Intelligent Weighing Technology Intell-Count IDC 3, Intell-Count IDC 6, Intell-Count IDC 15, Intell-Count IDC 30 User's Operation Manual

Page 1

A Higher Level of Precision…

A Higher Level of Performance

Intell-Count™ Dual Channel Counting Scale

IDC Series

User Operation Manual

Page 2

- 2 -

January 2009

Page 3

CONTENTS

SECTION 1 INTRODUCTION.............................................……………......................1

SECTION2 TECHNICAL SPECIFICATIONS ...................……...............................2

2.1 SPECIFICATIONS FOR THE LOCAL SCALE................………............................ 2

2.2 SPECIFICATIONS FOR THE REMOTE SCALE ..............……........................... 2

2.3 COMMON SPECIFICATIONS ............................................……......................... 2

SECTION3 INSTALLATION........................................………..................................... 3

3.1 LOCATING THE SCALES .............………............................................................ 3

3.2 SETTING UP THE SCALES...............………........................................................ 3

3.2.1 Setting up the local scale...............………........................................................ 3

3.2.2 Setting up the remote scale...............………....................................................... 4

3.2.3 Remote scale connection...............………........................................................ 4

3.2.4 Remote scale setup.……..............………....................................................…...4

SECTION4 KEY DESCRIPTIONS ..............................……....................................…..6

SECTION5 DISPLAYS...................................................…..................................…....7

5.1 WEIGHT WINDOW ......................................…...............................................…... 7

5.2 UNIT WEIGHT WINDOW...............................…..........................................…......7

5.3 COUNT WINDOW.............................................…..........................................…....7

SECTION6 OPERATION .........................................….......................................……..8

6.1 ZEROING AND TARING THE DISPLAY ...........................……..........................8

6.1.1 Zeroing ........…………………………………………..........……..........................8

6.1.2 Taring ......…………………………………..……………........……..........................9

6.1.3 Taring the remote scale................…………………….........……..........................9

6.2 MEMORY FUNCTIONS...............................................….................................... 10

6.2.1 Manual accumulation .................................................….................................. 10

6.2.2 Automatic accumulated total.....................................……................................. 10

6.3 PARTS COUNTING.........................................................…................................ 10

6.3.1 Weighing a sample to determine the Unit Weight .....……............................... 11

- i-

Page 4

6.3.2 Entering a known Unit Weight ......................................…............................... 11

6.3.3 Automatic update of unit weight....................................… .............................. 11

6.3.4 Count pre-set or check-weighing ......................................…............................ 12

6.4 PLU (Product Look Up)............................................................…...................... 12

6.4.1 Storing PLU’s manually.....………………………………………........................ 13

6.4.2 Entering description manually..........................……………...................... 14

6.4.3 Recalling PLU’s manually..............................………………............................ 15

SECTION7 PARAMETERS................................................................................... 16

7.1 USER PARAMETERS ........................................................….....….................... 16

7.2 USER PARAMETERS SETTING TABLE ...........................….....….................... 16

SECTION8 BATTERY OPERATION..........................................…....…................... 18

SECTION9 RS-232 OUTPUT ................................................................................... 19

9.1 INPUT COMMANDS FORMAT.........................................….......................... 19

9.2 STORING DATA VIA RS232 ...............................................…........................... 2 0

9.3 PLU ENTRY USING RS-232 INTERFACE.........................…........................... 20

SECTION10 CALIBRATION ......................................................….......................... 22

SECTION11 ERROR CODES.......................................................…........................ 23

SECTION12 TECHNICAL PARAMETERS..................................…......................... 24

- ii -

Page 5

- 1-

SECTION 1 INTRODUCTION

The IDC series offers a range of an accurate, fast and versatile counting scales that

can use one additional external platform (Remote scale) for weighing or counting of

heavier items.

These counting scales have the ability to store detailed information on the products

that are used most (PLU).

The scale can be operated using either pounds only, kilograms only or can be

switched between pounds and kilograms.

All have stainless steel weighing pan.

All the keypads are sealed, color coded membrane switches and the displays are

large easy to read liquid crystal type displays (LCD). The LCD’s are supplied with a

backlight.

All units include automatic zero tracking, audible alarm for pre-set weights, pre-set

tare and an accumulation facility that allows the count to be stored and recalled as

accumulated total.

The scales have an expanded bi-directional RS-232 interface for communication with

a PC or printer.

Page 6

- 2 -

SECTION 2 TECHNICAL SPECIFICATIONS

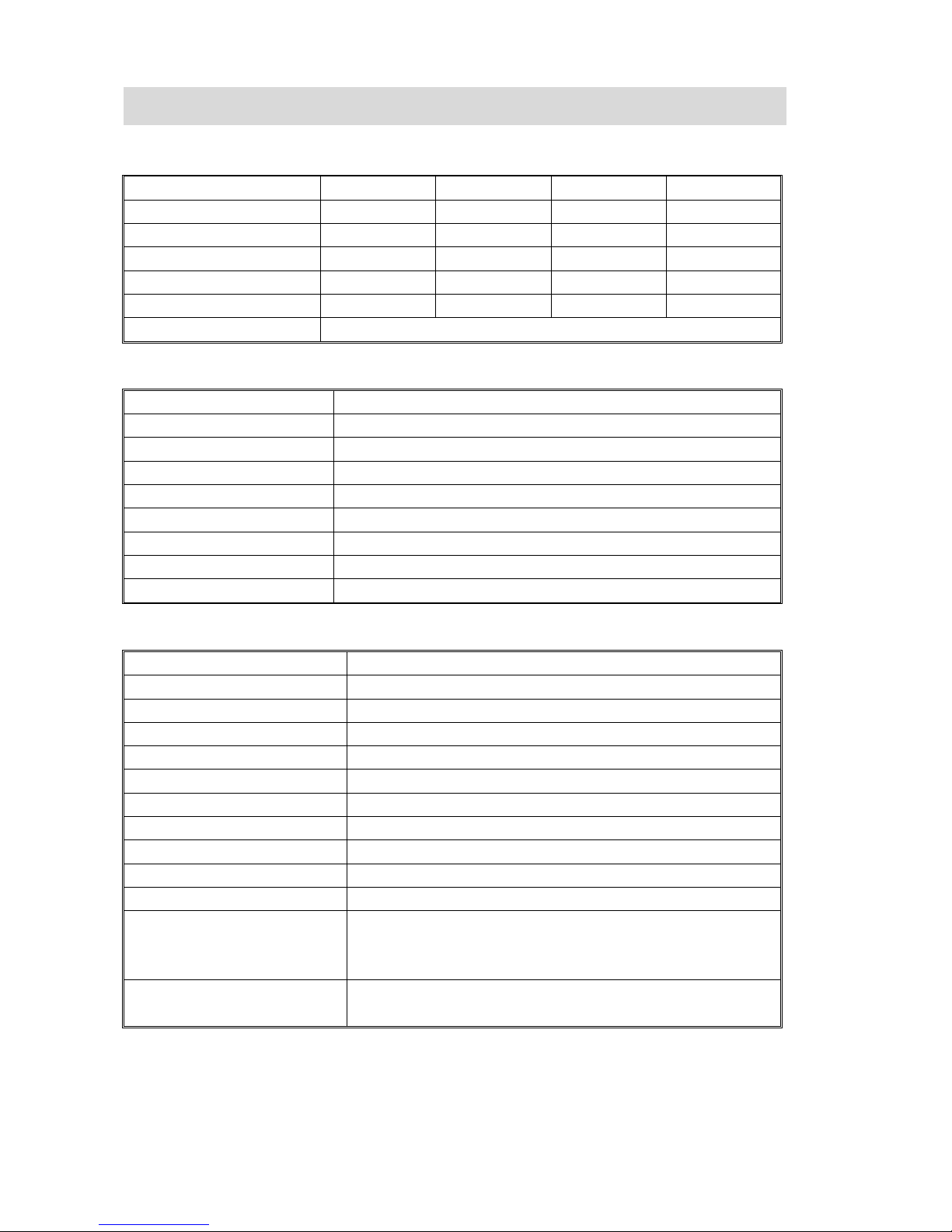

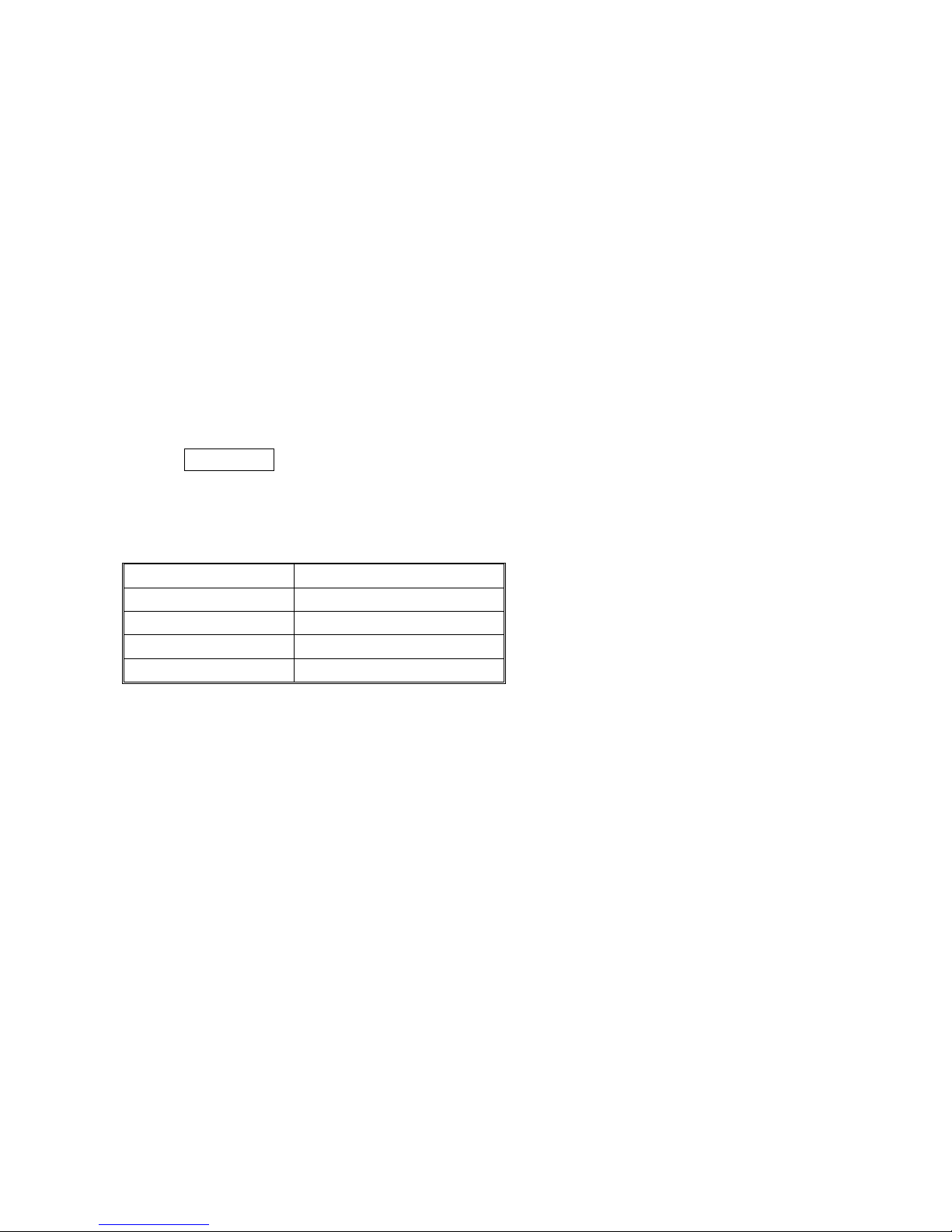

2.1 SPECIFICATIONS FOR THE LOCAL SCALE

Model

IDC 3

IDC 6

IDC 15

IDC 30

Maximum Capacity

3000 g

6000 g

15 kg

30 kg

Readability

0.05 g

0.1 g

0.2 g

0.5 g

Tare Range

-3 kg

-6 kg

-10 kg

-30 kg

Repeatability(Std Dev)

0.1 g

0.1 g

0.2 g

0.5 g

Linearity ±

0.1 g

0.2 g

0.5 g

1 g

Units of Measure

lb, kg

2.2 SPECIFICATIONS FOR THE REMOTE SCALE

Excitation voltage

5 VDC

Signal range

0-20 mv(allows 3 mv/v LC with 5mv zero offset)

Zero range

0-5 mv

Sensitivity

0.02 µv/internal ADC count or better

Internal ADC counts

500,000 maximum at 10 mv input

Load

87 ohm minimum, 4 X 350 ohm load cells

Connection

4 wire connection to load cells plus shield

Maximum cable length

20 ft - 6 meters

Termination

DB 9 subminiature plug on scale

2.3 COMMON SPECIFICATIONS

Interface

Bi-directional RS-232 Interface

Stabilization Time

2 Seconds

Operating Temperature

0°C - 40°C (32°F - 104°F)

Power supply

9 VDC 800 mA from external power supply

Calibration

Automatic external

Display

3 x 6 digits LCD digital display

Housing Indicator

ABS Plastic, Stainless Steel pan

Pan size

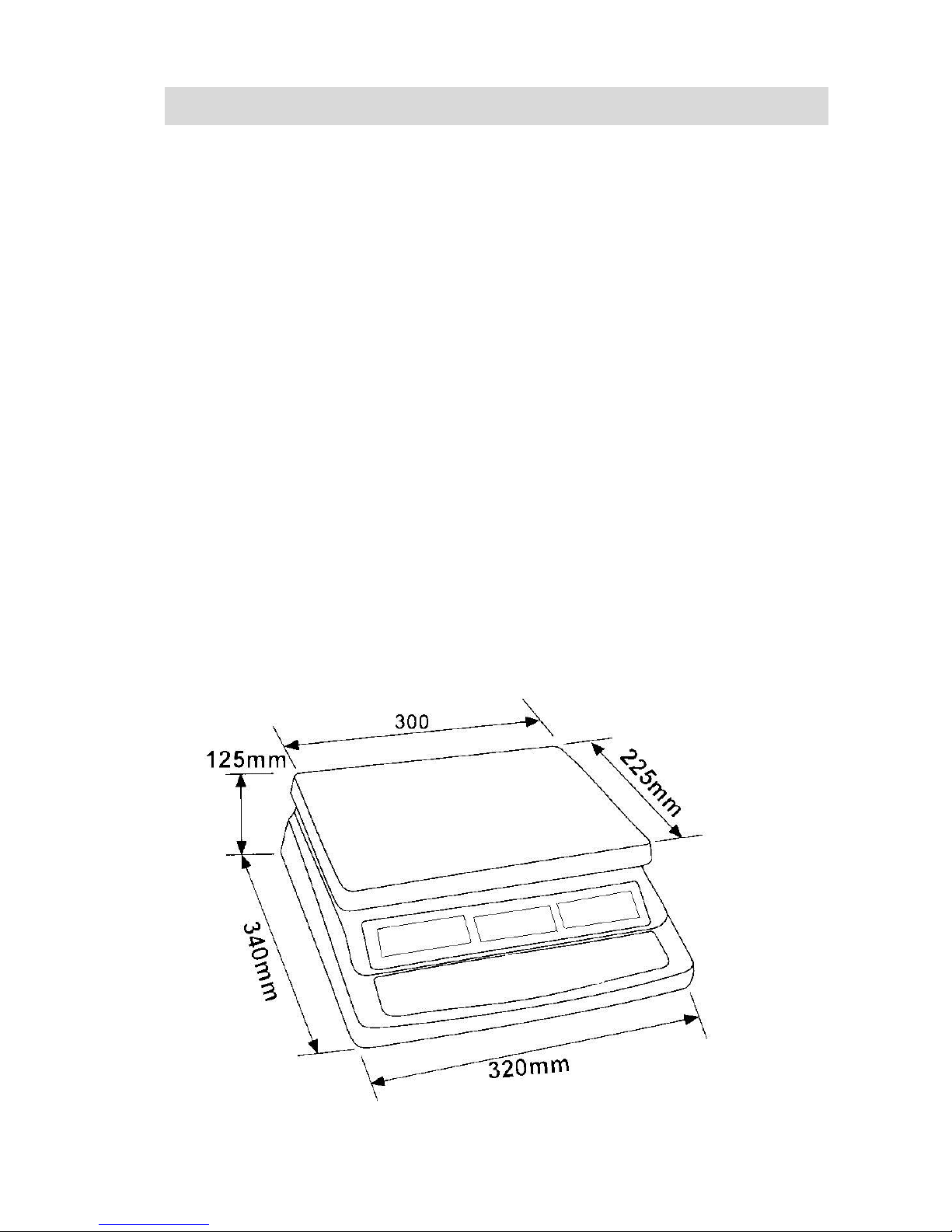

225 x 300mm / 8.9 x 11.8”

Overall dimensions

320 x 340 x 125mm / 12.6 x 13.4 x 4.9”

Net weight

3.8kg / 8.4lb

Applications

Counting Scale

Functions

Weighing, parts counting, accumulating memory,

preset count with alarm, up to 100 PLUs with

description, unit & tare weight

Other Features and Specs

Accuracy enhancement for parts counting,

internal rechargeable battery (~70 hours operation)

Page 7

- 3-

SECTION 3 INSTALLATION

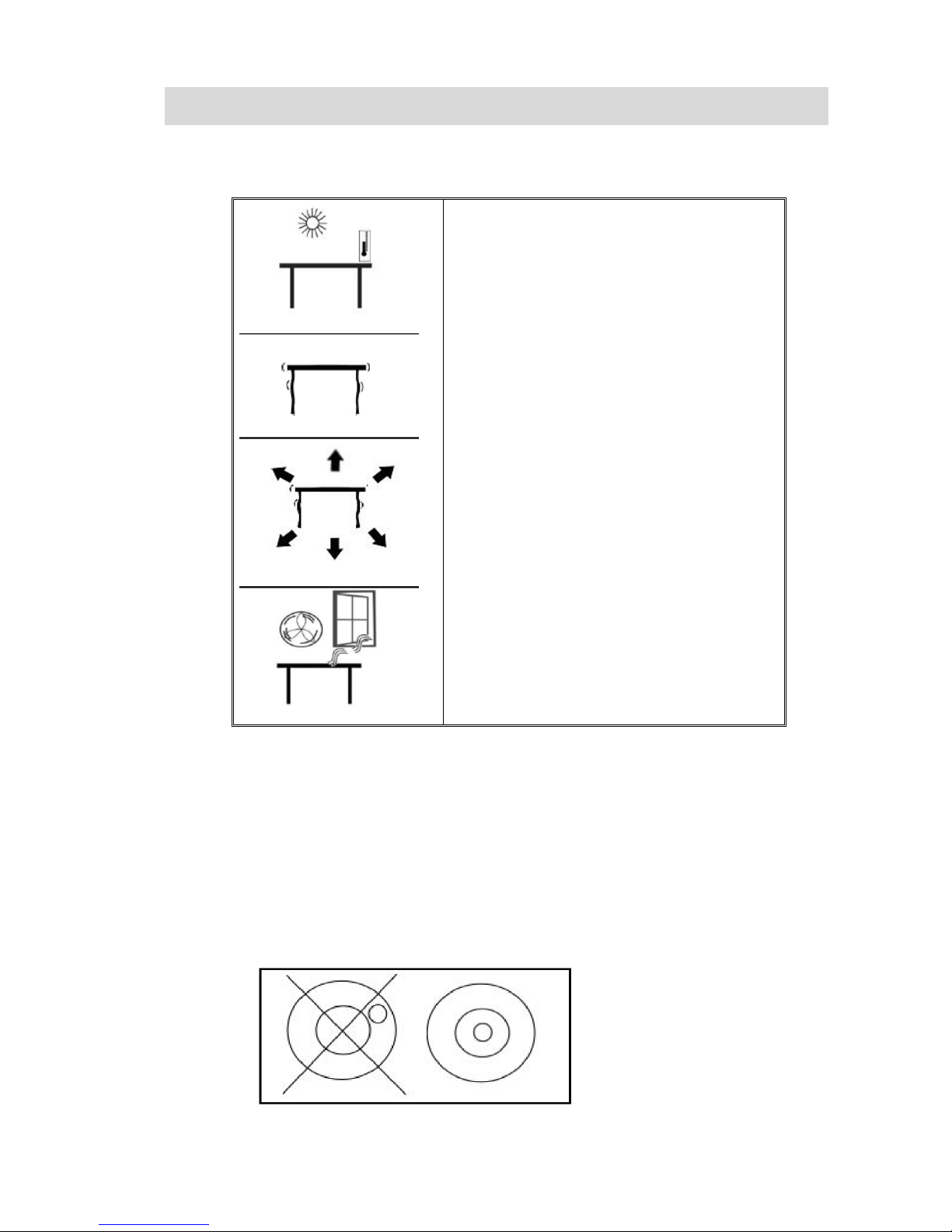

3.1 LOCATING THE SCALES

• The scales should not be placed in a

location that will reduce the accuracy.

• Avoid extremes of temperature. Do not

place in direct sunlight or near air

conditioning vents.

• Avoid unsuitable tables. The table or

floor must be rigid and not vibrate.

• Avoid unstable power sources. Do not

use near large users of electricity such as

welding equipment or large motors.

• Do not place near vibrating machinery.

• Avoid high humidity that might cause

condensation. Avoid direct contact with

water. Do not spray or immerse the

scales in water.

• Avoid air movement such as from fans or

opening doors. Do not place near open

windows or air-conditioning vents.

• Keep the scales clean. Do not stack

material on the scales when they are not

in use.

3.2 SETTING UP THE SCALES

3.2.1 SETTING UP THE LOCAL SCALE

• The IDC Series comes with a stainless steel platform packed separately.

• Place the platform in the locating holes on the top cover.

• Do not press with excessive force as this could damage the load cell inside.

• Level the scale by adjusting the four feet. The scale should be adjusted such that the

bubble in the spirit level is in the center of the level and the scale is supported by all

four feet.

Page 8

- 4 -

• Attach the power supply cable to the connector on the right side of the scale base.

Plug in the power supply module. The power switch is located at the right side of the

scale base.

• The scale will show the model number in the “Weight” display window (IDC 15where 15 denotes the maximum capacity of the scale in Kg) and the current software

revision numbers in the “Unit Weight” display window .

• Next follows a self-test. At the end of the self-test, it will display “0” in all three

displays, if the zero condition has been achieved.

3.2.2 SETTING UP THE REMOTE SCALE

• The IDC Series can be connected to any size of load cell type weighing base via the

Remote scale port on the left side of the scale case. Ensure you have the correct base

for the scale as each is matched for calibration.

• Place the remote scale platform in the position where it is to be used. Level the scale

by adjusting the four feet. If fitted with a spirit level then it should be adjusted such that

the bubble is in the center.

• Press Local/Rem key and test weighing performance.

3.2.3 REMOTE SCALE CONNECTION

The cable for the load cell connects to a DB 9 pin d-subminiature plug connector with

the following connections:

Pin numbers

Connection

Pins 1,2

Excitation+(5V)

Pins 4,5

Excitation- (0v)

Pin 7

Signal-

Pin 8

Signal+

(The sense wires connections of a six wire load cell are not used but can be

connected to the respective Excitation pins).

3.2.4 REMOTE SCALE SET UP

See Section 12 Technical Parameters to set capacity, etc.

The remote scale should set for a realistic resolution with respect to the input provided

by the load cell/s.

If a single 2mV/V load cell is fitted and more than 60% of the load cell is used for full

capacity then the high output of >6mV span makes it possible to set a high resolution.

If this criterion is met then the remote scale can be set to a high resolution with a

maximum of 1/30,000, for example: 300kg x 10g.

It will also be possible to sample on the remote scale with the same accuracy as the

local.

Where more than one load cell is fitted or the total load cell capacity is not utilized then

Page 9

- 5-

a reduced resolution should be selected in the remote scale technical set up. For

example, if a system uses four 2mV/V 1000kg load cells for a scale of 1000kg

capacity then the span output at full scale will be only 2.5mV.

In this situation the resolution should be reduced to give a good number of ADC

counts per displayed division, for example, set to 1:5000 or 1000kg x 0.2kg.

Setting a high resolution without providing a good input to the remote scale ADC will

not give better accuracy and may make the scale difficult to meet performance

specification.

For best performance ensure a minimum of 0.1uV/d.

Page 10

- 6 -

SECTION 4 KEY DESCRIPTIONS

0-9, •

These keys are used to manually enter a value for tare weights, unit weight and

sample size. A secondary function is to enter alpha-numeric characters for PLU

descriptions etc.

CE

Pressing this key clears the unit weight or an erroneous entry. It also clears the

memory accumulation when the total is displayed.

M+

This key is used to add the current count to the accumulator. It also recalls the

memory when pressed with no load on the scale. Up to 99 values or full capacity of

the weight display can be added. Also prints the displayed values when Auto print is

switched off.

Smpl

This is used to enter the number of items of a sample.

PLU

To store and recall the Piece Look Up sample information.

U. Wt./Units

This key is used to enter the weight of a sample manually. It will also change the

weighing units when other units are enabled.

PST

To set the upper limit for the number of items counted. When this upper limit is

exceeded the scale will sound the beeper. A secondary function is to use it for the

backlight control setting.

Local/Rem

This key is used to select the local or remote scale.

Tare

tares the scale by storing the current weight in the memory as a tare value,

subtracting the tare value from the total weight and displaying the results as a net

weight.

Zero

sets the zero point for all subsequent weighing by setting the display to zero.

Page 11

- 7-

SECTION 5 DISPLAYS

The scales have three display windows- Weight, Unit Weight and Count.

5.1 WEIGHT WINDOW

This consists of a 6 digit display to indicate the weight on the scale.

An arrow above the symbols will indicate the following:

Low battery,

Net Weight Display, "Net"

Stability indicator, “Stable”

Zero indicator, “Zero”

Unit in use indicator, “Lb” or “Kg”

5.2 UNIT WEIGHT WINDOW

• This display will show the unit weight of a sample. This value is either entered by the

user manually or computed by the scale. The unit of measure is either gram on all

scales with kilogram selected as weighing unit or in pounds.

• When the scale has determined that there is insufficient number of samples to

accurately determine the count, an arrow will be shown above "Smpl".

• When the unit weight is not large enough to determine an accurate count, the arrow

will show at "U.Wt".

• When a value has been entered into the memory, the arrow above "M+" will be on.

• In both the cases the scale continues to operate and the indicators are to alert the

user of a potential problem.

5.3 COUNT WINDOW

• This display will show the number of items on the scale or the value of the

accumulated count. See the OPERATION section.

• An arrow above the symbols will indicate the following:

Checkweighing is active during counting, "Ck Pcs"

Checkweighing is active during weighing, “Ck Wt”

Checkweighing is active, result is above the High Limit, “High”

Checkweighing is active, result is between the Low and High Limit, “OK”

Checkweighing is active, result is below the High Limit, “Low”

• Just under the “Count” display is an LED to indicate the status of the battery

charging. When the scale is plugged into the main power the internal battery will be

charged. If the LED is green, the battery has a full charge. If it is red, the battery

requires further charging and yellow indicates the battery is being charged.

Page 12

- 8 -

SECTION 6 OPERATION

• The basic weighing functions are same for both the scales- local and remote.

However the number of weighing divisions may be less on the remote scale

dependant on the total capacity of the load cell/s used.

• Each scale (local or remote) has the ability to count parts based on the current unit

weight. This is best obtained by performing a sample on the local scale which may

have the best sensitivity. Then the scale can be switched to the remote where large

quantities can be counted.

• Each scale has a separate tare value that can be entered through the keypad or by

placing a weight on the platform and pressing the Tare key. The tare value for each

scale is retained as the user switches between the remote and local scales.

• Either scale can be used to determine a unit weight.

• When the scale is switched from local to remote, a clear display will be shown to

identify the change and the scales will count based on the tare and unit weight

currently in use for the scale selected. Display for the change is:

“chAngE” ”LocAL“ and “chAngE” ”remotE “, The display will be based on the 7

segment interpretations, some of letters are shown later.

• The switch from local scale to remote scale should be possible at any time by

pressing the Local/Rem key or if the user enables the function it can happen anytime

the weight on the remote scale changes from negative value or zero to a positive

value greater than 50d.

NOTE: For frequently used items, counting is made easier by using PLU numbers

(Product Look Up). Up to 100 PLU’s can be stored and recalled. See section 6.4 on

PLU for details. Place the item on the pan and enter using the keypad “PLUxx” (where

xx is the PLU number associated with that item). The scale will display the Total

Weight, Unit weight and the Count of the item in the respective windows.

6.1 ZEROING AND TARING THE DISPLAY

When the gross weight is within ±2% of the zero, set at power on for either scale

then a new zero is set. If the gross weight is greater than ±2% then the tare

function is performed.

6.1.1 ZEROING

• You can press the Zero key at any time to set the zero point from which all

other weighing and counting is measured. When the zero point is obtained the

Weight display will show the indicator at “Zero”.

• The scale has an automatic re-zeroing function to account for minor drifting or

accumulation of material on the platform. However you may need to press the

Zero to re-zero the scale if small amounts of weight are still shown even when

Page 13

- 9-

the platform is empty.

6.1.2 TARING

Select the local or remote scale as applicable by pressing the Local/Rem key.

Preset tare values can be used with both the local and remote scale. If a new tare

value is to be used, there are two methods for entering a tare value. The first method

uses the weight on the platform and the second uses a value to be entered by the

user.

First method of entering a tare value:

• Zero the scale by pressing the Zero key, if necessary. The arrow indicator

over “Zero” will be on.

• Place a container on the platform, a value for its weight will be displayed.

• Press the Tare key to tare the scale. The weight that was displayed is stored

as the tare value and that value is subtracted from the display, leaving zero on

the display. The arrow over "Net" will be on. As product is added only the net

weight of the product will be shown. The scale could be tared a second time if

another type of product was to be added to the first one. Again only the weight

that is added after taring will be displayed.

• When the container is removed a negative value will be shown. If the scale

was tared just before removing the container this value is the gross weight of

the container plus all products that were removed. The zero indicator will also

be ON because the platform is back to the same condition as it was when the

Zero key was last pressed.

Second method of entering a tare value:

• This method allows you to enter a value for the tare weight from the keypad.

This is useful if all containers are the same or if the container is already full but

the net weight is required and the weight of the container is known.

• Remove all weights from the platform, press the Zero key to zero the display.

• Enter the value for the Tare weight including decimal point using the keypad,

press Tare to store the tare value. The weight will show a negative value equal

to the tare.

• Place the container on the platform.

• The display will then show the weight of the container minus the tare weight.

When the full container is placed on the platform the tare value will be

subtracted from the gross weight displaying only the net weight of the contents.

• If the value input is not consistent with the increment of the scale, the scale will

round the tare value to the nearest value possible. For example, if a tare value

of 103g is entered into the 60Kg scale with 5g readability, then the display will

show -105g.

• The tare value for each scale is held in memory so that they are not lost when

the active scale changes.

6.1.3 TARING THE REMOTE SCALE

Select the remote scale by pressing the Local/Rem key and then follow the same

procedure for taring as mentioned in the above sections.

Page 14

- 10 -

6.2 MEMORY FUNCTIONS

The M+ key will add the results of a weighing into memory, regardless of whether the

local or remote scale is being used for the weighing.

6.2.1 Manual accumulation

• The values (weight and count) shown on the display can be added to the

values in the accumulator by pressing the M+ key. The "Weight" display will

show the total weight, the "Count" display will show the total accumulated count

and the "Unit Weight" display shows the number of times items have been

added to the accumulation memory. The values will be displayed for 2 seconds

before returning to normal.

• The scale must return to zero or a negative number before another sample can

be added to the memory.

• More products can then be added and the M+ key pressed again. This can

continue for up to 99 entries or until the capacity of the “Weight” display is

exceeded.

• To observe the total value stored, press the M+ key when the scale is at zero.

The total will be displayed for 2 seconds.

• To clear the memory, first press M+ to recall the total from the memory and

then press CE to clear all values from the memory.

6.2.2 Automatic accumulated total

• The scale can be set to automatically accumulate total when a weight is placed

on the scale. This eliminates the need to press the M+ key to store values into

the memory. However the M+ key is still active and can be pressed to store the

values immediately. In this case, the values will not be stored when the scale

returns to zero.

• See PARAMETERS Section on enabling Automatic Accumulation.

6.3 PARTS COUNTING

The basic function of parts counting is same for both the scales. In order to do parts

counting it is necessary to know the average weight of the items to be counted. This

can be done either by weighing a known number of the items and letting the scale

determine the average unit weight or by manually inputting a known unit weight using

the keypad.

Either of the scales can be used to determine the sample unit weight or for the manual

entry which can be used to count using either of the scales.

It is possible to increase the accuracy of the unit weight at any time during the

counting process by entering the count displayed and then pressing the Smpl key.

You must ensure that the quantity displayed matches the quantity on the scale before

pressing the key. The unit weight can be adjusted based on a larger sample quantity.

This will give greater accuracy when counting larger sample sizes.

Page 15

- 11-

6.3.1 Weighing a sample to determine the Unit Weight

To determine the average weight of the items to be counted place a known quantity of

the items on the scale and then enter the quantity being weighed.

The scale will then divide the total weight by the number of samples and display the

average unit weight.

• Zero the scale by pressing the Zero key if necessary. If a container is to be

used, place the container on the scale and tare as discussed earlier.

• Place a known quantity of items on the scale. After the “Weight” display is

stable enter the quantity of items using the numeric keys followed by pressing

the Smpl key. The number of units will be displayed on the "Count" display and

the computed average weight will be shown on the "Unit Weight" display.

• As more items are added to the scale, the weight and the count will increase.

• If the scale is not stable, the calculation will not be completed.

• If the weight is below zero, “Count” display will show negative count.

6.3.2 Entering a known Unit Weight

• If the unit weight is already known then it can be entered using the keypad.

• Enter the value of the unit weight using the numeric keys followed by pressing

the U. Wt. key within few seconds while the display is flashing. If no action is

initiated within a few seconds, the "Unit Weight” display will revert to the

previous value, otherwise it will show the new value that has been entered.

• The sample is then added to the scale and the weight will be displayed as well

as the quantity based upon the unit weight. When weighing in kilograms the unit

weight is shown in grams. When weighing in pounds the unit weight is shown in

pounds.

• After the unit weight has been determined or entered, the scale can be used

for parts counting. The scale may be tared to account for the net weight as

discussed in an earlier section.

• After the scale is tared, the items to be counted are added and the "Count"

display will show the number of items computed using the weight and the unit

weight.

• It is possible to increase the accuracy of the unit weight at any time during the

counting process by manually entering the sample quantity and then pressing

Smpl. Ensure that the quantity displayed matches the quantity on the scale

before pressing the key. The unit weight will be adjusted based upon a larger

sample quantity

providing greater accuracy when counting larger sample sizes.

6.3.3 Automatic update of unit weight

• The scales will automatically update the unit weight when a sample less than

the initial sample count is added. A beep will be heard when the value is

updated. It is wise to check the quantity is correct when the unit weight has been

updated automatically.

• To lock the unit weight and prevent Auto-update, press U.Wt.

• This feature is turned off as soon as the number of items added exceeds the

Page 16

- 12 -

count used as a sample.

6.3.4 Count pre-set or check-weighing

Check-weighing (or Count Pre-setting) is a procedure to cause an alarm to sound

when the net weight (or the number of items) on the scale meets or exceeds a number

stored in memory. The value to be stored is entered from the keyboard.

SETTING OF PRESET LIMITS

It is possible to set a high and low limit for either counting or weighing (using net

weight). When the Pst key is pressed the user can select either counting or weighing

and then set the lower and upper limit.

For example:

ACTION

DISPLAYS

Press Pst

“PST ” “ nEt “ “ “ if currently in the weighing mode

Press U.Wt/Units

“PST ” “ cnt “ “ “ to toggle from weighing to counting

Press Tare

“Hi cnt” “0.3 234” “ ” The current high count limit is

displayed, press CE to clear and change if needed.

Press Tare

“lo cnt” “0.0234” “ ” The current low count limit is

displayed, press CE to clear and change if needed.

Press Tare

Return to weighing with limits set.

• Clearing of either or both the limits is allowed. Both limits cleared will disable the

Preset altogether.

• If Preset Weight was selected the first display would show “Hi net” and “lo net”.

• The beeper will work as described in the Beeper Parameter.

6.4 PLU (Product Look Up)

Product Look-Up (PLU) numbers are used to store information about the commonly

used items. The Tare Weight, Description of the product and Unit Weights for a

particular item are recalled by entering the PLU number for ease of operation.

The scale is capable of storing values for the Tare weight, Description and Unit

Weight for a maximum of up to 100 PLU numbers.

Tare Weight value is required for calculating the Net Weight where a container is used

during weighing. Descriptions are used for sending data over RS-232 for viewing or

printing and Unit Weight is used for parts counting.

These data should be entered against a particular PLU before the weighing

process starts so that the desired PLU’s can be recalled during the weighing

process. The data can be stored and recalled manually or by sending data over

RS-232 Interface.

Page 17

- 13-

6.4.1 STORING PLU’S MANUALLY

ACTIONS

DISPLAYS

REMARKS

Weight

Unit weight

Count

Press Zero if required.

“00000”

“ 0“

“ 0“

The scale is zeroed.

Note:

Enter or determine the Tare Weight when a container is to be used (see section 6.2 of

this User Manual). If a Tare value is used, the scale will be in the NET mode.

Enter or determine the Unit Weight as described in section 6.3.1 and 6.3.2 of this User

Manual.

The Tare and Unit Weight to be stored can be either taken from a weighing in process

or by manual entry of data.

Please find below an example for setting up “PLU 27” with Description as “M4 Nut”

and Unit weight of “0.015”.

For Example: how to store PLU 27. First you need to set the unit weight “0.015”

(press “0”,”.”,”0”,”1”,”5” keys to input, and then press “U.Wt” key), the “unit weight”

window will show “0.015”, and then press “PLU” key enter 27 press “PST” key

enter product name (description of the product) “M4 nUt” (“unit weight” windows

display), “brASS” (“count” window display) press “tare” key to sure, then the PLU

27 is stored in the scale.

ACTIONS

DISPLAYS

REMARKS

Weight

Unit weight

Count

Press PLU

“PLU ”

“ - -“

“ “

-

Press 2, 7

“PLU ”

“ 27”

“ “

-

Press Pst

“PLU 27”

“x x x x x x”

“x x x ”

The current description

will be shown with the

first character flashing.

The flashing digit can

be changed using the

numeric keypad.

Pressing the CE

key when the first

character is flashing

will clear all the

descriptions.

“PLU 27 ”

“ “

“ “

Continue to enter

characters until

description is

complete.

“PLU 27 ”

“M 4 Nut“

“Brass “

12 characters in

total spreading over

both the displays (UNIT

WEIGHT and COUNT).

Page 18

- 14 -

Note:

Hold “0-9” digit keys to input character, the “.” key to go back to the previous digit or

the “M+” key to advance to the next character.

A flashing character can be used for entering a space by pressing the 0 key for

slightly longer duration.

Tare value will only be stored with PLU data if the scale is in the NET mode. If the

container is less then the manual zero range which is set in "Technical parameters"

(default is 2% of capacity) then the scale will be Zeroed and no tare value will be

stored. To avoid this, use a larger container, reduce the zero range or use the digital

tare method.

6.4.2 ENTERING DESCRIPTION MANUALLY

The description can be up to 12 characters long and can be a mix of numbers,

symbols or letters.

During the procedure to set the description the numeric keypad will work in a similar

way to a mobile telephone. Pressing a number briefly will show the number and

holding it down will scroll through all the characters.

The numbers and characters are:

1

- / \ 2 A B C

3

D E F

4

G H I

5

J K L

6

M N O

7

P Q R S

8

T U V

9

W X Y Z

0

_ [ ] Where _ is a Space (Not underscore)

The limitations of the 7 segment display sometimes make it difficult to display some

letters. The characters and the displayed symbols are:

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z - / \ ( )

A B C D E F G H I J K L M N O P Q R S T U V W X Y

Z

The characters will be stored as text so the output of the RS-232 interface will be

correct.

The numbers 1 2 3 4 5 6 7 8 9 0 will be 1234567890

Note that this method is only used where alpha-numeric data is permitted. This is

used for the Description field and the User ID number, Scale ID number in the

parameters section.

Page 19

- 15-

6.4.3 RECALLING PLU’S MANUALLY

• To recall the PLU values the user should first select either local or remote scale as

the tare value stored will be specific to the scale selected.

• Then press the PLU key, enter the PLU number (00 – 99) then press the PLU key

again to recall the data.

• The display will show the results of the recall for 1 second then return to weighing

with the data in place.

For example:

• If the PLU key is held down after the numeric entry, it will show the description as

long as the key is pressed.

• In this example the display “PLU 27 ” “M 4 Nut“ “Brass “ shows the description for

1 second, if no data is stored then it will show “PLU 27” “ “ “ “.

• If the tare value is outside the range permitted for the selected scale (For example, if

the local scale is selected whereas the tare value applies to the remote scale, this

would exceed the capacity of the local scale) the “Weight” display would show zero

tare weight.

• If the tare value stored does not match the increment of the selected scale (For

example, storing -1.446 for a scale with d=0.05) then round the tare weight depending

on the scale resolution (For example, in this case, -1.45 would be used as the tare

value).

• If a PLU number is recalled that does not have any information stored against it, the

scale will continue to work with Tare and Unit weight unchanged.

PLU’s can be stored and recalled using RS-232 Interface (see section 9.1 and

9.2 of this user Manual).

ACTIONS

DISPLAYS

Press PLU

“PLU ”

“ - -“

“ “

Press 2, 7

“PLU ”

“ 27”

“ “

Press PLU

“PLU 27 ”

“M4 Nut“

“Brass “

After 1 second, it will return to normal

weighing with the Tare and Unit Weight

previously entered.

“ x x x x“

“ x x x x ”

“ x x“

Page 20

- 16 -

SECTION 7 PARAMETERS

The parameters are split into 2 sections, one for the managers and the other one for

Technical.

7.1 USER PARAMETERS

Enter the User Parameters section by pressing the Pst key during the self-test when

the power is turned on. This will allow the user to set the way he wants the scale to

work by choosing specific values from some options.

Press the U.Wt./Units key to scroll through the other parameters. To enter any

parameter, press the Tare key.

Press U.Wt./Units to scroll through the sub-parameters. To see the earlier setting,

press the Tare key. To change and scroll through the other available settings, press

U.Wt./Units . To choose the desired setting and thereby go back to the

sub-parameter, press the Tare key.

To return to the parameter, press the Zero key.

7.2 PARAMETER SETTING TABLE

PARAMETER

SUB-

PARAMETER

DISPLAYS AND SETTINGS

F1 oFF

bEEP

“bEEP" "oFF"

Beeper is set to off

“bEEP" "on I n "

Beeper is set to on between

limits

“bEEP” "on oUt”

Beeper is set to on outside

limits (when weight less than

min capacity, checkweighing

function will not available

EL

“LitE" “"oFF"

Backlight is set to off

“LitE" "on"

Set to on at all times

“LitE" "AUt"

Set to work automatically when

a weight is placed on the scale

or a key is pressed.

Un I t

“UnI t” ” KG Lb”

Kg/Lb both are enabled

”UnI t” “KiLo”

Kg only is enabled

”UnI t” “Lb”

Lb only is enabled

F2 Prt

P Mo dE

Print

Au oFF Prints only when the

Auto-Accumulation is set to off.

Au on Prints only when the

Auto-Accumulation is set to on.

Page 21

- 17-

P Cont

Sets the RS-232 interface to

print continuously and the

accumulation function is

disabled.

SEr r E

Sets the RS-232 to print

continuously the weight

only.(for remote display)

P bAU d

b 600

b 1200

b 2400

b 4800

b 9600

Sets the required baud rate

(speed for the RS- 232

communications).

Default rate is 4800.

PAritY

8 n 1

7 E 1

7 o 1

8 data bits, no parity

7 data bits, even parity

7 data bits, odd parity

ptype

tpup

lp50

Tpup:TSCALE Tpup printer

Lp50: TSCALE lp-50 printer

U id

“U id”

“ Abc234”

“ “

Shows the current user ID (if any).

Enter a new User ID as described in the description

under the PLU section. The ID can be alphanumeric,

but is limited to 6 characters.

SC id

“Sc id”

“ Abc234”

“ “

Shows the current scale ID (if any).

Enter a new Scale ID as described in the Description

under the PLU section. The ID can be alpha-numeric

but is limited to 6 characters.

tECH

Allows access to the Technical parameters using a

password. Not normally accessed by user.

Page 22

- 18 -

SECTION 8 BATTERY OPERATION

• The scales can be operated from the battery if desired. The battery life is

approximately 70 hours if only the basic unit is used. If a second platform is

used the battery life will be reduced.

• When the battery needs charging the arrow above the low battery symbol

under the “Weight” display will turn on. The battery should be charged as soon

as the arrow above the symbol is on. The scale will still operate for about 10

hours after which it will automatically switch off to protect the battery.

• To charge the battery simply plug into the mains power. The scale need not to

be turned on.

• The battery should be charged for 12 hours for full capacity.

• Just under the “Count” display is an LED to indicate the status of battery

charging. When the scale is plugged into the main power the internal battery will

be charged. If the LED is green the battery has a full charge. If it is red, the

battery is nearly discharged and yellow indicates the battery is nearly charged.

NOTE: It is recommended that the battery be charged before using the scale when the

unit has been unpacked.

Page 23

- 19-

SECTION 9 RS-232 OUTPUT

Specifications:

RS-232 output of weighing, data default settings

ASCII code

4800 Baud (600-9600 selectable)

8 data bits (8 data bits no parity, 7 data bits even and odd parity selectable)

No Parity

Connector style needed:

25 pin d-subminiature socket

Pin 2 Output

Pin 3 Input

Pin 7 Signal Ground

Sample of output:

9.1 INPUT COMMANDS FORMAT

The scale can be controlled with the following commands.

Input Commands:

• The scale has a number of commands to either cause an action or to enter data

into memory. The commands are all upper case and are summarised below.

• All commands are terminated by a carriage return (Enter button on PC keyboard)

with the line feed optional.

• If an illegal command is received or a command cannot be carried out then send

the command back with the addition of ER in front of it. For example if the

command is NN<cr><lf> then send back ER NN<cr><lf>.

Basic Commands:

LOCAL SCALE

ID: 123ABC

NAME:Text

12.456 kg NET

1.1234 g U.W.

11 PCS

TOTAL

- - - - - - - - - - - -

49.824 kg TW

44 TPC

4 No.

Page 24

- 20 -

PLUxx

Select PLU from scale memory to be used

T

Tare current weight value

T123.456

preset tare value is 123.456

Z

Zero the display

P

Print using selected format

M+

Store current results into memory and print

MR

Recall memory values to scale display

MC

Clear memory

U123.456

Store unit weight of 123.456(grams if in kilograms or pounds if

currently in pounds)

S123

Enter sample size of 123 parts. Same as pressing Smpl key.

SL

Select local scale to be used

SR

Select remote scale to be used

Immediate Printing Commands:

Command

Output from scale

\L

Scale: Local or Remote

\I

ID number same as PUID below

\S

Scale number same as PSID below

\N

Net weight

\G

Gross Weight

\T

Tare weight

\U

Unit weight

\P

Count

\C

Total Count

\W

Total Weight

\M

Number of items stored in memory

\B

A blank line printed

9.2 STORING DATA VIA RS232

To store data the commands are:

SUIDxxxxxx <CR>

Store user ID data

SSIDxxxxxx <CR>

Store scale ID data

SPLUxx,xxxxxxxxxxxx <CR>

Store text data for PLUxx

When PLU text data is stored the Scale used, current unit weight and current tare

value is also stored to that PLU number.

For the SPLU command the data is: PLU number (2 characters), (Comma) description

(max 12 characters).

If the fields are less than the maximum all characters need not be used.

9.3 PLU ENTRY USING RS-232 INTERFACE

Page 25

- 21-

This will allow the scale data to be sent from a PC program as well as from the keypad.

The most common PLUs can be stored and recalled from the scale memory. Other

PLU data can be stored on a PC, then the text data, unit weight and tare data can be

sent from the PC to PLU00. This can then be used and over written each operation.

OPERATION:

• Send tare data to set any tare value to be stored with PLU. i.e. “T0.150” <CR>.

If no tare is needed then you may send T0 to delete any present tare data.

• Send the unit weight to be stored with PLU. ie. “U12.3456” <CR>

• Send PLU text data to be stored with current TARE and U/W values. ie.

“SPLU01,Parts” <CR>

Page 26

- 22 -

SECTION 10 CALIBRATION

ACTION

DISPLAYS

During the self-test at power on, press the Zero key. The scale

will ask you to enter the password.

“ Pi n”

Default Password is 0000.

Enter “0” four times.

Password can be changed in technical parameters.

Press Tare.

“ Pi n” “ ----”

Select the scale to be set up by using the Local/Remote key.

Press the Tare key to enter the technical section.

“tEch” “ LocAL” “ “

“tEch” “rEmo tE” “ “

Use the U.Wt. to select the weighing unit to be used for setting

the calibration for the scale. The arrow in the “Weight” window will

indicate the unit selected.

Press the Tare key to continue.

“tEch” “ Uni t” “ “

You will enter Calibration. Display will ask you to unload any

weight on the platform. After “STABLE” indicator appears, press

the Tare key to continue.

“Un L o Ad”

Enter the calibration value to be loaded (E.G. for one lb

press 1, for two lb press 2) and press Tare. If a

calibration value has already been selected, press the

CE button to remove the unwanted calibration value

and then enter the new value.

Load the calibration weight onto the scale and press Tare again.

The scale will calibrate and commence a self test.

The calibration weight should be removed while the scale is

running the self-test.

The Calibration is complete.

“SEL” “ 0010”

“Lo Ad”

Page 27

- 23-

SECTION 11 ERROR CODES

During the initial power-on testing or during the operation, the scale may show an

error message. The meaning of the error messages are described below.

If an error message is shown, repeat the procedure that caused the message, such as

turning the balance on, calibration or any other functions. If the error message is still

shown then contact your dealer for further support.

ERROR CODE

DESCRIPTION

POSSIBLE CAUSES

Err 4

Initial Zero is greater

than the permissible

value (typically 4% of

maximum capacity)

when power is turned

on or when the Zero

key is pressed,

Weight on the pan when turning the

scale on.

Excessive weight on the pan when

zeroing the scale.

Improper calibration of the scale.

Damaged load cell.

Damaged Electronics.

Err 5

Keyboard error

Improper operation of the scale.

Err 6

A/D count is not correct

when turning the scale

on.

Platform is not installed.

Load cell may be damaged.

Electronics may be damaged.

FAIL H or FAIL L

Calibration error

Improper calibration.

If the problem persists contact your

dealer for assistance.

.

Page 28

- 24 -

SECTION 12 TECHNICAL PARAMETERS

The technical parameters accessed via the “tEch” prompt at the end of user

parameters and are password controlled to prevent unauthorized access.

These parameters set the metrology for the scales. Each scale is set independently.

The parameters will set capacity, division, decimal point position, initial zero range,

auto and manual zero range as well as factory calibration.

ACTION

DISPLAYS

Enter the User Parameters section by pressing the

Pst key during the self-test when the power is

turned on. This will allow the user to set the way he

wants the scale to work by choosing specific values.

“F1 off”

Press the U.Wt./Units key until the display shows

“tech”

“tech”

From the “tech” user parameter, Press the Tare key.

The scale will ask you to enter the password.

“ Pin”

Default Password is 0000. Enter “0” four times.

9999 will override any other user password. Press

Tare.

“ Pin” “ ----”

Select the scale to be set up by using the

Local/Rem key.

Press Tare to enter the technical section for that

scale.

“tEch” “ LocAL” “ “

“tEch” “rEmotE” “ “

Use the U.Wt./Units key to select the weighing unit

to be used for setting up the parameters for the

scale.

The arrow in the “Weight” window will indicate the

unit selected.

Press the Tare key to continue.

“tEch” “ Unit” “ “

To display raw count, press Tare. To escape raw

count, press Tare again.

Press the U.Wt./Units key to scroll through the

menus for the chosen scale. Use Tare to select and

set parameters and the Zero key to escape without

changing data as with the user parameter section.

“Cnt” (Cnt is raw count)

Both scales have the same

menus except that the

capacity of the local scale is

fixed and cannot be entered.

“CAp”. Scale capacity setting.

(in local scale you can’t set

capacity)

Page 29

- 25-

Use U.Wt/Unit to enter the decimal point position

and use the numeric keypad to select and press

Tare

To change the remote scale capacity (SEL), press

CE to clear and then enter the new value followed

by Tare

“dESC” “ 0.00”

“SEL” “0060”

To select the increment use the numeric keypad,

then press Tare

The display returns to CAp

“inC 1”

“CAp”

Press the U.Wt/Unit to go to the next menu.

“div” weighing division.

Press the U.Wt/Unit to go to the next menu, use the

Tare key to enter.

Use U.Wt/Unit to increment the values, then press

Tare.

“Azt” Autozero tracking

range.

Select from 0.5d 0.5d, 1d, 2,

4,d

“Azt”

Press the U.Wt/Unit to go to the next menu.

“0 Auto” Zero auto range at

power on.

Press the U.Wt/Unit key to go to the next menu.

Use the Tare key to enter.

“0 manl” Zero manual range.

Press the U.Wt/Unit key to go to the next menu.

Use the Tare key to enter.

Enter the new PIN number and press Tare

Confirm the new PIN number and press Tare

“Pin” Password number for

“tEch”.

“Pin1”

“Pin2”

“donE”

Press U.Wt./Units to continue or escape the

parameters by pressing Zero

Page 30

- 26 -

Intelligent Weighing Technology serves the industrial and laboratory markets in North America

with competitive pricing and value for money on a complete range of industrial and laboratory

scales and balances, force measurement and load monitoring technology from 0.01 mg to 275

tons.

We are the exclusive source for Intell-Lab™, Intell-Industrial™, Intell-Check™,

Intell-Count™, Intell-Weigh™, Intell-Base™, Intell-Scan™ and Intell-Print™ laboratory, industrial,

counting, analytical, precision and toploading balances, printers, peripherals and weighing

equipment.

We are the exclusive source for UWE weighing equipment in the US and the Caribbean.

We are the exclusive source for Intell-Lift™ Straightpoint (UK), Ltd. products in North

America, Mexico and the Caribbean.

We have a combined 50 years of experience in the weighing and measurement industry, both in

the USA and worldwide. With contacts in over 50 countries, we provide you with the weighing

and measurement equipment you need.

QUALITY - Products solidly built from the ground up with superior engineering and

components for exacting results.

VALUE - Equipment priced for real-world business applications, with superior service and

support.

EXPERIENCE - Expert advice to help you choose just the right product for your application.

Quality + Value + Experience…it adds up to the Intelligent Investment.

Intelligent Weighing Technology, Inc.

www.intelligentwt.com

© Intelligent Weighing Technology, Inc. All rights reserved worldwide.

The information contained herein is the property of Intelligent Weighing Technology, Inc. and is supplied without liability for errors or omissions. No part may be reproduced

or used except as authorized by contract or other written permission. The copyright and the foregoing restriction on reproduction and use extend to all media in which the

information may be embodies.

Loading...

Loading...