Intelligent Charging Limited IC48V Operator's Manual

IC48V Battery Charger/Analyser

Operator Manual

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 1 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

IC48V

BATTERY CHARGER

AND CAPACITY TESTER

OPERATORS MANUAL

IC48V Battery Charger/Analyser

Operator Manual

Table of Contents

1 Manual Revision History............................................................................................................4

2 Equipment Description..............................................................................................................5

2.1 General.............................................................................................................................5

2.1.1 Charging Modes..........................................................................................................5

2.1.2 Capacity Testing Modes...............................................................................................6

2.2 Component Parts...............................................................................................................8

2.3 Installation........................................................................................................................8

2.4 Front Panel Controls And Indicators....................................................................................9

2.5 Rear Panel Controls And Indicators....................................................................................11

3 Cell Monitor Interface..............................................................................................................12

3.1 General............................................................................................................................12

3.2 Charging With The Cell Monitor.........................................................................................12

3.2.1 Constant current charge............................................................................................12

3.3 Discharging With The Cell Monitor.....................................................................................13

3.3.1 Capacity Testing To Target Or Time...........................................................................13

3.3.2 Automatic Cell Balance...............................................................................................13

3.4 Monitor Only Mode...........................................................................................................13

3.5 Normal Charge or Capacity Test Mode...............................................................................13

3.6 Cell Monitor Extended Display Reference...........................................................................13

3.7 Printing Data When Using The Cell Monitor........................................................................14

3.8 Cell Number Reversal.......................................................................................................15

3.9 Cell Monitor Specifications................................................................................................15

4 Equipment Menu Operation.....................................................................................................16

4.1 Main Menu.......................................................................................................................16

4.2 Charging Menu.................................................................................................................17

4.3 Capacity Testing Menu......................................................................................................18

4.4 Library Menu....................................................................................................................19

4.5 Settings Menu..................................................................................................................20

4.6 Cell Monitor Menu............................................................................................................21

4.7 Process Operation Menu...................................................................................................22

5 Connecting A Battery...............................................................................................................23

6 Connecting The Flying Lead Cell Monitor..................................................................................25

7 Connecting The Crown............................................................................................................25

8 Battery Charge Operation........................................................................................................26

8.1 Constant Voltage Charge..................................................................................................26

8.2 Constant Current Charge..................................................................................................27

8.3 Multi-Step Constant Current Charge..................................................................................28

8.4 Constant Current Charge Using Cell Monitor.......................................................................29

8.5 Performing A Charge........................................................................................................30

8.5.1 CHARGE FROM A LIBRARY ENTRY..............................................................................30

8.5.2 CHARGE FROM MANUAL DATA...................................................................................30

8.5.3 CHARGE FROM PREVIOUS DATA................................................................................30

9 Battery Capacity Test or Discharge Operation...........................................................................31

9.1 Capacity Test To 100%....................................................................................................31

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 2 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

IC48V Battery Charger/Analyser

Operator Manual

9.2 Capacity Test To Target Voltage........................................................................................32

9.3 Capacity test Using Cell Monitor........................................................................................33

9.4 Automatic Cell Balancing...................................................................................................34

9.5 Full Battery Discharge.......................................................................................................35

9.6 Performing A Capacity Test...............................................................................................36

9.6.1 Capacity Test or Discharge From A Library Entry.........................................................36

9.6.2 Capacity Test or Discharge From Manual Data.............................................................36

9.6.3 Capacity Test or Discharge From Previous Data...........................................................36

10 Creating Or Modifying Library Entries.....................................................................................37

10.1 Data Entry Procedure......................................................................................................37

10.2 Entering Charge Data.....................................................................................................37

10.3 Entering Discharge Data.................................................................................................39

11 Process Mode........................................................................................................................40

11.1 Overview Of Operation...................................................................................................40

11.2 Process Menu.................................................................................................................40

11.2.1 Renaming a process.................................................................................................41

11.2.2 View or Edit A Process.............................................................................................41

11.3 Process Execution...........................................................................................................42

11.4 Process Termination.......................................................................................................42

12 Calibration............................................................................................................................44

12.1 Equipment Required.......................................................................................................44

12.2 Calibration Equipment Connection...................................................................................44

12.3 Check Procedure............................................................................................................44

12.4 Making Calibration Adjustment........................................................................................45

12.5 Reviewing Calibration Date.............................................................................................46

13 Miscellaneous Unit Functions..................................................................................................47

13.1 Description Of Stop Codes...............................................................................................47

13.2 Print Or Display Previous Operation Results......................................................................49

13.3 Changing The Date Format And Date Time......................................................................49

13.4 Modifying Display Intensity.............................................................................................50

13.5 Printing battery serial number.........................................................................................50

14 Service And Maintenance.......................................................................................................51

14.1 Calibration.....................................................................................................................51

14.2 Cleaning........................................................................................................................51

14.3 Battery Backup...............................................................................................................51

14.4 Printer Care....................................................................................................................52

14.4.1 Door Latch..............................................................................................................52

14.4.2 Paper Feed Button...................................................................................................52

14.4.3 Paper Roll Replacement...........................................................................................53

14.4.4 Ribbon Cartridge Replacement.................................................................................53

14.4.5 Consumables Available.............................................................................................54

15 Specifications........................................................................................................................55

16 Product Disposal Instructions.................................................................................................57

17 Product Warranty..................................................................................................................58

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 3 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

IC48V Battery Charger/Analyser

Operator Manual

1 Manual Revision History

Rev Date Description

1 17-09-2013 Written from an IC50A manual.

2 21-07-2015 Formatting changes..

3 21-04-2016 Corrected maximum charge current at 12V

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 4 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

IC48V Battery Charger/Analyser

Operator Manual

2 Equipment Description

2.1 General

The Battery Charger Analyser is an electronically controlled combined universal battery

charging unit with built in battery analysing (capacity testing) capabilities. It is housed

in a metal enclosure designed for bench mounting. As it is supplied it is designed to

work on a 240V supply. It can be operated on a 115V supply but it will exceed the fuse

rating if used on high charge rates.

Equipment control is via an interactive 253 x 32 dot matrix display and data entry is via

a 16-key keypad. Operating modes and functions are selected by the use of a simple

menu system. Access to charging and testing operations is performed by either entry of

eight digit battery library names, repeat of last charge or capacity test or new manual

parameters. During operation the display will show the instantaneous values of battery

voltage, current and time elapsed through the selected program.

Process modes can be created where complete unattended charging, capacity testing

and final charging can be performed. Up to 6 different charge or capacity test steps can

be created and up to 4 process programs can be stored in the unit. Each process step

has an optional delayed start for resting the battery and also each step can sound the

alarm with or without a pause in operation. The process is simply continued by pressing

a key on the keypad.

Battery data is stored internally in the units non-volatile memory. The operator can add

and modify this list by entering the details of the battery to be included on the display

and keyboard. Alphanumeric digits, up to a maximum of 8 digits, identify Battery library

entries

Batteries are connected to the front of the unit by means of two individual high current

connectors. Connection to the battery has to be made via the appropriate connectors

for that battery. The unit is supplied with M8 ring crimps that must have the

appropriate connector for the battery type being tested fitted.

The IC48V can: -

Charge 12V at 80.0A

Charge 24V batteries at 80.0A

Charge 48v batteries at 40.0A

Capacity Test 12V Batteries at 100.0A

Capacity test 24V batteries at 80.0A

Capacity test 48v batteries at 40.0A

The unit contains a high flow rate fan to extract the heat energy generated internally

when running in capacity test mode.

2.1.1 Charging Modes

CONSTANT VOLTAGE CHARGE

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 5 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

IC48V Battery Charger/Analyser

Operator Manual

Where the battery is charged at a reducing current when the constant voltage

threshold is met. Parameters for this mode are maximum charge time, optional

minimum current to stop charge and a current threshold, which can detect a

potentially faulty battery.

CONSTANT CURRENT CHARGE WITH TOP UP CHARGE

Where battery is charged at a constant current until a terminal voltage is met, at

this point it can be charged for an additional time at a user set current. The

overcharge voltage is set in this mode to prevent overcharging of the battery.

MULTIPLE STEP CONSTANT CURRENT CHARGE

Up to 4 constant current steps can be implemented for the charge cycle. this

mode also has an overcharge voltage setting to prevent overcharging of the

battery. Charge current can be set to zero for “rest” periods between charge

steps.

CONSTANT CURRENT USING CELL MONITOR

In this mode the battery will be charged at constant current with the charge

switching to the top up charge (if required) when all the cells reach the target

voltage specified.

2.1.2 Capacity Testing Modes

CAPACITY TEST TO 100 PERCENT

This mode will discharge the battery connected at the current specified for the

test duration specified thus reporting the battery capacity is 100% or more. The

capacity test will be stopped if the target voltage is reached before the full test

time has elapsed. During the capacity test and when it is terminated the display

will show the amount the capacity test is complete as a percentage.

CAPACITY TEST TO TARGET VOLTAGE

This mode will discharge the battery down to the terminal voltage specified thus

reporting the actual percentage capacity. The capacity test will be stopped if the

target threshold voltage is reached before the full test time has elapsed. During

the capacity test and when it is terminated the display will show the amount the

capacity test is complete as a percentage.

CAPACITY TEST WITH CELL MONITOR

This mode will discharge the battery connected at the current specified for the

test duration specified thus reporting the battery capacity is 100% or more. The

capacity test will be stopped if any cell reached the cell target voltage before the

full test time has elapsed. During the capacity test and when it is terminated the

display will show the amount the capacity test is complete as a percentage.

AUTOMATIC CELL BALANCE

This mode is designed to discharge the battery down to zero volts, where when

any cell reached zero volts a balancing resistor will automatically be placed

across it. When the battery total voltage reached near zero all the remaining

balancing resistors will be applied.

FULL DISCHARGE

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 6 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

IC48V Battery Charger/Analyser

Operator Manual

This mode will do a basic discharge of the battery at the current specified for the

time specified.

The unit can be set so that a predefined charge or capacity test can be scheduled to start at

up to 99.9h in the future. And if during this time the power is lost to the unit, such as a power

outage, the unit will continue to count down when the power is restored. Note: If the power

outage resumes after the elapsed time has been passed the predefined charge or capacity test

will not be executed.

The unit contains the software that will allow it to be calibrated by the end user doing away

with the need to send the unit to a service centre for periodic calibration. The re-calibration

process only takes a few minutes and this is done without the need to access the internals of

the unit.

The printer when fitted allows the operator to print hard copies of the charge and test results

upon completion of the test. This report can be used to complement the service schedule by

providing full traceability.

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 7 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

IC48V Battery Charger/Analyser

Operator Manual

2.2 Component Parts

Upon receipt of your new battery charger analyser unpack and check that all items are

present in the containing box.

STANDARD ITEMS

One IC48V Battery Charger Analyser

One power cord

One Set (+ve & -ve) standard battery leads.

One paper Copy Operators Manual

Certificate Of Conformity

Calibration Certificate

OPTIONAL ITEMS

Cell Monitor Interface

Cell Monitor Crown (to suit battery specified).

Battery specific connectors.

2.3 Installation

The Battery Charger Analyser should be mounted on a level surface such as a

workbench or sturdy shelf above the batteries with a loading weight of at least 50Kg.

The unit should be sited so that at least 10cm of airspace is available all round the sides

and top of the unit to allow free movement of air required for cooling.

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 8 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

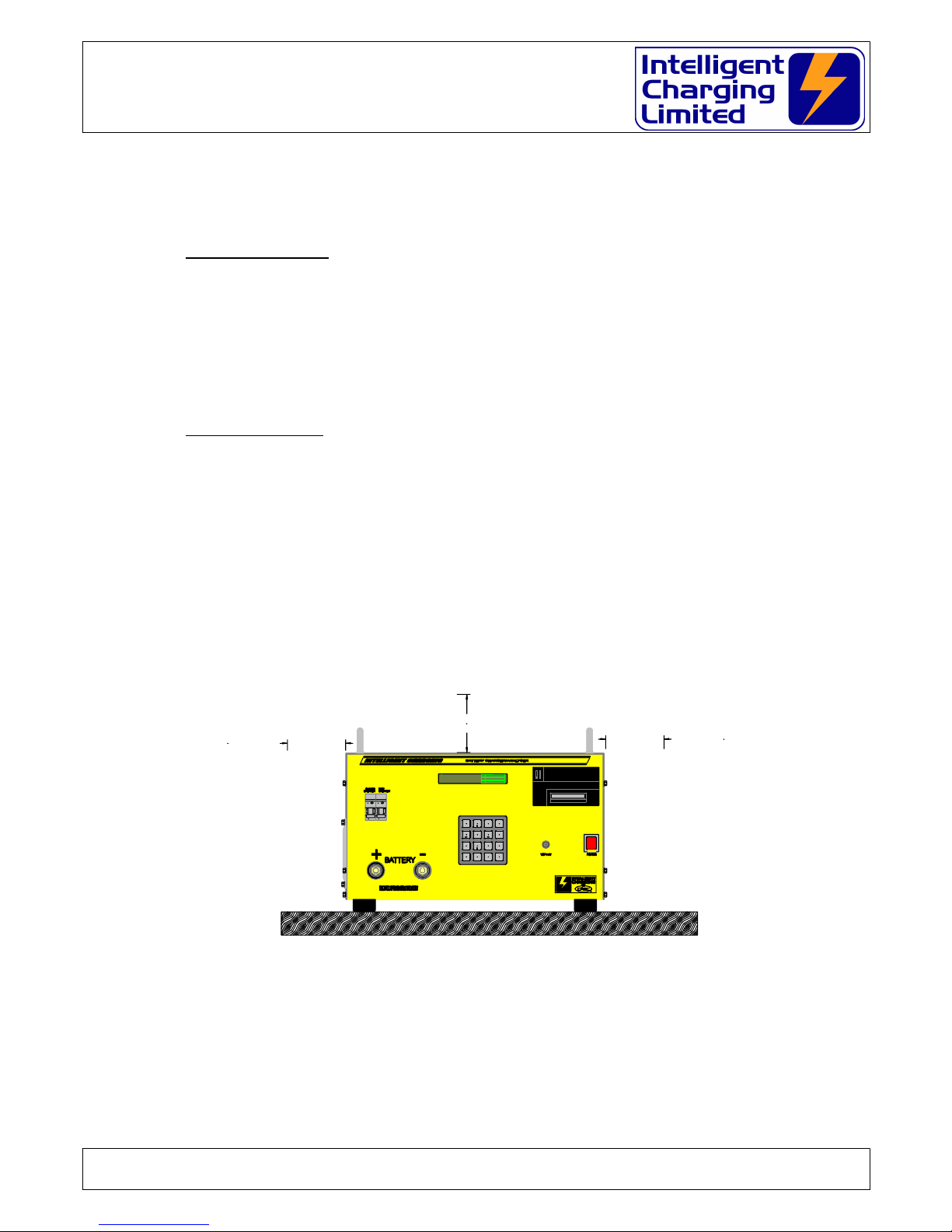

MEM

B63

ON

OFFIO

MEM

B63

ON

OFFIO

859 A

6 B

31 2

*

CLR

0

#

ENT

C

.

4

7

MB73+ MAIN A CHARGE

7-05-2006 16:30:15 B TEST

C SETTINGS

100.0 mm

100.0 mm

100.0 mm

IC48V Battery Charger/Analyser

Operator Manual

2.4 Front Panel Controls And Indicators

(A) – DISPLAY

All battery charger indications are made on this 256 x 32 dot matrix vacuum fluorescent

display.

(B) - BUILT IN PRINTER

If fitted the optional 24 column printer. On the non printer models this will be a

blanking plate.

(C) - MAINS POWER SWITCH

Pressing this switch activates mains power. It will illuminate to indicate power is being

applied to the unit.

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 9 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

G

F

E

D

C

B

A

I

H

J

IC48V Battery Charger/Analyser

Operator Manual

(D) - AUXILLIARY CONNECTOR

This 6 pin connector is the RS232 and power connector for the cell monitoring unit. It

can also be used for remote control operation with PC based software.

(E) – KEYPAD

All battery charge and capacity test functions are activated via this 16 key keypad.

(F) - NEGATIVE BATTERY TERMINAL

Connection of the negative battery lead is made to this terminal.

(G) - POSITIVE BATTERY TERMINAL

Connection of the positive battery lead is made to this terminal.

(H) - HEAT EXCHANGER EXHAUST FAN

During use the unit absorbs electrical power, which it turns into heat, this fan exit is

where the heat is extracted from the unit. It is important that it is not obstructed.

(I) & (J) - CHARGE & CAPACITY TEST CIRCUIT BREAKERS

The circuit breakers are fitted to prevent high currents from being driven into the

battery or into the unit should a fault condition occur. Always ensure that the circuit

breaker is in the ON position before starting a charge or capacity test.

WARNING

NEVER SWITCH THE CIRCUIT BREAK TO ON WHEN THE UNIT IS PERFORMING A

CHARGE OR CAPACITY TEST AS SEVERE DAMAGE MAY OCCUR TO THE BATTERY OR THE

EQUIPMENT

ALWAYS PRESS STOP FIRST

If the circuit breaker operates during a charge immediately press STOP and remove

power from the unit and disconnect the battery.

Operation of the circuit breaker is an indication of a fault and the unit will need to be

checked before using.

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 10 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

IC48V Battery Charger/Analyser

Operator Manual

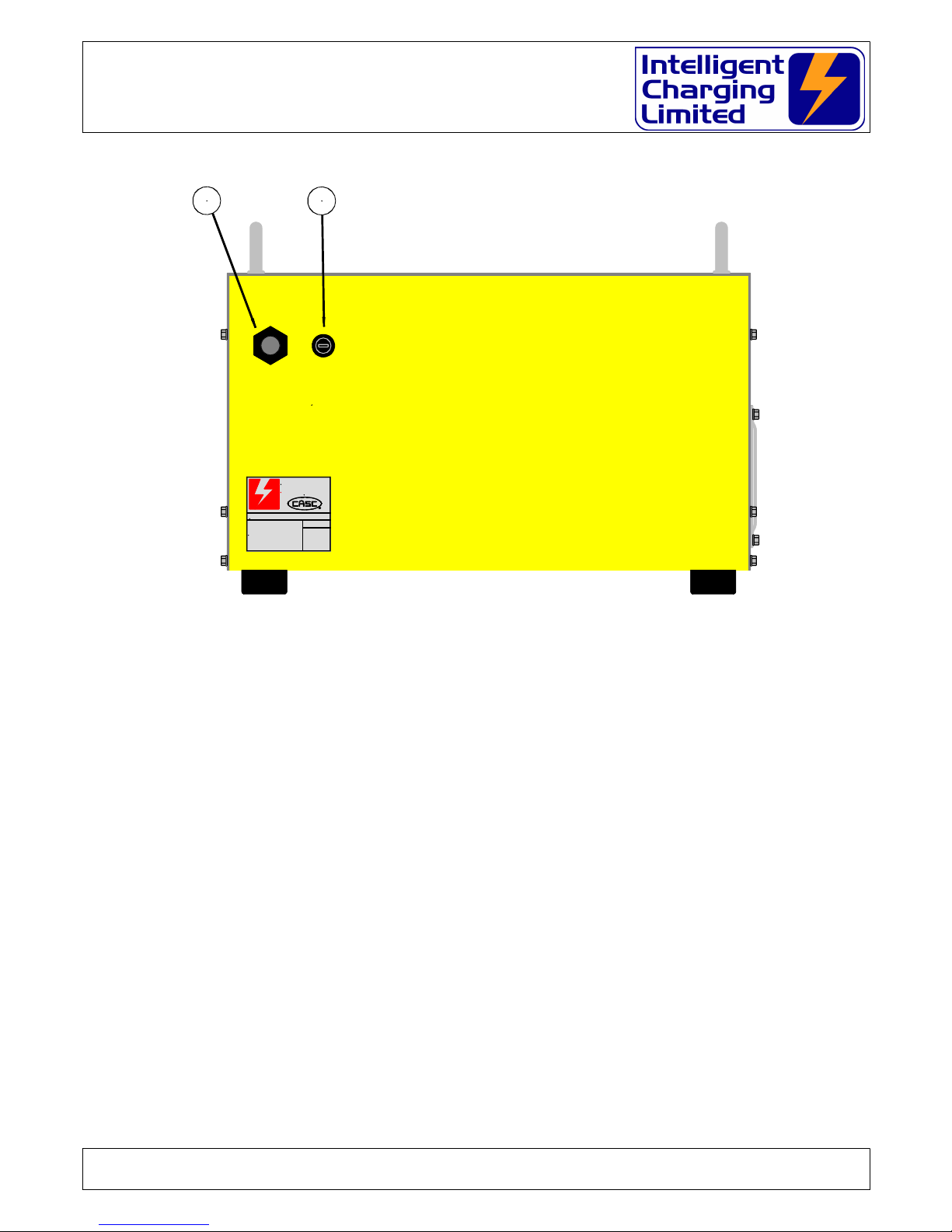

2.5 Rear Panel Controls And Indicators

(K) - Mains Lead

This is the entry point for the power lead into the unit. Always check that the lead is not

damaged before use.

(L) - Mains Fuse.

The mains fuse fitted to the IC48V is 16.0A Slow Blow 1¼”

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 11 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

MAINS 220V-240V 50Hz/60Hz 2.4KW

REPLACE ONLY WITH SAME TYPE FUSE 13A S/B

SERIAL No:

INTELLIGENT CHARGING

from

Controlled Access Storage Cabinets Ltd

Ford House, Dewing Road,

Rackheath Ind. Est. Norwich,

Norfolk, NR13 6PS, ENGLAND.

TEL: +44-1603-722770

FAX: +44-1603-722771

MAIL: sales@casc-ltd.com

CHARGING

INTELLIGENT

FROM

K L

IC48V Battery Charger/Analyser

Operator Manual

3 Cell Monitor Interface

3.1 General

The IC48V battery charger analysers have built in support for the cell-monitoring

interface.

This allows the monitoring of NiCd batteries of up to 20 cells. Contact us if cell

monitoring is required above 20 cells.

With the cell-monitoring interface connected two additional capacity test options

become available and one additional charge option.

When the cell monitor is in use two additional displays can be selected by pressing ‘B’

or ‘C’ keys on the keypad while the unit is running. Pressing ‘A’ key will return the

display back to the default display.

‘A’ Default display.

This is the conventional display which all modes of operation use.

‘B’ A textual list of cell voltages

This display will show all 20 cell voltages being measured as a simple list.

‘C’ A graphical bar graph.

This display will, show all 20 cell voltages being measured a graphical bar graph,

which will show the inter-relationship between each cell. Also displayed is a line

representing the target voltage. The battery voltage and charge of capacity test

current highest cell voltage, lowest cell voltage and the "cell focus" voltage are

shown in text format. By using the left and right arrow keys on the keypad a

highlight marker can be moved across each cell so that if one particular cell

voltage needs to be monitored it will be displayed by the right of the bar graph.

By pressing "0" and either "" or "" keys simultaneously will cause the 1.0V

display window to be shifted up or down the 2.0V range.

The cell monitor is supplied as an interface unit with 21 patch lead connection for

connecting to batteries via individual clamps. It has a connector fitted to it where

“crown” assembly can be plugged in. The “crown” arrangement is placed onto the top

of the battery with contact to the cells made via stainless test pins. The “crown”

arrangement is manufactured to suite one style of battery. If many different styles of

batteries are in use a “crown” will be required for each battery.

3.2 Charging With The Cell Monitor

3.2.1 Constant current charge.

In the constant current charge mode using the cell monitor interface the charge will

take place at the predefined constant current until all the cells have reached the target

set point typically 1.55V. At which time the charge rate will change to the additional

time rate and the charge will continue until the additional time has elapsed. If at any

time during the charge any cell voltage exceeds the cell overcharge voltage typically

1.65V the charge will stop. If a printer is connected to the unit the cell voltages can be

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 12 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

IC48V Battery Charger/Analyser

Operator Manual

printed at predefined timed intervals or can be printed by simply pressing the ‘.’ key. If

a printed report is required at the end of the charge, the final cell voltages will be

included.

3.3 Discharging With The Cell Monitor

3.3.1 Capacity Testing To Target Or Time

This capacity test mode allows you to discharge the battery at the required current for

your pre-selected time until one cell goes below a predefined target voltage typically

1.00V at which point the discharge stops and the battery capacity can be seen. If a

printer is connected to the unit the cell voltages can be printed at predefined timed

intervals or can be printed by simply pressing the ‘.’ key. If a printed report is required

at the end of the capacity test the final cell voltages will be included.

3.3.2 Automatic Cell Balance

This mode allows you to set a predefined discharge current to flatten the battery and to

perform an automatic cell balancing exercise. While during the discharge any cell

approaches 0.00V its balancing resistor will be switched in to reduce the reverse charge

effect. When the battery voltage falls below 3.0V and the discharge current falls below

2.0A the cell-monitoring interface will automatically switch in all the balancing resistors

and will remain it that state until either the CLR key is pressed or the Discharge Time

elapses.

3.4 Monitor Only Mode

A mode of operation is available where the cell monitor interface can be scanned while

the unit is idle. This is obtained through the SYSTEM menu. While in this mode the ‘B’

& ‘C’ keys will display the textual cell voltages or the bar graph respectively. While this

mode is active and the printer is installed a snapshot of the cell voltages can be printed

by pressing the ‘.’ key. When accessing the monitor mode the option of applying the

cell balancing resistors is available, so manual cell balancing can be applied.

3.5 Normal Charge or Capacity Test Mode

When activating the normal charge and capacity test modes if the unit detects that the

cell monitor is connected it will ask the operator if cell monitoring is required during the

operation. If this is selected the cell monitor will scan the cells and report the voltages

but will take no actions on individual cell voltages etc.

3.6 Cell Monitor Extended Display Reference

When performing a charge or capacity test the display will always default to showing

the main process conditions, but when the cell monitor is in use there are two

additional displays which give the operator a list of cell voltages at the instant in time or

a graphical bar display of the cell voltages. The alternative displays are viewed by

pressing either of the ‘A’, ‘B’ or ‘C’ keys on the keypad.

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 13 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

IC48V Battery Charger/Analyser

Operator Manual

The ‘A’ key changes the display to the main process conditions as shown:

The ‘B’ key changes the display to the full 20-cell voltage list as shown:

The ‘C’ key changes the display to a bar graph of cell voltages as shown:

While the graphical display is viewed the range of the display can be dynamically

changed from the default 0.8 to 1.8V to a bottom limit of 0.0V to 1.0V or an upper limit

of 1.0 to 2.0V by pressing and holding the "0" key and pressing the "" or ""

respectively. Each step is an increment or decrement of 0.1V.

3.7 Printing Data When Using The Cell Monitor

If the printer is fitted to the charger analyser and the cell monitor is in use there are

additional printing facilities available. When performing a charge or capacity test the cell

voltages can be printed manually at a time to suit you by simply pressing the ‘.’ key or

a print interval can be specified in minutes. When the cell monitor is in use the full list

of cell voltages will also be included in the final print at the end of the operation. The

cell monitor printout is a similar format to the figure below:

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 14 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

STOP

*

CLR

1.. 5 1.35V 1.35V 1.35V 1.35V 1.35V

6..10 1.35V 1.35V 1.35V 1.35V 1.35V

11..15 1.35V 1.35V 1.35V 1.35V 1.35V

16..20 1.35V 1.35V 1.35V 1.35V 1.35V

STOP

*

CLR

1.80

1.20

0.08

26.9V 0.0A

HIGH = 1.36V

LOW = 1.32V

C 01 = 1.32V

T1.55V 1.0A + 1.0A 1.0H O1.65V F 5.0H

27.6V 0.5A 0h00m00

MANUAL 24.0V CELL MONITOR CC CHARGE

STOP

*

CLR

IC48V Battery Charger/Analyser

Operator Manual

3.8 Cell Number Reversal

The cell monitor accessory is marked with cell numbers starting with #1 through to #20

(The maximum number of calls that can be monitored). Cell #1 is considered to be the

cell which is connected to the negative (-ve) cell end of the battery whereas cell #20

(in a 20 cell battery) is considered to be the cell which is connected to the positive

(+ve) end of the battery.

Many battery manufacturers use the reverse cell numbering where cell #1 is the

positive (+ve) end of the battery and in the case of a 20 cell battery the #20 cell is the

negative.

Because of this numbering technique the battery charger has an option in the cell,

monitor settings to “reverse” the cell numbering for display and printing purposes. The

cell displays show which is +ve end of the battery and which is the negative so that if

the cell numbering is reversed it is shown which way round the numbering takes.

3.9 Cell Monitor Specifications

Power +5.0V

Cell Voltage Range -2.5V to +2.5V

Max No. Cells 20

Full Scan Rate 5 seconds

Balance Switching current 2.0A

Balance continuous current 1.0A

Balance Resistance 1.0Ω ±1% 2W

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 15 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

-----------------------CELL VOLTAGES AT 1.5H

01 1.46V 02 1.46V

03 1.46V 04 1.46V

05 1.46V 06 1.46V

07 1.46V 08 1.46V

09 1.46V 10 1.45V Lo

11 1.46V Hi 12 1.46V

13 1.46V 14 1.46V

15 1.46V 16 1.46V

17 1.46V 18 1.46V

19 1.46V 20 1.46V

------------------------

IC48V Battery Charger/Analyser

Operator Manual

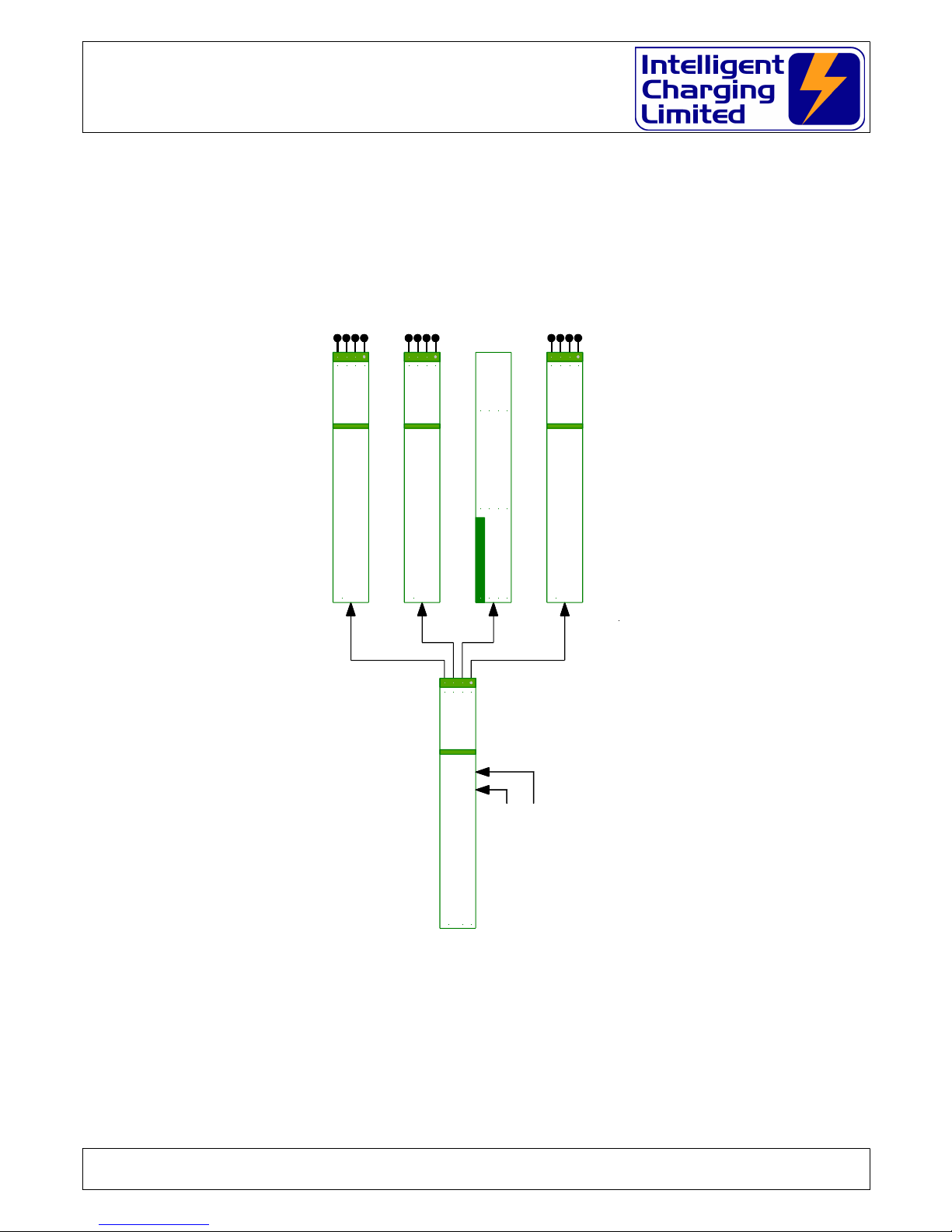

4 Equipment Menu Operation

The Battery Charger Analyser is operated by the use of a simple menu structure which is

accessed by simply pressing the A, B, C or ‘.’ keys. To get back to the main menu the CLR

key is pressed repeatedly. The following flowcharts illustrate the menu structure.

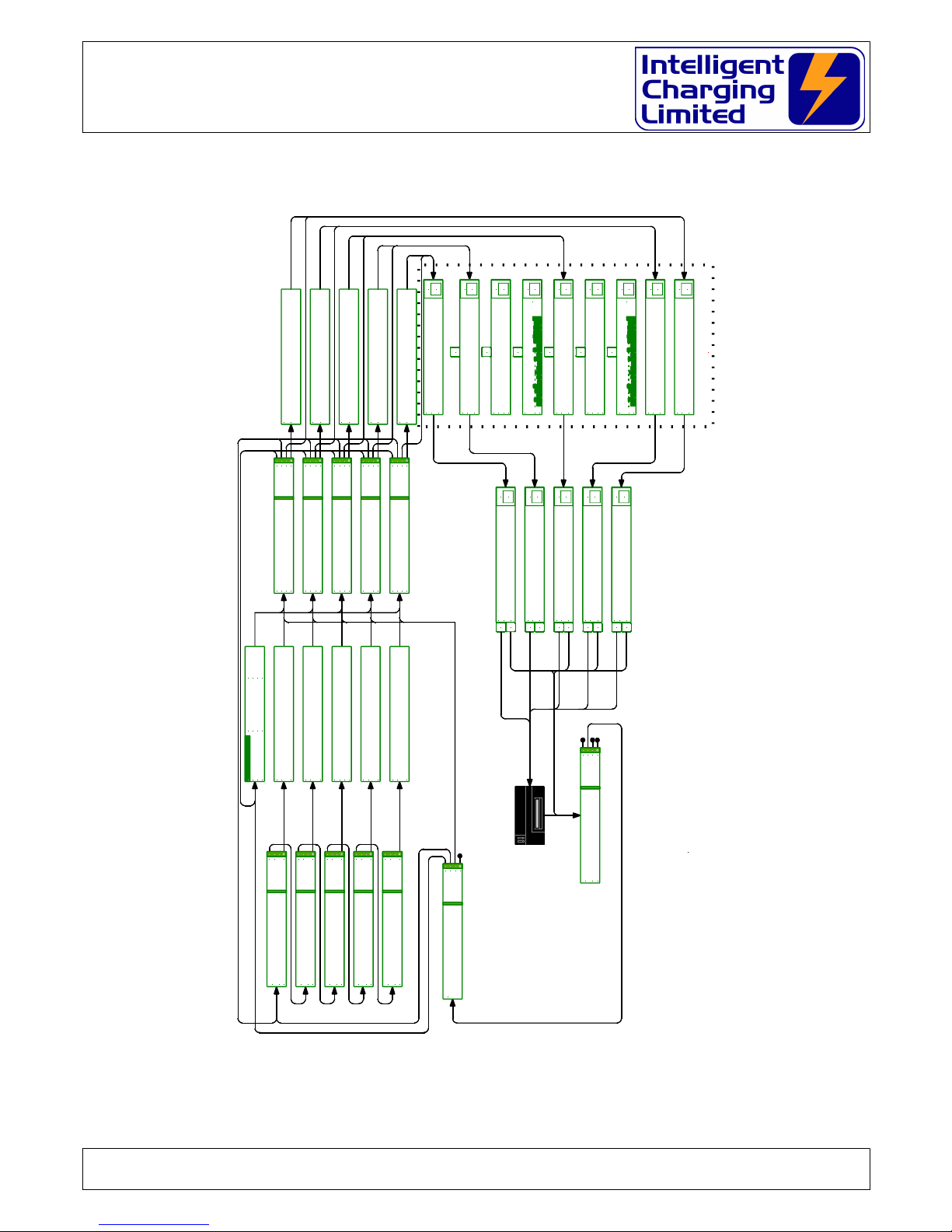

4.1 Main Menu

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 16 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

THE MAIN MENU

SETTINGS MENU

PRINT

SET CLOCK

SYSTEM

DISPLAY

ABC

DISCHARGE MENU

PREVIOUS

LIBRARY

MANUAL

PROCESS

ABC

CHARGE MENU

PREVIOUS

LIBRARY

MANUAL

PROCESS

ABC

26 Feb 2009 10:16 o CM TP

MB73P+ Bat 26.9V

** SERVICEABLE ** LIBRARY

CHARGE

DISCHARGE

SETTINGS

ABC

NO DATA

Move

CLR-Abort

ENT-Select

1 NO DATA 2 NO DATA

5 NO DATA

7 NO DATA 8 NO DATA

6 NO DATA

3 NO DATA 4 NO DATA

CM SHOWN WHEN CELL MONITOR IS CONNECTED

TP IS SHOWN WHEN TEMPERATURE PROBE IS CONNECTED

IC48V Battery Charger/Analyser

Operator Manual

4.2 Charging Menu

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 17 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

CHARGING IN PROGRESS

CHARGING OPERATIONS

A

ENT

CLR

ENT

CLR

ENT

CLR

ENT

CLR

C16..C20 1.35V 1.35V 1.35V 1.35V 1.35V

STOP

*

CLR

C 1..C 5 1.35V 1.35V 1.35V 1.35V 1.35V

C 6..C10 1.35V 1.35V 1.35V 1.35V 1.35V

C11..C15 1.35V 1.35V 1.35V 1.35V 1.35V

STOP

*

CLR

1.80

1.20

0.08

26.9V 0.0A

HIGH = 1.36V

LOW = 1.32V

C 01 = 1.32V

USE A/B TO CHARGE MODE

CHARGE MODE

CONSTANT VOLTAGE CHARGE

>> NEXT >>

<< PREV <<

ACCEPT

ABC

C

CHARGE MENU

PREVIOUS

LIBRARY

MANUAL

PROCESS

ABC

CHARGE MODE

CELL MONITOR CC CHARGE

>> NEXT >>

<< PREV <<

ACCEPT

ABC

USE A/B TO CHARGE MODE

CHARGE MODE

CONSTANT CURRENT CHARGE

>> NEXT >>

<< PREV <<

ACCEPT

ABC

USE A/B TO CHARGE MODE

USE A/B TO CHARGE MODE

CHARGE MODE

MULTI-STEP CHARGE

>> NEXT >>

<< PREV <<

ACCEPT

ABC

26 Feb 2009 10:16 o CM TP

MB73P+ Bat 26.9V

** SERVICEABLE ** LIBRARY

CHARGE

DISCHARGE

SETTINGS

ABC

NO DATA

éèêç Move

CLR-Abort

ENT-Select

1 NO DATA 2 NO DATA

5 NO DATA

7 NO DATA 8 NO DATA

6 NO DATA

3 NO DATA 4 NO DATA

Nominal Volts 12.0V Target Volts 13.8V

Min 0.0A Rise 0.0A Target Fail 5.0H

HELP LINE APPEARS HERE

Charge Amps 1.0A Charge Time 1.0H

TgFail 24.0H Ochg 1.65V CP 0m

Extra T 1.0H Extra Amps 0.5A

LIBRARY

MANUAL

TIMED

ABC

Target 1.55V Max Amps 1.0A

CELL MONITOR CC CHARGE 12.0V

STARTExtra Amps 0.5A For 1.0H Targ Fail 24.0H

Number If Cells 20 Cell Target Volts 1.55V

HELP LINE APPEARS HERE

Charge Amps 1.0A Overcharge Volts 1.65V

Cell Print 0H

Extra Amps 0.5A For 1.0H Targ Fail 24.0H

Nominal Volts 12.0V Target Volts 13.8V

HELP LINE APPEARS HERE

Charge Amps 1.0A Overcharge Volts 15.0V

TgFail 24.0H Overcharge 15.0V

Extra T 1.0H Extra Amps 0.5A

LIBRARY

MANUAL

TIMED

ABC

Target 13.8V Max Amps 1.0A

CONSTANT CURRENT CHARGE 12.0V

START

Overcharge Volts 15.0V

3: 1.0A 1.0H 4: 1.0A 1.0H

LIBRARY

MANUAL

TIMED

ABC

1: 1.0A 1.0H 2: 1.0A 1.0H

MULTI-STEP CHARGE 12.0V

START

Fail Tm 0.0H Amps Rise 0.0A

Run Tm 1.0H Min Amps 0.0A

LIBRARY

MANUAL

TIMED

ABC

Target 13.8V Max Amps 1.0A

CONSTANT VOLTAGE CHARGE 12.0V

START

T1.55V 1.0A + 1.0A 1.0H O1.65V F 5.0H

27.6V 0.5A 0h00m00

MANUAL 24.0V CELL MONITOR CC CHARGE

STOP

*

CLR

MANUAL 24.0V MULTI-STEP CHARGE

27.6V 0.5A 0h00m00

Step #1 1.0A For 1.0H Overchrg 13.2V

STOP

*

CLR

27.6V 0.5A 0h00m00

MANUAL 24.0V CONSTANT CURRENT CHARGE

T13.8V 1.0A + 1.0A 1.0H O13.2V F 5.0H

STOP

*

CLR

27.6V 0.5A 0h00m00

MANUAL 24.0V CONSTANT VOLTAGE CHARGE

T 13.8V 1.0A 1.0H M0.0A R0.0AF 5.0H

STOP

*

CLR

PRNT

#

ENT

27.6V 0.5A 0h00m00

MANUAL 24.0V STOPPED BY OPERATOR

T1.55V 1.0A + 1.0A 1.0H O1.65V F 5.0H

PRNT

#

ENT

MANUAL 24.0V STOPPED BY OPERATOR

27.6V 0.5A 0h00m00

Step #1 1.0A For 1.0H Overchrg 13.2V

PRNT

#

ENT

27.6V 0.5A 0h00m00

MANUAL 24.0V STOPPED BY OPERATOR

T13.8V 1.0A + 1.0A 1.0H O13.2V F 5.0H

PRNT

#

ENT

27.6V 0.5A 0h00m00

MANUAL 24.0V STOPPED BY OPERATOR

T 13.8V 1.0A 1.0H M0.0A R0.0AF 5.0H

Overcharge Volts 15.0V

Nominal Volts 12.0V Charge Step #4

HELP LINE APPEARS HERE

Charge Amps 1.0A Charge Time 1.0H

B

Delay Before CM CC CHARGE : 0.0H

Enter Delayed Start In Hours

Delay Before MS CHARGE : 0.0H

Enter Delayed Start In Hours

Delay Before CC CHARGE : 0.0H

Enter Delayed Start In Hours

Delay Before CV CHARGE : 0.0H

Enter Delayed Start In Hours

IC48V Battery Charger/Analyser

Operator Manual

4.3 Capacity Testing Menu

Doc: DWG1060-12-R3 IC48V Operators manual.odt Page 18 of 58 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 14/06/17

CAPACITY TEST IN PROGRESS

CAPACITY TESTING OPERATIONS

A

B

C

27.6V 0.5A 0h 0m 0

MANUAL 24.0V FULL DISCHARGE

Alarm 3.0V Amp 1.0A Tim 1.0H > 0.98H

STOP

*

CLR

27.6V 0.5A 0h 0m 0

MANUAL 24.0V AUTOMATIC CELL BALANCE

Balanced 0 Amp 1.0A Tim 1.0H > 0.98H

STOP

*

CLR

27.6V 0.5A 0h 0m 0

MANUAL 24.0V CAPACITY TEST CELL MON

Targ 1.00V Amp 1.0A Tim 1.0H > 0.98H

STOP

*

CLR

27.6V 0.5A 0h 0m 0

MANUAL 24.0V CAPACITY TEST TO 100%

Targ 1.0V Amp 1.0A Tim 1.0H > 0.98H

STOP

*

CLR

27.6V 0.5A 0h 0m 0

MANUAL 24.0V CAPACITY TEST TO TARGET

Targ 1.0V Amp 1.0A Tim 1.0H > 0.98H

STOP

*

CLR

A

B

C

ENT

CLR

ENT

CLR

ENT

CLR

ENT

CLR

ENT

CLR

DISCHARGE MODE

FULL DISCHARGE

>> NEXT >>

<< PREV <<

ACCEPT

ABC

USE A/B TO CHARGE MODE

27.6V 0.5A 0h 0m 0

MANUAL 24.0V CAPACITY TEST TO 100%

Targ 1.0V Amp 1.0A Tim 1.0H > 0.98H

STOP

*

CLR

27.6V 0.5A 0h 0m 0

MANUAL 24.0V CAPACITY TEST TO TARGET

Targ 1.0V Amp 1.0A Tim 1.0H > 0.98H

STOP

*

CLR

STOP

*

CLR

1.80

1.20

0.08

26.9V 0.0A

HIGH = 1.36V

LOW = 1.32V

C 01 = 1.32V

STOP

*

CLR

1.. 5 1.35V 1.35V 1.35V 1.35V 1.35V

6..10 1.35V 1.35V 1.35V 1.35V 1.35V

11..15 1.35V 1.35V 1.35V 1.35V 1.35V

16..20 1.35V 1.35V 1.35V 1.35V 1.35V

27.6V 0.5A 0h 0m 0

MANUAL 24.0V CAPACITY TEST CELL MON

Targ 1.00V Amp 1.0A Tim 1.0H > 0.98H

STOP

*

CLR

STOP

*

CLR

1.80

1.20

0.08

26.9V 0.0A

HIGH = 1.36V

LOW = 1.32V

C 01 = 1.32V

STOP

*

CLR

1.. 5 1.35V 1.35V 1.35V 1.35V 1.35V

6..10 1.35V 1.35V 1.35V 1.35V 1.35V

11..15 1.35V 1.35V 1.35V 1.35V 1.35V

16..20 1.35V 1.35V 1.35V 1.35V 1.35V

27.6V 0.5A 0h 0m 0

MANUAL 24.0V AUTOMATIC CELL BALANCE

Balanced 0 Amp 1.0A Tim 1.0H > 0.98H

STOP

*

CLR

27.6V 0.5A 0h 0m 0

MANUAL 24.0V FULL DISCHARGE

Alarm 3.0V Amp 1.0A Tim 1.0H > 0.98H

STOP

*

CLR

Delay Before FULL DISCHRG : 0.0H

Enter Delayed Start In Hours

Delay Before CELL BALANCE : 0.0H

Enter Delayed Start In Hours

Delay Before CELL CAPTEST : 0.0H

Enter Delayed Start In Hours

Delay Before CAPTEST TARG : 0.0H

Enter Delayed Start In Hours

Delay Before CAPTEST 100% : 0.0H

Enter Delayed Start In Hours

Discharge Time 1.0H

Discharge Amps 1.0A

LIBRARY

MANUAL

TIMED

ABC

Alarm Volts 3.0V

FULL DISCHARGE 24.0V

START

LIBRARY

MANUAL

TIMED

ABC

AUTOMATIC CELL BALANCE 12.0V

START

Discharge Time 1.0H

Discharge Amps 1.0A

LIBRARY

MANUAL

TIMED

ABC

Cell Target Volts 1.00V

CAPACITY TEST CELL MON 12.0V

START

Discharge Time 1.0H CP 0M

Discharge Amps 1.0A

LIBRARY

MANUAL

TIMED

ABC

Target Volts 10.0V

CAPACITY TEST TO TARGET 12.0V

START

Discharge Time 1.0H

Discharge Amps 1.0A

LIBRARY

MANUAL

TIMED

ABC

Target Volts 10.0V

CAPACITY TEST TO 100% 12.0V

START

Discharge Time 1.0H

Discharge Amps 1.0A

Nominal Volts 12.0V Alarm Volts 3.0V

HELP LINE APPEARS HERE

Discharge Amps 1.0A Test Time 1.0H

HELP LINE APPEARS HERE

Number Of Cells 20

Discharge Amps 1.0A Test Time 1.0H

Number Of Cells 20 Cell Target Volts 1.00V

HELP LINE APPEARS HERE

Cell Print Interval 0M

Discharge Amps 1.0A Test Time 1.0H

Nominal Volts 12.0V Target Volts 10.0V

HELP LINE APPEARS HERE

Discharge Amps 1.0A Test Time 1.0H

HELP LINE APPEARS HERE

Nominal Volts 12.0V Target Volts 10.0V

Discharge Amps 1.0A Test Time 1.0H

NO DATA

éèêç Move

CLR-Abort

ENT-Select

1 NO DATA 2 NO DATA

5 NO DATA

7 NO DATA 8 NO DATA

6 NO DATA

3 NO DATA 4 NO DATA

DISCHARGE MENU

PREVIOUS

LIBRARY

MANUAL

PROCESS

ABC

DISCHARGE MODE

AUTOMATIC CELL BALANCE

>> NEXT >>

<< PREV <<

ACCEPT

ABC

USE A/B TO CHARGE MODE

DISCHARGE MODE

CAPACITY TEST CELL MON

>> NEXT >>

<< PREV <<

ACCEPT

ABC

USE A/B TO CHARGE MODE

26 Feb 2009 10:16 o CM TP

MB73P+ Bat 26.9V

** SERVICEABLE ** LIBRARY

CHARGE

DISCHARGE

SETTINGS

ABC

DISCHARGE MODE

CAPACITY TEST TO 100%

>> NEXT >>

<< PREV <<

ACCEPT

ABC

USE A/B TO CHARGE MODE

DISCHARGE MODE

CAPACITY TEST TO TARGET

>> NEXT >>

<< PREV <<

ACCEPT

ABC

USE A/B TO CHARGE MODE

Loading...

Loading...