Page 1

MICR

OS

TEPPING

Patent Pending

FEATURES

• Integrated Microstepping Driver

and NEMA 34 High Torque 1.8°

Stepping Motor

• +24 to +75 VDC Input Volt age

• Low Cost

• Extremely Compact

• Optically Isolated Logic Inputs

will Accept +5 to +24 VDC

Signals, Sourcing or Sinking

• Automatic Current Re duc tion

• Confi gurable:

- Motor Run/Hold Current

- Motor Direction vs. Directio

Input

- Microstep Resolution to 256

Microsteps/Full Step

• Available Confi gurations:

- Single Shaft*

- Long Life Linear Actuator

- Internal Optical En cod er*

- Control Knob for Manual

Positioning*

- Integrated Planetary Gearbox*

• Three Stack Sizes Available*

• Current and Resolution May Be

Switched On-The-Fly

• Single Supply

• Interface Uses 12.0" (30.5cm)

Flying Leads

• Graphical User Interface (GUI)

for Quick and Easy Pa ram e ter

Setup

* Rotary Motor Only

DESCRIPTION

The MDrive NEMA 34 high torque

Integrated Motor and Driver is ide al

for designers who want the sim plic i ty

of a motor with on-board elec tron ics,

but without the expense of an indexer on each axis. The low cost

MDrive34 puts the system de sign er

in the driver’s seat to de cide the best

method of control. The MDrive34’s

integrated elec tron ics eliminate

the need to run the mo tor cabling

through the ma chine, re duc ing the

potential for prob lems due to elec tri cal noise.

The MDrive34 uses a NEMA 34

frame size 1.8° high torque motor com bined with a microstepping driver, and accepts up to 14

res o lu tion set tings from ½ to 256

microsteps per full step. Setup pa ram e ters in clude Microstep Resolution, Motor Run/Hold Current, and

Motor Di rec tion with respect to the

di rec tion in put. These set tings may

be changed on-the-fl y or down load ed

and stored in nonvol a tile mem o ry

with the use of a sim ple GUI which

is provided. This elim i nates the need

for external switch es or re sis tors.

Pa ram e ters are changed via an SPI

port. MDrive34 op er at ing volt age

ranges from +24 to +75 VDC.

The MDrive34 is available in multiple

con fi g u ra tions to fi t various system

needs including a single shaft rotary

motor with optional internal optical

encoder, a dual shaft rotary motor

with control knob, a planetary gearbox, or a long life Acme screw linear

actuator. The rotary MDrive34 is

available in single, double and triple

stack sizes: 24, 31 & 47. In ter face

con nec tions are ac com plished us ing

12.0" (30.5cm) fl ying leads.

The MDrive34 is a compact, pow-

er ful and inexpensive solution that

will reduce system cost, design and

as sem bly time for a large range of

step ping motor applications.

CONFIGURING

The IMS Motor Interface software

is an easy to in stall and use GUI

for con fi g ur ing the MDrive34 from

a computer parallel/SPI port. GUI

access is via the IMS SPI Interface included on the CD shipped

with the product, or download at

www.imshome.com. An optional

cable is avail able for ease of con nect ing and con fi g ur ing the MDrive.

.

The IMS Motor Interface features:

• Easy installation.

• Automatic detection of MDrive

version and communication

confi guration.

• Will not set out-of-range values.

• Tool-tips display valid range

setting for each option.

• Single screen interface

The IMS Motor Interface GUI sim pli fi es MDrive

confi guring with a single screen in ter face.

(below)

.

MDrive34 Microstepping Datasheet REV121704 1

Page 2

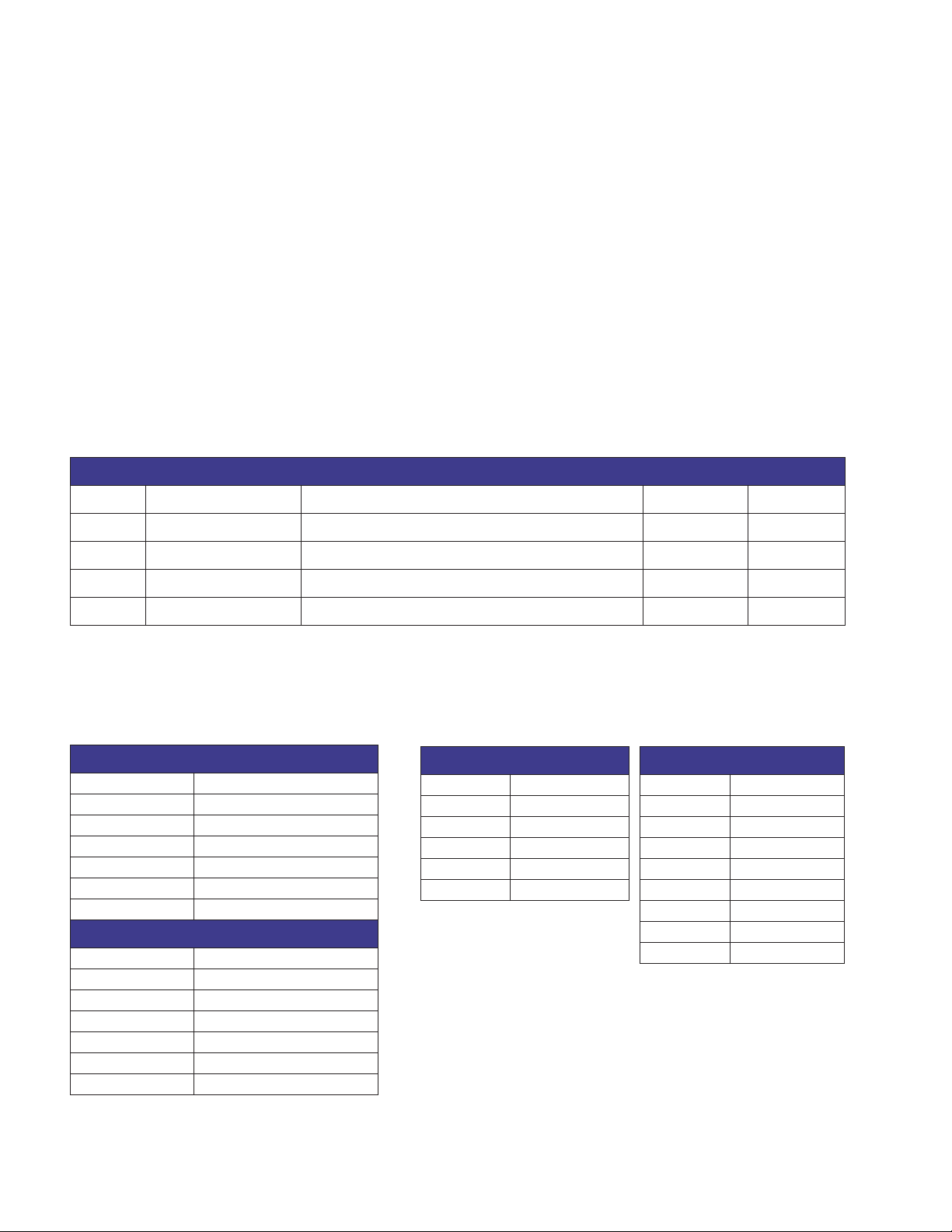

MDRIVE34 MICROSTEPPING SPECIFICATIONS

GENERAL SPEC I FI CA TIONS

Input Voltage (+V) Range*.....................................................................................+24 to +75 VDC

Isolated Inputs..................................................................................Step Clock, Direction & Enable

Isolated Input Voltage Range (Sourcing or Sinking) ......................................................+5 to +24 VDC

Step Frequency (Max).........................................................................................................2 MHz

Steps per Revolution ..................................................400, 800, 1000, 1600, 2000, 3200, 5000,

6400, 10000, 12800, 25000, 25600, 50000, 51200

Heat Sink Temperature (Max) ...............................................................................................85° C

Motor Temperature (Max)..................................................................................................100° C

Protection ................................................................................................................Over Voltage

*Power supply current requirements = 4A (maximum) per MDrive34.

Actual power supply current will depend on voltage and load.

PARAMETERS

SETUP PARAMETERS

NAME FUNCTION RANGE UNITS DEFAULT

MHC Motor Hold Current 0 to 100 percent 5

MRC Motor Run Current 1 to 100 percent 25

MSEL Microstep Resolution 2, 4, 5, 8, 10, 16, 25, 32, 50, 64, 125, 128, 250, 256 µsteps per step 256

DIR Motor Direction Override 0 / 1 -- CW

All parameters are set using the supplied IMS Motor Interface GUI and may be changed on-the-fl y.

An optional Parameter Setup Cable is rec om mend ed with fi rst orders.

WIRE/PIN ASSIGNMENTS

CONNECTOR P1 – Flying Leads

WIRE COLOR FUNCTION

White OPTOCOUPLER REFERENCE

Orange STEP CLOCK INPUT

Blue CW/CCW DIRECTION INPUT

Brown ENABLE INPUT

Black POWER GROUND

Red +V (+24 TO +75 VDC)

CONNECTOR P2 (SPI) – 10 Pin Pin-Header

PIN FUNCTION

4 CHIP SELECT

5 GROUND

6 +5 VDC OUTPUT

7 MASTER OUT - SLAVE IN

8 CLOCK

10 MASTER IN - SLAVE OUT

ENCODER WIRE ASSIGNMENTS

ENCODER – Single-End ENCODER – Differential

WIRE COLOR FUNCTION WIRE COLOR FUNCTION

Yellow/Black GROUND Yellow/Black GROUND

Yellow/Violet INDEX Yellow/Violet INDEX +

Yellow/Blue CHANNEL A Yellow/Blue CHANNEL A +

Yellow/Red +5 VDC INPUT Yellow/Red +5 VDC INPUT

Yellow/Brown CHANNEL B Yellow/Brown CHANNEL B +

Yellow/Gray INDEX –

Yellow/Green CHANNEL A –

Yellow/Orange CHANNEL B –

NOTE: For recommended mating connector information, refer to the product's Quick Reference at www.imshome.com/quick.html

MDrive34 Microstepping Datasheet REV121704 2

Page 3

MDRIVE34 MOTOR SPECIFICATIONS

MD3424 Single Stack

Holding Torque .................381.0 oz-in / 269 N-cm

Detent Torque .....................10.9 oz-in / 7.7 N-cm

2

Rotor Inertia ........0.01416 oz-in-sec

/ 1.0 kg-cm

Weight (Motor+Driver)...............67.4 oz / 1909 g

MD3431 Double Stack

Holding Torque .................575.0 oz-in / 406 N-cm

Detent Torque .................14.16 oz-in / 10.0 N-cm

Rotor Inertia ........ 0.02266 oz-in-sec2 / 1.6 kg-cm

Weight (Motor+Driver)................92.1 oz / 2609 g

TORQUE-SPEED CURVES

Rotary Motor

MD3424 Single Stack

24 VDC

45 VDC

75 VDC

24 VDC

45 VDC

75 VDC

282

247

Torque in N - cm

211

170

141

106

71

35

423

353

318

T

orque in N - cm

282

247

211

170

141

106

71

35

847

777

706

635

T

orque in N - cm

465

494

423

353

282

211

140

71

400

350

300

250

200

150

Torque in Oz - In

100

50

0

0 1000 2000 3000 4000 5000 6000 7000

Speed in Full Steps per Second

MD3431 Double Stack

550

500

450

400

350

300

250

200

Torque in Oz - In

150

100

50

0

0 1000 2000 3000 4000 5000 6000 7000

Speed in Full Steps per Second

MD3447 Triple Stack

1200

1100

1000

900

800

700

600

500

400

Torque in Oz - In

300

200

100

0

0 1000 2000 3000 4000 5000 6000 7000

Speed in Full Steps per Second

24 VDC

45 VDC

75 VDC

MD3447 Triple Stack

Holding Torque ...............1061.0 oz-in / 749 N-cm

Detent Torque .................19.83 oz-in / 14.0 N-cm

2

Rotor Inertia ........ 0.04815 oz-in-sec

2

/ 3.4 kg-cm

Weight (Motor+Driver)..............148.5 oz / 4209 g

MD3429 Linear Actuator

Maximum Thrust ....................... 500 lbs / 2224 N

Maximum Screw Defl ection............................. ± 1°

2

Backlash ............................ 0.005 in / 0.127 mm

Weight (without screw)............... 89.0 oz / 2523 g

FORCE-SPEED CURVES

Linear Actuator

24 VDC

500

450

400

350

300

250

200

Force in lbs

150

100

50

0

48 VDC

500

450

400

350

300

250

200

Force in lbs

150

100

50

0

75 VDC

500

450

400

350

300

250

200

Force in lbs

150

100

50

0

0 1000 2000 3000 4000 5000 6000

0 1000 2000 3000 4000 5000 6000

0 1000 2000 3000 4000 5000 6000

Load Limit 500lbs / 2224N

Speed in Full Steps per Second

Load Limit 500lbs / 2224N

Speed in Full Steps per Second

Load Limit 500lbs / 2224N

Speed in Full Steps per Second

Scre

Scre

Scre

Scre

Scre

Scre

Scre

Scre

Scre

Scre

Scre

Scre

w EScre

w D

w C

w B

w A

w EScre

w D

w C

w B

w A

w EScre

w D

w C

w B

w A

7000

7000

7000

2224

2002

1779

1557

1334

1112

890

667

445

222

2224

2002

1779

1557

1334

1112

890

667

445

222

2224

2002

1779

1557

1334

1112

890

667

445

222

2

Force in N

Force in N

Force in N

MDrive34 Microstepping Datasheet REV121704 3

Page 4

MDRIVE34 WITH PLANETARY GEARBOX

The MDrive34 is available with a Planetary Gearbox

option developed to increase torque at lower speeds,

enable better inertia matching and produce fi ner

positional resolutions. These effi cient, low maintenance Planetary Gearbox come fully assembled with

the MDrive and are offered in a large number of

reduction ratios in 1-, 2- and 3-stage confi gurations.

An optional NEMA Flange allows mounting the Planetary Gearbox to the load using a standard NEMA

bolt circle. Planetary Gearbox may be combined with

other MDrive34 options, however are unavailable on

Linear Actuator versions.

Parameters 1-Stage 2-Stage 3-Stage

Permitted Output Torque (oz-in/Nm)....................... 2832/20.0........8496/60.0.......16992/120.0

Gearbox Effi ciency..................................................... 0.80.................. 0.75...................0.70

Maximum Backlash (degree)....................................... 1.0° ...................1.5° ................... 2.0°

Ouput Side With Ball Bearing

Maximum Load, Radial (lb-force/N).......................... 90/400 ............135/600 .......... 225/1000

Maximum Load, Axial (lb-force/N)............................. 18/80 ..............27/120 ............. 45/200

Weight - Gearbox Only (oz/g).................................64.4/1827........ 89.5/2538........114.6/3248

Weight - Gearbox & NEMA Flange (oz/g) ................66.7/1890........ 92.6/2625........118.5/3360

PLANETARY GEARBOX MECHANICAL SPECIFICATIONS

Dimensions in Inches (mm)

Planetary Gearbox for MDrive34

M6 x 0.472 (12.0) DeepM6 x 0.472 (12.0) Deep

3.386 SQ.

(86.0 SQ.)

1.929

(49.0)

Ø 1.969 +0.0006/-0.0004

(Ø 50.0 +0.015/-0.010)

Ø 0.748 +0/-0.0008

(Ø 19.0 +0/-0.021)

1.575

(40.0)

0.197

(5.0)

k1 ±0.02 (±0.5)

Ø 3.189

(Ø 81.0)

Gearbox Ratios (Rounded)

1-Stage 2-Stage 3-Stage

3.70:1 13.73:1 50.89:1

5.18:1 15.88:1 58.85:1

6.75:1 18.36:1 68.06:1

19.20:1 71.16:1

22.20:1 78.71:1

25.01:1 92.70:1

26.85:1 95.17:1

28.93:1 99.50:1

34.97:1 107.20:1

45.56:1 115.07:1

MDRIVE34

123.97:1

129.62:1

139.13:1

149.90:1

168.84:1

181.24:1

195.26:1

236.09:1

307.54:1

Ø 2.56

(Ø 65.0)

Ctrg. DIN 332-D M6x16

Key DIN 6885-A-6x6x28mm

Planetary Gearbox with Optional NEMA Output Flange

1.811

4x Ø 0.217 (Ø 5.5) Hole

2.739

(69.58)

2.739

(69.58)

3.386 SQ.

(86.0 SQ.)

Ø 2.874 +0/-0.0012

(Ø 73.0 +0/-0.030)

Ø 0.748 +0/-0.0008

(Ø 19.0 +0/-0.021)

Ctrg. DIN 332-D M6x16

Key DIN 6885-A-6x6x28mm

(46.0)

1.575

(40.0)

0.079

(2.0)

0.394

(10.0)

k1 Gearbox

k2 Gearbox w/

NEMA Flange

k2 ±0.02 (±0.5)

Ø 3.189

(Ø 81.0)

MDrive34 Microstepping Datasheet REV121704 4

Gearbox Lengths

1-Stage 2-Stage 3-Stage

4.315

(109.6)

4.433

(112.6)

MDRIVE34

5.169

(131.3)

5.287

(134.3)

Inches (mm)

6.024

(153.0)

6.142

(156.0)

Page 5

MDRIVE34 MICROSTEPPING – MECHANICAL SPECIFICATIONS

Dimensions in Inches (mm)

Rotary MDrive34: Single Shaft, Control Knob & Encoder Versions

12.0" (30.5 cm)

Flying Leads

0.08 (2.0)

3.73

(94.7)

4X Ø 0.22 (Ø 5.5)

1.46 ±0.04

(37.0 ±1.0)

0.984 ±0.01

(25.0 ±0.25)

0.512 ±0.004

(13.0 ±0.1)

Ø 0.5512 +0/-0.0005

(Ø 14.0 +0/-0.013)

2.33

(59.2)

2.07

(52.6)

MDrive Lengths

Stack Size

3424 3.81 (96.8) 4.97 (126.2)

3431 4.60 (116.8) 5.76 (146.3)

3447 6.17 (156.7) 7.34 (186.4)

L

–

MAX2

Control Knob

Inches (mm)

L

MAX

SINGLE SHAFT or

ENCODER VERSION

Ø 1.90

(Ø 48.3)

L

MAX

L

MAX2

CONTROL KNOB VERSION

Linear Actuator MDrive34

12.0" (30.5 cm)

Flying Leads

L

0.06

(1.5)

0.39

(10.0)

MAX2

Ø 2.874 ±0.002

(Ø 73.0 ±0.05)

4X Ø 0.26

(Ø 6.6)

Ø 2.875 +0/-0.002

(Ø 73.03 +0/-0.05)

2.739 ±0.01 SQ.

(69.58 ±0.25 SQ.)

3.40 SQ.

(86.4 SQ.)

MDrive34 Top View

P1P2

Flying Leads

10 Pin Connector

2.33

(59.2)

3.73

(94.7)

0.625

(15.88)

2.07

(52.6)

4.46

(113.3)

6.00

(152.4)

0.39

(10.0)

0.1

(2.5)

Ø 0.30

(Ø 7.6)

0.71

(18.0)

7/16-14

UNC-2A THREAD

2.730 ±0.008 SQ.

(69.34 ±0.2 SQ.)

3.40 SQ.

(86.4 SQ.)

MDrive34 Microstepping Datasheet REV121704 5

Page 6

MDRIVE34 MICROSTEPPING – OPTIONS

Control Knob

The MDrive34 is available with a fac to ry-mount ed rear

control knob for man u al shaft positioning.

Screw A .............0.005”/full step

Screw B .............0.0025”/full step

Screw C ............. 0.00125”/full step

Screw D ............. 0.000625”/full step

Planetary Gearbox

Effi cient, low maintenance Planetary Gearbox are of-

fered assembled with the MDrive34. Details inside.

Encoder

The MDrive34 is available with a factory-mount ed in-

ternal op ti cal en cod er. Available line counts are 100,

200, 250, 400, 500 or 1000. All en cod ers, except

the 1000 line, have an in dex mark. Encoders are available in both single-end and dif fer en tial confi gurations.

Linear Actuator

The MDrive34 with long life Acme Screw Linear Actua-

tor is avail able with the following trav el/full step:

Screw E ............. 0.0005"/full step

Standard screw length is 6.0” (152.4mm) plus the

mounting end thread. Cus tom lengths up to 24.0”

are available without mounting end thread.

Linear Actuators are Non-Captive style. Contact the

factory regarding Captive Shaft or External styles.

Parameter Setup Cable

A low cost ac ces so ry which eliminates the need for

users to wire com mu ni ca tions. This 6' (1.8m) cable

includes built-in logic level shifting circuitry to ac com mo date the 3.3v por ts on some PCs and plugs in

easily to con nect a stan dard DB-25 PC par al lel/SPI

port to the MDrive's 10 pin pin-header (P2). Order

Cable Part No. MD-CC100-000.

ORDER INFORMATION

MDRIVE34 MICROSTEPPING OPTIONS

Control

Knob

Stack Sizes

24 = Single Stack

29 = Linear Actuator

31 = Double Stack

47 = Triple Stack

MDMF 34

Example #1: Part Number MDMF3431 is an MDrive34

Microstepping with Flying Leads, NEMA 34 motor, stack size 31.

†

Stack Size 29 is only available as a Linear Actuator and is the ONLY size Linear Actuator offered. (MDMF3429LX)

†

OPTION

Planetary

Gearbox

Internal

Encoder

Linear

Actuator

Screw Type (Travel/Full Step)

A = 0.005”

B = 0.0025”

C = 0.00125”

D = 0.000625”

E = 0.0005”

N

G

Gearbox Ratio

Rounded to Nearest Whole Number

E

S = Single End

D = Differential

†

L

Line Count

100, 200, 250, 400, 500, 1000

Custom Screw Length

Range 2.0” to 24.0”

Format XX.X

eg. 08.5 for an 8.5” Screw

(6.0” Screw Length Standard)

Example #2: MDMF3431N

Adds a Control Knob

to the part shown in example #1.

Example #3: MDMF3431G5

Rounding ratio to the nearest whole number,

the above adds a Planetary Gearbox with

5.18:1 ratio to the part shown in example #1.

Add -F if optional NEMA Flange is desired.

Example #4: MDMF3431ED500

Adds a 500 line count internal Differential

Encoder to the part shown in example #1.

Example #5: MDMF3429LA10.5

MDrive34 Microstepping Linear Actuator

with a 0.005”/Full Step Acme

Screw custom cut to 10.5”.

MAY NOT be combined with other options.

Note: MDrive34 Linear Actuator

Available ONLY in Stack Size 29

P.O. Box 457, 370 N. Main Street

Marlborough, CT 06447 U.S.A.

Phone: 860/295-6102

Fax: 860/295-6107

E-mail: info@imshome.com

Home Page: www.imshome.com

Distributed By:

TECHNICAL SUPPORT

Eastern U.S.

Phone: 860/295-6102

Fax: 860/295-6107

E-mail: etech@imshome.com

Western U.S.

Phone: 760/966-3162

Fax: 760/966-3165

E-mail: wtech@imshome.com

IMS MOTORS DIVISION

105 Copperwood Way, Suite H

Oceanside, CA 92054

Phone: 760/966-3162

Fax: 760/966-3165

E-mail: motors@imshome.com

Product information covered by IMS Product Disclaimer available at www.imshome.com.

Visit the IMS web site for the most up-to-date product information.

© 2002, 2004 Intelligent Motion Systems, Inc. All Rights Reserved. REV121704

IMS EUROPE

Hahnstrasse 10, VS-Schwenningen

Germany D-78054

Phone: +49/7720/94138-0

Fax: +49/7720/94138-2

E-mail: info@imseuropehome.com

European Sales Management

4 Quai Des Etroits

69005 Lyon, France

Phone: +33/4 7256 5113

Fax: +33/4 7838 1537

E-mail: bmartinez@imshome.com

German Sales/Technical Support

Phone: +49/35205/4587-8

Fax: +49/35205/4587-9

E-mail: hruhland@imshome.com

GmbH

Loading...

Loading...