Smart. Ecient. Endless

Operation

Manual

Model: i201X

i251X

Intellihot Direct Vent Boiler/ Combination Water

heater. This product complies with ANSI Z21.13(2010) / CSA 4.9 Low Pressure Boiler and with

ANSIZ21.10.3 (2011) / CSA 4.3 Gas Water Heater. For

use as potable water heating and space heating.

Y PRESET FOR USE WITH

(POUR INSTALLATION À L'INTÉRIEUR SEULEMENT)

OR

CT

FA

TION ONLY

PRÉRÉGLAGES D'USINE POUR UTILISATION AVEC

L

m

ALLA

TURE

NATURAL GAS

Amps

GAZ NA

: . . . . . . . . . . . . . . . .

ect-Vent Automatic Instantaneous

: Btu/hr Maximu

Dir

(Type de gaz)

olt, 60 Hz, 5

FOR INDOOR INST

120 V

. . . . . . . . . . . .

(Entrer le Classement)

pe of Gas

. . . . . . . . . . . .

Ty

Btu/hr Minimum . . .

Input Rating

. . . . . . . . . . . . .

Maximum Inlet Gas Pressure:

(Pression de gaz d'arrivée maximum)

. . . . . . . . . . . . .

Minimum Inlet Gas Pressure:

(Pression de gaz d'arrivée minimum)

ter Pressure:

. . . . . . . .

Wa

Minimum Inlet Gas Pressure (for adjustments): . .

(Pression de gaz d'arrivée minimum (pour ajustements))

ter Pressure:

Wa

ciency / :

(Côté)

Energy Factor:

. . . . . . . . . . . . . . . . . .

From

Minimum Clearances

(Dégagements minimums)

Non-Combustibles

(Des non-combustibles)

2 in (50.8 mm)

5/8 in (15.8 mm)

6 in (15.2 cm)

1/2 in (12.7 mm)

12 in (30.4 cm)

146.2)

From Combustible

Construction

(D'une construction

combustible)

6 in (15.2 cm)

5/8 in (15.8 mm)

6 in (15.2 cm)

2 in (50.8 mm)

12 in (30.4 cm)

Maximum

(Pression d'eau maximum)

Minimum

(Pression d'eau minimum)

Recovery Rating: . . . . . . . . . . . . . . . . . .

(Caractéristique de recouvrement)

Thermal Effi

(Efficacité thermique / Facteur énergétique)

NOx Emissions:

(Émissions de NOx)

(Pursuant to South Coast Air Quality Management District Rule 1

(conformément au règlement 1146.2 du "South Coast Air Quality Management District)

Top of heater

(Dessus du chauffe-eau)

Back of heater

(Arrière du chauffe-eau)

Front of heater

(Avantdu chauffe-eau)

Side

Bottom of cabinet

(Côté canalisation)

r

te

eset

er Hea

y Pr

Wat

al Gas

actor

F

tur

Na

(Réglage en usine pour gaz naturel)

199,000

C. (3.20 kPa)

20,000

. . .

13.0 W.

C. (2.00 kPa)

W.

8.0

C. (2.00 kPa)

8.0 W.

150 psi (1034 kPa)

15 psi (103 kPa)

265 GPH (1003 LPH)

Up to 98% / 0.94

(Jusqu'à 98 % / 0.94)

Less than 20 ppm

(Moins de 20 ppm)

Serial Number:

(Numéro de série)

Intellihot Green Technologies Inc

2900 W. Main St.

(877) 835- 1705

Galesburg, IL 61401

info@intellihot.com

.intellihot.com

Phone:

www

Email:

b:

We

Box if

Gas

Check

Converted to

Propane

Cocher la case si converti au gaz propane

sion* to

er

nv

Field Co

opane Gas

(Chauffe-eau automatique instantané à ventilation directe)

Pr

(Conversion* sur place au gaz propane)

199,000

0

C. (2.62 kPa)

20,00

W.

10.5

C. (0.76 kPa)

C. (2.74 kPa)

3.0 W.

W.

11.0

150 psi (1034 kPa)

15 psi (103 kPa)

265 GPH (1003 LPH)

Up to 98% / 0.94

(Jusqu'à 98 % / 0.94)

Less than 20 ppm

(Moins de 20 ppm)

*Refer to Installation and Operation

manual for conversion procedure.

(Se référer au manuel d'installation et

de fonctionnement pour la procédure de

conversion.)

(Collant ETL)

ETL STICKER

.

IGT-LBL-0005-01

Certified to

NSF/ANSI 372

WARNING

If the information in these instructions is not followed

exactly, a fire or explosion could result causing

property damage, personal injury, or death.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fire department.

— Installation and service must be performed by

a qualified installer, service agency, or the gas

supplier.

AVERTISSEMENT

Assurez-vous de bien suivre les instructions données

dans cette notice pour réduire au minimum le

risque d’incendie ou d’explosion ou pour éviter tout

dommage matériel, toute blessure ou la mort.

— Ne pas entreposer ni utiliser d’essence ou

ni d’autres vapeurs ou liquides inflammables

à proximité de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ

•

Ne pas tenter d’allumer d’appareil.

•

Ne touchez à aucun interrupteur; ne pas vous

servir des téléphones se trouvant dans

le bâtiment.

•

Appelez immédiatement votre fournisseur de gaz

depuis un voisin. Suivez les instructions

du fournisseur.

•

Si vous ne pouvez rejoindre le fournisseur,

appelez le service des incendies.

— L’installation et l’entretien doivent être assurés

par un installateur ou un service d’entretien

qualifié ou par le fournisseur de gaz.

To avoid product damage, personal injury, or

even possible death, carefully read, understand,

and follow all the instructions in the Installation

and Operation manuals before installing this

product. Improper installation, adjustment, alteration, or

maintenance can cause injury, loss of life, and/or property

damage. This water heater should be installed and

serviced by a qualified technician. The lack of proper

service can result in a dangerous condition.

This manual contains safety information, installation

instructions, and maintenance procedures. It must be left

with the homeowner or placed near the water heater in

a noncombustible place. The customer should retain this

manual for future reference.

Table of Contents

1. General Information

1.1 Items Shipped With Water Heater . . . . . . . . . . . . . . . 4

1.2 Contact Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Serial Number Plate Locations . . . . . . . . . . . . . . . . . . 4

2. Safety

2.1 Safety Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Installation Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Operation

3.1 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Display Icons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Turning Water Heater ON and OFF . . . . . . . . . . . . . . 8

3.4 Resetting (Clear) Error Codes . . . . . . . . . . . . . . . . . . . 8

3.5 Setting the Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.6 Setting the Domestic Water Temperature . . . . . . . 8

3.7 Setting Space Heating Temperature. . . . . . . . . . . . . 9

3.8 Real Time Parameter Display. . . . . . . . . . . . . . . . . . . . 9

3.9 Error Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4. Programming

4.1 Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Viewing and Setting Modes of Operation . . . . . . 11

5. Maintenance

5.1 Cleaning the Inlet Water Strainer. . . . . . . . . . . . . . . 15

5.2 Draining the Water Heater . . . . . . . . . . . . . . . . . . . . . 15

5.3 Filling the Water Heater . . . . . . . . . . . . . . . . . . . . . . . 16

6. Troubleshooting

6.1 Error Code Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2 Wiring Diagram Chart . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 Operational Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7. Serviceable Parts

7.1 Electrical Components . . . . . . . . . . . . . . . . . . . . . . . . 21

7.2 Blower, Gas Valve, and Exhaust. . . . . . . . . . . . . . . . . 22

7.3 Water Lines and Fittings . . . . . . . . . . . . . . . . . . . . . . . 23

7.4 Ignition Components. . . . . . . . . . . . . . . . . . . . . . . . . . 24

Multiple Units

8.

8.1 Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. Warranty. . . . . . . . . . . . . . . . . . . .

9

Product Warranty Card . . . . . . . . . . . . .

10.

. . . . . . . . . . . . . .27

. . . . . . . .29

3 Operation

1. General Information

—

Ne

pas en

t

r

ep

oser

n

i ut

ilise

r

d

’esse

nce

o

u

n

i

d’a

u

t

r

es

vape

u

rs ou

liq

uid

e

s

i

nf

l

a

mmab

les

à

p

r

oximit

é d

e cet

appa

r

eil

o

u

d

e t

o

u

t

a

ut

r

e

a

ppar

eil.

Q

UE

FA

I

R

E

S

I

VO

US

SEN

T

EZ

UN

E

O

DE

U

R

DE

GAZ

•

Ne

pas

t

e

nt

er

d

’al

lumer

d

’app

ar

eil

.

•

Ne t

ouchez à au

c

u

n

i

nt

e

r

r

upteur

;

n

e pa

s

vous

servi

r

d

e

s té

lé

ph

o

ne

s

s

e

t

ro

u

va

n

t

d

a

ns

l

e

b

â

t

im

ent

.

•

App

elez

i

mm

édi

at

ement

votre

f

our

n

iss

e

u

r

de ga

z

d

e

pu

is

un

vois

i

n.

Sui

vez

les

i

n

s

t

ruc

tio

n

s

du fo

ur

niss

e

ur.

•

Si

vous

n

e

p

ouvez r

e

jo

in

d

r

e l

e f

o

ur

ni

s

se

ur

,

appe

l

ez

le ser

vice

d

es

i

ncend

i

es

.

—

L’in

s

t

a

ll

a

t

io

n e

t

l

’en

t

ret

ie

n

d

oivent

êt

r

e

a

s

su

r

és

p

ar

un

i

n

st

a

ll

at

e

ur

o

u

u

n ser

vice

d’en

t

r

et

ien

qu

al

if

i

é

ou p

a

r

l

e

f

ou

rn

isseur

de ga

z.

A

VERTI

SSEME

N

T

A

ssur

e

zvo

u

s d

e

b

i

en

sui

vre

l

e

s

i

n

st

r

u

ct

i

on

s

do

nnée

s

dan

s

ce

t

t

e

not

ice

pou

r

r

éd

u

i

r

e

au

m

i

nim

um

le

r

i

sq

ue

d

’

in

cen

d

ie

ou

d

’

exp

lo

si

on

o

u

p

o

ur

é

vi

t

e

r

t

out

d

o

m

m

age

m

a

t

ér

iel

,

t

out

e b

le

ssu

r

e

o

u

l

a mo

r

t

.

—

Ne

pas

entre

p

ose

r

ni u

t

il

iser

d’e

ss

e

nce o

u

ni

d

’a

utr

es

vap

eur

s

ou l

iquid

es

infla

mmab

les

à

pr

oxi

mité de cet

a

ppar

eil

o

u

de tou

t

autre

appa

r

eil

.

Q

UE

FA

IR

E

SI V

O

U

S

SEN

TEZ

UN

E

ODE

U

R DE

G

AZ

•

Ne pas t

en

t

er

d

’al

lu

mer

d’a

ppar

eil

.

•

N

e

t

ouche

z

à a

ucun i

nt

e

r

r

u

pteu

r; ne

p

as

vous

se

rvi

r

de

s

té

lé

p

ho

nes s

e t

r

o

u

van

t d

an

s

le

bâtimen

t

.

•

A

p

pele

z

imm

édia

t

em

ent

vo

t

r

e f

ou

r

nisseu

r

de gaz

d

e

puis

u

n

vo

i

s

in.

Sui

v

ez

l

e

s

in

str

u

c

t

i

on

s

du f

o

u

rnisseur

.

•

S

i

vous

ne po

uvez r

e

joind

r

e

le

fou

r

nisseur

,

app

el

ez

l

e

ser

vice

des

i

ncendi

es

.

—

L’in

s

tall

a

t

io

n e

t

l’e

ntr

etien

doi

vent

ê

t

r

e assu

r

é

s

par

u

n

inst

a

llateu

r

ou

u

n

ser

vice

d’e

n

tr

et

ien

qual

if

i

é

ou pa

r

le

fou

r

nisseur

d

e gaz

.

AV

ER

TIS

SEMENT

A

ss

ur

e

zvo

us

de bi

en

sui

vre

l

e

s i

nstruction

s

d

onné

es

dan

s

cet

te

n

ot

i

c

e

po

u

r

rédui

r

e

au

m

i

n

im

uml

e

ri

sq

u

e

d

’

i

n

cen

d

i

e

ou

d

’

e

xplo

si

on

o

u

p

ou

r

é

vi

t

er

to

u

t

d

o

m

m

age

m

a

t

ériel

,

t

o

ut

e

bl

e

ssur

e

ou

l

a

m

o

r

t.

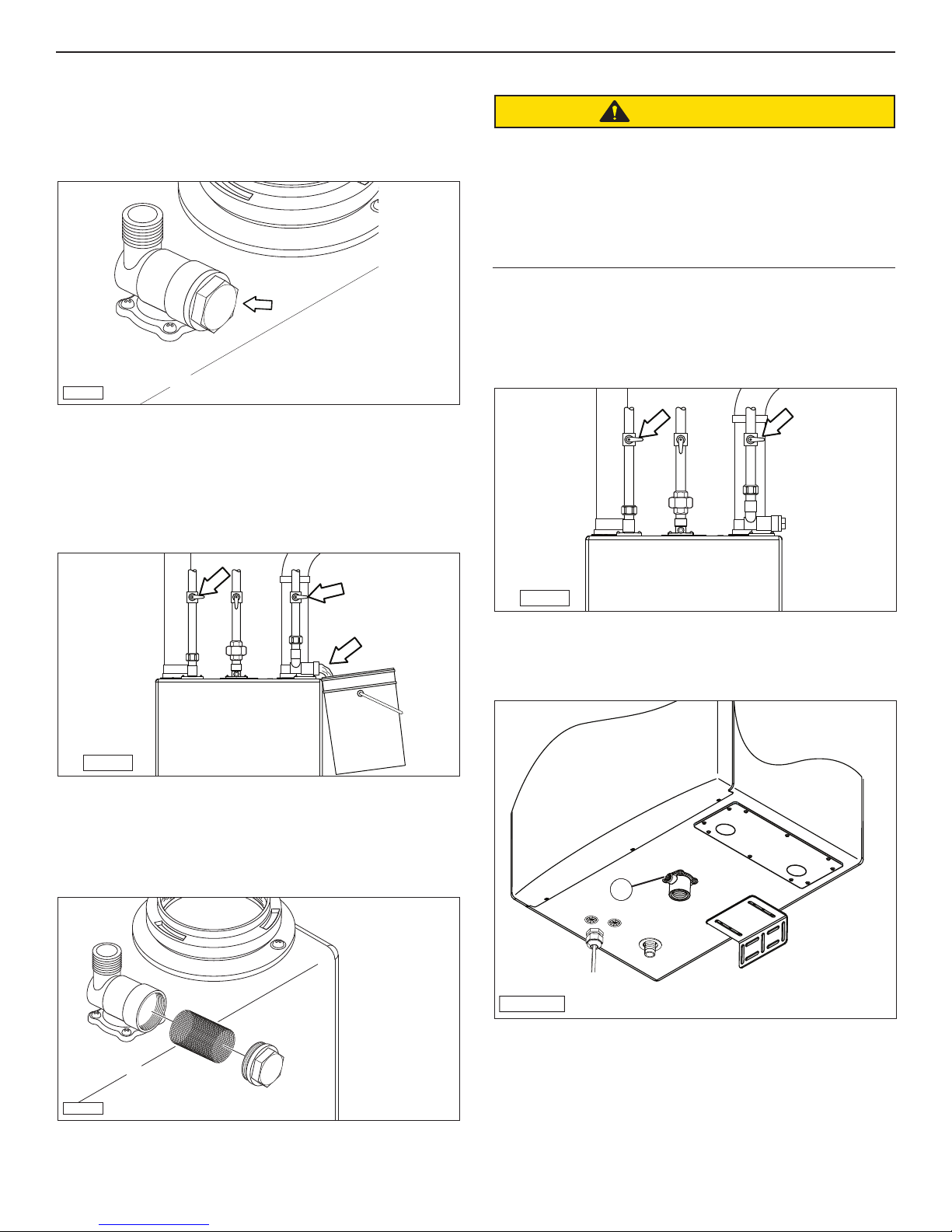

1.1 Items Shipped With Water Heater

The following items are shipped with the water heater; upper

mounting bracket (1), condensate drain (2), communication

cable (3), Operation manual (4), and Installation manual (5).

Note: Items 6 through 9 are spare parts shipped with the

unit. Two 10A bus fuses (6), electrode seal (7), O-rings

#015 (8), and 30psi relief valve (9).

5

6

7

1

S

mar

Operation

Manual

Model: i200X

i250X

Int

ellihot

heater

Direct Vent

.

(2010)

This

p

rodu

/

Boi

ANSIZ

CSA

ct complies

4.9 L

21.

use as

10.3

o

w

Pres

(2011) /

p

otable

CSA

water

heati

If

t

h

e

i

n

e

forma

WARNIN

x

a

c

tly

t

,

pr

i

o

n

o

a

p

in t

e

fi

rt

r

e o

h

y

e

da

s

e

r

ma

expl

i

n

G

str

g

e

u

,

o

c

pe

si

t

ion

—

o

r

son

n

s

D

c

i

o no

a

s

ou

l

n

i

nju

l

o

d

t

v

r

s

r

y

e

a

tore or

,

s

pors

or

u

l

d

t ca

e

o

an

a

us

t

th

her ap

d

.

e

liquids

ga

s

pliance.

oline

in t

or

h

ot

e

W

her

v

ic

H

init

A

f

la

T

•

y

T

D

o

of

O

not

t

D

his

O I

t

ry

F YOU

•

to

D

o

light any

no

SMELL

t

any

t

o

uc

appliance.

ph

h

GA

one in

an

•

y

Im

elec

me

yo

ur

t

di

rical s

n

at

build

e

e

i

g

l

y

hb

w

ing.

o

it

ins

c

c

r

a

’

h;

s

ll

t

ruc

p

do

y

h

o

t

ions.

o

ur g

n

•

e

I

.

f

F

a

y

ou

s sup

ol

l

c

o

f

annot

w

ir

e

th

p

depart

li

e

e g

r

reac

as su

me

h

yo

nt

— I

.

ur ga

n

s

t

s

allat

su

a

pplier,

ion

qu

alif

and

c

s

ied

upplier.

se

ins

r

v

ice

t

aller,

m

ust

s

erv

be

ic

pe

e

agency,

r

f

orm

or

8

SPARES

ler/ Combin

a

with

t

ion Wat

sure B

ANSI

o

er

Z21.13-

iler

4.

3 Ga

and

s Wa

with

ng a

t

nd

er Heater

spac

e

. F

h

e

or

ati

ng.

f

i

x

o

B

k

c

e

h

o

C

t

d

e

rt

e

v

n

o

s

C

a

G

e

ne

n

a

a

op

p

pr

o

z

r

ga

P

u

a

i

rt

e

nv

o

c

i

s

e

s

)

a

e

c

t

a

c

l

e

r

r

i

e

h

d

n

oc

o

C

i

t

a

l

i

t

H

n

T

ve

I

à

é

n

W

a

t

E

n

a

st

US

n

i

e

R

u

q

i

C

O

t

E

a

V

F

A

m

o

o

N

T

t

t

O

u

I

E

a

T

*

A

u

S

S

n

a

I

e

E

L

o

-

I

i

T

e

R

f

U

s

f

u

r

P

R

a

U

e

h

O

Y

v

P

(C

n

E

N

I

r

OR

S

Co

e

U

'

T

D

d

C

at

S

l

e)

E

n

s

e

)

A

G

a

i

T

A

a

F

N

op

L

F

He

E

G

G

pr

r

É

M

R

az

e

e

É

g

t

R

ULE

n

u

P

E

a

a

a

S

e

p

R

W

ac

U

l

o

p

E

r

s

r

RI

u

P

RAL GAS

u

s

t

TÉ

*

o

e

N

I

on

s

e

i

L'

s

e

À

er

r

v

an

N

P

t

O

on

I

C

T

n

(

ry

LA

a

L

t

o

t

TA

c

S

ns

N

)

a

I

l

s

ATU

I

e

L

R

F

a

ur

U

c

E

i

O

at

G

Y

R

t

n

P

(

L

l

U

0

a

az

T

N

a

g

0

r

A

0

ON

m

ur

N

,

u

o

o

t

9

p

t

9

a

AZ

ON

ne

1

u

i

I

G

N

s

T

u

A

n

A

t

e

L

e

n

g

L

.

a

e

l

A

g

.

T

é

V

-

R

.

S

(

0

t

0

N

.

I

c

0

,

.

e

R

0

)

.

s

ir

2

O

a

.

D

O

P

mp

.

k

D

A

.

N

2

I

5

6

.

.

,

0

R

2

z

.

0

(

O

H

0

.

.

,

F

C

0

9

.

6

9

W.

,

1

.

t

l

.

5

o

.

.

.

0

V

)

.

:

1

a

0

.

2

P

1

k

z)

6

0

a

7

0

g

.

0

0

,

mum

de

i

(

0

.

x

)

pe

2

y

s

a

a

T

.C

a

(

P

M

.

G

k

W

r

f

.

h

0

)

0

/

o

.

2

.

a

.

u

3

t

e

3

P

(

p

B

k

.

m

y

:

4

u

T

C

.

7

.

m

i

W

)

2

(

n

nt

i

.

0

e

.

m

C

M

3

e

.

)

s

r

1

s

a

W

h

a

l

/

P

C

.

0

u

k

.

e

t

l

.

1

0

r

e

1

0

r

.

.

t

B

n

2

g

.

E

(

(

n

i

.

.

t

C

a

.

.

)

R

.

W

a

t

.

P

u

0

.

k

)

p

.

8

a

n

4

.

I

P

3

k

.

0

.

1

.

0

.

(

0

i

:

.

.

s

e

2

.

(

r

p

.

u

.

0

s

5

.

s

1

.

W.C

re

.

)

P

0

.

a

.

s

8

P

a

.

k

G

.

.

3

t

0

.

.

e

um)

l

1

(

:

m

i

:

n

)

)

I

i

x

e

a

s

a

s

r

t

P

m

m

p

u

n

e

k

u

s

é

5

v

4

s

1

me

rri

e

im

3

t

a

r

'

0

x

s

d

)

P

a

1

z

u

j

a

(

H

s

M

i

g

d

P

a

s

a

de

L

p

G

r

n

)

t

3

o

0

o

i

e

0

f

s

5

um

l

(

s

0

1

m

e

n

i

r

1

I

)

e

n

)

(

i

P

r

(

s

)

t

m

.

u

m

n

a

H

e

e

s

é

.

P

m

v

s

k

e

.

t

e

GP

rri

imu

s

r

a

3

'

u

.

n

j

5

d

P

i

0

a

6

z

.

1

a

s

M

2

(

g

our

.

a

i

p

(

s

de

G

.

p

n

t

.

o

um

i

e

5

s

l

m

i

.

s

4

1

n

n

e

i

I

r

9

.

.

P

m

(

0

)

.

e

m

.

é

/

H

v

.

.

P

rri

.

%

mu

.

a

'

i

L

8

d

.

n

9

3

z

i

:

a

.

0

g

o

M

0

t

re

.

)

1

de

4

u

(

p

9

n

.

.

s

o

0

i

U

H

.

s

/

s

s

e

P

%

.

e

r

r

8

G

P

P

.

9

(

m

à

r

5

.

p

u'

6

e

t

q

p

.

2

a

us

0

.

J

(

W

2

.

n

.

)

m

:

4

a

u

.

9

um

h

re

.

t

m

.

0

u

i

im

x

s

/

s

x

.

s

s

a

ma

e

e

%

.

u

r

)

M

L

8

a

.

e

P

9

pm

n

d'

.

r

p

o

o

i

n

e

t

0

t

.

o

t

)

i

2

ra

4

s

e

a

e

p

.

9

s

.

d

p

e

0

r

U

W

.

O

/

P

ns

(

i

d

%

.

n

.

)

m

a

.

8

Mo

m

.

(

9

u

à

on

dure

.

i

.

m

t

e

u'

imu

.

a

c

nim

q

l

p

i

.

l

t

o

n

a

e

i

.

p

m

us

t

pr

.

J

s

n

u

(

.

M

n

0

o

a

I

i

.

on

t

e

i

o

a

.

2

s

l

t

d'

l

r

.

e

r

n

a

e

n

.

t

e

d

f

o

a

i

e

e

.

s

ins

onv

h

:

'

R

s

ur

t

c

*

d

e

g

d

r

l

é

s

or

e

P

n

f

r:

(

i

s

l

oc

t

nu

)

r

o

a

)

e

a

t

p

a

nt

nu

L

c

m

a

pm

l

R

a

a

u

p

me

r

m

a

e

u

y

0

F

r

r

.

r

2

v

po

re

y

e

.

é

ou

de

f

nt

v

g

c

e

r

e

ré

.

o

r

ns

m

i

e

e

c

e

o

.

S

n

de

(

e

M

(

.

E

:

onn

R

ue

i

/

t

q

.

i

)

t

y

s

i

.

onc

r

c

que

f

é

i

t

.

t

n

)

c

é

de

.

e

g

.

ra

i

r

on

i

.

s

Ca

ne

(

r

é

fi c

e

f

.

v

ur

E

e

.

on

t

l

c

c

.

Fa

/

.

e

rma

.

e

qu

i

.

h

)

rm

T

t

.

e

c

i

h

r

t

t

.

s

é

i

t

i

)

D

c

2

.

a

6

nt

c

i

4

:

e

f

1

f

s

m

1

E

(

n

e

ge

a

ul

o

i

n

R

a

t

s

c

M

i

s

r

y

t

t

i

s

l

i

mi

D

ua

E

Q

nt

R

r

x

i

)

me

E

A

x

O

t

ge

O

K

s

N

a

a

N

n

C

a

I

Co

de

M

T

h

t

y

t

i

S

ons

l

ou

i

s

S

L

ua

TL)

s

"

i

E

Q

u

m

r

d

i

nt

É

ET

(

A

2

a

l

.

t

6

s

ol

4

s

C

1

oa

(

1

e

C

c

nt

h

t

e

n

e

l

m

a

ou

e

r

l

ib

S

t

g

a

o

è

s

t

r

e

l

u

nt

bu

a

a

C

t

u

)

n

s

e

m

urs

m

Com

m

P

u

u

(

é

m

m

on

im

ni

orm

i

ti

n

m

nf

Fro

i

c

o

s

t

c

M

(

n

tru

e

s

m

on

i

ge

t

a

c

Con

g

u

r

é

t

D

s

(

on

c

)

e

l

une

b

i

m

D'

t

(

us

b

Fro

s

e

om

bl

c

sti

u

b

)

s

m

e

bl

)

i

t

m

c

Non-Co

.2

ombus

5

c

-

(1

n

o

n

n

i

s

6

e

D

(

r:

)

e

m

b

)

m

m

m

8

.

0

u

m

(5

.8

N

5

n

i

1

l

t

fo

l

l

o

we

d

u

s

i

ng

m

m

able

or an

y

S

not

us

e

from

a

p

p

l

i

e

r

’

s

a

ll

t

he

ed

by

t

he

ga

s

(

2

a

n

i

ri

8

/

e

)

5

e

i

r

S

é

s

)

r

de

u)

m

te

a

o

r

)

m

é

ea

e-e

m

m

f

.8

h

c

f

5

Nu

uf

(

o

2

1

.

p

n (

15

cha

(

i

u

To

8

d

/

in

5

s

6

u

s

s

e

(D

)

er

)

t

m

u)

a

m

a

m

e

c

h

2

.8

.

e-e

f

f

of

u

(50

k

(15

a

c

n

h

n

i

i

Ba

2

6

.

u c

d

c

e

n

)

I

èr

i

)

s

rr

e

m

cm

i

(A

4

m

r

g

0.

7

o

te

.

l

)

2

(3

u

o

ea

1

a

n

h

n

(

i

f

-e

n

h

2

i

o

e

c

1

ff

2

/

u

nt

1

Te

ro

ha

n

c

F

e

)

e

du

t

r

cm

n

a

4

G

.

t

0

o

(Av

3

(

h

i

.

n

l

t

i

l

e

S

2

t

1

té)

n

n

ô

i

I

a

(C

t

1

M

.

e

0

n

4

Side

W

bi

1

a

0

6

c

0

f

9

L

o

)

I

2

5

n

,

o

0

i

g

7

r

1

tom

1

sat

u

-0

i

l

-

5

b

Bot

0

5

s

na

0

3

a

le

-0

c

m

8

L

a

o

)

té

LB

c

7

G

-

ô

.

T

7

t

(C

G

8

I

ho

(

i

:

l

l

e

e

n

t

o

n

i

h

m

P

@

o

o

c

f

.

t

n

o

i

h

:

i

l

l

i

l

e

t

ma

n

i

E

w.

w

w

:

b

e

W

To avoi

e

d

ven

product dama

po

a

ssible

n

d f

p

ollow

roduct.

a

de

n

ge,

d

a

all th

Operati

th

maint

p

,

Impr

carefully

e

r

e

sona

enance

in

dama

o

o

pe

str

n

l inj

manu

r i

uctions in t

r

ge. T

can ca

e

n

u

s

a

stallation

erv

r

d

y

a

, understand,

,

his

ls

or

i

c

befor

use

ed

wat

s

erv

he Installat

by

injury

, adjustment, a

er

i

e

a

c

i

e

q

heater sh

nstalling

can re

ualied tec

,

loss

ion

sult

o

th

f lif

ould be

This

manual c

instr

u

ctions

w

it

h the

a

noncombu

ma

nual f

in

lterat

is

e

h

,

a

nic

an

dangerous con

i

ion

d/or

insta

a

n

. The

, or

property

ll

ed an

ontains safety

la

ck of pro

d

,

and

di

ti

homeo

on.

ma

per

i

inf

ntenance

o

w

r

ner

ma

stib

o

t

io

r

p

or

placed

n

le

roce

,

i

p

future r

ns

la

tallation

dures

ce.

nea

Th

efer

.

It

r

e

the

cu

ence.

m

stomer sh

ust

w

ater hea

be l

e

f

t

ould

ter

in

re

t

a

in

t

his

2

IQ-007-250X

Smar

Installation

Manual

Model: i200X

i250X

I

ntellih

h

o

e

t

Dir

ater. This

ect Ve

(2010)

n

produc

t Boile

/

ANSI

CS

A 4.9

t c

r

Z21.10.

/

omp

u

s

Low

e

a

lie

3

s

Pr

(2011)

s

pot

essur

a

b

le

/

e

CSA 4.3 Gas

wat

er hea

t

ing

and

If

t

h

e

i

n

e

fo

WARNING

x

a

rma

c

t

l

y

t

i

pr

,

o

n

o

a

p

i

n t

e

f

i

rt

re

h

y da

or

ese

mag

i

n

exp

str

e

uct

l

,

o

p

sio

e

i

—

o

r

s

n

n

o

s

D

n

c

is n

o

a

ou

l

no

i

n

l

o

d

j

t fo

u

t

r

v

s

re

y

apors

tore

,

l

s

l

o

o

u

we

r

l

t

d

c

or

e

other

ath

an

a

use gas

u

s

d

.

liquid

ap

plianc

oline

s

in t

or ot

e.

h

e

W

her

v

ic

HA

init

fla

T

•

y

D

mmable

T

of

o

O

no

t

D

h

t

O I

is or

t

ry

F

•

YOU

t

D

o

o

light an

no

SMEL

t

an

to

y

y

uc

ph

ap

L GA

h

one

plianc

an

•

y

S

I

in y

mmedi

elect

e.

o

ur build

rica

n

atel

ei

l

gh

swit

y

b

ing.

o

inst

c

r

c

all

’

h

s

; do

ructions.

y

p

h

our g

o

no

ne

•

I

t us

. F

f

a

y

o

s

ol

u

l

sup

c

o

f

a

w

ire

nnot

pl

the g

de

i

er

part

reac

fro

as

me

h

m a

y

nt

su

—

o

.

ur gas

ppl

I

n

i

stallat

e

r’

su

a

pplier,

ion

qu

and

alif

s

c

ied

u

a

se

pplier.

ll

t

ins

r

he

v

ice m

t

aller,

ust

s

erv

be

ic

per

e

ag

formed

enc

y

, or

by

th

e ga

Combination Wa

with

Boiler

d

i

ng

an

y

e

s

s

3

4

ANSI

ter

Z

21.

and

13-

w

Water

ith

sp

H

e

ate

a

ce he

r. Fo

a

r

t

ing.

f

i

x

o

B

k

c

e

h

o

C

t

d

rte

e

nv

o

s

C

a

G

e

ne

n

a

a

p

prop

o

z

r

ga

P

u

a

i

t

r

e

v

n

o

c

i

s

e

s

)

a

e

c

t

c

a

l

e

r

r

i

d

he

n

oc

o

C

i

t

a

l

i

t

H

n

T

ve

I

à

é

W

n

a

t

E

n

a

st

US

n

i

e

R

u

q

i

C

O

t

E

a

F

V

A

m

o

o

N

T

t

t

O

u

I

a

T

*

A

u

SE

S

n

a

I

e

E

L

-

o

I

i

T

e

R

U

ff

s

u

P

r

R

a

U

AS

e

h

O

Y

v

C

P

(

n

E

N

o

I

r

OR

S

C

U

'

T

te

D

d

)

C

S

l

e

E

n

A

)

e

s

G

a

i

T

p

A

F

a

N

Hea

o

L

F

r

E

G

p

G

r

É

M

z

R

a

e

e

É

LE

g

t

R

U

n

u

P

E

a

a

a

S

e

c

p

R

W

a

U

l

o

p

E

I

r

s

r

R

u

P

u

É

t

s

T

*

o

e

N

n

I

'

o

s

e

i

L

s

e

r

n

À

e

r

v

N

n

P

ta

O

o

C

TI

n

(

ry

a

TURAL G

LLA

t

o

t

s

TA

c

S

n

N

)

a

I

I

l

s

e

R

F

r

L

a

u

c

U

E

t

i

O

G

a

Y

R

t

n

P

(

L

U

z

0

a

a

T

NA

al

N

0

g

A

r

r

0

O

u

,

N

u

o

om

t

9

p

N

Z

9

a

e

A

O

n

ut

1

I

i

G

N

s

T

A

u

A

n

t

e

L

e

n

L

g

.

a

l

g

.

TA

é

Ve

-

R

.

S

(

0

t

0

N

.

c

I

0

,

.

e

R

0

r

)

.

s

i

2

O

a

p

.

D

O

P

m

.

k

D

A

N

2

.

I

5

.6

.

0

R

2

z,

.

0

(

O

H

0

.

.

,

F

C

0

9

.

6

9

.

W.

,

1

lt

.

5

o

.

.

.

0

V

)

:

1

.

a

0

.

2

P

1

k

)

z

m

6

0

7

0

u

ga

.

0

0

,

m

de

(

i

0

.

x

)

pe

2

s

a

a

C

Ty

(

P

M

k

Ga

W.

.

r

.

f

0

h

)

0

/

o

.

.

a

.2

u

3

t

e

P

3

(

p

k

B

.

m

y

:

4

u

T

C

.

7

.

m

i

2

)

W

n

nt

(

i

.

e

0

.

m

C

M

3

e

)

s

r

1

s

W.

h

a

l

/

Pa

C

.

0

k

u

.

e

l

1

0

r

.

Bt

1

0

re

.

.

nt

2

g

E

(

.

(

n

.

i

t

.

C

a

.

)

R

.

W.

a

t

P

0

u

.

.

k

)

p

.

8

n

4

.

I

Pa

3

.

k

.

0

1

.

0

(

.

0

i

:

.

.

s

2

re

(

p

.

.

u

0

s

.

C

5

.

s

1

.

W.

re

)

.

P

0

.

.

s

8

Pa

a

.

k

G

.

3

)

t

.

0

.

.

e

um

1

l

m

:

(

:

i

n

)

)

i

I

x

a

a

s

s

re

t

P

m

p

m

u

n

e

k

u

s

é

5

v

4

s

1

m

me

rri

3

i

t

a

re

'

x

0

s

d

)

P

1

a

z

u

j

a

(

H

s

M

i

g

d

P

a

s

a

L

de

p

G

r

)

t

3

on

0

o

i

e

0

f

s

5

um

l

s

0

(

1

m

e

n

i

r

1

I

)

n

)

(

P

i

re

(

s

)

m

.

u

m

nt

a

H

e

e

s

u

é

.

m

v

s

kP

e

ri

m

t

GP

r

.

i

s

re

a

3

'

u

.

n

5

j

d

0

i

a

P

6

z

1

a

.

s

M

2

g

(

.

our

a

i

p

(

s

de

G

.

p

t

.

on

um

i

e

5

s

l

m

i

.

s

4

1

n

n

i

re

9

.

I

.

P

m

(

0

)

e

m

.

.

é

/

H

v

u

.

.

P

rri

%

.

m

.

a

L

'

i

8

d

.

n

9

3

z

i

:

a

0

.

g

o

M

0

t

re

.

)

1

de

4

u

(

p

9

.

s

.

on

0

U

i

H

s

/

.

s

s

e

P

%

e

.

r

8

G

P

Pr

9

.

(

m

à

5

r

.

p

u'

6

e

q

t

p

2

.

s

a

u

0

.

J

(

2

W

.

n

.

)

m

:

4

a

e

u

.

9

h

um

r

.

t

m

0

u

i

im

.

x

s

/

s

x

a

.

s

s

a

m

e

e

%

u

.

)

M

L

8

a

.

e

m

Pr

9

p

d'

.

p

r

on

i

o

t

0

e

t

on

.

)

2

i

t

ra

4

s

a

e

p

.

9

s

.

de

p

e

0

r

U

O

W

.

/

P

ns

(

i

%

.

nd

o

.

)

m

a

.

8

M

m

(

.

9

u

u

.

à

on

dure

i

.

m

t

m

m

e

u'

i

a

.

ni

l

q

i

p

l

t

.

oc

s

n

a

r

e

.

i

m

p

t

u

p

.

J

u

(

ns

.

on

M

0

a

I

i

on

.

t

e

i

o

a

.

2

l

t

d'

l

rs

.

r

a

e

n

.

t

e

de

f

on

s

a

i

e

e

n

s

r

i

onv

h

'

.

:

s

u

c

*R

t

d

d

g

re

l

é

or

s

P

f

(

r:

in

l

s

oc

t

nue

)

r

o

a

)

e

a

t

p

a

nt

nu

m

L

a

e

c

l

pm

a

R

u

a

m

p

m

a

e

ur

0

r

F

r

2

ry

v

e

.

po

r

e

y

e

é

ou

d

f

.

nt

v

c

é

e

rg

r

.

o

re

ns

m

i

e

c

o

.

S

de

ne

(

e

M

(

E

:

.

R

ue

ionne

t

q

i

/

)

t

.

y

s

.

i

onc

r

f

c

que

é

i

t

e

.

t

n

)

c

é

d

e

g

.

ra

i

r

on.

a

i

c

.

C

ne

rs

(

é

fi

e

f

.

v

ur

E

e

.

on

t

l

c

c

.

a

Fa

/

.

e

rm

.

e

qu

i

.

h

)

rm

T

t

.

e

c

i

h

r

t

.

t

s

é

i

t

)

i

D

2

c

.

a

6

nt

c

4

i

:

e

f

1

f

s

1

m

E

(

e

n

ge

ul

o

i

na

R

a

t

s

c

M

i

s

r

i

y

t

t

i

s

l

i

m

D

ua

E

Q

nt

e

r

x

i

)

m

A

x

O

t

ge

O

s

N

N

a

na

CKER

o

a

I

C

de

M

T

h

t

y

t

S

i

ons

l

i

ou

a

s

S

L

u

TL)

s

"

i

Q

E

T

u

m

d

nt

É

E

(

Air

a

2

l

.

t

6

s

ol

4

s

C

1

oa

(

e

1

C

c

nt

h

t

n

e

e

l

a

m

ou

b

r

e

i

S

t

a

gl

o

s

t

e

rè

u

nt

u

b

a

a

Cl

u

t

m

)

s

n

s

e

m

ur

m

Co

m

u

P

u

(

é

m

n

m

m

i

m

i

o

o

n

i

i

or

r

t

m

in

F

c

onf

s

u

t

c

M

r

(

n

e

st

m

n

on

i

o

ge

t

a

c

C

g

ru

é

t

D

s

(

on

c

)

e

l

une

'

b

i

m

D

t

(

o

r

us

F

b

s

e

m

l

o

b

c

i

t

s

u

)

s

mb

e

)

bl

i

Co

t

m

n-

c

bus

.2

No

om

5

c

1

(

n-

n

i

no

s

6

e

D

(

r:

)

e

m

b

m

m

8

.

mm)

0

u

5

8

(

.

N

5

n

1

i

l

(

2

a

n

i

ri

8

/

e

)

5

e

ri

S

é

s

)

r

de

u)

e

m

t

a

o

r

a

e

é

-

m

e

e

m)

8

h

f

.

um

f

c

f

5

u

N

(

1

a

.2

(

h

5

p o

c

n

1

o

i

(

u

T

8

n

d

/

i

5

s

6

u

s

s

De

(

r

)

e

)

t

m

u

a

m)

a

m

e

c

e

h

-

8

2

.

e

.

f

f

0

5

f

o

5

u

(

(1

k

c

n

ha

i

in

c

2

Ba

6

u

.

d

c

e

n

r

I

iè

)

s

r

m)

r

m

e

c

i

A

(

m

4

r

g

.

e

0

7

t

.

lo

3

)

a

2

(

u

o

1

(

a

n

he

n

i

e

f

n

-

h

i

2

o

e

c

1

f

2

t

f

/

e

u

n

1

T

a

o

r

h

n

c

F

e

u

d

m)

t

re

c

n

a

4

G

.

v

t

0

A

o

3

(

(

h

i

.

l

t

in

l

)

S

e

2

t

1

té

n

i

In

a

(Cô

e

t

1

. M

d

e

0

i

n

i

4

S

W

b

1

a

0

6

c

0

f

9

o

IL

2

5

n)

,

m

0

io

g

t

o

7

r

t

1

a

t

1

u

-0

is

l

-

5

b

Bo

0

5

s

na

0

3

a

0

le

-

c

m

8

L

a

o

)

é

t

LB

7

G

-

.c

T

7

t

Cô

(

G

8

o

I

(

h

i

:

l

l

e

e

n

t

o

n

i

m

Ph

@

o

o

f

.c

t

in

o

h

:

l

li

i

l

a

e

t

m

in

E

.

ww

w

:

b

e

W

To

a

void

eve

pr

n

o

possible d

duct dama

and

pro

f

ollo

and O

du

e

w

ge,

ath,

ct.

all t

m

I

p

perati

aintenan

care

e

mproper

he

r

s

on

i

da

fully

nstructions in the Ins

on

al in

mag

manua

ce

re

inst

jury,

ca

e. T

service

a

d,

n

allation,

c

unde

his wa

or

ls

ause injur

befor

service can

d

by a

r

te

s

adj

tan

e

r h

i

qua

nstalli

ust

d,

talla

eater

y,

los

m

lied te

r

t

ent,

esult

io

s

should be

n

of

g

n

t

alt

li

his

Th

i

f

chnician.

n

e, and/

e

is manu

a

ration,

dange

inst

ins

or p

a

tr

The

al c

or

ro

lled a

u

r

ctio

opert

u

o

lac

with

s

n

co

ta

n

nd

k

s,

ins

ndition

of

a nonco

manua

y

and

the h

saf

prop

maintenance pr

ety information,

o

meowner o

.

er

mbusti

l for

ble

r

p

o

place

la

inst

f

cedures. I

u

ced

ture

a

lla

.

n

The

e

reference.

tio

ar

n

t

t must

he water

custom

be

er

heater in

left

sho

u

ld r

et

ain

this

1.2 Contact Information

Call us first if you have any questions about this product. We

can help you with questions about installation or operation,

or if there are damaged or missing parts when you unpack

this unit from the shipping box.

Stamp or write your dealer contact information here for future

reference.

Due to our policy of continuous product improvement and

technology, the design and/or technical specifications are

subject to change without notice.

Serial Number: ___________________________________

Date of Installation: ___ / ___ / ______

WARNING

Condensate drain line (2) is shipped from the factory with a

loop held together with plastic ties. Do not remove the ties

and/or straighten the loop. This loop forms an air block

(trap) which prevents carbon monoxide from exiting the

water heater through the drain line. Improper installation of

the drain line can result in excessive levels of carbon

monoxide, which can lead to severe personal injury or death.

1.1.1 Optional Items

1.3 Serial Number Plate Locations

Each unit’s heat exchanger module has its own ASME

certification plate (1). Rating plate (2) contains serial number

for the unit. Please provide this serial number when calling

for service or warranty.

Box if

opane

pr

Gas

Check

cte)

u gaz

e

i a

dir

ert

Converted to

ion

t

a

conv

til

si

Propane

ase

a c

é à ven

r l

Coche

stantan

n

ane)

i

prop

ersion* to

z

nv

matique

o

t

ace au ga

u au

fe-ea

f

Field Co

on* sur pl

au

(Ch

Propane Gas

)

T

onversi

C

(

LEMEN

EU

S

199,000

UR

E

I

az naturel)

g

y Preset

VEC

C. (2.62 kPa)

20,000

A

our

N

p

W.

O

I

N À L'INTÉR

ne

O

si

u

Factor

10.5

C. (0.76 kPa)

en

LLATI

TA

R UTILISAT

Natural Gas

églage

R

(

3.0 W.

UR INS

E POU

SIN

U

S D'

E

AG

L

G

FACTORY PRESET FOR USE WITH

ÉRÉ

PR

TUREL

Z NA

NATURAL GAS

A

G

Direct-Vent Automatic Instantaneous Water Heater

(Type

FOR INDOOR INSTALLA

120 Volt, 60 Hz, 5 Amps

(Ent

g

Type of Gas

Ratin

ée

Input

rriv

Rating an

(C

aractéris

d

safety inform

t

i

qu

es

et

r

ens

e

i

gnem

atio

e

n inside.

nt

s

d

e

s

é

c

u

ri

t

é

à

l

'

int

é

ri

e

ur)

d'a

az

Btu/hr Minimum . . .

g

rrivée

d'a

sion de

m Inlet Gas Pressure: . . . . . . . . . . . .

es

Maximum Inlet Gas Pressure: . . . . . . . . . . . .

ée

gaz

r

et Gas Pressure (for adjustments): . .

P

(

rriv

de

'a

n

sio

az d

m Inl

Minimu

g

es

r

e

P

(

ter Pressure:

u

m

sion d

es

Minimu

r

P

maxi

(

au

um)

mum Wa

m

sion d'e

m Water Pressure: . . . . . . . . . . . . .

es

Maxi

au mini

r

'e

P

(

ing: . . . . . . . . . . . . . . . . . .

couvr

re

sion d

es

Minimu

de

r

P

(

tique

Fac

ciency / :

/

ris

cté

ra

Recovery Rat

Ca

(

thermique

ité

ac

)

x

Thermal Effi

fic

f

E

(

de NO

oas

ns

sio

rè

NOx Emissions:

au

mis

É

nt

(

to South C

e

m

é

m

suant

or

f

n

(Pur

(co

ater

chauffe-

sus du

Top of he

Des

(

e-eau)

Back of heater

Arrière du chauffe-eau)

(

of heater

u chauff

d

ont

Fr

Avant

(

(Côté)

of cabine

ide

S

ottom

B

Côté canalisation)

(

e g

d

r le

re

maxi

mini

mini

m)

te

Air

t

emen

l

g

Minimum Clearances

eau)

t

W.C. (2.74 kPa)

(PO

11.0

199,000

C. (3.20 kPa)

20,000

TION ONLY

150 psi (1034 kPa)

m . . .

si (103 kPa)

13.0 W.

C. (2.00 kPa)

15 p

. . . . . . . . . . . . .

. . .

8.0 W.

:

C. (2.00 kPa)

)

az

seme

Clas

m)

u

m

m)

u

m

um (pour a

m

ement)

Energy Factor:

énergéti

ur

. . . . . . . . .

ty

ali

u

Q

146

t 1

a

(Dég

No

(

nt)

que)

na

a

M

du "Sou

.2

m

ge

n-Combust

s non-c

e

D

2 in (

5/8 in (15.8 mm)

6

1/2 in (12.7 mm)

12 in

: Btu/hr Maximu

te

jus

. . . . . . . . . . . . .

nt

e

m

e

g

th

s min

nt

e

From

ombu

50.8 mm)

in (15.2 cm)

(30.4 cm

)

265 GPH (1003 LP

.94

8.0W.

% / 0

1034 kPa)

98

qu'à

Up to 98% / 0.94

m)

us

p

and Op

(J

PH)

0 p

p

150 psi (

on

n

ati

in

io

all

Less than 20 ppm

d'

ers

ins de 2

el

la

v

o

n

M

(

15 psi (103 kPa)

co

to Inst

pour

r

o

nt

fer

e

l f

e

au manu

s))

R

m

nt

*

ua

er

e

n

ne

fér

m

n

ma

io

94)

ré

)

265 GPH (1003 L

e

0.

S

(

fonct

sion.

8 % /

de

onver

c

Up to 98% / 0.94

squ'à 9

m)

p

(Ju

p

20

TL)

de

E

t

n

Less than 20 ppm

Colla

(Moins

(

ETL STICKER

. . . . . . . .

)

ict

str

i

D

nt

e

m

2)

. . . . . . . . .

ge

46.

na

1

a

1

M

ty

Rule

ali

u

ble

ict

Q

str

i

t Air

D

ion

oas

n

C

io

ct

u

tr

nstruct

From Combusti

tible)

Co

cons

une

imums)

(D'

e)

combus

éri

ibles

es)

Serial Number:

6 in (15.2 cm)

uméro de s

ibl

8 mm)

N

st

(

cm)

5/8 in (15.

6 in (15.2

50.8 mm)

2 in (

Green Technologies Inc.

ot

12 in (30.4 cm)

Intellih

.com

)

ot

2900 W. Main St.

(877) 835- 1705

Galesburg, IL 61401

.intellih

Phone:

Email: info@intellihot.com

Web: www

1

2

H)

n

eratio

e.

et

n

de

edur

roc

llatio

édure

sta

oc

r

p

1

-0

T-LBL-0005

IG

An optional outdoor sensor can be purchased separately

connected to this unit (part number: IGT-SPR0074).

General Information

4

2. Safety

2.1 Safety Signal Words

DANGER

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. This signal

word is limited to the most extreme situations.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

NOTICE

Indicates that equipment or property damage can result if

instructions are not followed.

SAFETY

INSTRUCTIONS

Safety instructions (or equivalent) signs indicate specific

safety-related instructions or procedures.

Note: Contains additional information important to a

procedure.

2.2 Installation Warnings

WARNING

DO NOT use this water heater for any purpose other than

water heating.

Read, understand, and follow the Installation and Operation

manuals, including all warnings and precautions, before

operating this water heater. If you do not follow these

instructions exactly, a fire or explosion may result, causing

property damage, personal injury, or loss of life.

Follow all local codes and the most recent edition of the

National Fuel Gas Code (ANSI Z223.1/NFPA 54) in the USA or

the Natural Gas and Propane Installation Code in Canada

(CSA B149.1).

This water heater must be installed by a licensed plumber,

gas fitter, and/or professional service technician. Installation

by unqualified person(s) voids the warranty.

DANGER

A. This water heater does not have a pilot. It is equipped

with an ignition device which automatically lights the

burner. Do not try to light the burner manually.

B. BEFORE OPERATING, smell all around the water heater

area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire or

police department.

C. Use only your hand to turn the manual gas shut-off

valve. Never use tools. If manual gas shut-off valve will

not turn by hand, don’t try to repair it. Call a qualified

service technician. Force or attempted repair may

result in a fire or explosion.

WARNING

DO NOT use or store flammable liquids around the water

heater, including gasoline, oils, spray paints, etc.

DO NOT operate this water heater unless it is properly

vented to the outside (the exhaust vent piping must be

connected from the unit directly to the outside). Improper

venting can cause a build-up of carbon monoxide, which

can result in brain damage or death. Exhaust gases must

be completely expelled out of the building.

This water heater is factory preset for NATURAL GAS but

may be field converted for use with propane. For propane

conversion, refer to the Propane (LPG) Conversion section

of this manual. Connecting the water heater to any other

gas supply can result in property damage, serious injury,

or even death.

This water heater is suitable for use in potable water

heating applications. The cold and hot water fittings on

the top of the water heater MUST NOT be connected to any

heating system.

The water heater temperature is factory set to 120°F

(49°C). Hot water temperatures above 125°F can cause

severe burns instantly or death from scalds. If the

proposed water heater outlet temperature is to be set

above 125°F, installation of a thermostatically controlled

(or temperature limiting) mixing valve is recommended for

all hot water going to faucets to avoid the risk of scalding.

Examples include commercial applications where 140°F

(60°C) is often needed or if the space heating temperature

required is higher than the domestic hot water. Always

check the temperature of the hot water before bathing,

showering, washing, etc.

Protect against snow and debris accumulation around the

vent terminations. Regularly inspect the exhaust vent

pipe and the air intake pipe to ensure they remain clear

from obstructions at all times.

5 Safety Section

CAUTION

Make sure you know the location of the gas shut-off valve

and how to operate it. Immediately close the gas shut-off

valve if the water heater is subjected to fire, overheating,

flood, physical damage, or any other damaging condition

that might affect the operation of the unit. Have the water

heater checked by a qualified technician before resuming

operation.

If the water quality is known to have high acidity and/or

high hardness, water treatment is recommended. Consult

the local water authority.

SAFETY

INSTRUCTIONS

DO NOT use this appliance if any part has been under

water.

DO NOT reverse the cold water and gas connections as this

will damage the gas valve.

DO NOT overtighten fittings as damage may occur, causing

internal leakage.

The appliance should be located in an area where leakage

within the unit or at its connections will not result in

damage to the surrounding area. The manufacturer will

not be responsible for any damage resulting from leaking

if adequate drainage is not provided.

Safety Section 6

3. Operation

3.1 Control Panel

G

F

Mode

Time

E

D

A) LCD screen

The LCD display screen shows all information about the

operating functions of the water heater.

A

B) Arrow keys

Press the UP or DOWN arrows to adjust the value of the

selected feature, such as time or water temperature.

C) Enter button

To return to the Main or Home screen.

B

D) Power button

When the water heater is initially connected to an electrical

Enter

Power