Page 1

Intel® Xeon® Processor 5500 Series

Thermal/Mechanical Design Guide

March 2009

Document Number:321323-001

Page 2

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED,

BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS

PROVIDED IN INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER,

AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING T O SALE AND/OR USE OF INTEL PRODUCT S INCLUDING

LIABILITY OR WARRANTIES RELA TING T O FITNES S FOR A PARTICULAR PURPOSE, MERCHANT ABILITY, OR INFRINGEMENT OF ANY

PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. Intel products are not intended for use in medical, life savin g, or

life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked “reserved” or “undefined.” Intel

reserves these for future definition and shall have no responsibility whatsoev er for conflicts or incompatibilities arising from future

changes to them.

The Intel® Xeon® processor 5500 series and LGA1366 socket may contain design defects or errors known as errata which may

cause the product to deviate from published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Intel processor numbers are not a measure of performance. Processor numb ers differentia te features withi n each processo r family,

not across different processor families. See http://www.intel.com/products/processor_number for details. Over time processor

numbers will increment based on changes in clock, speed, cache, FSB, or other features, and increments are not intended to

represent proportional or quantitative increases in any particular feature. Current roadmap processor number progression is not

necessarily representative of future roadmaps. See www.intel.com/products/processor_number for details.

Intel® Turbo Boost Technology requires a PC with a processor with Intel Turbo Boost Technology capability. Intel Turbo Boost

Technology performance varies depending on hardware, software and overall system configuration. Check with your PC

manufacturer on whether your system delivers Intel Turbo Boost Technology. For more information, see www.intel.com.

Intel and the Intel logo are trademarks of Intel Corporation in the U.S and other countries.

* Other brands and names may be claimed as the property of others.

Copyright © 2009, Intel Corporation.

2 Thermal/Mechanical Design Guide

Page 3

Contents

1Introduction..............................................................................................................9

1.1 References.......................................................................................................10

1.2 Definition of Terms............................................................................................10

2 LGA1366 Socket ......................................................................................................13

2.1 Board Layout....................................................................................................15

2.2 Attachment to Motherboard................................................................................16

2.3 Socket Components...........................................................................................16

2.3.1 Socket Body Housing..............................................................................16

2.3.2 Solder Balls...........................................................................................16

2.3.3 Contacts ...............................................................................................17

2.3.4 Pick and Place Cover...............................................................................17

2.4 Package Installation / Removal ......... ..................................................................18

2.4.1 Socket Standoffs and Package Seating Plane..............................................18

2.5 Durability.........................................................................................................19

2.6 Markings..........................................................................................................19

2.7 Component Insertion Forces ...............................................................................19

2.8 Socket Size ......................................................................................................19

2.9 LGA1366 Socket NCTF Solder Joints.....................................................................20

3 Independent Loading Mechanism (ILM)...................................................................21

3.1 Design Concept.................................................................................................21

3.1.1 ILM Cover Assembly Design Overview.......................................................21

3.1.2 ILM Back Plate Design Overview...............................................................22

3.2 Assembly of ILM to a Motherboard.......................................................................23

4 LGA1366 Socket and ILM Electrical, Mechanical, and Environmental Specifications .27

4.1 Component Mass...............................................................................................27

4.2 Package/Socket Stackup Height ..........................................................................27

4.3 Socket Maximum Temperature............................................................................27

4.4 Loading Specifications.................................... .. .. .. ......................... .. .. .................28

4.5 Electrical Requirements......................................................................................28

4.6 Environmental Requirements .................................................................. ............29

5Thermal Solutions...................................................................................................31

5.1 Performance Targets..........................................................................................31

5.1.1 25.5 mm Tall Heatsink............................................................................33

5.2 Heat Pipe Considerations....................................................................................34

5.3 Assembly .........................................................................................................35

5.3.1 Thermal Interface Material (TIM)..............................................................36

5.4 Structural Considerations ...................................................................................36

5.5 Thermal Design.................................................................................................36

5.5.1 Thermal Characterization Parameter.........................................................36

5.5.2 Dual Thermal Profile ...............................................................................37

5.6 Thermal Features..............................................................................................38

5.6.1 Fan Speed Control..................................................................................39

5.6.2 PECI Averaging and Catastrophic Thermal Management...............................40

5.6.3 Intel® Turbo Boost Technology................................................................40

5.7 Thermal Guidance .............................................................................................40

5.7.1 Thermal Excursion Power for 95 W Processor .............................................40

5.7.2 Thermal Excursion Power for 80 W Processor .............................................41

5.7.3 Absolute Processor Temperature ..............................................................41

Thermal/Mechanical Design Guide 3

Page 4

6 Quality and Reliability Requirements .......................................................................43

6.1 Test Conditions .................................................................................................43

6.2 Intel Reference Component Validation ..................................................................45

6.2.1 Board Functional Test Sequence ...............................................................45

6.2.2 Post-Test Pass Criteria.............................................................................45

6.2.3 Recommended BIOS/Processor/Memory Test Procedures .............................46

6.3 Material and Recycling Requirements....................................................................46

A Component Su ppliers...............................................................................................47

A.1 Intel Enabled Supplier Information.......................................................................47

A.1.1 Intel Reference Thermal Solution..............................................................47

A.1.2 Intel Collaboration Thermal Solution..........................................................47

A.1.3 Alternative Thermal Solution ....................................................................48

A.1.4 Socket and ILM Components....................................................................49

B Mechanical Drawings ...............................................................................................51

C Socket Mechanical Drawings....................................................................................79

D Heatsink Load Metrology..........................................................................................85

E Embedded Thermal Solutions...................................................................................87

E.1 Performance Targets.................................................. ........................................87

E.2 Thermal Design Guidelines................................ .. ........................... .. ...................88

E.2.1 NEBS Thermal Profile ..............................................................................88

E.2.2 Custom Heat Sinks For UP ATCA...............................................................89

E.3 Mechanical Drawings and Supplier Information......................................................92

F Processor Installation Tool ......................................................................................97

Figures

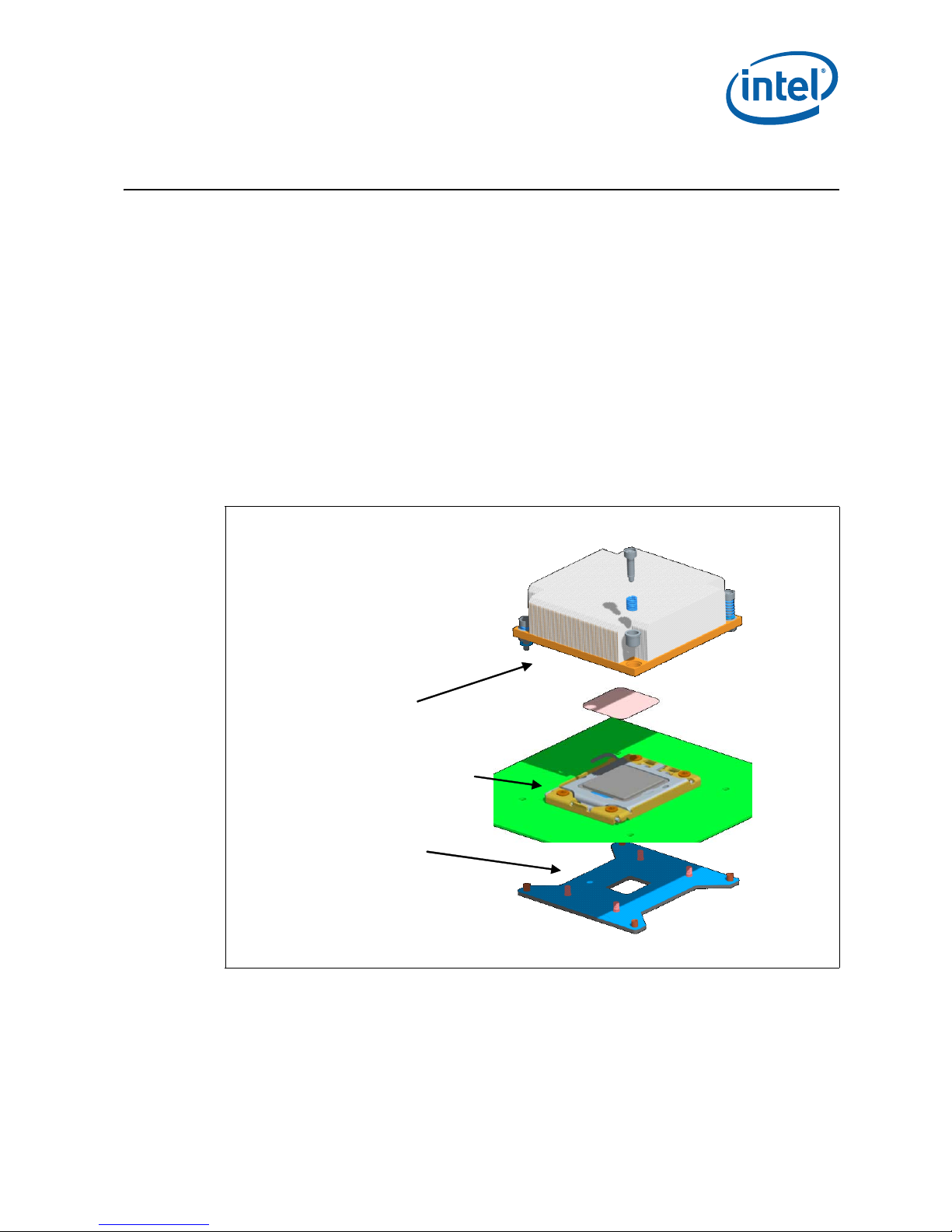

1-1 Intel® Xeon® 5500 Platform Socket Stack................................................................... 9

2-1 LGA1366 Socket with Pick and Place Cover Removed ....................................................13

2-2 LGA1366 Socket Contact Numbering (Top View of Socket).............................................14

2-3 LGA1366 Socket Land Pattern (Top View of Board) .......................................................15

2-4 Attachment to Motherboard .......................................................................................16

2-5 Pick and Place Cover.................................................................................................17

2-6 Package Installation / Removal Features......................................................................18

2-7 LGA1366 NCTF Solder Joints......................................................................................20

3-1 ILM Cover Assembly ................... .. ................................................... .. .. .. ...................22

3-2 Back Plate ...............................................................................................................23

3-3 ILM Assembly .................... ......................... .. .. .......................... .. .. ......................... ..24

3-4 Pin1 and ILM Lever...................................................................................................25

4-1 Flow Chart of Knowledge-Based Reliability Evaluation Methodology .................................30

5-1 1U Heatsink Performance Curves.................................... .. ..........................................32

5-2 TTV Die Size and Orientation......................................................................................34

5-3 1U Reference Heatsink Assembly................................................................................35

5-4 Processor Thermal Characterization Parameter Relationships..........................................37

5-5 Dual Thermal Profile .................................................................................................38

6-1 Example Thermal Cycle - Actual profile will vary ...........................................................45

B-1 Board Keepin / Keepout Zones (Sheet 1 of 4)...............................................................52

B-2 Board Keepin / Keepout Zones (Sheet 2 of 4)...............................................................53

B-3 Board Keepin / Keepout Zones (Sheet 3 of 4)...............................................................54

B-4 Board Keepin / Keepout Zones (Sheet 4 of 4)...............................................................55

B-5 1U Reference Heatsink Assembly (Sheet 1 of 2) ...........................................................56

B-6 1U Reference Heatsink Assembly (Sheet 2 of 2) ...........................................................57

4 Thermal/Mechanical Design Guide

Page 5

B-7 1U Reference Heatsink Fin and Base (Sheet 1 of 2) ......................................................58

B-8 1U Reference Heatsink Fin and Base (Sheet 2 of 2) ......................................................59

B-9 Heatsink Shoulder Screw (1U, 2U and Tower)..............................................................60

B-10Heatsink Compression Spring (1U, 2U and Tower)........................................................61

B-11Heatsink Retaining Ring (1U, 2U and Tower) ...............................................................62

B-12Heatsink Load Cup (1U, 2U and Tower).......................................................................63

B-132U Collaborative Heatsink Assembly (Sheet 1 of 2).......................................................64

B-142U Collaborative Heatsink Assembly (Sheet 2 of 2).......................................................65

B-152U Collaborative Heatsink Volumetric (Sheet 1 of 2).....................................................66

B-162U Collaborative Heatsink Volumetric (Sheet 2 of 2).....................................................67

B-17Tower Collaborative Heatsink Assembly (Sheet 1 of 2)..................................................68

B-18Tower Collaborative Heatsink Assembly (Sheet 2 of 2)..................................................69

B-19Tower Collaborative Heatsink Volumetric (Sheet 1 of 2) ................................................70

B-20Tower Collaborative Heatsink Volumetric (Sheet 2 of 2) ................................................71

B-211U Reference Heatsink Assembly with TIM (Sheet 1 of 2)..............................................72

B-221U Reference Heatsink Assembly with TIM (Sheet 2 of 2)..............................................73

B-232U Reference Heatsink Assembly with TIM (Sheet 1 of 2)..............................................74

B-242U Reference Heatsink Assembly with TIM (Sheet 2 of 2)..............................................75

B-25Tower Reference Heatsink Assembly with TIM (Sheet 1 of 2) .................. .. .. ...................76

B-26Tower Reference Heatsink Assembly with TIM (Sheet 2 of 2) .................. .. .. ...................77

C-1 Socket Mechanical Drawing (Sheet 1 of 4)...................................................................80

C-2 Socket Mechanical Drawing (Sheet 2 of 4)...................................................................81

C-3 Socket Mechanical Drawing (Sheet 3 of 4)...................................................................82

C-4 Socket Mechanical Drawing (Sheet 4 of 4)...................................................................83

D-1 Intel® Xeon® Processor 5500 Series Load Cell Fixture.................................................. 86

E-1 ATCA Heatsink Performance Curves............................................................................88

E-2 NEBS Thermal Profile................................................................................................89

E-3 UP ATCA Thermal Solution......... .. .. .......................... .. .. ......................... .. ...................90

E-4 UP ATCA System Layout ............................ .. ......................... ... .. ......................... .. .. ..90

E-5 UP ATCA Heat Sink Drawing ......................................................................................91

E-6 ATCA Reference Heat Sink Assembly (Sheet 1 of 2)......................................................93

E-7 ATCA Reference Heat Sink Assembly (Sheet 2 of 2)......................................................94

E-8 ATCA Reference Heatsink Fin and Base (Sheet 1 of 2)...................................................95

E-9 ATCA Reference Heatsink Fin and Base (Sheet 2 of 2)...................................................96

F-1 Processor Installation Tool.............................. .. .. ... ........................... .. .. .. ...................98

Thermal/Mechanical Design Guide 5

Page 6

Tables

1-1 Reference Documents ......................................................... .. .......................... .. ........10

1-2 Terms and Descriptions.............................................................................................10

4-1 Socket Component Mass............................................................................................27

4-2 1366-land Package and LGA1366 Socket Stackup Height ...............................................27

4-3 Socket and ILM Mechanical Specifications ....................................................................28

4-4 Electrical Requirements for LGA1366 Socket ................................................................29

5-1 Boundary Conditions and Performance Targets.............................................................31

5-2 Performance Expectations for 25.5 mm Tall Heatsink.....................................................33

5-3 Fan Speed Control, TCONTROL and DTS Relationship ....................................................39

5-4 T

CONTROL

6-1 Heatsink Test Conditions and Qualification Criteria........................................................43

A-1 Suppliers for the Intel Reference Thermal Solution........................................................47

A-2 Suppliers for the Intel Collaboration Thermal Solution ...................................................48

A-3 Suppliers for the Alternative Thermal Solution..............................................................48

A-4 LGA1366 Socket and ILM Components ........................................................................49

B-1 Mechanical Drawing List ............................................................................................51

C-1 Mechanical Drawing List ............................................................................................79

E-1 Boundary Conditions and Performance Targets.............................................................87

E-2 Embedded Heatsink Component Suppliers ...................................................................92

E-3 Mechanical Drawings List...........................................................................................92

Guidance ............. ......................... .. ......................... ... ......................... .. ....39

6 Thermal/Mechanical Design Guide

Page 7

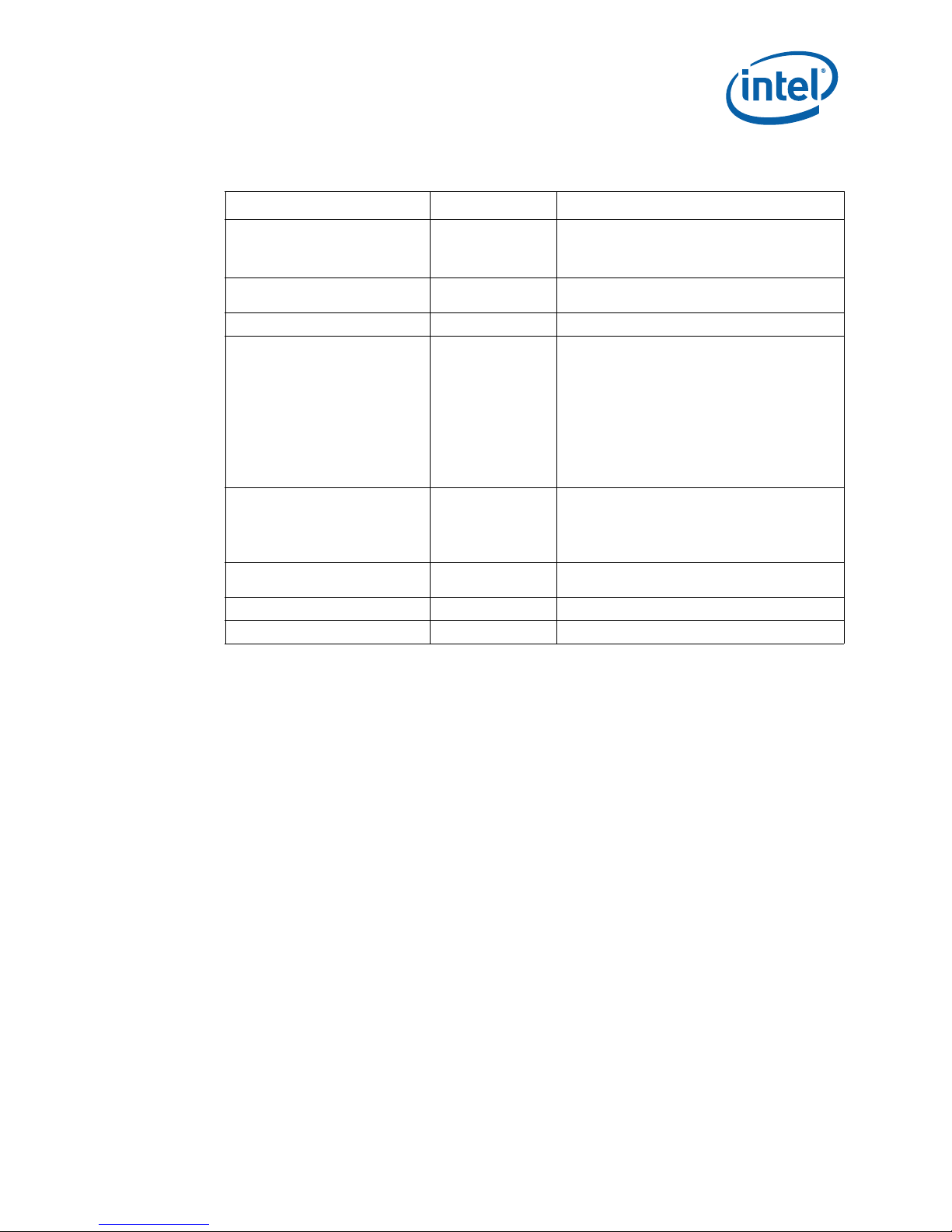

Revision History

Document Number Revision Number Description Revision Date

321323 001 Public Release March 2009

§

Thermal/Mechanical Design Guide 7

Page 8

8 Thermal/Mechanical Design Guide

Page 9

Introduction

1 Introduction

This document provides guidelines for the design of thermal and mechanical solutions

for 2-socket server and 2-socket Workstation processors in the Intel® Xeon® 5500

Platform. The processors covered include those listed in the Intel® Xeon® Processor

5500 Series Datasheet, Volume 1 and the follow-on processors. The design guidelines

apply to the follow-on processors in their current stage of development and are not

expected to change as they mature. The components described in this document

include:

• The processor thermal solution (heatsink) and associated retention hardware.

• The LGA1366 socket and the Independent Loading Mechanism (ILM) and back

plate.

Processors in 1-socket Workstation platforms are covered in the Intel® Xeon®

Processor 3500 Series Thermal/Mechanical Design Guide.

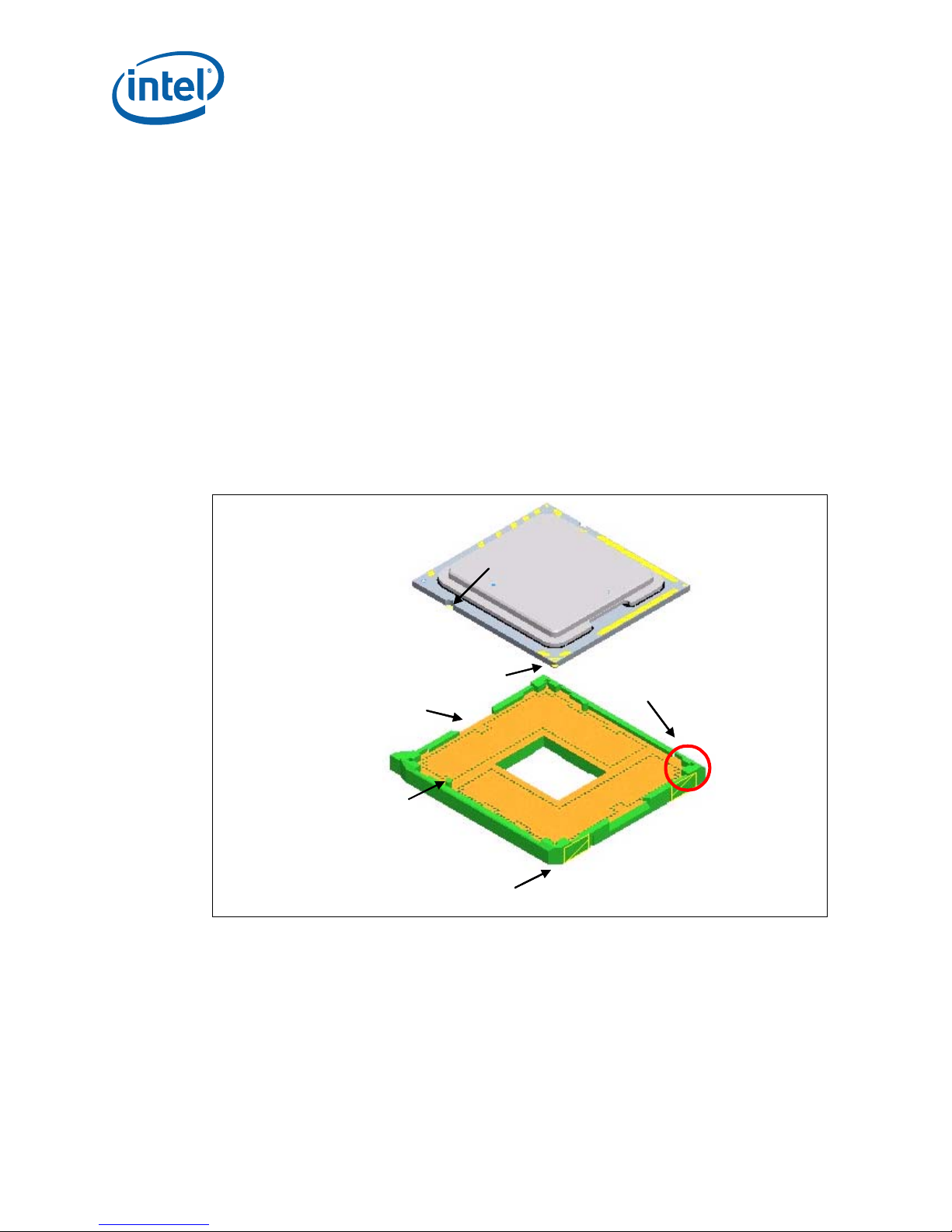

Figure 1-1. Intel® Xeon® 5500 Platform Socket Stack

Heatsink

Socket and IL M

Back Plate

The goals of this document are:

• To assist board and system thermal mechanical designers.

• To assist designers and suppliers of processor heatsinks.

Thermal profiles and other processor specifications are provided in the Datasheet.

Thermal/Mechanical Design Guide 9

Page 10

1.1 References

Material and concepts available in the following documents may be beneficial when

reading this document.

Table 1-1. Reference Documents

Document Location Notes

European Blue Angel Recycling Standards 2

Intel® Xeon® Processor 5500 Series Datasheet, Volume 1 321321 1

Intel® Xeon® Processor 5500 Series Mechanical Model 321326 1

Intel® Xeon® Processor 5500 Series Thermal Model 321327 1

Entry-level Electronics Bay Specification 3

Notes:

1. Document numbers indicated in Location column are subject to change. See the appropriate Electronic

Design Kit (EDK) for the most up-to-date Document number.

2. Available at http://www.blauer-engel.de

3. Available at http://ssiforum.oaktree.com/

Introduction

1.2 Definition of Terms

Table 1-2. Terms and Descriptions (Sheet 1 of 2)

Term Description

Bypass Bypass is the area between a passive heatsink and any object that can act to form a

DTS Digital Thermal Sensor reports a relative die temperature as an offset from TCC

FSC Fan Speed Control

IHS Integrated Heat Spreader: a component of the processor pac k age used to enhance the

ILM Independent Loading Mechanism provides the force needed to seat the 1366-LGA land

LGA1366 socket The processor mates with the system board through this surface mount, 1366-contact

PECI The Platform Environment Control Interface (PECI) is a one- wire in terface that pro vides

Ψ

CA

Ψ

CS

Ψ

SA

T

CASE

T

CASE_MAX

TCC Thermal Control Circuit: Thermal monitor uses the TCC to reduce the die temperature

duct. For this example, it can be expressed as a dimension away from the outside

dimension of the fins to the nearest surface.

activation temperature.

thermal performance of the package. Component thermal solutions interface with the

processor at the IHS surface.

package onto the socket contacts.

socket.

a communication channel between Intel processor and chipset components to external

monitoring devices.

Case-to-ambient thermal characterization parameter (psi). A measure of thermal

solution performance using t otal package power. Defined as (T

Package Power. Heat source should always be specified for Ψ measurements.

Case-to-sink thermal characterization parameter. A measure of thermal interface

material performance using total package po wer. Defined as (T

Package Power.

Sink-to-ambient thermal characterization parameter. A measure of heatsink thermal

performance using total package power. Defined as (T

The case temperature of the processo r measured at the geom etric ce nter of the t opside

of the IHS.

The maximum case temperature as specified in a component specification.

by using clock modulation and/or operating frequency and input voltage adjustment

when the die temperature is very near its operating limits.

– TLA) / Total

CASE

– TS) / Total

CASE

– TLA) / Total Package Power.

S

10 Thermal/Mechanical Design Guide

Page 11

Introduction

Table 1-2. Terms and Descriptions (Sheet 2 of 2)

Term Description

T

CONTROL

TDP Thermal Design Power: Thermal solution should be designed to dissipate this target

Thermal Monitor A power reduction feature designed to decrease temperature after the processor has

Thermal Profile Line that defines case temperature specification of a processor at a given power level.

TIM Thermal Interface Material: The thermally conductive compound between the heatsink

T

LA

T

SA

U A unit of measure used to define server rack spacing height. 1U is equal to 1.75 in, 2U

T

control.

power level. TDP is not the maximum power that the processor can dissipate.

reached its maximum operating temperature.

and the processor case. This material fills the air gaps and voids, and enhances the

transfer of the heat from the processor case to the heatsink.

The measured ambient temperature locally surrounding the proces sor. The ambient

temperature should be measured just upstream of a p assive he atsink or at the fan inle t

for an active heatsink.

The system ambient air temperature external to a system chassis. This temperature is

usually measured at the chassis air inlets.

equals 3.50 in, etc.

is a static value below TCC activation used as a trigger point for fan speed

CONTROL

§

Thermal/Mechanical Design Guide 11

Page 12

Introduction

12 Thermal/Mechanical Design Guide

Page 13

LGA1366 Socket

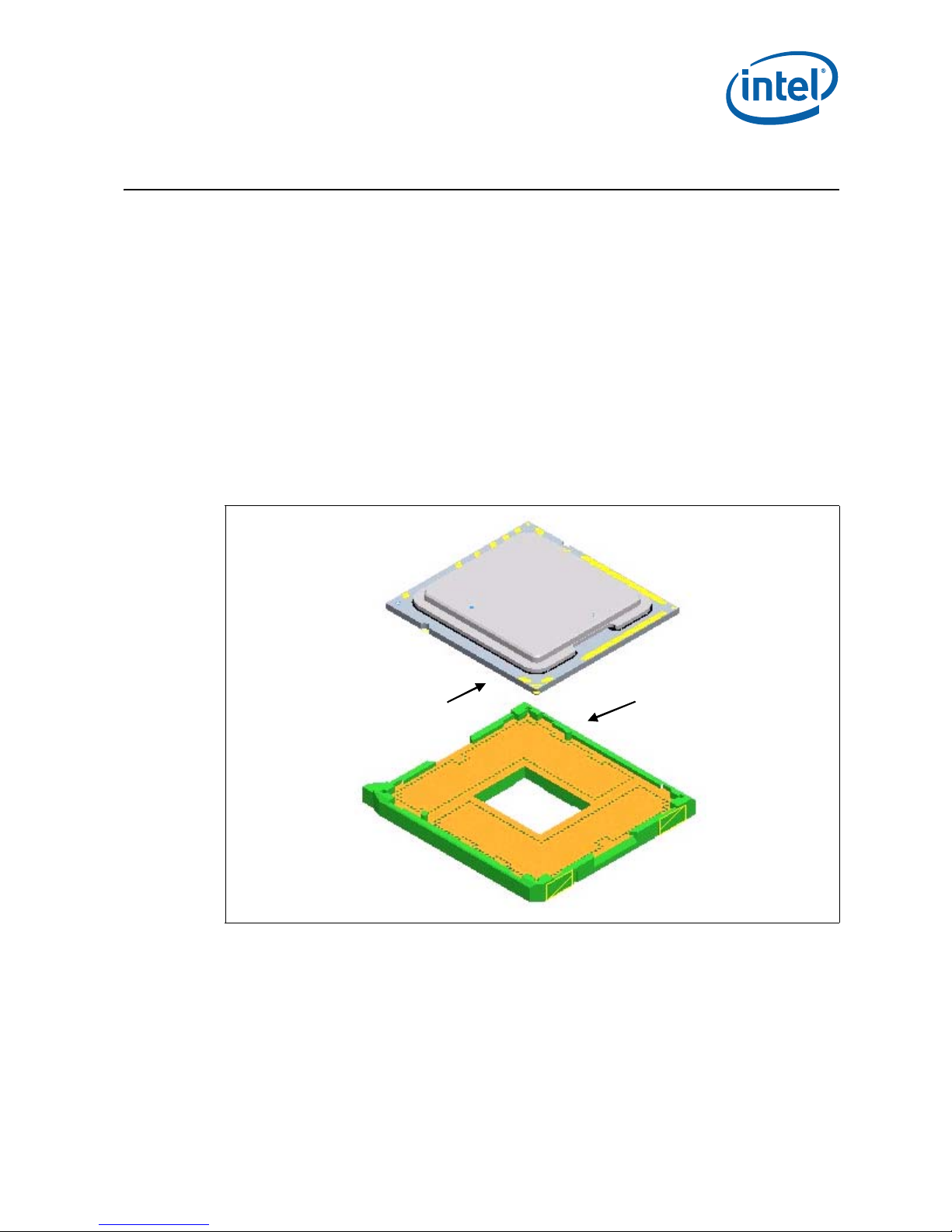

2 LGA1366 Socket

This chapter describes a surface mount, LGA (Land Grid Array) socket intended for

processors in the Intel® Xeon® 5500 Platform. The socket provides I/O, power and

ground contacts. The socket contains 1366 contacts arrayed about a cavity in the

center of the socket with lead-free solder balls for surface mounting on the

motherboard.

The socket has 1366 contacts with 1.016 mm X 1.016 mm pitch (X by Y) in a

43x41 grid array with 21x17 grid depopulation in the center of the array and selective

depopulation elsewhere.

The socket must be compatible with the package (processor) and the Independent

Loading Mechanism (ILM). The design includes a back plate which is integral to having

a uniform load on the socket solder joints. Socket loading specifications are listed in

Chapter 4.

Figure 2-1. LGA1366 Socket with Pick and Place Cover Removed

package socket

package

cavity

cavity

socket

Thermal/Mechanical Design Guide 13

Page 14

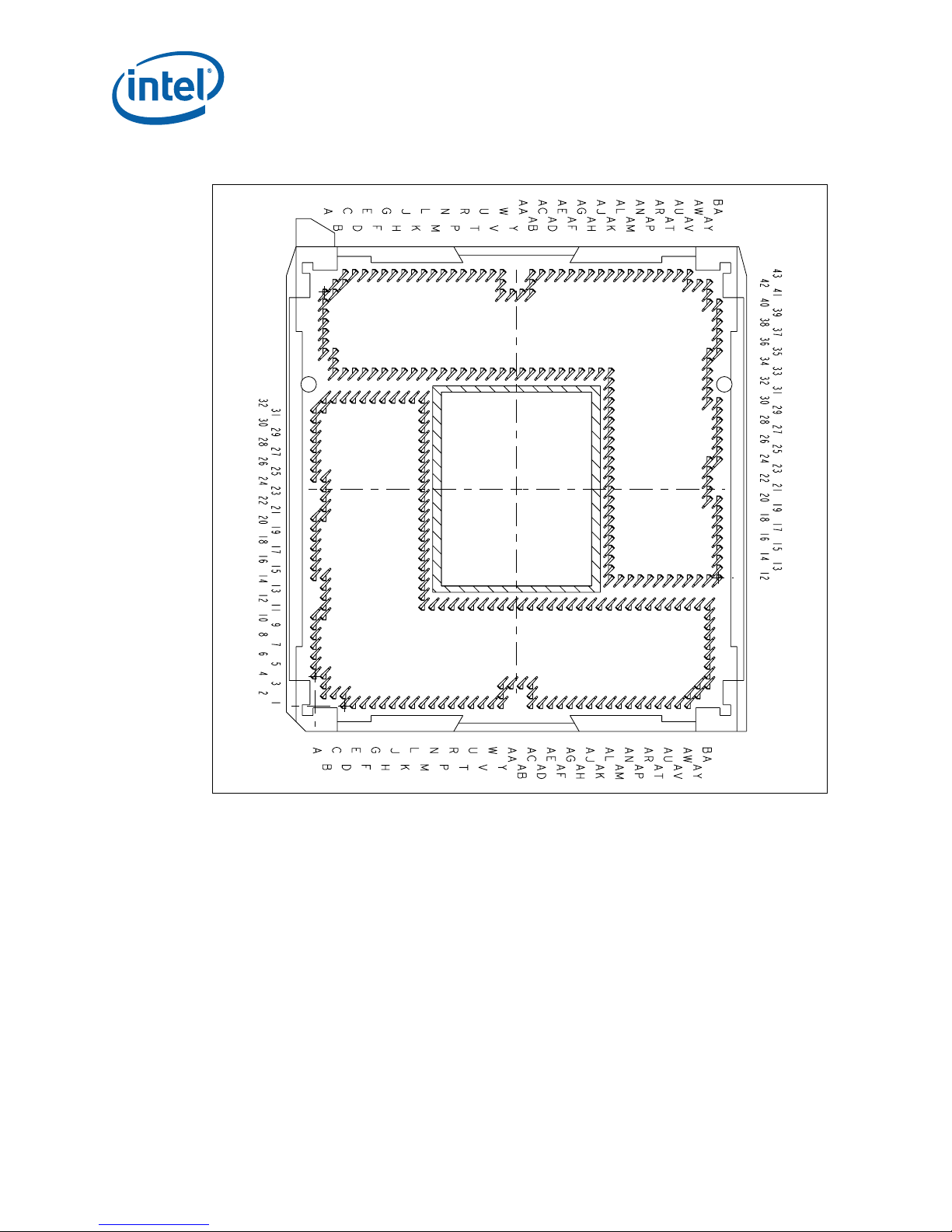

Figure 2-2. LGA1366 Socket Contact Numbering (Top View of Socket)

AP

AN

AM

AL

AK

AJ

AH

AG

AF

AE

AD

AC

AB

AA

Y

W

V

U

T

R

P

N

M

L

K

J

H

G

F

E

D

C

B

A

31 29 27 25 23 21 19 17 15 13 11 9 7 5

32 30 28 26 24 22 20 18 16 14 12 10 8 6 4

AR

AU

AT

LGA1366 Socket

BA

AY

AW

AV

43 41 39 37 35 33 31 29 27 25 23 21 19 17 15 13

42 40 38 36 34 32 30 28 26 24 22 20 18 16 14 12

BA

AY

AW

AV

AU

AT

AR

AP

AN

AM

AL

AK

AJ

AH

AG

AF

AE

AD

AC

AB

AA

Y

W

V

U

T

R

P

N

M

L

K

J

H

G

F

E

D

C

B

A

14 Thermal/Mechanical Design Guide

Page 15

LGA1366 Socket

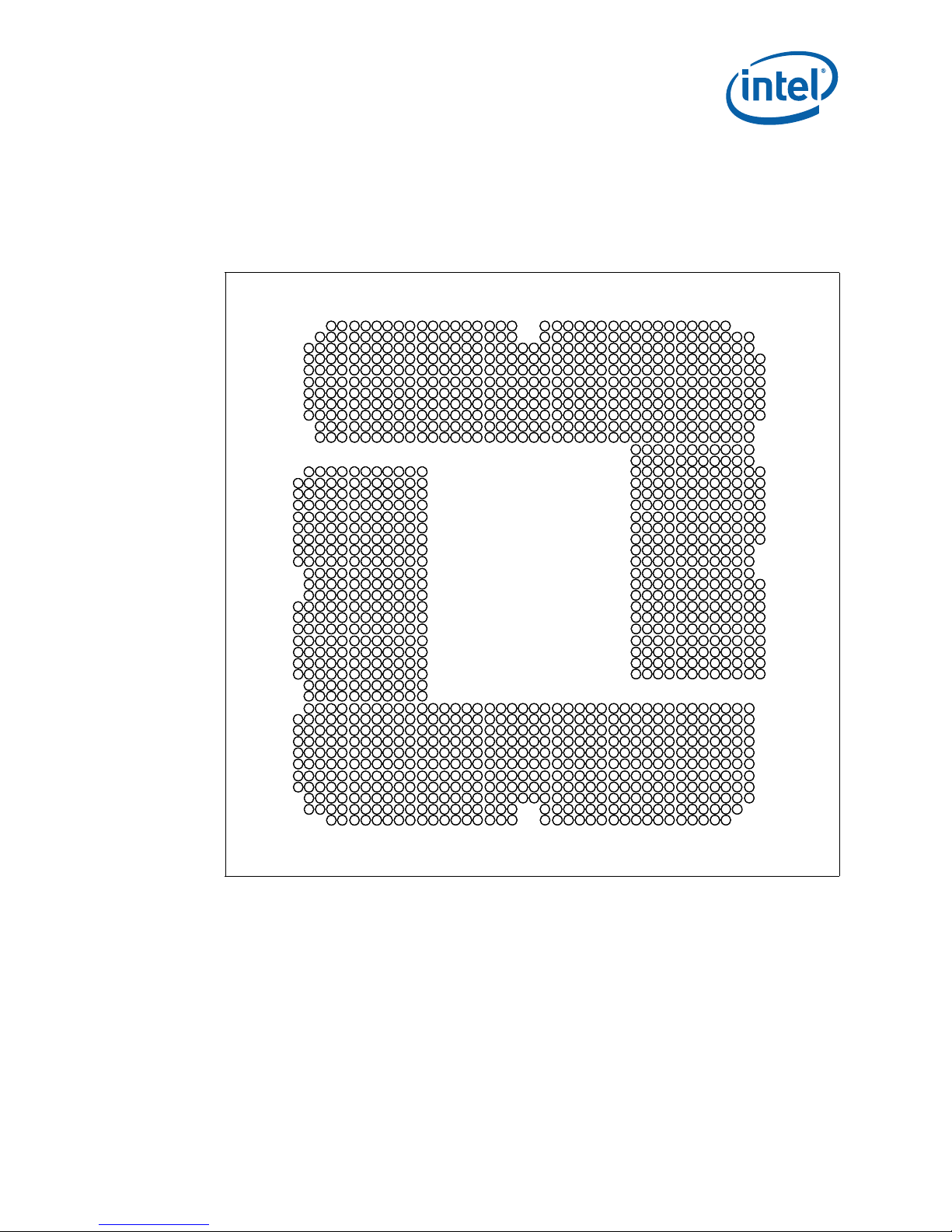

2.1 Board Layout

The land pattern for the LGA1366 socket is 40 mils X 40 mils (X by Y), and the pad size

is 18 mils. Note that there is no round-off (conversion) error between socket pitch

(1.016 mm) and board pitch (40 mil) as these values are equivalent.

Figure 2-3. LGA1366 Socket Land Pattern (Top View of Board)

A C E G J L N R U W AA AC AE AG AJ AL AN AR AU AW BA

B D F H K M P T V Y AB AD AF AH AK AM AP AT AV AY

32

32

31

31

30

30

29

29

28

28

27

27

26

26

25

25

24

24

23

23

22

22

21

21

20

20

19

19

18

18

17

17

16

16

15

15

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

A C E G J L N R U W AA AC AE AG AJ AL AN AR AU AW BA

B D F H K M P T V Y AB AD AF AH AK AM AP AT AV AY

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

Thermal/Mechanical Design Guide 15

Page 16

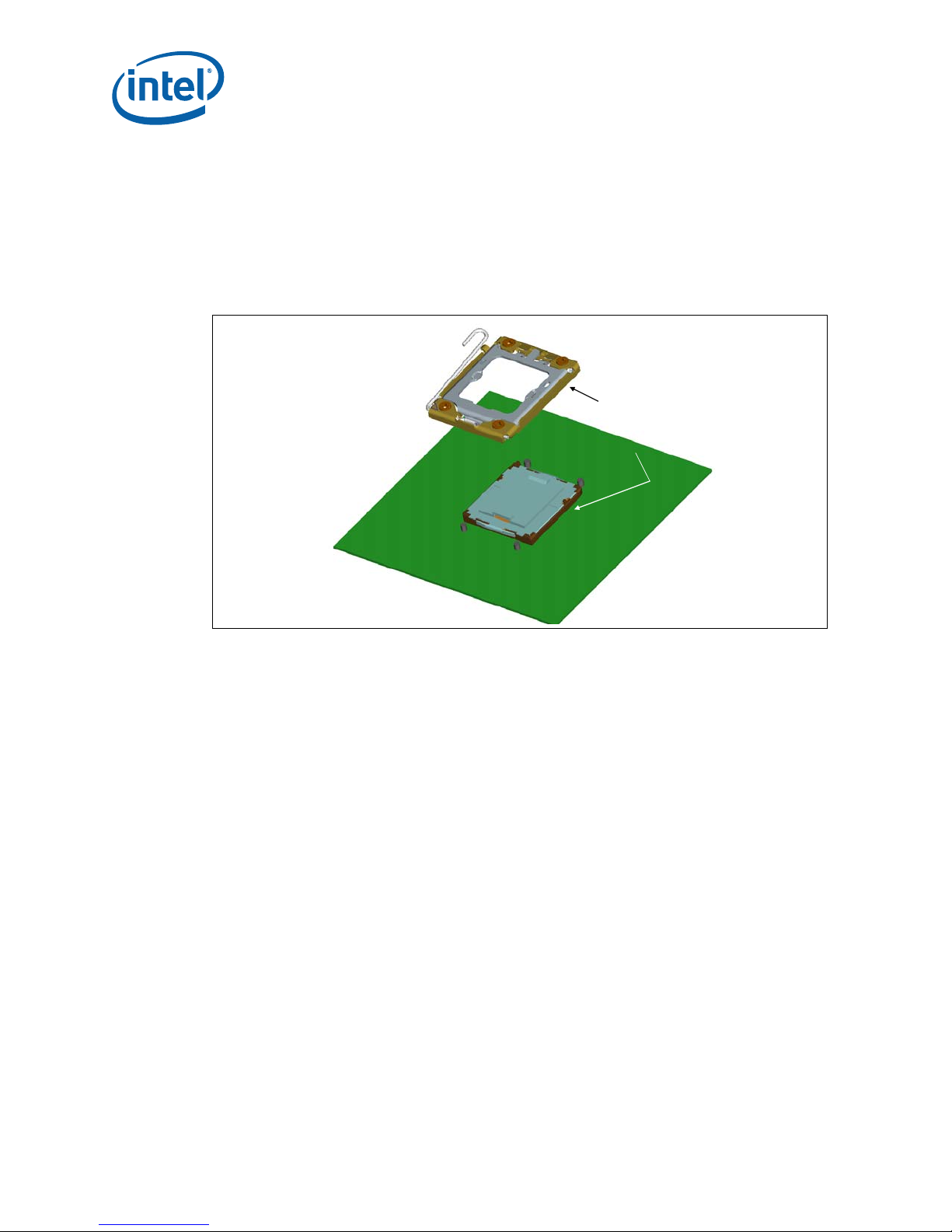

2.2 Attachment to Motherboard

The socket is attached to the motherboard by 1366 solder balls. There are no additional

external methods (that is, screw, extra solder, adhesive, and so on) to attach the

socket.

As indicated in Figure 2-4, the Independent Loading Mechanism (ILM) is not present

during the attach (reflow) process.

Figure 2-4. Attachment to Motherboard

LGA1366 Socket

ILM

LGA 1366 Socket

2.3 Socket Components

The socket has two main components, the socket body and Pick and Place (PnP) cover,

and is delivered as a single integral assembly. Refer to Appendix C for detailed

drawings.

2.3.1 Socket Body Housing

The housing material is thermoplastic or equivalent with UL 94 V -0 flame rating capable

of withstanding 260 °C for 40 seconds (typical reflow/rework). The socket coefficient of

thermal expansion (in the XY plane), and creep properties, must be such that the

integrity of the socket is maintained for the conditions listed in the LGA1366 Socket

Validation Re ports.

The color of the housing will be dark as compared to the solder balls to provide the

contrast needed for pick and place vision systems.

2.3.2 Solder Balls

A total of 1366 solder balls corresponding to the contacts are on the bottom of the

socket for surface mounting with the motherboard.

The socket has the following solder ball material:

• Lead free SAC (SnAgCu) solder alloy with a silver (Ag) content between 3% and

4% and a melting temperature of approximately 217 °C. The alloy must be

compatible with immersion silver (ImAg) motherboard surface finish and a SAC

alloy solder paste.

16 Thermal/Mechanical Design Guide

Page 17

LGA1366 Socket

The co-planarity (profile) and true position requirements are defined in Appendix C.

2.3.3 Contacts

Base material for the contacts is high strength copper alloy.

For the area on socket contacts where processor lands will mate, there is a 0.381 μm

[15 μinches] minimum gold plating over 1.27 μm [50 μinches] minimum nickel

underplate.

No contamination by solder in the contact area is allowed during solder reflow.

2.3.4 Pick and Place Cover

The cover provides a planar surface for vacuum pick up used to place components in

the Surface Mount Technology (SMT) manufacturing line. The cover remains on the

socket during reflow to help prevent contamination during reflow. The cover can

withstand 260 °C for 40 seconds (typical reflow/rework profile) and the conditions

listed in the LGA1366 Socket Validation Reports without degrading.

As indicated in Figure 2-5, the cover remains on the socket during ILM installation, and

should remain on whenever possible to help prevent damage to the socket contacts.

Cover retention must be sufficient to support the socket weight during lifting,

translation, and placement (board manufacturing), and during board and system

shipping and handling.

The covers are designed to be interchangeable between socket suppliers. As indicated

in Figure 2-5, a Pin1 indicator on the cover provides a visual reference for proper

orientation with the socket.

Figure 2-5. Pick and Place Cover

ILM

Installation

Pin 1 Pin 1

Thermal/Mechanical Design Guide 17

Pick and

Place Cover

Page 18

2.4 Package Installation / Removal

As indicated in Figure 2-6, access is provided to facilitate manual installation and

removal of the package.

To assist in package orientation and alignment with the socket:

• The package Pin1 triangle and the socket Pin1 chamfer provide visual reference for

proper orientation.

• The package substrate has orientation notches along two opposing edges of the

package, offset from the centerline. The socket has two corresponding orientation

posts to physically prevent mis-orientation of the package. These orientation

features also provide initial rough alignment of package to socket.

• The socket has alignment walls at the four corners to provide final alignment of the

package.

See Appendix F for information regard ing a tool designed to provide mechanical

.

Figure 2-6. Package Installation / Removal Features

assistance during processor installation and removal.

LGA1366 Socket

orientation

orientation

notch

notch

alignment

Pin1 triangle

Pin1 triangle

access

access

orientation

orientation

post

post

Pin1 chamfer

Pin1 chamfer

alignment

walls

walls

2.4.1 Socket Standoffs and Package Seating Plane

Standoffs on the bottom of the socket base establish the minimum socket height after

solder reflow and are specified in Appendix C.

Similarly, a seating plane on the topside of the socket establishes the minimum

package height. See Section 4.2 for the calculated IHS height above the motherboard.

18 Thermal/Mechanical Design Guide

Page 19

LGA1366 Socket

2.5 Durability

The socket must withstand 30 cycles of processor insertion and removal. The max

chain contact resistance from Table 4-4 must be met when mated in the 1st and 30th

cycles.

The socket Pick and Place cover must withstand 15 cycles of insertion and removal.

2.6 Markings

There are three markings on the socket:

• LGA1366: Font type is Helvetica Bold - minimum 6 point (2.125 mm).

• Manufacturer's insignia (font size at supplier's discretion).

• Lot identification code (allows traceability of manufacturing date and location).

All markings must withstand 260 °C for 40 seconds (typical reflow/rework profile)

without degrading, and must be visible after the socket is mounted on the

motherboard.

LGA1366 and the manufacturer's insignia are molded or laser marked on the side wall.

2.7 Component Insertion Forces

Any actuation must meet or exceed SEMI S8-95 Safety Guidelines for Ergonomics/

Human Factors Engineering of Semiconductor Manu facturing Equipment, example Table

R2-7 (Maximum Grip Forces). The socket must be designed so that it requires no force

to insert the package into the socket.

2.8 Socket Size

Socket information needed for motherboard design is given in Appendix C.

This information should be used in conjunction with the reference motherboard keep-

out drawings provided in Appendix B to ensure compatibility with the reference thermal

mechanical components.

Thermal/Mechanical Design Guide 19

Page 20

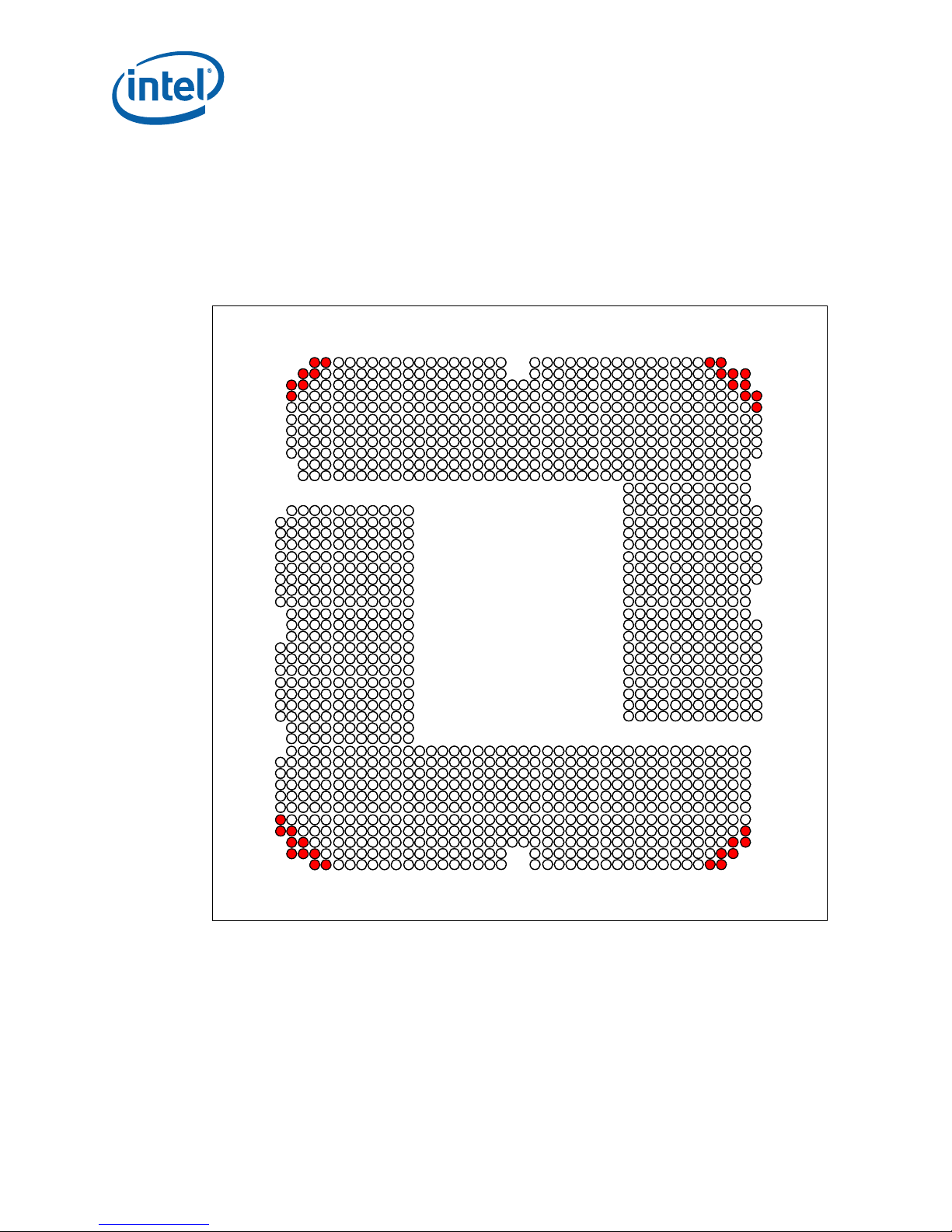

2.9 LGA1366 Socket NCTF Solder Joints

Intel has defined selected solder joints of the socket as non-critical to function (NCTF)

for post environmental testing. The processor signals at NCTF locations are typically

redundant ground or non-critical reserved, so the loss of the solder joint continuity at

end of life conditions will not affect the overall product functionality. Figure 2-7

.

Figure 2-7. LGA1366 NCTF Solder Joints

identifies the NCTF solder joints.

A C E G J L N R U W AA AC AE AG AJ AL AN AR AU AW BA

B D F H K M P T V Y AB AD AF AH AK AM AP AT AV AY

32

32

31

31

30

30

29

29

28

28

27

27

26

26

25

25

24

24

23

23

22

22

21

21

20

20

19

19

18

18

17

17

16

16

15

15

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

A C E G J L N R U W AA AC AE AG AJ AL AN AR AU AW BA

B D F H K M P T V Y AB AD AF AH AK AM AP AT AV AY

LGA1366 Socket

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

Note: For platforms supporting the DP processor land C3 is CTF.

20 Thermal/Mechanical Design Guide

§

Page 21

Independent Loading Mechanism (ILM)

3 Independent Loading

Mechanism (ILM)

The Independent Loading Mechanism (ILM) provides the force needed to seat the

1366-LGA land package onto the socket contacts. The ILM is physically separate from

the socket body. The assembly of the ILM to the board is expected to occur after wave

solder. The exact assembly location is dependent on manufacturing preference and test

flow.

Note: The ILM has two critical functions: deliver the force to seat the processor onto the

socket contacts and distribute the resulting compressive load evenly through the socket

solder joints.

Note: The mechanical design of the ILM is integral to the overall functionality of the LGA1366

socket. Intel performs detailed studies on integration of processor package, socket and

ILM as a system. These studies directly impact the design of the ILM. The Intel

reference ILM will be “build to print” from Intel controlled drawings. Intel recommends

using the Intel Reference ILM. Custom non-Intel ILM designs do not benefit from Intel's

detailed studies and may not incorporate critical design parameters.

3.1 Design Concept

The ILM consists of two assemblies that will be procured as a set from the enabled

vendors. These two components are ILM cover assembly and back plate.

3.1.1 ILM Cover Assembly Design Overview

The ILM Cover assembly consists of four major pieces: load lever, load plate, frame and

the captive fasteners.

The load lever and load plate are stainless steel. The frame and fasteners are high

carbon steel with appropriate plating. The fasteners are fabricated from a high carbon

steel. The frame provides the hinge locations for the load lever and load plate.

The cover assembly design ensures that once assembled to the back plate and the load

lever is closed, the only features touching the board are the captive fasteners. The

nominal gap of the frame to the board is ~1 mm when the load plate is closed on the

empty socket or when closed on the processor package.

When closed, the load plate applies two point loads onto the IHS at the “dimpled”

features shown in Figure 3-1. The reaction force from closing the load plate is

transmitted to the frame and through the captive fasteners to the back plate. Some of

the load is passed through the socket body to the board inducing a slight compression

on the solder joints.

Thermal/Mechanical Design Guide 21

Page 22

Figure 3-1. ILM Cover Assembly

Load Lever

Load Lever

Load Plate

Load Plate

Independent Loading Mechanism (IL M )

Captive Fastener (4x)

Captive Fastener (4x)

Frame

Frame

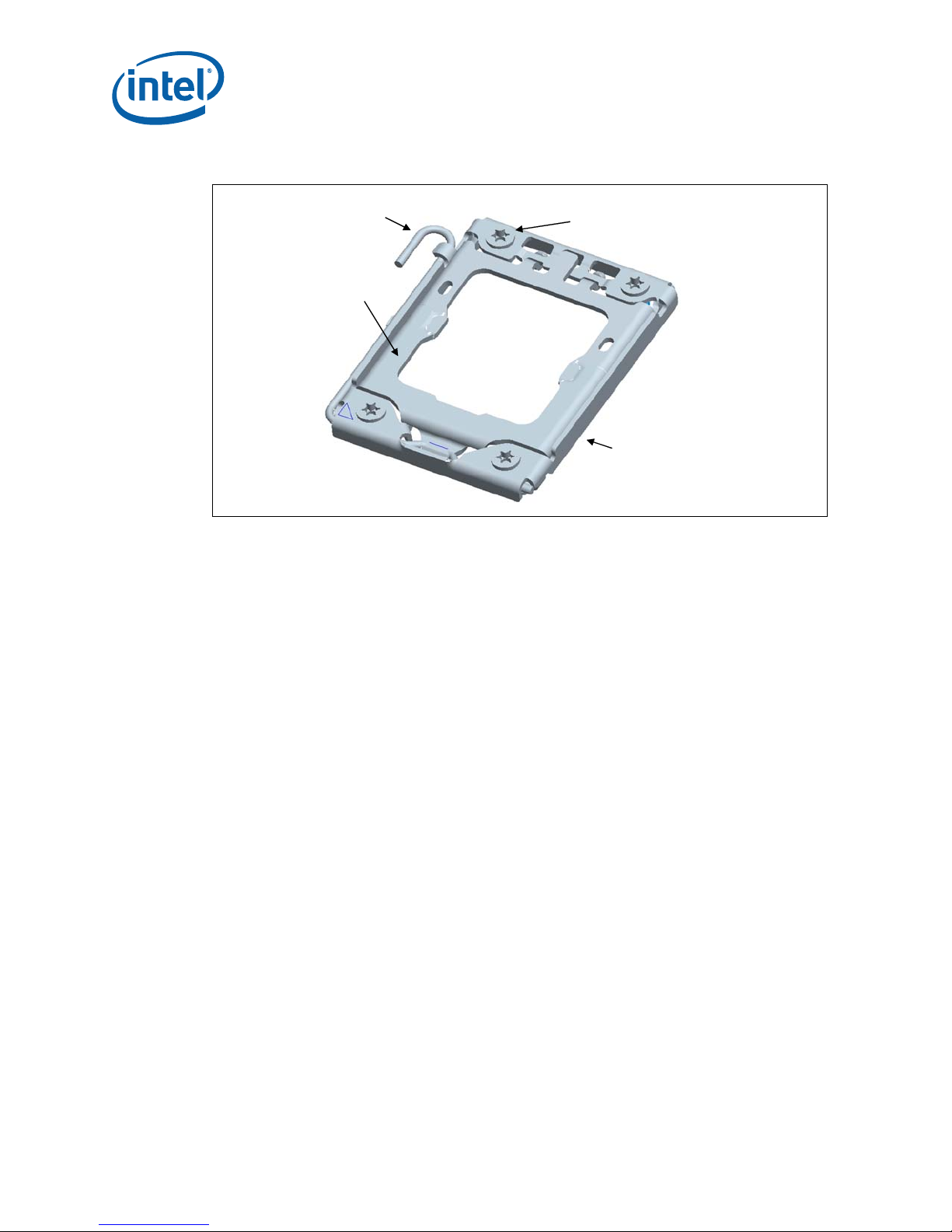

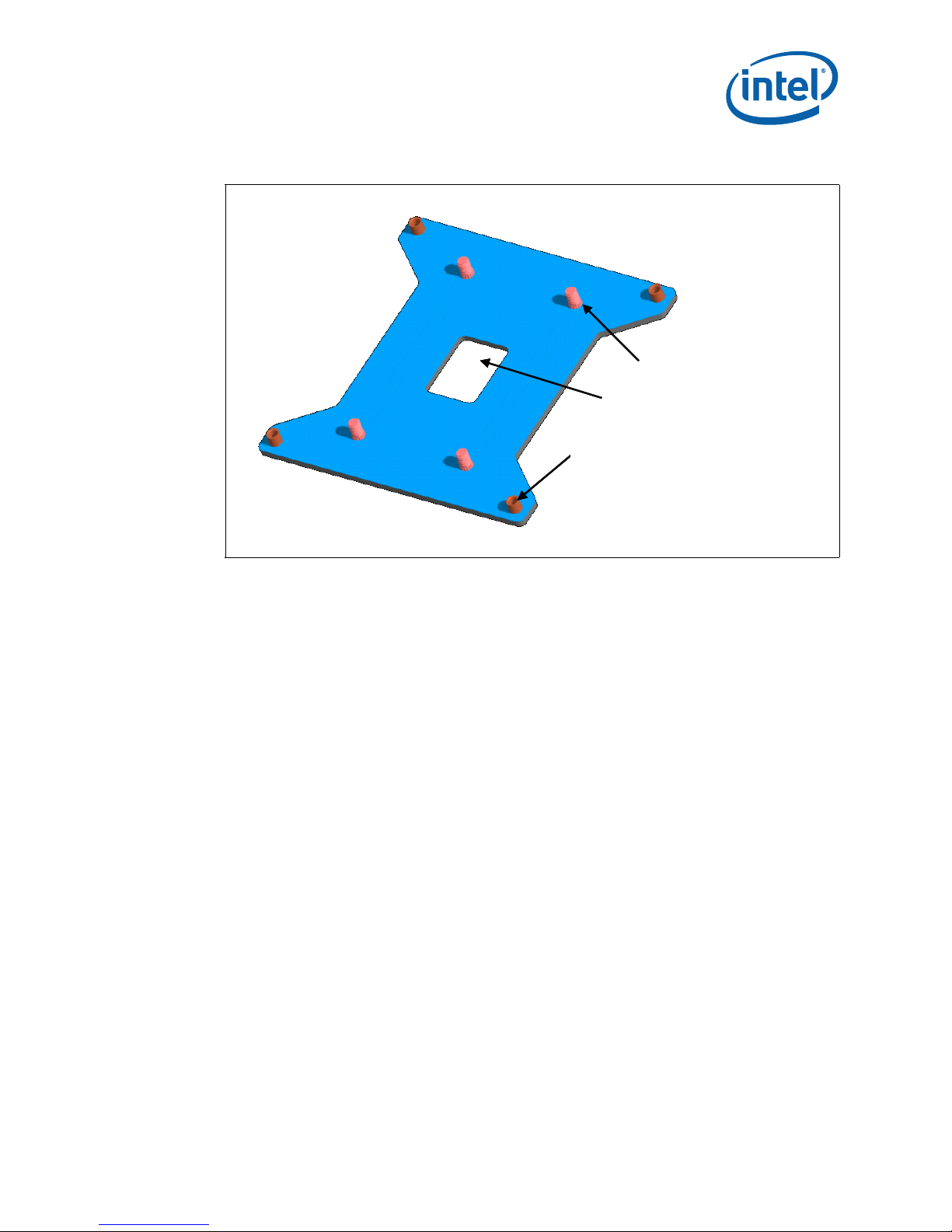

3.1.2 ILM Back Plate Design Overview

The unified back plate for 2-socket server and 2-socket Workstation products consists

of a flat steel back plate with threaded studs for ILM attach, and internally threaded

nuts for heatsink attach. The threaded studs have a smooth surface feature that

provides alignment for the back plate to the motherboard for proper assembly of the

ILM around the socket. A clearance hole is located at the center of the plate to allow

access to test points and backside capacitors. An additional cut-out on two sides

provides clearance for backside voltage regulator components. An insulator is preapplied.

Back plates for processors in 1-socket Workstation platforms are covered in the

Intel® Xeon® Processor 3500 Series Thermal/Mechanical Design Guide.

22 Thermal/Mechanical Design Guide

Page 23

Independent Loading Mechanism (ILM)

Figure 3-2. Back Plate

t

t

t

u

u

u

C

C

C

t

t

t

u

u

u

o

o

o

-

-

-

Threaded studs

Threaded studs

Threaded studs

Clearance hole

Clearance hole

Clearance hole

Threaded nuts

Threaded nuts

Threaded nuts

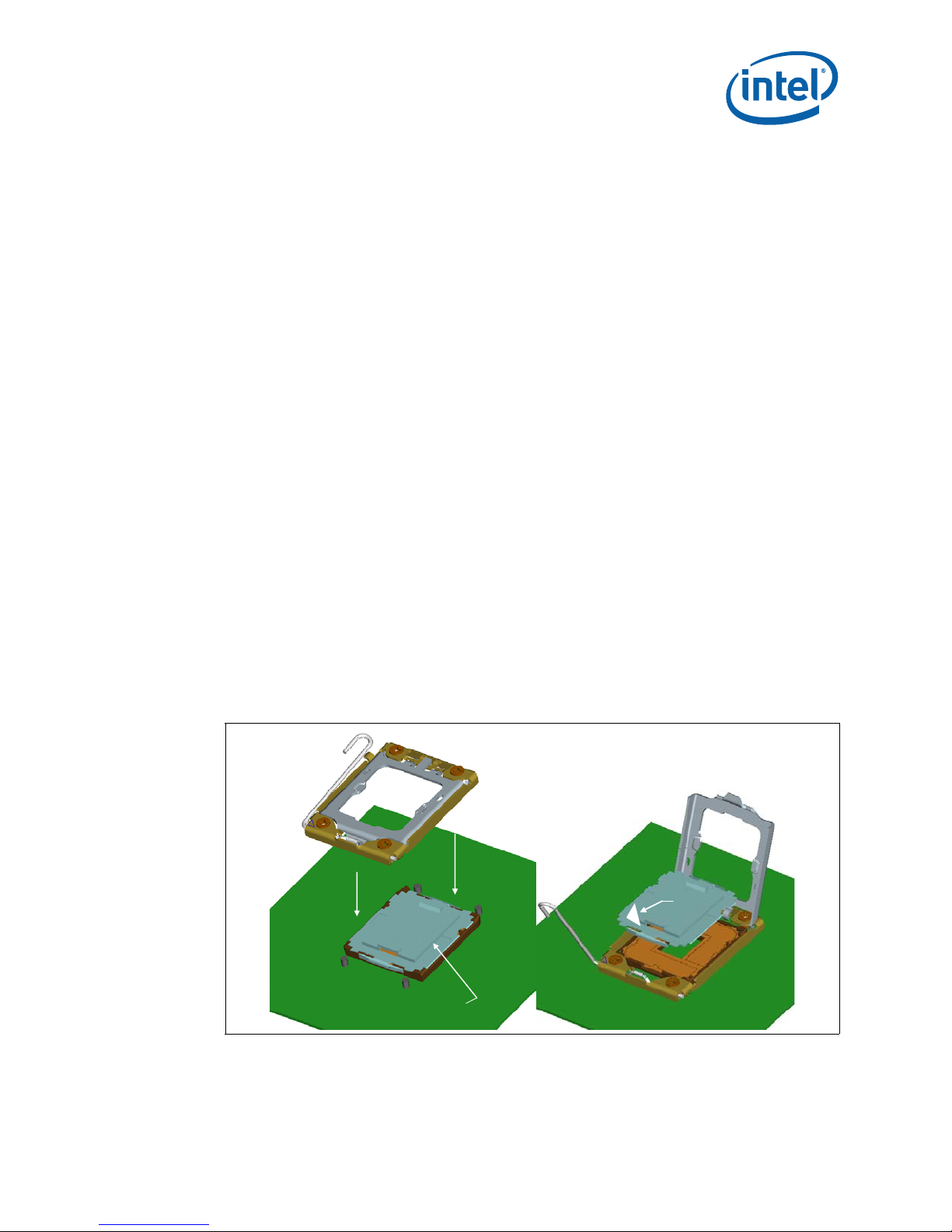

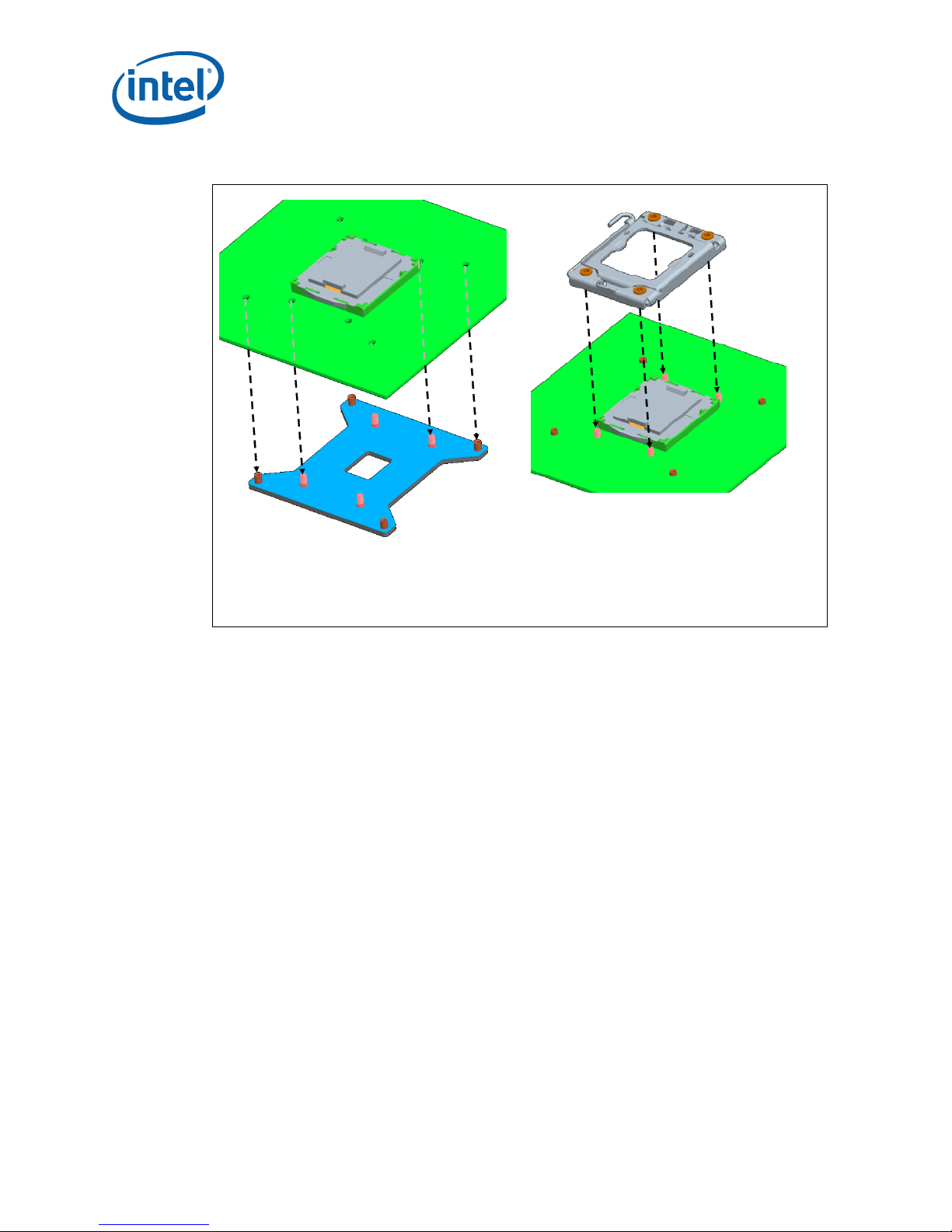

3.2 Assembly of ILM to a Motherboard

The ILM design allows a bottoms up assembly of the components to the board. In

step 1, (see Figure 3-3), the back plate is placed in a fixture. Holes in the motherboard

provide alignment to the threaded studs. In step 2, the ILM cover assembly is placed

over the socket and threaded studs. Using a T20 Torx* driver fasten the ILM cover

assembly to the back plate with the four captive fasteners. Torque to 8 ± 2 inchpounds. The length of the threaded studs accommodate board thicknesses from

0.062” to 0.100”.

Thermal/Mechanical Design Guide 23

Page 24

.

Figure 3-3. ILM Assembly

Independent Loading Mechanism (IL M )

Step 1: W ith so c k et b ody reflowe d on

Step 1: W ith so c k et b ody reflowe d on

board, and back plate in fixture, align

board, and back plate in fixture, align

board holes to back plate studs.

board holes to back plate studs.

Step 2: With back plate against bottom of

Step 2: With back plate against bottom of

board, align ILM cover assembly to back

board, align ILM cover assembly to back

plate studs.

plate studs.

24 Thermal/Mechanical Design Guide

Page 25

Independent Loading Mechanism (ILM)

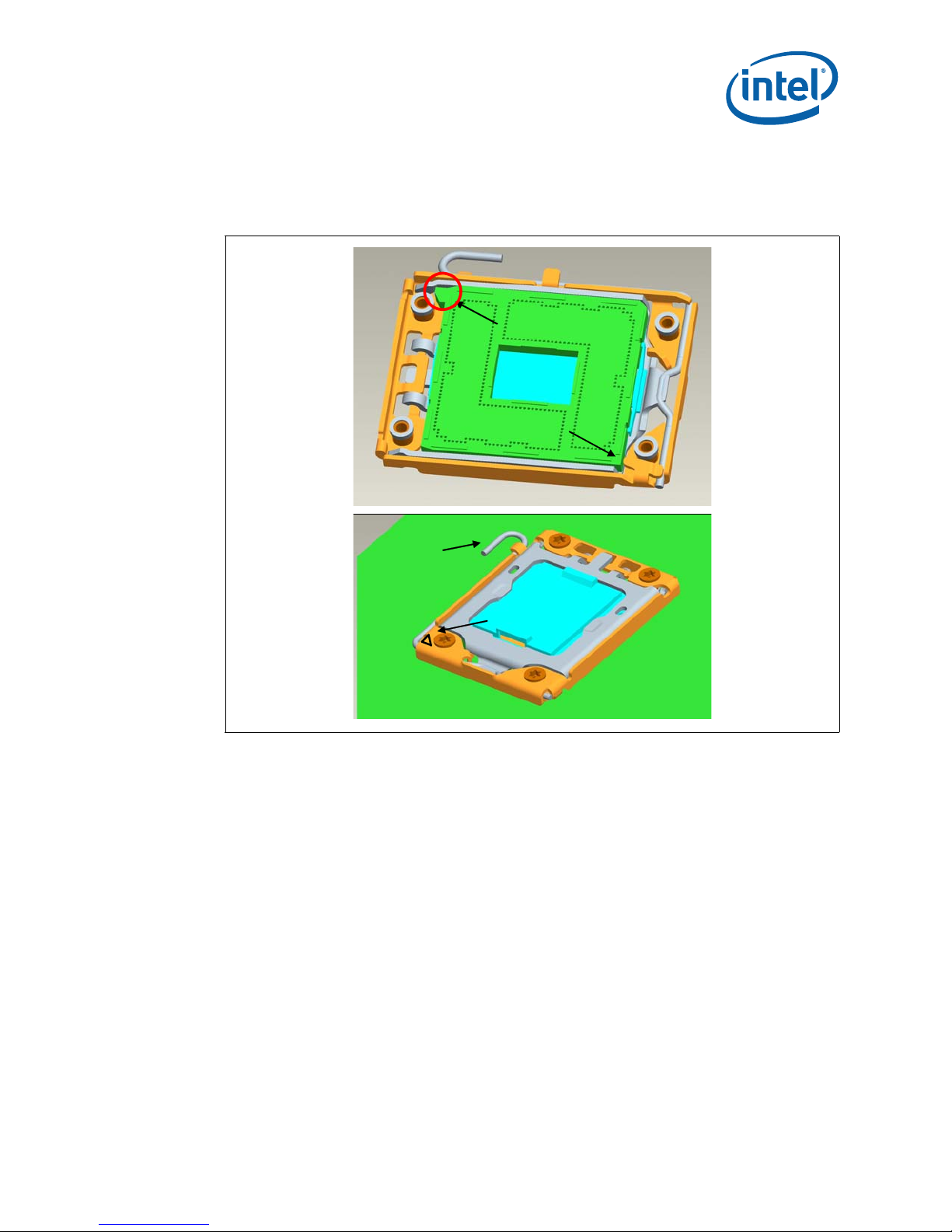

As indicated in Figure 3-4, socket protrusion and ILM key features prevent 180-degree

rotation of ILM cover assembly with respect to the socket. The result is a specific Pin 1

orientation with respect to the ILM lever.

Figure 3-4. Pin1 and ILM Lever

Protrusion

ILM Key

ILM

Lever

Pin 1

§

Thermal/Mechanical Design Guide 25

Page 26

Independent Loading Mechanism (IL M )

26 Thermal/Mechanical Design Guide

Page 27

LGA1366 Socket and ILM Electrical, Mechanical, and Environmental Specifications

4 LGA1366 Socket and ILM

Electrical, Mechanical, and

Environmental Specifications

This chapter describes the electrical, mechanical, and environmental specifications for

the LGA1366 socket and the Independent Loading Mechanism.

4.1 Component Mass

Table 4-1. Socket Component Mass

Component Mass

Socket Body, Contacts and PnP Cover 15 gm

ILM Cover 43 gm

ILM Back Plate for dual processor server products 100 gm

4.2 Package/Socket Stackup Height

Table 4-2 provides the stackup height of a processor in the 1366-land LGA package and

LGA1366 socket with the ILM closed and the processor fully seated in the socket.

Table 4-2. 1366-land Package and LGA1366 Socket Stackup Height

Integrated Stackup Height (mm)

From Top of Board to Top of IHS

Notes:

1. This data is provided for information only , and shou ld be deri v ed from: (a) the h eight of the s ocke t seating

plane above the motherboard after reflow, given in Appendix C, (b) the height of the package, from the

package seating plane to the top of the IHS, and accounting for its nominal variation and tolerances that

are given in the corresponding processor EMTS.

2. This value is a RSS calculation.

7.729 ± 0.282 mm

4.3 Socket Maximum Temperature

The power dissipated within the socket is a function of the current at the pin level and

the effective pin resistance. To ensure socket long term reliability, Intel defines socket

maximum temperature using a via on the underside of the motherboard. Exceeding the

temperature guidance may result in socket body deformation, or increases in thermal

and electrical resistance which can cause a thermal runaway and eventual electrical

failure. The guidance for socket maximum temperature is listed below:

• Via temperature under socket < 96 °C

Thermal/Mechanical Design Guide 27

Page 28

LGA1366 Socket and ILM Electrical, Mechanical, and Environmental Specifications

4.4 Loading Specifications

The socket will be tested against the conditions listed in the LGA1366 Socket Validation

Reports with heatsink and the ILM attached, under the loading conditions outlined in

this chapter.

Table 4-3 provides load specifications for the LGA1366 socket with the ILM installed.

The maximum limits should not be exceeded during heatsink assembly, shipping

conditions, or standard use condition. Exceeding these limits during test may result in

component failure. The socket body should not be used as a mechanical reference or

load-bearing surface for thermal solutions.

Table 4-3. Socket and ILM Mechanical Specifications

Parameter Min Max Notes

Static compressive load from ILM cover to

processor IHS

Heatsink Static Compressive Load 0 N [0 lbf] 266 N [60 lbf] 1, 2, 3

Total Static Compressive Load

(ILM plus Heatsink)

Dynamic Compressive Load

(with heatsink installed)

Pick and Place Cover Insertion / Removal force N/A 10.2 N [2.3 lbf]

Load Lever actuation force N/A 38.3 N [8.6 lbf] in the

470 N [106 lbf] 623 N [140 lbf] 3, 4

470 N (106 lbf) 890 N (200 lbf) 3, 4

N/A 890 N [200 lbf] 1, 3, 5, 6

vertical direction

10.2 N [2.3 lbf] in the

lateral direction.

Notes:

1. These specifications apply to uniform compressive loading in a direction perpendicular to the IHS top

surface.

2. This is the minimum and maximum static force that can be applied by the heatsink and it’s retention

solution to maintain the heatsink to IHS interface. This does not imply the Intel reference TIM is validated

to these limits.

3. Loading limits are for the LGA1366 socket.

4. This minimum limit defines the compress ive forc e required to electrically seat the processor onto the sock et

contacts.

5. Dynamic loading is defined as an 11 ms duration average load superimposed on the static load

requirement.

6. T est condition used a heatsink mass of 550 gm [1.21 lb] with 50 g acceler ation measured at heatsi nk mass.

The dynamic portion of this specification in the product application can have flexibility in specific values, but

the ultimate product of mass times acceleration should not exceed this dynamic load.

4.5 Electrical Requirements

LGA1366 socket electrical requirements are measured from the socket-seating plane of

the processor to the component side of the socket PCB to which it is attached. All

specifications are maximum values (unless otherwise stated) for a single socket

contact, but includes effects of adjacent contacts where indicated.

28 Thermal/Mechanical Design Guide

Page 29

LGA1366 Socket and ILM Electrical, Mechanical, and Environmental Specifications

Table 4-4. Electrical Requirements for LGA1366 Socket

Parameter Value Comment

Mated loop inductance, Loop

Mated partial mutual inductance, L

Maximum mutual capacitance, C.

Socket Average Contact R esistance

(EOL)

Max Individual Contact Resistance

(EOL)

Bulk Resistance Increase

Dielectric Withstand Voltage

Insulation Resistance

<3.9nH

NA

<1 pF

15.2 mΩ

≤ 100 mΩ

≤ 3 mΩ

360 Volts RMS

800 MΩ

The inductance calculated for two contacts,

considering one forward conductor an d one return

conductor. These values must be satisfied at the

worst-case height of the socket.

The inductance on a contact due to any single

neighboring contact.

The capacitance between two contacts

The socket average contact resistance target is

derived from average of every chain contact

resistance for each part used in testing, with a

chain contact resistance defined as the resistance

of each chain minus resistance of shorting bars

divided by number of lands in the daisy chain.

The specification listed is at room temperature

and has to be satisfied at all time.

Socket Contact Resistance: The resistance of

the socket contact, solderball, and interface

resistance to the interposer land.

The specification listed is at room temperature

and has to be satisfied at all time.

Socket Contact Resistance: The resistance of

the socket contact, solderball, and interface

resistance to the interposer land; gaps included.

The bulk resistance increase per contact from

24 °C to 107 °C

4.6 Environmental Requirements

Design, including materials, shall be consistent with the manufacture of units that meet

the following environmental reference points.

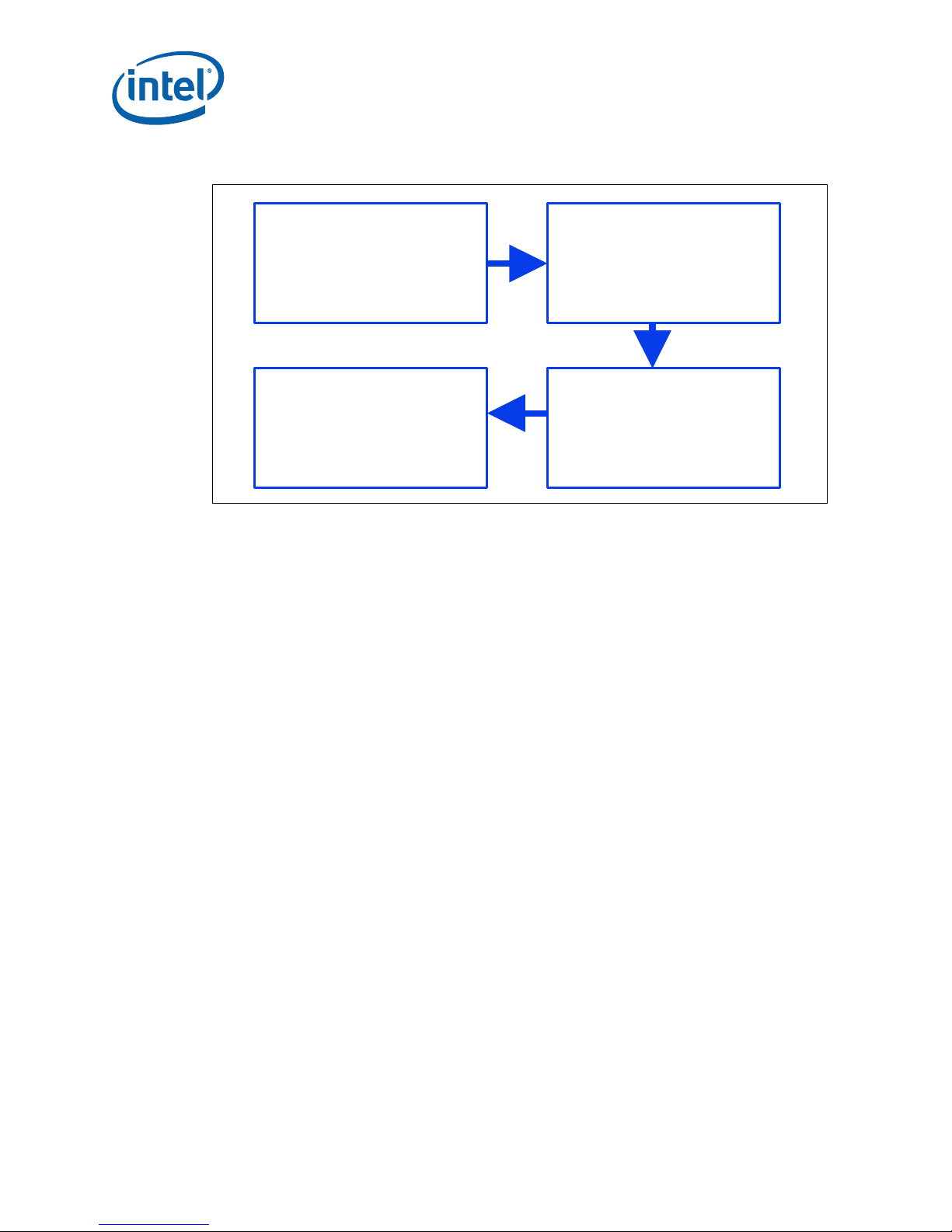

The reliability targets in this chapter are based on the expected field use environment

for these products. The test sequence for new sockets will be developed using the

knowledge-based reliability evaluation methodology, which is acceleration factor

dependent. A simplified process flow of this methodology can be seen in Figure 4-1.

Thermal/Mechanical Design Guide 29

Page 30

LGA1366 Socket and ILM Electrical, Mechanical, and Environmental Specifications

Figure 4-1. Flow Chart of Knowledge-Based Reliability Evaluation Methodology

Establish the

market/expected use

environment for the

technology

Develop Speculative

stress conditions based on

historical data, content

experts, and literature

search

Freeze stressing

requirements and perform

additional data turns

Perform stressing to

validate accelerated

stressing assumptions and

determine acceleration

factors

A detailed description of this methodology can be found at:

ftp://download.intel.com/technology/itj/q32000/pdf/reliability.pdf.

§

30 Thermal/Mechanical Design Guide

Page 31

Thermal Solutions

5 Thermal Solutions

This section describes a 1U reference heatsink, design targets for 2U and Tower

heatsinks, performance expectations for a 25.5 mm tall heatsink, and thermal design

guidelines for Intel® Xeon® Processor 5500 Series and the follow-on processors.

5.1 Performance Targets

Table 5-1 provides boundary conditions and performance targets for 1U, 2U and T ower

heatsinks. These values are used to generate processor thermal specifications and to

provide guidance for heatsink design.

Table 5-1. Boundary Conditions and Performance Targets

Parameter Value

Altitude, system

ambient temp

TDP 60W 80W 95W, Profile B 95W, Profile A 130W, WS

1

T

LA

2

Ψ

CA

3

Airflow

System height

(form factor)

Heatsink

volumetric

Heatsink

technology

8

49oC49

0.335oC/W 0.336oC/W 0.337oC/W 0.201oC/W 0.201oC/W

9.7 CFM @

0.20” dP

1U (EEB) 1U (EEB) 1U (EEB)

4

o

C49

9.7 CFM @

0.20” dP

90 x 90 x 27mm (1U)

Cu base, Al fins Cu/Al base, Al fins with heatpipes

Sea level, 35

o

C55

9.7 CFM @

0.20” dP

6

o

C

9

o

C40

30 CFM @

0.205” dP

5

2U (EEB) Pedestal (EEB)

90 x 90 x 64mm

6,7

(2U)

o

C

30 CFM @

0.205” dP

90 x 90 x 99mm

6

(Tower)

Notes:

1. Local ambient temperature of the air entering the heatsink.

2. Max target (mean + 3 sigma + offset) for thermal characterization parameter (Section 5.5.1).

3. Airflow through the heatsink fins with zero bypass. Max target for pr essure drop (dP) measured in inc hes H

4. Reference system configuration . Processor is downstream from memory in EEB (Entry-L evel Electronics Bay).

Ducting is utilized to direct airflow.

5. The 1U heatsink can also meet Profile B for the 95W processor in TEB (Thin Electronics Bay) under the

following conditions: TLA = 40ºC, ΨCA = 0.275ºC/W, airflow = 16 CFM @ 0.344” dP (these TEB values are

not used to generate processor thermal specifications). Processor is not downstream from memory in TEB.

Ducting is utilized to direct airflow.

6. Dimensions of heatsink do not include socket or processor.

7. The 2U heatsink height (64mm) + socket/processor height (7.729 mm, Table 4-2) complies with 76.2 mm

max height for EEB monoplanar boards (http://ssiforum.oaktree.com/

8. Passive heatsinks. PCM45F thermal interface material.

9. WS = Workstation.

Thermal/Mechanical Design Guide 31

).

O.

2

Page 32

For 1U reference heatsink, see Appendix B for detailed drawings. Table 5-1 specifies

Ψ

and pressure drop targets at 9.7 CFM. Figure 5-1 shows ΨCA and pressure drop for

CA

the 1U heatsink versus the airflow provided. Best-fit equations are provided to prevent

errors associated with reading the graph.

Figure 5-1. 1U Heatsink Performance Curves

Thermal Solutions

For 2U and Tower heatsink, see Appendix B for volumetric dr awings. Table 5-1 specifies

Ψ

and pressure drop targets at 30 CFM. At airflows other than 30 CFM, ΨCA and

CA

pressure drop will differ between suppliers as their heatpipe and fin geometries will

vary.

32 Thermal/Mechanical Design Guide

Page 33

Thermal Solutions

5.1.1 25.5 mm Tall Heatsink

For the 25.5 mm tall heatsink, Table 5-2 provides guidance regarding performance

expectations. These values are not used to generate processor thermal specifications.

Table 5-2. Performance Expectations for 25.5 mm Tall Heatsink

Parameter Value

Altitude, system

ambient temp

Sea level, 35

TDP 95W, Profile B

1

T

LA

2

Ψ

CA

3

Airflow

System height

(form factor)

Heatsink

volumetric

Heatsink

technology

Notes:

1. Local ambient temperature of the air entering the heatsink.

2. Max target (mean + 3 sigma + offset) for thermal characterization parameter (Section 5.5.1).

3. Airflow through the heatsink fins with zero bypass. Max target for pr essure drop (dP) measured in inc hes H

4. Reference system configuration. Processor is downstream from memory in SSI blade and EEB (Entry-Level

5. Dimensions of he atsink do not include socket or pr oce ssor. The 25.5 mm heatsi nk height + socket /processo r

6. Passive heatsinks. Dow Corning TC-1996 thermal interface material.

6

Electronics Bay), not in TEB (Thin Electronics Bay). Ducting is utilized to direct airflow.

height (7.729 mm, Table 4-2) complies with 33.5mm max height for SSI blade boards

(http://ssiforum.oaktree.com/

13.3 CFM @ 0.334” dP 10 CFM @ 0.210” dP 16 CFM @ 0.354” dP

4

50oC49

0.287oC/W 0.337oC/W 0.275oC/W

SSI blade 1U (EEB) 1U (TEB)

90 x 90 x 25.5mm (1U)

Cu base, Al fins

).

o

C

o

C40

5

o

C

O.

2

Thermal/Mechanical Design Guide 33

Page 34

5.2 Heat Pipe Considerations

Figure 5-2 shows the orientation and position of the TTV die. The TTV die is sized and

positioned similarly to the processor die.

Figure 5-2. TTV Die Size and Orientation

Figure 1 - Side Views of Package with IHS (not to scale)

Cache Cache Cache Cache

Cache

Die CL

Package CL

1.0

Core

Core 1

Core 2

Thermal Solutions

45

13.2

Core 4

Core 3

Uncore

42.5

19.3

NOT TO SCALE

All Dimensions in mm

34 Thermal/Mechanical Design Guide

Page 35

Thermal Solutions

5.3 Assembly

Figure 5-3. 1U Reference Heatsink Assembly

1U Reference Heatsink

1U Reference Heatsink

Captive Screw

Captive Screw

Thermal Interface Material:

Thermal Interface Material:

Honeywell PCM45F

Honeywell PCM45F

IHS: Integrated

IHS: Integrated

Heat Spreader

Heat Spreader

Threaded Nut

Threaded Nut

Reference Back Plate

Reference Back Plate

(Unified Back Plate)

(Unified Back Plate)

The assembly process for the 1U reference heatsink begins with application of

Honeywell PCM45F thermal interface material to improve conduction from the IHS.

Tape and roll format is recommended. Pad size is 35 x 35mm, thickness is 0.25mm.

Next, position the heatsink such that the heatsink fins are parallel to system airflow.

While lowering the heatsink onto the IHS, align the four captive screws of the heatsink

to the four threaded nuts of the back plate.

Using a #2 Phillips driver, torque the four captive screws to 8 inch-pounds.

This assembly process is designed to produce a static load of 39 - 51 lbf, for 0.062" -

0.100" board thickness respectively. Honeywell PCM45F is expected to meet the

performance targets in Table 5-1 from 30 - 60 lbf. From Table 4-3, the Heatsink Static

Compressive Load of 0 - 60 lbf allows for designs that v ary from the 1U reference

heatsink. Example: A customer’s unique heatsink with very little static load (as little as

0 lbf) is acceptable from a socket loading perspective as long as the T

is met.

Compliance to Board Keepout Zones in Appendix B is assumed for this assembly

process.

specification

CASE

Thermal/Mechanical Design Guide 35

Page 36

5.3.1 Thermal Interface Material (TIM)

TIM should be verified to be within its recommended shelf life before use.

Surfaces should be free of foreign materials prior to application of TIM.

Use isopropyl alcohol and a lint free cloth to remove old TIM before applying new TIM.

5.4 Structural Considerations

Mass of the 1U reference heatsink and the target mass for 2U and Tower heatsinks

does not exceed 500 gm.

From Table 4-3, the Dynamic Compressive Load of 200 lbf max allows for designs that

exceed 500 gm as long as the mathematical product does not exceed 200 lbf. Example:

A heatsink of 2-lb mass (908 gm) x 50 g (acceleration) x 2.0 Dynamic Amplification

Factor = 200 lbf. The Total Static Compressive Load (Table 4-3) should also be

considered in dynamic assessments.

The heatsink limit of 500 gm and use of back plate have eliminated the need for Direct

Chassis Attach retention (as used previously with the Intel® Xeon® processor 5000

sequence). Direct contact between back plate and chassis pan will help minimize board

deflection during shock.

Thermal Solutions

Placement of board-to-chassis mounting holes also impacts board deflection and

resultant socket solder ball stress. Customers need to assess shock for their designs as

their heatsink retention (back plate), heatsink mass and chassis mounting holes may

vary.

5.5 Thermal Design

5.5.1 Thermal Characterization Parameter

The case-to-local ambient Thermal Characterization Parameter (ΨCA) is defined by:

Equation 5-1.Ψ

Where:

Equation 5-2.Ψ

Where:

= (T

CA

T

CASE

T

LA

TDP = TDP (W) assumes all power dissipates through the integrated heat

= ΨCS + ΨSA

CA

Ψ

CS

Ψ

SA

CASE

- TLA) /

TDP

= Processor case temperature (°C). For T

appropriate Datasheet.

= Local ambient temperature in chassis at processor (°C).

spreader. This inexact assumption is convenient for heatsink design.

TTVs are often used to dissipate TDP. Correction offsets account for

differences in temperature distribution between processor and TTV.

= Thermal characterization parameter of the TIM (°C/W) is dependent

on the thermal conductivity and thickness of the TIM.

= Thermal characterization parameter from heatsink-to-local ambient

(°C/W) is dependent on the thermal conductivity and geometry of the

heatsink and dependent on the air velocity through the heatsink fins.

specification see the

CASE

Figure 5-4 illustrates the thermal characterization parameters.

36 Thermal/Mechanical Design Guide

Page 37

Thermal Solutions

Figure 5-4. Processor Thermal Characterization Parameter Relationships

5.5.2 Dual Thermal Profile

Processors that offer dual thermal profile are specified in the appropriate Datasheet.

Dual thermal profile helps mitigate limitations in volumetrically constrained form

factors and allows trade-offs between heatsink cost and TCC activation risk. For

heatsinks that comply to Profile B, yet do not comply to Profile A (1U heatsink in

Figure 5-5), the processor has an increased probability of TCC activation and an

associated measurable performance loss. Measurable performance loss is defined to be

any degradation in processor performance greater than 1.5%. 1.5% is chosen as the

baseline since run-to-run variation in a performance benchmark is typically between 1

and 2%.

Thermal/Mechanical Design Guide 37

Page 38

Figure 5-5. Dual Thermal Profile

_MAX_B

T

CASE

_MAX_A

T

CASE

Thermal Solutions

1U Heatsink

TEMPERATURE

40C

0W TDP

Compliance to Profile A ensures that no measurable performance loss will occur due to

TCC activation. It is expected that T CC would only be activated for very brief periods of

time when running a worst-case real world application in a worst-case thermal

condition. A worst-case real world application is a commercially available, useful

application which dissipates power above TDP for a thermally relevant timeframe. One

example of a worst-case thermal condition is when the processor local ambient

temperature is above the y-axis intercept for Profile A.

5.6 Thermal Features

More information regarding processor thermal features is contained in the appropriate

Datasheet.

2U Heatsink

POWER

38 Thermal/Mechanical Design Guide

Page 39

Thermal Solutions

5.6.1 Fan Speed Control

There are many ways to implement fan speed control. Using processor ambient

temperature (in addition to Digital Thermal Sensor) to scale fan speed can improve

acoustics when DTS > T

CONTROL

.

Table 5-3. Fan Speed Control, T

Condition FSC Scheme

DTS ≤ T

CONTROL

DTS > T

CONTROL

5.6.1.1 T

CONTROL

Factory configured T

Guidance

CONTROL

Letter or may be extracted by issuing a Mailbox or an RDMSR instruction. See the

Intel® Xeon® Processor 5500 Series Datasheet, Volume 1 for more information.

Due to increased thermal headroom based on thermal characterization on the latest

stepping of Intel® Xeon® Processor 5500 Series production processors, customers

have the option to reduce T

In some situations, use of reduced T

and improve acoustics. Implementation is optional. Alternately, the factory configured

T

CONTROL

values can still be used. There are no plans to change Intel's specification or

the factory configured T

To implement this guidance, customers must re-write code to set T

reduced values provided in the table below.

Table 5-4. T

CONTROL

Guidance

CONTROL

FSC can adjust fan speed to maintain DTS ≤ T

FSC should adjust fan speed to keep T

specification (increased acoustic region).

and DTS Relationship

CASE

(low acoustic region).

CONTROL

at or below the Thermal Profile

values are available in the appropriate Dear Customer

CONTROL

CONTROL

to values lower than the factory configured values.

CONTROL

Guidance can reduce average fan power

values on individual processors.

CONTROL

to the

T

TDP

95W -10 Intel® Xeon® Processor 5500 Series with 2.93 GHz Max Core Frequency

95W -1 Intel® Xeon® Processor 5500 Series frequencies lower than 2.93 GHz

80W -1 Intel® Xeon® Processor 5500 Series 2.53 GHz or lower, except Embedded (NEBS)

60W -1 Intel® Xeon® Processor 5500 Series 2.26 GHz or lower, except Embedded (NEBS)

CONTROL

Guidance

Implementation of T

(based on modeling of the Intel Reference Design). Implementation of T

CONTROL

Comment

Guidance above maintains Intel standards of reliability

CONTROL

of -1

may increase risk of throttling (Thermal Control Circuit activation). Increased TCC

activation may or may not result in measurable performance loss.

Thermal Profile still applies. If PECI >= T

CONTROL

Guidance, then the case temperature

must meet the Thermal Profile.

T

CONTROL

the factory configured T

Regardless of T

values for the follow-on processor are TBD but expected to be in the range of

values for Intel® Xeon® Processor 5500 Series.

CONTROL

CONTROL

values used in Intel® Xeon® Processor 5500 Series, BIOS

needs to identify the processor type. For the follow-on processor, the fan speed control

algorithm needs to use the follow-on processor's factory configured T

Thermal/Mechanical Design Guide 39

CONTROL

values.

Page 40

Thermal Solutions

5.6.2 PECI Averaging and Catastrophic Thermal Management

By averaging DTS over PECI, thermal solution failure can be detected and a soft

shutdown can be initiated to help prevent loss of data.

Thermal data is averaged over a rolling window of 256mS by default (X=8):

AVG

= AVG

N

* (1 – 1/2X) + Temperature * 1/2

N-1

X

Using a smaller averaging constant could cause premature detection of failure.

The Critical Temperature threshold generally triggers somewhere between PECI of

-0.75 and -0.50. To avoid false shutdowns, initiate soft shutdown at -0.25.

Since customer designs, boundary conditions, and failure scenarios differ, above

guidance should be tested in the customer’s system to prevent loss of data during

shutdown.

5.6.3 Intel® Turbo Boost Technology

Intel® Turbo Boost Technology (Intel® TBT) is a new feature available on certain

processor SKUs that opportunistically, and automatically, allows the processor to run

faster than the marked frequency if the part is operating below its power, temperature

and current limits.

Heatsink performance (lower Ψ

as described in Section 5.5.1) is one of several

CA

factors that can impact the amount of Intel® TBT frequency benefit. Intel® TBT

performance is also constrained by ICC, and VCC limits.

Increased IMON accuracy may provide more Intel® TBT benefit on TDP limited

applications, as compared to lower Ψ

, as temperature is not typically the limiter for

CA

these workloads.

With Intel® TBT enabled, the processor may run more consistently at higher power

levels (but still within TDP), and be more likely to operate above T

compared to when Intel® TBT is disabled. This may result in higher acoustics.

With Intel® TBT enabled, processors with dual thermal profiles (described in

Section 5.5.2, have greater potential for performance delta between Profile A and

Profile B platforms, as compared to previous platforms.

5.7 Thermal Guidance

5.7.1 Thermal Excursion Power for 95 W Processor

Under fan failure or other anomalous thermal excursions, Tcase may exceed Thermal

Profile B for a duration totaling less than 360 hours per year witho ut affecting long term

reliability (life) of the processor. For more typical thermal excursions, Thermal Monitor

is expected to control the processor power level as long as conditions do not allow the

Tcase to exceed the temperature at which Thermal Control Circuit (TCC) activation

initially occurred. Under more severe anomalous thermal excursions when the

processor temperature cannot be controlled at or below this Tcase level by TCC

activation, then data integrity is not assured. At some higher threshold, THERMTRIP#

will enable a shut down in an attempt to prevent permanent damage to the processor.

Thermal Test Vehicle (TTV) may be used to check anomalous thermal excursion

CONTROL

, as

40 Thermal/Mechanical Design Guide

Page 41

Thermal Solutions

compliance by ensuring that the processor Tcase value, as measured on the TTV, does

not exceed T case_max_B at the anomalous power level for the environmen tal condition

of interest. This anomalous power level is equal to 75% of the TDP limit.

5.7.2 Thermal Excursion Power for 80 W Processor

Under fan failure or other anomalous thermal excursions, Tcase may exceed the

thermal profile for a duration totaling less than 360 hours per year without affecting

long term reliability (life) of the processor. For more typical thermal excursions,

Thermal Monitor is expected to control the processor power level as long as conditions

do not allow the Tcase to exceed the temperature at which Thermal Control Circuit

(TCC) activation initially occurred. Under more severe anomalous thermal excursions

when the processor temperature cannot be controlled at or below this Tcase level by

TCC activation, then data integrity is not assured. At some higher threshold,

THERMTRIP# will enable a shut down in an attempt to prevent permanent damage to

the processor. Thermal Test Vehicle (TTV) may be used to check anomalous thermal

excursion compliance by ensuring that the processor Tcase value, as measured on the

TTV, does not exceed Tcase_max at the anomalous power level for the environmental

condition of interest. This anomalous power level is equal to 75% of the TDP limit.

5.7.3 Absolute Processor Temperature

Intel does not test any third party software that reports absolute processor

temperature. As such, Intel cannot recommend the use of software that claims this

capability. Since there is part-to-part variation in the TCC (thermal control circuit)

activation temperature, use of software that reports absolute temperature can be

misleading.

See the Intel® Xeon® Processor 5500 Series Datasheet, Volume 1 for details

regarding use of IA32_TEMPERATURE_TA RGET register to determine the minimum

absolute temperature at which the TCC will be activated and PROCHOT# will be

asserted.

§

Thermal/Mechanical Design Guide 41

Page 42

Thermal Solutions

42 Thermal/Mechanical Design Guide

Page 43

Quality and Reliability Requirements

6 Quality and Reliability

Requirements

6.1 Test Conditions

The Test Conditions provided in Table 6-1 address processor heatsink failure

mechanisms only. Test Conditions, Qualification and Visual Criteria vary by customer;

Table 6-1 applies to Intel requirements.

Socket T est Conditions are pro vided in the LGA1366 Socket V alidation Reports av ailable

from socket suppliers listed in Appendix A.

Table 6-1. Heatsink Test Conditions and Qualification Criteria (Sheet 1 of 2)

Assessment Test Condition Qualification Criteria

1) Humidity Non-operating, 500 hours, +85°C and 85%

2) Board-Level

UnPackaged Shock

3) Board-Level

UnPackaged Vibration

4) First Article

Inspection

5) Shipping Media:

Packaged Shock

6) Shipping Media:

Packaged Vibration

7) Gravitational

Evaluation

R.H.

50G+/-10%; 170+/-10% in/sec; 3 drops

per face, 6 faces.

5 Hz @ 0.01 g2/Hz to 20 Hz @ 0.02 g2/Hz

(slope up).

20 Hz to 500 Hz @ 0.02 g2/Hz (flat).

Input acceleration is 3.13 g RMS.

10 minutes/axis for all 3 axes on all

samples.

Random control limit tolerance is ±3 dB.

Not Applicable Meet all dimensions on 5 samples.

Drop height determined by weight and may

vary by customer; Intel requirement in

General Supplier Packaging Spec.

10 drops (6 sides, 3 edges, 1 corner)

0.015 g2/Hz @ 10-40 Hz, sloping to

0.0015 g2/Hz @ 500 Hz, 1.03 gRMS,

1 hour/axis for 3 axes

Required for heatpipe designs.

3 orientations (0°, +90°, -90°)

No visual defects.

As verified in wind tunnel:

•Mean Ψ

value in Table 5-1.

• Pressure drop not to exceed value in

Table 5-1.

No damage to heatsink base or pipe.

No visual defects.

As verified in wind tunnel:

•Mean Ψ

exceed value in Table 5-1.

• Pressure drop not to exceed value in

Table 5-1.

No damage to heatsink base or pipe.

No visual defects.

As verified in wind tunnel:

•Mean Ψ

exceed value in Table 5-1

• Pressure drop not to exceed value in

Table 5-1

Meet all CTF dimensions on 32 additional

samples with 1.33 Cpk (mean + 4s).

If samples are soft-tooled, a hard tool plan

must be defined.

No visual defects 1 box

No visual defects 1 box

As verified in wind tunnel, mean Ψ

+ offset not to exceed value in Table 5-1

+ 3s + offset not to exceed

CA

+ 2.54s + offset not to

CA

+ 2.54s + offset not to

CA

CA

+ 3s

Min

Sample

Size

15

15

15

37

15

Thermal/Mechanical Design Guide 43

Page 44

Quality and Reliability Requirements

Table 6-1. Heatsink Test Conditions and Qualification Criteria (Sheet 2 of 2)

Assessment Test Condition Qualification Criteria

8) Thermal

Performance

Using 1U heatsink and 1U airflow from

Table 5-1:

1) TTV @ 95W (Profile B), Note 1.

Using 2U heatsink and 2U airflow from

Table 5-1:

2) TTV @ 95W (Profile A), Note 1.

3) TTV @ 80W.

As verified in wind tunnel:

1) mean Ψ

Table 5-1 value for 95W in 1U.

2-4) mean Ψ

Table 5-1 value for 2U.

5-8) mean Ψ

Table 5-1 value for Tower.

+ 3s + offset not to exceed

CA

+ 3s + offset not to exceed

CA

+ 3s + offset not to exceed

CA

4) TTV @ 60W.

Using Tower heatsink and Tower airflow

from Table 5-1:

Min

Sample

Size

5 heatsinks

X 8 tests by

supplier.

Note 1: 30

heatsinks X

3 tests by

Intel.

5) TTV @ 130W, Note 1.

6) TTV @ 95W (Profile A).

7) TTV @ 80W.

8) TTV @ 60W.

9) Thermal Cycling Required for heatpipe designs.

Temperature range at pipe in heatsink