Intelligent Weighing Technology Intell-Lab IL-0.0001 g, Intell-Lab PB-0.001 g, Intell-Lab PB-0.01g Service Manual

Page 1

A Higher Level of Precision…

A Higher Level of Performance

Intell-Lab™

IL 0.0001 g

PB 0.001 g

PB 0.01 g

Service Manual

Page 2

Page 3

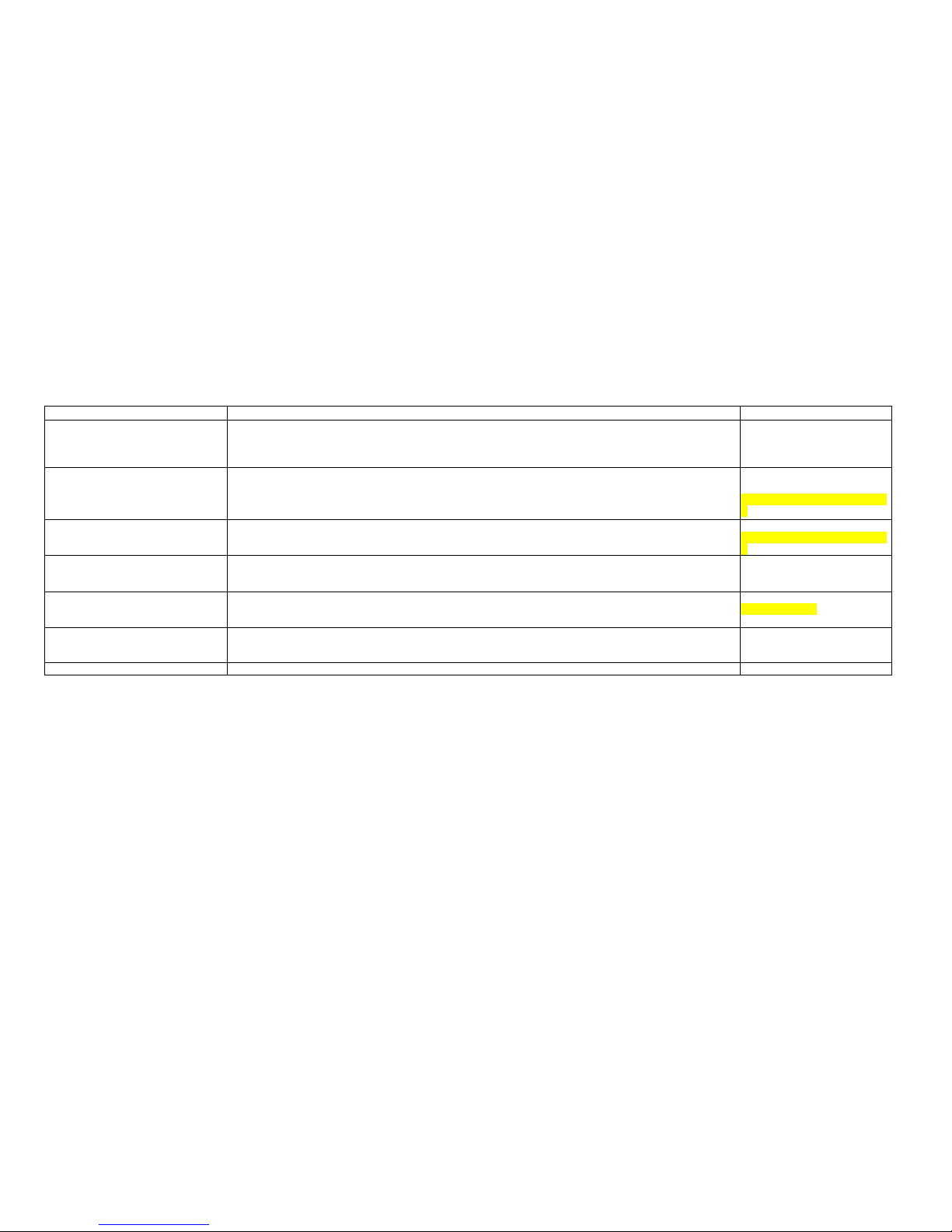

Problem and solution for balances model IL-0.0001, PB-0.001 and PB-0.01g

Fau lt

Pos sible c a u se

Ser vice Ta b l e

Balance not stable.

Dirt inside the magnet.

Bandy flexures.

Mechanical group service.(Clear

the magnet)

Mechanical group

service.(change

Display doesn’t move from zero

Mechanical group damage

Error linearity

A/D converter fail

Mechanical group service

Function linearity

Check_main_board_signals_EM

C

Display doesn’t work correctly

Display damage

No power supply.

No connection display.

Change_display

Check_main_board_signals_EM

C

Keyboard fail/

At power on if balance beeps.

No connection keyboard

No bottom keyboard

Change cable 14 poli

Change keyboard

Corner load not correct

Parallelogram guide damage

Corner load not regulated

Change parallelogram guide

Corner load EMc

Linearity not correct

Regulated linearity error.

Verify bandy flexures

Function_linearity_

Mechanical group service

Page 4

Mechanical group service IL-0.0001, PB-0.001, PB-0.01g

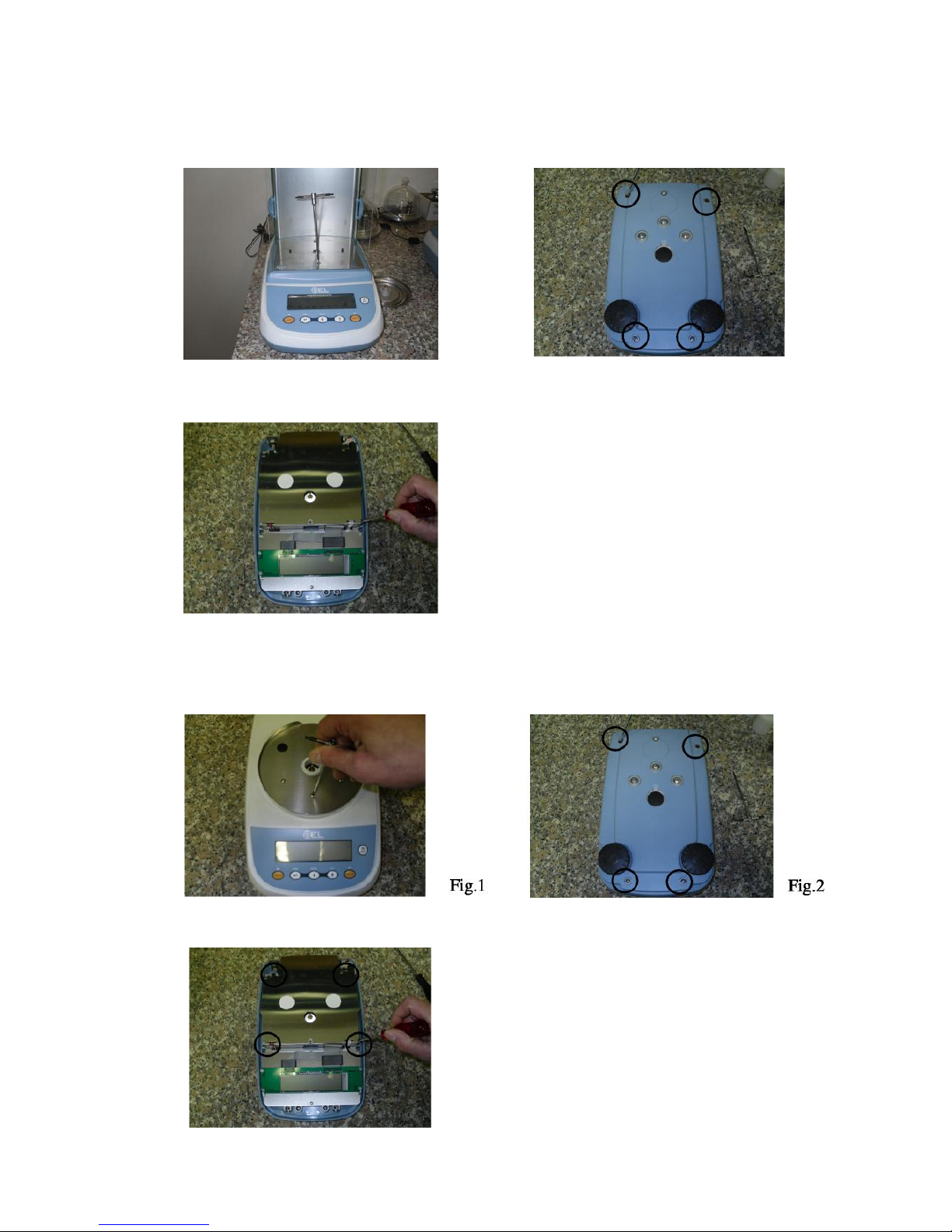

For Model IL0.0001

1. REMOVE THE BALANCE TOP COVER WITH DRAFTSHIELD (REMOVE ONE SCREW Fig.1 AND

FOUR SCREWS UNDER THE BALANCE Fig2

2. REMOVE THE COVER SHIELD OF MECHANICAL GROUP,

Fig.3

For Model PB-0.001

1. REMOVE THE BALANCE TOP COVER (REMOVE ONE SCREW Fig.1 AND FOUR SCREWS

UNDER THE BALANCE Fig2)

2. REMOVE THE COVER SHIELD OF MECHANICAL GROUP (REMOVE FOUR SCREWS Fig.3)

Fig.1

Fig.2

Fig.3

Fig.3

Page 5

For Model PB-0.01

1. REMOVE THE BALANCE TOP COVER (REMOVE ONE SCREW Fig.1 AND FOUR SCREWS

UNDER THE BALANCE Fig2)

2. REMOVE THE COVER SHIELD OF MECHANICAL GROUP (REMOVE FOUR SCREWS

Fig.3)

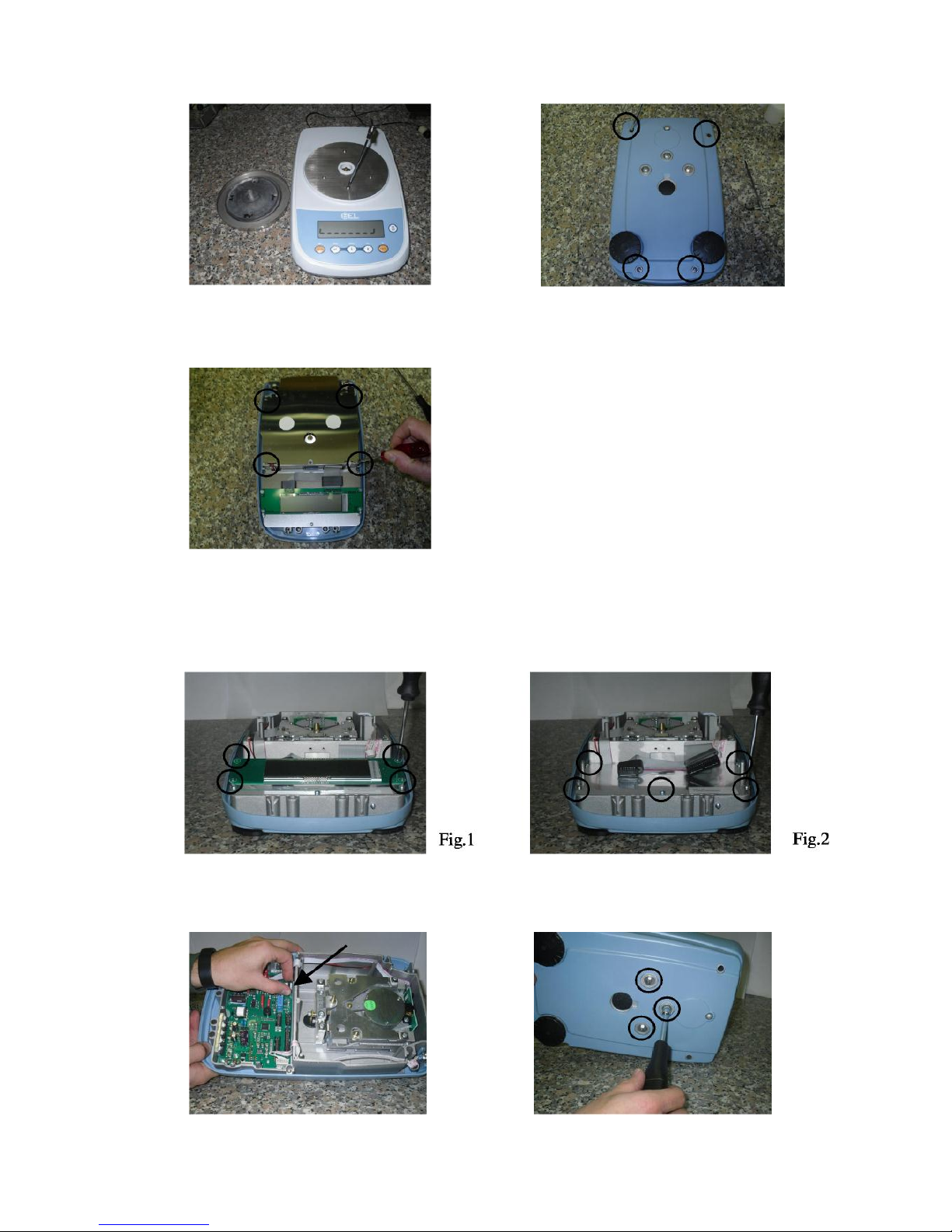

For all Model PB-0.01, PB-0.001, IL-0.0001

1. REMOVE THE DISPLAY BOARD (REMOVE FOUR SCREWS Fig.1) AND COVER SHIELD OF

MAINBOARD (REMOVE FIVE SCREWS Fig2)

2. REMOVE THE CABLE OF OPTICAL GROUP (Fig.3) AND THEN REMOVE THE MECHANICAL

GROUP (REMOVE THREE SCREWS UNDER THE BALANCE Fig.4)

Fig.1

Fig.2

Fig.3

Fig.3

Fig.4

Page 6

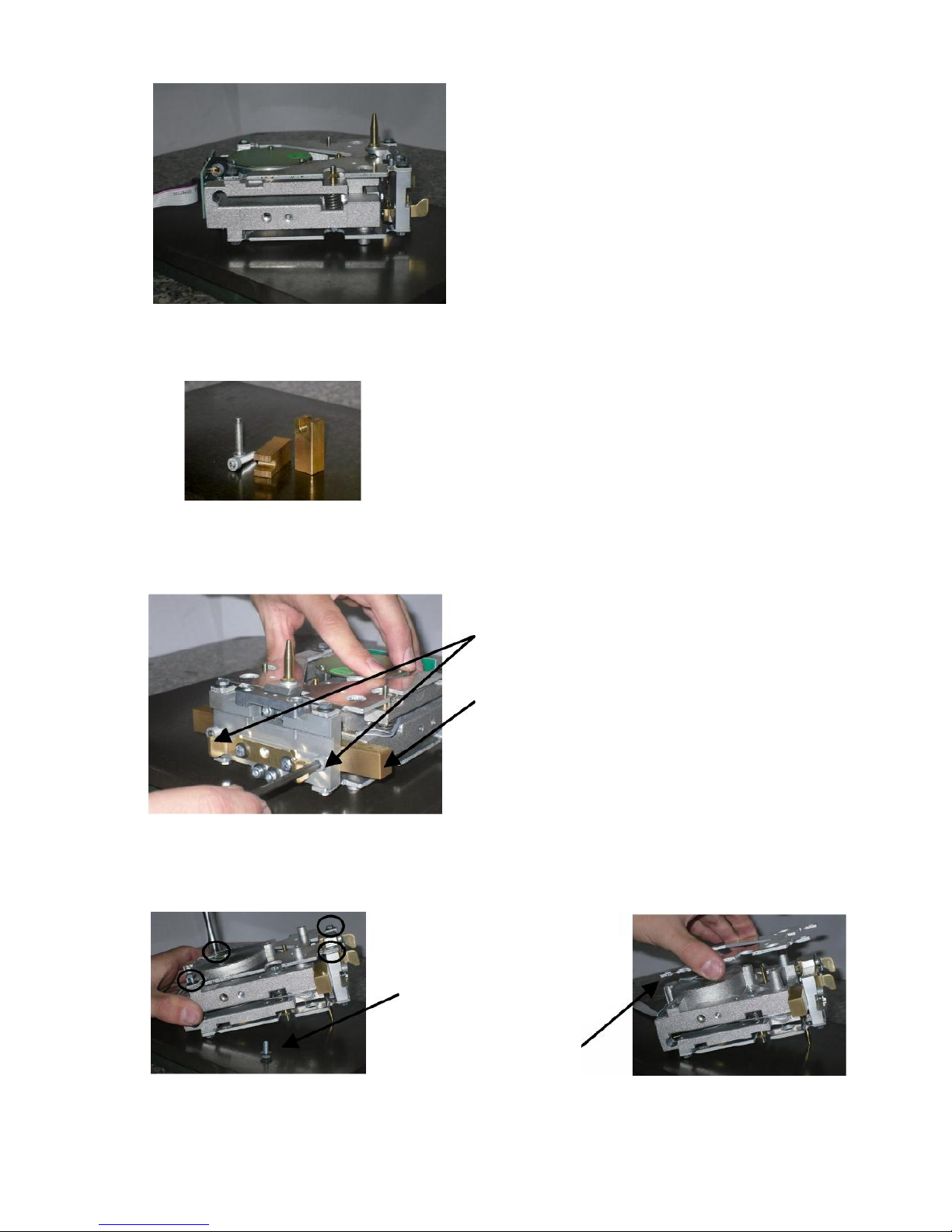

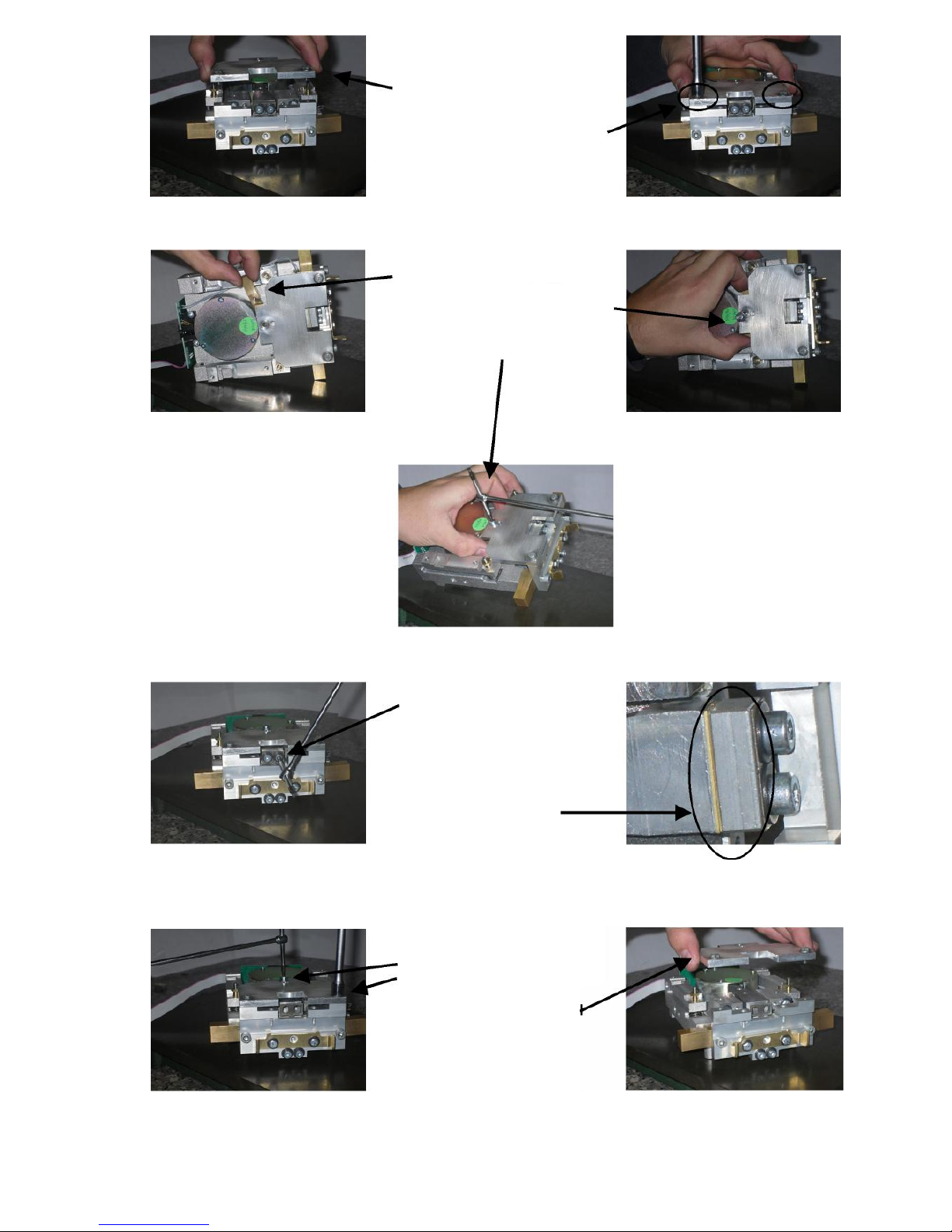

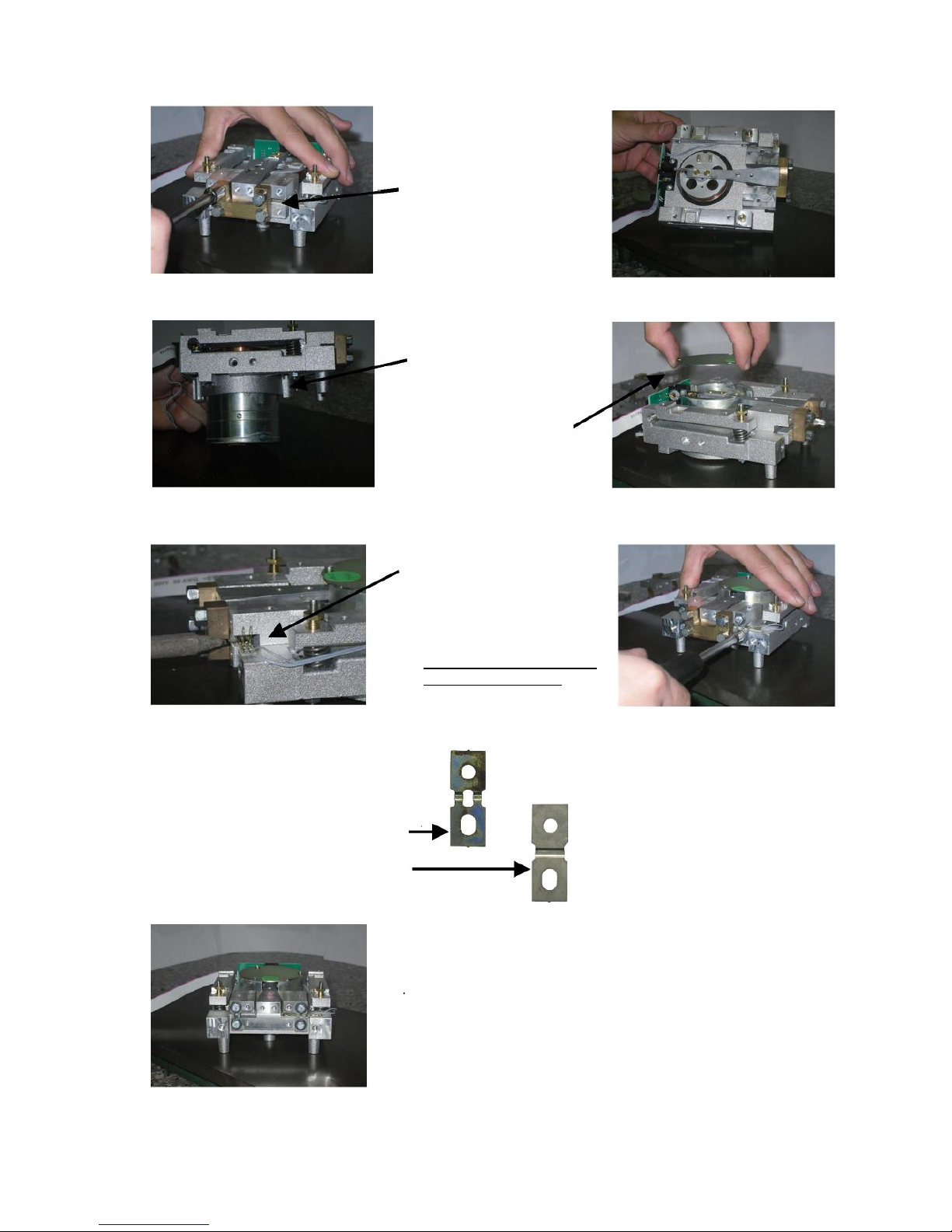

Disassembly group for all Model PB-0.01, PB-0.001, IL-0.0001

The mechanical group is the same for all model except for:

dimension of springs

dimension of spacers

cone

1. Take jigs for the moving pillar (two screws M5x20mm and two

spacers)

2. Insert the screws in the holes (left and right) of the

moving pillar

3. Insert the spacers in the space between moving pillar

and monobloc (left and right)

4. Fix the screws left and right

5. Turn up side down the group

6. Take tool n°7

7. Remove the four screws of

bottom parallelogram guide

9. Remove parallelogram,

handling it carefully

Page 7

9. Turn the group up

again

10. Remove the two

cone support’s

screws

11. Remove the cone

support

18. Take the jigs for vertical spring (n°2 screws M4x10mm, n°1

screw M4x22mm, n°1 clamping plate whit hole and n°1 tool to

fix the lever)

12. Take tool n°7

13. Remove the four

screws of top

parallelogram guide

15. Remove the top

parallelogram guide,

handle it carefully

17. Take tool n°7

17. Remove baricenter

from below the

monobloc

Page 8

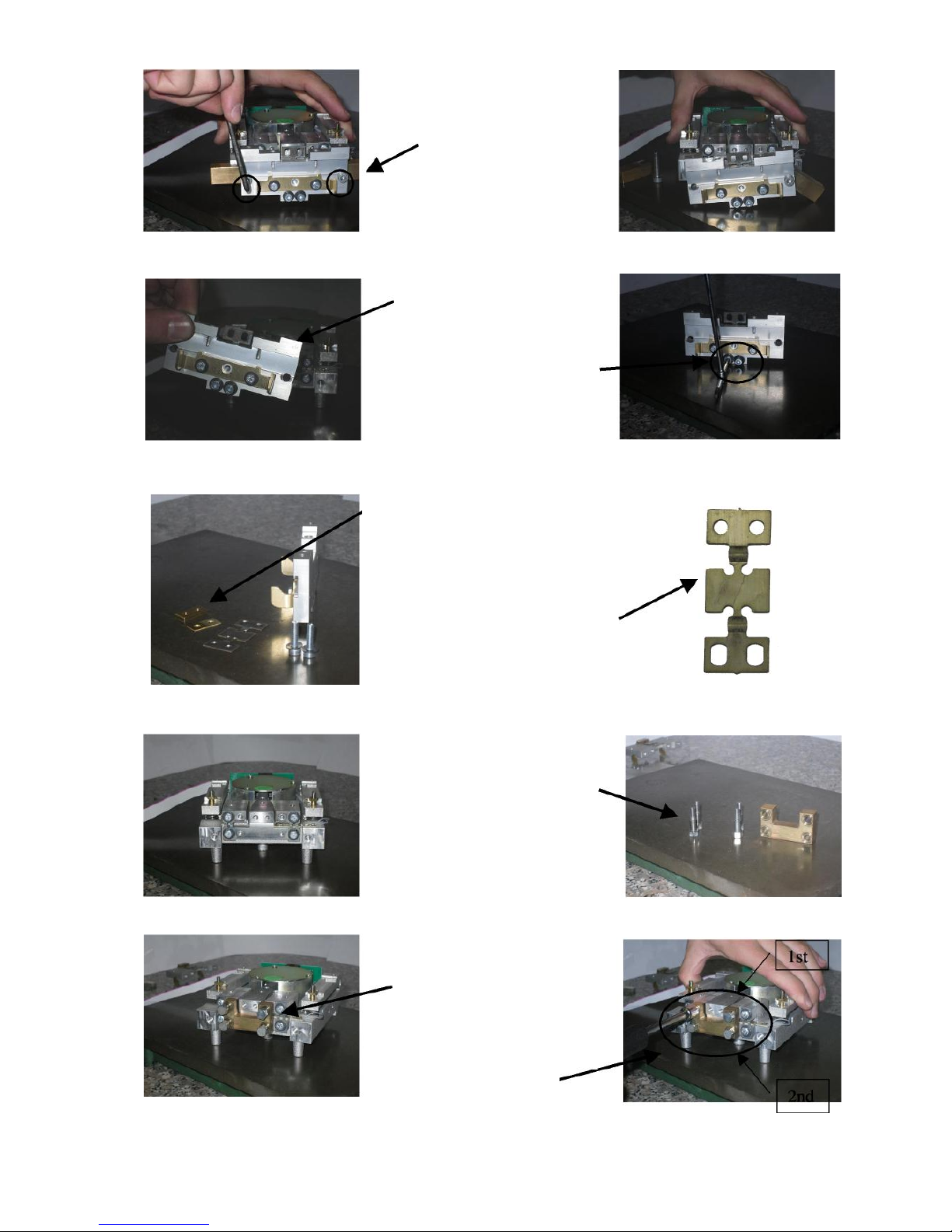

19. Position the jig on the

moving pillar

20. Insert two screws in the

holes of moving pillar and

fix them.

21. Insert the clamping plate.

23. Insert screw and fix

clamping plate with tool

n °3.

24. Remove top screws of

vertical spring, with tool n°3

26. Remove spacer lever for:

0.0001g= n°1x7mm,n°1x0.5mm

0.001g = n°1x4mm.

0.01g = 0mm

27. Remove screw of plate.

28. Remove screws of fixed

to moving pillar.

30. Remove jigs for

vertical spring.

Page 9

29. Remove moving pillar

30. Remove screws of fixed

vertical spring with tool n°3

28. Remove the screws and

spacer fixed jigs of moving

pillar.

Spa cer of mov ing pi llar fo r:

0.0001g

= n°1x0.5mm

0.001g

= n°1x4mm

0.01g

= n°1x7mm, n°1x0.5mm

Ver tic al spri ng:

0.0001g = Vertical spring 0.5/0.10mm

0.001g = Vertical spring 0.5/0.10mm

0.01g = Vertical spring 1/0.12mm

31. Take jigs for the lever (n°4

screws M4x19mm, n°1 tool

for fixing the lever)

33. Put the jig on the lever

34. Insert two screws in

to monobloc and two in

to lever.

35. Fix the screws: first

the top ones then the

bottom ones

Page 10

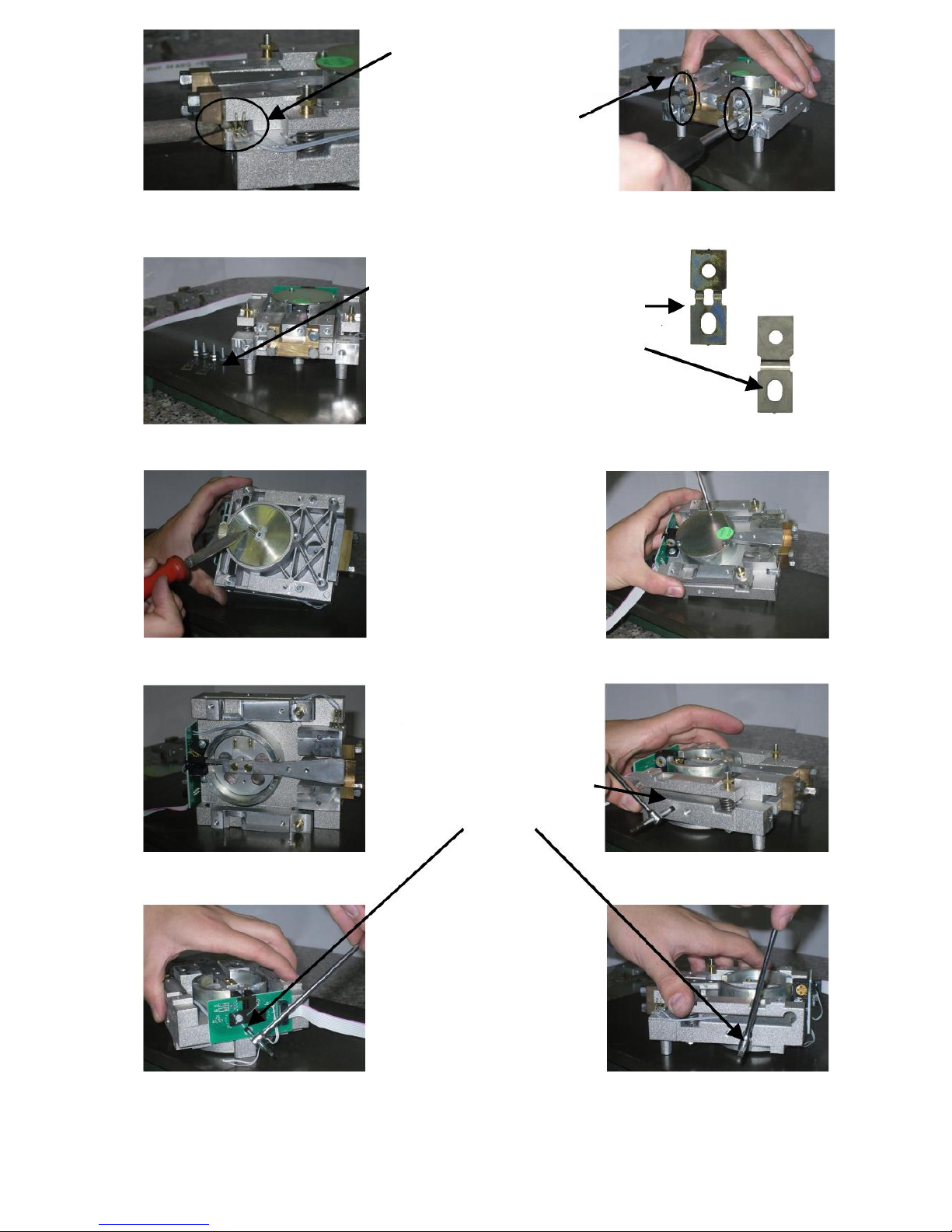

38. Unsolder the wire of

sensor

39. Remove n°3 screws that

fix the magnet cover

35. Unsolder the gold wires.

36. Remove n°4 screws that

the fulcrum flexures using

tool n°7.

38. Remove the fulcrum

flexures

Ful cru m fl exu res :

0.0001g = Fulcrum flexures 0.5/0.09mm

0.001g = Fulcrum flexures 0.5/0.09mm

0.01g = Fulcrum flexures 0.51/0.10mm

40. Remove magnet cover.

42. Remove n°5 grains (n°2

left and rigth side and n

°1 at rear side) that fix

the magnet.

Page 11

42. Remove magnet from

below the monobloc

C. Unsolder the wire of

coil.

D. Remove n°2 screws and

spacer of coil that fix the

lever to coil.

43. Clean the magnet with

air

44. Take a taper and

precision tweezer.

45. Put taper on the top of

precision tweezer so

that adhesive side is

outside.

46. Clean deeply the

magnet turning

precision tweezer

around of magnet.

Now if you need to remove the

lever to change the coil or lever

then follow points from A to E,

otherwise go to point 43.

A. Remove jigs for

lever (Remove n

screws).

C. Remove the lever.

Page 12

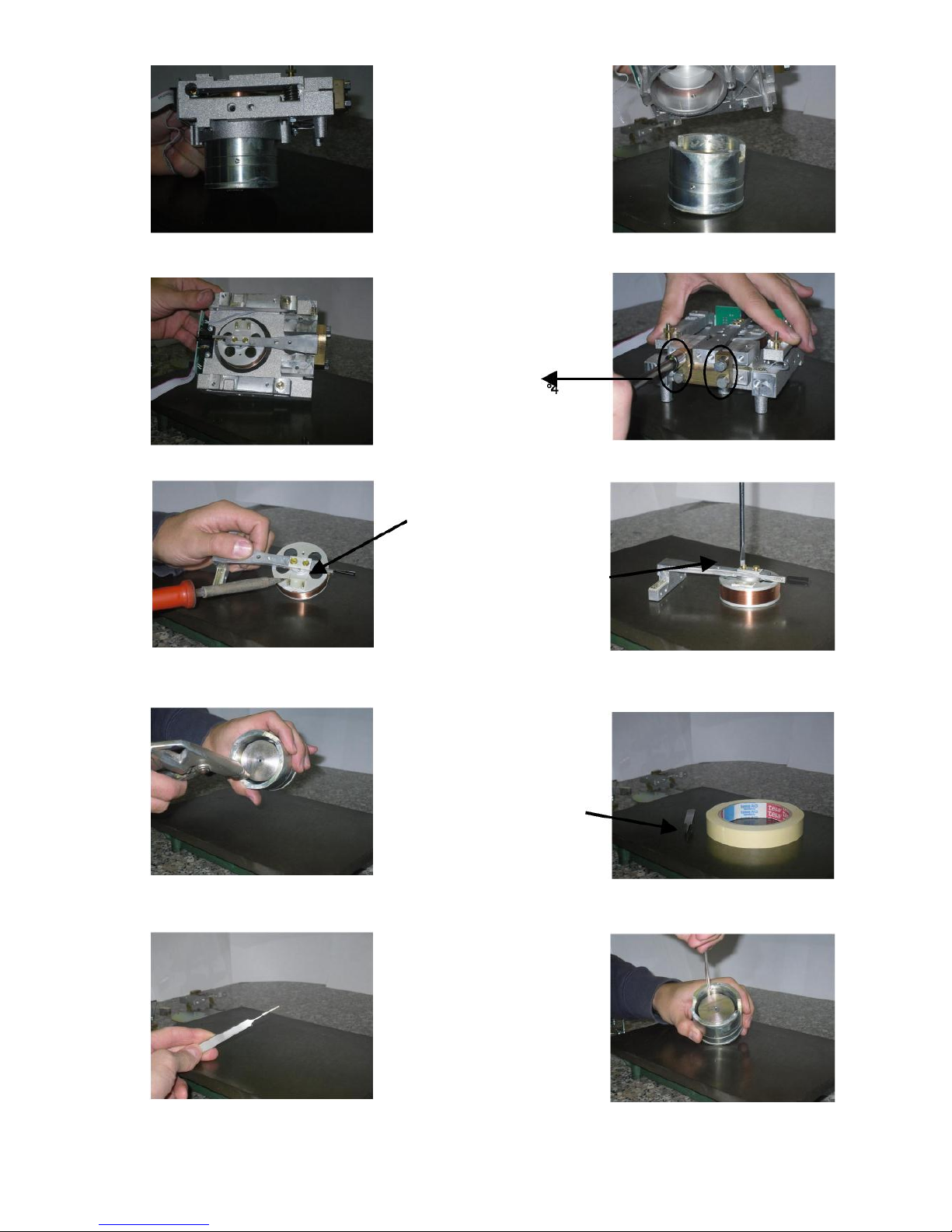

Now you can start assemble the mechanical group

47. Take jigs for level (n°4

screws M4x19mm, n°1

tool for fixing the lever).

48. Insert two screws in to

monobloc and two in to

lever.

49. Insert magnet from

below into monobloc

50. Put on the cover of

magnet (do not fix it).

Ful cru m fl exu res :

0.0001g = Fulcrum flexures 0.5/0.09mm

0.001g = Fulcrum flexures 0.5/0.09mm

0.01g = Fulcrum flexures 0.51/0.10mm

51. Solder the gold wires on

the lever.

52. Put fulcrum flexures with

four screws, and fix

them.(Position the flexures

with circular hole UP)

54. Remove the jig for the

Page 13

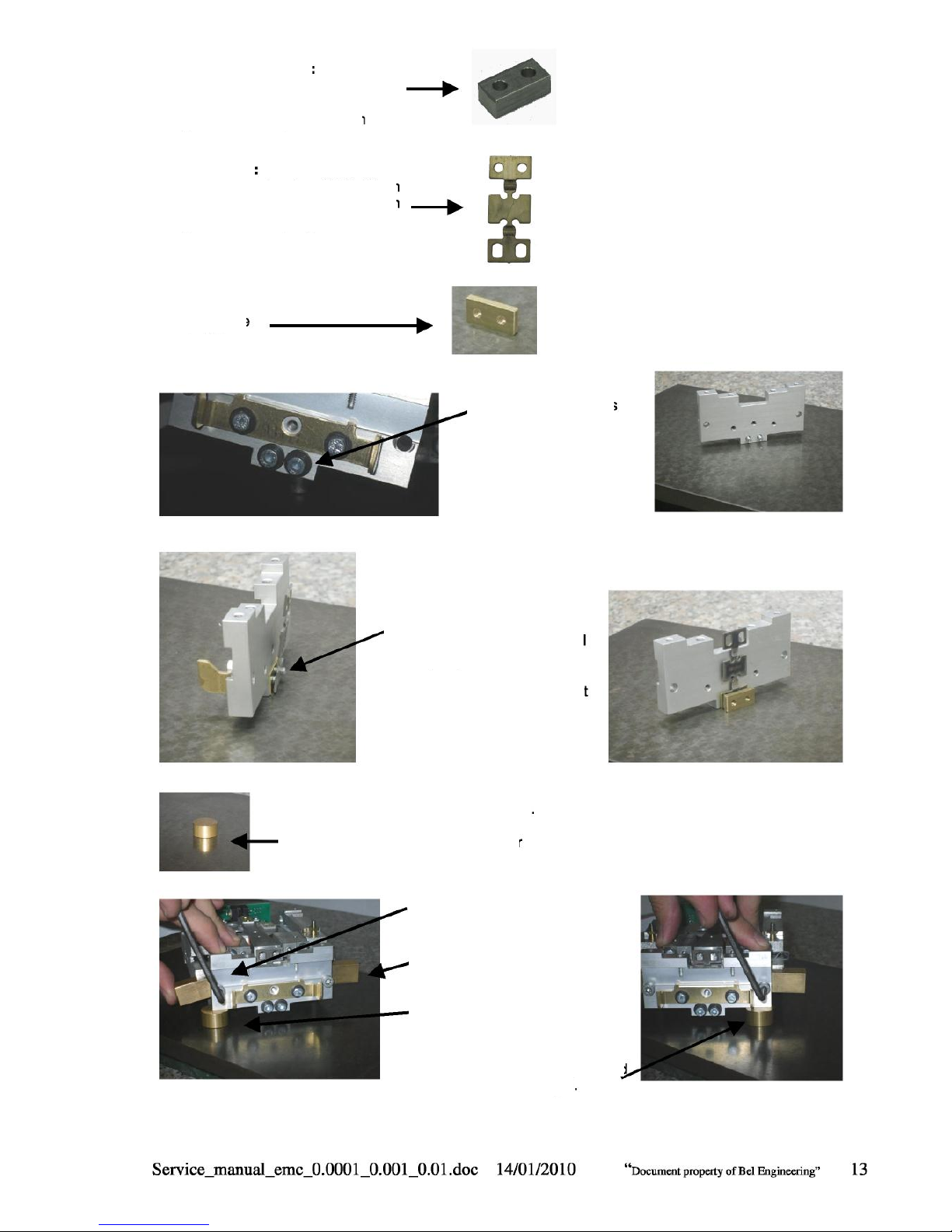

57. Take the jig for the vertical spring.

59. Take jig spacer for moving pillar

61. Insert screws in the holes

(left and right) of moving

pillar

62. Insert spacer between

moving pillar and monobloc

(left and right)

63. Put the jig spacer under the

left side of moving pillar and

fix the screw on left.

64. Put the jig spacer under the

right side of moving pillar and

fix the screw on right.

Clamping plate

54. Insert two screws

(M4x22mm) with

washer.

55. Insert the spacer on

moving pillar, and vertical

spring

57. Insert Clamping plate, but

do not strongly fix the

screws.

Spacer movin pill ar for:

0.0001g

= n°1x0.5mm

0.001g

= n°1x4mm

0.01g

= n°1x7mm, n°1x0.5mm

Vertical spring:

0.0001g

= Vertical spring

0.5/0.10mm

0.001g

= Vertical spring

0.5/0.10mm

0.01g

= Vertical spring

1/0.12mm

Page 14

66. Center the hole of the

vertical spring with the hole

of the lever.

68. Fix the two screws of

bottom vertical spring

70. Insert spacer of lever for:

0.0001 g=n °1 x7mm,n °1 x0.5mm

0.001g = n°1x4mm.

0.01g = 0mm

71. Insert top screws of vertical

spring, and fix them using

tool n°3

73. Remove the cover of

magnet

75. Insert jigs for centering the

lever

77. Fix the screws of coil.

79. Remove the screw that fix

the clamping plate of jig.

81. Remove screws that fix the

jig for vertical spring.

83. Remove jig for vertical

spring.

63. Put the top parallelogram

guide onto the group.

64. Insert the jigs for

centering the

parallelograms

65. Insert four top screws of

parallelogram guide and fix

them.

Page 15

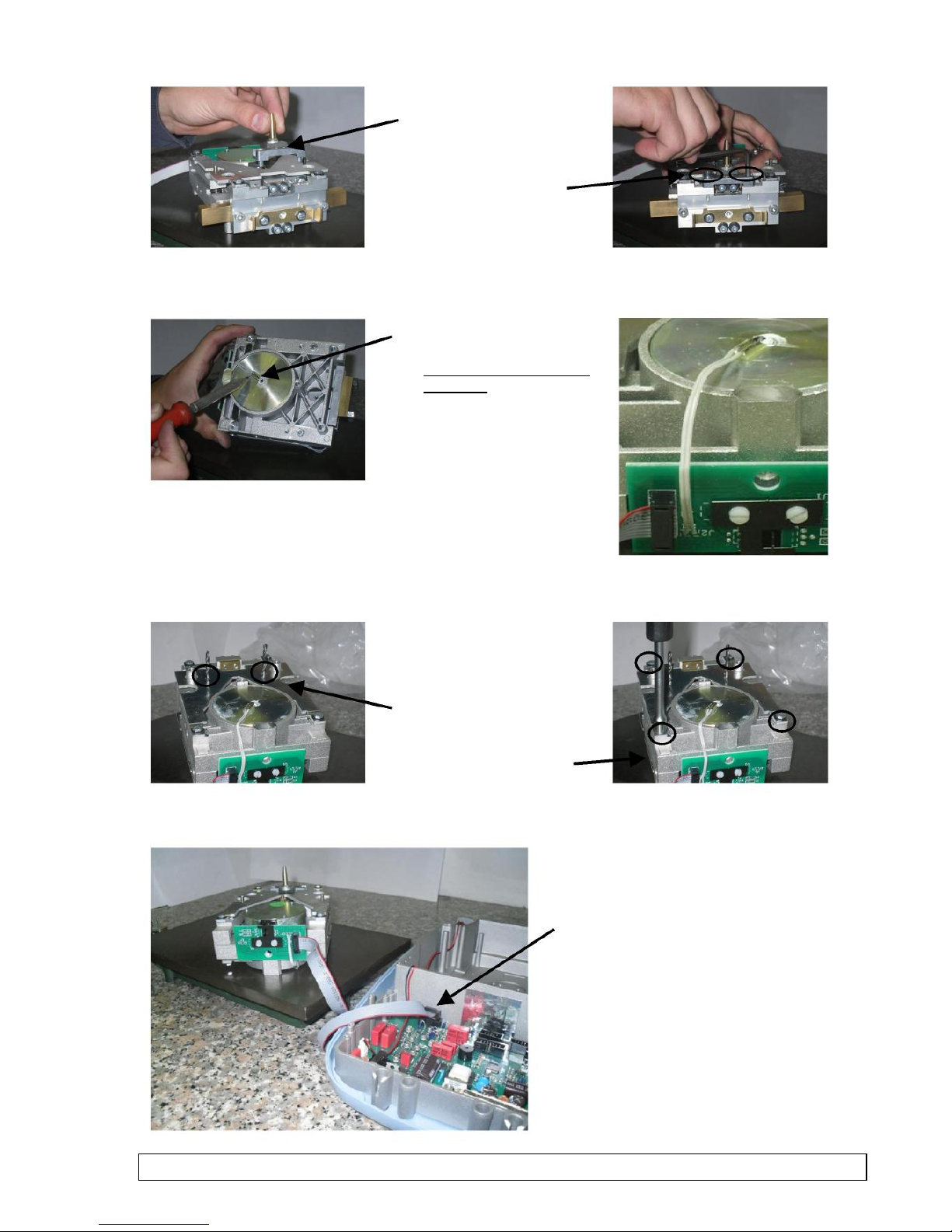

79. Put the bottom

parallelogram guide on

bottom of the group.

81. Insert the jigs for

centering parallelograms

83. Insert four screws of

parallelogram guide and fix

85. Turn up the group

87. Connect the group to the main board.

76. Put cone support on the

moving pillar

78. Insert two cone support’s

Screws and fix them

80. Solder the wire of

temperature sensor.

(Im por tan t: do not invert

the wires)

Page 16

Aut o c ali bra tion sys tem mo tor gr oup

84. Turn on the balance and center the lever. (when the

balance is turned on, the lever must exactly be

centered in the window).

85. Fix the screws

86. Fix the mechanical group in the bottom case.

87. Check the main board signals.

88. Regulate the corner load error of the balance.

89. Check and regulate linearity of balance.

Page 17

Corner load regulation for model EMC IL-0.0001, PB-0.001, PB-

0.01g

For Model IL-0.0001

1. REMOVE THE COVER WITH DRAFTSHIELD (REMOVE ONE SCREW Fig.1 AND FOUR

SCREWS UNDER THE BALANCE Fig2)

2. REMOVE LABELS ON THE HOLES (Fig 3)

3. CONNECT KEYBOARD, PUT THE PLATE WIHT WINDSHIELD AND TURN ON THE

BALANCE. (KEEP WARM UP FOR 20 MINUTES Fig 4.)

Fig.3

Fig.4

Page 18

For Model PM-0.001

1. REMOVE THE CAPS (Fig.5)

2. PUT THE PLATE AND TURN ON THE BALANCE. (KEEP WARM UP FOR 20 MINUTES.)

For Model M0.01

1. REMOVE DISK UNDER THE PLATE.(REMOVE FOUR SCREWS Fig.6)

2. PUT THE PLATE AND TURN ON THE BALANCE. (KEEP WARM UP FOR 20 MINUTES.)

For all Model PB-0.01, PB-0.001, IL-0.0001

TOOL NUMBER 8

FOR CORNER LOAD RAGULATION SCREW FOR CORNER LOAD REGULATION

Fig.5

Fig.6

Page 19

1. PUT THE WEIGHT (1/3 OF MAX RANGE) TO CHECK IN THE CENTER OF THE PLATE, AND

PRESS TARE.

2. MOVE THE WEIGHT IN THE POINT 2A, READ AND WRITE DOWN THE VALUE.

3. MOVE THE WEIGHT IN THE CENTER AND PRESS TARE.

4. MOVE THE WEIGHT IN THE POINT 2B, READ AND WRITE DOWN THE VALUE.

5. TAKE THE TOOL AND REGULATE AS ILLUSTRATED IN THE TABLE BELOW

IF THE CORNER 2A POSIT IVE(+) THEN

TURN THE TOOL CLOCKWISE

(SCREW A)

IF THE CORNER 2A NEGATIVE(-) THEN

TURN THE TOOL ANTICLOCKWISE

(SCREW A)

IF THE CORNER 2B POSITIVE(+) THEN

TURN THE TOOL ANTICLOCKWISE

(SCREW B)

IF THE CORNER 2B NEGATIVE(-) THEN

TURN THE TOOL CLOCKWISE

(SCREW B)

Attention: if the corner opposite can not corrected, check if the mechanical group is ok.

Page 20

PROCEDURE TO LINEARIZE EMC BALANCES IL-0.0001, PB-

0.001, PB-0.01g RELEASE R2.xx

For model with four point of linearity

1.

2.

3.

4.

5.

6.

Switch on balance.

After 30 min press ON/OFF button.

Press sequentially buttons ON/OFF - CAL – CAL.

You will see "Lin" on display, press ENTER to confirm..

The display shows on the left number “1” wait stability and after 3 seconds press CAL to confirm.

When the balance and show number 2 on the left put first weight, (table weight for linearity) wait

stability and after 3 seconds press CAL to confirm.

Put second weight, wait stability and after 3 seconds press CAL to confirm.

Put third weight, wait stability and after 3 seconds press CAL to confirm.

After this point, press CAL and keep it pressed until the display show number 3 on the left.

Then press ON/OFF to return to weighing mode.

Calibrated the balance and check linearity.

Attention: if you forget point 9 the data will not be stored and you will have to do again the

linearization procedure.

For model with seven point of linearity

Switch on balance.

After 30 min press ON/OFF button.

Press sequentially buttons ON/OFF - CAL – CAL.

You will see "Lin" on display, press ENTER to confirm..

The display shows on the left number “1” wait stability and after 3 seconds press CAL to confirm.

When the balance and show number 2 on the left put first weight, (table weight for linearity) wait

stability and after 3 seconds press CAL to confirm.

Put second weight, wait stability and after 3 seconds press CAL to

confirm. Put third weight, wait stability and after 3 seconds press CAL

to confirm. Put fourth weight, wait stability and after 3 seconds press

CAL to confirm. Put fifth weight, wait stability and after 3 seconds

press CAL to confirm. Put sixth weight, wait stability and after 3

seconds press CAL to confirm.

After this point, press CAL and keep it pressed until the display show number 3 on the

left. Then press ON/OFF to return to weighing mode.

Calibrated the balance and check linearity.

Attention: if you forget point 9 the data will not be stored and you will have to do again the

linearization procedure.

For model with twelve point of linearity

Switch on balance.

After 30 min press ON/OFF button.

Press sequentially buttons ON/OFF - CAL – CAL.

You will see "Lin" on display, press ENTER to confirm..

The display show on the left number “1” wait stability and after 3 seconds press CAL to confirm.

When the balance and show number 2 on the left put first weight, (table weight for linearity) wait

stability and after 3 seconds press CAL to confirm.

Put second weight, wait stability and after 3 seconds press CAL to

confirm. Put third weight, wait stability and after 3 seconds press CAL

to confirm. Put fourth weight, wait stability and after 3 seconds press

CAL to confirm. Put fifth weight, wait stability and after 3 seconds press

CAL to confirm. Put sixth weight, wait stability and after 3 seconds

press CAL to confirm. Put seventh weight, wait stability and after 3

seconds press CAL to confirm. Put eighth weight, wait stability and after

3 seconds press CAL to confirm. Put ninth weight, wait stability and

after 3 seconds press CAL to confirm. Put tenth weight, wait stability

and after 3 seconds press CAL to confirm. Put eleventh weight, wait

stability and after 3 seconds press CAL to confirm. Put twelfth weight,

wait stability and after 3 seconds press CAL to confirm.

The balance goes automatically in stand-by status ; press ON/OFF to return to weighing mode.

Calibrated the balance and check linearity.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

Page 21

Clear the linearity and calibration value:

1. Switch on balance.

2. Press sequentially buttons ON/OFF - CAL – CAL.

3. You will see "Lin" on display, press ENTER to confirm..

4. The display show on the left number “1 ” press MENU and keep it pressed until the display shows

CLEAR.

Page 22

Page 23

Page 24

MARK "M " 0.0110.l g

ODOIO

E

MORELLO

PORTATA(

RISOLUZ.4gti

L.inearita'fpBsi lassB FL

S

22C LCCC

v. v v.'

v - v v vv V ^ y

'./LC 2D

v.v v.'

C-' EC 3CC EC

-.

C-'KC g -3CCc -ELCCc

'./ 2 C 2 D

E2CC

-,

B _ " I'

i2 v2 C

u

v. v.

„ „u - 2vu uu - 3v uuu -v u uu -uv uu u -u v uc

6_= =

`.:'2 v v20

22v 2vvv

v.v v.'

v v 2vvv '?v

-.

C-' E CCg- 3 =c-L ECCc

BL___-

V55 C2 0

„ ' CC -3 CC -.E-,LCC

BL fE

VE2C2O

E2CC

C. v.'

u ?u"u 'L 2~vuu 32vuu ~vuuu ~?vu~

6L- '.E2

`.'v2v2C

V V V

. .,v g-2CCC -3CCCc-LCCCc - E C C Cc -6

TOP RAY 0.00l g

=D I C E

MODE LLO

PORTATA4g;

RISOLUZ.g }

Lin~arita' fpEei

Sa :a

D_r

TOP RAY

v.--

Page 25

Internal calibration

In these balance models there are 4 calibration modes:

From display zero condition, press and keep pressed the MENU button until the acoustic

alarm is over, then release the button. The message “unitS” will be visualized on display,

press then MENU button until you visualize “Calib” on display. Press PRINT to confirm.

1. Select the calibration mode you wish by pressing MENU button in sequence:

AUT-CAL: auto calibration

I-CAL: internal calibration

E-CAL: external calibration

TEC-CAL: technical calibration

2. Press PRINT button to confirm “AUT-CAL”, “I-CAL”, “E-CAL”. To confirm “TECCAL” keep pressed the PRINT button until the acoustic alarm is over.

3. After selection, the balance returns to calibration menu. Press and keep pressed

MENU button until the acoustic alarm is over, then release the button. Balance is again

ready for weighing operations.

Technical calibration (TEC-CAL)

This function allows to store the value of internal reference mass whenever checking or

assistance actions require it.

1. After having selected the TEC-CAL calibration mode, press CAL button at empty pan. It

will be displayed “CAL”.

2. When the value of calibration weight start flashing on display, load the weight on to the

balance pan.

3. Wait the acoustic alarm and that the displayed calibrated weight value stops flashing,

then unload the weight from balance pan.

4. When string “0.000” is displayed continuously, then press and keep pressed the PRINT

button. This starts the internal weight value automatic acquisition and store. During the

acquisition cycle,

Page 26

the display will show “TEC-MEM”.

5. After having stored the value of internal calibration weight, balance returns to normal

weighing conditions.

6. Return to calibration menu as described at paragraph 6.2 and set the desired

calibration mode: internal, automatic or external..

ATTENTION : this procedure must be effected only using E2-class reference masses.

Page 27

Change main board EMC series IL-0.0001, PB-0.001, PB-0.01g

1. REMOVE THE COVER OF BALANCE.(REMOVE THE SCREW ON THE TOP, AND

FOUR SCREWS ON THE BOTTOM.

2. REMOVE THE DISPLAY AND THE BOARD SHIELD.

3. DISCONNECT POWER SUPPLY, OPTICAL SENSOR CONNECTOR, RS232

CONNECTOR, KEYBOARD CONNECTOR, DISPLAY CONNECTOR, GEAR

CONNECTOR, AND UNSOLDER SIGNAL RESISTOR.

4. REMOVE SCREWS FIXED MAIN BOARD AND SINK.

Page 28

NOW YOU CAN ASSEMBLE THE NEW MAIN BOARD.

5. CONNECT, POWER SUPPLY, OPTICAL SENSOR, RS232, KEYBOARD,

DISPLAY, GEAR CONNECTOR AND SOLD SIGNAL RESISTOR.

6. FIX THE DISPLAY AND THE BOARD SHIELD.

7. FIX THE COVER OF BALANCE.

8. CHECK AND REGULATE CALIBRATION LINEARITY AND INTERNAL

CALIBRATION(TECH CAL).

IMPORTANT: When you order a new MAIN BOARD, please tell us the reference code printed on label on board shield (fig.1)

Page 29

Check of main board signals EMC series IL-0.0001, PB-0.001, PB-0.01g.

Tp2

AGND

Tp7

Reference 5V

Tp4

- 12 V

Tp3

+ 12

Tp1

DG

Tp5

+ 5

Signal Resistor

Tp 8

From –2,4V

(with unload

plate)

To +2,4V

(with

maximum

range on

plate)

Power

24 v AC

Keyboard Connector

Gear

connector

Tp 6

+ 3.3 V

Display

RS232

Connector

Page 30

Spare parts for balance EMC model IL-0.0001, PB-0.001,PB-

0.01g

Page 31

M0.0001g/M0.0001ig

CODE

DESCR IP TION

IMAGE

A7 13

A7 12

A7 11

ALLUMINIUM INTERNAL CASE

MECHANICAL GROUP SHIELD

MAIN BOARD SHIELD

ADJUSTABLE FEET PLASTIC CASE

HOOK CAP

DUST COVER ANALITICAL

LEVEL BUBBLE

KEYBOARD BEL ADT7 124

MAIN BOARD BILMSP430_427_REV2.1

ANALITICAL

A73 1

A503

A720

S3 14

S284

S304

OPTICAL SENSOR

DISPLAY BOARD

DISP_LCD_ADT7 1 24_REV 1.1

A7 19

A538

Page 32

Page 33

Page 34

Page 35

ONLY M0.0001ig

CO DE

DESC RIPTION

IMAG E

M642

INTERNAL WEIGTH 200g

Page 36

PB-0.001 g / PB-0.001 g

Page 37

PB-0.001 g / PB-0.001 g

CO DE DESCRI PTION IMAG E

A712 MECHANICAL GROUP SHIELD

A7 11

A7 13

A503

S3 13

MAIN BOARD SHIELD

ALLUMINIUM INTERNAL CASE

LEVEL BUBBLE

MAIN BOARD MSP430_427_REV2.1 6K

S284

S304

E3 18

S310

OPTICAL SENSOR

DISPLAY BOARD

DISP_LCD_ADT7 1 24_REV 1.1

LCD ADT7 124

CABLE 14 PIN FOR KEY CONNECTING

S3 11

CABLE 26 PIN FOR DISPLAY

CONNECTING

Page 38

M0.001g/M0.001ig

CO DE DESCRI PTION IMAG E

A720 KEYBOARD BEL ADT7 124

E493

E748

E496

M620

CABLE WITH DC PLUG

CABLE WITH RS232 CONNECTOR

CABLE WITH SENSOR TEMPERATURE

MONOBLOC

M109

LEVER WITH FLAG

M9 12

COIL

M20 1

MOVING PILLAR

Page 39

Page 40

Page 41

Page 42

Page 43

M0.01g/M0.01ig

A713 ALLUMINIUM INTERNAL CASE

A503

S3 13

LEVEL BUBBLE

MAIN BOARD MSP430_427_REV2.1

6K

S284

OPTICAL SENSOR

S304

E3 18

S310

S3 11

A720

DISPLAY BOARD

DISP_LCD_ADT7 1 24_REV 1.1

LCD ADT7 124

CABLE 14 PIN FOR KEY

CONNECTING

CABLE 26 PIN FOR DISPLAY

CONNECTING

KEYBOARD BEL ADT7 124

CABLE WITH DC PLUG

E493

CABLE WITH RS232 CONNECTOR

E748

Page 44

TEMPERATURE

M620

M109

M9 12

MONOBLOC

LEVER WITH FLAG

COIL

M20 1

MOVING PILLAR

M053

M054

MAGNETIC GROUP

COVER MAGNET

Page 45

Page 46

Page 47

ONLY M0.01ig

CO DE

DESC RIPTION

IMAG E

M641

INTERNAL WEIGHT 400g

M642

INTERNAL WEIGTH 200g

Loading...

Loading...