Page 1

Intel® Server Board S7200AP/APR

Intel® Compute Module

HNS7200AP/APR

Product Family

System Integration and Service Guide

A document providing instruction on installation and removal of subassemblies.

Revision 1.1

April 2018

Datacenter Systems Group

Page 2

<This page is intentionally left blank>

Page 3

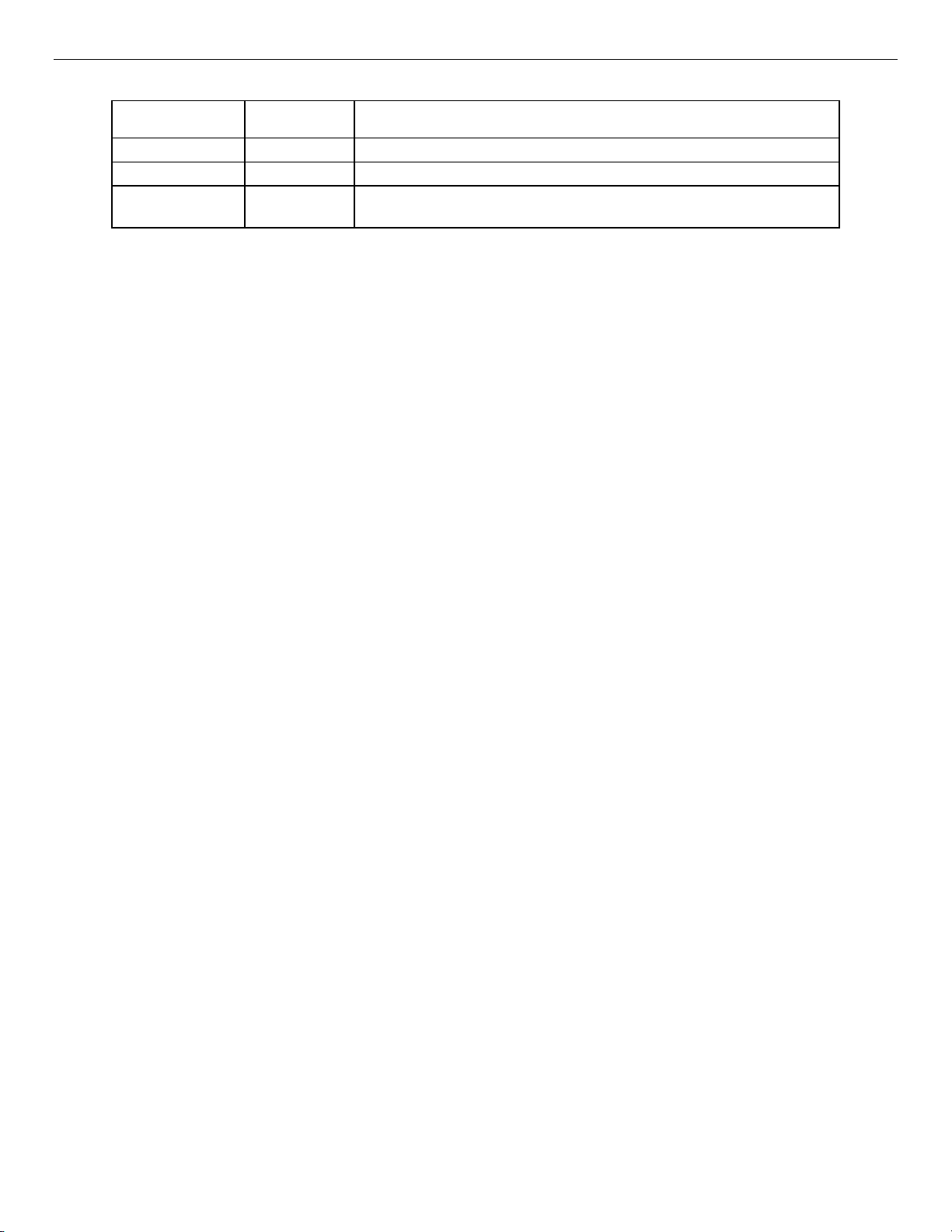

Revision

Number

Oct 2017

0.8

Update with Adams Pass Refresh information

Jan 2018

1.0

Update Processor Information; image modifications; warnings updated.

Updated Intel® Xeon™ Phi™ x205 Product Family CPUs to official marketing

name of

Revision History

Date

April 2018 1.1

Intel® Xeon™ Phi™ 72x5 Product Family CPUs

Modifications

Page 4

Disclaimers

No license (express or implied, by estoppel or otherwise) to any intellectual property rights is granted by this

document.

Intel disclaims all express and implied warranties, including without limitation, the implied warranties of

merchantability, fitness for a particular purpose, and non-infringement, as well as any warranty arising from

course of performance, course of dealing, or usage in trade.

This document contains information on products, services and/or processes in development. All information

provided here is subject to change without notice. Contact your Intel representative to obtain the latest.

The products and services described may contain defects or errors known as errata which may cause

deviations from published specifications. Current characterized errata are available on request.

Intel, and the Intel logo are trademarks of Intel Corporation in the U.S. and/or other countries.

*Other names and brands may be claimed as the property of others

© 2018 Intel Corporation.

Page 5

重要安全指导

Safety Information

Important Safety Instructions

Read all caution and safety statements in this document before performing any of the instructions. See also

Intel Server Boards and Server Chassis Safety Information at

http://www.intel.com/support/motherboards/server/sb/cs-010770.htm.

Wichtige Sicherheitshinweise

Lesen Sie zunächst sämtliche Warnund Sicherheitshinweise in diesem Dokument, bevor Sie eine der

Anweisungen ausführen. Beachten Sie hierzu auch die Sicherheitshinweise zu Intel-Serverplatinen und

Servergehäusen auf der

http://www.intel.com/support/motherboards/server/sb/cs-010770.htm.

Consignes de sécurité

Lisez attention toutes les consignes de sécurité et les mises en garde indiquées dans ce document avant de

suivre toute instruction. Consultez Intel Server Boards and Server Chassis Safety Information sur le site

http://www.intel.com/support/motherboards/server/sb/cs-010770.htm.

Instrucciones de seguridad importantes

Lea todas las declaraciones de seguridad y precaución de este documento antes de realizar cualquiera de las

instrucciones. Vea Intel Server Boards and Server Chassis Safety Information en

http://www.intel.com/support/motherboards/server/sb/cs-010770.htm.

在 执行任何指令之前, 请阅读本文档中的所有注意事项及安全声明。和/或

http://www.intel.com/support/motherboards/server/sb/cs-010770.htm 上的 Intel

Safety Information(《Intel 服务器主板与服务器机箱安全信息》)。

®

Server Boards and Server Chassis

Page 6

Warnings

Heed safety instructions: Before working with your server product, whether you are using this guide or any

other resource as a reference, pay close attention to the safety instructions. You must adhere to the assembly

instructions in this guide to ensure and maintain compliance with existing product certifications and approvals.

Use only the described, regulated components specified in this guide. Use of other products/components will

void the UL listing and other regulatory approvals of the product and will most likely result in noncompliance

with product regulations in the region(s) in which the product is sold.

System power on/off: Risk of electric shock or fire exist. Do not service the systems if energized by any source

of power. The power button DOES NOT turn off the system AC power. To remove power from the system, you

must unplug the AC power cords fully from the systems and from the wall outlet. Make sure the AC power cord

is unplugged before you open the chassis, add, or remove any components. Hazardous conditions, devices and

cables: Hazardous electrical conditions may be present on power, telephone, and communication cables. Turn

off the server and disconnect the power cord, telecommunications systems, networks, and modems attached

to the server before opening it. Otherwise, personal injury or equipment damage can result.

Liquid Cooling Solutions: Follow the power off guidance. Prior to powering up any compute modules, check

the liquid cooling system for leaks and/or damaged parts (e.g. tubing, fittings, and disconnects). Ensure that

all power is off prior to disconnecting any cooling quick disconnects. Do not to energize or power up any server

node if the liquid cooling system is compromised in any way. To reduce risk of damage to the cooling system,

use care when installing or removing server nodes. Avoid excessive force when connecting & disconnecting

quick disconnects. Keep cooling tubing clear of pinch points when sliding server nodes.

Installing or removing jumpers: A jumper is a small plastic encased conductor that slips over two jumper pins.

Some jumpers have a small tab on top that you can grip with your fingertips or with a pair of fine needle nosed

pliers. If your jumpers do not have such a tab, take care when using needle nosed pliers to remove or install a

jumper; grip the narrow sides of the jumper with the pliers, never the wide sides. Gripping the wide sides can

damage the contacts inside the jumper, causing intermittent problems with the function controlled by that

jumper. Take care to grip with, but not squeeze, the pliers or other tool you use to remove a jumper, or you may

bend or break the pins on the board.

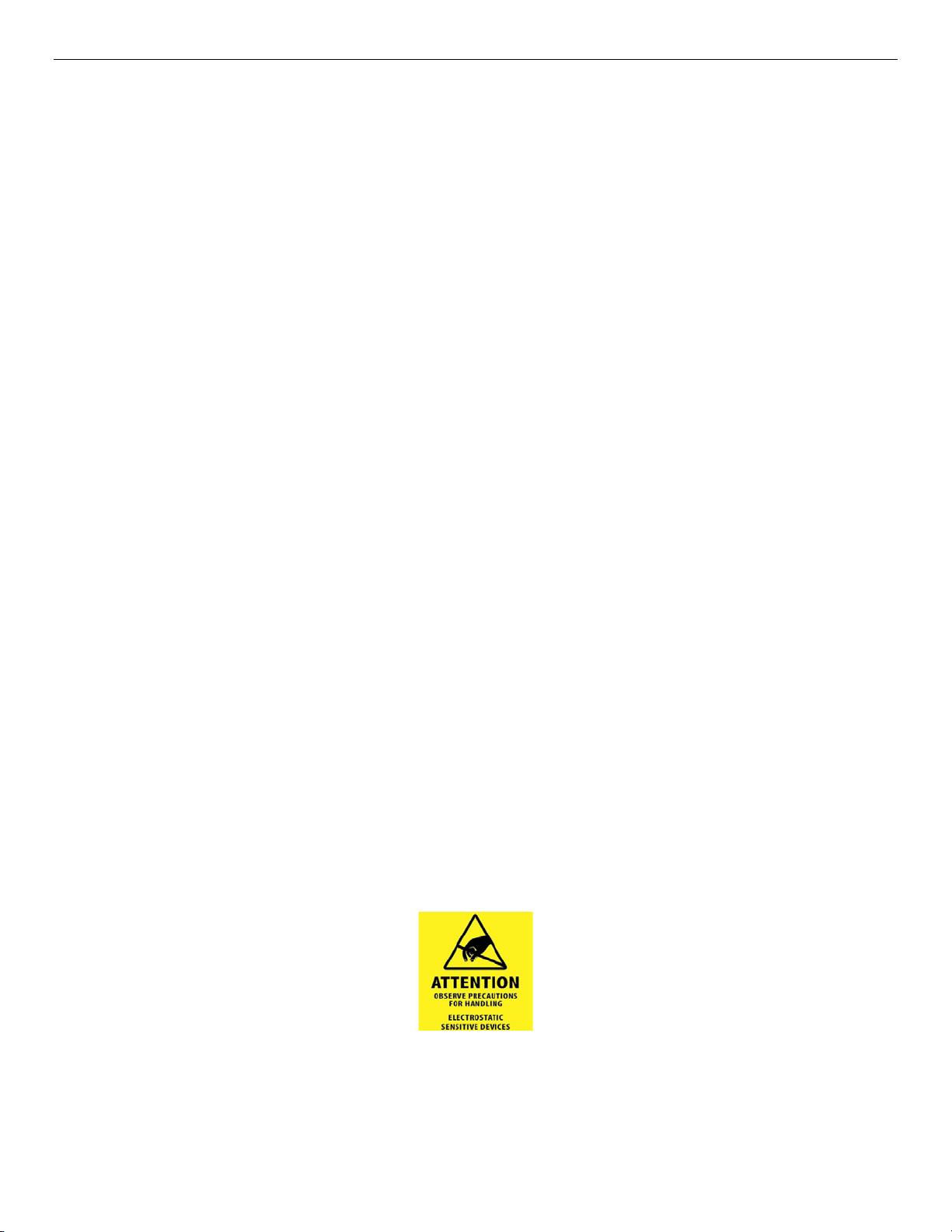

Electrostatic Discharge (ESD)

Electrostatic discharge can cause damage to your computer or the components within it. ESD can occur

without the user feeling a shock while working inside the system chassis or while improperly handling

electronic devices like processors, memory or other storage devices, and add-in cards.

Intel recommends the following steps be taken when performing any procedures described within this

document or while performing service to any computer system.

• Where available, all system integration and/or service should be performed at a properly equipped ESD

workstation.

• Wear ESD protective gear like a grounded antistatic wrist strap, sole grounders, and/or conductive shoes.

• Wear an anti-static smock or gown to cover any clothing that may generate an electrostatic charge.

Page 7

• Remove all jewelry.

• Disconnect all power cables and cords attached to the server before performing any integration or

service.

• Touch any unpainted metal surface of the chassis before performing any integration or service.

• Hold all circuit boards and other electronic components by their edges only.

• After removing electronic devices from the system or from their protective packaging, place them

component side up on to a grounded anti-static surface or conductive foam pad. Do not place electronic

devices on to the outside of any protective packaging.

Page 8

Preface

About this document

This document is written for system integrators and service technicians who are responsible for system

assembly, server upgrades, server repair, and component replacement.

This document is divided into two major sections. The first half of the document provides detailed

instructions on how to install critical components to the system like memory, processor and others. It will

guide you through the installation of system components and available accessories. The second half of the

document is focused on system service. It provides many reference diagrams used to identify all key

physical features of the system. It also provides detailed instructions for the replacement of field

replaceable components.

For the latest revision of this document, go to

Document Organization

Chapter 1 Product Features - provides a high level overview of the Intel® Compute Module HNS7200AP.

In this chapter, you will find a list of the compute module features and illustrations identifying the major

compute module components.

http://www.intel.com/support

Chapter 2 Hardware Installations and Upgrades - provides instructions on adding and replacing the

components. Use this chapter for step-by-step instructions and diagrams for installing or replacing the

components such as the processors, memory, and add-in cards, among other components.

Chapter 3 System Software Updates and Configuration - provides instructions on using the utilities that

are shipped with the board or that may be required to update the compute module. This includes

information for navigating through the BIOS Setup screens, performing a BIOS update, and resetting the

password or BIOS defaults.

Chapter 4 Server Utilities - provides instructions for server utilities.

Nomenclature

Throughout this manual “compute module” is the abbreviation of the Intel® Compute Module

HNS7200AP or HNS7200APR. It is also referred to as “compute node” or “node”.

Page 9

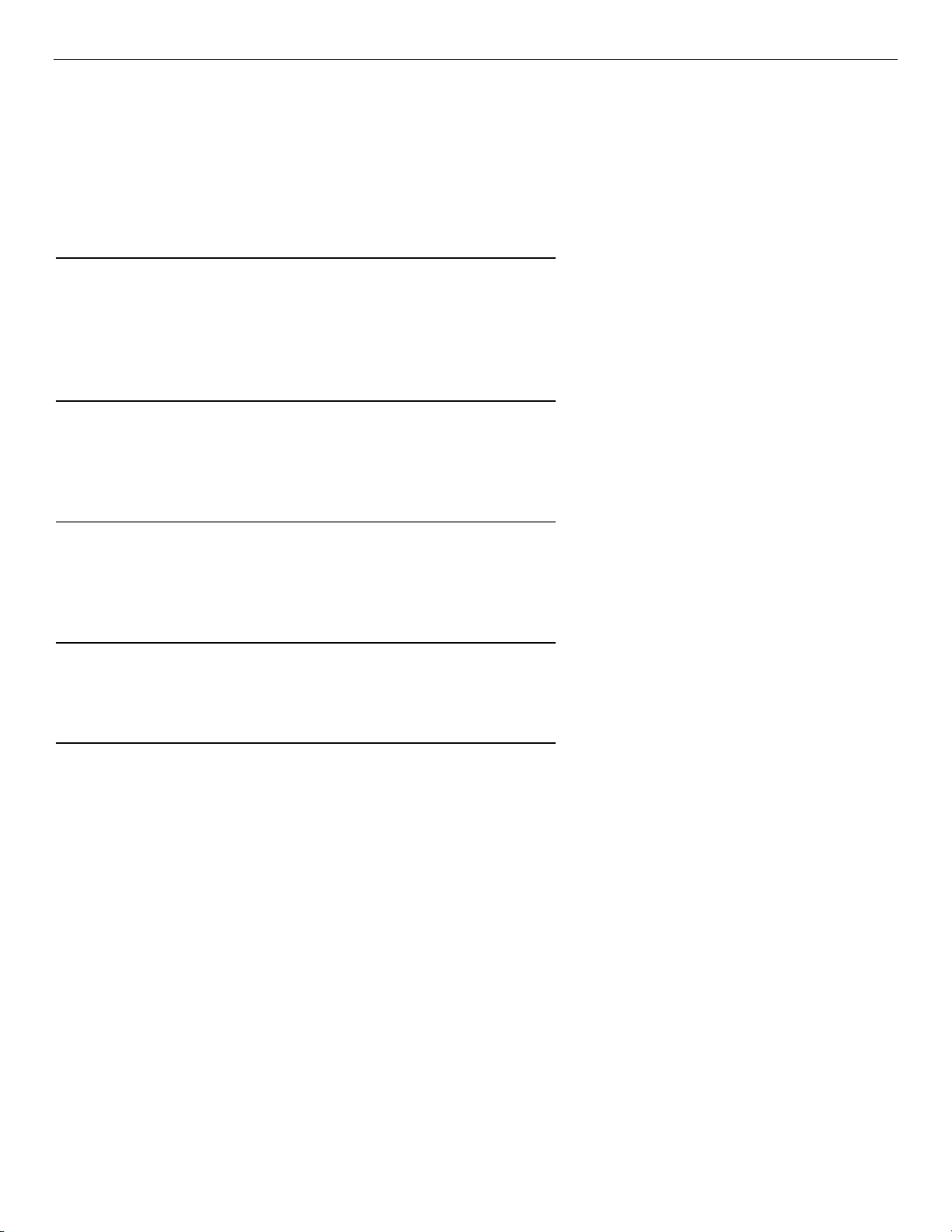

For this information or software

Use this Document or Software

For in-depth technical information

about this product

Intel ® Server Board S7200AP Product Family and Intel® Compute Module HNS7200AP

Product Family Technical Product Specification

For product list and supported Intel

spares and accessories

Spares and Accessories List and Configuration Guide

For server configuration guidance

and compatibility

Intel

®

Server Configurator tool

http://serverconfigurator.intel.com

For system power budget guidance

Power Budget Tool

Product Safety and Regulatory

document

Intel Server Products – Product Safety and Regulatory Compliance Document

Additional Information and Software

For additional information about this family of products or any of their supported accessories, refer to the

following resources available at

The server system has support for several software utilities which can be used to configure system

parameters and aid in troubleshooting system issues. All available utilities can be downloaded from the

following Intel web site:

http://downloadcenter.intel.com/

http://www.intel.com/support.

Table 1. Server System References

http://www.intel.com/support

Page 10

Table of Contents

1 Product Features .................................................................................................................................................... 1

1.1 Product Feature Overview ............................................................................................................................................... 2

1.1.1 Server Board Feature Set ....................................................................................................................................... 2

1.1.2 HNS7200AP Compute Module Feature Set .................................................................................................... 3

1.1.3 Chassis Feature Set for Intel® Compute Module HNS7200AP ................................................................ 4

1.1.4 HNS7200APR Compute Module Feature Set ................................................................................................. 6

1.1.5 Chassis Feature Set for Intel® Compute Module HNS7200APR ............................................................. 7

1.2 Back Panel Feature Identification................................................................................................................................. 7

1.3 Power Docking Board Features ..................................................................................................................................... 8

1.4 Bridge Board Feature Features ...................................................................................................................................... 8

1.5 Server Board Features ....................................................................................................................................................... 9

1.6 Intel® Light-Guided Diagnostics ................................................................................................................................. 10

1.7 Configuration and Recovery Jumpers ..................................................................................................................... 11

1.8 Advanced Management Options ............................................................................................................................... 12

1.8.1 Intel® Remote Management Module 4 Lite .................................................................................................. 12

2 Hardware Installations and Upgrades ........................................................................................................... 13

2.1 Before You Begin .............................................................................................................................................................. 13

2.1.1 Tools and Supplies Needed ................................................................................................................................ 13

2.1.2 System Reference ................................................................................................................................................... 13

2.2 Cable Routing .................................................................................................................................................................... 13

2.3 Removing and Installing the Air Duct ...................................................................................................................... 14

2.3.1 Removing the Air Duct .......................................................................................................................................... 14

2.3.2 Installing the Air Duct ........................................................................................................................................... 15

2.4 Processor Assembly Installation and Removal .................................................................................................... 16

2.4.1 Assembling the Processor Heat Sink Module (PHM) ............................................................................... 16

2.4.2 Processor Installation ........................................................................................................................................... 22

2.5 Processor Removal .......................................................................................................................................................... 26

2.5.1 PHM Disassembly ................................................................................................................................................... 27

2.6 Installation and Removal of the 1U LACC .............................................................................................................. 29

2.6.1 Removal of the 1U LACC Assembly ................................................................................................................ 29

2.6.2 Remove the CPU and Carrier Assembly ........................................................................................................ 33

2.6.3 Install the 1U LACC Assembly ........................................................................................................................... 33

2.7 Removing and Installing Riser 1 and Riser 2 ........................................................................................................ 38

2.7.1 Remove Riser 1 ........................................................................................................................................................ 38

2.7.2 Install Riser 1 ............................................................................................................................................................ 38

2.7.3 Remove Riser 2 ........................................................................................................................................................ 39

2.7.4 Install Riser 2 ............................................................................................................................................................ 39

2.8 Installing and Removing an Add-In Card - Riser Slot 1 .................................................................................... 40

2.8.1 Installing a PCIe* Add-In Card Riser 1 ............................................................................................................ 40

2.8.2 Removing a PCIe* Add-In Card Riser 1 .......................................................................................................... 41

2.9 Installing and Removing an Add-In Card - Riser Slot 2 .................................................................................... 43

2.9.1 Installing a PCIe* Add-In Card Riser 2 ............................................................................................................ 43

2.9.2 Removing a PCIe* Add-In Card from Riser 2 ............................................................................................... 45

Page 11

2.10 Installation and Removal of the Intel® Omni-Path Fabric Processor Kit. .................................................. 46

2.10.1 Fabric Processor Kit Components ................................................................................................................... 46

2.10.2 Fabric Processor Kit Cables ................................................................................................................................ 47

2.10.3 Installing the Fabric Processor Kit ................................................................................................................... 48

2.10.4 Removing the Fabric Processor Kit ................................................................................................................. 51

2.11 Installing and Removing the Memory ...................................................................................................................... 52

2.11.1 Installing the Memory ........................................................................................................................................... 52

2.11.2 Removing the Memory ......................................................................................................................................... 52

2.12 Installing and Removing the Intel® Remote Management Module 4 Lite ................................................. 53

2.12.1 Installing the Intel® RMM4 Lite .......................................................................................................................... 53

2.12.2 Removing the Intel® RMM4 Lite ........................................................................................................................ 53

2.13 Replacing the Bridge Board ......................................................................................................................................... 54

2.13.1 Installing the Bridge Board ................................................................................................................................. 54

2.13.2 Removing the Bridge Board ............................................................................................................................... 54

2.14 Replacing the Server Main Board .............................................................................................................................. 55

2.14.1 Removing the Server Board ............................................................................................................................... 55

2.14.2 Installing the Server Board ................................................................................................................................. 56

2.15 Installing and Removing the Power Docking Board .......................................................................................... 57

2.15.1 Removing the Power Docking Board .............................................................................................................. 57

2.15.2 Installing the Power Docking Board ................................................................................................................ 57

2.16 Replacing the Fan ............................................................................................................................................................ 58

2.16.1 Removing the Fan ................................................................................................................................................... 58

2.16.2 Installing the Fan ..................................................................................................................................................... 58

2.17 Replacing the Backup Battery .................................................................................................................................... 59

2.18 Installing and Removing the Intel® Trusted Platform Module ............................................................................... 60

2.18.1 Installing the TPM ................................................................................................................................................... 60

2.18.2 Removing the TPM ................................................................................................................................................. 60

2.19 Installing and Removing the VGA (Video) Debug Cable ......................................................................................... 61

2.19.1 Installing Video Debug Cable ............................................................................................................................ 61

2.19.2 Removing the Video Debug Cable ................................................................................................................... 62

3 System Software Updates and Configuration .............................................................................................. 63

3.1 Updating the System Software Stack ...................................................................................................................... 63

3.2 Using the BIOS Setup Utility ........................................................................................................................................ 63

4 Server Utilities .................................................................................................................................................... 65

4.1 Intel® System Information Retrieve Utility (Sysinfo) ............................................................................................ 65

4.2 Intel® One Boot Flash Update Utility (OFU) ........................................................................................................... 65

4.3 Intel® System Event Log (SEL) Viewer Utility.......................................................................................................... 65

4.4 Intel® System Configuration Utility (SYSCFG) ........................................................................................................ 65

Appendix A. Technical Reference ...................................................................................................................... 66

System Environmental Specifications .................................................................................................................................... 66

Appendix B. POST Code Diagnostic LED Decoder ......................................................................................... 67

Appendix C. POST Error Codes .......................................................................................................................... 75

Page 12

Appendix D. System Interconnects S7200AP / H2000G ............................................................................... 78

Appendix E. Regulatory and Compliance Information ................................................................................. 79

Appendix F. Getting Help .................................................................................................................................... 80

Warranty Information ................................................................................................................................................................... 80

Glossary ....................................................................................................................................................................... 81

Page 13

List of Figures

Figure 1. Intel® Compute Module HNS7200AP Product Family ........................................................................................ 1

Figure 2. Intel® Ser ver Board S7200AP Product Family .................................................................................................... 1

Figure 3. Intel® Ser ver Board S7200AP Rear Connectors .................................................................................................. 7

Figure 4. Intel® Compute Module HNS7200AP Rear Connectors ..................................................................................... 8

Figure 5. Power Docking Board Features ............................................................................................................................. 8

Figure 6. 6G SATA Bridge Board Features ............................................................................................................................ 8

Figure 7. Intel® Ser ver Board S7200AP Features ................................................................................................................ 9

Figure 8. Intel® Ser ver Board S7200APR ............................................................................................................................. 9

Figure 9. Intel® Light-Guided Diagnostic LEDs – Server Board ....................................................................................... 10

Figure 10. Configuration and Recovery Jumpers ............................................................................................................. 11

Figure 11. Cable Routing ...................................................................................................................................................... 13

Figure 12. Removing the Air Duct ....................................................................................................................................... 14

Figure 13. Installing the Air Duct ........................................................................................................................................ 15

Figure 14. Processor Heatsink Module (PHM) and Processor Socket Reference Diagram ......................................... 16

Figure 15. Processor Reference Diagram - Top and Bottom Views of Processor ......................................................... 17

Figure 16. Grasping the Heatsink Correctly ...................................................................................................................... 18

Figure 17. Placing the Processor Heat Sink on to a Flat Surface ................................................................................... 18

Figure 18. Alignment Features ............................................................................................................................................ 19

Figure 19. Processor Carrier Assembly .............................................................................................................................. 20

Figure 20. Processor Carrier Clip Sub-Assembly.............................................................................................................. 20

Figure 21. Orienting Processor Carrier Clip Sub-assembly to Heat Sink ...................................................................... 21

Figure 22. Processor Heat Sink Module (PHM) ................................................................................................................. 21

Figure 23. Processor Heat Sink Location ........................................................................................................................... 22

Figure 24. Plastic processor socket cover removal .......................................................................................................... 23

Figure 25. PHM Alignment to Bolster Plate ....................................................................................................................... 24

Figure 26. Correct Placement .............................................................................................................................................. 25

Figure 27. Installing the PHM .............................................................................................................................................. 25

Figure 28. Uninstalling the PHM ......................................................................................................................................... 26

Figure 29. Plastic processor socket cover Installation .................................................................................................... 26

Figure 30. PHM Disassembly ............................................................................................................................................... 27

Figure 31. Releasing the Processor Carrier Clip from the Heat Sink ............................................................................. 27

Figure 32. Releasing Processor from Carrier ..................................................................................................................... 28

Figure 33. 1U LACC Assembly ............................................................................................................................................. 29

Figure 34. 1U LACC Assembly installed in the system .................................................................................................... 29

Figure 35. Disconnect the Pump Cable (Fan Header J6J2) ............................................................................................. 30

Figure 36. Remove LACC brackets #1 ................................................................................................................................ 30

Figure 37. Remove LACC brackets #2 ................................................................................................................................ 31

Figure 38. Remove LACC brackets #3 ................................................................................................................................ 31

Figure 39. Remove Cold Plate Assembly ........................................................................................................................... 32

Figure 40. Lift out LACC Assembly ..................................................................................................................................... 32

Figure 41. Releasing CPU and Carrier from Cold Plate .................................................................................................... 33

Figure 42. 1U LACC Assembly ............................................................................................................................................. 33

Figure 43. Install CPU and Carrier to Cold LACC Cold Plate ........................................................................................... 34

Figure 44. Install the LACC assembly into the system ..................................................................................................... 35

Figure 44. Install the LACC assembly into the system ..................................................................................................... 35

Figure 45. Install brackets #1 .............................................................................................................................................. 35

Figure 46. Install LACC brackets #2 .................................................................................................................................... 36

Figure 47. Install LACC brackets #3 .................................................................................................................................... 36

Figure 48. Connect the Pump Cable (fan header J6J2) ................................................................................................... 37

Figure 49. Removing Riser 1 ................................................................................................................................................ 38

Figure 50. Installing Riser 1 ................................................................................................................................................. 39

Figure 51. Removing Riser 2 ................................................................................................................................................ 39

Figure 52. Installing Riser 2 ................................................................................................................................................. 40

Figure 53. Installing the PCIe* Add-In Card– Step 1 ........................................................................................................ 40

Figure 54. Installing the PCIe* Add-In Card – Step 2 ....................................................................................................... 41

Figure 55. Installing the PCIe* Add-In Card – Step 3 ....................................................................................................... 41

Figure 56. Removing the PCIe* Add-In Card – Step 1 ...................................................................................................... 42

Page 14

Figure 57. Removing the PCIe* Add-In Card – Step 2 ...................................................................................................... 42

Figure 58. Removing the PCIe* Add-In Card– Step 3 ....................................................................................................... 43

Figure 59. Installing the PCIe* Add-In Card– Step 1 ........................................................................................................ 44

Figure 60. Installing the PCIe* Add-In Card– Step 2 ........................................................................................................ 44

Figure 61. Installing the PCIe* Add-In Card– Step 3 ........................................................................................................ 44

Figure 62. Removing the PCIe* Add-In Card – Step 1 ...................................................................................................... 45

Figure 63. Lift out the Riser and Add-In-Card– Step 2 ..................................................................................................... 46

Figure 64. Remove the Add-In-Card from Riser 2– Step 3 .............................................................................................. 46

Figure 65. Installing the IFT Carrier .................................................................................................................................... 47

Figure 66. Intel® Omni-Path Sideband Cable Connection ............................................................................................... 47

Figure 67. Intel® Omni-Path Fabric Processor Cable ........................................................................................................ 47

Figure 68. Sideband Cable Connection ............................................................................................................................. 48

Figure 69. Installing the IFT Carrier .................................................................................................................................... 49

Figure 70. Fabric Processor and IFT Cable Connections ................................................................................................. 50

Figure 71. Disconnecting IFP Cables .................................................................................................................................. 51

Figure 72. Installing the Memory........................................................................................................................................ 52

Figure 73. Installing the Intel® RMM4 Lite ......................................................................................................................... 53

Figure 74. Installing the Bridge Board ............................................................................................................................... 54

Figure 75. Removing the Bridge Board .............................................................................................................................. 54

Figure 76. Removing the Cable Connections from the Server Board ............................................................................ 55

Figure 77. Removing the Server Board .............................................................................................................................. 55

Figure 78. Installing the Server Board ............................................................................................................................... 56

Figure 79. Connecting all Cables ........................................................................................................................................ 56

Figure 80. Removing the Power Docking Board ............................................................................................................... 57

Figure 81. Installing the Power Docking Board ................................................................................................................ 57

Figure 82. Removing the Fan ............................................................................................................................................... 58

Figure 83. Installing the Fan ................................................................................................................................................ 58

Figure 84. Replacing the Backup Battery .......................................................................................................................... 59

Figure 85. Installing the Intel® Trusted Platform Module ............................................................................................... 60

Figure 86. Video Cable Routing........................................................................................................................................... 61

Figure 87. Connecting video cable to board VGA connector .......................................................................................... 61

Figure 88. Reseat Riser with video cable ........................................................................................................................... 62

Figure 89. Video Cable Routing........................................................................................................................................... 62

Figure 90. POST Diagnostic LED Location ......................................................................................................................... 67

Figure 91. System Interconnect .......................................................................................................................................... 78

Page 15

List of Tables

Table 1. Server System References ..................................................................................................................................... vii

Table 2. Intel® Compute Module HNS7200AP Product Family Feature Set .................................................................... 3

Table 3. Intel® Server Board S7200APR (Refresh) Product Family Feature Set .............................................................. 4

Table 4. Intel® Compute Module HNS7200APR Product Family Feature Set .................................................................. 6

Table 5. Processor Carriers .................................................................................................................................................. 17

Table 6. Processor Heat Sinks ............................................................................................................................................. 22

Table 7. BIOS Setup: Keyboard Command Bar ................................................................................................................. 64

Table 8. System Environmental Limits Summary ............................................................................................................. 66

Table 9. POST Progress Code Decoding LED Example .................................................................................................... 68

Table 10. MRC Fatal Error Codes ......................................................................................................................................... 69

Table 11. MRC Progress Codes ............................................................................................................................................ 70

Table 12. POST Progress Codes .......................................................................................................................................... 71

Table 13. POST Error Codes and Messages ....................................................................................................................... 75

Table 14. POST Error Beep (with LED) Codes ................................................................................................................... 77

Tab le 1 5 . Integrated BMC Beep (with LED) Codes ............................................................................................................ 77

Page 16

Page 17

1 Product Features

This chapter briefly describes the main features of the Intel® Server Board S7200AP/APR and the Intel®

Compute Module HNS7200AP/APR. This includes illustrations of the products, a list of features, and

diagrams showing the location of important components and connections. The two main boards are

described in this document to include support for several chassis. The document includes updates for Intel®

Server Board S7200APR refresh product that is supported in the Intel® Server Chassis H2204XXLRE.

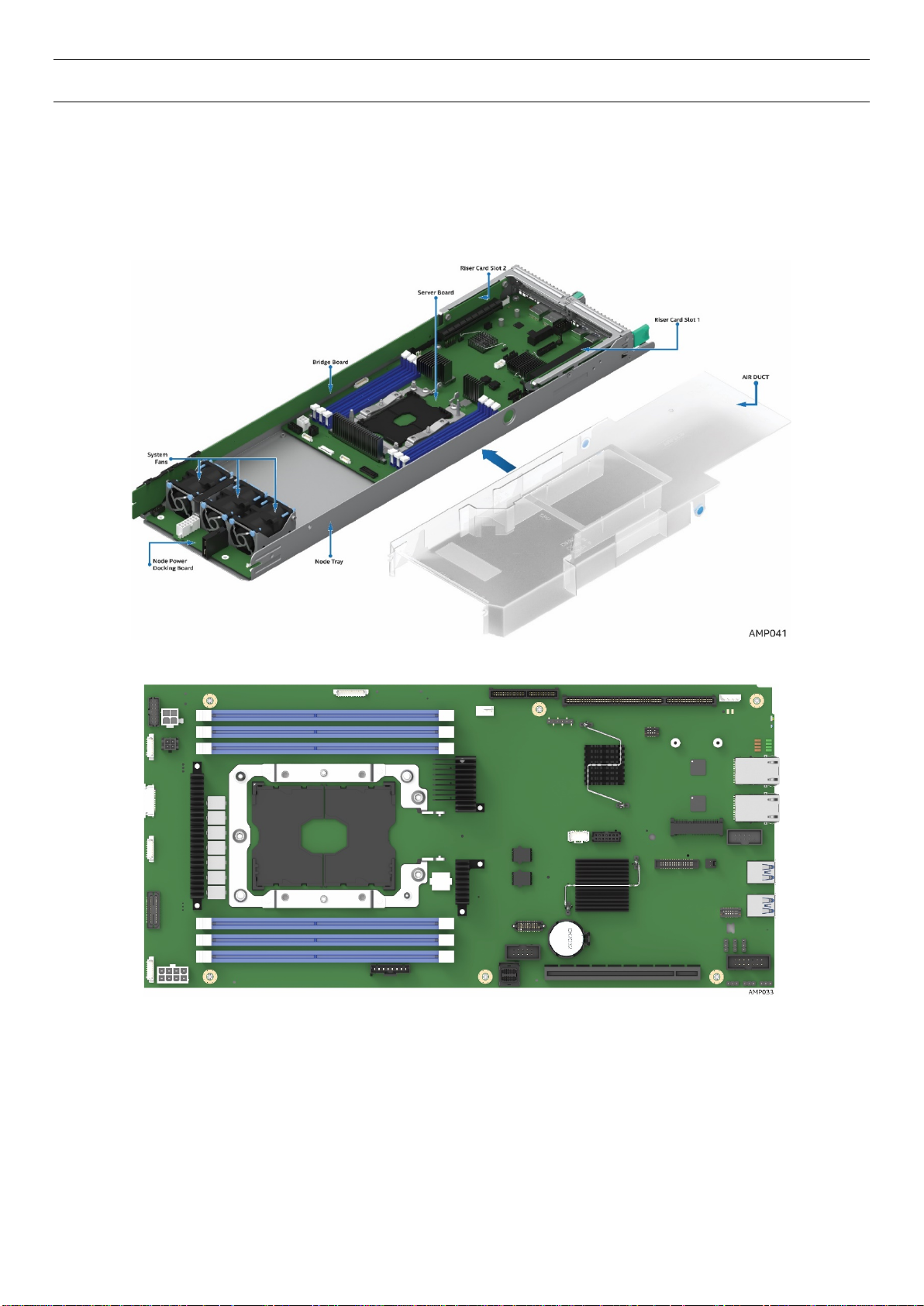

Figure 1. Intel® Compute Module HNS7200AP Product Family

Figure 2. Intel® Server Board S7200AP Product Family

Page 18

Feature

Description

Processor Support

Intel® Xeon™ Phi™ x200 Product Family

36 lanes of Integrated PCI Express® 3.0 low-latency I/O

Memory Support

Six DIMM slots in total across six memory channels

Max memory 384GB

Chipset

Intel C610 “Wellsburg” Platform Controller Hub (PCH)

External I/O Connections

Two USB 3.0 connectors

Two RJ-45 10/100/1000 Mbit Network Interface Controller (NIC) ports

Internal I/O

One USB 2.0 Header

One Serial Port A Header

PCIe Support

PCIe* 3.0 (2.5, 5, 8 GT/s)

Power Connections

• One 2x4 pin main power connector

One 4 pin power connector for disk drive power

System Fan Support

Three 40x56mm double rotor fans

One 4 pin CPU fan or liquid cooling pump support header

Video

128MB DDR3 memory

1.1 Product Feature Overview

1.1.1 Server Board Feature Set

Intel® Server Board S7200AP Product Family contains two server board options. Intel® Server Board

S7200AP supports Intel® Xeon™ Phi™ x200 CPUs (up to 230w TDP) in Intel® Server Chassis H2312XXLR2

and H2216XXLR2.

Intel® Server Board S7200APR supports both Intel® Xeon™ Phi™ x200 and Intel® Xeon™ Phi™ 72x5 Product

Family CPUs (up to 320w TDP) in Intel® Server Chassis H2204XXLRE.

This document describes the servicing of both compute modules. Although, these boards are

independent and stand-alone products, there are many features and service steps that are common to

each board. These common steps will be identified in its respective section.

The following tables list the common feature set, however, a board will be identified by its product code

when a described feature or function is unique to it.

Table 1. Intel® Server Board S7200AP Product Family Feature Set

connectors/headers

Single processor socket P (3647 pins)

Thermal Design Power (TDP) up to 230W

Registered DDR4 (RDIMM), Load Reduced DDR4 (LRDIMM)

Memory DDR4 data transfer rates of 2400/2666 MT/s

1 DIMM per channel

One TPM Header

One Intel® Omni-Path Fabric Signal Connector

One mSATA Connector

One Bridge Board Connector

One 2x7 pin header for system fan module

One Aux Front Panel Connector

Three 8-pin fan headers for non-Intel chassis support

One 4 pin CPU fan or liquid cooling pump support header

One PSU Control Header

One RMII header for Intel® RMM4 Lite

One internal RGB Video Header

• One 2x2 pin aux. power connector

•

Integrated 2D video graphics controller

Page 19

Feature

Description

Riser Support

One PCIe Gen3 x16 standard riser connector

On-board storage

controllers and options

Integrated 10-port SATA

o 4 ports to MiniSAS HD connector

Fabric

Dual port Intel® Omni-Path Fabric via

Single Port Intel® Omni-Path Fabric via x16 Gen 3 PCIe Adapter

Network (LAN)

Dual i210 Springvilles

to management traffic.

Server Management

Feature1

Description

Server Board

Intel® Xeon™ Phi™ x200 Product Family

CPUs with Integrated Intel® Omni-Path Fabric supported

Processor TDP Support

Maximum supported Thermal Design Power (TDP) of up to 230W

Heatsink

One 80x107mm 1U Heatsink

Fan

Three 40x56mm dual rotor system fans

Riser Support

One PCIe Gen3 x16 standard riser connector

Compute Module Board

One compute module power docking board

Air Duct

One transparent air duct

o Supports a low-profile adapter in Riser Slot 1

One PCIe Gen3 x20 HSEC-8 fine-pitch riser connector

o Supports a x16 low-profile adapter in Riser Slot 2

o Supports a x4 low-profile adapter in Riser Slot 2 when CPUs with

integrated Intel® Omni-Path Fabric are used

o 5 ports to bridge board,

o 1 port to mSATA

or

Dual 10/100/1000Gbe RJ45 connectors

NC_SI sideband to BMC. Option to host share or dedicate a Network port

Onboard Emulex* Pilot III* Controller

®

Support for Intel

Support for Intel

Support for Intel® Intelligent Power Node Manager

Remote Management Module 4 Lite solutions

®

System Management Software

Xeon™ Phi™ x200 Product Family

NOTE: The Riser Slot 1 on the server board is designed for plugging in ONLY the riser adapter. Plugging

in a PCIe* adapter directly into the riser slot may cause permanent server board and/or PCIe* card

damage.

1.1.2 HNS7200AP Compute Module Feature Set

Table 2. Intel® Compute Module HNS7200AP Product Family Feature Set

Single processor socket P (3647 pins)

Thermal Design Power (TDP) up to 230W

36 lanes of Integrated PCI Express® 3.0 low-latency I/O

One PCIe Gen3 x20 HSEC-8 fine-pitch riser connector

Bridge boards:

o Supports a low-profile adapter in Riser Slot 1

o Supports a x16 low-profile adapter in Riser Slot 2

o Supports a x4 low-profile adapter in Riser Slot 2 when CPUs

with integrated Intel® Omni-Path Fabric are used

o 6G SATA Bridge Board (Default)

Page 20

Feature1

Description

Form Factor

Length 14.17” (360m), width 6.81” (173mm)

Feature

Description

Dimensions (2U)

438mm x 86.9mm x 771/733mm

Node Support

Intel® Compute Module options:

Power Supply

2 x 2130W AC CRPS

System Cooling

3 dual rotor 40 x 56 mm fixed fans per node

PCIe support

Two low profile PCIe cards on riser 1 and 2

Storage

8 x 2.5” SATA drive Note: 2.5” SATA HDD installed in the 3.5” Drive Carrier

System SKUs

Support for H2312XXLR2 and H2216XXLR2 chassis only

NOTE: The table only lists features that are unique to the compute module or different with the server

board.

1. ONLY standard low profile PCIe* cards can be installed in the riser card slots.

1.1.3 Chassis Feature Set for Intel® Compute Module HNS7200AP

The following table lists a brief description of the 2U H2000G Chassis Product Family features,

17.24” width x 3.42 length x 30.35/28.86” height

HNS7200AP (up to four)

16 x 2.5” SATA drives

Bridge Board Options:

(1) 6G SATA only RAID 0, 1, 10 SW RAID ESRT2

Note: Intel® Compute Module HNS7200AP is not supported in Intel® Server Chassis H2204XXLRE

For additional details on chassis features, refer to the Intel® Server Chassis H2000G and H2000P Product

Family TPS and Service Guide.

Table 3. Intel® Server Board S7200APR (Refresh) Product Family Feature Set

Page 21

Feature

Description

Processor Support

Intel® Xeon™ Phi™ 72x5 Product Family

CPUs with Integrated Intel® Omni-Path Fabric supported

Memory Support

Six DIMM slots in total across six memory channels

Max memory 384GB

Chipset

Intel C610 “Wellsburg” Platform Controller Hub (PCH)

External I/O Connections

Two USB 3.0 connectors

Two RJ-45 10/100/1000 Mbit Network Interface Controller (NIC) ports

Internal I/O

One USB 2.0 Header

One Serial Port A Header

PCIe Support

PCIe* 3.0 (2.5, 5, 8 GT/s)

Power Connections

• One 2x4 pin main power connector

One 4 pin power connector for disk drive power

System Fan Support

Three 40x56mm double rotor fans

One 4 pin CPU fan or liquid cooling pump support header

Video

128MB DDR3 memory

Riser Support

One PCIe Gen3 x16 standard riser connector

On-board storage

o 4 ports to MiniSAS HD connector

Fabric

connectors/headers

Single processor socket P

Thermal Design Power (TDP) up to 320W with the 1U LACC thermal

solution

36 lanes of Integrated PCI Express® 3.0 low-latency I/O

Intel® Xeon™ Phi™ x200 Product Family

Single processor socket P (3647 pins)

Thermal Design Power (TDP) up to 230W (Air Cooled Heatsink)

36 lanes of Integrated PCI Express® 3.0 low-latency I/O

Registered DDR4 (RDIMM), Load Reduced DDR4 (LRDIMM)

Memory DDR4 data transfer rates of 2400/2666 MT/s

1 DIMM per channel

One TPM Header

One Intel® Omni-Path Fabric Signal Connector

One mSATA Connector

One Bridge Board Connector

One 2x7 pin header for system fan module

One Aux Front Panel Connector

Three 8 pin fan headers for third-party chassis support

One 4 pin CPU fan or liquid cooling pump support header

One PSU Control Header

One RMII header for Intel® RMM4 Lite

One internal RGB Video Header

• One 2x2 pin aux. power connector

•

Integrated 2D video graphics controller

o Supports a low-profile adapter in Riser Slot 1

One PCIe Gen3 x20 HSEC-8 fine-pitch riser connector

o Supports a x16 low-profile adapter in Riser Slot 2

controllers and options

Integrated 10-port SATA

Single Port Intel® Omni-Path Fabric via x16 Gen 3 PCIe Adapter

o Supports a x4 low-profile adapter in Riser Slot 2 when CPUs with

integrated Intel® Omni-Path Fabric are used

o 5 ports to bridge board,

o 1 port to mSATA

Page 22

Feature

Description

Network (LAN)

Dual i210 Springvilles

to management traffic.

RAID Support

Server Management

Onboard Emulex* Pilot III* Controller

Support for Intel

Intelligent Power Node Manager

Feature1

Description

Server Board

Intel® Xeon™ Phi™ 72x5 Product Family

CPUs with Integrated Intel® Omni-Path Fabric supported

Processor TDP Support

Maximum supported Thermal Design Power (TDP) of up to 320W

Heatsink

Liquid Assisted Air Cooling (LAAC)

Fan

Three 40x56mm dual rotor system fans

Riser Support

One PCIe Gen3 x16 standard riser connector

Compute Module Board

One compute module power docking board

Air Duct

One transparent air duct

Form Factor

Length 14.17” (360m), width 6.81” (173mm)

Dual 10/100/1000Gbe RJ45 connectors

NC_SI sideband to BMC. Option to host share or dedicate a Network port

Intel

Support for Intel

Support for Intel

®

Embedded Server RAID Technology 2 (ESRT2)

®

Remote Management Module 4 Lite solutions

®

System Management Software

®

NOTE: The Riser Slot 1 on the server board is designed for plugging in ONLY the riser adapter. Plugging

in a PCIe* adapter directly into the riser slot may cause permanent server board and/or PCIe* card

damage.

1.1.4 HNS7200APR Compute Module Feature Set

Table 4. Intel® Compute Module HNS7200APR Product Family Feature Set

Single processor socket P

Thermal Design Power (TDP) up to 320W with the 1U LACC

thermal solution

36 lanes of Integrated PCI Express® 3.0 low-latency I/O

Intel® Xeon™ Phi™ x200 Product Family

Single processor socket P (3647 pins)

Thermal Design Power (TDP) up to 230W (Air Cooled Heatsink)

36 lanes of Integrated PCI Express® 3.0 low-latency I/O

NOTE: The table only lists features that are unique to the compute module or different with the server

board.

1. ONLY standard low profile PCIe* cards can be installed in the riser card slots.

One 80x107mm 1U Heatsink-CPUs < 245W TDP

1U Liquid Assisted Air Cooling (LAAC) -CPUs > 245W TDP

o Supports a low-profile adapter in Riser Slot 1

One PCIe Gen3 x20 HSEC-8 fine-pitch riser connector

o Supports a x16 low-profile adapter in Riser Slot 2

o Supports a x4 low-profile adapter in Riser Slot 2 when CPUs

with integrated Intel® Omni-Path Fabric are used

Bridge boards:

o 6G SATA Bridge Board (Default)

Page 23

Feature

Description

Dimensions (2U)

438mm x 86.9mm x 771/733mm

Node Support

Intel® Compute Module options:

Power Supply

2 x 2130W AC CRPS

System Cooling

3 dual rotor 40 x 56 mm fixed fans per node

PCIe support

Two low profile PCIe cards on riser 1 and 2

Storage

4 x 2.5” SATA drive Note: 2.5” SATA HDD installed in the 3.5” Drive Carrier

System SKUs

Supported for H2204XXLRE chassis only

Label

Description

Label

Description

A

USB 3.0 Por t 1

B

USB 3.0 Por t 2

C

NIC port 1 (RJ45)

D

NIC port 2 (RJ45)

E

POST Code LEDs (8 LEDs)

F

ID LED

G

Status LED

1.1.5 Chassis Feature Set for Intel® Compute Module HNS7200APR

The following table lists a brief description of the 2U H2000-G Chassis Product Family features

17.24” width x 3.42 length x 30.35/28.86” height

HNS7200APR (up to four)

Bridge Board Options:

(1) 6G SATA only RAID 0, 1, 10 SW RAID ESRT2

Note: Intel® Compute Module HNS7200APR is not supported in Intel® Server Chassis H2312XXLR2 and

H2216XXLR2

For additional details on chassis features, refer to the Intel® Server Chassis H2000G Product Family TPS.

1.2 Back Panel Feature Identification

The Intel® Compute Module HNS7200AP product family has the following board rear connector placement

and features.

Figure 3. Intel® Server Board S7200AP Rear Connectors

Page 24

Label

Description

A

2x7 pin fan control connector

B

8 pin connector for fan 1

C

2x6 pin Minifit Jr. main power output

connector

D

8 pin connector for fan 2

E

12 pin connector for main power input

F

8 pin connector for fan 3

Label

Description

A

2x40 pin card edge connector (to the backplane)

B

2x40 pin card edge connector (to the baseboard slot)

Figure 4. Intel® Compute Module HNS7200AP Rear Connectors

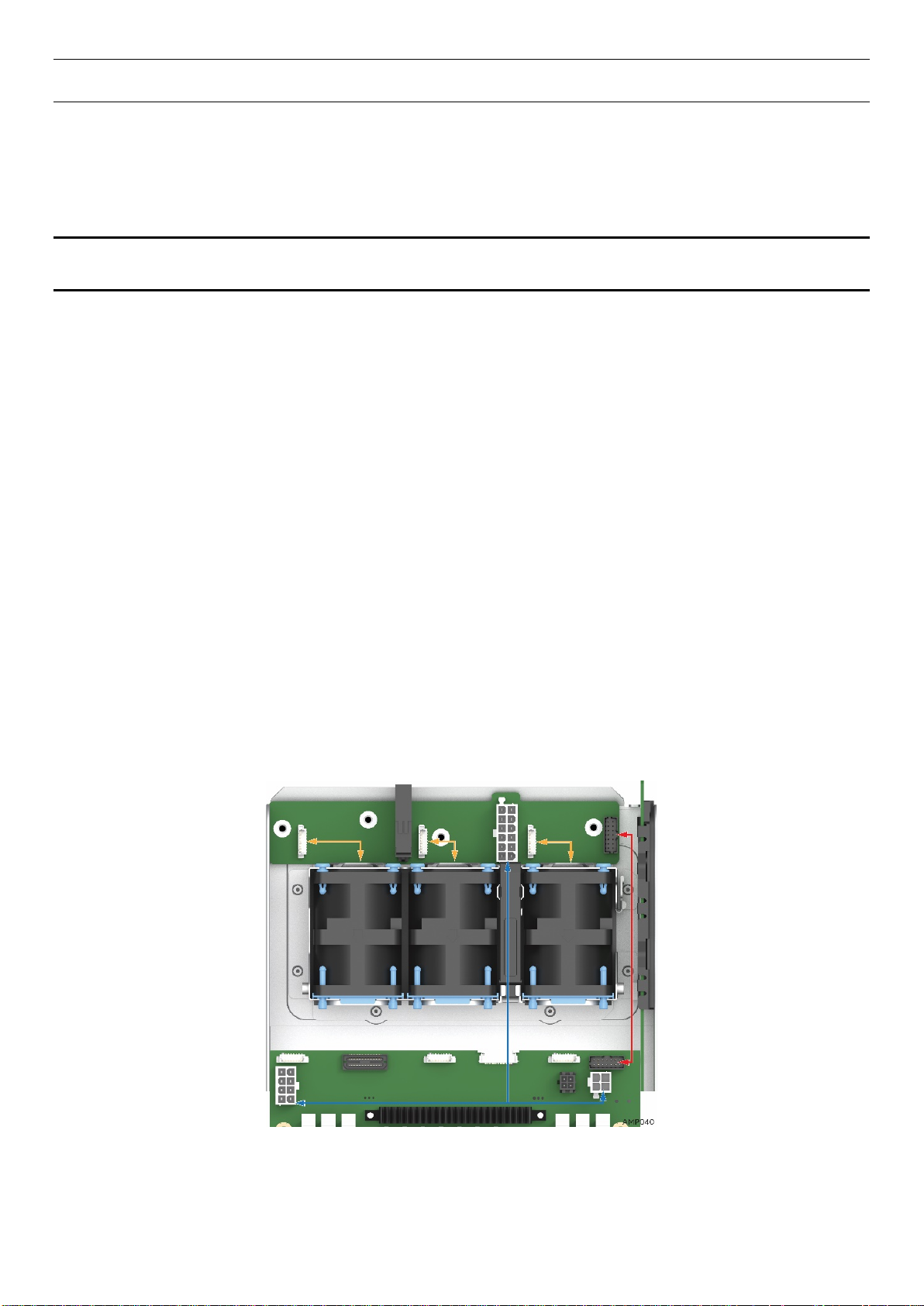

1.3 Power Docking Board Features

Figure 5. Power Docking Board Features

1.4 Bridge Board Feature Features

Figure 6. 6G SATA Bridge Board Features

Page 25

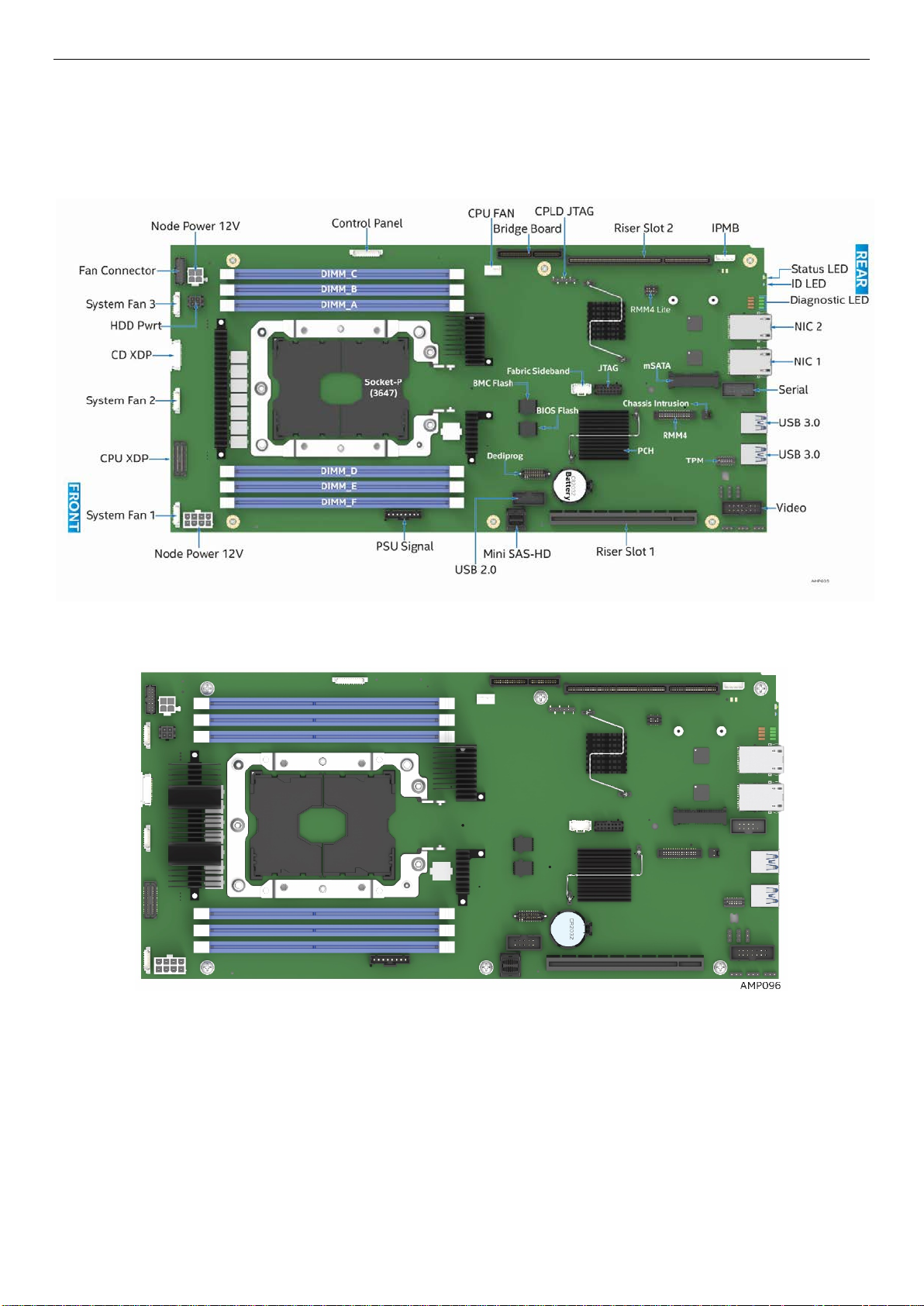

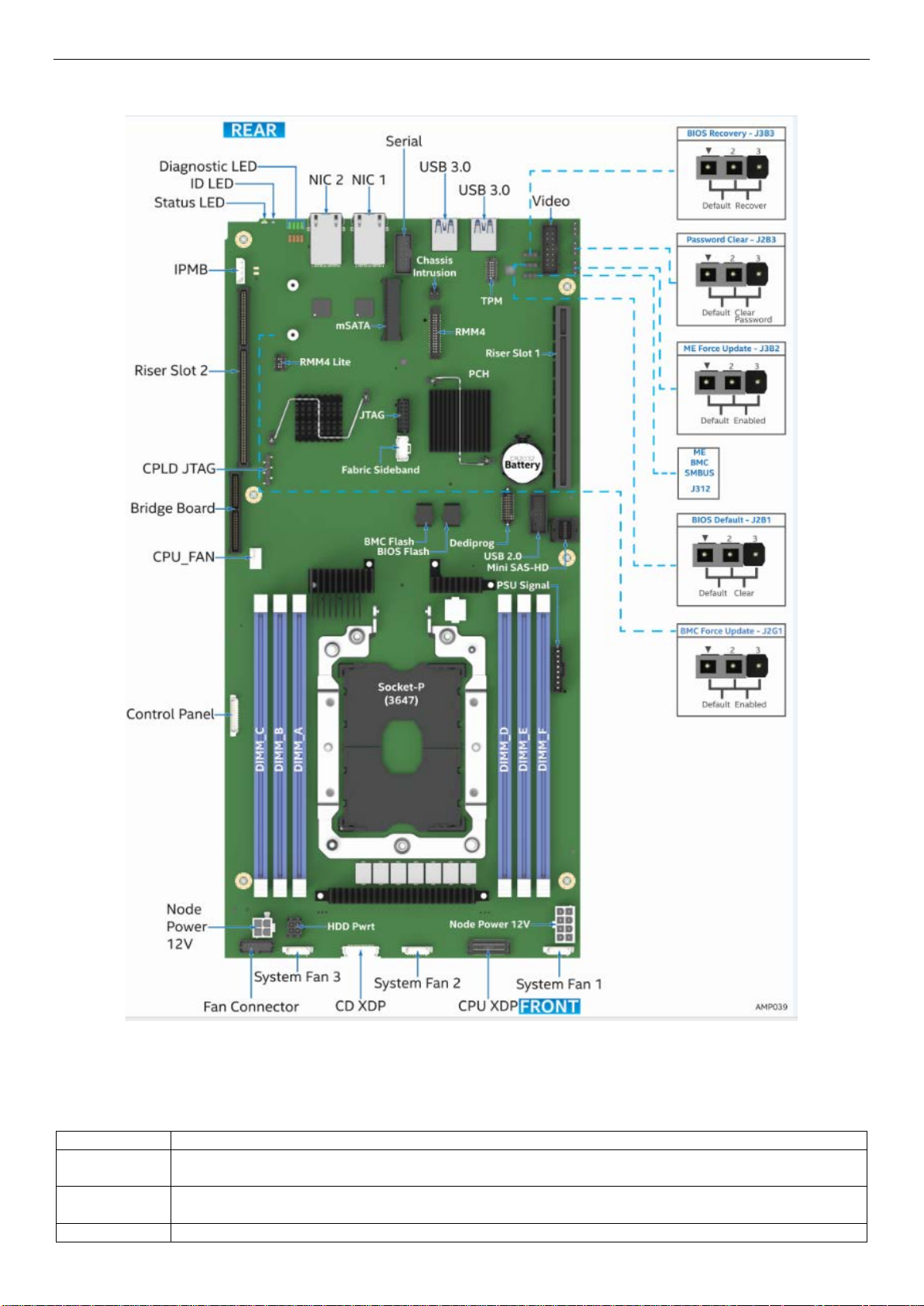

1.5 Server Board Features

This section helps you identify the components and connectors on the server board. Intel® Server Board

S7200AP features shown. All major features that are called out are common to both boards.

Figure 7. Intel® Server Board S7200AP Features

Figure 8. Intel® Server Board S7200APR

Page 26

1.6 Intel® Light-Guided Diagnostics

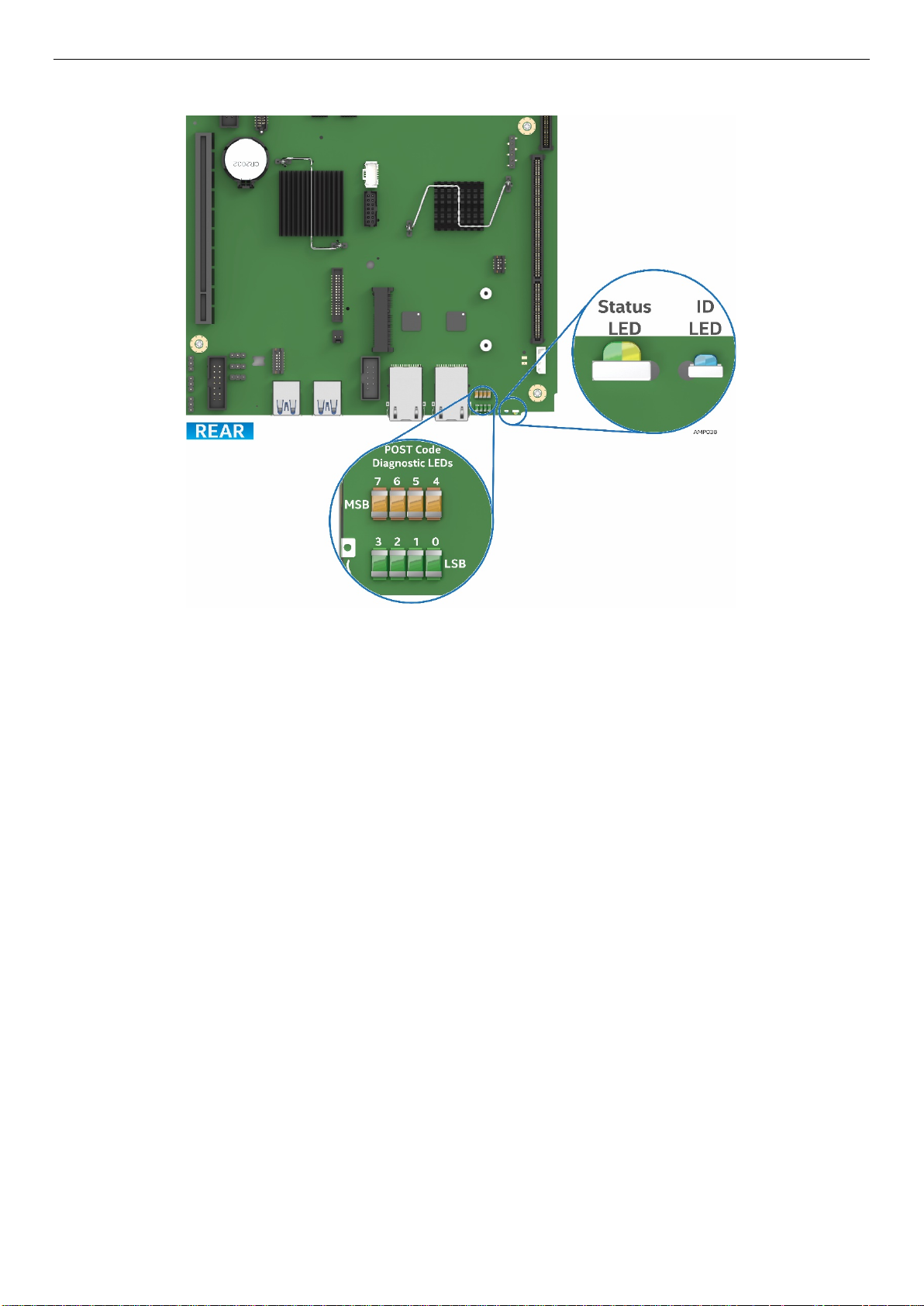

Figure 9. Intel® Light-Guided Diagnostic LEDs – Server Board

The POST Code Diagnostic LEDs on the server board change color or state (off, green, red, and amber)

according to the POST sequence.

The Status LED on the rear of the board shows the overall health of the system (green, blinking green,

blinking amber, amber, and off).

The Identification LED on the rear of the board helps identify the server from among several servers. The

ID LED is off by default, and blue when activated by button or software.

Page 27

Jumper Name

Description

BMC Force

Update (J2G1)

If pins 2-3 are selected, the Integrated BMC Force Update Mode is enabled. These pins should be selected

on 1-2 for normal system operation.

BIOS Default

(J2B1)

If pins 2-3 are selected, the BIOS settings are restored to the factory defaults on the next reset. These pins

should be selected on 1-2 for normal system operation.

BIOS Recovery

If the system BIOS is corrupted, an onboard backup copy of the BIOS can be loaded using the BIOS

1.7 Configuration and Recovery Jumpers

Figure 10. Configuration and Recovery Jumpers

Page 28

(J3B3)

Recovery Jumper. To load the backup BIOS image, move the jumper from pins 1-2 (default) to pins 2-3, and

for normal system operation.

Password

Clear(J2B3)

If pins 2-3 are selected, administrator and user passwords are cleared within five to ten seconds after the

system is powered on. These pins should be selected on 1-2 for normal system operation.

ME Force

Update (J3B2)

If pins 2-3 are selected, the ME Force Update Mode is enabled. These pins should be selected on 1-2 for

normal system operation.

power on the system. The system will boot to the backup BIOS image. These pins should be selected on 1-2

1.8 Advanced Management Options

1.8.1 Intel® Remote Management Module 4 Lite

The Intel® Remote Management Module 4 Lite plugs into a dedicated connector on the server board and

provides additional server management functionality to the compute module.

The Intel® Remote Management Module 4 Lite, together with the dedicated management port provides a

dedicated web server for viewing server information and remote control of the compute module. It also

provides Remote KVM Redirection and USB Media Redirection allowing USB devices attached to the remote

system to be used on the managed server.

For instructions on installing the Intel® Remote Management Module 4 Lite, see section 2.10.

Page 29

2 Hardware Installations and Upgrades

2.1 Before You Begin

Before working with your server product, closely review the Safety Information at the beginning of this

document.

NOTE: Prior to servicing the compute module or chassis, power down the server, unplug all peripheral

devices and the AC power cords.

2.1.1 Tools and Supplies Needed

• Phillips* (cross head) screwdriver (#1 bit and #2 bit)

• T30 Tor x bit screwdriver

• Flat head screwdriver

• Needle nosed pliers

• Anti-static wrist strap and conductive foam pad (recommended)

2.1.2 System Reference

All references to left, right, front, top, and bottom assume that the reader is facing the front of the chassis

as it would be positioned for normal operation.

2.2 Cable Routing

Each compute module is self-contained and can be hot swapped without any impact to other compute

modules. When you add or remove components from the compute module enclosure, ensure that cables

are routed correctly before plugging in the compute module back into the chassis. Use caution to ensure

that cables or wires are not pinched and that the airflow from the fans is not blocked. Use the figures

below to determine the correct cable routing. Section 2.2 applies to both server boards.

Figure 11. Cable Routing

NOTES:

• Orange line: Fan cable connection

• Blue line: Server board power cable connection

• Red line: Fan control signal cable connection

Page 30

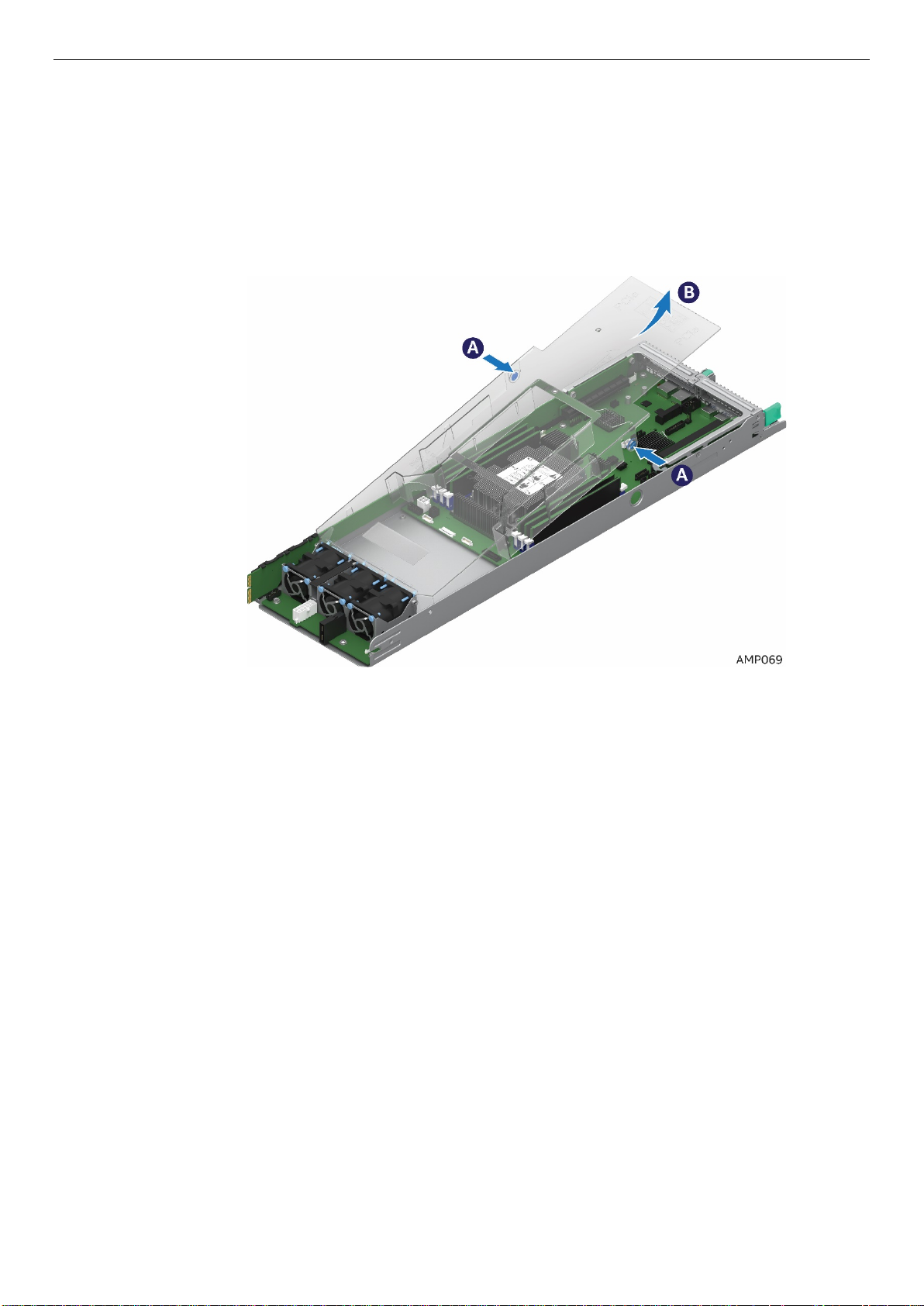

2.3 Removing and Installing the Air Duct

Always operate your compute module with the air duct in place. The air duct is required for proper airflow

within the compute module. Intel® Server Board S7200AP. Section 2.3 applies to both server compute

module.

2.3.1 Removing the Air Duct

1. Press and hold both the left and right side buttons of the air duct (See letter A).

2. Rotate the air duct more than 45 degrees and pull it out. (See letter B).

Figure 12. Removing the Air Duct

Page 31

2.3.2 Installing the Air Duct

NOTES: Ensure that all DIMM latches are closed before installing the air duct.

1. Align the front end of the air duct with the hinges on both sides of the fan bracket (See letter A).

2. Rotate the air duct (See letter B) and lower it down until the left and right side buttons snaps into place.

Figure 13. Installing the Air Duct

Page 32

2.4 Processor Assembly Installation and Removal

2.4.1 Assembling the Processor Heat Sink Module (PHM)

The processor heat sink module (PHM) refers to the sub-assembly where the heat sink and processor are

attached together prior to installation onto the server board.

Figure 14. Processor Heatsink Module (PHM) and Processor Socket Reference Diagram

Procedures described in the following sections must be followed in the order specified to properly

assemble the PHM, install it to, or remove it from the server board. These instructions assume that all the

PHM components are new and the thermal interface material (TIM) is already applied to the bottom of the

heat sink.

Required Tools:

• T-30 Torx screwdriver

• Flat head screwdriver

• Adequate ESD protective gear (wrist strap, ESD mat)

CAUTION: Refer to the “Warning” section at the beginning of this document for detailed ESD

precautions.

NOTE: Fabric supported processor models require the use of a Fabric Carrier assembly. Fabric Carrier

assemblies are sold separately and can be obtained by ordering the following Intel Accessory Kit - iPC

Page 33

Carrier Clip Model

iPN*

Carrier Clip Assembly

Standard Processor Carrier

AXX2PFABKIT. Refer to the Product Configuration Guide for this Intel Server product family for

additional ordering details.

WARNING: Attempting to use a standard processor carrier clip assembly with a fabric supported

processor may result in component damage and/or induce improper assembly of the PHM. See the

following table and figures for an overview of the different processor carrier and processors.

Table 5. Processor Carriers

(Default) Included with

Systems

H53249-00x

Fabric Processor Carrier

(Accessory)

H53248-00x

NOTE: * For reference only. Intel part numbers (iPN) are not used for ordering purposes.

Intel parts that are available as a Spare or Accessory are orderable via Intel Product Codes (iPC).

Figure 15. Processor Reference Diagram - Top and Bottom Views of Processor

Page 34

WARNING: Damage to the processor heat sink may occur when grasping the heat sink by the longer sides

and squeezing fins together. Processor heat sinks should only be grasped using the shorter edges of the

heat sink as shown in the following illustration.

Figure 16. Grasping the Heatsink Correctly

1. Remove the heat sink from its packaging. With the thermal interface material (TIM) facing up, place the

heat sink on to a flat surface as shown in the following illustration.

Figure 17. Placing the Processor Heat Sink on to a Flat Surface

CAUTION: Do not touch the sensitive contacts on the bottom side of the processor at any time

during PHM assembly or installation. In addition, the pins inside the processor socket are

extremely sensitive. A damaged processor socket may produce unpredictable system errors

2. If present, carefully remove the plastic protective cover from the bottom side of the processor.

NOTE: The PHM and processor socket include several alignment features as shown in the

following illustration to ensure proper assembly and installation. Care should be taken to ensure

components are accurately assembled and the PHM is oriented correctly to the processor socket

prior to installation.

Page 35

CAUTION: Handle the processor carefully. Do not touch the bottom-side contacts or components,

always grip the processor by its edges.

Figure 18. Alignment Features

Page 36

3. Orient the processor with the heat spreader side down so its alignment features match those of the

carrier clip as shown in the following figures.

Figure 19. Processor Carrier Assembly

4. Install the processor into the processor carrier clip until it snaps into place.

Figure 20. Processor Carrier Clip Sub-Assembly

CAUTION: A processor can dislodge from the processor carrier clip if the assembly is grasped by

the long narrow edges of the processor clip. The processor carrier assembly should only be

grasped using the shorter edges of the assembly.

5. If present, remove the protective film covering the TIM on the bottom side of the heat sink.

Page 37

6. Orient the processor carrier clip sub-assembly over the processor heat sink so that all corner features

are in alignment.

Figure 21. Orienting Processor Carrier Clip Sub-assembly to Heat Sink

7. Push the processor carrier clip sub-assembly down on to the processor heat sink until it snaps into

place, ensuring all four corners are secure.

Figure 22. Processor Heat Sink Module (PHM)

Page 38

2.4.2 Processor Installation

iPC - AXXAPHS

Table 6. Processor Heat Sinks

Intel Product Code (iPC) MM# Description

MM# - 942344

1U Standard Ex-Al 80mm x 107mm Heat

Sink

Figure 23. Processor Heat Sink Location

Page 39

1. Remove the plastic processor socket cover. Grasp the socket cover using the finger grips on each end

as shown in the following figure, (See letter A) then carefully pull up to remove (See letter B).

Figure 24. Plastic processor socket cover removal

NOTE: The processor socket cover should be saved for future use.

CAUTION: When re-installing the socket cover, make sure it properly snaps into place. Improper

installation will cause it to become loose and damage the processor socket.

2. Install PHM to Processor socket.

a. Align the mounting holes of the PHM (located on diagonal corners) to the bolster plate guide pins

of the processor socket as shown in the following figure.

Page 40

NOTE: Each of the two guide pins of the bolster plate has a different diameter. Each guide pin will have a

matching PHM mounting hole which allows for only one orientation when installed as shown in the

following figure. Look for the wide and narrow holes for proper and accurate alignment.

Figure 25. PHM Alignment to Bolster Plate

b. Lower the PHM onto the processor socket assembly.

CAUTION: Processor socket pins are delicate and bend easily. Use extreme care when placing the PHM

onto the processor socket.

Page 41

NOTE: See the illustration below and confirm proper PHM installation by visually checking whether or not

the PHM sits level with the processor socket assembly. The PHM is NOT installed properly if it does not sit

level with the processor socket assembly. Improperly installed PHMs cannot be fastened down. PHMs

can only be fastened down if correctly installed.

Figure 26. Correct Placement

3. Secure PHM to the processor socket assembly.

a) Using a T30 Torx bit screwdriver, securely tighten (12 in-lb.) each nut in the sequence shown on

the label located on the top of the heat sink. Follow the (#1→ #2 → #3→ #4) sequence when

tightening. Tighten each screw prior to moving to the next.

Figure 27. Installing the PHM

CAUTION: Failure to tighten the heat sink screws in the specified order may cause damage to the

processor socket assembly. Each heat sink screw should be fully tightened to 12 in-lb torque before

securing the next screw in the sequence.

Page 42

2.5 Processor Removal

WARNING: Processor heat sinks can become extremely hot during normal system operation. Before

attempting to remove the processor from the server board, ensure system power has been fully

disconnected and allow the processor heat sinks to fully cool before attempting to remove the PHM from

the server board.

1. Using a T30 Torx bit screwdriver, loosen each heat sink nut in the sequence shown on the label

affixed to the top side of the heat sink (#4→ #3 → #2→ #1) (See letter A). Loosen each screw all the

way prior to moving to the next.

2. Lift the PHM straight up from the server board until free from the bolster plate guide pins (See letter

B).

3.

Figure 28. Uninstalling the PHM

4. If a processor is not being installed, re-install the plastic processor socket cover.

Figure 29. Plastic processor socket cover Installation

Page 43

2.5.1 PHM Disassembly

1. Place the PHM (heat sink down) onto a flat surface.

2. To remove the processor and clip sub-assembly from the heat sink, using a flat head screw driver,

carefully release the bond between processor and heat sink as shown in the following illustration.

Figure 30. PHM Disassembly

3. Unlatch the hooks on each corner of the processor carrier clip to free the processor carrier from the

heat sink.

4. Carefully lift the processor sub-assembly away from the heat sink.

Figure 31. Releasing the Processor Carrier Clip from the Heat Sink

Page 44

5. Remove the processor from the processor carrier by carefully pushing back one of the latches located

on the ends of the processor and rotating the processor up and out of the processor carrier.

Figure 32. Releasing Processor from Carrier

Page 45

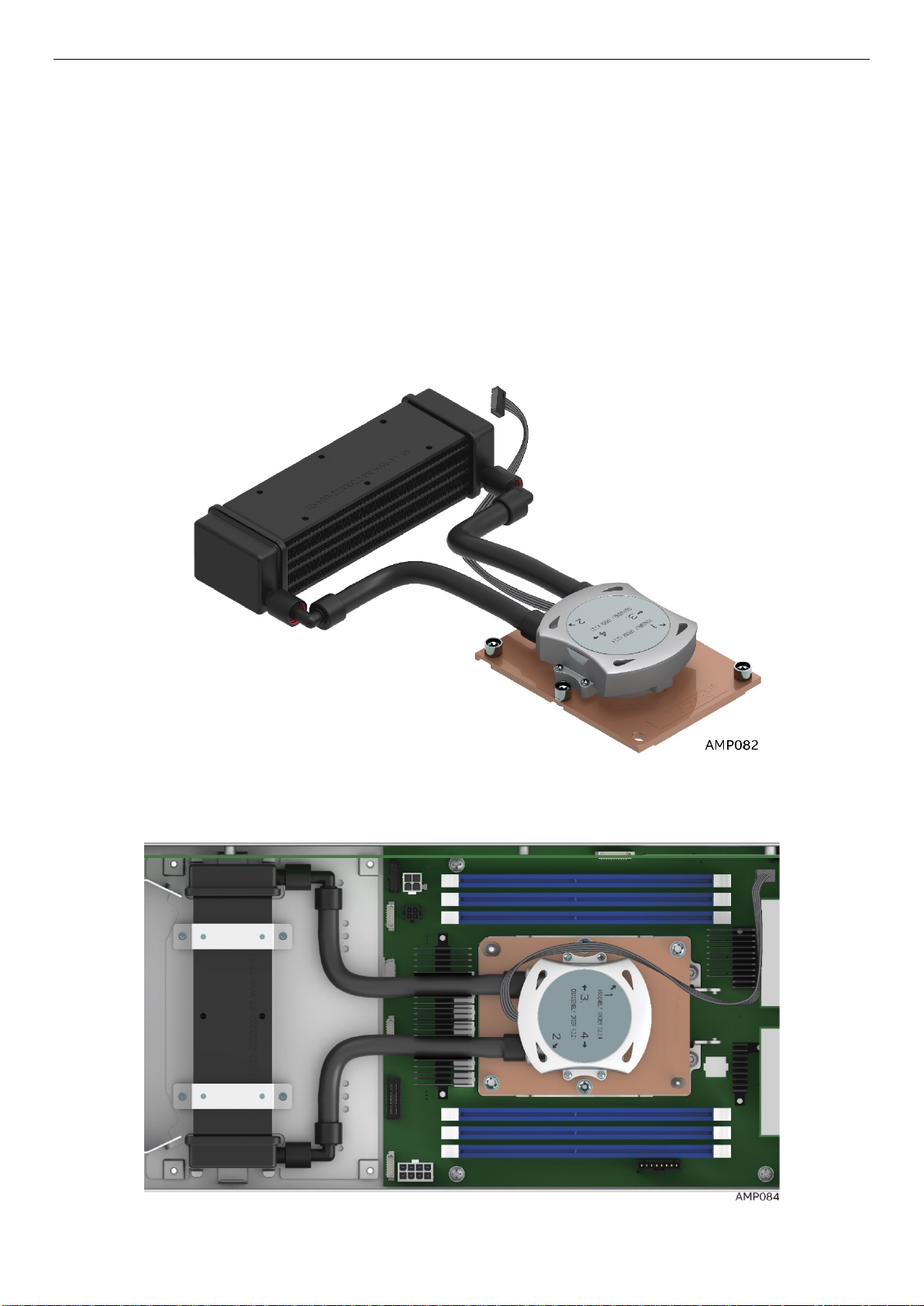

2.6 Installation and Removal of the 1U LACC

Intel® Server Board S7200APR and Intel® Server Compute Module HNS7200APRL product family support

the Intel® Xeon™ Phi™ processors Bootable CPUs (up to 320W TDP) in Intel® Server Chassis H2204XXLRE.

All Intel® Xeon™ Phi™ Processors x200 or 72x5 CPU SKUs at 245W or greater TDP require use of the Intel®

1U Liquid Assisted Air Cooling (LACC) solution for optimal thermal support. The Intel® Server Board

S7200APR product family Technical Product Specfication (TPS) decribes the 1U LAAC in detail. This

section of the Service Guide describes the installation and removal of the 1U LACC coolling solution.

Note: Passive Air Cooled Heatsinks are not supported on CPUs with TDPs equal to or higher than 245w

regardless of the supported CPU generation.

2.6.1 Removal of the 1U LACC Assembly

Figure 33. 1U LACC Assembly

Figure 34. 1U LACC Assembly installed in the system

Page 46

1. Power off the compute module and disconnect the power cable(s).

2. Remove the air duct. See section 2.3.1

3. Disconnect the pump cable that is connected to the 4-pin CPU Fan Header (J6J2)

.

Figure 35. Disconnect the Pump Cable (Fan Header J6J2)

4. Next, remove the LACC Heat Exchanger retaining brackets by removing the 4 screws.

Figure 36. Remove LACC brackets #1

Page 47

Figure 37. Remove LACC brackets #2

Figure 38. Remove LACC brackets #3

5. Finally, remove the LACC Cold Plate assembly. The LACC cold plate assembly is modeled after the

passive air heatsink assembly. The sequence and method of removing the cold plate is exactly the

same as the passive air heatsink. Follow carefully the screw loosening sequence. Refer to the passive

air heatsink removal instructions in Section 2.5

for detail.

Page 48

Figure 39. Remove Cold Plate Assembly

6. Carefully lift the LACC Assembly away from the node. Use two hands to grasp the heat exchanger and

cold plate to safely remove the LACC assembly.

Figure 40. Lift out LACC Assembly

Page 49

2.6.2 Remove the CPU and Carrier Assembly

1. Power off the compute module and disconnect the power cable(s).

2. Remove the air duct. See section 2.3.1

3. Follow the procedures in Section 2.6.1 for LACC assembly removal

4. Turn the LACC and cold plate assembly over as shown in Figure 41

5. The LACC cold plate assembly is modeled after the passive air heatsink assembly. The sequence and

method of removing the CPU and Carrier is exactly the same as the passive air heatsink. This step is

only required if the CPU requires replacement. For simplification, refer to the CPU and Carrier

removal instructions in Section 2.5

.

for detail.

Figure 41. Releasing CPU and Carrier from Cold Plate

2.6.3 Install the 1U LACC Assembly

Figure 42. 1U LACC Assembly

Page 50

1. Power off the compute module and disconnect the power cable(s).

2. Remove the air duct. See section 2.3.1

3. The LACC cold plate assembly is modeled after the passive air heatsink assembly. The sequence and

method of installing the CPU and Carrier is exactly the same as the passive air heatsink. This step is

only required if the CPU requires replacement or installation. For simplification, refer to the CPU and

Carrier installation instructions in Section 2.4

.

for detail.

Figure 43. Install CPU and Carrier to Cold LACC Cold Plate

4. Carefully place and position the LACC assembly back into the system by using two hands. Ensure that

it is properly aligned and that the cold plate aligns correctly with the CPU socket assembly and guide

pins.

Page 51

Figure 44. Install the LACC assembly into the system

5. Next, align and install the LACC cold plate assembly. Tighten the LACC Cold Plate assembly nuts. The

LACC cold plate assembly is modeled after the passive air heatsink assembly. The sequence and

method of tightening the cold plate screws is exactly the same as the passive air heatsink. Follow the

tightening sequence carefully. Refer to the passive air cooled heatsink installation instructions in

Section 2.4

for detail.

Figure 45. Install the LACC assembly into the system

6. Install the LACC Heat Exchanger retaining brackets by installing the 4 screws.

Figure 46. Install brackets #1

Page 52

Figure 47. Install LACC brackets #2

Figure 48. Install LACC brackets #3

Page 53

7. Connect the pump cable to the 4-pin CPU Fan Header (J6J2)

Figure 49. Connect the Pump Cable (fan header J6J2)

Page 54

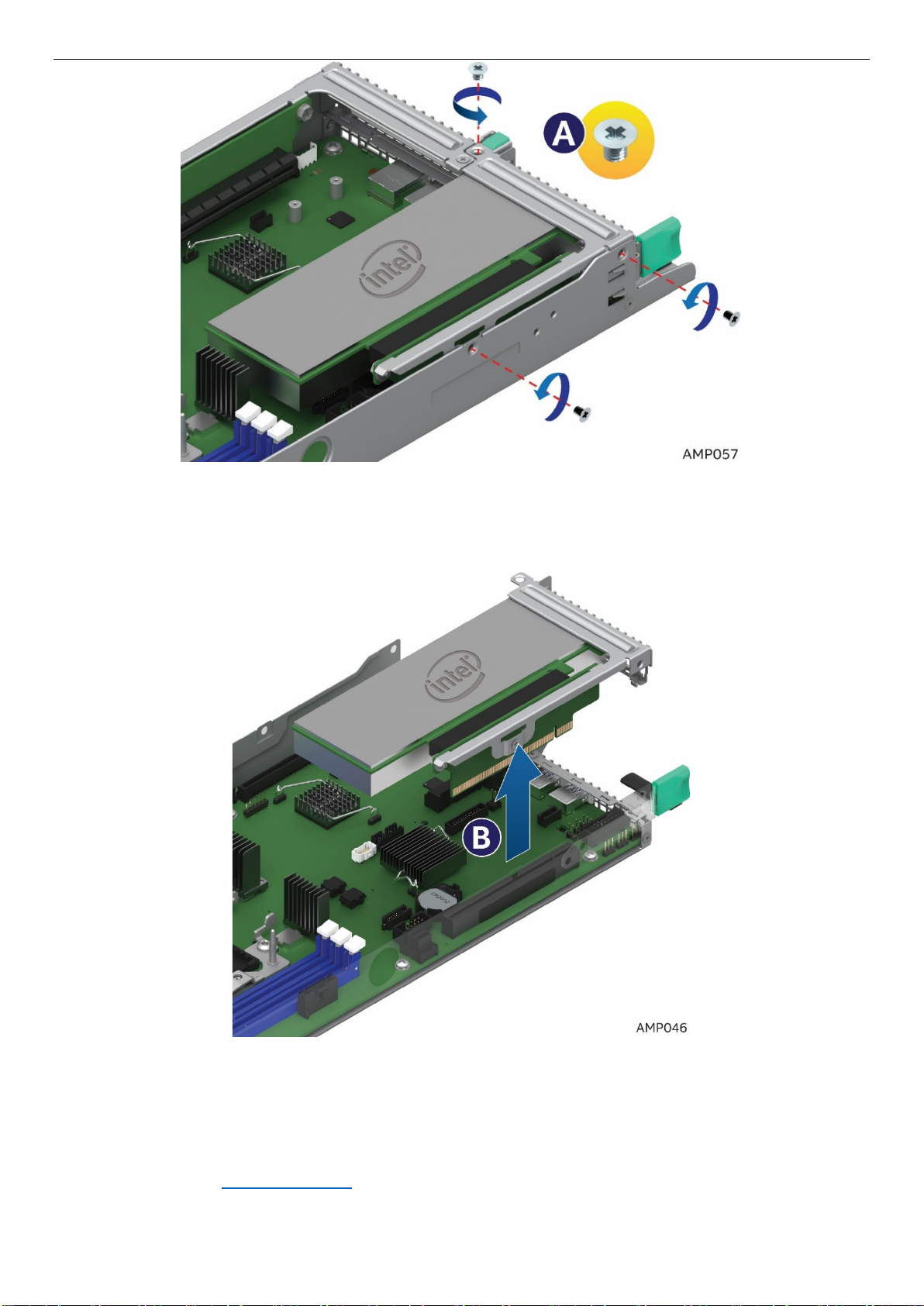

2.7 Removing and Installing Riser 1 and Riser 2

2.7.1 Remove Riser 1

1. Power off the compute module and disconnect the power cable(s).

2. Remove the air duct. See section 2.3.1

3. Loosen the 3 screws (See A )

4. Pull the riser straight up and out of the system (See B and C)

.

Figure 50. Removing Riser 1

2.7.2 Install Riser 1

1. Power off the compute module and disconnect the power cable(s).

2. Remove the air duct. See section 2.3.1

3. Align and insert Riser 1 into Riser Slot 1 (See A)