D-Flow

user manual

2 Intelligent Facility Solutions

Voltaje 220 - 240 V

Frecuencia

50 / 60 Hz

Aislamiento eléctrico

Clase II

Dimensiones

160 x 220 x 77 mm

Peso

0,8 Kg

Velocidad del aire

60 Km/h

Potencia Total

200 - 1.800 W

Consumo

0,9 - 7 A

rpm 9.000 -18.000 min

Temperatura aire

63

°C

Índice de protección

IP20

Nivel sonoro (a 2 m)

65 dBA

Voltaje 220 - 240 V

Frecuencia

50 / 60 Hz

Aislamiento eléctrico

Clase II

Dimensiones

160 x 220 x 77 mm

Peso

0,8 Kg

Velocidad del aire

60 Km/h

Potencia Total

200 - 1.800 W

Consumo

0,9 - 7 A

rpm 9.000 -18.000 min

Temperatura aire

63

°C

Índice de protección

IP20

Nivel sonoro (a 2 m)

65 dBA

Dimensiones

185 x 165 x 95 mm

Peso

0,75 Kg

Capacidad

1.250 m

l

Cantidad dispensada/pulsación

0,7 ml

Dimensiones

185 x 165 x 95 mm

Peso

0,75 Kg

Capacidad

1.250 m

l

Cantidad dispensada/pulsación

0,7 ml

Dimensiones

185 x 165 x 95 mm

Peso

0,75 Kg

Capacidad

1.250 m

l

Cantidad dispensada/pulsación

0,7 ml

Dimensiones

185 x 165 x 95 mm

Peso

0,75 Kg

Capacidad

1.250 m

l

Cantidad dispensada/pulsación

0,7 ml

HAND DRYERS

SENSOR OPERATED

Dualflow Plus

General description

The dualflow© Plus M14 240V is a fast, energy

efficient, ecologic, hygienic & stylish hand dryer.

“Hands in” model it has 2 pairs of IR sensors on

both sides of the upper covers

for instant hand

detection

Maximum air speed 410 Km/h.

Dries hands in only 8 / 15 seconds.

Motor power adjustable, allowing electricity

consumption to be regulated.

(Between 420 and

1.100W).

30 seconds safety timer.

Lowest noise level in its category. (62 dBA in ECO

mode).

Suitable for medium and high traffic facilities.

Easy maintenance.

Components & materials:

M14A: ABS cover, white finish.

M14AC: ABS cover, satin finish.

M14AB: ABS cover, black finish.

High speed class F universal brush motor,

adjustable from 19000 to 30000 rpm.

Biocote® antimicrobial and antibacterial protection

technology based on silver ions. These ions inhibit

the reproduction of micro-organisms in the product

throughout its lifetime.

H13 HEPA filt

er which eliminates more than the

99% of particles.

Base plate made in plastic PA6V0.

Removable water tank which it has valve for

emptying.

LED front light for fast diagnosis of the dryer (green

- machine running, blue - full tank, red - check

engine).

Optical and acoustic warning full tank.

No heating element.

Odor neutralizer (optional).

Technical Specifications:

(*) According to UNE EN ISO 11201:2010 V2 standard.

Dimensions:

Voltage

220- 240 V

Frequency

50/60 Hz

Electrical Isolation

Class I

Total power

420 – 1,100 W

Consumption

3.2 – 5 A

Motor power

420 – 1,100 W

Rpm

19,000 – 30,000

Heating element power

No Heating Element

Dimensions

665x320x228 mm

Weight

8.3 Kg

Cover thickness

3 mm

Drying time

8-15 sec

Effective airflow

94-165m3/h –1,570-2,750 l/min

Air velocity

234 – 410 Km/h

Air temperature (10 cm

distance/21ºC)

35 ºC

Sound pressure

(*)

(at 2m)

62 – 72 dBA

Protection rating

IPX4

white finish satin finish

M14AB

black finish

D-Flow 3

Operation

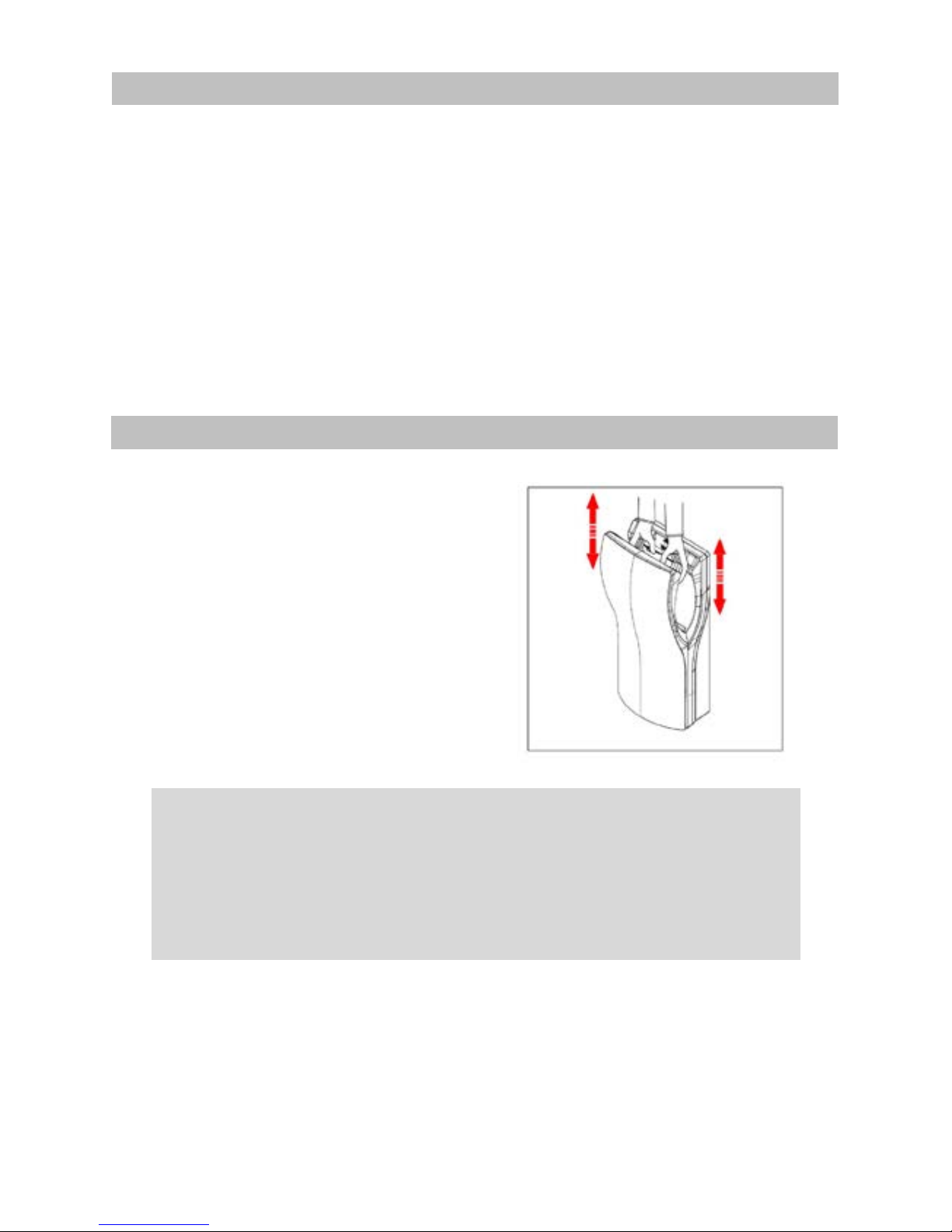

Place the hands between the air outflow valves, inside the hand dryer.

The dryer will start automatically, and go on with no interruption as long

as the hands are kept in the detection range of the sensor. Move the

hands vertically in order to dry them completely. The appliance will stop 2

seconds after the hands are removed from the airflow.

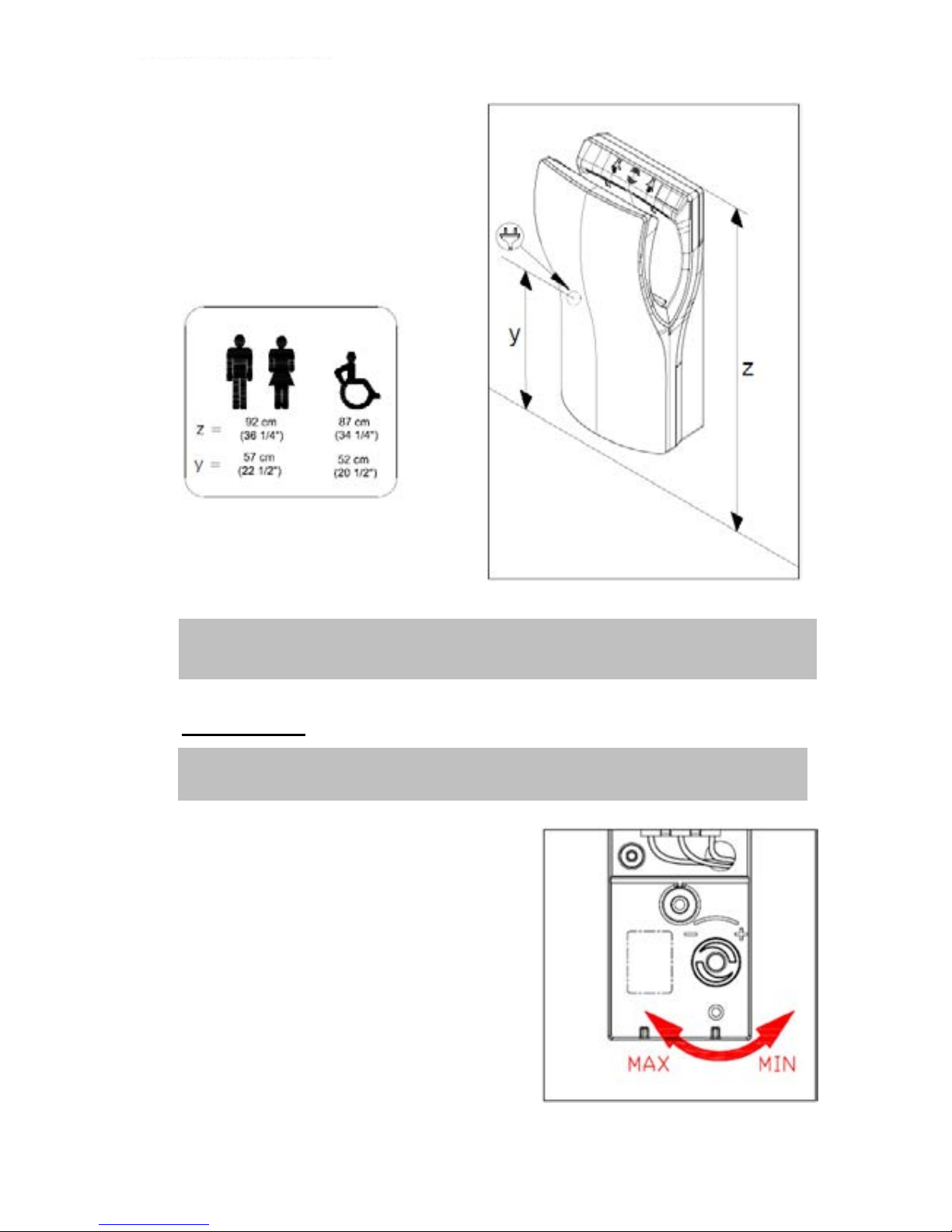

Mounting Recommended heights distance from the floor

Certificates & Qualifications

4 Intelligent Facility Solutions

Before to carry on any operation, please read carefully and take into account the

following safety instructions:

- Only a qualified technician can install, adjust and maintain this device. All this operations must

be always done according to the current legal European Standards of installation and according

the local installation regulations as well.

- Be careful when the casing of the appliance is dismantled because active parts of the device

become accessible and then there is a potential risk of an electric shock.

- Before any electrical manipulation, the electrical current must be cut in order to avoid any

electric shock risk

- The device must be fixed out of reach of a water source in order to fulfil the security distances

marked into the current IEC standards and as the following figure shows:

- Be careful because local installation requirements can ask more than 1 m of safety distance.

Take into account these local requirements as well.

- Hairdryers must be fixed out of reach of a person taking a bath or a shower.

- Means for disconnection, with contact separations at least 3 mm (0.12"), must be incorporated

in the fixing wiring involving all poles, accordingly to the current legal European Standards.

- The installer must make sure that the electric system is grounded in accordance with the law in

force.

- This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in a safe way and understand

the hazards involved. Children shall not play with the appliance. Cleaning and user

maintenance shall not be made by children without supervision.

- The device could not be installed on a normally inflammable surface.

- To fix the hand dryer to the wall follow the instructions of this manual and use the template

provided with the device as well. To fix the machine with adhesives or similar methods is

forbidden by the European safety standards.

SAFETY INSTRUCTIONS

ENGLISH

D-Flow 5

www.mediclinics.com

‘Dualflow Plus’ range hand dryers offer the following technical features:

Automatic operation. Hand detection is based on Infra Red (IR) movement sensors.

Two pairs of those sensors emit a continuous beam of IR light. The introduction of the

hands causes the interruption of the IR light beam and switch on the dryer.

The speed of the air generated by the hand dryer can be adjusted, to achieve an

optimum balance between the drying power and noise level.

Available finishes:

- White (M14A)

- Satin (M14ACS)

Dimensions: 656 mm (H) x 320 mm (W) x 226 mm (D).

Weight: 8.3 Kg

Mounting: Surface.

Means for disconnection with contact separations at least 3 mm (0.12")

must be incorporated in the fixing wiring.

INTRODUCTION

OPERATION

Figure 1

Hands must be introduced inside. Hand dryer starts

automatically after introducing hands.

Move hands vertically (as shown in Fig.1) in order

to dry them completely.

Green light (in standby state) led on top becomes to

orange colour when dryer is in use.

Maximum continuous operation time is T = 30 sec.

Drying time is less to it (Td ≈ 8 -12 sec).

After removing hands, dryer turns off automatically.

This appliance can be used by children aged from 8 years or above and

persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge if they have been given supervision or instruction

concerning use of the appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by people without the

proper training.

6 Intelligent Facility Solutions

Introduction

‘Dualflow Plus’ family of hand dryers offers the technical features as follows:

Automatic operation. Drying cycle starts when putting hands in. Two couple of IR

sensors detect hands introduction.

Dryer is a class I (earthed) electrical insulation device.

Drying process is based on powerful air curtains which remove water from hands.

Hand dryer has no heating element.

Speed of air can be adjusted in order to achieve an optimum balance between drying

power and noise level.

Light leds on top supply some information referred to the status of hand dryer.

Maximum time of continuous operation is T max = 30 sec.

Water from hands is collected in a removable tank which may be emptied and cleaned.

An HEPA filter is incorporated in the aspiration area whose state should be reviewed

periodically. The place of fitting the air inlet filter allows easy removal and replacement.

Optionally, in the aspiration area, an air-freshener can be incorporated.

Installation

ONLY A QUALIFIED TECHNICIAN CAN INSTALL, ADJUST AND MAINTAIN THIS HAND

DRYER.

The installation of the appliance is only allowed on fixed wiring.

Means for disconnection of the mains with contact separations at least 3 mm (0.12”) must be

incorporated in the fixing wiring.

The installer must make sure that the electric system is grounded in accordance with the law in

force.

Make sure that the electric system has a high-sensitivity breaker I n ≤ 0.03 A.

Make sure that the machine is disconnected from the electric power supply, before performing

maintenance operation.

To install the hand dryer follow the pictures contained in the figure 2.

The hand dryer must be fitted to the wall by using the upper metal plate (support) which is

supplied.

INSTALLATION AND MAINTENANCE BOOK (TECHNICAL STAFF)

D-Flow 7

www.mediclinics.com

After fitting the metal plate, the hand dryer should be hung on it. The lower screw fits safely the

appliance to the wall. So, to assemble the hand dryer the following steps must be done:

Make five 8 mm (0.31”) diameter drill holes in the wall using the provided template (1).

Clean the dust away and insert the wall plugs.

Screw the upper plate to the wall (2).

Plastic covers which protect the terminal block (inlet power supply) must be removed (3).

The hand dryer should be hung on the metal support which has been fitted to the wall (4).

Pass the electrical cables from mains through the 22 mm diameter hole located in the rear

plastic base3 plate. (5).

Connect the electrical wires to the hand dryer terminal block.

Two phases (N,L) and earth wires must be screwed in the right ways of the terminal block,

as indicated by the engraved letters (6).

After this operation has been done, plastic covers must be placed correctly (10).

Remove the air inlet filter casing (7).

Firmly place the lower screw for fixing the appliance completely (8).

Put the inlet air casing to its location (9).

Figure 2

8 Intelligent Facility Solutions

-14-

ATTENTION: WHEN THE CASING IS DISMANTELED ACTIVE PARTS OF THE DEVICE

BECOME ACCESSIBLE.

Installation height must be the showed in figure nº 3.

Maintenance

ONLY A QUALIFIED TECHNICIAN CAN INSTALL, ADJUST AND MAINTAIN THIS HAND

DRYER.

Adjust the speed of the motor

To adjust the speed of the motor turn

the sensor potentiometer wheel

as the picture 4 shows.

Figure 4

Figure 3

D-Flow 9

www.mediclinics.com

Pilot light information

Light leds on the top of the hand dryer (see figure 5) give advice about:

1: Standby (green colour) or

operation status (orange colour).

2: Red colour led bright when motor

has a problem of consumption

(due to brushes which may be wearing

out or due to a blocked or locked sate of motor).

3.- Blue colour led bright when cabinet of water is full.

Air filter

Air filter must be changed as the pictures of figure nº 6 shows.

No smell load charge

Figure nº 7 shows how to install the no smell charge.

Figure 5

Figure 6

Figure 7

10 Intelligent Facility Solutions

Water tank.

Water from hands drops directly to a removable water tank. When water from the removable

water tank reaches the ‘full level’ an acoustic alarm sounds and the blue pilot light bright (see

Fig. 5). In this case, water in the tank must be emptied.

Two options to remove the water from the water tank are available:

I. Press the two lateral clips and pull down the water tank, as the picture 8 shows.

Remove the water tank from its fitting place, empty and clean the tank and

re-place it.

II. Press the push button as indicated in Fig. 9 until remove all the water contained into the

water tank.

CONNECTION DIAGRAM

Figure 10

Figure 8 Figure 9

D-Flow 11

www.mediclinics.com

COMPONENT

NUMBER

CODE

Motor set 1 RC9111003SMD

Electronic control 2 RC9121012SMD

Air filter set 3 RCFILTROHEPA1

HEPA filter 4 RCFILTROHEPA2

Air-freshener 5 9481002

Figure 11

DANGER.

Electric shock risk

- The installer must make sure that the electric system is

grounded in accordance with the law in force.

- Make sure that the electric system has a high-sensitivity

breaker I n ≤ 0.03 A.

- Make sure the machine is disconnected from electric

power supply, before performing maintenance operation.

BASIC EXPLODED VIEW

12 Intelligent Facility Solutions

MANUAL DE MANTENIMIENTO

MAINTENANACE MANUAL

M14A / M14ACS DUALFLOW PLUS

Normas de seguridad

Todo proceso de instalación, mantenimiento y reparación debe ser

efectuado por personal técnico cualificado.

Mediclinics le recuerda la importancia de:

1.

Familiarizarse con el equipo y leer detenidamente el manual de

usuario antes de su manipulación.

2.

Desconectar la fuente de energía antes de iniciar cualquier proceso de

reparación o mantenimiento.

3. Actuar con precaución de acu

erdo a los procedimientos descritos en el

presente manual.

Mantenimiento general

Mantenimiento Preventivo – Limpieza

Inspeccionar las unidades con una periodicidad anual o semestral,

en

función de la carga de trabajo de la secadora.

Limpiar las partes activas de la unidad, como son: el motor, l

os detectores

LED y la placa electrónica, con un cepillo o pincel de cerdas suaves.

Mantener las aberturas de entrada y salida de aire libres de polvo y otras

obstrucciones, utilizando un cepillo o pincel de cerdas suaves.

Mantenimiento Correctivo – Recambios

Puede solicitar recambios de los elementos referenciados en el presente

manual, al servicio de recambios y reparaciones de Mediclinics.

C/ Casanova, 93. Pral. 2ª 08011 Barcelona.

Tel: 934 516 009. Fax: 934 516 367. Email: sca@mediclinics.com

Safety regulations

All installation, maintenance and repair tasks must be performed

by

qualified technicians.

Mediclinics reminds the importance of:

1. Becoming familiar with the equipment and carefully

reading the

user manual before handling.

2. Disconnecting power before

beginning any repair or maintenance

task.

3. Act with caution according to the procedures included

in this

manual.

General maintenance

Preventive Maintenance - Cleaning

Inspect the units annually or quarterly

, depending on the dryer’s

operating cycles.

Clean the active parts of the unit, such as: the motor, the

LED

detectors and the electronic circuit board with a soft brush.

Maintain the air inlet and outlet free of dust and other obstructions; use

a soft flat ended brush.

Corrective Maintenance – Spare Parts

You can order spare parts of the components shown herein.

Contact your closest dealer for further information.

D-Flow 13

LEYENDA DE LOS INDICADORES LED /LED INDICATORS LEGEND

Esperar 3-5 segundos a que la máquina se estabilize antes de diagnosticar algún problema.

Wait 3-5 seconds for the machine to stabilize before diagnosis of any problems.

Verde

Green

Off

Off

El secador está listo para funcionar en cuanto se introduzcan las manos.

The dryer is ready to run as soon as the hands are introduced.

Naranja

Orange

Off

Off

El secador está detectando las manos y el motor está funcionando correctamente.

The dryer is detecting the hands and the engine is running properly.

Off

Rojo

Red

Off

Avería en la electrónica o el motor

Electronics or motor are not working properly.

Naranja

Orange

Rojo

Red

Off

El secador está detectando las manos pero el motor no funciona correctamente.

Hands are detected but the engine is not working properly.

Verde o naranja

Green or Orange

Off

Azul

Blue

El depósito de agua está lleno. Sonará un pitido intermitente adicionalmente

The water tank is full. An intermittent whistle will sound additionally

Off

Off

Off

El secador está desconectado.

The dryer is disconnected.

14 Intelligent Facility Solutions

DESMONTAJE DEL FRONTAL - FRONT COVER REMOVAL

Extraiga el conjunto filtro, desclipándolo de la base.

___________________

Remove the filter assembly by unclipping it from the base.

Desatornillar, usando una llave allen de 2,5 mm, los 4

tornillos que sujetan el frontal a la base.

___________________

Unscrew the four screws securing the front cover to the

base. Use a 2.5 mm hexagonal spanner.

Mediante un suave pero firme tirón separe el frontal de la

base.

Después desliza el frontal hacia la parte superior.

___________________

With a gentle but steady pull separate the front of the base.

Then slide the front to the top.

Para realizar el montaje del frontal, siga los pasos anteriores en orden inverso.

To fit the front cover, follow the previous steps in reverse order.

D-Flow 15

CAMBIO DE MOTOR - MOTOR REPLACEMENT

Extraiga el conjunto filtro, desclipandolo de la base.

___________________

Remove the filter assembly by unclipping it from the base.

Desatornillar, usando una llave allen de 2,5 mm, los 4

tornillos que sujetan el frontal a la base.

___________________

Unscrew the four screws securing the front cover to the

base. Use a 2.5 mm hexagonal spanner.

Mediante un suave pero firme tirón separe el frontal de la

base.

Después desliza el frontal hacia la parte superior.

___________________

With a gentle but steady pull separate the front of the base.

Then slide the front to the top.

Desatornille los tornillos de fijación de la tapa circuito. Use

un destornillador de punta PZ2.

___________________

Unscrew both screws securing the electronic circuit board

cover. Use a cross head PZ2 screwdriver.

Retire la tapa.

___________________

Remove the lid.

16 Intelligent Facility Solutions

Desconecte los cables de motor y alimentación de los

terminales de la placa electrónica.

___________________

Unplug the motor and power wires from the electronic

circuit board terminal blocks.

Corte la brida de sujeción de los cables de motor y

alimentación.

___________________

Cut the tie securing motor and power wires.

Desatornille los 6 tornillos que fijan la tapa motor a la base.

Use un destornillador de punta PZ2.

___________________

Unscrew the 6 screws fixing the motor cover. Use a cross

head PZ2 screwdriver.

Mediante un suave pero firme tirón separe la tapa motor

de

la base.

___________________

With a gentle but steady pull separate the motor cover of

the base.

D-Flow 17

Desconecte los cables de alimentación del motor

presionando el clip de seguridad del conector y tirando del

conector suavemente.

___________________

Unplug the motor power wires pushing the safety clip of the

faston and pulling the faston out carefully.

Extraiga el motor.

___________________

Remove the motor.

Instale el nuevo motor siguiendo los pasos anteriores en sentido inverso.

Fit the new motor by following the previous steps in reverse order.

18 Intelligent Facility Solutions

CAMBIO DE ESCOBILLAS - BRUSHES REPLACEMENT

En caso necesario revise el apartado de cómo retirar el motor antes de continuar.

___________________

If necessary review the motor replacement section before continuing.

Una vez que el motor está fuera de la secadora, afloje los

tornillos que sujetan la escobilla. Utilice un destornillador

de punta PH1.

___________________

Once the motor is removed from the dryer, loosen the

screws holding the brush. Use a cross head PH1

screwdriver.

Retire la escobilla.

___________________

Remove the motor brush.

Realice el mismo proceso con la segunda escobilla del motor.

Realice el montaje siguiendo los pasos anteriores en sentido inverso.

Carry out the same procedure for the second motor brush.

Fit the new brushes following the previous steps in reverse order.

D-Flow 19

CAMBIO DE PLACA ELECTRÓNICA - ELECTRONIC CIRCUIT BOARD REPLACEMENT

Extraiga el conjunto filtro, desclipandolo de la base.

___________________

Remove the filter assembly by unclipping it from the base.

Desatornillar, usando una llave allen de 2,5 mm, los 4

tornillos que sujetan el frontal a la base.

___________________

Unscrew the four screws securing the front cover to the

base. Use a 2.5 mm hexagonal spanner.

Mediante un suave pero firme tirón separe el frontal de la

base.

Después desliza el frontal hacia la parte superior.

___________________

With a gentle but steady pull separate the front of the base.

Then slide the front to the top.

Desatornille los tornillos de fijación de la tapa circuito. Use

un destornillador de punta PZ2.

___________________

Unscrew both screws securing the electronic circuit board

cover. Use a cross head PZ2 screwdriver.

Retire la tapa.

___________________

Remove the lid.

20 Intelligent Facility Solutions

Desconecte los cables de motor y alimentación de los

terminales de la placa electrónica.

___________________

Unplug the motor and power wires from the electronic

circuit board terminal blocks.

Desconecte los cables de sensor de nivel, sensores

infrarrojos y pantalla led.

___________________

Unplug the water level sensor, infrared sensors and signal

board wires.

Abra la tapa lateral de conexiones.

___________________

Open the control switch cover.

Retire el eje del potenciómetro.

___________________

Release the potentiometer rod.

Extraiga la placa electrónica.

___________________

Remove the electronic circuit board.

Realizar el montaje siguiendo los pasos anteriores en sentido inverso.

Fit it following the previous steps in reverse order.

D-Flow 21

REGULACIÓN DE POTENCIA DEL MOTOR - MOTOR POWER ADJUSTMENT

Abra la tapa lateral de conexiones.

___________________

Open the control switch cover.

Utilizando un destornillador de punta plana

gire el potenciómetro en sentido anti horario para disminuir

la potencia del motor.

___________________

Using a flat head screwdriver, turn the potentiometer rod

counterclockwise to decrease the motor power.

Gire el eje del potenciómetro en sentido horario para

aumentar la potencia del motor.

___________________

Turn the potentiometer rod clockwise to increase the motor

power.

22 Intelligent Facility Solutions

CAMBIO DEL FILTRO DE ADMISIÓN - AIR INTAKE HEPA FILTER REPLACEMENT

Extraiga el conjunto filtro, desclipandolo de la base.

___________________

Remove the filter assembly by unclipping it from the base.

Con la ayuda de un destornillador de punta plana, extraiga

el filtro de su alojamiento.

Tenga cuidado de no dañar los plásticos.

___________________

Remove the filter from its housing. Use a flat head

screwdriver. Be careful of

not to damage plastic parts.

Proceda a cambiar el filtro y/o la pastilla neutralizadora de

olor según necesite. Para evitar dañar el filtro nuevo, evite

tocarlo por otro sitio que no sea el marco

___________________

Replace the filter and/or the freshener tablet, as needed.

To avoid damaging the new filter, avoid touching the filter

on other parts that are not the frame

Intelligent Facility Solutions Ltd

Electric Works

3 Concourse Way

Sheffield

S1 2BJ

T: +44 (0)114 2866394

email: service@ihdryers.co.uk

www.intelligenthanddryers.com

Loading...

Loading...