Intel Corporation PA28F016S3-120, PA28F004S3-150, PA28F004S3-120, PA28F008S3-120, PA28F016S3-150 Datasheet

E

PRODUCT PREVIEW

June 1997 Order Number: 290598-003

n

SmartVoltage Technology

Smart 3 Flash: 2.7V (Read-Only) or

3.3V V

CC

and 3.3V or 12V V

PP

n

High-Performance

120 ns Read Access Time

n

Enhanced Data Protection Features

Absolute Protection with VPP = GND

Flexible Block Locking

Block Write Lockout during Power

Transitions

n

Enhanced Automated Suspend Options

Program Suspend to Read

Block Erase Suspend to Program

Block Erase Suspend to Read

n

Industry-Standard Packaging

40-Lead TSOP, 44-Lead PSOP

n

High-Density 64-Kbyte Symmetrical

Erase Block Architecture

4 Mbit: Eight Blocks

8 Mbit: Sixteen Blocks

16 Mbit: Thirty-Two Blocks

n

Extended Cycling Capability

100,000 Block Erase Cycles

n

Low Power Management

Deep Power-Down Mode

Automatic Power Savings Mode

Decreases I

CC

in Static Mode

n

Automated Program and Block Erase

Command User Interface

Status Register

n

SRAM-Compatible Write Interface

n

ETOX™ V Nonvolatile Flash

Technology

Intel’s byte-wide Smart 3 FlashFile™ memory family renders a variety of density offerings in the same

package. The 4-, 8-, and 16-Mbit byte-wide FlashFile memories provide high-density, low-cost, nonv olatile,

read/write storage solutions for a wide range of applications. Their symmetrically-blocked architecture, fl exible

voltage, and extended cyc ling provide highly flexible components s uitable for resident flash arrays , SIMMs,

and memory cards. Enhanced suspend capabilities provide an ideal solution for code or data storage

applications. For secure code storage applications, such as networking, where code is either directly

executed out of flash or downloaded t o DRAM, the 4-, 8-, and 16-Mbit FlashFile mem ories offer three lev els

of protection: absolute protection with V

PP

at GND, selective hardware block locking, or flexible software

block locking. These alternatives give designers ultimate control of their code security needs.

This family of products is manufactured on Intel’s 0.4 µm ETOX™ V process technology. They come in

industry-standard packages: the 40-lead TSOP, ideal for board-constrained applications, and the rugged

44-lead PSOP. Based on the 28F008SA architecture, the byte-wide Smart 3 FlashFile memory family

enables quick and easy upgrades for designs that demand state-of-the-art technology.

BYTE-WIDE

SMART 3 FlashFile™ MEMORY FAMILY

4, 8, AND 16 MBIT

28F004S3, 28F008S3, 28F016S3

Includes Commercial and Extended Temperature Specifications

Information in this document is provided in connection with Intel products. No license, express or implied, by estoppel or

otherwise, to any intellectual property rights is granted by this document. Except as provi ded in Intel ’s Terms and Condi tions of

Sale for such products, Intel assumes no liability whatsoever, and Intel disclaims any express or implied warranty, relating to

sale and/or use of Intel products including liability or warranties relating to fitness for a particular purpose, merchantability, or

infringement of any patent, copyright or other intellectual property right. Intel products are not intended for use in medical, life

saving, or life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

The 28F004S3, 28F008S3, 28F016S 3 may contain design defects or errors known as errata which may cause the product to

deviate from published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an ordering number and are referenced in this document, or other Intel literature, may be

obtained from:

Intel Corporation

P.O. Box 7641

Mt. Prospect, IL 60056-7641

or call 1-800-879-4683

or visit Intel’s Website at http:\\www.intel.com

COPYRIGHT © INTEL CORPORATION, 1997 CG-041493

*Third-part

y

brands and names are the property of their respective owners

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

3

PRODUCT PREVIEW

CONTENTS

PAGE PAGE

1.0 INTRODUCTION .............................................5

1.1 New Features...............................................5

1.2 Product Overview.........................................5

1.3 Pinout and Pin Description...........................6

2.0 PRINCIPLES OF OPERATION .......................9

2.1 Data Protection ..........................................10

3.0 BUS OPERATION.........................................10

3.1 Read..........................................................10

3.2 Output Disable...........................................10

3.3 Standby......................................................10

3.4 Deep Power-Down.....................................10

3.5 Read Identifier Codes Operation................11

3.6 Write ..........................................................11

4.0 COMMAND DEFINITIONS............................11

4.1 Read Array Command................................14

4.2 Read Identifier Codes Command...............14

4.3 Read Status Register Command................14

4.4 Clear Status Register Command................14

4.5 Block Erase Command ..............................14

4.6 Program Command....................................15

4.7 Block Erase Suspend Command................15

4.8 Program Suspend Command.....................16

4.9 Set Block and Master Lock-Bit Commands 16

4.10 Clear Block Lock-Bits Command..............17

5.0 DESIGN CONSIDERATIONS........................25

5.1 Three-Line Output Control..........................25

5.2 RY/BY# Hardware Detection......................25

5.3 Power Supply Decoupling..........................25

5.4 V

PP

Trace on Printed Circuit Boards...........25

5.5 V

CC

, VPP, RP# Transitions .........................25

5.6 Power-Up/Down Protection........................25

6.0 ELECTRICAL SPECIFICATIONS..................26

6.1 Absolute Maximum Ratings........................26

6.2 Commercial Temperature Operating

Conditions.................................................26

6.2.1 Capacitance.........................................26

6.2.2 AC Input/Output Test Conditions .........27

6.2.3 Commercial Temperature

DC Characteristics..............................28

6.2.4 Commercial Temperature

AC Characteristics - Read-Only

Operations..........................................30

6.2.5 Commercial Temperature Reset

Operations..........................................31

6.2.6 Commercial Temperature

AC Characteristics - Write Operations32

6.2.7 Commercial Temperature Block Erase,

Program, and Lock-Bit Configuration

Performance.......................................34

6.3 Extended Temperature Operating

Conditions.................................................35

6.3.1 Extended Temperature

DC Characteristics..............................35

6.3.2 Extended Temperature

AC Characteristics - Read-Only

Operations..........................................35

APPENDIX A. Ordering Information..................36

APPENDIX B. Additional Information ...............37

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

4

PRODUCT PREVIEW

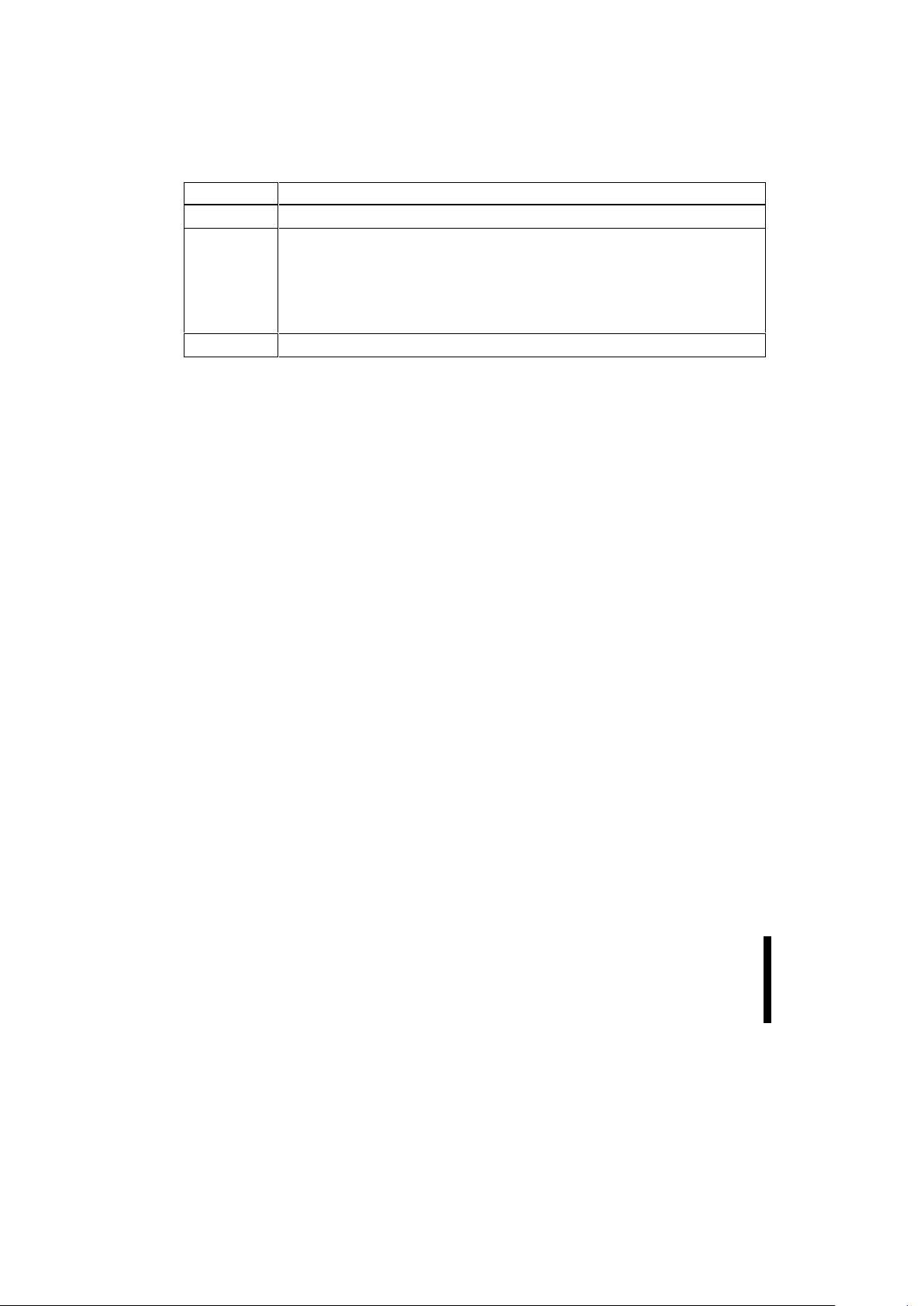

REVISION HISTORY

Number Description

-001 Original version

-002 Table 3 revised to reflect change in abbreviations from “W” for write to “P” for program.

Ordering information graphic (Appendix A) corrected: from PB = Ext. Temp. 44-Lead

PSOP to TB = Ext. Temp. 44-Lead PSOP

Updated Ordering Information and table

Correction to table, Section 6.2.3. Under I

LO

Test Conditions, previously read VIN = V

CC

or GND, corrected to V

OUT

= VCC or GND

Section 6.2.7, modified Program and Block Erase Suspend Latency Times

-003 Updated disclaimer

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

5

PRODUCT PREVIEW

1.0 INTRODUCTION

This datasheet contains 4-, 8-, and 16-Mbi t Smart 3

FlashFile memory specifications. Section 1

provides a flash memory ov ervi ew. Sec ti ons 2, 3, 4,

and 5 describe the memory organization and

functionality. Section 6 covers electrical

specifications for commercial and extended

temperature product offerings. The by te-wide Sm art

3 FlashFile memory family documentation also

includes application notes and design tools which

are referenced in Appendix B.

1.1 New Features

The byte-wide Smart 3 FlashFile memory family

maintains backwards-compatibility with Intel’s

28F008SA-L. Key enhancements include:

• SmartVoltage Technology

• Enhanced Suspend Capabilities

• In-System Block Locking

They share a compatible status register, software

commands, and pinouts. Thes e similarities enable

a clean upgrade from the 28F008SA-L to byte-wide

Smart 3 FlashFile products. When upgrading, it i s

important to note the following differences:

• Because of new feature and density options,

the devices have different device identifier

codes. This allows for software optimization.

• V

PPLK

has been lowered from 6.5V to 1. 5V to

support low V

PP

voltages during block erase,

program, and lock-bit confi guration operations.

Designs that switch V

PP

off during read

operations should transition V

PP

to GND.

• To take advantage of SmartVoltage technology, allow V

PP

connection to 3.3V.

For more details see application note

AP-625,

28F008SC Compatibility with 28F008SA

(order

number 292180)

.

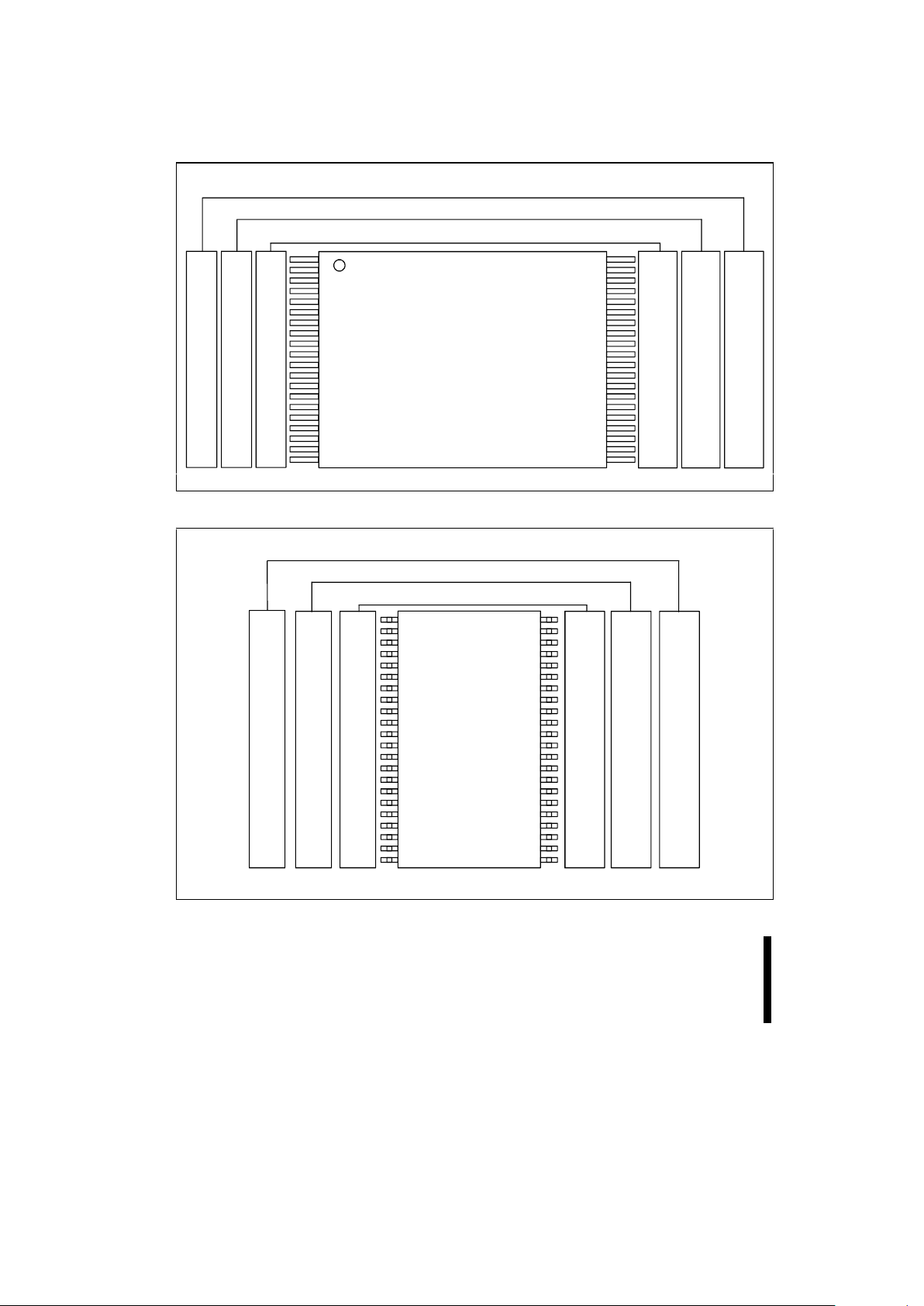

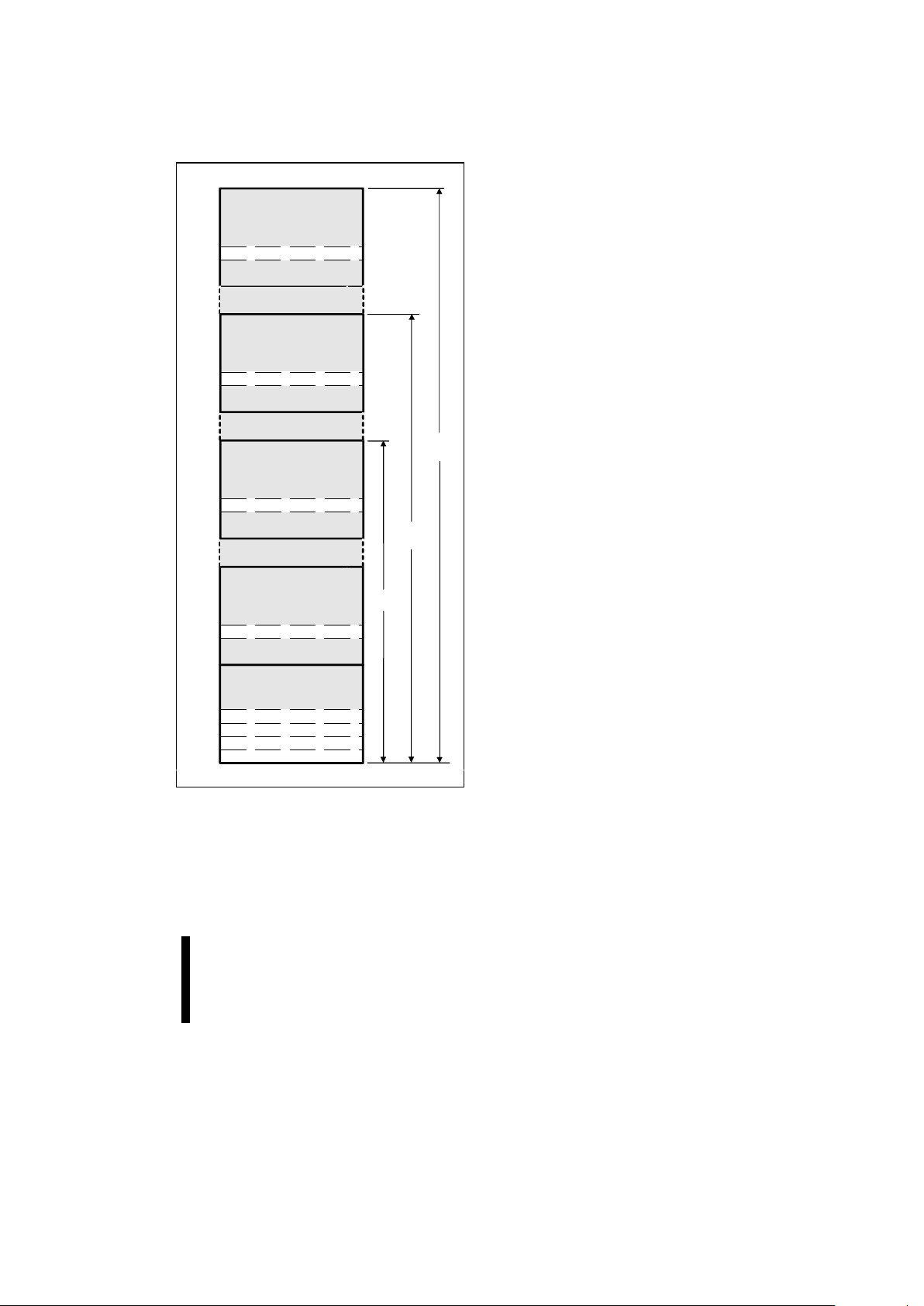

1.2 Product Overview

The byte-wide Smart 3 FlashFile memory family

provides density upgrades with pinout compatibility

for the 4-, 8-, and 16-Mbit densities. The 28F004S3,

28F008S3, and 28F016S3 are high-performance

memories arranged as 512 Kbyte, 1 Mbyte, and

2 Mbyte of 8 bits. This data is grouped in eight,

sixteen, and thirty-two 64-Kbyte blocks which are

individually erasable, lockable, and unlockable insystem. Figure 4 illustrates the memory

organization.

SmartVoltage technology enables fast factory

programming and low power designs. Specifically

designed for 3V systems, Smart 3 FlashFile

components support read operations at 2.7V (readonly) and 3.3V V

CC

and block erase and program

operations at 3.3V and 12V V

PP

. The 12V V

PP

option renders the fastest program performance

which will increase your factory throughput. With

the 3.3V V

PP

option, VCC and VPP can be tied

together for a simple, low-power 3V design. In

addition to the voltage flexibility, the dedicated V

PP

pin gives complete data protection when VPP ≤

V

PPLK

.

Internal V

PP

detection circuitry automatically

configures the device f or optimiz ed block eras e and

program operations.

A Command User Interface (CUI) serves as the

interface between the system processor and

internal operation of the device. A valid c ommand

sequence written to the CUI initiates device

automation. An internal Wri te State Machine (WSM)

automatically executes the algorithms and timings

necessary for block erase, program, and lock-bit

configuration operations.

A block erase operation erases one of the device’s

64-Kbyte blocks typically within 1.1 second

(12V V

PP

), independent of other blocks. Each block

can be independently erased 100,000 times

(1.6 million block erases per device). A block erase

suspend operation allows system software to

suspend block erase to read data from or program

data to any other block.

Data is programmed in byte increments typically

within 7.6 µs (12V V

PP

). A program suspend

operation permits system software to read data or

execute code from any other flash memory array

location.

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

6

PRODUCT PREVIEW

To protect programmed data, each block can be

locked. This block locking mechanism uses a

combination of bits, block lock-bits and a master

lock-bit, to lock and unlock individual blocks. The

block lock-bits gate block erase and program

operations, while the master lock-bit gates block

lock-bit configuration operations. Lock-bit configuration operations (Set Block Lock-Bit, Set Master

Lock-Bit, and Clear Block Lock-Bits commands) set

and clear lock-bits.

The status register and RY/BY# output indicate

whether or not the device is busy executing or

ready for a new command. Polling the status

register, system software retrieves WSM feedback.

The RY/BY# output gives an additional indicator of

WSM activity by providing a hardware status signal.

Like the status register, RY/BY#-low indicates that

the WSM is performing a block erase, program, or

lock-bit configuration operation. RY/BY#-high

indicates that the WSM is ready for a new

command, block erase is suspended, program is

suspended, or the device is in deep power-down

mode.

The Automatic Power Savings (APS) feature

substantially reduces active current when the

device is in static mode (addresses not switching).

In APS mode, the typical I

CCR

current is 3 mA.

When CE# and RP# pins are at VCC, the

component enters a CMOS standby mode. Driving

RP# to GND enables a deep power-down mode

which significantly reduces power consumption,

provides write protection, resets the device, and

clears the status register. A reset time (t

PHQV

) is

required from RP# switching high until outputs are

valid. Likewise, the device has a wake time (t

PHEL

)

from RP#-high until writes to the CUI are

recognized.

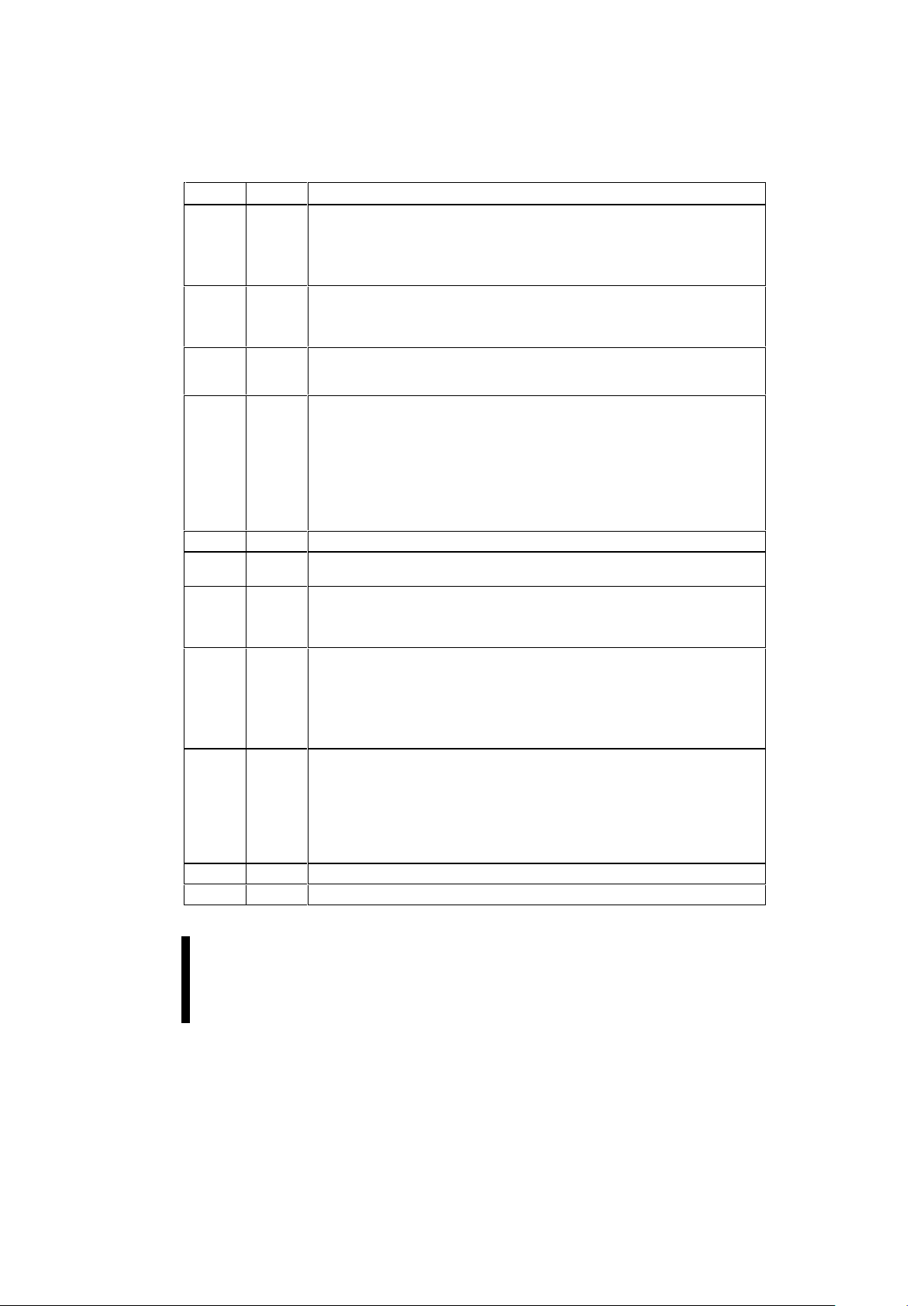

1.3 Pinout and Pin Description

The family of devices is available in 40-lead TSOP

(Thin Small Outline Package, 1.2 mm thick) and

44-lead PSOP (Plastic Small Outline Package).

Pinouts are shown in Figures 2 and 3.

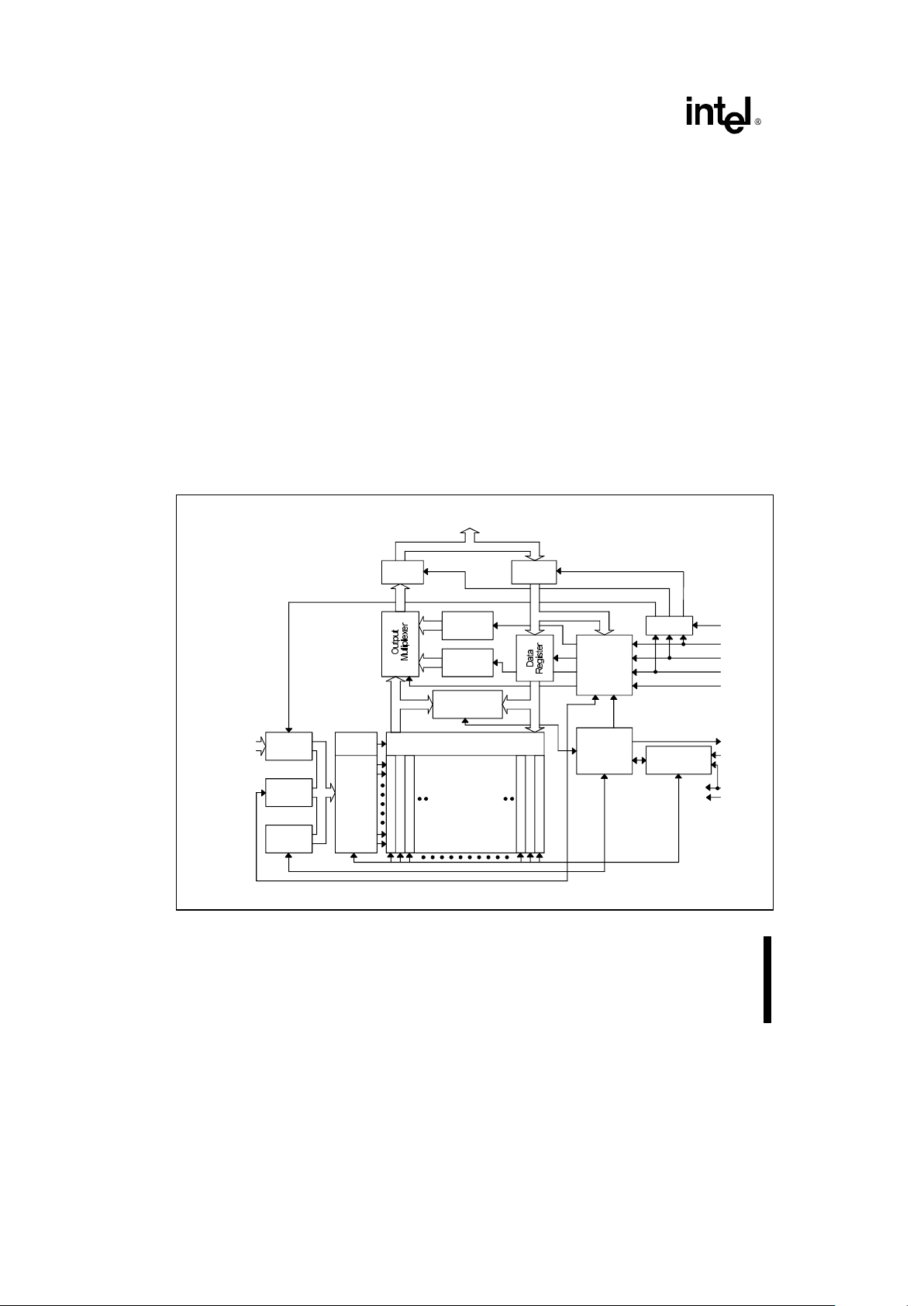

4-Mbit: A - A ,

8-Mbit: A - A ,

16-Mbit: A - A

0

18

0 19

0 20

Input

Buffer

Output

Buffer

Identifier

Register

Status

Register

Command

Register

I/O Logic

Data

Comparator

Input

Buffer

Address

Latch

Address

Counter

Y

Decoder

X

Decoder

Y Gating

4-Mbit: Eight

8-Mbit: Sixteen

16-Mbit: Thirty-Two

64-Kbyte Blocks

Write State

Machine

Program/Erase

Voltage Switch

CE#

WE#

OE#

RP#

RY/BY#

V

V

GND

DQ - DQ

PP

CC

V

CC

0 7

Figure 1. Block Diagram

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

7

PRODUCT PREVIEW

Table 1. Pin Descriptions

Sym Type Name and Function

A0–A

20

INPUT ADDRESS INPUTS: Inputs for addresses during read and write operations.

Addresses are internally latched during a write cycle.

4 Mbit → A

–A

8 Mbit → A

–A

16 Mbit → A0–A

20

DQ0–DQ7INPUT/

OUTPUT

DATA INPUT/OUTPUTS: Inputs data and commands during CUI write cycles;

outputs data during memory array, status register, and identifier code read cycles.

Data pins float to high-impedance when the chip is deselected or outputs are

disabled. Data is internally latched during a write cycle.

CE# INPUT CHIP ENABLE: Activates the device’s control logic, input buffers, decoders, and

sense amplifiers. CE#-high deselects the device and reduces power consumption to

standby levels.

RP# INPUT RESET/DEEP POWER-DOWN: When driven low, RP# inhibits write operations

which provides data protection during power transitions, puts the device in deep

power-down mode, and resets internal automation. RP#-high enables normal

operation. Exit from deep power-down sets the device to read array mode.

RP# at V

HH

enables setting of the master lock-bit and enables configuration of block

lock-bits when the master lock-bit is set. RP# = V

HH

overrides block lock-bits,

thereby enabling block erase and program operations to locked memory blocks.

Block erase, program, or lock-bit configuration with V

IH

< RP# < VHH produce

spurious results and should not be attempted.

OE# INPUT OUTPUT ENABLE: Gates the device’s outputs during a read cycle.

WE# INPUT WRITE ENABLE: Controls writes to the CUI and array blocks. Addresses and data

are latched on the rising edge of the WE# pulse.

RY/BY# OUTPUT READY/BUSY#: Indicates the status of the internal WSM. When low, the WSM is

performing an internal operation (block erase, program, or lock-bit). RY/BY#-high

indicates that the WSM is ready for new commands, block erase or program is

suspended, or the device is in deep power-down mode. RY/BY# is always active.

V

PP

SUPPLY BLOCK ERASE, PROGRAM, LOCK-BIT CONFIGURATION POWER SUPPLY:

For erasing array blocks, programming data, or configuring lock-bits.

Smart 3 Flash → 3.3V and 12V V

PP

With VPP ≤ V

PPL

K

, memory contents cannot be altered. Block erase, program, and

lock-bit configuration with an invalid V

PP

(see DC Characteristics) produce spurious

results and should not be attempted.

V

CC

SUPPLY DEVICE POWER SUPPLY: Internal detection automatically configures the device

for optimized read performance. Do not float any power pins.

Smart 3 Flash → 2.7V (Read-Only) and 3.3V V

CC

With VCC ≤ V

LKO

, all write attempts to the flash memory are inhibited. Device

operations at invalid V

CC

voltages (see DC Characteristics) produce spurious

results and should not be attempted. Block erase, program, and lock-bit

configuration operations with V

CC

< 3.0V are not supported.

GND SUPPLY GROUND: Do not float any ground pins.

NC NO CONNECT: Lead is not internally connected; it may be driven or floated.

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

8

PRODUCT PREVIEW

28F004S3

28F008S3

28F016S3

NC

CE#

RP#

A

18

A

13

A

17

A

14

A

16

A

15

A

12

A

11

A

10

A

9

A

8

A

7

A

6

A

5

A

4

V

CC

V

PP

NC

WE#

OE#

RY/BY#

GND

GND

DQ

6

DQ

7

DQ

5

A

0

A

1

A

2

A

3

DQ

3

DQ

2

DQ

1

DQ

0

NC

V

CC

A

19A19

DQ

4

A

20

40-LEAD TSOP

STANDARD PINOUT

10 mm x 20 mm

TOP VIEW

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

40

39

38

37

36

35

34

33

CE#

RP#

A

18

A

13

A

17

A

14

A

16

A

15

A

12

A

11

A

10

A

9

A

8

A

7

A

6

A

5

A

4

V

CC

V

PP

CE#

RP#

A

18

A

13

A

17

A

14

A

16

A

15

A

12

A

11

A

10

A

9

A

8

A

7

A

6

A

5

A

4

V

CC

V

PP

NC

WE#

OE#

RY/BY#

GND

GND

DQ

6

DQ

7

DQ

5

A

0

A

1

A

2

A

3

DQ

3

DQ

2

DQ

1

DQ

0

NC

V

CC

DQ

4

NC

WE#

OE#

RY/BY#

GND

GND

DQ

6

DQ

7

DQ

5

A

0

A

1

A

2

A

3

DQ

3

DQ

2

DQ

1

DQ

0

V

CC

DQ

4

Figure 2. TSOP 40-Lead Pinout

A

0

A

1

A

2

A

3

DQ

3

DQ

2

DQ

1

DQ

0

RP#

A

11

A

10

A

9

A

8

A

7

A

6

A

5

A

4

NC

NC

GND

GND

V

PP

28F004S3

28F008S3

28F016S3

A

0

A

1

A

2

A

3

DQ

3

DQ

2

DQ

1

DQ

0

RP#

A

11

A

10

A

9

A

8

A

7

A

6

A

5

A

4

NC

NC

GND

GND

V

PP

WE#

CE#

RY/BY#

DQ

6

DQ

7

DQ

5

NC

V

CC

A

18

A

13

A

17

A

14

A

16

A

15

A

12

NC

NC

NC

NC

OE#

V

CC

DQ

4

A

19

A

19

A

20

44-LEAD PSOP

13.3 mm x 28.2 mm

TOP VIEW

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

41

42

43

44

22

21

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

A

0

A

1

A

2

A

3

DQ

3

DQ

2

DQ

1

DQ

0

RP#

A

11

A

10

A

9

A

8

A

7

A

6

A

5

A

4

NC

NC

GND

GND

V

PP

WE#

CE#

RY/BY#

DQ

6

DQ

7

DQ

5

V

CC

A

18

A

13

A

17

A

14

A

16

A

15

A

12

NC

NC

NC

OE#

V

CC

DQ

4

WE#

CE#

RY/BY#

DQ

6

DQ

7

DQ

5

V

CC

A

18

A

13

A

17

A

14

A

16

A

15

A

12

NC

NC

NC

NC

OE#

V

CC

DQ

4

Figure 3. PSOP 44-Lead Pinout

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

9

PRODUCT PREVIEW

2.0 PRINCIPLES OF OPERATION

The byte-wide Smart 3 FlashFile memories i nclude

an on-chip WSM to manage block erase, program,

and lock-bit configuration functions. It allows for:

100% TTL-level control inputs, f ixed power s upplies

during block erasure, program, and lock-bit

configuration, and minimal process or overhead with

RAM-like interface timings.

After initial device power-up or return from deep

power-down mode (see Bus Operations), the

device defaults to read array mode. Mani pulation of

external memory control pins allow array read,

standby, and output disable operations.

Status register and identifier codes can be

accessed through the CUI independent of the V

PP

voltage. High voltage on VPP enables successful

block erasure, program, and lock-bit c onfiguration.

All functions associated with altering memory

contents—block erase, program, lock-bit

configuration, status, and identifier codes—are

accessed via the CUI and verified through the

status register.

Commands are written using standard microprocessor write timings . The CUI cont ents s erve as

input to the WSM that controls block erase,

program, and lock-bit configuration operati ons. The

internal algorithms are regulated by the WSM,

including pulse repetition, internal verification, and

margining of data. Addresses and data are

internally latched during write cycles. Writing the

appropriate command outputs array dat a, acces ses

the identifier codes, or outputs status register data.

Interface software that initiates and polls progress

of block erase, program, and lock-bit configuration

can be stored in any block. This code is c opied to

and executed from system RAM during flash

memory updates. After successful completion,

reads are again possible via the Read Array

command. Block erase suspend allows system

software to suspend a block erase to read data

from or program data to any other block . Program

suspend allows system software to suspend a

program to read data from any other flash memory

array location.

64-Kbyte Block

1FFFFF

31

1F0000

1EFFFF

1E0000

1DFFFF

1D0000

1CFFFF

1C0000

1BFFFF

30

29

28

27

1B0000

1AFFFF

1A0000

19FFFF

190000

18FFFF

180000

17FFFF

26

25

24

23

170000

16FFFF

160000

15FFFF

150000

14FFFF

140000

13FFFF

22

21

20

19

130000

12FFFF

120000

11FFFF

110000

10FFFF

100000

0FFFFF

18

17

16

15

0F0000

0EFFFF

0E0000

0DFFFF

0D0000

0CFFFF

0C0000

0BFFFF

14

13

12

11

0B0000

0AFFFF

0A0000

09FFFF

090000

08FFFF

080000

07FFFF

10

9

8

7

070000

06FFFF

060000

05FFFF

050000

04FFFF

040000

03FFFF

6

5

4

3

030000

02FFFF

020000

01FFFF

010000

00FFFF

000000

2

1

0

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

8-Mbit

16-Mbit

4-Mbit

Figure 4. Memory Map

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

10

PRODUCT PREVIEW

2.1 Data Protection

Depending on the application, the system designer

may choose to make the V

PP

power supply

switchable (available only when memory block

erase, program, or lock-bit configurat ion operations

are required) or hardwired to V

PPH1/2

. The device

accommodates either design practice and

encourages optimization of the processor-memory

interface.

When V

PP

≤ V

PPLK

, memory contents cannot be

altered. When high voltage is applied to V

PP

, the

two-step block erase, program, or lock-bit

configuration command sequences provides protection from unwanted operations. All write

functions are disabled when V

CC

voltage is below

the write lockout voltage V

LKO

or when RP# is at

V

IL

. The device’s block locking capabilit y provides

additional protection from i nadvertent code or data

alteration by gating erase and program operations.

3.0 BUS OPERATION

The local CPU reads and writes flash memory

in-system. All bus cycles to or from the flash

memory conform to standard microprocessor bus

cycles.

3.1 Read

Block information, i dent i fier codes, or status register

can be read independent of the V

PP

voltage. RP#

can be at either V

IH

or VHH.

The first task is to write the appropriat e read-mode

command (Read Array, Read Identifier Codes, or

Read Status Register) to the CUI. Upon initial

device power-up or after exit from deep powerdown mode, the device automati cally resets t o read

array mode. Four control pins dictate the data flow

in and out of the component: CE#, OE#, WE#, and

RP#. CE# and OE# must be driven active to obtai n

data at the outputs. CE# is the device selection

control, and when active enables the selected

memory device. OE# is the data out put (DQ

0

–DQ7)

control and when active drives the selected

memory data onto the I/O bus . WE # must be at V

IH

and RP# must be at VIH or VHH. Figure 15

illustrates a read cycle.

3.2 Output Disable

With OE# at a logic-high level (VIH), the device

outputs are disabled. Output pins DQ

0

–DQ7 are

placed in a high-impedance state.

3.3 Standby

CE# at a logic-high level (VIH) places the device in

standby mode which substantially reduces device

power consumption. DQ

0

–DQ7 outputs are placed

in a high-impedance state independent of OE#. If

deselected during block erase, program, or lock-bit

configuration, the devic e continues functioning and

consuming active power until the operation

completes.

3.4 Deep Power-Down

RP# at VIL initiates the deep power-down mode.

In read mode, RP#-low deselects the memory,

places output drivers in a high-impedance state,

and turns off all internal c ircuits. RP# mus t be held

low for time t

PLPH

. Time t

PHQV

is required after

return from power-down until initial m emory access

outputs are valid. After this wake-up interval,

normal operation is restored. The CUI resets to

read array mode, and the status regi ster is set to

80H.

During block erase, program, or lock-bit

configuration, RP#-low will abort the operation.

RY/BY# remains low until the reset operation is

complete. Memory contents being altered are no

longer valid; the data may be partially erased or

written. Time t

PHWL

is required after RP# goes to

logic-high (V

IH

) before another command can be

written.

As with any automated device, it is important to

assert RP# during system reset. When the system

comes out of reset, i t ex pect s t o read from t he f las h

memory. Automated flash memori es provide status

information when accessed during block erase,

program, or lock-bit confi guration modes. If a CPU

reset occurs with no flash memory reset, proper

CPU initialization may not occur because the flas h

memory may be providing status information

instead of array data. Int el’s flash memories allow

proper CPU initialization following a system reset

through the use of the RP# input. I n this applicati on,

RP# is controlled by the same RESET# signal that

resets the system CPU.

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

11

PRODUCT PREVIEW

000000

Block 0

Master Lock Configuration

000001

000002

000003

010000

010002

00FFFF

Device Code

Block 0 Lock Configuration

Manufacturer Code

Reserved For

Future Implementation

Block 1

Block 1 Lock Configuration

Reserved for

Future Implementation

01FFFF

Reserved for

Future Implementation

1F0000

1F0002

Block 31 Lock Configuration

Reserved for

Future Implementation

1FFFFF

Block 31

(Blocks 16 through 30)

(Blocks 8 through 14)

(Blocks 2 through 14)

070000

070002

Block 7

Block 7 Lock Configuration

Reserved for

Future Implementation

07FFFF

Reserved for

Future Implementation

0F0000

0F0002

Block 15

Block 15 Lock Configuration

Reserved for

Future Implementation

0FFFFF

8-Mbit

16-Mbit

4-Mbit

Reserved for

Future Implementation

Reserved for

Future Implementation

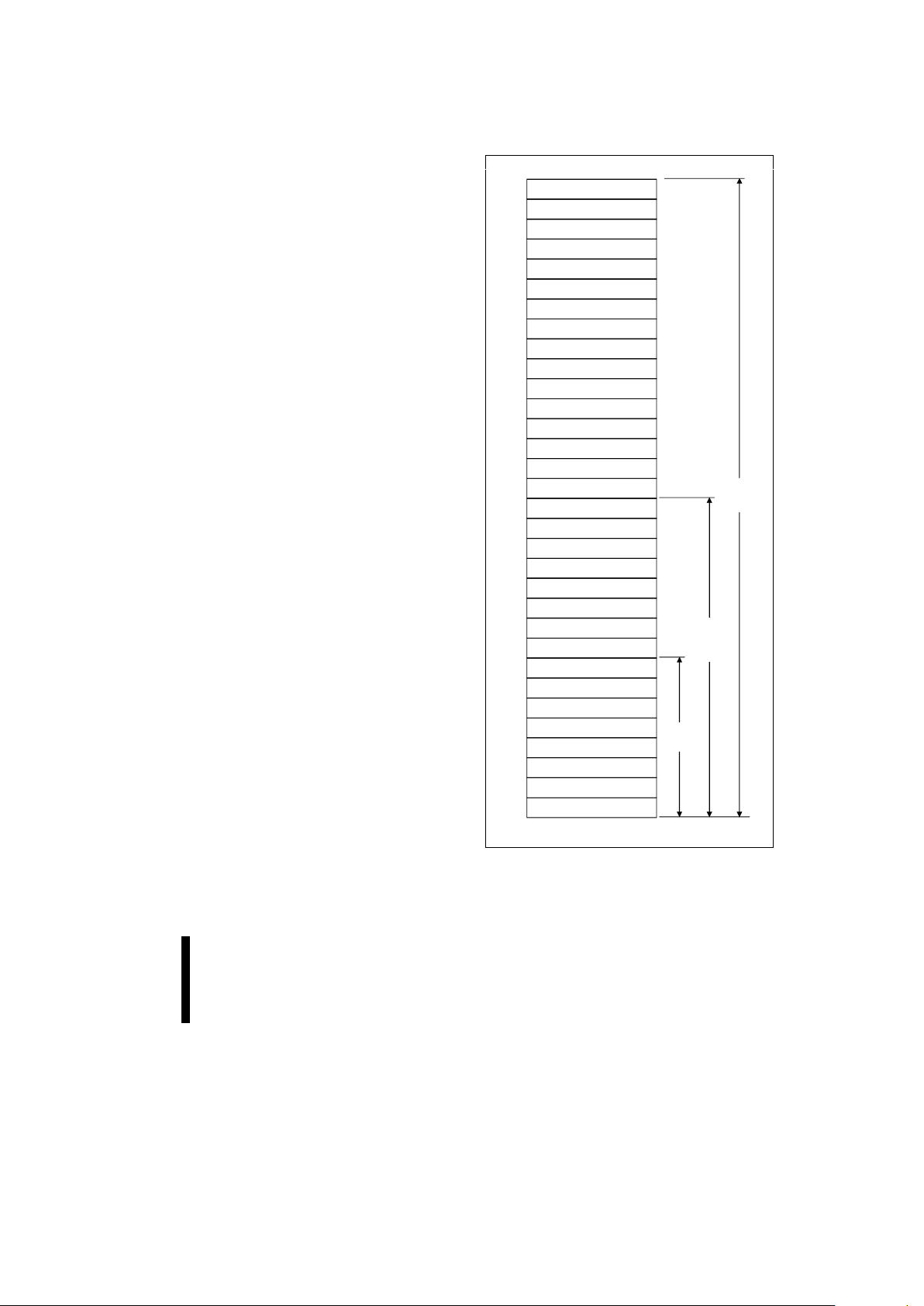

Figure 5. Device Identifier Code Memory Map

3.5 Read Identifier Codes

Operation

The read identifier codes operation outputs the

manufacturer code, device code, block lock

configuration codes for each bloc k, and mas ter lock

configuration code (see Figure 5). Using the

manufacturer and device codes, the system

software can automatical l y match the device with i ts

proper algorithms. The block lock and master lock

configuration codes identify locked and unlocked

blocks and master lock-bit setting.

3.6 Write

The CUI does not occupy an address able memory

location. It is wri tten when WE# and CE# are acti ve

and OE# = V

IH

. The address and data needed to

execute a command are latched on the risi ng edge

of WE# or CE# (whichever goes high first).

Standard microprocessor write timings are used.

Figure 17 illustrates a write operation.

4.0 COMMAND DEFINITIONS

When the VPP voltage ≤ V

PPLK

, read operations

from the status register, identif ier codes, or blocks

are enabled. Placing V

PPH1/2

on VPP enables

successful block erase, program, and lock-bit

configuration operations.

Device operations are selected by writing specific

commands into the CUI. Table 3 defines these

commands.

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

12

PRODUCT PREVIEW

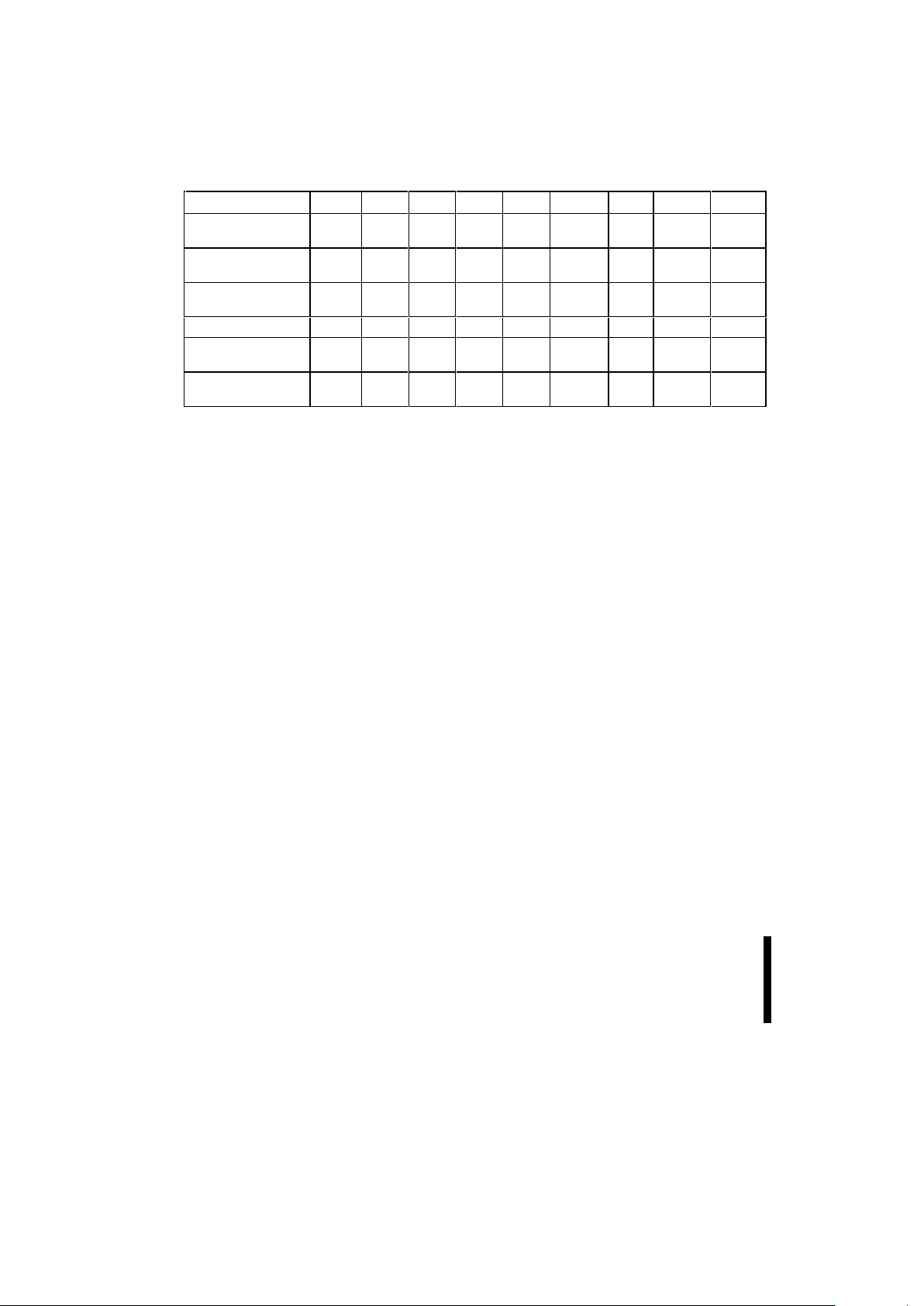

Table 2. Bus Operations

Mode Notes RP# CE# OE# WE# Address V

PP

DQ

0–7

RY/BY#

Read 1,2,3 VIH or

V

HH

V

IL

V

IL

V

IH

XXD

OUT

X

Output Disable 3 VIH or

V

HH

V

IL

V

IH

V

IH

X X High Z X

Standby 3 VIH or

V

HH

V

IH

X X X X High Z X

Deep Power-Down 4 V

IL

X X X X X High Z V

OH

Read Identifier Codes VIH or

V

HH

V

IL

V

IL

V

IH

See

Figure 5

X Note 5 V

OH

Write 3,6,7 VIH or

V

HH

V

IL

V

IH

V

IL

XXDINX

NOTES:

1. Refer to DC Characteristics. When V

PP

≤ V

PPLK

, memory contents can be read, but not altered.

2. X can be V

IL

or VIH for control and address input pins and V

PPLK

or V

PPH1/2

for VPP. See DC Characteristics for V

PPLK

and

V

PPH1/2

voltages.

3. RY/BY# is V

OL

when the WSM is executing internal block erase, program, or lock-bit configuration algorithms. It is V

OH

when the WSM is not busy, in block erase suspend, program suspend, or deep power-down mode.

4. RP# at GND ± 0.2V ensures the lowest deep power-down current.

5. See Section 4.2 for read identifier code data.

6. Command writes involving block erase, program, or lock-bit configuration are reliably executed when V

PP

= V

PPH1/2

and

V

CC

= V

CC2

(see Section 6.2 for operating conditions).

7. Refer to Table 3 for valid D

IN

during a write operation.

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

13

PRODUCT PREVIEW

Table 3. Command Definitions

(9)

Bus Cycles First Bus Cycle Second Bus Cycle

Command Req’d. Notes Oper

(1)

Addr

(2)

Data

(3)

Oper

(1)

Addr

(2)

Data

(3)

Read Array/Reset 1 Write X FFH

Read Identifier Codes ≥ 2 4 Write X 90H Read IA ID

Read Status Register 2 Write X 70H Read X SRD

Clear Status Register 1 Write X 50H

Block Erase 2 5 Write BA 20H Write BA D0H

Program 2 5,6 Write PA 40H

or

10H

Write PA PD

Block Erase and Program

Suspend

1 5 Write X B0H

Block Erase and Program

Resume

1 5 Write X D0H

Set Block Lock-Bit 2 7 Write BA 60H Write BA 01H

Set Master Lock-Bit 2 7 Write X 60H Write X F1H

Clear Block Lock-Bits 2 8 Write X 60H Write X D0H

NOTES:

1. Bus operations are defined in Table 2.

2. X = Any valid address within the device.

IA = Identifier Code Address: see Figure 5.

BA = Address within the block being erased or locked.

PA = Address of memory location to be programmed.

3. SRD = Data read from status register. See Table 6 for a description of the status register bits.

PD = Data to be programmed at location PA. Data is latched on the rising edge of WE# or CE# (whichever goes high first).

ID = Data read from identifier codes.

4. Following the Read Identifier Codes command, read operations access manufacturer, device, block lock, and master lock

codes. See Section 4.2 for read identifier code data.

5. If the block is locked, RP# must be at V

HH

to enable block erase or program operations. Attempts to issue a block erase or

program to a locked block while RP# is V

IH

will fail.

6. Either 40H or 10H are recognized by the WSM as the program setup.

7. If the master lock-bit is set, RP# must be at V

HH

to set a block lock-bit. RP# must be at VHH to set the master lock-bit. If the

master lock-bit is not set, a block lock-bit can be set while RP# is V

IH

.

8. If the master lock-bit is set, RP# must be at V

HH

to clear block lock-bits. The clear block lock-bits operation simultaneously

clears all block lock-bits. If the master lock-bit is not set, the Clear Block Lock-Bits command can be done while RP# is V

IH

.

9. Commands other than those shown above are reserved by Intel for future device implementations and should not be used.

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

14

PRODUCT PREVIEW

4.1 Read Array Command

Upon initial device power-up and after exit from

deep power-down mode, the device defaul t s to read

array mode. This operation is also initiated by

writing the Read Array command. The device

remains enabled for reads until another c ommand

is written. Once the internal WSM has started a

block erase, program, or lock-bit c onfiguration, the

device will not recognize the Read Array command

until the WSM completes its operation unless the

WSM is suspended via an Erase Suspend or

Program Suspend command. The Read Array

command functions independently of the V

PP

voltage and RP# can be VIH or VHH.

4.2 Read Identifier Codes

Command

The identifier code operation is initiat ed by writing

the Read Identifier Codes c ommand. Following the

command write, read cycles from addresses shown

in Figure 5 retrieve the manufacturer, devic e, block

lock configuration and master lock configuration

codes (see Table 4 for identifier code values). To

terminate the operation, write another valid

command. Like the Read Array command, the

Read Identifier Codes command functions

independently of the V

PP

voltage and RP# can be

V

IH

or VHH. Following the Read Identifier Codes

command, the subsequent information can be read.

Table 4. Identifier Codes

Code Address Data

Manufacturer Code 000000 89

4-Mbit 000001 A7

Device Code 8-Mbit 000001 A6

16-Mbit 000001 AA

Block Lock Configuration XX0002

(1)

• Block Is Unlocked DQ0 = 0

• Block Is Locked DQ0 = 1

• Reserved for Future Use DQ

1–7

Master Lock Configuration 000003

• Device Is Unlocked DQ0 = 0

• Device Is Locked DQ0 = 1

• Reserved for Future Use DQ

1–7

NOTE:

1. X selects the specific block lock configuration code to

be read. See Figure 5 for the device identifier code

memory map.

4.3 Read Status Register

Command

The status register may be read to det ermine when

a block erase, program, or l ock-bit configuration is

complete and whether the operation completed

successfully . It may be read at any time by writi ng

the Read Status Register command. After writing

this command, all subsequent read operations

output data from the status register until another

valid command is written. The status register

contents are latched on the falling edge of OE# or

CE#, whichever occurs first. OE# or CE# must

toggle to V

IH

to update the status regis ter lat ch. The

Read Status Register command functions

independently of the V

PP

voltage. RP# can be V

IH

or VHH.

4.4 Clear Status Register

Command

Status register bits SR. 5, S R.4, S R.3, and SR. 1 are

set to “1”s by the WSM and can only be reset by

the Clear Status Register command. These bits

indicate various failure c onditions (see Table 6). By

allowing system software to reset these bits,

several operations (such as cumulativ ely erasing or

locking multiple blocks or writing several bytes in

sequence) may be performed. The status register

may be polled to determine if an error occurred

during the sequence.

To clear the status register, the Clear Status

Register command (50H) is written. It functions

independently of the applied V

PP

voltage. RP# can

be V

IH

or VHH. This command is not functional

during block erase or program suspend modes.

4.5 Block Erase Command

Erase is executed one block at a time and init iated

by a two-cycle command. A block erase setup is

written first, followed by a block erase c onfirm. This

command sequence requires appropriate sequencing and an address within the block to be

erased (erase changes all block data to FFH).

Block preconditioning, eras e, and verify are handled

internally by the WSM (invisible to the system).

After the two-cycle block erase sequence is written,

the device automatically outputs status register

data when read (see Figure 6). The CPU can detect

block erase completion by analyzing the RY/BY#

pin or status register bit SR.7.

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

15

PRODUCT PREVIEW

When the block erase is complete, status register

bit SR.5 should be checked. If a block erase error is

detected, the status register should be cleared

before system software attempts corrective actions.

The CUI remains in read status register mode unti l

a new command is issued.

This two-step command sequence of set-up

followed by execution ensures t hat block contents

are not accidentally erased. An invalid Block Erase

command sequence will result in both status

register bits SR.4 and SR. 5 being set to “1.” Als o,

reliable block erasure can only occur when

V

CC

= V

CC2

and VPP = V

PPH1/2

. In the absence of

this high voltage, block contents are protected

against erasure. If block erase is attempted while

V

PP

≤ V

PPLK

, SR.3 and SR.5 will be set to “1.”

Successful block erase requires that the

corresponding block lock-bit be cleared or, if set,

that RP# = V

HH

. If block erase is attempted when

the corresponding block lock-bit is set and

RP# = V

IH

, the block erase will fail, and SR.1 and

SR.5 will be set to “1.” Block eras e operations with

V

IH

< RP# < VHH produce spurious results and

should not be attempted.

4.6 Program Command

Program is executed by a two-cycle command

sequence. Program setup (standard 40H or

alternate 10H) is written, f ollowed by a sec ond wri te

that specifies the addres s and data (latched on the

rising edge of WE#). The WSM then takes over,

controlling the program and verify algorithms

internally. After the program sequence is written,

the device automatically outputs status register

data when read (see Figure 7). The CPU can detect

the completion of the program ev ent by analyzing

the RY/BY# pin or status register bit SR.7.

When program is complete, status regist er bit SR.4

should be checked. If program error is detec ted, the

status register shoul d be c l eared. The internal WSM

verify only detects errors for “1”s that do not

successfully program to “0”s. The CUI remains in

read status register mode until it recei ves another

command.

Reliable program only occurs when V

CC

= V

CC2

and

V

PP

= V

PPH1/2

. In the absence of this high voltage,

memory contents are protected against program

operations. If a program operation is attempted

while V

PP

≤ V

PPLK

, the operation will fail, and s tatus

register bits SR.3 and SR.5 will be set to “1.”

A successful program operation also requires that

the corresponding block lock-bit be cleared or, if

set, that RP# = V

HH

. If a program operation is

attempted when the corresponding bloc k lock-bit is

set and RP# = V

IH

, the operation will fail, and SR.1

and SR.4 will be set to “1.” Program operat ions with

V

IH

< RP# < VHH produce spurious results and

should not be attempted.

4.7 Block Erase Suspend

Command

The Block Erase Suspend command allows

block-erase interruption to read or program data in

another block of memory. Once the block erase

process starts, writing the Block Erase Suspend

command requests that the WSM suspend the

block erase sequence at a predetermined point in

the algorithm. The device outputs status register

data when read after the Block Erase Suspend

command is written. Polling status register bits

SR.7 and SR.6 can determine when the block erase

operation has been suspended (both will be set t o

“1”). RY/BY# will also transition to V

OH

.

Specification t

WHRH2

defines the block erase

suspend latency.

At this point, a Read Array com mand c an be writ ten

to read data from blocks other than that which is

suspended. A Program command sequence can

also be issued during erase suspend to program

data in other blocks. Using the Program Suspend

command (see Section 4.8), a program operation

can also be suspended. During a program operati on

with block erase suspended, status register bit

SR.7 will return to “0” and the RY/BY# output will

transition to V

OL

. However, SR.6 will remain “1” to

indicate block erase suspend status.

The only other valid commands while bloc k eras e i s

suspended are Read Status Register and Block

Erase Resume. After a Block Erase Resume

command is written to t he flash memory, t he WSM

will continue the block erase process. Status

register bits SR.6 and SR.7 will automatically clear

and RY/BY# will return to V

OL

. After the Erase

Resume command is written, the device

automatically outputs status register data when

read (see Figure 8). V

PP

must remain at V

PPH1/2

(the same VPP level used for block erase) while

block erase is suspended. RP# must al so remain at

V

IH

or VHH (the same RP# level used for block

erase). Block erase cannot resume until program

operations initiated during block erase suspend

have completed.

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

16

PRODUCT PREVIEW

4.8 Program Suspend Command

The Program Suspend command allows program

interruption to read data in other flash memory

locations. Once the program proc ess starts , writing

the Program Suspend command request s that the

WSM suspend the program sequence at a

predetermined point in the algorithm. The device

continues to output st atus register data when read

after the Program Suspend command is written.

Polling status register bits SR.7 and SR.2 can

determine when the program operation has been

suspended (both will be set to “1”). RY/BY# will also

transition to V

OH

. Specification t

WHRH1

defines the

program suspend latency.

At this point, a Read Array com mand c an be writ ten

to read data from locations ot her than that which is

suspended. The only other valid commands while

program is suspended are Read Status Register

and Program Resume. After Program Resume

command is written to t he flash memory, t he WSM

will continue the program process. Status register

bits SR.2 and SR.7 will automatically clear and

RY/BY# will return to V

OL

. After the Program

Resume command is written, the device

automatically outputs status register data when

read (see Figure 9). V

PP

must remain at V

PPH1/2

(the same VPP level used for program) while in

program suspend mode. RP# must al so remain at

V

IH

or VHH (the same RP# level used for program).

4.9 Set Block and Master Lock-Bit

Commands

A flexible block locking and unlocking scheme is

enabled via a combination of block loc k-bits and a

master lock-bit. The block lock-bits gate program

and erase operations while the master lock-bit

gates block-lock bit modification. With the master

lock-bit not set, individual bloc k lock-bit s can be set

using the Set Block Lock-Bit command. The Set

Master Lock-Bit command, in conjunction with

RP# = V

HH

, sets the master lock-bit. After the

master lock-bit is set, subsequent setting of block

lock-bits requires both the Set Block Lock-Bit

command and V

HH

on the RP# pin. See Table 5 for

a summary of hardware and software write

protection options.

Set block lock-bit and master lock-bit are initiated

using two-cycle command sequence. The set block

or master lock-bit setup along with appropriate

block or device address is writt en followed by either

the set block lock -bi t confirm (and an address within

the block to be locked) or the set master lock-bit

confirm (and any device address). The WSM then

controls the set lock-bit algorithm. After the

sequence is written, the device automatically

outputs status register data when read (see

Figure 10). The CPU can detect t he completion of

the set lock-bit event by analyzing the RY/BY# pin

output or status register bit SR.7.

When the set lock-bit operati on is complete, stat us

register bit SR.4 should be checked. If an error is

detected, the status register s hould be cleared. The

CUI will remain in read status register mode until a

new command is issued.

This two-step sequence of setup followed by

execution ensures that lock -bit s are not acc idental ly

set. An invalid Set Block or Master Lock-Bit

command will result in status regist er bits SR.4 and

SR.5 being set to “1.” Also, reliable operations

occur only when V

CC

= V

CC2

and VPP = V

PPH1/2

. In

the absence of this high voltage, l ock-bit contents

are protected against alteration.

A successful set block lock-bit operation requires

that the master lock -bit be cleared or, if the master

lock-bit is set, that RP# = V

HH

. If it is attempted with

the master lock-bit set and RP# = V

IH

, the operation

will fail, and SR.1 and SR.4 will be set to “1.” A

successful set master lock-bit operation requires

that RP# = V

HH

. If it is attempted with RP# = VIH,

the operation will fail, and SR.1 and SR.4 will be set

to “1.” Set block and mast er lock -bit operations wit h

V

IH

< RP# < VHH produce spurious results and

should not be attempted.

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

17

PRODUCT PREVIEW

4.10 Clear Block Lock-Bits

Command

All set block lock-bits are c leared in parallel via the

Clear Block Lock-Bits command. With the master

lock-bit not set, bl ock loc k-bit s c an be c leared using

only the Clear Block Lock-Bits command. If the

master lock-bit is set, clearing block lock-bits

requires both the Clear Block Lock-Bits command

and V

HH

on the RP# pin. See Table 5 for a

summary of hardware and soft ware write protection

options.

Clear block lock-bits operation is initiated using a

two-cycle command sequence. A clear block

lock-bits setup is written first. Then, the device

automatically outputs status register data when

read (see Figure 11). The CPU can detect

completion of the clear block lock-bits event by

analyzing the RY/BY# pi n output or status register

bit SR.7.

When the operation is complete, status register bit

SR.5 should be checked. If a clear block lock-bit

error is detected, the status register should be

cleared. The CUI will remain in read status register

mode until another command is issued.

This two-step sequence of set-up followed by

execution ensures that block lock-bits are not

accidentally cleared. An invalid Clear Block

Lock-Bits command sequence will result in status

register bits SR.4 and SR. 5 being set t o “1.” Also, a

reliable clear block lock-bits operation can only

occur when V

CC

= V

CC2

and VPP = V

PPH1/2

. If a

clear block lock-bits operation is attempted while

V

PP

≤ V

PPLK

, SR.3 and SR.5 will be set to “1.” In the

absence of this high voltage, the block lock-bits

content are protected against alteration. A successful clear block lock-bits operation requires that

the master lock-bit is not s et or, if the master lock bit is set, that RP # = V

HH

. If it is attempted with the

master lock-bit set and RP# = V

IH

, SR.1 and SR.5

will be set to “1” and the operation will fail. A clear

block lock-bits operation with V

IH

< RP# < V

HH

produce spurious results and should not be

attempted.

If a clear block lock -bits operation i s aborted due t o

V

PP

or VCC transitioning out of vali d range or RP#

active transition, block lock-bit values are left in an

undetermined state. A repeat of clear block lockbits is required to initi alize bloc k loc k-bit content s t o

known values. Once the master lock-bit is set, it

cannot be cleared.

Table 5. Write Protection Alternatives

Operation

Master

Lock-Bit

Bloc

k

Lock-Bit RP# Effect

Block Erase or 0 VIH or VHHBlock Erase and Program Enabled

Byte Write X 1 V

IH

Block is Locked. Block Erase and Program Disabled

V

HH

Block Lock-Bit Override. Block Erase and Program

Enabled

Set Block 0 X VIH or VHHSet Block Lock-Bit Enabled

Lock-Bit 1 X V

IH

Master Lock-Bit is Set. Set Block Lock-Bit Disabled

V

HH

Master Lock-Bit Override. Set Block Lock-Bit

Enabled

Set Master X X V

IH

Set Master Lock-Bit Disabled

Lock-Bit V

HH

Set Master Lock-Bit Enabled

Clear Block 0 X VIH or VHHClear Block Lock-Bits Enabled

Lock-Bits 1 X V

IH

Master Lock-Bit is Set. Clear Block Lock-Bits

Disabled

V

HH

Master Lock-Bit Override. Clear Block Lock-Bits

Enabled

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

18

PRODUCT PREVIEW

Table 6. Status Register Definition

WSMS ESS ECLBS PSLBS VPPS PSS DPS R

76543210

NOTES:

SR.7 = WRITE STATE MACHINE STATUS

1 = Ready

0 = Busy

Check RY/BY# or SR.7 to determine block erase,

program, or lock-bit configuration completion.

SR.6

–0 are invalid while SR.7 =

“0.”

SR.6 = ERASE SUSPEND STATUS

1 = Block Erase Suspended

0 = Block Erase in Progress/Completed

SR.5 = ERASE AND CLEAR LOCK-BITS

STATUS

1 = Error in Block Erasure or Clear Lock-Bits

0 = Successful Block Erase or Clear Lock-Bits

If both SR.5 and SR.4 are “1”s after a block erase or

lock-bit configuration attempt, an improper

command sequence was entered.

SR.4 = PROGRAM AND SET LOCK-BIT

STATUS

1 = Error in Program or Set Master/Block

Lock-Bit

0 = Successful Program or Set Master/Block

Lock-Bit

SR.3 = V

STATUS

1 = V

Low Detect, Operation Abort

0 = V

PP

OK

SR.3 does not provide a continuous indication of

V

PP

level. The WSM interrogates and indicates the

V

PP

level only after a block erase, program, or lockbit configuration operation. SR.3 is not guaranteed

to reports accurate feedback only when V

PP

≠

V

PPH1/2

.

SR.2 = PROGRAM SUSPEND STATUS

1 = Program Suspended

0 = Program in Progress/Completed

SR.1 = DEVICE PROTECT STATUS

1 = Master Lock-Bit, Block Lock-Bit and/or

RP# Lock Detected, Operation Abort

0 = Unlock

SR.1 does not provide a continuous indication of

master and block lock-bit values. The WSM

interrogates the master lock-bit, block lock-bit, and

RP# only after a block erase, program, or lock-bit

configuration operation. It informs the system,

depending on the attempted operation, if the block

lock-bit is set, master lock-bit is set, and/or

RP# ≠ V

HH

.

SR.0 = RESERVED FOR FUTURE

ENHANCEMENTS

SR.0 is reserved for future use and should be

masked out when polling the status register.

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

19

PRODUCT PREVIEW

SR.7 =

0

1

Start

Write 20H,

Block Address

Write D0H,

Block Address

Full Status

Check if Desired

Block Erase

Complete

FULL STATUS CHECK PROCEDURE

1

0

Read Status Register

Data (See Above)

1

0

Read Status

Register

Suspend

Block Erase

Suspend Block

Erase Loop

Yes

No

1

0

Command Sequence

Error

SR.3 =

SR.5 =

SR.4,5 =

Block Erase

Error

Bus

Operation

Command Comments

Standby

Check SR.4,5

Both 1 = Command Sequence Error

Standby

SR.5, SR.4, SR.3 and SR.1 are only cleared by the Clear Status

Register command in cases where multiple blocks are erased

before full status is checked.

If error is detected, clear the Status Register before attempting

retry or other error recovery.

Check SR.5

1 = Block Erase Error

Standby

Bus

Operation

Command Comments

Write

Write

Erase Setup

Read

Data = 20H

Addr = Within Block to Be Erased

Check SR.7

1 = WSM Ready

0 = WSM Busy

Repeat for subsequent block erasures.

Full status check can be done after each block erase, or after a

sequence of block erasures.

Write FFH after the last operation to place device in read array mode.

Status Register Data

Standby

Erase

Confirm

Data = D0H

Addr = Within Block to Be Erased

Block Erase

Successful

Standby

Check SR.1

1 = Device Protect Detect

RP# = V , Block Lock-Bit Is Set

Only required for systems

implementing lock-bit configuration

0

1

Device Protect Error

SR.1 =

Check SR.3

1 = V Error Detect

PP

IH

V Range Error

PP

Figure 6. Automated Block Erase Flowchart

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

20

PRODUCT PREVIEW

SR.7 =

0

1

Start

Write 40H,

Address

Write Byte

Data and Address

Full Status

Check if Desired

Program Complete

FULL STATUS CHECK PROCEDURE

1

0

Read Status Register

Data (See Above)

1

0

Read

Status Register

V Range Error

Bus

Operation

Command Comments

Standby

Standby

Check SR.3

1 = V Error Detect

SR.4, SR.3 and SR.1 are only cleared by the Clear Status Registe r

command in cases where multiple loc ations are writ ten before

full status is checked.

If error is detected, clear the Status Register before attempting

retry or other error recovery.

Bus

Operation

Command Comments

Write

Write

Setup

Program

Data = Data to Be Programmed

Addr = Location to Be Programmed

Read

Data = 40H

Addr = Location to Be Programmed

Check SR.7

1 = WSM Ready

0 = WSM Busy

Repeat for subsequent byte writes.

SR full status che ck ca n be do ne af te r ea ch program, or after a

sequence of program operations.

Write FFH after the last program operation to reset device to

read array mode.

Standby

SR.3 =

SR.4 =

Program Error

Program Successful

Program

Status Register Data

Suspend

Program

Yes

No

Suspend

Program Loop

Standby

Check SR.4

1 = Program Error

0

1

Device Protect Error

SR.1 =

PP

Check SR.1

1 = Device Protect Detect

RP# = V , Block Lock-Bit Is Set

Only required for systems

implementing lock-bit configur ation

IH

PP

Figure 7. Automated Program Flowchart

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

21

PRODUCT PREVIEW

SR.7 =

0

1

Start

Write B0H

Read

Status Register

Write D0H

Block Erase Resumed

Bus

Operation

Command Comments

Write

Erase

Suspend

Read

Data = B0H

Addr = X

Check SR.7

1 = WSM Ready

0 = WSM Busy

Status Register Data

Addr = X

Standby

SR.6 =

Block Erase Completed

Write FFH

Read Array Data

Yes

0

1

Check SR.6

1 = Block Erase Suspended

0 = Block Erase Completed

Standby

Data = D0H

Addr = X

Write

Erase

Resume

Read or

Program

?

Done?

Program

Loop

Read Array

Data

Read

Program

No

Figure 8. Block Erase Suspend/Resume Flowchart

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

22

PRODUCT PREVIEW

SR.7 =

0

1

Start

Write B0H

Read

Status Register

Write D0H

Program Resumed

Bus

Operation

Command Comments

Write

Program

Suspend

Read

Data = B0H

Addr = X

Check SR.7

1 = WSM Ready

0 = WSM Busy

Status Register Data

Addr = X

Standby

SR.2 =

Write FFH

Read Array Data

Done

Reading

Program Completed

Write FFH

Read Array Data

Yes

No

0

1

Check SR.2

1 =Program Suspended

0 = Program Completed

Standby

Data = FFH

Addr = X

Write

Read array locations other

than that being data written.

Read

Data = D0H

Addr = X

Write

Read Array

Program

Resume

Figure 9. Program Suspend/Resume Flowchart

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

23

PRODUCT PREVIEW

SR.7 =

0

1

Start

Write 60H,

Block/Device Address

Write 01H/F1H,

Block/Device Address

Full Status

Check if Desired

Set Lock-Bit Complete

FULL STATU S CH E C K PR OCEDURE

1

0

Read Status Regis ter

Data (See Above)

1

0

Read Status

Register

V Range Error

1

0

Command Sequence

Error

SR.3 =

SR.4 =

SR.4,5 =

Set Lock-Bit Error

Bus

Operation

Command Comments

Standby

Check SR.4,5

Both 1 = Command Sequence Error

Standby

SR.5, SR.4, SR.3 and SR.1 are only cleared by the Clear Status

Register command in cases where multiple lock-bits are set before

full status is checked.

If error is detected, clear the Status Register before attempting retry

or other error recovery.

Check SR.4

1 = Set Lock-Bit Reset Error

Standby

Bus

Operation

Command Comments

Write

Write

Set

Block/Master

Lock-Bit Setup

Read

Data = 60H

Addr = Block Address (Block),

Device A ddress (Master)

Check SR.7

1 = WSM Ready

0 = WSM Busy

Repeat for subsequent lock-bit set operations.

Full status check can be done after each lock-bit set operation or after

a sequence of lock-bit set operation s.

Write FFH after the last lock-bit set operation to place device in

read array mode.

Status Register Data

Standby

Set

Block or Master

Lock-Bit Confirm

Data = 01H (Block),

F1H (Master)

Addr = Block Address (Block),

Device A ddress (Master)

Set Lock-Bit Successful

Standby

0

1

Device Protect Er ror

SR.1 =

Check SR.3

1 = V Error Detect

PP

PP

Check SR.1

1 = Device Protect Detect

RP# = V ,

(Set Master Lock-Bit Operation)

RP# = V , Master Lock-Bit Is Set

(Set Block Lock-Bit Operation)

IH

HH

Figure 10. Set Block and Master Lock-Bit Flowchart

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

24

PRODUCT PREVIEW

SR.7 =

0

1

Start

Write 60H

Write D0H

Full Status

Check if Desired

Clear Block Lock-Bi t s

Complete

FULL STATUS CHECK PROC EDURE

1

0

Read Status Register

Data (See Above)

1

0

Read Status

Register

V Range Error

1

0

Command Sequence

Error

SR.3 =

SR.5 =

SR.4,5 =

Clear Block Lock-Bits

Error

Bus

Operation

Command

Comments

Standby

Check SR.4,5

Both 1 = Command Sequence Error

Standby

SR.5, SR.4, SR.3 and SR.1 are only cleared by the Clear Status

Register command.

If error is detected, clear the Status Register before attempting

retry or other error recovery.

Check SR.5

1 = Clear Block Lock-Bits Error

Standby

Bus

Operation

Command Comments

Write

Write

Clear Block

Lock-Bits Setup

Read

Data = 60H

Addr = X

Check SR.7

1 = WSM Ready

0 = WSM Busy

Write FFH after the Clear Block Lock-Bits operation to place device

to read array mode.

Status Registe r Data

Standby

Clear Block

Lock-Bits Confirm

Data = D0H

Addr = X

Clear Block Lock-Bits

Successful

Standby

0

1

Device Protect Error

SR.1=

Check SR.3

1 = V Error Detect

PP

PP

Check SR.1

1 = Device Protect Detect

RP# = V , Master Lock-Bit Is Set

IH

Figure 11. Clear Block Lock-Bits Flowchart

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

25

PRODUCT PREVIEW

5.0 DESIGN CONSIDERATIONS

5.1 Three-Line Output Control

Intel provides three control inputs to accommodate

multiple memory connections : CE#, OE#, and RP#.

Three-line control provides for:

a. Lowest possible memory power dissipation.

b. Data bus contention avoidance.

To use these control inputs effic iently, an address

decoder should enable CE# while OE# should be

connected to all memory devic es and the system’s

READ# control line. This as sures t hat onl y s elected

memory devices have active outputs while deselected memory devices are in standby mode.

RP# should be connected to the system

POWERGOOD signal to prevent unintended writes

during system power transitions. POWERGOOD

should also toggle during system reset.

5.2 RY/BY# Hardware Detection

RY/BY# is a full CMOS output that provides a

hardware method of detecting block eras e program

and lock-bit configuration completion. This output

can be directly connected to an interrupt input of

the system CPU. RY/BY# transitions low when the

WSM is busy and returns t o V

OH

when it is finished

executing the internal algorithm. During suspend

and deep power-down modes, RY/BY# remains at

V

OH

.

5.3 Power Supply Decoupling

Flash memory power switching characteristics

require careful device decoupling. System

designers are interested in three supply current

issues: standby current levels, activ e current levels

and transient peaks produced by falling and rising

edges of CE# and OE#. Two-line c ont rol and proper

decoupling capacitor selection will suppress

transient voltage peaks. E ach devic e should hav e a

0.1 µF ceramic capacitor connected between its

V

CC

and GND and between its VPP and GND.

These high-frequency, low-inductance capacitors

should be placed as close as possible to pac kage

leads. Additionally, for ev ery ei ght dev ices , a 4. 7 µF

electrolytic capacitor should be placed at the array’s

power supply connection between V

CC

and GND.

The bulk capacitor will overcome voltage slumps

caused by PC board trace inductance.

5.4 VPP Trace on Printed Circuit

Boards

Updating flash memories that reside in the target

system requires that the printed circuit board

designer pay attention to the V

PP

power supply

trace. The V

PP

pin supplies the memory cell current

for byte writing and block eras ing. Use si milar trac e

widths and layout considerat ions given to the V

CC

power bus. Adequate VPP supply traces and

decoupling will decrease V

PP

voltage spikes and

overshoots.

5.5 VCC, VPP, RP# Transitions

Block erase, program and l ock-bit conf iguration are

not guaranteed if V

PP

or VCC fall outside of a valid

voltage range (V

CC2

and V

PPH1/2

) or

RP# ≠ V

IH

or VHH. If VPP error is detected, status

register bit SR.3 is set to “1” along with SR.4 or

SR.5, depending on the attempted operat i on. If RP#

transitions to V

IL

during block erase, program, or

lock-bit configuration, RY/BY# will remain low until

the reset operation is compl ete. Then, t he operat ion

will abort and the device will enter deep powerdown. The aborted operation may leave data

partially altered. Therefore, the c ommand sequenc e

must be repeated after normal operation is

restored.

5.6 Power-Up/Down Protection

The device is designed to offer protection against

accidental block erasure, byte writing, or lock-bit

configuration during power transiti ons. Upon powerup, the device is indifferent as to which power

supply (V

PP

or VCC) powers-up first. Internal

circuitry resets the CUI to read array mode at

power-up.

A system designer must guard against spurious

writes for V

CC

voltages above V

LKO

when VPP is

active. Since both WE# and CE # must be low for a

command write, driving eit her input s ignal to V

IH

will

inhibit writes. The CUI’s two-step command

sequence architecture provides an added level of

protection against data alteration.

In-system block lock and unlock renders additional

protection during power-up by prohibiting block

erase and program operations. The device is

disabled while RP# = V

IL

regardless of its control

inputs state.

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

26

PRODUCT PREVIEW

6.0 ELECTRICAL SPECIFICATIONS

6.1 Absolute Maximum Ratings*

Temperature under Bias.................–10°C to +80°C

Storage Temperature ...................–65°C to +125°C

Voltage On Any Pin

(except V

PP,

and RP#)............–2.0V to +7.0V

(2)

VPP Voltage............................. –2.0V to +14.0V

(1,2)

RP# Voltage.......................... –2.0V to +14.0V

(1,2,4)

Output Short Circuit Current....................100 mA

(3)

NOTICE: This datasheet contains information on products

in the design phase of development. Do not finalize a

design with this information. Revised information will be

published when the product is available. Verify with your

local Intel Sales office that you have the latest datasheet

before finalizing a design

.

*

WARNING: Stressing the device beyond the “Absolute

Maximum Ratings” may cause permanent damage. These

are stress ratings only. Operation beyond the “Operating

Conditions” is not recommended and extended exposure

beyond the “Operating Conditions” may affect device

reliability

.

NOTES:

1. All specified voltages are with respect to GND. Minimum DC voltage is –0.5V on input/output pins and –0.2V on V

CC

, RP#,

and V

PP

pins. During transitions, this level may undershoot to –2.0V for periods <20 ns. Maximum DC voltage on

input/output pins and V

CC

is VCC +0.5V which, during transitions, may overshoot to VCC +2.0V for periods <20 ns.

2. Maximum DC voltage on V

PP

and RP# may overshoot to +14.0V for periods <20 ns.

3. Output shorted for no more than one second. No more than one output shorted at a time.

4. RP# voltage is normally at V

IL

or VIH. Connection to supply of VHH is allowed for a maximum cumulative period of 80 hours.

6.2 Commercial Temperature Operating Conditions

Commercial Temperature and VCC Operating Conditions

Symbol Parameter Notes Min Max Unit Test Condition

T

A

Operating Temperature 0 +70 °C Ambient Temperature

V

CC1

VCC Supply Voltage (2.7V–3.6V) 1 2.7 3.6 V

V

CC2

VCC Supply Voltage (3.3V ± 0.3V) 3.0 3.6 V

NOTE: