Intell-Print OM-192-S

Dot Matrix Printer

A Higher Level of Precision…

A Higher Level of Performance

User Operation Manual

1

2

1. INTRODUCTION

OM19X is a dot matrix impact printer that is available in 24 column, OM190,

and 40 column, OM192, models. It is compact and reliable with a variety

of features and options suitable for a wide array of applications including

medical and industrial instruments, point of sale, test and measurement,

security, time and attendance, etc.

1.1 Features

x Easy paper loading and ribbon replacement

x Serial RS-232C or Centronics parallel

x Multiple international character set

x Auto power off features.

x User selectable options stored in non-volatile ram.

x Watch dog software shuts off power to the print head and carriage motor in a

paper jam situation.

x Full 96 ASCII set (plus additional European/Chinese and scientific

characters).

x 32kbyte buffer.

x Double width printing.

x Double height printing.

x Underlining.

x Built-in tab stops.

x Vertical tab.

x Form feed.

x Self-test.

x Inverted printing (data mode only).

x Graphics.

x Reset command.

x Software diagnostic mode.

x DH technology 1000 emulation.

x Epson ESC/POS emulation.

x Citizen 560 emulation.

2. SPECIFICATIONS

2 -1. General specifications.

Model OM190 OM192

Print method Shuttle impact dot matrix (8 pins)

No. of columns 24 40

Printing speed 2.5 lps 1.7 lps

No. of dots per

line

Dot Size 0.33 (H) x 0.38 (W) mm

Character size

(mm)

Line Spacing 3 dot lines

Font size (5+1) x 7

Interface Type S: RS-232C serial

Emulation Epson ESC/POS, Citizen 560,

Data buffer 1 KB

Ink ribbon ERC-09 or ERC-22 (Purple or black)

Paper

No. of copies Original + 1 copy

Power supply

Dimensions (mm) 178 (L) x 105 (W) x 82 (H)

Reliability (MCBF) 1.5 million lines 0.9 million lines

Weight 400 g or 0.88 lbs

Safety approvals CE

Operating

condition

1.7 (W) x 2.6 (H) 1.1 (W) x 2.6 (H)

144 240

Type P: Centronics parallel

DH1000

Width 57.5 r 0.5 mm

Diameter 60 mm (Max)

9VDCr10% 2.0 A

0to50qC 10to80%RH

(Operating)

2 -2. Printer types and models:

Printer types and models are selected according to the following designation:

X: Designates column capacity: 0 24 columns

Y: Designates interface type S Serial interface

OM19X

-Y-Z

2 40 columns

P Parallel interface

3

4

Z: Designates input voltage for the external power adaptor

Blank 110VAC WA Without adaptor

220 220 –240 VAC SMPS 90-240VAC

3. Setting up the printer

3-1. Unpacking.

The items illustrated below are included with your printer. If any items are

damaged or missing, please contact your dealer for assistance.

Printer , Paper Roll, Power Supply, Ribbon (installed), Manual, and Interface

Cable.

Printer Paper roll

Power Adapter Interface Cable

3-2. Selecting a Place

1. Protect your printer from excessive heat such as direct sunlight or

heaters.

2. Avoid exposing the printer to excessive dust and humidity.

3. Place the printer on a firm, level surface free from intense vibration or

shock.

3 -3 Connecting the Power Adapter

This printer requires an external power supply. Be sure to use a power supply

that matches the specifications.

1. Make sure the power switch is OFF .

2. Insert the output plug of the power adapter into the DC jack of the printer.

3. Plug the adapter or the power supply’s cord into an outlet.

4. For best results use one of the following Omniprint adapters:

OMPS190-915-NA (120VAC input)

OMPS190-915-EU (220-240VAC input)

OMPS190-915-SMPS (90-240VAC input)

Output: 9VDC 1.5A , 2.1mm x 5.5mm female plug , Center positive

3-4 Connecting the Interface Cable

You need an appropriate serial interface or parallel interface cable to connect

your computer to the printer.

3-4-1 Serial Interface Cable: OM19

1. Make sure that both the printer and computer are turned off.

2. The serial printer comes with a DB-25 female connector. Plug the DB-25

male end of the cable into the printer connector, as shown above.

-S

5

3. Use a screw driver to fasten the cable screws to the two nut screws

installed on the printer connector.

4. Connect the other end, DB9-F connector, to your computer.

5. Use Omniprint part number:

CBL-625F-25M (DB-25 male on the host side)

CBL-69F-25M (DB-9 male on the host side)

3-4-2 Parallel Interface Cable: OM19

-P

1. Make sure that both the printer and computer are turned off.

2. The parallel printer comes with a DB-25 male connector. Plug the DB-25

female end of the cable into the printer connector, as shown above.

3. Use a screw driver to fasten the cable screws to the two nut screws

installed on the printer connector.

4. Connect the other end, DB25-M connector , to your computer.

5. Use Omniprint part number:

CBL-625M-25F-STR

3-5 Installing the Ribbon Cartridge

1. Turn the printer off before you open the printer cover.

2. Remove the old ribbon by pressing on the front right hand corner of the

cassette where marked “PUSH”.

3. Turn the ribbon cassette’s knob in the direction of the arrow to take up

any slack in the ribbon.

4. Insert the ribbon between the printer head and platen, as shown above,

and push the cassette down until it snaps in place.

5. Turn the knob a few times again to take up any slack in the ribbon.

6. Use the following part number for ordering new ribbons:

6

Regular ERC-09- (PforpurpleorBforblack)

Long Life ERC-22- (PforpurpleorBforblack)

©

3-6 Loading Paper

Use a paper roll that meets the specifications. Do not use paper rolls that are

glued to the core. Make sure data is not being transmitted to the printer while

loading paper.

`````

PUSH

ribbon

change

1. Cut the leading edge of the paper roll straight at a right angle, as shown

above.

2. Remove the old paper roll, if any, and press the FEED button until any

excess paper left in the mechanism is out. Do not pull the paper out of

the printer mechanism paper inlet.

3. Mount the paper roll on the paper roll holder by gently bending the plastic

tab, on the right, and insert the roll so that the holes in the core align with

the axes of the paper roll holder. Make sure that the two holders are

completely inside the core so that the paper roll can move freely without

much friction, i.e. the core inside diameter is larger than the paper roll

holder’s outside diameter.

7

4. Hold the both edges of the paper and insert it straight into the paper slot.

5. Press the FEED button until approximately two inches of paper is fed

through the mechanism.

6. Tear the excess paper against the serrated edge and close the cover.

7. Use the following Omniprint part number to reorder paper:

PP-225-135 1 ply paper roll

PP-225-90WC 2 ply paper roll

4. External Appearance.

Cover top

Paper cover

Control panel

Top cover

On Off

Roll paper

Roll paper

Paper roll holder

Bottom cover

8

Interface connector DC Jack

5. Control Panel

The control panel features four buttons and one LED to indicate printer status.

ON BUTTON: Press the ON button to power up the printer. A red LED inside

the button will light up. The printer goes ON LINE ready to receive data from the

host.

OFF BUTTON: Press the OFF button once to turn the power OFF.

FEED BUTTON: When the FEED button is pressed and then released within

0.5 sec., the paper feeds only one line. When the FEED button is held

depressed for more than 0.5 sec., the paper feeds continuously.

SEL BUTTON: The SEL button is used to change the printer setting. (Please

refer to the SET UP section for details)

STATUS LED: The LED is located inside the ON button and lights up when

power to the printer is on. The LED flashes every second when the printer head

jams and every 0.2 second in the case of mechanism malfunction.

9

6. Running the Self Test

Any time you want to check the performance of your printer you can run the self

test described below. This shows whether your printer is working correctly.

1. While holding down the FEED button, turn the printer on.

2. The printer prints the model name, EPROM revision installed, and a few

lines of the rotating character set.

3. The printer will automatically stop printing at the completion of the self

test and enter the normal mode.

NOTE: THE PRINTER WILL GO OFF LINE AND WILL NOT COMMUNICATE

WITH THE HOST WHILE IT IS IN SELF TEST MODE.

7. Default settings

Your printer is supplied with the following default setting.

DATA BITS 8

P ARITY NONE

BAUD RATE 9600

CHARACTER SET U.S.

PRINT MODE TEXT

AUTO-OFF 5MIN

EMULATION STANDARD

(ESC/POS)

DTR NORMAL

INTERFACE SERIAL

The factory default settings can be restored by simultaneously pressing the

FEED and SEL buttons at power up. Releasing the FEED button before the SEL

button will save the revised settings.

8. Set-up mode

8.1 Set-up By Control Panel Buttons

You can change the printer serial interface, character table, emulation, and print

mode settings by following the procedure below:

10

1. By turning the power on while pressing the SEL button the printer will

print the current configuration and get in SET-UP mode.

2. The power LED will flash every second to indicate the printer is in SETUP m ode.

3. By pressing the FEED button, in SET -UP mode, you can scroll through

the printer parameters in the order shown in the table below.

4. Pressing the SEL button will cause the setting of a parameter to

change in the sequence shown below.

5. Once the desired setting is selected, it can be saved by pressing the

SEL button while pressing the FEED button.

NOTE: IF NO BUTTONS ARE PRESSED FOR 15 SECONDS, THE SET-UP

MODE IS AUTOMATICALLY TERMINATED WITHOUT CHANGING THE

ORIGINAL PARAMETERS.

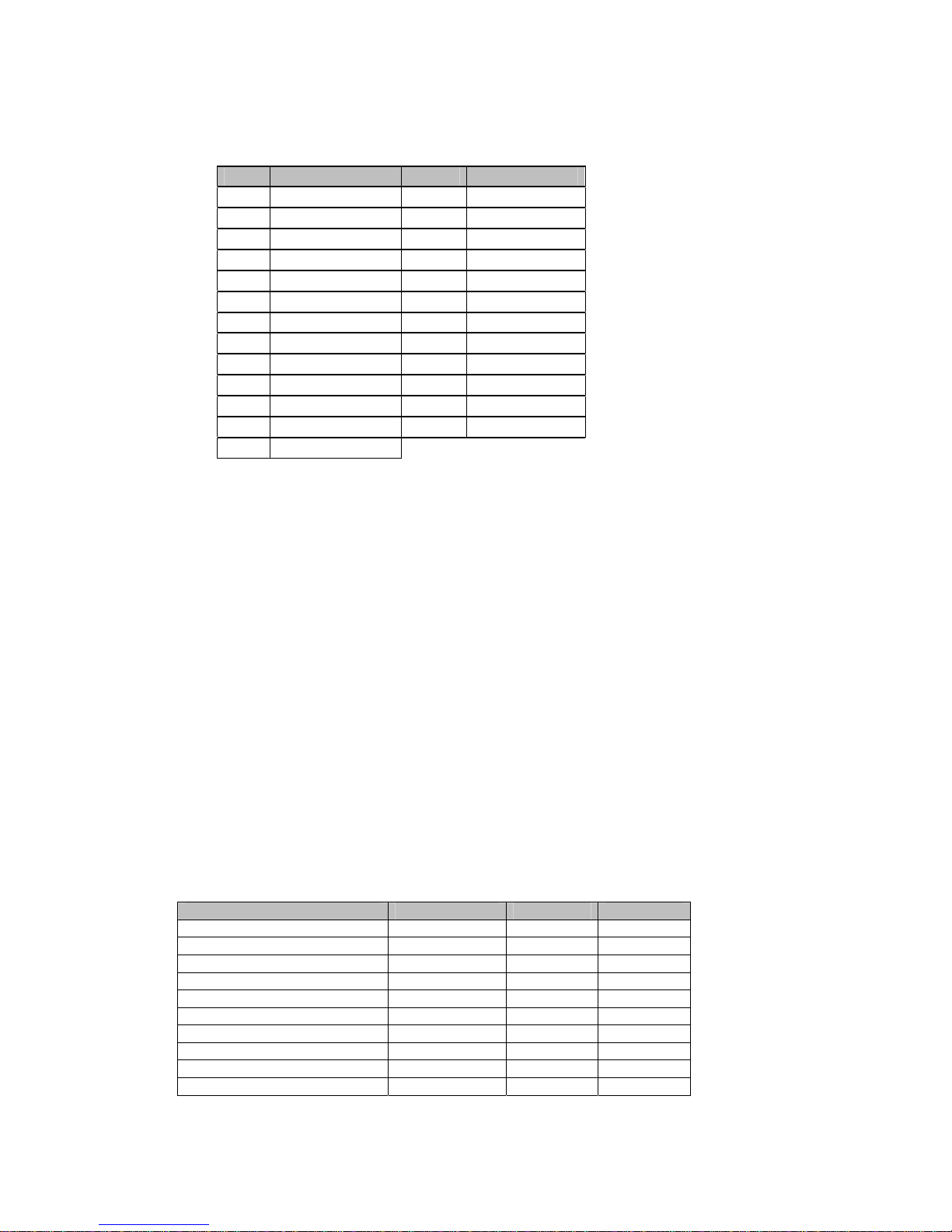

PARAMET ER (FEED Button) STATUS (SEL Button)

8BIT DATANUMBER OF DATA BITS

7BIT DATA

SERIAL PARITY

SERIAL BAUD RATE

CHARACTER SET

AUTO POWER OFF

EMULATION

NO PARITY

ODD PARITY

EVEN PARITY

2400 BAUD

4800 BAUD

9600 BAUD

19200 BAUD

U.S.A.

FRANCE

GERMANY

U.K.

DENMARK I

SWEDEN

ITALY

SPAIN

JAPAN

NORWAY

DENMARK II

TEXT(NORMAL PRINT)PRINT MODE

DATA(INVERTED PRINT)

5MIN

1MIN

DISABLE

STANDARD(DH1000)

CITIZEN 560

ESC/POS

NORMALDTR

INVERTED

8.2 Set-up Through the Data Port

11

If the printer is turned on while pressing the SEL and FEED buttons,

simultaneously, and only the SEL button is released, the printer will print : “nvr

comms ready>”

At this point the printer is waiting to receive data in the following format : SETUP mode + Carriage Return +n1+…n10

(n1 to n10 are hex number) the SET-UP mode followed by a carriage return

indicates that the printer should expect parameter data as shown in the table

below.

Upon receiving information in the correct format, the printer will print : “data

ok,nvr updated !”.

Note : If no data is received within 15 seconds or the FFED button is released

before the procedure is complete, then the new setting will not be saved and the

printer will print : “set error nvr unchanged “.

8.3 NVR COMMS

STRING “ SET-UP MODE”,ODH,N1,N2,N3,N4…..

1 Data bit 7 8

2 Parity EVEN ODD NONE

3 Baud rate 19200 9600 4800 2400

4 Country

5 Print mode DATA TEXT

6 Auto off Disable 1MIN 5MIN

7 Emulation

8 Printing Invert

9 Zero Status

10 Reverse

future

0 12345678910

Denmark2 Norway Japan Spain Italy SwedenDenmarkIU.K. GermanyFranceU.S.A.

ESC/PO

S

560

Norma

l

Standar

d

8.4 Diagnostic Mode

To get in the diagnostic mode, perform self-test and keep pressing the FEED

button until “diagnostic modes” is printed. Press the FEED button to end. The

power-on indicator will flash every two seconds. Following is an example of the

diagnostic mode:

Abc de fg …….normal print

Abcide nfogm ……diagnostic print out

In the above example the following sequence of characters was sent :

Character f, single width(o),character g, carriage return(m).

12

9. Accessories

1) Paper: 57.5mm+/-0.5mm(width) , 60mm max(roll diameter) , 85 microns

(thickness)

PP-225-80 1-ply paper roll

PP-225-75W C 2-ply paper roll

2) Ribbon specification : ERC-09 P (Purple) or B (Black) Standard

cartridge

ERC-22 P (Purple) or B (Black) Long Life Cartridge

3) Interface Cable: 6 foot long, shielded cable with molded connectors.

CBL-625M-25F-STR Parallel cable

CBL-625F-25M Serial cable w/ DB-25F host

side

CBL-69F-25M Serial cable w/ DB-9F host side

4)Power Supply: Output: 9VDC 1.5A , 2.1mm x 5.5mm female plug , center

positive.

OMPS190-915-NA 120VAC input

OMPS190-915-EU 220-240VAC input

OMPS190-915-SMPS 90-240VAC input

10. Troubleshooting

1) IF THE POWER LED DOES NOT COME ON.

Make sure the power supply cables are securely plugged into the printer, the

adapter, and the power outlet. Also, make sure that power is supplied to the

power outlet. If the outlet is controlled by a switch or timer, use another outlet.

1)IF THE POWER LED IS ON BUT PAPER DOES NOT FEED.

This may be a head jam condition, first turn off the printer and make sure there

is no paper stuck in the mechanism; however do not use force or a sharp object

to remove the jammed paper .

2)IF THE PAPER IS NOT FEEDING PROPERLY.

If the printout looks squashed, make sure that the paper roll moves freely on the

paper holder. If the paper is wrinkled on the edges, the roll may not loaded

correctly. In that case remove the paper and reload.

4) IF THE PRINTER SOUNDS LIKE IT IS PRINTING BUT NOTHING IS

13

PRINTED

Make sure a ribbon cartridge is installed properly that is not worn out. Please

note that the ribbon needs to be in front of the paper.

If the printout is faint, turn the knob on the cartridge in the direction of the arrow.

Also, see if the knob turns when the FEED button is pushed, if it does not, then

the advance gear on the ribbon or the mechanism may be defective or worn out.

3)IF THE PRINTER DOES NOT COMMUNICATE WITH THE HOST.

Run the self test to check that the printer works properly. If the self test does not

work contact your dealer or qualified service person. If the self test works

properly, check the following:

A. You are using the right interface cable.

B. The connection on both ends of the cable between the printer and

the host.

C. The data transmission setting may be different between the printer

and the host. Use the SET-UP instructions to change the settings, if

necessary.

4)IF A LINE OF DOTS IS MISSING IN THE PRINTOUT.

The print head may be damaged. Contact your dealer or qualified service

person.

11. Interface connections

The OM19 printer is available in RS-232C serial and Centronics compatible

parallel versions. The interface type is printed on the self-test printout. The

connector for the serial interface is a DB25 female and male for parallel.

11-1. SERIAL INTERFACE

11-1-1 Serial Interface Specifications

Data Transmission Method: Asynchronous serial interface

Baud Rate: User selectable from 2400, 4800, 9600, 19.2K

Word Length: Start bit 1 bit

Data bit 7 or 8 bit

Parity Odd, Even, None

Stop bit 1 bit

Signal Polarity: MARK: Logic “1” (-10V)

SPACE: Logic “0” (+10V)

14

Input Control (DTR signal) : Mark: Data transmission not possible

Space: Data transmission possible

11-1-2 Connector Pin Assignment

FUNCTION PIN NUMBER INPUT-OUTPUT

RXD 3 IN

TXD 2 OUT

CTS 5 IN

RTS 4 OUT

DSR 6 IN

GND 7,9,14

*POWER 12,13,16 IN

NC 5,6,8,10,11,15,17-19,21-

25

F-GND 1

DTR 20 OUT

*Pleasenotethatsomemodelscanbesetatthefactorytoreceivepowerthroughthe

serial port.

11-1-3 Serial Interface Timing Diagram

11-2. P ARALLEL INTERFACE

11-2-1 Parallel Interface Specifications

Data Transmission Method: 8 bit parallel, DATA0

Synchronization: Via e

Handshaking: ACK and BUSY signals

Data Transfer Rate: 1000 to 6000 characters per second

Logic Level: Compatible with TTL level

11-2-2 Parallel Connector Pin Assignment

–DATA7

xternal STROBE pulses

15

PIN FUNCTION PIN FUNCTION

1STROBE 14 N.C.

2 DATA 0 15 N.C.

3 DATA 1 16 N.C.

4 DATA 2 17 N.C.

5 DATA 3 18 N.C.

6DATA4 19 +9V

7DATA5 20 +9V

8DATA6 21 GND

9DATA7 22 GND

10 ACK 23 GND

11 BUSY 24 GND

12 N.C. 25 GND

13 N.C.

Printer is capable of receiving data from the host while the BUSY signal is in the

LOW state and communication will be interrupted when the signal is HIGH>

12. COMMAND CODES

12.1 COMMAND SUMMARY FOR DH1000 EMULATION

FUNCTION KEYSTROKE HEX DECIMAL

HORIZONTAL TAB CTRL I 09H 9

LINE F EED CTRL J 0AH 10

FORM FEED CTRL K 0BH 11

VERTICAL TAB CTRL L,n 0CH,n 12,n

CARRIAGE RETURN CTRL M 0DH 13

DOUBLE WIDTH CTRL N 0EH 14

SINGLE WIDTH CTRL O 0FH 15

RESET CTRL Q 11H 17

UNDERLINE CTRL U 15H 21

UNDERLINE RELEASE CTRL X 18H 24

16

REVERSE PRINT CTRL Y 19H 25

DOUBLE HEIGHT CTRL Z 1AH 26

GRAPHICS CTRL [,n 1BH, n 27,n

12.2 COMMAND SUMM ARY FOR EPSON ESC/POS EMULATION

FUNCTION KEYSTROKE HEX DECIMAL

HORIZONTAL TAB CTRL I 09H 9

LINE F EED CTRL J 0AH 10

FORM FEED CTRL L 0CH 12

CARRIAGE RETURN CTRL M 0DH 13

SET PRINT MODE ESC ! n 1BH,21H,n 27,33,n

INITIALIZE PRINT ESC @ 1BH,40H 27,64

CHARACTER SET ESC R n 1BH,52H,n 27,82,n

PRINT & FEED ESC d n 1BH,64H,n 27,100,n

STATUS REQUEST ESC v 1BH,76H 27,118

INVERTED PRINTING ESC { n 1BH,7BH,n 27,123,n

SET FORM LENGTH ESC C n 1BH,43H,n 27,67,n

12.3 COMMAND SUMMARY FOR CITIZEN 560 EMULATION

FUNCTION KEYSTROKE HEX DECIMAL

LINE F EED CTRL J 0AH 10

FORM FEED CTRL L 0CH 12

CARRIAGE RETURN CTRL M 0DH 13

REVERSE PRINT CTRL T 14H 20

CLEAR BUFFER CTRL X 18H 24

GRAPHIC P RINT ESC K 1BH,4BH

PAGE LENGTH/FORMAT ESC C 1BH,43H

PAGING IS OFF ESC 0 1BH,4FH

2.75MM SPACING ESC1 1BH,31H

5.5MM SPACING ESC 2 1BH,32H

DOUBLE WIDTH 1EH 30

SINGLE WIDTH 1FH 31

COMMANDS

ACKNOWLEDGED

BUT NOT

EXECUYED

11.2 COMMAND DESCRIPTIONS

11.2.1 COMMAND DESCRIPTION FOR DH1000 EM ULATION

TAB(09H) : Moves the print position to the nest horizontal tab position. The default tab positions

are at every 8 character intervals. This command will be ignored unless the nest horizontal tab

position is set.

LINE FEED(0AH) : Prints the data in the print buffer and feeds one line based on the current

line spacing . IF LF+CR IS SENT, CR WILL BE IGNORED TO AVOID DOUBLE FEEDING.

FORM FEED(0BH) : The printer fast feeds to the top of form set by software. Any character in

the buffer will be printed and the buffer pointer will be reset.

VERTICAL TAB(0CH,N) : Printer feeds the paper by N lines. N is a single byte hex number in

the 0<n<20h range. Note that a vertical tab will print the contents of the line buffer before being

executed.

17

CR(0DH) : This command prints the data in the print buffer and feeds one line. If a LF is sent

immediately after CR, it will be ignored to avoid double printing. When the line buffer is full, ie

upon receiving the 24

th

and 40thcharacters in the case of OM190 and OM192, respectively, the

printer will automatically print the data in the buffer. If CR or LF is sent, they will be ignored in

this situation.

DOUBLE WIDTH(0EH) : Upon receiving this command the printer will go in the double wide

mode and remains in this mode until terminated by the single wide command or completion of

the current line. If the last character of a line is double wide but there is room only for a single

wide character, it will be printed in single width.

SINGLE WIDTH(0FH) : Printer reverts back to single width printing. Single and double wide

characters can be combined anywhere on a line.

RESET(11H) : This commands causes the printer to be set to power up default conditions.

NOTE THAT THIS WILL NOT CLEAR THE BUFFER OF ANY DATA PREVIOUSLY SENT.

UNDERLINE(15H) : Characters sent after this command will be underlined. Tabs are not

underlined. Underlining is terminated by the underline release command or upon completion of

the current line.

UNDERLINEL RELEASE(18H) : Terminates the underline mode.

REVERSE PRINT(1AH) : This command causes the printer to print white o n black. You can

toggle between reverse and normal anywhere on a line but the reverse print mode will

automatically be terminated at the end of a line.

DOUBLE HEIGHT(1AH) : Upon receiving this command the printer will go in the double high

mode and re mains in this mode until terminated by the single wide command or completion of

the current line.

NOTE THAT DOUBLE HEIGHT AND SINGLE HEIGHT CHARACTERS CANNOT BE

COMBINED ON THE SAME LINE.

GRAPHICS(1BH,N) : This command causes the printer to go in the bit image printing mode.

The number of graphic bytes sent will depend on the type of mechanism. For each graphic byte

sent to the printer, 6 out of 8 bits are used to form the graphic string (LSB is the right most dot).

N is the number of times the string will be repeated for a repetitive pattern, 0N255 lines. The

print buffer will be printed first if not empty.

EXAMPLE : TO REPEAT A S TRING OF DATA BYTES,D1----D24 OVER TWO ROWS FOR

OM190: SEND : 1BH,D1-------------D24. FOR A NON -REPEATED STRING SEND :1BH,01H,D1-

---D24.

11.2.2 EPSON ESC/POS COMMAND DESCRIPTION

TAB(09H) : : Moves the print position to the next horizontal tab position. The default tab

positions are at every 8 character intervals. This command will be ignored unless the nest

horizontal tab position is set.

LINE FEED(0AH) : Prints the data in the print buffer and feeds one line based on the current

line spacing . IF LF+CR IS SENT, CR WILL BE IGNORED TO AVOID DOUBLE FEEDING.

FORM FEED(0CH) : Prints the current line and feeds the number of lines programmed by using

the ESC C command.

18

CR(0DH) : This command prints the data in the print buffer and feeds one line. If a LF is sent

immediately after CR, it will be ignored t o avoid double printing.

ESC ! n(1BH,21H,n) : Sets the print mode according to the following table. n is a single byte in

which each bit sets the printing function. Note that underline cannot be used with a horizontal

tab and any combination of double height and width can be used. Default is n=0.

Bit Off/On Hex Decim

Function

al

0,1,

--- --- --- Undefined

2

Off 00 0 Emphasized mode

3

off

Off 00 0 Double-height off

4 On 10 16 Double-height on

Off 00 0 Double-width off

5

On 20 32 Double-width on

6 --- --- --- Undefined

Off 00 0 Underline mode off

7 On 80 128 Underline mode on

ESC @(1BH,40H) : Initialize the printer. C lears the print buffer and resets the printer to default

values.

ESC R n(1BH,52H,n) : Selects the international character set form the following table

n Character set

0U.S.A.

1 France

2 Germany

3U.K.

4 Denmark I

5 Sweden

6Italy

7Spain

8 Japan

9Norway

10 Denmark II

ESC d n(1BH,64H,n) : Prints the data in the print buffer and feed n lines.

ESC v(1BH,76H) : The current printer status is transmitted to the host upon receipt of this

command. The printer transmits one byte of data to the host indicating the status of the paper

out detector. It takes the form of a single byte which is fixed at 0(to indicate paper in) for printer.

The Byte is sent reg ardless of the CTS handshaking signal.

ESC { n(1BH,7BH,n) : Inverted print command. If n=1 then printing will be is inverted and text

will be printed from right to left. For normal printing n=0. The default mode is set by the

programmed parameters in the printer.

ESC C n(1BH,43H,n) : Set form length. When used in conjunction with the form feed

command(0ch), the printer will feed n l ines. NOTE THAT IF n=0,THEN THERE WILL BE N O

LINE FEED.

19

11.2.3 COMMAND DESCRIPTION FOR CBM560 EMULA T ION

LINE FEED (0AH) : Prints the data in the print buffer and feeds one line.

FORM FEED(0CH) : Form feeds after printing. This is fixed at three lines.

CR(0DH) : Feeds a new line after printing.

REVERSE PRINT(14H) : This command causes the printer to print white on black. You can

toggle between reverse and normal anywhere on a line but the reverse print mode will

automatically be terminated at the end of a line.

CLEAR BUFFER(18H) : All the data in the print buffer, received prior to this command, will be

cleared; however, this code is treated as data in the graphics mode.

DOUBLE WIDTH(1EH) : Upon receiving this command the printer will go in the double wide

mode and remains in this mode until terminated by the single wide or LF command or

completion of the current line. If the last character of a line is double wide but there is room only

for a single wide character, it will be printed in single width.

SINGLE WIDTH(1FH) : Printer reverts back to single width printing. Single and double wide

characters can be combined anywhere on a line.

APPENDIX 1. INTERNATIONAL CHARACTERS SET

20

APPENDIX 2. PRINTABLE CHARACTER SET

21

APPENDIX 3. EXTERNAL DIMENSIONS

22

23

Loading...

Loading...