E

PRELIMINARY

July 1998 Order Number: 290580-005

n

Flexible SmartVoltage Technology

2.7 V–3.6 V Read/Program/Erase

12 V VPP Fast Production

Programming

n

2.7 V or 1.65 V I/O Option

Reduces Overall System Power

n

High Performance

2.7 V–3.6 V: 90 ns Max Access Time

3.0 V–3.6 V: 80 ns Max Access Time

n

Optimized Block Sizes

Eight 8-KB Blocks for Data,

Top or Bottom Locations

Up to Sixty-Three 64-KB Blocks for

Code

n

Block Locking

VCC-Level Control through WP#

n

Low Power Consumption

10 mA Typical Read Current

n

Absolute Hardware-Protection

VPP = GND Option

VCC Lockout Voltage

n

Extended Temperature Operation

–40 °C to +85 °C

n

Flash Data Integrator Software

Flash Memory Manager

System Interrupt Manager

Supports Parameter Storage,

Streaming Data (e.g., Voice)

n

Automated Program and Block Erase

Status Registers

n

Extended Cycling Capability

Minimum 100,000 Block Erase

Cycles Guaranteed

n

Automatic Power Savings Feature

Typical I

CCS

after Bus Inactivity

n

Standard Surface Mount Packaging

48-Ball µBGA* Package

48-Lead TSOP Package

40-Lead TSOP Package

n

Footprint Upgradeable

Upgrade Path for 4-, 8-, 16-, and 32Mbit Densities

n

ETOX™ VI (0.25 µ) Flash Technology

The Smart 3 Advanced Boot Block, manuf actured on Intel’s latest 0. 25 µ technology, represents a featurerich solution at overall lower system cost. Smart 3 flash memory devices incorporate low voltage capability

(2.7 V read, program and erase) with high-speed, low-power operation. Several new features have been

added, including the ability to drive the I/O at 1.65 V, which significantly reduces system active power and

interfaces to 1.65 V controllers. A new blocking scheme enables code and data storage within a single

device. Add to this t he Intel-developed Flash Data Integrat or (FDI) software, and you have a c ost-effective,

monolithic code plus data storage solution. Smart 3 Advanced Boot Block products will be available in 40lead and 48-lead TSOP and 48-ball µBGA* packages. Additional i nformation on this product family c an be

obtained by accessing Intel’s WWW page: http://www.intel.com/design/flash.

SMART 3 ADVANCED BOOT BLOCK

4-, 8-, 16-, 32-MBIT

FLASH MEMORY FAMILY

28F400B3, 28F800B3, 28F160B3, 28F320B3

28F008B3, 28F016B3, 28F032B3

Information in this document is provided in connection with Intel products. No license, express or implied, by estoppel or

otherwise, to any intellectual property rights is granted by this document. Except as provided i n Intel’s Terms and Conditi ons of

Sale for such products, Intel assumes no liability whatsoever, and Intel disclaims any express or implied warranty, relating to

sale and/or use of Intel products including liability or warranties relating to fitness for a particular purpose, merchantability, or

infringement of any patent, copyright or other intellectual property right. Intel products are not intended for use in medical, life

saving, or life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

The 28F400B3, 28F800/008B3, 28F160/016B3, 38F320/032B3 may contain design defects or errors known as errata which

may cause the product to deviate from published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an ordering number and are referenced in this document, or other Intel literature, may be

obtained from:

Intel Corporation

P.O. Box 5937

Denver, CO 80217-9808

or call 1-800-548-4725

or visit Intel’s Website at http://www.intel.com

COPYRIGHT © INTEL CORPORATION 1996, 1997,1998 CG-041493

*Third-part

y

brands and names are the property of their respective owners

E SMART 3 ADVANCED BOOT BLOCK

3

PRELIMINARY

CONTENTS

PAGE PAGE

1.0 INTRODUCTION .............................................5

1.1 Smart 3 Advanced Boot Block Flash

Memory Enhancements ..............................5

1.2 Product Overview.........................................6

2.0 PRODUCT DESCRIPTION..............................6

2.1 Package Pinouts..........................................6

2.2 Block Organization.....................................11

2.2.1 Parameter Blocks................................11

2.2.2 Main Blocks.........................................11

3.0 PRINCIPLES OF OPERATION .....................11

3.1 Bus Operation............................................12

3.1.1 Read....................................................13

3.1.2 Output Disable.....................................13

3.1.3 Standby...............................................13

3.1.4 Deep Power-Down / Reset..................13

3.1.5 Write....................................................13

3.2 Modes of Operation....................................14

3.2.1 Read Array..........................................14

3.2.2 Read Identifier.....................................15

3.2.3 Read Status Register ..........................16

3.2.4 Program Mode.....................................16

3.2.5 Erase Mode.........................................17

3.3 Block Locking.............................................20

3.3.1 WP# = V

IL

for Block Locking................20

3.3.2 WP# = V

IH

for Block Unlocking............20

3.4 V

PP

Program and Erase Voltages ..............20

3.4.1 V

PP

= VIL for Complete Protection .......20

3.5 Power Consumption...................................20

3.5.1 Active Power .......................................21

3.5.2 Automatic Power Savings (APS) .........21

3.5.3 Standby Power....................................21

3.5.4 Deep Power-Down Mode.....................21

3.6 Power-Up/Down Operation.........................21

3.6.1 RP# Connected to System Reset ........21

3.6.2 V

CC

, VPP and RP# Transitions.............21

3.7 Power Supply Decoupling ..........................22

4.0 ELECTRICAL SPECIFICATIONS..................23

4.1 Absolute Maximum Ratings........................23

4.2 Operating Conditions..................................24

4.3 Capacitance...............................................24

4.4 DC Characteristics .....................................25

4.5 AC Characteristics—Read Operations .......28

4.6 AC Characteristics—Write Operations........30

4.7 Program and Erase Timings.......................31

5.0 RESET OPERATIONS ..................................33

6.0 ORDERING INFORMATION..........................34

7.0 ADDITIONAL INFORMATION.......................36

APPENDIX A: Write State Machine

Current/Next States.....................................37

APPENDIX B: Access Time vs.

Capacitive Load...........................................38

APPENDIX C: Architecture Block Diagram ......39

APPENDIX D: Word-Wide Memory Map

Diagrams......................................................40

APPENDIX E: Byte Wide Memory Map

Diagrams......................................................43

APPENDIX F: Program and Erase Flowcharts.45

SMART 3 ADVANCED BOOT BLOCK E

4

PRELIMINARY

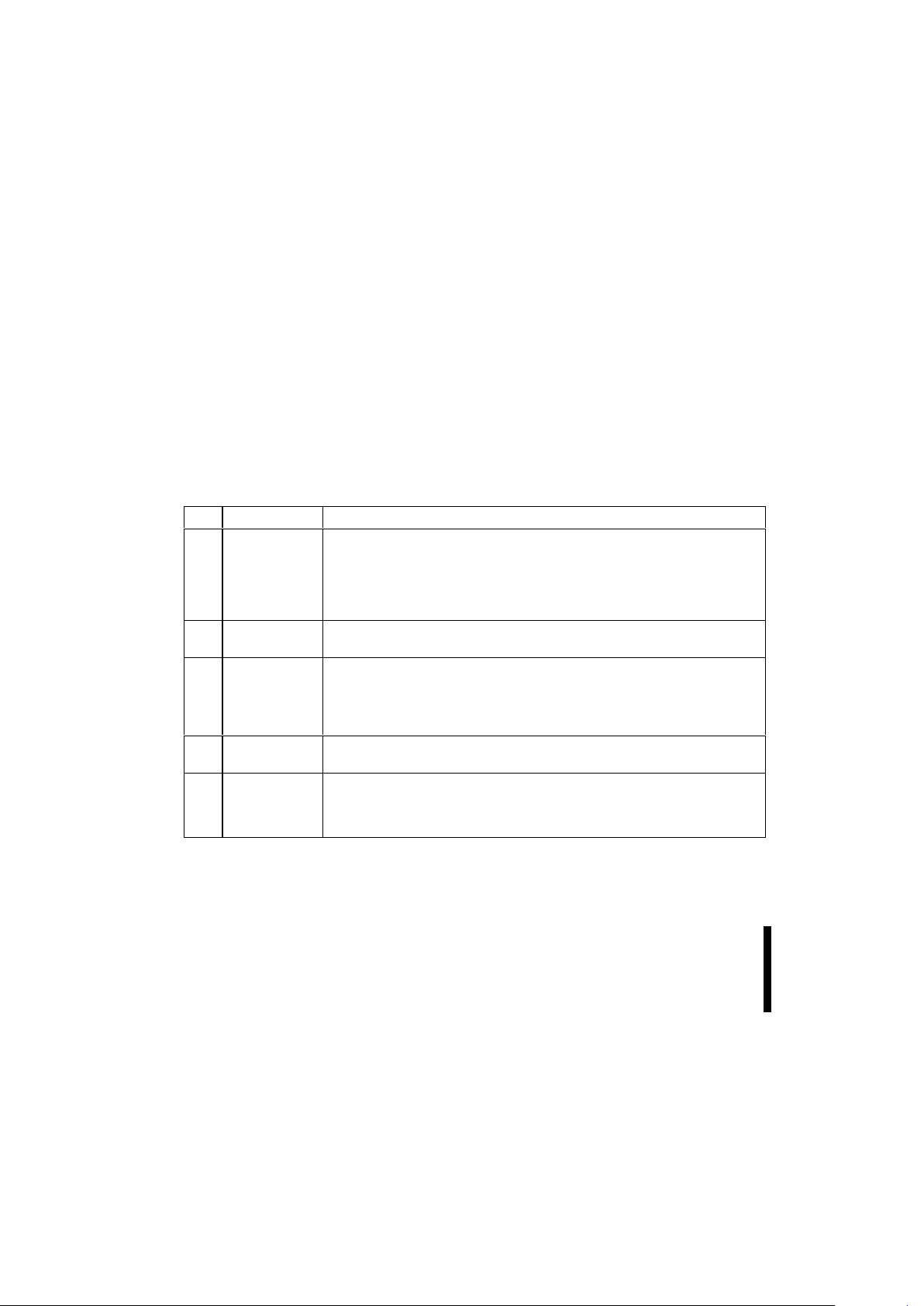

REVISION HISTORY

Number Description

-001 Original version

-002 Section 3.4,

VPP Program and Erase Voltages

, added

Updated Figure 9:

Automated Block Erase Flowchart

Updated Figure 10:

Erase Suspend/Resume Flowchart

(added program to table)

Updated Figure 16:

AC Waveform: Program and Erase Operations

(updated notes)

I

PPR

maximum specification change from ±25 µA to ±50 µA

Program and Erase Suspend Latency specification change

Updated Appendix A:

Ordering Information

(included 8 M and 4 M information)

Updated Figure, Appendix D:

Architecture Block Diagram

(Block info. in words not

bytes)

Minor wording changes

-003 Combined byte-wide specification (previously 290605) with this document

Improved speed specification to 80 ns (3.0 V) and 90 ns (2.7 V)

Improved 1.8 V I/O option to minimum 1.65 V (Section 3.4)

Improved several DC characteristics (Section 4.4)

Improved several AC characteristics (Sections 4.5 and 4.6)

Combined 2.7 V and 1.8 V DC characteristics (Section 4.4)

Added 5 V V

PP

read specification (Section 3.4)

Removed 120 ns and 150 ns speed offerings

Moved

Ordering Information

from Appendix to Section 6.0; updated information

Moved

Additional Information

from Appendix to Section 7.0

Updated figure Appendix B,

Access Time vs. Capacitive Load

Updated figure Appendix C,

Architecture Block Diagram

Moved Program and Erase Flowcharts to Appendix E

Updated

Program Flowchart

Updated

Program Suspend/Resume Flowchart

Minor text edits throughout.

-004 Added 32-Mbit density

Added 98H as a reserved command (Table 4)

A

1–A20

= 0 when in read identifier mode (Section 3.2.2)

Status register clarification for SR3 (Table 7)

V

CC

and V

CCQ

absolute maximum specification = 3.7 V (Section 4.1)

Combined I

PPW

and I

CCW

into one specification (Section 4.4)

Combined I

PPE

and I

CCE

into one specification (Section 4.4)

Max Parameter Block Erase Time (t

WHQV2/tEHQV2

) reduced to 4 sec (Section 4.7)

Max Main Block Erase Time (t

WHQV3/tEHQV3

) reduced to 5 sec (Section 4.7)

Erase suspend time @ 12 V (t

WHRH2/tEHRH2

) changed to 5 µs typical and 20 µs

maximum (Section 4.7)

Ordering Information

updated (Section 6.0)

Write State Machine Current/Next States Table updated (Appendix A)

Program Suspend/Resume Flowchart updated (Appendix F)

Erase Suspend/Resume Flowchart updated (Appendix F)

Text clarifications throughout

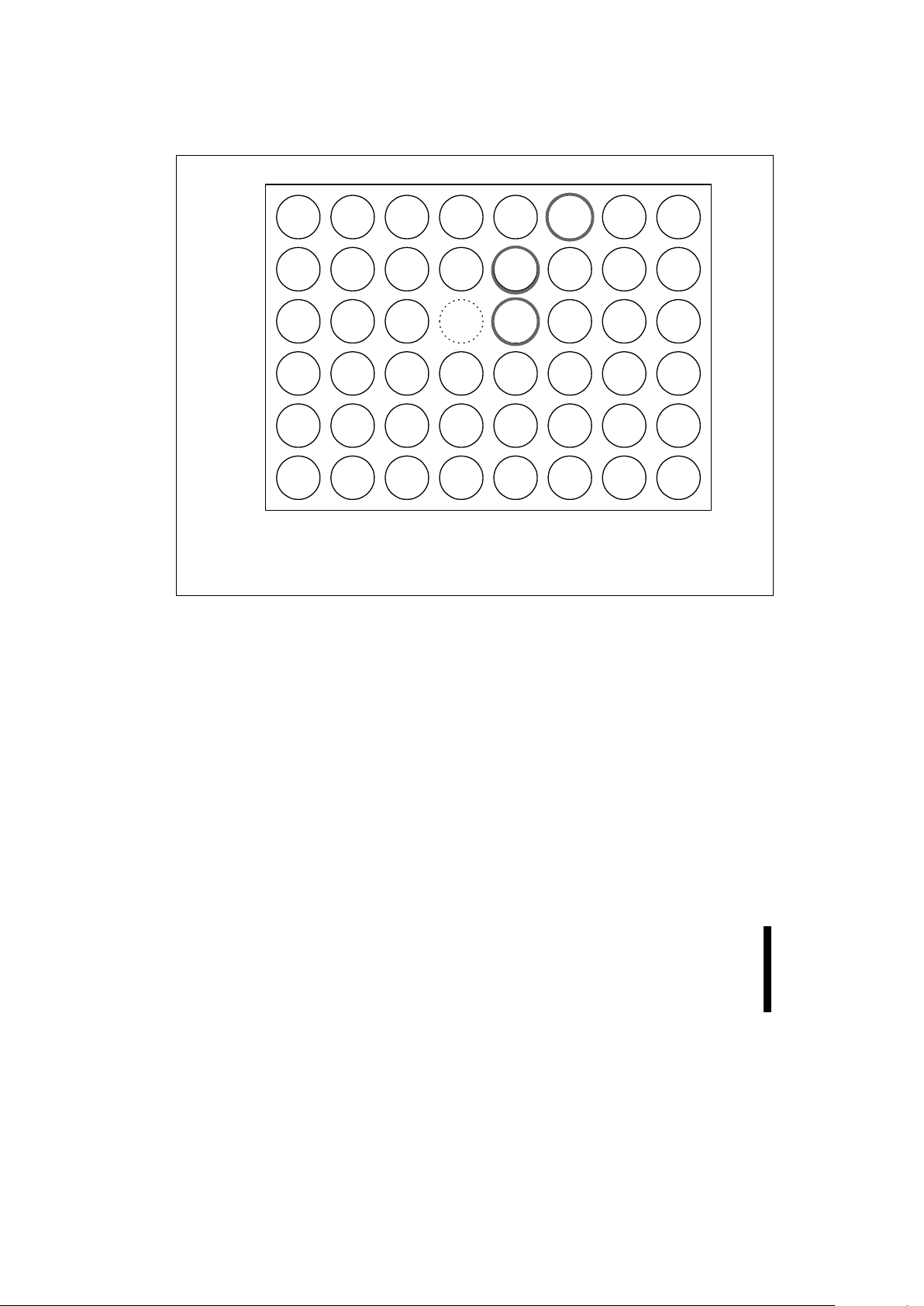

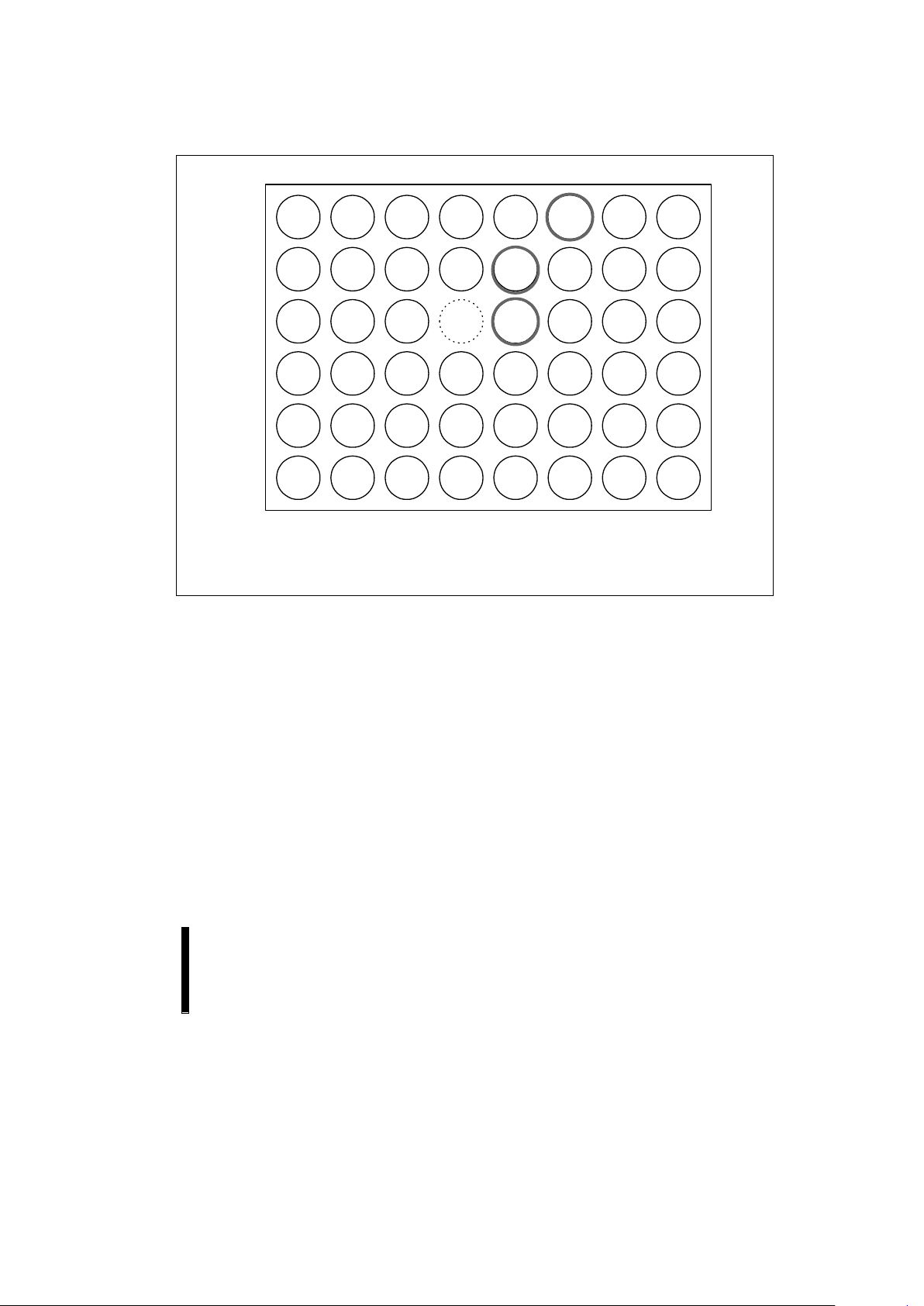

-005 µBGA package diagrams corrected (Figures 3 and 4)

I

PPD

test conditions corrected (Section 4.4)

32-Mbit ordering information corrected (Section 6)

µBGA package top side mark information added (Section 6)

E SMART 3 ADVANCED BOOT BLOCK

5

PRELIMINARY

1.0 INTRODUCTION

This datasheet contains the specifications for the

Advanced Boot Block flas h mem ory fam ily , whic h is

optimized for low power, portable systems. This

family of products f eatures 1.65 V–2.5 V or 2.7 V–

3.6 V I/Os and a low V

CC/VPP

operating range of

2.7 V–3.6 V for read, program, and erase

operations. In addition this family is capable of fast

programming at 12 V. Throughout this document,

the term “2.7 V” refers to the full voltage range

2.7 V–3.6 V (except where noted otherwise) and

“V

PP

= 12 V” refers to 12 V ±5%. Section 1.0 and

2.0 provide an overview of the fl ash memory famil y

including applications, pinouts and pi n descriptions.

Section 3.0 describes t he mem ory organiz ation and

operation for these products. Sections 4.0 and 5.0

contain the operating specifications. Finally,

Sections 6.0 and 7.0 provide ordering and other

reference information.

1.1 Smart 3 Advanced Boot Block

Flash Memory Enhancements

The Smart 3 Advanced Boot Block flash memory

features

• Enhanced blocking for easy segmentation of

code and data or additional design flexibility

• Program Suspend to Read command

• V

CCQ

input of 1.65 V–2.5 V on all I/Os. See

Figures 1 through 4 for pinout diagrams and

V

CCQ

location

• Maximum program and erase time specifi cation

for improved data storage.

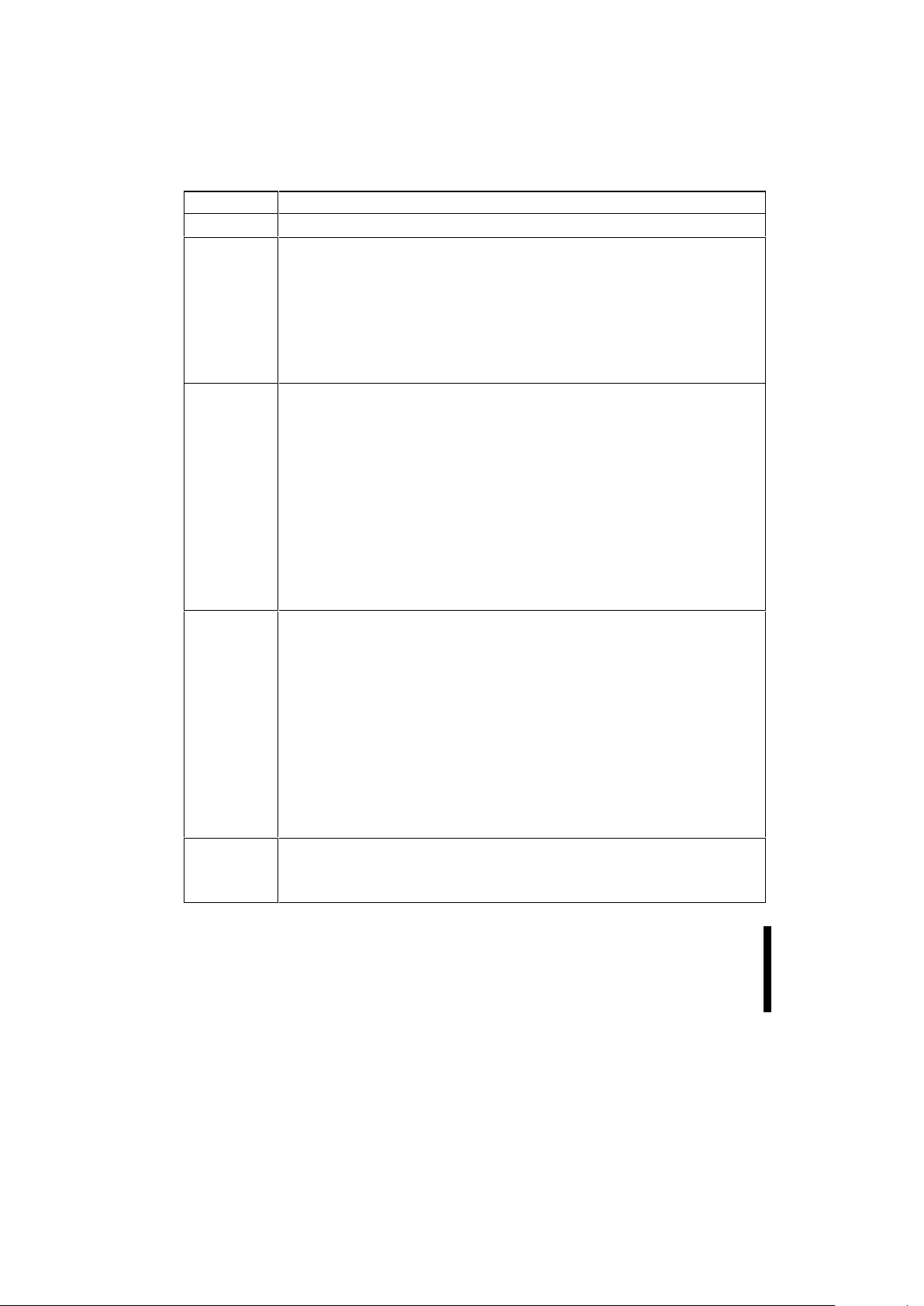

Table 1. Smart 3 Advanced Boot Block Feature Summary

Feature 28F008B3, 28F016B3,

28F032B3

(1)

28F400B3

(2),

28F800B3,

28F160B3, 28F320B3

Reference

VCC Read Voltage 2.7 V– 3.6 V Section 4.2, 4.4

V

CCQ

I/O Voltage 1.65 V–2.5 V or 2.7 V– 3.6 V Section 4.2, 4.4

VPP Program/Erase Voltage 2.7 V– 3.6 V or 11.4 V– 12.6 V Section 4.2, 4.4

Bus Width 8-bit 16 bit Table 3

Speed 80 ns, 90 ns, 100 ns, 110 ns Section 4.5

Memory Arrangement 1024 Kbit x 8 (8 Mbit),

2048 Kbit x 8 (16 Mbit),

4096 Kbit x 8 (32 Mbit)

256 Kbit x 16 (4 Mbit),

512 Kbit x 16 (8 Mbit),

1024 Kbit x 16 (16 Mbit)

2048 Kbit x 16 (32 Mbit)

Section 2.2

Blocking (top or bottom) Eight 8-Kbyte parameter blocks and

Seven 64-Kbyte blocks (4-Mbit) or

Fifteen 64-Kbyte blocks (8-Mbit) or

Thirty-one 64-Kbyte main blocks (16-Mbit)

Sixty-three 64-Kbyte main blocks (32-Mbit)

Section 2.2

Appendix D

Locking WP# locks/unlocks parameter blocks

All other blocks protected using V

PP

Section 3.3

Table 8

Operating Temperature Extended: –40 °C to +85 °C Section 4.2, 4.4

Program/Erase Cycling 100,000 cycles Section 4.2, 4.4

Packages 40-lead TSOP

(1)

, 48-Ball

µBGA* CSP

(2)

48-Lead TSOP, 48-Ball

µBGA CSP

(2)

Figure 3, Figure 4

NOTES:

1. 4-Mbit and 32-Mbit density not available in 40-lead TSOP.

2. 4-Mbit density not available in µBGA* CSP.

SMART 3 ADVANCED BOOT BLOCK E

6

PRELIMINARY

1.2 Product Overview

Intel provides the most flexible voltage solution in

the flash industry, prov iding three discrete voltage

supply pins: V

CC

for read operation, V

CCQ

for output

swing, and V

PP

for program and erase operation. All

Smart 3 Advanced Boot Block flash memory

products provide program/erase capability at 2.7 V

or 12 V [for fast production programming] and read

with V

CC

at 2.7 V. Since many designs read from

the flash memory a large percentage of the time,

2.7 V V

CC

operation can provide substant ial power

savings.

The Smart 3 Advanced Boot Block flash memory

products are available in either x8 or x16 pac kages

in the following densit ies: (see

Ordering Information

for availability.)

• 4-Mbit (4,194,304-bit) flash memory organized

as 256 Kwords of 16 bits each or 512 Kbytes of

8-bits each

• 8-Mbit (8,388,608-bit) flash memory organized

as 512 Kwords of 16 bits each or 1024 Kbytes

of 8-bits each

• 16-Mbit (16,777,216-bit) flash memory

organized as 1024 Kwords of 16 bits each or

2048 Kbytes of 8-bits each

• 32-Mbit (33,554,432-bit) flash memory

organized as 2048 Kwords of 16 bits each or

4096 Kbytes of 8-bits each

The parameter blocks are located at either the top

(denoted by -T suffix) or the bot t om (-B suffix) of t he

address map in order to accommodate different

microprocessor protocols for kernel code location.

The upper two (or lower two) parameter blocks can

be locked to provide complete code security for

system initialization code. Locking and unlocking is

controlled by WP# (see Section 3.3 for details).

The Command User Interface (CUI) s erves as the

interface between the microprocessor or

microcontroller and the internal operation of the

flash memory. The internal Write State Machine

(WSM) automatically executes the algorithms and

timings necessary for program and erase

operations, including verification, thereby unburdening the microprocessor or microcontroller.

The status register indicates t he status of the WSM

by signifying block erase or word program

completion and status.

The Smart 3 Advanced Boot Bl ock flash memory is

also designed with an Automatic Power Savings

(APS) feature which minimizes system current

drain, allowing for very low power designs. This

mode is entered following the completion of a read

cycle (approximately 300 ns later).

The RP# pin provides additional protection agains t

unwanted command writes that may occur during

system reset and power-up/down sequences due to

invalid system bus conditions (see Section 3.6).

Section 3.0 gives detailed explanation of the

different modes of operation. Complete c urrent and

voltage specifications can be found in the

DC

Characteristics

section. Refer to

AC Characteristics

for read, program and erase performance

specifications.

2.0 PRODUCT DESCRIPTION

This section explains device pin description and

package pinouts.

2.1 Package Pinouts

The Smart 3 Advanced Boot Bl ock flash memory is

available in 40-lead TSOP (x8, Figure 1), 48-lead

TSOP (x16, Figure 2) and 48-ball µBGA pac kages

(x8 and x16, Figure 3 and Figure 4 respectively ). In

all figures, pin changes necessary for density

upgrades have been circled.

E SMART 3 ADVANCED BOOT BLOCK

7

PRELIMINARY

A

17

GND

A

20

A

19

A

10

DQ

7

DQ

6

DQ

5

DQ

4

V

CCQ

V

CC

NC

DQ

3

DQ

2

DQ

1

DQ

0

OE#

GND

CE#

A

0

A

16

A

15

A

14

A

13

A

12

A

11

A

9

A

8

WE#

RP#

V

PP

WP#

A

18

A

7

A

6

A

5

A

4

A

3

A

2

A

1

16 M

8 M

Advanced Boot Block

40-Lead TSOP

10 mm x 20 mm

TOP VIEW

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

0580_01

NOTES:

1. 40-Lead TSOP available for 8- and 16-Mbit densities only.

2. Lower densities will have NC on the upper address pins. For example, an 8-Mbit device will have NC on Pin 38.

Figure 1. 40-Lead TSOP Package for x8 Configurations

Advanced Boot Block

48-Lead TSOP

12 mm x 20 mm

TOP VIEW

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

A

16

V

CCQ

GND

DQ

15

DQ

7

DQ

14

DQ

6

DQ

13

DQ

5

DQ

12

DQ

4

V

CC

DQ

11

DQ

3

DQ

10

DQ

2

DQ

9

DQ

1

DQ

8

DQ

0

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

A

15

A

14

A

13

A

12

A

11

A

10

A

9

A

8

NC

A

20

WE#

RP#

V

PP

WP#

A

19

A

18

A

17

A

7

A

6

A

5

21

22

23

24

OE#

GND

CE#

A

0

28

27

26

25

A

4

A

3

A

2

A

1

32 M

4 M

16 M

8 M

0580_02

NOTE:

Lower densities will have NC on the upper address pins. For example, an 8-Mbit device will have NC on Pins 9 and 15.

Figure 2. 48-Lead TSOP Package for x16 Configurations

SMART 3 ADVANCED BOOT BLOCK E

8

PRELIMINARY

A

14

A

15

A

16

A

17

V

CCQ

A

12

A

10

A

13

NC

A

11

A

8

WE#

A

9

D

5

D

6

V

PP

RP#

NC

NC

WP#

A

19

A

21

D

2

D

3

A

20

A

18

A

6

NC

NC

A

7

A

5

A

3

CE#

D

0

A

4

A

2

A

1

A

0

GND

GND D

7

NC D

4

V

CC

NC D

1

OE#

A

B

C

D

E

F

13254768

16M

32M

8M

0580_04

NOTE:

1. Shaded connections indicate the upgrade address connections. Lower density devices will not have the upper address

solder balls. Routing is not recommended in this area. A

20

is the upgrade address for the 16-Mbit device. A

21

is the

upgrade address for the 32-Mbit device.

2. 4-Mbit density not available in µBGA* CSP.

Figure 3. x8 48-Ball µBGA* Chip Size Package (Top View, Ball Down)

E SMART 3 ADVANCED BOOT BLOCK

9

PRELIMINARY

A

13

A

14

A

15

A

16

V

CCQ

A

11

A

10

A

12

D

14

D

15

A

8

WE#

A

9

D

5

D

6

V

PP

RP#

D

11

D

12

WP#

A

18

A

20

D

2

D

3

A

19

A

17

A

6

D

8

D

9

A

7

A

5

A

3

CE#

D

0

A

4

A

2

A

1

A

0

GND

GND D

7

D

13

D

4

V

CC

D

10

D

1

OE#

A

B

C

D

E

F

13254768

16M

32M

8M

0580_03

NOTES:

1. Shaded connections indicate the upgrade address connections. Lower density devices will not have the upper address

solder balls. Routing is not recommended in this area. A19 is the upgrade address for the 16-Mbit device. A20 is the

upgrade address for the 32-Mbit device.

2. 4-Mbit density not available in µBGA* CSP.

Figure 4. x16 48-Ball µBGA* Chip Size Package (Top View, Ball Down)

SMART 3 ADVANCED BOOT BLOCK E

10

PRELIMINARY

The pin descriptions table details the usage of each device pin.

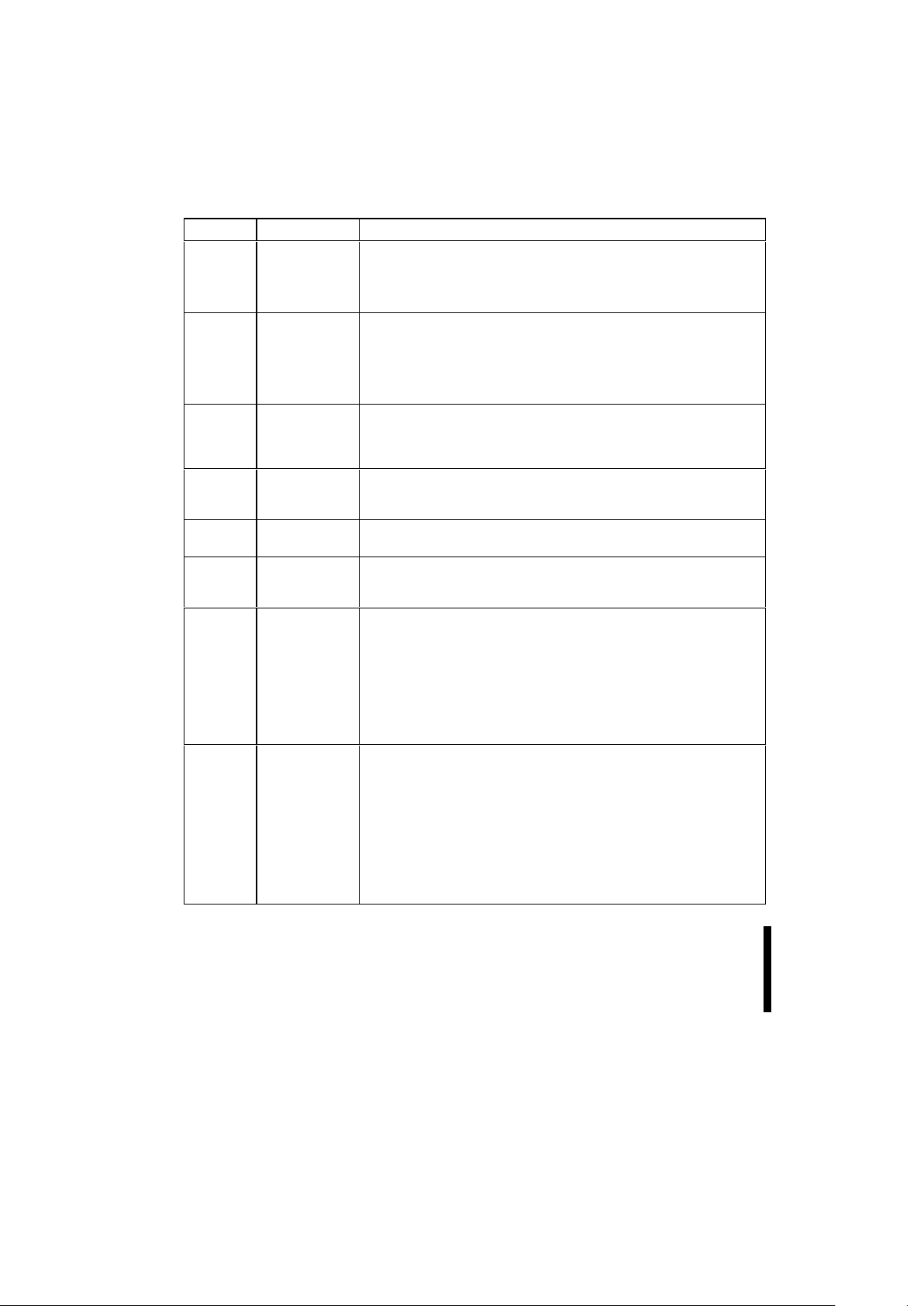

Table 2. Smart 3 Advanced Boot Block Pin Descriptions

Symbol Type Name and Function

A0–A

21

INPUT

ADDRESS INPUTS for memory addresses. Addresses are internally

latched during a program or erase cycle.

28F008B3: A[0-19], 28F016B3: A[0-20], 28F032B3: A[0-21],

28F800B3: A[0-17], 28F800B3: A[0-18], 28F160B3: A[0-19],

28F320B3: A[0-20]

DQ0–DQ7INPUT/OUTPUT DATA INPUTS/OUTPUTS: Inputs array data on the second CE# and

WE# cycle during a Program command. Inputs commands to the

Command User Interface when CE# and WE# are active. Data is

internally latched. Outputs array, identifier and status register data. The

data pins float to tri-state when the chip is de-selected or the outputs are

disabled.

DQ8–DQ15INPUT/OUTPUT DATA INPUTS/OUTPUTS: Inputs array data on the second CE# and

WE# cycle during a Program command. Data is internally latched.

Outputs array and identifier data. The data pins float to tri-state when the

chip is de-selected. Not included on x8 products.

CE# INPUT CHIP ENABLE: Activates the internal control logic, input buffers,

decoders and sense amplifiers. CE# is active low. CE# high de-selects

the memory device and reduces power consumption to standby levels.

OE# INPUT OUTPUT ENABLE: Enables the device’s outputs through the data

buffers during a read operation. OE# is active low.

WE# INPUT WRITE ENABLE: Controls writes to the Command Register and memory

array. WE# is active low. Addresses and data are latched on the rising

edge of the second WE# pulse.

RP# INPUT RESET/DEEP POWER-DOWN: Uses two voltage levels (VIL, VIH) to

control reset/deep power-down mode.

When RP# is at logic low, the device is in reset/deep power-down

mode, which drives the outputs to High-Z, resets the Write State

Machine, and minimizes current levels (I

CCD

).

When RP# is at logic high, the device is in standard operation.

When RP# transitions from logic-low to logic-high, the device resets all

blocks to locked and defaults to the read array mode.

WP# INPUT WRITE PROTECT: Provides a method for locking and unlocking the two

lockable parameter blocks.

When WP# is at logic low, the lockable blocks are locked,

preventing program and erase operations to those blocks. If a program

or erase operation is attempted on a locked block, SR.1 and either SR.4

[program] or SR.5 [erase] will be set to indicate the operation failed.

When WP# is at logic high, the lockable blocks are unlocked and

can be programmed or erased.

See Section 3.3 for details on write protection.

E SMART 3 ADVANCED BOOT BLOCK

11

PRELIMINARY

Table 2. Smart 3 Advanced Boot Block Pin Descriptions (Continued)

Symbol Type Name and Function

V

CCQ

INPUT OUTPUT VCC: Enables all outputs to be driven to 1.8 V – 2.5 V while

the V

CC

is at 2.7 V–3.3 V. If the VCC is regulated to 2.7 V–2.85 V, V

CCQ

can be driven at 1.65 V–2.5 V to achieve lowest power operation (see

Section 4.4,

DC Characteristics

.

This input may be tied directly to V

CC

(2.7 V–3.6 V).

V

CC

DEVICE POWER SUPPLY: 2.7 V–3.6 V

V

PP

PROGRAM/ERASE POWER SUPPLY: Supplies power for program

and erase operations. V

PP

may be the same as VCC (2.7 V–3.6 V) for

single supply voltage operation. For fast programming at manufacturing,

11.4 V–12.6 V may be supplied to V

PP

. This pin cannot be left floating.

Applying 11.4 V–12.6 V to V

PP

can only be done for a maximum of 1000

cycles on the main blocks and 2500 cycles on the parameter blocks.

V

PP

may be connected to 12 V for a total of 80 hours maximum (see

Section 3.4 for details).

V

PP

< V

PPLK

protects memory contents against inadvertent or

unintended program and erase commands.

GND GROUND: For all internal circuitry. All ground inputs must be

connected.

NC NO CONNECT: Pin may be driven or left floating.

2.2 Block Organization

The Smart 3 Advanced Boot Block is an

asymmetrically-blocked architecture that enables

system integration of code and data within a single

flash device. Each block can be erased

independently of the others up to 100,000 times.

For the address locations of each block, see the

memory maps in Appendix D.

2.2.1 PARAMETER BLOCKS

The Smart 3 Advanced Boot Block flash memory

architecture includes parameter bl ocks to facilitate

storage of frequently updated small parameters

(e.g., data that would normally be stored in an

EEPROM). By using software techniques, the wordrewrite functionality of EEPROMs can be emulated.

Each device contains eight parameter blocks of

8-Kbytes/4-Kwords (8192 bytes/4,096 words) each.

2.2.2 MAIN BLOCKS

After the parameter blocks, the remainder of the

array is divided into equal si ze main blocks (65,536

bytes / 32,768 words) for data or c ode storage. The

4-Mbit device contains seven main blocks; 8-Mbit

device contains fifteen main blocks; 16-Mbit flash

has thirty-one main blocks; 32-Mbit has sixty-three

main blocks.

3.0 PRINCIPLES OF OPERATION

Flash memory combines EEPROM functionality

with in-circuit electrical program and erase

capability. The Smart 3 Advanc ed Boot Block f lash

memory family utilizes a Command User Interface

(CUI) and automated algorithms to si mpli fy program

and erase operations. The CUI allows for 100%

CMOS-level control inputs and fi xed power suppli es

during erasure and programming.

SMART 3 ADVANCED BOOT BLOCK E

12

PRELIMINARY

When VPP < V

PPLK

, the device will only execute the

following commands successfully: Read Array,

Read Status Register, Clear Status Register and

Read Identifier. The device provides standard

EEPROM read, standby and output disable

operations. Manufacturer identification and device

identification data can be accessed through the

CUI. All functions associated with altering m emory

contents, namely program and erase, are

accessible via the CUI. The internal Write State

Machine (WSM) completely automates program

and erase operations while the CUI si gnals the s tart

of an operation and the status register reports

status. The CUI handles t he WE# interface to the

data and address latches, as well as system status

requests during WSM operation.

3.1 Bus Operation

Smart 3 Advanced Boot Block flash memory

devices read, program and erase in-system via the

local CPU or microcontroller. All bus cycles to or

from the flash memory conform to standard

microcontroller bus cycles. Four control pins dictate

the data flow in and out of the flash component:

CE#, OE#, WE# and RP#. These bus operations

are summarized in Table 3.

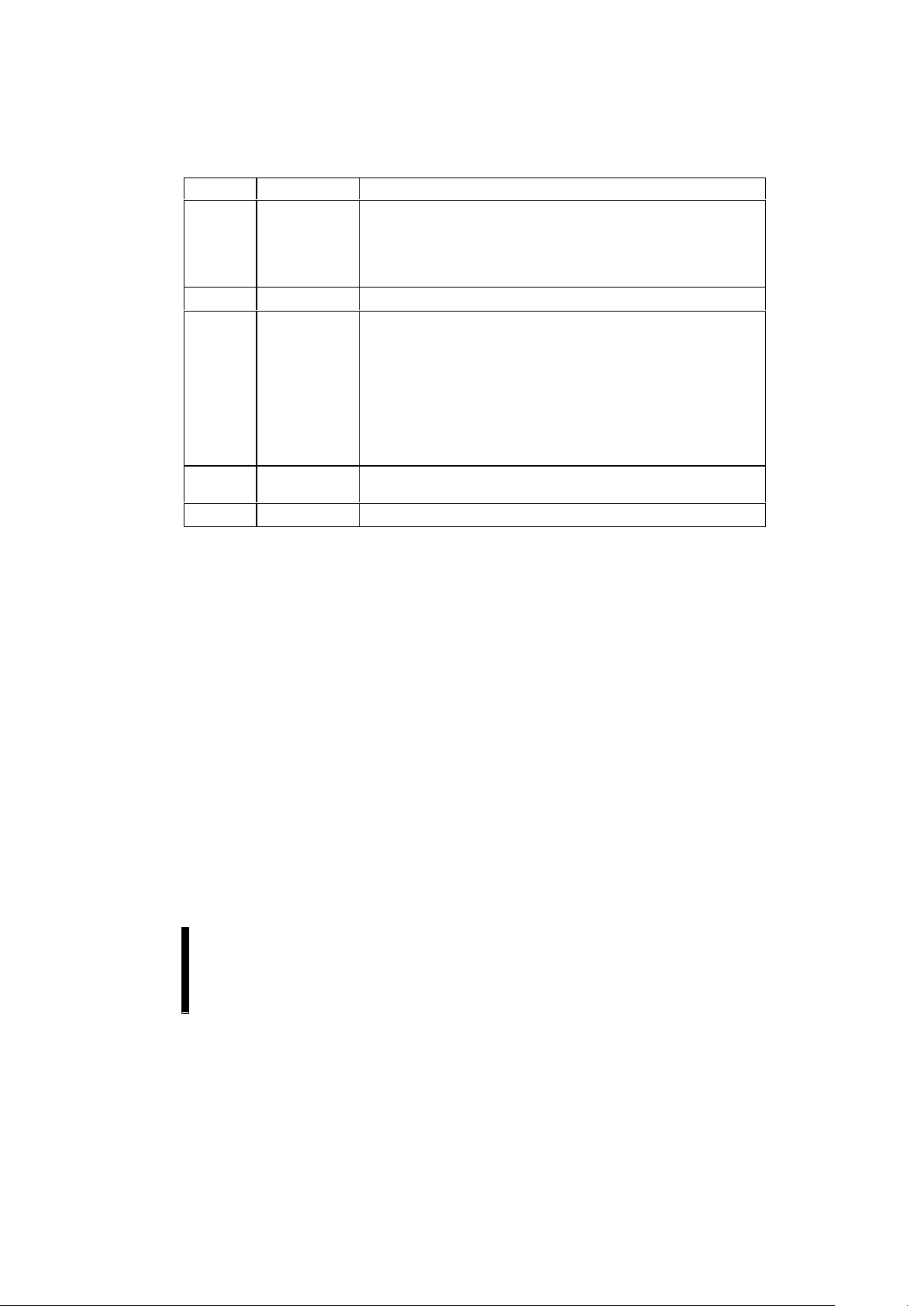

Table 3. Bus Operations

(1)

Mode Note RP# CE# OE# WE# DQ

0–7

DQ

8–15

Read (Array, Status, or

Identifier)

2–4 V

IH

V

IL

V

IL

V

IH

D

OUT

D

OUT

Output Disable 2 V

IH

V

IL

V

IH

V

IH

High Z High Z

Standby 2 V

IH

V

IH

X X High Z High Z

Reset 2, 7 V

IL

X X X High Z High Z

Write 2, 5–7 V

IH

V

IL

V

IH

V

IL

D

IN

D

IN

NOTES:

1. 8-bit devices use only DQ[0:7], 16-bit devices use DQ[0:15]

2. X must be V

IL

, VIH for control pins and addresses.

3. See

DC Characteristics

for V

PPLK

, V

PP1

, V

PP2

, V

PP3

, V

PP4

voltages.

4. Manufacturer and device codes may also be accessed in read identifier mode (A

1–A21

= 0). See Table 4.

5. Refer to Table 6 for valid D

IN

during a write operation.

6. To program or erase the lockable blocks, hold WP# at V

IH

.

7. RP# must be at GND ± 0.2 V to meet the maximum deep power-down current specified.

E SMART 3 ADVANCED BOOT BLOCK

13

PRELIMINARY

3.1.1 READ

The flash memory has four read modes available:

read array, read identifier, read status and read

query. These modes are accessibl e independent of

the V

PP

voltage. The appropriate Read Mode

command must be issued t o the CUI to enter the

corresponding mode. Upon initial dev ice power

-

up

or after exit from reset, the device automatically

defaults to read array mode.

CE# and OE# must be driven active to obtain dat a

at the outputs. CE# is the device sel ection control;

when active it enables the flash memory device.

OE# is the data output control and it drives the

selected memory data onto t he I/ O bus. For all read

modes, WE# and RP# must be at V

IH

. Figure 7

illustrates a read cycle.

3.1.2 OUTPUT DISABLE

With OE# at a logic

-

high level (VIH), the device

outputs are disabled. Output pins are placed in a

high

-

impedance state.

3.1.3 STANDBY

Deselecting the device by bri nging CE# to a logic

-

high level (VIH) places the device in standby mode,

which substantially reduces device power

consumption without any latency for subsequent

read accesses. In standby, outputs are placed in a

high-impedance state independent of OE#. If

deselected during program or erase operat ion, the

device continues to c onsume active power unt il the

program or erase operation is complete.

3.1.4 DEEP POWER-DOWN / RESET

From read mode, RP# at V

IL

for time t

PLPH

deselects the memory, places output drivers in a

high

-

impedance state, and turns off all internal

circuits. After return from reset, a time t

PHQV

is

required until the initial read access outputs are

valid. A delay (t

PHWL

or t

PHEL

) is required after

return from reset before a write can be initiated.

After this wake

-

up interval, normal operation is

restored. The CUI resets to read array mode, and

the status register is set to 80H. This cas e is shown

in Figure 9A.

If RP# is taken low for time t

PLPH

during a program

or erase operation, the operation will be aborted

and the memory contents at the aborted location

(for a program) or block (for an erase) are no longer

valid, since the data may be partially erased or

written. The abort process goes through the

following sequence: When RP# goes low, the

device shuts down the operation in progress, a

process which takes time t

PLRH

to complete. After

this time t

PLRH

, the part will either reset to read

array mode (if RP# has gone high during t

PLRH

,

Figure 9B) or enter reset mode (if RP# is st ill logic

low after t

PLRH

, Figure 9C). In both cases, after

returning from an aborted operation, the relevant

time t

PHQV

or t

PHWL/tPHEL

must be waited before a

read or write operation is initiat ed, as discussed in

the previous paragraph. However, in this case,

these delays are referenced to the end of t

PLRH

rather than when RP# goes high.

As with any automated device, it is important to

assert RP# during system reset. When the system

comes out of reset, proc essor expec ts to read from

the flash memory. Automated flash memories

provide status information when read during

program or block erase operations. I f a CPU reset

occurs with no flash memory reset, proper CPU

initialization may not occur because the flash

memory may be providing status information

instead of array data. Intel ’s Flash memories allow

proper CPU initialization following a system reset

through the use of the RP# input. In this applic at i on,

RP# is controlled by the same RESET# signal that

resets the system CPU.

3.1.5 WRITE

A write takes place when both CE# and WE# are

low and OE# is high. Commands are written to the

Command User Interface (CUI) using standard

microprocessor write timings to control flash

operations. The CUI does not occupy an

addressable memory location. The address and

data buses are latched on the rising edge of the

second WE# or CE# pulse, whichever occ urs first.

Figure 8 illustrates a program and erase operation.

The available commands are shown in Table 6, and

Appendix A provides detailed information on

moving between the different modes of operation

using CUI commands.

SMART 3 ADVANCED BOOT BLOCK E

14

PRELIMINARY

There are two commands that modify array data:

Program (40H) and Erase (20H). Writing either of

these commands to the internal Command User

Interface (CUI) initiates a sequence of internally

-

timed functions that culminate in the c ompletion of

the requested task (unless that operati on is aborted

by either RP# being driven to V

IL

for t

PLRH

or an

appropriate suspend command).

3.2 Modes of Operation

The flash memory has four read modes and two

write modes. The read modes are read array, read

identifier, read status and read query (see A ppendix

C). The write modes are program and block erase.

Three additional modes (erase suspend to program,

erase suspend to read and program suspend to

read) are available only during suspended

operations. These modes are reached using the

commands summarized in Table 4. A

comprehensive chart showing t he state transitions

is in Appendix A.

3.2.1 READ ARRAY

When RP# transitions from V

IL

(reset) to VIH, the

device defaults to read array mode and will res pond

to the read control inputs (CE#, address i nputs , and

OE#) without any additional CUI commands.

When the device is in read array mode, four control

signals control data output:

• WE# must be logic high (V

IH

)

• CE# must be logic low (V

IL

)

• OE# must be logic low (V

IL

)

• RP# must be logic high (V

IH

)

In addition, the address of the desired loc ati on mus t

be applied to the address pins. If the dev ice is not

in read array mode, as would be t he case after a

program or erase operation, the Read Array

command (FFH) must be written to the CUI before

array reads can take place.

Table 4. Command Codes and Descriptions

Code Device Mode Description

00,

01,

60,

2F,

C0,

98

Invalid/

Reserved

Unassigned commands that should not be used. Intel reserves the right to

redefine these codes for future functions.

FF Read Array Places the device in read array mode, such that array data will be output on the

data pins.

40 Program

Set-Up

This is a two-cycle command. The first cycle prepares the CUI for a program

operation. The second cycle latches addresses and data information and

initiates the WSM to execute the Program algorithm. The flash outputs status

register data when CE# or OE# is toggled. A Read Array command is required

after programming to read array data. See Section 3.2.4.

10 Alternate

Program Set-Up

(See 40H/Program Set-Up)

20 Erase

Set-Up

Prepares the CUI for the Erase Confirm command. If the next command is not

an Erase Confirm command, then the CUI will (a) set both SR.4 and SR.5 of the

status register to a “1,” (b) place the device into the read status register mode,

and (c) wait for another command. See Section 3.2.5.

E SMART 3 ADVANCED BOOT BLOCK

15

PRELIMINARY

Table 4. Command Codes and Descriptions (Continued)

Code Device Mode Description

D0 Erase Confirm

Program / Erase

Resume

If the previous command was an Erase Set-Up command, then the CUI will

close the address and data latches, and begin erasing the block indicated on the

address pins. During erase, the device will only respond to the Read Status

Register and Erase Suspend commands. The device will output status register

data when CE# or OE# is toggled.

If a program or erase operation was previously suspended, this command will

resume that operation

B0 Program / Erase

Suspend

Issuing this command will begin to suspend the currently executing

program/erase operation. The status register will indicate when the operation

has been successfully suspended by setting either the program suspend (SR.2)

or erase suspend (SR.6) and the WSM status bit (SR.7) to a “1” (ready). The

WSM will continue to idle in the SUSPEND state, regardless of the state of all

input control pins except RP#, which will immediately shut down the WSM and

the remainder of the chip if it is driven to V

IL

. See Sections 3.2.4.1 and 3.2.5.1.

70 Read Status

Register

This command places the device into read status register mode. Reading the

device will output the contents of the status register, regardless of the address

presented to the device. The device automatically enters this mode after a

program or erase operation has been initiated. See Section 3.2.3.

50 Clear Status

Register

The WSM can set the block lock status (SR.1) , VPP status (SR.3), program

status (SR.4), and erase status (SR.5) bits in the status register to “1,” but it

cannot clear them to “0.” Issuing this command clears those bits to “0.”

90 Read Identifier Puts the device into the intelligent identifier read mode, so that reading the

device will output the manufacturer and device codes (A

0

= 0 for manufacturer,

A

0

= 1 for device, all other address inputs must be 0). See Section 3.2.2.

NOTE: See Appendix A for mode transition information.

3.2.2 READ IDENTIFIER

To read the manufacturer and device codes, the

device must be in read identif ier mode, which can

be reached by writing the Read Identif ier command

(90H). Once in read identifier mode, A

0

= 0 outputs

the manufacturer’s identification code and A

0

= 1

outputs the device identifier (see Table 5) Note:

A

1—A21

= 0. To return to read array mode, write t he

Read Array command (FFH).

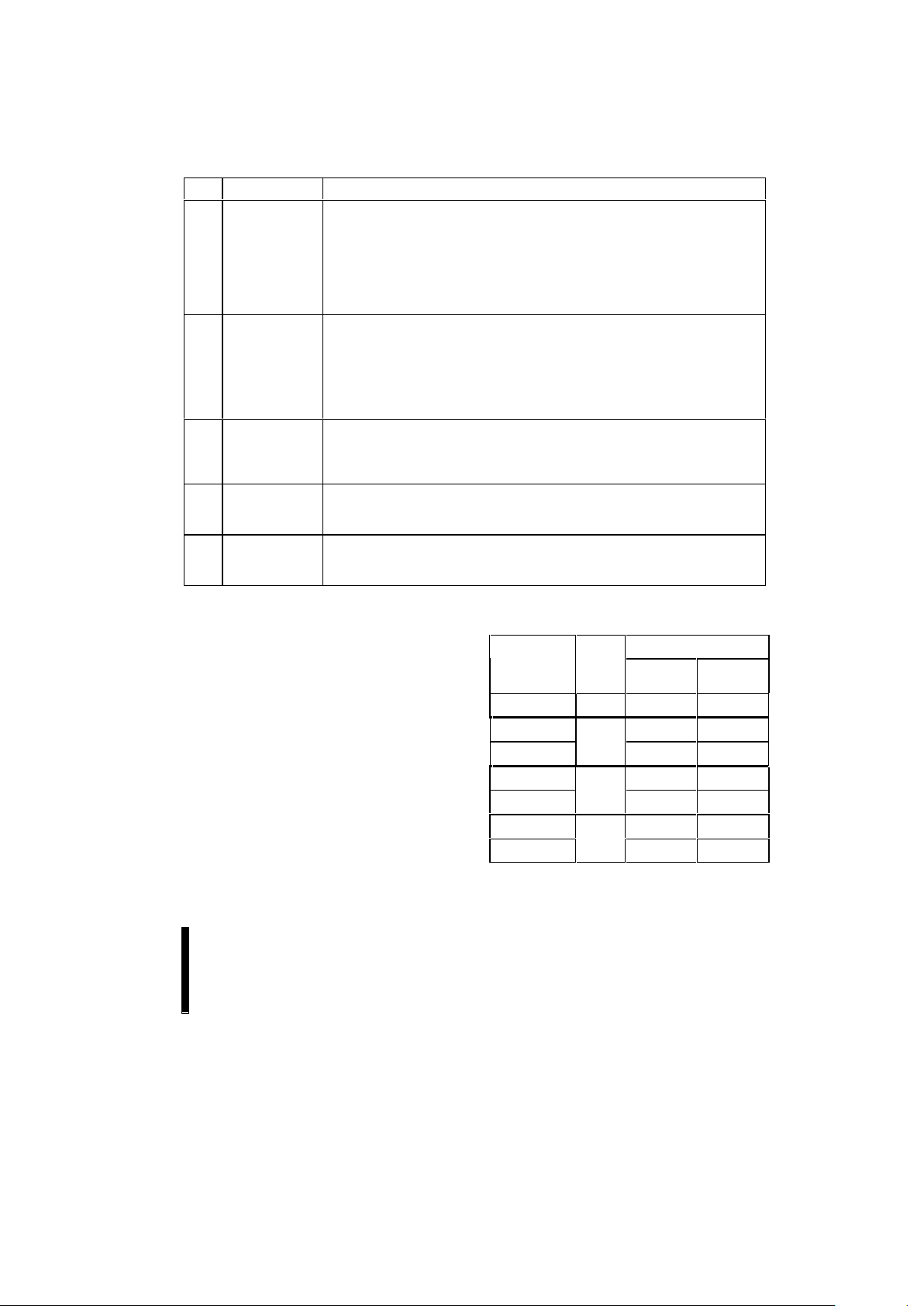

Table 5. Read Identifier Table

Device Identifier

Size Mfr. ID -T

(Top Boot)-B(Bot. Boot)

28F400B3 0089H 8894H 8895H

28F008B3 0089H D2 D3

28F800B3 8892H 8893H

28F016B3 0089H D0 D1

28F160B3 8890H 8891H

28F032B3 0089H D6 D7

28F320B3 8896 8897

SMART 3 ADVANCED BOOT BLOCK E

16

PRELIMINARY

3.2.3 READ STATUS REGISTER

The device status register indicates when a

program or erase operation is complete and the

success or failure of that operation. To read the

status register issue the Read Status Register

(70H) command to the CUI. This causes all

subsequent read operations to output data f rom the

status register until anot her command is written to

the CUI. To return to reading from the array, issue

the Read Array (FFH) command.

The status register bits are output on DQ

0

–DQ7.

The upper byte, DQ

8

–DQ15, outputs 00H during a

Read Status Register command.

The contents of the stat us register are latched on

the falling edge of OE# or CE#. This prevents

possible bus errors which might occur if status

register contents change whi le being read. CE# or

OE# must be toggled with each subsequent s tatus

read, or the status register will not indicate

completion of a program or erase operation.

When the WSM is active, SR.7 will indicate the

status of the WSM; the rem aining bits in the stat us

register indicate whether or not the WSM was

successful in performi ng the desired operation (see

Table 7).

3.2.3.1 Clearing the Status Register

The WSM sets status bits 1 t hrough 7 to “1,” and

clears bits 2, 6 and 7 to “0,” but cannot clear status

bits 1 or 3 through 5 to “0.” Becaus e bits 1, 3, 4 and

5 indicate various error conditions, these bits can

only be cleared through the Clear Status Regi ster

(50H) command. By allowi ng the system software

to control the resetting of these bits, several

operations may be performed (such as cum ulati vel y

programming several addresses or eras ing multiple

blocks in sequence) before reading the status

register to determine if an error oc curred during that

series. Clear the status register before beginning

another command or sequence. Note, again, that

the Read Array command must be issued before

data can be read from the memory array.

3.2.4 PROGRAM MODE

Programming is executed using a two

-

write

sequence. The Program Setup command (40H) is

written to the CUI followed by a second write whic h

specifies the address and data to be programmed.

The WSM will execute a sequence of internally

timed events to program desired bits of the

addressed location, then Verify the bits are

sufficiently programmed. Programming the memory

results in specific bits within an address location

being changed to a “0.” If the user attempts to

program “1”s, the memory cell contents do not

change and no error occurs.

The status register indicates programming status:

while the program sequence executes , status bit 7

is “0.” The status regist er can be polled by toggling

either CE# or OE#. While programming, the only

valid commands are Read Status Register,

Program Suspend, and Program Resume.

When programming is complete, the Program

Status bits should be c hecked. If the programming

operation was unsuccessf ul, bit SR.4 of the status

register is set to indi cate a program f ailure. If S R.3

is set then V

PP

was not within acceptable l i m i ts, and

the WSM did not execute the program command. If

SR.1 is set, a program operation was att empted on

a locked block and the operation was aborted.

The status register should be cleared before

attempting the next operati on. Any CUI instruction

can follow after programming is completed;

however, to prevent inadvertent status register

reads, be sure to reset the CUI to read array mode.

3.2.4.1 Suspending and Resuming

Program

The Program Suspend halts the in-progress

program operation to read data from another

location of memory. Onc e the programming process

starts, writing the Program Suspend command to

the CUI requests that the WSM suspend the

program sequence (at predetermined points in t he

program algorithm). The device continues to output

status register data after the Program Suspend

command is written. Polling status register bits

SR.7 and SR.2 will determine when the program

operation has been suspended (both will be set t o

“1”). t

WHRH1/tEHRH1

specify the program suspend

latency.

E SMART 3 ADVANCED BOOT BLOCK

17

PRELIMINARY

A Read Array command can now be writt en to the

CUI to read data from blocks other than that which

is suspended. The only other v alid c ommands while

program is suspended, are Read Status Register,

Read Identifier, and Program Resume. After the

Program Resume command is written to the f lash

memory, the WSM will continue with the program

process and status regis ter bits SR.2 and SR.7 wil l

automatically be cleared. After the Program

Resume command is written, the device

automatically outputs status register data when

read (see Appendix F for

Program Suspend and

Resume Flowchart

). VPP must remain at the same

V

PP

level used for program while in program

suspend mode. RP# must also remain at V

IH.

3.2.5 ERASE MODE

To erase a block, write the Erase Set

-

up and Erase

Confirm commands to the CUI, along with an

address identifying the block to be erased. This

address is latched internally when the Erase

Confirm command is iss ued. Block erasure results

in all bits within the block being s et to “1.” Only one

block can be erased at a time. The WSM will

execute a sequence of internally-timed events to

program all bits within the block to “0,” eras e all bits

within the block to “1,” t hen verify t hat all bits within

the block are sufficiently erased. While the erase

executes, status bit 7 is a “0.”

When the status register indicates that erasure is

complete, check the erase status bi t to verify that

the erase operation was successful. If the erase

operation was unsuccessful, SR.5 of the status

register will be set to a “1,” indicating an erase

failure. If V

PP

was not within acceptable l imits after

the Erase Confirm command was issued, t he WSM

will not execute the erase sequence; instead, SR.5

of the status register is set to indicate an erase

error, and SR.3 is set to a “1” to i dentify that V

PP

supply voltage was not within acceptable limits.

After an erase operation, clear the status register

(50H) before attempting the next operation. Any

CUI instruction can follow after erasure is

completed; however, to prevent inadvertent status

register reads, it is adv isable to place the flash i n

read array mode after the erase is complete.

3.2.5.1 Suspending and Resuming Erase

Since an erase operation requires on the order of

seconds to complete, an Erase Suspend com mand

is provided to allow erase-s equence interruption in

order to read data from or program data to another

block in memory. Once the erase sequence is

started, writing the Erase Suspend comm and to the

CUI requests that the WSM pause the erase

sequence at a predetermined point in the erase

algorithm. The status register will indicate if/when

the erase operation has been suspended.

A Read Array/Program command can now be

written to the CUI in order to read data from/

program data to blocks other than the one currently

suspended. The Program command can

subsequently be suspended to read yet another

array location. The only valid commands while

erase is suspended are Erase Resume, Program,

Read Array, Read Status Register, or Read

Identifier. During erase sus pend mode, the c hip can

be placed in a pseudo-standby mode by t ak ing CE#

to V

IH

. This reduces active current consumption.

Erase Resume continues the eras e sequenc e when

CE# = V

IL

. As with the end of a standard erase

operation, the status register must be read and

cleared before the next instruction is issued.

SMART 3 ADVANCED BOOT BLOCK E

18

PRELIMINARY

Table 6. Command Bus Definitions

(1, 4)

First Bus Cycle Second Bus Cycle

Command Notes Oper Addr Data Oper Addr Data

Read Array Write X FFH

Read Identifier 2 Write X 90H Read IA ID

Read Status Register Write X 70H Read X SRD

Clear Status Register Write X 50H

Program 3 Write X 40H / 10H Write PA PD

Block Erase/Confirm Write X 20H Write BA D0H

Program/Erase Suspend Write X B0H

Program/Erase Resume Write X D0H

NOTES: PA: Program Address PD: Program Data BA: Block Address

IA: Identifier Address ID: Identifier Data SRD: Status Register Data

1. Bus operations are defined in Table 3.

2. Following the Intelligent Identifier command, two read operations access manufacturer and device codes. A

0

= 0 for

manufacturer code, A

0

= 1 for device code. A1—A

21

= 0.

3. Either 40H or 10H command is valid although the standard is 40H.

4. When writing commands to the device, the upper data bus [DQ

8

–DQ15] should be either VIL or VIH, to minimize current

draw.

E SMART 3 ADVANCED BOOT BLOCK

19

PRELIMINARY

Table 7. Status Register Bit Definition

WSMS ESS ES PS VPPS PSS BLS R

76543210

NOTES:

SR.7 = WRITE STATE MACHINE STATUS (WSMS)

1 = Ready

0 = Busy

Check Write State Machine bit first to determine

word program or block erase completion, before

checking program or erase status bits.

SR.6 = ERASE-SUSPEND STATUS (ESS)

1 = Erase Suspended

0 = Erase In Progress/Completed

When erase suspend is issued, WSM halts

execution and sets both WSMS and ESS bits to “1.”

ESS bit remains set at “1” until an Erase Resume

command is issued.

SR.5 = ERASE STATUS (ES)

1 = Error In Block Erasure

0 = Successful Block Erase

When this bit is set to “1,” WSM has applied the

max. number of erase pulses to the block and is still

unable to verify successful block erasure.

SR.4 = PROGRAM STATUS (PS)

1 = Error in Word Program

0 = Successful Word Program

When this bit is set to “1,” WSM has attempted but

failed to program a word.

SR.3 = VPP STATUS (VPPS)

1 = V

PP

Low Detect, Operation Abort

0 = V

PP

OK

The V

PP

status bit does not provide continuous

indication of V

PP

level. The WSM interrogates V

PP

level only after the Program or Erase command

sequences have been entered, and informs the

system if V

PP

has not been switched on. The VPP is

also checked before the operation is verified by the

WSM. The V

PP

status bit is not guaranteed to report

accurate feedback between V

PPLK

max and V

PP1

min

or between V

PP1

max and V

PP4

min.

SR.2 = PROGRAM SUSPEND STATUS (PSS)

1 = Program Suspended

0 = Program in Progress/Completed

When program suspend is issued, WSM halts

execution and sets both WSMS and PSS bits to “1.”

PSS bit remains set to “1” until a Program Resume

command is issued.

SR.1 = Block Lock Status

1 = Program/Erase attempted on locked

block; Operation aborted

0 = No operation to locked blocks

If a program or erase operation is attempted to one

of the locked blocks, this bit is set by the WSM. The

operation specified is aborted and the device is

returned to read status mode.

SR.0 = RESERVED FOR FUTURE

ENHANCEMENTS (R)

This bit is reserved for future use and should be

masked out when polling the status register.

SMART 3 ADVANCED BOOT BLOCK E

20

PRELIMINARY

3.3 Block Locking

The Smart 3 Advanced Boot Block flash memory

architecture features two hardware-lockable

parameter blocks.

3.3.1 WP# = V

IL

FOR BLOCK LOCKING

The lockable blocks are locked when WP# = V

IL

;

any program or erase operation to a locked bloc k

will result in an error, which will be reflected in the

status register. For top configuration, the top two

parameter blocks (blocks #69 and #70, blocks #37

and #38 for the 16-Mbit, blocks #21 and #22 for the

8-Mbit, blocks #13 and #14 for the 4-Mbit) are

lockable. For the bottom c onfiguration, the bottom

two parameter blocks (blocks #0 and #1 for 4-/8-/

16-/32-Mbit) are lockable. Unlocked blocks can be

programmed or erased normally (unless V

PP

is

below V

PPLK

).

3.3.2 WP# = V

IH

FOR BLOCK UNLOCKING

WP# = V

IH

unlocks all lockable blocks.

These blocks can now be programmed or erased.

Note that RP# does not override WP# locking as in

previous Boot Block devices. WP# cont rol s all block

locking and V

PP

provides protection against

spurious writes. Table 8 defi nes the writ e protec tion

methods.

Table 8. Write Protection Truth Table for

Advanced Boot Block Flash Memory Family

V

PP

WP# RP# Write Protection

Provided

XXVILAll Blocks Locked

V

IL

XVIHAll Blocks Locked

≥ V

PPLKVIL

V

IH

Lockable Blocks

Locked

≥ V

PPLKVIH

V

IH

All Blocks Unlocked

3.4 VPP Program and Erase

Voltages

Intel’s Smart 3 products provide in-system

programming and erase at 2.7 V. For customers

requiring fast programming in their manufacturing

environment, Smart 3 includes an additional lowcost 12 V programming feature.

The 12 V V

PP

mode enhances programming

performance during the short period of t i me typically

found in manufacturing processes; however, it is

not intended for extended use. 12 V may be applied

to V

PP

during program and erase operations for a

maximum of 1000 cycles on the main blocks and

2500 cycles on the parameter blocks. V

PP

may be

connected to 12 V for a total of 80 hours max imum.

Stressing the device beyond these limits may cause

permanent damage.

During read operations or idle times, V

PP

may be

tied to a 5 V supply. For program and erase

operations, a 5 V s upply is not permitted. The V

PP

must be supplied with either 2. 7 V–3.6 V or 11.4 V–

12.6 V during program and erase operations.

3.4.1 V

PP

= VIL FOR COMPLETE

PROTECTION

The V

PP

programming voltage can be held low for

complete write protection of all blocks in the flash

device. When V

PP

is below V

PPLK

, any program or

erase operation will result in a error, prompting the

corresponding status register bit (SR.3) to be set.

3.5 Power Consumption

Intel® Flash devices have a tiered approach to

power savings that can significantly reduce ov erall

system power consumption. The Automatic Power

Savings (APS) feature reduces power consumption

when the device is select ed but idle. If the CE# is

deasserted, the flash enters its standby mode,

where current consumption is even lower. The

combination of these features can minimize

memory power consumption, and therefore, overall

system power consumption.

E SMART 3 ADVANCED BOOT BLOCK

21

PRELIMINARY

3.5.1 ACTIVE POWER

With CE# at a logic

-

low level and RP# at a logic

-

high level, the device is in the ac ti ve mode. Refer t o

the DC Characteristic t ables for I

CC

current values.

Active power is the largest contributor to overall

system power consumption. Minimizing the active

current could have a profound effect on system

power consumption, especial ly for battery

-

operated

devices.

3.5.2 AUTOMATIC POWER SAVINGS (APS)

Automatic Power Savings provides low

-

power

operation during read mode. After data is read from

the memory array and the address lines are

quiescent, APS circuitry places the device in a

mode where typical current is comparable t o I

CCS

.,

The flash stays in thi s st atic s tate wit h outputs valid

until a new location is read.

3.5.3 STANDBY POWER

With CE# at a logic

-

high level (VIH) and device in

read mode, the flash memory is in standby mode,

which disables much of the device’s circuitry and

substantially reduces power consumption. Outputs

are placed in a high

-

impedance state independent

of the status of the OE# signal. If CE# trans itions t o

a logic

-

high level during erase or program

operations, the device will continue to perform the

operation and consume corresponding act iv e power

until the operation is completed.

System engineers should anal yz e the breakdown of

standby time versus active time and quantify the

respective power consumption in each mode for

their specific application. This will provide a more

accurate measure of applicat ion

-

specific power and

energy requirements.

3.5.4 DEEP POWER-DOWN MODE

The deep power-down mode is activated when RP#

= V

IL

(GND ± 0.2 V). During read modes, RP#

going low de-selects the memory and places the

outputs in a high impedance s tate. Recovery from

deep power-down requires a minimum time of t

PHQV

(see

AC Characteristics—Read Operations

).

During program or erase modes, RP# transi tioning

low will abort the in-progress operation. The

memory contents of the address being program med

or the block being erased are no longer valid as the

data integrity has been comprom ised by the abort.

During deep power-down, all internal circuits are

switched to a low power savings mode (RP#

transitioning to V

IL

or turning off power to the devic e

clears the status register).

3.6 Power-Up/Down Operation

The device is protected against accidental block

erasure or programming during power transitions.

Power supply sequencing is not required, since the

device is indifferent as to which power supply , V

PP

or VCC, powers-up first.

3.6.1 RP# CONNECTED TO SYSTEM

RESET

The use of RP# during system reset is important

with automated program/erase devices since the

system expects to read from the flash memory

when it comes out of reset . If a CPU reset occurs

without a flash memory reset, proper CPU

initialization will not occur because the flash

memory may be providing status information

instead of array data. Int el recommends c onnecting

RP# to the system CPU RESET# signal to allow

proper CPU/flash initialization following system

reset.

System designers must guard against spurious

writes when V

CC

voltages are above V

LKO

. Since

both WE# and CE# must be low for a command

write, driving either signal to V

IH

will inhibit writ es to

the device. The CUI architecture prov ides addi tional

protection since alterat ion of memory contents c an

only occur after success ful completion of the twostep command sequences. The device is also

disabled until RP# is brought to V

IH

, regardless of

the state of its c ontrol inputs. By holding t he device

in reset (RP# connected to system PowerGood)

during power-up/down, invalid bus conditions during

power-up can be masked, providing yet another

level of memory protection.

3.6.2 V

CC

, VPP AND RP# TRANSITIONS

The CUI latches commands as issued by system

software and is not altered by V

PP

or CE#

transitions or WSM actions. Its default state upon

power-up, after exit from reset mode or after V

CC

transitions above V

LKO

(Lockout voltage), is read

array mode.

SMART 3 ADVANCED BOOT BLOCK E

22

PRELIMINARY

After any program or block erase operation is

complete (even after V

PP

transitions down to

V

PPLK

), the CUI must be reset t o read array mode

via the Read Array command if access to the fl ash

memory array is desired.

3.7 Power Supply Decoupling

Flash memory’s power switching characteristics

require careful device decoupling. System

designers should consider three supply current

issues:

1. Standby current levels (I

CCS

)

2. Read current levels (I

CCR

)

3. Transient peaks produced by falling and rising

edges of CE#.

Transient current magnitudes depend on t he devic e

outputs’ capacitiv e and inductive loading. Two-line

control and proper decoupling capacitor selection

will suppress these transient voltage peaks. Each

flash device should have a 0.1 µF ceramic

capacitor connected between eac h V

CC

and GND,

and between its V

PP

and GND. These highfrequency, inherently low-inductance capacitors

should be placed as close as possible to the

package leads.

E SMART 3 ADVANCED BOOT BLOCK

23

PRELIMINARY

4.0 ELECTRICAL SPECIFICATIONS

4.1 Absolute Maximum Ratings*

Extended Operating Temperature

During Read.......................... –40 °C to +85 °C

During Block Erase

and Program.......................... –40 °C to +85 °C

Temperature Under Bias ....... –40 °C to +85 °C

Storage Temperature................. –65 °C to +125 °C

Voltage on Any Pin

(except V

CC

, V

CCQ

and VPP)

with Respect to GND............. –0.5 V to 3.7 V

(1)

VPP Voltage (for Block

Erase and Program)

with Respect to GND.....–0.5 V to +13.5 V

(1,2,4)

VCC and V

CCQ

Supply Voltage

with Respect to GND........... –0.2 V to +3.7 V

(5)

Output Short Circuit Current.....................100 mA

(3)

NOTICE: This datasheet contains preliminary information on

new products in production. Do not finalize a desi gn with

this information. Revised information will be published when

the product is available. Verify with your local Intel Sales

office that you have the latest datasheet before finalizing a

design.

* WARNING: Stressing the device beyond the "Absolute

Maximum Ratings" may cause permanent damage. These

are stress ratings only. Operation beyond the "Operating

Conditions" is not recommended and extended exposure

beyond the "Operating Conditions" may effect device

reliability.

NOTES:

1. Minimum DC voltage is –0.5 V on input/output pins, with allowable undershoot to –2.0 V for periods < 20 ns. Maximum DC

voltage on input/output pins is V

CC

+ 0.5 V, with allowable overshoot to VCC + 1.5 V for periods < 20 ns.

2. Maximum DC voltage on V

PP

may overshoot to +14.0 V for periods < 20 ns.

3. Output shorted for no more than one second. No more than one output shorted at a time.

4. V

PP

Program voltage is normally 2.7 V–3.6 V.

5. Minimum DC voltage is –0.5 V on V

CC

and V

CCQ

, with allowable undershoot to –2.0 V for periods < 20 ns. Maximum DC

voltage on V

CC

and V

CCQ

pins is VCC + 0.5 V, with allowable overshoot to VCC + 1.5 V for periods < 20 ns.

SMART 3 ADVANCED BOOT BLOCK E

24

PRELIMINARY

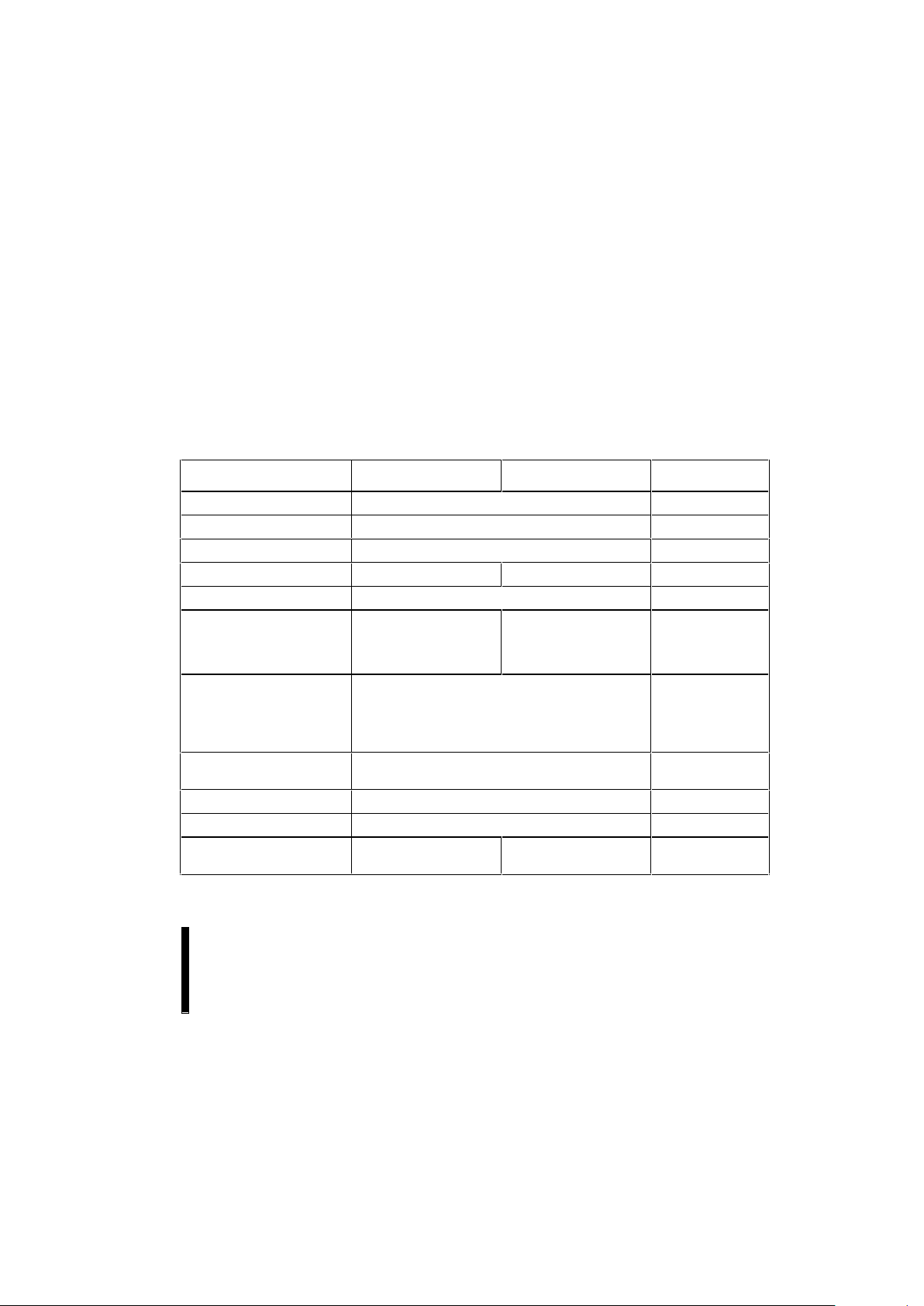

4.2 Operating Conditions

Symbol Parameter Notes Min Max Units

T

A

Operating Temperature –40 +85 °C

V

CC1

VCC Supply Voltage 1 2.7 3.6 Volts

V

CC2

2.7 2.85

V

CC3

2.7 3.3

V

CCQ1

I/O Supply Voltage 1 2.7 3.6 Volts

V

CCQ2

1.65 2.5

V

CCQ3

1.8 2.5

V

PP1

Program and Erase Voltage 1 2.7 3.6 Volts

V

PP2

2.7 2.85

V

PP3

2.7 3.3

V

PP4

2, 3 11.4 12.6

Cycling Block Erase Cycling 3 100,000 Cycles

NOTES:

1. V

CC1

, V

CCQ1

, and V

PP3

must share the same supply when all three are between 2.7 V and 3.6 V.

2. During read operations or idle time, 5 V may be applied to V

PP

indefinitely. VPP must be at valid levels for program and

erase operations

3. Applying V

PP

= 11.4 V–12.6 V during a program/erase can only be done for a maximum of 1000 cycles on the main blocks

and 2500 cycles on the parameter blocks. V

PP

may be connected to 12 V for a total of 80 hours maximum. See Section 3.4

for details.

4.3 Capacitance

TA = 25 °C, f = 1 MHz

Sym Parameter Notes Typ Max Units Conditions

C

IN

Input Capacitance 1 6 8 pF VIN = 0 V

C

OUT

Output Capacitance 1 10 12 pF V

OUT

= 0 V

NOTE:

1. Sampled, not 100% tested.

E SMART 3 ADVANCED BOOT BLOCK

25

PRELIMINARY

4.4 DC Characteristics

(1)

V

CC

2.7 V–3.6 V 2.7 V–2.85 V 2.7 V–3.3 V

V

CCQ

2.7 V–3.6 V 1.65 V–2.5 V 1.8 V–2.5 V

Sym Parameter Note Typ Max Typ Max Typ Max Unit Test Conditions

I

LI

Input Load Current 6 ± 1 ± 1 ± 1 µA VCC = VCCMax

V

CCQ

= V

CCQ

Max

V

IN

= V

CCQ

or GND

I

LO

Output Leakage

Current

6 ± 10 ± 10 ± 10 µA VCC = VCCMax

V

CCQ

= V

CCQ

Max

V

IN

= V

CCQ

or GND

I

CCSVCC

Standby Current 6 18 35 20 50 150 250 µA VCC = VCCMax

CE# = RP# = V

CC

or during Program/

Erase Suspend

I

CCDVCC

Power-Down

Current

6 7 20 7 20 7 20 µA VCC = VCCMax

V

CCQ

= V

CCQ

Max

V

IN

= V

CCQ

or GND

RP# = GND ± 0.2 V

I

CCRVCC

Read Current 4,6 10 18 8 15 9 15 mA VCC = VCCMax

V

CCQ

= V

CCQ

Max

OE# = V

IH

, CE# =V

IL

f = 5 MHz, I

OUT

=0mA

Inputs = V

IL

or V

IH

I

PPDVPP

Deep Power-

Down Current

0.2 5 0.2 5 0.2 5 µA RP# = GND ± 0.2 V

V

PP

≤ V

CC

I

PPRVPP

Read Current 2 ±15 2 ±15 2 ±15 µA V

PP

≤ V

CC

3 50 200 50 200 50 200 µA V

PP

> V

CC

I

CCW+

I

PPW

VCC + VPP Program

Current

3,6 18 55 18 55 18 55 mA VPP =V

PP1, 2, 3

Program in Progress

10 30 10 30 10 30 mA V

PP

= V

PP4

Program in Progress

I

CCE

+

I

PPE

VCC + VPP Erase

Current

3,6 20 45 21 45 21 45 mA VPP = V

PP1, 2, 3

Program in Progress

16 45 16 45 16 45 mA V

PP

= V

PP4

Program in Progress

I

PPES

I

PPWS

VPP Erase Suspend

Current

3 50 200 50 200 50 200 µA VPP = V

PP1, 2, 3, 4

Program or Erase

Suspend in Progress

SMART 3 ADVANCED BOOT BLOCK E

26

PRELIMINARY

4.4 DC Characteristics (Continued)

V

CC

2.7 V–3.6 V 2.7 V–2.85 V 2.7 V–3.3 V

V

CCQ

2.7 V–3.6 V 1.65 V–2.5 V 1.8 V–2.5 V

Sym Parameter Note Min Max Min Max Min Max Unit Test Conditions

V

IL

Input Low Voltage –0.4 0.4 –0.2 0.2 –0.2 0.2 V

V

IH

Input High Voltage

V

CCQ

–0.4V

V

CCQ

–0.2V

V

CCQ

–0.2V

V

V

OL

Output Low

Voltage

0.10 -0.10 0.10 -0.10 0.10 V VCC = VCCMin

V

CCQ

= V

CCQ

Min

I

OL

= 100 µA

V

OH

Output High

Voltage

V

CCQ

–0.1V

V

CCQ

–0.1V

V

CCQ

–0.1V

VV

CC

= VCCMin

V

CCQ

= V

CCQ

Min

I

OH

= –100 µA

V

PPLKVPP

Lock-Out

Voltage

2 1.5 1.5 1.5 V Complete Write

Protection

V

PP1VPP

during 2 2.7 3.6 V

V

PP2

Program and 2 2.7 2.85 V

V

PP3

Erase Operations 2 2.7 3.3 V

V

PP4

2,5 11.4 12.6 11.4 12.6 11.4 12.6 V

V

LKOVCC

Prog/Erase

Lock Voltage

1.5 1.5 1.5 V

V

LKO2VCCQ

Prog/Erase

Lock Voltage

1.2 1.2 1.2 V

NOTES:

1. All currents are in RMS unless otherwise noted. Typical values at nominal V

CC

, TA = +25 °C.

2. Erase and program are inhibited when V

PP

< V

PPLK

and not guaranteed outside the valid VPP ranges of V

PP1

, V

PP2, VPP3

and V

PP4.

For read operations or during idle time, a 5 V supply may be applied to VPP indefinitely. However, VPP must be at

valid levels for program and erase operations.

3. Sampled, not 100% tested.

4. Automatic Power Savings (APS) reduces I

CCR

to approximately standby levels in static operation.

5. Applying V

PP

= 11.4 V–12.6 V during program/erase can only be done for a maximum of 1000 cycles on the main blocks

and 2500 cycles on the parameter blocks. V

PP

may be connected to 12 V for a total of 80 hours maximum. See Section 3.4

for details. For read operations or during idle time, a 5 V supply may be applied to V

PP

indefinitely. However, VPP must be

at valid levels for program and erase operations.

6. Since each column lists specifications for a different V

CC

and VCCQ voltage range combination, the test conditions VCCMax,

V

CCQ

Max, VCCMin, and V

CCQ

Min refer to the maximum or minimum VCC or V

CCQ

voltage listed at the top of each column.

E SMART 3 ADVANCED BOOT BLOCK

27

PRELIMINARY

TEST POINTSINPUT

OUTPUT

V

CCQ

0.0

V

CCQ

2

V

CCQ

2

0580_05

NOTE:

AC test inputs are driven at V

CCQ

for a logic “1” and 0.0V for a logic “0.” Input timing begins, and output timing ends, at V

CCQ

/2.

Input rise and fall times (10%–90%) <10 ns. Worst case speed conditions are when V

CCQ

= V

CCQ

Min.

Figure 5. Input Range and Measurement Points

C

L

Out

V

CCQ

Device

under

Test

R

1

R

2

0580_06

NOTE:

See table for component values.

Figure 6. Test Configuration

Test Configuration Component Values for Worst

Case Speed Conditions

Test Configuration C

L

(pF) R1 (Ω)R2 (Ω)

V

CCQ1

Standard Test 50 25 K 25 K

V

CCQ2

Standard Test 50 16.7 K 16.7 K

NOTE:

C

L

includes jig capacitance.

SMART 3 ADVANCED BOOT BLOCK E

28

PRELIMINARY

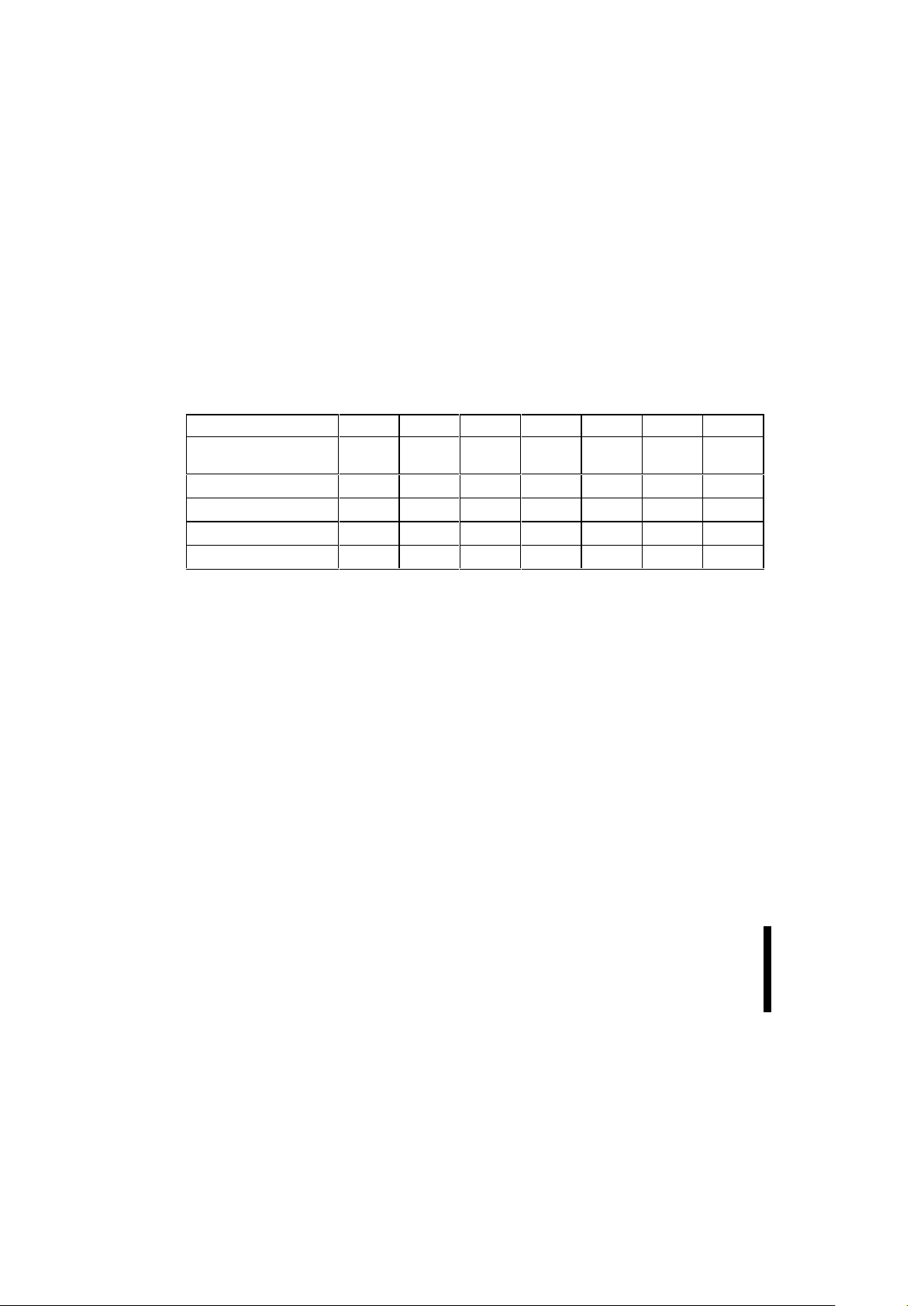

4.5 AC Characteristics —Read Operations

(1)

Product 3.0 V–3.6 V 80 ns 100 ns

2.7 V–3.6 V 90 ns 110 ns

# Sym Parameter Note Min Max Min Max Min Max Min Max Unit

R1 t

AVAV

Read Cycle Time 80 90 100 110 ns

R2 t

AVQV

Address to

Output Delay

80 90 100 110 ns

R3 t

ELQV

CE# to Output

Delay

2 80 90 100 110 ns

R4 t

GLQV

OE# to Output

Delay

2 30303030ns

R5 t

PHQV

RP# to Output

Delay

600 600 600 600 ns

R6 t

ELQX

CE# to Output in

Low Z

30000ns

R7 t

GLQX

OE# to Output in

Low Z

30000ns

R8 t

EHQZ

CE# to Output in

High Z

3 25252525ns

R9 t

GHQZ

OE# to Output in

High Z

3 25252525ns

R10 t

OH

Output Hold from

Address, CE#, or

OE# Change,

Whichever

Occurs First

30000ns

NOTES:

1. See

AC Waveform: Read Operations

.

2. OE# may be delayed up to t

ELQV–tGLQV

after the falling edge of CE# without impact on t

ELQV

.

3. Sampled, but not 100% tested.

E SMART 3 ADVANCED BOOT BLOCK

29

PRELIMINARY

Address Stable

Device and

Address Selection

IH

V

IL

V

ADDRESSES (A)

IH

V

IL

V

IH

V

IL

V

IH

V

IL

V

CE# (E)

OE# (G)

WE# (W)

DATA (D/Q)

IH

V

IL

V

RP#(P)

OL

V

OH

V

High Z

Valid Output

Data

Valid Standby

High Z

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

0580_07

Figure 7. AC Waveform: Read Operations

SMART 3 ADVANCED BOOT BLOCK E

30

PRELIMINARY

4.6 AC Characteristics —Write Operations

(1)

Product 3.0 V – 3.6 V 80 100

2.7 V – 3.6 V 90 110

# Symbol Parameter Note Min Min Min Min Unit

W1

t

PHWL

/

t

PHEL

RP# High Recovery to WE#

(CE#) Going Low

600 600 600 600 ns

W2

t

ELWL

/

t

WLEL

CE# (WE#) Setup to WE#

(CE#) Going Low

0000ns

W3

t

ELEH

/