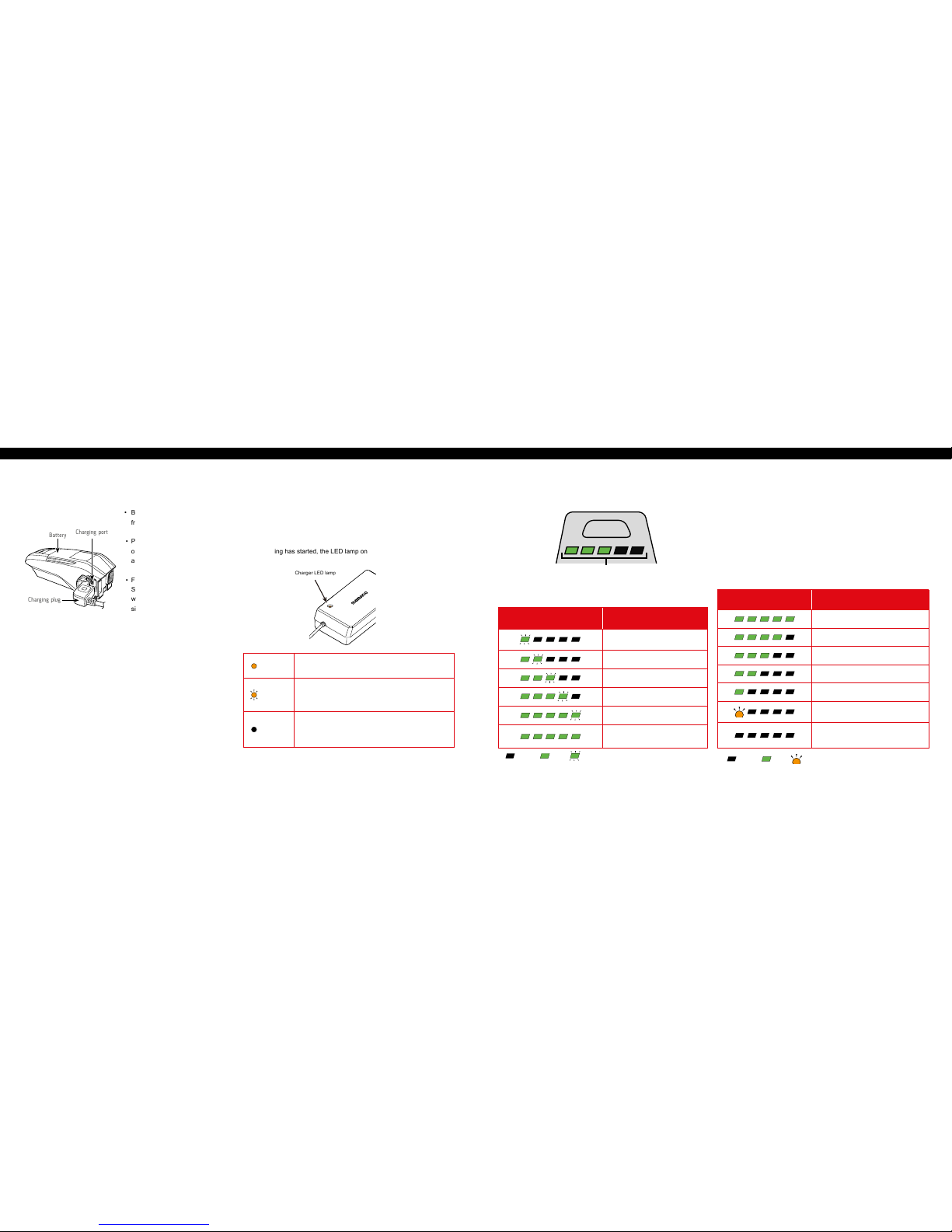

Battery Level Indication

The current batte ry level can be checked by pressing the ba ttery's

power button. NOTE: W hen remaining battery capacit y is low, system

functions begin t o shut off in the following order.

1. Power assistanc e (Assist mode automatically switc hes to

[ECO] and then assista nce shuts off. The switch to [ECO]

occurs earlie r if a battery-powered light i s connected.)

2. Gear shift ing

3. Light

Battery level indication*1 Battery level

0% - 20%

21% - 40%

41% - 60%

61% - 80%

81% - 99%

100%

*1 : No light : Lit up : Blinking

About the Battery LED Lamp

You can check the current c harging status on the LED lamp on th e battery.

Battery LED l amps

Lit up

Charging (Within 1 hour after the completion of charging)

Blinking

Charging error

Turn ed of f

Battery disconnected

(1 hour or more after th e completion of chargi ng)

About the Charger L ED Lamp

After charging has started, the LED lamp on the charger lights up.

Charger LED lamp

Battery Charging

• Bat tery can be charged in the Tazer

frame or outside of Tazer fram e.

• Pull back tab of rubberize d cover

on the back of the batte ry to

access plug inter face.

• For best charging results plu g

Shimano charger directly into a

wall outlet, then plug c harger into

side of battery.

• Both the Shimano Batter y and

Shimano Charger indicator lights

should light up, the yellow c harger

light shows it’s charging. While

the Green lights on t he battery will

blink as they are charging and be

completely solid when fully charged.

• W hen Battery is completely

charged, both it and t he charger

will turn off.

Charging plug

Battery

Charging port

<BT-E8010>

charging time for the

504 Wh Model battery

• 8 0% in 2.5 hours

• 10 0% in 5 hours

Battery level indication*1 Battery level

100% - 81%

80% - 61%

60% - 41%

40% - 21%

20% - 1%

0%

(When batter y is not installed on bic ycle)

0%, Power off / Shutd own

(When batter y is installed on bicyc le)

*1 : No light : Lit up : Blinking

(Charging-in-Progress Indication)

Page 11

20 // tazer user manual INTENSE CYCLES // 2 1

removing the battery //

A Remove battery do or by using

two ngers to compress or pull

the snap lock tab bac k toward

the door. This will allow the d oor

to pivot open so it is now angl ed

off the downtube (Ima ges #1, #2).

B Lift the door up at the a ngle it’s

at, freeing the lower l ocating tab

from the frame (Imag e #3).

C With your right han d, insert

battery key into lock .

D With your left hand, u nfold and

hold battery pu ll strap.

E Turn battery key a quarter t urn

with right hand (Imag e #4).

F Pull battery strap with left hand

until the batter y has moved past

the front lock (Imag e #5).

G Release the key. The key can

now be removed and place d in a

safe, easy to access lo cation.

H Continue pulling battery pull

strap with left han d while holding

onto the top of batter y with right

hand. The batter y will continue to

pivot off the lower mo unt and out

of the downtube (Image # 6).

I Lift the batter y out and away from

the downtube (Image #7).

installing the battery //

A Place p ull strap on batter y as

shown, then lift bat tery up with

two hands, left han d on the pull

strap and right hand at to p of

battery (Image #1).

B Angle the bottom of bat tery into the

lower mount of the downtub e and

push it into the lower mount . The

bottom of the batte ry should now be

hooked into the lower bat tery mount.

With it hooked it should n ow pivot

into the lower batter y mount as the

top of the battery i s pushed toward

the upper batter y mount (Image #2).

C Continue pushin g the top of the

battery so that it s lides into the

upper mount then clic ks and locks

into place.

D Conrm the battery has clicked

and is fully seated in the t op

battery mount by tu gging on the

battery pull str ap. If battery moves

away from the mount then pu sh it

back against mount unti l battery

is fully seated (Image # 3). The

battery pull st rap can now be

folded onto itself so i t doesn’t

obstruct the bat tery door.

E Re-instal l the battery do or

with t he lower tab tting into the

downtube opening rst (Image #4).

F Once the battery d oor fully slides

down into the door open ing, pivot

the door in a closing m otion

(Image #5) .

G As the door is nearing the closed

position at the top of th e door give

the door a good push to a llow the

door’s snap lock feat ure to engage

into the downtub e (Image #6).

6

2

2

5

7

1

3 4

4

5

3

1

6

Page 12

about the

controls

22 // tazer user manual INTENSE CYCLES // 2 3

Batt er y Le ve l In di cato r

You can check the batter y level on the cycle computer while ridi ng.

dis play Battery level

81% - 100%

61% - 80%

41% - 60%

21% - 40%

1% - 20%*

0%

*The batter y level indicator bl inks red when remain ing battery

capacity fa lls to this level.

Basic Screen Display

Displays the status of t he power assisted bicycle, traveling data.

(A) (B)

(C)(D)(E)

A. Bat tery level indicator

Displays the curre nt battery level.

B. G ear position

Displays the curre ntly set gear

position. (Only displ ays when

electronic gear s hifting is in use)

C. Assist gauge

Displays the assistance.

D. Assist mode display

Displays the curre nt assist mode.

(Assist mode automat ically switches

to [ECO] as remaining bat tery

capacity dec lines. The switch to

[ECO] occurs earl ier if a battery–

powered light is connected.)

E. Current speed

Displays the curre nt speed. The

display can be switche d between

km/h and mph.

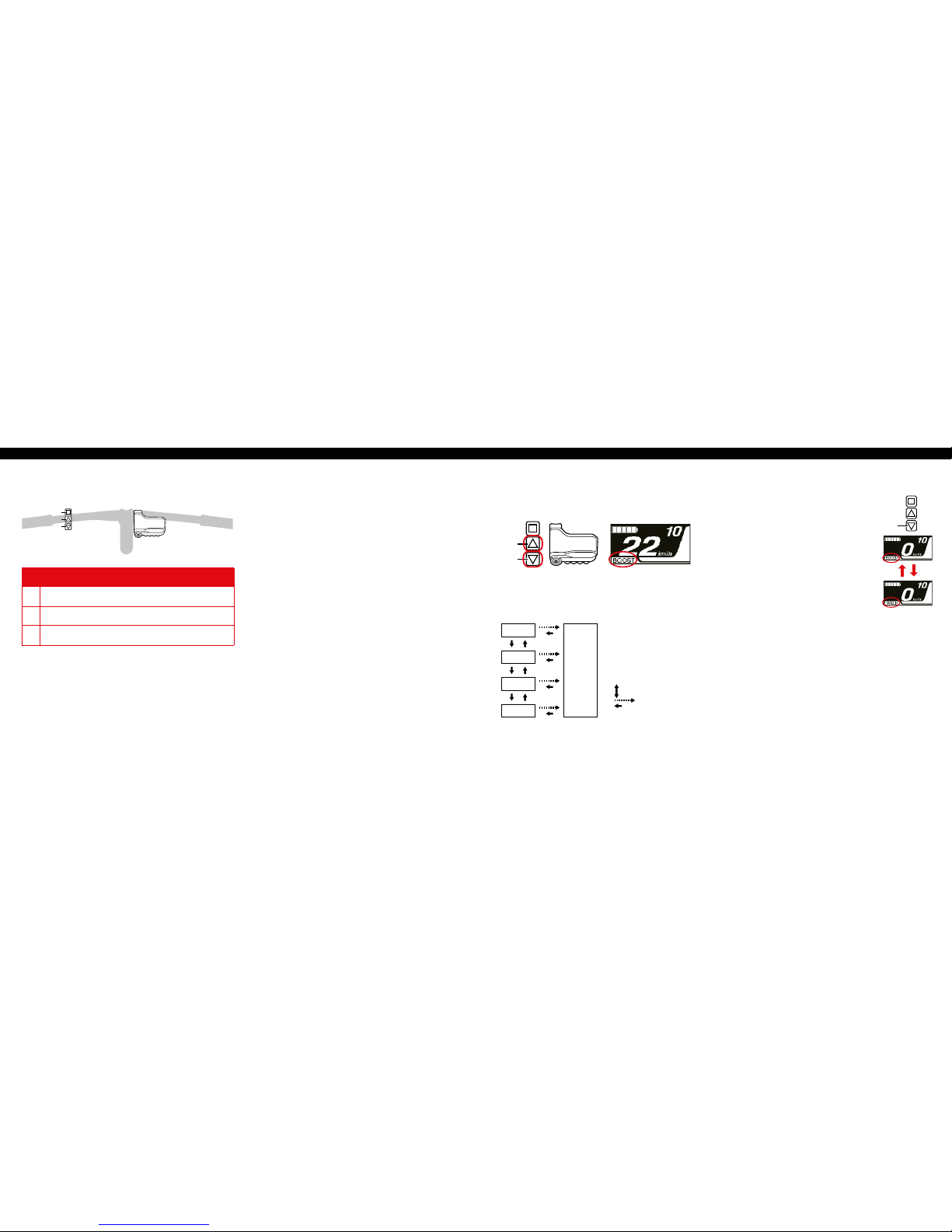

A. C ycle computer

B. Assist switch

C. S hift switch

(not spec'd for Tazer)

D. Drive unit

E. TL-EW0 2

CYCLE COMPUTER DISPLAY AND SETTING //

turning the power on/off //

cable connecting //

connecting switches and the

drive unit to the cycle computer

Turning the power ON and OF F

via the battery

• P ress the power button on the batter y. The LED lamps

will light up indicating remaining battery capacity.

NOTE:

• W hen turning on the power, check that the bat tery is

rmly attache d to the holder.

• Po wer cannot be turned on while charg ing.

• D o not place your foot on the pedals when t urning on.

A system error may result.

Automatic power off function

If the bicycle has not move d for over 10 minutes, the power

will automaticall y turn off. NOTE: the system can be forc ed

to powe r off by holdi ng down the power butt on for 6 seco nds.

(A)

(D)

(E)

(B) (C)

NOTE:

• B e sure to attach dummy plugs to any unused po rts.

• T he electric wire connecto r can be connected to any port of

the cycle computer, but we rec ommend you connect the assist

switch to the switch-side port.

Page 13

24 // tazer user manual INTENSE CYCLES // 2 5

NOTEs on walk assist mode

• I f Y is not pressed for one minute or more, th e mode active before

[WALK] mode wa s set, is re-activated.

• I f the bicycle is not moved after [WAL K] mode is activated, walk

assist is automatic ally inactivated. To re-activate [WALK ] mode,

momentarily rel ease Y and then hold down Y.

• T he walk assist function can oper ate at a maximum of 3.7 mph.

• T he assistance level and speed var y with the gear position.

• T he intelligent walk assist functio n activates when an electric shi fting

system such as XTR, D EORE XT SEIS is connected. Syste m

individually suppl ies assist power to detect gear positi on.

• " Intelligent walk assist" suppo rt rider more torque output in s teep

climb conditio n in lower side gears.

• "Q uick walk assist" function w orks by holding down SW from any mode.

BOOST

WALK

TRAIL

ECO

OFF

BOOST: Assist boost

TRAIL: Assist trail

ECO: Assist eco

OFF: Assist off

WALK: Walk assist

Changing assist mode

X1Y1

SW-E8000-L/SC-E8000

X1

Y1

SW-E6000/SC-E6010

SC-E8000

SC-E6010

Assist high

Assist normal

Assist eco

Assist off

Walk assist

: Short press Y1

BOOST

WALK

TRAIL

: Short press X

Changing assist mode

X1Y1

SW-E8000-L/SC-E8000

X1

Y1

SW-E6000/SC-E6010

SC-E8000

SC-E6010

Assist high

Assist normal

Assist eco

Assist off

Walk assist

: Short press Y1

: Short press X1

BOOST

WALK

TRAIL

ECO

: Short press Y

Changing assist mode

X1Y1

SW-E8000-L/SC-E8000

X1

Y1

SW-E6000/SC-E6010

SC-E8000

SC-E6010

Assist high

Assist normal

Assist eco

Assist off

Walk assist

: Short press Y1

: Short press X1

: Long press Y1

BOOST

WALK

TRAIL

ECO

: Long press Y

Changing assist mode

X1Y1

SW-E8000-L/SC-E8000

X1

Y1

SW-E6000/SC-E6010

SC-E8000

SC-E6010

Assist high

Assist normal

Assist eco

Assist off

Walk assist

: Short press Y1

: Short press X1

: Long press Y1

: Short press X1 (This operation is for canceling

BOOST

WALK

TRAIL

ECO

: Short press X

(This operation i s for canc eling [WALK] mode)

*The Walk assis t mode function may n ot

be able to be used in c ertain region s.

(SC-E8000)

X

Y

(SW-E6000-L / SC-E8000)

assist modes

To help maximize battery p erformanc e and efficie ncy, select an

appropriate as sist mode for your spec ic application.

Changing assist mode

Press X or Y to switch assi st modes.

switching to walk assist mode

1. With your feet off t he pedals and current speed

at [0 mph], hold down Y until [ WALK] displays.

NOTE: A warning tone wi ll sound while switching

is in progress if it is n ot possible to switch to

[WALK] mode b ecause the current speed is not

[0 mph] or there is pressu re on the pedals etc.

2. Release Y when (WALK) displays.

3. Hol d down Y again to activate walk assist. Walk

assist remains acti ve provided Y is being held down.

4. To cancel ( WALK) mode, release Y and press X .

When (WALK) mod e is canceled, the mode active

before (WALK) mo de was set, is re-activated.

YX

Y

B O O S T //

Use when powerf ul assistance is required, suc h as when riding up

steep uphill slopes. T his mode is designed for use on ste ep inclines

and precipitous mo untains. When riding on level publi c roads with

trafc lig hts, the assistance pr ovided may be excessive, in which

case, switch to [ECO] mod e.

t r a i l //

Use when an intermedi ate level of assistance is needed, such as

when you want to enjoy ridin g comfortab ly on a gentle slope or

level ground.

eco //

Use when you want to enjoy long d istance riding on level ground.

When pedaling is not ver y strong, the amou nt of assistance is

reduced and energy consumption is lessened.

walk //

This mode is part icularly useful when walking the bicyc le, taking

the bicycle out up an inc line or when it is bear ing a heavy load.

It is also useful when wal king the bicycle ac ross uneven terrain

such as rocky area s.

assist and shift switches //

X

Y

A

SW-E6000-L

X Switchi ng assist modes: the level of assi stance becomes stron ger

Y Switching assi st modes: the level of assistanc e becomes weaker

A Changing the cycle computer display

Page 14

26 // tazer user manual INTENSE CYCLES // 2 7

maintenance

maintenance SchedulE* //

Action Every Ride

500 Miles or

1 Month

2000 Miles or 6

Months

4000 Miles o r

1 Year

Tires

Check air pres sure, inspect tread an d sidewalls for tears a nd

punctures

X

Chain

Brush off and l ubricate X

Brakes

Squeeze brakes and conrm function X

General

Clean comple te bike of mud and debris X

Headset

Check adjustment X

Box Link

Add grease thru zerk ttings X

Frame Pivots

Check torques X

Spokes

Inspect for damage, check tension X

Shock and Fo rk

Check air pres sure, inspect for leak s X

Deraileur Cables

Inspect and lub e X

Seatpo st

Clean and regre ase interface wit h frame X

Frame Pivots

Remove pivot bolts, check bearings for pitting and wear X

Headset

Disassemble stem, headset and fork. Check bearings for

pitting and wear

X

Hubs

Pull wheels of f, check hub bearings f or pitting and wear X

Bottom Bracket

Remove crank arm s and check BB bearin gs for pitting and

wear

X

Brakes

Replace brake pads X

Chain

Inspect for damage and check for stretching X

General

Complete Tune-Up X

Shock and Fo rk

Overhaul See MFG Recommendations

general service and care //

You have purchased a high performance bicycle

which requires a ce rtain level of ser vice and

maintenance to sustain the level of performance

your frame was designe d around. Proper care will

also ensure the bike is safe t o ride at all levels. It

is important to re ad and understand t he carbon

care information as well as follow the maintenance

schedule and inspec t your bicycle before each ride.

These will not only hel p to limit or avoid costly

repairs but will als o help to avoid injury du e to

service neglect and component failure.

carbon care //

Intense Cycles empl oys advanced compo site techniques and ma terials

in our frames which d o require a cert ain level of care and mainten ance

to ensure a safe experie nce at the high level of performanc e each frame

is designed around. N ot following these guideline s will decrease the level

of performanc e and possibly cause injury or de ath.

• U se a soft cloth with warm soapy water to c lean the carbon surface s.

Do not use high pressur e washers, abrasive cloths or clea ners.

• B e sure all frame surfaces in co ntact with cables are protecte d.

Cable housing rubb ing on carbon can wear over time.

• B e sure brake levers, handle bar ends and the fo rk crown do not

contact the fram e at full rotation.

• N ever clamp any part of a carbon fram e in a bike stand or car rack.

• A lways inspect your frame if you experi ence any chain suck.

• A lways inspect your frame in full af ter a crash to be sure there is

no damage. Look for cra cks, dents or loose bers. If you disc over

damage in any degree it ’s best to have your frame inspected by a

qualied Intense Cyc les dealer. Any direct impact to the frame c an

cause serious structural damage.

• U se high grade waterproof grease on se at post, BB and head set

bearing contac t areas with the carbon.

• N ever ream or face a carbon frame.

• B e sure to follow all recommended tor que settings.

• Use only genuine replacement par ts for safety-critical components.

* The above mainten ance schedule is on ly a guideline. Refer to c omponent manufa ctuter for speci c instruction o n maintaining thei r parts.

Page 15

28 // tazer user manual INTENS E CYCLES // 2 9

Error indication t ype Indication condition

Lighting patter n *1

Recovery

System error

Communicati on error with

the bicycle system

Make sure that the ca ble is not loose or improp erly connected. If the

situation does n ot improve, contact the pla ce of purchase.

Temperature

protection

If the temperatur e exceeds

the guaranteed operating

range, the batte ry output

is turned off.

Leave the batter y in a cool place away from dir ect sunlight until the

internal temper ature of the battery dec reases sufcient ly. If the situation

does not improve, co ntact the place of purch ase.

Security

authentication

error

This is displayed if a

genuine drive uni t is not

connected.

This is displayed if

any of the cables are

disconnected.

Connect a genui ne battery and drive uni t.

Check the cond ition of the cables.

If the situation d oes not improve, contact t he place of purchase.

Charging error

This is displayed if a n error

occurs during charging.

Remove the charger f rom the battery and pr ess the power button. If an

error appears contact an agency.

Battery malfunction

Electrical failure inside

the battery

Connect the ch arger to the battery an d then remove the charger. Press

the power button w ith only the battery c onnected.

If an error appea rs with only the batt ery connected , contact the plac e of purchase.

*1 : No light : Lighting up : Blinking

Code Display preconditions

Operational r estriction when a n error is being disp layed

Remedy

W010

Temperature of the drive u nit

is higher than it is d uring times

of normal operation.

Power assistance may be lower than usual.

Stop using the ass ist function until the te mperature of the

drive unit drops. I f the situation does not imp rove, contact

the place of purc hase.

W011

The traveling spe ed cannot be

detected.

The maximum spe ed up to which power

assistance is p rovided may be lower than

usual.

Check that the spe ed sensor is properly i nstalled. If the

situation does n ot improve, contact the pla ce of purchase.

W013

Initializati on of torque

sensor was not com pleted

successfully.

Power assistance may be lower than usual.

With your foot of f the pedal, press the bat tery power

button and turn o n the power again. If the situa tion does

not improve, conta ct the place of purchase.

W032

An electroni c derailleur may

have been installe d in place of

a mechanical derailleur.

Power assistanc e provided in [WALK] m ode

may be lower than usual.

The walk assist mo de function may not be

able to be used in cer tain regions.

Reinstall the der ailleur for which the syst em is congured

to support. If t he situation does not imp rove, contact the

place of purchas e.

Warning Messages on the Cycle Computer

This disappear s if the error is xed.

TROUBLESHOOTING //

Battery LED Lamp Error Indications

System errors and similar warnings are indicated by the battery LED lamps through various lighting patterns.

Reference //

Shimano Steps E8000 User Manual: ht tp://si.shimano.com /pdfs/um/UM-72F0A-006-00 -ENG.pdf

Page 16

INTENSE CYCLES // 3 1 30 // This declaration of conformity is specic to countries following CE marking directives.

INTENSE TAZER MANuAL //

Declaration of Conformity

Hereby confirm s the following p roducts:

Product Name: INTENSE TAZER e-Bike

Year of Construction: 2018 / 2019

Conformity with all applicable provisions from

the Machiner y Directive (2006/42 /EC).

The machine confo rms to all applicable provisions of th e

Directive 2014/30/EU Electromagnetic Compatibility Directive.

These standa rds were applied:

EN 15194 / 2017 Bicycles:

Electrically power assisted bicycles, EPAC Bicycles.

ISO 4210-2 Bicycles: Safety requirements for bicycles.

Technical documentation from:

INTENSE CYCLES

42380 Rio Nedo

Temecula, CA 92590- 3708, USA

TEL: 1.951.296.9596

Place and Date of i ssue of this

Declaration of Conformity:

Temecula, CA, August 15, 2018.

Jeff Steber

CEO/ Founder

Chad Peterson

COO/ Product Manager

Chris Knutson

Engineer

The Manufacturer

INTENSE CYCLES

42380 Rio Nedo

Temecula, CA 92590- 3708, USA

TEL: 1.951.296.9596

Tazer intende d for Offroad Use .

Page 17

P h o n e :

+1(951)-307-9211

Customer Service:

techcenter@intensecycles.com

General Info:

info@intensecycles.com

Media, Marketing, Sponsorship:

marketing@intensecycles.com

Intense Cycles USA 42380 rio nedo Temecula, Ca. 92590

www.INTENSeCYCLES.com

330026

Loading...

Loading...