Intel Corporation G28F016S3-150, G28F016S3-120, G28F008S3-150, G28F008S3-120 Datasheet

E

PRELIMINARY

December 1997

Order Number: 290598-004

n

SmartVoltage Technology

Smart 3 Flash: 2.7 V or 3.3 V V

CC

and 2.7 V, 3.3 V or 12 V V

PP

n

High-Performance

120 ns Read Access Time

n

Enhanced Data Protection Features

Absolute Protection with V

PP

= GND

Flexible Block Locking

Block Write Lockout during Power

Transitions

n

Enhanced Automated Suspend Options

Program Suspend to Read

Block Erase Suspend to Program

Block Erase Suspend to Read

n

Industry-Standard Packaging

40-Lead TSOP, 44-Lead PSOP

and 40 Bump µBGA* CSP

n

High-Density 64-Kbyte Symmetrical

Erase Block Architecture

4 Mbit: Eight Blocks

8 Mbit: Sixteen Blocks

16 Mbit: Thirty-Two Blocks

n

Extended Cycling Capability

100,000 Block Erase Cycles

n

Low Power Management

Deep Power-Down Mode

Automatic Power Savings Mode

Decreases I

CC

in Static Mode

n

Automated Program and Block Erase

Command User Interface

Status Register

n

SRAM-Compatible Write Interface

n

ETOX™ V Nonvolatile Flash

Technology

Intel’s byte-wide Smart 3 FlashFile™ memory family renders a variety of density offerings in the same

package. The 4-, 8-, and 16-Mbit byte-wide FlashFile memories provide high-density, low-cost, nonv olatile,

read/write storage solutions for a wide range of applications. Their symmetrically-blocked architecture, fl exible

voltage, and extended cyc ling provide highly flexible components s uitable for resident flash arrays , SIMMs,

and memory cards. Enhanced suspend capabilities provide an ideal solution for code or data storage

applications. For secure code storage applications, such as networking, where code is either directly

executed out of flash or downloaded t o DRAM, the 4-, 8-, and 16-Mbit FlashFile mem ories offer three lev els

of protection: absolute protection with V

PP

at GND, selective hardware block locking, or flexible software

block locking. These alternatives give designers ultimate control of their code security needs.

This family of products is manufactured on Intel’s 0.4 µm ETOX™ V process technology. They come in

industry-standard packages: the 40-lead TSOP, ideal for board-constrained applications, and the rugged

44-lead PSOP. Based on the 28F008SA architecture, the byte-wide Smart 3 FlashFile memory family

enables quick and easy upgrades for designs that demand state-of-the-art technology.

BYTE-WIDE

SMART 3 FlashFile™ MEMORY FAMILY

4, 8, AND 16 MBIT

28F004S3, 28F008S3, 28F016S3

Includes Commercial and Extended Temperature Specifications

Information in this document is provided in connection with Intel products. No license, express or implied, by estoppel or

otherwise, to any intellectual property rights is granted by this document. Except as provi ded in Intel ’s Terms and Condi tions of

Sale for such products, Intel assumes no liability whatsoever, and Intel disclaims any express or implied warranty, relating to

sale and/or use of Intel products including liability or warranties relating to fitness for a particular purpose, merchantability, or

infringement of any patent, copyright or other intellectual property right. Intel products are not intended for use in medical, life

saving, or life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

The 28F004S3, 28F008S3, 28F016S 3 may contain design defects or errors known as errata which may cause the product to

deviate from published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an ordering number and are referenced in this document, or other Intel literature, may be

obtained from:

Intel Corporation

P.O. Box 5937

Denver, CO 80217-9808

or call 1-800-548-4725

or visit Intel’s Website at http:\\www.intel.com

COPYRIGHT © INTEL CORPORATION, 1997 CG-041493

*Third-party brands and names are the property of their respective owners.

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

3

PRELIMINARY

CONTENTS

PAGE PAGE

1.0 INTRODUCTION .............................................5

1.1 New Features...............................................5

1.2 Product Overview.........................................5

1.3 Pinout and Pin Description...........................6

2.0 PRINCIPLES OF OPERATION .....................11

2.1 Data Protection ..........................................12

3.0 BUS OPERATION.........................................12

3.1 Read..........................................................12

3.2 Output Disable...........................................12

3.3 Standby......................................................12

3.4 Deep Power-Down.....................................12

3.5 Read Identifier Codes Operation................13

3.6 Write ..........................................................13

4.0 COMMAND DEFINITIONS............................13

4.1 Read Array Command................................16

4.2 Read Identifier Codes Command...............16

4.3 Read Status Register Command................16

4.4 Clear Status Register Command................16

4.5 Block Erase Command ..............................16

4.6 Program Command....................................17

4.7 Block Erase Suspend Command................17

4.8 Program Suspend Command.....................18

4.9 Set Block and Master Lock-Bit Commands 18

4.10 Clear Block Lock-Bits Command..............19

5.0 DESIGN CONSIDERATIONS........................27

5.1 Three-Line Output Control..........................27

5.2 RY/BY# Hardware Detection......................27

5.3 Power Supply Decoupling..........................27

5.4 V

PP

Trace on Printed Circuit Boards...........27

5.5 V

CC

, VPP, RP# Transitions .........................27

5.6 Power-Up/Down Protection........................27

5.7 V

PP

Program and Erase Voltages on Sub-

0.4µ S3 Memory Family ............................28

6.0 ELECTRICAL SPECIFICATIONS..................29

6.1 Absolute Maximum Ratings........................29

6.2 Commercial Temperature Operating

Conditions.................................................29

6.3 Capacitance...............................................29

6.4 DC Characteristics— Commercial

Temperature..............................................30

6.5 AC Characteristics—Read-Only

Operations—Commercial Temperature.....34

6.6 AC Characteristics—Write Operations—

Commercial Temperature..........................36

6.7 Block Erase, Program, and Lock-Bit

Configuration Performance—Commercial

Temperature..............................................38

6.8 Extended Temperature Operating

Conditions.................................................39

6.9 DC Characteristics—Extended

Temperature..............................................39

6.10 AC Characteristics—Read-Only

Operations—Extended Temperature.........39

7.0 ORDERING INFORMATION..........................40

8.0 ADDITIONAL INFORMATION.......................40

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

4

PRELIMINARY

REVISION HISTORY

Number Description

-001 Original version

-002 Table 3 revised to reflect change in abbreviations from “W” for write to “P” for program.

Ordering information graphic (Appendix A) corrected: from PB = Ext. Temp. 44-Lead

PSOP to TB = Ext. Temp. 44-Lead PSOP

Updated Ordering Information and table

Correction to table, Section 6.2.3. Under I

LO

Test Conditions, previously read VIN = V

CC

or GND, corrected to V

OUT

= VCC or GND

Section 6.2.7, modified Program and Block Erase Suspend Latency Times

-003 Updated disclaimer

-004

Added 2.7 V V

PP

specifications.

Added µBGA* CSP pinouts and corrected error in PSOP pinout

Added Design Consideration for V

PP

Program and Erase Voltages on future sub-0.4µ

devices.

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

5

PRELIMINARY

1.0 INTRODUCTION

This datasheet contains 4-, 8-, and 16-Mbi t Smart 3

FlashFile memory specifications. Section 1.0

provides a flash memory overview. Sections 2.0,

3.0, 4.0, and 5.0 describe t he memory organiz ation

and functionality. Section 6.0 covers electrical

specifications for commercial and extended

temperature product offerings. Ordering inform ation

is provided in Section 7.0. Finally, the byte-wide

Smart 3 FlashFile memory family documentation

also includes application notes and design tools

which are referenced in Section 8.0.

1.1 New Features

The byte-wide Smart 3 FlashFile memory family

maintains backwards-compatibility with Intel’s

28F008SA-L. Key enhancements include:

• SmartVoltage Technology

• Enhanced Suspend Capabilities

• In-System Block Locking

They share a compatible status register, software

commands, and pinouts. Thes e similarities enable

a clean upgrade from the 28F008SA-L to byte-wide

Smart 3 FlashFile products. When upgrading, it i s

important to note the following differences:

• Because of new feature and density options,

the devices have different device identifier

codes. This allows for software optimization.

• V

PPLK

has been lowered from 6.5 V to 1.5 V to

support low V

PP

voltages during block erase,

program, and lock-bit confi guration operations.

Designs that switch V

PP

off during read

operations should transition V

PP

to GND.

• To take advantage of SmartVoltage technology, allow V

PP

connection to 3.3 V.

For more details see application note

AP-625,

28F008SC Compatibility with 28F008SA

(order

number 292180)

.

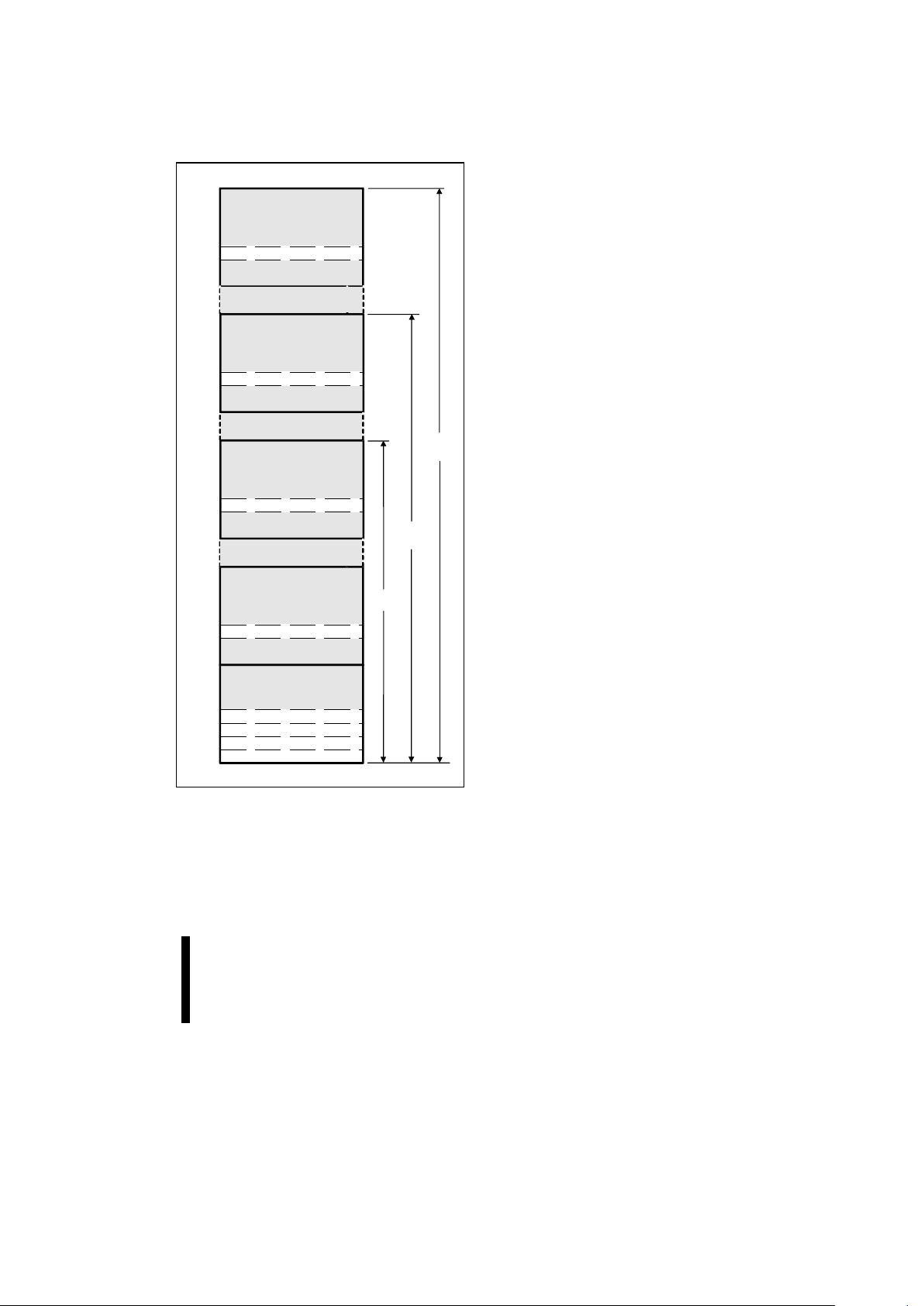

1.2 Product Overview

The byte-wide Smart 3 FlashFile memory family

provides density upgrades with pinout compatibility

for the 4-, 8-, and 16-Mbit densities. The 28F004S3,

28F008S3, and 28F016S3 are high-performance

memories arranged as 512 Kbyte, 1 Mbyte, and

2 Mbyte of eight bits. This data is grouped i n eight,

sixteen, and thirty-two 64-Kbyte blocks which are

individually erasable, lockable, and unlockable insystem. Figure 5 illustrates the memory

organization.

SmartVoltage technology enables fast factory

programming and low power designs. Specifically

designed for 3 V systems, Smart 3 FlashFile

components support read operations at 2.7 V and

3.3 V V

CC

and block erase and program operations

at 2.7 V, 3.3 V and 12 V V

PP

. The 12 V VPP option

renders the fastest program perf ormance which will

increase your factory t hroughput. With the 2.7 V or

3.3 V V

PP

option, VCC and VPP can be tied together

for a simple, low-power 2.7 V or 3 V design. In

addition to the voltage flexibility, the dedicated V

PP

pin gives complete data protection when VPP ≤

V

PPLK

.

Internal V

PP

detection circuitry automatically

configures the device f or optimiz ed block eras e and

program operations.

A Command User Interface (CUI) serves as the

interface between the system processor and

internal operation of the device. A valid c ommand

sequence written to the CUI initiates device

automation. An internal Wri te State Machine (WSM)

automatically executes the algorithms and timings

necessary for block erase, program, and lock-bit

configuration operations.

A block erase operation erases one of the device’s

64-Kbyte blocks typically within 1.1 second

(12 V V

PP

), independent of other blocks. Each block

can be independently erased 100,000 times

(1.6 million block erases per device). A block erase

suspend operation allows system software to

suspend block erase to read data from or program

data to any other block.

Data is programmed in byte increments typically

within 7.6 µs (12 V V

PP

). A program suspend

operation permits system software to read data or

execute code from any other flash memory array

location.

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

6

PRELIMINARY

To protect programmed data, each block can be

locked. This block locking mechanism uses a

combination of bits, block lock-bits and a master

lock-bit, to lock and unlock individual blocks. The

block lock-bits gate block erase and program

operations, while the master lock-bit gates block

lock-bit configuration operations. Lock-bit configuration operations (Set Bloc k Lock-Bit, Set M aster

Lock-Bit, and Clear Bloc k Loc k-Bit s c ommands) set

and clear lock-bits.

The status register and RY/BY# output indicate

whether or not the device is busy executing or

ready for a new command. Polling the status

register, system software retrieves WSM feedback.

The RY/BY# output gives an addi tional indicator of

WSM activity by provi ding a hardware st atus s ignal.

Like the status register, RY/BY#-low indicates that

the WSM is performing a bl ock erase, program, or

lock-bit configuration operation. RY/BY#-high

indicates that the WSM is ready for a new

command, block erase is suspended, program is

suspended, or the device is in deep power-down

mode.

The Automatic Power Savings (APS) feature

substantially reduces active current when the

device is in stati c mode (addresses not switching).

In APS mode, the typical I

CCR

current is 3 mA.

When CE# and RP# pins are at V

CC

, the

component enters a CMOS s tandby mode. Driving

RP# to GND enables a deep power-down mode

which significantly reduces power consumption,

provides write protection, resets the device, and

clears the status register. A reset time (t

PHQV

) is

required from RP# switching high until output s are

valid. Likewise, t he device has a wake time (t

PHEL

)

from RP#-high until writes to the CUI are

recognized.

1.3 Pinout and Pin Description

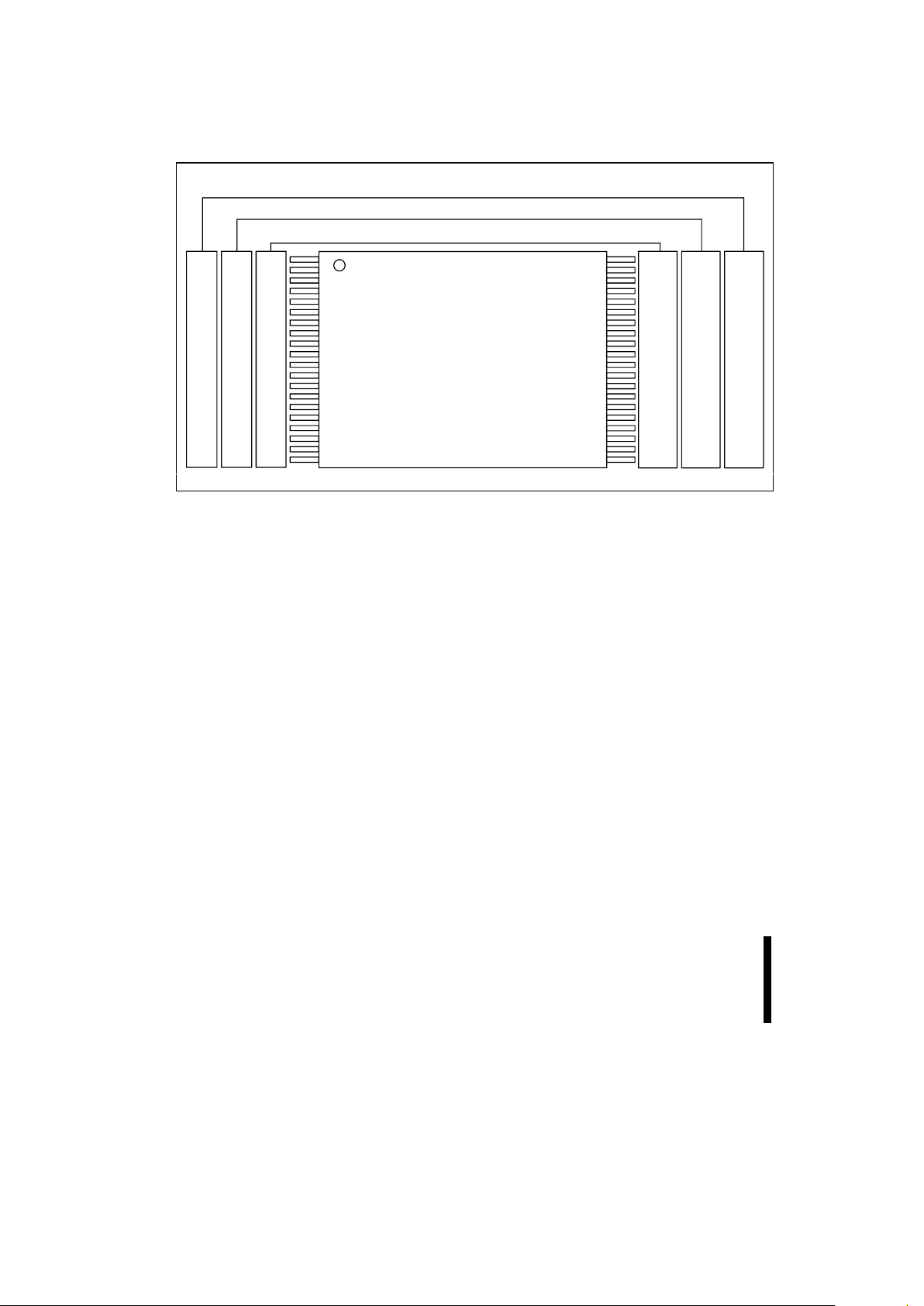

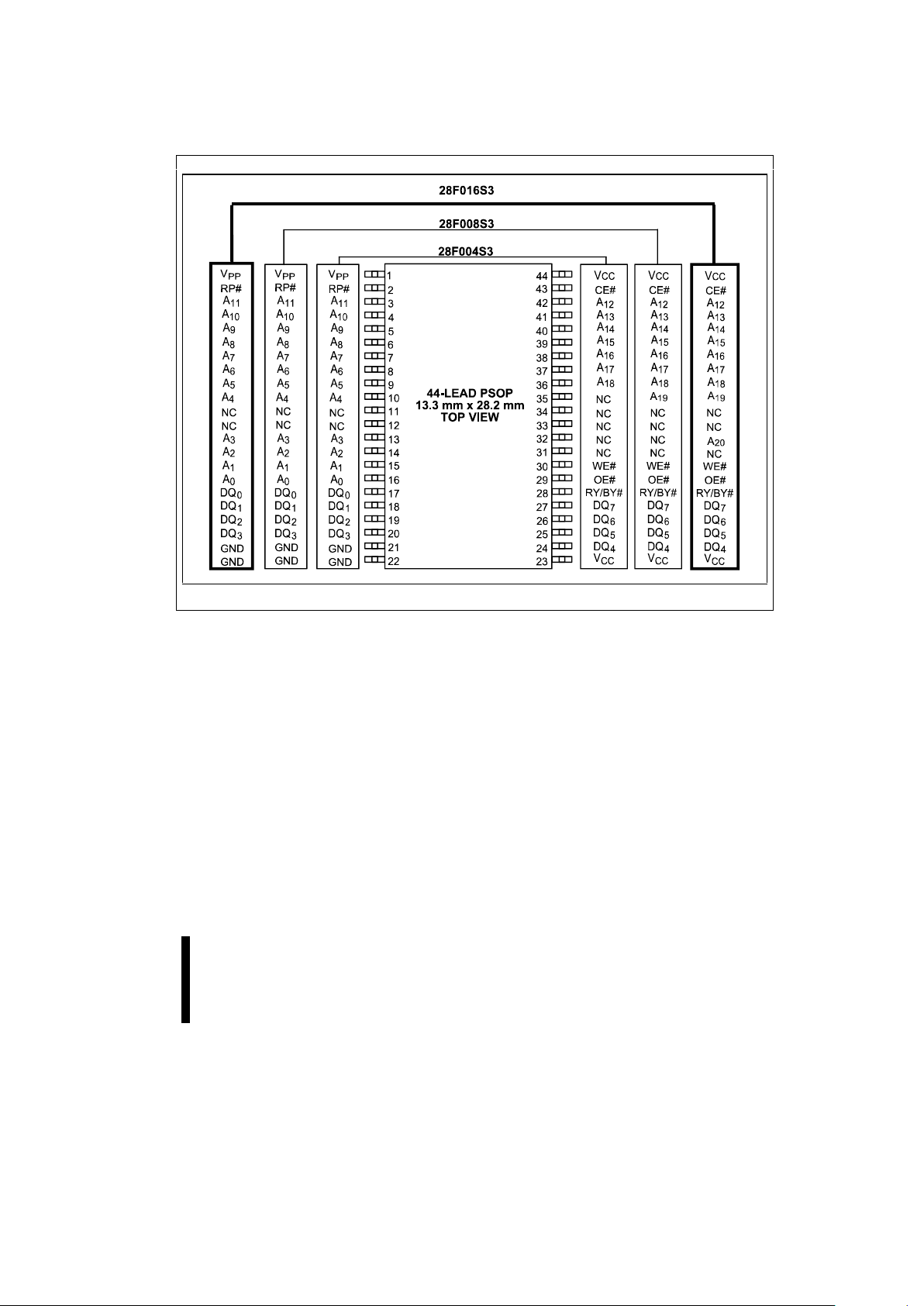

The family of devices is availabl e in 40-lead TSOP

(Thin Small Outline Package, 1.2 mm thick), 44lead PSOP (Plastic Sm all Out line P ack age) and 40bump µBGA* CSP (28F008S3 and 28F016S3 only).

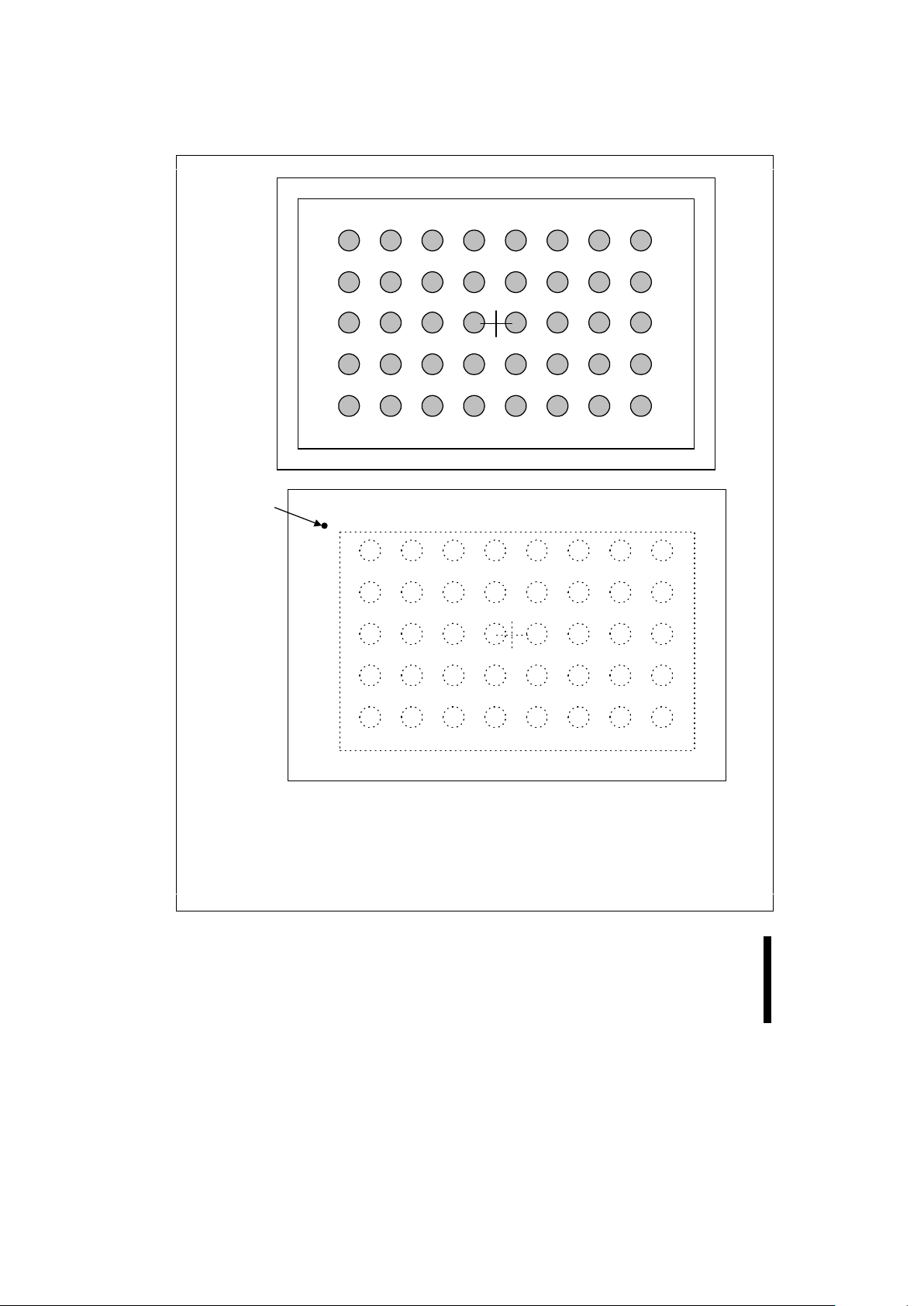

Pinouts are shown in Figures 2, 3 and 4.

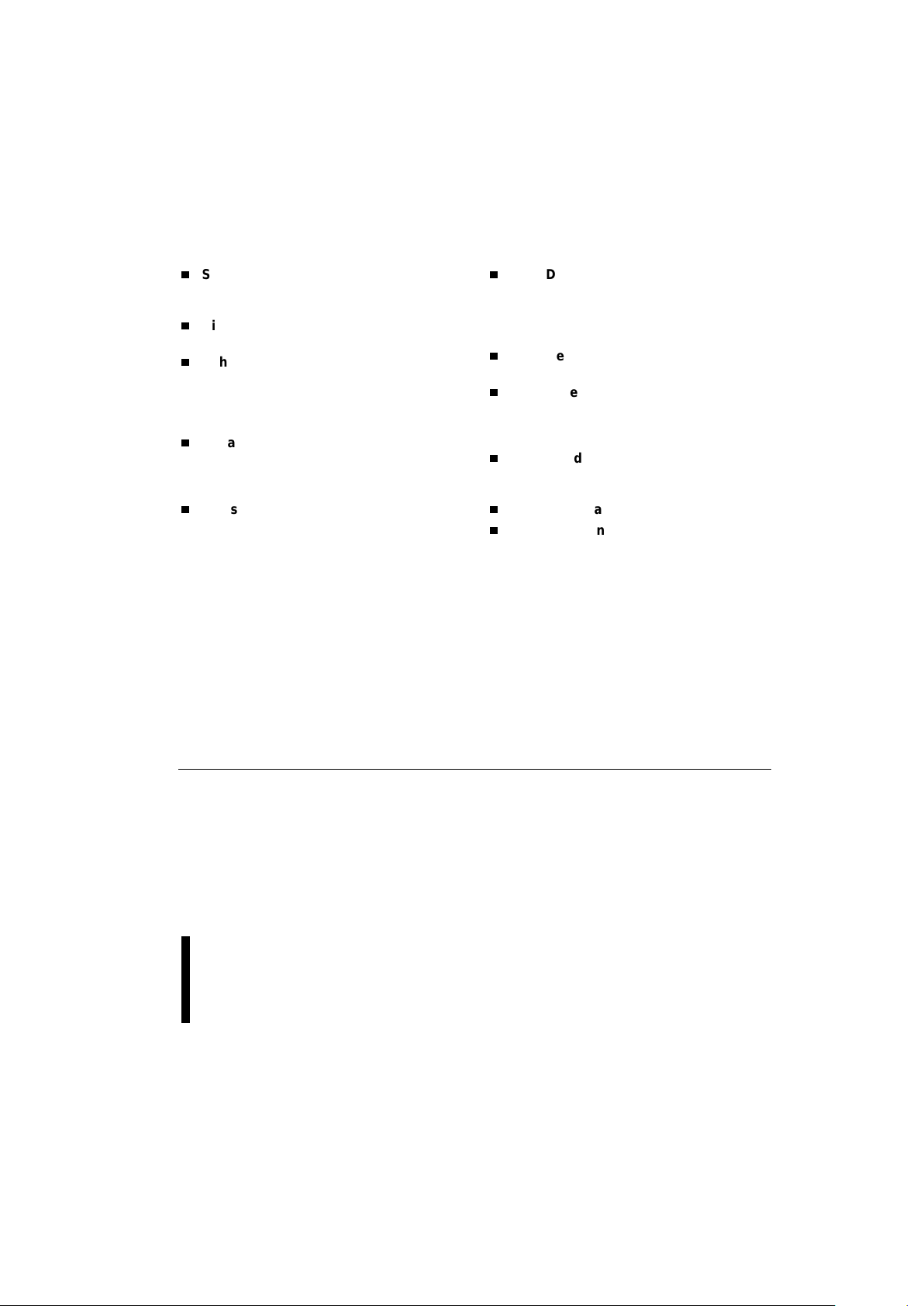

4-Mbit: A - A ,

8-Mbit: A - A ,

16-Mbit: A - A

0

18

0

19

020

Input

Buffer

Output

Buffer

Identifier

Register

Status

Register

Command

Register

I/O Logic

Data

Comparator

Input

Buffer

Address

Latch

Address

Counter

Y

Decoder

X

Decoder

Y Gating

4-Mbit: Eight

8-Mbit : S ixteen

16-Mbit: Thirty-Two

64-Kbyte Blocks

Write State

Machine

Program/Erase

Voltage Switch

CE#

WE#

OE#

RP#

RY/BY#

V

V

GND

DQ - DQ

PP

CC

V

CC

07

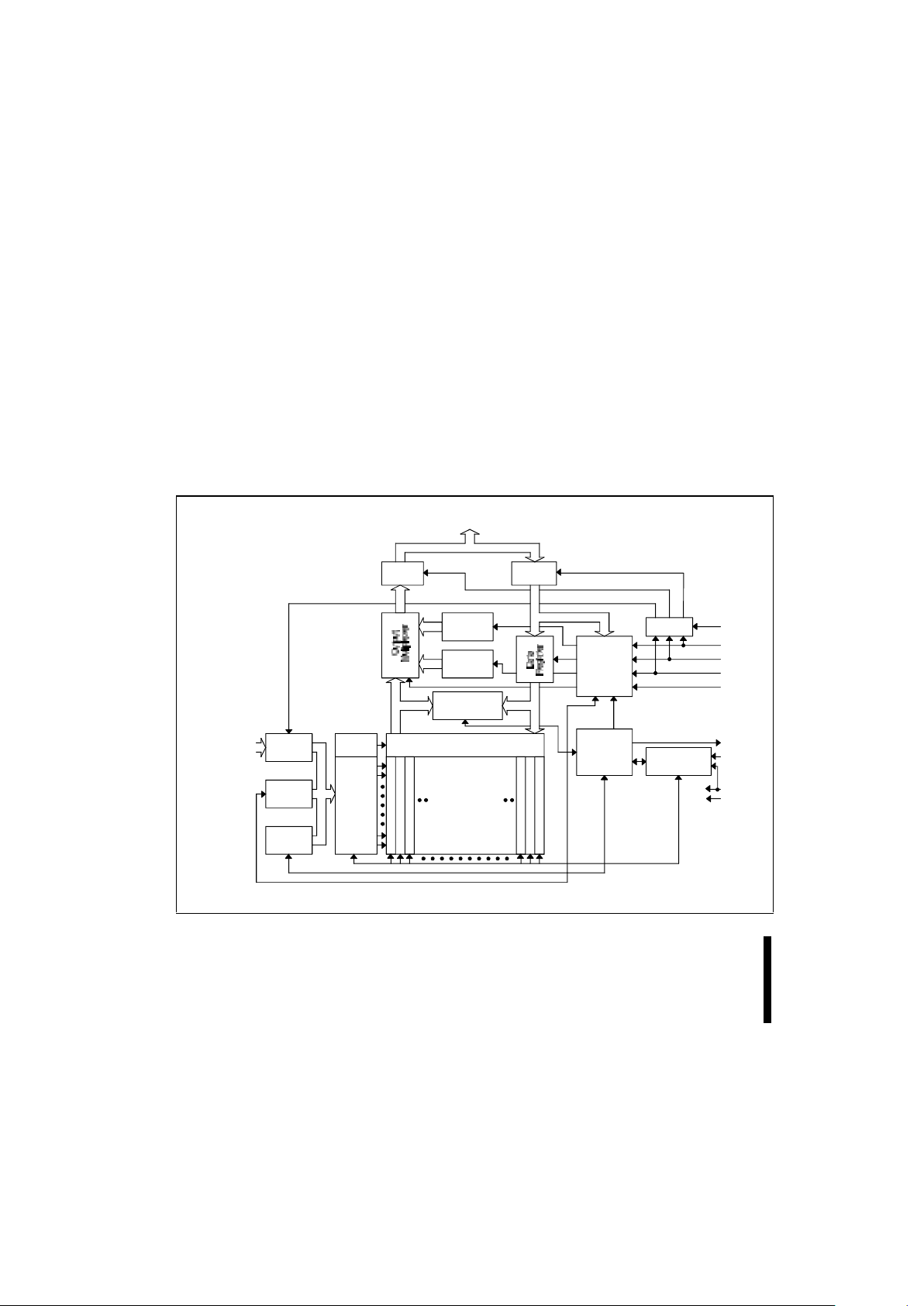

Figure 1. Block Diagram

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

7

PRELIMINARY

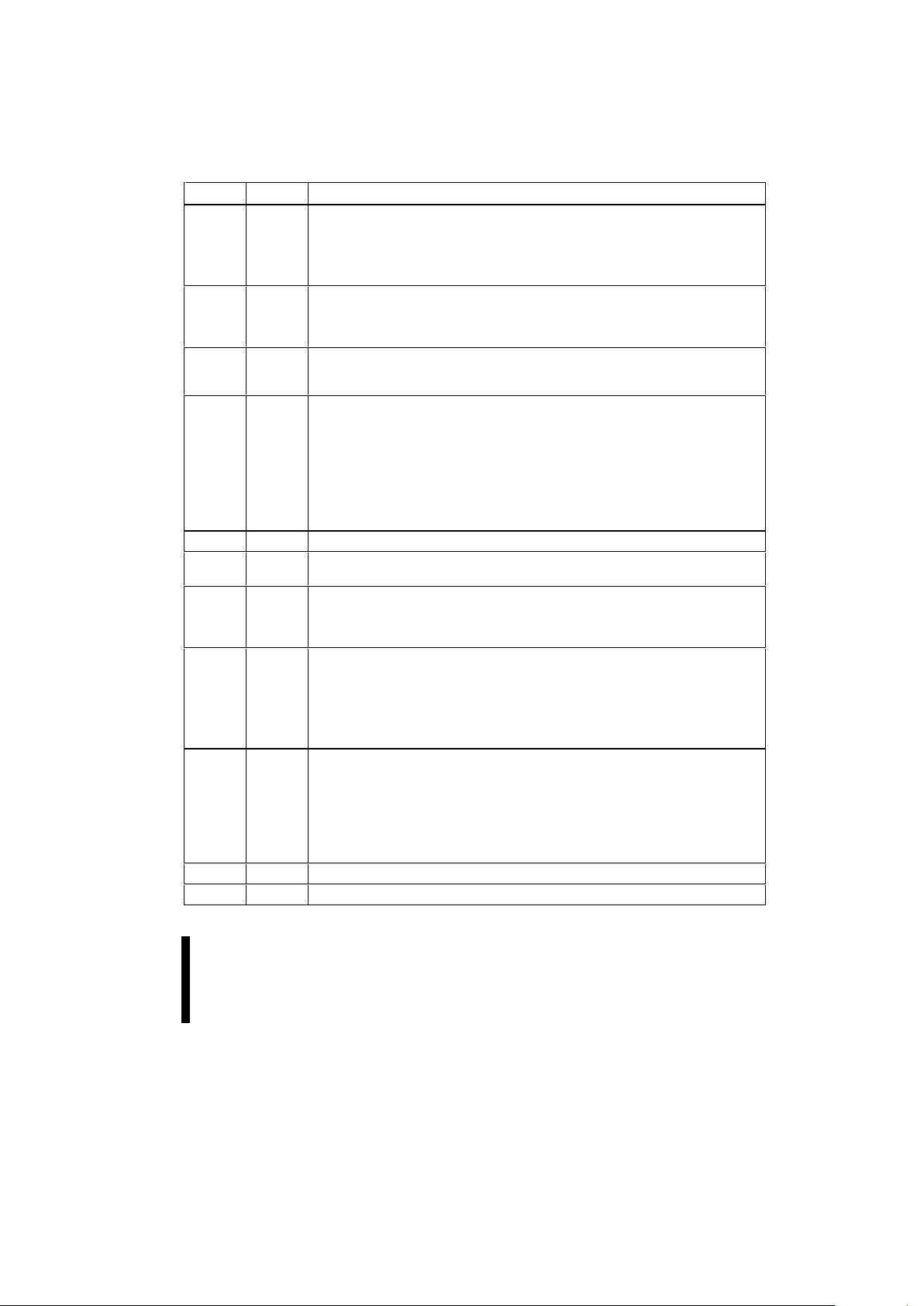

Table 1. Pin Descriptions

Sym Type Name and Function

A0–A

20

INPUT ADDRESS INPUTS: Inputs for addresses during read and write operations.

Addresses are internally latched during a write cycle.

4 Mbit → A

0

–A

8 Mbit → A0–A

16 Mbit → A0–A

20

DQ0–DQ7INPUT/

OUTPUT

DATA INPUT/OUTPUTS: Inputs data and commands during CUI write cycles;

outputs data during memory array, status register, and identifier code read cycles.

Data pins float to high-impedance when the chip is deselected or outputs are

disabled. Data is internally latched during a write cycle.

CE# INPUT CHIP ENABLE: Activates the device’s control logic, input buffers, decoders, and

sense amplifiers. CE#-high deselects the device and reduces power consumption to

standby levels.

RP# INPUT RESET/DEEP POWER-DOWN: When driven low, RP# inhibits write operations

which provides data protection during power transitions, puts the device in deep

power-down mode, and resets internal automation. RP#-high enables normal

operation. Exit from deep power-down sets the device to read array mode.

RP# at V

HH

enables setting of the master lock-bit and enables configuration of block

lock-bits when the master lock-bit is set. RP# = V

HH

overrides block lock-bits,

thereby enabling block erase and program operations to locked memory blocks.

Block erase, program, or lock-bit configuration with V

IH

< RP# < VHH produce

spurious results and should not be attempted.

OE# INPUT OUTPUT ENABLE: Gates the device’s outputs during a read cycle.

WE# INPUT WRITE ENABLE: Controls writes to the CUI and array blocks. Addresses and data

are latched on the rising edge of the WE# pulse.

RY/BY# OUTPUT READY/BUSY#: Indicates the status of the internal WSM. When low, the WSM is

performing an internal operation (block erase, program, or lock-bit). RY/BY#-high

indicates that the WSM is ready for new commands, block erase or program is

suspended, or the device is in deep power-down mode. RY/BY# is always active.

V

PP

SUPPLY BLOCK ERASE, PROGRAM, LOCK-BIT CONFIGURATION POWER SUPPLY:

For erasing array blocks, programming data, or configuring lock-bits.

Smart 3 Flash → 2.7 V, 3.3 V and 12 V V

PP

With VPP ≤ V

PPLK

, memory contents cannot be altered. Block erase, program, and

lock-bit configuration with an invalid V

PP

(see

DC Characteristics

) produce spurious

results and should not be attempted.

V

CC

SUPPLY DEVICE POWER SUPPLY: Internal detection automatically configures the device

for optimized read performance. Do not float any power pins.

Smart 3 Flash → 2.7 V and 3.3 V V

CC

With VCC ≤ V

LKO

, all write attempts to the flash memory are inhibited. Device

operations at invalid V

CC

voltages (see

DC Characteristics

) produce spurious

results and should not be attempted. Block erase, program, and lock-bit

configuration operations with V

CC

< 2.7 V are not supported.

GND SUPPLY GROUND: Do not float any ground pins.

NC NO CONNECT: Lead is not internally connected; it may be driven or floated.

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

8

PRELIMINARY

28F004S3

28F008S3

28F016S3

NC

CE#

RP#

A

18

A

13

A

17

A

14

A

16

A

15

A

12

A

11

A

10

A

9

A

8

A

7

A

6

A

5

A

4

V

CC

V

PP

NC

WE#

OE#

RY/BY#

GND

GND

DQ

6

DQ

7

DQ

5

A

0

A

1

A

2

A

3

DQ

3

DQ

2

DQ

1

DQ

0

NC

V

CC

A

19A19

DQ

4

A

20

40-LEAD TSOP

STANDARD PINOUT

10 mm x 20 mm

TOP VIEW

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

40

39

38

37

36

35

34

33

CE#

RP#

A

18

A

13

A

17

A

14

A

16

A

15

A

12

A

11

A

10

A

9

A

8

A

7

A

6

A

5

A

4

V

CC

V

PP

CE#

RP#

A

18

A

13

A

17

A

14

A

16

A

15

A

12

A

11

A

10

A

9

A

8

A

7

A

6

A

5

A

4

V

CC

V

PP

NC

WE#

OE#

RY/BY#

GND

GND

DQ

6

DQ

7

DQ

5

A

0

A

1

A

2

A

3

DQ

3

DQ

2

DQ

1

DQ

0

NC

V

CC

DQ

4

NC

WE#

OE#

RY/BY#

GND

GND

DQ

6

DQ

7

DQ

5

A

0

A

1

A

2

A

3

DQ

3

DQ

2

DQ

1

DQ

0

V

CC

DQ

4

Figure 2. TSOP 40-Lead Pinout

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

9

PRELIMINARY

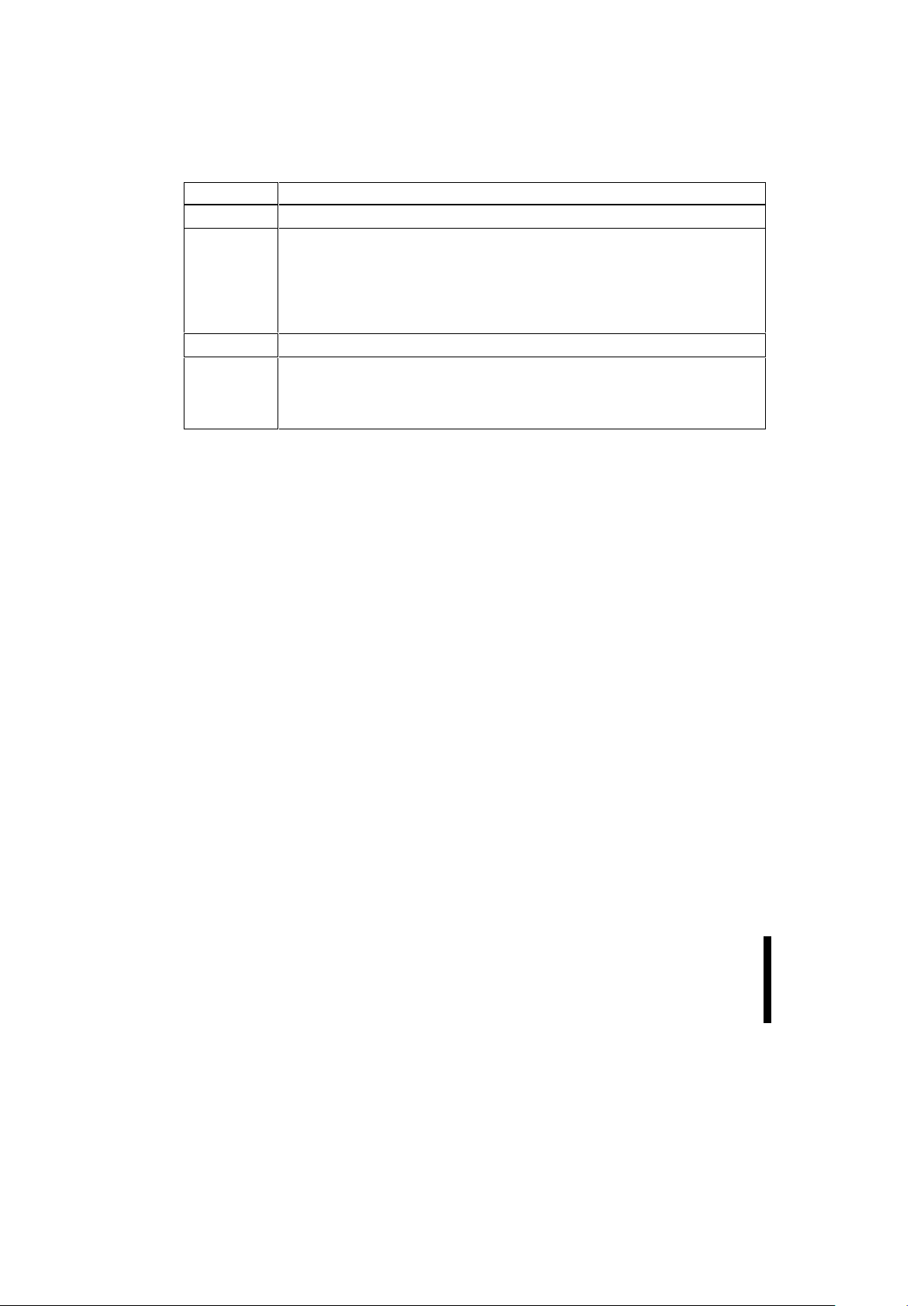

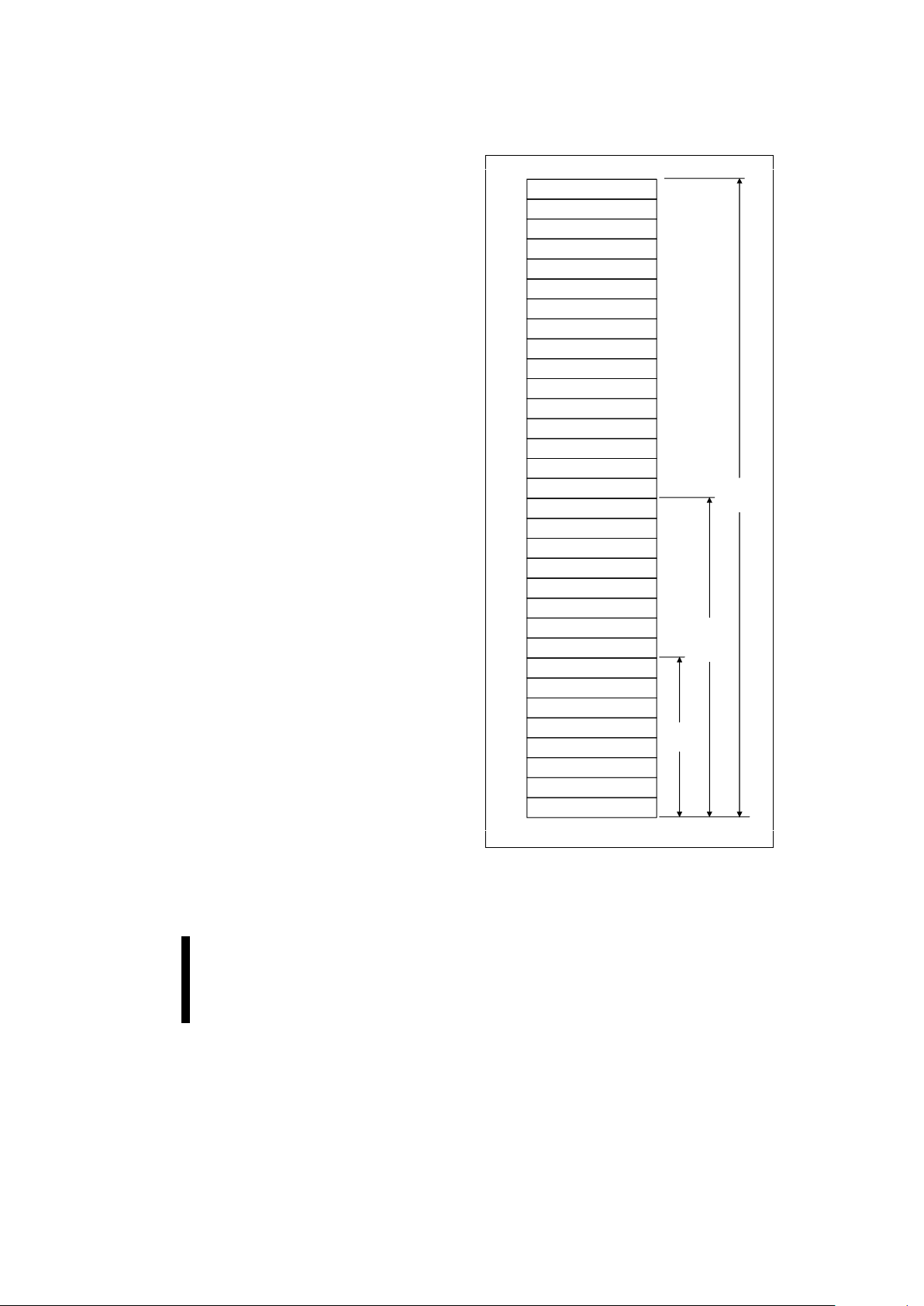

Figure 3. PSOP 44-Lead Pinout

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

10

PRELIMINARY

A

9

A

7

RP# V

PP

V

CC

A

12

A

17

A

18

A

16

A

14

CE# A

13

A

11

A

10

A

6

A

4

RY/BY#A

3

NCA

8

A

19

A

5

A

20

A

2

A

0

D

4

D3GNDD

1

D6WE#

OE#D

7

D

2

V

CC

GND D

5

D

0

A

1

A

15

87654321

A

B

C

D

E

A

B

C

D

E

A

15

A

17

A

12

V

CC

V

PP

RP# A

7

A

6

A

10

A

11

CE#A

13

A

14

A

16

A

18

NC RY/BY# A

19

NC A

8

A

3

A

5

A

4

A

2

A

0

D

1

D

3

GNDD

4

D

6

WE#

OE# D

7

D

5

V

CC

GND D

2

D

0

A

1

A

9

12345678

Pin #1

Indicator

Top View - Bump Side Down

Bottom View - Bump Side Up

This is the view of the package as surface mounted on the board.

Note that the signals are mirror images of bottom view.

NOTES:

1. Figures are not drawn to scale.

2. Address A20 is not included in the 28F008S3.

3. More information on µBGA* packages is available by contacting your Intel/Distribution sales office.

Figure 4. µBGA* CSP 40-Bump Pinout (28F008S3 and 28F016S3)

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

11

PRELIMINARY

2.0 PRINCIPLES OF OPERATION

The byte-wide Smart 3 FlashFile memories i nclude

an on-chip WSM to manage block erase, program,

and lock-bit configuration functions. It allows for:

100% TTL-level control inputs, f ixed power s upplies

during block erasure, program, and lock-bit

configuration, and minimal process or overhead with

RAM-like interface timings.

After initial device power-up or return from deep

power-down mode (see

Bus Operations

), the

device defaults to read array mode. Mani pulation of

external memory control pins allow array read,

standby, and output disable operations.

Status register and identifier codes can be

accessed through the CUI independent of the V

PP

voltage. High voltage on VPP enables successful

block erasure, program, and lock-bit c onfiguration.

All functions associated with altering memory

contents—block erase, program, lock-bit

configuration, status, and identifier codes—are

accessed via the CUI and verified through the

status register.

Commands are written using standard microprocessor write timings . The CUI cont ents s erve as

input to the WSM that controls block erase,

program, and lock-bit configuration operati ons. The

internal algorithms are regulated by the WSM,

including pulse repetition, internal verification, and

margining of data. Addresses and data are

internally latched during write cycles. Writing the

appropriate command outputs array dat a, acces ses

the identifier codes, or outputs status register data.

Interface software that initiates and polls progress

of block erase, program, and lock-bit configuration

can be stored in any block. This code is c opied to

and executed from system RAM during flash

memory updates. After successful completion,

reads are again possible via the Read Array

command. Block erase suspend allows system

software to suspend a block erase to read data

from or program data to any other block . Program

suspend allows system software to suspend a

program to read data from any other flash memory

array location.

64-Kbyte Block

1FFFFF

31

1F0000

1EFFFF

1E0000

1DFFFF

1D0000

1CFFFF

1C0000

1BFFFF

30

29

28

27

1B0000

1AFFFF

1A0000

19FFFF

190000

18FFFF

180000

17FFFF

26

25

24

23

170000

16FFFF

160000

15FFFF

150000

14FFFF

140000

13FFFF

22

21

20

19

130000

12FFFF

120000

11FFFF

110000

10FFFF

100000

0FFFFF

18

17

16

15

0F0000

0EFFFF

0E0000

0DFFFF

0D0000

0CFFFF

0C0000

0BFFFF

14

13

12

11

0B0000

0AFFFF

0A0000

09FFFF

090000

08FFFF

080000

07FFFF

10

9

8

7

070000

06FFFF

060000

05FFFF

050000

04FFFF

040000

03FFFF

6

5

4

3

030000

02FFFF

020000

01FFFF

010000

00FFFF

000000

2

1

0

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

64-Kbyte Block

8-Mbit

16-Mbit

4-Mbit

Figure 5. Memory Map

BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY E

12

PRELIMINARY

2.1 Data Protection

Depending on the application, the system designer

may choose to make the V

PP

power supply

switchable (available only when memory block

erase, program, or lock-bit configurat ion operations

are required) or hardwired to V

PPH1/2

. The device

accommodates either design practice and

encourages optimization of the processor-memory

interface.

When V

PP

≤ V

PPLK

, memory contents cannot be

altered. When high voltage is applied to V

PP

, the

two-step block erase, program, or lock-bit

configuration command sequences provides protection from unwanted operations. All write

functions are disabled when V

CC

voltage is below

the write lockout voltage V

LKO

or when RP# is at

V

IL

. The device’s block locking capabilit y provides

additional protection from i nadvertent code or data

alteration by gating erase and program operations.

3.0 BUS OPERATION

The local CPU reads and writes flash memory

in-system. All bus cycles to or from the flash

memory conform to standard microprocessor bus

cycles.

3.1 Read

Block information, i dent i fier codes, or status register

can be read independent of the V

PP

voltage. RP#

can be at either V

IH

or VHH.

The first task is to write the appropriat e read-mode

command (Read Array, Read Identifier Codes, or

Read Status Register) to the CUI. Upon initial

device power-up or after exit from deep powerdown mode, the device automati cally resets t o read

array mode. Four control pins dictate the data flow

in and out of the component: CE#, OE#, WE#, and

RP#. CE# and OE# must be driven active to obtai n

data at the outputs. CE# is the device selection

control, and when active enables the selected

memory device. OE# is the data out put (DQ

0

–DQ7)

control and when active drives the selected

memory data onto the I/O bus . WE # must be at V

IH

and RP# must be at VIH or VHH. Figure 17

illustrates a read cycle.

3.2 Output Disable

With OE# at a logic-high level (VIH), the device

outputs are disabled. Output pins DQ

0

–DQ7 are

placed in a high-impedance state.

3.3 Standby

CE# at a logic-high level (VIH) places the device in

standby mode which substantially reduces device

power consumption. DQ

0

–DQ7 outputs are placed

in a high-impedance state independent of OE#. If

deselected during block erase, program, or lock-bit

configuration, the devic e continues functioning and

consuming active power until the operation

completes.

3.4 Deep Power-Down

RP# at VIL initiates the deep power-down mode.

In read mode, RP#-low deselects the memory,

places output drivers in a high-impedance state,

and turns off all internal c ircuits. RP# mus t be held

low for time t

PLPH

. Time t

PHQV

is required after

return from power-down until initial m emory access

outputs are valid. After this wake-up interval,

normal operation is restored. The CUI resets to

read array mode, and the status regi ster is set to

80H.

During block erase, program, or lock-bit

configuration, RP#-low will abort the operation.

RY/BY# remains low until the reset operation is

complete. Memory contents being altered are no

longer valid; the data may be partially erased or

written. Time t

PHWL

is required after RP# goes to

logic-high (V

IH

) before another command can be

written.

As with any automated device, it is important to

assert RP# during system reset. When the system

comes out of reset, i t ex pect s t o read from t he f las h

memory. Automated flash memori es provide status

information when accessed during block erase,

program, or lock-bit confi guration modes. If a CPU

reset occurs with no flash memory reset, proper

CPU initialization may not occur because the flas h

memory may be providing status information

instead of array data. Int el’s flash memories allow

proper CPU initialization following a system reset

through the use of the RP# input. I n this applicati on,

RP# is controlled by the same RESET# signal that

resets the system CPU.

E BYTE-WIDE SMART 3 FlashFile™ MEMORY FAMILY

13

PRELIMINARY

000000

Block 0

Master Lock Configuration

000001

000002

000003

010000

010002

00FFFF

Device Code

Block 0 Lock Configuration

Manufacturer Code

Reserved For

Future Implementation

Block 1

Block 1 Lock Configuration

Reserved for

Future Implementation

01FFFF

Reserved for

Future Implementation

1F0000

1F0002

Block 31 Lock Configuration

Reserved for

Future Implementation

1FFFFF

Block 31

(Blocks 16 through 30)

(Blocks 8 through 14)

(Blocks 2 through 14)

070000

070002

Block 7

Block 7 Lock Configuration

Reserved for

Future Implementation

07FFFF

Reserved for

Future Implementation

0F0000

0F0002

Block 15

Block 15 Lock Configuration

Reserved for

Future Implementation

0FFFFF

8-Mbit

16-Mbit

4-Mbit

Reserved for

Future Implementation

Reserved for

Future Implementation

Figure 6. Device Identifier Code Memory Map

3.5 Read Identifier Codes

Operation

The read identifier codes operation outputs the

manufacturer code, device code, block lock

configuration codes for each bloc k, and mas ter lock

configuration code (see Figure 6). Using the

manufacturer and device codes, the system

software can automatical l y match the device with i ts

proper algorithms. The block lock and master lock

configuration codes identify locked and unlocked

blocks and master lock-bit setting.

3.6 Write

The CUI does not occupy an address able memory

location. It is wri tten when WE# and CE# are acti ve

and OE# = V

IH

. The address and data needed to

execute a command are latched on the risi ng edge

of WE# or CE# (whichever goes high first).

Standard microprocessor write timings are used.

Figure 18 illustrates a write operation.

4.0 COMMAND DEFINITIONS

When the VPP voltage ≤ V

PPLK

, read operations

from the status register, identif ier codes, or blocks

are enabled. Placing V

PPH1/2

on VPP enables

successful block erase, program, and lock-bit

configuration operations.

Device operations are selected by writing specific

commands into the CUI. Table 3 defines these

commands.

Loading...

Loading...