Vision Meter Family

User’s Manual

Partnered with

Intellimeter.ca

Table of Contents

Introduction ................................................................................................... 3

1. Product Description .................................................................................. 3

1.1 ST Single Phase Meter ...............................................................................................3

1.2 XT Poly Phase Meter .................................................................................................4

1.3 Network Connectivity ................................................................................................4

1.4 Weight ........................................................................................................................4

1.5 Temperature ...............................................................................................................5

1.6 Frequency ...................................................................................................................5

1.7 Catalog Information ...................................................................................................5

1.8 Operational Theory ....................................................................................................6

2. Installation ................................................................................................. 7

2.1 Meter Installation .......................................................................................................7

3. Operational Instructions .......................................................................... 9

3.1 Nameplate Information ..............................................................................................9

3.2 Display Information .................................................................................................10

3.3 Accumulation Modes ...............................................................................................11

3.4 Instantaneous Power .................................................................................................11

4. Maintenance ............................................................................................ 12

4.1 Test Procedure ..........................................................................................................12

4.2 Service ......................................................................................................................14

4.3 Storage ......................................................................................................................14

4.4 Troubleshooting .......................................................................................................14

5. Diagrams .................................................................................................. 15

5.1 ST Single Phase Meter .............................................................................................16

5.2 XT Poly Phase Meter ...............................................................................................17

6. Supplementary Information .................................................................. 18

6.1 ANSI C12.10 Internal Connections .........................................................................18

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Page 2

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

Introduction

The Vision Meter Family consists of a variety of single phase and poly phase meters with

network connectivity options. Meters can be ordered to include either Data on Demand ™,

Airpoint ™, or both hardware options. All Vision meters are programmed through the

Vision 20/20 software which is included in all Vision meters. All meters are designed with

a lifetime to exceed 20 years, meeting or exceeding ANSI standards, using digital

measurement technology.

1. Product Description

The Vision Metering family of meters includes single phase (ST) meters and poly phase

(XT) meters. The meters are configured to the customer’s specifications within a tolerance

of (+/-0.15%) from the factory, ensuring a smooth installation process and accurate

measurement. Also standard is the ability to complete delivered, received, and net

metering.

1.1 ST Single Phase Meter

The standard (ST) model meter has been designed with cost in mind, yet considers

upgradability by offering features that can be added on at a later date.

The ST single phase meter can be configured for a number of options:

Available in Form 1S, 2S, 3S, 4S, & 12S. Other forms are available upon request.

Available in 120V, 240V, or 480V rated Voltage.

Displays kWh, instantaneous demand, volts, and amperes

Standard functions include Time of Use, Load Profile, Demand.

Comes in Class 320, Class 200, 100, and transformer rated types.

Optional 15 Year Battery

Optional radio with Data On Demand or ERT transmission capabilities

ERC and FCC/NTC Approved

Customer Programmable (with Vision 20/20 software)

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Figure 1

Page 3

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

1.2 XT Poly Phase Meter

The XT Poly Phase meter is equipped with the features present in the ST meter model

with the following features in addition:

Available in ANSI Forms:

1S, 2S, 3S, 5S, 6S, 8S/9S, 12S/25S, 13S, 15S/16S, 35S, 45S

Power Supply capable of handling 120V – 480V

Optional KYZ output for additional pulse generation capabilities

The XT meter has been designed to accommodate all metering forms and to provide a

platform for AMR/AMI manufacturers to add communication hardware as needed to the

meter unit. Literature is available to assist customers.

Figure 2

1.3 Network Connectivity

The XT meter includes an internal HP RF radio that operates on the 900 MHz band

transmitting SCM data. The ST and XT models can be ordered to include Airpoint high

power automatic meter reading hardware.

1.4 Weight

The shipping weight for each type of meter is different and is as follows:

Single Phase ST meter with Polycarbonate Housing

o Single meter: 1.5 lbs

o 4 meter box: 7.0 lbs

o Pallet of 120: 229 lbs

Polyphase ST meter with Polycarbonate Cover

o Single meter: 2.0 lbs

o 4 meter box: 9 lbs

o Pallet of 96: 241 lbs

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Page 4

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

Singlephase XT meter with Glass Cover

o Single meter: 2.4 lbs

o 4 meter box: 10.6 lbs

o Pallet of 120: 337 lbs

1.5 Temperature

Vision meters are specified to perform from -40° C to 85° C. The LCD may cease to

function in adverse cold weather below -30 ° C, or excessive heat, above 80° C. Storage

temperature should be between -40° C to 85° C.

1.6 Frequency

Vision meters can accurately measure energy associated with 50 Hz or 60 Hz electric

systems. Operating frequency is set at the factory and must be specified when ordering

the meter.

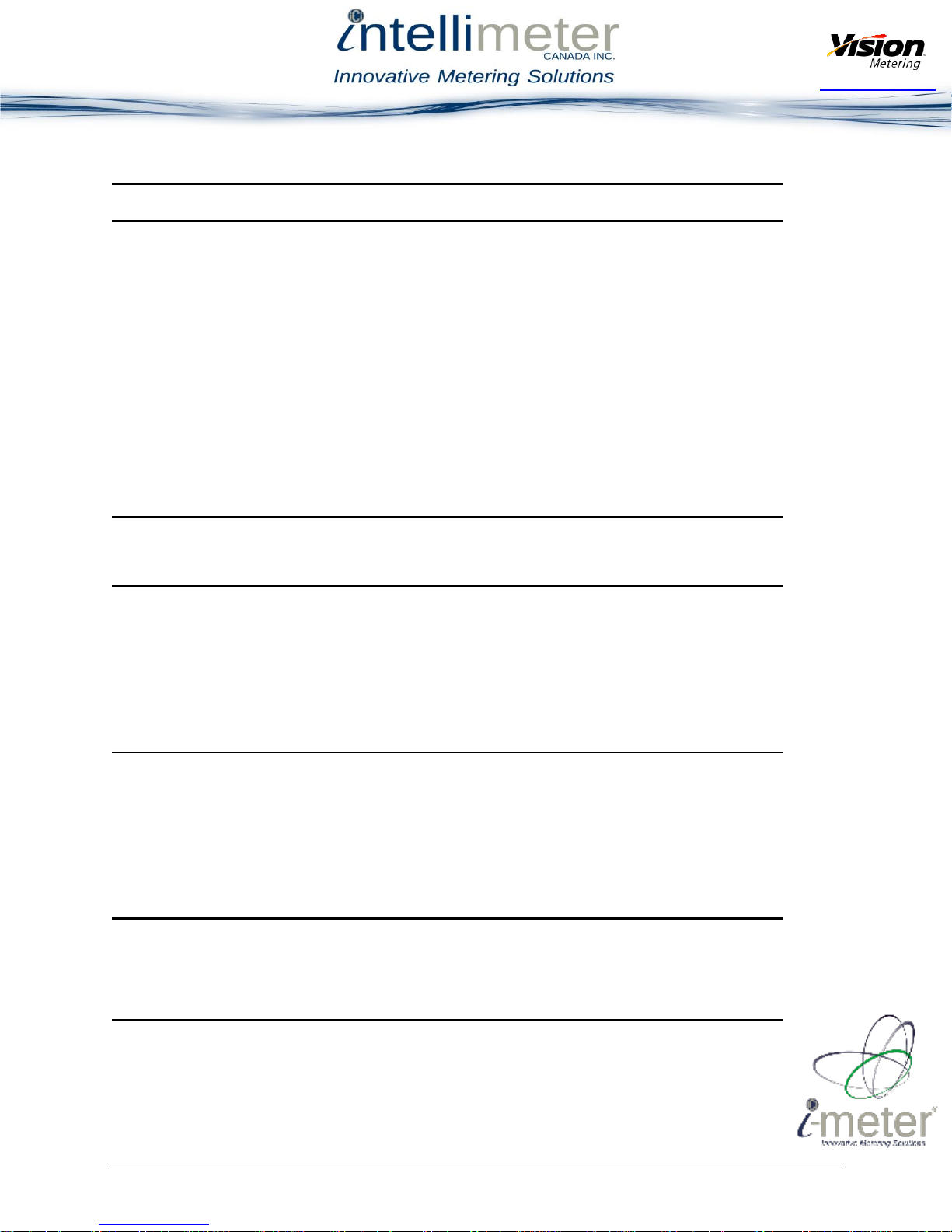

1.7 Catalog Information

The catalog displays information regarding the different meters included in the catalog

through an alphanumeric code, as shown in Figure 3.

Note: Demand meters must be built on the Vision XT platform with a 120V-480V power

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Figure 3

supply.

Page 5

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

1.8 Operational Theory

The operations within the meter are explained as follows:

The meter is driven by a microcontroller powered by a DC source drawing power

from line voltage. An analog to digital converter is connected to before and after

the current transformer to measure Watt-hours.

The microcontroller stores accumulated data in the NVRAM and displays the

data as programmed in Vision 20/20. This data is stored in RAM that is nonvolatile, thus power does not need to be applied for the data to be retained.

The LCD is powered through the microcontroller and displays according to the

user’s settings.

The block diagram in Figure 4 shows the component interaction within the Vision

family of meters.

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Figure 4

Page 6

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

2. Installation

WARNING: The Vision ST and XT models contain dangerous levels of voltage. The

meter should never be disassembled, exposure to electrical connections within an energized

meter can result in serious injury or death.

Both the Vision ST and XT models come in a variety of ANSI standard forms. The physical

dimensions of the ST and XT models are different, as are the features on the polycarbonate

cover. The XT polycarbonate cover includes a turnkey feature that enables connection with

the internal button interface without removing the polycarbonate protective housing.

2.1 Meter Installation

The installation of the Vision meters should be handled by licensed professionals. The

meter is plugged into the meter socket jaws, engaging the terminals and connecting the

meter to the grid. Refer to Section 6 for supplementary diagrams of the common ANSI

electric meter forms.

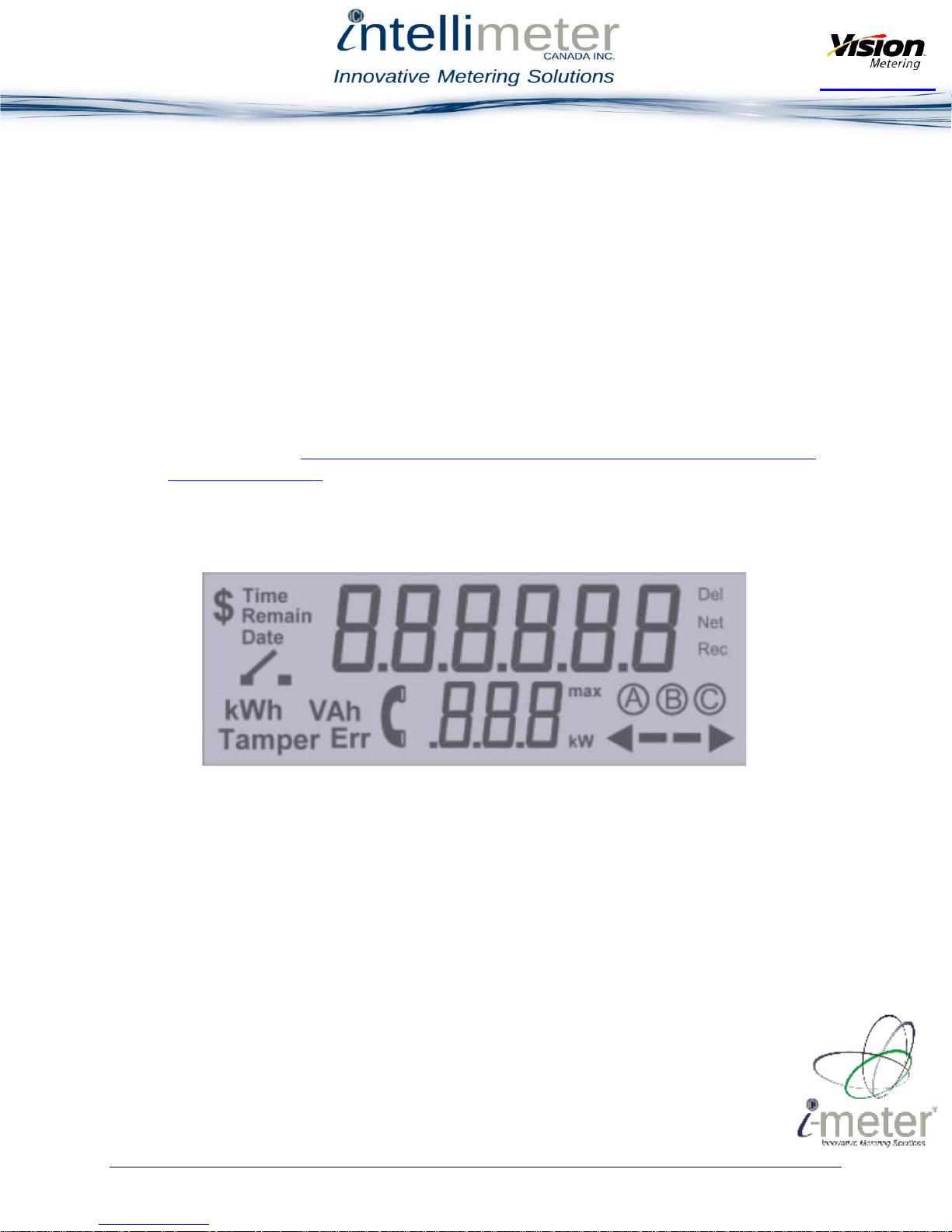

Upon powering the meter, verify meter operations by checking the display. As shown in

Figure 5, the LCD display will energize.

As each meter is configured to the specifications provided by the customer, the meter

settings will already be installed on the meter as tested at the factory. After installation and

powering of the meter, the meter settings should be checked for proper operation of the

meter. As shown in Figure 6 on page 8, the front of the meter contains the optical port

connection necessary for communicating with meter.

The LCD display meets or exceeds ANSI C12.1, C12.10, C12.20, C37.90.1 standards.

Note: Both an optical port and Vision 20/20 are required to read the meter settings.

Refer to the Vision Metering website for a current version of the Vision 20/20

software as well as the associated user’s manual.

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Figure 5

Page 7

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

Figure 6

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Figure 7

Page 8

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

Attach the optical port as shown in Figure 7 on page 8. Using the Vision 20/20 software,

click Read Meter to transfer the data on the meter to the Vision 20/20 software. If the

configuration screen in Vision 20/20 is populated with the correct test data, the meter can

be concluded to be operating correctly.

3. Operational Instructions

3.1. Nameplate Information

As shown in Figure 6 and in Figure 7 on page 8, the nameplates have different layouts.

Displayed on the front of the meter is the operating voltage, the current measurement class,

the form type, the Kh value, and the test amperage value.

The nameplate information is displayed differently on the ST and the XT variants, though

the information displayed on either nameplate is the same.

The nameplate information shown in Figure 8 is as follows:

1. Power Supply Voltage Rating

2. Current Class

3. Watts used by the meter

4. Form Type based on ANSI C12.10

5. Kt value for one revolution, in Wh

6. Test Amperage Rating

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Figure 8

Page 9

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

3.2. Display Information

The liquid crystal display (LCD) on the front of the meter can be programmed to display

variety of values. On the top row of the display, the accumulated information is displayed.

Both the accumulated and displayed information can be programmed using the included

Vision 20/20 software. The ability to check if a switch is present in the meter is also

included in the Vision 20/20 software suite.

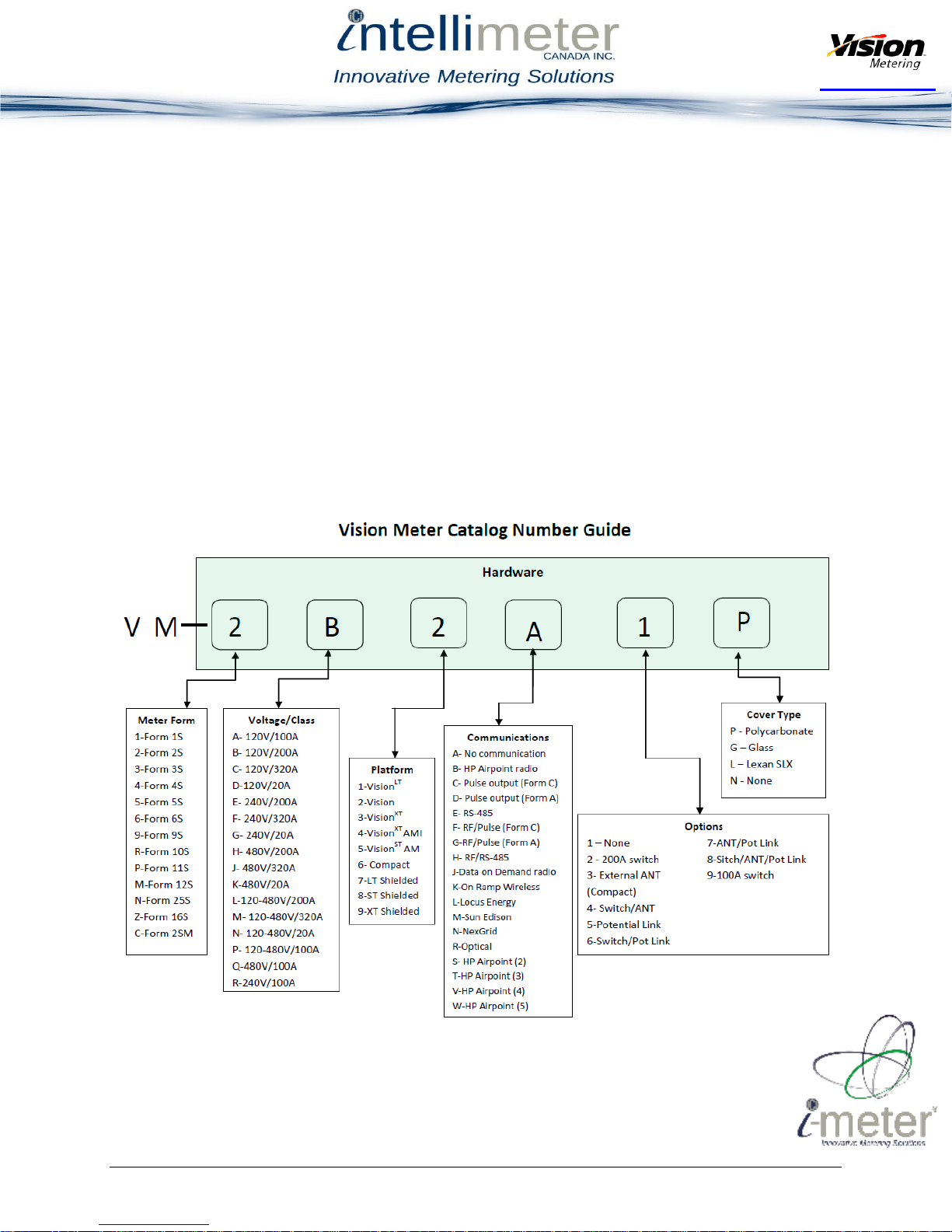

As shown in Figure 9, the LCD displays a variety of information:

1. The main six digit display shows the programmed data as set in Vision 20/20

2. Operating Mode indicator

3. Phase Letter indicator

4. When displayed, the arrow to the right indicates energy is being delivered to the

load, the arrow to the left indicates the customer is generating energy to the grid.

This set of four symbols is also used to emulate a Watt-hour disk unit.

5. Max Demand displayed in kW

6. Phone Symbol – When displayed, indicates that communication is in progress. If

icon is constant, indicates transmission of data, if blinking, indicates data loss.

7. Tamper error indicator

8. kWh/VAh mode for six digit segment

9. Switch Open indicator – if blinking, indicates a switch failure

10. Dollar Sign – Not Used

11. Time Display Settings

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Figure 9

Page 10

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

3.3. Accumulation Modes

Accumulated information can be set to display the following modes:

Net Metering (Delivered – Received):

The Net Metering mode measures both the delivered and received power and takes the

difference. This mode is most appropriate for renewable energy generation provided by a

grid connected customer that draws more power than generated.

Delivered Only:

The Delivered Only mode allows only the power delivered to the customer to be

recorded. This mode is the most common metering mode on residential systems. It is anti

- tampering mode as well. If power is flowing in received direction, meter will also

record it as delivered.

Received Only:

The Received Only mode allows only the power delivered from the customer to the grid

to be measured. This mode is most appropriate when the customer has a large generation

facility with no demand.

3.4. Instantaneous Power

When enabled in the display settings, the lower three digit display will display the

instantaneous demand experienced by the meter. Decimal location and demand range can

be set by changing the Precision Settings using Vision 20/20 software.

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Page 11

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

4. Maintenance

4.1. Test Procedures

All Vision Meters are equipped with a Light Emitting Diode (LED) and a phototransistor

for ensuring proper calibration of the meter according to ANSI standard C12.20. The

infrared LED emits pulses indicating kWh accumulation. Each pulse represents Kt,

measured in Wh of energy accumulated by the meter. An optical probe and the associated

driver is required to communicate the pulse information from the optical port to the

connected computer.

Figure 10 shows the Optical Port, showing both the LED and the Phototransistor in the

configuration present on all Vision Metering optical ports:

1. Infrared LED 2. Phototransistor

Testing of the meter unit involves reading test data fed to the meter, which if the meter

operates correctly, should be read with the desired accuracy to the Vision 20/20 software.

Emulation of a disk analog system is accomplished using the symbol in the bottom right

corner of the LCD as shown in Figure 11 on page 13. The emulation procedure consists of

blinking the various sections of the symbol to show that a revolution has occurred. The 10step emulation procedure is shown in Figure 11 on page 13.

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Figure 10

Page 12

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

Figure 11

The emulation procedure starts as soon as load is applied. It is preferable that this load be

well known and constant for the test procedure. The disk emulation is completed by

timing the full cycle for Kt. For higher accuracy, increase the number of cycles per test.

A general testing procedure for disk emulation of electric meters is listed below:

1. Record the Kt value recorded on the nameplate of the meter.

2. Select the desired voltage and current on test equipment, ensuring the device

ratings are within the range of the desired specifications.

3. Install the meter to the test socket, ensuring the correct form socket is selected

4. Attach the optical probe to the optical port.

5. Using standard test procedure, begin testing after 15 seconds so the demand is

stabilized.

6. To ensure accurate measurement, establish a minimum of 30 seconds test time to

reduce human error caused by the imprecise start and stop times.

7. Compare the values given from the test to the values displayed on the unit. If the

values are within a reasonable error margin, the meter can be concluded to be

working properly.

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Page 13

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

Name

Code

Display

Blocking

Cause

Required Action

ERR_UNPROGRAMMED

001

No

Meter is not programmed

or in a factory default state

This error is set when

firmware takes default

setting data during

initialization after power

was up.

ERR_CONFIG

002

Yes

Meter detected a

configuration error

Currently not supported

by meter

ERR_SELFCHK

003

Yes

Meter detected a self-check

error:

Meter tried to recover

reading data from backup

memory after power was

up and did not found any

good records

Reset the meter.

ERR_RAMFAILURE

004

Yes

Meter detected a RAM

Memory failure

Currently not supported

by meter

ERR_ROMFAILURE

005

Yes

Meter detected a ROM

Memory failure

Currently not supported

by meter

ERR_NONVOLMEMFAILURE

006

Yes

Meter detected a nonvolatile memory failure.

Meter tried to save reading

data in the EEPROM

memory unsuccessfully.

Call to the manufacturer

if this error has not gone

after 5 minutes.

ERR_CLOCK

007

No

Meter detected a clock

error

Currently not supported

by meter

ERR_MEASUREMENT

008

Yes

Meter detected a

measurement element error

Currently not supported

by meter

ERR_LOWBATTERY

009

No

Meter detected a low

battery error

Replace the battery

ERR_LOWLOSSPOTENTIAL

010

No

Meter detected one of the

device potential that is

below a predetermined

Check the meter

connection to the

network.

4.2. Service

Vision Meters are calibrated at the factory and do not require any maintenance. If there

are issues with the meter, contact Vision Metering for assistance.

4.3. Storage

Vision meters are durable devices, yet they should be stored with care. Extreme

temperature and humidity levels should be avoided during storage.

4.4. Troubleshooting

Troubleshooting of Vision Meters is accomplished by reading the error codes given by

the meter and performing the correct repair procedures. The complete table of error

codes and the required actions, is given in the table on pages 13-14.

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Page 14

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

value.

Check if the meter formfactor settings matches

the faceplate label.

ERR_DEMANDOVERLOAD

011

No

Meter detected a demand

threshold overload

Currently not supported

by meter

ERR_POWERFAILURE

012

No

Meter detected a power

failure. Power register in

the computation engine

was corrupt

Cycle meter power. Call

to the manufacturer if

this error has not gone.

ERR_TAMPERDETECT

013

Yes

Meter detected tamper

activity. Used on meters

with the tamper sensors

Reset the tamper flag.

ERR_REVERSEROTATION

014

No

Meter detected reverse

rotation

Currently not supported

by meter

ERR_RADIO

101

Yes

Meter detected an error in

the radio chip. Used on

meters with the radio

communication

Cycle meter power. Call

to the manufacturer if

this error has not gone.

ERR_POWERSWITCH

102

No

Meter detected a power

switch error. Used on

meters with the

connect/disconnect switch.

Can be switch board or

switch malfunctioning

Replace switch board or

power switch

ERR_NOTCALIBRATED

103

No

Meter is not calibrated

Calibrate the meter

5. Diagrams

The physical dimensions of both types of meters are shown below. It may be desired to

acquire more information about the different types of form standards, it is recommended

to reference a reliable source for this information. Refer to

meteringforlinemen.com/diagrams for sample information about ANSI form standards.

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Page 15

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

5.1 ST Single Phase Meter

Figure 12

The ST single phase meter has a different physical layout than the XT model. The ST series

of meters do not have as many features available and the exterior housing reflects the

difference. ST meters are available in both polycarbonate and glass housing types.

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Page 16

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

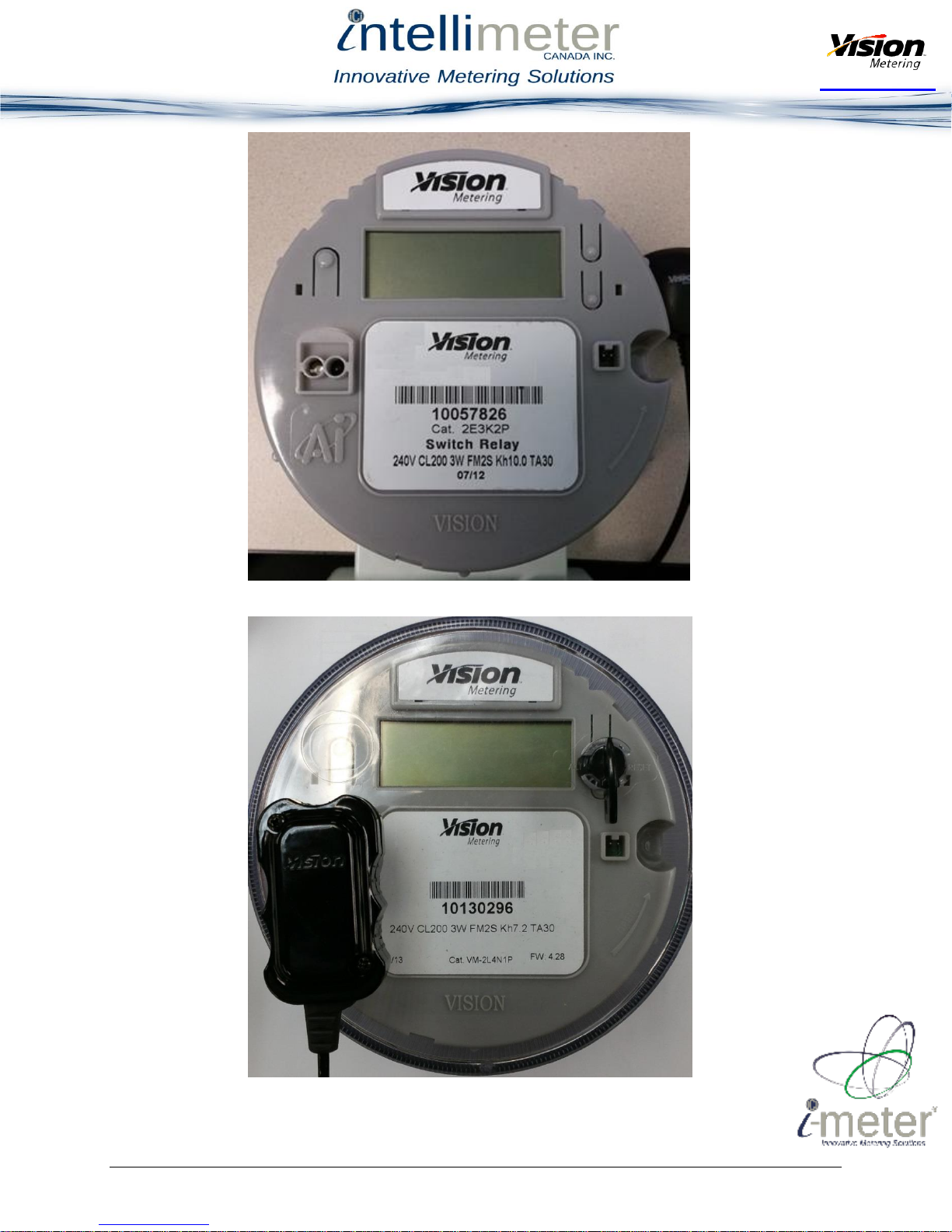

5.2 XT Poly Phase Meter

Figure 13

Figure 14

Figure 15

The XT series meters have a different layout which includes an external switch to select

the settings for the meter. The XT series are readily available only in a polycarbonate

housing. To obtain an exterior housing in glass on the XT meters, a custom order must be

made, contact Vision Metering for custom orders.

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Page 17

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

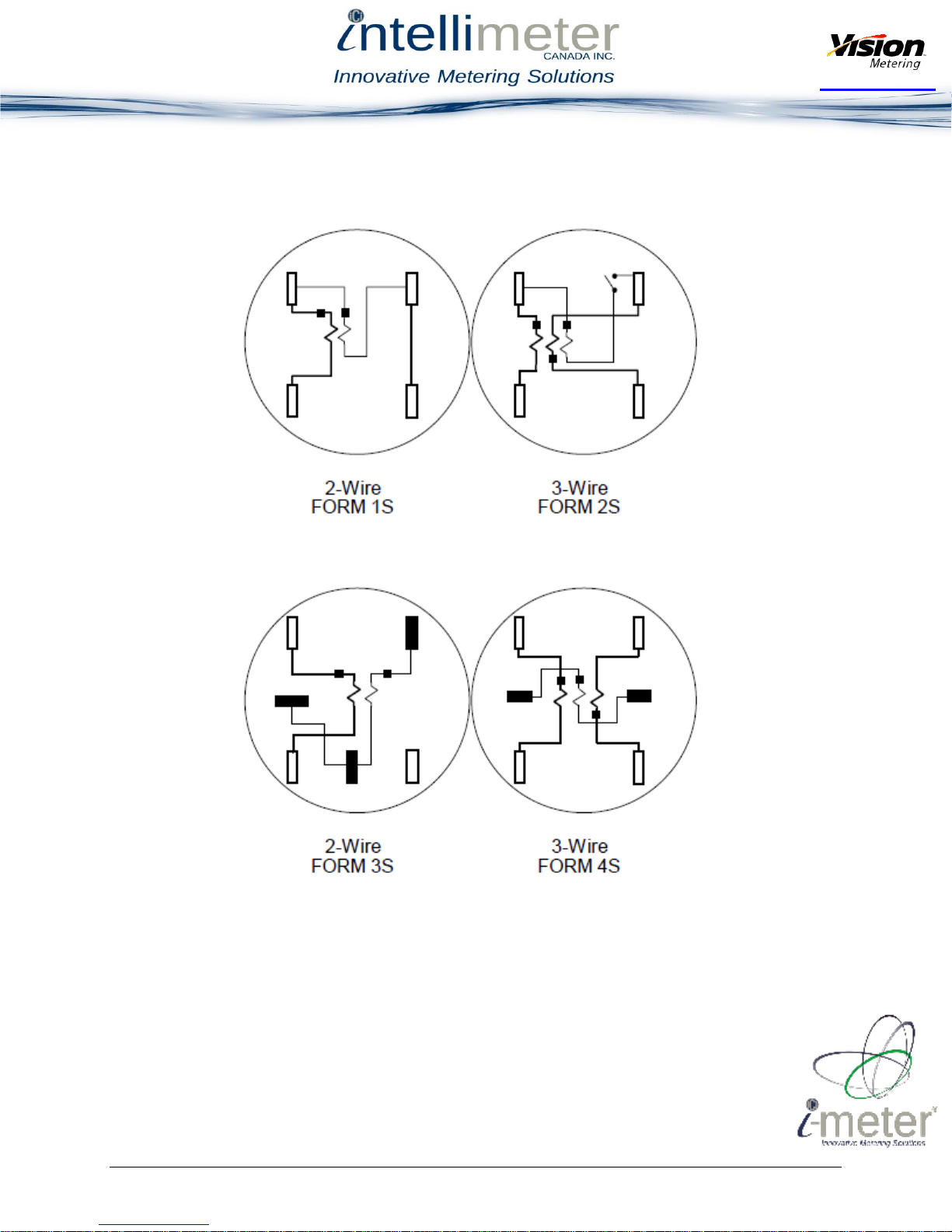

6. Supplementary Information

6.1. ANSI C12.10 Internal Connections

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Figure 16

Page 18

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Figure 17

Page 19

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Partnered with

Intellimeter.ca

1125 Squires Beach Road, Pickering, ON, L1W 3T9 • Tel: (905) 839-9199

Figure 18

Page 20

Intellimeter Canada Inc.

Copyright 2015 © Vision Metering, LLC

Loading...

Loading...