Page 1

Intell-Print Thermal Printer

OM7212

A Higher Level of Precision…

A Higher Level of Performance

User Operation Manual

Page 2

Page 3

WARNINGS

x Do not subject your printer to excessive force or shock such as treading on it, dropping it, or hitting it.

x Do not install your printer in locations with poor ventilation or in locations in which the air contains salt or toxic gases.

x Do not use your printer at a voltage other than the specified voltage or at frequencies other than the specified frequencies.

x Only power the printer with the supplied adapter and specified battery.

x Do not insert or remove the power cable or interface cable by pulling on the cable.

x Do not drop or insert foreign objects like paper clips, pins, etc. into the equipment. In such case remove the object, if

accessible, or contact your reseller for help.

x Do not attempt to disassemble or modify your printer. Any such unauthorized action will void the warranty and may cause a

fire hazard or electric shock.

x Do not spill or s pray any liquids onto the printer. In such case, immediately turn off the power, remove the power supply

cable, and contact your reseller for help.

x Do not plug in your printer to a receptacle and/or power-strip with too many other devices on the s ame circuit.

Page 4

ELECTRONIC EMISSION NOTICES

FEDERAL COMMUNICATIONS COMMISSION (FCC) STATEMENT

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy, and if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more

of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult your authorized reseller or service representative for help.

Properly shielded and grounded cables and connectors must be used in order to meet FCC emission limits. Proper cables and

connectors are available from OMNIPrint authorized dealers.

INDUSTRY CANADA CLASS A EMISSION COMPLIANCE STATEMENT

This Class A digital apparatus meets all the requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

EUROPEAN UNION – EMISSION DIRECTIVE

This product is in conformity with the protection requirements of EU Council Low Voltage Directive 73/23/EEC and

Electromagnetic Compatibility Directive 89/336/ECC on the approximation of the laws of the member states of the EEC

Commission.

Intelligent Weighing Technology, Inc. cannot accept responsibility for any failure to satisfy the protection requirements resulting

from a non-recommended modification of the product.

This product has been tested and found to comply with the limits for Class A Information Technology Equipment according to

CISPR 22 / European Standard EN 55022. In a domestic environment this product may cause radio interference in which case

the user may be required to take adequate measures.

Page 5

1 INTRODUCTION ......................................................................................................7

Table of Con tents

1.1 Features......................................................................................................7

2 SPECIFICATIONS .............................................................................................8

2.1 General Specifications .................................................................................8

3 Setting up the printer ..........................................................................................9

3.1 Unpacking....................................................................................................9

3.2 Selecting a Place ........................................................................................9

3.3 Connecting the Power Adapter ............................................................................................................10

3.4 Bat t e r y ......................................................................................................................................................................10

3.4. 1 Operat i o n W it h o u t a B a t t e r y P ack ................................................................................ 10

3.4. 2 Operat i o n W it h a Batt e r y P ack ........................................................................................10

3.4.3 Charging procedure ................................................................................................................. 10

3.4. 4 Repla c i n g th e B a t tery P a c k ................................................................................................. 12

3.5 Connecting the Interface Cable .......................................................................................................... 13

3.5.1 Serial Interface Cable: OM7212-S ................................................................................. 13

3.6 Loading Paper .................................................................................................................................................. 14

3.7 At t a c h i n g the B e l t Cl i p .................................................................................................................................15

4 External Appearance ................................................................................................ .............................................16

5 Control Panel ................................................................ ...............................................................................................17

6 Running the Self Test................................................................................................ .............................................17

7 Ac c e ssor i e s ................................................................................................................................................................... 18

8 Co m m u nic at i o n s Inte r f a c e s ................................ ...............................................................................................19

8.1 RS23 2 ....................................................................................................................................................................... 19

8.1. 1 Seri a l I nterf a c e S p ecif i c a t i o ns ......................................................................................... 19

8.1.2 RJ12 Connector Pin Assignment: .................................................................................19

8.2 Inf r a r e d ( IR) T r a n s m issi o n ....................................................................................................................... 19

8.2. 1 Guid e l i n e s fo r I R Commu n i c a t i o n ...................................................................................19

8.3 Blu e t o o t h ................................................................................................................................................................ 20

8.3. 1 Blu e t o o t h Devi c e A d dress ( B D Addre s s ) .................................................................20

8.3. 2 Blu e t o o t h Devi c e N am e ( B D N am e) ........................................................................... 20

8.3.3 Maximum Simultaneous Connections ........................................................................ 20

8.3. 4 PI N C o d e ............................................................................................................................................ 21

8.4 802.11b (Wireless Ethernet) .................................................................................................................21

8.4.1 802.11b Configuration Description ................................................................................ 21

8.4. 2 TCP / I P P rotoc o l C o n f igu r a t i o n Des c r i p t i o n ........................................................... 21

8.4.3 802.1 1b Network Identification Name .......................................................................22

8.4.4 Name Resolution Issues (Attention: Network Administrators) ..........22

9 Us e r -Co n f i g u r a b le P r i n t er S e t t i n gs ............................................................................................................ 24

9.1 Sleep Timeout Duration..............................................................................................................................24

9.2 Pri n t D a rk nes s................................................................................................................................ ....................24

9.3 Sel e c t S e rial C o m m u nicat i o n P aram et e r s .................................................................................. 25

9.4 Hardware Handshaking.............................................................................................................................. 25

9.5 XO N / XOF F F l ow C o n t r o l ........................................................................................................................... 26

9.6 802.11b Wireless Network Settings.................................................................................................. 26

9.7 TCP / I P P rot o c o l Network S e tti n gs ..................................................................................................... 28

9.8 802.11b Wireless Network Name ..................................................................................................... 29

9.9 Dip S w i t c h S e t t i n g s ................................ ........................................................................................................29

9.9. 1 Baud R a t e .......................................................................................................................................... 29

9.9. 2 Rese r v e d S witc h e s ..................................................................................................................... 29

9.9.3 Ignore Carriage Return Mode ............................................................................................ 29

9.9. 4 Hex D u m p Mode ..........................................................................................................................29

10 Troubleshooting ........................................................................................................................... 30

APP E N D I X 1 I N T E R N A T I ONAL C H A R A C T E R S SET ................................ .............................................31

Page 6

1 INTRODUCTION

The OM7212 is a thermal line printer designed for portable, wireless applications.

1.1 Features

x Easy paper loading with clamshell mechanism design

x Conforming to RS-232C serial

x Portable, powered by a Lithium-Ion Battery

x Wireless IrDA Communication (optional)

x Wireless Bluetooth Communication (optional)

x Paper out sensor

x Light weight

x Belt clip for hands free operation

x Multiple international character set

x Automatic s leep mode for battery charge conservation

x Watch dog software shuts off power to the print head in the case of a paper jam

x Full 96 ASCII set (plus additional European/Chinese and scientific characters)

x Optional flash memory for storing logo, etc.

x Epson ESC/POS emulation

x Bit mapped g raphics with 200 dots per inch resolution

Page 7

2 SPECIFICATIONS

2.1 General Specifications

Print method Thermal line printing

No. of columns 32 (Font A) and 42(Font B)

Printing speed 60 mm/sec

No. of dots per line 384 at 8 dots/mm resolution

Dot Size 0.125 (W) x 0.125 (H) mm

Character size

(Font Size)

1.125 x 3.0 mm (9 x 24)

1.5 x 3.0 mm (12 x 24)

Font size 12 x 24 (Font A) and 9 x 24 (Font B)

IrDA (optional) IrDA V1. 1 standard or proprietary

STX/ETX protocol

Bluetooth

Bluetooth 1.1 compliant

(optional)

WiFi (optional) 802.1 1b wireless

Cable Interface RS-232C serial

Emulation Epson ESC/POS

Battery Lithium-Ion 8.4V / 1 800mA

Paper Width 58 ± 0.5 mm

Diameter 45 mm (Max)

Max Print Width 48 mm

Power supply 12 VDC ±10% 2 A

Dimensions (mm) 85 (W ) x 145 (D) x 75 (H)

Reliability (MCBF) 15 million Lines, 50 million Pulses, 50

km

Weight 400 g (0.88 lbs)

Safety approvals FCC, CE, UL, cUL

Operating

condition

0to50

°C 10to80%RH

(Operating)

Page 8

3 Setting up the printer

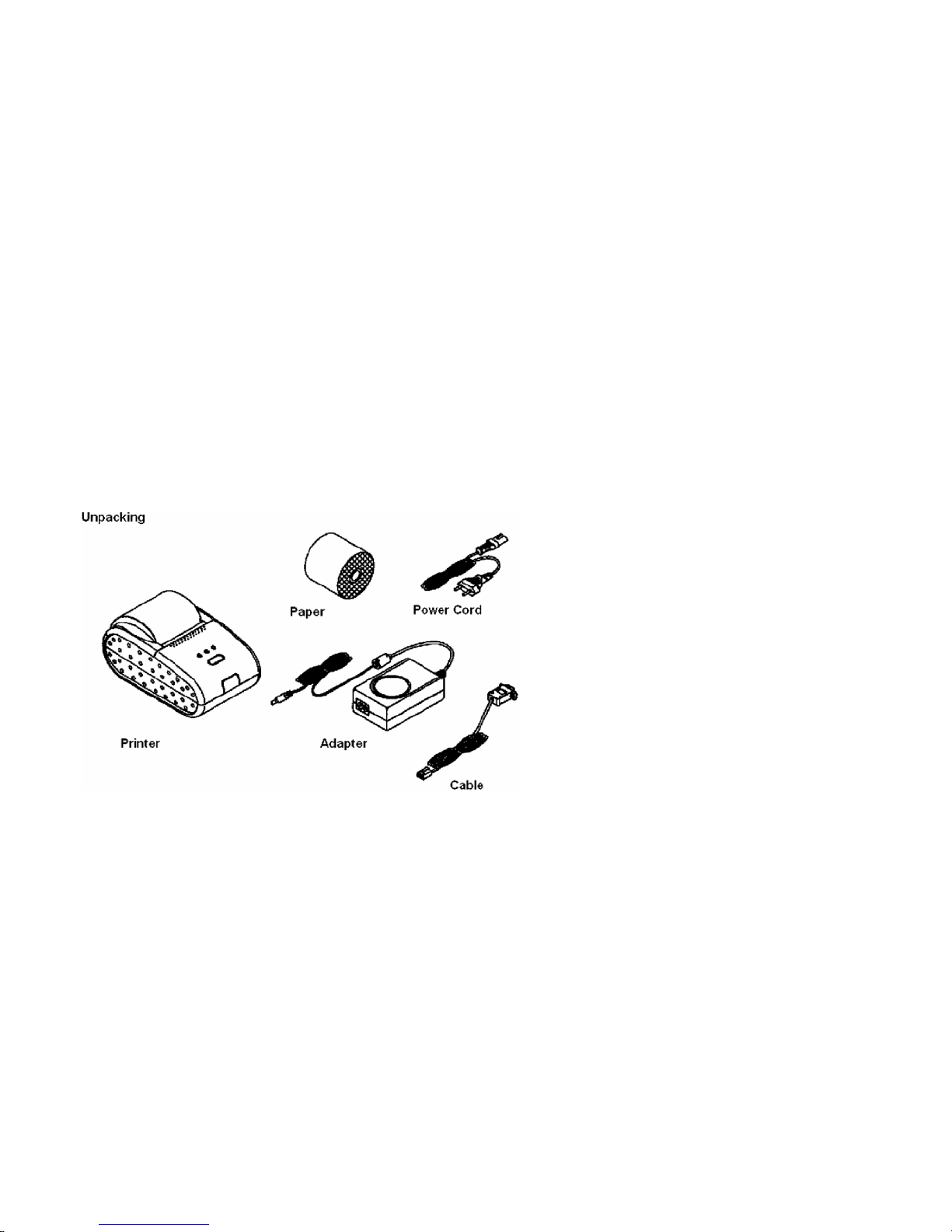

3.1 Unpacking

The items illustrated below are included in the printer package. If any items are damaged or missing, please contact your dealer

for assistance:

3.2 Selecting a Place

Printer

Paper Roll

Power Supply

Manual

Belt Clip

Interface Cable (optional)

1. Protect your printer from excessive heat such as direct sunlight or heaters.

2. Avoid exposing the printer to excessive dust and humidity.

3. Place the printer on a firm, level surface free from intense vibration or shock.

Page 9

3.3 Connecting the Power Adapter

This printer requires an external power supply. An approved Class 2 power supply is required for the operation of this product.

1. Make sure the power switch is turned off.

2. Insert the output plug of the power adapter into the printer DC jack.

3. Plug in the adapter or the power supply’s cord to an outlet.

4. Only use one of the following OMNIPrint adapters:

OMPS7205-915-NA (120 VAC input)

OMPS7205-915-EU (220-240VAC input)

OMPS7205-1220-SMPS (90-240VAC input)

Output: 12VDC 2.0A , 2.1mm x 5.5mm female plug , Center positive.

3.4 Battery

3.4.1 Operation Without a Battery Pack

If your printer has dip switches then the sliding switch in the dip switch well must be set so the actuator is adjacent to the dip

switches. If your printer does not have dip switches, and has been specified to operate without a battery, then no configuration is

necessary. The printer power must be off before actuating any of the switches in the dip switch well. If your printer does not

have dip switches, and has not been specified to operate without a battery, then it must be operated with a battery pack.

Actuator adjacent to dip switches 3.4.2 Operation With a Battery

Pack

If your printer has dip s witches then the sliding switch in the dip switch well must be positioned away from the dip switches. The

printer power must be off before actuating any of the switches in the dip switch well. If your printer does not have dip switches

then no configuration is necessary to operate with a battery.

Actuator away from dip switches

3.4.3 Charging procedure

Page 10

The printer is equipped with a lithium-ion battery pack. Although the battery pack is charged when they are shipped from the

factory, your unit may have discharged. Please recharge the pack with the appropriate AC adapter before using the printer. Turn

the printer off and plug the adapter into an AC outlet and connect the cable to the printer. The battery pack takes 3 hours to

become fully charged.

NOTES:

Make sure you turn off the power switch before charging the battery pack.

Do not charge the pack longer than 24 hours, or the batteries may deteriorate.

The printer can be used immediately after the adapter is connected.

The room temperature should be between 5 and 40

°C during charging.

With the Bluetooth or WiFi options, the true charge state of the battery can only

be determined with the printer’s power turned off.

Page 11

3.4.4 Replacing the Battery Pack

Renew the battery pack if it discharges within an extremely short time.

1. Replace the cell with:

Li-ION 8.4V, 1800 mAH, OMNIPrint Part No.: OMBP-7212-18, or Li-ION 8.4V, 2400 mAH, OMNIPrint Part

No.: OMBP-7212-24

Use of another cell may present a risk of fire or explosion. Replacement cells can be obtained from OMNIPrint by visiting

www.omniprintinc.com.

CAUTION: The cell used in this device may present a fire or chemical burn hazard if mistreated. Do not disassemble, heat

above 100°C (212°F), or incinerate.

2. Turn the printer off.

3. Turn the printer over. Open the battery lid using the tip of your finger, a coin, etc. Avoid using a sharp object.

4. Take the battery pack out by pulling on the ribbon wrapped around it.

5. Disconnect the battery connector and remove the battery pack. Install the new

battery pack and attach the battery connector in the correct direction. Please

note that the connectors are keyed to ensure the right polarity is maintained.

6. Attach the battery cover.

7. Dispose of used cell promptly. Keep away from children.

Make sure you turn off the power switch.

Do not disassemble the battery pack.

Hold the connector body not the lead, when disconnecting the battery connector.

Do not short-circuit the battery pack terminals.

Do not throw the used battery in fire.

Page 12

3.5 Connecting the Interface Cable

Properly shielded serial interface cable must be used to connect your computer to the printer. Observe the following precautions

when connecting the printer to the host computer.

Power to the host must be off.

The printer power switch must be turned off.

Attach the appropriate interface cable.

Make sure all connectors are inserted correctly.

3.5.1 Serial Interface Cable: OM7212-S

1. Make sure that both the printer and computer are turned off.

2. Serial printers come with an RJ-12 connector. Plug the RJ-12 end of the cable into the printer receptacle, as shown

above.

3. Connect the other end, DB9-F connector, to your computer.

4. Use OMNIPrint part number:

CBL7205-69F (DB-9 male on the host side)

Page 13

3.6 Loading Paper

Use a paper roll that meets the specifications. Do not use paper rolls that are glued to the core. Make sure data is not being

transmitted to the printer while loading paper.

1. Open the printer paper c over by firmly holding the printer in one hand and

gently lift the paper cover by applying an equal force on both sides.

2. Remove the old paper roll, if any, by gently removing the spindle from the roll

holder. Do not pull the paper out of the printer. Always use the FEED button.

3. Put the spindle inside the new roll’s core and gently insert it on the printer’s roll

holder until it snaps in on both ends.

4. Align the paper so it is straight and its core is parallel to the spindle. Make sure the paper is curling up.

5. Pull the paper so that the leading edge of the paper goes at least two inches beyond the printer tear bar.

6. Close the printer paper cover and make sure its snaps in on both ends.

7. Press the FEED button to make sure the roll is properly loaded. If you notice

any wrinkles or creases on the edges of the paper try loading the paper again.

8. Tear the excess paper against the serrated edge.

NOTE: You do not have to use the spindle but it is recommended in order to: 1) Reduce tension on the paper; 2) Stop the roll

from rattling inside the cover in portable applications.

Page 14

3.7 Attaching the Belt Clip

Please follow the following procedure if you desire to use the included belt clip:

Turn the printer over. Hold the printer s uch that the IrDA window is towards you. You will notice two rectangular holes

in the middle of the printer case.

Hold the belt clip facing the outside surface.

Insert the belt clip’s front tab perpendicularly into the hole closer to you.

Lower the belt clip until its other tab goes inside the second hole. The clip must be in a horizontal position parallel to the

printer bottom case.

Press the belt clip’s edge away from you towards you until it snaps in.

Page 15

4 External Appearance

Page 16

5 Control Panel The control panel features one button and three LEDs

POWER SWTICH: The power switch is a slide type located in the rear of the printer. Use this switch to power the printer, reset,

or get the printer out of sleep mode.

FEED BUTTON: Press the FEED button once to advance one line or hold down for continuous paper feeding.

POWER LED: Green LED, when blinking, indicates power is on. Red LED, when blinking, indicates low battery.

ERROR LED: Red LED, when blinking, indicates an error condition. The most common error conditions are out of paper, cover

open.

CHARGER LED:

a) Green indicates the battery if fully charged.

b) Red indicates battery is charging.

c) When the adapter is not plugged in the Charger LED will be off.

6 Running the Self Test

Any time you want to check the performance of your printer you can run the self test as follows:

1. While holding down the FEED button, turn the printer on.

2. The printer prints the model name, and firmware revision installed along with other configuration information.

3. The printer will automatically stop printing at the completion of the self test. If the FEED button is pressed again, a

character pattern will be printed. If the printing the character test pattern is not desired, cycle the power on the printer to

resume normal operation.

NOTE: THE PRINTER MAY GO OFF LINE AND W ILL NOT COMMUNICATE WITH THE HOST WHILE IT IS IN SELF TEST

MODE.

Page 17

7 Accessories

1) Paper: 58mm+/-0.5mm(width) , 1.75” max(roll diameter) , 85 microns (thickness) TP-60-70

2) Interface Cable: 6 foot long, shielded cable with molded connectors.

3) Power Supply: Output: 12VDC 2.0A , 2.1mm x 5.5mm female plug , center positive.

CBL7205-625F Serial cable w/ DB-25F host side

CBL7205-69F Serial cable w/ DB-9F host side

OMPS7205-915-NA 120VAC input

OMPS7205-9 15-EU 220-240VAC input

OMPS7205-1220-SMPS 90-240VAC input

Page 18

8 Communications Interfaces

The standard communications interface for the OM7212 printer is RS-232. The printer uses an RJ12 connector for this serial

interface.

8.1 RS232

8.1.1 Serial Interface Specifications

Data Transmission Method: Asynchronous serial interface

Baud Rate: User selectable 2400 to 115200

Word Format: Start bit 1 bit

Data Length 7 or 8 bits

Parity Odd, Even, None

Stop bit 1 bit

Hardware Handshaking: Mark: Data transmission not possible Space: Data transmission possible

8.1.2 RJ12 Connector Pin Assignment:

Signal Polarity: MARK: Logic “1” (-10V) SPACE: Logic “0” (+10V)

FUNCTION

PIN No. INPUT-OUTPUT

F-GND 1 GND

TXD 2 OUT

RXD 3 IN

RTS 4 OUT

DSR 5 IN

DTR 6 OUT

8.2 Infrared (IR) Transmission

If your OM7212 is configured with the optional IR transceiver, it is capable of communicating via an IrDA 1.1 connection. To

determine if your printer is configured with an IR transceiver, print a test label as outlined in section 6 and look for the section

labeled “IR Port”.

8.2.1 Guidelines for IR Communication

Turn the printer on.

Place the host within 1 m (39 inches) of the printer’s IR port.

Make sure the host’s transmitter/receiver is within a 15 degree angle from the center axis of the printer lens. Please

refer to the drawing below:

Page 19

8.3 Bluetooth

If your OM7212 is configured with the optional Bluetooth radio, it is capable of communicating via the Bluetooth Serial Port

Profile (SPP). The Bluetooth SPP is a wireless serial port cable replacement connection. To determine if your printer is

configured with a Bluetooth radio, print a test label as outlined in section 6 and look for the section labeled “Bluetooth”.

8.3.1 Bluetooth Device Address (BD Address)

Each printer configured with the Bluetooth options, contains a unique address used to establish a Bluetooth c onnection. The BD

Address for each printer is printed on the test label under the Bluetooth section. Follow the instructions in section 6 to print a test

label.

8.3.2 Bluetooth Device Name (BD Name)

The Printers are configured with a friendly name to help identify the correct printer when making a Bluetooth connection. The BD

Name for each printer is OM7212 – nnnn where nnnn is the last four digits of the printer’s serial number. e.g. If the printer’s

serial number is 123456789, the BD Name will be OM7212 – 6789.

8.3.3 Maximum Simultaneous Connections

The OM7212 will allow only one Bluetooth SPP connection at a time.

Page 20

8.3.4 PIN Code

Each Bluetooth enabled OM7212 contains a PIN code to help ensure you connect to the printer that you intend to. When

establishing a Bluetooth connection for the first time, you will be prompted by the host device to enter the PIN of the OM7212.

The PIN is the last four digits of the printer’s serial number. e.g. If the printer’s serial number is 123456789, the PIN will be 6789.

8.4 802.11b (Wireless Ethernet)

If your OM7212 is configured with the optional 802.11b wireless Ethernet radio component, the printer can be used in an

802.11b wireless network in a variety of configurations. Supported modes of operation include: Access Point (existing

infrastructure); Ad-hoc / peer -to-peer; 64 and 128 bit WEP encryption as well as unencrypted data transfer; Static and Dynamic

IP address a llocation.

8.4.1 802.11b Configuration Description

This section describes the wireless network configuration process to allow the printer to participate on your new or existing

wireless network.

First, it is necessary to determine what network mode the printer will need to operate in. If there will be a wireless router or other

device acting as an Access Point (AP) on the i ntended wireless network, then the printer needs to be configured for AP mode. If

the intended network includes only workstations (such as a collection of laptop computers), or you do not currently have a

wireless network, then the printer needs to be configured for Ad-hoc mode. The mode can be altered as needed as the network

environment evolves.

Both modes require an SSID to identify the wireless network to all participants. In the case of an existing network, you will need

to set this to match the network’s SSID.

Additionally, the degree of encryption used needs to be determined as well. For existing networks, these settings must be

configured to match the intended network. If setting up a new network, the encryption settings can be configured as needed for

your purposes. These settings include Encryption Mode, at least one Encryption Key, and Use Encryption Key Entry.

Finally, if using Ad-hoc mode, the network channel needs to be set as well for the desired network (For AP mode, the channel is

automatically acquired from the AP during the connection negotiation process).

8.4.2 TCP/IP Protocol Configuration Description

All 802.1 1b wireless Ethernet communications utilize the TCP/IP protocol suite for operation on the network.

The printer uses TCP port 9100 for raw data transfer.

If your network will have a DHCP-enabled server or router on it (most wireless routers can be configured to provide DHCP

services), the simplest and most flexible configuration available for the printer is to enable dynamic IP Address Allocation via

DHCP. If there is no DHCP server available, or you have a need for a statically assigned

Page 21

IP on your network, then you must configure the IP Address Allocation setting to static.

If using static allocation mode, three additional settings must also be configured: Static IP Address, Static IP Address Mask, and

Static IP Gateway. These settings will all depend on how the network is currently configured, and as such, cannot be

enumerated here. Contact your network administrator for more information about configuring a static IP address for your

network.

8.4.3 802.11b Network Identification Name

In order to provide a means of identification on the wireless network, a setting is available to assign a name or other

personalized string of up to 15 characters in length. This will allow you to refer to printers uniquely by name on the network. The

printer provides a default name of “OM7212”.

If two or more printers, having the same assigned network name (whether by using the default setting or having similar name

assignments, as above), are active at the same time on the same network, additional name modification steps are taken to

ensure a unique name to each. For every printer with the same name that joins the network after the first, an additional

numerical suffix is added to the name. For example, using the default name “OM7212”: the first printer joining the network will

use the name “OM7212”; the second will have its name appended to “OM7212-2”; the third, “OM7212-3”, etc.

Because this name modification technique is dynamic in nature, the resulting network name that a printer ends up using can

vary based on the presence or absence of other like-named printers, every time the printer joins the network. Setting unique

names for each printer is therefore recommended if using more than a single printer on the same network.

8.4.4 Name Resolution Issues (Attention: Network Administrators)

There are two options available when it comes to name resolution with OmniPrint printers. The first, and probably most widely

used, is broadcast name resolution by way of NetBIOS over TCP/IP (NBT), courtesy of its Name Management Protocol (NMP).

Smaller Windows-based networks without a local DNS server will use this option for both static and dynamic IP address

allocation modes. This mode is more flexible than using the DNS solution (described below), as it requires no additional network

configuration, but the broadcast mechanism limits the scope of the printer to a single network subnet.

The s econd option requires a local DNS server, and works best with the static IP address allocation mode, but can be made to

work with Dynamic-DNS, if a DHCP server-side update mechanism is available – the printer cannot do its own Dynamic-DNS

update. In this case, a network administrator needs to configure the DNS server to provide a valid name -to-IP mapping for the

intended printers. Note that this mode is less flexible than the first option, but allows the printer to be used in a larger-scaled

network.

This configuration is entirely client (and DNS server)-specific, as the printer has no need for name resolution i tself; the client

machines are the ones who need to resolve the printer’s name. For W indows, the determining factors are whether or not the

client machine uses a DNS server to do name resolution, and then whether the DNS server has an entry to resolve the specified

printer’s name. If these are both true, then DNS name resolution will be used. If either of these are not true, then the client

Windows machine will resort to the broadcast resolution method.

Other operating systems may require the DNS method to be used, as they may not have the capability to do broadcast name

resolution.

Note: NetBIOS name server (NBNS; WINS in Windows) support currently does not exist in OmniPrint printers. Windows is

always able to use broadcast resolution as a lowest common denominator, and the presence of a NBNS/WINS server is never

guaranteed.

Page 22

Page 23

9 User-Configurable Printer Settings

Configuration commands are sent to the printer to change the printer’s non-volatile settings.

After sending the desired sequence of command functions to the printer, allow the printer to remain idle for two seconds. Within

that time, the printer will save the new settings to non-volatile memory. The POWER LED will blink red briefly during this

process. Note that if the configuration commands do not differ from the current settings, the POWER LED will not blink red.

Some functions, when changed, will take effect immediately, while others (such as communication settings) won't become

active until the printer power is cycled off and back on. This is notated for each command function. If your printer has dip

switches then the ser ial co m munication settings must be set with t he dip switches.

9.1 Sleep Timeout Duration

ESCcc3,n,

Range:

Default:

Descripti

on:

Example

:

ASCII ESC c c 3 , 1 ,

Hex1B6363 332C312C

Dec27999951444944

9.2 Print Darkness

0

~ n ~ 255

0

Sets the number of minutes the printer will wait before

entering power saver mode. Setting n = 0 disables power-

saver mode. Note that data will be lost when waking a

printer from power saver mode.

<Esc>cc3, 1,

ESCcc4,n,

Range:

Default:

Descripti

on:

Example

:

ASCII ESC c c 3 , 8 0 ,

Hex1B6363332C38302C

20

~ n ~ 150

100

Adjusts the relative darkness of the pri nt as percentage of

nominal (default) value.

<Esc>cc4,80,

Dec27 99995144 564844

Page 24

9.3 Select Serial Communication Parameters

ESC c c 32 , BaudRate ,Parity,DataBits,StopBits

Range: BaudRate = 2400, 4800, 9600, 19200, 38400, 57600, or 115200

Parity = N (no parity), E (even p arity), or O (odd parity) 7

1

~ StopBits ~ 2

Default: 19200,N,8,1

Description: Sets the serial communication parameters. The printer must be reset for the new settings to take

effect. If your printer has dip switches then the serial communication settings must be set with the

dip switches.

Example: <Esc>cc32,19200,N,8,1,

ASCII ESC C c 3 2 , 1 9

Hex1B636333322C3139

Dec27 99995150444957

ASCII200, N, 8,

Hex32 30302C4E2C3831

Dec50 48484478445649

ASCII 1 ,

Hex 63 2C

Dec 99 44

~ DataBits ~ 8

9.4 Hardware Handshaking

ESC c c 33 , n ,

Range:

Default:

Descrip

tion:

Exampl

e:

ASCII ESC c c 3 3 , 1 ,

Hex1B6363 33332C312C

Dec27 99995151444944

n = 0 disables hardware handshaking

n = 1 enables hardware handshaking

1 (enabled)

Determines whether or not the printer uses hardwired

signals to control the data flow into the printer’s serial

port. <Esc>cc33, 1,

Page 25

9.5 XON/XOFF Flow Control

S

,

,

ESC c c 34 , n ,

Range: n = 0 disables XON/XOFF flow control

n = 1 enables XON/XOFF flow control

Default: 0 (disabled)

Description: Determines whether or not the printer uses XON and XOFF characters to control the data flow into

the printer’s serial port.

Decimal HEX

XON 17 11

XOFF 19 13

Example: <Esc>cc34, 1,

ASCII ESC c c 3 4 , 1 ,

Hex1B636333342C312C

Dec2799995152444944

9.6 802.11b Wireless Network

ettings ESC c c 48

Function

Function:

Paramete

rs: P1

Range:

Default:

Descripti

on:

Example:

Function: Parameters: P1

Range: Default: Description:

Example:

1 : Set Network Mode

1(P1)

0: Ad-hoc / peer-to-peer mode

1: AP (Access Point) / infrastructure mode

1

The network operating mode for the 802.1 1b

connectivity. <Esc>cc48, 1,0,

2 : Set SSID

1(P1)

(1 – 32 character string): the

SSID string to use “default”

The SSID for the

802.11b connectivity.

<Esc>cc48,2,“MyNewW

ifiNetwork”

Page 26

Functio

n:

Parame

ters: P1

Range:

Default:

Descrip

3 : Set Channel (Ad-hoc mode)

1(P1)

1 – 14: the channel # to use

6

The channel # to use for the 802.1 1b connectivity in

ad-hoc mode.

<Esc>cc48,3,9,

tion:

Exampl

e:

Function: 4 : Set Encryption Mode

Parameters: 1 (P1)

P1 Range: 0: No encryption

2: WEP 64-bit encryption

3: WEP 128-bit encryption

Default: 0

Description: The encryption protocol to use for the 802.1 1b connectivity. Example: <Esc>cc48,4,3,

Function: 5 : Set Encryption Key Parameters: 2 (P1, P2)

P1 Range: 1 - 4: The encryption key entry # to set

P2 Range: (10 character hex string): the W EP 64 -bit key

(26 character hex string): the W EP 128-bit key

(0 characters): clears key

Default: <none>

Description: Sets one of four possible encryption keys to use for the 802.1 1b connectivity. These keys must

coincide with the current WEP setting (Function #4 above), i.e. Encryption Mode set to 3 requires a 26

character string here

Example: <Esc>cc48,5,2,“1234567890ABCDEF1234567890”

Function: 6 : Set Active Encryption Key

Parameters: 1 (P1)

P1 Range: 1 - 4: The active encryption key

Default: <none>

Description: The encryption key to use for the 802.1 1b connectivity. This key must already be defined (Function #5

above).

Example: <Esc>cc48,6,2,

Function: 7 : Set Secure Mode

Parameters: 1 (P1)

Page 27

P1

S

,

Range:

Default:

Descrip

tion:

0: WEP keys are printed on test label

1: WEP keys are NOT printed on test label

0

If set, allows for a more secure network environment by

disabling the output of WEP keys on test label

printouts. <Esc>cc48,7,1,

Exampl

e:

9.7 TCP/IP Protocol Network

ettings ESC c c 49

Function

Function: 1 : Set IP Address Allocation mode

Parameters: 1 (P1)

P1 Range: 0: Dynamic (DHCP)

1: Static

Default: 0

Description: The IP address allocation mode for the TCP/IP protocol. Example: <Esc>cc49,1,1,

Functio

n:

Parame

ters: P1

Range:

Default:

Descrip

tion:

Exampl

e:

Functio

n:

Parame

ters: P1

Range:

Default:

Descrip

tion:

Exampl

e:

Functio

n:

Parame

ters: P1

Range:

Default:

Descrip

tion:

Exampl

e:

2:SetStaticIPAddress

1(P1)

(x.x.x.x): Dotted decimal IP address notation, (0

255) <none>

The IP address to use for static allocation

mode. <Esc>cc49,2,192.168.1 .21,

3 : Set Static IP Address Mask

1(P1)

(x.x.x.x): Dotted decimal IP address notation, (0

255) <none>

The IP address mask to use for static allocation

mode. <Esc>cc49,3,255.255.0.0,

4 : Set Static IP Gateway

1(P1)

(x.x.x.x): Dotted decimal IP address notation, (0

255) <none>

The gateway to use for static allocation

mode. <Esc>cc49,4,192.168.1 .1,

~ x ~

~ x ~

~ x ~

Page 28

9.8 802.11b Wireless Network Name

ESCcc50,Name

Function: 2 : Set Network Name

Range: (1 – 32 character string): desired printer identificati on name

Default: “OM7212”

Description: The network name to use for identific atio n on the 802.1 1b network.

Example: <Esc>cc50,“MyPrinter”

9.9 Dip Switch Settings

If your printer has dip s witches the n the serial communication baud rate, carriag e return mo de, and he x dump modes

are set with the dip s witches. Print ers withou t dip s witches are controlled by parameter commands.

9.9.1 Baud Rate

Configure the switches as shown to set the pri nter for the desired baud rate.

Baud Rate SW1 SW 2 SW3

1200 ON ON ON

2400 ON ON OFF

4800 ON OFF ON

9600 ON OFF OFF

19200 OFF ON ON

38400 OFF ON OFF

57600 OFF OFF ON

115200 OFF O FF OFF

Default serial communication is N, 8, 1 (No parity, 8 data bits, 1 stop bit)

9.9.2 R eserved Switches

Switches 4-6 are reser ved and shou ld be left i n the OFF pos ition.

9.9.3 Ignore Carriage Return Mod e

Setting switch 7 to the ON posi tion causes the printer to ignore any car riage retu rns sent.

SW7

ON Ignore Carriage Return

9.9.4 Hex Dump Mode

Setting switch 8 to the ON position puts the printer into Hex Dump Mode. In this mode the printer will disp lay the dat a

received in hexadecimal.

SW8

OFF Use Ca rriage Ret urn

ONHexDumpModeOnOFFHexDumpModeOff

Page 29

10 Troubleshooting

1) IF THE POWER LED DOES NOT COME ON.

Make sure the battery is securely plugged into the printer, the adapter, and the power outlet. Also, make sure that power is

supplied to the power outlet. If the outlet is controlled by a switch or timer, use another outlet. If using the printer on batteries,

make sure the battery is charged and securely plugged in.

1) IF THE POWER LED IS ON BUT PAPER DOES NOT FEED.

This may be a head jam condition, first turn off the printer and make sure there is no paper stuck in the mechanism; however do

not use force or a sharp object to remove the jammed paper.

2) IF THE PAPER IS NOT FEEDING PROPERLY.

If the printout looks squashed, make sure that the paper roll moves freely on the paper holder. If the paper is wrinkled on the

edges, the roll may not be loaded properly. In that case remove the paper and reload and make sure the paper path is straight.

3) IF THE PRINTER DOES NOT COMMUNICATE WITH THE HOST.

Run the self test to check that the printer works properly. If the self test does not work contact your dealer or qualified service

person. If the self test works properly, check the following:

x You are using the right interface cable.

x The connection on both ends of the cable between the printer and the host.

x The data transmission setting may be different between the printer and the host. Use the self test to check the printer

configuration.

x If using the IrDA port, make sure the printer is within 1 m of the host.

x If using the IrDA port, make sure nothing is between the host and the printer or blocking the lenses.

x If using the IrDA port outdoors change the orientation of the printer to avoid excessive light.

4)IFALINEOFDOTSISMISSINGINTHEPRINTOUT.

The print head may be damaged. Contact your dealer or qualified service person.

5) IF THE PRINTER ERROR LED IS BLINKING.

Printer is out of paper, the cover is open, or the battery is low.

Page 30

APPENDIX 1 I NTERNATIONAL CHARACTERS SET

Page 31

Intelligent Weighing Technology serves the industrial and laboratory markets in North America with

competitive pricing and value for money on a complete range of industrial and laboratory scales and

balances, force measurement and load monitoring technology from 0.01 mg to 275 tons.

We are the exclusive source for Intell- Lab, Intell- Industrial, Intell-Check, Intell-Count,IntellWeigh, Intell-Base, Intell-Scan and Intell-Print laboratory, industrial, counting, analytical, precision

and toploading balances, printers, peripherals and weighing equipment.

We are the exclusive source for UWE weighing equipment in the US and the Caribbean.

We are the exclusive source for Intell-Lift Straightpoint (UK), Ltd. products in North America,

Mexico and the Caribbean.

We have a combined 50 years of experience in the weighing and measurement industry, both in the USA

and worldwide. With contacts in over 50 countries, we provide you with the weighing and measurement

equipment you need.

QUALITY - Products solidly built from the ground up with superior engineering and components for

exacting results.

VALUE - Equipment priced for real-world business applications, with superior service and support.

EXPERIENCE - Expert adv ice to help you choose just the right product for your application.

Quality + Value + Experience…it adds up to the Intelligent Investment.

Loading...

Loading...