Page 1

T

TM

intelligent motion systems, inc.

Excellence in Motion

TM

OPERATING INSTRUCTIONS

Page 2

The information in this book has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for inaccuracies.

Intelligent Motion Systems, Inc., reserves the right to make changes without further notice to any products

herein to improve reliability, function or design. Intelligent Motion Systems, Inc., does not assume any liability

arising out of the application or use of any product or circuit described herein; neither does it convey any

license under its patent rights of others. Intelligent Motion Systems and are trademarks of Intelligent

TM

Motion Systems, Inc.

Intelligent Motion Systems, Inc.’s general policy does not recommend the use of its products in life support or

aircraft applications wherein a failure or malfunction of the product may directly threaten life or injury. Per

Intelligent Motion Systems, Inc.’s terms and conditions of sales, the user of Intelligent Motion Systems, Inc.,

products in life support or aircraft applications assumes all risks of such use and indemnifies Intelligent Motion

Systems, Inc., against all damages.

© 2002 Intelligent Motion Systems, Inc.

All Rights Reserved

Page 3

Table of Contents

Part 1: General Information And Hardware Information

Section 1.1: Introduction to the MDrive17 Motion Control ....................................................................................................................... 5

Introduction to the MDrive17 Motion Control ................................................................................................................................................................................5

Feature Summary .........................................................................................................................................................................................................................5

Section 1.2: MDrive17 Motion Control Specifications ............................................................................................................................... 6

Section Overview .........................................................................................................................................................................................................................6

Rotary Motor Specifications ......................................................................................................................................................................................................... 6

Mechanical Specifications - Dimensions in Inches (mm) ...................................................................................................................................................6

MDrive Motion Control 1713 Motor Specs and Speed/T orque Curves................................................................................................................................ 6

MDrive Motion Control 1715 Motor Specs and Speed/T orque Curves................................................................................................................................ 7

MDrive Motion Control 1719 Motor Specs and Speed/T orque Curves................................................................................................................................ 7

Linear Motor Specifications ..........................................................................................................................................................................................................7

Mechanical Specifications - Dimensions in Inches (mm) ...................................................................................................................................................7

Speed-Force Curve: 24 VDC ..............................................................................................................................................................................................8

Linear Actuator MDrive Motion Control 1713 Specs and Speed-Force Curves ..................................................................................................................8

Speed-Force Curve: 45 VDC ..............................................................................................................................................................................................8

MDrive17 Motion Control ACME Screw ...............................................................................................................................................................................9

General Specifications..................................................................................................................................................................................................................9

General Specifications................................................................................................................................................................................................................ 10

Power Supply Requirements ......................................................................................................................................................................................................10

Recommended IMS Power Supplies.................................................................................................................................................................................. 10

Thermal Specifications ...............................................................................................................................................................................................................10

Section 1.3: Introduction to the MDrive23 Motion Control ..................................................................................................................... 11

Introduction to the MDrive23 Motion Control .............................................................................................................................................................................. 11

Feature Summary ....................................................................................................................................................................................................................... 11

Section 1.4: MDrive23 Motion Control Specifications ............................................................................................................................. 12

Section Overview .......................................................................................................................................................................................................................12

Rotary Motor Specifications ....................................................................................................................................................................................................... 12

Mechanical Specifications - Dimensions in Inches (mm) .................................................................................................................................................12

MDrive Motion Control 2218 Motor Specs and Speed/T orque Curves.............................................................................................................................. 12

MDrive Motion Control 2222 Motor Specs and Speed/T orque Curves.............................................................................................................................. 13

MDrive Motion Control 2231 Motor Specs and Speed/T orque Curves.............................................................................................................................. 13

Linear Motor Specifications ........................................................................................................................................................................................................13

Mechanical Specifications - Dimensions in Inches (mm) .................................................................................................................................................13

Speed-Force Curve: 24 VDC ............................................................................................................................................................................................ 14

Linear Actuator MDrive Motion Control 2218 Specs and Speed-Force Curves ................................................................................................................14

Speed-Force Curve: 45 VDC ............................................................................................................................................................................................ 14

MDrive23 Motion Control ACME Screw .............................................................................................................................................................................15

General Specifications................................................................................................................................................................................................................15

General Specifications................................................................................................................................................................................................................16

Power Supply Requirements ......................................................................................................................................................................................................16

Recommended IMS Power Supplies.................................................................................................................................................................................. 16

Thermal Specifications ...............................................................................................................................................................................................................16

Part 2: Connecting, Configuring And Programming The MDrive Motion Control

Section 2.1: Interfacing the MDrive Motion Control ................................................................................................................................. 19

Section Overview .......................................................................................................................................................................................................................19

Layout and Interface Guidelines ................................................................................................................................................................................................19

Recommended Wiring ............................................................................................................. ..........................................................................................19

Pin Configuration and Descriptions ............................................................................................................................................................................................ 19

Interfacing Power........................................................................................................................................................................................................................ 20

Interfacing RS-485 Communications .........................................................................................................................................................................................20

Single MDrive ....................................................................................................................................................................................................................20

Multiple MDrive Motion Control System (Party Mode) ......................................................................................................................................................21

Interfacing the Digital I/O ...........................................................................................................................................................................................................22

Uses of the Digital I/O ......................................................................................................................................................................................................22

Interfacing Inputs .............................................................................................................................................................................................................. 22

Interfacing Outputs ...........................................................................................................................................................................................................24

Interfacing the Analog Input .......................................................................................................................................................................................................25

Sample Usage ................................................................................................................................................................................................................... 25

Section 2.2: MDrive Motion Control Software Introduction ................................................................................................................... 26

Section Overview .......................................................................................................................................................................................................................26

Installing and Using IMS T erminal...............................................................................................................................................................................................26

System Requirements ......................................................................................................................................................................................................26

Installation .........................................................................................................................................................................................................................26

Using the IMS Terminal Software ......................................................................................................................................................................................27

Setting the Programmable Function Keys ........................................................................................................................................................................28

Upgrading the MDrive Motion Control Firmware......................................................................................................................................................................... 28

MDrive Motion Control Programming.......................................................................................................................................................................................... 29

Operational Modes .............................................................................................................................................................................................................29

Basic Components of MDrive Motion Control Software ............................................................................................................................................................29

Instructions........................................................................................................................................................................................................................ 29

Variables ............................................................................................................................................................................................................................29

Flags.................................................................................................................................................................................................................................. 30

Keywords ...........................................................................................................................................................................................................................30

Most Commonly Used Variables and Commands ...................................................................................................................................................................... 30

1

Page 4

Variables ............................................................................................................................................................................................................................30

Math Functions ..................................................................................................................................................................................................................31

Motion Commands.............................................................................................................................................................................................................31

I/O Commands ..................................................................................................................................................................................................................32

System Instructions .......................................................................................................................................................................................................... 32

Program Instructions ......................................................................................................................................................................................................... 32

Section 2.3: MDrive Motion Control Command Set Summary ............................................................................................................... 35

Setup Instructions, Variables and Flags .....................................................................................................................................................................................35

Miscellaneous Instructions, Variables and Flags ........................................................................................................................................................................35

Motion Instructions, Variables and Flags.................................................................................................................................................................................... 35

I/O Instructions, Variables and Flags ......................................................................................................................................................................................... 36

Program Instructions, Variables and Flags.................................................................................................................................................................................36

Position Related Instructions, Variables and Flags ....................................................................................................................................................................37

Encoder Related Instructions, Variables and Flags....................................................................................................................................................................37

Mathematical Functions.............................................................................................................................................................................................................. 37

Section 2.4: MDrive Motion Control Command Set .................................................................................................................................. 38

Appendix A: ASCII TABLE ................................................................................................................................................................................64

Appendix B: Error Codes ................................................................................................................................................................................. 65

List of Figures

Figure 1.1 Rotary MDrive17 Motion Control Mechanical Specifications ..................................................................................................................................6

Figure 1.2 Rotary MDrive17 Motion Control 1713 Speed/Torque Data.....................................................................................................................................6

Figure 1.3 Rotary MDrive17 Motion Control 1715 Speed/Torque Data.....................................................................................................................................7

Figure 1.4 Rotary MDrive17 Motion Control 1719 Speed/Torque Data.....................................................................................................................................7

Figure 1.5 Linear Actuator MDrive17 Motion Control Mechanical Specifications .....................................................................................................................7

Figure 1.6 Speed-Force Curve - 24VDC (100% Current) .........................................................................................................................................................8

Figure 1.7 Speed-Force Curve - 45VDC (100% Current) .........................................................................................................................................................8

Figure 1.8 Rotary MDrive23 Motion Control Mechanical Specifications ................................................................................................................................12

Figure 1.9 Rotary MDrive23 Motion Control 2218 Speed/Torque Data...................................................................................................................................12

Figure 1.10 Rotary MDrive23 Motion Control 2222 Speed/Torque Data................................................................................................................................... 13

Figure 1.11 Rotary MDrive23 Motion Control 2231 Speed/Torque Data................................................................................................................................... 13

Figure 1.12 Linear Actuator MDrive23 Motion Control Mechanical Specifications ...................................................................................................................13

Figure 1.13 Speed-Force Curve - 24VDC (100% Current) .......................................................................................................................................................14

Figure 1.14 Speed-Force Curve - 45VDC (100% Current) .......................................................................................................................................................14

Figure 2.1 Power Supply Interface .........................................................................................................................................................................................20

Figure 2.2 RS-485 Interface, Single MDrive Motion Control ..................................................................................................................................................20

Figure 2.3 RS-485 Interface, Multiple MDrive Motion Control System ..................................................................................................................................21

Figure 2.4 Input Interfaced to a Switch ..................................................................................................................................................................................22

Figure 2.5 Input Interfaced to a PLC ...................................................................................................................................................................................... 22

Figure 2.6 TTL Interface to an Input Group ............................................................................................................................................................................23

Figure 2.7 Output Interfaced to an LED ................................................................................................................................................................................. 24

Figure 2.8 Output Interfaced to a Relay ................................................................................................................................................................................ 24

Figure 2.9 Outputs Interfaced tp LED’s as a Group............................................................................................................................................................... 24

Figure 2.10 Analog Input Interface ...........................................................................................................................................................................................25

Figure 2.11 IMS Terminal Window ............................................................................................................................................................................................. 26

Figure 2.12 IMS Terminal Preferences......................................................................................................................................................................................27

Figure 2.13 IMS Terminal Upgrader Window ............................................................................................................................................................................. 28

List of T ables

T able 1.1 Rotary MDI1713 Motor Specifications .....................................................................................................................................................................6

T able 1.2 Rotary MDI1715 Motor Specifications .....................................................................................................................................................................7

T able 1.3 Rotary MDI1719 Motor Specifications .....................................................................................................................................................................7

Table 1.4 Linear Actuator MDrive17 Motion Control Motor Specifications ..............................................................................................................................8

Table 1.5 ACME Screws for Linear Actuator MDrive17 Motion Control ..................................................................................................................................9

T able 1.6 Rotary MDI2218 Motor Specifications ...................................................................................................................................................................12

T able 1.7 Rotary MDI2222 Motor Specifications ...................................................................................................................................................................13

T able 1.8 Rotary MDI2231 Motor Specifications ...................................................................................................................................................................13

Table 1.9 Linear Actuator MDrive23 Motion Control Motor Specifications ............................................................................................................................14

Table 1.10 ACME Screws for Linear Actuator MDrive23 Motion Control ................................................................................................................................15

T able 2.1 P1 Pin Configuration and Description .................................................................................................................................................................... 19

T able 2.2 P2 Pin Configuration and Description .................................................................................................................................................................... 20

T able 2.3 Input Functions ......................................................................................................................................................................................................22

T able 2.4 I/O Group Truth Table.............................................................................................................................................................................................23

T able 2.5 Output Functions ...................................................................................................................................................................................................24

T able 2.6 Microstep Resolution Settings ...............................................................................................................................................................................51

2

Page 5

Part 1: General Information

and Hardware Specifications

3

Page 6

Intentionally Left Blank

4

Page 7

Section 1.1

Introduction to the MDrive17 Motion Control

Introduction to the MDrive17 Motion Control

The MDrive17 Motion Control offers the system designer a low-cost, intelligent motion controller integrated with a NEMA 17 high

torque stepping motor and a +12 to +48 VDC microstepping drive.

The MDrive17 Motion Control adds a versatile array of functions by combining a complete programmable motion controller with

our already compact and cost effective standard MDrive17, adding little cost and no increase in size. Standard offerings include four

5 to 24 volt programmable I/O points, one 10-bit 0 to 5 volt analog input, 0 to 5 MHz step clock rate, microstep resolution up to

51,200 steps per revolution and a full featured easy-to-program instruction set.

The MDrive17 Motion Control communicates using the RS-485 communications protocol, this allows for point-to-point or multi-

drop communications using one communications port. Addressing and hardware support up to 62 MDrive nodes in a system. The

communications BAUD rate is software selectable and ranges from 4.8 kbps to 115 kbps.

The MDrive17 is also available with an optional closed loop control. The closed loop configuration adds a 512 line (2048 count)

internal magnetic rotary encoder with index mark without increasing the length of the unit. Closed loop configuration adds position

maintenance, stall detection and find index mark.

A vailable motor configurations include: single shaft, double shaft with control knob, and long life ACME screw linear actuator .

Rotary versions are available in three stack lengths: 13, 15 & 19. Interface connections are accomplished using either a 7 position

terminal block or optional 12” flying leads.

Feature Summary

! Integrated Microstepping Drive/Motion Controller with Optional Encoder/NEMA 17 High Torque Stepping Motor

! +12 to +48VDC Input Voltage

! Low Cost

! Extremely Compact

! Available Configurations: Single Shaft*, Linear Actuator, Integral Encoder*, Double Shaft with Knob for Manual

! Three Motor Stack Lengths Available*

! Single Power Supply

! Microstep Resolution up to 51,200 Steps Per Revolution

! Open Loop or Optional Closed Loop Control

! Programmable Motor Run and Hold Current Settings

! Four 5 to 24 VDC Programmable I/O Points

! One Analog 10 Bit, 0 to 5 Volt Analog Input

! 0 to 5 MHz Step Clock Rate, SelecTable 1. in 0.59 Hz Increments

! RS-485 Communications Protocol

! Communications BAUD Rate SelecTable 1. from 4.8 kbps to 115 kbps

! 62 Software Addresses for Multidrop Communications

! Simple 1 and 2 Character Programming Instructions

! Pluggable Terminal Strip or 12” Flying Lead Interface

! Optional Integrated RS-232 to RS-485 Converter/Communications Cable

*Rotary Motor Only

Positioning*

5

Page 8

Section 1.2

MDrive17 Motion Control Specifications

Section Overview

This section contains mechanical, motor and electrical specifications specific to each version of the MDrive17 Motion Control.

Shown are:

!

! Linear Motor Specifications

! General Specifications

! Power Supply Requirements

! Thermal Specifications

Rotary Motor Specifications

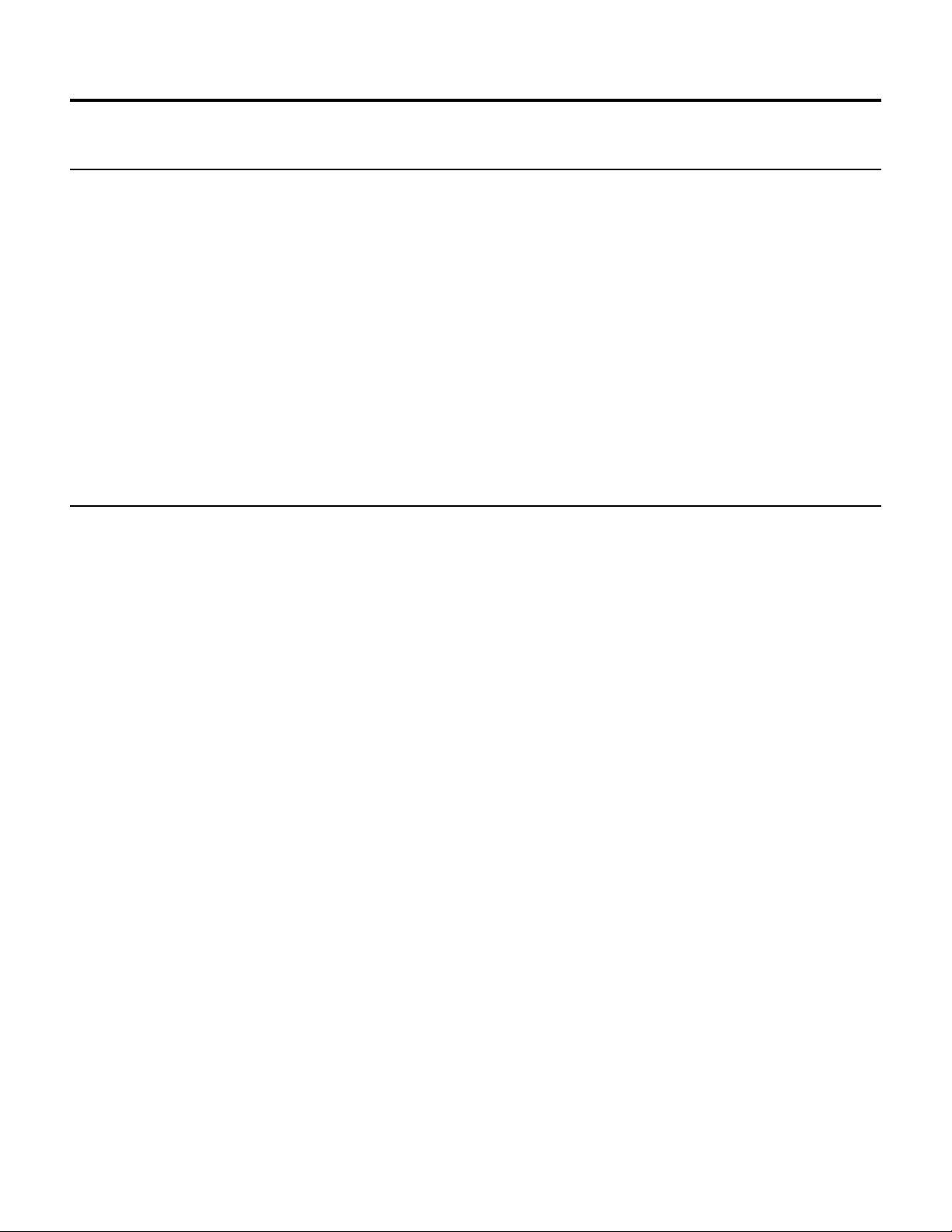

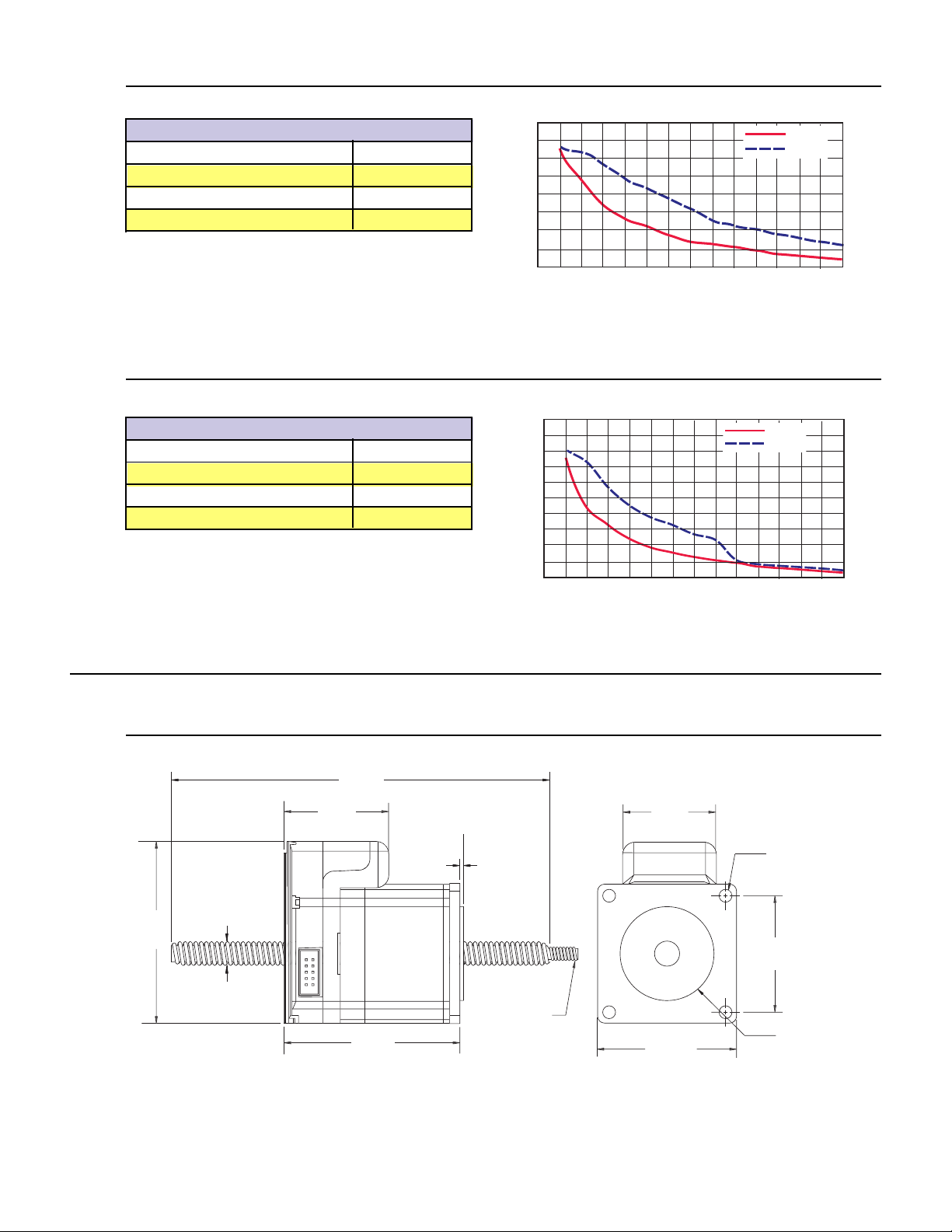

Mechanical Specifications - Dimensions in Inches (mm)

Rotary Motor Specifications

Standard Rotary Motor (L

Stack In (mm)

1713 2.187 (55.56)

1715 2.407 (61.15)

1719 2.786 (70.77)

Figure 1.1: Rotary MDrive17 Motion Control Mechanical Specifications

MDrive Motion Control 1713 Motor Specs and Speed/Torque Curves

MDI1713

Holding Torque oz-in (N-cm) 32 (22.6)

Detent Torque oz-in (N-cm) 2.0 (1.4)

Rotor Inertia oz-in-sec2 (kg-cm2) 0.00053 (0.038)

Weight (Motor+Driver) oz (gm) 8.26 (234.2)

T able 1.1: Rotary MDI1713 Motor Specifications

MAX

)

Figure 1.2: Rotary MDrive Motion Contr ol 1713 Speed/Torque Data

Control Knob (L

Stack In ( mm)

1713 2.774 (69.71)

1715 2.965 (75.30)

1719 3.343 (84.92)

MAX2

)

6

Page 9

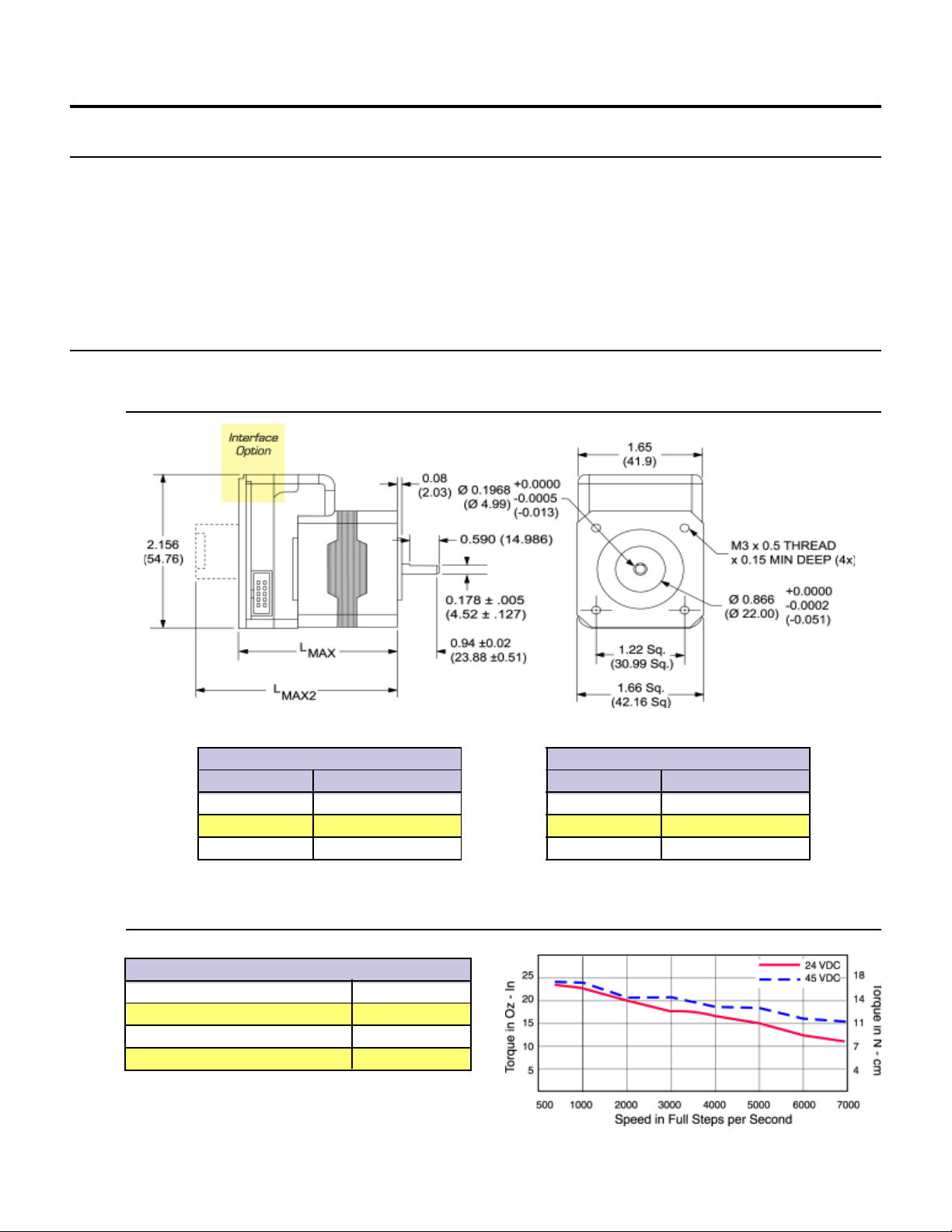

MDrive Motion Control 1715 Motor Specs and Speed/Torque Curves

MDI1715

Holding Torque oz-in (N-cm) 60 (42.4)

Detent Torque oz-in (N-cm) 2.5 (1.8)

Rotor Inertia oz-in-sec2 (kg-cm2) 0.00080 (0.057)

Weight (Motor+Driver) oz (gm) 10.42 (295.4)

T able 1.2: Rotary MDI1715 Motor Specifications

Figure 1.3: Rotary MDrive Motion Contr ol 1715 Speed/Torque Data

MDrive Motion Control 1719 Motor Specs and Speed/Torque Curves

MDI1719

Holding Torque oz-in (N-cm) 74.9 (52.9)

Detent Torque oz-in (N-cm) 4.0 (2.8)

Rotor Inertia oz-in-sec2 (kg-cm2) 0.0116 (0.082)

Weight (Motor+Driver) oz (gm) 11.80 (334.5)

T able 1.3: Rotary MDI1719 Motor Specifications

Linear Motor Specifications

Mechanical Specifications - Dimensions in Inches (mm)

Figure 1.4: Rotary MDrive Motion Control 1719 Speed/Torque Data

Figure 1.5: Linear Actuator MDrive17 Motion Control Mechanical Specifications

7

Page 10

Linear Actuator MDrive Motion Control 1713 Specs and Speed-Force

Curves

MDI17 Linear Actuator

Maximum Thrust lbs (kg) 50 (22.7)

Maximum Screw Deflection ±1 °

Backlash inches (mm) 0.005 (0.127)

Weight (Motor+Driver) oz (gm) 9.2 (0.127)

T able 1.4: Linear Actuator MDrive17 Motion Contr ol Motor Specifications

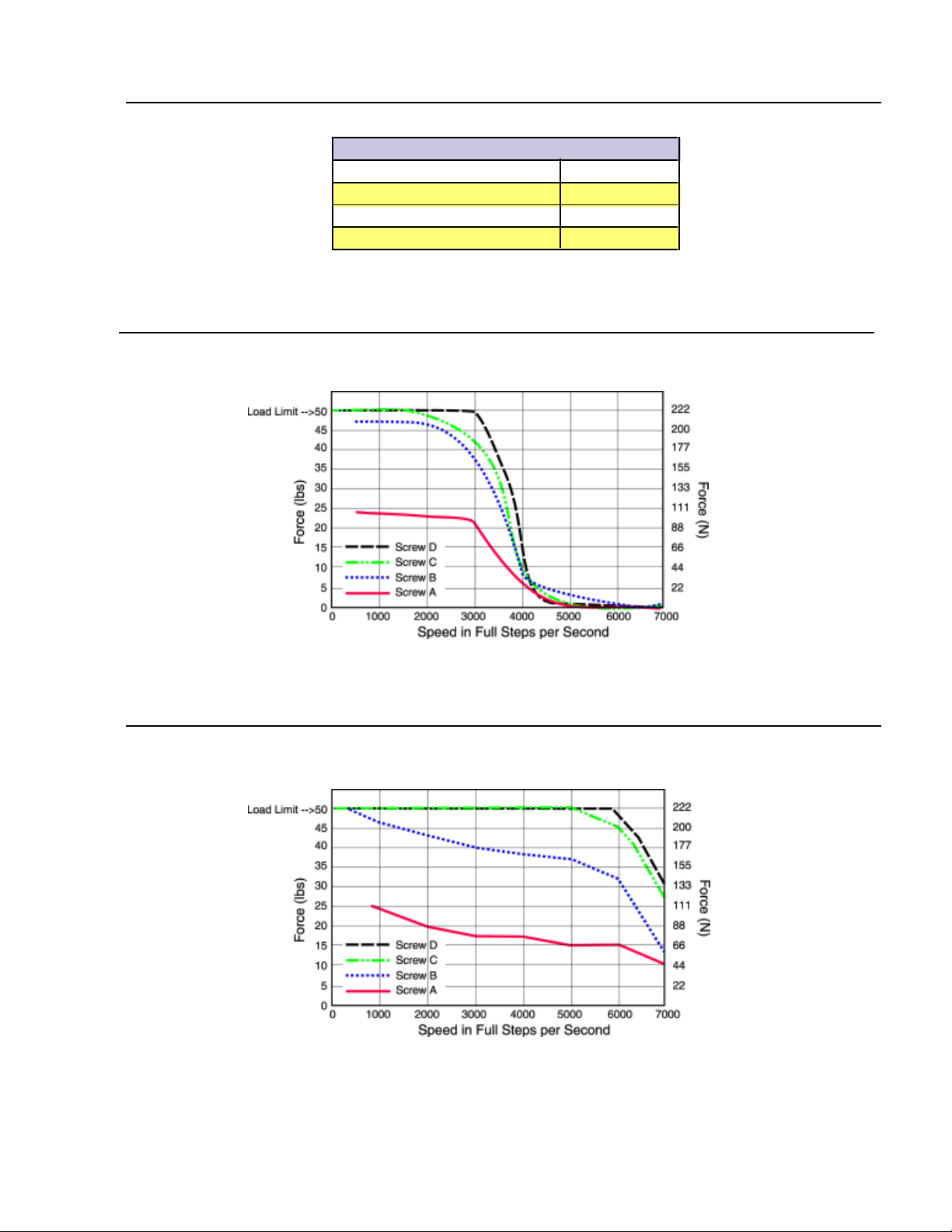

Speed-Force Curve: 24 VDC

Refer to Table 1. 5 for screw pitch information

Figure 1.6: Speed-Force Curve - 24VDC (100% Current)

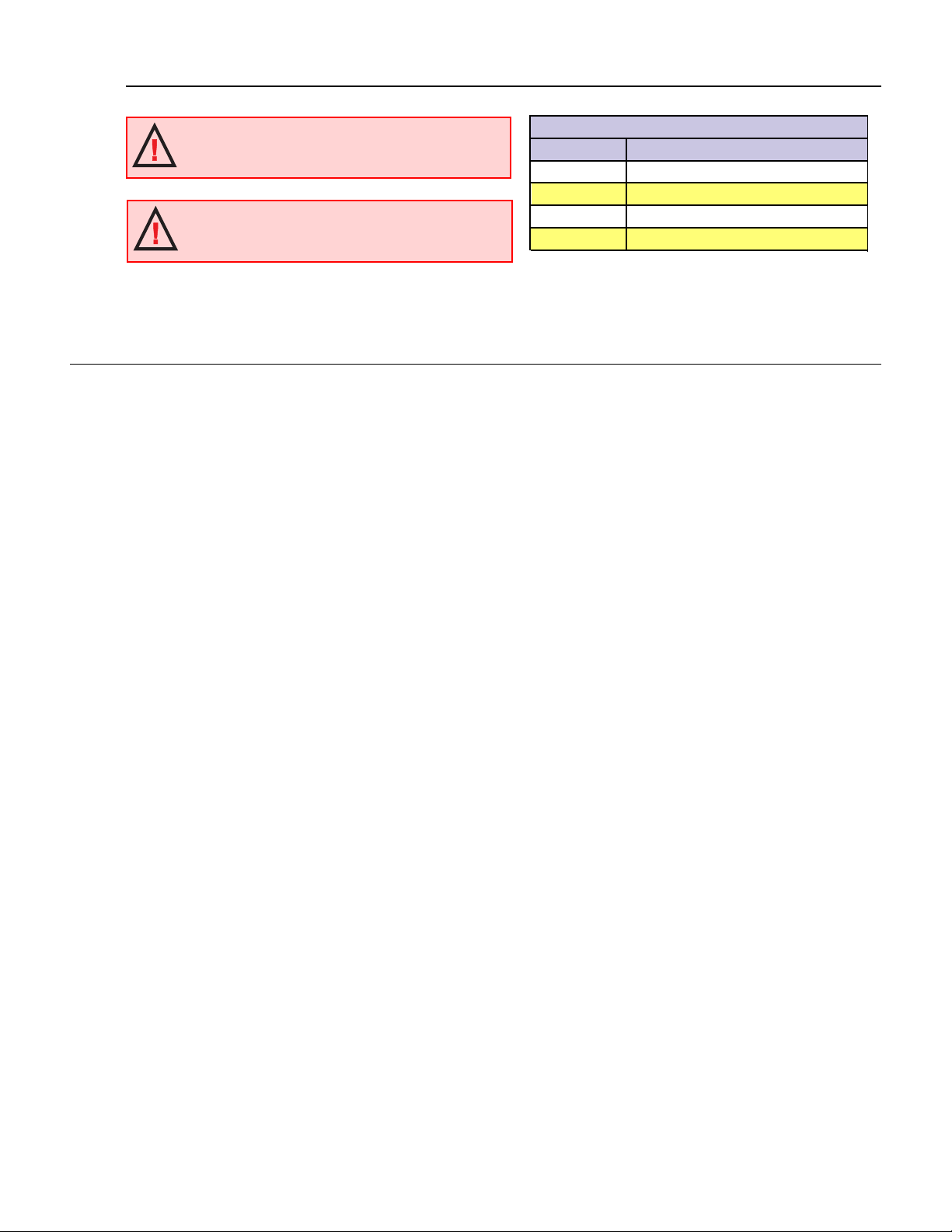

Speed-Force Curve: 45 VDC

Refer to Table 1. 5 for screw pitch information

Figure 1.7: Speed-Force Curve - 45VDC (100% Current)

8

Page 11

MDrive17 Motion Control ACME Screw

WARNING: The maximum axial load limit for the

MDrive17 Linear motor is 50 lbs (22.7 kg). Do not

exceed this rating!

WARNING: The ACME Screw MUST NOT deflect

more than ± 1 degree perpendicular to the motor face.

Additional support for radial loads may be required!

General Specifications

Input Voltage (+V)

Range ......................................................................................................................... +12 to +48 VDC

Analog Input

Resolution ................................................................................................................. 10 Bit

V oltage Range............................................................................................................. 0 to +5 Volts

Programmable I/O

Number ...................................................................................................................... 4

Interface Type ........................................................................................................... Open Collector

V oltage Range............................................................................................................. 0 to +24 VDC

Output Sink Current ................................................................................................. 700 mA

Protection .................................................................................................................. Over Temp., Short Circuit, Inductive Clamp

MDI17 ACME Screws

Screw Travel/Full Step - Inches (mm)

A 0.00125 (0.3175)

B 0.000625 (0.015875)

C 0.0003125 (0.079375)

D 0.00015625 (0.00396875)

Table 1.5: ACME Screws for the MDI17 Linear Actuator

Communication

Protocol ..................................................................................................................... RS-485, Full/Half Duplex SelecTable 1.

BAUD Rate ............................................................................................................... 4800, 9600, 19.2k, 38.0k, 115.2k

Motion

Microstep Resolution (Open Loop Configuration)

Number of Settings ................................................................................................... 14

Steps per Revolution ................................................................................................ 400, 800, 1000, 1600, 2000, 3200, 5000

6400, 10000, 12800, 25000, 25600, 50000

51200

Microstep Resolution (Closed Loop Configuration)

Steps per Revolution (Fixed).................................................................................... 51200

Encoder (Optional)

Type .......................................................................................................................... Internal, Magnetic

Resolution ................................................................................................................. 512 Lines/2048 counts per Revolution

Counters

Type .......................................................................................................................... Position(C1), Encoder (C2)

Resolution ................................................................................................................. 32 Bit

Edge Rate (Max)........................................................................................................ 5 MHz

Velocity

Range ......................................................................................................................... ±5,000,000 Steps per Second

Resolution ................................................................................................................. 1 Step per Second

Acceleration/Deceleration

Range ......................................................................................................................... 1.5 x 109 Steps per Second

Resolution ................................................................................................................. 90.9 Steps per Second

2

2

9

Page 12

General Specifications

Software

Program and Data Storage ......................................................................................... Non-Volatile

User Program Space .................................................................................................. 767 Bytes

User Registers ........................................................................................................... 4 - 32 Bit

Math Functions ......................................................................................................... +, -, x, ÷, <>, =, <, <=, >, >=, AND, OR,

Branch Functions ...................................................................................................... Branch & Call (Conditional)

Predefined I/O Functions

Inputs ........................................................................................................................ Home, Limit +, Limit -, Go, Stop, Pause,

Outputs ..................................................................................................................... Moving, Fault

Trip Functions .......................................................................................................... Input, Position

Party Mode Node Addresses.................................................................................... 62

Encoder Functions .................................................................................................... Stall Detect, Position Maintenance,

Protection

Types ......................................................................................................................... Thermal

Power Supply Requirements

Each MDrive will require a maximum power supply current of 2A. Actual power supply current will depend upon the load and

duty cycle.

XOR, NOT

Jog +, Jog -, Analog Input

Find Index

Recommended IMS Power Supplies

Listed below are the power supplies recommended for use with both voltage ranges of the MDrive17 Motion Control.

Unregulated Linear Supply

Input Specifications

AC Input V oltage Range .................................................................................................... 102-132VAC/Optional 240VAC

Frequency ........................................................................................................................... 50-60Hz

Output Specifications

Voltage (Nominal - No Load)............................................................................................ 40 VDC

Current (Peak) ................................................................................................................... 4 Amps

Current (Continuous) ......................................................................................................... 2 Amps

Unregulated Switching Supply

Input Specifications

AC Input V oltage Range .................................................................................................... 102-132VAC

Frequency ........................................................................................................................... 50-60Hz

Output Specifications

Voltage (Nominal - No Load)............................................................................................ 45 VDC

Current (Peak) ................................................................................................................... 3 Amps

Current (Continuous) ......................................................................................................... 1.5 Amps

Thermal Specifications

Because the MDrive consists of two core components, a drive and a motor, close attention must be paid to the thermal environment

where the device is used. The following maximum temperatures apply to the MDrive17:

Heatsink Temperature

Max.................................................................................................................................... 85°C

Motor Temperature

Max.................................................................................................................................... 100°C

IP404(MDI17)

ISP200-4(MDI17)

/Optional 240VAC

10

Page 13

Section 1.3

Introduction to the MDrive23 Motion Control

Introduction to the MDrive23 Motion Control

The MDrive23 Motion Control offers the system designer a low-cost, intelligent motion controller integrated with a NEMA 23 high

torque stepping motor and a +12 to +48 VDC microstepping drive.

The MDrive23 Motion Control adds a versatile array of functions by combining a complete programmable motion controller with

our already compact and cost effective standard MDrive23, adding little cost and no increase in size. Standard offerings include four

5 to 24 volt programmable I/O points, one 10-bit 0 to 5 volt analog input, 0 to 5 MHz step clock rate, microstep resolution up to

51,200 steps per revolution and a full featured easy-to-program instruction set.

The MDrive23 Motion Control communicates using the RS-485 communications protocol, this allows for point-to-point or multidrop communications using one communications port. Addressing and hardware support up to 62 MDrive nodes in a system. The

communications BAUD rate is software selectable and ranges from 4.8 kbps to 115 kbps.

The MDrive23 is also available with an optional closed loop control. The closed loop configuration adds a 512 line (2048 count)

internal magnetic rotary encoder with index mark without increasing the length of the unit. Closed loop configuration adds position

maintenance, stall detection and find index mark.

A vailable motor configurations include: single shaft, double shaft with control knob, and long life ACME screw linear actuator .

Rotary versions are available in three stack lengths: 18, 22 & 31. Interface connections are accomplished using either a 7 position

terminal block or optional 12” flying leads.

Feature Summary

! Integrated Microstepping Drive/Motion Controller with Optional Encoder/NEMA 23 High Torque Stepping Motor

! +12 to +48VDC Input Voltage

! Low Cost

! Extremely Compact

! Available Configurations: Single Shaft*, Linear Actuator, Integral Encoder*, Double Shaft with Knob for Manual

! Three Motor Stack Lengths Available*

! Single Power Supply

! Microstep Resolution up to 51,200 Steps Per Revolution

! Open Loop or Optional Closed Loop Control

! Programmable Motor Run and Hold Current Settings

! Four 5 to 24 VDC Programmable I/O Points

! One Analog 10 Bit, 0 to 5 Volt Analog Input

! 0 to 5 MHz Step Clock Rate, Selectable in 0.59 Hz Increments

! RS-485 Communications Protocol

! Communications BAUD Rate Selectable from 4.8 kbps to 115 kbps

! 62 Software Addresses for Multidrop Communications

! Simple 1 and 2 Character Programming Instructions

! Pluggable Terminal Strip or 12” Flying Lead Interface

! Optional Integrated RS-232 to RS-485 Converter/Communications Cable

*Rotary Motor Only

Positioning*

11

Page 14

Section 1.4

5

(

)

500

(

)

SQ.

EQ. SPAC

A

2

.

0.230 .005

(

)

0

)

MDrive23 Motion Control Specifications

Section Overview

This section contains mechanical, motor and electrical specifications specific to each version of the MDrive23 Motion Control.

Shown are:

!

! Linear Motor Specifications

! General Specifications

! Power Supply Requirements

! Thermal Specifications

Rotary Motor Specifications

Mechanical Specifications - Dimensions in Inches (mm)

Rotary Motor Specifications

Interface

Option

1.62

41.28

0.060

(1.53)

0.810 ± .030

(20.57 ±.76)

0.590

(14.86)

1.

38.10

4 x Ø 0.205 (5.21)

±.010 (.25) HOLES

ED ON

.625 (66.68) DBC

2.907

(73.84)

L

MAX

L

MAX2

Standard Rotary Motor (L

MAX

)

Stack In (mm)

2218 2.632 (66.85)

2222 3.000 (76.20)

2231 3.960 (100.58)

5.84

.2500 (6.35

Ø

0.2495 (6.34)

Ø 1.500 ±.002

(Ø 38.10 ±.05)

.127

1.860

(47.24 SQ.)

2.22 SQ.

(56.39 SQ.)

Control Knob (L

MAX2

)

Stack In ( mm)

2218 3.088 (78.44)

2222 3.537 (89.84)

2231 4.416 (112.17)

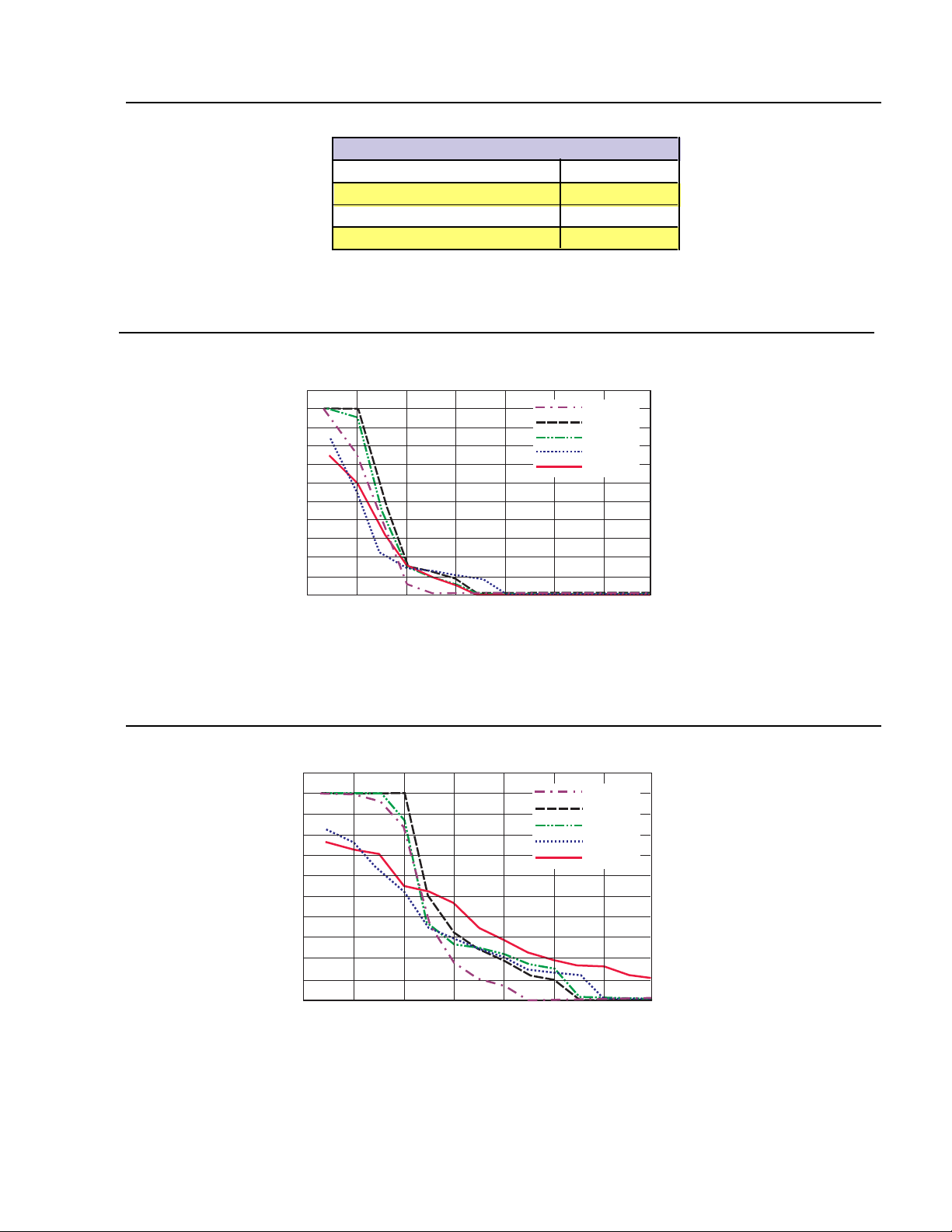

Figure 1.8: Rotary MDrive23 Motion Control Mechanical Specifications

MDrive Motion Control 2218 Motor Specs and Speed/Torque Curves

MDI2218

Holding Torque oz-in (N-cm) 90 (64)

Detent Torque oz-in (N-cm) 3.5 (2.5)

Rotor Inertia oz-in-sec2 (kg-cm2) 0.0025 (0.18)

Weight (Motor+Driver) oz (gm) 20.1 (569.8)

T able 1.6: Rotary MDI2218 Motor Specifications

70

60

50

40

30

20

Torque in Oz - In

10

0

0 1000 2000 3000 4000 5000 6000 7000

Speed in Full Steps per Second

24 VDC

45 VDC

49

Torque in N - cm

42

35

28

21

14

7

Figure 1.9: Rotary MDrive Motion Contr ol 2218 Speed/Torque Data

12

Page 15

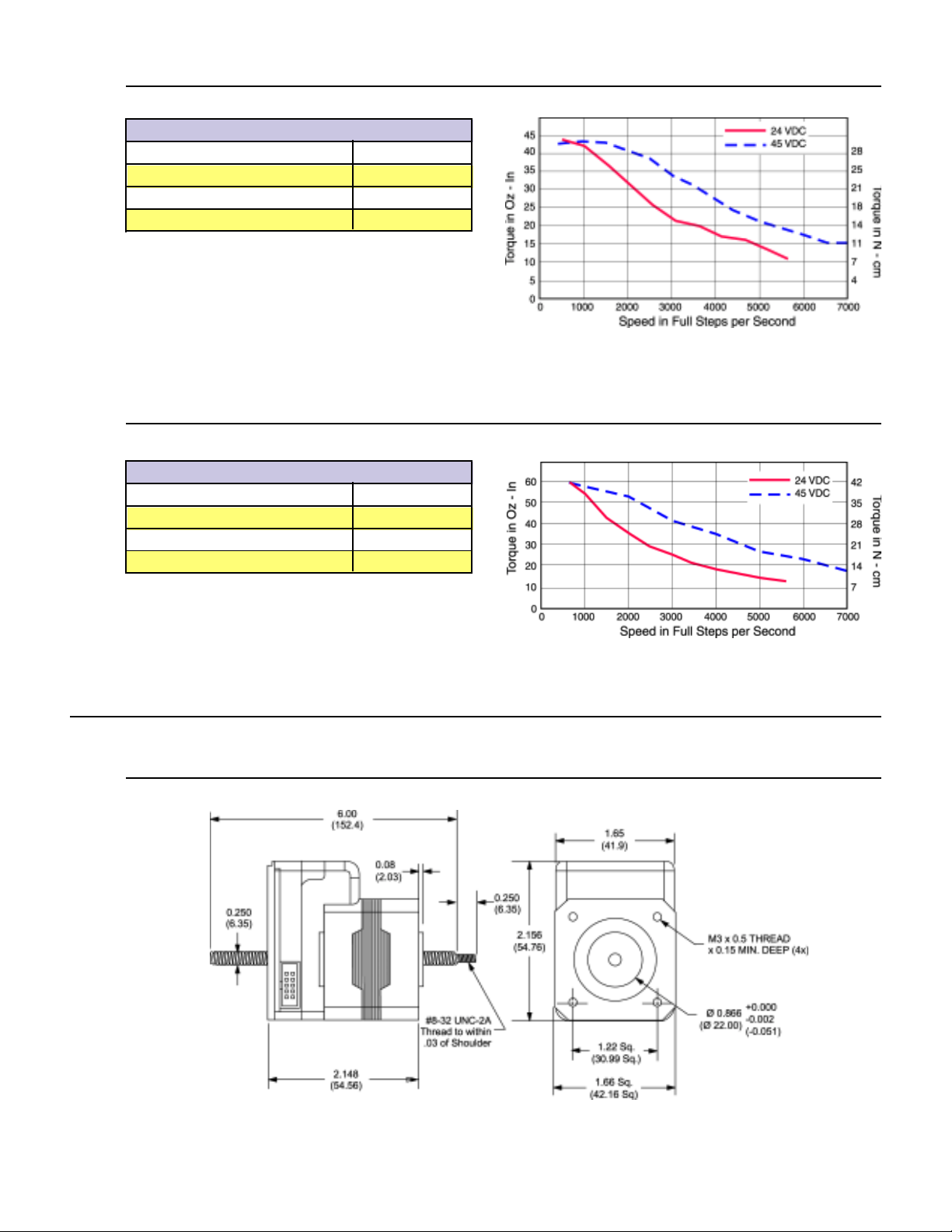

MDrive Motion Control 2222 Motor Specs and Speed/Torque Curves

5

(

)

Q.

(

)

(

)

(

)

Q

A

.

Ø

5

A

(

)

OF SHOU

R

MDI2222

Holding Torque oz-in (N-cm) 144 (102)

Detent Torque oz-in (N-cm) 5.6 (3.92)

Rotor Inertia oz-in-sec2 (kg-cm2) 0.0037 (0.26)

Weight (Motor+Driver) oz (gm) 24.4 (691.7)

T able 1.7: Rotary MDI2222 Motor Specifications

140

120

100

80

60

40

Torque in Oz - In

20

0

0 1000 2000 3000 4000 5000 6000 7000

Speed in Full Steps per Second

Figure 1.10: Rotary MDrive Motion Contr ol 2222 Speed/Torque Data

MDrive Motion Control 2231 Motor Specs and Speed/Torque Curves

MDI2231

Holding Torque oz-in (N-cm) 239 (169)

Detent Torque oz-in (N-cm) 9.7 (6.86)

Rotor Inertia oz-in-sec2 (kg-cm2) 0.0065 (0.46)

Weight (Motor+Driver) oz (gm) 38.5 (1091.5)

T able 1.8: Rotary MDI2231 Motor Specifications

225

200

175

150

125

100

75

Torque in Oz - In

50

25

0

0 1000 2000 3000 4000 5000 6000 7000

Speed in Full Steps per Second

24 VDC

45 VDC

24 VDC

45 VDC

99

Torque in N - cm

85

71

56

42

28

14

159

141

124

Torque in N - cm

106

88

71

53

35

18

Linear Motor Specifications

Mechanical Specifications - Dimensions in Inches (mm)

6.000

(152.40)

1.62

41.28

0.375

2.907

(73.84)

(9.525)

2.630

(66.80)

Figure 1.11: Rotary MDrive Motion Control 2231 Speed/Torque Data

1.500

38.10

4 x Ø 0.205 (5.21)

0.060

(1.53)

1/4-20 UNC-2

THREAD TO

WITHIN .050

LDE

1.3

2.22 S

56.39 SQ.

±.010 (.25) HOLES

E

. SPACED ON

2.625 (66.68) DBC

1.860 SQ..

47.24 SQ.

00 ±.002

1.

(Ø 38.10 ±.05)

Figure 1.12: Linear Actuator MDrive23 Motion Control Mechanical Specifications

13

Page 16

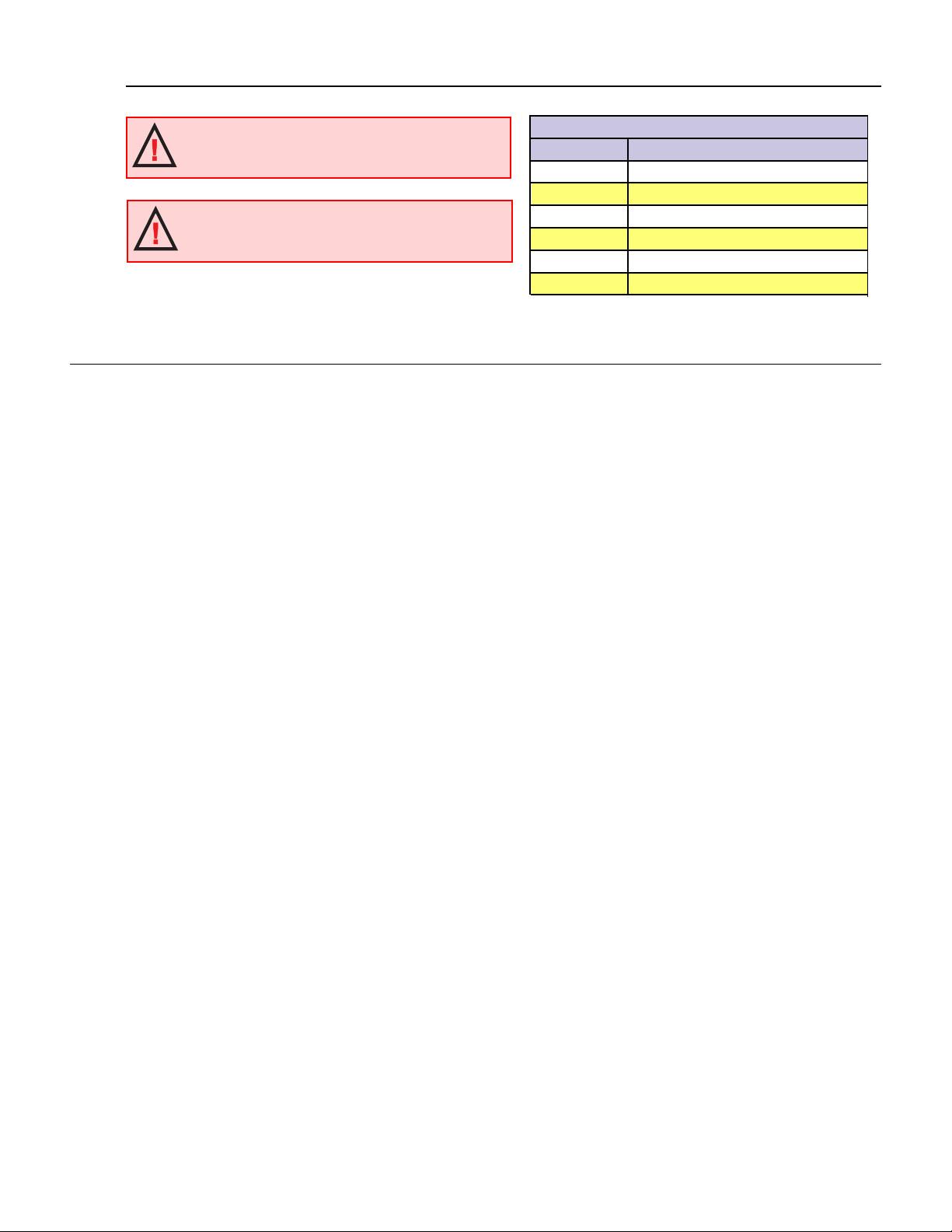

Linear Actuator MDrive Motion Control 2218 Specs and Speed-Force

Curves

MDI23 Linear Actuator

Maximum Thrust lbs (kg) 200 (90.7)

Maximum Screw Deflection ±1 °

Backlash inches (mm) 0.005 (0.127)

Weight (Motor+Driver) oz (gm) 20.4 (578.3)

T able 1.9: Linear Actuator MDrive23 Motion Contr ol Motor Specifications

Speed-Force Curve: 24 VDC

Refer to Table 1.10 for screw pitch information

200

180

160

140

120

100

80

60

40

20

Force (lbs) Load Limit 200 lbs

0

0 1000 2000 3000 4000 5000 6000 7000

Speed in Full Steps per Second

Figure 1.13: Speed-Force Curve - 24VDC (100% Current)

Speed-Force Curve: 45 VDC

Refer to Table 1.10 for screw pitch information

200

180

160

140

120

100

80

60

40

Force (lbs) Load Limit 200 lbs

20

0

0 1000 2000 3000 4000 5000 6000 7000

Screw E

Screw D

Screw C

Screw B

Screw A

Scre w E

Scre w D

Scre w C

Scre w B

Scre w A

Speed in Full Steps per Second

890

Force (N)Load Limit 890N

801

712

623

534

445

356

267

178

89

890

Force (N)Load Limit 890N

801

712

623

534

445

356

267

178

89

Figure 1.14: Speed-Force Curve - 45VDC (100% Current)

14

Page 17

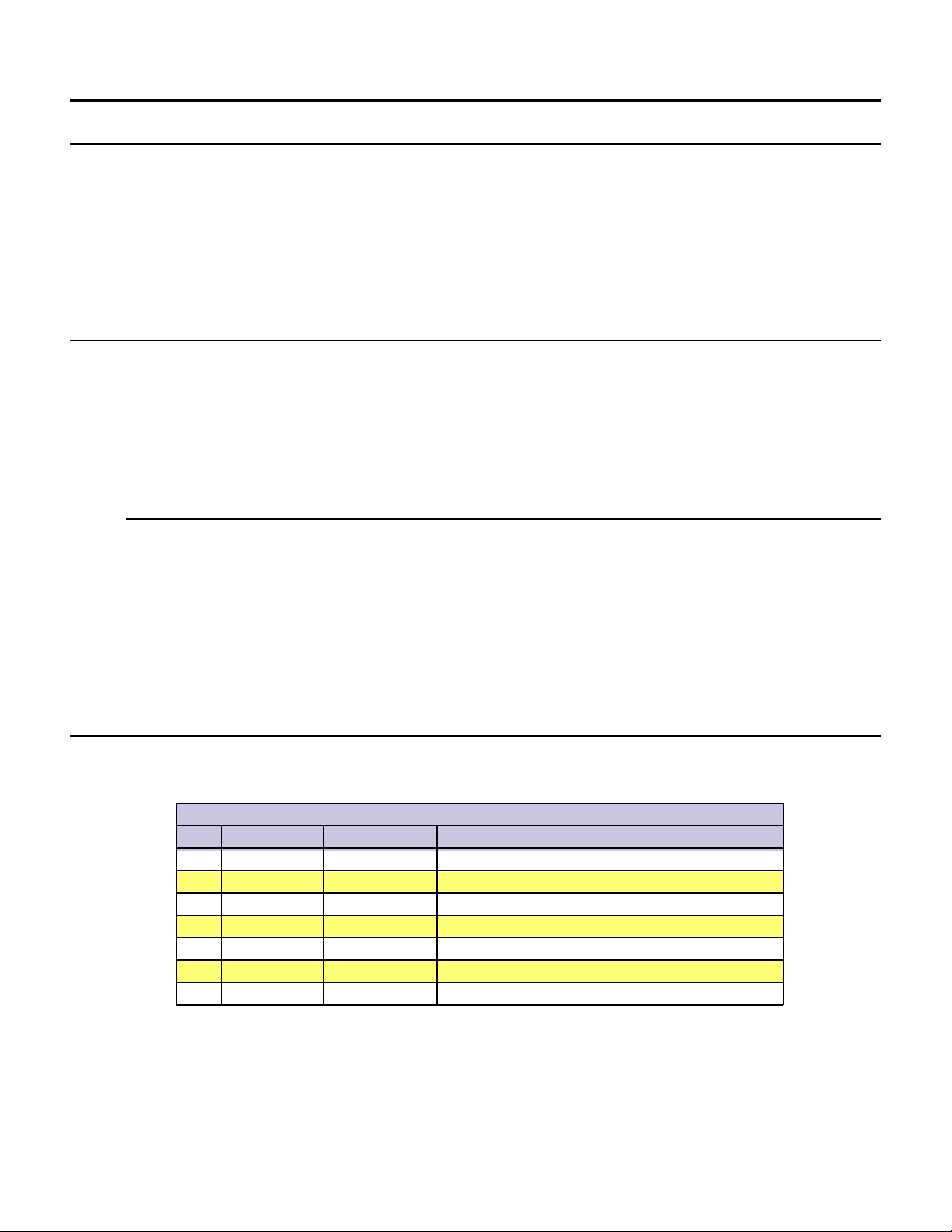

MDrive23 Motion Control ACME Screw

WARNING: The maximum axial load limit for the

MDrive23 Linear motor is 200 lbs (90.7 kg). Do not

exceed this rating!

WARNING: The ACME Screw MUST NOT deflect

more than ± 1 degree perpendicular to the motor face.

Additional support for radial loads may be required!

General Specifications

Input Voltage (+V)

Range ......................................................................................................................... +12 to +48 VDC

Analog Input

Resolution ................................................................................................................. 10 Bit

V oltage Range............................................................................................................. 0 to +5 Volts

Programmable I/O

Number ...................................................................................................................... 4

Interface Type ........................................................................................................... Open Collector

V oltage Range............................................................................................................. 0 to +24 VDC

Output Sink Current ................................................................................................. 700 mA

Protection .................................................................................................................. Over Temp., Short Circuit, Inductive Clamp

MDI23 ACME Screws

Screw Travel/Full Step - Inches (mm)

F 0.002 (0.0508)

A 0.001 (0.0254)

B 0.000833 (0.0211582)

C 0.0005 (0.0127)

D 0.0004167 (0.00793750)

E 0.0003125 (0.0079375)

T able 1.10: ACME Screws for the MDI23 Linear Actuator

Communication

Protocol ..................................................................................................................... RS-485, Full/Half Duplex Selectable

BAUD Rate ............................................................................................................... 4800, 9600, 19.2k, 38.0k, 115.2k

Motion

Microstep Resolution (Open Loop Configuration)

Number of Settings ................................................................................................... 14

Steps per Revolution ................................................................................................ 400, 800, 1000, 1600, 2000, 3200, 5000

6400, 10000, 12800, 25000, 25600, 50000

51200

Microstep Resolution (Closed Loop Configuration)

Steps per Revolution (Fixed).................................................................................... 51200

Encoder (Optional)

Type .......................................................................................................................... Internal, Magnetic

Resolution ................................................................................................................. 512 Lines/2048 counts per Revolution

Counters

Type .......................................................................................................................... Position(C1), Encoder (C2)

Resolution ................................................................................................................. 32 Bit

Edge Rate (Max)........................................................................................................ 5 MHz

Velocity

Range ......................................................................................................................... ±5,000,000 Steps per Second

Resolution ................................................................................................................. 1 Step per Second

Acceleration/Deceleration

Range ......................................................................................................................... 1.5 x 109 Steps per Second

Resolution ................................................................................................................. 90.9 Steps per Second

2

2

15

Page 18

General Specifications

Software

Program and Data Storage ......................................................................................... Non-Volatile

User Program Space .................................................................................................. 767 Bytes

User Registers ........................................................................................................... 4 - 32 Bit

Math Functions ......................................................................................................... +, -, x, ÷, <>, =, <, <=, >, >=, AND, OR,

Branch Functions ...................................................................................................... Branch & Call (Conditional)

Predefined I/O Functions

Inputs ........................................................................................................................ Home, Limit +, Limit -, Go, Stop, Pause,

Outputs ..................................................................................................................... Moving, Fault

Trip Functions .......................................................................................................... Input, Position

Party Mode Node Addresses.................................................................................... 62

Encoder Functions .................................................................................................... Stall Detect, Position Maintenance,

Protection

Types ......................................................................................................................... Thermal

Power Supply Requirements

Each MDrive will require a maximum power supply current of 2A. Actual power supply current will depend upon the load and

duty cycle.

XOR, NOT

Jog +, Jog -, Analog Input

Find Index

Recommended IMS Power Supplies

Listed below are the power supplies recommended for use with both voltage ranges of the MDrive23 Motion Control.

Unregulated Linear Supply

Input Specifications

AC Input V oltage Range .................................................................................................... 102-132VAC/Optional 240V AC

Frequency ........................................................................................................................... 50-60Hz

Output Specifications

Voltage (Nominal - No Load) ............................................................................................ 40 VDC

Current (Peak) ................................................................................................................... 4 Amps

Current (Continuous) ......................................................................................................... 2 Amps

Unregulated Switching Supply

Input Specifications

AC Input V oltage Range .................................................................................................... 102-132VAC

Frequency ........................................................................................................................... 50-60Hz

Output Specifications

Voltage (Nominal - No Load) ............................................................................................ 45 VDC

Current (Peak) ................................................................................................................... 3 Amps

Current (Continuous) ......................................................................................................... 1.5 Amps

Thermal Specifications

Because the MDrive consists of two core components, a drive and a motor, close attention must be paid to the thermal environment

where the device is used. The following maximum temperatures apply to the MDrive23:

Heatsink Temperature

Max.................................................................................................................................... 85°C

Motor Temperature

Max.................................................................................................................................... 100°C

IP404(MDI23)

ISP200-4(MDI23)

/Optional 240VAC

16

Page 19

Part 2: Connecting, Configuring

and Programming the

MDrive Motion Control

17

Page 20

Intentionally Left Blank

18

Page 21

Section 2.1

Interfacing the MDrive Motion Control

Section Overview

This section will acquaint the user with connecting and using the MDrive Motion Control.

!

! Pin Configuration and Descriptions

! Interfacing Power

! Interfacing RS-485 Communications

! Interfacing Digital I/O

! Interfacing Analog Input

Layout and Interface Guidelines

Logic level cables must not run parallel to power cables. Power cables will introduce noise into the logic level cables and make your

system unreliable.

Logic level cables must be shielded to reduce the chance of EMI induced noise. The shield needs to be grounded at the signal source

to earth. The other end of the shield must not be tied to anything, but allowed to float. This allows the shield to act as a drain.

Power supply leads to the driver need to be twisted. If more than one driver is to be connected to the same power supply, run

separate power and ground leads from the supply to each driver.

Recommended Wiring

Layout and Interface Guidelines

The following wiring/cabling is recommended for use with the MDrive Motion Control:

Power

Belden Part# 9740 or equivalent 18 Gauge

Logic Wiring (I/O, Communications)

Wire Size .............................................................................................................. 20-22 AWG

General Practices

The following wire strip length is recommended:

Wire Strip Length................................................................................................. 0.250” (6.0 mm)

Pin Configuration and Descriptions

Connector P1

Pin # Flying Lead Function Description

1 White/Yellow I/O1 Open Collector I/O Point #1, +5 to +24VDC

2 White/Orange I/O2 Open Collector I/O Point #2, +5 to +24VDC

3 White/Violet I/O3 Open Collector I/O Point #3, +5 to +24VDC

4 White/Blue I/O4 Open Collector I/O Point #4, +5 to +24VDC

5 Green Analog Input 10 Bit, 0 to 5V Analog Input

6 Black GND Ground

7 Red +V +12 to +48 VDC Power Supply Input

T able 2.1: P1 Pin Configuration and Description

19

Page 22

Pin # Function Description

1- 5 N/C Reserved

6 RX+ RS-485 Receive +

7 RX- RS-485 Receive 8 TX- RS-485 Transmit 9 TX+ RS-485 Transmit +

10 GND Communications Ground

Interfacing Power

Connector P2 - 10 Pin Header

T able 2.2: P2 Pin Configuration and Description

An advantage of the MDrive Motion Control is

that only a single +12 to +48VDC unregulated

linear or unregulated switching power supply is

required to power the control circuitry and motor

power.

A maximum of 2A output is required from the

supply for each MDrive. Note that the actual

+12 to +48 VDC

Unregulated

Linear or

Unregulated

Switching

Power Supply

power required will be based upon the load and

duty cycle.

Wiring should be accomplished using shielded

twisted pair Belden Part# 9740 or equivalent 18

PWR GND

+VDC

OUTPUT

Gauge. The shield should be attached to earth at

the power supply end and left floating at the

MDrive end.

Interfacing RS-485 Communications

The MDrive Motion Control

communicates to the host using the

RS-485 protocol. Communications

may be configured as either half or

full duplex using the EM (Echo

Mode) Instruction. RS-485 may be

used in two ways: either to communicate to a single MDrive Motion

Control, or to address up to 62

individually named MDrive nodes in a

multidrop system.

MDrive23 Motion Control

PIN 1

Shielded Twisted Pair 18 AWG

Earth

Figure 2.1: Power Supply Interface

Single MDrive

Optionally available for the MDrive

Motion Control is a communications

cable, IMS P/N MD-CC200-000,

which has built-in RS-232 to RS-485

conversion circuitry . This will allow

you to connect the serial port of your

PC directly to the MDrive Motion

Control.

Figure 2.2: RS-485 Interface, Single MDrive Motion Control

20

Page 23

Multiple MDrive Motion Control System (Party Mode)

In systems with multiple controllers it is necessary to communicate with the control modules using party mode (PY=1) of operation. The MDrive Motion Control nodes in the system are configured in software for this mode of operation by setting the Party

Flag (PY) to True (1). It is necessary for all of the nodes in a system to have this configuration selected. When operating in party

mode each MDrive Motion Control in the system will need a unique address, or name, to identify it in the system. This is

accomplished by using the software command DN, or Device Name. For example, to set the name of an MDrive to “A” you would

use the following command: DN=65 or DN=”A” (65 is the ASCII decimal equivalent of uppercase A). The factory default name is

“!”. The asterisk character “*” is used to issue global commands to every device in the system. See Appendix A for ASCII table.

In setting up your system for party operation the most practical approach would be to observe the following steps:

1. Connect the first MDrive Motion Control to the Host PC configured for Single Mode Operation.

2. Establish communications. Using the command DN name the MDrive Motion Control. This can be any upper or

3. Set the party flag PY=1. Remove power.

4. Connect the next MDrive Motion Control in the system, set the party flag to true.

5. Establish communications with this module using the factory default name “!”. This name cannot be reused.

6. Repeat the last two steps for each additional MDrive in the system.

lower case ASCII character or number 0-9.

Rename and save the new name. Remove power.

Figure 2.3: RS-485 Interface, Multiple MDrive Motion Control System

21

Page 24

Interfacing the Digital I/O

The MDrive Motion Control comes standard with a set of four (4) open collector +5 to +24VDC I/O point which may be

programmed individually as either general purpose or dedicated inputs or outputs, or collectively as a group.

The digital I/O may be defined as either active HIGH or active LOW . When the I/O is configured as active HIGH, the level is +5 to

+24 VDC and the state will be read/set as a “1”. If the level is 0 VDC then the state will be read/set as “0”. Inversely, if co nfigured as

active LOW, then the state of the I/O will be read/set as a “1” when the level is LOW, and a “0” when the level is HIGH. The active

HIGH/LOW state is configured by the third parameter of the I/O Setup (S1-4) variable, which is explained further on. The goal of this

I/O configuration scheme is to maximize compatibility between the MDrive Motion Control and standard sensors and switches.

The MDrive Motion Control’s I/O scheme is a powerful tool for machine and process control.

Uses of the Digital I/O

The I/O may be utilized to receive input from external devices such as sensors, switches or PLC outputs. When configured as outputs,

devices such as relays, solenoids, LED’s and PLC inputs may be controlled from the MDrive Motion Control.

Each I/O point may be individually programmed to any one of 9 dedicated input functions, 3 dedicated output functions, or as

general purpose inputs or outputs. The I/O may be addressed individually, or as a group. The active state of the line or group may

also be set. All of these possible functions are accomplished with of the I/O Setup Variable (S1-4).

Interfacing Inputs

The MDrive Motion Conrol inputs may be interfaced to a variety of sinking devices. A single input may be programmed to be a

general purpose user input, or to one of nine dedicated input functions. These then may be programmed to have an active state of

either HIGH or LOW.

Additionally the inputs may read as a group using the “IN” keyword. This will display as a decimal between 0 and 15 representing

the 4 bit binary number. Used thus Input 1 is the Least Significant Bit (LSB) and Input 4 will be the Most Significant Bit (MSB).

Interfacing a Single Input Examples

Input Functions

S<point>= Function Active

0 General Purpose 0/1

1 Home 0/1

2 Limit + 0/1

3 Limit - 0/1

4 G0 0/1

5 Soft Stop 0/1

6 Pause 0/1

7 Jog + 0/1

8 Jog - 0/1

10 Index (encoder only) 0/1

T able 2.3: Input Functions

Figure 2.4: Input Interfaced to a Switch

Figure 2.5: Input Interfaced to a PLC

22

Page 25

Interfacing Inputs as a Group Example

+5VDC

Sample Software Configuration

'set inputs to user inputs active low,

S1=0,0

S2=0,0

S3=0,0

S4=0,0

PR IN 'Read BCD State of Input Group

Figure 2.6: TTL Interface to Input Group

MDrive23 Motion Control

PIN 1

Truth T able - I/O Used as a Group

DEC IO4 IO3 IO2 IO1

00000

10001

20010

30011

40100

50101

60110

70111

81000

91001

101010

111011

121100

131101

141110

151111

Table 2.4: I/O Group Truth Table

23

Page 26

Interfacing Outputs

PIN 1

MDrive23 Motion Control

Sample Software Configuration

'set outputs to user outputs active low,

S1=16,0

S2=16,0

S3=16,0

S4=16,0

OT=<0-15> `Set outputs as 1 value

+5 to +24VDC

The MDrive Motion Control Outputs may be configured as either general purpose or set to one of two dedicated functions, Fault or

Moving. These outputs will sink up to 700 mA max and may be connected to +5 to +24VDC. Note that a current limiting resistor may

be required to limt the current to 700 mA.

As with the inputs the MDrive Motion Control Outputs may be used singularly or collectively as a group.

Interfacing a Single Output Examples

+5 to +24 V

Sample Software Configuration #1: FAULT

S4=18,0 'Set IO4 to Fault, Active State=LOW

Sample Software Configuration #2: MOVING

S4=17,0 'Set IO4 to Moving, Active State=LOW

(LED will illuminate when Axis is moving)

Figure 2.7: Output Interfaced to an LED

+5 to +24 V

*External Resistor may be needed to

limit output sink current to 700mA

MDrive23 Motion Control

PIN 1

MDrive23 Motion Control

PIN 1

Input Functions

S<point>= Function Active

16 General Purpose 0/1

17 Fault 0/1

18 Moving 0/1

T able 2.5: Output Functions

Sample Software Configuration #1: FAULT

S4=18,0 'Set IO4 to Fault, Active State=LOW

Sample Software Configuration #2: General Purpose

S4=16,0 'Set IO4 to General Purpose, Active State=LOW

Figure 2.8: Output Interfaced to a Relay

Interfacing Outputs as a Group Example

To write to the outputs as a group the OT instruction is

used. This will give you a binary output of 0000 to 1111

from a decimal entry of 0-15. Output 1 will be the Least

Significant Bit (LSB), Output 4 will be the Most Significant

Bit (MSB).

See Table 2.4 for Truth Table.

Figure 2.9: Outputs Interfaced to LED’s as a Group

24

Page 27

Interfacing the Analog Input

The analog input of the MDrive Motion Control is a 0 to 5V, 10 bit resolution input. This offers the user the ability to receive input

from temperature, pressure or other forms of sensors, and then control events based upon the input.

The value of this input will be read using the I5 instruction, which has a range of 0 to 1024, where 0 = 0 volts and 5 = 5.0 volts. You

may then use the program branch (BR) or subroutine call (CL) instructions to control events within the system.

Sample Usage

‘*********Main Program***********

PG 100 ‘start prog. at address 100

LB A1 ‘label program A1

CL A2, I5<500 ‘Call Sub A2, If I5 is less than 500

CL A3, I5>524 ‘Call Sub A3, If I5 is greater than 524

BR A1 ‘loop to A1

E ‘End

PG ‘Exit program

‘*********Subroutines************

LB A2 ‘label subroutine A2

MA 2000 ‘Move Absolute 2000 steps

H ‘Hold program execution until motion ceases

RT ‘return from subroutine

LB A3 ‘label subroutine A3

MA -2000 ‘Move Absolute -2000 steps

H ‘Hold program execution until motion ceases

RT ‘return from subroutine

Figure 2.10: Analog Input Interface

25

Page 28

Section 2.2

MDrive Motion Control Software Introduction

Section Overview

This section will acquaint the user with basics of MDrive Motion Control Programming

!

! Upgrading the MDrive Firmware

! The MDrive Program

Installing and Using IMS Terminal

System Requirements

! IBM Compatible PC.

! Windows 95/98 or Windows NT4.0 SP6, Windows 2000 SP2, Windows XP

! 10 MB hard drive space.

! A free serial communications port.

Installation

The IMS T erminal software is a programming/communications interface. This program was created by IMS to simplify programming and upgrading the MDrive Motion Control. The IMS Terminal is also necessary to upgrade the software in your MDrive

Motion Control. These updates will be posted to the IMS website at www.imshome.com as they are made available.

Installing IMS Terminal Software

To install the IMS Terminal to your hard drive, insert the IMS CD into your CD-ROM Drive. The installation front-end will

automatically open.

Follow the on-screen instructions to complete the installation.

Figure 2.11: IMS Terminal W indow

26

Page 29

1) To open the IMS Terminal select Start > Programs > IMS Terminal > IMS T erminal.

2) Click the File Menu Item “Edit>Preferences”.

3) Click the “Comm Settings” tab.

4) Select the Communications Port that you will be using with your MDrive Motion Control.

5) The BAUD rate is already set to the MDrive Motion Control default. Do not change this setting until you have

6) The “Window Size” settings are strictly optional. You may set these to whatever size is comfortable to you.

7) Click “OK”. The settings will be automatically saved upon a normal shutdown.

8) Apply power to the MDrive Motion Control. A sign-on message should appear in the terminal window.

established communications with the MDrive Motion Control.

If you can see this sign-on message then you are up and running! If the sign-on banner does not appear, try using a software reset:

hold down the “Ctrl” key and press “C” (^C). If the sign-on banner still does not appear then there may be a problem with either

the hardware or software configuration of the MDrive Motion Control or Host PC.

Using the IMS Terminal Software

The IMS Terminal software is an easy to setup and use interface for MDrive Motion Control programming. It is also required to

upgrade the firmware in the MDrive Motion Control.

Configuring Communications Settings

The communications settings are configured by means of the

“Preferences Dialog”. This dialog is accessed through the

“Edit > Preferences” menu item or by clicking the “Preferences” icon on the toolbar. The preferences dialog gives the

user the ability to set the format for text size, font and

color, as well as general communications settings. It is set

by default to the optimum communications settings for the

MDrive Motion Control. If you change the BAUD rate