TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 1 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

DANGER

Disconnect the

mains supply before

removing this cover

MEM

Bxx

ON

OFFIO

MEM

Bxx

ON

OFFIO

MEM

Bxx

ON

OFFIO

MEM

Bxx

ON

OFFIO

VOLTS TIME

AMPS

TEST

END ONE

VOLTSTIME

AMPS

TEST

END

%

%

ALARM

POWER SWITCH

POWER SWITCHPOWER SWITCH

POWER SWITCH

KEEP AIRFLOW C LEAR

KEEP AIRFLOW C LEARKEEP AIRFLOW C LEAR

KEEP AIRFLOW C LEAR

10cm

10cm10cm

10cm

KEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEARKEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEAR

10cm

10cm10cm

10cm

EXTD

ENTR

DISP DATA

A SET PROC

V SETCHRG BATT

TEST ONE T SET

START

STOP MUTE

EXTD

ENTR

DISP DATA

A SET PROC

V SETCHRG BATT

TEST T SET

START

STOP

TS25 MKII

TS25-BAS1-KIT

TS25-BAS1-CAN-240

Battery Charger/Analyser

Operators Manual

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

TABLE OF CONTENTS

1 MANUAL REVISION HISTORY 4

2 TS25 MKII DESCRIPTION 5

3 CONTROLS AND INDICATORS 7

3.1 DISPLAY 8

3.2 POWER SWITCH 9

3.3 AUDIBLE ALARM 9

3.4 CHARGE & CAPACITY TEST CIRCUIT BREAKERS 9

3.5 BATTERY CONNECTORS 9

3.6 KEYBOARD 10

4 USING THE TS25 MKII 11

4.1 CONNECTING BATTERIES 11

4.2 CAPACITY TESTING BATTERIES 14

4.3 CHARGING BATTERIES 17

4.4 ENTERING BATTERY DATA 20

4.5 USING THE ONE MODE OF OPERATION 22

4.6 RESETTING THE TS25 MKII 22

4.7 DISPLAY MNEMONICS 24

4.8 ERROR CODES 25

5 CALIBRATION 27

5.1 EQUIPMENT REQUIRED 27

5.2 PERFORMANCE CHECKING 27

5.3 RE-CALIBRATION 28

5.4 CALIBRATION PROBLEMS 29

5.5 CALIBRATION EQUIPMENT CONNECTIONS 30

6 ROUTINE MAINTENANCE 31

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 2 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

6.1 INTERNAL BATTERY REPLACEMENT 31

7 BATTERY LIBRARY 32

7.1 RETRIEVING A LIBRARY ITEM 32

7.2 ENTERING OR MODIFYING A LIBRARY ENTRY 32

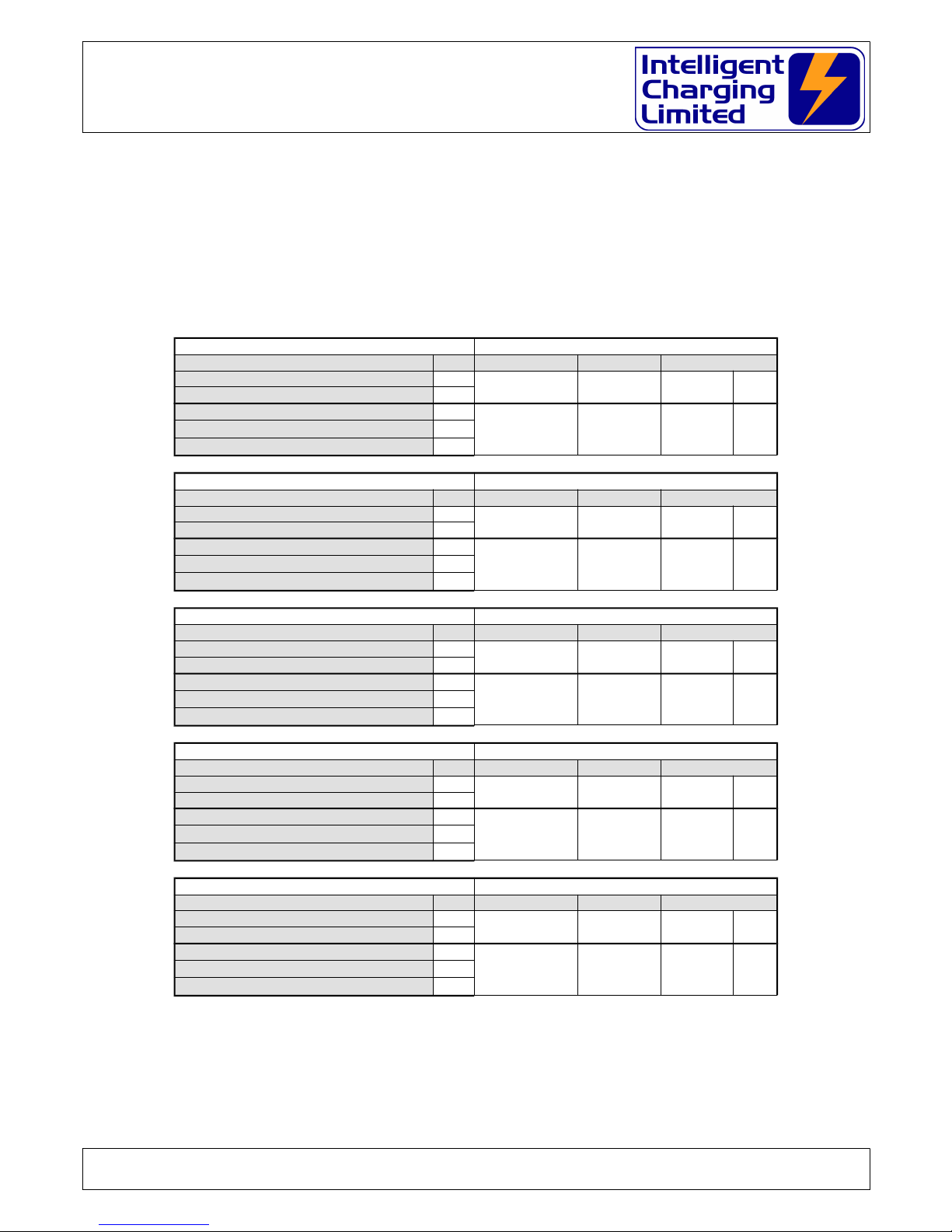

8 DEFAULT BATTERY LIBRARY 33

9 SPECIFICATIONS 43

10 PRODUCT DISPOSAL INSTRUCTIONS 44

11 PRODUCT WARRANTY 45

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 3 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

1 Manual Revision History

Rev Date Description

0 08-03-2007 FIRST WRITTEN

1 01-11-2007 Detail Changes

2 26-02-2008 Added calibration procedures and maintenance.

3 05-03-2008 Added battery connection diagrams

4 11-03-2008 Added Controls & Indicators Section

5 11-05-2008 Added Enersys batteries 9750D0740 & 0744 to library. More error fault codes

added.

6 13-06-2008 Added new error code where if current fails to be driven then warning 14 occurs.

7 19-06-2008 Added text about warning 15 for detection of battery voltage greater than target

while constant voltage charging.

8 25-06-2008 Changed library entry 61 to correct part No.

9 02-07-2008 Added comment on suitability of capacity test parameters for Enersys 9750-0744

Battery

10 12-08-2008 Corrected position of CHRG & TEST on keypad legend.

11 26-01-2009 Added Enersys 9750D0730 to built in library

12 30-09-2014 Corrected annotation on keypad diagram CHRG and TEST reversed.

13 21-11-2014 Reworded the data entry paragraphs in section 4.4 to make clearer.

14 20-01-2015 Graphic images of TS25 amended as they show CHRG & TEST reversed.

15 21-07-2015 Formatting changes.

16 23-09-2015 Corrected use of “efficiency” where should read “capacity”. Corrected resolution for

capacity test time.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 4 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

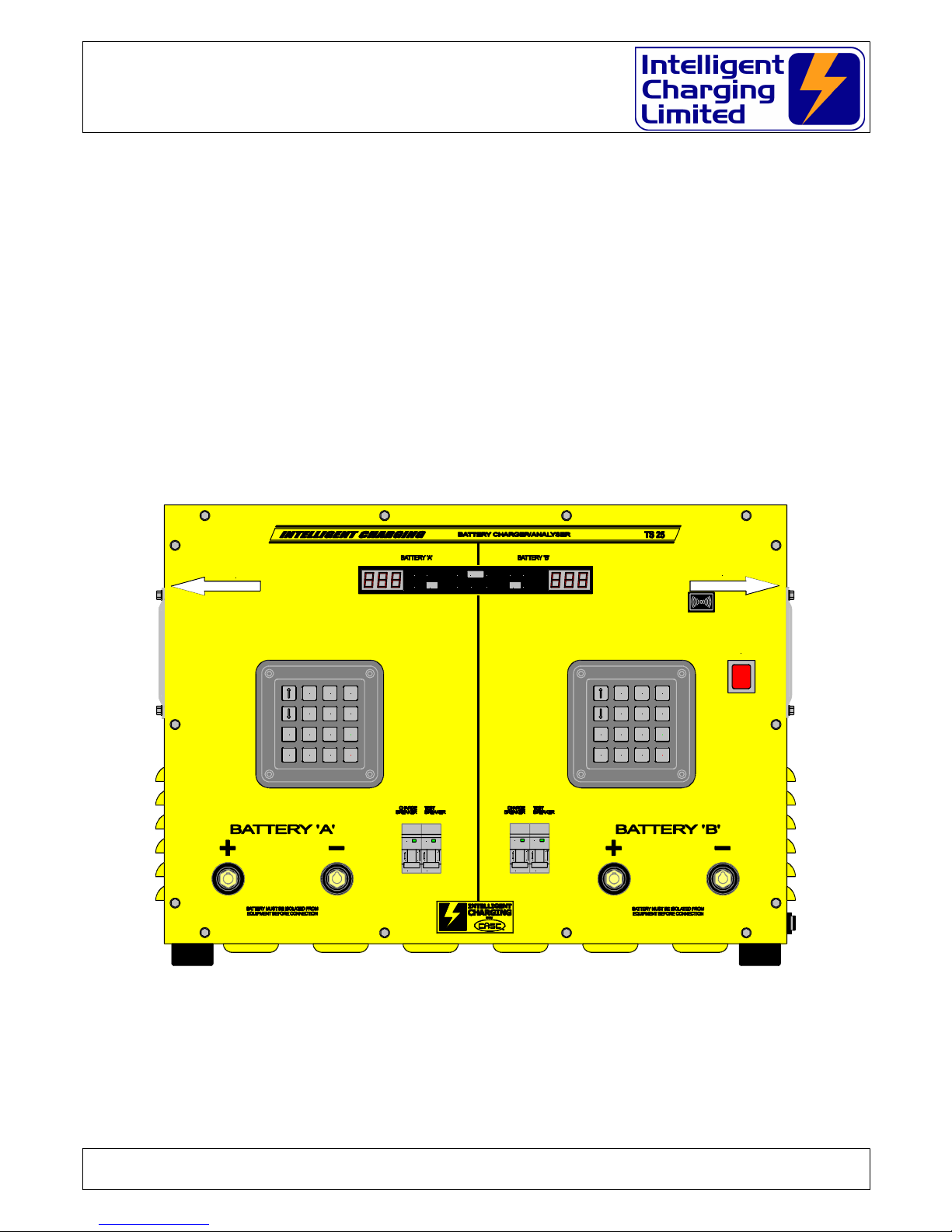

2 TS25 MKII DESCRIPTION

The TS25 MKII Dual Channel Battery Charger / Analyser is an electronically controlled

combined universal battery charging unit with built in battery analysing capabilities. It is

housed in a heavy-duty metal enclosure designed to free stand on a workbench. As it is

supplied it is configured for use from a standard 240V 50/60Hz supply.

Equipment control is via an interactive numeric display and led state indicators. Data entry is

via two 16-key keypads. Each channel displayed data and data entry is independent of the

status of the other channel. So new processes can be set up even when the other channel is

in the middle of a charge or capacity test.

Battery data is stored internally in the unit in battery-backed memory. A list of commonly

used batteries is included along with the accepted charging and testing data. The operator

can extend or modify this list by entering the details of the battery to be included on the

display and keyboard. The battery library data can be restored to the defaults by a special

key sequence permitted via the keyboard.

Batteries are connected to the front of the unit by means of two individual heavy duty

connectors. Connection to the battery has to be made via the appropriate connectors for

that battery. Contact Intelligent-Charging for special lead sets made to order.

The TS25 MKII has extended operating capabilities compared to its predecessor the TS25.

Maximum charge current has been increased to 12A per channel, and capacity testing still

remains at 25A per channel.

The TS25 MKII still has paralleling mode where using a common paired cable both channels

can be run in parallel to provide a charge capability of 24A and a capacity test capability of

50A.

There are two capacity test programs built into the unit and these can be selected via the

configuration menu and capacity testing can be performed such that it will stop testing when

a battery reached 100% or less, or alternately can carry on capacity testing until the battery

reached the set termination threshold and thus reporting the actual battery capacity greater

than 100%.

There are three charging modes built into the unit, for Lead Acid (Pb) constant voltage

charging can be performed for a fixed period of time and for Nickel Cadmium (NiCd)

constant current charging can be performed with termination on time and over voltage

parameters, and also for Nickel Cadmium batteries a new charge mode which allows a

constant current charge to be performed up until a voltage set point, where the charge will

then continue charging until the additional time specified has passed.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 5 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

The TS25 MKII contains the ability that will allow it to be calibrated by the end user. The

equipment needed is a good 24V battery, an ammeter capable of reading up to 25A (or a

shunt and milli-voltmeter combination) and a voltmeter capable of reading up to 30V. The

re-calibration process only takes a few minutes and this is done without the need to access

the interior of the TS25 MKII.

The TS25 MKII no longer supports deep discharge recovery mode. It is thought that if a

battery requires this level of charge to "recover" it then the battery is not fit for use anyway

and should be disposed of for re-cycling.

The TS25 MKII contains two hi flow rate fans to extract the heat energy generated internally

when running in capacity test mode.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 6 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

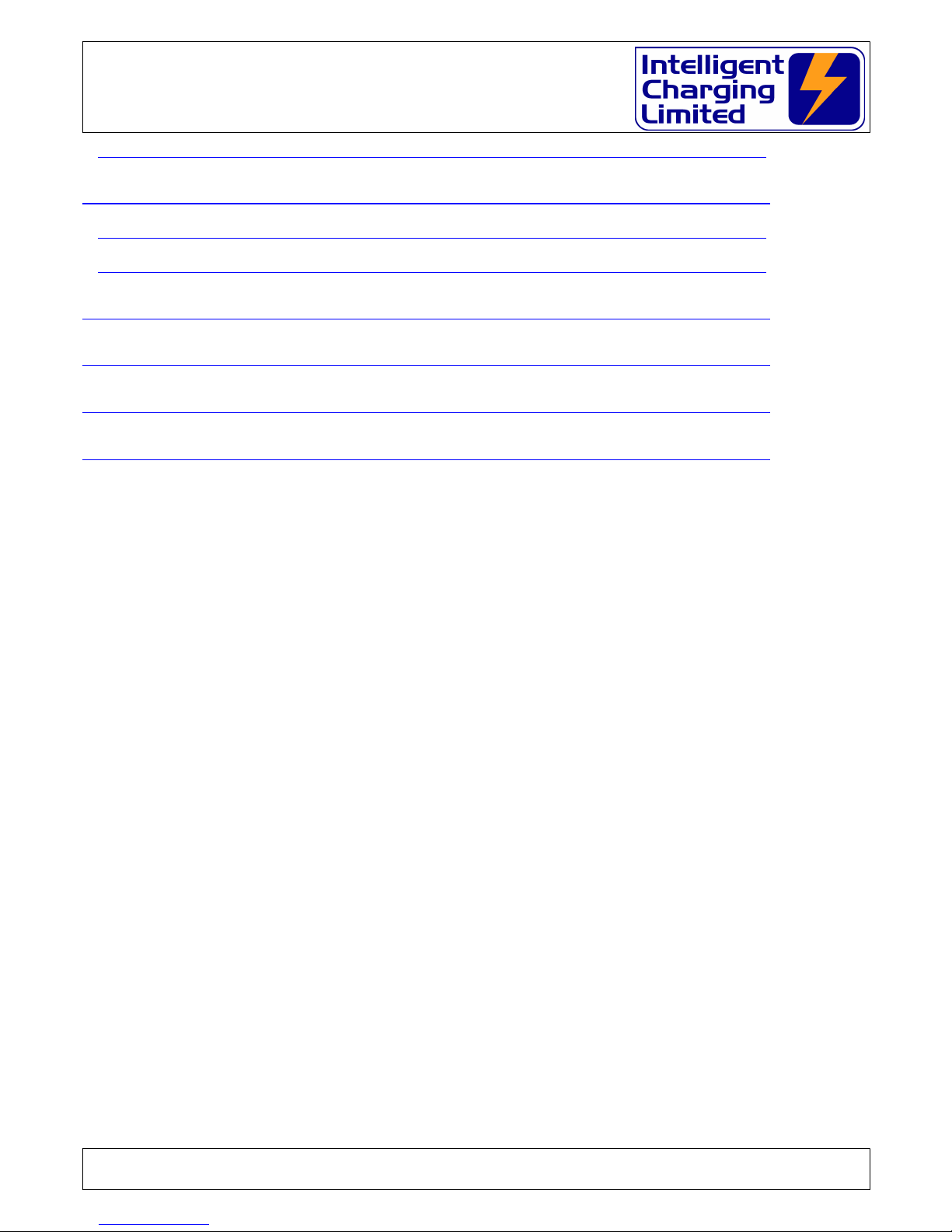

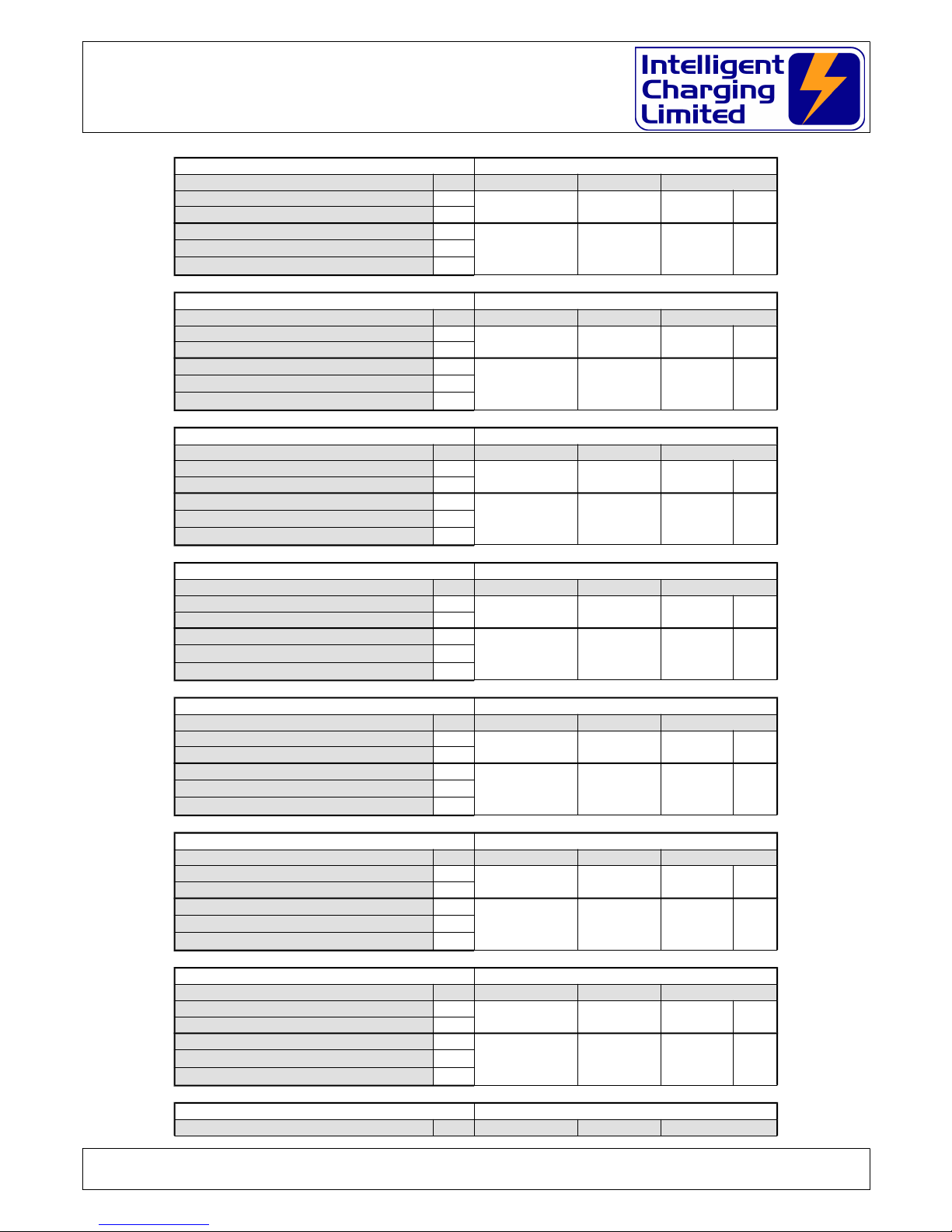

3 CONTROLS AND INDICATORS

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 7 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

A CHANNEL DISPLAY B CHANNEL DISPLAY

AUDIBLE ALARM

POWER SWITCH

AC POWER FUSE & INLET

B CHANNEL DATA

ENTRY KEYPAD

A CHANNEL DATA

ENTRY KEYPAD

CHANNEL A POSITIVE

BATTERY LEAD CONNECTOR

CHANNEL A NEGATIVE

BATTERY LEAD CONNECTOR

CHANNEL B NEGATIVE

BATTERY LEAD CONNECTOR

CHANNEL B POSITIVE

BATTERY LEAD CONNECTOR

CHANNEL A CHARGE SAFETY BREAKER

CHANNEL A CAPACITY TEST SAFETY CIRCUIT BREAKER

CHANNEL B CAPACITY TEST SAFETY CIRCUIT BREAKER

CHANNEL A CHARGE SAFETY CIRCUIT BREAKER

DANGER

Disconnect the

mains supply before

removing this cover

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

VOLTS TIME

AMPS

TEST

END ONE

VOLTSTIME

AMPS

TEST

END

%

%

ALARM

POWER SWITCH

POWER SWITCH

POWER SWITCH

POWER SWITCH

KEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEAR

10cm

10cm

10cm

10cm

KEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEAR

10cm

10cm

10cm

10cm

EXTD

ENTR

DISP DATA

A SET PROC

V SETCHRG BATT

TEST ONE T SET

START

STOP MUTE

EXTD

ENTR

DISP DATA

A SET PROC

V SETCHRG BATT

TEST T SET

START

STOP

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

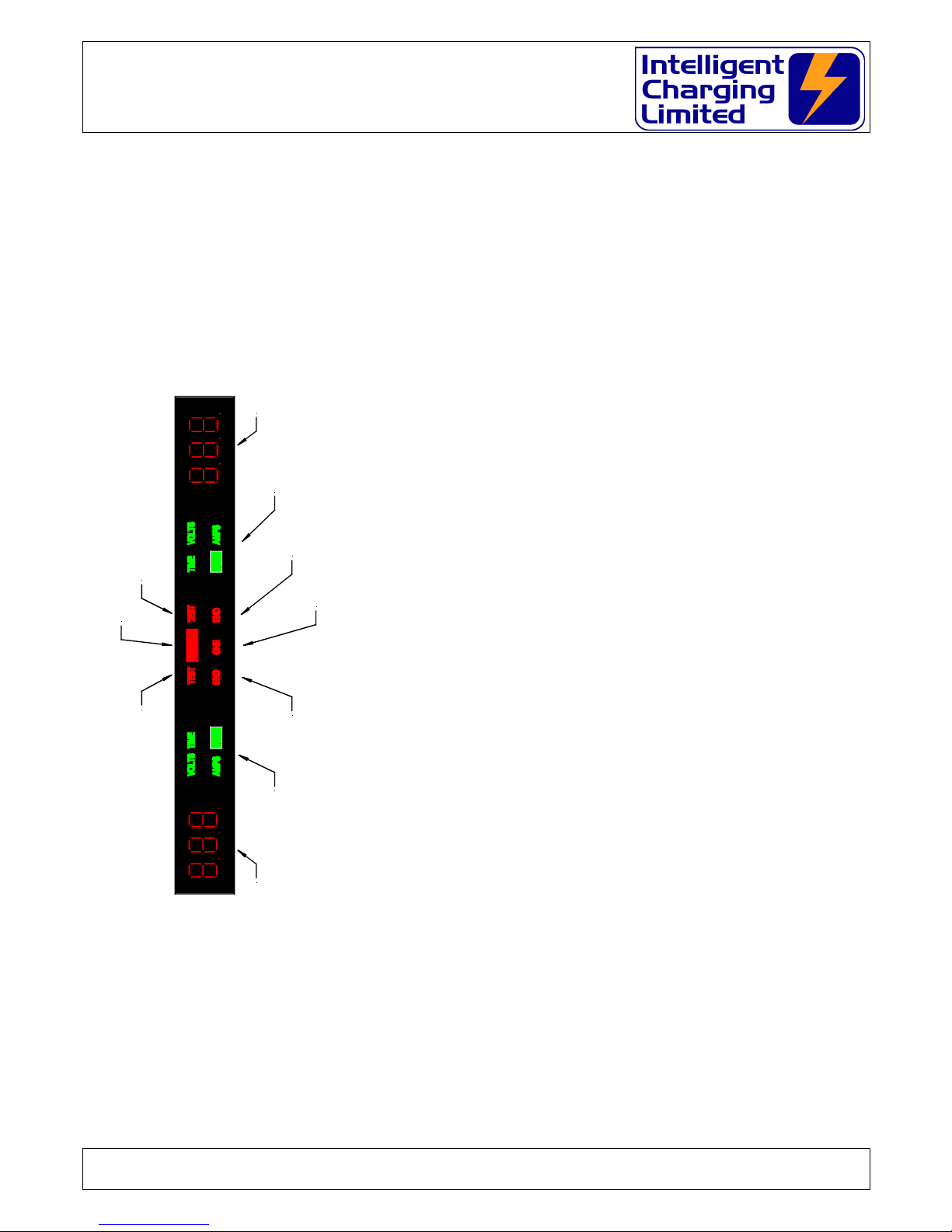

3.1 DISPLAY

• NUMERIC DISPLAY

o Voltage is displayed in volts to a resolution of 0.1V

o Current is displayed in Amperes to a resolution of

0.1A

o Capacity test time is displayed in minutes to a

resolution of 1 minute.

o Charge time is displayed in Hours to a resolution of

0.1H (One tenth). Capacity test time is displayed in

Minutes to a resolution of 1 Minute.

o Battery capacity is displayed in percent to a

resolution of 1%.

• NUMERIC DISPLAY INDICATORS

o VOLTS illuminated means voltage is being displayed

or entered.

o AMPS illuminated means current is being displayed

or entered.

o TIME illuminated means time is being displayed or

entered.

o % Illuminated means that battery capacity is being

displayed.

o TEST illuminated means that the unit is set to

capacity test mode otherwise it is set to charge

mode.

o END illuminated means that the unit is stopped.

o ALARM illuminated means that the unit has just

stopped and the alarm has sounded.

o ONE illuminated means that ONE mode has been

selected and the paralleling leads must be used.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 8 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

%

%

ALARM

CHANNEL A NUMERIC DISPLAY CHANNLE B NUMERIC DISPLAY

CHANNEL A NUMERIC DISPLAY MODE INDICATOR CHANNEL B NUMERIC DISPLAY MODE INDICATOR

ILLUMINATED IF CAPTEST SELECTED ILLUMINATED IF CHANNEL B CAPTEST MODE IS SELECTED

ILLUMINATED IF THE CHARGER ALARM HAS SOUNDED

ILLUMINATED IF CHANNEL A IS STOPPED ILLUMINATED IF CHANNEL B IS STOPPED

ILLUMINATED IF THE "ONE" MODE OF OPERATION IS SELECTED

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

3.2 POWER SWITCH

Operation of this switch will either apply or remove the ac inlet power from the TS25

MKII

WARNING

AVOID REMOVING THE POWER FROM THE UNIT WHILE THE UNIT IS

PERFORMING A CAPACITY TEST OR CHARGE.

3.3 AUDIBLE ALARM

When a charge or capacity test has completed or stopped in error the audible alarm

will sound until the MUTE or STOP key is pressed.

3.4 CHARGE & CAPACITY TEST CIRCUIT BREAKERS

The circuit breakers are fitted to prevent high currents from being driven into the

battery or into the unit should a fault condition occur. Always ensure that the circuit

breaker is in the ON position before starting a charge or capacity test.

WARNING

NEVER SWITCH THE CIRCUIT BREAK TO ON WHEN THE UNIT IS PERFORMING

A CHARGE OR CAPACITY TEST AS SEVERE DAMAGE MAY OCCUR TO THE

BATTERY OR THE TS25 MKII

ALWAYS PRESS STOP FIRST

If the circuit breaker operates during a charge immediately press STOP on BOTH

charger channels and remove power from the unit and disconnect the battery.

Operation of the circuit breaker is an indication of a fault and the unit will need to be

checked before use.

3.5 BATTERY CONNECTORS

The battery terminal are where the supplied leads are connected to the TS25 MKII. It

is recommended that replacement leads are always purchased from Intelligent

Charging.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 9 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

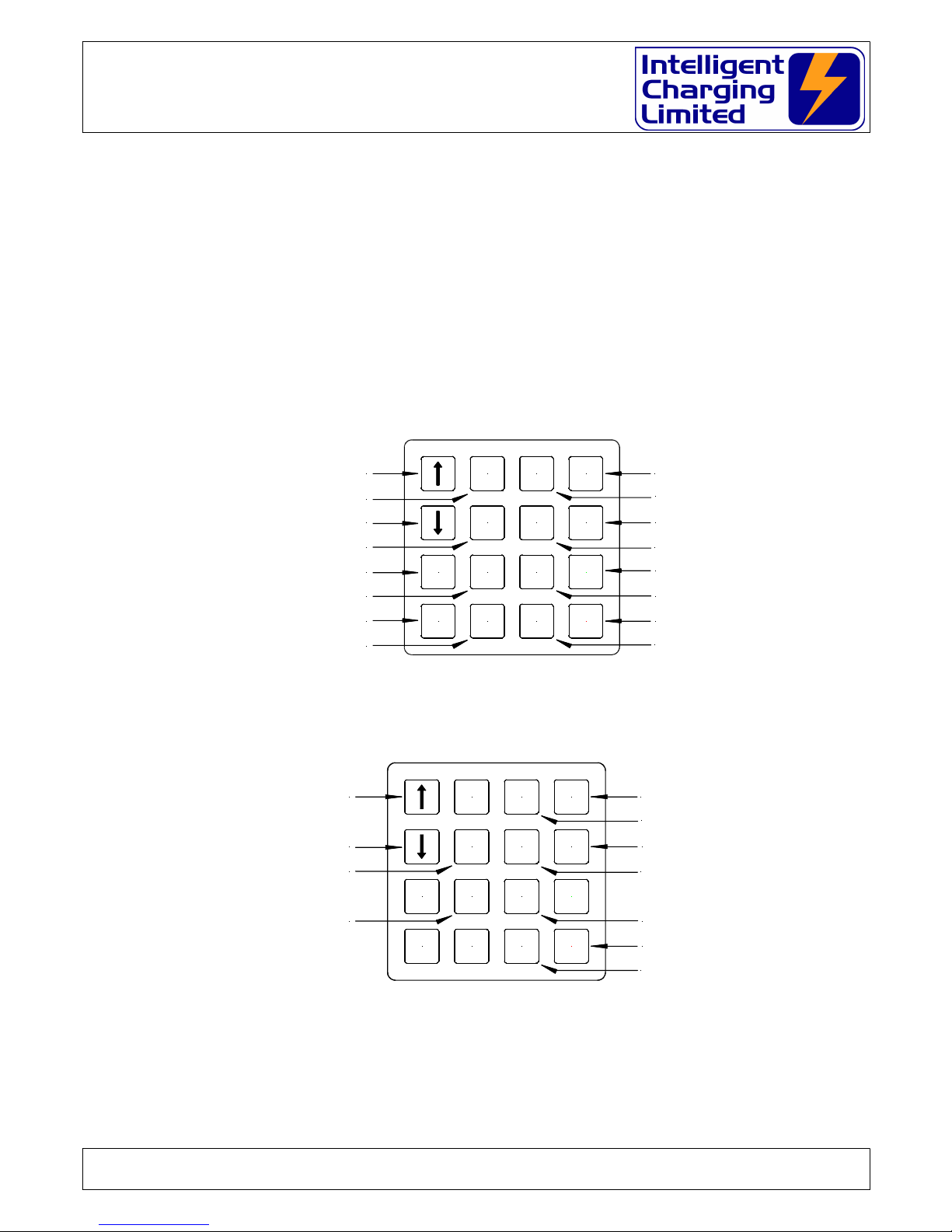

3.6 KEYBOARD

Each keypad on the unit controls only information for that channel, except when the

unit is put into ONE mode both keypads control the ONE mode of operation. The only

difference is that if a data entry function is invoked in the channel B keypad the data

entry will always have to be performed on the right hand keypad. There are 16 keys

on each keypad and each key performs a particular function depending if the channel

is running or stopped.

3.6.1 STOPPED KEY MAPPING

3.6.2 RUNNING KEY MAPPING

Increases Display Brighness

Reduces Display Brightness

2 X To Initiate CALIBRATION

Briefly Displays Battery Number

Cycles Through Displayed Data

Briefly Displays Battery Data

Breifly Displays The Battery AMPS

Breifly Displays The Battery VOLTS

Briefly Displays The Battery TIME

Manually STOPS The CHARGE/CAPACITY TEST

Breifly Displays The Battery MODE

EXTD

ENTR

DISP DATA

A SET PROC

V SETCHRG BATT

TEST ONE T SET

START

STOP

Note keys that have no comments against them do nothing while RUNNING

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 10 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

Increases Display Brighness

Reduces Display Brightness

Selects CAPACITY TEST MODE

Selects CHARGE MODE

2 X To Save Battery Data Into The LIBRARY

Selects A Battery From The LIBRARY

2 X Reset Parameters In The Unit

Cycles Through Displayed Data

Briefly Displays Battery Data

Enters The Battery AMPS

Enters The Battery VOLTS

Enters The Battery TIME

Starts CHARGE/CAPACITY TEST

Clears The Display And Alarm

On CHANNEL A (ONE) Selects ONE Mode

On CHANNEL B (MUTE) Stops The Audible Alarm

Enters The Battery MODE

EXTD

ENTR

DISP DATA

A SET PROC

V SETCHRG BATT

TEST ONE T SET

START

STOP

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

4 USING THE TS25 MKII

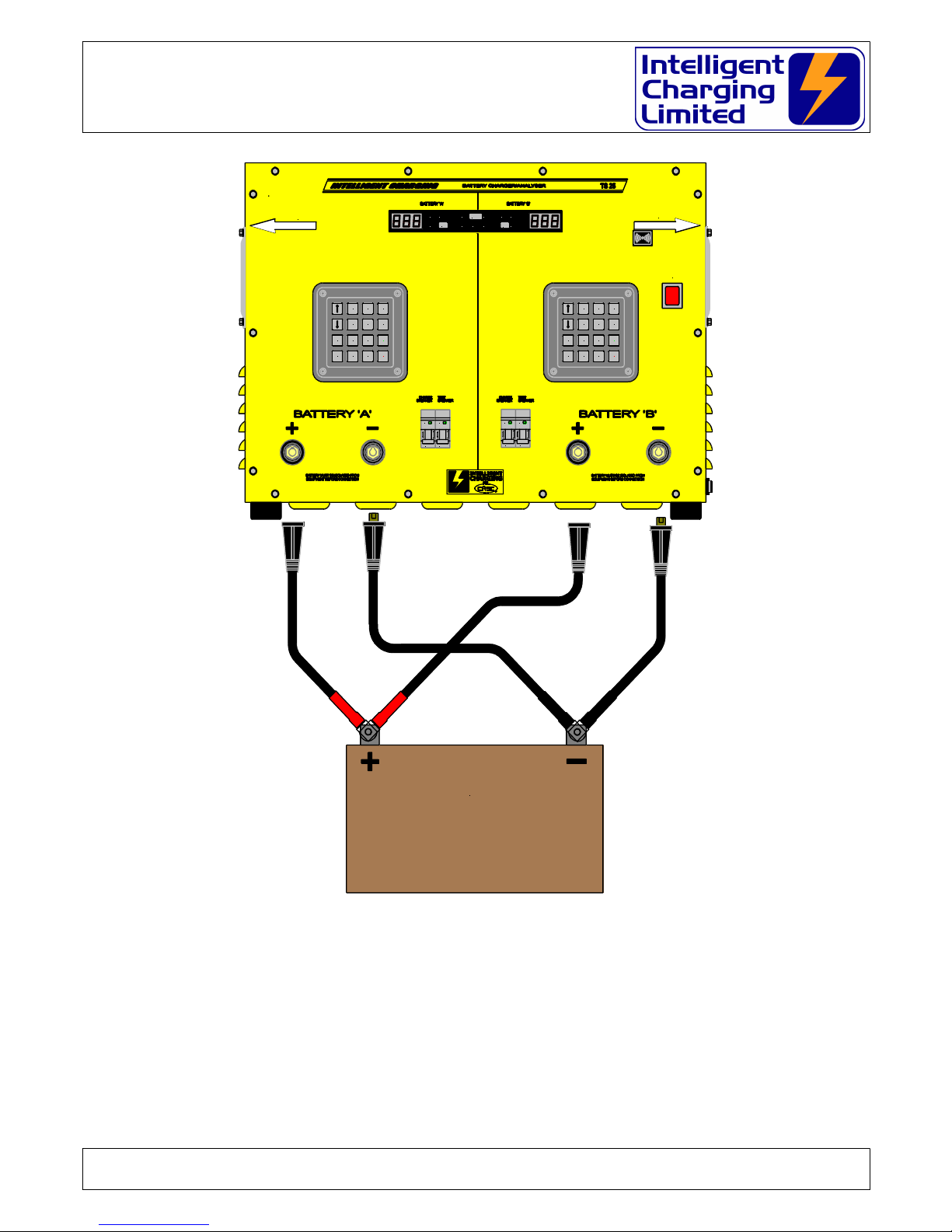

4.1 CONNECTING BATTERIES

For all methods of use of the battery charger the battery to be tested or charged must

only be connected when the charger is either:

SWITCHED OFF

or

SWITCHED ON AND END LAMP ILLUMINATED

Connecting a battery while the charge is operational would damage the equipment,

and possible draw an electrical arc that, may cause an explosion from the venting

gases being emitted from the battery.

Care must also be executed in ensuring that the bared ends of the battery leads do

not come in contact with the metalwork of the charger as this may also cause

electrical arcing and or explosion risk.

WARNING

THE BATTERY SHOULD NEVER BE CONNECTED OR DISCONNECTED FROM THE

UNIT WHEN A CHARGE OR TEST IS IN PROGRESS AS ARCING CAN OCCUR

CAUSING AN EXPLOSION FROM GASSES VENTING FROM BATTERIES BEING

PROCESSED

THE BATTERY SHOULD ALWAYS BE ISOLATED FROM ANY EQUIPMENT

BEFORE BEING CONNECTED

Stray ground loops between the attached equipment and the TS25 MKII could cause

catastrophic damage to the unit and the attached equipment.

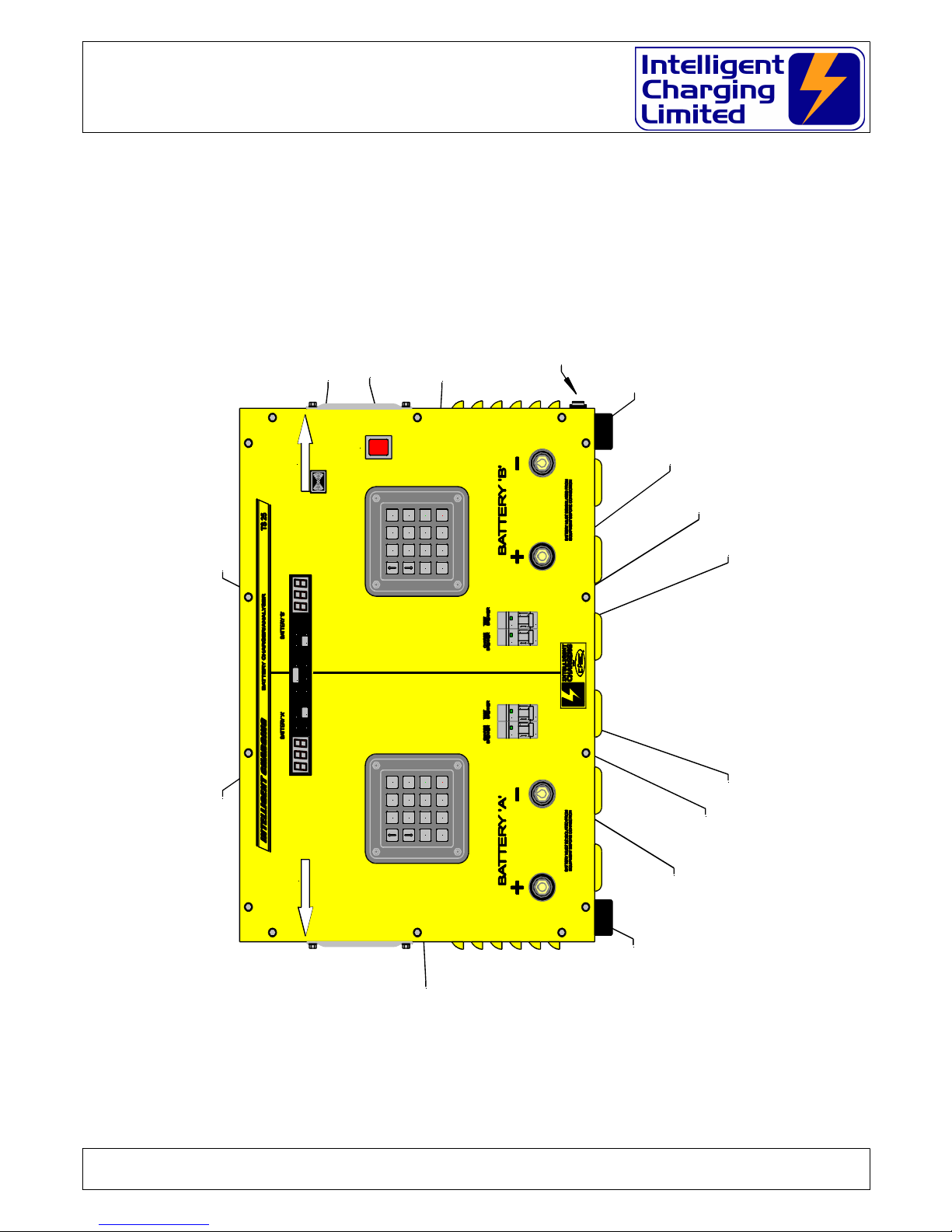

The battery or batteries must be connected to the TS25 MKII as shown in the

following diagram: -

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 11 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

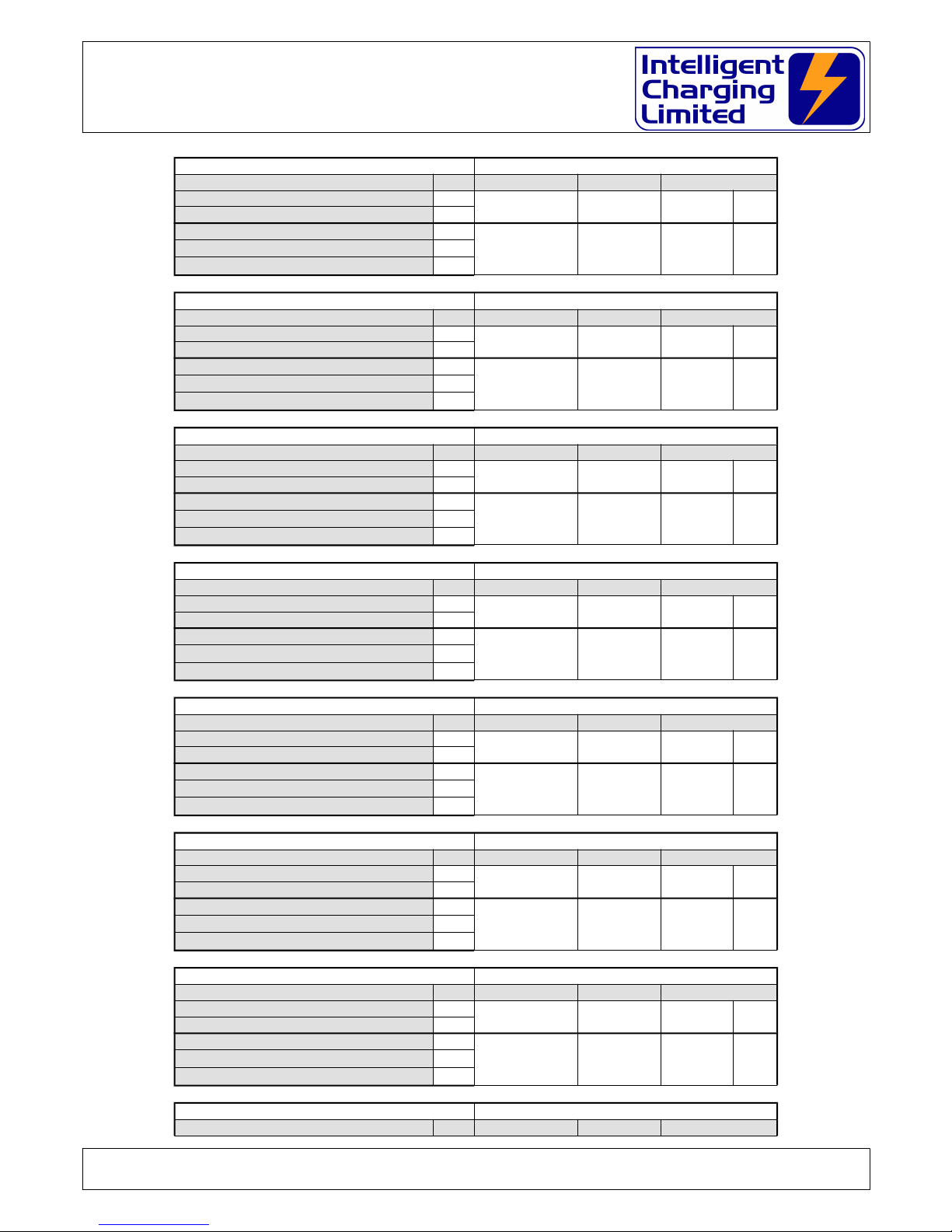

SINGLE OR TWIN CHANNEL BATTERY CONNECTION

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 12 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

AVIATION BATTERY

AVIATION BATTERY

BATTERY #1

BATTERY #2

DANGER

Disconnect the

mains supply before

removing this cover

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

VOLTS TIME

AMPS

TEST

END ONE

VOLTSTIME

AMPS

TEST

END

%

%

ALARM

POWER SWIT CH

POWER SWIT CH

POWER SWIT CH

POWER SWIT CH

KEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEAR

10cm

10cm

10cm

10cm

KEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEAR

10cm

10cm

10cm

10cm

EXTD

ENTR

DISP DATA

A SET PROC

V SETCHRG BATT

TEST ONE T SET

START

STOP MUTE

EXTD

ENTR

DISP DATA

A SET PROC

V SETCHRG BATT

TEST T SET

START

STOP

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

BATTERY CONNECTION WHEN USING “ONE” MODE OF OPERATION

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 13 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

AVIATION BATTERY

DANGER

Disconnect the

mains supply before

removing this cover

MEM

Bxx

ON

OFFIO

MEM

Bxx

ON

OFFIO

MEM

Bxx

ON

OFFIO

MEM

Bxx

ON

OFFIO

VOLTS TIME

AMPS

TEST

END ONE

VOLTSTIME

AMPS

TEST

END

%

%

ALARM

POWER SWITCH

POWER SWITCHPOWER SWITCH

POWER SWITCH

KEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEARKEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEAR

10cm

10cm10cm

10cm

KEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEARKEEP AIRFLOW CLEAR

KEEP AIRFLOW CLEAR

10cm

10cm10cm

10cm

EXTD

ENTR

DISP DATA

A SET PROC

V SETCHRG BATT

TEST ONE T SET

START

STOP MUTE

EXTD

ENTR

DISP DATA

A SET PROC

V SETCHRG BATT

TEST T SET

START

STOP

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

4.2 CAPACITY TESTING BATTERIES

The main purpose of a capacity test is to establish that a battery under test can

maintain current output as specified by its ampere hour rating above a certain

terminal voltage.

As a rule of thumb a battery will maintain an output voltage5/6ths above its terminal

voltage for one hour if discharged at its ampere hour rating. A battery that can

maintain this is considered 100% or more of its rated capacity.

For example a 24V 20 A/H battery would be capacity tested at 20A for one hour and

have the voltage end point set to 20V. If after a one hour discharge at 20A the battery

terminal voltage was greater than 20V the battery would be considered at least 100%

efficient.

Intelligent Charging do not make any recommendations on what point a battery is

considered not efficient enough to be used, although a rule of thumb is that a battery

less than 80% should be discarded where it it's use is considered critical.

The TS25 MKII has two capacity test modes: -

Perform a capacity test only to the time period specified.

This mode will auto terminate the process if either the battery voltage reaches

the voltage end point, or if the total capacity test time is achieved. At the end of

the test the TS25 MKII will report a percentage of 100% or less depending on

why the capacity test was terminated.

Perform a capacity test until the final voltage is reached.

This mode will perform a capacity test until the voltage end point is reached. At

the end of test the TS25 MKII will report a percentage, which is the true

capacity of the battery, which may be more than 100%. This method is

sometimes employed so that records of battery deterioration over time or use

can be monitored.

4.2.1 MANUAL CAPACITY TEST

To perform a manual capacity test four parameters have to be programmed.

These are: -

Capacity test current (Amperes).

Capacity test time (Minutes)

Capacity test voltage end point (Volts)

Capacity test mode (Time or Volts)

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 14 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

To program these values the TS25 MKII needs to powered and not performing

either a capacity test or charge on the channel to be used.

Press ASET to change the capacity test amperes.

Press VSET to change the capacity test voltage end point.

Press TSET to change the capacity test duration.

Press PROC to change the capacity test mode.

See section 4.4 ENTERING BATTERY DATA for details on how to enter the

required parameters.

4.2.2 LIBRARY CAPACITY TEST

To perform a capacity test from the library the library number has to be selected

first. To select the library number the following procedure has to be performed.

Press the BATT key. The display will show the current library item selected and

the rightmost digit will be flashing. Enter the library number by using the and

keys and the EXTD key to move to the next digit. Only library numbers 01 to

99 can be selected.

The TS25 MKII needs to be placed in capacity test mode by pressing TEST and

ensuring that the visual indicator TEST is illuminated.

4.2.3 REVIEWING CAPACITY TEST PARAMETERS

Once these values have been programmed into the unit they can be reviewed by

selecting the DISP key to cycle the display between VOLTS, AMPS,TIME and

% and then pressing the DATA key. This display will show the values

programmed in and the corresponding indicator will flash. Note when the %

indicator is lit there is no data to display. To check the capacity test mode simple

press the TEST key and the current capacity test mode will be displayed TIM or

VOL.

4.2.4 STARTING A CAPACITY TEST

Before a capacity test is performed for the first time it is important that the

parameters are reviewed using the reviewing feature above as incorrect

parameters could damage the battery under test.

Once satisfied that he data is correct the battery to undergo the capacity test

must be connected to the unit. Care must be taken when connecting batteries

which are not fitted with non reversible connectors, i.e. where the use of

crocodile clamps are implemented, as damage to the battery and or unit may

occur if a capacity test is started with reverse connection.

To begin the capacity test press START. The display will momentarily display

RUN, the END light will extinguish and it will then display battery voltage. During

the normal capacity test process the DISP key may be pressed to cycle the

display between

VOLTS, AMPS,TIME and %. The DATA key can also be

pressed to review the parameters programmed in for the current test under

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 15 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

progress. If the TEST key is pressed this will briefly display the current test

mode.

4.2.5 STOPPING A CAPACITY TEST

At any time during the capacity test the process can be terminated by simply

pressing the STOP key. When the STOP key is pressed the process will be

terminated immediately and the display will show END and the END led will remain

illuminated.

The display will remain in this state until either MUTE of STOP is pressed.

4.2.6 CAPACITY TEST AUTO TERMINATE

If the capacity test has been programmed to auto terminate on time then the

process will automatically stop when either the battery voltage falls below the

voltage end point or when the capacity test time has elapsed.

If the capacity test has been programmed to auto terminate only when the

voltage falls below the voltage end point, then the process will stop when the

battery voltage falls below the voltage end point.

In both cases the capacity test process will terminate immediately, the audible

alarm will sound and the ALARM and END lights will illuminate and the display will

show the reason for terminating the process.

To clear the alarm the MUTE or STOP key must be pressed. Upon these being

pressed the display will show the actual capacity percent value.

Process termination codes:

E 1 The process time is complete.

E 2 Battery voltage has reached the voltage end point.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 16 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

4.3 CHARGING BATTERIES

To keep batteries in good condition it is important that correct charging procedures

are observed.

The TS25 MKII is an important tool in ensuring the its flexibility allows the user to

choose charge processes that are best suited to the battery. The TS25 MKII has two

inbuilt charging processes that suite a wide range of batteries.

The use of constant voltage charging is best suited to lead acid types of batteries and

the TS25 MKII controls constant voltage charging to ensure that no excess of current

can be driven into the batteries causing it damage.

Constant voltage charging is achieved by inserting a maximum specified current into a

battery until its terminal voltage reached the voltage set point. Once this voltage set

point has been reached the unit will reduce the current injected to maintain the

voltage set point. The charging process will continue until the charge time has

elapsed.

Constant current charging is employed mainly for Nickel Cadmium and Nickel Metal

hydride types if batteries, where a constant current can be driven into a battery for a

specified time and parameters can be set to prevent over charging.

Constant current charging is achieved by the unit driving a specified constant current

into the battery for a specified amount of time. During this time it will monitor the

battery voltage and auto terminate the process if this voltage is reached. This voltage

set point can be either the rise point of the battery or can be used as an over-voltage

parameter.

The TS25 MKII has a new charge mode implemented, which is more suitable to

alkaline batteries. In this mode known as Constant Current Plus mode the unit will

drive the constant current into the battery until the voltage set point is reached. Once

this point is reached the unit will continue charging at the same current for the time

specified.

4.3.1 MANUAL CHARGING

The unit required four parameters to perform a constant voltage charge. These

are: -

Maximum charge current (Amperes).

Charge time or charge additional time (Hours).

Voltage set point (Volts).

Charge mode.

To program these values the unit needs to powered and not performing either a

capacity test or charge on the channel to be used.

Press ASET to change the charge amperes.

Press VSET to change the charge test voltage set point.

Press TSET to change the charge duration or additional time.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 17 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

Press PROC to change the charge mode.

See section 4.4 ENTERING BATTERY DATA for details on how to enter the

required parameters.

4.3.2 LIBRARY CHARGING

To perform a charge from the library the library number has to be selected first.

To select the library number the following procedure has to be performed.

Press the BATT key. The display will show the current library item selected and

the rightmost digit will be flashing. Enter the library number by using the and

keys and the EXTD key to move to the next digit. Only library numbers 01 to

99 can be selected.

The unit needs to be placed in charge mode by pressing CHRG and ensuring that

the visual indicator TEST is extinguished.

4.3.3 REVIEWING CHARGE PARAMETERS

Once these values have been programmed into the unit they can be reviewed by

selecting the DISP key to cycle the display between VOLTS, AMPS and TIME

and then pressing the DATA key. This display will show the values programmed

in and the corresponding indicator will flash. To check the charge mode simply

press the CHRG key and the current charge mode will be displayed CV, CC or CCA.

4.3.4 STARTING A CHARGE

Before a charge is performed for the first time it is important that the parameters

are reviewed using the reviewing feature above as incorrect parameters could

damage the battery under charge.

Once satisfied that he data is correct the battery to undergo charging must be

connected to the unit. Care must be taken when connecting batteries which are

not fitted with non reversible connectors, i.e. where the use of crocodile clamps

are implemented, as damage to the battery and or TS25 MKII may occur if a

charge is started in reverse connection.

To begin the charge press START. The display will momentarily display RUN, the

END light will extinguish and it will then display battery voltage. During the

normal charge process the DISP key may be pressed to cycle the display

between VOLTS, AMPS and TIME. The DATA key can also be pressed to review

the parameters programmed in for the current test under progress. Pressing the

CHRG key will also briefly display the current charge mode.

4.3.5 STOPPING A CHARGE

At any time during the charge the process can be terminated by simply pressing

the STOP key. When the STOP key is pressed the process will be terminated

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 18 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

immediately and the display will show END and the END led will remain

illuminated.

The display will remain in this state until either MUTE of STOP is pressed.

4.3.6 CHARGE PROCESS AUTO TERMINATE

If constant voltage charging the process will automatically stop when the test

time has been completed.

If constant current charging is programmed then the charge will terminate on the

full charge time completed or if the battery terminal voltage reached the voltage

set point.

If constant current with additional time mode is being performed then the unit

will stop when the additional time has been used or if the voltage set point is not

reached within 24 hours of the charge starting.

In all cases the charge process will terminate immediately, the audible alarm will

sound and the ALARM and END lights will illuminate and the display will show the

reason for terminating the process.

To clear the alarm the MUTE or STOP key must be pressed.

Process termination codes:

E 1 The process time or additional time is complete.

E 3 Voltage set point reached (Constant Current Mode Only).

E 4 The voltage set point has not been reached within 24Hours.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 19 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

4.4 ENTERING BATTERY DATA

In all cases of entering battery data the channel that data is to be entered on must be

in the stopped state. This is indicated by the END lamps being illuminated.

4.4.1 SETTING CAPACITY TEST MODE

Press PROC the display will flash the current mode on the display. Using the

and arrow keys the flashing display can be changed from TIM to VOL and visa

versa. Once selection has been made the ENTR key will be pressed to program

this parameter into the unit. If no change is required then simply pressing STOP

will clear the display.

TIM Programs the capacity testing mode to auto terminate when the battery

voltage falls below the voltage end point or when the time up has been

reached.

VOL Programs the capacity testing mode to only auto terminate when the

voltage end point has been reached.

4.4.2 SETTING THE CHARGE MODE

Press PROC the display will flash the current mode on the display. Using the

and arrow keys the flashing display can be changed from CV, CC and CCA and

visa versa. Once selection has been made the ENTR key will be pressed to

program this parameter into the unit. If no change is required then simply

pressing STOP will clear the display.

CV Programs the charge mode to perform a constant voltage charge where the

charge current is not exceeded until the voltage set point is reached at

which point it reduces current to maintain the voltage set point until the

charge time is completed.

CC Programs the charge mode to perform constant current charging for the

time specified terminating abnormally if the voltage set point is reached.

CCA Programs the charge mode to perform constant current charging until the

voltage set point is reached and then continue charging at the same current

until the additional time has elapsed.

4.4.3 ENTERING CURRENT DATA

Press the ASET key. The current setting will be displayed. The rightmost digit will

be flashing and can be modified by pressing the and arrow keys. Pressing

the EXTD key will cause the middle digit to flash and this can then be modified by

using the and arrow keys. Pressing the EXTD key again will cause the

leftmost digit to flash and this can then be modified using the and arrow

keys. If the EXTD key is pressed again the rightmost digit will then flash. This

cycle is repeated each time the EXTD key is pressed. The values cannot be

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 20 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

modified to greater than 12.0A for charge mode and 25.0A for capacity test

mode.

Note: In ONE mode the maximum values that can be entered are 24.0A for

charge mode and 50.0A for capacity test mode.

4.4.4 ENTERING VOLTAGE DATA

Press the VSET key. The current setting will be displayed. The rightmost digit will

be flashing and can be modified by pressing the and arrow keys. Pressing

the EXTD key will cause the middle digit to flash and this can then be modified by

using the and arrow keys. Pressing the EXTD key again will cause the

leftmost digit to flash and this can then be modified using the and arrow

keys. If the EXTD key is pressed again the rightmost digit will then flash. This

cycle is repeated each time the EXTD key is pressed. The voltage value to be

entered cannot exceed 45.0V and the display will not allow digits to be

incremented above this amount.

4.4.5 ENTERING CAPACITY TEST TIME

Press the TSET key. The current setting will be displayed. The rightmost digit will

be flashing and can be modified by pressing the and arrow keys. Pressing

the EXTD key will cause the middle digit to flash and this can then be modified by

using the and arrow keys. Pressing the EXTD key again will cause the

leftmost digit to flash and this can then be modified using the and arrow

keys. If the EXTD key is pressed again the rightmost digit will then flash. This

cycle is repeated each time the EXTD key is pressed. The value entered is in

minutes and the maximum time that can be entered is 999 minutes.

4.4.6 ENTERING CHARGE TIME

Press the VSET key. The current setting will be displayed. The rightmost digit will

be flashing and can be modified by pressing the and arrow keys. Pressing

the EXTD key will cause the middle digit to flash and this can then be modified by

using the and arrow keys. Pressing the EXTD key again will cause the

leftmost digit to flash and this can then be modified using the and arrow

keys. If the EXTD key is pressed again the rightmost digit will then flash. This

cycle is repeated each time the EXTD key is pressed. The value entered is in

hours and the maximum time than can be entered in 99.9H.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 21 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

4.5 USING THE ONE MODE OF OPERATION

The TS25MKII has a special feature in that if higher currents for charging or capacity

testing are required the unit can be "paralleled". Using special paired cables, which

connect, channel A and channel B together both channels can be used in unison.

WARNING

PAY CAREFUL ATTENTION TO BATTERY CONNECTION

WHEN USING “ONE” MODE

Control of the unit is all achieved through the use of the channel A keypad and the

channel B keypad only mimics some of the channel A functions. The channel B display

will change to an alternative display to channel A when the DISP key is pressed.

All operation of the equipment is the same as when using an individual channel, with

the exception that higher currents can be entered for capacity testing and charging.

If a library item has been written in one mode, it will only be recalled in ONE mode if

the current exceeds the single channel limitations of the unit.

Certain actions cannot be performed in ONE mode and these are reported on the

display in the form of an error message and buzzer sound.

4.6 RESETTING THE TS25 MKII

The TS25 MKII keeps users modified data in battery backed RAM. It may be necessary

at some time to reset this data to the defaults. Three sets of data can be reset.

4.6.1 GENERAL PARAMETER DATA

The general parameter data covers the current battery data that is set and

indicators to general unit operation. It is not usually necessary to reset this data

as is checked internally for correctness, but when the unit has been serviced and

the battery backup removed the general parameter data can be come corrupt

and may need resetting through the use of this function.

4.6.2 DEFAULT LIBRARY DATA

The operator may want at some time to reset the internal data library back to

the default battery library, this function copies the internal library into the user

definable battery library. Warning: The use of this function will remove all user

defined library items.

4.6.3 CALIBRATION PARAMETERS

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 22 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

After unit servicing where the battery-backed memory has been reset the

calibration parameters may become corrupt and need resetting to enable the unit

to operate correctly so that a correct calibration can be performed. The default

calibration values are correct at time of manufacture, but in time as components

deteriorate re-calibration will be necessary to keep output to specified tolerances.

4.6.4 SELECTING RESET MODE

To perform this function both channels must be STOPPED. Press EXTD twice

rapidly. The display will flash three numeric digits. These correspond to the

firmware release of the unit. By pressing the and arrow keys the display can

be changed to show PRS, LRS or CRS. Once selection is made on the display the

ENTR key must be pressed to invoke the operation. If the operation needs to be

cancelled i.e. if confirmation of firmware revision number is all that was needed

then hitting the STOP key will abort the reset mode.

PRS Parameter Reset.

LRS Library Reset

CRS Calibration Reset

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 23 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

4.7 DISPLAY MNEMONICS

The following is a list of all the display mnemonics, which appear on the unit together

with a short description for their appearance.

Mnemonic Description

LIB

Battery data has been written back to the library.

RUN

A Charge or Capacity test has just been started.

END

A Charge or Capacity test has been stopped by the

STOP key.

CAL

Calibration mode has been selected.

PRS

Parameter reset selection or action.

LRS

Library reset selection or action.

CRS

Calibration reset selection or action.

TIM

Capacity test terminated on time selection or setting

VOL

Capacity test terminates on voltage set point only

selection or setting.

CV

Constant voltage charge selection or setting.

CC

Constant current charge selection or setting.

CCA

Constant current charge with additional time on voltage

set point selection or setting.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 24 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

4.8 ERROR CODES

Mnemonic Description

E 1

Charge or Capacity test time up completed. Indicates

that either a charge or capacity test has completed its

allotted time.

E 2

Capacity test voltage end point reached. Indicated that

the battery voltage has reached the voltage end point

and the capacity test has stopped.

E 3

Constant Current charge voltage set point met.

Indicates that the battery voltage has reached the

voltage set point.

E 4

Constant current additional time mode voltage set point

not reached with 24 hours. In this mode the unit will not

allow a constant charge to be permitted for more that

24Hrs, it is possible that the battery undergoing charge

has the wrong data set or has developed an internal

fault.

E 5

Error in voltage calibration data input. When the voltage

data is input to the unit it check to ensure that the

calibration scale factor falls within specified boundaries

to prevent inadvertently entered wrong values being

used. If this error is received repeatedly when

calibrating it also indicates that the unit has a

malfunction and requires service.

E 6

Error in current calibration data input. When the current

data is input to the unit it check to ensure that the

calibration scale factor falls within specified boundaries

to prevent inadvertently entered wrong values being

used. If this error is received repeatedly when

calibrating it also indicates that the unit has a

malfunction and requires service.

E 7

Voltage imbalance in ONE mode. When running in ONE

mode the unit checks the difference in voltage between

channel A and channel B. If this condition is met it

means that one channel has not been connected or that

calibration needs to be checked.

E 8

Library item recalled needs ONE mode and a charge or

test is being performed. When a library item has been

selected which required ONE mode this condition will be

displayed if either channel A or channel B is currently

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 25 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

undergoing a charge or capacity test.

E 9

No battery voltage detected. Either battery open circuit

voltage is below 0.4V, reversed or has been

disconnected during operation.

E10

This error occurs if the unit detects current settings

greater than the capacity of the unit.

E11

Current overload in capacity test mode detected. Occurs

when a battery voltage and current combination exceeds

750W per channel.

E12

Internal demand low error. This indicates a fault where

the actual current is more than 10A of expected current.

E13

This code is displayed when the unit is first powered and

is an indication that the internal battery needs replacing.

Note that when this occurs the unit will have loaded it’s

default calibration data and re-calibration after battery

replacement will be required.

E14

Charging or Capacity Testing has stopped because the

unit cannot detect any amps flowing.

E15

While constant voltage charging if the charger detects a

battery voltage 10V greater that the target voltage the

unit will stop and report this warning.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 26 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

5 CALIBRATION

It is recommended that during the yearly routine maintenance the calibration check is

performed to ensure that the battery charger and capacity tester is still performing to its

specifications. The following procedure should be observed in order to perform this check.

5.1 EQUIPMENT REQUIRED

In addition to the TS25 MKII that is going to undergo a calibration check, the following

is a list of equipment that will be required to perform the calibration routines.

• A ammeter shunt such as the Intelligent Charging SHUNT60A or any ammeter

shunt combination capable of at least 60A measurement to one decimal place.

• A milli-voltmeter to be used in conjunction with the SHUNT60A set to read millivolts between 0 and 60mV with a resolution of no less that 0.1mV.

• A voltmeter capable of measuring the voltage from a 24V battery and with a

resolution of no less that 0.1V.

• A test battery of good condition which is capable of being charged for a short

duration at 10A and can be used in capacity test mode at 25A. A 25A or Lead Acid

battery of 25A/H is recommended.

5.2 PERFORMANCE CHECKING

There are two stages in the recalibration. The initial stage is to check that the TS25

MKII is still working within the correct performance characteristics. If the unit is still

working within tolerance then re-calibration does not need to be performed.

Performance checking will then not need to be done for another year.

To execute a performance check the following procedure must be observed.

5.2.1 Charge Calibration Check:

Connect the measuring equipment in accordance with the calibration equipment

connection diagram to Channel A.

• Set the battery charger to CHRG mode.

• Set the charge mode to CC using the PROC key.

• Set charge amps to 10A using the ASET key.

• Set the voltage threshold to 30V using the VSET key.

• Set the charge duration to 0.1H using the TSET key.

• Press START to begin the charge process.

• Allow the charge current to stabilise.

• Take note of the readings of both the measurement equipment and the

readings on the charger display.

• If the readings are more than 1 digit different then the recalibration procedure

must be followed to correct the difference.

• Once this process is completed press STOP to end the charge.

• Charge circuit calibration is complete.

• This process must then be completed for channel B.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 27 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

5.2.2 Capacity Test Calibration Check.

Connect the measuring equipment in accordance with the calibration equipment

connection diagram to Channel A.

• Set the battery charger to test mode.

• Set capacity test amps to 25A using the ASET key.

• Set the termination voltage to 20V using the VSET key.

• Set the capacity test duration to 010 using the TSET key.

• Press START to begin the capacity test process.

• Allow the capacity test current to stabilise.

• Take note of the readings of both the measurement equipment and the

readings on the charger display.

• If the readings are more than 1 digit different then the recalibration procedure

must be followed to correct the difference.

• Once this process is completed press STOP to end the capacity test.

• Capacity test circuit calibration is complete.

• This process must then be completed for channel B.

5.3 RE-CALIBRATION

The TS25 MKII keeps a calibration constant value stored internally which it uses for

calculating true voltage and current from it’s internal measurement circuitry. Because

of component tolerances and tolerance drift with time (decay) the values created at

manufacturing time can cause measurement errors due to this decay. Modern

components are much more stable than their older counterparts so re-calibration is

less necessary, but the checking is essential to ensure that the correct voltages and

currents are used to charge and capacity test your batteries.

If the procedures identified above requires the unit to be recalibrated then the

following re-calibration method needs to be followed.

5.3.1 Charge Re-Calibration:

Connect the measuring equipment in accordance with the calibration equipment

connection diagram to Channel A.

• Set the battery charger to CHRG mode.

• Set the charge mode to CC using the PROC key.

• Set charge amps to 10A using the ASET key.

• Set the voltage threshold to 30V using the VSET key.

• Set the charge duration to 0.1H using the TSET key.

• Press START to begin the charge process.

• Allow the charge current to stabilise.

• Press the ENTR key rapidly twice

• The display will briefly display CAL.

• To re-calibrate current press ASET.

• Enter the number of amps displayed on the measuring equipment, then press

ENTR.

• The charger will adjust the charge amps so that the measuring equipment will

then display the same as the charger.

• To recalibrate voltage press VSET

• Enter the number of volts as displayed on the measuring equipment and press

ENTR.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 28 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

• The charger display will then adjust the display to show the same reading as

the measuring equipment.

• Once the process is completed press STOP to end the charge.

• Charge circuit calibration is complete.

• If necessary the same process is performed for channel B.

5.3.2 Capacity Test Re-Calibration.

Connect the measuring equipment in accordance with the calibration equipment

connection diagram to Channel A.

• Set the battery charger to test mode.

• Set capacity test amps to 25A using the ASET key.

• Set the termination voltage to 20V using the VSET key.

• Set the capacity test duration to 010 using the TSET key.

• Press START to begin the capacity test process.

• Allow the capacity test current to stabilise.

• Press the ENTR key rapidly twice

• The display will briefly display CAL.

• To re-calibrate current press ASET.

• Enter the number of amps displayed on the measuring equipment, then press

ENTR.

• The charger will adjust the charge amps so that the measuring equipment will

then display the same as the charger.

• To recalibrate voltage press VSET

• Enter the number of volts as displayed on the measuring equipment and press

ENTR.

• The charger display will then adjust the display to show the same reading as

the measuring equipment.

• Once this process is completed press STOP to end the capacity test.

• Capacity test circuit calibration is complete.

• If necessary the same process is performed for channel B.

5.4 CALIBRATION PROBLEMS

The TS25 MKII has in-built protection to prevent erroneous calibration data from being

entered.

When performing a re-calibration the unit will validate the data to ensure that it is

within reasonable boundaries. If when entering measurements into the unit it beeps

and displays E 6 then the volts or amps you are trying to enter are invalid.

If the same error is displayed on repeat attempts it is an indication of a breakdown in

the internal circuitry and the unit will need to be quarantined and returned to

Intelligent Charging for service.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 29 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

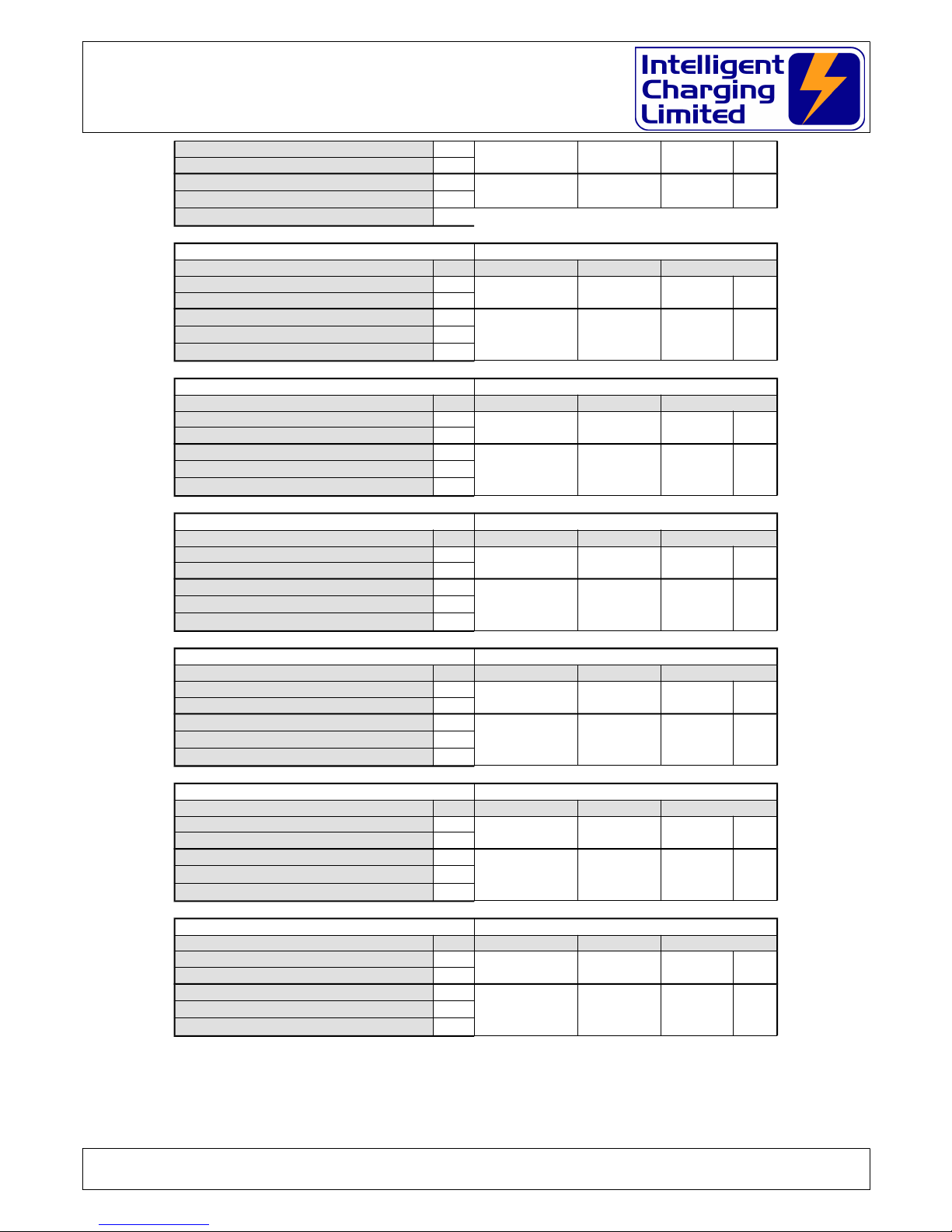

5.5 CALIBRATION EQUIPMENT CONNECTIONS

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 30 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

INTELLIGENT CHARGING

SHUNT60A

AVIATION BATTERY 24V 25A/H

200m

2

20

200

1000

V d.c.

700

200

20

200m

V a.c.

200u

2m

20m

200m

2

10

A a.c.

10

2

200m

20m

2m

200u

20u

OFF

20m

DIGITAL MULTIMETER DMM01

AMPS

DMM SET TO READ 0-20mV

VOLTS

DMM SET TO READ 0-200V

200m

2

20

200

1000

V d.c.

700

200

20

200m

V a.c.

200u

2m

20m

200m

2

10

A a.c.

10

2

200m

20m

2m

200u

20u

OFF

20m

DIGITAL MULTIMETER DMM01

DANGER

Disconnect the

mains supply before

removing this cover

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

MEM

Bxx

ON

OFF

I

O

VOLTS TIME

AMPS

TEST

END ONE

VOLTSTIME

AMPS

TEST

END

%%

ALARM

POWER SWITCH

POWER SWITCH

POWER SWITCH

POWER SWITCH

KEEP AIRFLOW C LEAR

KEEP AIRFLOW C LEAR

KEEP AIRFLOW C LEAR

KEEP AIRFLOW C LEAR

10cm

10cm

10cm

10cm

KEEP AIRFLOW C LEAR

KEEP AIRFLOW C LEAR

KEEP AIRFLOW C LEAR

KEEP AIRFLOW C LEAR

10cm

10cm

10cm

10cm

EXTD

ENTR

DISP DATA

A SET PROC

V SETCHRG BATT

TEST ONE T SET

START

STOP MUTE

EXTD

ENTR

DISP DATA

A SET PROC

V SETCHRG BATT

TEST T SET

START

STOP

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

6 ROUTINE MAINTENANCE

Your TS25 MKII is designed to give you many years of trouble free use and Intelligent

Charging recommends that at least once per year the following routine maintenance checks

should be followed.

• Perform a calibration check as covered in the CALIBRATION section.

• Ensure that the cooling fans can run freely and are not clogged with dust and dirt.

• Ensure that all the inlet vents are free from obstructions and if necessary clear any

obstructions.

• Inspect the battery leads to ensure that the connections are still sound and there is no

evidence of fraying of cable strands at the connectors and no build up of corrosion due

to battery acid or alkaline. If the connectors are broken or damaged they should be

replaced. Replacement charger connectors can be purchased from Intelligent Charging.

• Inspect the power cord for damage and replace if necessary.

• If required by local regulations perform a PAT test on the equipment in accordance with

the regulations in force.

6.1 INTERNAL BATTERY REPLACEMENT

The internal parameters of the TS25 MKII are maintained by a single coin cell

mounted on the display PCB at the front of the unit. This should be changed every 5-6

years. If it should fail during use the error code E13 will be displayed when power is

applied to the unit.

The cell is a standard Lithium button cell number CR2024. When replacing

the battery please observe the correct methods of disposal of the old

battery in accordance with your local regulations.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 31 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

7 BATTERY LIBRARY

The TS25 MKII has 99 sets of built in data, which can be recalled quickly to perform both

charging and capacity testing. Recalling library data is covered in the sections on capacity

testing and charging.

7.1 RETRIEVING A LIBRARY ITEM

Press the BATT key. The display will show the current library item selected and

the rightmost digit will be flashing. Enter the library number by using the and

keys and the EXTD key to move to the next digit. Only library numbers 01 to

99 can be selected.

The leftmost digit is used to select which library database the item is to be

retrieved from.

'0' Indicates that the item is to be retrieved from the user data base where

items can be modified.

'1' Indicates that the item is to be retrieved from the units internal fixed

battery library. Items from this database cannot be written back.

As supplied or when a library reset is performed the modifiable database is the

same as the un-modifiable database.

7.2 ENTERING OR MODIFYING A LIBRARY ENTRY

In order for a library item to be modified it must be recalled first, modified, and

then written back.

Recall the library item you wish to modify using the procedure above.

Follow the procedures for manual charging or capacity testing to set the ASET,

VSET and TSET and PROC parameters.

Once these have been reviewed the battery library data can be written back by

pressing the ENTR key rapidly twice. This means the ENTR key must be pressed

twice within 0.6 Second. The display will briefly show LIB to confirm that the item

has been applied to the units’ internal memory.

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 32 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

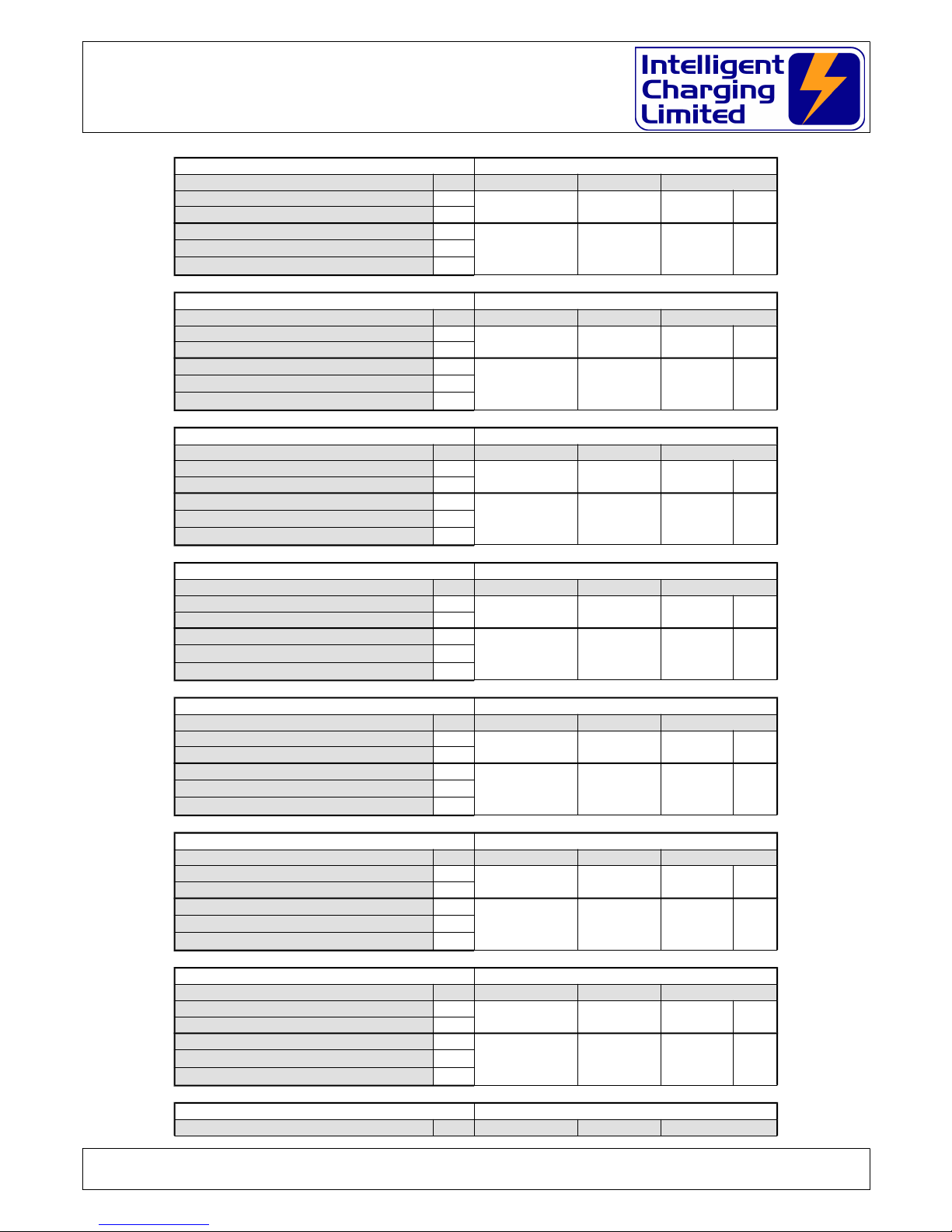

8 DEFAULT BATTERY LIBRARY

The TS25 MKII comes with a built in list of battery parameters of commonly used batteries.

Intelligent Charging provides this list as guidelines only and do not take any responsibility for

the fitness of purpose of these parameters. In all cases the operator must ensure that any

parameters selected are suitable for the battery being charged or capacity tested. Always

refer to the manufacturers data sheets for proper care and use of batteries.

00 USER

MODE

VOLTS AMPS TIME

Captest on time

0.0 0.0 60 m

Captest on voltage

Constant Voltage Charge

0.0 0.0 0.0 hConstant Current Charge

C C Charge with Additional Time

01 CONCORDE BB 638/U

MODE

VOLTS AMPS TIME

Captest on time

21.0 31.0 60 m

Captest on voltage

Constant Voltage Charge

29.0 20.0 6.0 hConstant Current Charge

C C Charge with Additional Time

02 HAWKER 9750T0663

MODE

VOLTS AMPS TIME

Captest on time

20.0 25.0 60 m

Captest on voltage

Constant Voltage Charge

29.0 20.0 6.0 hConstant Current Charge

C C Charge with Additional Time

03 OLDHAM

MODE

VOLTS AMPS TIME

Captest on time

10.0 50.0 60 m

Captest on voltage

Constant Voltage Charge

14.5 20.0 8.0 hConstant Current Charge

C C Charge with Additional Time

04 SONNENSCHEIN A512/6.5S

MODE

VOLTS AMPS TIME

Captest on time

10.0 6.5 60 m

Captest on voltage

Constant Voltage Charge

14.4 3.25 4.0 hConstant Current Charge

C C Charge with Additional Time

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 33 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

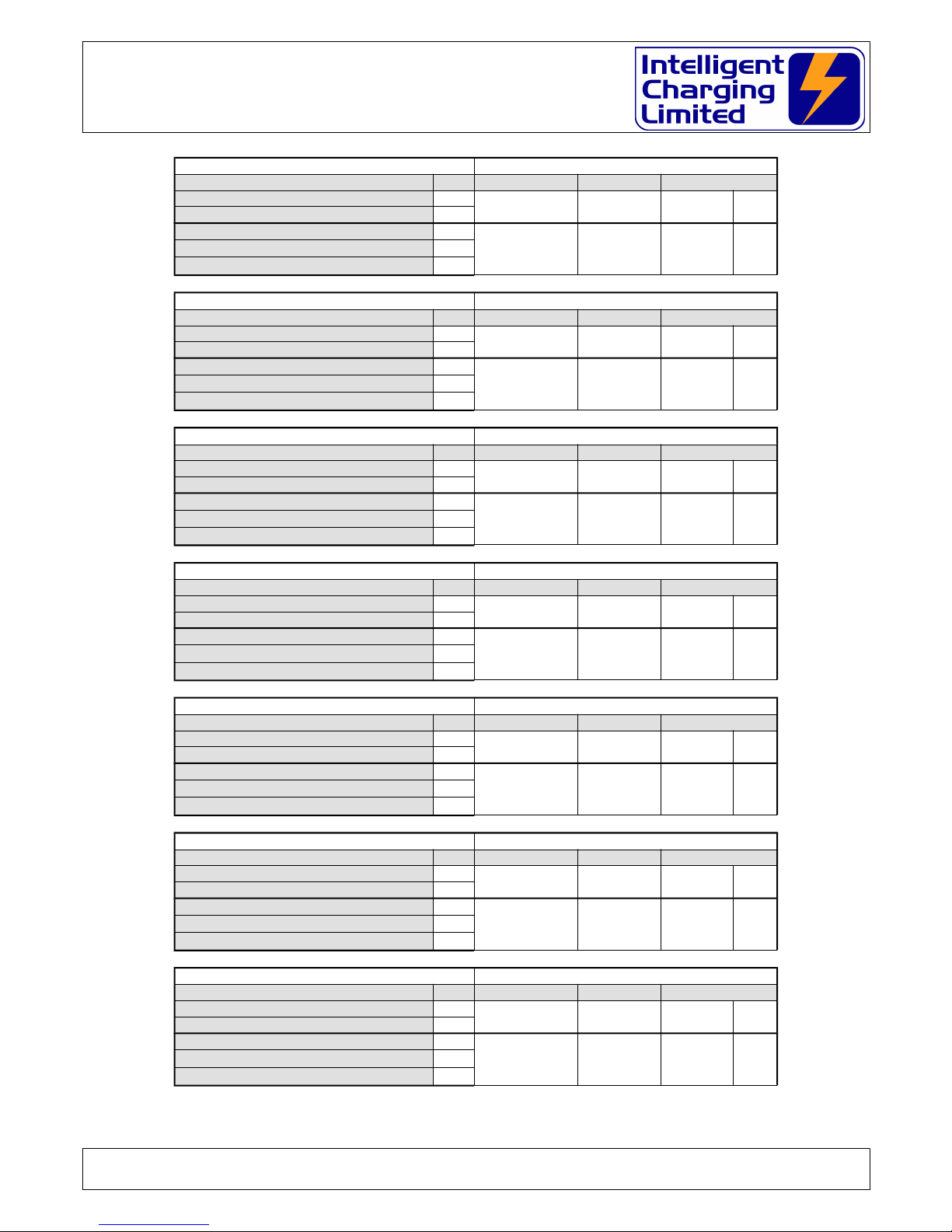

05 SONNENSCHEIN A512/24

MODE

VOLTS AMPS TIME

Captest on time

20.0 24.0 60 m

Captest on voltage

Constant Voltage Charge

28.8 15.0 6.0 hConstant Current Charge

C C Charge with Additional Time

06 SONNENSCHEIN A506/10S

MODE

VOLTS AMPS TIME

Captest on time

10.0 5.0 60 m

Captest on voltage

Constant Voltage Charge

7.25 5.0 4.0 hConstant Current Charge

C C Charge with Additional Time

07 SONNENSCHEIN A200

MODE

VOLTS AMPS TIME

Captest on time

10.0 40.0 60 m

Captest on voltage

Constant Voltage Charge

14.4 20.0 8.0 hConstant Current Charge

C C Charge with Additional Time

08 HAWKER ENERGY 9750D07545

MODE

VOLTS AMPS TIME

Captest on time

20.0 18.0 60 m

Captest on voltage

Constant Voltage Charge

29.0 9.0 4.0 hConstant Current Charge

C C Charge with Additional Time

09 YUASA NP-24-12B

MODE

VOLTS AMPS TIME

Captest on time

10.0 24.0 60 m

Captest on voltage

Constant Voltage Charge

14.4 20.0 6.0 hConstant Current Charge

C C Charge with Additional Time

10 CIBL 6XNM11WL

MODE

VOLTS AMPS TIME

Captest on time

10.0 32.0 60 m

Captest on voltage

Constant Voltage Charge

14.5 20.0 8.0 hConstant Current Charge

C C Charge with Additional Time

11 AC DELKO 30-55

MODE

VOLTS AMPS TIME

Captest on time

10.0 55.0 60 m

Captest on voltage

Constant Voltage Charge

14.5 20.0 8.0 hConstant Current Charge

C C Charge with Additional Time

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 34 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

12 TUNGSTONE 12C48

MODE

VOLTS AMPS TIME

Captest on time

10.0 48.0 60 m

Captest on voltage

Constant Voltage Charge

14.5 20.0 8.0 hConstant Current Charge

C C Charge with Additional Time

13 LUCAS 15

MODE

VOLTS AMPS TIME

Captest on time

10.0 50.0 60 m

Captest on voltage

Constant Voltage Charge

14.5 20.0 8.0 hConstant Current Charge

C C Charge with Additional Time

14 SONNENSCHIEN A508/3.5S

MODE

VOLTS AMPS TIME

Captest on time

6.7 3.5 60 m

Captest on voltage

Constant Voltage Charge

9.6 2.0 4.0 hConstant Current Charge

C C Charge with Additional Time

15 GATES ENERGY 0809-0010

MODE

VOLTS AMPS TIME

Captest on time

3.3 5.0 60 m

Captest on voltage

Constant Voltage Charge

4.85 2.0 4.0 hConstant Current Charge

C C Charge with Additional Time

16 YUASA NP2.6-6

MODE

VOLTS AMPS TIME

Captest on time

5.0 2.6 60 m

Captest on voltage

Constant Voltage Charge

7.25 1.0 4.0 hConstant Current Charge

C C Charge with Additional Time

17 AC DELCO 20-55

MODE

VOLTS AMPS TIME

Captest on time

10.0 27.5 120 m

Captest on voltage

Constant Voltage Charge

14.5 20.0 8.0 hConstant Current Charge

C C Charge with Additional Time

18 HAWKER 9750-0741

MODE

VOLTS AMPS TIME

Captest on time

20.0 18.0 60 m

Captest on voltage

Constant Voltage Charge

29.0 20.0 4.0 hConstant Current Charge

C C Charge with Additional Time

19 HAWKER ENERGY 9750F0540

MODE

VOLTS AMPS TIME

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 35 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

Captest on time

20.0 40.0 60 m

Captest on voltage

Constant Voltage Charge

29.0 20.0 8.0 hConstant Current Charge

C C Charge with Additional Time

20 YUASA NP4-6

MODE

VOLTS AMPS TIME

Captest on time

5.0 4.0 60 m

Captest on voltage

Constant Voltage Charge

7.25 2.0 4.0 hConstant Current Charge

C C Charge with Additional Time

21 HAWKER 9750-0647

MODE

VOLTS AMPS TIME

Captest on time

20.0 25.0 60 m

Captest on voltage

Constant Voltage Charge

29.0 20.0 6.0 hConstant Current Charge

C C Charge with Additional Time

22 HAWKER 9750-0751

MODE

VOLTS AMPS TIME

Captest on time

20.0 25.0 60 m

Captest on voltage

Constant Voltage Charge

29.0 18.0 6.0 hConstant Current Charge

C C Charge with Additional Time

23 OLDHAM CROMPTON 4V10

MODE

VOLTS AMPS TIME

Captest on time

3.3 10.0 60 m

Captest on voltage

Constant Voltage Charge

4.85 5.0 4.0 hConstant Current Charge

C C Charge with Additional Time

24 HAWKER ENERGY 97500640

MODE

VOLTS AMPS TIME

Captest on time

20.0 25.0 60 m

Captest on voltage

Constant Voltage Charge

29.0 20.0 6.0 hConstant Current Charge

C C Charge with Additional Time

25 OLDHAM C

MODE

VOLTS AMPS TIME

Captest on time

10.8 40.0 60 m

Captest on voltage

Constant Voltage Charge

14.5 20.0 8.0 hConstant Current Charge

C C Charge with Additional Time

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 36 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

26 CHLORIDE 6 MNA 17

MODE

VOLTS AMPS TIME

Captest on time

10.8 2.5 60 m

Captest on voltage

Constant Voltage Charge

14.5 1.0 4.0 hConstant Current Charge

C C Charge with Additional Time

27 YUASA NP38-12

MODE

VOLTS AMPS TIME

Captest on time

10.0 38.0 60 m

Captest on voltage

Constant Voltage Charge

14.4 20.0 8.0 hConstant Current Charge

C C Charge with Additional Time

28 HAWKER ENERGY 9750T0675

MODE

VOLTS AMPS TIME

Captest on time

20.0 25.0 60 m

Captest on voltage

Constant Voltage Charge

29.0 20.0 6.0 hConstant Current Charge

C C Charge with Additional Time

29 MARATHON CA54-3

MODE

VOLTS AMPS TIME

Captest on time

19.0 5.5 60 m

Captest on voltage

Constant Voltage Charge

29.0 0.5 2.0 hConstant Current Charge

C C Charge with Additional Time

30 GRIMES 61-0478-1

MODE

VOLTS AMPS TIME

Captest on time

0.0 0.0 0 m

Captest on voltage

Constant Voltage Charge

11.0 0.3 16.0 hConstant Current Charge

C C Charge with Additional Time

31 LITTON 51008

MODE

VOLTS AMPS TIME

Captest on time

19.0 14.0 60 m

Captest on voltage

Constant Voltage Charge

29.45 3.0 5.0 hConstant Current Charge

C C Charge with Additional Time

32 GRIMES 61-2275-1

MODE

VOLTS AMPS TIME

Captest on time

14.0 0.75 60 m

Captest on voltage

Constant Voltage Charge

20.0 0.75 2.0 hConstant Current Charge

C C Charge with Additional Time

33 SAFT 715737-2

MODE

VOLTS AMPS TIME

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 37 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

Captest on time

24.0 1.9 60 m

Captest on voltage

Constant Voltage Charge

36.0 0.38 4.0 h

Constant Current Charge

C C Charge with Additional Time

34 VARTA F19/40H1

MODE

VOLTS AMPS TIME

Captest on time

19.0 36.0 60 m

Captest on voltage

Constant Voltage Charge

28.5 3.6 5.0 hConstant Current Charge

C C Charge with Additional Time

35 VARTA F20/25H1

MODE

VOLTS AMPS TIME

Captest on time

20.0 23.0 60 m

Captest on voltage

Constant Voltage Charge

30.0 2.3 5.0 hConstant Current Charge

C C Charge with Additional Time

36 VARTA F20/40H1WT

MODE

VOLTS AMPS TIME

Captest on time

20.0 36.0 60 m

Captest on voltage

Constant Voltage Charge

30.0 8.0 2.0 hConstant Current Charge

C C Charge with Additional Time

37 VARTA F20/40H1CWT

MODE

VOLTS AMPS TIME

Captest on time

20.0 36.0 60 m

Captest on voltage

Constant Voltage Charge

30.0 8.0 2.0 hConstant Current Charge

C C Charge with Additional Time

38 VARTA F20/40H1C

MODE

VOLTS AMPS TIME

Captest on time

20.0 36.0 60 m

Captest on voltage

Constant Voltage Charge

30.0 8.0 2.0 hConstant Current Charge

C C Charge with Additional Time

39 SAFT 400A1

MODE

VOLTS AMPS TIME

Captest on time

20.0 40.0 60 m

Captest on voltage

Constant Voltage Charge

30.0 4.0 5.0 hConstant Current Charge

C C Charge with Additional Time

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 38 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

40 BAT170

MODE

VOLTS AMPS TIME

Captest on time

20.0 23.0 60 m

Captest on voltage

Constant Voltage Charge

30.0 2.3 5.0 hConstant Current Charge

C C Charge with Additional Time

41 SAFT 10VR2C

MODE

VOLTS AMPS TIME

Captest on time

10.0 1.6 60 m

Captest on voltage

Constant Voltage Charge

17.5 0.2 16.0 hConstant Current Charge

C C Charge with Additional Time

42 SAFT/VARTA 10/RSH 1.3

MODE

VOLTS AMPS TIME

Captest on time

10.0 1.2 60 m

Captest on voltage

Constant Voltage Charge

15.0 0.24 4.00 hConstant Current Charge

C C Charge with Additional Time

43 AEA/SAFT 10/KRH 35/92

MODE

VOLTS AMPS TIME

Captest on time

10.0 7.0 60 m

Captest on voltage

Constant Voltage Charge

15.0 1.4 4.0 hConstant Current Charge

C C Charge with Additional Time

44 AEA/SAFT KRH 44/91/HBG

MODE

VOLTS AMPS TIME

Captest on time

10.0 10.0 60 m

Captest on voltage

Constant Voltage Charge

15.0 2.0 4.0 hConstant Current Charge

C C Charge with Additional Time

45 SAFT 10VR7F

MODE

VOLTS AMPS TIME

Captest on time

10.0 7.0 60 m

Captest on voltage

Constant Voltage Charge

18.0 0.7 16.0 hConstant Current Charge

C C Charge with Additional Time

46 AEA/SAFT KRH 35/92/HHG

MODE

VOLTS AMPS TIME

Captest on time

1.0 7.0 60 m

Captest on voltage

Constant Voltage Charge

1.5 1.4 4.0 hConstant Current Charge

C C Charge with Additional Time

47 SAFT BAT161 (25106)

MODE

VOLTS AMPS TIME

Doc: DWG1044-09-R16 TS25 MKII Operators manual.odt Page 39 of 46 Copyright Material of Intelligent Charging Limited © 2015

Printed On : 12/06/17

TS25 MKII : TS25-BAS1-KIT : TS25-BAS1-CAN-240

Battery charger/analyser : Operators Manual

Captest on time

20.0 23.0 60 m

Captest on voltage

Constant Voltage Charge

30.0 2.3 5.0 h

Constant Current Charge

C C Charge with Additional Time

48 SAFT 40100

MODE

VOLTS AMPS TIME

Captest on time

20.0 40.0 60 m

Captest on voltage

Constant Voltage Charge

30.0 4.0 5.0 hConstant Current Charge

C C Charge with Additional Time

49 SAFT 23396 / VP230KH

MODE

VOLTS AMPS TIME

Captest on time

20.0 22.0 60 m

Captest on voltage

Constant Voltage Charge

30.0 2.2 5.0 hConstant Current Charge

C C Charge with Additional Time

50 SAFT 20-VO KHP

MODE

VOLTS AMPS TIME

Captest on time

20.0 23.0 60 m

Captest on voltage

Constant Voltage Charge

30.0 2.3 5.0 hConstant Current Charge

C C Charge with Additional Time

51 VARTA 5KBM 344/100

MODE

VOLTS AMPS TIME

Captest on time

5.0 0.55 60 m

Captest on voltage

Constant Voltage Charge

7.5 0.12 5.0 hConstant Current Charge

C C Charge with Additional Time

52 ALCAD 5XM 325

MODE

VOLTS AMPS TIME

Captest on time

5.0 32.0 60 m

Captest on voltage

Constant Voltage Charge

7.5 6.4 4.0 hConstant Current Charge

C C Charge with Additional Time

53 SAFT A40279-1

MODE

VOLTS AMPS TIME

Captest on time

20.0 37.0 60 m

Captest on voltage

Constant Voltage Charge

30.0 3.7 5.0 hConstant Current Charge

C C Charge with Additional Time