ProMill 8000 Milling Center

USER'S GUIDE

Catalog # 200066 Rev C

Copyright © Intelitek Inc.

ProMill 8000 Milling Center User's Guide

Catalog #200066 Rev C

August 2016

website: http://www.intelitek.com

email: info@intelitek.com

Tel: (603) 625-8600

Fax: (603) 437-2137

All rights reserved. No part of this publication may be stored in a retrieval system, or reproduced in any way,

including but not limited to photocopy, photography, magnetic or other recording, without the prior agreement and

written permission of the publisher. Program listings may be entered, stored and executed in a computer system,

but not reproduced for publication.

Every effort has been made to make this book as complete and accurate as possible. However, no warranty of

suitability, purpose, or fitness is made or implied. Intelitek is not liable or responsible to any person or entity for loss

or damage in connection with or stemming from the use of the software, hardware and/or the information

contained in this publication.

Intelitek bears no responsibility for errors that may appear in this publication and retains the right to make changes

to the software, hardware and manual without prior notice.

Safety

Provides essential safety instructions that must be followed to prevent operator injury or

death.

Product Care

Provides recommendations for reducing the chance of machine damage.

Take Note

Provides important information about your product.

Warnings

The operation of rotating machinery should only be attempted by experienced, knowledgeable

individuals.

Read the entire contents of this guide before running the ProMill 8000 Milling Center.

To avoid possible injury always observe the safety precautions described in this User's Guide.

The following icons indicate important information throughout this User’s Guide.

Table of Contents

i

Table of Contents

Using this Guide ............................................................................................................................................................ iv

1. Safety Guidelines .................................................................................................................................................. 1

1.1. Detailed Safety Guidelines............................................................................................................................................. 1

1.2. Safety Checklist ............................................................................................................................................................. 5

2. Introducing the ProMill 8000 ................................................................................................................................ 6

2.1. Overview of Standard Features ..................................................................................................................................... 6

2.2. ProMill 8000 Components ............................................................................................................................................. 8

2.3. Overview of CNCBase/Motion Control Software ........................................................................................................ 12

2.4. Standard Accessories ................................................................................................................................................... 12

2.5. Optional Accessories ................................................................................................................................................... 13

3. Installing the Hardware and Software ................................................................................................................ 14

3.1. Preparing for Installation ............................................................................................................................................. 14

3.2. Installing the Hardware ............................................................................................................................................... 18

3.3. Installing the Software................................................................................................................................................. 20

3.4. Contacting Technical Support ...................................................................................................................................... 33

3.5. Returning Defective Products ...................................................................................................................................... 33

4. Maintaining the ProMill 8000 ............................................................................................................................. 35

4.1. Cleaning the Milling Center ......................................................................................................................................... 35

4.2. Maintaining Individual Milling Machine Components ................................................................................................. 36

4.3. Maintenance Schedule Summary ................................................................................................................................ 38

4.4. Adjusting and Maintaining the Pneumatic Systems .................................................................................................... 39

4.5. Maintaining the PC in a Shop Environment ................................................................................................................. 41

5. Using the Control Software ................................................................................................................................. 42

5.1. Launching the Control Software .................................................................................................................................. 42

5.2. Selecting Online or Simulation Mode .......................................................................................................................... 44

5.3. Software Interface ....................................................................................................................................................... 45

5.4. Homing ........................................................................................................................................................................ 61

5.5. Opening an NC File ...................................................................................................................................................... 62

5.6. Verifying an NC Program ............................................................................................................................................. 64

5.7. Running an NC Program .............................................................................................................................................. 71

5.8. Accessing Help ............................................................................................................................................................. 72

6. Installing a Tool ................................................................................................................................................... 73

Table of Contents

ii

6.1. Removing the Tool Holder from the Spindle ............................................................................................................... 74

6.2. Inserting the Tool into the Tool Holder ....................................................................................................................... 74

6.3. Inserting the Tool Holder into the Spindle .................................................................................................................. 75

7. Tutorial: Milling a Sample Part ............................................................................................................................ 77

7.1. Reviewing Safety Procedures ...................................................................................................................................... 78

7.2. Preparing Tools and Materials ..................................................................................................................................... 78

7.3. Opening the Sample NC File ........................................................................................................................................ 78

7.4. Determining the Stock Size .......................................................................................................................................... 79

7.5. Configuring the Verify Settings .................................................................................................................................... 80

7.6. Defining the Tool ......................................................................................................................................................... 84

7.7. Verifying the Program ................................................................................................................................................. 86

7.8. Turning On and Homing the Machine ......................................................................................................................... 87

7.9. Mounting the Workpiece ............................................................................................................................................ 88

7.10. Setting the Axes Zero Positions ................................................................................................................................... 88

7.11. Performing a Dry Run .................................................................................................................................................. 93

7.12. Running the Program................................................................................................................................................... 94

8. Basic CNC Programming ...................................................................................................................................... 96

8.1. Elements of an NC Part Program ................................................................................................................................. 96

8.2. General Programming Suggestions ............................................................................................................................. 97

8.3. Reviewing an NC Program ........................................................................................................................................... 98

8.4. NC Codes ..................................................................................................................................................................... 98

9. NC Programming Routines ................................................................................................................................ 129

9.1. Linear Interpolation Programming ............................................................................................................................ 129

9.2. Circular Interpolation Programming in the XY Plane ................................................................................................. 130

9.3. Circular Interpolation Programming in Other Planes ................................................................................................ 132

9.4. Rapid Traverse Programming .................................................................................................................................... 133

9.5. Helical Interpolation Programming ........................................................................................................................... 134

9.6. Canned Cycle Programming ...................................................................................................................................... 135

9.7. Subprogram Programming ....................................................................................................................................... 143

10. Multiple Tool Programming .............................................................................................................................. 145

10.1. Specifying the Tools ................................................................................................................................................... 146

10.2. Configuring the ATC ................................................................................................................................................... 146

10.3. Writing an NC Program for Multiple Tools ................................................................................................................ 147

10.4. Establishing the Reference Tool ................................................................................................................................ 148

10.5. Setting Tool Offsets ................................................................................................................................................... 149

10.6. Testing the Multi-tool Program ................................................................................................................................. 152

Table of Contents

iii

10.7. Tutorial: Running a Multi-tool Program .................................................................................................................... 153

11. An Introduction to CNC Milling ......................................................................................................................... 158

11.1. Understanding Coordinate Systems .......................................................................................................................... 158

11.2. Setting Spindle Speeds .............................................................................................................................................. 161

11.3. Setting Feed Rate and Depth of Cut .......................................................................................................................... 162

11.4. Selecting Lubricants and Coolants ............................................................................................................................. 163

11.5. Tool Types ................................................................................................................................................................. 163

11.6. Sharpening the Tools ................................................................................................................................................. 165

12. Automation lntegration .................................................................................................................................... 166

12.1. Integration Instructions ............................................................................................................................................. 166

12.2. CNC Programming for Robotic Communication ........................................................................................................ 169

12.3. Sample Robot - CNC Communication Sequence ........................................................................................................ 171

12.4. Sample Robotic - CNC lntegration Programs ............................................................................................................. 179

Using this Guide

iv

Using this Guide

Welcome to the ProMill 8000 User’s Guide.

This guide is designed to help you install and begin using the ProMill 8000 hardware and software. The

later chapters provide an NC programming reference.

We recommend that you use the guide as follows.

1. Read chapter 1 Safety Guidelines. Review this chapter often.

2. Read chapter 2 Introducing the ProMill 8000.

3. Install the hardware and software as described in chapter 3 Installing the Hardware and

Software.

4. Read chapter 4 Maintaining the ProMill 8000.

5. Read chapter 5 Using the Control Software.

6. Read chapter 6 Installing a Tool

7. Follow the instructions in the tutorial presented in chapter 7 Tutorial: Milling a Sample Part.

8. Use the remaining chapters as a reference guide for NC programming.

a. Chapter 8 Basic CNC Programming presents guidelines for writing basic NC programs, and lists

and describes the use of all codes available for use with the ProMill 8000.

b. Chapter 9 NC Programming Routines provides instructions with examples for advanced NC

programming routines.

c. Chapter 10 Multiple Tool Programming provides instructions for configuring the control

software and writing NC code for programs that require the use of more than one cutting

tool. The chapter also presents step-by-step instructions for milling a sample part using

multiple tools.

d. Chapter 11 An Introduction to CNC Milling provides a basic introduction to the theory of CNC

milling.

e. Chapter 12 Automation lntegration provides instructions for integrating the ProMill 8000 in a

robotic environment.

1 Safety Guidelines

1.1 Detailed Safety Guidelines

1

Section Contents: Safety Guidelines

Section

Name

Page

1.1

Detailed Safety Guidelines

1

1.2

Safety Checklist

5

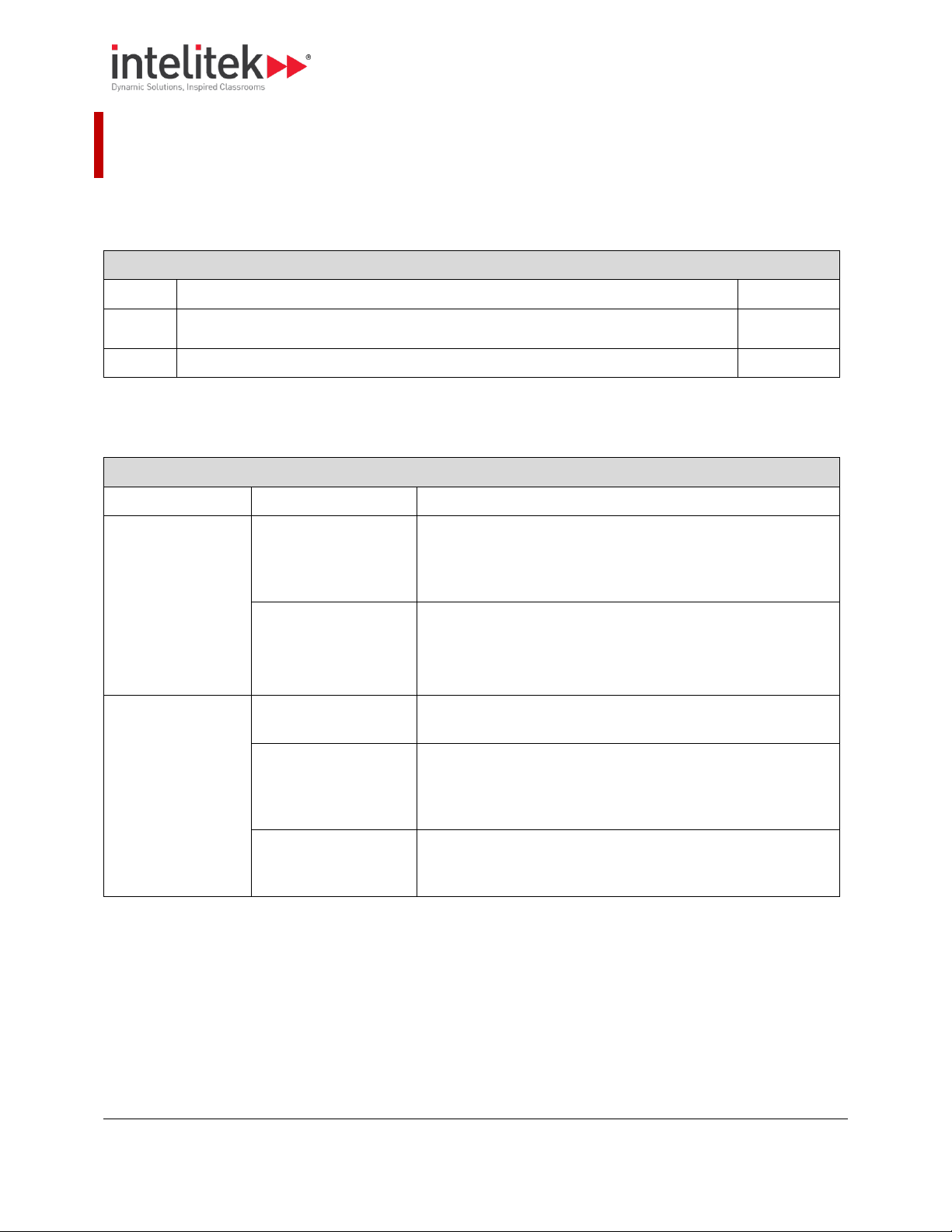

Info Table: Safety Guidelines

Category

Guideline

Comment

Operator knowledge

and authorization

Review the User’s

Guide.

Read this guide carefully before you use the milling center and

keep it readily accessible for quick reference. Know the intended

applications and limitations of the milling center as well as its

hazards.

Keep untrained visitors

away from the

equipment.

Children and visitors unfamiliar with the hazards of rotating

machinery should always be kept away from the work area.

Behavior

Do not overreach.

Keep your footing and balance at all times so you won’t fall

against or clutch at the moving machine.

Do not operate the

machine under the

influence of alcohol or

drugs.

Alcohol or drugs may impair your judgment and reaction time,

which could contribute to an on-the-job accident.

Avoid distractions

while running the

machine.

Use simple common sense and pay attention while operating

any piece of machinery.

1. Safety Guidelines

The safety rules presented here should be reviewed and practiced by all operators of the ProMill 8000

milling center.

This section presents the following information:

1.1. DETAILED SAFETY GUIDELINES

The table below provides detailed safety instructions.

1 Safety Guidelines

1.1 Detailed Safety Guidelines

2

Work Area

Keep the work area

clean.

Cluttered work areas and bench tops invite accidents.

Avoid a dangerous

environment.

Don’t use the milling center in damp or wet locations. Never

operate electrical equipment in the presence of volatile and

flammable petroleum-based solvents and lubricants.

Keep coolant away

from electrical

components.

Do not allow coolant to splash into or near the computer.

Clothing and Hair

Avoid loose hair and

clothing.

Don't wear loose clothing or jewelry that can get caught in

moving parts. Wear a hat or hair net, or tie your hair back to

keep it away from moving parts.

Safety Equipment

Wear safety glasses.

During operation any power tool can throw foreign objects and

harmful chemicals into your eyes. Always put on safety glasses

or eye shields before starting up the milling center. Safety

glasses or shields should provide full protection at the sides, as

well as the front of the eyes.

Ground all tools.

The milling center has an AC power cord terminated by a threeprong plug. The power cord should be plugged into a threehole, grounded receptacle. If a grounding adapter is used to

accommodate a two-prong receptacle, the adapter wire must

be attached to a known ground. Never remove the third prong

from the plug on the AC power cord.

Keep the safety door

closed while machine

is in motion.

The safety door should remain in place whenever the spindle

motor is on or the cross slide is moving.

Remove adjusting keys

and wrenches.

Make it a habit to check that keys and adjusting wrenches are

removed from the milling center before using the machine.

Emergency Stop

Stopping the machine.

Before you run the ProMill 8000 for the first time, you should

know how to stop the machine should an emergency situation

arise.

To initiate an emergency stop on the milling center, either:

Press the Emergency Stop button, or

Turn the machine off at the power switch.

In non-emergency situations, the machine can be stopped in the

following ways:

Simultaneously press the Control and Space Bar keys

on the computer keyboard

Activate one of the limit switches

Activate the safety door interlock switch.

When to use the

Emergency Stop.

You should use the Emergency Stop button to disconnect power

to the milling center when faced with a problem such as a tool

breaking or a collision occurring, and while performing routing

operations, such as when changing tools or mounting or

removing a workpiece.

1 Safety Guidelines

1.1 Detailed Safety Guidelines

3

Using the machinemounted emergency

stop button.

There is an Emergency Stop button located on the front panel of

the milling center; it has an oversized red cap.

To engage: Press the button in.

To release: Turn the button clockwise, it will pop out on its own.

Using the software

stop button.

The execution of the part program can be interrupted by

pressing the Control and Spacebar buttons on the computer

keyboard. Unlike using the Emergency Stop button, this method

of stopping the milling center does not cause the software to

lose track of the tool position.

Operation Rules

General

Proper setup of the milling center is essential for safe milling.

These procedures must be followed each time a new tool is

mounted. General setup requirements for the milling center

include checking components for cleanliness and lubrication,

mounting the cutting tool, mounting the workpiece, and setting

the spindle rotation speed.

Avoid accidental

starting.

Make sure the power switch is off before plugging in the milling

center power cord.

Check milling machine

components.

Always examine the machine to be sure that the work area is

free of shavings and particles from previous operations. Remove

such debris from the milling machine to avoid possible binding

of components which may result in possible damage to the

milling machine, the workpiece, or the operator.

Always make sure the machine is properly lubricated.

Do not force a tool.

Select the feed rate and depth of cut that are best suited to the

design, construction, and purpose of the cutting tool. It is

always better to take too light a cut than too heavy a cut.

Use the right tool.

Select the type of cutting tool best suited to the milling

operation. Don't force a tool or attachment to do a job it wasn't

designed for.

Maintain cutting tools

in good condition.

Keep cutting tools sharp and clean. Lubricate and clean milling

center components on a regular basis.

Mount the cutting tool

correctly.

Each cutting tool used in the milling operation must be sharp

and properly installed in the spindle. The cutting edge of the

tool must be on the centerline or just below the centerline

(0.004 inch or 0.1 mm maximum) of the axis of rotation of the

milling machine

Secure the workpiece.

Be certain that the workpiece is firmly clamped to the table or

secured in a vice.

Tighten all holding,

locking and driving

devices.

Tighten the work holders and tool holders. Do not over tighten

these devices. Over tightening may damage threads or warp

parts, thereby reducing accuracy and effectiveness.

Turn the spindle by

hand before starting.

Manually turning the spindle allows you to safely determine

that the tool will not hit the milling center bed, cross slide, or

stock on start up.

1 Safety Guidelines

1.1 Detailed Safety Guidelines

4

Set the spindle rotation

speed.

The ProMill Milling Center is equipped with an electronically

controlled spindle motor which produces a comprehensive

range of spindle rotation speeds. Speed can be set with the

Control Software or by using an S code in the NC program.

Always use a safe spindle speed.

Accessories

Use recommended

accessories only.

To avoid stressing the milling center and creating a hazardous

milling environment, use only those accessories designed for

use with the ProMill 8000, available through Intelitek

Corporation.

1 Safety Guidelines

1.2 Safety Checklist

5

Post copies of this checklist in the work area. Verify that all items are checked-off prior to each

operation of the ProMill milling center.

1.2. SAFETY CHECKLIST

Before you enter the work area:

Put on safety glasses.

Tie back loose hair and clothing.

Remove jewelry including rings, bracelets and wristwatches.

Before milling a part:

Make sure you have the correct tool for the job.

Secure the tool properly.

Make sure all tool positions have been properly initialized.

Verify the NC program on the computer.

Remove all loose parts and pieces from the machine.

Remove adjusting keys and wrenches from the machine.

Close the safety door.

Only operate the machine after being properly trained in its use.

Perform a dry run:

Make certain there is no workpiece in place.

Run the NC program to make sure all the moves make sense before running the program

with a workpiece in place.

After completing the dry run, properly secure the workpiece to the machine.

Keep fluids away from all electrical connections, electronic or electrical devices, the computer, and

nearby electrical outlets.

While milling a part:

Do not touch moving or rotating parts.

Press the Emergency Stop button before opening the safety door.

Only open the safety door after the spindle has stopped rotating.

Press the Emergency Stop button whenever changing tools or mounting or removing a workpiece.

Release the Emergency Stop button only after closing the safety door.

Keep all unauthorized persons away from the work area.

2 Introducing the ProMill 8000

2.1 Overview of Standard Features

6

Section Contents: Introducing the ProMill 8000

Section

Name

Page

2.1

Overview of Standard Features.

6

2.2

ProMill 8000 Components

8

2.3

Overview of CNCBase/Motion Control Software.

12

2.4

Standard Accessories

12

2.5

Optional Accessories

13

Info Table: Standard Features

Network and software features

Ethernet-based control

PC-based CNC software

EIA RS-274D standard G&M code programming

A built-in full-screen NC program editor with graphic tool path

verification

Multiple tool programming

Help functions on screen

Standard hardware features

4th axis ready

Brushless spindle motor

Pneumatic drawbar

2. Introducing the ProMill 8000

The ProMill 8000 is a versatile PC-based CNC milling center that enables you to deliver robust instruction

in computer numerical control and advanced manufacturing.

The ProMill 8000 comes equipped with 3-axis stepper motors, ball screws, a variable speed A/C

powered brushless spindle motor, limit/home switches, and an ISO 20 taper spindle with a 10 mm

maximum tool diameter and 150 mm throat.

This CNC system requires no assembly and is ready to run on an Ethernet port on a standard PC, and fits

comfortably into any classroom without sacrificing features.

Like larger industrial machines, the ProMill 8000 uses EIA, ISO, and Fanuc-compatible G&M code

programs to cut parts in a variety of materials.

This section presents the following information:

2.1. OVERVIEW OF STANDARD FEATURES

Some of the ProMill Milling Center’s most notable hardware and software features are listed in the table

below:

2 Introducing the ProMill 8000

2.1 Overview of Standard Features

7

Standard milling specifications

y-axis travel of 6 inches (152 mm)

X-axis travel of 10.24 inches (260mm)

Z-axis travel of 7.09 inches (180mm)

Feed rates up to 20 IPM (500mm/min) (rapid traverse up to 79 IPM

(2000mm/min))

Computer-controlled spindle speeds from 100 to 5,000 RPM

Safety features

Full enclosure with automatic safety door lock

Automatic diagnostics and power cut off protection

Safety door and limit switches

Emergency stops from the milling center and computer keyboard

Machine ready optional accessories

Coolant ready

Jog pendant ready

Robotic integration ready with 6 inputs, 6 outputs

2 Introducing the ProMill 8000

2.2 ProMill 8000 Components

8

Section Contents: Components

2.2.1 External View, pg. 9

2.2.2 Right Side Panel, pg. 10

2.2.3 Enclosure , pg. 11

2.2.4 Rear Pneumatics Panel, pg. 12

2.2. PROMILL 8000 COMPONENTS

This section shows the location of major components of the ProMill 8000, arranged by the view from

which they are visible:

2 Introducing the ProMill 8000

2.2 ProMill 8000 Components

9

1. Safety shield (door)

2. Jog pendant (optional)

3. Emergency stop switch

2.2.1. External View

The external view is shown below.

Notes:

The Safety door encloses the milling area to help protect the operator from flying chips. A

magnetic shield interlock switch prevents the machine from operating with the shield open.

The Emergency Stop button is used to halt machine operation. When pushed, machine

operation stops immediately. To resume operation, the button must be rotated clockwise and

will then pop out on its own. It is important that this button be pushed in (i.e. engaged) before

performing any manual operation, such as changing the stock or tooling.

2 Introducing the ProMill 8000

2.2 ProMill 8000 Components

10

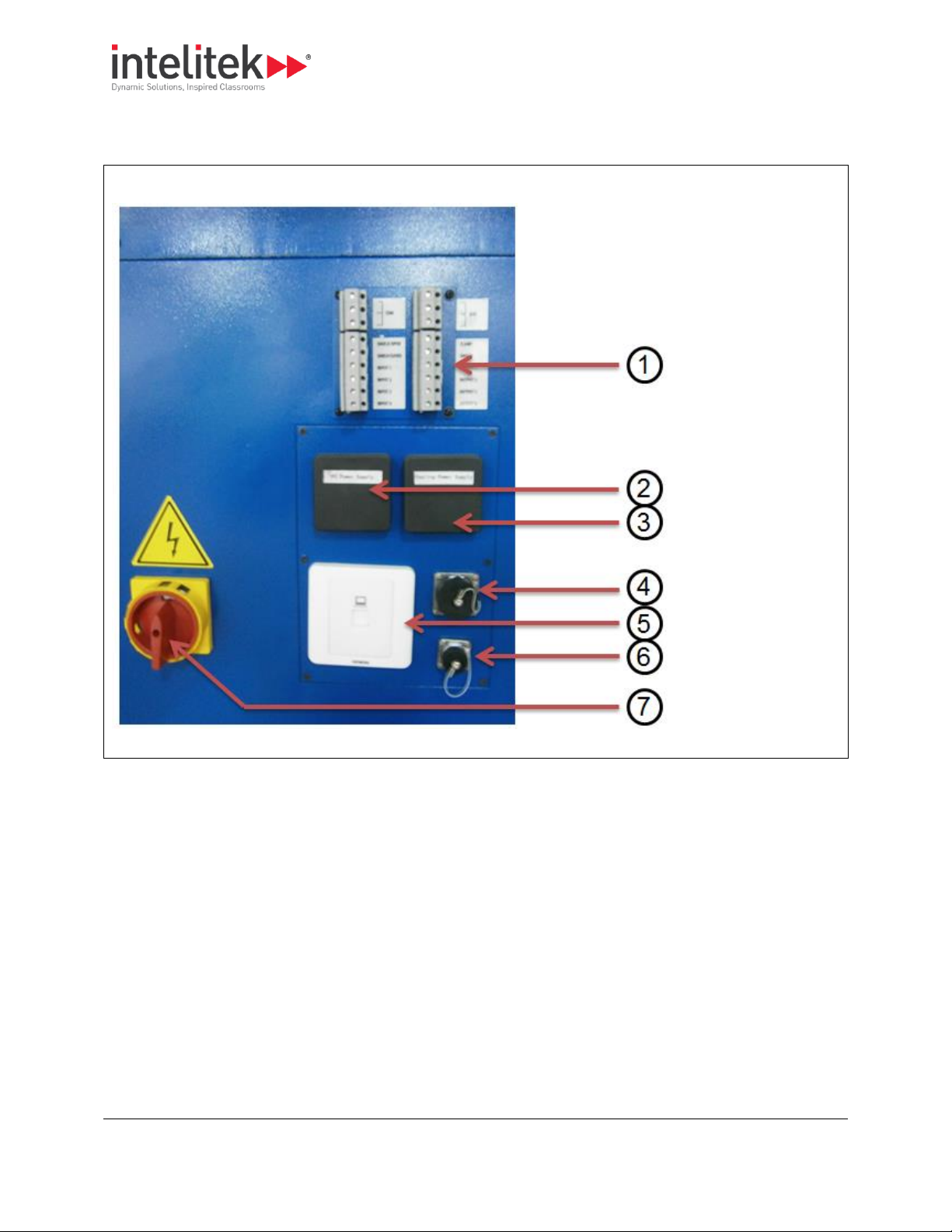

1. I/O ports

2. PC power supply

3. Coolant power

supply

4. Jog pendant port

5. Ethernet port

6. FANUC panel port

7. On/off switch

2.2.2. Right Side Panel

The graphic below shows the machine as viewed from the right side.

2 Introducing the ProMill 8000

2.2 ProMill 8000 Components

11

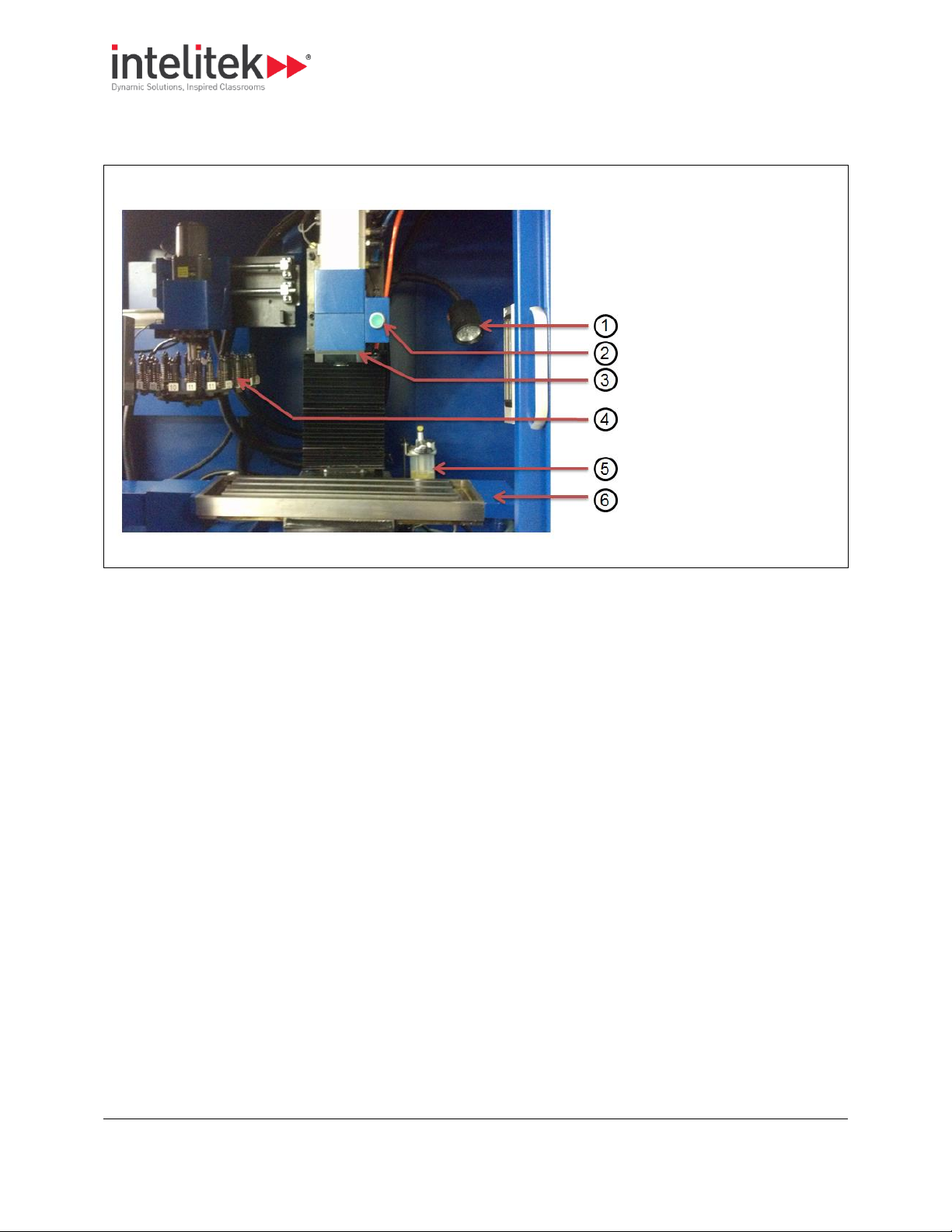

1. Work light

2. Tool release button

3. Spindle Head

4. Automatic tool changer

(optional)

5. Lubricant reservoir

6. Cross-slide

2.2.3. Enclosure

The graphic below shows the contents exposed by opening the safety shield.

2 Introducing the ProMill 8000

2.4 Standard Accessories

12

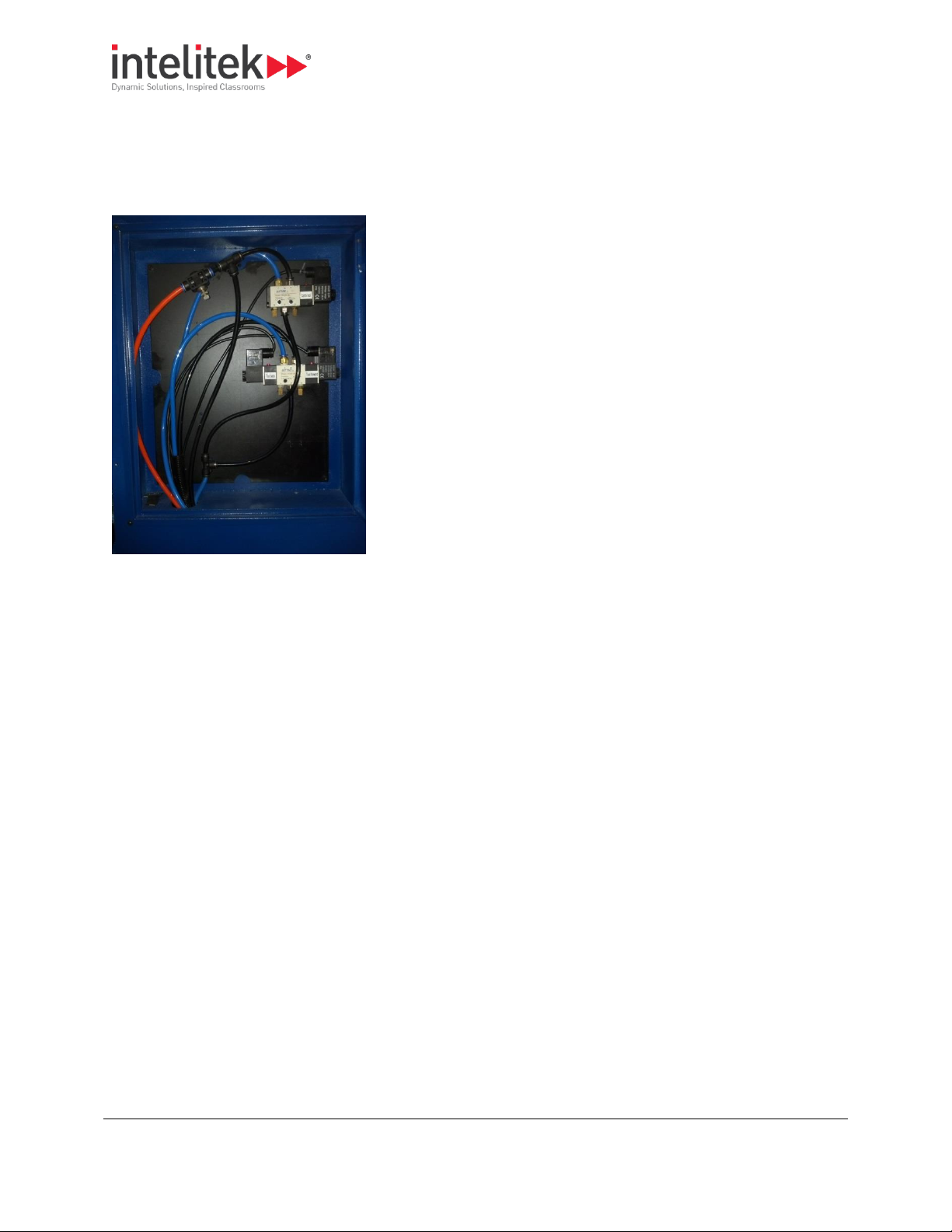

2.2.4. Rear Pneumatics Panel

The pneumatic controls for the 12 station tool changer (optional) and drawbar air-blast are located in

the rear pneumatics panel. For more information, see 4.4 Adjusting and Maintaining the Pneumatic

Systems, pg. 39.

2.3. OVERVIEW OF CNCBASE/MOTION CONTROL SOFTWARE

The heart of the ProMill 8000 milling center is the control software (CNCMotion or CNCBase) that runs

on your computer. Using industry standard EIA RS- 274D NC codes, the control software provides for

two-axis CNC programming and milling.

The control software is extremely easy to use with all necessary functions readily available to run a part

program.

CNCBase and CNCMotion differ only in that CNCMotion provides 3D simulation of the milling procedure.

2.4. STANDARD ACCESSORIES

The accessory kit supplied with the milling center contains all the tools and hardware necessary for

installing and maintaining the milling center. Additional tool holding devices and tools are available as

options.

2 Introducing the ProMill 8000

2.5 Optional Accessories

13

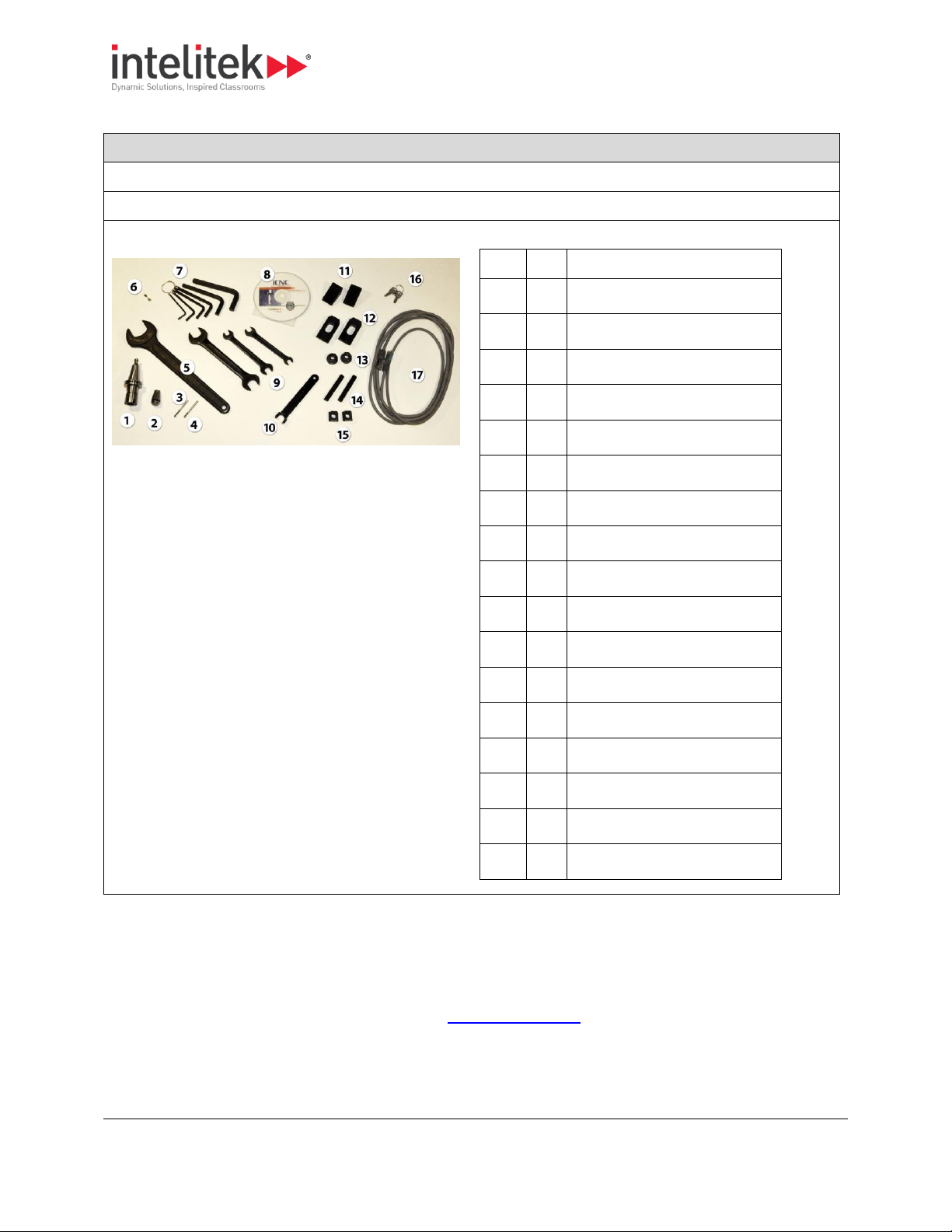

Info Table: Standard Accessories

One shot lubrication system

Internal work light

Milling center accessory package:

Item

Qty

Description

1 1 ISO 20 Tool holder

2 1 ER 16 Collet - 4mm diameter

3 1 3mm End mill 3mm shank

4 1 1/8" End mill 1/8" shank

5 1 Tool holder wrench - 30mm

6 1 5mm x 20mm Fuse

7 1 Allen wrenches, set of 6

8 1 CNCBase control software

9 1 Open-ended wrenches, set of 3

10 1 Tool holder nut wrench

11 2 Step block

12 2 Step clamp

13 2 Hex-head nut

14 2 Threaded shank

15 2 T-nut

16 2 Electrical panel keys

17 1 Ethernet cable

This table below lists the standard accessories supplied with the ProMill 8000.

2.5. OPTIONAL ACCESSORIES

Intelitek offers a variety of milling center accessories, CAM software, curriculum, and documentation.

For more information about these products call your Intelitek dealer, call Intelitek directly at (800)2212763 or (603) 413-2600, or browse our web site www.intelitek.com.

3 Installing the Hardware and Software

3.1 Preparing for Installation

14

Procedure Outline: Installation

No.

Step

Section

Page

1

Prepare your hardware for installation.

3.1

14

2

Install the hardware.

3.2

18

3

Install and configure the software.

3.3

20

Section Contents: Installing the Hardware and Software

Section

Name

Page

3.4

Contacting Technical Support

33

3.5

Returning Defective Products

33

Procedure Outline: Preparing for Installation

No.

Step

Page

1

Verify that the computer to be used with the milling center meets minimum requirements.

14 2 Prepare a work space for the milling center.

15

3

Remove the crating.

15 4 Unpack and set up the milling center.

16

5

Check your shipment to ensure that all items ordered are present and undamaged.

16

6

Register your milling center to activate the warranty.

17

3. Installing the Hardware and Software

This section presents instructions for installing the hardware and software components.

This section also presents the following information.

3.1. PREPARING FOR INSTALLATION

This section presents instructions for preparing the work space and machine for installation.

3.1.1. Verifying Computer Requirements

Use the checklist below to ensure that the computer that will be attached to the milling center meets

minimum requirements.

3 Installing the Hardware and Software

3.1 Preparing for Installation

15

Checklist: Verifying Computer Requirements

Windows 7/Windows 8/Windows 10 - 32 or 64bit

512 MB RAM (1 GB Recommended)

CD-ROM

100 MB of available hard drive space (300 MB Recommended)

VGA graphics or better graphics display (minimum 256 colors)

Available Ethernet port

A mouse or other pointing device

ATX Power Supply (Recommended)

Note: Your operating system might have additional hardware requirements.

Checklist: Preparing the Work Space

For customers in the U.S.A.: A 120VAC, 15 Amp outlet

For international customers: A 220VAC, 8 Amp outlet

A personal computer running Windows 95 or Windows NT version 3.51 (or higher). See section 3.3.1

Verifying Computer Requirements, pg. 20, for a complete list of the necessary computer equipment.

Product Care

We recommend the use of a voltage surge protector and line filter to protect your computer

system.

Procedure: Removing the Crating

1. Inspect the crating for any visible signs of damage. If there is damage to the crating, contact the shipping

company and Intelitek Customer Support.

2. Cut any banding on the outside of the crate.

3. Remove the top of the crate.

4. Remove the sides of the crate.

Intelitek is not responsible for any damage caused during shipping when components are

not returned in the original packing materials.

Store the packing materials at least until the installation is complete and proper operation

has been verified.

3.1.2. Preparing the Work Space

Use the checklist below to ensure that the work space is ready for the installation of the machine.

3.1.3. Removing the Crating

Follow the procedure below when removing the crating after delivery of the product.

3 Installing the Hardware and Software

3.1 Preparing for Installation

16

Procedure: Unpacking and Setting up the Milling Center

1. Position the pallet near the location at which you'll set the milling center.

2. Remove the staples that attach the bottom of the cardboard container to the pallet.

3. Cut the banding around the container.

4. Lift the cardboard cover off the top of the container.

5. Remove the sides of the container.

6. Inspect the milling center chassis for signs of visual damage such as a broken shield, a dent in the chassis,

or damaged cables.

7. Call Intelitek Customer Support if any damage is noted.

8. Remove the four bolts that hold the milling center base to the pallet, using a 19mm wrench.

9. Store the bolts and other packaging materials, in case the product has to be returned or transported.

10. Lift the milling center off of the pallet and place it at its designated location.

11. Position the milling center correctly for milling.

12. Remove the protective paper from the safety door.

13. Open the front door and remove the components from the enclosure.0.

Procedure: Checking your Shipment

1. Locate the packing slip. This slip lists all of the items you should have received with your milling center.

2. Check that all items on the packing slip are present. See the checklist below.

3. Contact Intelitek Customer Support immediately if any item is missing. 0.

Checklist: Checking your Shipment

No.

Item

1

ProMill 8000 Milling Center

2

Installation disk for CNCBase/Motion software

3

Documentation pack

Take Note

3.1.4. Unpacking and Setting up the Milling Center

Follow this procedure for unpacking and setting up the milling center.

3.1.5. Checking your Shipment

Follow this procedure for checking your shipment once unpacked.

Use this checklist to ensure that all items listed on the packing slip are present in the delivery.

3 Installing the Hardware and Software

3.1 Preparing for Installation

17

4

Accessory kit

The accessory kit should include the following:

Item

Qty

Description

1 1 ISO 20 Tool holder

2 1 ER 16 Collet - 4mm diameter

3 1 3mm End mill 3mm shank

4 1 1/8" End mill 1/8" shank

5 1 Tool holder wrench - 30mm

6 1 5mm x 20mm Fuse

7 1 Allen wrenches, set of 6

8 1 CNCBase control software

9 1 Open-ended wrenches, set of

3

10 1 Tool holder nut wrench

11 2 Step block

12 2 Step clamp

13 2 Hex-head nut

14 2 Threaded shank

15 2 T-nut

16 2 Electrical panel keys

17 1 Ethernet cable

5

Additional accessories ordered

Procedure: Registering Your Milling Center

1. Locate the box that contains the documentation and installation disk.

2. Locate the registration card within that box.

3. Complete the card, printing all information clearly.

4. Return the card to Intelitek Customer Support at the address below,

3.1.6. Registering Your Milling Center

Follow this procedure to register your milling center.

3 Installing the Hardware and Software

3.2 Installing the Hardware

18

Intelitek Customer Support

18 Tsienneto Road

Derry, NH 03039

USA

or fax to 603-625-21370.

Procedure Outline: Hardware Installation

No.

Step

Section

Page

1

Connect the milling center to a computer.

3.2.1

18 2 Connect the milling center to a power source.

3.2.2

19 3 Install additional accessories purchased.

3.2.3

19

Safety

Do not connect power to the milling center or the computer until instructed to do so in the

following procedures.

Procedure: Connecting the Milling Center to a Computer

1. If not done previously, verify that the computer you are planning to use meets minimum requirements.

See 3.1.1 Verifying Computer Requirements, pg. 14.

3.2. INSTALLING THE HARDWARE

This section presents instructions for installing the ProMill 8000 hardware.

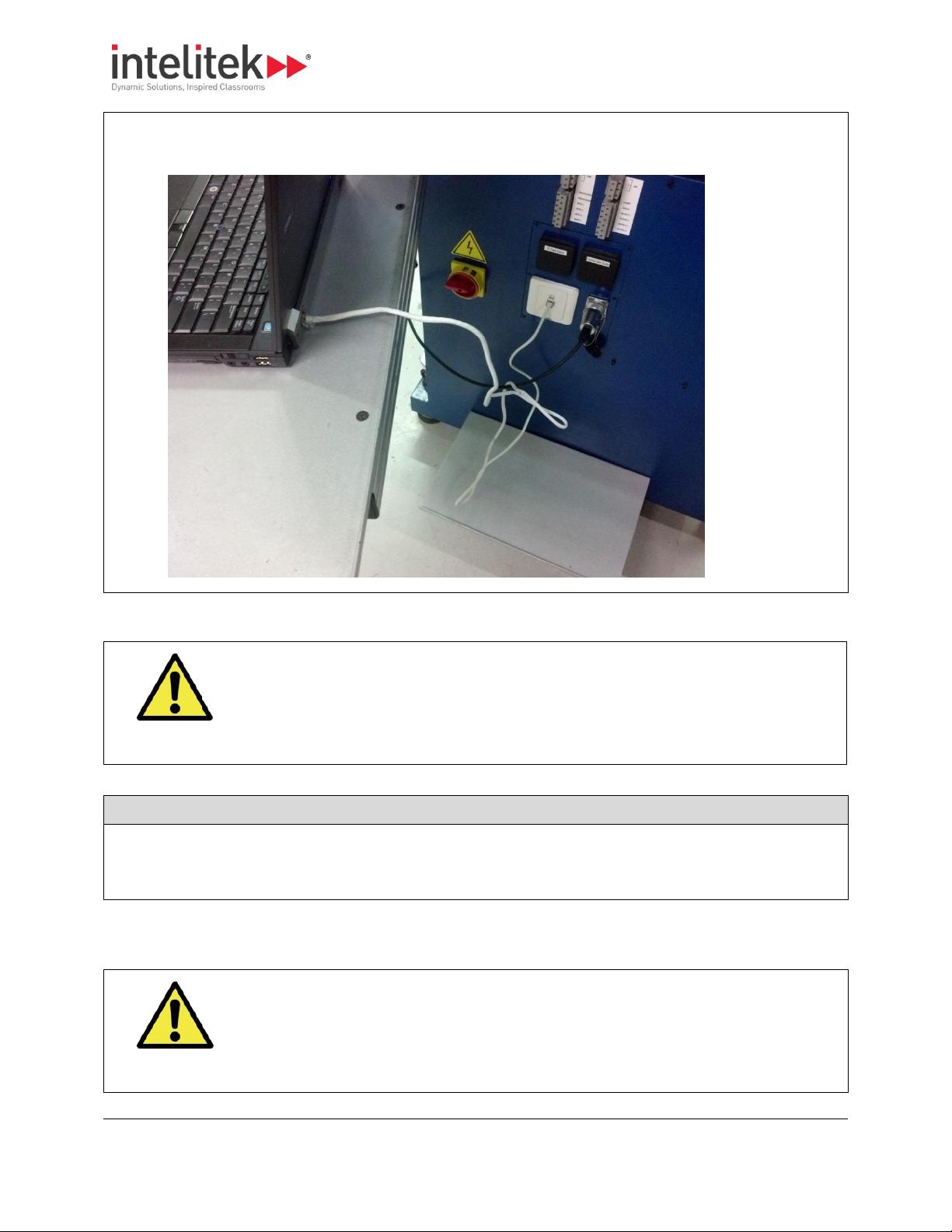

3.2.1. Connecting the Milling Center to a Computer

Follow the procedure below to connect the milling center to a computer.

You will connect the milling center directly to a computer. Connection to the network (if required) is

provisioned by the computer.

3 Installing the Hardware and Software

3.2 Installing the Hardware

19

2. Use a cable with 8P8C (RJ-45) connectors at both ends to connect the milling center to the computer, as

shown below. 0.

Safety

The milling center has an AC power cord terminated by a three-prong plug. The power cord

should be plugged into a three-hole, grounded receptacle. If a grounding adapter is used to

accommodate a two-prong receptacle, the adapter wire must be attached to a known

ground. Never remove the third prong from the plug on the AC power cord.

Procedure: Connecting the Power

1. Ensure that the milling center’s power switch, located at its side, is set to the OFF position.

2. Connect the power cord from the milling center to the power source. 0.

Safety

To avoid stressing the milling center and creating a hazardous milling environment, use only

those accessories designed for use with the ProMill milling center, available through Intelitek

Corporation.

3.2.2. Connecting the Power

Follow the procedure below to connect the milling center to a power supply.

3.2.3. ProMill 8000 Installing Accessories

Each accessory kit is supplied with an installation guide.

3 Installing the Hardware and Software

3.3 Installing the Software

20

Product Care

Complete the hardware and software installation procedures (see 3.3 Installing the Software

below), and test the functioning of the basic machine, before installing accessories.

Procedure Outline: Software Installation

No.

Step

Section

Page

1

Ensure that your computer meets the minimum requirements.

3.3.1

20 2 Run the installation to install the software.

3.3.2

21

3

Configure the software for your machine and accessories.

3.3.4

25 4 Configure the IP address of the milling center

3.3.5

29

Section Contents: Installing the Software

Section

Name

Page

3.3.6

Uninstalling the Software

31

3.3. INSTALLING THE SOFTWARE

This section presents instructions for installing the control software (CNCMotion or CNCBase) on the

computer.

This section also presents the following information:

3.3.1. Verifying Computer Requirements

If not done previously, verify that the computer you are planning to use meets the minimum

requirements. See 3.1.1 Verifying Computer Requirements, pg. 14.

If installing the software on a computer to be used only for writing and verifying NC programs, but not

for interacting with the hardware itself, the requirement for LAN cards is not relevant.

3 Installing the Hardware and Software

3.3 Installing the Software

21

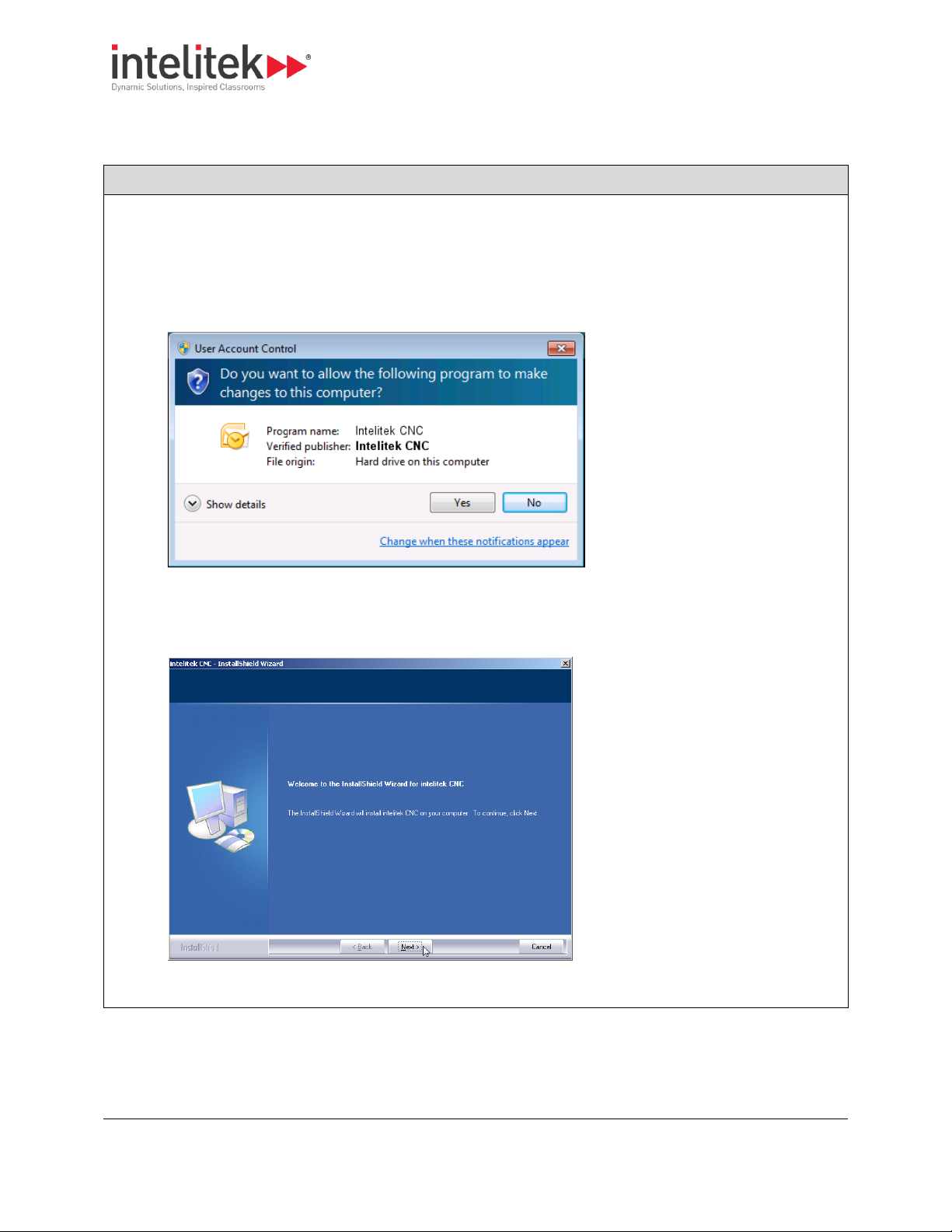

Procedure: Running the Installation

1. Insert the installation disk into the CD/DVD drive. The installation program should open automatically.

If the installation does not open automatically, navigate to the Install folder and launch the program

iCNC.exe.

2. If the User Account Control message displays, click Yes.

The installation begins and the Welcome screen is displayed.

3. Click Next.

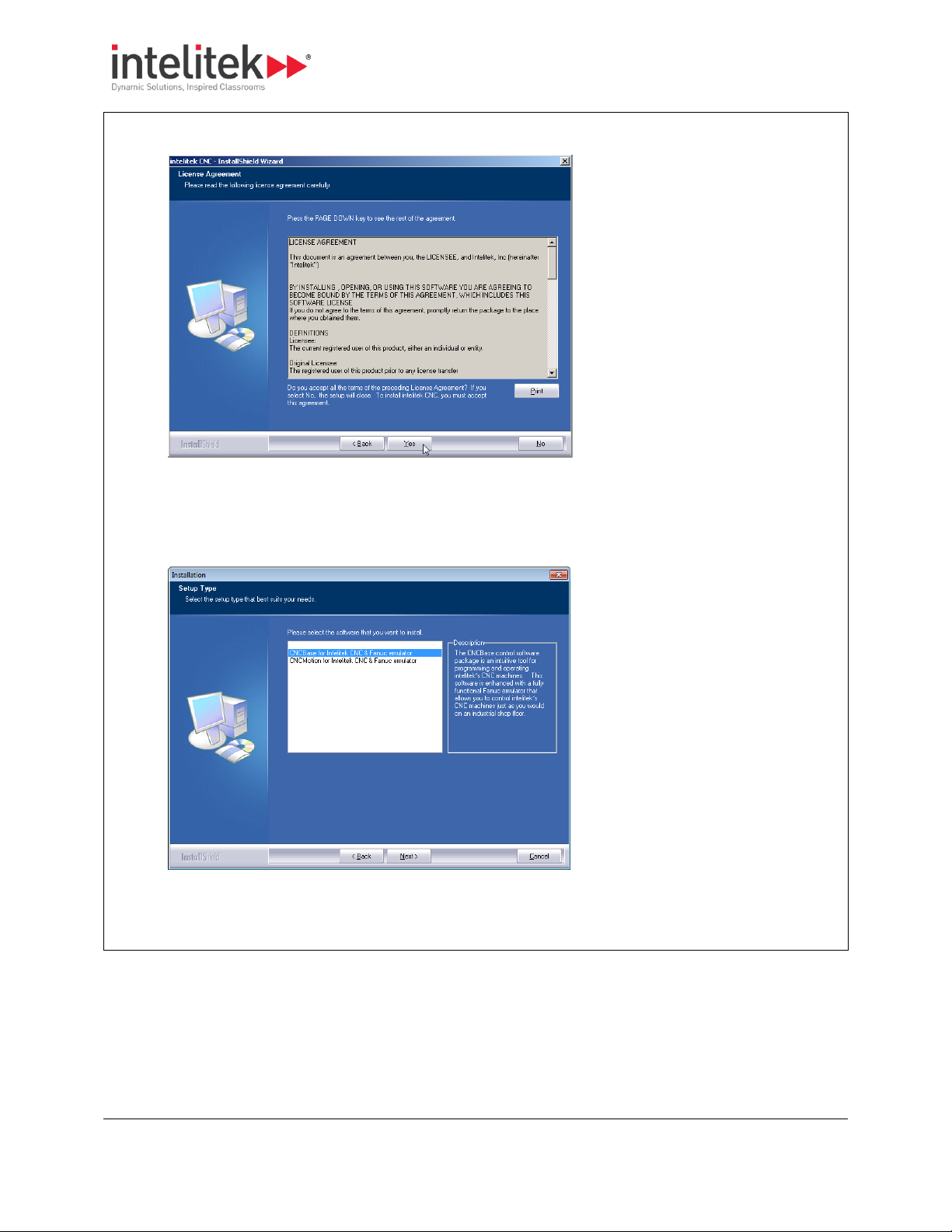

The License Agreement is displayed.

3.3.2. Running the Installation

Follow the procedure below to run the installation.

3 Installing the Hardware and Software

3.3 Installing the Software

22

4. Click Yes to accept and continue.

The Software Selection screen is displayed.

5. Select the software to install. It is important that the software you select here matches the license you

have purchased.

6. Click Next.

The Machine Selection screen is displayed.

3 Installing the Hardware and Software

3.3 Installing the Software

23

7. Select the machine you will be using. It is important that the machine selected matches the license you

have purchased.

8. Click Next.

The Configuration Options screen is displayed.

9. Select whether the configuration and sample programs are to be exclusive to each user (first option) or

common to all users (second option). The first option is recommended when running software in

simulation mode. The second option is highly recommended when running software with a physical CNC

machine.

10. Click Next.

The Choose Destination Location screen is displayed.

3 Installing the Hardware and Software

3.3 Installing the Software

24

11. If necessary, click Browse to change the destination folder.

12. Click Next.

The Ready to Install screen is displayed.

13. Click Install.

3 Installing the Hardware and Software

3.3 Installing the Software

25

14. Wait while installation is performed.

The InstallShield Wizard Complete screen is displayed.

15. Select Yes, I want to restart my computer now.

16. Click Finish.

Your computer will restart and installation will be finalized.0.

Procedure Outline: Configuring the Software

No.

Step

Section

Page

1

Run the configuration program.

3.3.4.1

20 2 Change configuration settings using the configuration program.

3.3.4.2

21

3.3.3. Licensing the Software

For details on licensing your software and managing or transferring your license, refer to the Licensing

Help document that can be found in the Books folder of the software installation disk. You can also

access the Licensing Help document by clicking the Help button during software registration.

Note that CNCBase does not require registration. If you have purchased CNCMotion, that software does

require registration.

3.3.4. Configuring the Software

The installation program automatically configures most software parameters based on the selections

you make during installation.

The Configuration Program can be used to:

Modify selections made during installation.

Configure machine accessories installed.

This section presents instructions for configuring the control software (CNCMotion or CNCBase) on the

computer.

3 Installing the Hardware and Software

3.3 Installing the Software

26

3

Add optional accessories to the machine.

3.3.4.3

28

Procedure: Running the Configuration Program

1. Ensure that CNCBase/Motion is not currently running.

2. Click the Windows Start button.

3. Click All Programs.

4. Locate and click the CNCBase/Motion for Intelitek CNC & Fanuc emulator folder.

5. Click CNCBase/Motion Configuration.0.

The CNC Configuration window displays.

3.3.4.1. Running the Configuration Program

The Configuration Program is launched from your Windows Start menu.

If you try to launch the Configuration Program while the CNCBase/Motion software is open, you will be

asked to close CNCBase/Motion first.

3 Installing the Hardware and Software

3.3 Installing the Software

27

Procedures: Using the Configuration Program

To

Instructions

View all available settings

Click the tabs at the top of the window.

Access online help

Click the Help button.

Save changes made

Click OK. Clicking OK will close the configuration program.

Make all required changes before clicking OK.

Info Table: CNC Configuration Program Tabs

Tab

Main Options

Welcome

Units (Inch or Metric)

3.3.4.2. Using the Configuration Program

The table below summarizes the use of the configuration program.

The table below summarizes the configuration options available on each of the four tabs of the CNC

Configuration Program.

3 Installing the Hardware and Software

3.3 Installing the Software

28

General

Run in offline (simulation) or online

mode. For more information on

switching between offline and

online modes, see 5.2 Selecting

Online or Simulation Mode, pg. 44.

NC programming settings

User inputs mapping

Options

Lists installed options and allows

you to install addition options. Click

Reinstall to install others.

For more information, see 3.3.4.3

Adding Installed Optional

Accessories, pg. 28.

Machine

Configuration

Allows you to select a different

machine, and to save and load

previously defined configurations.

3.3.4.3. Adding Installed Optional Accessories

Optional accessories are available for the ProMill 8000 (see 2.5 Optional Accessories, pg. 13). After

installing the accessory hardware, the control software must be reconfigured.

Detailed instructions are provided in the installation guide supplied with each accessory. General

instructions are provided below.

3 Installing the Hardware and Software

3.3 Installing the Software

29

Procedure: Configuring Control Software for New Accessory

1. Run the configuration program. (See 3.3.4.1 Running the Configuration Program, pg. 26.)

2. Click the Options tab.

3. Click Reinstall.

The Reinstall Options window is displayed.

4. Select the option to be added.

5. Click Reinstall.0.

The Reinstall Options window closes. The selected option is now listed in the Installed Options list.

Follow the procedure below to configure the control software for a new accessory.

3.3.5. Configuring the IP Address

Before using the hardware, you must configure its IP address on the network.

This utility configures the IP address of the computer’s LAN adapter.

3 Installing the Hardware and Software

3.3 Installing the Software

30

Take Note

You must have administrator access to your computer to run the Machine IP Changer

utility.

Take Note

To reconnect to the network over the LAN, you will need to restore the settings of your

LAN adapter.

Procedure: Configuring the IP Address

1. Run the Machine IP Configuration utility. To do so, locate the CNCBase/Motion for Intelitek CNC & Fanuc

emulator folder and click Machine IP Configuration.

2. Click Yes if asked for permission.

3. From the dropdown list, select the local area network or network card that you wish to use for the CNC

machine.

4. Click Continue.

Follow the procedure below to configure the IP address.

3 Installing the Hardware and Software

3.3 Installing the Software

31

5. Click Yes when asked for confirmation of your selection.

When the process is finished, Machine IP Changer displays the configuration for all active network

connections.

6. Click OK to close the program.0.

Procedure: Uninstalling the Software

1. Click the Windows Start button.

2. Click All Programs.

3. Locate and click the CNCBase/Motion for Intelitek CNC & Fanuc emulator folder.

4. Click Uninstall.

3.3.6. Uninstalling the Software

When necessary, follow the procedure below to uninstall the software.

3 Installing the Hardware and Software

3.3 Installing the Software

32

5. Click Yes if the User Account Control message displays.

The Uninstall Wizard is displayed, asking for confirmation.

6. Click Yes to uninstall CNCBase/Motion.

7. Wait while the software is uninstalled.

The Uninstall Complete window is displayed.

8. Select Yes, I want to restart my computer now.

9. Click Finish.

Your computer will restart and uninstallation will be finalized.0.

3 Installing the Hardware and Software

3.5 Returning Defective Products

33

Info Table: Requirements for Technical Support

The product serial number

The name of the owner of the product

The specifications of your computer (e.g. version of

Windows, hard drive size, clock speed, etc.)

Notes on any error messages received

Take Note

When you call, make sure you have access to both your milling center and your computer.

This will allow our technical support representatives to walk through the problem with you.

Info Table: Intelitek Technical Support Contact Details

Toll-free (U.S. only)

(800) 221-2763

Direct Dial

(603) 413-2600

e-mail

support@intelitek.com

Web site

www.intelitek.com

Take Note

Intelitek will not be responsible for any damage incurred during shipping when components

are not returned in the original packing materials.

Procedure: Returning Defective Products

1. Contact Intelitek Technical Support and describe the problem.

2. If the Technical Support representative decides that the product is defective and has to be returned, the

Technical Support representative will issue a Return Materials Authorization number (RMA). Store this

3.4. CONTACTING TECHNICAL SUPPORT

Should you require technical assistance, contact your local Intelitek dealer. If you are unable to resolve

your problem through your local dealer, free technical support is available by phone or email from 8:15

A.M. to 5:00 P.M. EST.

Make sure you have the following information gathered before contacting our Technical Support group.

Technical support contact details:

3.5. RETURNING DEFECTIVE PRODUCTS

Intelitek products (excluding software) carry a one-year limited warranty from date of purchase.

Defective products may be returned for repair or replacement according to the conditions outlined in

the Terms and Conditions of Sale agreement.

Follow the procedure below to return defective products.

3 Installing the Hardware and Software

3.5 Returning Defective Products

34

number safely.

3. Pack the product to be returned in its original packaging and crate, as was packed originally.

4. Write the RMA number and your return address on the outside of the product carton or crate. Failure to

do so can result in a delay in the return of your product.

5. Have the package returned to Intelitek’s offices, as directed by the Technical Support representative. 0.

4 Maintaining the ProMill 8000

4.1 Cleaning the Milling Center

35

Product Care

Preventative maintenance of the ProMill 8000 is essential for ensuring a long and troublefree service life.

Maintaining the Milling Center

Description

Section

Page

Keep the machine clean.

4.1

35

Maintaining individual milling machine components.

4.2

36

Follow a maintenance schedule.

4.3

38

Adjust the pneumatic systems.

4.4

39

Maintaining a computer in a shop environment.

4.4

39

Checklist: Cleaning the Milling Center

Remove all chips from the machine after every use.

Pay particular attention to the bellows. If chips build up on top of the bellows, they may fall behind the

bellows and interfere with ball screw operation.

Product Care

If you clean a component of the milling center that requires lubrication, make sure to

relubricate it after cleaning.

4. Maintaining the ProMill 8000

This section presents instructions for maintaining the milling center and computer.

4.1. CLEANING THE MILLING CENTER

Keeping your machine clean is the easiest and most important maintenance practice.

4 Maintaining the ProMill 8000

4.2 Maintaining Individual Milling Machine Components

36

Maintaining the Milling Center Components

Task

Section

Page

Maintaining the Milling Machine Bed

4.2.1

36

Maintaining the Milling Machine Bed Linear Bearings

4.2.2

37

Maintaining the Ball Screw

4.2.3

37

Maintaining the Spindle Motor Belt

4.2.4

38

Product Care

Use 15 weight way oil only.

4.2. MAINTAINING INDIVIDUAL MILLING MACHINE COMPONENTS

Each of the milling center’s major components must undergo routine maintenance.

This section provides maintenance instructions for each major component.

These tasks provide maintenance instructions for each major component:

4.2.1. Maintaining the Milling Machine Bed

The milling machine bed, saddle, and ball screw all require constant lubrication to prevent wear and

rust. The ProMill 8000 is supplied with a one-shot system that simplifies lubrication of these

components.

4 Maintaining the ProMill 8000

4.2 Maintaining Individual Milling Machine Components

37

Guidelines: Lubricating the Milling Machine Bed

B

Operate the one-shot lubricating

system before each use.

To operate, pull on the handle of

the one-shot lubricating system

and release.

Keep the reservoir filled with 15

weight way oil.

Maintain a film of lubricant on the

surface of the milling machine bed

to minimize friction and wear.

Ensure that all non-painted

surfaces on the milling machine

are coated with oil to prevent rust.

Follow the guidelines below to ensure proper lubrication of the milling machine bed.

4.2.2. Maintaining the Milling Machine Bed Linear Bearings

Play in the table could indicate that the milling machine bed bearings require adjustment. The bearings

are factory-adjusted and should be checked at least every three months.

Contact your Intelitek customer service group for maintenance or service instructions.

4.2.3. Maintaining the Ball Screw

The ProMill 8000 Milling Center uses pre-loaded ball screws on both axes. The screws are lubricated at

the factory with a special long-life, waterproof ball screw lubricant. Additionally, the ball screw is

lubricated via the one-shot lubrication system.

One-shot lubrication should be performed before each use of the machine. See 4.2.1 Maintaining the

Milling Machine Bed, pg. 36, for instructions.

4 Maintaining the ProMill 8000

4.3 Maintenance Schedule Summary

38

Product Care

Call Intelitek Customer Service if the belt makes a squealing sound.

Guidelines: Maintenance Schedule

Continuously

Before Every

Use

After Every Use

Every 2 Months

Every 3 Months

Clean chips from

the milling

center

X

Coat exposed

surfaces with

light oil

X

Activate the oneshot lubrication

system

X

Maintain the

level of 15

weight way oil in

the one-shot

lubricating

system

X

Check and adjust

the milling

machine bed

linear bearings

X

4.2.4. Maintaining the Spindle Motor Belt

The spindle motor belt will wear out quickly if it becomes loose. If a belt squeals at slow speeds, it may

be loose or worn.

The spindle drive belt is inside the spindle head.

4.3. MAINTENANCE SCHEDULE SUMMARY

Follow the maintenance schedule outlined in the table below.

4 Maintaining the ProMill 8000

4.4 Adjusting and Maintaining the Pneumatic Systems

39

1. Drawbar regulator

2. Airblast

3. ATC regulator

Section Contents: Adjusting and Maintaining Pneumatic Systems

Section

Name

Page

4.4.1

Adjusting the Flow Controls

40

4.4.2

Adjusting the Air Pressure

40

4.4.3

Maintaining the Pneumatic Oil

40

4.4. ADJUSTING AND MAINTAINING THE PNEUMATIC SYSTEMS

Both the ATC and the drawbar air-blast are pneumatically powered. The pneumatic controls for both

systems are located in the rear pneumatics panel, as shown below.

This section presents the following information:

4 Maintaining the ProMill 8000

4.4 Adjusting and Maintaining the Pneumatic Systems

40

Info Table: Adjusting Pneumatic Flow Controls

Orange Pipe

Turn Clockwise (Close)

Reduce air-blast pressure

Turn Counter-clockwise (Open)

Increase air-blast pressure

1. Pressure control unit

2. Pressure gauge

3. Oil chamber

4. Filter/dryer vial

4.4.1. Adjusting the Flow Controls

The three flow control units are located in the rear pneumatics panel. The flow control units are

adjusted as follows:

4.4.2. Adjusting the Air Pressure

The air pressure should be set to 80 psi. The air pressure is adjusted using the control unit on the

regulator, located on the right side of the machine.

4.4.3. Maintaining the Pneumatic Oil

The oil flow rate is factory-adjusted and does not require maintenance.

The oil level in the oil chamber (see picture above) should be checked regularly and filled when empty.

Use standard pneumatic tool oil only.

4 Maintaining the ProMill 8000

4.5 Maintaining the PC in a Shop Environment

41

Guidelines: Maintaining the PC in a Shop Environment

Keep the computer and peripherals (mouse, keyboard, external drive, printer, etc.) out of direct sunlight,

away from sources of heat, and in a relatively clean environment (i.e., not right next to the foundry room).

Keep liquids (soda, coffee, cutting fluid, grease) away from the computer and peripherals.

Keep oil, grease, metal chips and excess dust away from the computer, keyboard and other peripherals.

Consider erecting a clear plastic shield between the computer and the milling machine to keep chips off

the computer.

Use grounded three-prong outlets for the computer and peripherals. Take precautions against current

overload. A line-surge suppression unit can be purchased at your local computer store to help alleviate

this problem.

Don’t block the vent holes in the computer or drives; they are required for air circulation.

4.5. MAINTAINING THE PC IN A SHOP ENVIRONMENT

Maintaining a personal computer and software in a shop environment requires extra precautionary

measures. See your owner’s manual for maintenance procedures specific to your computer.

Follow the guidelines listed in this table.

5 Using the Control Software

5.1 Launching the Control Software

42

Section Contents: Control Software

Section

Name

Page

5.1

Launching the Control Software

42

5.2

Selecting Online or Simulation Mode

44

0

Software Interface

45

5.4

Homing

61

5.5

Opening an NC File

62

5.6

Verifying an NC Program

64

5.7

Running an NC Program

71

5.8

Accessing Help

72

Safety

1. The safety door should be closed, and the Emergency Stop button released, before

launching the software in on-line mode.

2. The milling center must be powered up and connected to the computer before

launching the software in on-line mode.

3. Review the complete guidelines in chapter 1 Safety Guidelines, pg. 1.

Procedure: Launching the Control Software

1. If you intend to use the milling center, follow the safety information above.

2. Click the Windows Start button .

3. Click All Programs.

5. Using the Control Software

The control software, CNCBase or CNCMotion, is used to control all aspects of machine function, to edit

and run NC programs, and to verify those programs in simulation mode. CNCMotion additionally

provides 3D simulation of the milling procedure.

For installation and configuration instructions, see 3.3 Installing the Software.

This section presents the following information.

5.1. LAUNCHING THE CONTROL SOFTWARE

CNCBase/Motion can be used with or without the milling center attached to the computer. If you intend

to use the milling center, follow these safety guidelines before launching the software.

Follow this procedure to launch the control software.

5 Using the Control Software

5.1 Launching the Control Software

43

4. Locate and click the CNCBase/Motion for Intelitek CNC folder.

5. Click CNCBase/Motion for Intelitek CNC

6. Click No if the message below displays. This message is only displayed the first time the software is run

after installation.0.

The software opens.

5 Using the Control Software

5.2 Selecting Online or Simulation Mode

44

Safety

1. The safety door should be closed, and the Emergency Stop button

released, before launching the software in on-line mode.

2. The milling center must be powered up and connected to the

computer before launching the software in on-line mode.

Procedure: Selecting On-line or Simulation Mode

1. Launch CNCBase/Motion.

2. Click Setup in the main menu.

The two modes are listed at the top of the Setup menu. The mode that is currently active is checked.

3. To change the mode, click the unchecked mode.

A confirmation message is displayed.

4. Click Yes. 0.

The software restarts and opens in the selected mode.

5.2. SELECTING ONLINE OR SIMULATION MODE

Both CNCBase and CNCMotion can be run in two modes:

On-line mode

For use when controlling the ProMill 8000.

Simulation mode

For use without the ProMill 8000 connected. In simulation mode, you can write, edit, and verify

NC programs as in on-line mode, but you cannot control or send NC programs to the ProMill

8000.

Follow this procedure to toggle between on-line and simulation mode.

5 Using the Control Software

5.3 Software Interface

45

Section Contents: The Software Interface

Section

Name

Page

5.3.1

Toolbars

45

5.3.2

Information Areas

53

5.3.3

Program Editing Window

56

5.3.4

Control Panels

58

Section Content: Toolbars

Section

Name

Page

5.3.1.1

Main Menu

45

5.3.1.2

Standard Toolbar

49

5.3.1.3

Tool Menu and ATC Control Toolbar

50

5.3.1.4

Outputs Toolbar

52

5.3.1.5

lnputs Toolbar

53

Info Table: Main Menu

Menu

Option

Function

File

New

Opens a new, blank Program Editing window.

See 5.3.3 Program Editing Window, pg. 56.

Open

Opens an NC program that was saved previously.

See 5.5 Opening an NC File, pg. 62.

Close

Closes the currently active Program Editing window.

5.3. SOFTWARE INTERFACE

You should become familiar with the main parts of the control software screen prior to use.

This section provides information on the following screen areas:

5.3.1. Toolbars

This section includes information on the following toolbars:

5.3.1.1. Main Menu

The Main Menu contains all of the menu commands. For an explanation of each menu and its relative

commands, refer to the online help.

This table summarizes all options listed in the main menu.

5 Using the Control Software

5.3 Software Interface

46

Save

Saves the program in the currently active Program Editing window,

using its current name.

Save as

Saves the program in the currently active Program Editing window,

under a new name that you specify.

Print

Prints the NC program in the currently active Program Editing

window.

Print setup

Opens the Print Setup window in which you can set up a printer for

printing NC programs.

Choose machine

For selecting which NC machine configuration is in use.

See 3.3.4 Configuring the Software, pg. 25.

Save a copy of current

configuration

Saves the current machine configuration, so that you can reload it

later.

See 3.3.4 Configuring the Software, pg. 25.

Exit

Closes the software. If you have made any unsaved changes to an NC

program, you will be asked for confirmation before closing.

Edit

Undo

Undo the most recent editing command.

Redo

Redo the most recent Undo command.

Cut

Cut selected text to the clipboard.

Copy

Copy selected text to the clipboard.

Paste

Paste text from the clipboard into the current NC program.

Clear

Delete selected text.

Delete Line

Delete the line the cursor is currently on.

Find

Locate a sequence of characters in an NC program.

Replace

Replace one sequence of characters with another, one or more

times.

Goto Line

Jump to a particular line in the NC program.

Note: The Goto Line does not reference the "N" code in the NC file.

The line number is counted starting at one and increments in steps of

one, regardless of the numbering used in the NC code.

Renumber

Modify or insert N codes in an NC program.

Lock

Lock or unlock the Program Edit Window to prevent or allow

modification to the NC program.

Select Font

Change the font currently being used in the Program Editing window.

View

Actual Position

Open or close the Actual Position Window.

See 5.3.2.2 Actual Position Panel, pg. 54.

5 Using the Control Software

5.3 Software Interface

47

Absolute Position

Open or close the Absolute Position Window.

See 5.3.2.2 Actual Position Panel, pg. 54.

Machine Info

Open or close the Machine Info panel.

See 5.3.2.3 Machine Info Panel, pg. 55.

Jog Control

Open or close the Jog Control Panel.

See 5.3.4.1 The Jog Control Panel, 58.

Operator Panel

Open or close the Operator Panel.

See 5.3.4.2 The Operator Panel, pg. 60.

Verify Window

Open or close the Verify Window.

See 5.6 Verifying an NC Program, pg. 64.

Toolbars

Open or close one of the toolbars.

Program

Run/Continue

Start or resume running the current NC program.

See 5.7 Running an NC Program, pg. 71.

Verify

Verify the current NC program.

See 5.6 Verifying an NC Program, 64.

Estimate Runtime

Estimate the runtime of the current NC program.

Pause

Pause the NC program after the current line of NC code finishes

executing. Spindle continues to turn.

Feedhold

Immediately pauses the NC program. Stops movement of all axes

while the spindle continues to turn.

Stop

Immediately halts the currently running NC program. Stops both axes

movement and spindle.

Tool

Setup Library

Define tools.

See 5.3.1.3 Tool

Menu and ATC

Control Toolbar, pg.

50.

Select Tool Wizard

Opens the Tool Height Setup Wizard. The

assists in setting tool heights and offsets.

Select Tool…

Select a tool to use from a menu.

Configure ATC

Set tools for use in the ATC.

Operate ATC

Manually operate the ATC.

Setup

On-line

Change from simulation mode to on-line.

Simulation

Click to change from on-line mode to simulation mode.

Set Position

Establish the X, Y, and Z position of the tool.

See 5.4 Homing, pg. 61.

Zero Position

Set the current tool position to X=0, Y=0, Z=0.

See 5.4 Homing, pg. 61.

5 Using the Control Software

5.3 Software Interface

48

Jog Settings

Establish speed and distance parameters for jogging the tool.

See 5.3.4.1 The Jog Control Panel, 58.

Run Settings

Establish options for running an NC part program.

See 5.7 Running an NC Program, pg. 71.

Verify Settings

Establish options for verifying an NC part program.

See 5.6 Verifying an NC Program, 64.

Set/Check Home

Establish or check a fixed known position on the machine.

See 5.4 Homing, pg. 61.

Goto Position

Automatically move the tool to a specific set of coordinates.

Units

Select imperial or metric units of measure.

Coordinate Systems

Define multiple coordinate systems.

Offsets

Modify the table of offset values used for certain NC codes.

Spindle

Specify a spindle speed if you have not used an S code in your NC

program.

Backlash

Define the amount of play in the turning screws.

Soft Limits

Establish and configure software limits for each axis.

Preferences

Establish defaults for saving files and security features.

Window

Run and Edit Screen

Loads the preset display configuration for running NC programs:

Operator panel, Verify window, Machine info.

Verify Screen

Loads the preset display configuration for verifying NC programs:

Verify window, Machine info.

Program Screen

Select how multiple NC program windows display: tiled or cascading.

Close all windows

Closes all software panels and windows, including NC programs.

Help

Help

Opens the built-in Help system.

Tip of the day

Shows a specific tip to help you take more advantage of the software.

About

Shows software version and copyright information.

5 Using the Control Software

5.3 Software Interface

49

Info Table: Standard Toolbar

Icon

Name

Function

New

Opens a new NC part program file.

Open

Opens an existing NC part program file.

Save

Saves the current NC part program file to disk or drive.

Verify

Verifies the program.

Run

Runs the current NC part program, and recommences the program after a

pause.

Pause

Causes the currently running program to pause once the current block in the

NC program is complete. The program will continue from the next line once

the operator resumes operation.

Feedhold

Pauses the currently running program immediately, even if the current block

in the NC program has not been fully executed. The spindle continues

spinning. The program will continue from the point at which it stopped once

the operator resumes operation.

Stop

Halts the currently running NC part program.

Home

Opens the Machine Home window.

Available in CNCMotion Only

Show 3D

Image

Toggles the 3D display on and off.

Redirect

Camera

Initiates camera redirection: after clicking this icon, click any point on the 3D

image to center the camera on that point.

Follow Me

Camera

Initiates camera following mode: after clicking this icon, click any point on

the 3D image to center the camera on that point. If that point moves during

simulation, the camera will readjust to keep that point at the center of focus.

Drag Image

Initiates image dragging mode: after clicking this icon, click and drag the 3D

image to reposition it within the window.

5.3.1.2. Standard Toolbar

The Standard Toolbar provides easy access to the most often used commands available in the software.

The Standard Toolbar includes the buttons below:

When using CNCMotion, the following additional buttons are present:

5 Using the Control Software

5.3 Software Interface

50

Save Camera

Position

Saves the current viewing angle and position of the 3D window. The next