Label Printer

User’s Guide

For All Series Printer s

Changing the way the world prints labels…

PROPRIETARY NOTICE AND LIABILITY DISCLAIMER

The information disclosed in this document, including all designs and related materials, is

the valuable property of IntelliTech International Incorporated (IntelliTech) and/or its licensors. IntelliTech and/or its licensors, as appropriate, reserve all patent, copyright and

other proprietary rights to this document, including all design, manufacturing, reproduction, use, and sales rights thereto, except to the extent said rights are expressly granted to

others.

The IntelliTech product(s) discussed in this document are warranted in accordance with the

terms of the Warranty Statement accompanying each product. However, actual

performance of each such product is dependent upon factors such as system configuration,

customer data, and operator control. Since implementation by customers of each product

may vary, the suitability of specific product configurations and applications must be

determined by the customer and is not warranted by IntelliTech.

To allow for design and specification improvements, the information in this document is

subject to change at any time, without notice. Reproduction of this document or portions

thereof without prior written approval of IntelliTech is prohibited.

IntelliBar is a trademark of IntelliTech International, Inc.

Copyright 1998 - 2012

IntelliTech International Inc.

43 Broad Street

Hudson, MA 01749

http://www.intellitech-intl.com

All Rights Reserved

Contents

Preface........................................................................................................................ xi

Abbreviations.............................................................................................................xiii

General Information

Models 48 and 412.....................................................................................................1-2

Model 88.....................................................................................................................1-3

Hardware Description...............................................................................................1-5

Power Supply......................................................................................................1-5

Control Panel......................................................................................................1-5

Main Board.........................................................................................................1-5

Ribbon and Label Feed Mechanisms.................................................................1-7

Print Mechanism.................................................................................................1-9

Memory Expansion..................................................................................................1-10

Options.....................................................................................................................1-10

User-Installable Options...................................................................................1-10

Factory-Installable Options.................................................................................1-11

Specifications.............................................................................................................1-12

Interface.....................................................................................................................1-14

Parallel Interface.................................................................................................1-14

IEEE 1284 Cable Requirements..................................................................1-14

Serial Interface....................................................................................................1-14

Data Transmission.......................................................................................1-15

Section 2 Setup

Unit Setup..................................................................................................................2-1

Connecting the Power Cord...............................................................................2-5

Connecting the Communicat i ons In t erface Cables............................................2-6

Label and Ribbon Requirements........................................................................2-10

IntelliBar Ribbons........................................................................................2-12

Ribbon/Label Combination................................................................................2-14

Loading Labels....................................................................................................2-15

Models 48 and 412.......................................................................................2-15

Contentsiv

Model 88.......................................................................................................2-23

Installing the T hermal Ribbon...........................................................................2-26

Model 48 or 412...........................................................................................2-26

Model 88.......................................................................................................2-30

Print Head Removal and Installation.......................................................................2-34

Print Head Removal...........................................................................................2-35

Model 48 and Model 412.............................................................................2-35

Model 88.......................................................................................................2-38

Print Head Installation.......................................................................................2-40

Model 48 and 412.........................................................................................2-40

Model 88.......................................................................................................2-41

Print Head Voltage Adjustment.........................................................................2-42

Section 3 Unit Operation

Controls and Indicators......................................................................................3-1

Self-Test...............................................................................................................3-4

Test Page......................................................................................................3-6

Bar Code......................................................................................................3-7

Menu Tree...........................................................................................................3-7

Default Factory Settings..............................................................................3-7

Changing Settings........................................................................................3-9

Controlling the Printer................................................................................3-20

LCD Display Messages.......................................................................................3-26

Printing Modes..........................................................................................................3-30

Standard Mode...................................................................................................3-30

Peel-Off Mode.....................................................................................................3-30

Tear-Off Mode....................................................................................................3-31

Cut-Off Mode......................................................................................................3-31

Section 4 Options

Memory Expansion....................................................................................................4-1

IntelliTech Internationa l Inc. O pti o ns......................................................................4-3

User-Installable Options.....................................................................................4-3

Factory-Installable Options.................................................................................4-3

Memory Expansion Module Installation (All Models).............................................4-4

Installing SIMMs................................................................................................4-7

Contents

v

Label Cutter Installation Procedure Overview (Model 48 and 412)

A. Remove the Standard Peel-Off Assembly (Model 48 and 412)

B. Install the Cutter Option (Model 48 and 412)

........................................4-14

C. Configure the Printer to Use the Cutter (Model 48 and 412)

Internal Rewinder (Model 48 and 412)

Loading Labels

....................................................................................................4-16

Loading Labels in Standard Mode

Loading Labels in Peel-Off Mode

.....................................................................4-16

..............................................................4-16

...............................................................4-19

......................4-11

............4-12

................4-15

Section 5 Cleaning and Adjustments

Cleaning.....................................................................................................................5-1

External Cleaning...............................................................................................5-1

Internal Cleaning................................................................................................5-1

Print Head...........................................................................................................5-3

Platen Roller........................................................................................................5-3

Sensors.................................................................................................................5-4

Print Position Adjustment.........................................................................................5-5

Print Head Voltage Adjustment................................................................................5-6

Correcting Poor Print Quality...................................................................................5-6

Print Head Adjustments.....................................................................................5-7

Media Mismatch.................................................................................................5-7

Density.................................................................................................................5-7

Resistance Value.................................................................................................5-7

Print Head Latch................................................................................................5-8

Print Speed..........................................................................................................5-8

Ribbon Guide Plate............................................................................................5-8

Bad Print Head...................................................................................................5-8

Mechanical Adjustments...........................................................................................5-9

Model 48 and 412..............................................................................................5-10

Label Width Guides (Model 48 and 412)..................................................5-10

Horizontal Print Head Alignment (Model 48 and 412)..............................5-11

Print Head Pressure Knob for Label Thickness (Model 48 and 412)........5-13

Print Head Balance Lever for Label Width Adjustment (Model 48

and 412)....................................................................................................5-14

Print Head Position Dial for Label Thickness Adjustment (Model 48

and 412)....................................................................................................5-15

Ribbon Guide Plate (Model 48 and 412).....................................................5-18

Contentsvi

Sample Adjustment......................................................................................5-19

Timing Belt Tension Adjustment (Model 48 and 412)...............................5-20

Model 88..............................................................................................................5-21

Label Width and Pressure Adjustment (Model 88)....................................5-21

Label Thickness Dial (Model 88).................................................................5-23

Ribbon Tension Plate (Model 88)................................................................5-24

Print Density Adjustment..........................................................................................5-26

Section 6 Troubleshooting

Troubleshooting the Problem....................................................................................6-1

Using LCD Display Error Messages..........................................................................6-2

Correcting Print Quality...........................................................................................6-6

Top-Level Problem Solving.......................................................................................6-8

Common Questions and Answers.....................................................................6-17

Fax Form.............................................................................................................6-24

Appendix A Packing

Glossary

Proprietary Notice and Liability Disclaimer

Preface

This IntelliBar User Guide contains the information necessary to set up and maintain the

IntelliBar Models 48, 412, and 88 bar code printers.

*

The manual is organized as follows:

A list of the abbreviations us ed in this manual follows the preface.

Section 1 General Information provides an overview of the IntelliBar printers. This

chapter explains the main features of the printers and their options. This section also lists

printer specifications.

Section 2 Setup describes how to set up the printer.

Section 3 Unit Operation describes control panel buttons, status messages, menus, and

memory settings for the printer.

Section 4 Options provides information on the various IntelliBar user and dealer

installable options, including installation procedures .

Section 5 Cleaning and Adjustments contains instructions for cleaning and adjusting the

printer.

Section 6 Troubleshooting provides troubleshooting aids that include error codes, test

samples, and troubleshooting procedures. This section also contains information on getting

service and support and printer warranty terms and limitations.

Appendix A Packing provides packing information.

The Glossary at the end of this manual provides a list of IntelliBar and bar code printing

terms and briefly defines each one.

NOTE:

For updates on IntelliBar printer

specifications and other information about

IntelliTech International, Inc. products, visit our

web site at http://www.intellibar.com.

*

"This information is subject to change wi thout notice. This information is provided "as is" wit hout either express or

implied warranty.

Intelli

Tech shall not be liable in any event for any special, indirect or consequential damages or any damages whatsoever

resulting from loss of data, profits or use, for any reason or in any action, arising out of or in connection with the use or

performance of this information. "

Intelli

Tech International, Inc. disclaims any and all warranties with regard to this information.

Abbreviations

xiii

Aampere

AC alternating current

ACK acknowledge

ASCII American Standard Code for

Information Interchange

BIOS basic input/output system

bit binary digit

bp i bits per inch

bps bits per second

C centigrade

CD carrier detect

CLK clock

cm cen timeter

CM OS complementary me tal oxide

semiconductor

COM communication

CPU central processing unit

cpi characters per inch

CTS clear to send

DACK DMA ackno wledge

FAX facsimile transmission

FCC Federal Communications

Commission

FG frame ground

FRU field-replaceable unit

GB gigabyte

GND ground

HEX hexadecimal

HM I h orizontal motion ind ex

HP Hewlett Packard

Hz hertz

IC integrat ed circuit

ID identification

in. inch

IPB illustrated par ts breakdown

I/O input/output

ips inches pe r second

IRQ interrupt request

ISO Internat ional Standards

Organization

DC direct current

DIP dual in- line pa ckage

DMA direct memory access

dpi dots per inch

DRAM dynamic RA M

DSR data set ready

DT direct thermal application

DTE data terminal equipment

DTR data terminal ready

EPROM erasable programmable

read-only memory

EEPROM electrically erasable

programmable read-only

memory

ETX end-of-text

F Fahrenheit

K kilo (1024)

k kilo (1000)

KB kilobyte

kg kilogram

kHz kilohertz

LAN local area network

lb pound

LCD liquid crystal display

LED light-emitting dio de

lpi lines pe r inch

LSB least-significant bit

Mmega

mA milliamps

max maximum

MB megabyte

MHz megahertz

xiv Abbreviations

mm millimeter

ms millisecond

MSB most-significant bit

NC not co nnected

NMI non-maskable interrupt

ns nanosecond

PC personal computer

PCB printed circuit bo ar d

PCL p rinter control language

PDL page descriptio n language

pixel picture element

p-p peak-to-peak

PROM programmable ROM

P.S. power supply

RAM random-access memory

ROM read-on ly memory

rpm revolutions per minute

Wwrite

*

R read

RD received data

RTS request to send

R/W read/write

Sslave

SD send data

SG signal ground

SIMM single inlin e memory mo dule

STB strobe

SW switch

TD transmit data

TG tag stock application

TSC Technical Support Center

TT thermal transfer applicatio n

TTL transisto r / transist or logic

tpi tracks per inch

Vvolt

Vdc volts, direct current

VRAM virtual RAM

Wwatt

*

"This information is subject to change without notice.

This information is provided "as is" without either express or implied warranty.

Inc. disclaims any and all warranties with regard to

this information.

event for any special, indirect or consequential damages or any damages whatsoever resulting from loss of

data, profits or use, for any reason or in any action,

arising out of or in connection with the use or performance of this information."

Intelli

Intelli

Tech International,

Tech shall not be liable in any

Section 1

General Information

Th e IntelliBar is a thermal label printer that us es ind ustry-sta ndard printer command

languages t o produce high-resolution fonts, graphics, and bar co des o n t hermal transfer or

direct thermal paper or s yn thetic rolls of labels o r tag stock.

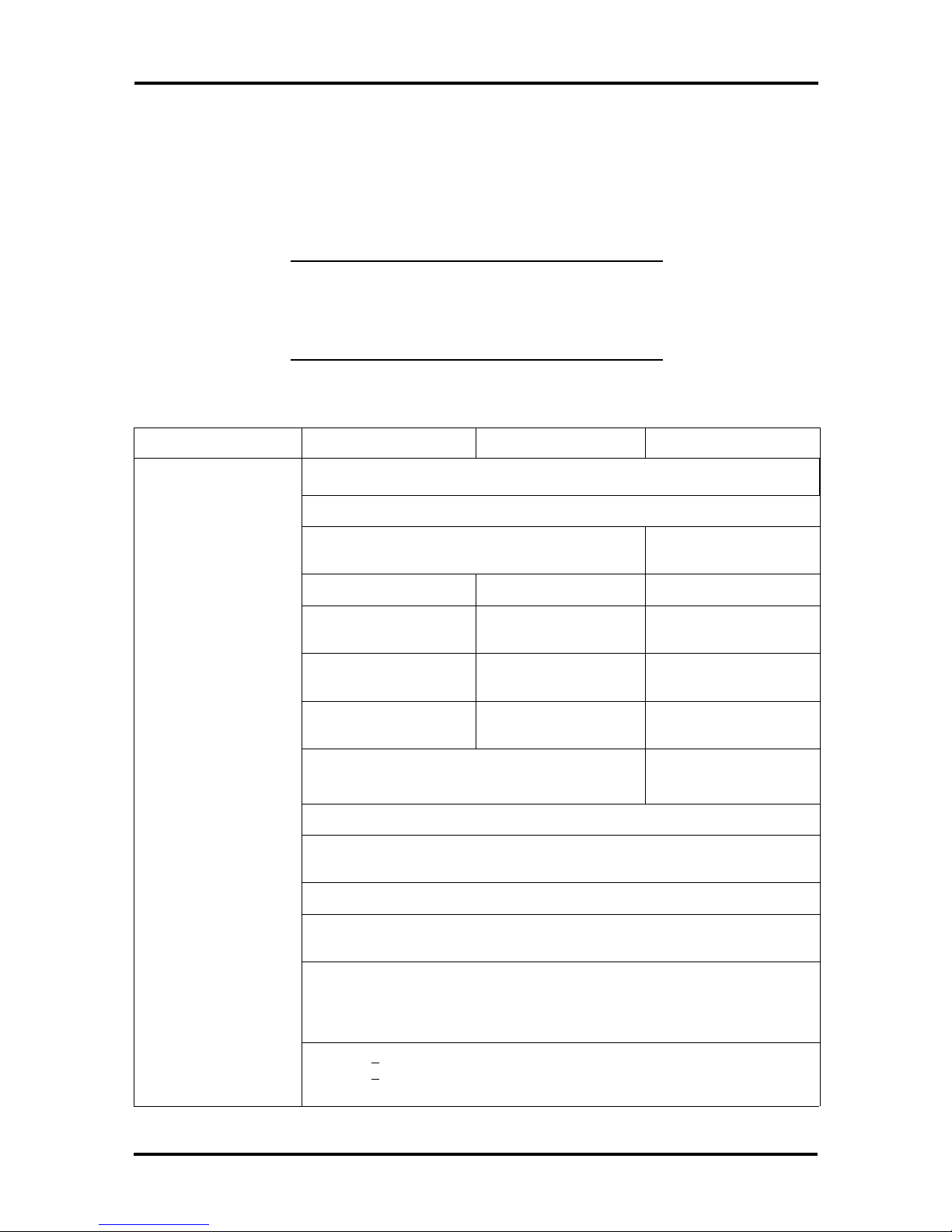

Th e IntelliBar print er family consists of four series diffe rentiated by the printer comma n d

language, emulation, and connectivity as listed in Table 1-1.

Table 1-1 IntelliBar Printer Product Line

Series Name Pri nter Command

Language

IntelliBar Standard

Series

IntelliBar AS Series AFP/IPDS,

IntelliBar ax Series SCS,

IntelliBar LPR Series IGP/PGL, IGP/VGL

Hewlett Packar d

Printer Control

Language 5

(HP PCL5)

HP PCL5

HP PCL5

Magnum Code V,

HP PCL5

Emulation Connectivity

LaserJet III IEEE 1284 parallel,

RS-232/RS422C serial

IBM 4028 IEEE 1284 parallel,

RS-232/RS422C serial,

10BaseT Twinax or Coax

IBM 5020 10BaseT Twinax or Coax,

IEEE 1284 parallel,

RS-232/RS422C serial

Printronix,

Centronics,

QMS

10BaseT Twinax or Coax,

IEEE 1284 parallel,

RS-232/RS422C serial

Each series consists of three models: Model 48, Model 412 and Model 88. All models print

using either th e thermal transfer or dir ect thermal printing method d escribed later in this

section. As standard features, all printers have 300 x 300 dots per inch (dpi) print

resolution, par allel an d serial communicat ion ports, and label p eel- off ca pability. The

In telliB ar AS, ax , and LPR Ser ies have the ad ditional standard feature of twinax and coax

connectivity. Each model also features a control panel and LCD display for simple printer

installa tio n and use (see “Co ntr ol Panel” in this section).

The Model 48 and Mo del 412 print labels up to a maximum width of 4.37 inches (111 mm).

The Model 88 prints labels up to a maximum width of 8.65 inches (220 mm). Label length is

model and memory dependent. I n the Model 48 and Model 412, memory can be expanded

t o increase lab el leng th, overall printer per formance, and data throug hput. The I nte lliBar

automat ically senses label length at power-on and provides a backfeeding capability used

with tear-off, pee l-off, or cut -off printing modes.

1-2 General Information

Print output can include text and graphics in addition to high-density bar codes, ext ending

t he IntelliBar printer’s versatility for any label prin ting need .

Depending on t h e IntelliBar model and the ma in board revision, ot her feature s inclu de:

an operating speed of up to 8 inches per seco nd (ips) for the Model 48 and Model

88, and 12 ips for t he Model 412.

HP PCL 5 compatibility and LaserJe t III printer command set emulation with 14

bitmap and eight outline fonts ( in addition to specific printer command languages

fo r th e var ious Int elliBar printer series as describ ed in Table 1-1). Support

includes all PCL 5 commands and func tio n s wit h several additional co mmand

extensions to deal with special printer featur es that ar e no t available in the HP

LaserJet (see t he IntelliBar Programmer’s Reference Guide for more

information).

a minimum of 2 MB of random-access memory (RAM) expandable (in the Model

48 and Model 412) using SIMM option inst allation (see “Memory Expansion” in

t his section).

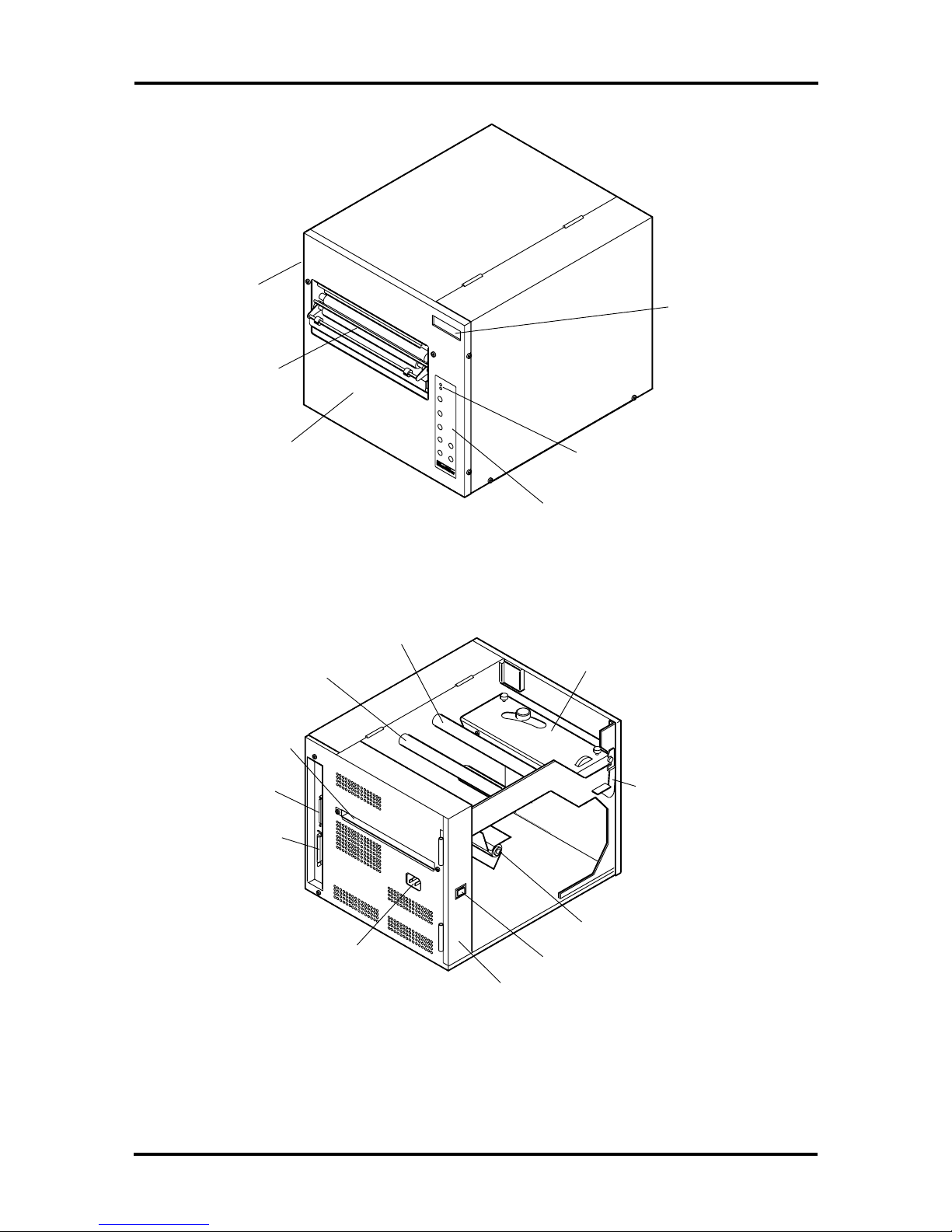

MODELS 48 AND 412

Features common to Models 48 and 412 are shown in Figure 1-1 and Figure 1-2 and

described in the following subsections. For printer specifications, see “Specifications” in this

section.

LCD Display

Lamps

Control

Pane l

Power Switch

Access

Handle

Label Release

Paper Slot

Label Exit

Slot

Front Panel

Figure 1-1 Model 48 and Model 412 Features (Front and Left Side View)

General Information 1-3

Left Side

Panel

External

Label

Entrance

Slot

Serial

Port

Parallel

Port

AC Power

Inlet

Power Supply

Label Supply

Spindle

Front Panel

Latch

Print Head

Print Head

Release Lever

Ribbon Takeup

Spindle

Ribbon Supply

Spindle

Figure 1-2 Model 48 and Model 412 Features (Rear and Left Side View)

MODEL 88

The features of the Model 88 are shown in Figure 1-3 and Figure 1-4 and described in the

following subsections. For printer specifications, see “Specifications” in this section.

1-4 General Information

Access

Handle

(hidden)

Label Exit

Slot

Front

Panel

Figure 1-3 Model 88 Feature s (Front and Right Side View)

Control

Panel

LCD Display

Lamps

Ribbon T ak eup

Spindle

Print Head

Label Supply

Spindle

Power Switch

Print Head

Release Latch

External

Label

Entrance

Slot

Serial

Port

Parallel

Port

Ribbon Supply

Spindle

AC Power

Inlet

Power Supply

Figure 1-4 Model 88 Features (Rear and Left Side View)

General Information 1-5

HARDWARE DESCRIPTION

Printer operat ions are coordinated by control panel settings and the main boar d components

under DC voltage from t he po wer supply. The fo llowing subsections describe how pr inting

is carried o u t.

power supply

co ntrol pa nel

main board

ribbo n and paper feed mechanisms

print mechanism (printer engine)

Power Supply

Alt er nat ing current (AC) is fed directly into the po wer supply and converted into the

various DC voltages that drive and cont r ol printer operat ion (+5 V, +12 V, - 12 V, +18 V,

+24 V). The power supply contains one replaceable fuse.

Control Panel

The contro l panel contains t he LCD display, power and alert indicators, and butto ns that

allow you t o cont rol and monitor printer operation. The 2-line display provides printer

status and err or messages and the printer settings menu tree. The power indicator shows

whether the printer is turned on or off, while the alert indicator shows whether the print er

has a fault or error condition that may affect o per ation. The co nt r ol panel buttons allow yo u

to view or change the printer settings (user parameters) via the menu tree.

For more infor mation, see Sect ion 3, “Unit Operation.”

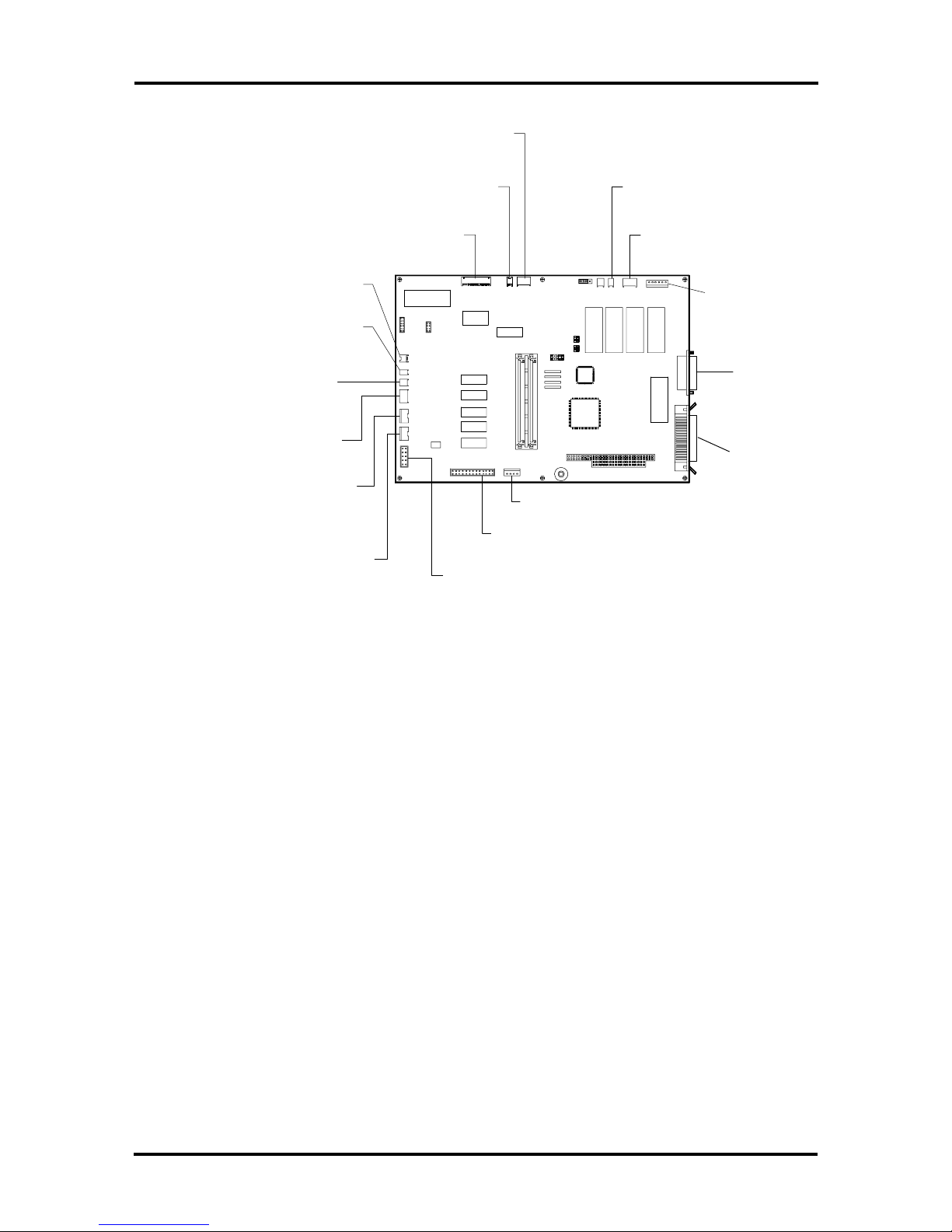

Main Board

The main board (located behind the right side panel) controls communications between the

computer and printer engine and coor dinates the printer’s logic and mechanical functions.

The printing pro cess begins when t he co mputer sends dat a to the main board thro ugh either

the serial or parallel interface. T he main bo ar d r eceives and int er pr ets the data (HP LaserJet

emulation and HP PCL language), develops the data in RAM, transmits the data t o the print

head for thermal tr ansference, and coordinates the paper and ribbon feeding mechanisms.

Th e main boar d is fun ctionally divided into two a reas: t he main or control area fo r image

(video) processing and the sub area for engine contr ol and print processing.

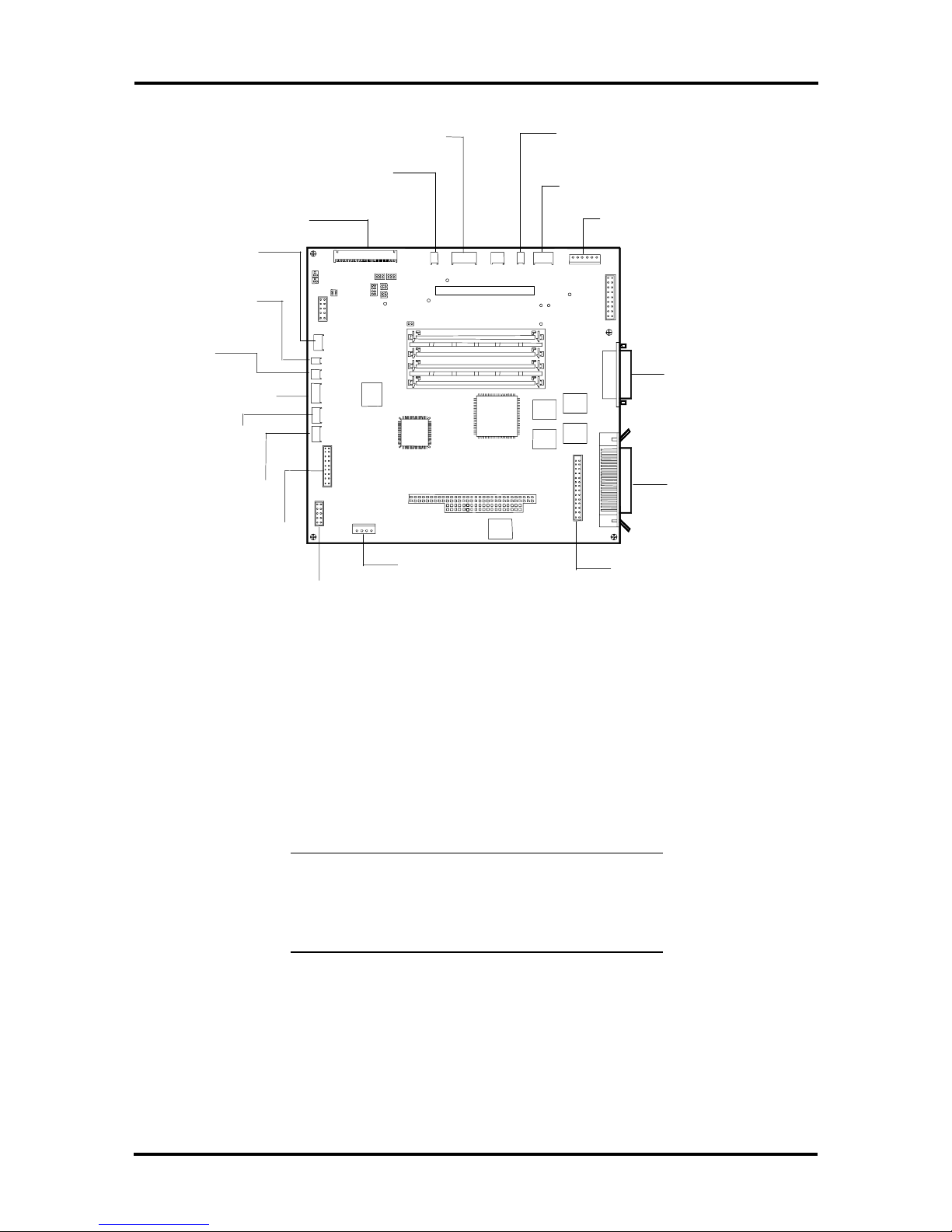

Figure 1-5 and Figure 1-6 show t he locations of the connectors on each main board

revision.

1-6 General Information

CN11 (Power)

6-pin

CN7 (Power)

2-pin

CN6 (Print Head)

14-pin

CN8 (Front Panel

Open) 4-pin

CN4 (Label Sensor Diode)

2-pin

CN3 (Label Sensor LED)

3-pin

CN2 (Label Cutter Option)

5-pin

CN1 (Ribbon Present)

4-pin

CN5 (Print Head Open

/Closed) 4-pin

CN13 (Control Panel Print Mode - Peel, Cut,

Rewind) 10-pin

CN12 (Power)

4-pin

P3 (Control Panel)

26-pin

CN14 (Model 412

Pre-Heater) 2-pin

CN17 (Stepper

Motor) 4-pin

CN16 (Stepper

Motor) 6-pin

P2 (Serial)

25-pin

P1 (Parallel)

36-pin

Figure 1-5 Main Board Revision 12, 13, or 14 Connector Locations

General Information 1-7

CN 6 (Print Head)

14-pin

CN 8 (Front P anel

O p en) 4-pin

CN 4 (Label S ensor

Diode) 2-pin

CN3 (Lab el

S ensor LE D )

3-pin

CN2 (Lab el

C utte r Optio n )

5-pin

CN1 (R ibbon

Present)

4-pin

CN 5 (Print Head

O p en/Closed

P3 (Control

Panel) 26-pin

CN13 (C ontrol P anel P rint M od e - P eel,

Cut, Rewind) 10-pin

CN 11 (P ow er)

6-pin

CN7 (Pow er)

2-pin

CN 12 (P ow er)

4-pin

CN14 ( Powe r fo r Mo del 412 Pre-Heater )

2-pin

CN17 (Stepper Motor

Power) 4-pin

CN 16 (S tepper

M otor) 6-pin

P2 (S erial)

25-pin

P1 (P arallel)

36-pin

Parallel Port Bus

Connector

Figure 1-6 Main Board Revision 15 and 16 Connector Locations

Ribbon and Label Feed Mechanisms

This section describes the thermal transfer printing process carried out by the ribbon and

label feed mech anisms.

NOTE:

ribbon is required a nd heat se nsitive labels or tag

stock are printed on directly, is not described in

t his section.

During the thermal tr ansfer process, the ribbon and label feed mechanisms move the ribbon

and labels between the platen and t hermal print head. T his confined space causes the ribbon

to pr ess against the label. Ink fro m the ribbon is applied to the label each time it crosses the

print head by the heating of individual print head elements (resistor s) . The combination of

heat from the resistors and pressure between t he ribbon and label lays down the printed

image.

Direct thermal printing, where no

1-8 General Information

The ribbo n is fed by the stepper mot or and is controlled by the main boar d and LED sensor

settings (ribbon end sensor).

During the printing process, t he label feed mechanism moves the label from the supply roller

to the thermal print head and platen. Labels are fed by the stepper motor and by friction

with the ribbon. Label feeding is coordinated by the main board, s ensor se ttings ( label

sensor), and the co nt r ol panel (see Section 3 for contro l panel settings that affect label

feeding).

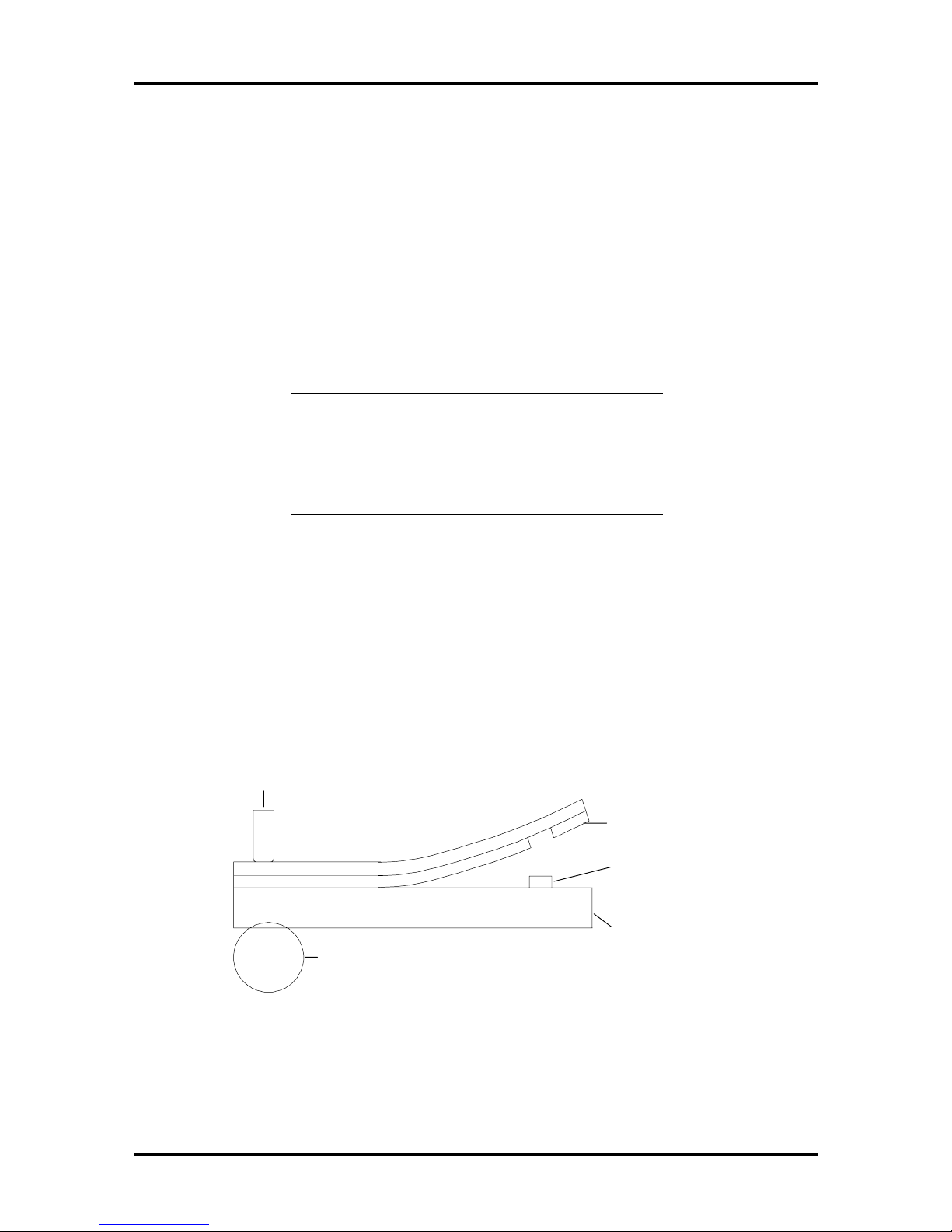

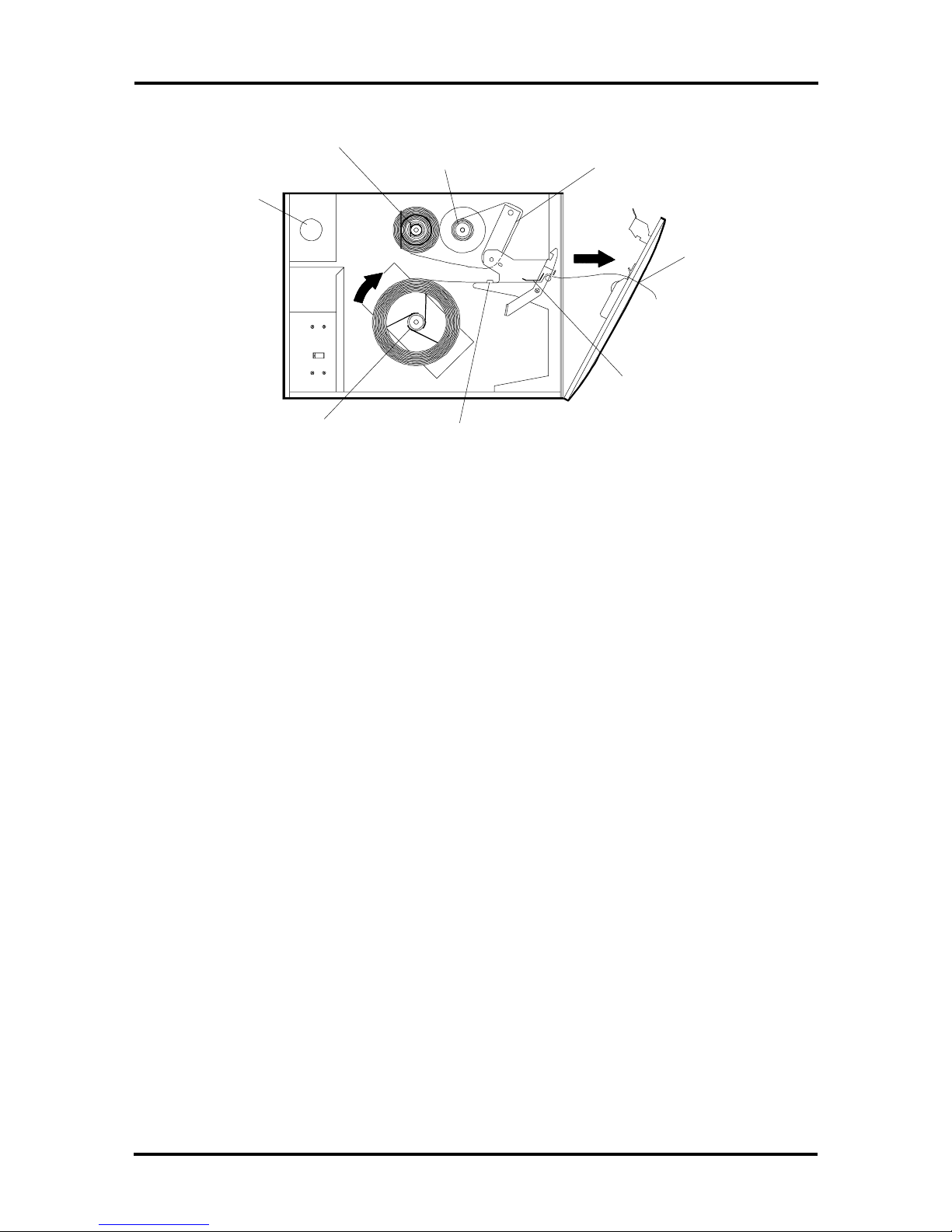

Figure 1-7 shows a simplified view o f how thermal transference works. A cut-away diagram

of the ribbon and label feed mechanism subassemblies for the Mo del 48 and 412 printers is

provided in Figure 1-8.

NOTE: The ribbon and label feed subassemblies

in the Model 88 printer differ in appearance from

the Model 48 and 412, but the theory of

operation is essentially identical as described

below.

When the label and ribbon are fed between the platen and thermal print head, the label

se nsor detects the loca tio n of the 0 .08 -inch (2 mm) minimum gap between the lab els o n the

paper roll and thus determines the pos ition of the first print line on t he label. A print

command is then sent to the thermal print head by the engine control processor on the main

board (see “Print Mechanism”).

Simultaneously, heat builds up in the thermal head heater, which contains a bank of resistor s

that selectively heat up, forming a printable image. The heat t r ansfers ink on the ribbon t o

areas on the label surface t hat correspond to the heat ed r esistors. This process fuses the

image to t he label.

Thermal Head

Thermal Transfer

Ink

Transferred Ink

Label

Platen

Figure 1-7 Thermal Transference

General Information 1-9

Ribbon Supply

Spindle

Stepper

Motor

Label Supply

Spindle

Figure 1-8 Ribbon and La bel Feed Mechanisms (Model 48 and 412)

Print Mechanism

Ribbon Take-Up

Spindle

Label Width

Guide

Print Head

(Open)

Label Exit

Slot

Sensor

Plate

Printer engine functions are controlled by t he engine control processor on the main board

sub-area. The engine control processo r sends cont rol signals in response t o commands and

data received from the computer via the PC/AT co r e. T he co ntr ol and data signals heat the

thermal print head element s ( r esisto r s) as previously described in “Ribbon and Paper Feed

Mechanisms.” Control and data signals from the engine control processor also drive the

stepper motor fo r feeding the ribbon and labels through the printer. When the label or

ribbon s ensors d etect that the printer has r un out of labels or ribbon (or w hen label jams

occur), the information is relayed from the engine control processor, and t he appropriat e

message appears on the contro l panel LCD (see Section 3 for display messages).

Depending on print speed, a specified “high” o r “low” voltage is sent from the power

supply to the heater inside the thermal print head. During normal speed printing (2.4 ips to

12 ips) typically used with wax ribbons, the power supply provides a “high” voltage of

approximately 24V. This vo ltage can be changed using the cont r ol panel menu buttons (see

“Print Head Volt age Adjustment” in Section 5).

During low speed printing (0.6 ips to 1.6 ips) typically used with resin ribbons, a “low”

voltage of approximat ely 12V is used. This voltage can also be changed using the control

panel menu buttons (see “Print Head Voltage Adjustment ” in Section 5).

1-10 General Information

Print speed is controlled by sending the appro pr iate st r obe (STB) pulse (STB1 or STB2

applied pulse) according to t he t emperatur e information sent from the print head thermist or.

For high speed printing (10 ips to 12 ips), the print head is pre-heat ed to an optimum head

temperature of 50o C per resistor. I f the head temperatur e exceeds 70o C, printing stops and

a head temperature message is reported on the control panel (see Section 2 for display

messages).

NOTE: During print ing, the actual temperature

of a resistor can exceed 200o C for a few

milliseconds.

MEMORY EXPANSION

Depending on t he main b oard revision installed in the printer, memory expansion ca n be

done in the Int elliBar Mo del 48 and 412 through the purchase of industry-standard, userinst allable, SIMM memor y modules made for Apple or PC products. SIMM modules are

available from retail or mail order compute r hardware suppliers. T h ese modu les install in

pairs in two expansion slots on the main boar d and increase the printer’s standard memory

capacity fro m the standard 2 MB to a maximum o f 10 MB.

NOTE: The Model 88 contains a total of 10 MB

o f sta ndard print er memory which is not

expandable.

See Table 4-1 and Table 4-2 in Sectio n 4 for memory installat ion guidelines and procedures.

OPTIONS

IntelliTech I nternational, Inc. option s for the Int elliBar printer ar e divid ed into two

categor ies: user-installable and factory-inst allable. Each cat egory is described below.

Section 4 provides additio nal information on IntelliTech International, Inc. printer options

(including installation procedures and dealer order numbers) .

User-Installable Options

Us er installable opt ions for the IntelliBar Models 4 8 and 412 include the following.

Label Cutter (Model 2401) — Let s you quickly print and process labels for

immediate application . This use r-installable opt ion fits in the front panel in pla ce

of the standard peel-off assembly. You must also remove the tear bar from above

the platen roller ( see Section 3 for label cutter installation procedures).

General Information 1-11

The cutter is designed for users who require on-demand label print ing (usually one

label at a t ime) and the convenience of a label precut and ready to apply. The

printer can be pro gr ammed to print a number of labels (up to 32, 767) and then

perform the cut function.

The cutter is designed to cut o nly paper or synthetic label backing (liner) and can

also c ut co ntinuous med ia that c ontains no rubber ba s ed adhesives.

NOTE: The maximum t h ickness of labels used

with the cutter option is 0.005 in. (0. 127 mm).

External Rewinder (Model 2402) — Mounts in front of the printer and rewinds

labels. Allows you t o output labels t hat can be conveniently spooled for storage or

shipment to anoth er location .

Factory-Installable Options

Fa ctory-inst allable option s for the IntelliBar Mode ls 48 and 412 include the following.

Internal Rewinder (Model 2405) — This option mo unt s inside the IntelliBar and

can be used to spoo l printed media (labels and backing paper) for convenient

stor age or transport ation o f labels in volume quantity. You can also use the

rewinder option to spoo l only the backing paper in peel-off print mode.

Reflective Label Sensor (Model 2404) — This field- or dealer-installable option

replaces the printer’s standard, t r ansmissive (see-through) label sensor. This

option reflects light off the black stripe when tag o r ticket stock is fed through t he

printer and thereby detects the label’s home position (used for determining the

first print line on the label). This option can also be used on butt-cut o r specialty

die-cut labels.

1-12 General Information

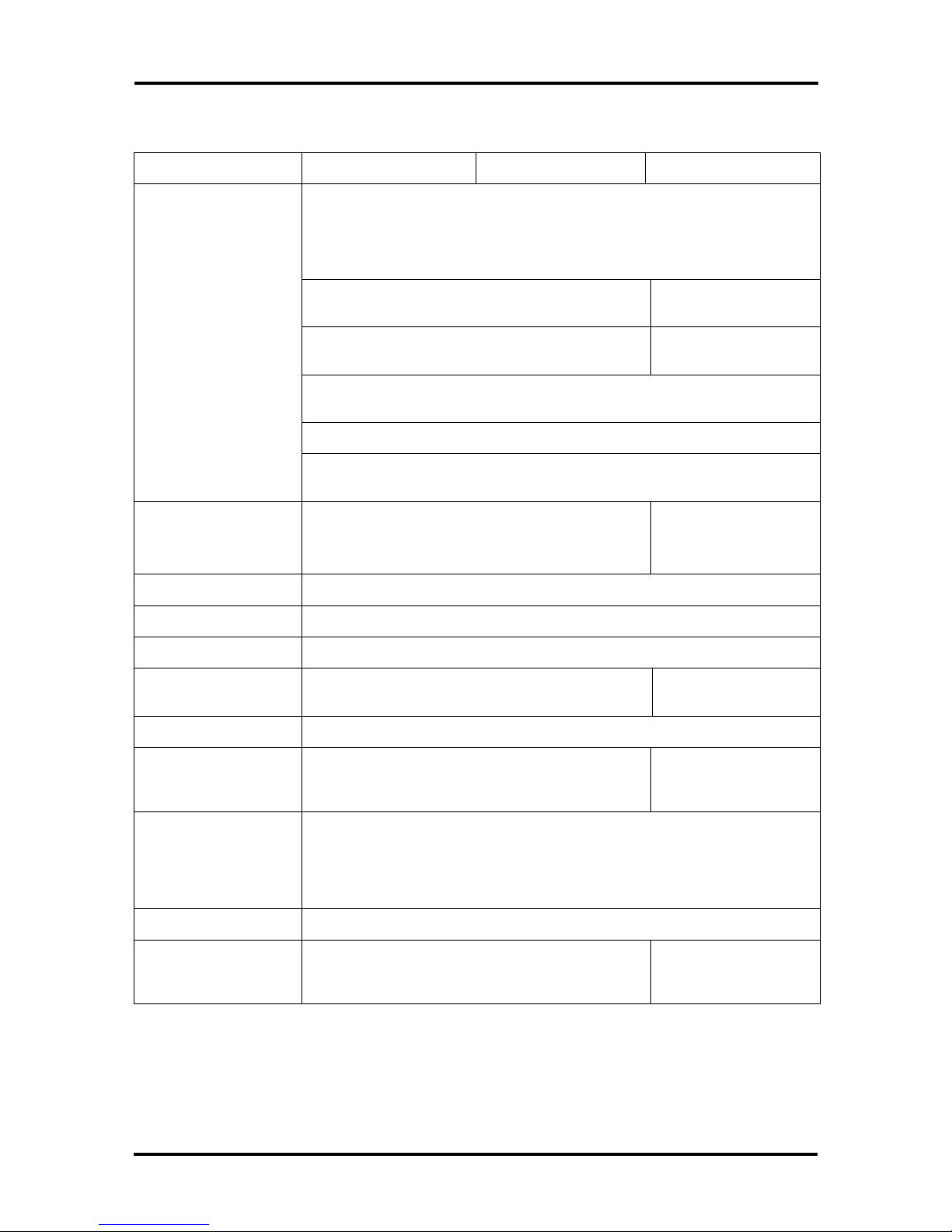

SPECIFICATIONS

Table 1-2 lists printer spec ificat ions for the IntelliBar St anda rd series. Specificat ions for the

In telliB ar AS Series, ax S eries, an d LPR Series are the s ame except as differ entiate d in

Table 1-1 for the printer command language, emulat ion, and connectivit y.

NOTE:

specifications and other informatio n about

IntelliTech International, Inc. product s, visit our

Web sit e at

Table 1-2 IntelliBar Standard Series Specifications

Feature Model 48, 48E Model 412, 412E Model 88, 88E

Print method Thermal transfer or direct thermal

Resolution 300 x 300 dots per inch (11.81 dots per mm)

For updates on IntelliBar print er

http://www.intellibar.c o m

.

Print widths 4.37" (111 mm) maxim um) 8.65 in. (220 mm)

maximum

Print length (standar d)* 14 in. (356 m m) 28 in. (711. 2 mm) 14 in. ( 356 mm)

Print length

(maximum)*

Print speed .6 in. up to 8 in. per

Memory 2 MB standard, 10 MB

Dimensions 12.4 in. H x 9.4 in. W x 16 in. D

Control Panel LCD, 16 character, 2 line status and error displ ay

Interface IEEE 1284 (parall el) and RS-232C/RS-422C (serial)

Emulation Hewlett Packard LaserJet III (HP PCL 5, HP GL/2)

Fonts 14 bit map fonts, 8 AGFA IntelliFont scalable typefaces (CG Times, Univers

Bar codes UPC-A, UPC-E, EAN/JAN-13, EAN/JAN-8, UPC/EAN ext ension (2 of 5 digi t

99 in. (2,515 mm) 99 i n. (2,515 mm) 99 i n. ( 2,515 mm)

.6 in. up to 12 in. per

second

maximum

(315 H mm x 239 m m W x 406 mm D)

Bold)

supplemental), 3 of 9 ( Code 39), Extended 3 of 9, Interleaved 2 of 5, Code 128,

Codebar, Zip +4, Postnet, MSI Plessey, Code 93, Extended 93, UCC-128,

HIBC, PDF417

second

2 MB standard, 10 MB

maximum

Baud rate: 1200 - 38, 400 bps

.6 in. up to 8 in. per

second

10 MB standard (not

expandable)

13.2 in. H x 14.4 in. W

x 17 in. D (335 mm H x

366 mm W x 432 mm D)

Electrical 115 VAC + 10%, 50/60 Hz.

230 VAC + 10% 50/60 Hz

IEEE 1284 compl iant cable required

* See Section 2 for pri nt media specif ications.

General Information 1-13

Table 1-2 IntelliBar Standard Series Specifications

Feature Model 48, 48E Model 412, 412E Model 88, 88E

Operating environment 41o F – 104o F (5o C – 40 C); below 85%

non-condensing humidi t y

Agency certifications UL-1950, C-UL, FCC Class A (115 VAC); TUV EN69050, CE mark (230 VAC)

User-installabl e options Label Backing Cutter: Model No. 2401**

External Label Rewinder: Model No. 2402

Factory-install ed

options

Warr ant y ( U. S) One-year l imited warranty; printhead warranted for 90 days or 500,000 linear

Media Die cut and continuous paper stocks, synthetic stocks, tag st ock, t icket stock

Label finishing Standard: Cont inuous, tear off and on-demand peel off (self strip). Cut off:

Label specifications Label print width: .75 in. min. to 4.37 in. max.

Reflective Sensor (Model 2404)

Internal Rewinder (Model 2405)

inches, whichever comes first

optional

(19 mm to 111 mm)

Label print length: .5 in. minimum . to 99 in. maximum *** (13 mm to 2,515 m m)

Minimum. label gap: .125 in. (3.2 mm)

Maximum label thickness: .01 i n. (.245 mm)

Maximum roll diameter: 8 in. (203 m m); 7 in.(178

mm) with Internal Rewinder installed

Inner core diameter: 3 in. (76. 2 mm)

Label Cutter: 240X

Reflective Sensor 240X

Internal Rewinder 240X

4.37 in. m inimum to

8.65 in. m aximum

(111 mm to 222 mm)

8 in. (203 m m)

Label web width: .75 in. m in. to 4.56 in. max.

(19 mm to 116 mm)

Ribbon types Express W ax for hi gh- speed printing up t o 12 inches per second

Dura Wax for econom ical printing

Rugged Resin for durability and smudge resistance

Dura Resin Plus for chemical, heat and scrat ch r esistance

Dura Wax/Resin for monochromatic color pri nt i ng

Ribbon length Wax Ribbons: 1, 475 f eet (450 m eters); Resin Ribbons: 984 f eet (300 m eters)

Ribbon widths 1.06 in., 2.12 in. , 3.27 in., 4.37 in.

(27 mm, 54 mm, 83 m m, 111 mm)

** Not int ended for use with rubber-based adhesives.

*** Wi t h addi t ional optional memory i nst alled and page protect turned off.

4.56 in. m in. to 9.5 in.

max. (116 m m to 241

mm)

4.37 in., 7 i n. , 8. 65 in.

(111 mm, 178 mm, 222

mm)

1-14 General Information

INTERFACE

This section descr ibes IntelliBar interfaces for communicating with the host computer or

network co mputer. T he printer is equipped with two interface communication ports:

36-pin IEEE 1284 parallel (connector P1)

25-pin RS-232C serial/RS-422 serial (connector P2)

To select the interface, use the control panel menu tree as described in Section 3.

Parallel Interface

This section descr ibes the IntelliBar parallel por t interf ace.

The IEEE 1284 parallel input allows no parameters. It always accepts 8-bit data with no

parity. For communication functions, it reserves the same set of characters reserved by the

serial po r t, wit h t he exception of X-ON and X-OFF characters.

Note that the IEEE 1284 parallel interface is essentially an input- only channel. The parallel

port communicat es in one direction, which is from the host computer to the printer.

IEEE 1284 Cable Requirements

The cable co nnected to the parallel int er face port must be fully shielded and fitted with t he

proper connector shell. Keep parallel cables as shor t as possible (8 ft. maximum) and do not

rout e or connect them near electrical conduits or high-voltage po wer lines.

To ensure the cable meets IEEE 1284 specifications, a cable labeled IEEE-1284 compliant

is required and is a simple wa y to guarantee good cable desig n . A cable with this label

contains the IEEE 1284-standard of 36 twisted-pair wires and is properly shielded.

Serial Interface

This section descr ibes the IntelliBar serial interface. I nt e lliBar serial co mmunica tio ns meets

the follo wing specifications:

asynchronous

8 data bits per character

no p arity

one start bit

one stop bit

Three parameters are used to control serial communicatio n: channel, baud rate, and

options.

General Information 1-15

The baud rate is given as an integer (such as 1200 or 9600), and t he maximum supported

baud rate is 38,400 bits per second (bps). Standard baud rates suppor ted by the IntelliBar

are as follo ws.

300

600

1200

2400

4800

9600

19,200

38,400

Data Transmission

The printer uses Robust X–ON/X–OFF prot ocol to contro l transmitted and received

character flow.

At power-on, the serial contr oller carries out communicat ion as soon as the hardware and

software are initia lized. Hence, the first cha racter sent in X-ON/X-OFF mode will be X-ON

(rather than X-OFF).

Available in Menu Mode using the control panel menu buttons, Robust X-ON/X-OFF flow

cont rol det ermines if ad ditional X-ONs should be transmitted.

If Robust X-O N/X-ON is set to ON (th e default), additional X-ONs will be transmitted at

one second intervals unt il data is received. I f it is set to OFF using the control panel (see

Section 3), no additional X-ONs are sent.

NOTE: Th e information in this section is subject

to change without notice. This information is

provided "as is " wit hou t either express or implied

warranty. IntelliTech International, I n c. d isclaims

any and all warranties with regard to this

information. IntelliTech shall not b e liable in any

event for any special, indirect or consequential

damages or any damages whatsoever resulting

from loss of data, profits or use, for any reason

or in any action, arising out of or in connection

with the use or performance of this information.

Section 2

Setup

Th is section provides p rint er setup information, wh ich includes inst ruc tio n s on connecting

power and interface cables, replacing the thermal ribbo n, and replacing the label roll. See

Sect ion 3 for in struction s on in sta lling memory a nd printer opt ions.

In additio n, t his section includes instructions on printin g test labels to chec k pr inter

operat ion before performing service or as a check after performing service.

Th is sec tio n also provides information on using the p rint er’s con trol pa nel buttons to affect

operat ion. Contr ol panel LED indicators, status messages, menu descriptions, and factory

settings of printer operating parameters are described. The 2-line by 16-charact er liquid

crystal display (LCD) on the control panel shows the printer’s operational stat us, error

codes, and parameter values. The LCD also displays the menus used t o change printer

parameters.

UNIT SETUP

Printer operat ion and print quality are affected by the environment in which the printer is

placed. When setting up the printer or do ing any service procedure, always be sure the

printer meets the environmental specifications listed below and the media specifications in

Section 1 of this manual. If the print er has not yet been unpacked (or t o repack it for

shipping), see Appendix A fo r unpacking/packing procedur es.

Th e IntelliBar is designed to function reliably even under ha rsh c onditio ns, s uch as th ose

that might be present in manufact ur ing or warehouse environment s.

Optimu m print quality is achieved under the follow ing condition s:

Temperature: 41° to 104° F (5° to 40° C)

Relative humidity: 15 to 85%

To maintain the best conditions for trouble-free operation, observe t he following

enviro nmental standards.

Place the printer in a well-ventilated area. Adequat e clearance should be provided

on all sides of the unit to allow heat to dissipate.

A minimum of 14 inches of clearance is needed above the Model 48 and 412

printers to open the hinged access door o n t he left side of the unit. Fo r the Model

88, a minimum of 11 inches is needed to open t he t op cover.

2-2 Setup

Note the printer dimensions and the clearance guidelines shown in the fo llowing

figures.

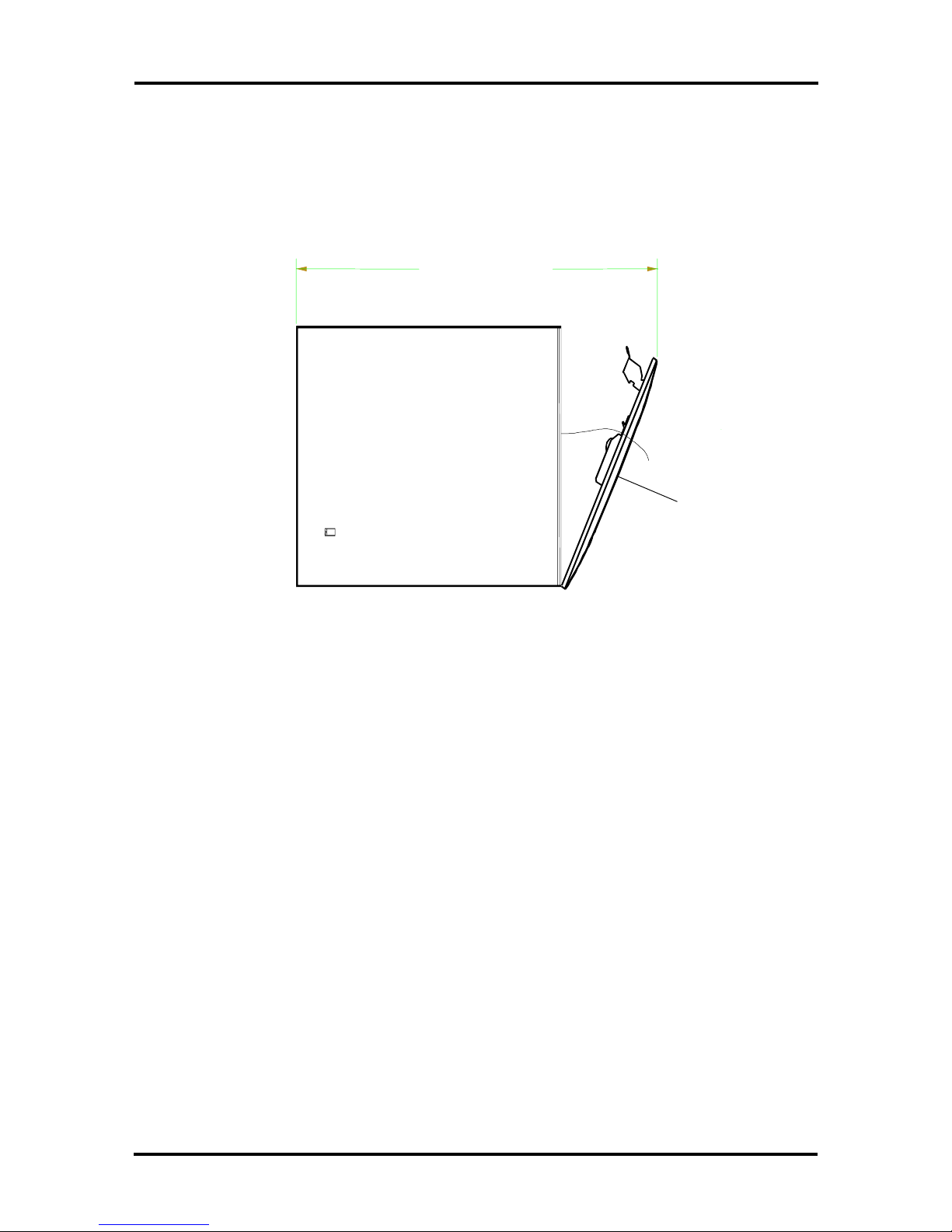

Wit h t he front panel open on the Model 48 and 412, the dist ance from the front of

the printer to t he back (printer depth) is 24.5 inches

24.50 Inches

Front Panel

Figure 2-1 Printer Depth (Model 48 and 412)

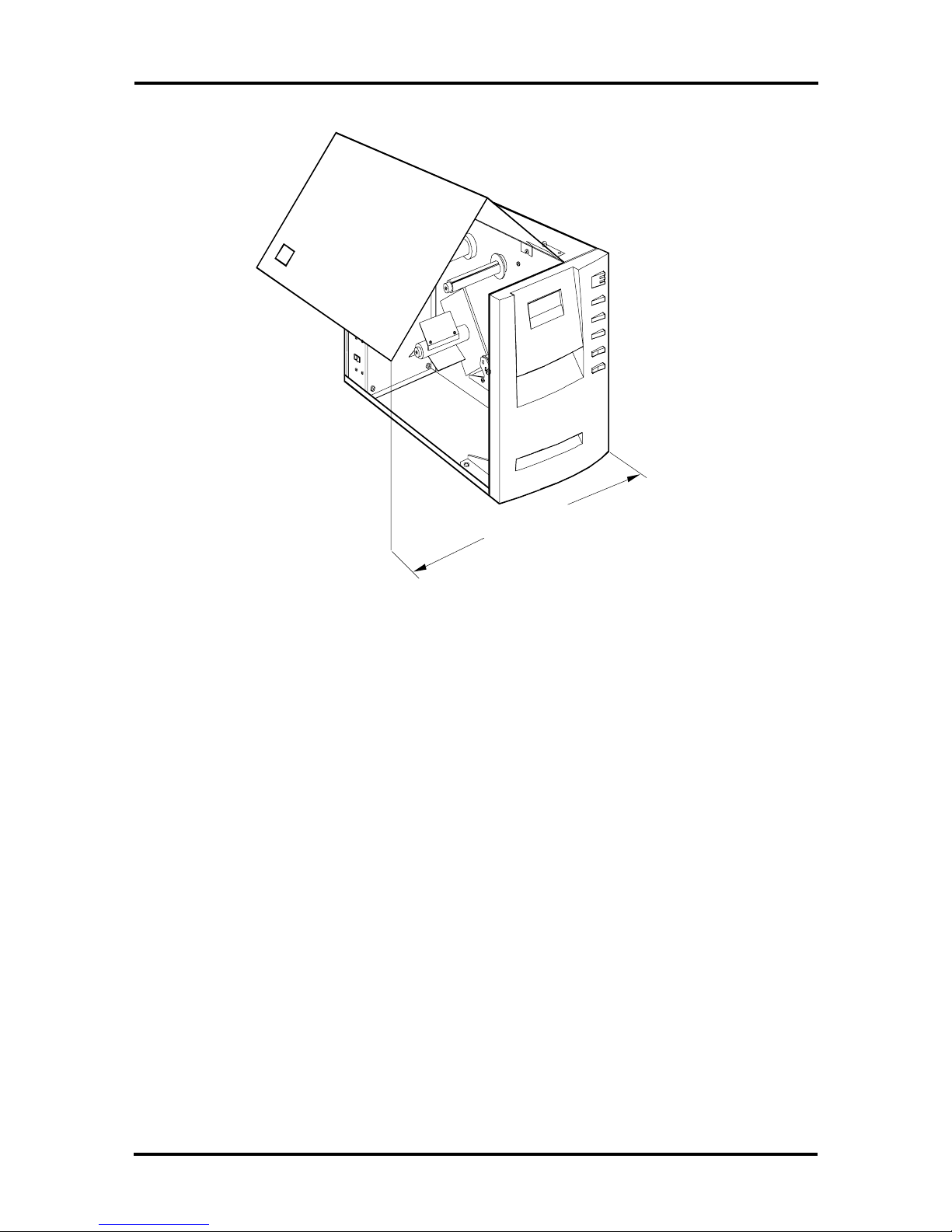

With the left side cover open, t he distance from the left side of the Model 48 and

Model 412 to the right side (printer width) is 17 inches.

Setup 2-3

17.00 Inches

Figure 2-2 Printer Width (Model 48 and 412)

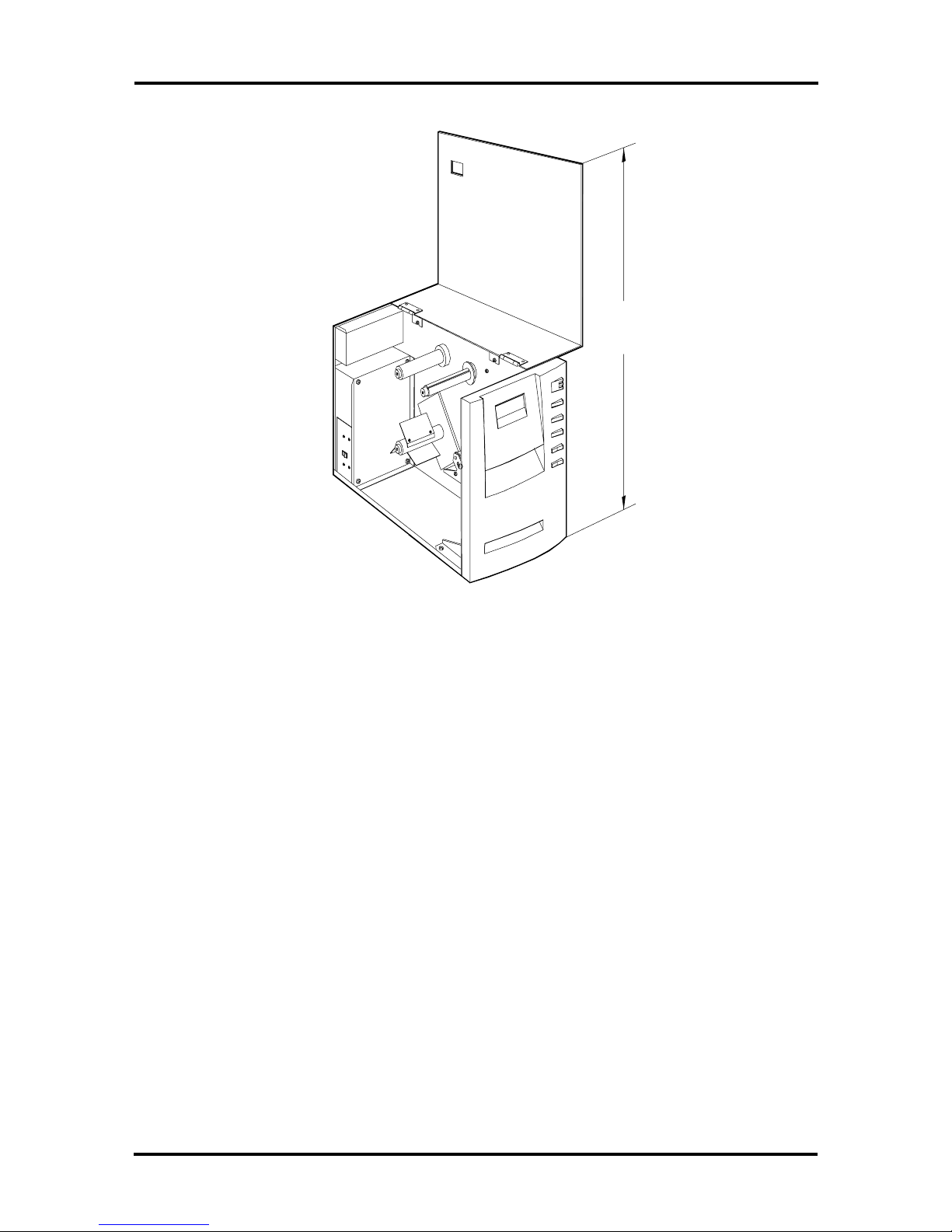

With the left side cover completely open, the distance from the bott om of the

Model 48 and Model 412 t o the top (printer height ) is 24.25 inches.

2-4 Setup

24.25 Inches

Figure 2-3 Printer Height (Model 48 and 412)

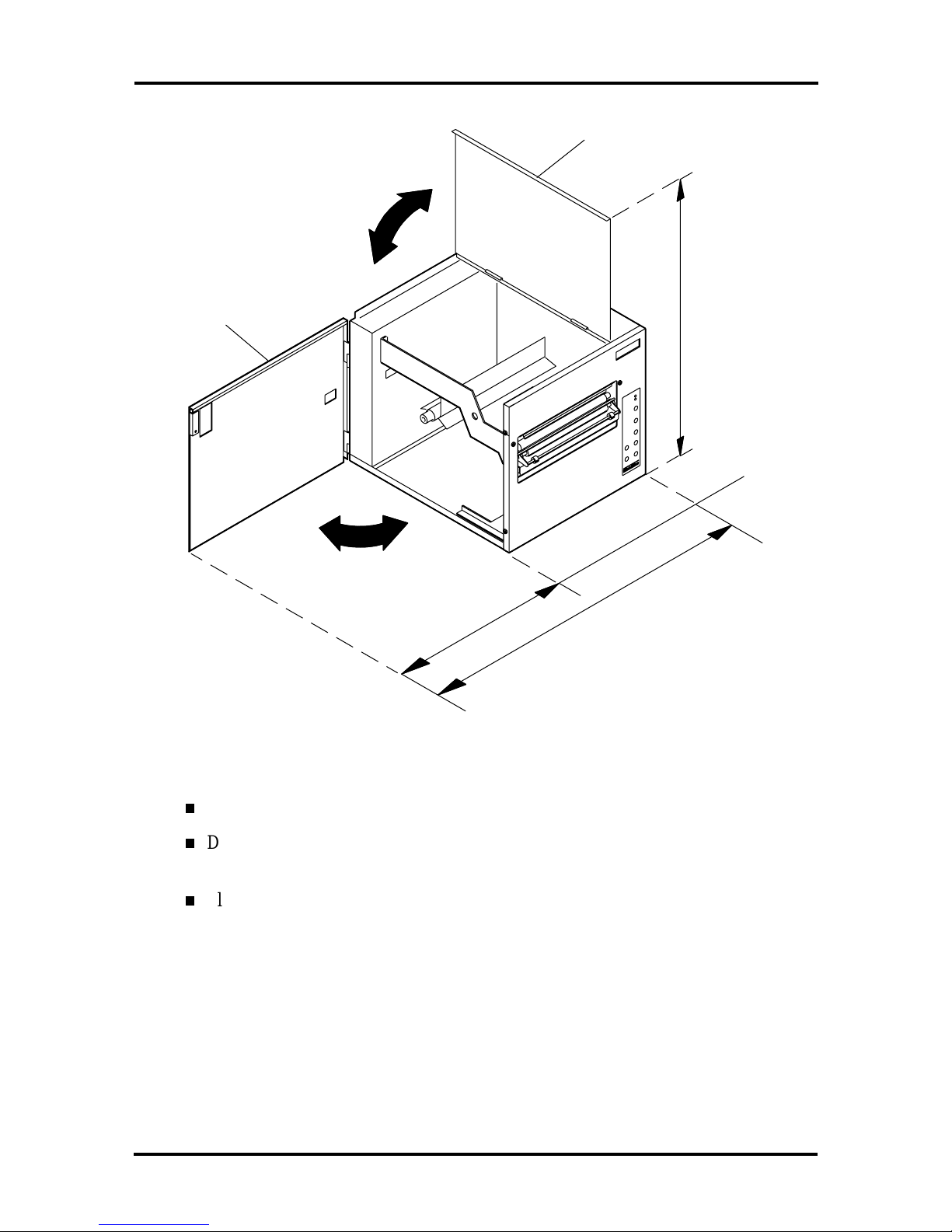

The following figure shows the width and height specifications fo r the Model 88

printer with the top and side covers open.

Top Cover

Setup 2-5

Side Cover

16.5"

30.5"

Figure 2-4 Printer Clearances (Model 88)

25"

Keep the printer away from direct sunlight.

Do not expo se the printer to extreme changes in temperature, as might occur near

a heating or air condit ioning unit.

Place the printer away from devices that generate str ong magnetic fields such as

electric mo tors or t ransformers.

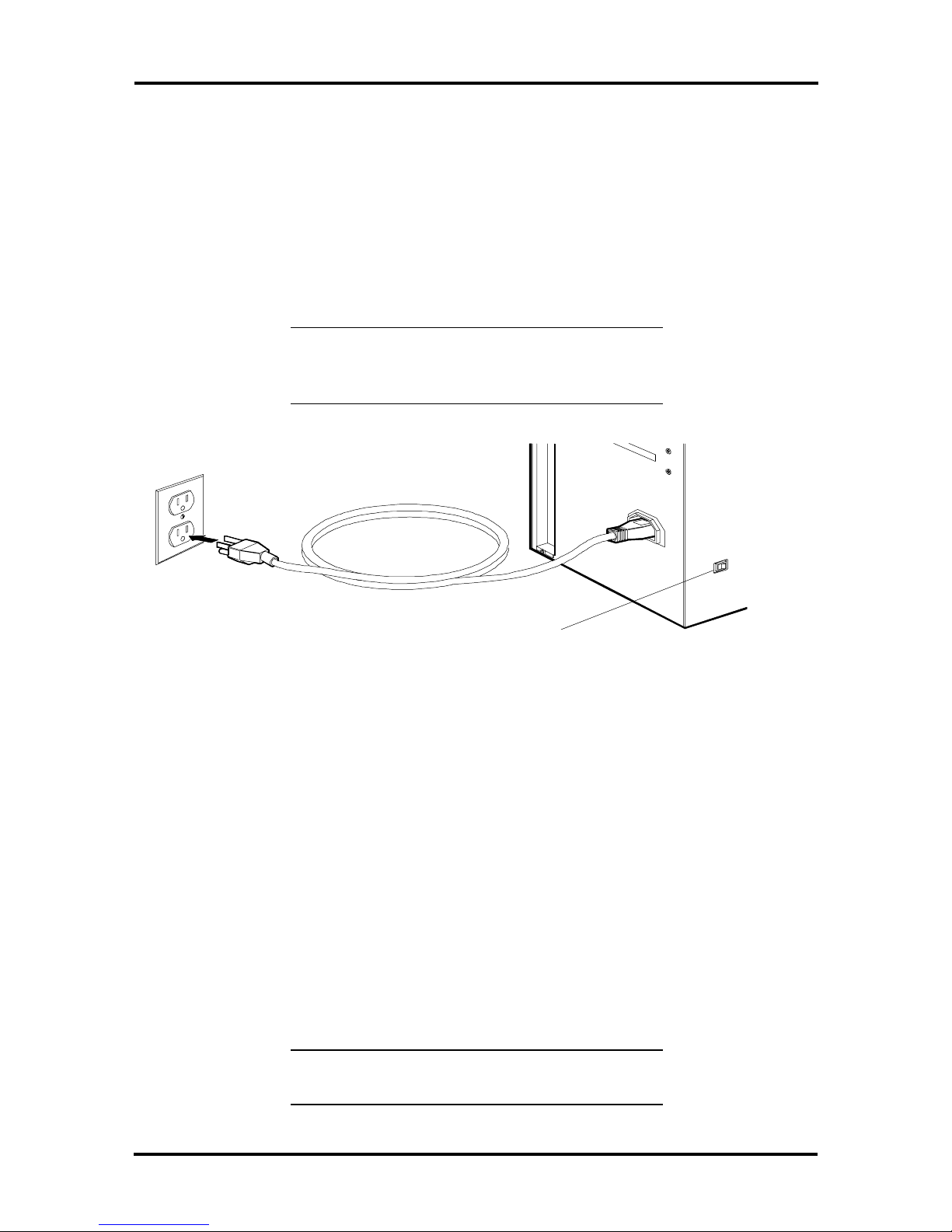

Connecting the Power Cord

The power cor d supplied with the printer plugs into the ac inlet connector on the back of

the printer. The ot her (male) end of the power cord plugs into a properly grounded, threeprong wall receptacle or other grounded po wer outlet. Always ensure the power switch is in

the OFF position before plugging in the cord. Figure 2-5 shows the location of the power

cord inlet connector and power switch and explains the power switch markings.

2-6 Setup

Th e power source for the IntelliBa r is either 110Vac ±10%, 50/60Hz or 220Vac ±10%,

50/60Hz (for “E” Versions). Voltage higher or lower than specified can cause printer

malfunctions.

The electric power line should be free fro m electric noise caused by other machines. A

dedica ted power line for th e IntelliBar, separate fr om noise p roducing equipmen t, is

reco mmende d and must be in close pr oximity to the pr in ter. I f a separate line (for e xample,

a different wall receptacle) is not available, use a noise filter (pur chasable from an electrical

supplies dealer).

CAUTION: Turn off the printer before plugging

in the power cord, and always use a properlygrounded power outlet.

Power Switch

0=Off

1=On

Figure 2-5 Connecting Power

Connecting the Communications Interface Cables

The following subsections describe how t o install the communications int er face cable in the

In telliBar s tandar d, AS Series, and ax S eries printers.

Standard IntelliBar Communications Interface

The back of the print er has one RS-232C/RS - 422 serial inter face port and one Cent r onics

parallel interface port.

Figure 2-6 identifies the interface port s.

When plugging in the interface cable, observe the alignment shape of the connectors to

ensure proper co nnection.

CAUTION: Turn off the computer and printer

before installing or removing any interface cable.

Rear Interfac e

Panel

Serial Port

Parallel Port

Setup 2-7

Figure 2-6 Interface Ports (Standard IntelliBar Series)

Use the correct type of interface cable when connecting the printer to the computer. A

description of each interface type is provided in Section 1 (see “Int er face”). Attach the

interface cable as follows.

1. Make sure the power to the printer is turned off.

2. Connect the interface cable t o the appropriate standard Int e lliBar Ser ies interface

port ( see Figure 2-6).

3. Secure the cable with the indicated screws o r clips.

For example, the RS-232C serial cable has two screws attached to the cable

connector.

4. If a grounding wire is att ached t o the interface cable, secure the wire to the one o f

the screws on the printer’s rear interface panel (see Figure 2-6).

5. Co nnect t he o ther end o f the interface cable to the computer according to the

manufactur er ’s instructions.

2-8 Setup

IntelliBar AS Series and ax Series Communication Interfaces

For IBM AS/400 and System 3X computers, set up t he IntelliBar printer to op erate in an

AFP/IPDS (AS Series) or SCS/EBCDIC (ax Series) configuration as follows:

1. Attach the twinax or coax cable adapter to the 15-pin port on t he interface board

(see Figure 2-7).

2. If connecting to a twinax host, set the I/O address o n t he four-segment switch

bank to the cor r ect value for your configuration (see Table 2-1). Obtain

information about your configuration’s address from your system administrato r.

If connecting to a coax host, set all the switches to OFF.

Table 2-1 IntelliBar AS Series I/O Address

Switch Settings (Twinax Connection)

Twinax

Address

0 Off Of f Of f Off

1 On Off Off Off

2 Off On Off Of f

3 On On Off Off

4 Off Of f On Off

5 On Off On Off

6 Off On On Of f

Figure 2-7 shows a clo se- up view of the rear of the printer with the int er face

Switch

Segment 1

Switch

Segment 2

Switch

Segment 3

Switch

Segment 4

board installed.

Interface

Board

LED

Setup 2-9

Interface Board

Switch Bank

Interface Board

IEEE 1284 Parallel Port

5 mm Hex Nut

Interface Board

RS232C Serial Port

(9-pin)

5 mm Hex Nut

Interface Board

Twinax/Coax Port (15-pin )

5 mm Hex Nut

Main

Board

LED

Main Board RS232C/422

Seria l Port

Main Board IEEE 1284

Parallel Port

Figure 2-7 Interface Board Connector, LED, and S w itch Locations

4. Turn on the printer and the host computer. After approximately 8 to 10 seco nds,

the LED on the interface board lights gr een, indicating that the host has

es tablished communication wit h the printer.

5. Check the status of the printer at the host. The host automatically co nfigures the

printer for AFP/IPDS (AS interface boar d installed) or SCS (ax interface boar d

installed).

After auto configuration, the print er is ready to receive print jobs.

2-10 Setup

Label and Ribbon Requirements

Print quality depends on fact ors such as the t ype of ribbo n and labels being used. Label

thickness and abrasion levels and the resistance of ribbo ns and labels to extreme

t emperatures all play an important role in maintaining the life of the print head and ensuring

print quality.

For best results , use high-qu ality la bels (die-cut, butt-cut, or contin uous forms) that mee t

the specifications listed in Table 2-2.

Table 2-2 Label Specifications

Measurement Minimum Specification Maximum Specification

*

Width

Model 48, 412: 0.75 in. (19

mm)

Model 48, 412: 4.56 in.

(116 mm ) maximum

Model 48, 412: 4.56 in. (116

mm)

Length 0.51 in. (13 mm) 99 in. (2.51 m); requires

Thickness 0.0025 in. (0.0635 mm) 0.01 in. ( 0.245 mm)

Gap 0.125 in. (3.2 mm) 1.5 x length of label

*Label specifications depend on the label stock. Maximum widt h of adhesive label stock (i ncluding backing

paper) or tag stock is 4.56 in. (116 mm) for the Model 48 and Model 412 and 9.5 in (241 m m) for the Model

88. Figure 2-8 provides label specifications for die-cut labels only. Maximum width of the print line (pri nt abl e

width) on the label is 4.37 i n. (111 mm) for t he Model 48 and Model 412 and 8.65 in. (220 mm) for the Model

88.

NOTE:

For updates on IntelliBar lab el

Model 88: 9.5 in.

(241 mm ) maximum

additional memory

specifications and other informatio n about labels

orderable through IntelliTech International, Inc.,

visit o ur Web site at

http://www.intellibar.c o m

.

.08 inches (2mm)

(

)

Unprintable Area

Top and Bottom

4.56 inches (116 mm) maximum web

width (Model 48 and 412)

9.5 inches (241 mm) maximum web

Model 88

width

AAAAAAA.......................................AAAA

Setup 2-11

Printable widths:

4.37 inches

(111 mm) maximum

(Model 48 and 412)

8.65 inches

(222 mm) maximum

(Model 88)

.5 inches (13mm)

Min. Label Length

for die-cut labels

99 inches (2.51m)

Max. Label Length

for die-cut labels

.125 inches

(3.2 mm) Min.

gap for die-cut

labels

Label Web W idth

Figure 2-8 Paper Specifications

2-12 Setup

IntelliBar Ribbons

In telliTech Int erna tio nal, Inc. offers t hree categories of thermal transfer ribbons:

wax (IntelliTech Express Wax ™ and IntelliTech D ura Wax™)

wax/r esin (IntelliTech D ura W ax/R esin™

resin ( Int elliTe ch Rugged Resin™ and Dura Resin Plus™).

Each category is manufactured with high quality materials to the following specifications to

fit par ticular operat ing conditions and purpo ses:

thickness – 5 microns

rib bon backing mater ial – polyester film

ink mate rial

— Express Wax, black

— Dura Wax, black

— Dura Wax/Resin, co lors (see Table 2-4)

— Rugged Resin, black

— Dura R esin Plus, black

ribbon length – 990 ft. (300 m) fo r r esin type; 1485 ft. (450 mm) fo r wax type

ribbon widths – Model 48 and 412 Model 88

1.06 in. (27 mm) 6.64 in. (165.0 mm)

2.13 in. (54 mm) 8.65 in. (220.0 mm)

3.27 in. (83 mm

4.37 in. (111 mm)

Th e following tables list IntelliTech order n umbers for IntelliBar black a nd color ribbons.

Setup 2-13

Table 2-3 IntelliBar Black Ribbons∗∗∗∗

Description Width Length Order Number

Ex pr ess Wax 1.08 inches (27 m m) 450 meters (1,475 feet) 50-101

2.20 inches (54 m m) 450 meters (1,475 feet) 50-102

3.32 inches (83 m m) 450 meters (1,475 feet) 50-103

4.44 inches (111 m m) 450 meters (1,475 feet) 50-104

6.64 inches (165 m m) 450 meters (1475 feet) 50-201

8.88 inches (222 m m) 450 meters (1,475 feet) 50- 202

Dura Wax 1.08 inches (27 m m) 450 meters (1,475 feet) 50-101

2.20 inches (54 m m) 450 meters (1,475 feet) 50-102

3.32 inches (83 m m) 450 meters (1,475 feet) 50-103

4.44 inches (111 m m) 450 meters (1,475 feet) 50-104

6.64 inches (165 m m) 450 meters (1475 feet) 50-203

8.88 inches (222 m m) 450 meters (1,475 feet) 50- 204

Rugged Resin 1.08 inc hes (27 mm) 300 met er s (990 feet) 50-109

2.20 inches (54 m m) 300 meters (990 feet) 50-110

3.32 inches (83 m m) 300 meters (990 feet) 50-111

4.44 inches (111 m m) 300 meters (990 feet) 50-112

6.64 inches (165 m m) 300 meters (990 feet) 50-205

8.88 inches (222 m m) 300 meters (990 feet) 50-206

Dura Resin Plus 1.08 inches (27 mm) 300 meter s (990 feet) 50-113

2.20 inches (54 m m) 300 meters (990 feet) 50-114

3.32 inches (83 m m) 300 meters (990 feet) 50-115

4.44 inches (111 m m) 300 meters (990 feet) 50-116

6.64 inches (165 m m) 300 meters (990 feet) 50-207

8.88 inches (222 m m) 300 meters (990 feet) 50-208

∗

This page was prepared September 1999. For an up-to-date listing of IntelliBar ribbons, please call

800-694-3034.

Intelli

Tech at

2-14 Setup

Table 2-4 IntelliBar Color Ribbons∗∗∗∗

Description Color Width Length Order Nu mber

Dura Wax/Resin White 1.08 inches (27 mm) 300 met er s (990 feet) 50- 501

White 2.20 inches (54 mm) 300 meter s (990 feet) 50- 502

White 3.32 inches (83 mm) 300 meter s (990 feet) 50- 503

White 4.44 inches (111 mm) 300 meter s (990 feet) 50- 504

White 6.64 inches (165 mm) 300 meter s (990 feet) 50- 505

White 8.88 inches (222 mm) 300 meter s (990 feet) 50-506

Process

cyan

Process

cyan

Process

cyan

Process

cyan

Process

cyan

Process

cyan

Process

magenta

Process

magenta

Process

magenta

Process

magenta

1.08 i nc hes (27 mm) 300 met er s (990 feet) 50- 508

2.20 i nc hes (54 mm) 300 met er s (990 feet) 50- 509

3.32 i nc hes (83 mm) 300 met er s (990 feet) 50- 510

4.44 i nc hes (111 mm) 300 meters (990 feet) 50-511

6.64 i nc hes (165 mm) 300 meters (990 feet) 50-512

8.88 i nc hes (222 mm) 300 meters (990 feet) 50-513

1.08 i nc hes (27 mm) 300 met er s (990 feet) 50- 515

2.20 i nc hes (54 mm) 300 met er s (990 feet) 50- 516

3.32 i nc hes (83 mm) 300 met er s (990 feet) 50- 517

4.44 i nc hes (111 mm) 300 meters (990 feet) 50-518

Process

magenta

Process

magenta

Process

yellow

Process

yellow

∗

This page was prepared July 1999. For an up-to-date listi ng of IntelliBar ribbons, please call

800-694-3034.

6.64 i nc hes (165 mm) 300 meters (990 feet) 50-519

8.88 i nc hes (222 mm) 300 meters (990 feet) 50-520

1.08 i nc hes (27 mm) 300 met er s (990 feet) 50- 522

2.20 i nc hes (54 mm) 300 met er s (990 feet) 50- 523

Intelli

Tech at

Setup 2-15

Table 2-4 IntelliBar Color Ribbons∗∗∗∗

Description Color Width Length Order Nu mber

Dura Wax/Resin Process

yellow

Process

yellow

Process

yellow

Process

yellow

Lemon

yellow

Lemon

yellow

Lemon

yellow

Lemon

yellow

Process

cyan

Lemon

yellow

3.32 i nc hes (83 mm) 300 met er s (990 feet) 50- 524

4.44 i nc hes (111 mm) 300 meters (990 feet) 50-525

6.64 i nc hes (165 mm) 300 meters (990 feet) 50-526

8.88 i nc hes (222 mm) 300 meters (990 feet) 50-527

1.08 i nc hes (27 mm) 300 met er s (990 feet) 50- 529

2.20 i nc hes (54 mm) 300 met er s (990 feet) 50- 530

3.32 i nc hes (83 mm) 300 met er s (990 feet) 50- 531

4.44 i nc hes (111 mm) 300 meters (990 feet) 50-532

6.64 i nc hes (165 mm) 300 meters (990 feet) 50-533

8.88 i nc hes (222 mm) 300 meters (990 feet) 50-534

Orange 1.08 inches (27 mm) 300 meters (990 feet) 50-536

Orange 2.20 inches (54 mm) 300 meters (990 feet) 50-537

Orange 3.32 inches (83 mm) 300 meters (990 feet) 50-538

Orange 4.44 inches (111 mm) 300 meters (990 feet) 50-539

Orange 6.64 inches (165 mm) 300 meters (990 feet) 50-540

Orange 8.88 inches (222 mm) 300 meters (990 feet) 50-541

Dark

1.08 i nc hes (27 mm) 300 met er s (990 feet) 50- 543

orange

Dark

2.20 i nc hes (54 mm) 300 met er s (990 feet) 50- 544

orange

Dark

3.32 i nc hes (83 mm) 300 met er s (990 feet) 50- 545

orange

Dark

4.44 i nc hes (111 mm) 300 meters (990 feet) 50-546

orange

∗ This page was prepared July 1999. For an up-to-date listing of IntelliBar ribbons, please call IntelliTech at

800-694-3034.

2-16 Setup

Table 2-4 IntelliBar Color Ribbons∗∗∗∗

Description Color Width Length Order Nu mber

Dura Wax/Resin Dark

6.64 i nc hes (165 mm) 300 meters (990 feet) 50-547

orange

Dark

8.88 i nc hes (222 mm) 300 meters (990 feet) 50-548

orange

Red 1.08 inches (27 mm ) 300 met er s (990 feet) 50-550

Red 2.20 inches (54 mm ) 300 met er s (990 feet) 50-551

Red 3.32 inches (83 mm ) 300 met er s (990 feet) 50-552

Red 4.44 inches (111 mm ) 300 met er s (990 feet) 50- 553

Red 6.64 inches (165 mm ) 300 met er s (990 feet) 50- 554

Red 8.88 inches (222 mm ) 300 met er s (990 feet) 50-555

Burgundy 1.08 inches (27 mm) 300 meters (990 feet) 50-557

Burgundy 2.20 inches (54 mm) 300 meters (990 feet) 50-558

Burgundy 3.32 inches (83 mm) 300 meters (990 feet) 50-559

Burgundy 4.44 inches (111 mm) 300 meters (990 feet) 50-560

Burgundy 6.64 inches (165 mm) 300 meters (990 feet) 50-561

Burgundy 8.88 inches (222 mm) 300 meters (990 feet) 50-562

Shamrock

1.08 i nc hes (27 mm) 300 met er s (990 feet) 50- 564

Green

Shamrock

2.20 i nc hes (54 mm) 300 met er s (990 feet) 50- 565

Green

Shamrock

3.32 i nc hes (83 mm) 300 met er s (990 feet) 50- 566

Green

Shamrock

4.44 i nc hes (111 mm) 300 meters (990 feet) 50-567

Green

Shamrock

6.64 i nc hes (165 mm) 300 meters (990 feet) 50-568

Green

Shamrock

8.88 i nc hes (222 mm) 300 meters (990 feet) 50-569

Green

Forrest

1.08 i nc hes (27 mm) 300 met er s (990 feet) 50- 571

Green

Forrest

2.20 i nc hes (54 mm) 300 met er s (990 feet) 50- 572

Green

∗ This page was prepared July 1999. For an up-to-date listing of IntelliBar ribbons, please call IntelliTech at 800-694-

3034.

Setup 2-17

Table 2-4 IntelliBar Color Ribbons∗∗∗∗

Description Color Width Length Order Nu mber

Dura Wax/Resin Forrest

3.32 i nc hes (83 mm) 300 met er s (990 feet) 50- 573

Green

Forrest

4.44 i nc hes (111 mm) 300 meters (990 feet) 50-574

Green

Forrest

6.64 i nc hes (165 mm) 300 meters (990 feet) 50-575

Green

Forrest

8.88 i nc hes (222 mm) 300 meters (990 feet) 50-576

Green

Royal Blue 1.08 inches (27 mm) 300 meters (990 feet) 50-578

Royal Blue 2.20 inches (54 mm) 300 meters (990 feet) 50-579

Royal Blue 3.32 inches (83 mm) 300 meters (990 feet) 50-580

Royal Blue 4.44 inches (111 mm) 300 meters (990 feet) 50-581

Royal Blue 6.64 inches (165 mm) 300 meters (990 feet) 50-582

Royal Blue 8.88 inches (222 mm) 300 meters (990 feet) 50-583

Midnight

1.08 i nc hes (27 mm) 300 met er s (990 feet) 50- 585

Blue

Midnight

2.20 i nc hes (54 mm) 300 met er s (990 feet) 50- 586

Blue

Midnight

3.32 i nc hes (83 mm) 300 met er s (990 feet) 50- 587

Blue

Midnight

4.44 i nc hes (111 mm) 300 meters (990 feet) 50-588

Blue

Midnight

6.64 i nc hes (165 mm) 300 meters (990 feet) 50-589

Blue

Midnight

8.88 i nc hes (222 mm) 300 meters (990 feet) 50-590

Blue

Brown 1.08 inches (27 mm) 300 met er s (990 feet) 50-592

Brown 2.20 inches (54 mm) 300 met er s (990 feet) 50-593

Brown 3.32 inches (83 mm) 300 met er s (990 feet) 50-594

Brown 4.44 inches (111 mm) 300 met er s (990 feet) 50-595

Brown 6.64 inches (165 mm) 300 met er s (990 feet) 50-596

Brown 8.88 inches (222 mm) 300 met er s (990 feet) 50-597

∗ This page was prepared July 1999. For an up-to-date listing of IntelliBar ribbons, please call IntelliTech at 800-694-

3034.

2-18 Setup

Ribbon/Label Combination

Re fer to Table 2-5 for general guidelin es in selecting the ribbo n /label comb ination be st

suited for the application and environmental variables that affect print quality.

Table 2-5 Ribbon/ Label Selection Matrix

Application Ribbon

Description

For economical high to medium speed

printi ng.

For economical yet more durable

medium speed printing. Used in

environments that require some

smudge and scratch resistant c apability.

Used in harsh environments needing

smudge and scratch resistant materials.

For medium speeds.

For low speed print ing. Permanent bar

codes. Suitable for harsh envi r onments.

Smudge and super scratch proof.

Solvent, heat, and wash proof.

For color printing.

Express Wax Coated or uncoated paper

Dura W ax Coated label and tag stock

Rugged Resin Excellent on synthetic label

Dura Resin Plus Exc ellent on synthetic label

Dura Wax Resin Good all around, versatile use on

Label Description

stock only.

only. Also for use with smooth

uncoated stocks. Economical

labels f or many applicati ons.

stock and coated paper. Not

recommended for uncoated

paper stock.

stock. Not recommended for

coated or uncoated paper

stock.

many paper and synthetic stocks.

To help you further identify the ribbon/label combination that meets your needs, Table 2-6

provides information about average ink-to-label t r ansfer and smudge characteristics. This

information sho uld only be used as a guideline, since ribbon/la bel pe rformance is also

dependent on print speeds, print head energy levels, print head position, and other factors.

CAUTION:

head and reduce repair costs, use ribbons that are

the same width or slightly wider than the

labels.

To avoid undue wear on the print

Express Wax

Dura Wax

Rugged

Resin

Dura Resin

Plus

Dura

Wax/Resin

Rating Print Quality Smudge & Scratch Resistance

NR Not recommende d Not recommended

Setup 2-19

Table 2-6 Ribbon a nd Label Type Performance Guidel i nes

Uncoated Paper Coated Paper Polypropylene Polyester

Print

Quality

NR NR

Excellent No change to printed image

Good Slight effect to printed image

Fair Some e ffect to printed image

Marginal Noticeable effect to printed image

Smudge &

Scratch

Resistance

Print

Quality

Smudge &

Scratch

Resistance

Print

Quality

Smudge &

Scratch

Resistance

Print

Quality

Smudge &

Scratch

Resistance

NR

Loading Labels

To load a label ro ll, proceed as follows depending on your IntelliBar mode l and w hether

you are operat ing the printer in st andard, tear-off, cut-off, or peel-off print modes. For

information on selecting the print mod e for your printer t hro ugh the c ontro l pane l menu

butto n, see Section 3, “Unit Operation.”

Models 48 and 412

Th e following subsection desc ribes how to load labels for the Int elliBar Mo dels 48 and 412.

See “Mode l 88” later in this sect ion to load labels in the IntelliBar Model 88 printer.

Standard Mode, Tear-Off Mode, Cut-Off Mode (Models 48 and 412)

If the printer is operating in standard, tear-off, or cut-o ff mode, follow these steps to load

labels.

Open the printer’s left side cover. Open and lower the front panel by pressing the

1.

front panel release latch (see Figure 2-9).

Place the label roll o n the label supply spindle, label side up, so the roll unwinds in

2.

the clockwise direction.

Pull up t he print head release lat ch and raise the print head.

3.

2-20 Setup

Raise print head.

Pull blue handle

to open front

panel .

Mount label

media roll.

Pull up blue

print head

release latch.

Figure 2-9 Mounting the Label Rol l (Model 48 and 412)

4. Raise the label sensor plate and gently rout e the label backing paper (liner)

between the white teflon label width guides, under the label sensor plate, and over

the platen roller (see Figure 2-10).

Adjust label width guide

to label edge.

Setup 2-21

Lift label sensor

plate and pull

labels through.

Platen Roller

Center labe l

sensor over

label.

Figure 2-10 Installing Labels (Model 48 and 412)

NOTE: Make sure the label sensor mounted o n

the sensor plate is positioned in the center of the

label and is not o v er a label g ap. If it is not

centered, slide the sensor assembly to the left or

right as required (see Figure 2-11).

2-22 Setup

Sensor Plate

Label Sensor

Label

Figure 2-11 Label Sensor Location (Model 48 and 412)

5. Rou te the la bel liner through the exit slot in the fron t panel.

6. Close and latch t he print head assembly, making sure the print head is securely

latched.

7. Make sure the inside edge o f the label backing paper is to uching the inside label

width guide (see Figure 2-12). (If it is not, open the print head, realign the label

media, and close the print head). Slide the outside label width guide up to the

edge of the label backing paper t o prevent liner mistracking (skew).

Inside Label Width

Guide

Label Sensor Pla te

Label Me dia

Outside Label Width

Guide

Figure 2-12 Label Width Guides (Model 48 and 412)

Setup 2-23

8. Close the front panel and left side cover.

9. Turn on the printer and wait for it to initialize (“OFFLINE, INITIALIZE”

appears in the 2-line control panel LCD display). During initialization, several

labels will feed cons ecutively and e xit the label exit slot as th e pr inter

automat ically measures the la bel gap and labe l length.

After the printer has measu red the label g ap an d label length, feedin g stop s.

“ONLINE, READY” appears in th e 2- lin e control panel LCD d isplay.

10. From the contr ol panel, select the desired “PRINT MENU, PRINT MODE , ”

parameter (see Sect ion 3 for in formation on using the control panel menu button

and menu tree to set the standard, tear-off, or cut-off print mode parameter).

NOTE:

If you want to op er ate in standard

mode, you do not need to set the print mode

parameter if you are loading labels for the first

time after taking the printer out of the box. The

“S TANDARD” print mode paramet er is the

default that is set at the factory.

2-24 Setup

Peel-Off Mode (Models 48 and 412)

If the printer operates in peel-off mode (with no cut ter option installed), follow these steps

t o load labels.

1. Load labels as described in steps 1 through 9 in the previous subsection.

2. Fro m the co nt r ol panel, select the “LABEL MENU, LABEL MEASURE,

FIXED” parameter as follows (see also “Menu Tree” later in this section).

Press the Menu button (“MAIN MENU”, “PRINT MENU” appear s in the

LCD display).

Press Next (“MAIN MENU”, “LABEL MENU” ap p ear s in the LCD display).

Press Select (“LABEL MENU”, “LABEL TYPE” appears in the LCD

display).

Press Next (“LABEL MENU”, “MEASU RE LABEL” appears in the LCD

display).

Press Select (“MEASURE LABEL”, “AUTOMATIC” appears in the LCD

display).

Press Next (“MEASURE LABEL”, “FIXED” appears in the LCD display).

Press Select (“MEASURE LABEL, “FIXED” appears with an asterisk).

Press the Online button (“ONLINE, RE ADY” appears in the control panel

LCD).

This setting ensures that no more than one label advances during subsequent

power-on initialization routines, avoiding po ssible label jams at the label exit slot.

3. From the contr ol panel, select the “PRINT MENU, PRINT MODE , PEEL-OFF”

parameter as follo ws ( see also “Menu Tree” later in this sectio n).

Press the Online butto n (OFF LINE, PAUSE appear s in the 2-line cont r ol

panel LCD display).

Press the Menu button (“MAIN MENU”, “PRINT MENU” appear s in the

LCD display).

Press Select (“PRINT MENU”, “PRINT METHOD” appears in the LCD

display.

Press Next (“PRINT MENU”, “PRINT MODE” appear s in the LCD display.

Press Select. One of the print modes other than peel off appears in the LCD

display (“STANDARD”, “TEAR OFF”, or “CUT OFF”) depending on the

print mode that you previously selected (“STANDARD” is the factory

default) .

Setup 2-25

Press Next until “PEEL OFF” appears.

Press Select (“PRINT MODE , “PEEL OFF” appears with an asterisk).

4. Open the front panel and print head.

5. Rero ute the label strip downward past the peel-off ro ller and through the label

release paper slot (see Figure 2-13).

Platen Roller

Peel-off/Tear Bar

Peel-off

Roller

Label Release

Paper Slot

Figure 2-13 Peel-Off Mode Label Routing (Model 48 and 412)

6. While gen tly pulling the liner downward, c lose and latch the prin t head assembly,

making sure the print head is securely latched. Then close and latch the front

panel.

Figure 2-14 sho ws a cut-away view of the label routing path for peel-off mode.

2-26 Setup

Peel-off/Tear Bar

Label Me dia

Label

Platen Roller

Backing

Paper

Peel-Off

Roller

Label Rel ease

Paper Slot

Figure 2-14 Model 48 and 412 Peel-Off Mode Label Routing – Cut-Away View

7. Press Online. Two labels w ill feed cons ecutively. The first label will fee d and

separate (peel) from the backing paper (liner) and exit t he label exit slot. (T he

liner exits through the label release paper slot.) After the first label feed s, manually

remove this label from the lab el exit slo t and then wait fo r th e sec ond label to

finish feeding.

When the second label has fed, the printer pauses. “PEE L OFF LABEL” appears

in the control panel LCD disp lay.

8. Remove the label from the exit s lot . When you have removed the label, the label

roll will a utomatically back up so that the next label is in posit ion for printing.

“ONLINE, READY” will appear in the control panel LCD.

Setup 2-27

Model 88

Th e following subsection desc ribes how to load labels for the Int elliBar Mo del 88. S ee