WARNING

— Ne pas entreposer ni utiliser d’essence ou

ni d’autres vapeurs ou liquides inammables

à proximité de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ

•

Ne pas tenter d’allumer d’appareil.

•

Ne touchez à aucun interrupteur; ne pas vous

servir des téléphones se trouvant dans

le bâtiment.

•

Appelez immédiatement votre fournisseur de gaz

depuis un voisin. Suivez les instructions

du fournisseur.

•

Si vous ne pouvez rejoindre le fournisseur,

appelez le service des incendies.

— L’installation et l’entretien doivent être assurés

par un installateur ou un service d’entretien

qualié ou par le fournisseur de gaz.

AVERTISSEMENT

Assurez-vous de bien suivre les instructions données

dans cette notice pour réduire au minimum le

risque d’incendie ou d’explosion ou pour éviter tout

dommage matériel, toute blessure ou la mort.

If the information in these instructions is not followed

exactly, a re or explosion could result causing

property damage, personal injury, or death.

— Do not store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

re department.

— Installation and service must be performed by

a qualied installer, service agency, or the gas

supplier.

Operation & Installation Manual

iN401

iN501

Thank you for purchasing this Intellihot unit.

This unit is designed for years of trouble free operation, and I urge you to read and follow the

instructions in this “Operation & Installation Manual.”

Our mission to create a better heating system began back in the winter of 2005 when a tank

water heater broke down and ooded my basement. By combining the principles of a diesel

engine’s robustness, robotics intelligence, and marine environment durability, we set out to

design a unit from the ground up that would outperform and outlast all others.

Quickly, our goal grew from not just making a better water heater, but creating an intelligent

water heating and delivery system. Innovation is our hallmark and simplicity, eciency, and

durability are at the core of every lntellihot product.

Our products are proudly engineered and built in Galesburg, Illinois. lntellihot has helped

commercial customers throughout the nation save thousands of dollars while eliminating

downtime. Our talented team of dedicated professionals is ready to assist you and help your

business succeed.

I thank you for purchasing our lntellihot products.

Sincerely,

Sri Deivasigamani

CEO, lntellihot Inc.

Table of Contents

1. General Information

1.1 Items Shipped With Water Heater..........2

1.2 Serial Number Locations .................2

2. Safety

2.1 Safety Signal Words.....................3

2.2 Installation Warnings ....................3

3. TechnicalSpecications

3.1 ....................5

Specifications Chart. .

3.2 Nomenclature..........................6

3.3 High Elevation Installations ...............6

3.4 ClearanceRequirements .................6

3.5 7

Connection Specifications. ...............

3.6 Exhaust Gas Standards ..................7

3.7 Overall Dimensions......................8

3.8 ...................9

Configuration Options

4. Quick Reference Installation Guide

4.1 Install the Water Heater..................11

4.2 Pre-Startup Instructions .................11

5. Preparation Before Installation

5.1 Selecting an Indoor Installation Site ....... 13

6. Gas Connection

6.1 QuickReferenceInstallationInstructions ... 14

6.2 Fuel Source .......................... 14

6.3 GasPressureRequirements ............. 14

6.4 GasPressureRegulator ................. 14

6.4.1 VentingofGasSupplyRegulators... 15

6.5 Length of Gas Supply Line ............... 15

6.6 Gas Piping Material .................... 15

6.7 DetermineCorrectGasPipeDiameter ..... 15

Gas Pipe Drip Leg and Shut-off Valve

6.8 15

6.9 ConnectingGasLinetoUnit ............. 16

6.10 Gas Pipe Sizing Tables ...................17

.....

7. Air Intake Inlet and Exhaust Gas Outlet Pipe

Connections

7.1 QuickReferenceInstallationGuide ........ 19

7.2 TypicalSingleUnitAirIntakeInletand

Exhaust Gas Outlet Pipe Installation ....... 19

7.3 Two Pipe Vent System (Direct Vent) ......20

7.3.1 ....20

7.3.2 ...... 21

7.3.3 SideWallAirIntakeInletandExhaust

7.3.4 RoofAirIntakeInletandExhaust

Single Pipe Venting System (Power Vent)

7.4

7.4.1 SingleUnit .....................22

7.4.2 MultipleUnits ................... 23

7.5 CombustionAirRequirements ............ 24

7.6 IntakeAirInletandExhaustGasOutlet

Pipe Diameter and Length ...............24

7.7 ........25

Venting Clearance Specifications. .

7.8 Exhaust Gas Outlet Pipe Materials ........26

7.9 AirIntakeInletPipeVentMaterials ........26

7.10 RecommendedExhaustGasOutletPipe

Transitions ........................... 27

Single Unit Configurations. . . . .

Multiple Unit Configurations .

Gas Outlet Pipe Termination ....... 21

Gas Outlet Pipe Termination .......22

..22

8. Water Connections

8.1 QuickReferenceInstallationInstructions ...28

8.2 HotWaterConnection..................28

8.3 ColdWaterConnection .................29

8.4 29CondensateDrainLine ......... .........

9. Electrical Power

9.1 ElectricalRecommendations ............. 31

9.2 ConnectionInstructions................. 31

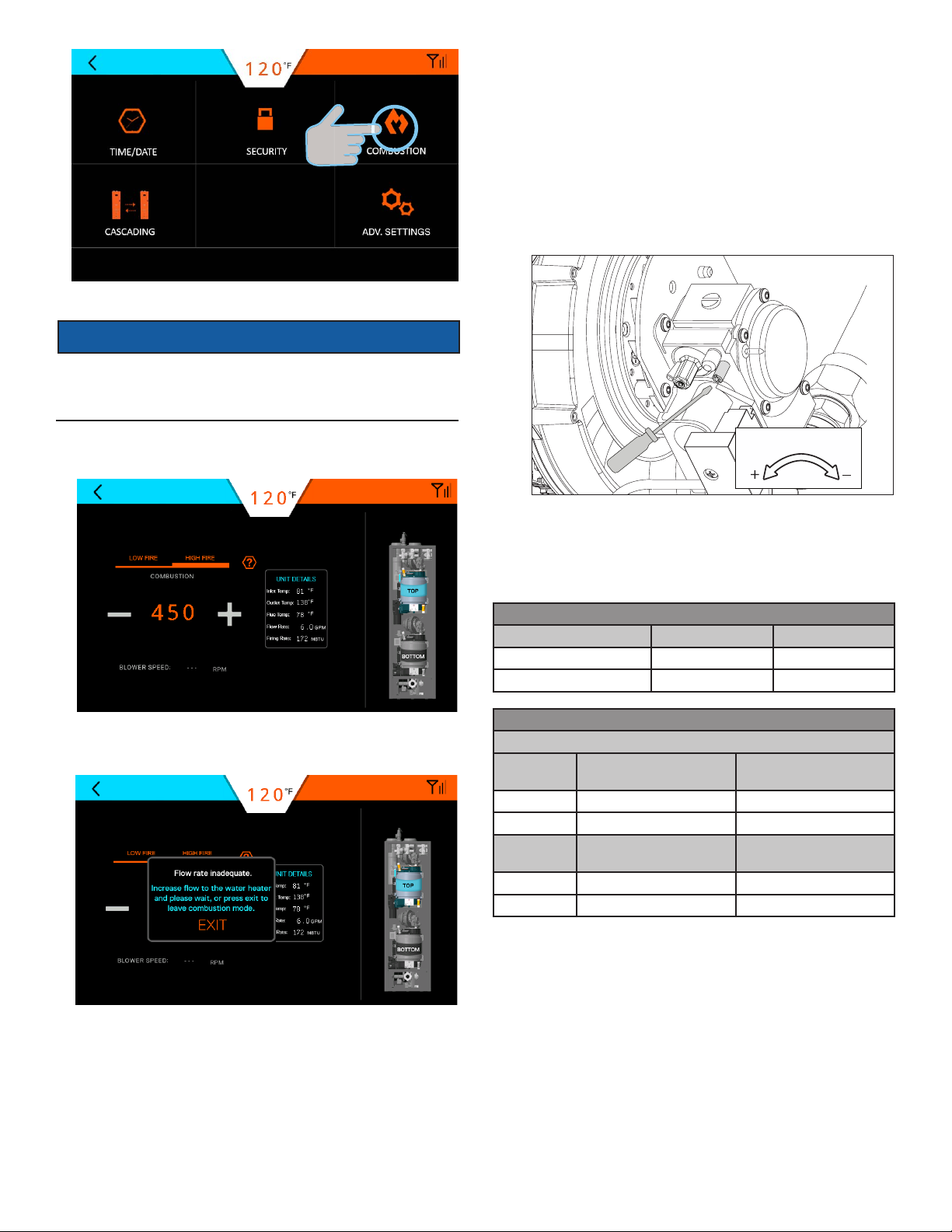

10. Adjusting CO2 Level

10.1 General Information ....................32

10.2 AdjustmentProcedure .................. 32

11. Natural Gas to Propane Conversion

11.1 General Information ....................35

11.2 ConversionProcedure .................35

12. Operation

12.1 ControlPanel ......................... 37

12.2 Turning Water Heater ON and OFF ........ 37

12.3 Setting the Time ......................38

12.4 AdjustingtheWaterTemperature .........38

12.5 Security .............................39

12.5.1 Setting Passcode Protection....... 39

12.5.2 ChangingPasscode ..............40

12.5.3 Forgot Passcode ................ 41

12.6 N/A ............................. 41

12.7 Temp / Flow ......................... 41

12.8 Life Screen.......................... 42

12.9 Unit Information ...................... 43

12.10

More Screens. ........................ 44

12.10.1 Cellular ........................44

12.10.2 Error History ...................44

12.10.3telliCareService

(Subscribe at Startup)............45

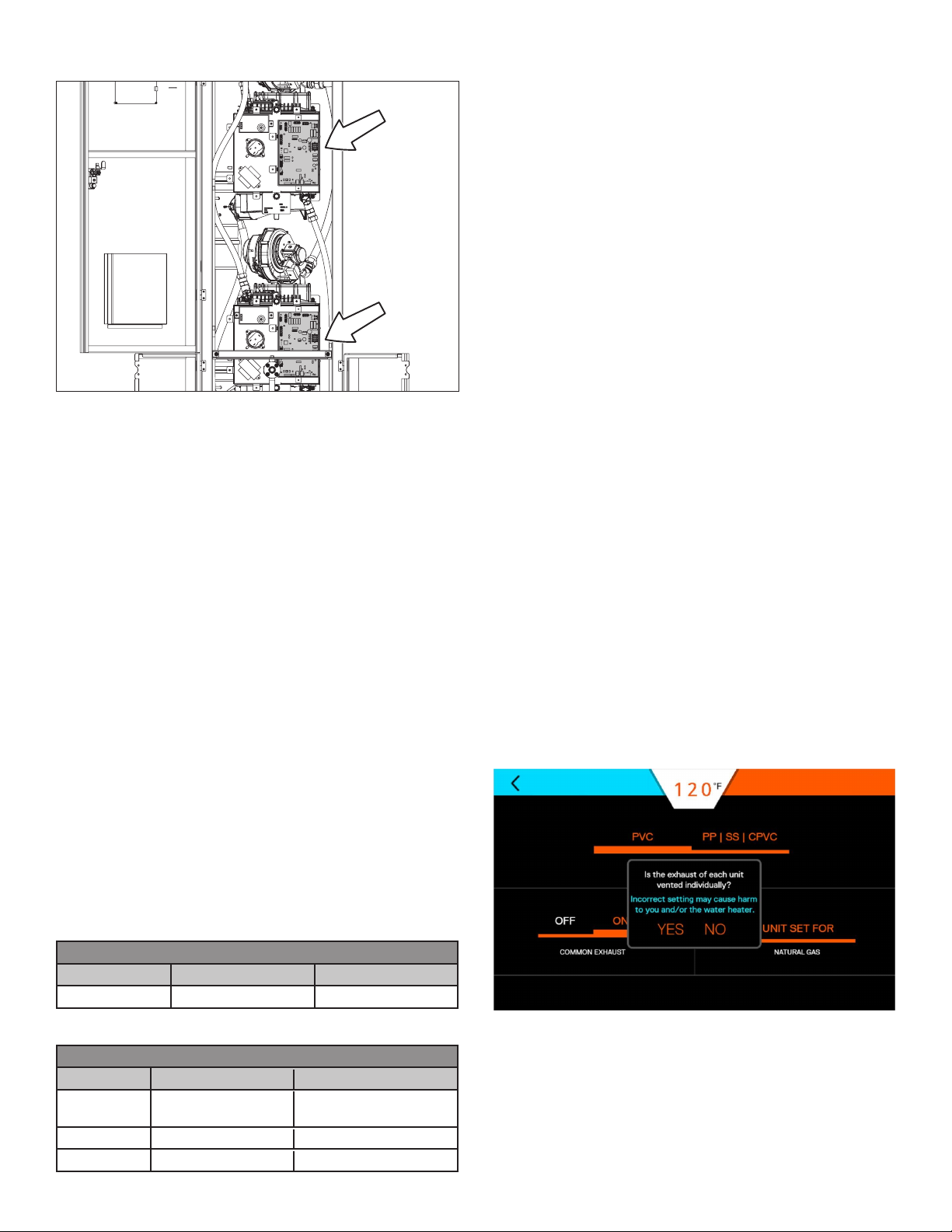

13. Connecting Multiple Units

13.1 General Information ....................48

13.2 Installation Procedure ..................48

13.2.1 telliCareforMultipleUnits.........49

13.3 VentingforMultipleUnits ...............49

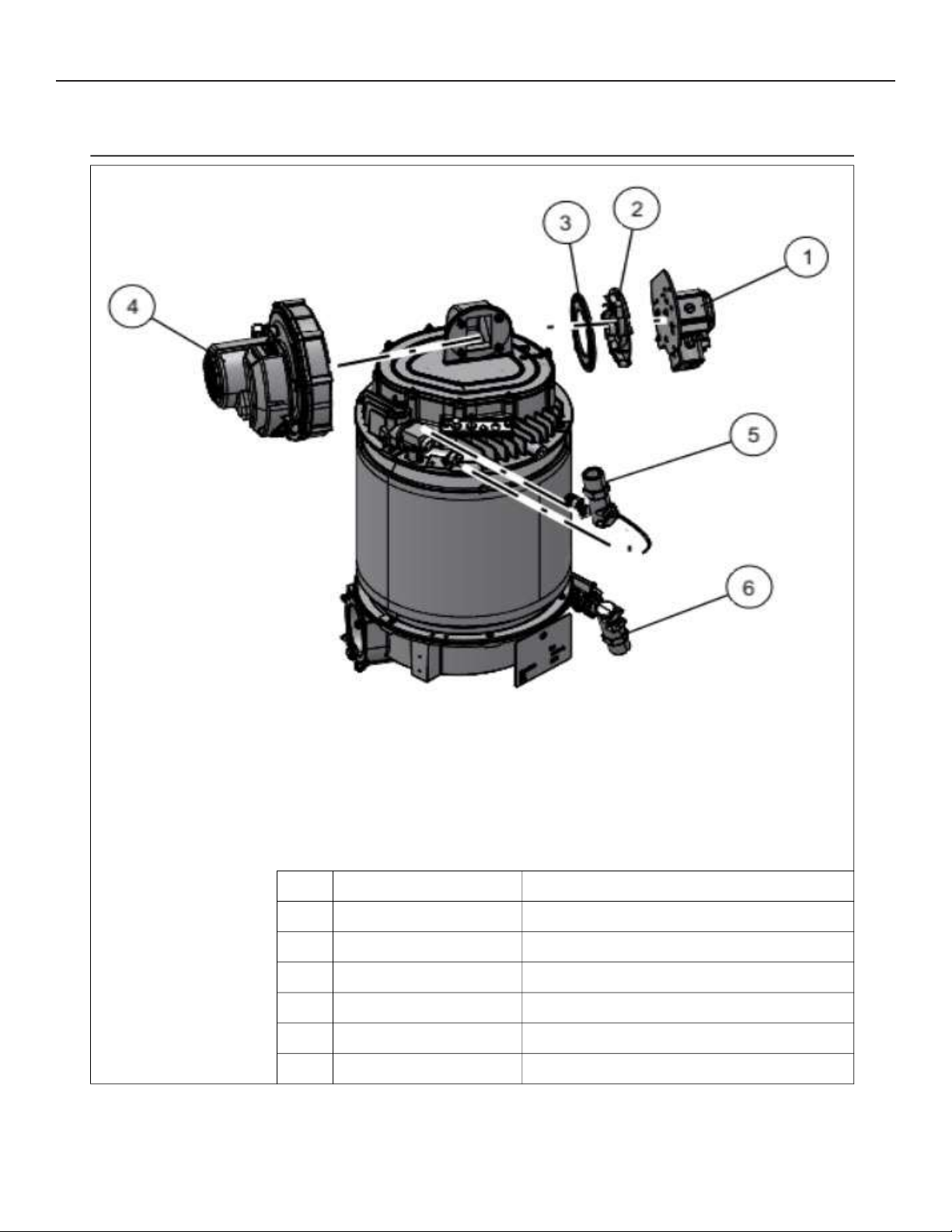

14. Maintenance

14.1 Maintenance-FreeCirculationPump.......50

14.2 Heat Engine Locations ..................50

14.3 CondensateSedimentCupCleaning .......50

15. Wiring Diagrams and Troubleshooting

15.1 OperationalFlowChart .................53

15.2 CompleteWiringDiagram(allmodels) .....54

15.3 ControlBoardWiringDiagram............55

15.4 Troubleshooting Guide..................56

16. Serviceable parts. . . . . . . . . . . . . . . . . . . . . . .

17. Requirements for State of Massachusetts

17.1 Notice Before Installation .............

18. Warranty

18.1 Warranty. ..............

Product Warranty

19.

19.1 Warranty. ..............

..............

..............

57

68

69

71

WARNING

DANGER

— Ne pas entreposer ni utiliser d’essence ou

ni d’autres vapeurs ou liquides inammables

à proximité de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ

• Ne pas tenter d’allumer d’appareil.

•

Ne touchez à aucun interrupteur; ne pas vous

servir des téléphones

se trouvant dans

le bâtiment.

• Appelez immédiatement votre fournisseur de gaz

depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur,

appelez le service des incendies.

— L’installation et

l’entretien doivent être assurés

par un installateur ou un service d’entretien

qualié ou par le fournisseur de gaz.

AVERTISSEMENT

Assurez-vous de bien suivre les instructions données

dans cette notice pour réduire au minimum le

risque d’incendie ou d’explosion ou pour éviter tout

dommage matériel, toute blessure ou la mort.

If the information in these instructions is not followed

exactly, a re or explosion could result causing

property damage, personal injury, or death.

— Do not store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

•

Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

re department.

— Installation and

service must be performed

a qualied installer, service agency, or the gas

supplier.

This product complies with ANSIZ21.10.3 (2011) / CSA 4.3 Gas Water Heater. For use as potable water heating.

To avoid product damage, personal injury, or

product. Improper installation, adjustment, alteration,

or maintenance can cause injury, loss of life, and/or

property damage. This water heater should be installed

and serviced by a qualified technician. The lack of

proper service can result in a dangerous condition.

Due to Intellihot’s policy of continuous product improvement

and technology, the design and/or technical specifications in

this manual are subject to change without notice.

This manual contains safety information, installation

instructions, and maintenance procedures. It must be left

with the homeowner or placed near the water heater in a

noncombustible location. The customer should retain this

manual for future reference.

even possible death, carefully read, understand,

and follow all the instructions in this Operation

and Installation manual before installing this

by

Certified to

NSF/ANSI 372

Contact Information

Call us, your dealer, first if you have any questions about this

product. We can help answer questions about installation,

operation, or if there are damaged or missing parts when

unpacking this unit from the shipping box.

Dealer Contact Information

1 iN401 - iN501

May2019-Revision00

1. General Information

1.1 Items Shipped With Water Heater

The shown in the illustration are shipped loose with the water

heater.

Temperature and

Pressure Relief Valve

(must be installed)

Communication

Cable

Keys

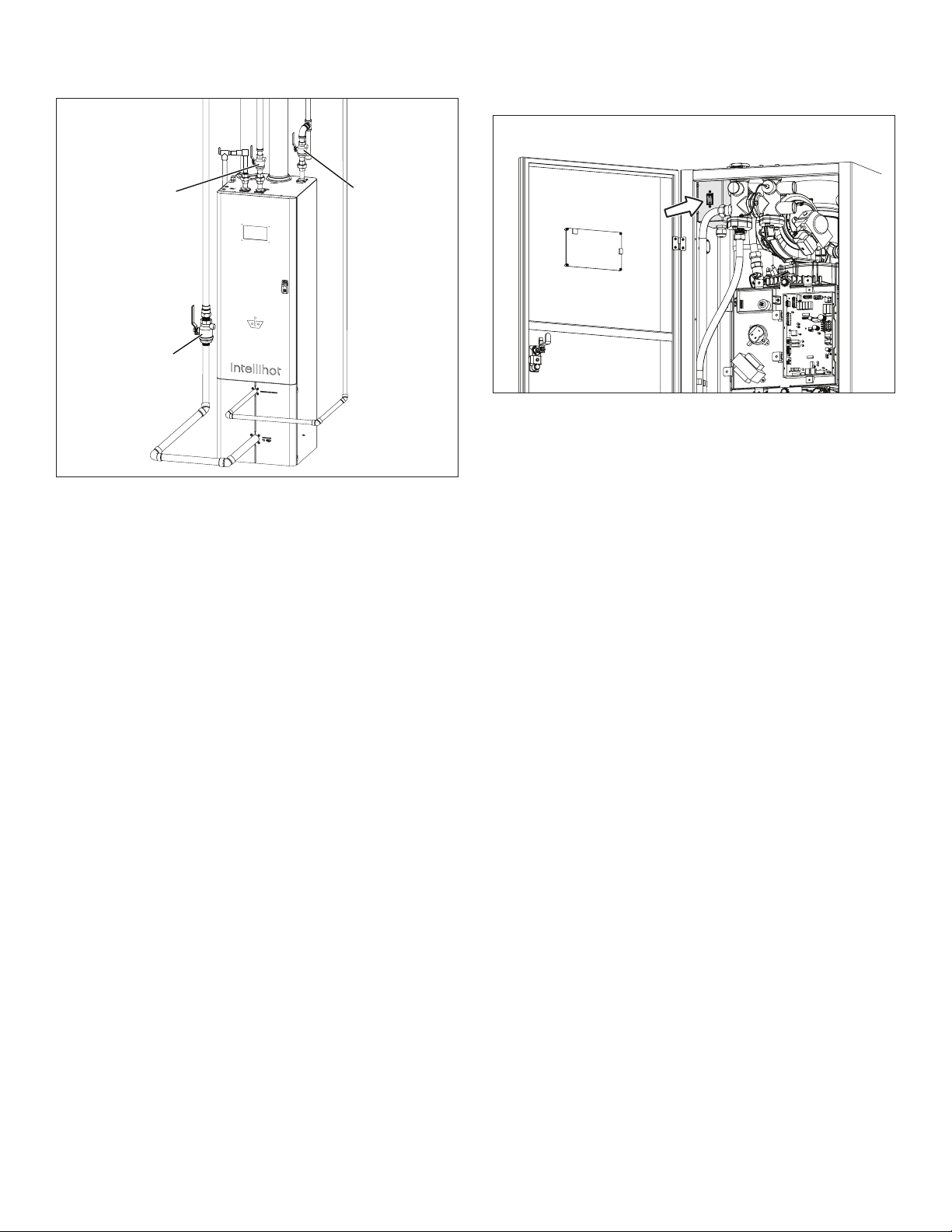

1.2 Serial Number Locations

The unit’s serial number is located on the left side of the

unit. Please provide this serial number when inquiring about

service or warranty solutions. ASME detail is located on the

information plate attached to the cabinet next to the rating

label on the left side.

UnitSerialNumber:______________________________

HeatEngine1(ASME)SerialNumber:_____________

HeatEngine2(ASME)SerialNumber:_____________

DateofInstallation:___ / ___ / ______

Operator

Manual

iN401 - iN501 General Information 2

May2019-Revision00

2. Safety

DANGER

WARNING

CAUTION

NOTICE

SAFETY

INSTRUCTIONS

WARNING

DANGER

WARNING

2.1 Safety Signal Words

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury. This

signal word is limited to the most extreme situations.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Indicates that equipment or property damage can result if

instructions are not followed.

A. This water heater does not have a pilot. It is equipped

with an ignition device which automatically lights the

burner. Do not try to light the burner manually.

B. BEFORE OPERATING, smell all around the water

heater area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will settle

on the floor.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire or

police department.

C. Use only your hand to turn the manual gas shut-off

valve. Never use tools. If manual gas shut-off valve will

not turn by hand, don’t try to repair it. Call a qualified

service technician. Force or attempted repair may

result in a fire or explosion.

Safety instructions (or equivalent) signs indicate

specific safety-related instructions or procedures.

Note: Contains additional information important to a

procedure.

2.2 Installation Warnings

DO NOT use this water heater for any purpose other

than water heating.

Read, understand, and follow the Installation and Operation

manuals, including all warnings and precautions, before

operating this water heater. If you do not follow these

instructions exactly, a fire or explosion may result, causing

property damage, personal injury, or loss of life.

Follow all local codes and the most recent edition of the

National Fuel Gas Code (ANSI Z223.1/NFPA 54) in the USA

or the Natural Gas and Propane Installation Code in Canada

(CSA B149.1).

This water heater must be installed by a licensed plumber,

gas fitter, and/or professional service technician. Installation

by unqualified person(s) voids the warranty.

Designed for operations at outlet temperature(s) not in

excess of 190°F (88°C).

DO NOT use or store flammable liquids around the water

heater, including gasoline, oils, spray paints, etc.

DO NOT operate this water heater unless it is properly

vented to the outside (the exhaust vent piping must be

connected from the unit directly to the outside). Improper

venting can cause a build-up of carbon monoxide, which

can result in brain damage or death. Exhaust gases must

be completely expelled out of the building.

This water heater is factory preset for NATURAL GAS

but may be field converted for use with propane.

For propane conversion, refer to the Propane (LPG)

Conversion section of this manual. Connecting the

water heater to any other gas supply can result in

property damage, serious injury, or even death.

This water heater is suitable for use in potable water

heating applications. The cold and hot water fittings on

the top of the water heater MUST NOT be connected to

any heating system.

The water heater temperature is factory set to 120°F

(49°C). Hot water temperatures above 125°F can cause

severe burns instantly or death from scalds. If the

proposed water heater outlet temperature is to be set

above 125°F, installation of a thermostatically controlled

(or temperature limiting) mixing valve is recommended

for all hot water going to faucets to avoid the risk

of scalding. Examples include commercial applications

where 140°F (60°C) is often needed or if the space

heating temperature required is higher than the domestic

hot water. Always check the temperature of the hot

water before bathing, showering, washing, etc.

Protect against snow and debris accumulation around

the vent terminations. Regularly inspect the exhaust

vent pipe and the air intake pipe to ensure they remain

clear from obstructions at all times.

3 iN401 - iN501 Safety

May2019-Revision00

CAUTION

Make sure you know the location of the gas shut-off

SAFETY

INSTRUCTIONS

valve and how to operate it. Immediately close the

gas shut-off valve if the water heater is subjected to

fire, overheating, flood, physical damage, or any other

damaging condition that might affect the operation of

the unit. Have the water heater checked by a qualified

technician before resuming operation.

If the water quality is known to have high acidity and/

or high hardness, water treatment is recommended.

Consult the local water authority.

DO NOT use this appliance if any part has been under

water.

DO NOT reverse the cold water and gas connections as

this will damage the gas valve.

DO NOT overtighten fittings as damage may occur,

causing internal leakage.

The appliance should be located in an area where leakage

within the unit or at its connections will not result in

damage to the surrounding area. The manufacturer

will not be responsible for any damage resulting from

leaking if adequate drainage is not provided.

iN401 - iN501 Safety 4

May2019-Revision00

3. Technical Specifications

3.1 Specifications Chart

Technical Data

Type Indoor, Floor-Mounted

Fuel Preset for natural gas but convertible to propane

Minimum Input (BTUs/hour) 30,000

Maximum Input (BTUs/hour) 399,999 499,999

Maximum Output (BTUs/hour) 375,999 469,999

Thermal Efficiency 94%

Turn Down Ratio (TDR) 13.3:1 16.7:1

Water Inlet / Outlet Connection 1-1/2” NPT

Gas Inlet Connection 1-1/2” NPT

Condensate Drain Connection 3/4” PVC

Maximum Condensate Flow Rate (GPM) 2.8 3.6

Dimensions H X W X D (inches) 67.5 X 20 X 20 (15.6 cu. ft)

Service Clearances 1” on all sides, 6” on top, 12” in front (Required for proper service)

Weight (lbs) 345

Venting Type

Venting Materials (USA) Sch. 40 PVC, Sch. 40 CPVC, Polypropylene, Stainless Steel (AL29-4C)

Venting Materials (Canada) Type BH Gas Vent Classes: II A (PVC), II B (CPVC), II C (Polypropylene), I (AL294C SS)

Venting Size (Diameter) 4”

Max 4” Vent Length – Single Pipe/Power Vent 250’ * 180’ *

Max 4” Vent Length – Two Pipe / Direct Vent 125’ * 90’ *

* Venting Note: From the maximum length above, deduct 5 ft. per 90° elbow and 2 ft. per 45° elbow.

Ignition Electronic Spark Ignition

Temperature Range 100°F – 190°F

Temperature Stability +/- 4°F

Installation Location Ambient Temperature 40°F – 130°F

Safety Flame Rod, Thermal Fuse, Overheat Prevention Device, Fan Speed Monitor, Flue Temperature Monitor, Blocked Vent Detector, Dual Flame

Water Pressure Min / Max (PSI) 30/160

NG/LP- Min. Gas Pressure (Full Fire)

NG/LP - Maximum Static Gas Pressure

Gas Pressure for Adjustments

Electrical 120V AC, 60 Hz

Power Consumption Max 9.5 Amps, 16W (Standby)

Internal Water Volume (gallons) 1

Features and Approvals iN401 iN501

Built-In Redundancy Multiple Heat Exchangers with Individual Control

Cascading

Common Venting Yes, Up to 4 Units

Heat Exchanger Expandable, Stainless 316L

Appliance Certication to ANSI Z21.10.3 ETL

SCAQMD Ultra Low Nox (under 20 PPM)

ASME HLW

Performance Specification

Hot Water Output (45°F Rise) 16.8 21.0

Hot Water Output (70°F Rise) 10.8 13.5

Hot Water Output (90°F Rise) 8.4 10.5

Hot Water Output (100°F Rise) 7.6 9.4

Hot Water Output (140°F Rise) 5.4 6.7

Warranty Heat Engine Coil – 10 years, All Other Parts – 2 years

iN401 iN501

Direct Vent (2 pipe – air intake and exhaust gas outlet), Power Vent (1 pipe – exhaust gas only)

8” W.C. for Natural Gas, 11” W.C. for Propane

Specification

Sensing

2.5” W.C.

14” W.C.

Masterless,, Automatic Rotation

Note: Due to continuous product improvements, the design and technical specifications are subject to change without notice.

5 iN401 - iN501 Technical Specifications

May2019-Revision00

3.2 Nomenclature

Exhaust Port

Pressure

Relief Valve

Hot Water Outlet

Air Intake

Gas Inlet

3.3 High Elevation Installations

For operation at elevations above 2,000 feet, the hot water

delivery capacity should be reduced by 4% for each 1,000

feet above sea level.

Clearance Requirements

In order for the water heater to operate properly and

efficiently, the clearances specified in the table below are

required.

1”

6”

(top)

Recirculation Inlet

Cold Water Inlet

1”

1”

Service Clearances. If multiple units are installed, the side clearance can be

shared between the two units.

Location Required

From

Combustibles

Top 6” (15 cm) 2” (51 cm) 6” (15 cm)

Back 5/8” (16 mm) 5/8” (16 mm) 1” (25 mm)

Sides 1” (25 mm) 1/2” (13 mm) 1” (25 mm)

Front 2” (5 cm) 2” (5 cm) 12” (31 cm)

Bottom 0” (0 mm) 0” (0 mm) 0” (0 mm)

1

Service clearances are required dimensions to allow for normal

service of the unit.

From Non-

Combustibles

12”

Service

Clearance

1

Drain

Hose

iN401 - iN501 Technical Specifications 6

May2019-Revision00

3.4 Connection Specifications

Connections

Description Specification

2

GasSupplyInletConnection 1-1/2” NPT

WaterSupplyInletConnection 1-1/2” NPT

HeatedWaterOutletConnection 1-1/2” NPT

Exhaust Gas Vent

AirIntakeInlet

1

1

4” Polypropylene

4” Polypropylene

CondensateDrainConnection 3/4”

120

Power Supply

1

Use the 4” adapter provided when using PVC or CPVC pipe.

2

Using sizes other than specified can cause damage to the water heater

VACPower, Max. 9.5A

and will void the warranty.

3.5 Exhaust Gas Standards

CO2 and CO Standards

Description CO

High Fire 9.1% to 9.3% < 200 ppm

Low Fire 9.1% to 9.3% < 60 ppm

High Fire 10.1% to 10.5% < 200 ppm

Low Fire 10.1% to 10.5% < 60 ppm

Range (%) Max. CO Level (ppm)

2

Natural Gas

Propane Gas

7 iN401 - iN501 Technical Specifications

May2019-Revision00

3.6 Overall Dimensions

1-1/2 NPT GAS INLET

4" PVC OR PP AIR INTAKE

429,00

[16.89]

4" PVC OR PP EXHAUST

ELECTRICAL ACCESS PANEL

3X 90,00

[3.54]

279,00

[10.98]

90,00

[3.54]

254,00

[10.00]

405,50

[15.96]

356,81

[14.05]

TOP

1-1/2 NPT WATER OUTLET

3/4" NPT T&P PORT

158,00

[6.22]

3X 24,00

[0.94]

60,00

[2.36]

POWER

(CABLE STRAIN RELEIF)

254,00

[10.00]

508,00

[20.00]

29,77

[1.17]

FRONT DISPLAY

3/4" PVC CONDENSATE DRAIN

REAR

134,25

[5.29]

50,80

[2.00]

102,45

[4.03]

303,11

[11.93]

50,80

[2.00]

25,00

[0.98]

54,36

[2.14]

151,55

[5.97]

SIDE

262,50

[10.33]

465,14

[18.31]

160,34

[6.31]

254,00

[10.00]

FRONT

1713,50

[67.46]

RECIRCULATION RETURN

1-1/2" NPT WATER INLET

3,99

[0.16]

3X ?15,88

[0.63]

BOTTOM

iN401 - iN501 Technical Specifications 8

May2019-Revision00

3.7 Configuration Options

Cold Water Supply

Gas Supply

Expansion

Tank

HOT WATER FIXTURES

Hot Water

Supply

LEGEND

Pressure Relief Valve

Isolation Valve

Check Valve

Pipe Coupling

Pipe Cap

Recirculation Pump

System with no storage tank and without mixing valve.

Cold Water Supply

Gas Supply

Expansion Tank

Recirculation Line

HOT WATER FIXTURES

Supply

Traditional

Tank-Type Heater

Hot Water Return

LEGEND

Pressure Relief Valve

Isolation Valve

Check Valve

Pipe Coupling

Pipe Cap

Recirculation Pump

Hot Water Return

Recirculation Line

Multiple unit system with mixing valve but no storage tank.

9 iN401 - iN501 Technical Specifications

May2019-Revision00

Cold Water Supply

Gas Supply

HOT WATER FIXTURES

Hot Water

Supply

LEGEND

Pressure Relief Valve

Isolation Valve

Check Valve

Pipe Coupling

Pipe Cap

Recirculation Pump

Expansion

Hot Water Return

Tank

Recirculation Line

Multiple unit system with mixing valve but no storage tank.

iN401 - iN501 Technical Specifications 10

May2019-Revision00

4. Quick Reference Installation Guide

Air Intake

4.1 Install the Water Heater

When installing the water heater, follow all local building

codes and the current edition of the National Fuel Gas Code

(ANSI Z223.1/NFPA 54) in the USA, or National Gas and

Propane Installation Code (CAN/CGA B149.1) in Canada.

Note: For water heater installations in Massachusetts,

refer to section, “16. Requirements for State of

Massachusetts” on page 60.

1. Select an installation location

For an interior or exterior location refer to section “5.

Preparation Before Installation” on page 13.

2. Check the quality of the water to determine if additional

treatment would be beneficial to the function and

efficiency of the water heater. For additional information

refer to section “5. Preparation Before Installation” on

page 13.

3. Make all necessary gas connections.

For additional information refer to section “6. Gas

Connection” on page 14.

4. Make all necessary venting connections.

For additional information refer to section “7. Air Intake

Inlet and Exhaust Gas Outlet Pipe Connections” on page

19.

5. Make all necessary water connections.

For additional information refer to section “8. Water

Connections” on page 28.

6. Make all necessary electrical connections.

“9. Electrical Power” on page 31.

4.2 Pre-Startup Instructions

1. Recheck the hot and cold water lines, the gas line,

condensate drain line, the fresh air inlet, and exhaust vent

to make sure they are properly connected.

Exhaust Port

Gas Inlet

Pressure

Relief Valve

Hot Water Outlet

Recirculation Inlet

Note: For additional electrical protection, the use of

a surge protection device is recommended. Damage

caused by power surges is not covered by the warranty.

7. If necessary, convert the water heater from the factory

preset of using natural gas to using propane. Refer to “11.

Natural Gas to Propane Conversion” on page 35 for

the required instructions.

8. As part of the propane conversion process, the CO

and CO values must be adjusted. This process is also

2

required when installing the water heater at altitudes over

8,000 feet. This procedure should be performed only by

a qualified technician. To check and/or adjust the CO

and CO levels, refer to “10. Adjusting CO2 Level” on page

2

32.

9. If connecting multiple units together, refer to “13.

Connecting Multiple Units” on page 48.

10. Fill out the Warranty Card and return it to Intellihot. For

a copy of the card go to “18. Product Warranty” on page

63.

Cold Water Inlet

11 iN401 - iN501 QuickReferenceInstallationGuide

May2019-Revision00

2. Open the gas supply valve, cold water valve, and hot water

valve.

5. Turn ON the power switch at the electrical junction box

and turn ON the ON/OFF switch inside the front cabinet

door. The water heater’s display panel should turn ON.

Hot

Water

Valve

Cold

Water

Valve

Gas

Valve

3. With the unit OFF, open a nearby hot water faucet and

allow the water to run through the unit until all the air is

removed from the water lines and from the water heater.

4. If multiple units are being installed, follow these

instructions for each unit.

6. Follow the instructions in this manual and on the unit’s

display screen. For additional information refer to section

“12. Operation” on page 37.

iN401 - iN501 QuickReferenceInstallationGuide 12

May2019-Revision00

5. Preparation Before Installation

NOTICE

5.1 Selecting an Indoor Installation Site

Note: When installing the water heater, follow all local

building codes and the current edition of the National

Fuel Gas Code (ANSI Z223.1/NFPA 54) in the USA,

or National Gas and Propane Installation Code (CAN/

CGA B149.1) in Canada when installing this product.

Note: For water heater installations in Massachusetts,

refer to section “16. Requirements for State of

Massachusetts” on page 60.

1. Select an interior location for the installation. Each

installation is unique; therefore, take the time to find the

best location for the water heater.

a. Install the water heater near locations that use hot

water, such as bathroom, kitchen, or laundry room

faucets.

b. Select a location that minimizes the length of the

water pipe.

c. If the distances are long or if the faucet or appliance

requires “instant” hot water, we recommend running

a recirculation line back to the water heater from the

farthest fixture.

d. Insulate the hot water supply and recirculation lines.

e. Select a location away from foot traffic and away from

areas where dust, debris, chemical agents, or other

combustible materials could accumulate.

f. Allow sufficient space for service and maintenance

access to all gas, water, and drain connections.

g. Make sure the location meets all building code

requirements.

2. Minimize the distance that the exhaust gas outlet and air

intake inlet must travel to an exterior wall.

a. The exhaust vent outlet must not be located next to

a walkway, near soffit vents, crawl space vents, or

other areas where condensate (water vapor) could

cause damage or create a hazard. Refer to the

Venting Clearance Specications section for additional

information.

b. The fresh air inlet vent must be separated from the

exhaust vent per guidelines in section “7. Air Intake

Inlet and Exhaust Gas Outlet Pipe Connections” on

page 19.

c. Contaminated or dirty air drawn into the intake pipe

can damage the water heater. The warranty does not

cover damage caused by airborne contaminants.

3. Locate the unit close to a drain and near gas and water

connections.

The water heater produces a significant amount of

condensate during normal operation and should be

located near a suitable drain where damage from a

possible leak will be minimal. Installing the water heater

in a location without a drain will void the warranty

and the manufacturer will not be responsible for any

resulting water damages that may occur. For additional

information, refer to the Condensate Line Installation

section.

4. Locate the water heater and all the water pipes in an area

where the ambient temperature always remains above

freezing.

a. When the water heater is connected to an electrical

power supply, it will automatically prevent the water

from freezing inside the unit.

b. The unit’s freeze protection system will not prevent

the water in the external piping from freezing.

In cold climates, if there is a power failure, the unit’s freeze

protection system will not operate and can result in water

freezing inside the heat engine. To prevent damage to

the water heater, turn OFF the gas supply and inlet water

valve. Drain the unit completely. Damage caused by

freezing water is not covered by the warranty.

5. Select an appropriate location for the combustion air and

exhaust pipes to exit the building, as shown in the Venting

Clearance Specications section in this manual.

6. Check the water quality.

Proper maintenance of the water heater is required to

ensure that the water meets EPA quality standards. The

following table shows the maximum contaminant levels

allowed, based on the EPA National Secondary Drinking

Water Regulations (40 CFR Part 143.3). Refer to section

“17. Warranty” on page 61 for additional information.

If you suspect that your water is contaminated in any

way, discontinue use of the water heater and contact an

authorized technician or licensed professional.

If the incoming water is known to have a high mineral

content or “hardness” (see warranty section), treatment

is recommended upstream from the water heater.

13 iN401 - iN501 Preparation Before Installation

May2019-Revision00

6. Gas Connection

WARNING

NOTICE

FIRE AND/OR EXPLOSION HAZARD

To avoid serious injury or even death, the gas line

installation and the gas line inlet pressure test must be

done by a licensed professional.

Always match the water heater with the type of gas

supplied to the unit (natural gas or propane). The water

heater is factory preset for natural gas.

Make sure the gas line pressures are within normal

limits. Pressures outside normal limits can result in

poor performance and hazardous operating conditions.

6.1 Quick Reference Installation Instructions

1. Determine fuel source; natural gas or propane as shown in

“6.2 Fuel Source” on page 14.

2. Measure gas pressure as shown in “6.3 Gas Pressure

Requirements” on page 14.

3. Install a gas pressure regulator and vent line if gas

pressure is above maximum recommendations as shown

in “6.4 Gas Pressure Regulator” on page 14.

4. Measure the length of the supply line as shown in “6.5

Length of Gas Supply Line” on page 15”.

5. Select the proper gas piping material as shown in “6.6

Gas Piping Material” on page 15.

6. Select the proper gas piping diameter as shown in “6.7

Determine Correct Gas Pipe Diameter” on page 15.

7. Install a drip leg on the gas piping as shown in “6.8 Gas

Pipe Drip Leg and Shut-off Valve” on page 15.

8. Install a manual shut-off valve as shown in “6.8 Gas Pipe

Drip Leg and Shut-off Valve” on page 15.

9. Test all gas line connections for leaks.

6.2 Fuel Source

1. Natural gas is the factory preset.

2. To convert the unit to propane, refer to the Propane

(LPG) Conversion section in this manual.

6.3 Gas Pressure Requirements

iN series water heaters are designed to operate at gas

pressures as low as 2.5” WC (at maximum firing rate). Gas

inlet pressures to each unit should not exceed 14” WC under

any condition (when unit is firing or not firing).

Do not fire (operate) the water heater until all connections

have been completed and the heat engine is filled with

water.

iN401 - iN501 GasConnection 14

May2019-Revision00

Natural Gas Static Gas Pressure

Parameters Specifications

Minimum Static Gas Pressure

RecommendedGasPressure 8”W.C.

Maximum Static Gas Pressure 14”W.C.

2.5”W.C.(non-corrugated,black

iron)

6.4 Gas Pressure Regulator

1. If

the gas inlet pressure is higher than recommended,

install a gas pressure regulator to lower gas pressure to

an acceptable level.

2. The gas pressure regulator must have the same or higher

minimum to maximum modulation range as the model it is

regulating. For example, an iN401 gas pressure regulator

should have a modulation range of 30,000 BTU/h to

399,999 BTU/h.

3. Regulators should be mounted with a minimum of 12” of

straight length pipe on either side and a recommended 6

ft from the appliance. If regulator manufacturer

recommends more distance, then follow their guidelines.

4. When multiple units are connected use a dedicated gas

pressure regulator for each unit.

5. To convert the unit to propane, refer to the Propane

(LPG) Conversion section in this manual. For additional

information refer to “11. Natural Gas to Propane

Conversion” on page 35.

6.4.1 Venting of Gas Supply Regulators

Make sure the gas supply regulator is properly vented by

following all local codes and the gas regulator manufacturer’s

recommendations.

1. The vent pipe must be at least the same size as the

regulator vent.

2. When multiple units are connected, each regulator must

have a separate vent line.

3. Vent lines must not be connected together or connected

with any other appliance requiring external venting.

4. When selecting the size, the pipe diameter must be

increased by one size for every 20 feet of pipe.

a. Each 90° elbow is equivalent to approximately:

4.5 feet for nominal pipe sizes of up to 1-1/2”

10.5 feet for nominal pipe sizes of up to 4”.

b. Each 45° elbow is equivalent to approximately:

2 feet for nominal pipe sizes of up to 1-1/2”

5 feet for nominal pipe sizes of up to 4”.

6.5 Length of Gas Supply Line

1. Make sure the length supply line is correctly sized.

a. Measure the length of the gas supply line from the

gas meter to the water heater or other appliances

requiring gas. The diameter of the pipe must be in

relation to the length.

b. The total length of gas piping, as well as fitting pressure

drop, must be considered when sizing the gas piping.

Total equivalent length should be calculated from the

meter or source location to the last heater connected.

c. Gas pipe size should be selected on the total

equivalent length. The gas volume for cfh flow will be

the input divided by the calorific value of the fuel to be

supplied.

d. Use the Gas Pipe Sizing tables in this manual or refer

to the gas line manufacturers sizing information to

determine the correct diameter for the supply pipe.

e. The diameter of the gas lines, shown in the illustration,

will vary according to the specific installation

requirements.

6.6 Gas Piping Material

1. All gas piping and components must comply with NFPA

local codes, and utility requirements minimum. Only gas

approved fittings, valves, or pipe should be utilized.

2. Standard industry practice for gas piping is Schedule 40

iron pipe and fittings. All high and low gas pressure piping

systems must comply with local utility and building codes.

3. Assembled piping should be clean of all scale, debris,

metal particles, or foreign material.

4. The piping must be supported from the floor, ceiling, or

walls and by the water heater itself.

6.7 Determine Correct Gas Pipe Diameter

Note: The water heater should be the first appliance to be

connected to the gas supply line.

1. Determine the gas requirement of the water heater(s)

and other appliances requiring gas.

2. Size the pipe diameter according to the COMBINED total

maximum BTUH volume for all the appliances as if they

were all operating at the same time. Use the “6.10 Gas

Pipe Sizing Tables” on page 17.

3. Select the proper header pipe according to the number of

units being connected together, as shown in the chart.

Header Sizing for Multiple iN Units

Number of

Heaters

Sch 40 Iron

Pipe

1 2 3 4

2” 2” 3” 3”

4. The maximum pressure drop from the source to the final

water heater must not exceed 0.3” W.C.

5. The maximum gas flow rate required is the sum of

the maximum inputs of each unit divided by the heat

of combustion of the fuel supplied at the location,

(approximately 1,030 BTU per cubic foot for natural gas

or 2,520 BTU per cubic foot for propane).

Note: The fuel supplier or utility should be consulted to

confirm that sufficient volume and normal pressure is

provided to the building at the discharge side of the

gas meter or supply pipe.

6.8 Gas Pipe Drip Leg and Shut-off Valve

1. Install a gas pipe drip leg on each water heater to prevent

dirt, condensation, or debris from entering the gas inlet.

Drip Leg

2. Local codes may require multiple units to have a full size

drip leg on the main gas supply line and one on each unit.

3. The drip leg should have a removable clean-out cap.

4. The gas pipe must not be supported by the drip leg.

5. Following local building codes when selecting and installing

a shut-off valve.

15 iN401 - iN501 GasConnection

May2019-Revision00

6. Local codes may require multiple units to have a shut-off

NOTICE

valve on the main gas supply line and one on each unit.

6.9 Connecting Gas Line to Unit

Note:Always clean the inside of the gas line of any dirt or

debris before connecting the piping to the unit.

Main Supply

Line

Manual

Manual

Shut-off

Valve

Drip

Leg

Manual

Shut-off

Valve

Shut-off

Valve

Drip

Leg

Manual

Shut-off

Valve

Manual

Shut-off

Valve

Drip

Leg

Main Supply

Line

Drip

Leg

Drip

Leg

2. Install a manual shut-off valve as described in “6.8 Gas

Pipe Drip Leg and Shut-off Valve” on page 15

Shut-off

Valve

Union

3. Install a drip leg in “6.8 Gas Pipe Drip Leg and Shut-off

Valve” on page 15.

4. Continue installing pipe to reach the main gas supply

connection.

5. Test all gas pipe connections.

a. All the gas pipe connections should be tested as

prescribed in NFPA 54.

b. In multiple unit applications, each unit should be

isolated before testing any piping system may exceed

the allowable pressure of 14.0” W.C..

1. Install a 4-5/8” OD flanged steel coupling and gasket with

a short piece of 1-1/4” NPT black pipe.

Do not fire (operate) the water heater until all connections

have been completed and the heat engine is filled with

water.

iN401 - iN501 GasConnection 16

May2019-Revision00

6.10 Gas Pipe Sizing Tables

This information is for reference only. Refer to gas pipe manufacturer specifications for actual delivery capacity. Contact the

local gas supplier for actual BTU/ft3 rating. This data copied from the National Fire Protection Association Article 54 (NFPA

54).

Pipe Sizes and BTU/h Capacity (NATURAL GAS). Use this table for static gas pressure

LESS THAN 5” W.C.

Length

including

fittings (feet)

10 360,000 678,000 1,390,000 2,090,000 4,020,000 6,400,000 11,300,000 23,100,000

20 247,000 466,000 957,000 1,430,000 2,760,000 4,400,000 7,780,000 15,900,000

30 199,000 374,000 768,000 1,150,000 2,220,000 3,530,000 6,250,000 12,700,000

40 - 320,000 657,000 985,000 1,900,000 3,020,000 5,350,000 10,900,000

50 - 284,000 583,000 873,000 1,680,000 2,680,000 4,740,000 9,660,000

60 - 257,000 528,000 791,000 1,520,000 2,430,000 4,290,000 8,760,000

70 - 237,000 486,000 728,000 1,400,000 2,230,000 3,950,000 8,050,000

80 - 220,000 452,000 677,000 1,300,000 2,080,000 3,670,000 7,490,000

90 - 207,000 424,000 635,000 1,220,000 1,950,000 3,450,000 7,030,000

100 - - 400,000 600,000 1,160,000 1,840,000 3,260,000 6,640,000

125 - - 355,000 532,000 1,020,000 1,630,000 2,890,000 5,890,000

150 - - 322,000 482,000 928,000 1,480,000 2,610,000 5,330,000

175 - - 296,000 443,000 854,000 1,360,000 2,410,000 4,910,000

200 - - 275,000 412,000

Note: BTU/h capacities are based on specific gravity of 0.6, pressure drop of 0.5” WC

3⁄4" 1" 1-1/4" 1-1/2" 2" 2-1/2" 3" 4"

794,000 1,270,000 2,240,000 4,560,000

Pipe Sizes and BTU/h Capacity (NATURAL GAS). Use this table for static gas pressure

GREATER THAN 5” W.C.

Length

including

fittings (feet)

10 404,000 949,000 1,787,000 3,669,000 5,497,000 10,588,000 16,875,000 29,832,000 43,678,000

20 286,000 652,000 1,228,000 2,522,000 3,778,000 7,277,000 11,598,000 20,503,000 30,020,000

30 233,000 524,000 986,000 2,025,000 3,034,000 5,844,000 9,314,000 16,465,000 24,107,000

40 202,000 448,000 844,000 1,733,000 2,597,000 5,001,000 7,971,000 14,092,000 20,632,000

50 - 397,000 748,000 1,536,000 2,302,000 4,433,000 7,065,000 12,489,000 18,286,000

60 - 360,000 678,000 1,392,000 2,085,000 4,016,000 6,401,000 11,316,000 16,569,000

70 - 331,000 624,000 1,280,000 1,919,000 3,695,000 5,889,000 10,411,000 15,243,000

80 - 308,000 580,000 1,191,000 1,785,000 3,437,000 5,479,000 9,685,000 14,181,000

90 - 289,000 544,000 1,118,000 1,675,000 3,225,000 5,140,000 9,087,000 13,305,000

100 - 273,000 514,000 1,056,000 1,582,000 3,046,000 4,856,000 8,584,000 12,568,000

125 - 242,000 456,000 936,000 1,402,000 2,700,000 4,303,000 7,608,000 11,139,000

150 - 219,000 413,000 848,000 1,270,000 2,446,000 3,899,000 6,893,000 10,093,000

175

200 - - 353,000 726,000 1,087,000 2,094,000 3,337,000 5,900,000 8,638,000

Note: For 1/2” line BTU/h capacities are based on specific gravity of 0.6, pressure drop of 4.6” WC and 5.0” WC. For all other line sizes, capacities are

based on specific gravity of 0.6, pressure drop of 3.0” WC

1/2" 3⁄4" 1" 1-1/4" 1-1/2" 2" 2-1/2" 3" 4"

- 202,000 380,000 780,000 1,169,000 2,251,000 3,587,000 6,342,000 9,285,000

17 iN401 - iN501 GasConnection

May2019-Revision00

Pipe sizes and BTU/h capacity (PROPANE). Use this table for static gas pressure

GREATER THAN 5” W.C.

Length

including

fittings (feet)

10 409,000 608,000 1,150,000 2,350,000 3,520,000 6,790,000 10,800,000 19,100,000 39,000,000

20 289,000 418,000 787,000 1,620,000 2,420,000 4,660,000 7,430,000 13,100,000 26,800,000

30 236,000 336,000 632,000 1,300,000 1,940,000 3,750,000 5,970,000 10,600,000 21,500,000

40 204,000 287,000 541,000 1,110,000 1,660,000 3,210,000 5,110,000 9,030,000 18,400,000

50 - 255,000 480,000 985,000 1,480,000 2,840,000 4,530,000 8,000,000 16,300,000

60 - 231,000 434,000 892,000 1,340,000 2,570,000 4,100,000 7,250,000 14,800,000

80 - 212,000 400,000 821,000 1,230,000 2,370,000 3,770,000 6,670,000 13,600,000

100 - - 372,000 763,000 1,140,000 2,200,000 3,510,000 6,210,000 12,700,000

125 - - 349,000 716,000 1,070,000 2,070,000 3,290,000 5,820,000 11,900,000

150 - - 330,000 677,000 1,010,000 1,950,000 3,110,000 5,500,000 11,200,000

175 - - 292,000 600,000 899,000 1,730,000 2,760,000 4,880,000 9,950,000

200 - - 265,000 543,000 814,000 1,570,000 2,500,000 4,420,000 9,010,000

Note: The line BTU/h capacities are based on specific gravity of 1.5, pressure drop of 0.5” WC.

1/2" 3⁄4" 1" 1-1/4" 1-1/2" 2" 2-1/2" 3" 4"

iN401 - iN501 GasConnection 18

May2019-Revision00

7. Air Intake Inlet and Exhaust Gas Outlet Pipe Connections

DANGER

WARNING

CAUTION

WARNING

3. Determine the straight line distance and the number of

elbows required to route the air intake inlet and exhaust

gas outlet pipes to their termination point.

Improper venting of the water heater will result in

excessive levels of carbon monoxide, which can lead to

severe personal injury or death. This water heater must

be vented in accordance with the “Venting of Equipment”

section of the latest edition of the ANSI Z223.1 / NFPA

54 (Natural Fuel Gas Code) in the USA, or in Canada

refer to the “Venting Systems and Air Supply for

Appliances” section in the latest version of CAN/CGA

B149.1 (Natural Gas and Propane Installation Code), and

all applicable local building codes. Vent installation

should be performed only by a licensed professional.

“7.6 Intake Air Inlet and Exhaust Gas Outlet Pipe

Diameter and Length” on page 24.

4. Determine the diameter of pipe required to properly bring

in intake air and vent exhaust gas.

“7.6 Intake Air Inlet and Exhaust Gas Outlet Pipe

Diameter and Length” on page 24.

5. Verify the location of the air intake inlet and exhaust gas

outlet terminations are within state and local codes.

“7.7 Venting Clearance Specifications” on page 25.

6. Select an approved material for the air intake inlet piping.

“7.8 Exhaust Gas Outlet Pipe Materials” on page 26.

7. Select an approved material for the exhaust gas outlet

piping. “7.9 Air Intake Inlet Pipe Vent Materials” on page

26.

BREATHING HAZARD

CARBON MONOXIDE GAS

Do not operate flood damaged water heaters.

•

Install venting system according to the

•

required codes and material manufacturers

specifications.

Do not obstruct fresh air intakes or exhaust

•

outlets. Adequately support all vent system

piping.

Do not place vapor emitting products near

•

water heater or air intake.

•

Place working carbon monoxide detectors

outside each sleeping area.

Do not operate the water heater before

•

properly installing the exhaust outlet.

•

Visually inspect the vent system and

eliminate any possible area where

condensation could create a blockage of

intake or exhaust air.

Breathing concentrated levels of carbon

monoxide, even for a short period of time, will

cause brain damage and can even lead to

death.

7.2 Typical Single Unit Air Intake Inlet and

Exhaust Gas Outlet Pipe Installation

1. Select one of the two venting configurations: two pipes

(direct vent) configuration or with one pipe (power vent)

configuration.

2. Select the desired termination location and make sure

each pipe terminates within all local and state codes.

3. Select the desired material for the air intake inlet and

exhaust gas outlet pipes.

This water heater has a factory preset control to limit

the exhaust gas temperature to 149°F (65°C) when

the PVC is selected in the “Flue Type” programming

section. As a result, the water heater can be vented

with Schedule 40 PVC. If the incoming (or recirculation

return) water temperature does not exceed 150°F

(66°C), the exhaust gas temperature will not exceed

149°F (65°C).

Note: This water heater falls into the Category IV appliance.

7.1 Quick Reference Installation Guide

1. Select the desired type of venting system: Two Pipe Vent

System (Direct) or Single Pipe Vent System (Power).

“7.3 Two Pipe Vent System (Direct Vent)” on page 20.

“7.4 Single Pipe Venting System (Power Vent)” on page

22.

2. Select the desired termination of the air intake inlet and

exhaust gas outlet pipe; outside wall or roof.

“7.3.3 Side Wall Air Intake Inlet and Exhaust Gas Outlet

Pipe Termination” on page 21.

“7.3.4 Roof Air Intake Inlet and Exhaust Gas Outlet Pipe

Termination” on page 22.

When the unit is set for CPVC (polypropylene pipe),

flue temperatures can reach 190°F (88°C). PVC pipe

will melt at temperatures above 149°F (65°C) and could

therefore result in a fire. Make sure the setting and the

type of material being used for the flue are compatible.

For this application use Schedule 80 CPVC or Approved

Polypropylene in the USA or Type BH Special Gas Vent

Class IIB (CPCV) or Class IC (Polypropylene) that

conforms to ULC-S636 in Canada.

19 iN401 - iN501 AirIntakeInletandExhaustGasOutletPipeConnections

May2019-Revision00

SAFETY

INSTRUCTIONS

SAFETY

INSTRUCTIONS

7.3 Two Pipe Vent System (Direct Vent)

On multiple unit installations, the air intake inlet and

exhaust gas outlet piping from each water heater must

be connected into the properly-sized common piping.

Use the table in “7.6 Intake Air Inlet and Exhaust Gas

Outlet Pipe Diameter and Length” on page 24 to

determine the diameter of the common connecting

piping between each individual water heater.

4. Determine the length and corresponding diameter for the

air inlet pipe and route the pipe to the desired termination

location.

a. For termination of the pipe to the outside, continue

installing the required pipe to a suitable outside

location. Glue all connections, making sure the joints

are sealed airtight.

b. Install suitable pipe support hangers every 4 to 5 feet,

or as local building codes require.

IH-39

7.3.1 Single Unit Configurations

The water heater can be directly vented without any

modification using a 4 inch diameter pipe.

The following diagrams represent some typical direct venting

configurations and are included to assist in designing the

vent system. Possible configurations are not limited to the

following diagrams.

Exhaust

Intake

Air

Exhaust

c. To configure the unit for power vent, insert a 3’

section of 3” pipe.

5. Determine the length and corresponding diameter for the

exhaust gas outlet pipe and route it to a suitable outside

location.

a. Glue all connections, making sure the joints are sealed

airtight.

b. Install all horizontal exhaust gas outlet piping with a

minimum 2 degree (1/4” per foot) slope back toward

the water heater. This allows any condensate that

accumulates in the exhaust gas outlet pipe to properly

drain back into the unit.

c. Install suitable pipe support hangers every 4 to 5 feet,

or as local building codes require.

Do not connect any other appliance vents to the water

heater inlet or outlet pipes.

6. If multiple units are installed, make sure the diameter of

the connecting exhaust gas outlet pipe is properly sized

for the number of units being installed.

Intake

Air

Exhaust

Intake

Air

iN401 - iN501 AirIntakeInletandExhaustGasOutletPipeConnections 20

May2019-Revision00

7.3.2 Multiple Units Configurations

18” - 36” or over 72”

When more than one unit is installed, refer to “7.6 Intake Air

Inlet and Exhaust Gas Outlet Pipe Diameter and Length” on

page 24.

Connecting multiple units together requires proper sizing of

the air intake inlet and exhaust gas outlet pipes. Up to four

water heaters can be connected (cascaded) together. Units

which share a common vent must be connected together in

a cascading configuration, as described in “13. Connecting

Multiple Units” on page 48.

The following diagrams represent some typical direct venting

configurations and are included to assist in designing the

vent system. Possible configurations are not limited to the

following diagrams.

Exhaust

7.3.3 Side Wall Air Intake Inlet and Exhaust Gas

Outlet Pipe Termination

1. Terminate the air intake inlet pipe with a 90° elbow

(angled down). Use a flange and PVC screen (not

supplied).

2. Terminate the exhaust gas outlet pipe on the exterior wall

at least 12” above ground and at least 18” away from the

air intake inlet pipe, or as required by local building codes.

In areas of high snow fall, protect the vent terminations

from blockage. Use a flange and PVC guard.

Exhaust

Intake Air

Intake

Air

Exhaust

Intake

Air

Exhaust

IQ-020

Single unit.

See

Note A

Exhaust

Intake Air

IQ-020a

Multiple units.

Note A: The distance between any exhaust gas outlet and

air intake inlet pipe should be between 18 and 36

inches apart. If this minimum specification cannot

be met, the air intake inlet and exhaust gas outlet

pipes should be 72 inches apart or more.

3. To avoid moisture and frost build-up to openings on

adjacent homes, use 45° elbows, 90° elbows, or tees

for the vent termination to direct the exhaust gas fumes

away from the building.

Intake

Air

21 iN401 - iN501 AirIntakeInletandExhaustGasOutletPipeConnections

May2019-Revision00

7.3.4 Roof Air Intake Inlet and Exhaust Gas Outlet

Pipe Termination

Venting the unit through the roof is also an option. With this

installation method, the terminations must extend at least 12”

over maximum potential snow levels, or as required by local

building codes. In areas of high snow fall, protect the vent

terminations from blockage.

Terminate the air intake inlet pipe with a 90° elbow (angled

down). A suitable roof flashing and vent cap (not supplied)

should be installed.

7.4 Single Pipe Venting System (Power Vent)

7.4.1 Single Unit

The following illustrations represent some typical power

venting configurations and are included to assist in designing

the vent system. Possible configurations are not limited to

these designs.

Single unit.

Exhaust

12” USA or

18” Canada

over maximum

snow level or

as required by

local code

3’ Minimum

Exhaust

See

Note A

12” Minimum

12” USA or

18” Canada

over maximum

snow level or as

required by local

code

Intake Air

Intake

Air

Exhaust

Intake

Air

Exhaust

Exhaust

Intake

Air

Intake

Air

Intake Air

Multiple units.

Note A: The distance between any exhaust gas outlet and

air intake inlet pipe should be between 18 and 36

inches apart. If this minimum specification cannot

be met, the air intake inlet and exhaust gas outlet

pipes should be 72 inches apart or more.

iN401 - iN501 AirIntakeInletandExhaustGasOutletPipeConnections 22

May2019-Revision00

Intake

Air

Exhaust

Intake

Air

Intake

Air

7.4.2 Multiple Units

When installing multiple units, refer to “7.6 Intake Air Inlet

and Exhaust Gas Outlet Pipe Diameter and Length” on page

24.

Connecting multiple units together requires proper sizing of

the air intake inlet and exhaust gas outlet pipes. Up to four

water heaters can be connected (cascading) together. Units

which share a common vent must be connected together in

a cascading configuration, as described in “13. Connecting

Multiple Units” on page 48

Exhaust

Intake

Air

Intake

Air

Intake

Air

Intake

Air

Exhaust

Exhaust

Intake

Air

Decommisioined

Air Intake and Gas Exhaust

Intake

Air

23 iN401 - iN501 AirIntakeInletandExhaustGasOutletPipeConnections

May2019-Revision00

7.5 Combustion Air Requirements

SAFETY

INSTRUCTIONS

SAFETY

INSTRUCTIONS

When using the single exhaust gas outlet pipe or power vent

method, the following table outlines the required opening

sizes for the combustion and ventilation air coming into the

room and the required CFM requirements per water heater:

Required Combustion & Ventilation Air Opening Sizes (sq. in) Per Heater Per Boiler Room:

Model Input Air Type

iN401 399,999

iN501 499,999

*Where two openings are used, one must be within 12 inches of the floor and the other opening must be within 12 inches of the ceiling of the mechanical

room.

**Where one opening is required, it must be located within 12 inches of the ceiling.

CombustionAir 72 100

VentilationAir 72 100 200 400

CombustionAir 90 125

VentilationAir 90 125 250 500

Required

CFM

openings*, direct

Do not operate the unit in an area that will draw in outside

air contaminated with high levels of dust, sawdust,

aerosols such as paint, or other airborne contaminants.

If necessary, purchase and install appropriate air screens

and follow a regular cleaning program to ensure an

adequate supply of clean, outside combustion air.

Air is drawn directly from outside into the

mechanical room

through two

or vertical

through one

opening**

125

125

through two

horizontal ducts

200 400

250 500

Air is drawn

from another

interior space

inside the

building

7.6 Intake Air Inlet and Exhaust Gas Outlet Pipe Diameter and Length

The iN401 and iN501 come factory installed with 4 inch

polypropylene (PP) venting. The following chart outlines the

maximum length of venting allowable for each model.

A vent system’s length is calculated by adding the length

of all straight runs used (both horizontal and vertical) and

then adding the equivalent lengths of each turn (90° or 45°

elbow) used in the system.

A vent system’s length must not exceed the maximum

length outlined in the chart below.

Maximum Pipe Length in Feet

Number

of Units

1

2

3

4

PV = Power Vent

DV = Direct Vent

Note:

Venting

Type

1 pipe - PV 250 180 250 250 250 250

2 pipe - DV 125 90 125 125 125 125

1 pipe - PV 82 50 250 250 250 250

2 pipe - DV 41 25 125 125 125 125

1 pipe - PV 40 250 176 250 250

2 pipe - DV 20 125 88 125 125

1 pipe - PV 250 250

2 pipe - DV 125 125

4” Diameter 6” Diameter 8” Diameter

iN401 iN501 iN401 iN501 iN401 iN501

Reduce the maximum equivalent length above by 5 feet per 90° elbow used and by 2 feet per 45° elbow used. Do not exceed the

above set limits.

Diameter, Model, and Length in Feet

iN401 - iN501 AirIntakeInletandExhaustGasOutletPipeConnections 24

May2019-Revision00

7.7 Venting Clearance Specifications

IQ-010

B

K

F

B

J

G

D

E

B

Fixed

Closed

Fixed

Closed

Operable

Gas Meter/Regulator

B

B

V

V

V

V

I

V

V

V

V

V

X

X

B

C

H

L

A

A

M

Operable

Inside Corner

Detail

Air Inside Inlet

Vent Terminal

Area Where Terminal is Not Permitted

V

X

Venting Clearance Specifications

Clearance Distance

Item Description

A Clearances above grade, veranda, porch, deck, or balcony 1 foot 1 foot

B Clearances to window or door that may be opened 1 foot** 3 feet

C Clearances to permanently closed window * *

D Vertical clearance to a ventilated soffit, eves, or overhang * *

E Clearances to unventilated soffit, eves, or overhang * *

F Clearances to outside corner * *

G Clearances to inside corner * *

H Clearances to each side of centerline extended from meter/regulator * 3 feet within a height

I Clearances to gas meter regulator vent outlet * 3 feet

J Clearances to non-mechanical air supply inlet or combustion air inlet to any other appliance 1 foot** 3 feet

Clearances to mechanical air supply inlet 3 feet above if within

K

10 feet horizontally

L Clearances to above paved sidewalk or paved driveway on public property * 7 feet

M Clearances under veranda, porch, deck, or balcony * 1 foot

*Per local/gas supplier codes. Use clearances in accordance with local building codes and local gas supplier.

** For single vent pipe/direct 4 feet (1.2 m) below or to the side of opening and 1 foot above opening.

1

In accordance with Z223.1

2

InaccordancewithCSAB149.1

Note: The vent for this appliance shall not terminate:

Over public walkways; or

25 iN401 - iN501 AirIntakeInletandExhaustGasOutletPipeConnections

Near soffit vents or crawl space vents or other areas where condensate or

vapor could create a nuisance or hazard or cause property damage; or

Where condensate vapor could cause damage or could be detrimental to the

operation of regulators, relief valves, or other equipment.

USA

1

Canada

15 feet above meter/

regulator assembly

6 feet

May2019-Revision00

2

7.8 Exhaust Gas Outlet Pipe Materials

SAFETY

INSTRUCTIONS

SAFETY

INSTRUCTIONS

For Canadian installations, plastic exhaust gas outlet

piping must comply with CAN/CGA B149.1 and be

certified to the Standard For Type BH Gas Venting

Systems, ULC-S636. Components of this listed system

must not be interchanged with other vent systems

or unlisted pipes or fittings. All plastic components

and specified primers and glues must be from a single

system manufacturer and must not be intermixed with

another system manufacturer’s products.

All units come factory installed with 4 inch polypropylene

(PP) venting. A polypropylene to PVC adapter is included

with each unit to enable the use of PVC exhaust gas outlet

pipe. The maximum allowable venting distances are the

same regardless of vent material selected.

The materials listed in the tables below outline the acceptable

exhaust gas outlet pipe materials:

United States Exhaust Gas Outlet Pipe Standards

Material Description*

Exhaust

Gas

Outlet

Pipe

PVCSchedule40(ASTMD1785)

CPVCSchedule40,80

ApprovedPolypropylene

AL29-4CStainlessSteel

If the inlet/return water temperature will exceed 150°F

(66°C), do not use PVC pipe. Follow the display prompts

to set the maximum water temperature for the exhaust gas

outlet pipe material being used.

Canadian Exhaust Gas Outlet Pipe Standards

Material Description (approved to ULC-S636)**

TypeBHSpecialGasVentClassIIA(PVC)

Exhaust

Gas

Outlet

Pipe

*Note: Use of cellular core PVC (ASTM F891), cellular core CPVC, or Radel

(polyphenylsulfone) in nonmetallic venting systems is prohibited. Covering

non-metallic vent pipe and fittings with thermal insulation is prohibited.

**Note: The components (pipe, fittings, primers, and glues) must

be from a single manufacturer; do not interchange. Follow the vent

manufacturer’s certified instructions.

TypeBHSpecialGasVentClassIIB(CPVC)

TypeBHSpecialGasVentClassIIC(Polypropylene)

TypeBHSpecialGasVentClassI(AL29-4CStainless

Steel)

Do not use cellular foam core pipe to vent exhaust

gases.

This water heater has a built-in exhaust gas outlet temperature

control that limits the exhaust gas temperature to a maximum

of 149°F (65°C) for PVC pipe. In commercial applications

which require higher water temperatures, exhaust gas

temperature can reach 190°F (88°C) and require materials

such as polypropylene (PP), stainless steel (SS), or CPVC.

If the temperature approaches the upper limit, the burner

will turn off automatically to protect the vent pipe. Once the

exhaust gas temperature has dropped to a normal operating

level, the unit will automatically restart.

7.9 Air Intake Inlet Pipe Vent Materials

The air intake inlet pipe can be of any plastic or metal vent

material available. ABS, PVC, polypropylene, galvanized steel,

and/or flexible corrugated ducting are all examples. When

using a corrugated material, ensure there is no inadvertent

crimping or blockage to the air intake inlet pipe.

Refer to the table below for a list of approved materials.

United States Vent Pipe Standards

Material Description

PVCSchedule40

Vent Pipe

Material Description

Vent Pipe

Note: In addition to these charts, it is recommended to

consult the most recent edition of ANSI Z223.1/NFPA 54 or

CAN/CGA B149.1, as well as all applicable local codes and

regulations when selecting vent pipe materials.

CPVCSchedule80

ApprovedPolypropylene

Canadian Vent Pipe Standards

TypeBHSpecialGasVentClassIIA(PVC)

TypeBHSpecialGasVentClassIIB(CPVC)

TypeBHSpecialGasVentClassIIC(Polypropylene)

iN401 - iN501 AirIntakeInletandExhaustGasOutletPipeConnections 26

May2019-Revision00

7.10 Recommended Exhaust Gas Outlet Pipe

Transitions

45°

Do not direct exhaust gas from opposite directions. Use a 45 degree

transition, as shown.

3X DIA. MIN

1/4” Rise Per

Foot Run

Condensate

1/4” Rise Per

Foot Run

Drain

Condensate

Drain

Do not transition into a reducer or use a t-fitting. Transitions should always

be directed into a straight run of pipe.

Do not use 90 degree transition into a reducer or a straight pipe.

Do not use reducers in a straight run of pipe.

27 iN401 - iN501 AirIntakeInletandExhaustGasOutletPipeConnections

May2019-Revision00

8. Water Connections

NOTICE

CAUTION

WARNING

NOTICE

Note: For flow rate changes faster than 10 gpm in one

second, a water hammer arrester must be installed to

prevent damage to the water heater.

8.1 Quick Reference Installation Instructions

1. Install the hot water pipe and the pressure relief valve

(furnished with the water heater) as per “8.2 Hot Water

Connection” on page 28.

When tightening any fittings to the connections on the

water heater, care should be exercised not to overtighten

these joints and damage the unit.

2. Install the cold water pipe as per “8.3 Cold Water

Connection” on page 29.

3. Install a condensate drain line as per “8.4 Condensate

Drain Line” on page 29.

4. After installation has been completed, fill and test the

water heater for proper flow and inspect for leaks.

5. Run the hot water for a few minutes and then clean the

inlet water strainer located on the cold water inlet fitting.

This strainer must be cleaned periodically to maintain

proper water flow.

8.2 Hot Water Connection

Install and connect the hot water lines. Keep the hot water

pipes as short as possible to deliver hot water to the fixtures

quickly. If an optional hot water storage tank is required,

connect the hot water lines to this tank also.

Since each installation is different, it is up to the installer to

route the water lines using the most efficient routing. The

drawings shown here are only suggestions indicating the

items needed for the installation.

To prevent serious personal injury, do not install any

shut-off device between the water heater and the

pressure relief valve. This valve is designed to release

abnormally high pressure within the water heater in the

event of a system problem.

The pressure relief valve must be rated at 150 psi, the

maximum btu/h output of the unit, and comply with all local

building codes and standards. Do not install any restrictions

or other valves prior to the pressure relief valve.

To prevent adverse health issues, only materials (pipes,

fittings, valves, solder, etc.) that are approved for use

in potable water systems should be used.

1. Connect a 1-1/2” NPT coupler to the water heater’s hot

water connection.

2. Install a 1-1/2” union connection.

3. Install the supplied 3/4” 150 psi maximum pressure relief

valve, into the port on the top of the unit.

4. Following local building codes, install a 1-1/2” manual

shut-off valve with 1-1/2” NPT fittings.

iN401 - iN501 WaterConnections 28

May2019-Revision00

5. Install and route a discharge pipe from pressure relief

valve to within six inches of the floor and directed away

from walkways or other appliances.

a. Route the relief valve to within six inches of the floor

to prevent injury in the event of a discharge.

b. The diameter of the pipe from the relief valve must be

equal to the outlet size of the relief valve.

c. Do not use reducers in the outlet pipe.

d. Do not install any valves, restrictions, elbows, or other

blockages in the outlet pipe.

e. For multiple unit installations, the outlet piping must

not be connected together. Each pipe must be

separately routed to a suitable drain.

6. Connect the unit to the building’s hot water pipes. If

multiple water heaters are being installed, the diameter of

both the main cold water pipes and the main hot water

pipes need to be sized by an engineering professional.

7. To conserve energy, insulate all hot water pipes and

recirculation pipes.

SAFETY

INSTRUCTIONS

Do not insulate the pressure relief valve.

CAUTION

8. With the unit OFF, open a nearby hot water faucet and

allow the water to flow through the unit until all the

trapped air is exhausted from the water pipes and from

the water heater.

9. Leak test the water piping. Repair any leaks immediately.

8.3 Cold Water Connection

Install and connect the cold water pipes.

Note 1: If the incoming water is known to have a high

mineral content or “hardness” (see “17. Warranty”

on page 61), treatment is recommended

upstream from the water heater.

When the water heater is installed in a closed loop

recirculation system, and if the cold water supply pipe has

a back flow preventer, then an expansion tank should be

installed to allow for water expansion as per the diagrams in

“3.7 Configuration Options” on page 9.

To prevent adverse health issues, only materials (pipes,

fittings, valves, solder, etc.) that are approved for use

in potable water systems should be used.

Note: Isolation valve kits can be used if incoming water

treatment is anticipated (such as a water softener) due to

hardness levels or heavy usage of the unit.

6. With the unit OFF, open a nearby cold water faucet

and allow the water to flow through the unit until all the

trapped air is exhausted from the water pipes and from

the water heater.

7. Leak test the water pipes. Repair any leaks immediately.

8.4 Condensate Drain Line

Due to its efficient design, the water heater produces

condensate (water) as a normal by-product of heating the

water.

This condensate is acidic, with a pH level between 3 and 4.

Local building codes may require an in-line neutralizer, such as

the iB3001, to be installed (not included) to treat this water.

The maximum condensate flow rate is 3.6 GPH.

1. Install a 3/4” flexible hose to the hose connection on the

water heater.

a. If a floor drain is used to remove the discharge, route

the drain hose over or into the drain.

Note: Ensure that the flex tube is not pinched or kinked.

The tube should freely drain. The tube termination

should not be immersed in water.

1. Connect a 1-1/2” NPT coupler to the water heater’s cold

water connection.

2. Install a 1-1/2” union connection.

Shut-off

Valve

Union

3. Following local building codes, install a 1-1/2” manual

shut-off valve with 1-1/2” NPT fittings.

4. Connect the unit to the existing cold water pipes.

5. Connect the unit to the building’s cold water pipes. If

multiple water heaters are being installed, the diameter

of the main cold water pipe needs to be sized by an

engineering professional.

2. Follow applicable local codes and if required, install in-line

neutralizer (iB3001 )to treat the acidic condensate.