Datasheet E28F800B5-T90, E28F800B5-T70, E28F800B5-B90, E28F800B5-B70 Datasheet (Intel Corporation)

E

PRODUCT PREVIEW

December 1996 Order Number: 290599-003

n

SmartVoltage Technology

Smart 5 Flash: 5V Reads,

5V or 12V Writes

Increased Programming Throughput

at 12V V

PP

n

Very High-Performance Read

2-, 4-Mbit: 60 ns Access Time

8-Mbit: 70 ns Access Time

n

x8/x16-Configurable Input/Output Bus

n

Low Power Consumption

Max 60 mA Read Current at 5V

Auto Power Savings: <1 mA Typical

Standby Current

n

Optimized Array Blocking Architecture

16-KB Protected Boot Block

Two 8-KB Parameter Blocks

96-KB and 128-KB Main Blocks

Top or Bottom Boot Locations

n

Extended Temperature Operation

–40°C to +85°C

n

Industry-Standard Packaging

44-Lead PSOP, 48-Lead TSOP

n

Extended Block Erase Cycling

100,000 Cycles at Commercial Temp

10,000 Cycles at Extended Temp

n

Hardware Data Protection Feature

Absolute Hardware-Protection for

Boot Block

Write Lockout during Power

Transitions

n

Automated Word/Byte Program and

Block Erase

Command User Interface

Status Registers

Erase Suspend Capability

n

SRAM-Compatible Write Interface

n

Reset/Deep Power-Down Input

Provides Low-Power Mode and

Reset for Boot Operations

n

Pinout Compatible 2, 4, and 8 Mbit

n

ETOX™ Flash Technology

0.6 µ ETOX IV Initial Production

0.4 µ ETOX V Later Production

Intel’s word-wide Smart 5 boot bloc k flash memory family provides 2-, 4-, and 8-Mbit memories featuring

high-density, low-cost, nonvolatile, read/write storage solutions for a wide range of applications. Their

asymmetrically-blocked architecture, flexible voltage, and extended cycling provide highly flexible

components suitable for em bedded code exec ution applic ations, suc h as network ing inf rastruct ure and offic e

automation.

Based on Intel’s boot bloc k archit ecture, the word-wide Sm art 5 boot bloc k memory family enables quic k and

easy upgrades for designs that demand state-of-the-art technology. This family of products comes in

industry-standard packages: the 48-lead TSOP, ideal for board-constrained applications, and the rugged,

easy to handle 44-lead PSOP.

SMART 5 BOOT BLOCK

FLASH MEMORY FAMILY

2, 4, 8 MBIT

28F200B5, 28F400B5, 28F800B5

Information in this document is provided in connection with Intel products. No license, express or implied, by estoppel or

otherwise, to any intellectual property rights is granted by this document. Except as provi ded in Intel ’s Terms and Condi tions of

Sale for such products, Intel assumes no liability whatsoever, and Intel disclaims any express or implied warranty, relating to

sale and/or use of Intel products including liability or warranties relating to fitness for a particular purpose, merchantability, or

infringement of any patent, copyright or other intellectual property right. Intel products are not intended for use in medical, life

saving, or life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

The 28F200B5, 28F400B5, 28F800B5 may contain design defects or errors known are errata. Current characterized errata are

available on request.

*Third-party brands and names are the property of their respective owners.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an ordering number and are referenced in this document, or other Intel literature, may be

obtained from:

Intel Corporation

P.O. Box 7641

Mt. Prospect, IL 60056-7641

or call 1-800-879-4683

COPYRIGHT © INTEL CORPORATION, 1996 CG-041493

E SMART 5 BOOT BLOCK MEMORY FAMILY

3

PRODUCT PREVIEW

CONTENTS

PAGE PAGE

1.0 INTRODUCTION.............................................5

1.1 New Features in the Smart 5 Memory

Products .....................................................5

1.2 Product Overview ........................................5

2.0 PRODUCT DESCRIPTION..............................6

2.1 Pin Descriptions...........................................6

2.2 Pinouts.........................................................8

2.3 Memory Blocking Organization ..................10

2.3.1 Boot Block........................................... 10

2.3.2 Parameter Blocks................................ 10

2.3.3 Main Blocks.........................................10

3.0 PRINCIPLES OF OPERATION..................... 13

3.1 Bus Operations..........................................13

3.1.1 Read...................................................13

3.1.2 Output Disable ....................................14

3.1.3 Standby...............................................14

3.1.4 Word/Byte Configuration.....................14

3.1.5 Deep Power-Down/Reset....................14

3.1.6 Write ................................................... 14

3.2 Modes of Operation ...................................16

3.2.1 Read Array.......................................... 16

3.2.2 Read Identifier.....................................16

3.2.3 Read Status Register.......................... 16

3.2.4 Word/Byte Program.............................17

3.2.5 Block Erase......................................... 17

3.3 Boot Block Locking ....................................24

3.3.1 V

PP

= VIL for Complete Protection....... 24

3.3.2 WP# = V

IL

for Boot Block Locking .......24

3.3.3 RP# = V

HH

or WP# = VIH for Boot Block

Unlocking...........................................24

3.3.4 Note for 8-Mbit 44-PSOP Package...... 24

4.0 DESIGN CONSIDERATIONS........................24

4.1 Power Consumption...................................24

4.1.1 Active Power.......................................24

4.1.2 Automatic Power Savings (APS) .........24

4.1.3 Standby Power....................................25

4.1.4 Deep Power-Down Mode.....................25

4.2 Power-Up/Down Operation.........................25

4.2.1 RP# Connected To System Reset.......25

4.3 Board Design.............................................25

4.3.1 Power Supply Decoupling....................25

4.3.2 V

PP

Trace On Printed Circuit Boards...25

5.0 SPECIFICATIONS.........................................26

5.1 Absolute Maximum Ratings........................26

5.2 Test Conditions..........................................26

5.3 Operating Conditions .................................27

5.4 Reset Operations.......................................27

5.6 Electrical Specifications .............................28

DC Characteristics Table...........................28

AC Characteristics: Read Operations

Table........................................................30

AC Characteristics: Write Operations

Table........................................................32

Erase and Program Timings ......................34

APPENDIX A: Ordering Information.................35

APPENDIX B: Write State Machine: Current-

Next State Chart..........................................36

APPENDIX C: Product Block Diagram .............37

APPENDIX D: Additional Information...............38

SMART 5 BOOT BLOCK MEMORY FAMILY E

4

PRODUCT PREVIEW

REVISION HISTORY

Number Description

-001 Original Version

-002 Minor changes throughout document.

Section 3.1.5 and Figure 13 redone to clarify program/erase operation abort.

Information added to Table 2, Figure 1, and Section 3.3 to clarify WP# on 8-Mbit,

44-PSOP.

Read and Write Waveforms changed to numbered format.

Typical numbers removed from DC Characteristics and Erase/Program Timings.

-003 Minor text changes throughout document.

Figure 1, 44-PSOP pinout: mistake on pin 3 on 2-Mbit pinout corrected from A

17

to NC.

Specs t

EHQZ

and t

GHQZ

improved.

Explanations of program/erase abort commands reworked in Table 6, Command

Codes.

E SMART 5 BOOT BLOCK MEMORY FAMILY

5

PRODUCT PREVIEW

1.0 INTRODUCTION

This datasheet contains specifications for 2-, 4-,

and 8-Mbit Smart 5 boot block flash memories.

Section 1 provides a feature overview. Sections 2,

3, and 4 describe the product and functionality.

Section 5 details the electrical and timing

specifications for both commercial and extended

temperature operation.

1.1 New Features in the

Smart 5 Memory Products

The Smart 5 boot block flas h memory fami ly of fers

identical features with the BV/CV/BE/CE

SmartVoltage products, except the Smart 5 boot

block -B5 parts only support 5V V

CC

read voltage.

The following differences dist inguish the Smart 5

boot block products from their predecessors:

• A delay is required if the part i s reset during an

in-progress program or erase operation.

• On the fly word-byte mode switching is no

longer supported. Word-byte mode must be

configured at power-up and remain stable

during operation.

• Write operations are no longer specified as

WE#- or CE#-controlled in favor of a simpler

“unified” write method, which is compatible

with either of the old methods.

1.2 Product Overview

The word-wide Smart 5 boot block memory family

provides pinout-compatible f lash memories at the

2-, 4- and 8-Mbit densities. The 28F200B5,

28F400B5, and 28F800B5 can be configured to

operate either in 16-bit or 8-bit bus mode, wit h the

data divided into individually erasable blocks.

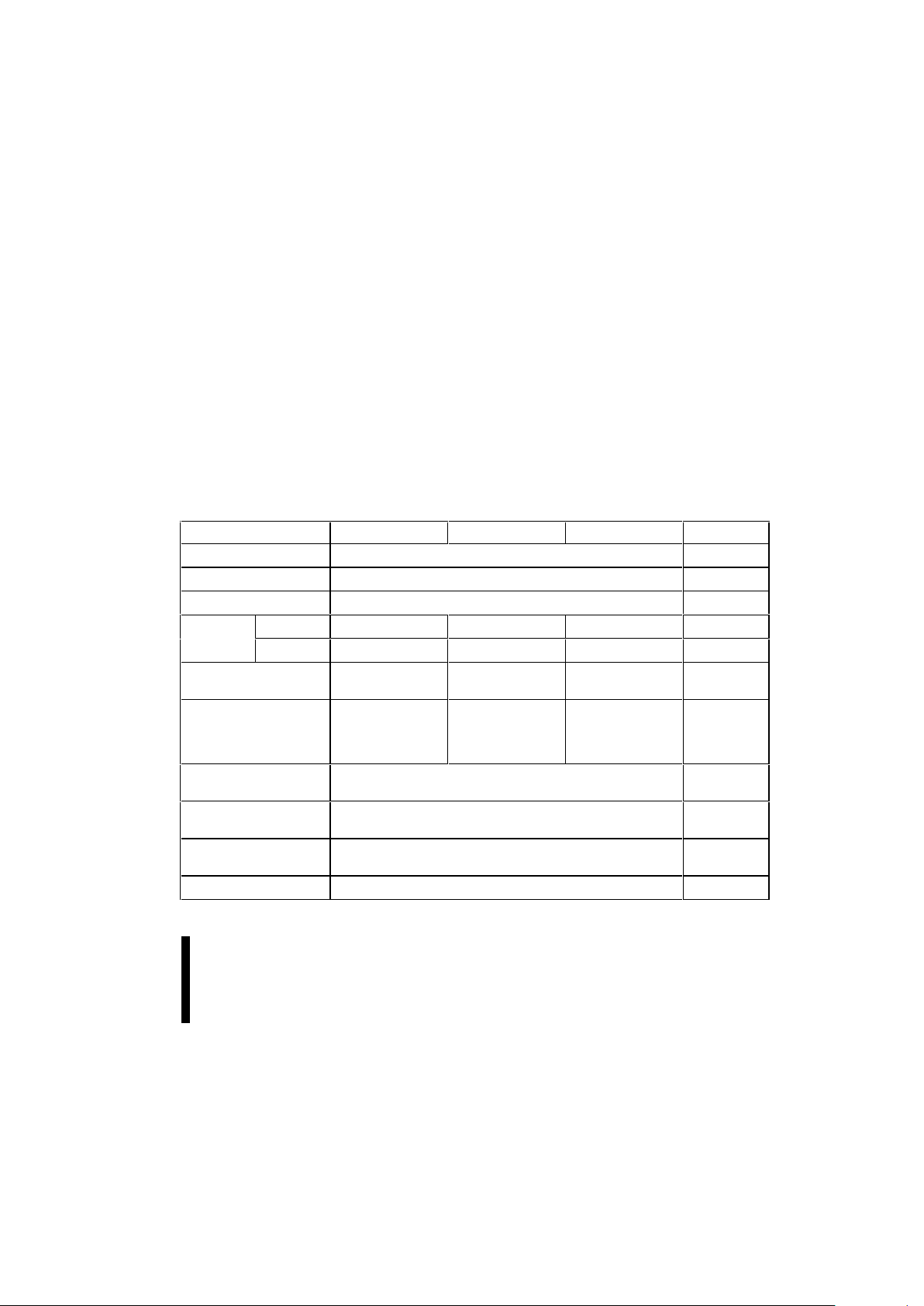

Table 1. Smart 5 Boot Block Family: Feature Summary

Feature 28F200B5 28F400B5 28F800B5 Reference

VCC Read Voltage 5V ± 5%, 5V ± 10% Table 10

VPP Prog/Erase Voltage 5V ± 10% or 12V ± 5%, auto-detected Table 10

Bus-width 8- or 16-bit configurable Table 2

Speed (ns) Commercial 60, 80 60, 80 70, 90 Table 14

Extended 80 80 90 Table 14

Memory Arrangement x8: 256K x 8

x16: 128K x 16

x8: 512K x 8

x16: 256K x 16

x8: 1M x 8

x16: 512K x 16

Blocking

(Top or Bottom boot

locations available)

1 x 16k Boot Block

2 x 8k Parameter

1 x 96k Main Block

1 x 128k Main Block

1 x 16k Boot Block

2 x 8k Parameter

1 x 96k Main Block

3 x 128k Main Block

1 x 16k Boot Block

2 x 8k Parameter

1 x 96k Main Block

7 x 128k Main Block

Sect. 2.3,

Fig. 3-6

Locking Boot Block lockable using WP# and/or RP#

All others protectable using V

PP

switch

Sect. 3.3

Operating Temperature Commercial: 0°C – +70 °C

Extended: -40°C – +85 °C

Table 10

Erase Cycling 100,000 cycles at Commercial Temperature

10,000 cycles at Extended Temperature

Packages 44-PSOP, 48-TSOP Figs. 1-2

SMART 5 BOOT BLOCK MEMORY FAMILY E

6

PRODUCT PREVIEW

SmartVoltage technology enables fast factory

programming and low-power designs. Specifically

designed for 5V systems, Smart 5 components

support read operations at 5V V

CC

and internally

configure to program/erase at 5V or 12V . The 12V

V

PP

option renders the fastest program and erase

performance which will increase your factory

throughput. With the 5V V

PP

option, VCC and V

PP

can be tied together for a simple 5V design. In

addition, the dedicated V

PP

pin gives complete dat a

protection when V

PP

≤ V

PPLK

.

The memory array is asymmetrically divided into

blocks in an asymmetrical architecture to

accommodate microprocessors that boot from the

top (denoted by -T suffix ) or the bottom (-B suffix)

of the memory map. The blocks include a

hardware-lockable boot block (16,384 bytes), two

parameter blocks (8,192 bytes each) and main

blocks (one block of 98,304 bytes and additional

block(s) of 131,072 bytes). See Figures 3–6 for

memory maps. Each block can be independently

erased and programmed 100,000 times at

commercial temperature or 10,000 times at

extended temperature. Unlike erase operations,

which erase all locations within a block

simultaneously, each byte or word in the flash

memory can be programmed independentl y of other

memory locations.

The hardware-lockable boot block provides

complete code security for the k ernel code required

for system initialization. Locking and unlocking of

the boot block is controlled by WP# and/or RP#

(see Section 3.3 for details).

The system processor interfaces to the flash device

through a Command User Interface (CUI), using

valid command sequences to initiate device

automation. An internal Wri te State Machine (WSM)

automatically executes the algorithms and timings

necessary for program and erase operations. The

Status Register (SR) indicates the status of the

WSM and whether it successfully completed the

desired program or erase operation.

The Automatic Power Savings (APS) feature

substantially reduces active current when the

device is in stati c mode (addresses not switching).

In APS mode, the typical I

CCR

current is 1 mA.

When CE# and RP# pins are at V

CC

, the

component enters a CMOS s tandby mode. Driving

RP# to GND enables a deep power-down mode

which significantly reduces power consumption,

provides write protection, resets the device, and

clears the status register. A reset time (t

PHQV

) is

required from RP# switching high until output s are

valid. Likewise, t he device has a wake time (t

PHEL

)

from RP#-high until writes to the CUI are

recognized. See Section 4.2.

The deep power-down mode can also be used as a

device reset, allowing the flash to be reset along

with the rest of the system. For example, when the

flash memory powers-up, it automatically defaults

to the read array mode, but during a warm system

reset, where power continues uninterrupted to the

system components, the flash memory could

remain in a non-read mode, such as erase.

Consequently, the system Reset signal should be

tied to RP# to reset the memory to normal read

mode upon activation of the Res et signal. Thi s also

provides protection against unwanted command

writes due to invalid system bus conditions during

system reset or power-up/down sequences.

These devices are configurable at power-up for

either byte-wide or word-wide input/output using the

BYTE# pin. Please see Table 2 for a detailed

description of BYTE# operations, especially the

usage of the DQ

15/A–1

pin.

These Smart 5 memory products are available in

the 44-lead PSOP (Plasti c Small Outline P ackage),

which is ROM/EPROM-com patible, and the 48-lead

TSOP (Thin Small Outline Pack age, 1.2 mm thick)

as shown in Figure 1, and 2, respectively.

2.0 PRODUCT DESCRIPTION

This section describes the pinout and block

architecture of the device family.

2.1 Pin Descriptions

The pin descriptions table details t he usage of eac h

of the device pins.

E SMART 5 BOOT BLOCK MEMORY FAMILY

7

PRODUCT PREVIEW

Table 2. Pin Descriptions

Symbol Type Name and Function

A0–A

18

INPUT

ADDRESS INPUTS for memory addresses. Addresses are internally latched

during a write cycle.

28F200: A[0-16], 28F400: A[0-17], 28F800: A[0-18]

A

9

INPUT ADDRESS INPUT: When A9 is at VHH the signature mode is accessed. During

this mode, A

0

decodes between the manufacturer and device IDs. When BYTE#

is at a logic low, only the lower byte of the signatures are read. DQ

15/A–1

is a

don’t care in the signature mode when BYTE# is low.

DQ0–DQ

7

INPUT/

OUTPUT

DATA INPUTS/OUTPUTS: Inputs array data on the second CE# and WE# cycle

during a Program command. Inputs commands to the Command User Interface

when CE# and WE# are active. Data is internally latched during the write cycle.

Outputs array, Intelligent Identifier and Status Register data. The data pins float to

tri-state when the chip is de-selected or the outputs are disabled.

DQ8–DQ

15

INPUT/

OUTPUT

DATA INPUTS/OUTPUTS: Inputs array data on the second CE# and WE# cycle

during a Program command. Data is internally latched during the write cycle.

Outputs array data. The data pins float to tri-state when the chip is de-selected or

the outputs are disabled as in the byte-wide mode (BYTE# = “0”). In the byte-wide

mode DQ

15/A–1

becomes the lowest order address for data output on DQ0–DQ7.

CE# INPUT CHIP ENABLE: Activates the device’s control logic, input buffers, decoders and

sense amplifiers. CE# is active low. CE# high de-selects the memory device and

reduces power consumption to standby levels. If CE# and RP# are high, but not

at a CMOS high level, the standby current will increase due to current flow

through the CE# and RP# input stages.

OE# INPUT OUTPUT ENABLE: Enables the device’s outputs through the data buffers during

a read cycle. OE# is active low.

WE# INPUT WRITE ENABLE: Controls writes to the Command Register and array blocks.

WE# is active low. Addresses and data are latched on the rising edge of the WE#

pulse.

RP# INPUT RESET/DEEP POWER-DOWN: Uses three voltage levels (VIL, VIH, and VHH) to

control two different functions: reset/deep power-down mode and boot block

unlocking. It is backwards-compatible with the BX/BL/BV products.

When RP# is at logic low, the device is in reset/deep power-down mode,

which puts the outputs at High-Z, resets the Write State Machine, and draws

minimum current.

When RP# is at logic high, the device is in standard operation. When RP#

transitions from logic-low to logic-high, the device defaults to the read array mode.

When RP# is at V

HH

, the boot block is unlocked and can be programmed or

erased. This overrides any control from the WP# input.

SMART 5 BOOT BLOCK MEMORY FAMILY E

8

PRODUCT PREVIEW

Table 2. Pin Descriptions (Continued)

Symbol Type Name and Function

WP# INPUT WRITE PROTECT: Provides a method for unlocking the boot block with a logic

level signal in a system without a 12V supply.

When WP# is at logic low, the boot block is locked, preventing program and

erase operations to the boot block. If a program or erase operation is attempted

on the boot block when WP# is low, the corresponding status bit (bit 4 for

program, bit 5 for erase) will be set in the Status Register to indicate the operation

failed.

When WP# is at logic high, the boot block is unlocked and can be

programmed or erased.

NOTE: This feature is overridden and the boot block unlocked when RP# is at

V

. This pin can not be left floating. Because the 8-Mbit 44-PSOP package does

not have enough pins, it does not include this pin and thus 12V on RP# is

required to unlock the boot block. See Section 3.3 for details on write protection.

BYTE# INPUT BYTE# ENABLE: Configures whether the device operates in byte-wide mode (x8)

or word-wide mode (x16). This pin must be set at power-up or return from deep

power-down and not changed during device operation. BYTE# pin must be

controlled at CMOS levels to meet the CMOS current specification in standby

mode.

When BYTE# is at logic low, the byte-wide mode is enabled, where data is

read and programmed on DQ

0

–DQ7 and DQ15/A–1 becomes the lowest order

address that decodes between the upper and lower byte. DQ

8

–DQ14 are tri-stated

during the byte-wide mode.

When BYTE# is at logic high, the word-wide mode is enabled, where data is

read and programmed on DQ

0

–DQ15.

V

CC

DEVICE POWER SUPPLY: 5.0V ± 10%

V

PP

PROGRAM/ERASE POWER SUPPLY: For erasing memory array blocks or

programming data in each block, a voltage either of 5V ± 10% or 12V ± 5% must

be applied to this pin. When V

PP

< V

PPL

K

all blocks are locked and protected

against Program and Erase commands.

GND GROUND: For all internal circuitry.

NC NO CONNECT: Pin may be driven or left floating.

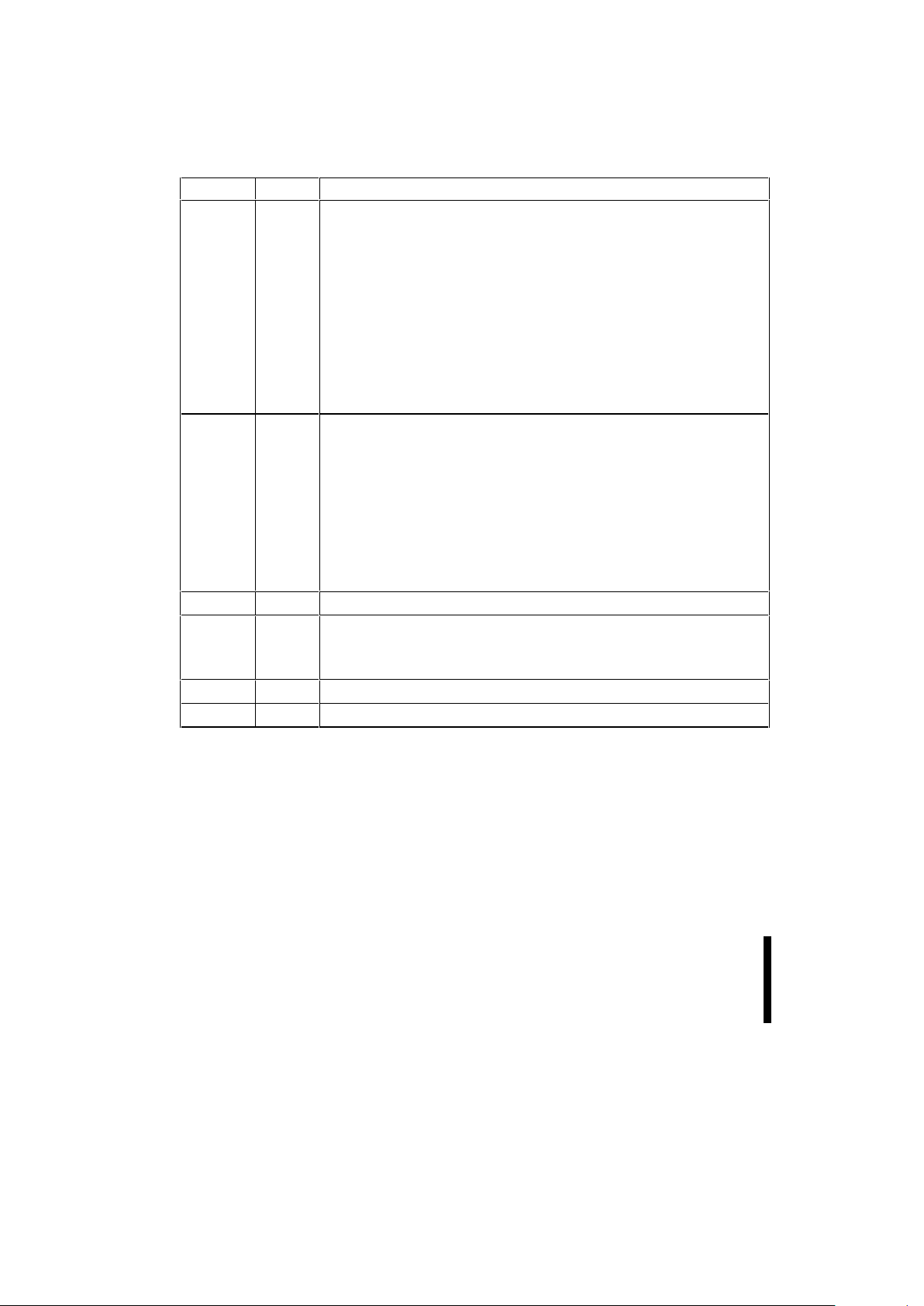

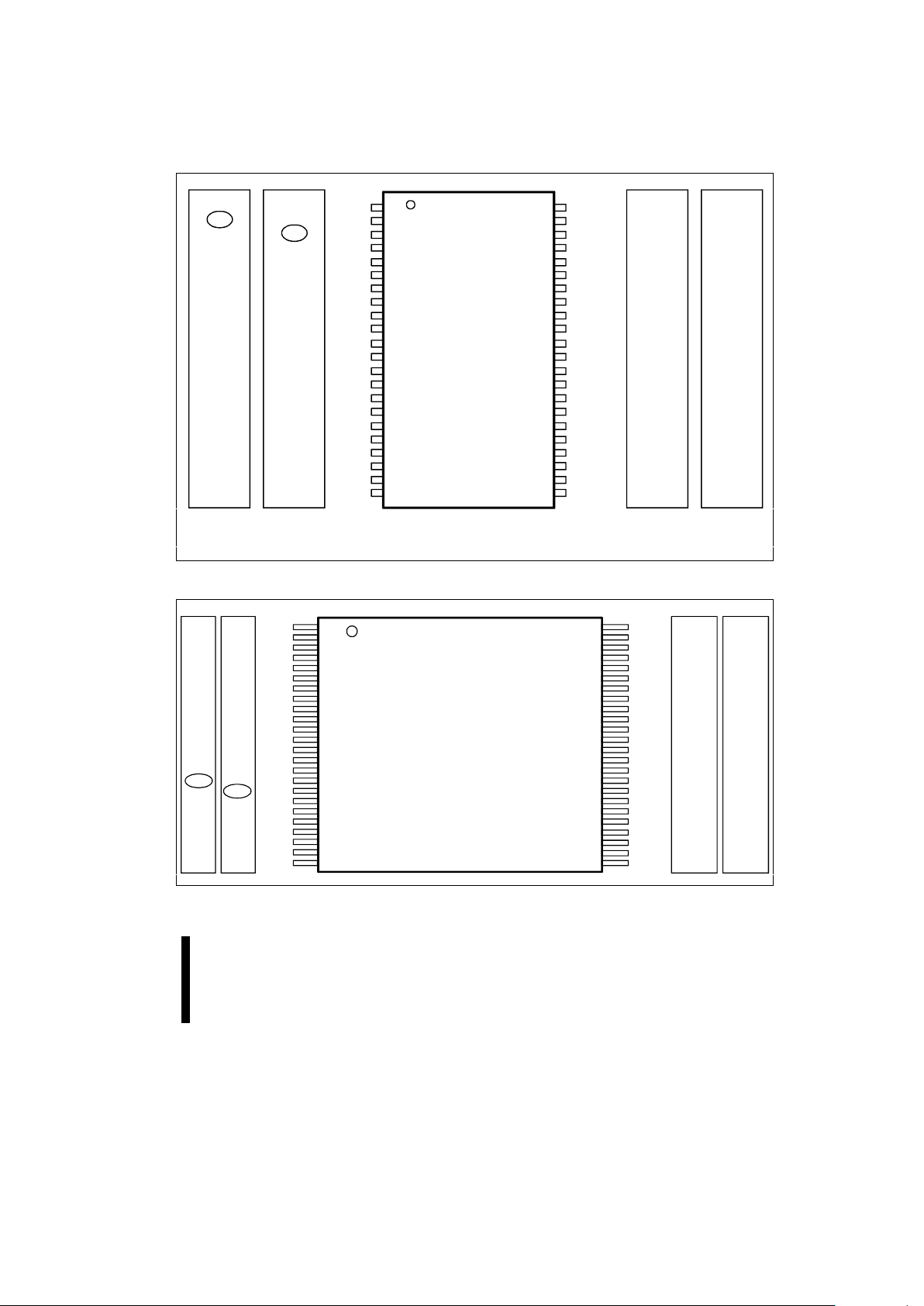

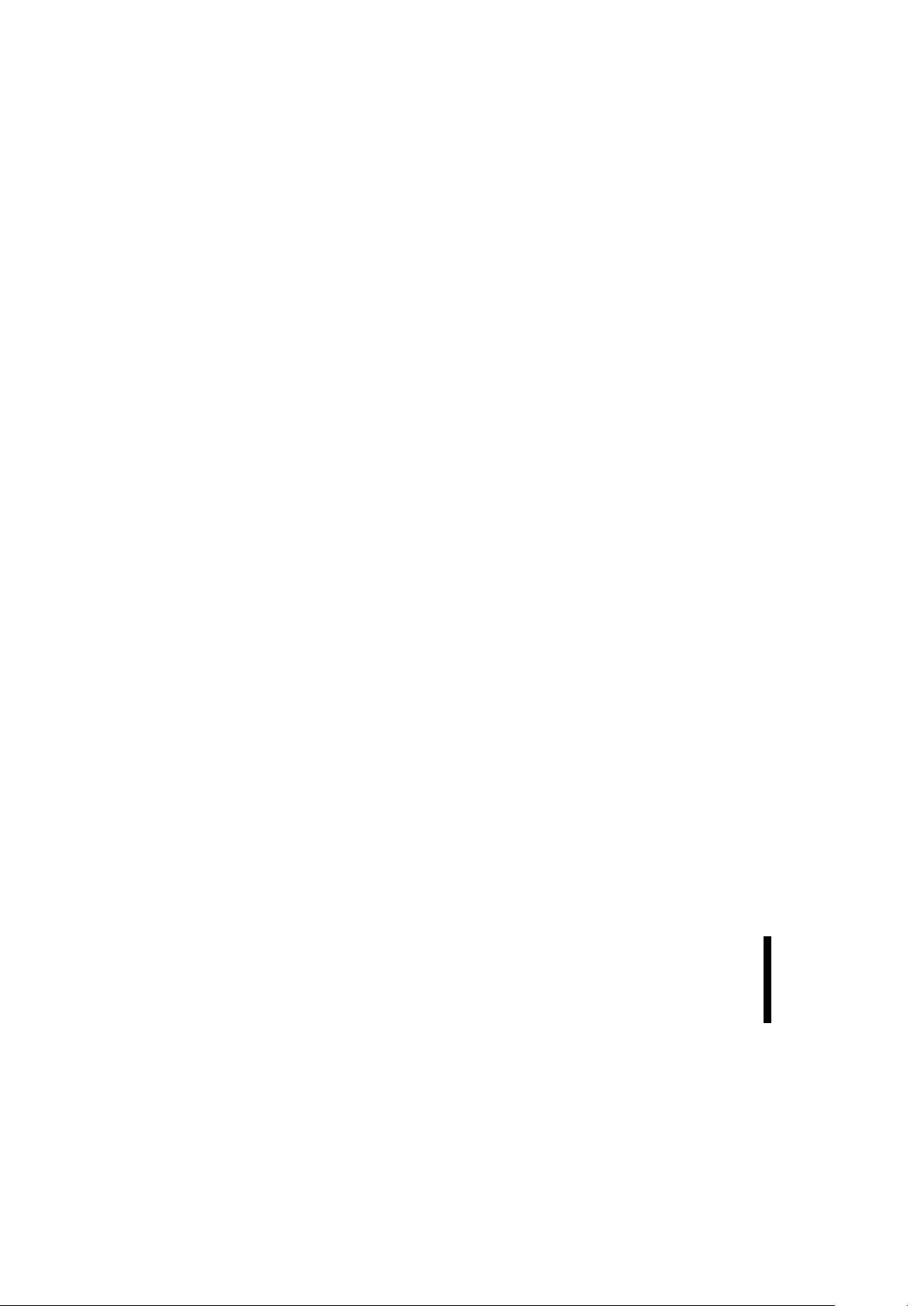

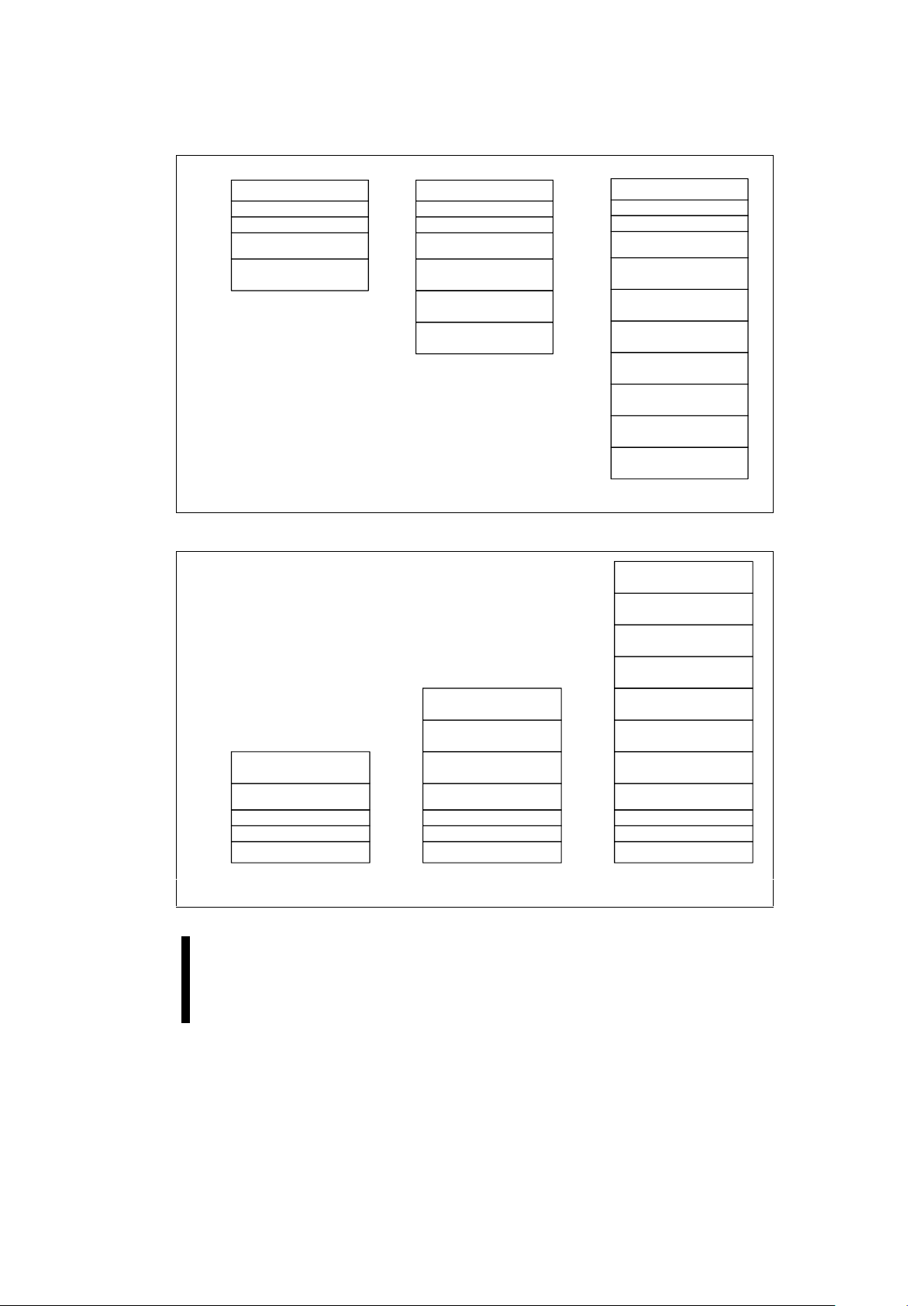

2.2 Pinouts

Intel’s Smart 5 boot block architecture provides

upgrade paths in each package pinout up to the

8-Mbit density. The 44-lead PSOP pinout follows

the industry-standard ROM/EPROM pinout, as

shown in Figure 1. Designs with space concerns

should consider the 48-lead pinout shown in

Figure 2.

Pinouts for the corresponding 2-, 4- and 8-Mbit

components are provided on the same di agram for

convenient reference. 2-Mbit pinouts are given on

the chip illustration in the center, with 4-Mbit and

8-Mbit pinouts going outward from the center.

E SMART 5 BOOT BLOCK MEMORY FAMILY

9

PRODUCT PREVIEW

PA28F200

Boot Block

44-Lead PSOP

0.525" x 1.110"

TOP VIEW

GND

WE#

RP#

BYTE#

A

8

A

9

A

11

A

12

A

13

A

14

A

16

DQ

7

DQ

14

DQ

6

DQ

13

DQ

12

DQ

4

V

CC

DQ

5

A

10

A

15

32

31

30

29

28

27

26

25

24

23

33

34

35

36

37

38

39

40

41

42

43

44

22

21

20

19

17

18

1

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

28F400 28F400

DQ

15 -1

/A

CE#

GND

OE#

V

PP

28F800 28F800

A

17

A

7

A

6

A

5

A

4

A

3

A

2

A

1

A

0

DQ

0

DQ

8

DQ

1

DQ

9

DQ

2

DQ

10

DQ

3

DQ

11

A

18

CE#

GND

OE#

V

PP

A

17

A

7

A

6

A

5

A

4

A

3

A

2

A

1

A

0

DQ

0

DQ

8

DQ

1

DQ

9

DQ

2

DQ

10

DQ

3

DQ

11

WP#

CE#

GND

OE#

V

PP

NC

A

7

A

6

A

5

A

4

A

3

A

2

A

1

A

0

DQ

0

DQ

8

DQ

1

DQ

9

DQ

2

DQ

10

DQ

3

DQ

11

WP#

GND

WE#

RP#

BYTE#

A

8

A

9

A

11

A

12

A

13

A

14

A

16

DQ

7

DQ

14

DQ

6

DQ

13

DQ

12

DQ

4

V

CC

DQ

5

A

10

A

15

DQ

15 -1

/A

GND

WE#

RP#

BYTE#

A

8

A

9

A

11

A

12

A

13

A

14

A

16

DQ

7

DQ

14

DQ

6

DQ

13

DQ

12

DQ

4

V

CC

DQ

5

A

10

A

15

DQ

15 -1

/A

0599-01

NOTE: Pin 2 is WP# on 2- and 4-Mbit devices but A18 on the 8-Mbit because no other pins were available for the high order

address. Thus, the 8-Mbit in 44-PSOP cannot unlock the boot block without RP# = VHH. See Section 3.3 for details. To allow

upgrades to 8-Mbit from 2/4-Mbit in this package design pin 2 to control WP# at the 2/4-Mbit level and A18 at the 8-Mbit density.

Figure 1. 44-Lead PSOP Pinout Diagram

28F200

Boot Block

48-Lead TSOP

12 mm x 20 mm

TOP VIEW

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

24

23

22

21

20

19

17

18

1

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

25

26

27

28

29

30

31

32

CE#

OE#

GND

A

0

V

CC

GND

BYTE#

A

16

DQ

15

/A

-1

DQ

7

DQ

14

DQ

6

DQ

13

DQ

5

DQ

12

DQ

4

DQ

11

DQ

10

DQ

2

DQ

9

DQ

1

DQ

8

DQ

0

DQ

3

CE#

OE#

GND

A

0

V

CC

GND

BYTE#

A

16

DQ

15

/A

-1

DQ

7

DQ

14

DQ

6

DQ

13

DQ

5

DQ

12

DQ

4

DQ

11

DQ

10

DQ

2

DQ

9

DQ

1

DQ

8

DQ

0

DQ

3

CE#

OE#

GND

A

0

V

CC

GND

BYTE#

A

16

DQ

15

/A

-1

DQ

7

DQ

14

DQ

6

DQ

13

DQ

5

DQ

12

DQ

4

DQ

11

DQ

10

DQ

2

DQ

9

DQ

1

DQ

8

DQ

0

DQ

3

28F400 28F80028F40028F800

RP#

WE#

NC

NC

NC

WP#

A

15

A

14

A

13

A

12

A

11

A

10

A

9

A

8

V

PP

A

17

A

6

A

7

A

4

A

5

A

3

A

2

RP#

WE#

NC

NC

NC

WP#

A

15

A

14

A

13

A

12

A

11

A

10

A

9

A

8

V

PP

A

6

A

7

A

4

A

5

A

3

A

2

RP#

WE#

NC

NC

NC

WP#

A

18

A

15

A

14

A

13

A

12

A

11

A

10

A

9

A

8

V

PP

A

17

A

6

A

7

A

4

A

5

A

3

A

2

NC

NC

NC

1

A

1

A

1

A

0599-02

Figure 2. 48-Lead TSOP Pinout Diagram

SMART 5 BOOT BLOCK MEMORY FAMILY E

10

PRODUCT PREVIEW

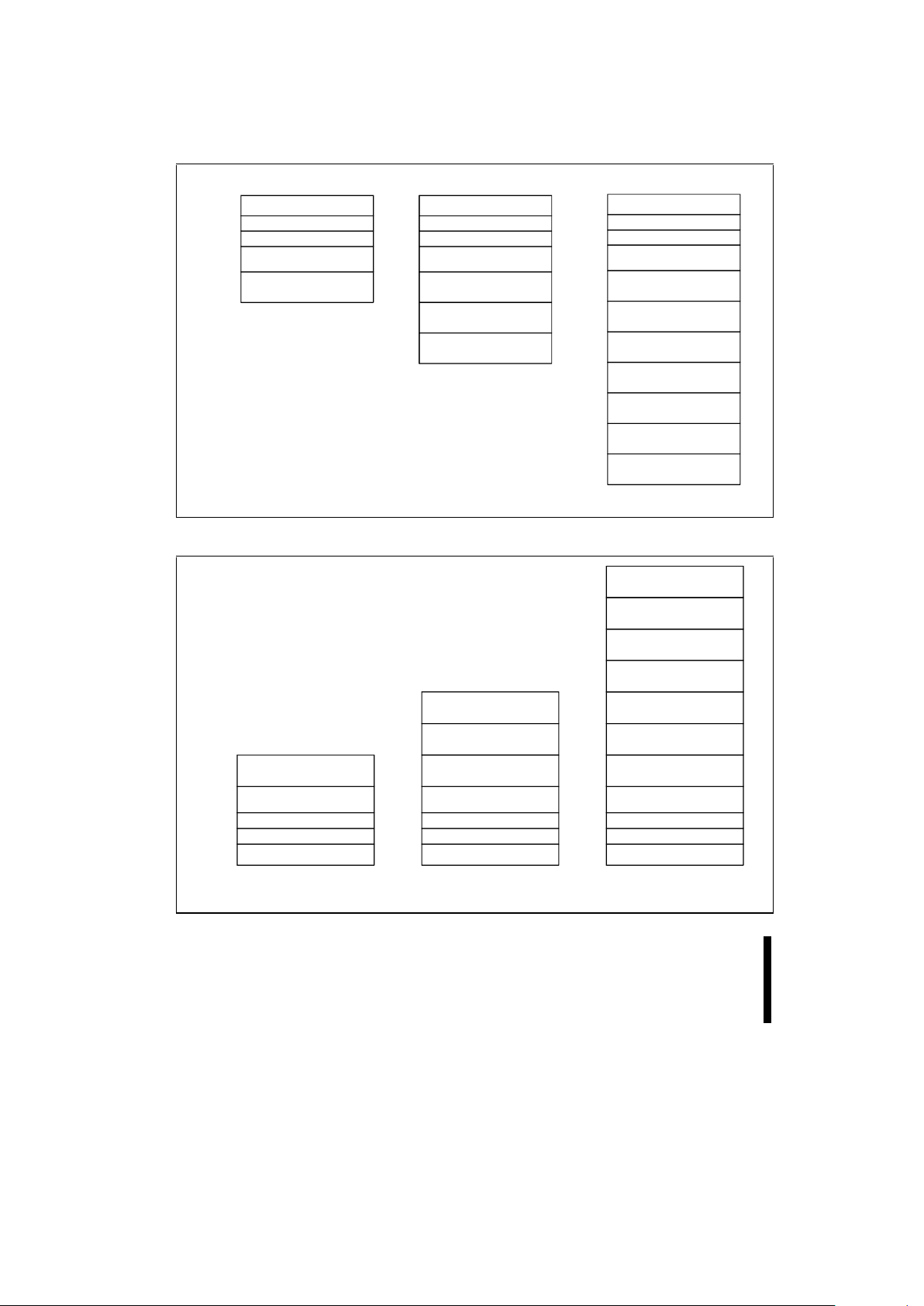

2.3 Memory Blocking Organization

The boot block product family features an

asymmetrically-blocked architecture providing

system memory integration. Each erase block can

be erased independently of the others up to

100,000 times for commerc ial temperature or up to

10,000 times for extended tem perature. The block

sizes have been chosen to optimize their

functionality for common appli cations of nonvolatile

storage. The combination of block sizes in the boot

block architecture allow the integration of several

memories into a single chip. For the address

locations of the blocks, see the memory maps in

Figures 3, 4, 5 and 6.

2.3.1 ONE 16-KB BOOT BLOCK

The boot block is intended to repl ace a dedicated

boot PROM in a microprocess or or microcontrollerbased system. The 16-Kbyte (16,384 bytes) boot

block is located at either the top (denoted by -T

suffix) or the bottom (-B suffix) of the address m ap

to accommodate different microproces sor protocols

for boot code location. This boot block features

hardware controllable write-protection to protec t the

crucial microprocessor boot code from accidental

modification. The protection of the boot block is

controlled using a combinati on of the V

PP

, RP#, and

WP# pins, as is detailed in Section 3.3.

2.3.2 TWO 8-KB PARAMETER BLOCKS

Each boot block component c ontains two parameter

blocks of 8 Kbytes (8,192 bytes) each to facilitate

storage of frequently updated s mall param eters t hat

would normally require an EEPROM. By using

software techniques, the byte-rewrite functionality

of EEPROMs can be emulated. These tec hniques

are detailed in Intel’s application note,

AP-604

Using Intel’s Boot B lock Flash Memory Parameter

Blocks to Replace EEPROM

. The parameter blocks

are not write-protectable.

2.3.3 MAIN BLOCKS - ONE 96-KB +

ADDITIONAL 128-KB BLOCKS

After the allocation of address space to the boot

and parameter blocks, the remainder is divided into

main blocks for data or code storage. Each device

contains one 96-Kbyte (98,304 byte) block and

additional 128-Kbyte (131,072 byte) blocks. The

2-Mbit has one 128-KB block; the 4-M bit , t hree; and

the 8-Mbit, seven.

E SMART 5 BOOT BLOCK MEMORY FAMILY

11

PRODUCT PREVIEW

128-Kbyte MAIN BLOCK

8-Kbyte PARAMETER BLOCK

16-Kbyte BOOT BLOCK

8-Kbyte PARAMETER BLOCK

96-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

00000H

0FFFFH

10000H

1FFFFH

20000H

2FFFFH

30000H

3FFFFH

40000H

4FFFFH

50000H

5FFFFH

60000H

6FFFFH

70000H

7BFFFH

7C000H

7CFFFH

7D000H

7DFFFH

7E000H

7FFFFH

28F800-T

128-Kbyte MAIN BLOCK

8-Kbyte PARAMETER BLOCK

16-Kbyte BOOT BLOCK

8-Kbyte PARAMETER BLOCK

96-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

00000H

0FFFFH

10000H

1FFFFH

20000H

2FFFFH

30000H

3BFFFH

3C000H

3CFFFH

3D000H

3DFFFH

3E000H

3FFFFH

28F400-T

128-Kbyte MAIN BLOCK

8-Kbyte PARAMETER BLOCK

16-Kbyte BOOT BLOCK

8-Kbyte PARAMETER BLOCK

96-Kbyte MAIN BLOCK

00000H

0FFFFH

10000H

1BFFFH

1C000H

1CFFFH

1D000H

1DFFFH

1E000H

1FFFFH

28F200-T

0599-03

NOTE: Word addresses shown.

Figure 3. Word-Wide x16-Mode Memory Maps (Top Boot)

128-Kbyte MAIN BLOCK

8-Kbyte PARAMETER BLOCK

16-Kbyte BOOT BLOCK

8-Kbyte PARAMETER BLOCK

96-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

7FFFFH

70000H

6FFFFH

60000H

5FFFFH

50000H

4FFFFH

40000H

3FFFFH

30000H

2FFFFH

20000H

1FFFFH

10000H

0FFFFH

04000H

03FFFH

03000H

02FFFH

02000H

01FFFH

00000H

28F800-B

128-Kbyte MAIN BLOCK

8-Kbyte PARAMETER BLOCK

16-Kbyte BOOT BLOCK

8-Kbyte PARAMETER BLOCK

96-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

3FFFFH

30000H

2FFFFH

20000H

1FFFFH

10000H

0FFFFH

04000H

03FFFH

03000H

02FFFH

02000H

01FFFH

00000H

28F400-B

128-Kbyte MAIN BLOCK

8-Kbyte PARAMETER BLOCK

16-Kbyte BOOT BLOCK

8-Kbyte PARAMETER BLOCK

96-Kbyte MAIN BLOCK

1FFFFH

10000H

0FFFFH

04000H

03FFFH

03000H

02FFFH

02000H

01FFFH

00000H

28F200-B

0599-04

NOTE: Word addresses shown.

Figure 4. Word-Wide x16-Mode Memory Maps (Bottom Boot)

SMART 5 BOOT BLOCK MEMORY FAMILY E

12

PRODUCT PREVIEW

128-Kbyte MAIN BLOCK

8-Kbyte PARAMETER BLOCK

16-Kbyte BOOT BLOCK

8-Kbyte PARAMETER BLOCK

96-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

00000H

1FFFFH

20000H

3FFFFH

40000H

5FFFFH

60000H

7FFFFH

80000H

9FFFFH

A0000H

BFFFFH

C0000H

DFFFFH

E0000H

F7FFFH

F8000H

F9FFFH

FA000H

FBFFFH

FC000H

FFFFFH

28F800-T

128-Kbyte MAIN BLOCK

8-Kbyte PARAMETER BLOCK

16-Kbyte BOOT BLOCK

8-Kbyte PARAMETER BLOCK

96-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

00000H

1FFFFH

20000H

3FFFFH

40000H

5FFFFH

60000H

77FFFH

78000H

79FFFH

7A000H

7BFFFH

7C000H

7FFFFH

28F400-T

128-Kbyte MAIN BLOCK

8-Kbyte PARAMETER BLOCK

16-Kbyte BOOT BLOCK

8-Kbyte PARAMETER BLOCK

96-Kbyte MAIN BLOCK

00000H

1FFFFH

20000H

37FFFH

38000H

39FFFH

3A000H

3BFFFH

3C000H

3FFFFH

28F200-T

Byte-Mode Addresses

0599-05

NOTE: In x8 operation, the least significant system address should be connected to A-1.

Figure 5. Byte-Wide x8-Mode Memory Maps (Top Boot)

128-Kbyte MAIN BLOCK

28F200-B

8-Kbyte PARAMETER BLOCK

16-Kbyte BOOT BLOCK

28F400-B

8-Kbyte PARAMETER BLOCK

96-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

8-Kbyte PARAMETER BLOCK

16-Kbyte BOOT BLOCK

8-Kbyte PARAMETER BLOCK

96-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

8-Kbyte PARAMETER BLOCK

16-Kbyte BOOT BLOCK

8-Kbyte PARAMETER BLOCK

96-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

128-Kbyte MAIN BLOCK

FFFFFH

E0000H

DFFFFH

C0000H

BFFFFH

A0000H

9FFFFH

80000H

7FFFFH

60000H

5FFFFH

40000H

3FFFFH

20000H

1FFFFH

08000H

07FFFH

06000H

05FFFH

04000H

03FFFH

00000H

28F800-B

7FFFFH

60000H

5FFFFH

40000H

3FFFFH

20000H

1FFFFH

08000H

07FFFH

06000H

05FFFH

04000H

03FFFH

00000H

3FFFFH

20000H

1FFFFH

08000H

07FFFH

06000H

05FFFH

04000H

03FFFH

00000H

Byte-Mode Addresses

0599-06

NOTE: In x8 operation, the least significant system address should be connected to A-1.

Figure 6. Byte-Wide x8-Mode Memory Maps (Bottom Boot)

E SMART 5 BOOT BLOCK MEMORY FAMILY

13

PRODUCT PREVIEW

3.0 PRINCIPLES OF OPERATION

The system processor accesses the Smart 5 boot

block memories through the Command User

Interface (CUI), which accepts commands written

with standard microprocessor write timings and

TTL-level control inputs. The flash can be s witched

into each of its read and write modes through

commands issued to the CUI.

The flash memory has three read modes and two

write modes. The read modes are read array, read

identifier, and read status. The write modes are

program and block erase. An additional mode,

erase suspend to read, is available only during

suspended block erasures. A comprehensive chart

showing the state transitions is in Appendix B.

After initial device power-up or return from deep

power-down mode, the device defaults to read

array mode. In this mode, manipulation of the

memory control pins allows array read, standby,

and output disable operations. The other read

modes, read identifier and read st atus register, can

be reached by issuing the appropriate c ommand to

the CUI. Array data, Identifier codes and status

register results can be accessed using these

commands independently from the V

PP

voltage.

Read identifier mode can also be accessed by

PROM programming equipment by raising A

9

to

high voltage (V

ID

).

CUI commands sequences also control the write

functions of the flas h memory, Program and E rase.

Issuing program or erase command sequences

internally latches addresses and data and initiates

Write State Machine (WSM) operations t o execute

the requested write function. The WSM internally

regulates the program and erase algorithms,

including pulse repetition, internal verification, and

margining of data, freeing t he host processor from

these tasks and allowing precise control for high

reliability. To execute Program or Erase

commands, V

PP

must be at valid write voltage (5V

or 12V).

While the WSM is executing a program operati on,

the device defaults to t he read stat us regist er mode

and all commands are ignored. Thus during the

programming process, only s tatus regis ter data can

be accessed from the device. While the WSM is

executing a erase operation, the device also

defaults to the read status register mode but one

additional command is available, erase suspend to

read, which will suspend the erase operation and

allow reading of array data. The suspended eras e

operation can be completed by issuing the Erase

Resume command. After the program or erase

operation has completed, the device remains in

read status register mode. From this mode any of

the other read or write modes can be reached with

the appropriate command. For example, to read

data, issue the Read Array command. Additional

Program or Erase commands can also be issued

from this state.

During program or erase operations, the array data

is not available for reading or code execution,

except during an erase suspend. Cons equently, the

software that initiates and polls progres s of program

and erase operations must be copied to and

executed from system RAM during flash memory

update. After successful completion, reads are

again possible via the Read Array command.

Each of the device modes will be discussed in

detail in the following sections.

3.1 Bus Operations

The local CPU reads and writes flash memory insystem. All bus cycles to or from the flash memory

conform to standard microprocessor bus cycles.

Four control pins dictate t he data flow in and out of

the component: CE#, OE#, WE#, and RP#. These

bus operations are summarized in Table 3 and 4.

3.1.1 READ

The flash memory has three read modes av ailable,

read array, read identifier, and read s tatus. These

read modes are accessible independent of the V

PP

voltage. RP# can be at either VIH or VHH. The

appropriate read-mode command must be is sued t o

the CUI to enter the corresponding mode. Upon

initial device power-up or after exit from deep

power-down mode, the device automatically

defaults to read array mode.

CE# and OE# must be driven active to obtain dat a

at the outputs. CE# is the device s election control,

and, when active, enables the selected memory

device. OE# is the data output (DQ

0

–DQ15) control

and when active drives the s elected memory data

onto the I/O bus. In read modes , WE# must be at

V

IH

and RP# must be at VIH or VHH. Figure 14

illustrates a read cycle.

SMART 5 BOOT BLOCK MEMORY FAMILY E

14

PRODUCT PREVIEW

3.1.2 OUTPUT DISABLE

With OE# at a logic-high level (V

IH

), the device

outputs are disabled. Output pins DQ

0

–DQ15 are

placed in a high-impedance state.

3.1.3 STANDBY

Deselecting the device by bringi ng CE# to a logichigh level (V

IH

) places the device in standby mode

which substantially reduces device power

consumption. In standby, outputs DQ

0

–DQ

15

are

placed in a high-impedance state independent of

OE#. If deselected during program or erase

operation, the device continues functioning and

consuming active power until the operation

completes.

3.1.4 WORD/BYTE CONFIGURATION

The device can be configured for either an 8-bit or

16-bit bus width by setting the BYTE# pin before

power-up.

When BYTE# is set to logic low, the byte-wide

mode is enabled, where data is read and

programmed on DQ

0

–DQ7 and DQ15/A–1 becomes

the lowest order address that decodes bet ween the

upper and lower byte. DQ

8

–DQ14 are tri-stated

during the byte-wide mode.

When BYTE# is at logic high, the word-wide mode

is enabled, and data is read and programmed on

DQ

0

–DQ15.

3.1.5 DEEP POWER-DOWN/RESET

RP# at V

IL

initiates the deep power-down mode,

also referred to as Reset mode.

From read mode, RP# going low for time t

PLPH

deselects the memory, places output drivers in a

high-impedance state, and turns off all internal

circuits. After return from power-down, a time t

PHQV

is required until the initial mem ory access outputs

are valid. A delay (t

PHWL

or t

PHEL

) is required after

return from power-down before a write can be

initiated. After this wake-up interval, normal

operation is restored. The CUI resets t o read array

mode, and the status register is set to 80H. This

case is shown in Figure 13A.

If RP# is taken low for time t

PLPH

during a program

or erase operation, the operation will be aborted

and the memory contents at the aborted location

(for a program) or block (for an erase) are no longer

valid, since the data may be partially erased or

written. The abort process goes through the

following sequence: When RP# goes low, the

device shuts down the operation in progress, a

process which takes time t

PLRH

to complete. After

this time t

PLRH

, the part will either reset to read

array mode (if RP# has gone high during t

PLRH

,

Figure 13B) or enter deep power-down mode (if

RP# is still logic low after t

PLRH

, Figure 13C). In

both cases, after returning from an aborted

operation, the relevant time t

PHQV

or t

PHWL/tPHEL

must be waited before a read or write operati on is

initiated, as discussed in the previous paragraph.

However, in this case, these delays are ref erenced

to the end of t

PLRH

rather than when RP# goes high.

As with any automated device, it is important to

assert RP# during system reset. When the system

comes out of reset, proc essor expect s to read from

the flash memory. Automated flash memories

provide status information when read during

program or block erase operations. I f a CPU reset

occurs with no flash memory reset, proper CPU

initialization may not occur because the flash

memory may be providing status information

instead of array data. Int el’s Flash memories all ow

proper CPU initialization following a system reset

through the use of the RP# input. I n this applicati on,

RP# is controlled by the same RESET# signal that

resets the system CPU.

3.1.6 WRITE

The CUI does not occupy an address able memory

location. Instead, commands are written into the

CUI using standard microprocessor write timings

when WE# and CE# are low, OE# = V

IH

, and the

proper address and data (command) are pres ented.

The address and data for a com mand are latched

on the rising edge of WE# or CE#, whichever goes

high first. Figure 15 illustrates a write operation.

E SMART 5 BOOT BLOCK MEMORY FAMILY

15

PRODUCT PREVIEW

Table 3. Bus Operations for Word-Wide Mode (BYTE# = VIH)

Mode Notes RP# CE# OE# WE# A

9

A

0

V

PP

DQ

0–15

Read 1,2,3 V

IH

V

IL

V

IL

V

IH

XXX D

OUT

Output Disable V

IH

V

IL

V

IH

V

IH

X X X High Z

Standby V

IH

V

IH

XXXXXHigh Z

Deep Power-Down 9 V

IL

XXXXXXHigh Z

Intelligent Identifier

(Mfr.)

4VIHV

IL

V

IL

V

IH

V

ID

V

IL

X 0089 H

Intelligent Identifier

(Device)

4,5 V

IH

V

IL

V

IL

V

IH

V

ID

V

IH

X See

Table 5

Write 6,7,8 V

IH

V

IL

V

IH

V

IL

XXX D

IN

Table 4. Bus Operations for Byte-Wide Mode (BYTE# = VIL)

Mode Notes RP# CE# OE# WE# A

9

A0A

–1

V

PP

DQ

0–7

DQ

8–14

Read 1,2,3 V

IH

V

IL

V

IL

V

IH

XXXXD

OUT

High Z

Output

Disable

V

IH

V

IL

V

IH

V

IH

XXXXHigh Z High Z

Standby V

IH

V

IH

XXXXXXHigh Z High Z

Deep PowerDown

9VILXXXXXXXHigh Z High Z

Intelligent

Identifier

(Mfr.)

4V

IH

V

IL

V

IL

V

IH

V

ID

V

IL

X X 89H High Z

Intelligent

Identifier

(Device)

4,5 V

IH

V

IL

V

IL

V

IH

V

ID

V

IH

X X See

Table

5

High Z

Write 6,7,8 V

IH

V

IL

V

IH

V

IL

XXXXDINHigh Z

NOTES:

1. Refer to DC Characteristics.

2. X can be V

IL

, VIH for control pins and addresses, V

PPLK

or V

PPH

for VPP.

3. See DC Characteristics for V

PPLK

, V

PPH1

, V

PPH2

, VHH, VID voltages.

4. Manufacturer and device codes may also be accessed via a CUI write sequence, A

0

selects, all other addresses = X.

5. See Table 5 for device IDs.

6. Refer to Table 7 for valid D

IN

during a write operation.

7. Command writes for block erase or program are only executed when V

PP

= V

PPH1

or V

PPH2

.

8. To program or erase the boot block, hold RP# at V

HH

or WP# at VIH. See Section 3.3.

9. RP# must be at GND ± 0.2V to meet the maximum deep power-down current specified.

SMART 5 BOOT BLOCK MEMORY FAMILY E

16

PRODUCT PREVIEW

3.2 Modes of Operation

The flash memory has three read modes and two

write modes. The read modes are read array, read

identifier, and read status. The write modes are

program and block erase. An additional mode,

erase suspend to read, is available only during

suspended block erasures. These modes are

reached using the commands summarized in

Table 6. A comprehensive chart showi ng the state

transitions is in Appendix B.

3.2.1 READ ARRAY

After initial device power-up or return from deep

power-down mode, the device defaults to read

array mode. This mode can also be entered by

writing the Read Array command (FFH). The devi ce

remains in this mode until another command is

written.

Data is read by presenting the address of the read

location in conjunction with a read bus operation.

Once the WSM has started a program or block

erase operation, the device will not recognize the

Read Array command until the WS M completes its

operation unless the WSM is suspended via an

Erase Suspend command. The Read Array

command functions independently of the V

PP

voltage and RP# can be VIH or VHH.

During system design, consideration should be

taken to ensure address and control inputs meet

required input slew rates of <10 ns as defined in

Figures 10 and 11.

3.2.2 READ IDENTIFIER

To read the manufacturer and device codes, the

device must be in intelligent identifier read mode,

which can be reached using two methods: by

writing the intelligent identifier command (90H) or

by taking the A

9

pin to VID. Once in intelligent

identifier read mode, A

0

= 0 outputs the

manufacturer’s identification code and A

0

= 1

outputs the device code. In byte-wide mode, only

the lower byte of the above signatures is read

(DQ

15/A–1

is a “don’t care” in this mode). See

Table 5 for product signatures. To return to read

array mode, write a Read Array command (FFH).

Table

5

. Word-Mode

Intelligent Identifier Codes

Product Mfr. ID Device ID

-T

Top Boot-BBottom Boot

28F200 0089 H 2274 H 2275 H

28F400 0089 H 4470 H 4471 H

28F800 0089 H 889C H 889D H

NOTE: In byte-mode, the upper byte will be tri-stated.

3.2.3 READ STATUS REGISTER

The device Status Register indicates when a

program or erase operation is complete, and the

success or failure of that operation. The status

register is output when the devi ce is read in read

status register mode, which can be entered by

issuing the Read Status (70H) command to the

CUI. This mode is automatically entered when a

program or erase operation is initiated, and the

device remains in this mode after t he operation has

completed. The status register bit codes are

defined in Table 8

The Status Register bits are output on DQ

0

–DQ7, in

both byte-wide (x8) or word-wide (x16) m ode. In the

word-wide mode, the upper byte, DQ

8

–DQ15,

outputs 00H during a Read Status comm and. In the

byte-wide mode, DQ

8

–DQ14 are tri-stated and

DQ

15/A–1

retains the low order address function.

Note that the contents of the Status Register are

latched on the falling edge of OE# or CE#,

whichever occurs last in the read cycle. This

prevents possible bus errors which might occur if

Status Register cont ents change while being read.

CE# or OE# must be toggled wit h each subs equent

status read, or the Status Register will not indicate

completion of a program or erase operation.

To return to reading from the array, is sue a Read

Array (FFH) command.

3.2.3.1 Clearing the Status Register

Status register bits SR.5, S R.4, and SR. 3 are set to

“1”s when appropriate by the WSM but can only be

reset by the Clear Status Register command.

These bits indicate various failure conditions (see

Table 8). By requiring system software to reset

these bits, several operations (suc h as cum ulati vely

E SMART 5 BOOT BLOCK MEMORY FAMILY

17

PRODUCT PREVIEW

erasing multiple blocks or programming several

bytes in sequence) may be performed before

polling the Status Regist er to determine if an error

occurred during the series.

Issue the Clear Status Regis ter command (50H) to

clear the status register. I t functions independently

of the applied V

PP

voltage and RP# can be VIH or

V

HH

. This command is not functional during block

erase suspend modes. Resett ing the part with RP#

also clears the Status Register.

3.2.4 WORD/BYTE PROGRAM

Word or byte program operations are execut ed by a

two-cycle command sequence. Program Setup

(40H) is issued, followed by a second write that

specifies the address and data (latched on the

rising edge of WE# or CE#, whichev er comes f irst).

The WSM then takes over, c ontrolling the program

and program verify algorithms int ernally. While the

WSM is working, the device automatically enters

read status register mode and remai ns there after

the word/byte program is compl ete. (see Figure 7).

The completion of the program event i s indicated on

status register bit SR.7.

When a word/byte program is complete, check

status register bit S R.4 for an error flag (“1”). The

cause of a failure may be found on SR.3, which

indicates “1” if V

PP

was out of program/erase

voltage range (V

PPH1

or V

PPH2

). The Status

Register should be cleared before the next

operation. The internal WSM verify only detects

errors for “1”s that do not successfully write to “0”s.

Since the device remains in Status Regis ter Read

mode after programming is c ompleted, a command

must be issued to switch to another mode before

beginning a different operation.

3.2.5 BLOCK ERASE

A block erase changes all block data to 1’s

(FFFFH) and is initiated by a two-cycle command.

An Erase Setup command (20H) is issued first,

followed by an Erase Confirm command (D0H)

along with an address within the target bl ock. The

address will be latched at the risi ng edge of WE# or

CE#, whichever comes first.

Internally, the WSM will program all bits in the block

to “0,” verify all bits are adequately programm ed to

“0,” erase all bits to “1,” and verify that all bit s in t he

block are sufficiently erased. After block erase

command sequence is issued, the device

automatically enters read status register mode and

outputs status register data when read (see

Figure 8). The completion of the erase event i s

indicated on status register bit SR.7.

When an erase is complete, check status register

bit SR.5 for an error flag (“1”). The caus e of a failure

may be found on SR.3, which indic ates “1” if V

PP

was out of program/erase volt age range (V

PPH1

or

V

PPH2

). If an Erase Setup (20H) com mand is is sued

but not followed by an Erase Confirm (D0H)

command, then both the Program Status (SR.4)

and the Erase Status (SR.5) will be set to “1.”

The Status Register should be cleared before the

next operation. Since the dev ice remains in Status

Register Read mode after erasing is complet ed, a

command must be issued to switch to another

mode before beginning a different operation.

3.2.5.1 Erase Suspend/Resume

The Erase Suspend command (B0H) int errupts an

erase operation in order to read data in another

block of memory. While the erase is in progress,

issuing the Erase Suspend c ommand requests that

the WSM suspend the erase algorithm after a

certain latency period. The device outputs Status

Register data when read after the Erase Suspend

command is issued. S tatus Register bits SR.7 and

SR.6 indicate when the block erase operation has

been suspended (both will be set to “1”).

At this point, a Read Array command (FFH) can be

written to read from blocks other than that which is

suspended. The only other valid commands at this

time are Erase Resume (D0H) or Read Status

Register.

During erase suspend mode, the chip c an go into a

pseudo-standby mode by taki ng CE# to V

IH

, which

reduces active current draw. V

PP

must remain at

V

PPH1

or V

PPH2

(the same VPP level used for block

erase) while erase is suspended. RP# must also

remain at V

IH

or VHH (the same RP# level us ed for

block erase).

To resume the erase operation, enable the chip by

taking CE# to V

IL

, then issue the Erase Resume

command, which continues the erase s equence to

completion. As with the end of a standard erase

operation, the status regis ter m ust be read, c leared,

and the next instruction issued in order to continue.

SMART 5 BOOT BLOCK MEMORY FAMILY E

18

PRODUCT PREVIEW

Table 6. Command Codes and Descriptions

Code Device Mode Description

00 Invalid/

Reserved

Unassigned commands that should not be used. Intel reserves the right to redefine

these codes for future functions.

FF Read Array Places the device in read array mode, so that array data will be output on the data

pins.

40 Program

Set-Up

Sets the CUI into a state such that the next write will load the Address and Data

registers. The next

write after the Program Set-Up command will latch addresses

and data on the rising edge and begin the program algorithm. The device then

defaults to the read status mode, where the device outputs Status Register data

when OE# is enabled. To read the array, issue a Read Array command.

To cancel a program operation after issuing a Program Set-Up command, write all

1’s (FFH for x8, FFFFH for x16)

to the CUI. This will return to read status register

mode after a standard program time without modifying array contents. If a program

operation has already been initiated to the WSM this command can not cancel that

operation in progress.

10 Alternate

Prog Set-Up

(See 40H/Program Set-Up)

20 Erase

Set-Up

Prepares the CUI for the Erase Confirm command. If the next command is not an

Erase Confirm command, then the CUI will set both the Program Status (SR.4) and

Erase Status (SR.5) bits of the Status Register to a “1,” place the device into the

read Status Register state, and wait for another command without modifying array

contents. This can be used to cancel an erase operation after the Erase Setup

command has been issued. If an operation has already been initiated to the WSM

this can not cancel that operation in progress.

D0 Erase

Resume/

Erase

Confirm

If the previous command was an Erase Set-Up command, then the CUI will latch

address and data, and begin erasing the block indicated on the address pins.

During erase, the device will respond only to the Read Status Register and Erase

Suspend commands and will output Status Register data when OE# is toggled low.

Status Register data is updated by toggling either OE# or CE# low.

B0 Erase

Suspend

Valid only while an erase operation is in progress and will be ignored in any other

circumstance. Issuing this command will begin to suspend erase operation. The

Status Register will indicate when the device reaches erase suspend mode. In this

mode, the CUI will respond only to the Read Array, Read Status Register, and

Erase Resume commands and the WSM will also set the WSM Status bit to a “1”

(ready). The WSM will continue to idle in the SUSPEND state, regardless of the

state of all input control pins except RP#, which will immediately shut down the

WSM and the remainder of the chip, if it is made active. During a suspend

operation, the data and address latches will remain closed, but the address pads

are able to drive the address into the read path. See Section 3.2.5.1.

70 Read Status

Register

Puts the device into the read status register mode, so that reading the device

outputs status register data, regardless of the address presented to the device.

The device automatically enters this mode after program or erase has completed.

This is one of the two commands that is executable while the WSM is operating.

See Section 3.2.3.

E SMART 5 BOOT BLOCK MEMORY FAMILY

19

PRODUCT PREVIEW

Table 6. Command Codes and Descriptions (Continued)

Code Device Mode Description

50 Clear Status

Register

The WSM can only set the Program Status and Erase Status bits in the status

register to “1”; it cannot clear them to “0.”

The status register operates in this fashion for two reasons. The first is to give the

host CPU the flexibility to read the status bits at any time. Second, when

programming a string of bytes, a single status register query after programming the

string may be more efficient, since it will return the accumulated error status of the

entire string. See Section 3.2.3.1.

90 Intelligent

Identifier

Puts the device into the intelligent identifier read mode, so that reading the device

will output the manufacturer and device codes. (A

= 0 for manufacturer,

A

0

= 1 for device, all other address inputs are ignored). See Section 3.2.2.

Table 7. Command Bus Definitions

First Bus Cycle Second Bus Cycle

Command Note Oper Addr Data Oper Addr Data

Read Array Write X FFH

Intelligent Identifier 2,4 Write X 90H Read IA IID

Read Status Register 3 Write X 70H Read X SRD

Clear Status Register 3 Write X 50H

Word/Byte Program 6,7 Write PA 40H/10H Write PA PD

Block Erase/Confirm 5 Write BA 20H Write BA D0H

Erase Suspend Write X B0H

Erase Resume Write X D0H

ADDRESS DATA

BA = Block Address SRD = Status Register Data

IA = Identifier Address IID = Identifier Data

PA = Program Address PD = Program Data

X = Don’t Care

NOTES:

1. Bus operations are defined in Tables 3 and 4.

2. IA = Identifier Address: A

0

= 0 for manufacturer code, A0 = 1 for device code.

3. SRD - Data read from Status Register.

4. IID = Intelligent Identifier Data. Following the Intelligent Identifier command, two read operations access manufacturer and

device codes.

5. BA = Address within the block being erased.

6. PA = Address to be programmed. PD = Data to be programmed at location PA.

7. Either 40H or 10H commands is valid.

8. When writing commands to the device, the upper data bus [DQ

8

–DQ15] = X which is either VIL or VIH, to minimize current

draw.

SMART 5 BOOT BLOCK MEMORY FAMILY E

20

PRODUCT PREVIEW

Table 8. Status Register Bit Definition

WSMS ESS ES DWS VPPS R R R

76543210

NOTES:

SR.7 WRITE STATE MACHINE STATUS

1 = Ready (WSMS)

0 = Busy

Check WSM bit first to determine word/byte

program or block erase completion, before

checking Program or Erase Status bits.

SR.6 = ERASE-SUSPEND STATUS (ESS)

1 = Erase Suspended

0 = Erase In Progress/Completed

When Erase Suspend is issued, WSM halts

execution and sets both WSMS and ESS bits to

“1.” ESS bit remains set to “1” until an Erase

Resume command is issued.

SR.5 = ERASE STATUS (ES)

1 = Error In Block Erasure

0 = Successful Block Erase

When this bit is set to “1,” one of the following has

occurred:

1. V

PP

out of range.

2. WSM has applied the max number of erase

pulses to the block and is still unable to verify

successful block erasure.

3. Erase Setup command was followed by a

command other than Erase Confirm.

SR.4 = PROGRAM STATUS (DWS)

1 = Error in Byte/Word Program

0 = Successful Byte/Word Program

When this bit is set to “1,” one of the following has

occurred:

1. V

PP

out of range.

2. WSM has applied the max number of program

pulses and is still unable to v erify a successf ul

program.

3. Erase Setup command was followed by a

command other than Erase Confirm.

SR.3 = VPP STATUS (VPPS)

1 = V

PP

Low Detect, Operation Abort

0 = V

PP

OK

The V

PP

Status bit does not provide continuous

indication of V

PP

level. The WSM interrogates V

PP

level only after the Program or Erase command

sequences have been entered, and informs the

system if V

PP

is out of range. The VPPStatus bit is

not guaranteed to report accurate feedback

between V

PPLK

and V

PPH

.

SR.2-SR.0 = RESERVED FOR FUTURE

ENHANCEMENTS (R)

These bits are reserved for future use and should

be masked out when polling the Status Register.

E SMART 5 BOOT BLOCK MEMORY FAMILY

21

PRODUCT PREVIEW

SR.7 = 1

?

NO

YES

Start

Write 40H,

Word/Byte Address

Write Word/Byte

Data/Address

Full Stat us

Check if Desired

Word/Byte Program

Complete

FULL STATUS CHECK PROCED URE

1

0

Read Status Register

Data (See Above)

1

0

Read

Status Register

VPP Range Error

Bus

Operation

Command Comments

Standby

Standby

Check SR.3

1 = V

PP

Low Detect

SR.3 MUST be cleared, if set during a program attempt,

before further attempts are allowed by the Write State Machine.

SR.4 is only cleared by the Clear Status Register Command, in cases

where multiple bytes are programmed before full status is checked.

If error is detected, clear the Status Register before attempting

retry or other error recovery.

Bus

Operation

Command Comments

Write

Write

Setup

Program

Data = Data to Program

Addr = Location to Program

Read

Data = 40H

Addr = Word/Byte to Program

Check SR.7

1 = WSM Ready

0 = WSM Busy

Repeat for subsequent word/byte program operations.

SR Full Status Check can be done after each word/byte

program operation, or after a sequence of word/byte programs.

Write FFH after the last program operation to reset device to

read array mode.

Standby

SR.3 =

SR.4 =

Word/Byte Program

Error

Word/Byte Program

Successful

Check SR.4

1 = Word Byte Program Error

Program

Status Register Data

Toggle CE# or OE#

to Update SRD.

0599-07

Figure 7. Automated Word/Byte Program Flowchart

SMART 5 BOOT BLOCK MEMORY FAMILY E

22

PRODUCT PREVIEW

SR.7 =

0

1

Start

Write 20H,

Block Address

Write D0H and

Block Address

Full Status

Check if Desired

Block Erase

Complete

FULL STATUS CHECK PROCEDURE

1

0

Read Status Register

Data (See Above)

1

0

Read Status

Register

V Range Error

PP

Suspend

Erase

Suspend Erase

Loop

YES

NO

1

0

Command Sequence

Error

SR.3 =

SR.5 =

SR.4,5 =

Block Erase

Error

Bus

Operation

Command Comments

Standby

Check SR.4,5

Both 1 = Command

Sequence Error

Standby

Check SR.3

1 = V Low Detect

SR.3 MUST be cleared, if set during an erase attempt, before further

attempts are allowed by the Write State Machine.

SR.5 is only cleared by the Clear Status Register Command, in

cases where multiple blocks are erase before full status is checked.

If error is detected, clear the Status Register before attempting

retry or other error recovery.

Check SR.5

1 = Block Erase Error

Standby

Bus

Operation

Command Comments

Write

Write

Erase Setup

Read

Data = 20H

Addr = Within Block to be Erased

Check SR.7

1 = WSM Ready

0 = WSM Busy

Repeat for subsequent block erasures.

Full Status Check can be done after each block erase, or after a

sequence of block erasures.

Write FFH after the last operation to reset device to read array mode.

Status Register Data

Toggle CE# or OE#

to Update Status Register

Standby

Erase

Confirm

Data = D0H

Addr = Within Block to be Erased

Block Erase

Successful

PP

0599-08

Figure 8. Automated Block Erase Flowchart

E SMART 5 BOOT BLOCK MEMORY FAMILY

23

PRODUCT PREVIEW

SR.7 =

0

1

Start

Write B0H

Read

Status Register

Write D0H

Erase Resumed

Bus

Operation

Command Comments

Write

Erase

Suspend

Read

Data = B0H

Addr = X

Check SR.7

1 = WSM Ready

0 = WSM Busy

Status Register Data

Toggle CE# or OE#

to update SRD.

Addr = X

Standby

CSR.6 =

Write FFH

Read Array Data

Done

Reading

Erase Completed

Write FFH

Read Array Data

YES

NO

0

1

Check SR.6

1 = Erase Suspended

0 = Erase Completed

Standby

Data = FFH

Addr = X

Write

Read array data from block other

than the one being erased.

Read

Data = D0H

Addr = X

Write

Read Array

Erase Resume

0599-09

Figure 9. Erase Suspend/Resume Flowchart

SMART 5 BOOT BLOCK MEMORY FAMILY E

24

PRODUCT PREVIEW

3.3 Boot Block Locking

The boot block family architecture features a

hardware-lockable boot block so that the kernel

code for the system can be kept secure while the

parameter and main blocks are programmed and

erased independently as necessary. Only the boot

block can be locked independently from the other

blocks.

3.3.1 V

PP

= VIL FOR COMPLETE

PROTECTION

For complete write protection of all blocks in the

device, the V

PP

voltage can be held low. When V

PP

is below V

PPLK

, any program or erase operation will

result in a error in the Status Register.

3.3.2 WP# = V

IL

FOR BOOT BLOCK

LOCKING

When WP# = V

IL

, the boot block is loc ked and any

program or erase operation to the boot block will

result in an error in the Status Register. All other

blocks remain unlocked in this condition and can be

programmed or erased normally. Note that this

feature is overridden and the boot block unlocked

when RP# = V

HH

.

3.3.3 RP# = V

HH

OR WP# = VIH FOR BOOT

BLOCK UNLOCKING

Two methods can be used to unlock the boot block:

1. WP# = V

IH

2. RP# = V

HH

If both or either of these t wo condit ions are met , the

boot block will be unlocked and can be

programmed or erased.

The truth table, Table 9, clearly defines the write

protection methods.

3.3.4 NOTE FOR 8-MBIT 44-PSOP

PACKAGE

The 8-Mbit in the 44-PSOP pack age does not have

a WP# because no other pins were availabl e for t he

8-Mbit upgrade address. Thus, in this densitypackage combination only, V

HH

(12V) on RP# is

required to unlock the boot block and unlocking with

a logic-level signal is not possible. If this unlocking

functionality is required, and 12V i s not av ailable insystem, please consider using the 48-TSOP

package, which has a WP# pin and can be

unlocked with a logic-level signal. A ll other densitypackage combinations have WP# pins.

Table 9. Write Protection Truth Table

V

PP

RP# WP# Write Protection

Provided

V

IL

X X All Blocks Locked

≥ V

PPLKVIL

X All Blocks Locked

(Reset)

≥ V

PPLKVHH

X All Blocks Unlocked

≥ V

PPLKVIH

VILBoot Block Locked

≥ V

PPLKVIH

VIHAll Blocks Unlocked

4.0 DESIGN CONSIDERATIONS

The following section discusses recommended

design considerations which can improve the

robustness of system designs using flash memory.

4.1 Power Consumption

Intel flash components contai n features designed to

reduce power requirements. The fol lowing sections

will detail how to take advantage of these features.

4.1.1 ACTIVE POWER

Asserting CE# to a logic-low level and RP# to a

logic-high level places the device in the active

mode. Refer to the DC Characteristics table for I

CCR

current values.

4.1.2 AUTOMATIC POWER SAVINGS (APS)

Automatic Power Savings (APS) provides lowpower operation in active mode. P ower Reduction

Control (PRC) circuitry allows the device to put

itself into a low current state when not being

accessed. After data is read from the memory

array, PRC logic controls the device’s power

consumption by entering the APS mode where

typical I

CC

current is less than 1 mA. The device

stays in this static state with outputs valid until a

new location is read.

E SMART 5 BOOT BLOCK MEMORY FAMILY

25

PRODUCT PREVIEW

4.1.3 STANDBY POWER

When CE# is at a logic-high level (V

IH

), and the

device is not programming or eras ing, the memory

enters in standby mode, which disables much of the

device’s circuitry and substantially reduces power

consumption. Outputs (DQ

0

–DQ15 or DQ0–DQ7) are

placed in a high-impedance state independent of

the status of the OE# s ignal. When CE # is at logichigh level during program or erase operations, the

device will continue to perform the operation and

consume corresponding active power until the

operation is completed.

4.1.4 DEEP POWER-DOWN MODE

The Smart 5 boot block family supports a low

typical I

CCD

in deep power-down mode, which t urns

off all circuits to s ave power. This m ode is ac tiv ated

by the RP# pin when it is at a logic-low

(GND ± 0.2V).

Note: BYTE# pin must be at CMOS

levels to meet the I

CCD

specification.

During read modes, the RP# pin going low deselects the memory and pl aces the out put driv ers in

a high impedance state. Recovery from the deep

power-down state, requires a mi nimum access ti me

of t

PHQV

. RP# transitions to VIL, or turning power off

to the device will clear the Status Register.

During an program or erase operation, RP# going

low for time t

PLPH

will abort the operation, but the

location’s memory contents will no longer valid and

additional timing must be met. See Section 3.1.5

and 6.1 for additional information.

4.2 Power-Up/Down Operation

The device protects against accidental block

erasure or programming during power transitions.

Power supply sequencing is not required, so either

V

PP

or VCC can power-up first. The CUI defaults to

the read mode after power-up, but the system must

drop CE# low or present an address to receive valid

data at the outputs.

A system designer must guard against spurious

writes when V

CC

voltages are above V

LKO

and V

PP

is active. Since both WE# and CE# mus t be low for

a command write, driving either signal to V

IH

will

inhibit writes to t he device. Additi onal l y, alteration of

memory can only occur after successful completion

of a two-step command sequences. The device is

also disabled until RP# is brought t o V

IH

, regardless