Page 1

FORCE

POWER DRIVE

MOTION CONTROL

[with optional CANopen]

Excellence in Motion

TM

TM

FEATURES

• Highly Integrated, High Performance

Microstepping Driver and Motion Controller

• Advanced 2nd Generation Current

Control for Exceptional Performance

and Smoothness

• Single Supply: +12 to +75 VDC

• Low Cost

• Compact Package

• High Output Current up to 5 Amps RMS,

7 Amps Peak (Per Phase)

• Auxiliary Logic Power Supply Input

• 20 Microstep Resolutions up to

51,200 Steps Per Rev Including:

Degrees, Metric, Arc Minutes

• Open or Optional Closed Loop Control

Programmable Motor Run and Hold Currents

•

• One 10 Bit Analog Input Selectable: 0 to

+10 VDC

• 0 to 5MHz Step Clock Rate

Selectable in 0.59Hz In cre ments

• RS-422/485 or Optional CANopen*

Communications

• 62 Software Addresses for

Multi-Drop Communications

• Simple 1 to 2 Character Instructions

• 8 I/O Lines, +24 VDC Tolerant,

Sourcing or Sinking, Inputs and Outputs

• Electronic Gearing

• Open Loop or Optional External/Remote

Encoder for Closed Loop Control

• High Speed Position Capture Input or

Trip Output

• Dual Mounting Confi gurations

• Pluggable Locking Wire Crimp Interface

*CANopen may not support some objects.

, 0 to +5 VDC, 0-20 mA, 4-20 mA

DESCRIPTION

The Motion Control MForce PowerDrive

offers system designers a low cost,

high performance microstepping driver

integrated with an in tel li gent, programmable motion con trol ler.

The unsurpassed smoothness and

performance delivered by MForce PowerDrives are achieved through IMS's

advanced 2nd generation current

control. By applying innovative techniques to control current fl ow through

the motor, resonance is signifi cantly

dampened over the entire speed range

and audible noise is reduced.

Motion Control MForce PowerDrives

accept a broad input voltage range

from +12 to +75 VDC, delivering

enhanced performance and speed.

Oversized input capacitors are used

to minimize power line surges, reducing problems that can occur with long

runs and multiple drive systems. An

extended operating range of –40° to

+85°C provides long life, trouble free

service in demanding environments.

A high, per phase output current of up

to 5 Amps RMS, 7 Amps Peak, allows

the compact MForce PowerDrive to

control a broad array of motors from

size 23 to size 42.

Standard features include eight +5 to

+24 volt general pur pose I/O lines and

the capability of electronic gearing by

following a rotary or linear axis at an

electronically controlled ratio, or an

output clock can be generated fi xed to

the internal step clock. Also included

are one 10 bit analog in put, 0 to

5MHz step clock rate, 20 microstep

res o lu tions up to 51,200 steps per

rev o lu tion, and full fea tured easy-toprogram in struc tion set.

MForce PowerDrives are available

with optional closed loop con trol. This

increases functionality by adding stall

detection, position main te nance and

fi nd index mark. The closed loop confi guration offers an expanded choice of

line counts and resolutions by interfacing to a remotely mounted user-supplied external encoder.

Motion Control MForce PowerDrives

com mu ni cate over RS-422/485 which

al lows for point-to-point or multiple unit

con fi g u ra tions utilizing one com mu ni ca tion port. Addressing and hard ware

support up to 62 uniquely addressed

units com mu ni cat ing over a single line.

Baud rate is selectable from 4.8 to

115.2kbps.

Optional communication protocols

include CANopen. The CAN bus is

2.0B active (11 and/or 29 bit) and

is capable of all standard frequencies

from 10kHz to 1MHz. CANopen features include node guarding, heartbeat

producer, SDOs and PDOs. Highlights

include variable PDO mapping and extended node identifi er.*

The versatile Motion Control MForce

PowerDrive comes with dual mounting

confi gurations to fi t various system

needs. All in ter face con nec tions are accomplished using pluggable locking wire

crimp connectors, with the exception of

the CANopen option which uses a DB9

connector. Optional cables are available

for ease of connecting and confi guring

the MForce, and are recommended

with fi rst order.

The Motion Control MForce PowerDrive

is a compact, powerful and inexpensive

solution that will reduce system cost,

design and assembly time for a large

range of applications.

www.imshome.com

Page 2

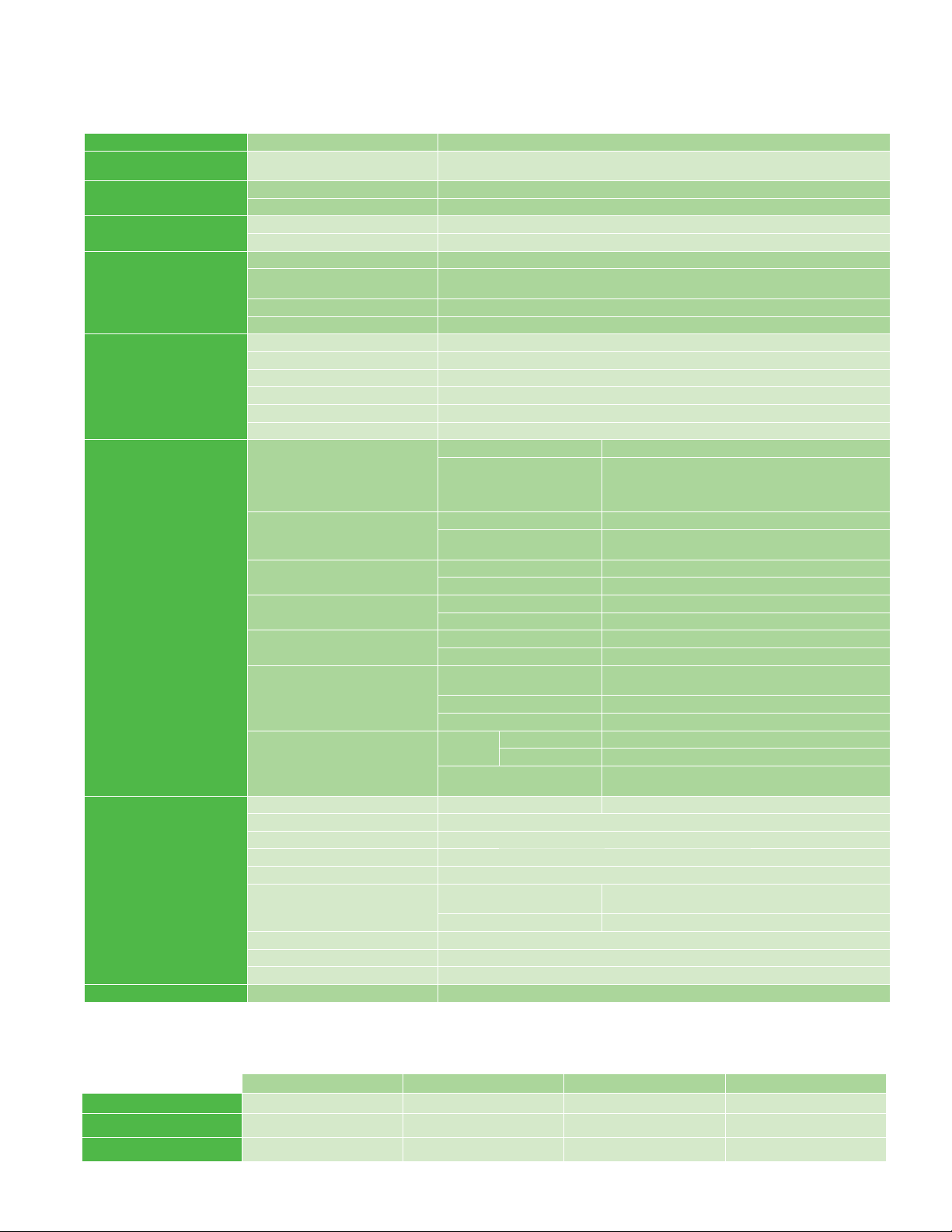

MForce PowerDrive

–

STANDARD SPEC I FI CA TIONS

MOTION CONTROL

INPUT VOLTAGE (+V)

AUX. LOGIC INPUT VOLTAGE

OUTPUT CURRENT

ANALOG INPUT

GENERAL PURPOSE I/O

COMMUNICATION

MOTION

SOFTWARE

‡

THERMAL

Adjusting the microstep resolution can increase the range.

Range +12 to +75 VDC

Range

RMS (Max) 5 Amps

Peak (Per Phase) 7 Amps

Resolution 10 Bit

Voltage Range 0 to +5 VDC, 0 to +10 VDC,

Number/Type 8 Sourcing or Sinking Outputs/Inputs

Logic Range

Output Sink Current Up to 600 mA per Channel

Protection Over Temp, Short Circuit, Transient Over Voltage, Over Voltage, Inductive Clamp

Type (Standard) RS-422/485

Baud Rate 4.8 to 115.2kbps

Type (Optional) CANopen DSP-402 (V2.0), DS-301 (V3.0), 2.0B Active

ID 11 and/or 29 Bit

Isolation Galvanic

Features Node Guarding, Heartbeat, SDOs, PDOs (Variable Mapping)

Open Loop Confi guration or

Optional Closed Loop Confi guration

Optional Remote Encoder

Closed Loop Confi guration

Counters

Velocity

Accel/Decel

Electronic Gearing

High Speed I/O

Program Storage Type/Size Flash/6384 Bytes

User Registers (4) 32 Bit

User Program Labels and Variables 192

Math Functions +, –, ×, ÷, >, <, =, <=, >=, AND, OR, XOR, NOT

Branch Functions Branch & Call

General Purpose I/O

Functions

Trip Functions Trip on Input, Trip on Position, Trip on Time, Trip Capture

Party Mode Addresses 62

Encoder Functions Stall Detection, Position Maintenance, Find Index

Heat Sink Temperature –40° to +85°C

+12 to +24 VDC

Maintains power to control and feedback circuits (only) when input voltage is removed.

0-20 mA, 4-20 mA

Sourcing Outputs +12 to +24 VDC, Inputs and Sinking Outputs Tolerant to +24 VDC,

Inputs TTL Level Compatible

Number of Settings 20

200,

400, 800, 1000, 1600, 2000, 3200, 5000,

Steps Per Revolution

Type User-Supplied Differential Encoder

Resolution

Type Position, En cod er/32 Bit

Edge Rate (Max) 5 MHz

Range +/- 5,000,000 Steps Per Second

Resolution 0.5961 Steps Per Second

Range 1.5 x 10

Resolution 90.9 Steps Per Second

Range‡/Resolution/Threshold

(External Clock In)

Input Filter Range 50 nS to 12.9 µS (10 MHz to 38.8 kHz)

Range‡ (Secondary Clock Out) 1 to 1

Position

Capture

Trip Output –

Speed/Resolution/Threshold

Inputs

Outputs Moving, Fault, Stall, Velocity Change, General Purpose

Input Filter Range 50 nS to 12.9

Resolution 32 Bit

6400, 10000, 12800,

40000, 50000, 51200, 36000 (0.01 deg/µstep),

21600 (1 arc minute/µstep), 25400 (0.001mm/µstep)

User-Defi ned

Note: µstep/rev 2X the encoder count/rev minimum

9

Steps Per Second

0.001 to 2.000/32 Bit/TTL

150 nS/32 Bit/TTL

Home, Limit Plus, Limit Minus, Go, Stop, Pause, Jog

Plus, Jog Minus, Analog In, General Purpose

20000

, 25000, 25600,

2

2

µ

S (10 MHz to 38.8 kHz)

MOTOR RECOMMENDATIONS

IMS PART NUMBERS

SINGLE LENGTH

DOUBLE LENGTH

TRIPLE LENGTH

2 MForce PowerDrive – Motion Control REV052307

Size 23 (2.4 Amps) Size 23 (3.0 Amps) Size 23 (6.0 Amps) Size 34 (6.4 Amps)

M-2218-2.4 M-2218-3.0 M-2218-6.0 M-3424-6.3

M-2222-2.4 M-2222-3.0 M-2222-6.0 M-3431-6.3

M-2231-2.4 M-2231-3.0 M-2231-6.0 M-3447-6.3

Page 3

MOTOR PERFORMANCE — Speed-Torque

NEMA 23 — 2.4 Amps RMS

225

200

C

175

150

B

125

100

75

A

Torque in Oz - In

50

25

0

0

1000

2000

3000

(300)

(600)

(900)

4000

(1200)

5000

(1500)

24 VDC

45 VDC

75 VDC

(1800)

6000

7000

(2100)

159

141

124

106

88

71

53

35

18

NEMA 23 — 3.0 Amps RMS

225

Torque in N - cm

200

175

150

125

100

75

Torque in Oz - In

50

25

0

Speed in Full Steps per Second (RPM)

NEMA 23 — 6.0 Amps RMS

225

200

C

175

150

B

125

100

A

75

Torque in Oz - In

50

25

0

0

1000

2000

3000

(300)

(600)

(900)

4000

(1200)

5000

(1500)

24 VDC

45 VDC

75 VDC

(1800)

6000

7000

(2100)

159

141

124

106

88

71

53

35

18

NEMA 34 — 6.3 Amps RMS

1000

Torque in N - cm

900

800

700

600

500

400

300

orque in Oz - In

T

200

100

0

Speed in Full Steps per Second (RPM)

PIN ASSIGNMENTS

P1: I/O CONNECTOR

Pluggable Locking

Wire Crimp

Standard

Pin 1 I/O Power I/O Power

Pin 2 I/O Ground I/O Ground

Pin 3 I/O 1 I/O 1

Pin 4 I/O 2 I/O 2

Pin 5 I/O 3 I/O 3

Pin 6 I/O 4 I/O 4

Pin 7 I/O 9 I/O 9

Pin 8 I/O 10 I/O 10

Pin 9 I/O 11 I/O 11

Pin 10 I/O 12 I/O 12

Pin 11 Capture/Trip I/O Capture/Trip I/O

Pin 12 Analog In Analog In

Pin 13 Step/Clock I/O Step/Clock I/O

Pin 14 Direction/Clock I/O Direction/Clock I/O

Pin 15

Pin 16 Channel A –

Pin 17 Channel B +

Pin 18 Channel B –

not applicable

Pin 19 Index +

Pin 20 Index –

P2: COMM CONNECTOR

RS-422/485

Friction Lock Wire Crimp Function DB9 Function

Pin 1 TX +

Pin 2 Comm Ground

Pin 3 RX – Pin 3 CAN –V

Pin 4 TX – Pin 4 Aux Power

Pin 5

Aux-Logic (+12 to +24 VDC)

Pin 6 RX +

Pin 7 RX + Pin 7 CAN High

Pin 8 RX – Pin 8 No Connect

Pin 9 TX + Pin 9 CAN +V

Pin 10 TX –

P3: POWER CONNECTOR

Wire Crimp Function

Pin 1 +V (+12 to +75 VDC)

Pin 2 Power/Aux Ground

Function

With Optional Remote

Encoder Closed Loop Control

Channel A +

CANopen

Pin 1 No Connect

Pin 2 CAN Low

Pin 5 Shield

Pin 6 CAN –V

P4: MOTOR CONNECTOR

Wire Crimp

Pin

1 Phase A

Function

Pin 2 Phase /A

Pin 3 Phase B

Pin 4 Phase /B

C

B

A

0

1000

2000

(600)

3000

(900)

(300)

Speed in Full Steps per Second (RPM)

C

B

A

0 1000

2000

(600)

3000

(900)

(300)

Speed in Full Steps per Second (RPM)

MECHANICAL SPECIFICATIONS

Dimensions in Inches (mm)

FRONT VIEW

2.116

(53.75)

BOTTOM VIEW

3.897

(98.98)

0.417 TYP .

(10.59 TYP .)

Connector Options

P2

Pluggable Locking Wire Crimp

4000

(1200)

4000

(1200)

2X 0.580

(2X 14.73)

0.225

(5.72)

2.931 TYP .

(74.45 TYP .)

P3 P1

5000

(1500)

5000

(1500)

0.308 TYP .

(7.82 TYP .)

P4

24 VDC

45 VDC

75 VDC

(1800)

(1800)

159

141

124

106

88

71

53

35

18

6000

7000

(2100)

706

635

24 VDC

465

45 VDC

494

75 VDC

423

353

282

211

140

6000

71

7000

(2100)

3.473

(88.21)

Connector Options

3.00 ±0.01

(76.2 ±0.25)

2.950

(74.93)

(88.21)

P2

P3 P1

Remote Encoder Option

Torque in N - cm

T

orque in N - cm

3.473

P4

Single Stack

A

Double Stack

B

Triple Stack

C

0.160 ±0.01

(4.06 ±0.25)

Ø 0.160 ±0.01 Thru

(Ø 4.06 ±0.25 Thru)

4X #6 Screws

for Flat Mount

CANopen with DB9

Ø 0.187 ±0.01

(Ø 4.75 ±0.25)

2X #8 Screws

for End Mount

P3 P1

P2

MForce PowerDrive – Motion Control REV052307 3

P4

Page 4

MForce PowerDrive

–

MOTION CONTROL

OPTIONS

Remote Encoder

For optional closed loop control, Motion Control MForce

PowerDrives are available with differential encoder inputs

for use with a remote encoder (not supplied).

Motors and Encoders

IMS offers a wide range of motors, encoders and accessories

recommended for interface with the Motion Control MForce

PowerDrive. For complete specifi cations on these products,

please visit the IMS web site at www.imshome.com.

Power Supplies

IMS recommends the following power supplies for operat-

ing the MForce PowerDrive: IP804, IP806, ISP300-7. For

complete power supply specifi cations, visit the IMS web site

at www.imshome.com.

ORDER INFORMATION

FORCE

POWER DRIVE

MOTION CONTROL

TM

P2: Communications

RL = RS-422/485 with 10-Pin Friction Lock Wire Crimp

CB = CANopen with DB9 Connector

P3: Power

2-Pin Locking Wire Crimp

P1: I/O

14-Pin Locking Wire Crimp

(20-Pin with Remote Encoder)

Example: Part Number MFI3CRL34N7

with 14-pin I/O interface, 2-pin power interface, RS-422/485 communications with

10-pin friction lock wire crimp connector and 4-pin motor interface.

Option: Include -EE to part number for optional interface to remote encoder (not supplied).

ACCESSORIES

Communications Converter Cable and Adapter

With an in-line RS-422 converter, this optional 12.0' (3.6m)

cable and adapter, MD-CC400-000 and MD-ADP-H, facilitate

the parameter setting of a single Motion Control MForce PowerDrive from its P2 connector to a PC's USB port with pluggable mating connectors. Recommended with fi rst order.

Prototype Development Cables

To speed prototyping, 10.0' (3.0m) development cables are

available with pluggable locking wire crimp mates to:

I/O: 14-pin Connector ....................... PD14-2334-FL3

I/O:

20-pin Remote Encoder Connector

.... PD20-3400-FL3

Power: 2-pin Connector ..................... PD02-3400-FL3

Comm: 10-pin Connector ................... PD10-1434-FL3

Motor Interface: 4-pin

Accessories details at: www.imshome.com/cables_cordsets.html

Connector ........... PD04-MF34-FL3

OPTION

MFI3C 34N7 – EE

Remote Encoder Interface

For Closed Loop Control

(Encoder Not Supplied)

P4: Motor Interface

4-Pin Locking Wire Crimp

is a Motion Control MForce PowerDrive

www.imshome.com

370 N. Main St., P.O. Box 457

Marlborough, CT 06447 U.S.A.

Phone: 860/295-6102

Fax: 860/295-6107

E-mail: info@imshome.com

DISTRIBUTED BY:

intelligent motion systems, INC.

TECHNICAL SUPPORT (U.S.A.)

Phone: 860/295-6102

Fax: 860/295-6107

E-mail: etech@imshome.com

IMS ASIA PACIFIC OFFICE

30 Raffl es Pl., 23-00 Caltex House

Singapore 048622

Phone: +65/6233/6846

Fax: +65/6233/5044

E-mail: wllee@imshome.com

Excellence in Motion

IMS EUROPEAN SALES MGT.

4 Quai Des Etroits

69005 Lyon, France

Phone: +33/4 7256 5113

Fax: +33/4 7838 1537

E-mail: bmartinez@imshome.com

IMS UK Ltd.

25 Barnes Wallis Road

Segensworth East

Fareham, Hampshire PO15 5TT

Phone: +44/0 1489-889825

Fax: +44/0 1489-889857

E-mail: mcheckley@imshome.com

© Intelligent Motion Systems, Inc. All Rights Reserved. REV052307

IMS Product Disclaimer and most recent product information at www.imshome.com.

U.S.A. SALES OFFICES

Eastern Region

Phone: 973/661-1270

Fax: 973/661-1275

E-mail: jroake@imshome.com

Central Region

Phone: 260/402-6016

Fax: 419/858-0375

E-mail: dwaksman@imshome.com

Western Region

Phone: 602/578-7201

E-mail:

dweisenberger@imshome.com

Loading...

Loading...