Page 1

EDAS CE Manual

www.edasce.com

855M536

Copyright 2001-07 by Intelligent Instrumentation Incorporated, Tucson, Arizona, U.S.A.

All rights reserved.

Page 2

Warranty and Repair Policy Statement

General

Seller warrants that its products furnished hereunder will, at the time of delivery, be free from defects in material and

workmanship and will conform to Seller's published specifications applicable at the time of sale. Seller's obligation or

liability to Buyer for products which do not conform to above stated warranty shall be limited to Seller, at Seller's sole

discretion, either repairing the product, replacing the product with a like or similar product, or refunding the purchase

price of the nonconforming product, provided that written notice of said nonconformance is received by Seller within the

time periods set forth below:

a. For all software products, including licensed programs, ninety (90) days from date of initial delivery to

Buyer;

b. For all hardware products (excluding batteries), including complete systems, fifteen (15) months from date

of initial delivery to Buyer, subject to the additional conditions of paragraph c) below;

c. In the event that Buyer's returned product is a Discontinued product and is not repairable for any reason,

Seller may elect to replace it with like or similar product that is, in Seller's sole judgment, the closest

equivalent to the returned product. Seller does not warrant that such replacement product will be an exact

functional replacement of the returned product.

Further, all products warranted hereunder for which Seller has received timely notice of nonconformance must be

returned FOB Seller's plant no later than thirty (30) days after the expiration of the warranty periods set forth above.

These warranties provided herein shall not apply to any products which Seller determines have been subjected, by

Buyer or others, to operating and/or environmental conditions in excess of the limits established in Seller's published

specifications or otherwise have been the subject of mishandling, misuse, neglect, improper testing, repair, alteration or

damage. THESE WARRANTIES EXTEND TO BUYER ONLY AND NOT TO BUYER'S CUSTOMERS OR USERS OF

BUYER'S PRODUCT AND ARE IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS, IMPLIED OR

STATUTORY INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT SHALL SELLER BE LIABLE FOR INCIDENTAL, SPECIAL OR CONSEQUENTIAL

DAMAGES. Seller's liability for any claim of any kind shall in no case exceed the obligation or liability specified in this

Warranty clause.

Technical Assistance and Service

Seller's warranty as herein set forth shall not be enlarged, diminished or affected by, and no obligation or liability shall

arise or grow out of, Seller's rendering of technical advice, facilities or service in connection with Buyer's order of the

goods furnished hereunder. Products returned for warranty service, but which are found to be fully functional and in

conformance with specifications may be subject to a nominal service charge and return freight charges. Periodic recalibration of products, if required, is the responsibility of Buyer and is not provided under this Warranty.

Online Support

Online support is available through technical support links on Intelligent Instrumentation’s 24-hour World Wide Web site

at

http:// www.EDASce.com

developments, announcements, application notes, application examples, and other useful information. The site and

support areas continue to grow as new products, updates, and features are added.

. The site contains information on Intelligent Instrumentation’s products, new

Email Support

Intelligent Instrumentation’s technical support can be reached via email. When sending an email message, be sure to

include complete contact information as well as a detailed description of the problem and the products being used to:

support@edasce.com

ii

Page 3

Static Sensitivity

Seller ships all static-susceptible products in anti-static packages. Seller's Warranty as herein set forth shall not cover

warranty repair or replacement for products damaged by static due to Buyer's failure to use proper protective procedures

when handling, storing, or installing products.

Trademarks

FactoryView®, DASport™, EDAS®, EDAS® CE, UDAS™, Intelligent Instrumentation® are trade names and/or

trademarks of Intelligent Instrumentation®, Inc.

Other products or brand names are trademarks or registered trademarks of their respective companies.

Use of Equipment

Intelligent Instrumentation Inc., assumes no responsibility for any direct, indirect or consequential loss or damages

resulting from misuse of the equipment or for improper or inadequate maintenance of the equipment or for any such

damage or loss resulting from the use of other equipment, attachments, accessories, and repairs at any time made to or

placed upon the equipment or any replacement thereof. Furthermore, Intelligent Instrumentation Inc., makes no

representations or warranties, either expressed or implied, in connection with the use of the equipment in the event it is

improperly used, repaired or maintained.

FCC Radio Frequency Interference Statement

This equipment generates and uses radio frequency energy, and may cause interference to radio or television reception.

Per FCC rules, Part 15, Subpart J, operation of this equipment is subject to the conditions that no harmful interference is

caused and that interference must be accepted that may be caused by other incidental or restricted radiation devices,

industrial, scientific or medical equipment, or from any authorized radio user.

The operator of a computing device may be required to stop operating his device upon a finding that the device is

causing harmful interference and it is in the public interest to stop operation until the interference problem has been

corrected.

The user of this equipment is responsible for any interference to radio or television reception caused by the equipment.

It is the responsibility of the user to correct such interference.

Revision History

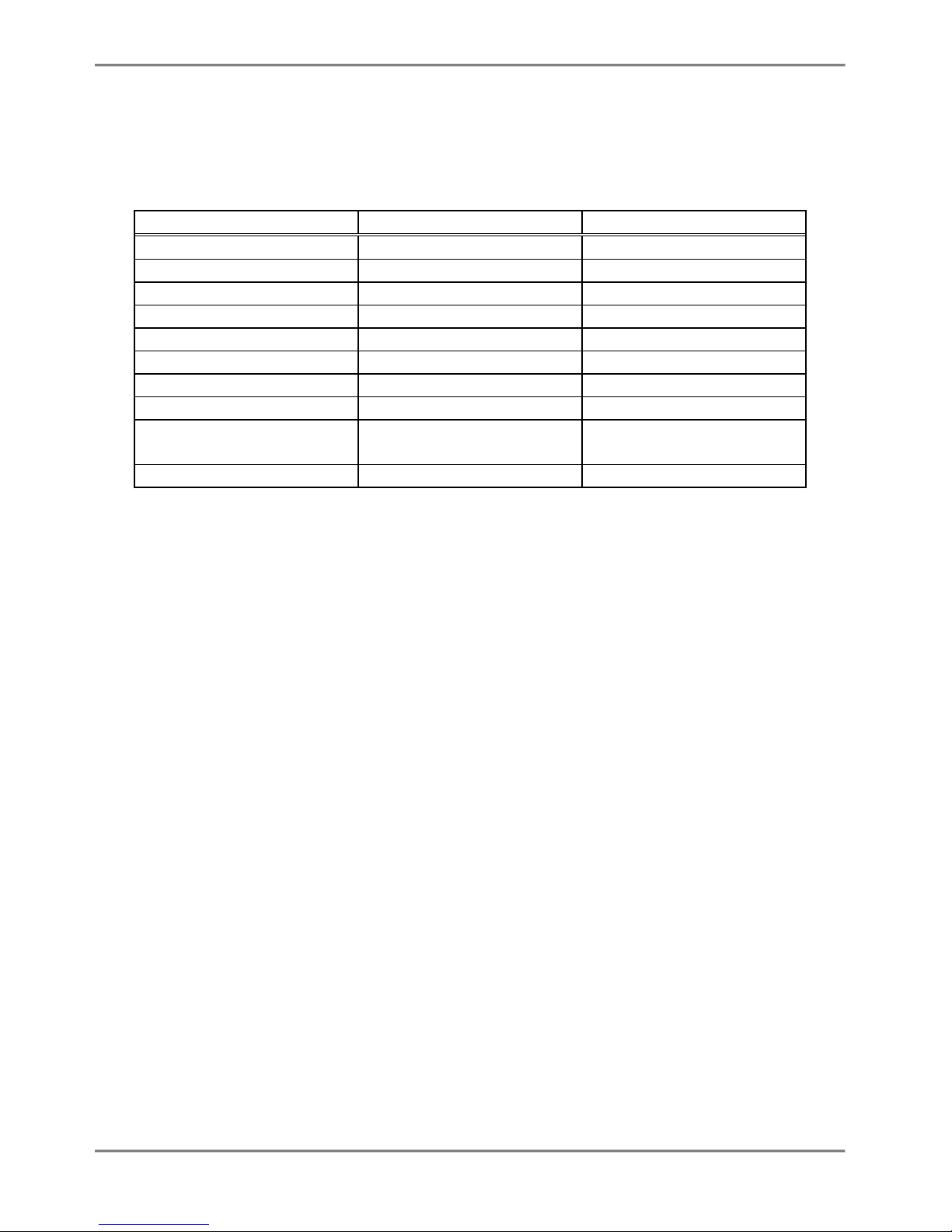

Version Date Revision

1.0 10-30-2006 Initial Release

1.1 8-21-2007 Added EDAS-2005M-2

iii

Page 4

Table of Contents

Chapter 1: Hardware and Installation ......................................... 1

1.1 Modules................................................................. 1

1.1.1 Base Unit ........................................................... 1

1.1.2 Power Supply ........................................................ 6

1.1.3 Digital I/O Module .................................................. 8

1.1.4 Analog Input Module ................................................ 12

1.1.5 Digital Input Module ............................................... 17

1.1.6 Digital Output Modules ............................................. 19

1.1.7 Analog Output Module ............................................... 21

1.1.8 Serial Module ...................................................... 23

1.1.9 Relay Output Module ................................................ 25

1.1.10 Digital Output (Triac) Module ..................................... 27

1.1.11 Quadrature Module ................................................. 29

1.2 Installation........................................................... 31

1.2.1 DIN rail Mounting ................................................. 31

1.2.2 Attaching a module to a DIN Rail ................................... 31

1.2.3 Removing Modules from a DIN Rail ................................... 32

Chapter 2: Utilities ........................................................ 34

2.1 Summary of Utilities................................................... 34

2.1.1 MonitorCE .......................................................... 35

2.1.2 LCmdSet ............................................................ 35

2.1.3 Remote Manager ..................................................... 35

2.1.4 DebugLauncher ...................................................... 35

2.1.5 TimeSync ........................................................... 35

2.1.6 SerialSocket ....................................................... 36

2.1.7 CEFlush ............................................................ 36

2.2 MonitorCE.............................................................. 37

2.2.1 Required Tools ..................................................... 37

2.2.2 Configuring the Communications Program ............................. 37

2.2.3 Starting a MonitorCE Program Session ............................... 38

2.2.4 MonitorCE Program Commands ......................................... 39

2.3 LCmdSet................................................................ 41

2.3.1 Running LCmdSet .................................................... 41

2.3.2 Making a Telnet Connection using HyperTerminal ..................... 41

2.3.3 Issuing Commands ................................................... 41

2.3.4 Set Commands ....................................................... 42

2.3.5 Show Commands ...................................................... 42

2.3.6 Change Commands .................................................... 44

2.3.7 Operational Commands ............................................... 46

2.4 Remote Manager......................................................... 47

2.4.1 WebDevice .......................................................... 47

2.4.2 Using the Remote Manager ........................................... 48

2.4.3 Remote Manager Home Page ........................................... 49

2.4.4 Application Manager ................................................ 52

2.4.5 File Manager ....................................................... 53

2.4.6 Module Manager ..................................................... 54

2.4.7 System Manager ..................................................... 55

2.4.8 Security Manager ................................................... 55

2.4.9 Update Manager ..................................................... 58

2.4.10 Developer’s Guide ................................................. 58

2.5 DebugLauncher.......................................................... 59

2.5.1 Setting Up DebugLauncher ........................................... 59

2.5.2 debugworkstations.txt File Format .................................. 59

2.5.3 Changing the contents of debugworkstations ......................... 60

2.6 TimeSync............................................................... 61

2.6.1 Running TimeSync ................................................... 61

2.6.2 Command Line Arguments ............................................. 61

2.7 SerialSocket........................................................... 63

2.7.1 Configuring the COM ports .......................................... 63

2.7.2 Running the SerialSocket Utility ................................... 63

iv

Page 5

2.7.3 Testing SerialSocket with Hyperterminal ............................ 63

2.8 CEFlush................................................................ 65

2.8.1 Saving Registry Settings ........................................... 65

Chapter 3: Developing Custom Programs ....................................... 67

3.1 Setting up your Development Computer................................... 67

3.1.1 System Requirements ................................................ 68

3.1.2 Installing eMbedded Visual Tools ................................... 68

3.1.3 Installing the EDAS CE SDK ......................................... 68

3.1.4 Setting up Communications to the EDAS CE ........................... 69

3.2 Writing Custom Programs................................................ 76

3.2.1 Generating an EDAS CE Application .................................. 76

3.2.2 Sample Programs .................................................... 83

3.3 Loading Custom Programs................................................ 84

3.3.1 Remote File Viewer ................................................. 84

Chapter 4: CE Link API for EDAS CE .......................................... 85

4.1 Overview............................................................... 85

4.1.1 Interfacing to the I/O system ...................................... 85

4.1.2 Function Calls ..................................................... 86

4.1.3 Header Files ....................................................... 90

4.1.4 DLLs on the EDAS CE ................................................ 90

4.1.5 Registry Entries on the EDAS CE .................................... 91

4.2 CE Link API Function Descriptions...................................... 92

4.2.1 Initialization and De-initialization Calls ......................... 92

4.2.2 Unpaced Analog Input Calls ......................................... 94

4.2.3 Paced Analog Input Calls .......................................... 101

4.2.4 Analog Output ..................................................... 112

4.2.5 Digital Input and Output (Port or Byte) ........................... 114

4.2.6 Digital Input and Output (Individual Bit) ......................... 120

4.2.7 Rate Generator Functions .......................................... 130

4.2.8 Quadrature Functions .............................................. 132

4.2.9 Alarm Functions ................................................... 141

4.2.10 System and Utility Functions ..................................... 152

4.2.11 System Calibration ............................................... 156

4.2.12 Memory Management ................................................ 160

4.3 Return Error Codes for CE Link and EDAS CE API Functions.............. 163

Index ...................................................................... 179

v

Page 6

This page intentionally left blank.

vi

Page 7

Chapter 1:Hardware and Installation

The EDAS CE is an open-architecture monitoring and control system based

on the Windows CE operating system. The EDAS CE features a 32-bit

processor with built-in 10/100BaseT Ethernet connectivity and a modular

I/O system. This combination makes the EDAS CE suitable for a wide range

of monitoring and control systems. The EDAS CE’s open architecture allows

the user to develop a wide range of embedded control, machine and process

monitoring applications using C/C++ or WebDevice development tools.

The built-in 10/100BaseT network, including a TCP/IP stack, enables

applications running on the EDAS CE unit to communicate with other

computers and other EDAS CE units on a network. The EDAS CE can operate

as a stand-alone system or as part of a plant- or factory- wide

monitoring/control system.

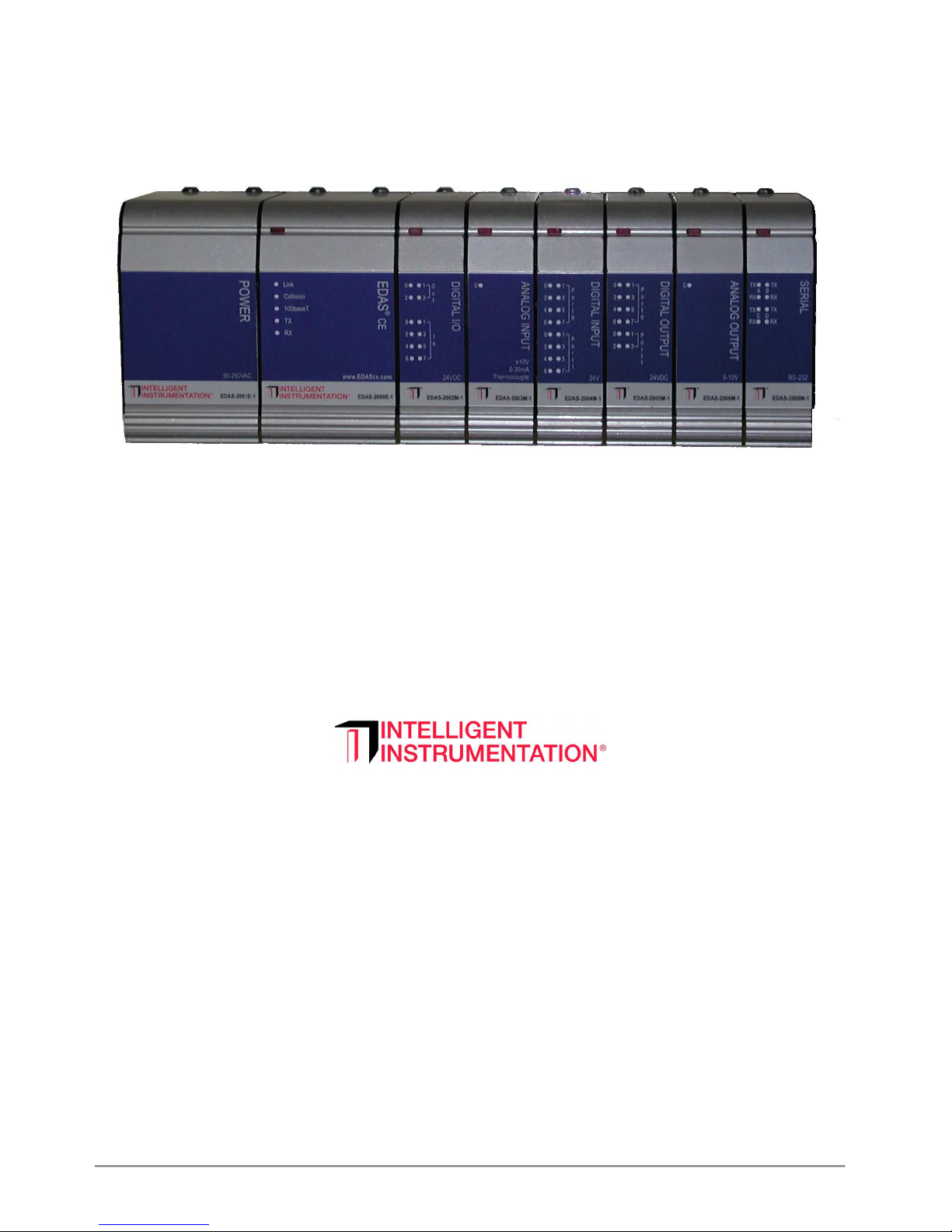

FIGURE 1.1 Typical EDAS CE System

1.1 Modules

An EDAS CE system consists of a power module, a base unit and I/O modules

as needed to meet the specific needs of the targeted application. All the

modules are plug-and-play, requiring no system configuration. Up to 12

I/O modules may be used, allowing for systems of up to 192 I/O points.

1.1.1 Base Unit

Each system requires one EDAS-2000E base (processor) unit. The base unit

includes the CPU, Ethernet connectivity, and an RS-232 port. The 32-bit

Hardware and Installation 1

Page 8

embedded processor runs the Windows CE 3.0 operating system, providing

real-time and multi-tasking capabilities.

FIGURE 1.2 EDAS-2000E Base Unit

The EDAS-2000E base unit includes the following features:

o 32 Bit embedded processor

o Windows CE Operating System

o 64 MB RAM

o 64 MB CompactFlash (1GB maximum)

o 1 RS-232 serial port

o Optional Non-volatile Battery RAM (128 kB)

o Network standards (TCP/IP, UDP, SNMP, DHCP)

o WebDevice (embedded Web server)

1.1.1.1 Application Development

Applications may be developed to execute on the EDAS CE using Microsoft’s

eMbedded Visual Tools and the eMbedded Visual C/C++ programming language.

Applications developed in C/C++ use the CE Link API for reading and

writing I/O points on the optional modules. Network and serial port

communications use the standard Windows 32 API. See Chapter 3:

Developing Custom Programs.

The EDAS CE includes a program (suprcate.exe) that runs on the EDAS CE as

a data server. A PC or other computer can open a connection and issue

commands to read and write the EDAS CE I/O points. Applications which

communicate with suprcate.exe use the Net Link API. The Net Link API

supports Visual C/C++ and Visual Basic on the Windows (98/Me/NT/2000)

Hardware and Installation 2

Page 9

Platform and C on Unix platforms. See the Net Link Manual for more

information.

1.1.1.2 EDAS-2000E Base Unit Specifications

All specifications are typical at 25° C unless otherwise noted.

Parameter Condition Specification

Processor AMD Elan SC400

Operating System Windows CE 3.0

DRAM Memory 64 MB

72-pin EDO SIMM 60 ns

Compact Flash 64 MB (1GB maximum)

Ethernet 10/100BaseT (RJ-45)

Serial Port 1 RS-232 (up to 115 k Baud)

Power consumption +5 VDC 1.5 A maximum

Dimensions inches

mm

Temperature Range Operating 0-60 °C

TABLE 1.1 EDAS-2000E-1 Base Unit Specifications

4.55D x 5.9H x 3.35W

116D x 150H x 85W

1.1.1.3 Ethernet

The base unit features a 10/100BaseT port. The unit has 5 red LED’s used

to display information about the Ethernet connection.

1. Link: Good link when on.

2. Collision: Collision detected when on.

3. 100BaseT: Indicates 100BaseT connection when on. When off,

connection is 10BaseT or no connection exists.

4. TX: Transmitting.

5. RX: Receiving.

1.1.1.4 Serial Port

The unit has a single serial port, COM1. The serial port can be used to

configure the unit’s network settings and real-time clock. See section

2.2 MonitorCE.

An application may read and write data to this port (COM1) using the

standard Win32 API.

Hardware and Installation 3

Page 10

1.1.1.5 Real-Time Clock Battery

The base unit contains a 3.0 V lithium battery that powers the Real-Time

Clock when external power is absent. Battery life is approximately two

years when the unit is not powered. When the unit is on external power,

battery life is longer since the battery does not have an appreciable

power draw in this condition. To replace the battery, remove the right

hand cover of the unit.

FIGURE 1.3 Real-time Clock Battery and DRAM Access

Hardware and Installation 4

Page 11

1.1.1.6 DRAM

The EDAS-2000E can use up to 64 Mbytes of DRAM. The DRAM is industry

standard 5 V, 72- pin EDO or FPM. To change the DRAM module, remove the

right hand cover of the unit.

1.1.1.7 Compact Flash

The EDAS-2000E uses standard Compact Flash memory for non-volatile

storage of the operating system and drivers. The remaining memory can be

used by the applications for non-volatile application or data storage.

The CompactFlash is accessed as part of the unit’s file system. The

CompactFlash can be replaced with a larger card to providing additional

storage capability.

1.1.1.8 Reset/Watchdog Timer

The unit has a watchdog timer that may be activated by an application.

When the watchdog timer is activated, an application must "tickle" the

timer every 2000 ms or the unit will reboot.

1.1.1.9 NV-RAM Option

The EDAS-2000E is available with an optional 128 kbytes of battery RAM.

The NV-RAM provides high speed non-volatile storage. Applications such a

fast control loops can use the NV-RAM to hold state variables, allowing

an application to recover variables after a power loss.

The NV-RAM is memory mapped to 0xA0000 to 0xBFFFF.

Hardware and Installation 5

Page 12

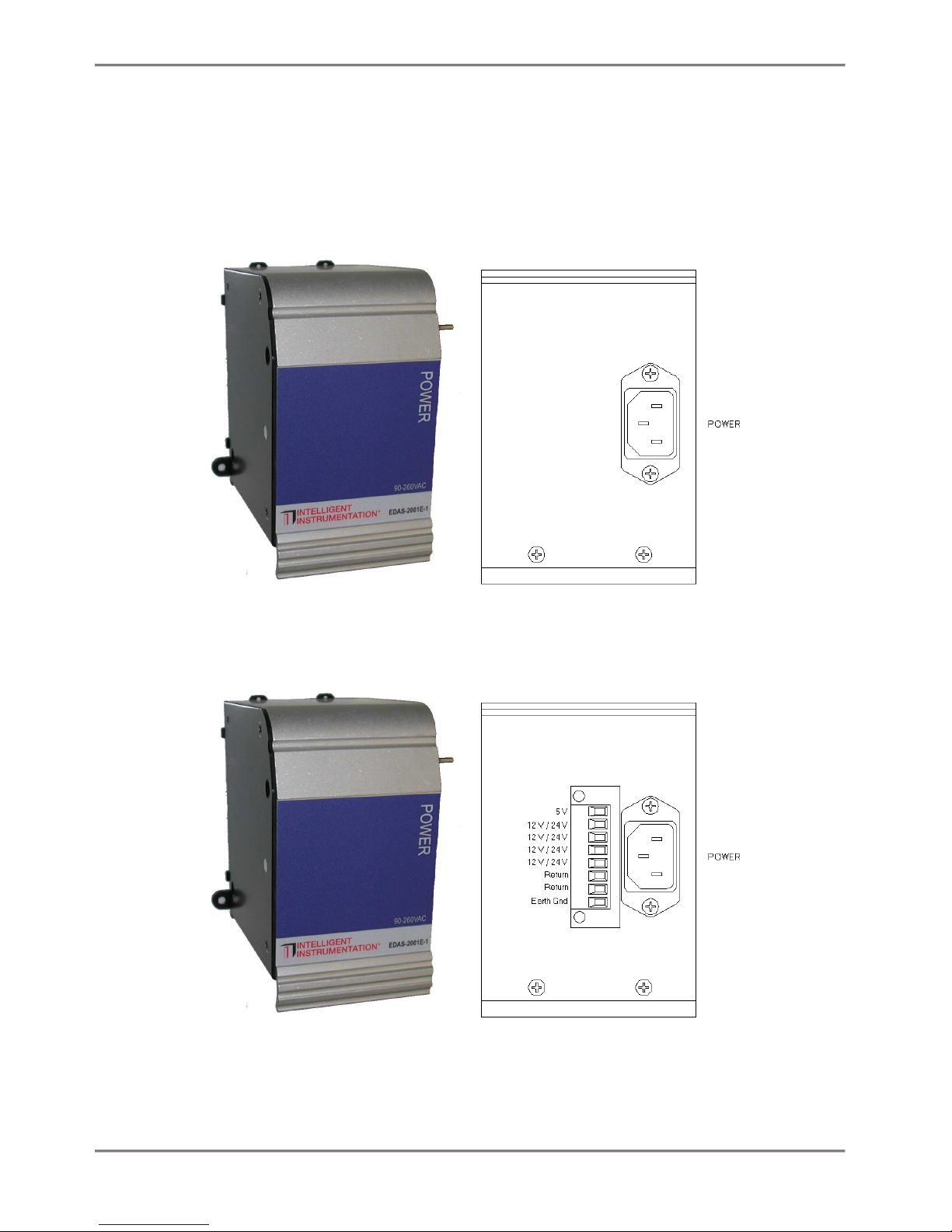

1.1.2

The EDAS-2001E power supply module provides power for the base unit and

attached modules. The EDAS-2001E can accept line voltages of 90 - 260

VAC @ 50 - 60 Hz.

Power Supply

FIGURE 1.4 EDAS-2001E-1 Power Supply Module

FIGURE 1.5 EDAS-2001E-2 and -3 Power Supply Module

Hardware and Installation 6

Page 13

1.1.1.10 EDAS-2001E Power Supply Specifications

The EDAS-2001E supplies 5 VDC power to the CPU module which in turn

supplies power to the I/O modules. The -2 and -3 have quick a disconnect

connector that can be used to pull 5VDC and 12 VDC (-2) or 24 VDC (-3)

power from the supply to power other components in your system.

All specifications are typical at 25° C unless otherwise noted.

Parameter Condition Specification

Input Voltage 90 - 260 VAC

Input Frequency 50 - 60 Hz

Output Voltage

EDAS-2001E-1 5.0 V +/- 5%

EDAS-2001E-2 5.0 V +/- 5%

12.0 V +/- 5%

EDAS-2001E-3 5.0 V +/- 5%

24.0 V +/- 5%

Output Current

EDAS-2001E-1 5 V 10.0 A max

EDAS-2001E-2 5 V

12 V

EDAS-2001E-3 5 V

24 V

Agency Approvals Tested to UL 60950

Dimensions inches

mm

Temperature Range Operating 0-60 °C

TABLE 1.2 EDAS-2001E Power Supply Specifications

7.0 A max

2.5 A max

7.0 A max

2.0 A max

4.55D x 5.9H x 3.35W

116D x 150H x 85W

1.1.1.11 Power Connector

The EDAS-2001E has a standard IEC power connector. Due to the wide range

of power sources and distance from the EDAS system a power cord is not

included with this module.

Hardware and Installation 7

Page 14

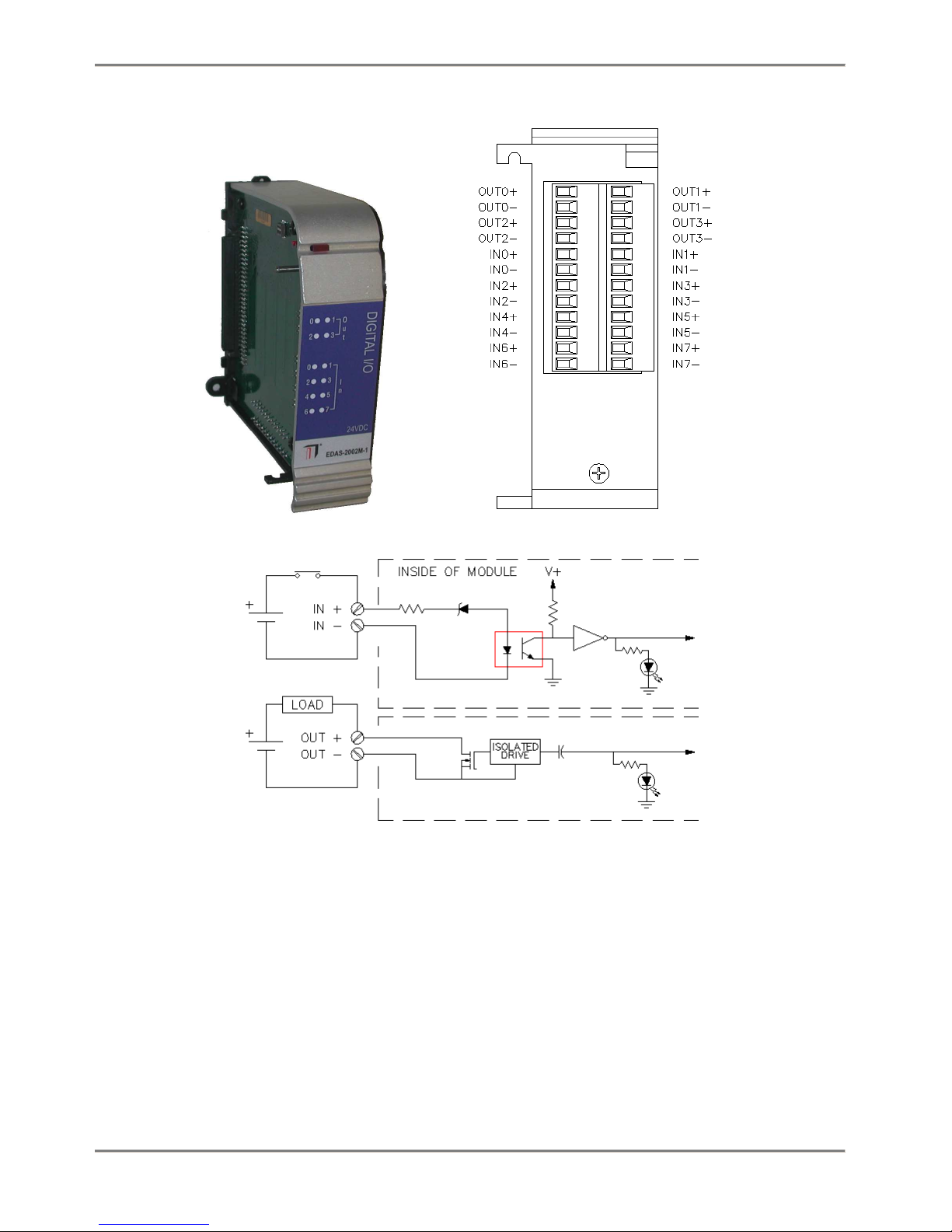

1.1.3 Digital I/O Module

The EDAS-2002M Digital I/O Module has 8 digital inputs and 4 digital

outputs. The digital inputs and outputs are designed for 24 VDC

operation. All of the digital inputs and outputs provide 500 V channel

to channel isolation with one return per channel. LEDs provide visual

feedback on the channels’ current states. The digital inputs can be

individually configured for normal (high/low), counter or latched

operation. The digital outputs can individually configured for normal

(open/closed), pulsed, delayed and square wave output.

Hardware and Installation 8

Page 15

FIGURE 1.6 EDAS-2002M Digital I/O module

1.1.1.12 Input Functions

The Digital I/O Module provides the following digital input functions.

The inputs can be configured on a channel by channel basis.

o Normal: Reads the current sates of the input (low/high).

o Counter: 24 bit up/down counter, 250 Hz maximum count rate.

o Latched: The input is latched on a low-to-high, high-to-low, or any

change of state.

Hardware and Installation 9

Page 16

o High Speed Counter: Channel 0 only, 16-bit counter at 20 kHz maximum

count rate.

1.1.1.13 Output Functions

The Digital I/O Module provides the following digital output functions.

The outputs can be configured on a channel by channel basis.

o Normal: Set output to desired state (open/closed)

o Pulsed: Set output active for a specified amount of time.

o Delayed: Set output active after the specified time delay.

o Square wave: Generate a square wave with the specified period, 250 Hz

maximum.

1.1.1.14 EDAS-2002M Digital I/O Module Specifications

All specifications are typical at 25° C unless otherwise noted.

Parameter Condition Specification

Digital Input 8 inputs

Input Voltage Low 3.0 V max

Input Current Low Vin = 0.5 V > 500 nA

Input Voltage High 9 V min, 30 V max

Input Current High Vin = 24 V 5 mA max

Low Speed Counter Ch 0 through 7

Size 24 bit

Frequency 250 Hz max

High Speed Counter Channel 0 only

Size 16 bit

Frequency 20 kHz max

Digital Output FET output 4 Outputs

On resistance

On current 0.5 A max

On Voltage 0.8 V max

Off Voltage 27 V max

Isolation Inputs and Outputs

Channel - Channel 500 V max

Channel - Bus 1500 V max

Current Consumption 5 V 200 mA max

Dimensions inches

mm

Temperature Range Operating 0-60 °C

0.03 Ω

4.55D x 5.9H x 1.74W

116D x 150H x 42W

Hardware and Installation 10

Page 17

TABLE 1.3 EDAS 2002M-1 Digital I/O Module Specifications

Hardware and Installation 11

Page 18

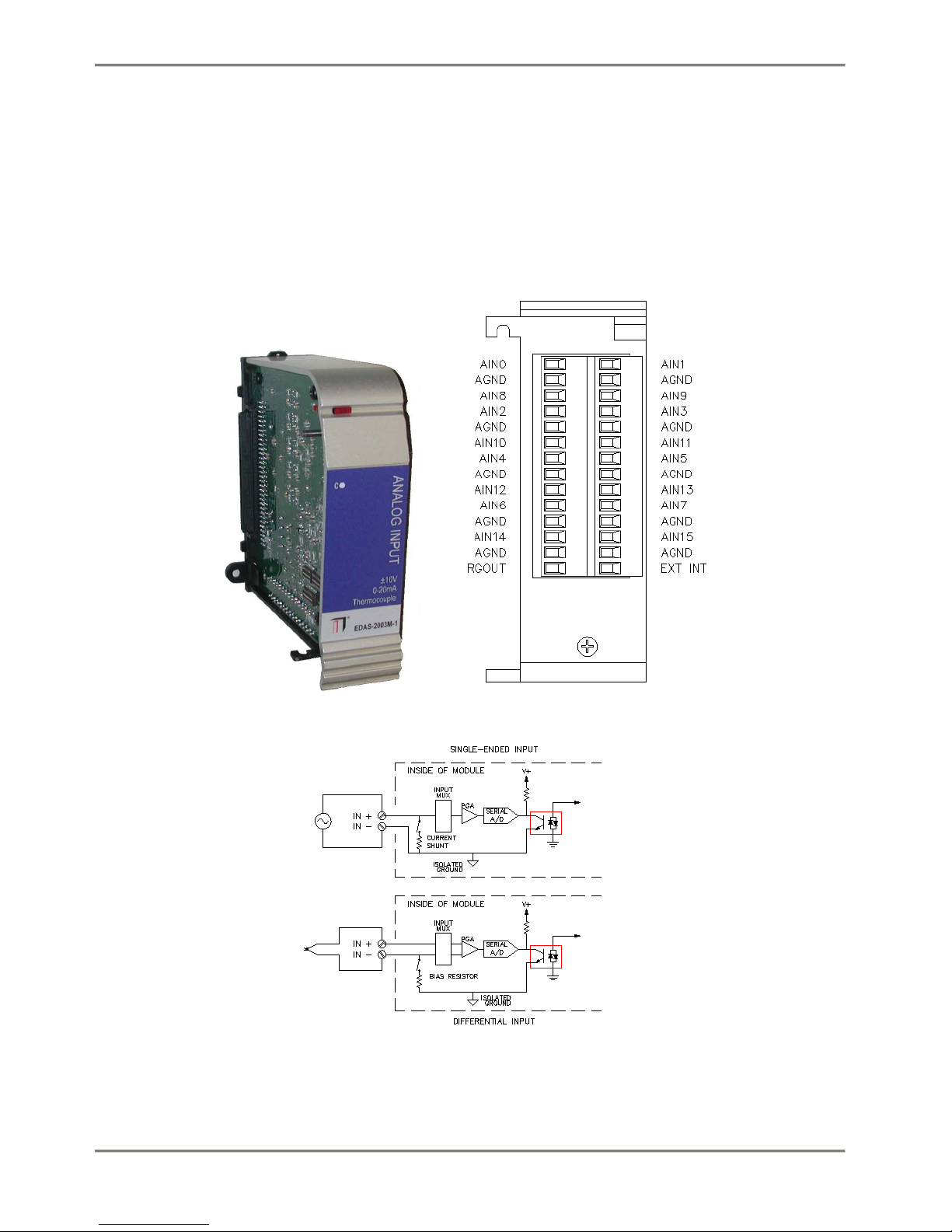

1.1.4 Analog Input Module

The EDAS-2003M Analog Input Module can read voltage, current and

thermocouple inputs. Voltage, current or thermocouple readings can be

configured on a channel by channel basis, allowing one analog input

module to read a combination of voltage, current or thermocouple inputs.

FIGURE 1.7 EDAS-2003M Analog Input module

Hardware and Installation 12

Page 19

The analog input stage consists of a 16 channel multiplexer (MUX),

followed by a programmable gain amplifier (PGA), feeding a 12-bit analog

to digital converter (ADC). The output of the ADC is isolated and

presented to the system bus. The MUX is capable of providing 16 singleended inputs, 8 differential inputs or a mixed combination to the PGA.

The PGA has gains of 1, 10 and 100. The ADC supports 0-10 V and ±10 V

ranges.

Current Readings: the module has 16 resistors (500 Ω) that may be

switched between the individual input channels and ground allowing the

unit to make current measurements in the range 0-20 mA.

Thermocouple readings: the module features a built-in Cold Junction

Compensator (CJC), which may be switched in to channel zero.

Additionally the module has 100 kΩ input bias return resistors that may

be switched in to provide an input bias current path for the PGA

1.1.1.15 Configuring Inputs

Each Analog Input channel can be configured for voltage input, current

input, or thermocouple input.

To configure a channel for voltage input:

1: Set the appropriate switches to disable current mode (SW2-1

through SW2-8 and SW3-1 through SW3-8). See the table below.

2: Set the appropriate switches to disable input ground return

resistor (SW1-1 through SW1- 8).

3: The gain and range are set through software control.

To configure a channel for 0-20 mA current input:

1: Set the appropriate switches to enable current mode (SW2-1 through

SW2-8 and SW3-1 through SW3-8). See the table below. This

configuration requires the channel to be read as a single-ended

input.

2: Set the appropriate switches to disable ground return (SW1-1

through SW1-8).

3: In software set the PGA gain to 1 and the ADC Range to 0-10 V.

To configure an input for thermocouple input:

Note: Thermocouple can only be read on differential input channels 1

through 7. Channel 0 is used to read the CJC value.

1: Enable the differential ground return switches for the appropriate

channels (SW1-1 through SW1-8). See table below.

Hardware and Installation 13

Page 20

2: Enable the CJC circuit (SW3-9). This will connect the CJC circuit

to channel 0 to be read as a single-ended analog input. If SW3-10

is turned on with SW3-9, the CJC may be read in differential mode.

Switch Number Switch ON Switch OFF

SW1-1 GND return for differential Channel A0 No GND return

SW1-2 GND return for differential Channel A1 No GND return

SW1-3 GND return for differential Channel A2 No GND return

SW1-4 GND return for differential Channel A3 No GND return

SW1-5 GND return for differential Channel A4 No GND return

SW1-6 GND return for differential Channel A5 No GND return

SW1-7 GND return for differential Channel A6 No GND return

SW1-8 GND return for differential Channel A7 No GND return

SW2-1 Current mode enable Channel 8 Voltage mode enable Channel 8

SW2-2 Current mode enable Channel 9 Voltage mode enable Channel 9

SW2-3 Current mode enable Channel 10 Voltage mode enable Channel 10

SW2-4 Current mode enable Channel 11 Voltage mode enable Channel 11

SW2-5 Current mode enable Channel 12 Voltage mode enable Channel 12

SW2-6 Current mode enable Channel 13 Voltage mode enable Channel 13

SW2-7 Current mode enable Channel 14 Voltage mode enable Channel 14

SW2-8 Current mode enable Channel 15 Voltage mode enable Channel 15

SW3-1* Current mode enable Channel 0 Voltage mode enable Channel 0

SW3-2 Current mode enable Channel 1 Voltage mode enable Channel 1

SW3-3 Current mode enable Channel 2 Voltage mode enable Channel 2

SW3-4 Current mode enable Channel 3 Voltage mode enable Channel 3

SW3-5 Current mode enable Channel 4 Voltage mode enable Channel 4

SW3-6 Current mode enable Channel 5 Voltage mode enable Channel 5

SW3-7 Current mode enable Channel 6 Voltage mode enable Channel 6

SW3-8 Current mode enable Channel 7 Voltage mode enable Channel 7

SW3-9 CJC enable CJC Disable

SW3-10 CJC differential mode CJC single-ended mode

* must be OFF when CJC circuit is enabled

Ground return resistors are 100 kΩ

TABLE 1.4 Current and Ground Return Resistor Switch Settings

1.1.1.16 Hardware / Software Pacing

The Analog Input Module has provisions for pacing (starting) conversions

by software or by one of two hardware start convert sources. These two

hardware sources are an internal 24-bit Rate Generator and a digital

input (EXT INT). The EXT INT input may also be used as a trigger signal

Hardware and Installation 14

Page 21

to control when conversions are started and stopped. This allows for the

support of Stop on Trigger, Stop on delay after Trigger, Start on Trigger

and N Conversions after Trigger modes.

1.1.1.17 Channel Scanner

The Analog Input Module has a hardware channel scanner that scans

channels 0 through N. The scanner increments the channel by one each time

a conversion is started and wraps back to channel 0. The value of N is

set by software.

1.1.1.18 Rate Generator

The Analog Input Module provides a 24-bit rate generator to pace (start)

conversions. The base clock for this rate generator is 4 MHz providing a

resolution of 250 nsec. This allows the rate generator to be set to an

output range of 2 MHz to 0.238 Hz (4.2 s). The Rate Generator output is

also available on the RGOUT terminal on the I/O connector.

1.1.1.19 EDAS 2003M Analog Input Specifications

All specifications are typical at 25 °C unless otherwise noted.

Parameter Condition Specification

Number of Channels Single-ended 16

Differential 8

Resolution 12 bits (1 part in 4096)

Voltage Ranges Gain = 1 ±10 V, 0 to 10 V

Gain = 10 ±1 V, 0 to 1 V

Gain = 100 ±0.1 V, 0 to 0.1 V

Current Ranges Gain = 1 0 to 20 mA

Overvoltage Protection Power on or off -40 V to +55 V

Gain Accuracy Gain = 1 ±0.012%

Gain = 10 ±0.08%

Gain = 100 ±0.08%

Input Offset Voltage Gain = 1 ±1.2 mV

Gain = 10 ±0.12 mV

Gain = 100 ±0.012 mV

Input Bias Current 500 pA

Hardware and Installation 15

Page 22

Input Impedance Voltage Mode

Current Mode

Common-Mode Range ±10 V

Common-Mode Rejection Ratio Gain = 1 80 dB

Gain = 10 86 dB

Gain = 100 92 dB

Noise RMS/p-p G=1 0.5 LSB/2 LSB

Mono tonicity No missing codes 12 bits

Linearity ±1 LSB

Rate Generator Resolution 250 nS

Output Frequency 0.238 Hz to 200 kHz

Isolation Input to Bus

VAC rms for 60 s

Power Consumption +5 V 400 mA

Dimensions inches

mm

Temperature Range Operating 0-60 °C

TABLE 1.5 EDAS-2003M Analog Input Module Specifications

10 GΩ || 3 pF

487 Ω

1500 V

4.55D x 5.9H x 1.74W

116D x 150H x 42W

Hardware and Installation 16

Page 23

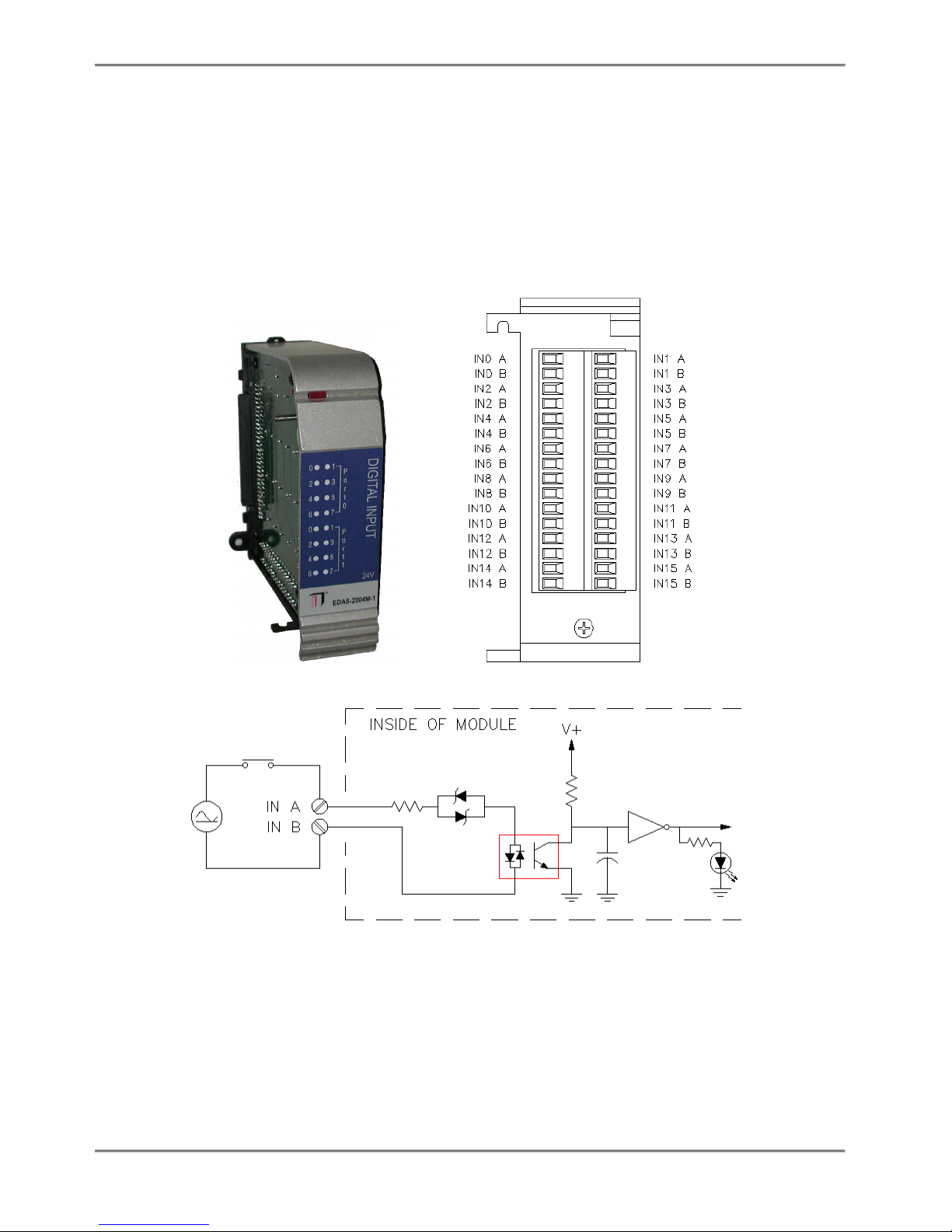

1.1.5 Digital Input Module

The EDAS-2004M Digital Input Module provides 16 channels of 5V, 24 V, 120

V or 240 V input. The digital inputs provide 500 V channel-to-channel

isolation with one return per channel. The 16 channels are arranged as

two 8 bit ports, Port 0 and Port 1. LEDs provide visual feedback on the

channels’ present states.

FIGURE 1.8 EDAS-2004M Digital Input module

Hardware and Installation 17

Page 24

1.1.1.20 EDAS-2004M Digital Input Module Specifications

All specifications are typical at 25° C unless otherwise noted.

Parameter Condition Specification

Digital Inputs Opto Isolators 16 inputs

EDAS-2004M-1

Low 0-3 V

High 9-30 V

Current Vin = 24V 2 mA max

EDAS-2004M-2

Low 0-20 V

High 70-130 V

Current Vin = 120V 2 mA max

EDAS-2004M-3

Low 0-40 V

High 140-250 V

Current Vin = 240V 2 mA max

EDAS-2004M-4

Low 0-1 V

High 2-10 V

Current Vin = 5V 3 mA max

Turn-on time 6 mS max

Turn-off time 35 mS max

Isolation Outputs

Channel - Channel 500 V max

Bus - Channel 1500 V max

Current Consumption 5 V 500 mA max

Dimensions inches

mm

Temperature Range Operating 0-60 °C

TABLE 1.6 EDAS-2004M Digital Input Module Specifications

4.55D x 5.9H x 1.74W

116D x 150H x 42W

Hardware and Installation 18

Page 25

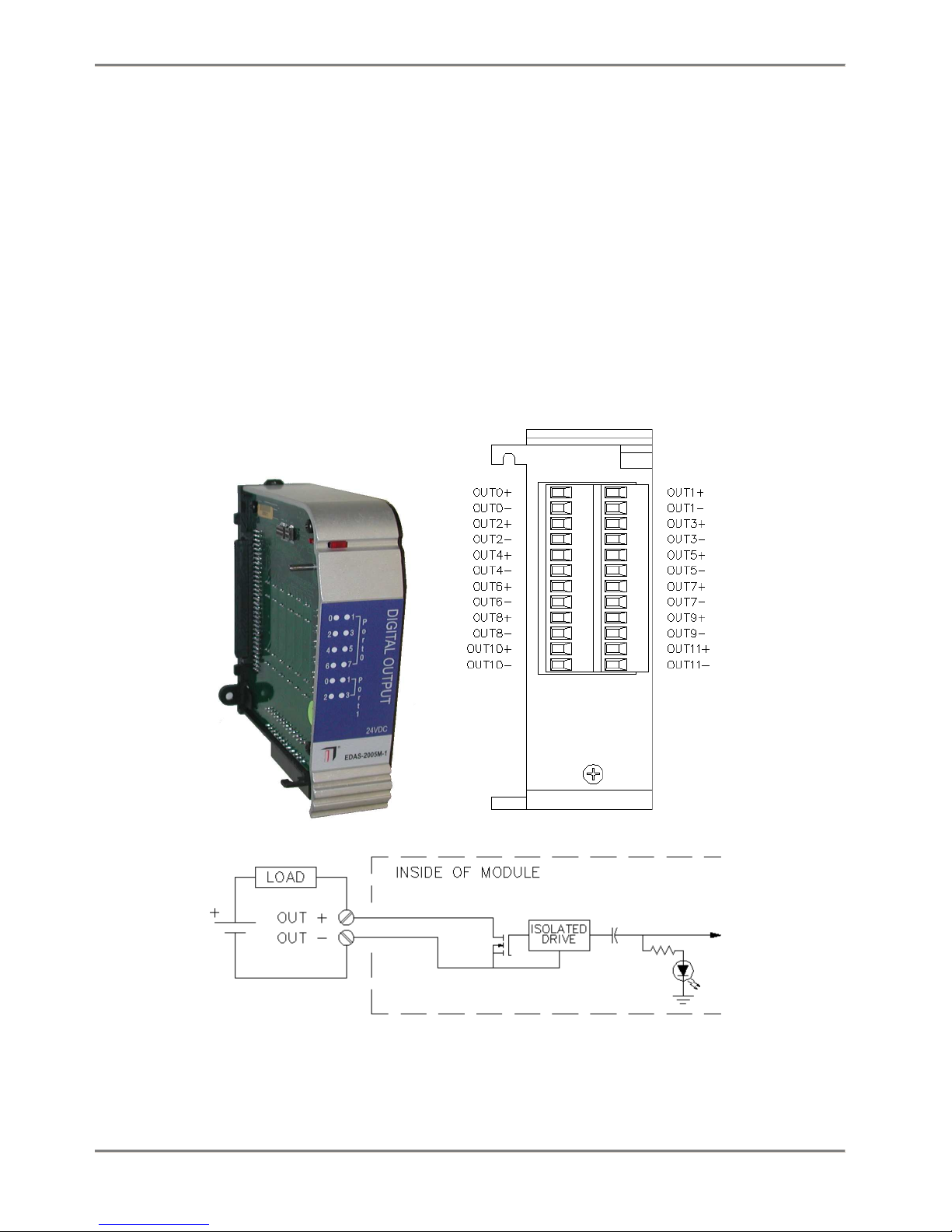

1.1.6 Digital Output Modules

The EDAS-M Digital Output Modules provide 12 channels of open drain, 24

VDC (EDAS-2005M-1) or 360 VDC (EDAS-2005M-2) digital outputs. The digital

outputs have 500 V channel-to-channel isolation with one return per

channel. The 12 channels are arranged as two ports. Port 0 has 8

channels and Port 1 has 4 channels. This module supports read back

allowing the software to determine the value last commanded for each

output. Each channel has a hardware switch that determines the channel’s

power-on state. When a switch is in the on position during the power-up

reset, the corresponding channel will be turned on.

FIGURE 1.9 EDAS-2005M Digital Output Modules

Hardware and Installation 19

Page 26

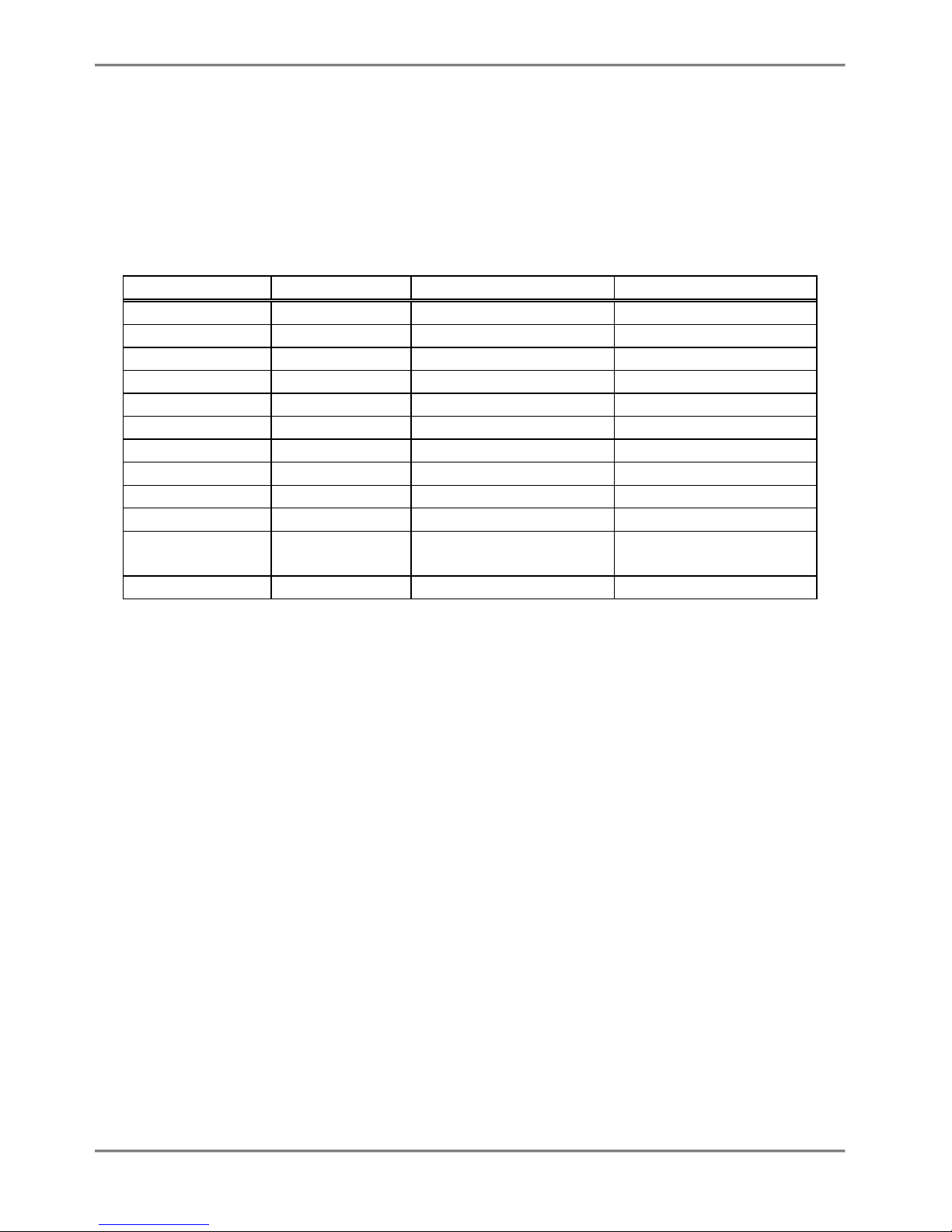

1.1.1.21 EDAS-2005M Digital Output Modules Specifications

All specifications are typical at 25° C unless otherwise noted. Maximum

voltage or current are dependent on power dissipation. Please contact support for particular

current/voltage operating points.

TABLE 1.7 EDAS-2005M Digital Output Modules Specifications

Parameter Condition Specification EDAS-2005M-1 Specification EDAS-2005M-2

Digital Output FET output 12 channels, 27VDC max 12 channels, 360VDC max

On resistance 0.03 Ω 5 Ω, typ

On current 0.5 A max 260 mA max

On Voltage 0.8 VDC max 2 VDC max

Off Voltage 27 VDC max 360 VDC max

Isolation Outputs

Channel - Channel 500 V max 500 V max

Channel - Bus 1500 V max 1500 V max

Current Consumption 5 V 160 mA max 160 mA max

Dimensions inches

mm

Temperature Range Operating 0-60 °C 0-60 °C

4.55D x 5.9H x 1.74W

116D x 150H x 42W

4.55D x 5.9H x 1.74W

116D x 150H x 42W

Hardware and Installation 20

Page 27

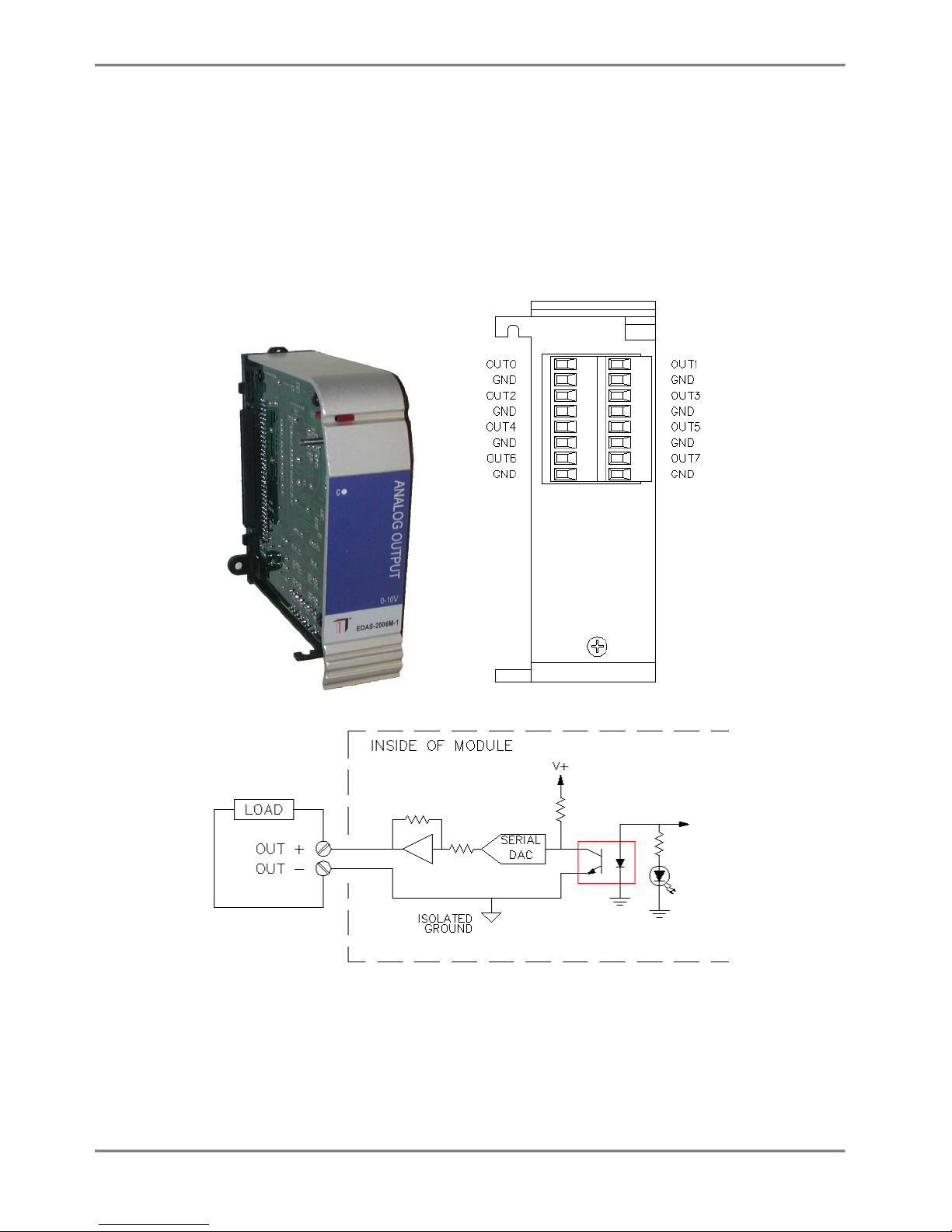

1.1.7 Analog Output Module

The EDAS-2006M Analog Output Module provides 8 channels of 0 to 10 V

analog output. This module uses eight 12-bit digital-to-analog converters

(DAC). The module has a single LED that will blink when an output is

updated.

FIGURE 1.10 EDAS-2006M Analog Output Module

Hardware and Installation 21

Page 28

1.1.1.22 EDAS-2006M Analog Output Module Specifications

All specifications are typical at 25° C unless otherwise noted.

Parameter Condition Specification

Number of Outputs 8

Resolution 12-bits (2.44 mV)

Output Range 0-10 V

Output current 10 mA max

Accuracy +/- 5.2 LSB (13 mV)

Isolation Outputs

Bus - Channel 1500 V max

Current Consumption 5V 450 mA max

Dimensions inches

mm

Temperature Range Operating 0-60 °C

TABLE 1.8 EDAS-2006M Analog Output Module Specifications

4.55D x 5.9H x 1.74W

116D x 150H x 42W

Hardware and Installation 22

Page 29

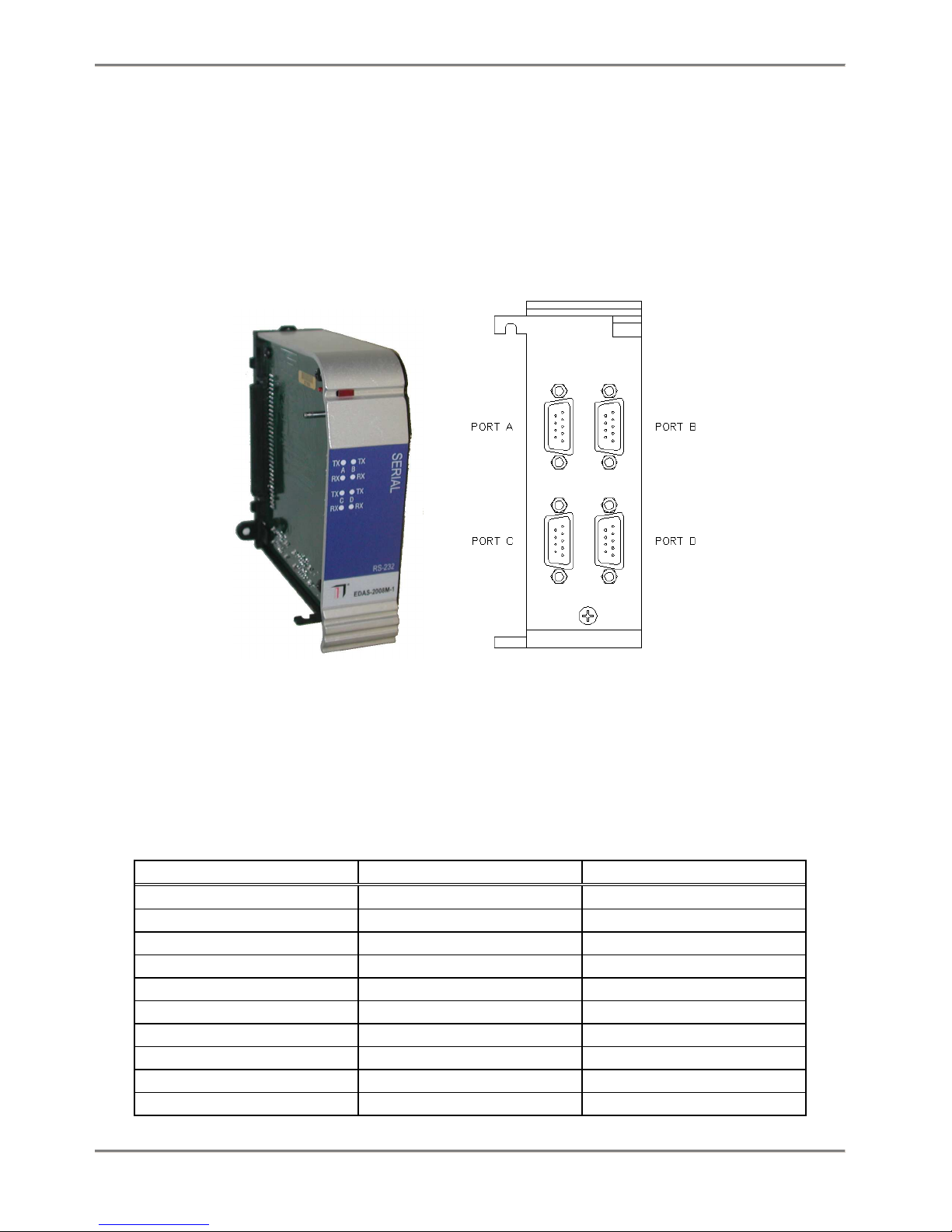

1.1.8 Serial Module

The EDAS-2008M Serial Module provides four RS-232 serial ports. The

serial ports are interfaced through 9-pin D-subminiature connectors on

the bottom of the unit. The EDAS- 2000E base unit can support 6 serial

modules for a total of 25 serial ports, one on the base plus 24 on

additional serial modules.

FIGURE 1.11 EDAS-2008M Serial Port Module

1.1.1.23 EDAS-2008M Serial Module Specifications

All specifications are typical at 25° C unless otherwise noted.

Parameter Condition Specification

Number of Ports 4 Ports

Serial Outputs

Output Voltage Low 3 kΩ load -5.0 V max

Output Voltage High 3 kΩ load +5.0 V max

Serial Inputs

Input Impedance 3 kΩ min 7 kΩ max

Input Threshold Low 0.8 V min

Input Threshold Low 2.4 V max

Isolation None

Dimensions inches 4.55D x 5.9H x 1.74W

Hardware and Installation 23

Page 30

mm 116D x 150H x 42W

Temperature Range Operating 0-60° C

TABLE 1.9 EDAS-2008M Serial Port Module Specifications

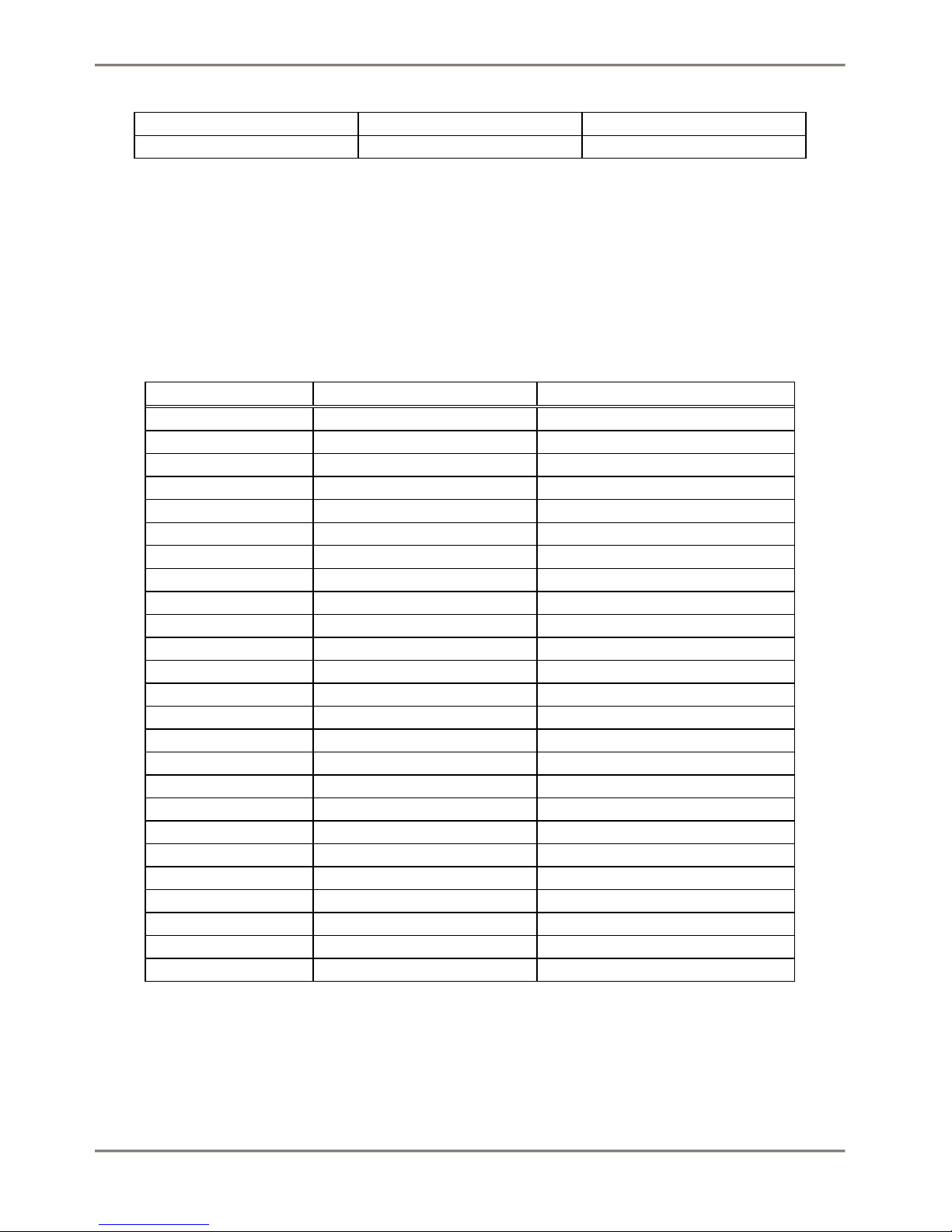

1.1.1.24 COM port mappings

The COM ports on the serial module are mapped as COM2 through COM9 on the

first two serial module, SER1 through SER8 on the next two and ASY1

through ASY8 on the last two. .

Port Mapping

COM1 COM1 CPU

COM2 Port A 1

COM3 Port B 1

COM4 Port C 1

COM5 Port D 1

COM6 Port A 2

COM7 Port B 2

COM8 Port C 2

COM9 Port D 2

SER1 Port A 3

SER2 Port B 3

SER3 Port C 3

SER4 Port D 3

SER5 Port A 4

SER6 Port B 4

SER7 Port C 4

SER8 Port D 4

ASY1 Port A 5

ASY2 Port B 5

ASY3 Port C 5

ASY4 Port D 5

ASY5 Port A 6

ASY6 Port B 6

ASY7 Port C 6

ASY8 Port D 6

Port

TABLE 1.10 COM port mappings

Module

Hardware and Installation 24

Page 31

1.1.9 Relay Output Module

The EDAS-2010M Relay Output Module provides 12 channels of singlepole/single-throw normally open relay contacts capable of switching 2 A

at either 250 VAC or 30 VDC. This module has power-up initialization

hardware allowing the configuration of the power-up state of each output.

FIGURE 1.12 EDAS-2010M Relay Output Module

Hardware and Installation 25

Page 32

1.1.1.25 EDAS-2010M Relay Output Module Specifications

All specifications are typical at 25° C unless otherwise noted.

Parameter Condition Specification

Relay Output Contact closure 12 outputs

Closed resistance 0.03 Ω

Closed current 2.0 A max

Voltage 250 VAC max, 30 VDC max

Isolation Outputs

Channel - Channel 500 V max

Bus - Channel 1500 V max

Current Consumption 5 V 450 mA max

Dimensions inches

Mm

Temperature Range Operating 0-60 °C

TABLE 1.11 EDAS-2010M Relay Output Module Specifications

4.55D x 5.9H x 1.74W

116D x 150H x 42W

Hardware and Installation 26

Page 33

1.1.10 Digital Output (Triac) Module

The EDAS-2011M Digital Output Module provides 12 solid state (triac)

outputs capable of switching 2 A at 120 VAC. This module has power-up

initialization hardware allowing users to configure the power-up state of

each output.

FIGURE 1.13 EDAS-2011M Digital Output (Triac) module

Hardware and Installation 27

Page 34

1.1.1.26 EDAS-2011M Digital Output Module (Triac)

Specifications

Parameter Condition Specification

Triac Output Contact closure 12 outputs

Closed resistance 0.03 Ω

Switching current 25° C

60° C

Voltage 24 VAC to 240 VAC

Isolation Outputs

Channel – Channel 500 V max

Bus – Channel 1500 V max

Current Consumption 5 V 200 mA max

Dimensions inches

mm

Temperature Range Operating 0-60° C

TABLE 1.12 EDAS-2011M Digital Output Module Specifications

2.0 A max

1.0 A max

4.55D x 5.9H x 1.74W

116D x 150H x 42W

Hardware and Installation 28

Page 35

1.1.11 Quadrature Module

The EDAS-2015M Quadrature Module provides 2 independent quadrature

decoder channels which can also be used as high-speed 32-bit counter

channels. Each channel also provides two outputs which can be controlled

manually or configured to output counter channel state information. Each

channel also provides two inputs which can be used for counter channel

control or for general-purpose digital input.

FIGURE 1.14 EDAS-2015M Quadrature module

Hardware and Installation 29

Page 36

1.1.1.27 EDAS-2015M Quadrature Module Specifications

Parameter Condition Specification

Quadrature Inputs/Up-Down

Counters

Inputs 24VDC compatible 2 count control per quadrature

General-purpose Modes Separately configured for each

Outputs 24VDC compatible 2 per quadrature channel, 5-

Comparator Modes Separately configured for each

Isolation Channel – Channel 500 V max

Bus – Channel 1500 V max

Current Consumption 5 V 200 mA max

Dimensions inches

Temperature Range Operating 0-60° C

TABLE 1.13 EDAS-2015M Quadrature Module Specifications

2. Maximum input rate is

500kSteps/second, 2MHz for

counting

channel, 2 general purpose, 0-3V

low, 9-30V high

Latch, preload, enable, general-

input

output

mm

purpose

30VDC

<, >, <=, >=, =, ≠, general purpose

4.55D x 5.9H x 1.74W

116D x 150H x 42W

Hardware and Installation 30

Page 37

1.2 Installation

1.1.12 DIN rail Mounting

The EDAS CE systems was designed to be mounted using 35 mm DIN-rails. 35

mm DIN-rails are available in 7.5 mm and 15 mm heights.

FIGURE 1.15 Side View of DIN rail for 7.5 mm and 15 mm heights

The EDAS CE modules are attached to the DIN-rial by first hooking the

bottom of the DIN-rail clip on the DIN-rail and the rotating the EDAS CE

module until it snaps on to the DIN-rail.

FIGURE 1.16 Installing modules on a DIN rail

1.1.13 Attaching a module to a DIN Rail

The EDAS CE modules are installed one at a time on to the DIN rail and

then slid together. Install the Power Supply module first, followed by

the Base unit, followed by I/O modules.

Hardware and Installation 31

Page 38

1.1.14 Removing Modules from a DIN Rail

Using a screwdriver, lift the retaining spring until the module releases

from the DIN rail. Note: Some modules have two retaining springs. To

release the module from the DIN rail, lift both retaining springs.

Hardware and Installation 32

Page 39

Chapter 2:Utilities

2.1 Summary of Utilities

The EDAS CE unit is shipped with a number of pre-installed utilities

which are summarized in the table shown below. These utilities simplify

the development and deployment of applications on the EDAS CE. A brief

description of each utility follows the table shown below.

MonitorCE

Configure network settings

Upload / download files

Run an application

View a list of running applications

Terminate an application

Reboot the EDAS CE

Write an application

Set the unit’s real-time clock

Remotely communicate with serial ports

Save registry settings

* See Chapter 3: Developing Custom Programs for more information.

TABLE 2.1 Utility Program Cross-reference

LCmdSet

Remote Manager

Time Synchronization

SerialSocket

CE Flush

eMbedded Visual Tools *

Utilities 33

Page 40

1.1.15 MonitorCE

The MonitorCE program allows a computer to connect to the EDAS CE in

order to set the unit’s network parameters and real-time clock. With a

null modem cable connected between COM1 on the EDAS CE and one of the

computer’s serial ports, a communications application, such as

HyperTerminal, may be used to configure many of the EDAS CE’s operating

parameters.

1.1.16 LCmdSet

The LCmdSet application runs on the EDAS CE, allowing a remote client to

open a Telnet session over the Ethernet network to the EDAS CE. Through

this Telnet session, you can change the EDAS CE’s network configuration,

serial port configurations, run programs and reboot the unit. The LCmdSet

utility can only be used to change configuration settings after the

initial configuration settings are made using the MonitorCE program and a

functional network connection has been established.

If the EDAS CE will be running on a network accessible from the Internet,

be sure to configure the security settings of LCmdSet.

1.1.17 Remote Manager

The Remote Manager is a Web-based management tool that allows a user to

perform management functions on the EDAS CE unit using a Web browser. A

user with the correct user name and password can download and upload

files, run and terminate programs, reboot the unit, read and write the

unit’s I/O points, etc.

1.1.18 DebugLauncher

The DebugLauncher application runs on the EDAS CE unit and enables the

EDAS CE to make a connection to Microsoft eMbedded Visual Tools on a

development computer. This allows remote downloading and debugging of

custom programs.

1.1.19 TimeSync

The Time Synchronization application runs on the EDAS CE and can be

configured to synchronize the EDAS CE’s real-time clock with an external

time standard. This is useful for having the real-time clock maintain

time in synchronization with other devices.

Utilities 34

Page 41

1.1.20 SerialSocket

The SerialSocket application runs on the EDAS CE, providing a bridge

between the unit’s Ethernet and serial ports. When the SerialSocket

program is running on the EDAS CE, a remote computer can open a TCP/IP

socket to the EDAS CE and send and receive data to and from the EDAS CE’s

serial ports. This is useful for remotely accessing serial devices

connected to the EDAS CE’s COM ports.

1.1.21 CEFlush

The CEFlush program runs on the EDAS CE unit to write the current

registry settings to the Compact Flash card. This application is

typically used by developers that need to change registry settings.

Utilities 35

Page 42

2.2 MonitorCE

The MonitorCE program is used to configure the unit’s network setting and

real-time clock. By connecting a null modem cable between the serial

port on the EDAS-2000E and a serial port on a computer, a serial

communications program such as HyperTerminal can be used to configure the

EDAS CE. The EDAS CE’s network settings must be configured before any

network communications can be established. The MonitorCE program

automatically executes on the EDAS CE unit at start-up.

When the MonitorCE program is running, it monitors COM1 for commands.

When another application running on the EDAS CE attempts to open COM1,

the MonitorCE program closes, allowing the new program to take ownership

of COM1. If another program closes MonitorCE, restart the EDAS CE unit to

start it again.

1.1.22 Required Tools

To configure an EDAS CE unit, you need the following items:

o NULL modem serial cable to connect the EDAS CE to a computer.

o A computer with an RS-232 port and a serial communications program,

such as HyperTerminal.

Connect the NULL modem serial cable to the EDAS CE base unit’s COM1 port

and connect the other end of the cable to any available serial port on

the computer.

1.1.23 Configuring the Communications Program

Run a serial communications program, such as HyperTerminal, on the

computer and configure it as follows:

Baud rate: 9600

Parity: None

Data bits: 8

Stop bits:1

No flow control

Line terminator: CRLF (carriage return/line feed)

Instructions for using HyperTerminal follow in the next section.

Utilities 36

Page 43

2.2.1.1 Using HyperTerminal

This section discusses the HyperTerminal serial communications program.

However, other serial communications programs can be used.

To start HyperTerminal:

1. Open HyperTerminal using the Start menu on the computer. Click the

Hypertrm.exe icon.

2. In the Connection Description dialog, in the name field, type a

session name. Select an icon, and click the OK button.

3. In the Connect To dialog, verify the COMx port to which you connected

the null modem cable is selected and click the OK button. The COMx

Properties dialog opens.

4. In the Port Settings tabbed dialog, enter the Port Settings provided

above, and click the OK button.

5. In the New Connection window, open the File menu and select

Properties.

6. In the dialog named for the session that you named, select the

Settings tab.

7. Click the ASCII Setup button.

8. In the ASCII Setup dialog, in the ASCII Sending section of the

dialog, select the checkboxes for Send line ends with line feeds and

Echo typed characters locally.

9. In the ASCII Receiving section of the dialog, select the checkbox for

Append line feeds to incoming line ends and click the OK button.

10. In the dialog named for the session that you named, click the OK

button.

11. When you close the New Connection window, a pop-up dialog asks if you

want to save the new session that you named. Click the Yes, No, or

Cancel buttons.

1.1.24 Starting a MonitorCE Program Session

With the serial communications program running on the computer and the

EDAS CE powered up, start a MonitorCE program session. Note: From the

time power is applied to the EDAS CE it will take approximately 30

seconds before the MonitorCE will be ready to accept a connection.

To start a MonitorCE program session:

1. In the serial communications program window, type the special string,

@@@@ and press the Enter key.

In response, the EDAS CE sends a message to the hyperteminal

communications window that reads: MonitorCE Activated.

Utilities 37

Page 44

2. In the serial communication program window, to display help

information, type h and press the Enter key.

3. The EDAS CE responds with the current command set.

The backspace key is not supported in the MonitorCE program. If you use

Note:

the backspace key the command or parameters will not be correctly processed.

If inadvertently used the backspace, press enter and reissue the command

without using the backspace key.

1.1.25 MonitorCE Program Commands

TABLE 2.2 MonitorCE Program Commands contains the MonitorCE program

command syntax to use when the serial communications program is running.

Parameter Description Command Syntax

Note: nnn.nnn.nnn.nnn represents the new parameter value for the IP address, Subnet mask,

Gateway address, or DebugWorkstation address. For WINS and DNS: nnn.nnn.nnn.nnn is new

first entry and yyy.yyy.yyy.yyy is new second entry (if required).

IP Address:

Viewing:

Changing:

Gateway Address:

Viewing:

Changing:

Subnet Mask Address:

Viewing:

Changing:

WINS Address:

Viewing:

Changing:

DHCP Enable Flag:

Viewing:

Changing:

DNS Address:

Viewing:

Changing:

Debugging Operations

IP Address of Host:

Setting:

Ethernet Address:

Viewing:

NRI

NInnn.nnn.nnn.nnn

NRG

NGnnn.nnn.nnn.nnn

NRS

NSnnn.nnn.nnn.nnn

NRW

NWnnn.nnn.nnn.nnn yyy.yyy.yyy.yyy

NRP

NPn where n = 1 to enable, n = 0 to disable

NRD

NDnnn.nnn.nnn.nnn yyy.yyy.yyy.yyy

DBGnnn.nnn.nnn.nnn

NRE

Utilities 38

Page 45

, y = number of minutes the desired

Real Time Clock:

Setting Month:

Setting Day of the Month:

Setting Year:

Setting Hours:

Setting Minutes:

Setting Seconds:

Set Real-time Clock:

View Real-time Clock Setting:

Daylight savings time:

Get current time zone:

Setting current time zone:

TABLE 2.2 MonitorCE Program Commands

TIOx, where x = value from 1 - 12. Example: 3 = March

TIDx, where x = value from 1 and 31.

TIYxxxx, where x = year using four digits.

TIHx, where x = value between 0 and 24.

TIMx, where x = value between 0 and 60.

TISx, where x = value between 0 and 60.

TIR

TIV

DSTx, set x to 1 to enable; set x to 0 to disable.

GTZ

STZxyyy zz, where x = + or time zone is from GMT, z = registry index of desired time zone.

Utilities 39

Page 46

2.3 LCmdSet

The LCmdSet application on the EDAS CE unit acts as a server for the

Telnet protocol. This application facilitates an Ethernet connection

between a EDAS CE unit running the LCmdSet utility and a computer running

a Telnet client application.

When this program starts, the application begins listening for one TCP

connection to the Telnet port. Only one active client at a time may be

connected to the unit via this port. When one client disconnects, another

client connection can be accepted.

1.1.26 Running LCmdSet

The EDAS CE unit ships with LCmdSet located in \Storage Card\LCmdSet.exe. A

shortcut is included in \Storage Card\Startup to launch LCmdSet at power-up.

1.1.27 Making a Telnet Connection using

HyperTerminal

1. On a computer with TCP/IP connectivity to the EDAS CE, open the

HyperTerminal folder using the Start menu on the computer. Click the

Hypertrm.exe icon.

2. In the Connection Description dialog, enter a name for the

connection, select an icon, and click the OK button.

3. In the Connect To dialog, select TCP/IP (Winsock), enter the EDAS

CE’s IP address in the Host address field, leave the port number set

to 23 and press OK.

1.1.28 Issuing Commands

At the

command, simply type the command followed by any command parameters and

press <enter>.

remote>

2.3.1.1 Examples

To view the EDAS CE’s IP address: type

show ipaddress<enter>

The unit will respond with:

prompt you can issue commands to the EDAS CE. To issue a

IP address: nnn.nnn.nnn.nnn (adapter 0)

where nnn.nnn.nnn.nnn is the IP address of the EDAS CE unit.

To set the EDAS CE IP address, you must be privileged. To become

privileged, you must enter a password. Type

Utilities 40

Page 47

set privileged<enter>

When the EDAS CE responds with

password>

type

system<enter>

You will now be privileged and will be allowed to change the unit’s IP

address. To change the IP address, type

change ipaddress nnn.nnn.nnn.nnn<enter>

where nnn.nnn.nnn.nnn is the new IP address for the unit.

The unit will respond with

Changed IP address: nnn.nnn.nnn.nnn (adapter 0)

1.1.29 Set Commands

Set Commands

SET PRIVILEGED

Instructs the server to allow privileged commands. When the Set Privileged command is received,

the client is prompted for the privileged password, which LCmdSet does not echo. If the password

matches, the privileged mode is entered. The default password is

using the CHANGE PRIVPASS command.

SET NOPRIVILEGE

Instructs the server to return to the unprivileged mode.

SET ECHO ON | OFF

Overrides the echo setting negotiated between LCmdSet and the client terminal program with

respect to echo. Set the echo on or

TABLE 2.3 LCmdSet SET Commands

off

.

system

. It can be changed

1.1.30 Show Commands

Notes for Show commands:

1. The IP address (ipaddr), subnet mask (mask), and gateway address

(gateway) are entered and displayed in dotted decimal notation

(127.0.0.1)

Utilities 41

Page 48

2. The optional ADAPTER parameter defaults to zero, which corresponds

to the built-in LAN9000-compatible adapter.

3. The values displayed for IP addresses, the subnet mask, DHCP, and

DNS and WINS lists may not be the operational settings. The settings are

stored in the registry and will be applied at the next reboot.

Show Command Function Calls

IPADDRESS [ADAPTER n]

Displays the IP address of the indicated network adapter.

SUBNET MASK [ADAPTER n]

Displays the subnet mask for the indicated network adapter. The default is adapter 0, which is the

built-in Ethernet.

GATEWAY [ADAPTER n]

Displays the gateway address for the indicated network adapter.

DHCP [ADAPTER n]

Displays the status of the DHCP option for the indicated network adapter (ON or OFF).

DNSLIST [ADAPTER n]

Displays the list of DNS addresses configured for the indicated network adapter. Items in the list

are separated by semicolons.

WINSLIST [ADAPTER n]

Displays the list of WINS addresses configured for the indicated network adapter. Items in the list

are separated by semicolons.

ADAPTERNAME [ADAPTER n]

Displays the name of the network adapter which corresponds to the indicated network adapter

number. This might be necessary to identify which network adapter to use when changing an

option for an adapter other than the default.

ASSIGNED [ADAPTER n]

Displays the IP address, subnet mask, gateway address, DNS server list, WINS server list, and

DHCP server assigned to the unit by DHCP on the last restart of the unit. If the unit is configured

for statically-assigned addresses, the command fails. The command will fail after changing the

DHCP flag during the same session.

SPEED [PORT portnum]

Displays the baud rate setting stored in the configuration of the indicated serial port.

PARITY [PORT portnum]

Displays the parity setting stored in the configuration of the indicated serial port.

FLOWCONTROL [PORT portnum]

Displays the flow control option (handshaking) in the stored configuration for the indicated serial

port.

STOPBITS [PORT portnum]

Displays the number of stop bits in the stored configuration for the indicated serial port. The

default is port 1, COM1.

CHARSIZE [PORT portnum]

Displays the character size (number of data bits) in the stored configuration for the indicated

serial port.

Utilities 42

Page 49

DATETIME

Enables or disables DHCP control over the unit’s network configuration for the specified adapter.

Displays the current local date and time of the unit. The date is displayed in mm/dd/yyyy (month/

day/year).

TIMEZONE

Displays the time zone of the unit, including the offset from GMT. It also displays whether the

unit’s time zone is presently observing Daylight Savings Time or Standard Time.

PROCESSLIST

Displays a list of the processes running on the unit. Displays the process ID, which can be used

to terminate the process using the STOP command, and the exe file of the process.

DEBUGWORKSTATIONS

Displays the list of debugworkstations specified in the debugworkstations.txt file on the unit in the

\Storage Card folder. Items in the list are separated by semicolons.

TABLE 2.4 LCmdSet SHOW Commands

1.1.31 Change Commands

Notes for Change commands:

1. The commands in this section require the client be in the

privileged mode. See section 1.1.29.

2. After issuing a change command it takes several seconds for the

registry to write to persistent storage, wait for the "remote>" prompt

before rebooting the unit.

3. The IP address (ipaddr), subnet mask (mask), and gateway address

(gateway) are entered and displayed in dotted decimal notation

(127.0.0.1)

4. The optional ADAPTER parameter defaults to zero, which corresponds

to the built-in LAN9000-compatible adapter.

5. For any network settings to take effect the unit must be rebooted.

Change Commands

IP ADDRESS ipaddr [ADAPTER n]

Changes the IP address for a network adapter in the unit.

When this command is performed, the DHCP flag for the adapter is automatically set to OFF.

SUBNET MASK mask [ADAPTER n]

Sets the subnet mask for a network adapter in the unit.

When this command is performed, the DHCP flag for the adapter is automatically set to OFF.

GATEWAY gateway [ADAPTER n]

Sets the gateway address for a network adapter in the unit.

When this command is performed, the DHCP flag for the adapter is automatically set to OFF.

DHCP ON | OFF [ADAPTER n]

Utilities 43

Page 50

When this option is set to ON, the IP address, subnet mask, and gateway address of the adapter

are automatically set to 0.0.0.0.

DNSLIST iplist [ADAPTER n]

Changes the DNS addresses for a network adapter in the unit.

The list can contain multiple IP addresses, separated by semicolons.

WINLIST iplist [ADAPTER n]

Changes the WINS addresses for a network adapter in the unit.

The list can contain multiple IP addresses, separated by semicolons.

SPEED baudrate [PORT portnum]

Sets the baud rate for the indicated serial port. Port 1 corresponds to COM1.

The new configuration is effective the next time an application that uses the settings stored in the

registry opens the port.

PARITY NONE | EVEN | ODD [PORT portnum]

Sets the parity for the indicated serial port.

The new configuration is effective the next time an application that uses the settings stored in the

registry opens the port.

FLOW CONTROL NONE | XONXOFF | CTSRTS | DSRDTR [PORT portnum]

Sets the flow control option (handshaking) for the indicated serial port.

The new configuration is effective the next time an application that uses the settings stored in the

registry opens the port.

STOPBITS 1 | 15 | 2 [PORT PORTNUM]

Sets the number of stop bits for the specified serial port (the default is 1, for COM1). The value 15

indicates 1.5 stop bits.

The new configuration takes effect the next time an application that uses the settings stored in the

registry opens the port.

CHARSIZE 7 | 8 [PORT portnum]

Sets the character size for the specified serial port (the number of data bits).

The new configuration takes effect the next time an application that uses the settings stored in the

registry opens the port.

DATETIME mm/dd/yyyy hh:mm:ss

Sets the date and local time of the unit using the format month, day, year, hour, minute, second.

TIMEZONE gmtOffset [DST]

Sets the time zone of the unit. The gmtOffset specifies the offset of the unit’s time zone, in hours,

from GMT. The offset may be fractional (such as 7.5), and/or negative (such as -7). If the DST

flag is set to 1, the unit’s time zone is presumed to be operating in Daylight Savings Time. If the

flag is set to 0, Standard Time is assumed. If there are multiple time zones at the offset specified

in the command, the server will display a list of matching time zones for selection.

PRIVPASS

Changes the privileged password for the unit.

LCmdSet prompts for the new password and saves it to the registry.

Utilities 44

Page 51

DEBUGWORKSTATIONS wslist

Changes the contents of the debugworkstations.txt file on the \Storage Card to include the

specified list of workstation IP addresses and TCP/IP port numbers. The format is

nnn.nnn.nnn.nnn[:port] where the port is optional and the default is 5000. The list can contain

multiple items separated by semicolons.

REGISTRY [REMOVEACTIVE | REMOVEALL | FLUSH]

Used to delete the persistent registry files or to force the registry to be flushed.

TABLE 2.5 LCmdSet CHANGE Commands

1.1.32 Operational Commands

All of the commands in this section except QUIT require the client be in

the privileged mode..

Operational Commands

QUIT

Instructs LCmdSet to close the connection to the client and return to the idle state, waiting for a

new client to connect.

REBOOT

Instructs the unit to be rebooted.

RUN program [commandline]

Instructs LCmdSet to execute the indicated program on the unit, passing the specified command

line, if any.

STOP pid

Instructs the LCmdSet to terminate the indicated program on the unit. The pid is retrieved from

the list of running processes via the SHOW PROCESSLIST command.

TERMINATE

Instructs the LCmdSet utility to close.

TABLE 2.6 LCmdSet Operational Commands

Utilities 45

Page 52

2.4 Remote Manager

The Remote Manager utility provides basic unit management functionality,

including access to the file system, application management, reboot

capability, and security settings. The Remote Manager is a Web-based

application that uses a series of Web pages as the user interface. To

access the Remote Manager, use a browser, such as Internet Explorer, and

enter the EDAS CE unit’s IP address in the URL window.

A Remote Manager user can perform the following tasks:

Assign the EDAS CE unit a name, description, and location.

Perform file management on the unit: uploading, downloading, copying,

and deleting files, creating new folders and deleting existing ones.

Configure, read and write the analog, digital and serial I/O.

Manage applications running on the unit, including viewing a list of

applications currently executing, launching applications, and

terminating applications.

Reboot the EDAS CE unit.

Control the security settings, user name and password, for the above

capabilities.

Update content on the unit’s Compact Flash card.

Access the Developers Guide for information on using WebDevice to

extend the embedded Web site to create custom applications.

Note: Most content is password protected. The default user name and

password for all protected sections is:

user name: admin

password: admin

To change the passwords, refer to section 1.1.40 Security Manager.

1.1.33 WebDevice

WebDevice is an embedded Web server that comes preinstalled on the EDAS

CE. In addition to serving standard HTML, GIF and JPG content, WebDevice

can execute server side scripts to provide dynamic content. The Remote

Manager’s functionality is implemented using WebDevice’s server side

scripting capabilities.

In addition to enabling the features and functionality of the Remote

Manager, WebDevice can be used to build other Web-based applications that

run on the EDAS CE. Applications such as machine monitoring and remote

data logging can be implemented using WebDevice’s scripting language. A

user can extend the EDAS CE’s embedded Web site by uploading additional

HTML pages, images and WebDevice script files. This allows the EDAS CE’s

Utilities 46

Page 53

Web interface to be fully customized to meet the application and user

needs.

Information on WebDevice’s server side scripting language can be accessed

via Remote Manager. Use the "Developers Guide" link on the Remote

Manager home page.

The EDAS CE unit ships with WebDevice located on the Compact Flash card

at \Storage Card\WebDevice\Wd_Edasce.exe. A shortcut is included in \Storage

Card\Startup folder to cause WebDevice to start at power-up. If you do not

want WebDevice to run on power-up, simply remove the shortcut.

If WebDevice is not running, it can be started remotely using LCmdSet.

See section 2.3 LCmdSet.

1.1.34 Using the Remote Manager

To use the Remote Manager, run a Web browser on a computer and point the

browser to the desired EDAS CE unit by entering the EDAS CE unit’s IP

address in the browser’s address (URL) window.

Troubleshooting Errors

If a 404 page not found error occurs:

1. Enter http://IP in the address window, where IP is the EDAS CE unit’s

IP address. Some browsers require the leading http:// as part of the

URL.

2. Verify network connectivity between the computer and the EDAS CE by

pinging the EDAS CE unit.

a. On a Windows computer, open a Command line window.

b. Type ping IP where IP is the IP address of the EDAS CE unit.

If a time-out occurs, this indicates a network problem with the PC,

the EDAS CE unit, or the network connecting them.

3. Verify the WebDevice program is running by using LCmdSet. See section

2.3 LCmdSet.

Password Protection

All sections of the Remote Manager are password protected with the

exception of the Home page, Help and the Developers Guide. The default

user name and password is:

user name: admin

password: admin

The user name and password can be changed using the Security Manager.

See section 1.1.40 for more information.

Utilities 47

Page 54

Help Links

The Remote Manager includes context-sensitive help. To access help, use

the Help link located in the upper right-hand corner of all pages.

Other Management Capabilities

For additional information on using other Remote Manager capabilities not

included in this manual, refer to the Remote Manager Help pages.

1.1.35 Remote Manager Home Page

Access the Remote Manager home page by entering the EDAS CE unit’s IP

address in the browser’s URL window.

FIGURE 2.1 EDAS CE Remote Manager Home Page

Utilities 48

Page 55

2.4.1.1 EDAS CE Information

The information section of the EDAS CE home page displays the unit’s:

o IP Address

o Name

o Location

o Description

To edit the name, location, and description information, click any of the

links, Name, Location, or Description, to open the information page.

Edit the information and click the Update link. To exit without making

any changes click the Back link.

FIGURE 2.2 Edit Terminal Information Page

Utilities 49

Page 56

2.4.1.2 Management

This section of the home page provides links to the six management

sections of the Remote Manager Web site and to the Developers Guide

section.

o Application Manager - View, terminate and run applications on the EDAS

CE.

o File Manager - View folder listing, upload files, download files, run

programs, etc.

o Module Manager - View attached modules; configure, read and write I/O

points.

o System Manager - Reboot the EDAS CE.

o Security Manager - View and edit user names and passwords.

o Update Manager - Access and download software updates to the EDAS CE.

o Developers Guide - Access to WebDevice scripting documentation and

samples.

Utilities 50

Page 57

1.1.36 Application Manager

The Application Manager enables you to view the programs that are

currently running on the EDAS CE, terminate a program, run a program and

create shortcuts to run programs in the startup folder.

FIGURE 2.3 Application Manager

Utilities 51

Page 58

1.1.37 File Manager

The File Manager allows a user to view files, download files, upload

files, delete files, run programs and WebDevice script’s, create

shortcuts to programs in the startup folder, create new folders, delete

folders and copy files from one folder to another on the EDAS CE.

Utilities 52

FIGURE 2.4 File Manager

Page 59

1.1.38 Module Manager

The EDAS CE module manager allows the user to view the attached modules,

configure the I/O points on a module and read or write the I/O points

.

FIGURE 2.5 EDAS CE Module Manager

Utilities 53

Page 60

1.1.39 System Manager

The System Management page allows the user to reboot the EDAS CE.

FIGURE 2.6 Remotely Rebooting the EDAS CE

1.1.40 Security Manager

The Security Manager allows a user to modify the access privileges for

the EDAS CE through WebDevice. WebDevice uses a folder-based

user/password system. A folder can be assigned a single user name and

password to restrict access to the contents of the folder. The folder

structure of the Remote Manager allows for different user/password access

to the different management sections

The Security Manager page provides a cross reference between the

management function and the folder. For example to restrict access to

the File Manager, you must assign a user name and password to the folder

/file.

Utilities 54

Page 61

To add password protection to a folder, remove protection or edit

existing user/password, click on the Edit/Remove link and alter the

setting for the desired folder.

FIGURE 2.7 Security Management main page

Utilities 55

Page 62

The WebDevice Server System Configuration page shown in FIGURE 2.8

WebDevice Server System Configuration page, displays the existing

protected folders. Simply use the Edit or Remove link for the desired

folder to change its setting. To add password protection to a folder that

is not listed, use the Add New Protected Folder link.

FIGURE 2.8 WebDevice Server System Configuration page

Utilities 56

Page 63

1.1.41 Update Manager

The Update Manager allows the user to have the EDAS CE check the

instrument.com Web site, or a user-created Web site on a corporate

server, for new software updates. New updates may be downloaded by the

EDAS CE directly from the instrument.com Web site or the corporate site.

FIGURE 2.9 Update Manager

1.1.42 Developer’s Guide

The Developer’s Guide link provide links to the WebDevice help pages and

to www.edasce.com Web site for example script samples.

The WebDevice help pages explain the server side scripting language and

include a complete function reference.

Utilities 57

Page 64

2.5 DebugLauncher

In order to download and debug applications on the EDAS CE unit using

eMbedded Visual Tools (eVT), a connection must be established between the

EDAS CE and your development PC. The program on the EDAS CE that

provides this connection is DebugLauncher.exe. When the DebugLauncher

application runs, it reads the text file \Storage Card\debugworkstations.txt to

obtain the IP address(s) of the development PC(s). It then enables

communications between the EDAS CE and the development PC. If

DebugLauncher does not find a debugworkstaions.txt file or the file is

empty, DebugLauncher simply exits. The EDAS CE ships with a shortcut to

DebugLauncher.exe included in \Storage Card\Startup folder to launch

DebugLauncher at power-up.

1.1.43 Setting Up DebugLauncher

To set up the DebugLauncher:

1. Set the contents of debugworkstations.txt

2. Reboot the EDAS CE.

1.1.44 debugworkstations.txt File Format

debugworkstations.txt should contain zero or more IP addresses each on a

separate line. Optionally, it can also include the TCP/IP port number on

which the development PC is listening. The format of an entry in the

debugworkstations.txt file is as follows:

<ip address>[:<tcp port>]

The <ip address> field is a dotted decimal representation of the IP

address. 127.0.0.5, for example. The optional <tcp port> is the decimal

port number on which the development PC is listening. The default tcp

port is 5000. Two example lines are shown below. The first uses the

default port address 5000, the second uses port 4500.

127.0.0.5

172.16.3.55:4500

On Windows XP machines, port 5000 is typically in use, thus you must

Note:

use a different port number. We recommend port 4500.

Utilities 58

Page 65

1.1.45 Changing the contents of debugworkstations

The debugworkstations.txt file can be changed using the MonitorCE or LCmdSet

applications. See section 2.2 MonitorCE or section 2.3 LCmdSet for

instructions.

After making changes to the debugworkstations.txt file, the EDAS CE unit must be

rebooted for the changes to take effect.

Utilities 59

Page 66

2.6 TimeSync

The TimeSync program allows synchronization of the EDAS CE unit’s clock

with an external time standard. The unit supports clock synchronization

through the Internet Standard specification RFC 868, also known as the

TCP TIME protocol.

The time standard obtained from the Web site