*Other brands and names are the property of their respective owners.

Information in this document is provided in connection with Intel products. Intel assumes no liability whatsoever, including infringement of any patent or

copyright, for sale and use of Intel products except as provided in Intel’s Terms and Conditions of Sale for such products. Intel retains the right to make

changes to these specifications at any time, without notice. Microcomputer Products may have minor variations to this specification known as errata.

November 1995COPYRIGHT©INTEL CORPORATION, 1995 Order Number: 290207-010

28F010

1024K (128K x 8) CMOS FLASH MEMORY

Y

Flash Electrical Chip-Erase

Ð 1 Second Typical Chip-Erase

Y

Quick Pulse Programming Algorithm

Ð10 ms Typical Byte-Program

Ð 2 Second Chip-Program

Y

100,000 Erase/Program Cycles

Y

12.0Vg5% V

PP

Y

High-Performance Read

Ð 65 ns Maximum Access Time

Y

CMOS Low Power Consumption

Ð 10 mA Typical Active Current

Ð50 mA Typical Standby Current

Ð 0 Watts Data Retention Power

Y

Integrated Program/Erase Stop Timer

Y

Command Register Architecture for

Microprocessor/Microcontroller

Compatible Write Interface

Y

Noise Immunity Features

Ð

g

10% VCCTolerance

Ð Maximum Latch-Up Immunity

through EPI Processing

Y

ETOXTMNonvolatile Flash Technology

Ð EPROM-Compatible Process Base

Ð High-Volume Manufacturing

Experience

Y

JEDEC-Standard Pinouts

Ð 32-Pin Plastic Dip

Ð 32-Lead PLCC

Ð 32-Lead TSOP

(See Packaging Spec., OrderÝ231369)

Y

Extended Temperature Options

Intel’s 28F010 CMOS flash memory offers the most cost-effective and reliable alternative for read/write

random access nonvolatile memory. The 28F010 adds electrical chip-erasure and reprogramming to familiar

EPROM technology. Memory contents can be rewritten: in a test socket; in a PROM-programmer socket; onboard during subassembly test; in-system during final test; and in-system after-sale. The 28F010 increases

memory flexibility, while contributing to time and cost savings.

The 28F010 is a 1024 kilobit nonvolatile memory organized as 131,072 bytes of 8 bits. Intel’s 28F010 is

offered in 32-pin plastic dip or 32-lead PLCC and TSOP packages. Pin assignments conform to JEDEC

standards for byte-wide EPROMs.

Extended erase and program cycling capability is designed into Intel’s ETOX (EPROM Tunnel Oxide) process

technology. Advanced oxide processing, an optimized tunneling structure, and lower electric field combine to

extend reliable cycling beyond that of traditional EEPROMs. With the 12.0V V

PP

supply, the 28F010 performs

100,000 erase and program cycles well within the time limits of the Quick Pulse Programming and Quick Erase

algorithms.

Intel’s 28F010 employs advanced CMOS circuitry for systems requiring high-performance access speeds, low

power consumption, and immunity to noise. Its 65 nanosecond access time provides no-WAIT-state performance for a wide range of microprocessors and microcontrollers. Maximum standby current of 100 mA translates into power savings when the device is deselected. Finally, the highest degree of latch-up protection is

achieved through Intel’s unique EPI processing. Prevention of latch-up is provided for stresses up to 100 mA

on address and data pins, from

b

1V to V

CC

a

1V.

With Intel’s ETOX process base, the 28F010 builds on years of EPROM experience to yield the highest levels

of quality, reliability, and cost-effectiveness.

28F010

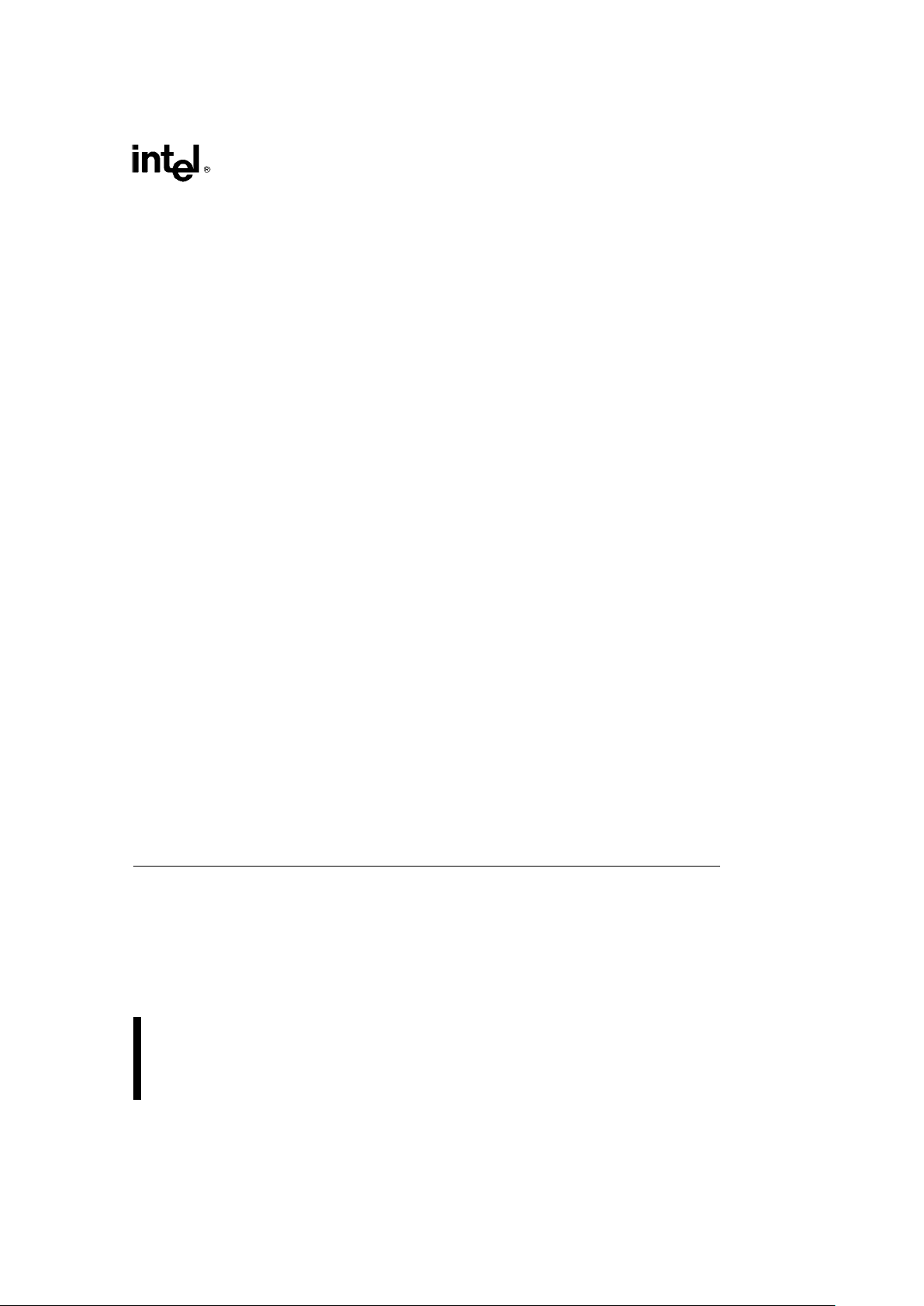

290207– 1

Figure 1. 28F010 Block Diagram

Table 1. Pin Description

Symbol Type Name and Function

A0–A

16

INPUT ADDRESS INPUTS for memory addresses. Addresses are internally

latched during a write cycle.

DQ0–DQ7INPUT/OUTPUT DATA INPUT/OUTPUT: Inputs data during memory write cycles;

outputs data during memory read cycles. The data pins are active high

and float to tri-state OFF when the chip is deselected or the outputs

are disabled. Data is internally latched during a write cycle.

CE

Ý

INPUT CHIP ENABLE: Activates the device’s control logic, input buffers,

decoders and sense amplifiers. CE

Ý

is active low; CEÝhigh

deselects the memory device and reduces power consumption to

standby levels.

OE

Ý

INPUT OUTPUT ENABLE: Gates the devices output through the data buffers

during a read cycle. OE

Ý

is active low.

WE

Ý

INPUT WRITE ENABLE: Controls writes to the control register and the array.

Write enable is active low. Addresses are latched on the falling edge

and data is latched on the rising edge of the WE

Ý

pulse.

Note: With V

PP

s

6.5V, memory contents cannot be altered.

V

PP

ERASE/PROGRAM POWER SUPPLY for writing the command

register, erasing the entire array, or programming bytes in the array.

V

CC

DEVICE POWER SUPPLY (5Vg10%)

V

SS

GROUND

NC NO INTERNAL CONNECTION to device. Pin may be driven or left

floating.

2

28F010

28F010

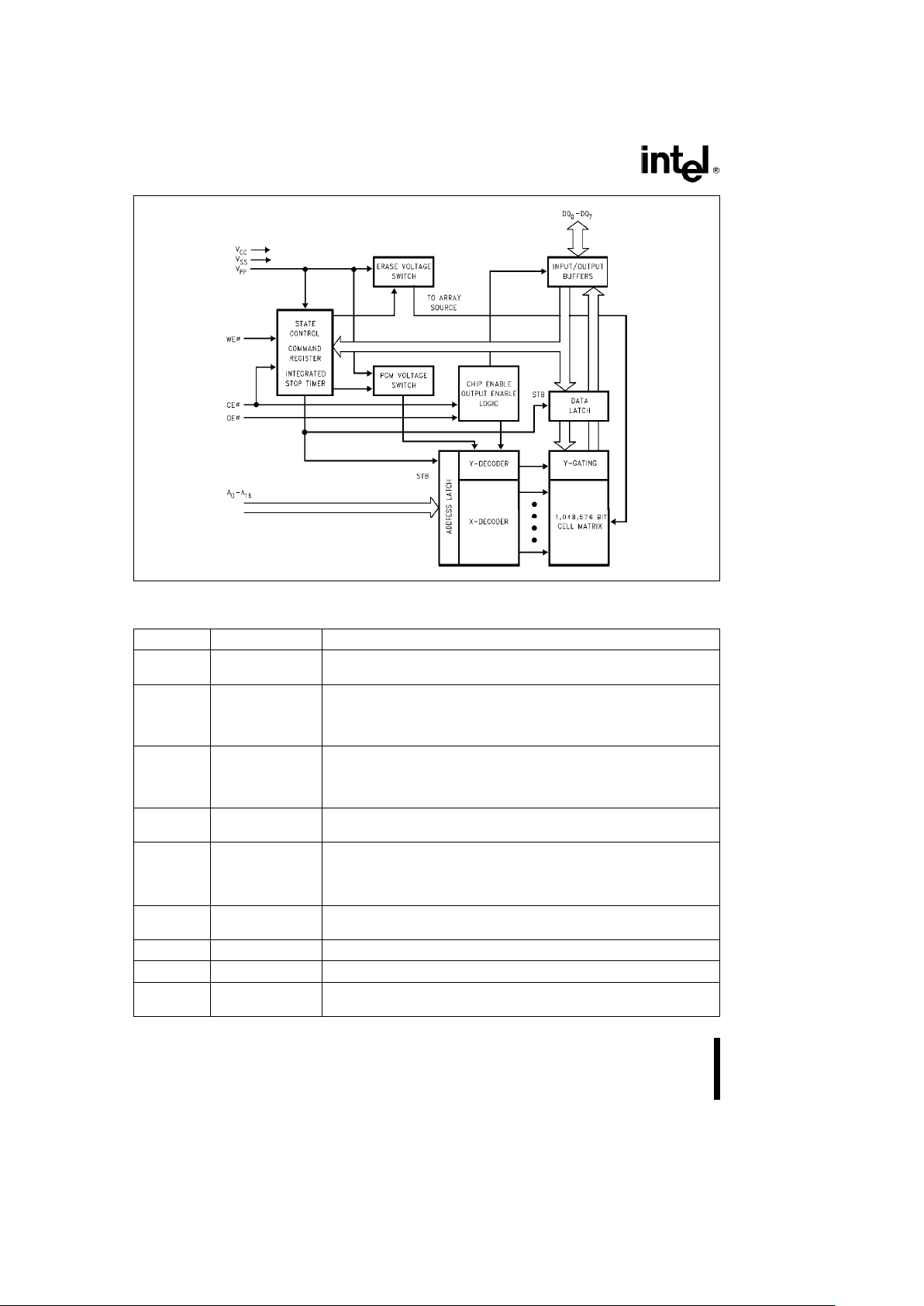

290207– 2

290207– 3

290207– 17

290207– 18

Figure 2. 28F010 Pin Configurations

3

28F010

APPLICATIONS

The 28F010 flash memory provides nonvolatility

along with the capability to perform over 100,000

electrical chip-erasure/reprogram cycles. These features make the 28F010 an innovative alternative to

disk, EEPROM, and battery-backed static RAM.

Where periodic updates of code and data-tables are

required, the 28F010’s reprogrammability and nonvolatility make it the obvious and ideal replacement

for EPROM.

Primary applications and operating systems stored

in flash eliminate the slow disk-to-DRAM download

process. This results in dramatic enhancement of

performance and substantial reduction of power

consumption Ð a consideration particularly important in portable equipment. Flash memory increases

flexibility with electrical chip erasure and in-system

update capability of operating systems and application code. With updatable code, system manufacturers can easily accommodate last-minute changes as

revisions are made.

In diskless workstations and terminals, network traffic reduces to a minimum and systems are instanton. Reliability exceeds that of electromechanical

media. Often in these environments, power interruptions force extended re-boot periods for all networked terminals. This mishap is no longer an issue

if boot code, operating systems, communication protocols and primary applications are flash-resident in

each terminal.

For embedded systems that rely on dynamic RAM/

disk for main system memory or nonvolatile backup

storage, the 28F010 flash memory offers a solid

state alternative in a minimal form factor. The

28F010 provides higher performance, lower power

consumption, instant-on capability, and allows an

‘‘execute in place’’ memory hierarchy for code and

data table reading. Additionally, the flash memory is

more rugged and reliable in harsh environments

where extreme temperatures and shock can cause

disk-based systems to fail.

The need for code updates pervades all phases of a

system’s life Ð from prototyping to system manufacture to after-sale service. The electrical chip-erasure

and reprogramming ability of the 28F010 allows incircuit alterability; this eliminates unnecessary handling and less-reliable socketed connections, while

adding greater test, manufacture, and update flexibility.

Material and labor costs associated with code

changes increases at higher levels of system integration Ð the most costly being code updates after

sale. Code ‘‘bugs’’, or the desire to augment system

functionality, prompt after-sale code updates. Field

revisions to EPROM-based code requires the removal of EPROM components or entire boards. With

the 28F010, code updates are implemented locally

via an edge-connector, or remotely over a communcation link.

For systems currently using a high-density static

RAM/battery configuration for data accumulation,

flash memory’s inherent nonvolatility eliminates the

need for battery backup. The concern for battery

failure no longer exists, an important consideration

for portable equipment and medical instruments,

both requiring continuous performance. In addition,

flash memory offers a considerable cost advantage

over static RAM.

Flash memory’s electrical chip erasure, byte programmability and complete nonvolatility fit well with

data accumulation and recording needs. Electrical

chip-erasure gives the designer a ‘‘blank slate’’ in

which to log or record data. Data can be periodically

off-loaded for analysis and the flash memory erased

producing a new ‘‘blank slate’’.

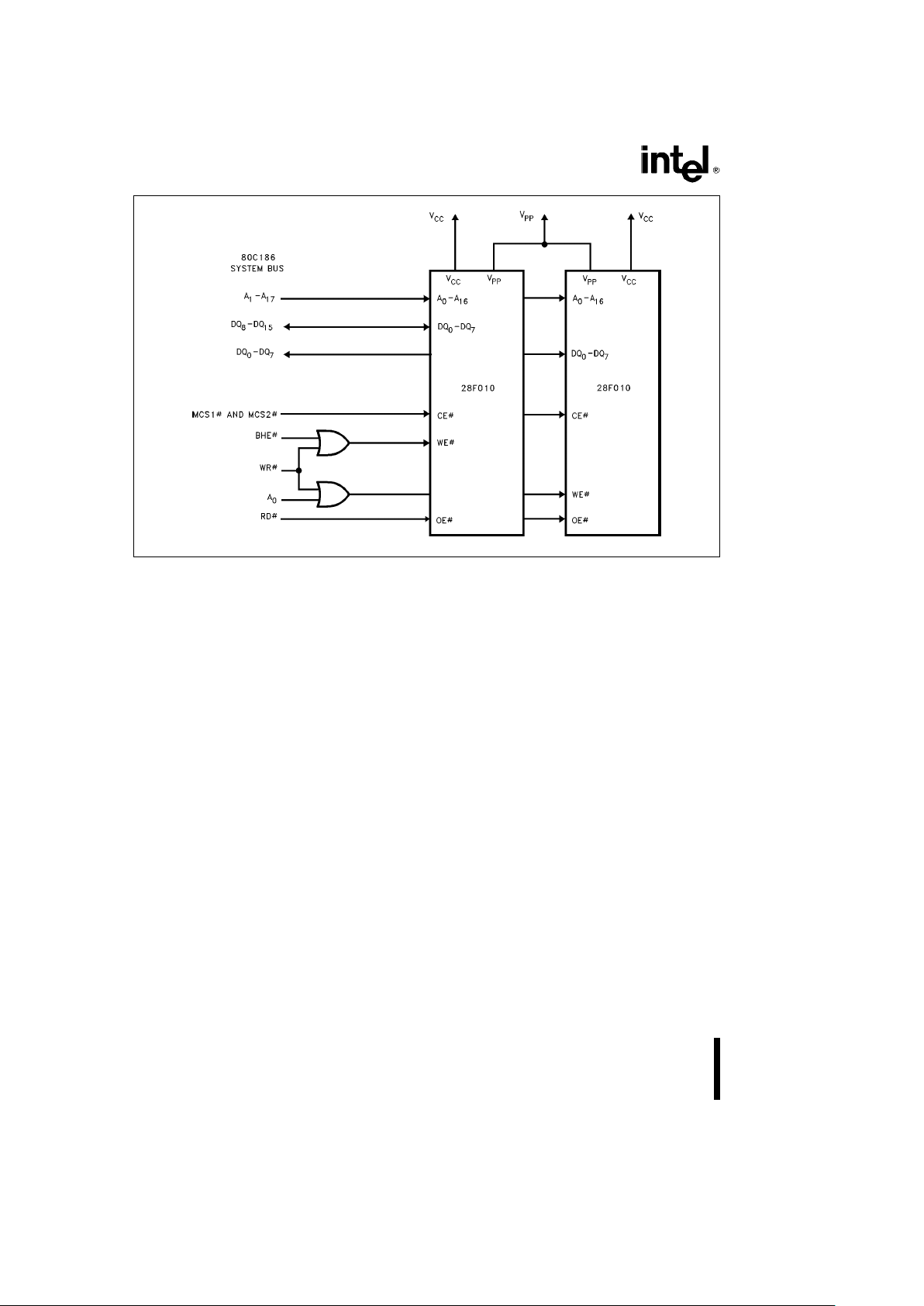

A high degree of on-chip feature integration simplifies memory-to-processor interfacing. Figure 4 depicts two 28F010s tied to the 80C186 system bus.

The 28F010’s architecture minimizes interface circuitry needed for complete in-circuit updates of

memory contents.

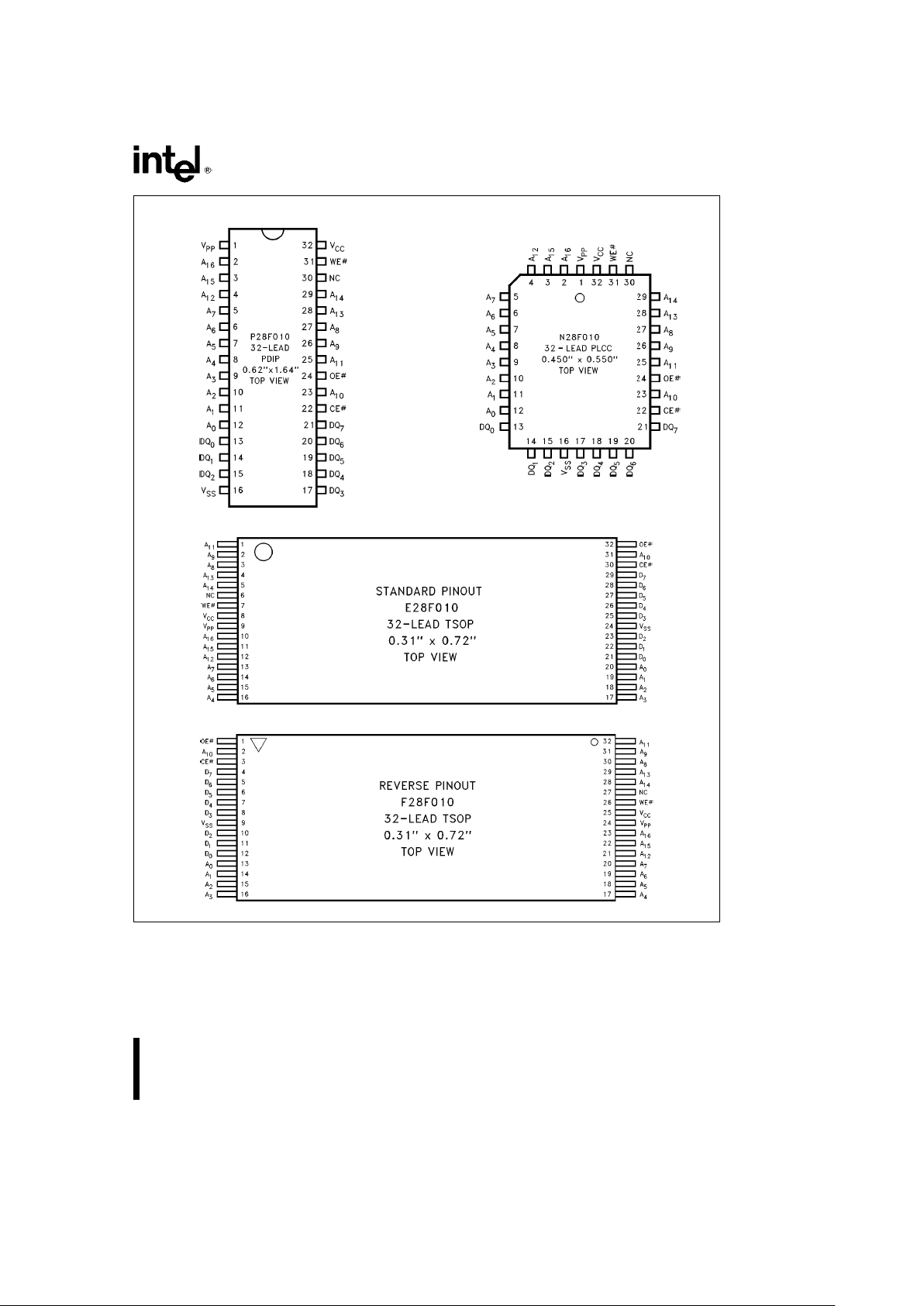

The outstanding feature of the TSOP (Thin Small

Outline Package) is the 1.2 mm thickness. With standard and reverse pin configurations, TSOP reduces

the number of board layers and overall volume necessary to layout multiple 28F010s. TSOP is particularly suited for portable equipment and applications

requiring large amounts of flash memory. Figure 3

illustrates the TSOP Serpentine layout.

With cost-effective in-system reprogramming, extended cycling capability, and true nonvolatility,

the 28F010 offers advantages to the alternatives:

EPROMs, EEPROMs, battery backed static RAM,

or disk. EPROM-compatible read specifications,

straight-forward interfacing, and in-circuit alterability

offers designers unlimited flexibility to meet the high

standards of today’s designs.

4

28F010

Figure 3. TSOP Serpentine Layout

290207– 21

5

28F010

290207– 4

Figure 4. 28F010 in a 80C186 System

PRINCIPLES OF OPERATION

Flash-memory augments EPROM functionality with

in-circuit electrical erasure and reprogramming. The

28F010 introduces a command register to manage

this new functionality. The command register allows

for: 100% TTL-level control inputs; fixed power supplies during erasure and programming; and maximum EPROM compatibility.

In the absence of high voltage on the V

PP

pin, the

28F010 is a read-only memory. Manipulation of the

external memory-control pins yields the standard

EPROM read, standby, output disable, and Intelligent Identifier operations.

The same EPROM read, standby, and output disable

operations are available when high voltage is applied to the V

PP

pin. In addition, high voltage on V

PP

enables erasure and programming of the device. All

functions associated with altering memory contentsÐIntelligent Identifier, erase, erase verify, program, and program verifyÐare accessed via the

command register.

Commands are written to the register using standard

microprocessor write timings. Register contents

serve as input to an internal state-machine which

controls the erase and programming circuitry. Write

cycles also internally latch addresses and data

needed for programming or erase operations. With

the appropriate command written to the register,

standard microprocessor read timings output array

data, access the Intelligent Identifier codes, or output data for erase and program verification.

Integrated Stop Timer

Successive command write cycles define the durations of program and erase operations; specifically,

the program or erase time durations are normally

terminated by associated program or erase verify

commands. An integrated stop timer provides simplified timing control over these operations; thus eliminating the need for maximum program/erase timing

specifications. Programming and erase pulse durations are minimums only. When the stop timer terminates a program or erase operation, the device enters an inactive state and remains inactive until receiving the appropriate verify or reset command.

Write Protection

The command register is only active when VPPis at

high voltage. Depending upon the application, the

system designer may choose to make the V

PP

power supply switchableÐavailable only when memory

updates are desired. When V

PP

e

V

PPL

, the con-

6

28F010

Table 2. 28F010 Bus Operations

Mode V

PP

(1)

A0A9CEÝOEÝWEÝDQ0–DQ

7

Read V

PPLA0

A

9

V

IL

V

IL

VIHData Out

Output Disable V

PPL

XXVILV

IHVIH

Tri-State

READ-ONLY

Standby V

PPL

XXVIHX X Tri-State

Intelligent Identifier (Mfr)

(2)

V

PPLVILVID

(3)

V

IL

V

IL

VIHDatae89H

Intelligent Identifier (Device)

(2)

V

PPLVIHVID

(3)

V

IL

V

IL

VIHDataeB4H

Read V

PPHA0

A

9

V

IL

V

IL

VIHData Out

(4)

READ/WRITE

Output Disable V

PPH

XXVILV

IHVIH

Tri-State

Standby

(5)

V

PPH

XXVIHX X Tri-State

Write V

PPHA0

A

9

V

IL

V

IHVIL

Data In

(6)

NOTES:

1. Refer to DC Characteristics. When V

PP

e

V

PPL

memory contents can be read but not written or erased.

2. Manufacturer and device codes may also be accessed via a command register write sequence. Refer to Table 3. All other

addresses low.

3. V

ID

is the Intelligent Identifier high voltage. Refer to DC Characteristics.

4. Read operations with V

PP

e

V

PPH

may access array data or the Intelligent Identifier codes.

5. With V

PP

at high voltage, the standby current equals I

CC

a

IPP(standby).

6. Refer to Table 3 for valid Data-In during a write operation.

7. X can be V

IL

or VIH.

tents of the register default to the read command,

making the 28F010 a read-only memory. In this

mode, the memory contents cannot be altered.

Or, the system designer may choose to ‘‘hardwire’’

V

PP

, making the high voltage supply constantly

available. In this case, all Command Register functions are inhibited whenever V

CC

is below the write

lockout voltage V

LKO

. (See Power Up/Down Protection) The 28F010 is designed to accommodate either design practice, and to encourage optimization

of the processor-memory interface.

The two-step program/erase write sequence to the

Command Register provides additional software

write protections.

BUS OPERATIONS

Read

The 28F010 has two control functions, both of which

must be logically active, to obtain data at the outputs. Chip-Enable (CE

Ý

) is the power control and

should be used for device selection. Output-Enable

(OE

Ý

) is the output control and should be used to

gate data from the output pins, independent of device selection. Refer to AC read timing waveforms.

When VPPis high (V

PPH

), the read operation can be

used to access array data, to output the Intelligent

Identifier codes, and to access data for program/

erase verification. When V

PP

is low (V

PPL

), the read

operation can only access the array data.

Output Disable

With OE

Ý

at a logic-high level (VIH), output from the

device is disabled. Output pins are placed in a highimpedance state.

Standby

With CE

Ý

at a logic-high level, the standby operation disables most of the 28F010’s circuitry and substantially reduces device power consumption. The

outputs are placed in a high-impedance state, independent of the OEÝsignal. If the 28F010 is deselected during erasure, programming, or program/

erase verification, the device draws active current

until the operation is terminated.

Intelligent Identifier Operation

The Intelligent Identifier operation outputs the manufacturer code (89H) and device code (B4H). Programming equipment automatically matches the device with its proper erase and programming algorithms.

7

28F010

With CEÝand OEÝat a logic low level, raising A9

to high voltage V

ID

(see DC Characteristics) activates the operation. Data read from locations 0000H

and 0001H represent the manufacturer’s code and

the device code, respectively.

The manufacturer- and device-codes can also be

read via the command register, for instances where

the 28F010 is erased and reprogrammed in the target system. Following a write of 90H to the command register, a read from address location 0000H

outputs the manufacturer code (89H). A read from

address 0001H outputs the device code (B4H).

Write

Device erasure and programming are accomplished

via the command register, when high voltage is applied to the V

PP

pin. The contents of the register

serve as input to the internal state-machine. The

state-machine outputs dictate the function of the

device.

The command register itself does not occupy an addressable memory location. The register is a latch

used to store the command, along with address and

data information needed to execute the command.

The command register is written by bringing WE

Ý

to

a logic-low level (V

IL

), while CEÝis low. Addresses

are latched on the falling edge of WE

Ý

, while data is

latched on the rising edge of the WE

Ý

pulse. Stan-

dard microprocessor write timings are used.

Refer to AC Write Characteristics and the Erase/

Programming Waveforms for specific timing

parameters.

COMMAND DEFINITIONS

When low voltage is applied to the V

PP

pin, the contents of the command register default to 00H, enabling read-only operations.

Placing high voltage on the V

PP

pin enables read/

write operations. Device operations are selected by

writing specific data patterns into the command register. Table 3 defines these 28F010 register

commands.

Table 3. Command Definitions

Command Cycles

Req’d

Bus

First Bus Cycle Second Bus Cycle

Operation

(1)

Address

(2)

Data

(3)

Operation

(1)

Address

(2)

Data

(3)

Read Memory 1 Write X 00H

Read Intelligent Identifier 3 Write IA 90H Read IA ID

Codes

(4)

Set-up Erase/Erase

(5)

2 Write X 20H Write X 20H

Erase Verify

(5)

2 Write EA A0H Read X EVD

Set-up Program/Program

(6)

2 Write X 40H Write PA PD

Program Verify

(6)

2 Write X C0H Read X PVD

Reset

(7)

2 Write X FFH Write X FFH

NOTES:

1. Bus operations are defined in Table 2.

2. IA

e

Identifier address: 00H for manufacturer code, 01H for device code.

EA

e

Erase Address: Address of memory location to be read during erase verify.

PA

e

Program Address: Address of memory location to be programmed.

Addresses are latched on the falling edge of the WE

Ý

pulse.

3. ID

e

Identifier Data: Data read from location IA during device identification (Mfre89H, DeviceeB4H).

EVD

e

Erase Verify Data: Data read from location EA during erase verify.

PD

e

Program Data: Data to be programmed at location PA. Data is latched on the rising edge of WEÝ.

PVD

e

Program Verify Data: Data read from location PA during program verify. PA is latched on the Program command.

4. Following the Read inteligent ID command, two read operations access manufacturer and device codes.

5. Figure 6 illustrates the Quick Erase Algorithm.

6. Figure 5 illustrates the Quick Pulse Programming Algorithm.

7. The second bus cycle must be followed by the desired command register write.

8

28F010

Read Command

While VPPis high, for erasure and programming,

memory contents can be accessed via the read

command. The read operation is initiated by writing

00H into the command register. Microprocessor

read cycles retrieve array data. The device remains

enabled for reads until the command register contents are altered.

The default contents of the register upon V

PP

power-up is 00H. This default value ensures that no spurious alteration of memory contents occurs during

the V

PP

power transition. Where the VPPsupply is

hard-wired to the 28F010, the device powers-up and

remains enabled for reads until the command-register contents are changed. Refer to the AC Read

Characteristics and Waveforms for specific timing

parameters.

Intelligent Identifier Command

Flash memories are intended for use in applications

where the local CPU alters memory contents. As

such, manufacturer- and device-codes must be accessible while the device resides in the target system. PROM programmers typically access signature

codes by raising A9 to a high voltage. However, multiplexing high voltage onto address lines is not a desired system-design practice.

The 28F010 contains an Intelligent Identifier operation to supplement traditional PROM-programming

methodology. The operation is initiated by writing

90H into the command register. Following the command write, a read cycle from address 0000H retrieves the manufacturer code of 89H. A read cycle

from address 0001H returns the device code of

B4H. To terminate the operation, it is necessary to

write another valid command into the register.

Set-up Erase/Erase Commands

Set-up Erase is a command-only operation that

stages the device for electrical erasure of all bytes in

the array. The set-up erase operation is performed

by writing 20H to the command register.

To commence chip-erasure, the erase command

(20H) must again be written to the register. The

erase operation begins with the rising edge of the

WE

Ý

pulse and terminates with the rising edge of

the next WE

Ý

pulse (i.e., Erase-Verify Command).

This two-step sequence of set-up followed by execution ensures that memory contents are not accidentally erased. Also, chip-erasure can only occur when

high voltage is applied to the V

PP

pin. In the absence

of this high voltage, memory contents are protected

against erasure. Refer to AC Erase Characteristics

and Waveforms for specific timing parameters.

Erase-Verify Command

The erase command erases all bytes of the array in

parallel. After each erase operation, all bytes must

be verified. The erase verify operation is initiated by

writing A0H into the command register. The address

for the byte to be verified must be supplied as it is

latched on the falling edge of the WE

Ý

pulse. The

register write terminates the erase operation with the

rising edge of its WE

Ý

pulse.

The 28F010 applies an internally-generated margin

voltage to the addressed byte. Reading FFH from

the addressed byte indicates that all bits in the byte

are erased.

The erase-verify command must be written to the

command register prior to each byte verification to

latch its address. The process continues for each

byte in the array until a byte does not return FFH

data, or the last address is accessed.

In the case where the data read is not FFH, another

erase operation is performed. (Refer to Set-up

Erase/Erase). Verification then resumes from the

address of the last-verified byte. Once all bytes in

the array have been verified, the erase step is complete. The device can be programmed. At this point,

the verify operation is terminated by writing a valid

command (e.g. Program Set-up) to the command

register. Figure 6, the Quick Erase algorithm, illustrates how commands and bus operations are combined to perform electrical erasure of the 28F010.

Refer to AC Erase Characteristics and Waveforms

for specific timing parameters.

Set-up Program/Program Commands

Set-up program is a command-only operation that

stages the device for byte programming. Writing 40H

into the command register performs the set-up

operation.

Once the program set-up operation is performed,

the next WE

Ý

pulse causes a transition to an active

programming operation. Addresses are internally

latched on the falling edge of the WE

Ý

pulse. Data

is internally latched on the rising edge of the WE

Ý

pulse. The rising edge of WEÝalso begins the programming operation. The programming operation

terminates with the next rising edge of WE

Ý

, used

to write the program-verify command. Refer to AC

Programming Characteristics and Waveforms for

specific timing parameters.

9

28F010

Program-Verify Command

The 28F010 is programmed on a byte-by-byte basis.

Byte programming may occur sequentially or at random. Following each programming operation, the

byte just programmed must be verified.

The program-verify operation is initiated by writing

C0H into the command register. The register write

terminates the programming operation with the rising edge of its WE

Ý

pulse. The program-verify operation stages the device for verification of the byte

last programmed. No new address information is

latched.

The 28F010 applies an internally-generated margin

voltage to the byte. A microprocessor read cycle

outputs the data. A successful comparison between

the programmed byte and true data means that the

byte is successfully programmed. Programming then

proceeds to the next desired byte location. Figure 5,

the 28F010 Quick Pulse Programming algorithm, illustrates how commands are combined with bus operations to perform byte programming. Refer to AC

Programming Characteristics and Waveforms for

specific timing parameters.

Reset Command

A reset command is provided as a means to safely

abort the erase- or program-command sequences.

Following either set-up command (erase or program)

with two consecutive writes of FFH will safely abort

the operation. Memory contents will not be altered.

A valid command must then be written to place the

device in the desired state.

EXTENDED ERASE/PROGRAM CYCLING

EEPROM cycling failures have always concerned

users. The high electrical field required by thin oxide

EEPROMs for tunneling can literally tear apart the

oxide at defect regions. To combat this, some suppliers have implemented redundancy schemes, reducing cycling failures to insignificant levels. However, redundancy requires that cell size be doubledÐ

an expensive solution.

Intel has designed extended cycling capability into

its ETOX flash memory technology. Resulting improvements in cycling reliability come without increasing memory cell size or complexity. First, an

advanced tunnel oxide increases the charge carrying ability ten-fold. Second, the oxide area per cell

subjected to the tunneling electric field is one-tenth

that of common EEPROMs, minimizing the probability of oxide defects in the region. Finally, the peak

electric field during erasure is approximately

2 MV/cm lower than EEPROM. The lower electric

field greatly reduces oxide stress and the probability

of failure.

The 28F010 is capable or 100,000 program/erase

cycles. The device is programmed and erased using

Intel’s Quick Pulse Programming and Quick Erase

algorithms. Intel’s algorithmic approach uses a series of operations (pulses), along with byte verification, to completely and reliably erase and program

the device.

For further information, see Reliability Report RR-60.

QUICK PULSE PROGRAMMING ALGORITHM

The Quick Pulse Programming algorithm uses programming operations of 10 ms duration. Each operation is followed by a byte verification to determine

when the addressed byte has been successfully programmed. The algorithm allows for up to 25 programming operations per byte, although most bytes

verify on the first or second operation. The entire

sequence of programming and byte verification is

performed with V

PP

at high voltage. Figure 5 illus-

trates the Quick Pulse Programming algorithm.

QUICK ERASE ALGORITHM

Intel’s Quick Erase algorithm yields fast and reliable

electrical erasure of memory contents. The algorithm employs a closed-loop flow, similar to the

Quick Pulse Programming algorithm, to simultaneously remove charge from all bits in the array.

Erasure begins with a read of memory contents. The

28F010 is erased when shipped from the factory.

Reading FFH data from the device would immediately be followed by device programming.

For devices being erased and reprogrammed, uniform and reliable erasure is ensured by first programming all bits in the device to their charged state

(Data

e

00H). This is accomplished, using the Quick

Pulse Programming algorithm, in approximately two

seconds.

Erase execution then continues with an initial erase

operation. Erase verification (data

e

FFH) begins at

address 0000H and continues through the array to

the last address, or until data other than FFH is encountered. With each erase operation, an increasing

number of bytes verify to the erased state. Erase

efficiency may be improved by storing the address of

the last byte verified in a register. Following the next

erase operation, verification starts at that stored address location. Erasure typically occurs in one second. Figure 6 illustrates the Quick Erase algorithm.

10

28F010

290207– 5

Bus

Command Comments

Operation

Standby Wait for VPPRamp to V

PPH

(1)

Initialize Pulse-Count

Write Set-up Data

e

40H

Program

Write Program Valid Address/Data

Standby Duration of Program

Operation (t

WHWH1

)

Write Program

(2)

DataeC0H; Stops Program

Verify Operation

(3)

Standby t

WHGL

Read Read Byte to Verify

Programming

Standby Compare Data Output to Data

Expected

Write Read Datae00H, Resets the

Register for Read Operations

Standby Wait for VPPRamp to V

PPL

(1)

NOTES:

1. See DC Characteristics for the value of V

PPH

and

V

PPL

.

2. Program Verify is only performed after byte programming. A final read/compare may be performed (optional) after the register is written with the Read command.

3. Refer to principles of operation.

4. CAUTION: The algorithm MUST BE FOLLOWED

to ensure proper and reliable operation of the device.

Figure 5. 28F010 Quick Pulse Programming Algorithm

11

28F010

290207– 6

Bus

Command Comments

Operation

Entire Memory Muste00H

Before Erasure

Use Quick Pulse

Programming Algorithm

(Figure 5)

Standby Wait for V

PP

Ramp to V

PPH

(1)

Initialize Addresses and

Pulse-Count

Write Set-up Data

e

20H

Erase

Write Erase Datae20H

Standby Duration of Erase Operation

(t

WHWH2

)

Write Erase

(2)

AddreByte to Verify;

Verify Data

e

A0H; Stops Erase

Operation

(3)

Standby t

WHGL

Read Read Byte to Verify Erasure

Standby Compare Output to FFH

Increment Pulse-Count

Write Read Datae00H, Resets the

Register for Read Operations

Standby Wait for VPPRamp to V

PPL

(1)

1. See DC Characteristics for the value of V

PPH

and

V

PPL

.

2. Erase Verify is performed only after chip-erasure. A

final read/compare may be performed (optional) after

the register is written with the read command.

3. Refer to principles of operation.

4. CAUTION: The algorithm MUST BE FOLLOWED

to ensure proper and reliable operation of the device.

Figure 6. 28F010 Quick Erase Algorithm

12

28F010

DESIGN CONSIDERATIONS

Two-Line Output Control

Flash-memories are often used in larger memory arrays. Intel provides two read-control inputs to accommodate multiple memory connections. Two-line

control provides for:

a. the lowest possible memory power dissipation

and,

b. complete assurance that output bus contention

will not occur.

To efficiently use these two control inputs, an address-decoder output should drive chip-enable,

while the system’s read signal controls all flashmemories and other parallel memories. This assures

that only enabled memory devices have active outputs, while deselected devices maintain the low

power standby condition.

Power Supply Decoupling

Flash-memory power-switching characteristics require careful device decoupling. System designers

are interested in three supply current (I

CC

) issuesÐ

standby, active, and transient current peaks produced by falling and rising edges of chip-enable. The

capacitive and inductive loads on the device outputs

determine the magnitudes of these peaks.

Two-line control and proper decoupling capacitor

selection will suppress transient voltage peaks.

Each device should have a 0.1 mF ceramic capacitor

connected between V

CC

and VSS, and between V

PP

and VSS.

Place the high-frequency, low-inherent-inductance

capacitors as close as possible to the devices. Also,

for every eight devices, a 4.7 mF electrolytic capacitor should be placed at the array’s power supply

connection, between V

CC

and VSS. The bulk capaci-

tor will overcome voltage slumps caused by printed-

circuit-board trace inductance, and will supply

charge to the smaller capacitors as needed.

VPPTrace on Printed Circuit Boards

Programming flash-memories, while they reside in

the target system, requires that the printed circuit

board designer pay attention to the V

PP

power sup-

ply trace. The V

PP

pin supplies the memory cell current for programming. Use similar trace widths and

layout considerations given the V

CC

power bus. Ad-

equate V

PP

supply traces and decoupling will de-

crease V

PP

voltage spikes and overshoots.

Power Up/Down Protection

The 28F010 is designed to offer protection against

accidental erasure or programming during power

transitions. Upon power-up, the 28F010 is indifferent

as to which power supply, V

PP

or VCC, powers up

first. Power supply sequencing is not required. Internal circuitry in the 28F010 ensures that the command register is reset to the read mode on power

up.

A system designer must guard against active writes

for V

CC

voltages above V

LKO

when VPPis active.

Since both WE

Ý

and CEÝmust be low for a com-

mand write, driving either to V

IH

will inhibit writes.

The control register architecture provides an added

level of protection since alteration of memory contents only occurs after successful completion of the

two-step command sequences.

28F010 Power Dissipation

When designing portable systems, designers must

consider battery power consumption not only during

device operation, but also for data retention during

system idle time. Flash nonvolatility increases the

usable battery life of your system because the

28F010 does not consume any power to retain code

or data when the system is off. Table 4 illustrates the

power dissipated when updating the 28F010.

Table 4. 28F010 Typical Update Power Dissipation

(4)

Operation Notes

Power Dissipation

(Watt-Seconds)

Array Program/Program Verify 1 0.171

Array Erase/Erase Verify 2 0.136

One Complete Cycle 3 0.478

NOTES:

1. Formula to calculate typical Program/Program Verify Power

e

[

V

PP

c

Ý

BytesctypicalÝProg Pulses (t

WHWH1

c

I

PP2

typicalat

WHGL

c

I

PP4

typical)

]

a

[

V

CC

c

Ý

BytesctypicalÝProg Pulses (t

WHWH1

c

I

CC2

typicalat

WHGL

c

I

CC4

typical].

2. Formula to calculate typical Erase/Erase Verify Power

e

[

V

PP(VPP3

typicalct

ERASE

typicalaI

PP5

typicalct

WHGL

c

Ý

Bytes)

]

a

[

V

CC(ICC3

typicalct

ERASE

typicalaI

CC5

typicalct

WHGL

c

Ý

Bytes)].

3. One Complete Cycle

e

Array PreprogramaArray EraseaProgram.

4. ‘‘Typicals’’ are not guaranteed, but based on a limited number of samples from production lots.

13

28F010

ABSOLUTE MAXIMUM RATINGS*

Operating Temperature

During Read АААААААААААААААААА0

§

Ctoa70§C

(1)

During Erase/Program ААААААААА0§Ctoa70§C

(1)

Operating Temperature

During Read ААААААААААААААА

b

40§Ctoa85§C

(2)

During Erase/Program ААААААb40§Ctoa85§C

(2)

Temperature Under Bias АААААААb10§Ctoa80§C

(1)

Temperature Under Bias АААААААb50§Ctoa95§C

(2)

Storage Temperature ААААААААААb65§Ctoa125§C

Voltage on Any Pin with

Respect to Ground АААААААААА

b

2.0V toa7.0V

(3)

Voltage on Pin A9with

Respect to Ground ААААААА

b

2.0V toa13.5V

(3, 4)

VPPSupply Voltage with

Respect to Ground

During Erase/Program ÀÀÀÀ

b

2.0V toa14.0V

(3, 4)

VCCSupply Voltage with

Respect to Ground АААААААААА

b

2.0V toa7.0V

(3)

Output Short Circuit CurrentААААААААААААА100 mA

(5)

NOTICE: This is a production data sheet. The specifications are subject to change without notice.

*

WARNING: Stressing the device beyond the ‘‘Absolute

Maximum Ratings’’ may cause permanent damage.

These are stress ratings only. Operation beyond the

‘‘Operating Conditions’’ is not recommended and extended exposure beyond the ‘‘Operating Conditions’’

may affect device reliability.

OPERATING CONDITIONS

Symbol Parameter

Limits

Unit

Min Max

T

A

Operating Temperature

(1)

070

§

C

T

A

Operating Temperature

(2)

b

40

a

85

§

C

V

CC

VCCSupply Voltage (10%)

(6)

4.50 5.50 V

V

CC

VCCSupply Voltage (5%)

(7)

4.75 5.25 V

NOTES:

1. Operating Temperature is for commercial product as defined by this specification.

2. Operating Temperature is for extended temperature products as defined by this specification.

3. Minimum DC input voltage is

b

0.5V. During transitions, inputs may undershoot tob2.0V for periods less

than 20 ns. Maximum DC voltage on output pins is V

CC

a

0.5V, which may overshoot to V

CC

a

2.0V for

periods less than 20 ns.

4. Maximum DC voltage on A

9

or VPPmay overshoot toa14.0V for periods less than 20 ns.

5. Output shorted for no more than one second. No more than one output shorted at a time.

6. See High Speed AC Input/Output reference Waveforms and High Speed AC Testing Load Circuits for

testing characteristics.

7. See AC Input/Output reference Waveforms and AC Testing Load Circuits for testing characteristics.

DC CHARACTERISTICSÐTTL/NMOS COMPATIBLEÐCommercial Products

Symbol Parameter Notes

Limits

Unit Test Conditions

Min Typical

(4)

Max

I

LI

Input Leakage Current 1

g

1.0 mAV

CC

e

VCCMax

V

IN

e

VCCor V

SS

I

LO

Output Leakage Current 1

g

10 mAV

CC

e

VCCMax

V

OUT

e

VCCor V

SS

I

CCS

VCCStandby Current 1 0.3 1.0 mA V

CC

e

VCCMax

CE

Ý

e

V

IH

I

CC1

VCCActive Read Current 1 10 30 mA V

CC

e

VCCMax, CE

Ý

e

V

IL

fe6 MHz, I

OUT

e

0mA

14

28F010

DC CHARACTERISTICSÐTTL/NMOS COMPATIBLEÐCommercial Products

(Continued)

Symbol Parameter Notes

Limits

Unit Test Conditions

Min Typical

(4)

Max

I

CC2

VCCProgramming Current 1, 2 1.0 10 mA Programming in Progress

I

CC3

VCCErase Current 1, 2 5.0 15 mA Erasure in Progress

I

CC4

VCCProgram Verify Current 1, 2 5.0 15 mA V

PP

e

V

PPH

Program Verify in Progress

I

CC5

VCCErase Verify Current 1, 2 5.0 15 mA V

PP

e

V

PPH

Erase Verify in Progress

I

PPS

VPPLeakage Current 1

g

10 mAV

PP

s

V

CC

I

PP1

VPPRead Current 1 90 200 mAV

PP

l

V

CC

or Standby Current

g

10.0 V

PP

s

V

CC

I

PP2

VPPProgramming Current 1, 2 8.0 30 mA V

PP

e

V

PPH

Programming in Progress

I

PP3

VPPErase Current 1, 2 6.0 30 mA V

PP

e

V

PPH

Erasure in Progress

I

PP4

VPPProgram Verify Current 1, 2 2.0 5.0 mA V

PP

e

V

PPH

Program Verify in Progress

I

PP5

VPPErase Verify Current 1, 2 2.0 5.0 mA V

PP

e

V

PPH

Erase Verify in Progress

V

IL

Input Low Voltage

b

0.5 0.8 V

V

IH

Input High Voltage 2.0 V

CC

a

0.5 V

V

OL

Output Low Voltage 0.45 V V

CC

e

VCCMin

I

OL

e

5.8 mA

V

OH1

Output High Voltage 2.4 V V

CC

e

VCCMin

I

OH

eb

2.5 mA

V

ID

A9Intelligent Identifer Voltage 11.50 13.00 V

I

ID

A9Intelligent Identifier Current 1, 2 90 200 mAA

9

e

V

ID

V

PPLVPP

during Read-Only 0.00 6.5 V NOTE: Erase/Program are

Operations Inhibited when V

PP

e

V

PPL

V

PPHVPP

during Read/Write 11.40 12.60 V

Operations

V

LKOVCC

Erase/Write Lock Voltage 2.5 V

DC CHARACTERISTICSÐCMOS COMPATIBLEÐCommercial Products

Symbol Parameter Notes

Limits

Unit Test Conditions

Min Typical

(4)

Max

I

LI

Input Leakage Current 1

g

1.0 mAV

CC

e

VCCMax

V

IN

e

VCCor V

SS

I

LO

Output Leakage Current 1

g

10 mAV

CC

e

VCCMax

V

OUT

e

VCCor V

SS

I

CCS

VCCStandby Current 1 50 100 mAV

CC

e

VCCMax

CE

Ý

e

V

CC

g

0.2V

I

CC1

VCCActive Read Current 1 10 30 mA V

CC

e

VCCMax, CE

Ý

e

V

IL

fe6 MHz, I

OUT

e

0mA

15

28F010

DC CHARACTERISTICSÐCMOS COMPATIBLEÐCommercial Products (Continued)

Symbol Parameter Notes

Limits

Unit Test Conditions

Min Typical

(4)

Max

I

CC2

VCCProgramming Current 1, 2 1.0 10 mA Programming in Progress

I

CC3

VCCErase Current 1, 2 5.0 15 mA Erasure in Progress

I

CC4

VCCProgram Verify Current 1, 2 5.0 15 mA V

PP

e

V

PPH

, Program

Verify in Progress

I

CC5

VCCErase Verify Current 1, 2 5.0 15 mA V

PP

e

V

PPH

, Erase

Verify in Progress

I

PPS

VPPLeakage Current 1

g

10 mAV

PP

s

V

CC

I

PP1

VPPRead Current, ID 1 90 200 mAV

PP

l

V

CC

Current or Standby Current

g

10 V

PP

s

V

CC

I

PP2

VPPProgramming 1, 2 8.0 30 mA V

PP

e

V

PPH

Current Programming in Progress

I

PP3

VPPErase Current 1, 2 6.0 30 mA V

PP

e

V

PPH

Erasure in Progress

I

PP4

VPPProgram Verify 1, 2 2.0 5.0 mA V

PP

e

V

PPH

, Program

Current Verify in Progress

I

PP5

VPPErase Verify 1, 2 2.0 5.0 mA V

PP

e

V

PPH

, Erase

Current Verify in Progress

V

IL

Input Low Voltage

b

0.5 0.8 V

V

IH

Input High Voltage 0.7 V

CC

V

CC

a

0.5 V

V

OL

Output Low Voltage 0.45 V V

CC

e

VCCMin

I

OL

e

5.8 mA

V

OH1

Output High Voltage

0.85 V

CC

V

V

CC

e

VCCMin, I

OH

eb

2.5 mA

V

OH2

V

CC

b

0.4 V

CC

e

VCCMin, I

OH

eb

100 mA

V

ID

A9Intelligent Identifier 11.50 13.00 V

Voltage

I

ID

A9Intelligent Identifier 1, 2 90 200 mAA

9

e

V

ID

Current

V

PPLVPP

during Read-Only 0.00 6.5 V NOTE: Erase/Programs are

Operations Inhibited when V

PP

e

V

PPL

V

PPHVPP

during Read/Write 11.40 12.60 V

Operations

V

LKOVCC

Erase/Write Lock 2.5 V

Voltage

16

28F010

DC CHARACTERISTICSÐTTL/NMOS COMPATIBLEÐExtended Temperature

Products

Symbol Parameter Notes

Limits

Unit Test Conditions

Min Typical

(4)

Max

I

LI

Input Leakage Current 1

g

1.0 mAV

CC

e

VCCMax

V

IN

e

VCCor V

SS

I

LO

Output Leakage Current 1

g

10 mAV

CC

e

VCCMax

V

OUT

e

VCCor V

SS

I

CCSVCC

Standby Current 1 0.3 1.0 mA V

CC

e

VCCMax

CE

Ý

e

V

IH

I

CC1VCC

Active Read Current 1 10 30 mA V

CC

e

VCCMax, CE

Ý

e

V

IL

fe6 MHz, I

OUT

e

0mA

I

CC2VCC

Programming Current 1, 2 1.0 30 mA Programming in Progress

I

CC3VCC

Erase Current 1, 2 5.0 30 mA Erasure in Progress

I

CC4VCC

Program Verify Current 1, 2 5.0 30 mA V

PP

e

V

PPH

Program Verify in Progress

I

CC5VCC

Erase Verify Current 1, 2 5.0 30 mA V

PP

e

V

PPH

Erase Verify in Progress

I

PPSVPP

Leakage Current 1

g

10 mAV

PP

s

V

CC

I

PP1

VPPRead Current 1 90 200 mAV

PP

l

V

CC

or Standby Current

g

10.0 V

PP

s

V

CC

I

PP2

VPPProgramming Current 1, 2 8.0 30 mA V

PP

e

V

PPH

Programming in Progress

I

PP3

VPPErase Current 1, 2 6.0 30 mA V

PP

e

V

PPH

Erasure in Progress

I

PP4

VPPProgram Verify Current 1, 2 2.0 5.0 mA V

PP

e

V

PPH

Program Verify in Progress

I

PP5

VPPErase Verify Current 1, 2 2.0 5.0 mA V

PP

e

V

PPH

Erase Verify in Progress

V

IL

Input Low Voltage

b

0.5 0.8 V

V

IH

Input High Voltage 2.0 V

CC

a

0.5 V

V

OL

Output Low Voltage 0.45 V V

CC

e

VCCMin

I

OL

e

5.8 mA

V

OH1

Output High Voltage 2.4 V V

CC

e

VCCMin

I

OH

eb

2.5 mA

V

ID

A9Intelligent Identifer Voltage 11.50 13.00 V

I

ID

A9Intelligent Identifier Current 1, 2 90 500 mAA

9

e

V

ID

V

PPLVPP

during Read-Only 0.00 6.5 V NOTE: Erase/Program are

Operations Inhibited when V

PP

e

V

PPL

V

PPHVPP

during Read/Write 11.40 12.60 V

Operations

V

LKOVCC

Erase/Write Lock Voltage 2.5 V

17

28F010

DC CHARACTERISTICSÐCMOS COMPATIBLEÐExtended Temperature

Products

Symbol Parameter Notes

Limits

Unit Test Conditions

Min Typical

(4)

Max

I

LI

Input Leakage 1

g

1.0 mAV

CC

e

VCCMax

Current V

IN

e

VCCor V

SS

I

LO

Output Leakage 1

g

10 mAV

CC

e

VCCMax

Current V

OUT

e

VCCor V

SS

I

CCS

VCCStandby 1 50 100 mAV

CC

e

VCCMax

Current CE

Ý

e

V

CC

g

0.2V

I

CC1

VCCActive Read 1 10 30 mA V

CC

e

VCCMax, CE

Ý

e

V

IL

Current fe10 MHz, I

OUT

e

0mA

I

CC2

VCCProgramming 1, 2 1.0 10 mA Programming in Progress

Current

I

CC3

VCCErase Current 1, 2 5.0 30 mA Erasure in Progress

I

CC4

VCCProgram Verify 1, 2 5.0 30 mA V

PP

e

V

PPH

Current Program Verify in Progress

I

CC5

VCCErase Verify 1, 2 5.0 30 mA V

PP

e

V

PPH

Current Erase Verify in Progress

I

PPS

VPPLeakage Current 1

g

10 mAV

PP

s

V

CC

I

PP1

VPPRead Current, 1 90 200 mAV

PP

l

V

CC

ID Current or

g

10 V

PP

s

V

CC

Standby Current

I

PP2

VPPProgramming 1, 2 8.0 30 mA V

PP

e

V

PPH

Current Programming in Progress

I

PP3

VPPErase Current 1, 2 6.0 30 mA V

PP

e

V

PPH

Erasure in Progress

I

PP4

VPPProgram Verify 1, 2 2.0 5.0 mA V

PP

e

V

PPH

Current Program Verify in Progress

I

PP5

VPPErase Verify 1, 2 2.0 5.0 mA V

PP

e

V

PPH

Current Erase Verify in Progress

V

IL

Input Low Voltage

b

0.5 0.8 V

V

IH

Input High Voltage 0.7 V

CC

V

CC

a

0.5 V

V

OL

Output Low Voltage 0.45 V V

CC

e

VCCMin

I

OL

e

5.8 mA

V

OH1

Output High Voltage

0.85 V

CC

V

V

CC

e

VCCMin

I

OH

eb

2.5 mA

V

OH2

V

CC

b

0.4 V

CC

e

VCCMin

I

OH

eb

100 mA

V

ID

A9Intelligent Identifer 11.50 13.00 V

Voltage

I

ID

A9Intelligent Identifier 1, 2 90 500 m AA

9

e

V

ID

Current

18

28F010

DC CHARACTERISTICSÐCMOS COMPATIBLEÐExtended Temperature

Products (Continued)

Symbol Parameter Notes

Limits

Unit Test Conditions

Min Typical

(4)

Max

V

PPL

VPPduring Read-Only 0.00 6.5 V NOTE: Erase/Programs are

Operations Inhibited when V

PP

e

V

PPL

V

PPH

VPPduring Read/Write 11.40 12.60 V

Operations

V

LKO

VCCErase/Write Lock 2.5 V

Voltage

CAPACITANCE T

A

e

25§C, fe1.0 MHz

Symbol Parameter Notes

Limits

Unit Conditions

Min Max

C

IN

Address/Control Capacitance 3 8 pF V

IN

e

0V

C

OUT

Output Capacitance 3 12 pF V

OUT

e

0V

NOTES:

1. All currents are in RMS unless otherwise noted. Typical values at V

CC

e

5.0V, V

PP

e

12.0V, Te25§C. These currents

are valid for all product versions (packages and speeds).

2. Not 100% tested: characterization data available.

3. Sampled, not 100% tested.

4. ‘‘Typicals’’ are not guaranteed, but based on a limited number of samples from production lots.

19

28F010

AC TESTING INPUT/OUTPUT

WAVEFORM

(1)

290207– 7

AC test inputs are driven at VOH(2.4 V

TTL

) for a Logic

‘‘1’’ and V

OL

(0.45 V

TTL

) for a Logic ‘‘0’’. Input timing

begins at V

IH

(2.0 V

TTL

) and VIL(0.8 V

TTL

). Output tim-

ing ends at V

IH

and VIL. Input rise and fall times (10%

to 90%)

k

10 ns.

HIGH SPEED AC TESTING INPUT/OUTPUT

WAVEFORM

(2)

290207– 8

AC test inputs are driven at 3.0V for a Logic ‘‘1’’ and

0.0V for a Logic ‘‘0’’. Input timing begins, and output

timing ends, at 1.5V. Input rise and fall times (10% to

90%)

k

10 ns.

AC TESTING LOAD CIRCUIT

(1)

C

L

e

100 pF

CLincludes Jig Capacitance

290207– 22

R

L

e

3.3 KX

HIGH SPEED AC TESTING LOAD CIRCUIT

(2)

C

L

e

30 pF

CLincludes Jig Capacitance

290207– 23

R

L

e

3.3 KX

AC TEST CONDITIONS

(1)

Input Rise and Fall Times (10% to 90%) АААААА10 ns

Input Pulse Levels АААААААААААААААА0.45V and 2.4V

Input Timing Reference Level ААААААА0.8V and 2.0V

Output Timing Reference Level АААААА0.8V and 2.0V

Capacitive LoadАААААААААААААААААААААААААА100 pF

HIGH-SPEED AC TEST CONDITIONS

(2)

Input Rise and Fall Times (10% to 90%) АААААА10 ns

Input Pulse Levels ААААААААААААААААА0.0V and 3.0V

Input Timing Reference Level АААААААААААААААА1.5V

Output Timing Reference Level АААААААААААААА1.5V

Capacitive LoadААААААААААААААААААААААААААА30 pF

NOTES:

1. Testing characteristics for 28F010-65 in standard configuration, and 28F010-90, 28F010-120, and 28F010-150.

2. Testing characteristics for 28F010-65 in high speed configuration.

20

28F010

AC CHARACTERISTICSÐRead Only OperationsÐCommercial and Extended

Temperature Products

Versions

V

CC

g

5% 28F010-65

(4)

Unit

V

CC

g

10% 28F010-65

(5)

28F010-90

(5)

28F010-120

(5)

28F010-150

(5)

Symbol Characteristic Notes Min Max Min Max Min Max Min Max Min Max

t

AVAV

/t

RC

Read Cycle Time 65 70 90 120 150 ns

t

ELQV

/t

CE

CE

Ý

Access Time 65 70 90 120 150 ns

t

AVQV

/t

ACC

Address Access Time 65 70 90 120 150 ns

t

GLQV

/t

OE

OE

Ý

Access Time 25 28 35 50 55 ns

t

ELQX

/t

LZ

CE

Ý

to Low Z 2, 3 0 0 0 0 0 ns

t

EHQZ

Chip Disable to Output 2 35 40 45 55 55 ns

in High Z

t

GLQX

/t

OLZ

OE

Ý

to Output 2, 3 0 0 0 0 0 ns

in Low Z

t

GHQZ

/t

DF

Output Disable to Output 2 30 30 30 30 35 ns

in High Z

t

OH

Output Hold from Address, 1, 2 0 0 0 0 0 ns

CE

Ý

,orOE

Ý

Change

t

WHGL

Write Recovery Time 6 6 6 6 6 ms

before Read

NOTES:

1. Whichever occurs first.

2. Sampled, not 100% tested.

3. Guaranteed by design.

4. See High Speed AC Input/Output reference Waveforms and High Speed AC Testing Load Circuits for testing characteristics.

5. See AC Input/Output reference Waveforms and AC Testing Load Circuits for testing characteristics.

21

28F010

Figure 7. AC Waveforms for Read Operations

290207– 9

22

28F010

AC CHARACTERISTICSÐWrite/Erase/Program Only Operations

(1)

Ð

Commercial and Extended Temperature Products

Versions

V

CC

g

5% 28F010-65

(4)

Unit

V

CC

g

10% 28F010-65

(5)

28F010-90

(5)

28F010-120

(5)

28F010-150

(5)

Symbol Characteristic Notes Min Max Min Max Min Max Min Max Min Max

t

AVAV

/t

WC

Write Cycle Time 65 70 90 120 150 ns

t

AVWL

/t

AS

Address Set-Up Time 0 0 0 0 0 ns

t

WLAX

/t

AH

Address Hold Time 40 40 40 40 40

ns

655

t

DVWH

/t

DS

Data Set-Up Time 40 40 40 40 40

ns

655

t

WHDX

/t

DH

Data Hold Time 10 10 10 10 10 ns

t

WHGL

Write Recovery Time 6 6 6 6 6 ms

before Read

t

GHWL

Read Recovery Time 2 0 0 0 0 0 ns

before Write

t

ELWL

/t

CS

Chip Enable Set-Up Time 15 15 15 15 15 ns

before Write

t

WHEH

/t

CH

Chip Enable Hold Time 0 0 0 0 0 ns

t

WLWH

/t

WP

Write Pulse Width 40 40 40 60 60

ns

655

t

WHWL

/t

WPH

Write Pulse Width High 20 20 20 20 20 ns

t

WHWH1

Duration of Programming 3 10 10 10 10 10 ms

Operation

t

WHWH2

Duration of Erase 3 9.5 9.5 9.5 9.5 9.5 ms

Operation

t

VPEL

V

PP

Set-Up Time to 2 1 1 1 1 1 ms

Chip Enable Low

NOTES:

1. Read timing characteristics during read/write operations are the same as during read-only operations. Refer to AC Characteristics for Read-Only Operations.

2. Guaranteed by design.

3. The integrated stop timer terminates the programming/erase operations, thus eliminating the need for a maximum specification.

4. See High Speed AC Input/Output reference Waveforms and High Speed AC Testing Load Circuits for testing characteristics.

5. See AC Input/Output reference Waveforms and AC Testing Load Circuits for testing characteristics.

6. Minimum specification for Extended Temperature product.

23

28F010

290207– 13

Figure 8. Typical Programming Capability

290207– 14

Figure 9. Typical Program Time at 12V

290207– 15

Figure 10. Typical Erase Capability

290207– 16

Figure 11. Typical Erase Time at 12V

24

28F010

Figure 12. AC Waveforms for Programming Operations

290207– 10

25

28F010

Figure 13. AC Waveforms for Erase Operations

290207– 11

26

28F010

AC CHARACTERISTICSÐAlternative CEÝ-Controlled WritesÐCommercial and

Extended Temperature

Versions

V

CC

g

5% 28F010-65

(2, 4)

Unit

V

CC

g

10% 28F010-65

(5)

28F010-90

(5)

28F010-120

(5)

28F010-150

(5)

Symbol Characteristic Notes Min Max Min Max Min Max Min Max Min Max

t

AVAV

Write Cycle Time 65 70 90 120 150 ns

t

AVEL

Address Set-Up Time 0 0 0 0 0 ns

t

ELAX

Address Hold Time 45 45 45 55 55

ns

660

t

DVEH

Data Set-Up Time 35 35 35 45 45

ns

650

t

EHDX

Data Hold Time 10 10 10 10 10 ns

t

EHGL

Write Recovery Time 6 6 6 6 6 ms

before Read

t

GHWL

Read Recovery Time 2 0 0 0 0 0 ns

before Write

t

WLEL

Write Enable Set-Up Time 0 0 0 0 0 ns

before Chip Enable

t

EHWH

Write Enable Hold Time 0 0 0 0 0 ns

t

ELEH

Write Pulse Width 45 45 45 70 70

ns

660

t

EHEL

Write Pulse Width High 20 20 20 20 20 ns

t

EHEH1

Duration of Programming 3 10 10 10 10 10 ms

Operation

t

EHEH2

Duration of Erase 3 9.5 9.5 9.5 9.5 9.5 ms

Operation

t

VPEL

V

PP

Set-Up Time to Chip 2 1 1 1 1 1 ms

Enable Low

NOTE:

1. Read timing characteristics during read/write operations are the same as during read-only operations. Refer to AC Characteristics for Read-Only Operations.

2. Guaranteed by design.

3. The integrated stop timer terminates the programming/erase operations, thus eliminating the need for a maximum specification.

4. See High Speed AC Input/Output reference Waveforms and High Speed AC Testing Load Circuits for testing characteristics.

5. See AC Input/Output reference Waveforms and AC Testing Load Circuits for testing characteristics.

6. Minimum specification for Extended Temperature product.

27

28F010

ERASE AND PROGRAMMING PERFORMANCE

Parameter Notes Min Typical Max Unit

Chip Erase Time 1, 3, 4 1 10 Sec

Chip Program Time 1, 2, 4 2 12.5 Sec

NOTES:

1. ‘‘Typicals’’ are not guaranteed, but based on samples from production lots. Data taken at 25

§

C, 12.0V VPP.

2. Minimum byte programming time excluding system overhead is 16 msec (10 msec program

a

6 msec write recovery),

while maximum is 400 msec/byte (16 msec x 25 loops allowed by algorithm). Max chip programming time is specified lower

than the worst case allowed by the programming algorithm since most bytes program significantly faster than the worst case

byte.

3. Excludes 00H programming prior to erasure.

4. Excludes system level overhead.

28

28F010

NOTE:

Alternative CE

Ý

-Controlled Write Timings also apply to erase operations.

Figure 14. Alternate AC Waveforms for Programming Operations

290207– 19

29

28F010

ORDERING INFORMATION

290207– 20

VALID COMBINATIONS:

P28F010-65 N28F010-65 TN28F010-90

P28F010-90 N28F010-90

P28F010-120 N28F010-120

P28F010-150 N28F010-150

E28F010-65 F28F010-65 TE28F010-90

E28F010-90 F28F010-90 TF28F010-90

E28F010-120 F28F010-120

E28F010-150 F28F010-150

ADDITIONAL INFORMATION

Order

Number

ER-20, ‘‘ETOX Flash Memory Technology’’ 294005

ER-24, ‘‘Intel Flash Memory’’ 294008

ER-28, ‘‘ETOX III Flash Memory Technology’’ 294012

RR-60, ‘‘ETOX Flash Memory Reliability Data Summary’’ 293002

AP-316, ‘‘Using Flash Memory for In-System Reprogrammable Nonvolatile Storage’’ 292046

AP-325 ‘‘Guide to Flash Memory Reprogramming’’ 292059

REVISION HISTORY

Number Description

007 Removed 200 ns Speed Bin

Revised Erase Maximum Pulse Count for Figure 5 from 3000 to 1000

Clarified AC and DC Test Conditions

Added ‘‘dimple’’ to F TSOP Package

Corrected Serpentine Layout

008 Corrected AC Waveforms

Added Extended Temperature Options

009 Added 28F010-65 and 28F010-90 speeds

Revised Symbols, i.e., CE

,OE, etc. to CEÝ,OEÝ, etc.

010 Completion of Read Operation Table

Labelling of Program Time in Erase/Program Table

Textual Changes or Edits

Corrected Erase/Program Times

30

Loading...

Loading...