Page 1

REVISION 2.21

OCTOBER 2016

Intel® Server Chassis H2000G

Product Family

Technical Product Specification

A document providing an overview of product features, functions,

architecture, and support specifications

INTEL® SERVER PRODUCTS AND SOLUTIONS

Page 2

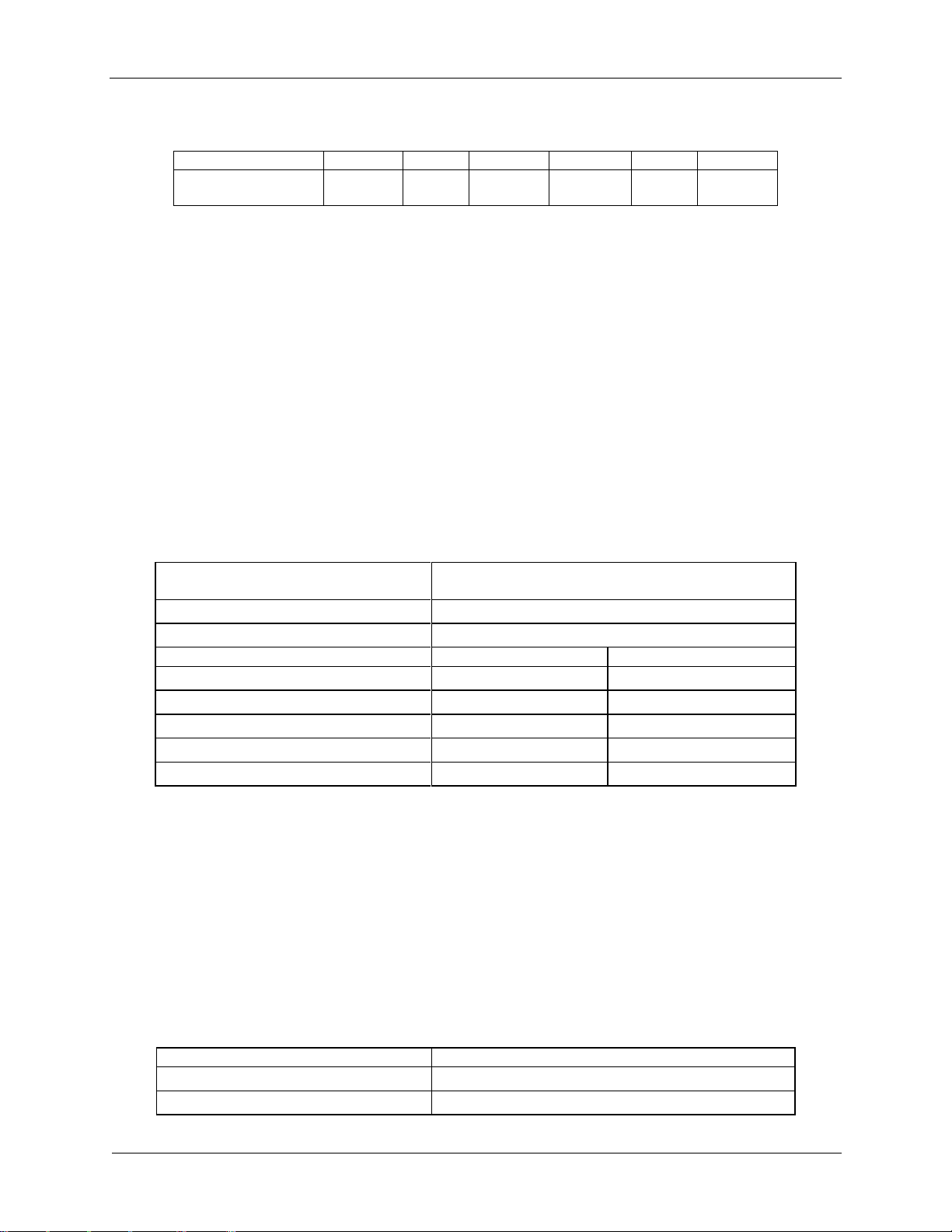

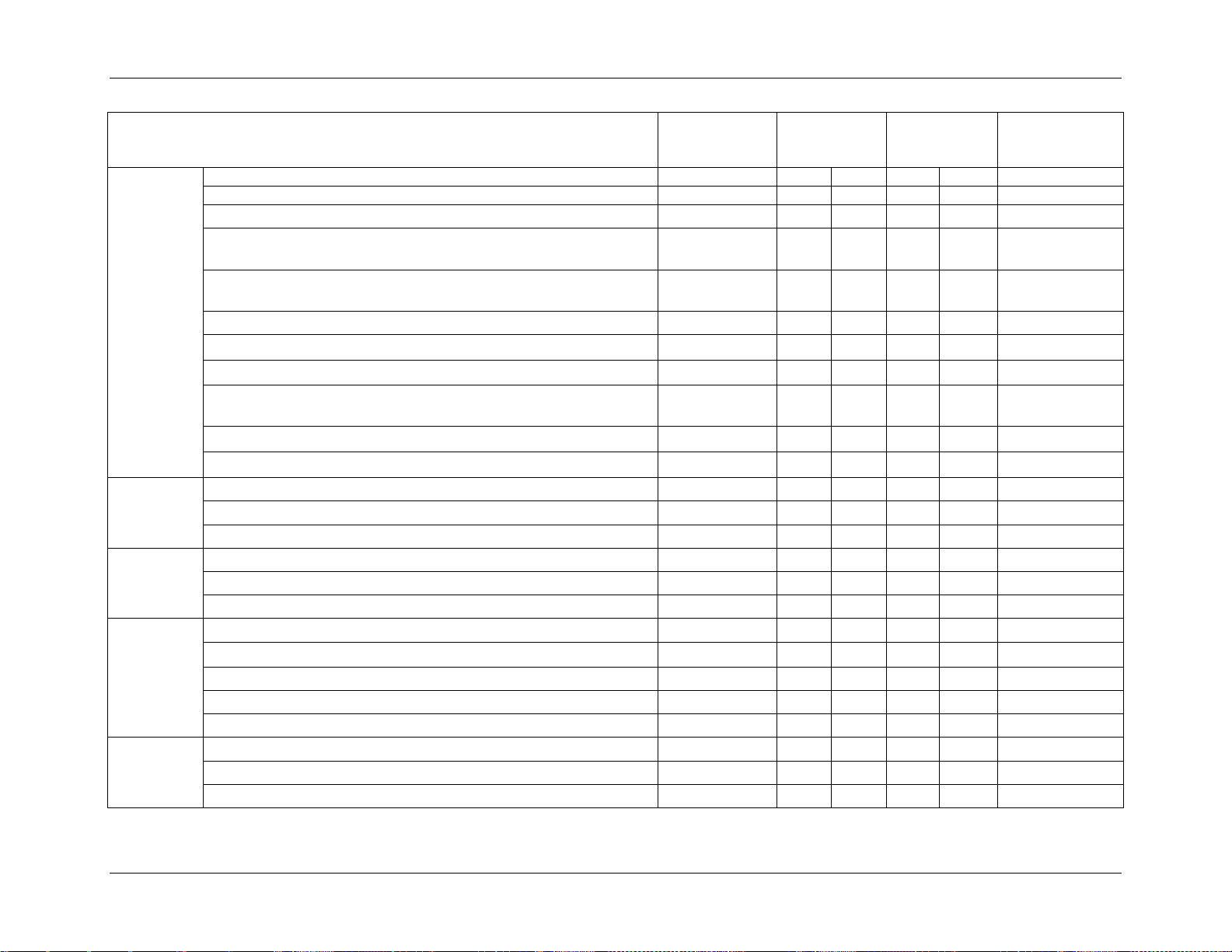

Revision History Intel® Server Chassis H2000G Product Family TPS

ii

Date

Revision

Number

Modifications

August, 2014

1.20

1st External Public Release

November, 2014

1.30

Added S2600TP and HNS2600TP

Updated the package dimensions in the Chassis Feature Set table

December, 2014

1.40

Added Appendix C System Configuration Table for Thermal Compatibility

February, 2015

1.41

Updated the System Environmental Limits Summary table and the

specification data for the AC Power Supply Unit table

August, 2015

1.50

Added Intel® Server Chassis H2224XXKR2

November, 2015

1.51

Corrected some information

April, 2016

1.60

Added Intel® Server Chassis H2224XXLR2

Added FXX2130PCRPS

May, 2016

2.0

Applied new format version definition

May, 2016

2.10

Added CFM specification for H2224XXKR2 and H2224XXLR2

June, 2016

2.20

Added Intel® Server Chassis H2312XXLR2 and H2216XXLR2

Added S7200AP references

October, 2016

2.21

Added Intel® SATA SSD support for H2224XXKR2 and H2224XXLR2

Typographical corrections

Revision History

Revision 2.21

Page 3

Intel® Server Chassis H2000G Product Family TPS Disclaimers

iii

Disclaimers

Information in this document is provided in connection with Intel® products. No license, express or implied, by

estoppel or otherwise, to any intellectual property rights is granted by this document. Except as provided in Intel's

Terms and Conditions of Sale for such products, Intel assumes no liability whatsoever, and Intel disclaims any

express or implied warranty, relating to sale and/or use of Intel products including liability or warranties relating to

fitness for a particular purpose, merchantability, or infringement of any patent, copyright or other intellectual

property right. Intel products are not intended for use in medical, lifesaving, or life sustaining applications. Intel

may make changes to specifications and product descriptions at any time, without notice.

A "Mission Critical Application" is any application in which failure of the Intel Product could result, directly or

indirectly, in personal injury or death. SHOULD YOU PURCHASE OR USE INTEL'S PRODUCTS FOR ANY SUCH

MISSION CRITICAL APPLICATION, YOU SHALL INDEMNIFY AND HOLD INTEL AND ITS SUBSIDIARIES,

SUBCONTRACTORS AND AFFILIATES, AND THE DIRECTORS, OFFICERS, AND EMPLOYEES OF EACH, HARMLESS

AGAINST ALL CLAIMS COSTS, DAMAGES, AND EXPENSES AND REASONABLE ATTORNEYS' FEES ARISING OUT OF,

DIRECTLY OR INDIRECTLY, ANY CLAIM OF PRODUCT LIABILITY, PERSONAL INJURY, OR DEATH ARISING IN ANY

WAY OUT OF SUCH MISSION CRITICAL APPLICATION, WHETHER OR NOT INTEL OR ITS SUBCONTRACTOR WAS

NEGLIGENT IN THE DESIGN, MANUFACTURE, OR WARNING OF THE INTEL PRODUCT OR ANY OF ITS PARTS.

Designers must not rely on the absence or characteristics of any features or instructions marked "reserved" or

"undefined." Intel reserves these for future definition and shall have no responsibility whatsoever for conflicts or

incompatibilities arising from future changes to them.

The Intel® Server Chassis H2000G Product Family may contain design defects or errors known as errata which may

cause the product to deviate from published specifications. Current characterized errata are available on request.

This document and the software described in it are furnished under license and may only be used or copied in

accordance with the terms of the license. The information in this manual is furnished for informational use only, is

subject to change without notice, and should not be construed as a commitment by Intel Corporation. Intel

Corporation assumes no responsibility or liability for any errors or inaccuracies that may appear in this document

or any software that may be provided in association with this document.

Except as permitted by such license, no part of this document may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means without the express written consent of Intel Corporation.

Copies of documents which have an order number and are referenced in this document, or other Intel literature,

may be obtained by calling 1-800-548-4725, or go to: http://www.intel.com/design/literature.htm.

Intel and Xeon are trademarks or registered trademarks of Intel Corporation.

*Other brands and names may be claimed as the property of others.

Copyright © 2015 Intel Corporation. All rights reserved.

Revision 2.21

Page 4

Table of Contents Intel® Server Chassis H2000G Product Family TPS

iv

Table of Contents

1. Introduction ........................................................................................................................................ 1

1.1 Chapter Outline .................................................................................................................................... 1

1.2 Server Board Use Disclaimer .......................................................................................................... 2

2. Product Overview .............................................................................................................................. 3

2.1 Chassis Views ........................................................................................................................................ 5

2.2 Environmental Limits ......................................................................................................................... 7

2.3 Chassis Parts ......................................................................................................................................... 8

2.4 Drive and Peripheral Bays ............................................................................................................ 11

2.5 Front Bezel Support ........................................................................................................................ 12

2.6 Rack and Cabinet Mounting Options ....................................................................................... 12

3. Power Subsystem ........................................................................................................................... 13

3.1 Power Supply Overview ................................................................................................................ 13

3.1.1 Power Supply Dimension.............................................................................................................. 13

3.1.2 AC Power Supply Unit General Data ........................................................................................ 14

3.1.3 AC Input Connector ......................................................................................................................... 14

3.1.4 AC Power Cord Specification Requirements ........................................................................ 14

3.1.5 Power Supply Unit DC Output Connector ............................................................................. 15

3.1.6 Handle Retention ............................................................................................................................. 15

3.1.7 LED Marking and Identification .................................................................................................. 16

3.1.8 Power Distribution Module .......................................................................................................... 16

3.1.9 Power Interposer Board ................................................................................................................ 17

3.1.10 Power Cage Output Pin Assignment ........................................................................................ 18

3.2 AC Input Specification .................................................................................................................... 19

3.2.1 Input Voltage and Frequency ...................................................................................................... 19

3.2.2 AC input Power Factor ................................................................................................................... 19

3.2.3 Efficiency .............................................................................................................................................. 19

3.2.4 AC Line Fuse ....................................................................................................................................... 19

3.2.5 AC Line Inrush .................................................................................................................................... 20

3.2.6 AC Line Dropout/Holdup .............................................................................................................. 20

3.2.7 AC Line Fast Transient (EFT) Specification ............................................................................ 20

3.2.8 Hot Plug ................................................................................................................................................ 20

3.2.9 Susceptibility Requirements ........................................................................................................ 21

3.2.10 Electrostatic Discharge Susceptibility ..................................................................................... 21

3.2.11 Fast Transient/Burst........................................................................................................................ 21

3.2.12 Radiated Immunity .......................................................................................................................... 21

Revision 2.21

Page 5

Intel® Server Chassis H2000G Product Family TPS Table of Contents

v

3.2.13 Surge Immunity ................................................................................................................................. 21

3.2.14 AC Line Transient Specification ................................................................................................. 22

3.2.15 Power Recovery ................................................................................................................................ 22

3.2.16 Voltage Interruptions ..................................................................................................................... 22

3.2.17 AC Line Isolation ............................................................................................................................... 22

3.2.18 AC Power Inlet ................................................................................................................................... 23

3.3 DC Output Specification ................................................................................................................ 24

3.3.1 Output Power/Currents ................................................................................................................. 24

3.3.2 Standby Output ................................................................................................................................ 24

3.3.3 Voltage Regulation .......................................................................................................................... 24

3.3.4 Dynamic Loading .............................................................................................................................. 25

3.3.5 Capacitive Loading .......................................................................................................................... 25

3.3.6 Ripple/Noise ....................................................................................................................................... 25

3.3.7 Grounding............................................................................................................................................ 25

3.3.8 Closed Loop Stability...................................................................................................................... 26

3.3.9 Residual Voltage Immunity in Standby Mode ...................................................................... 26

3.3.10 Common Mode Noise ..................................................................................................................... 26

3.3.11 Soft Starting ....................................................................................................................................... 26

3.3.12 Zero Load Stability Requirement ............................................................................................... 26

3.3.13 Hot Swap Requirement .................................................................................................................. 27

3.3.14 Forced Load Sharing ....................................................................................................................... 27

3.3.15 Timing Requirement ....................................................................................................................... 27

3.4 Power Supply Cold Redundancy Support ............................................................................. 29

3.4.1 1600W CRPS Cold Redundancy ................................................................................................ 29

3.4.2 2130W CRPS Cold Redundancy ................................................................................................ 29

3.5 Control and Indicator Functions ................................................................................................ 30

3.5.1 PSON# Input Signal ......................................................................................................................... 30

3.5.2 PWOK (power good) Output Signal .......................................................................................... 30

3.5.3 SMBAlert# Signal.............................................................................................................................. 31

3.6 Protection Circuits ........................................................................................................................... 32

3.6.1 Current Limit (OCP) ......................................................................................................................... 32

3.6.2 Over Voltage Protection (OVP) ................................................................................................... 32

3.6.3 Over Thermal Protection .............................................................................................................. 32

3.7 PMBus* ................................................................................................................................................. 33

3.7.1 PSU Address Lines A0 .................................................................................................................... 33

3.7.2 Accuracy ............................................................................................................................................... 34

3.8 Power Management Policy ........................................................................................................... 35

Revision 2.21

Page 6

Table of Contents Intel® Server Chassis H2000G Product Family TPS

vi

4. Cooling Subsystem ........................................................................................................................ 36

4.1 Power Supply Fans .......................................................................................................................... 36

4.2 Drive Bay Population Requirement .......................................................................................... 37

5. Drive Support .................................................................................................................................. 38

5.1 Drive Bays Scheme .......................................................................................................................... 38

5.2 Drive Carrier ........................................................................................................................................ 40

5.3 Hot-Swap Drive Support ............................................................................................................... 42

5.3.1 Backplane Feature Set ................................................................................................................... 42

5.3.2 3.5" Hot Swap Backplane Connector Scheme ..................................................................... 43

5.3.3 2.5" Hot Swap Backplane Connector Scheme ..................................................................... 45

5.3.4 SAS/PCIe* SFF Combo 24 x 2.5" Hot Swap Backplane .................................................... 47

5.3.5 Backplane Interposer Board ........................................................................................................ 48

5.3.6 Backplane LED Support ................................................................................................................. 49

5.3.7 Backplane Connector Definition ................................................................................................ 50

5.3.8 Backplane Interposer Board Connectors ............................................................................... 54

6. Front Panel Control and Indicators ............................................................................................ 57

6.1 Control Panel Button ...................................................................................................................... 57

6.2 Control Panel LED Indicators ...................................................................................................... 58

6.2.1 Power LED ........................................................................................................................................... 58

6.2.2 Status LED ........................................................................................................................................... 59

6.2.3 ID LED .................................................................................................................................................... 61

Appendix A: Integration and Usage Tips .......................................................................................... 63

Appendix B: Statement of Volatility .................................................................................................. 64

Appendix C: System Configuration Table for Thermal Compatibility ....................................... 65

Glossary ................................................................................................................................................... 73

Reference Documents ........................................................................................................................... 75

Revision 2.21

Page 7

Intel® Server Chassis H2000G Product Family TPS List of Figures

vii

List of Figures

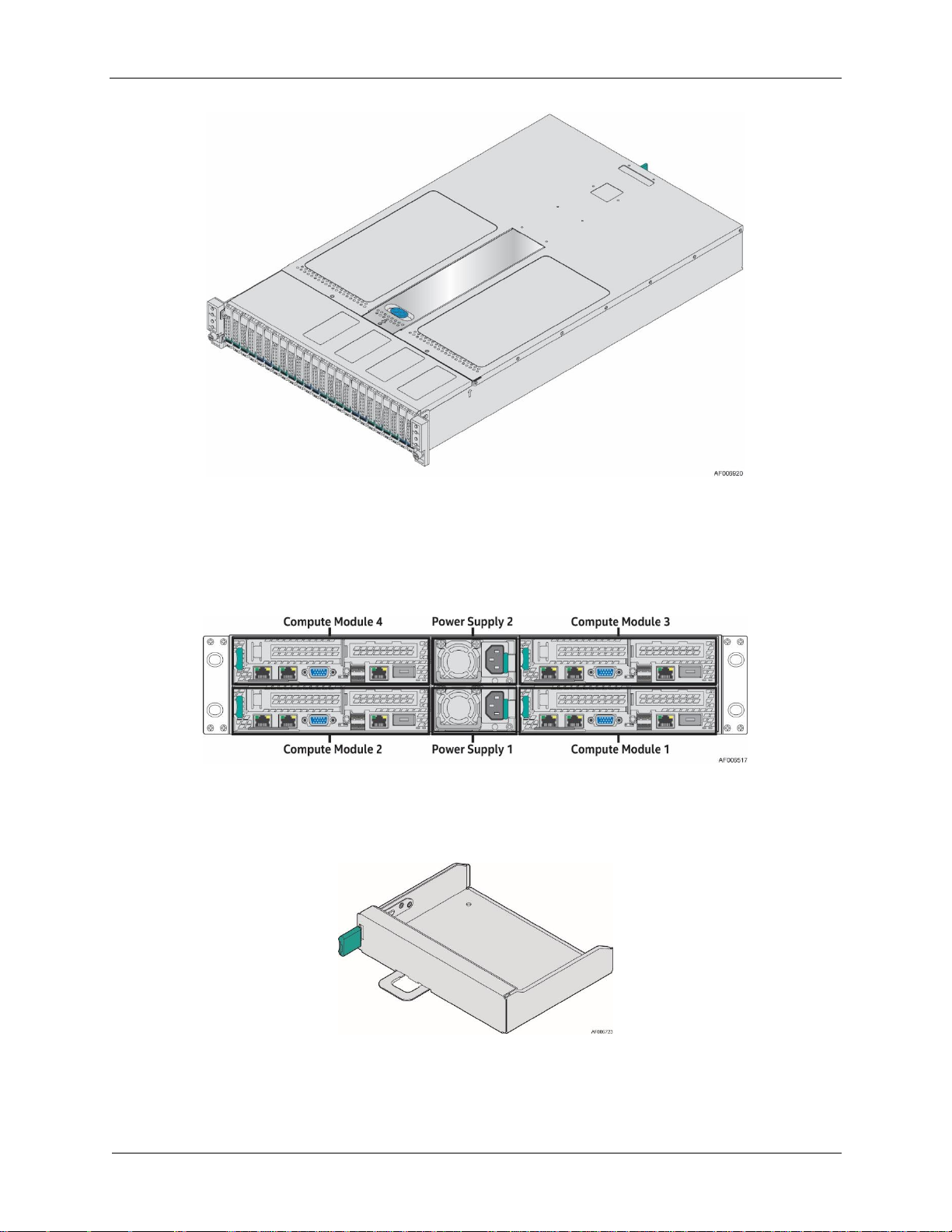

Figure 1. Server Chassis Overview (12 x 3.5” drive bay) ................................................................................ 5

Figure 2. Server Chassis Overview (16 x 2.5” drive bay) ................................................................................ 5

Figure 3. Server Chassis Overview (24 x 2.5” drive bay) ................................................................................ 6

Figure 4. Server Chassis Rear View ......................................................................................................................... 6

Figure 5. Dummy Tray Cover ..................................................................................................................................... 6

Figure 6. Major Server Chassis Parts (12 x 3.5” drive bay) ............................................................................ 8

Figure 7. Major Server Chassis Parts (16 x 2.5” drive bay) ............................................................................ 9

Figure 8. Major Server Chassis Parts (24 x 2.5” drive bay) ......................................................................... 10

Figure 9. 12 x 3.5” Drive Chassis Front View .................................................................................................... 11

Figure 10. 16 x 2.5” Drive Chassis Front View ................................................................................................. 11

Figure 11. 24 x 2.5” Drive Chassis Front View ................................................................................................. 11

Figure 12. Front Bezel ............................................................................................................................................... 12

Figure 13. 1600W and 2130W AC Power Supply Module Overview .................................................... 13

Figure 14. AC Power Supply Unit Dimension Overview .............................................................................. 14

Figure 15. Power Cage Overview .......................................................................................................................... 16

Figure 16. Power Interposer Board Top View ................................................................................................. 17

Figure 17. Power Distribution Board ................................................................................................................... 18

Figure 18. AC Power Cord Specification ............................................................................................................ 23

Figure 19. Turn On/Off Timing (Power Supply Signals) .............................................................................. 28

Figure 20. Power Supply Device Address ......................................................................................................... 33

Figure 21. PMBus Monitoring Accuracy ............................................................................................................. 34

Figure 22. 12 x 3.5” Drive Configuration ........................................................................................................... 38

Figure 23. 16 x 2.5” Drive Configuration ........................................................................................................... 38

Figure 24. 24 x 2.5” Drive Configuration ........................................................................................................... 39

Figure 25. 3.5" Drive Carrier Overview ............................................................................................................... 40

Figure 26. 2.5" Drive Carrier Overview ............................................................................................................... 40

Figure 27. 2.5" Drive/PCIe* SFF Device Carrier Overview ........................................................................... 41

Figure 28. Combo Backplane Kit Device Carrier Identification ................................................................ 41

Figure 29. 3.5" Drive Carrier Support 2.5” SSD ............................................................................................... 41

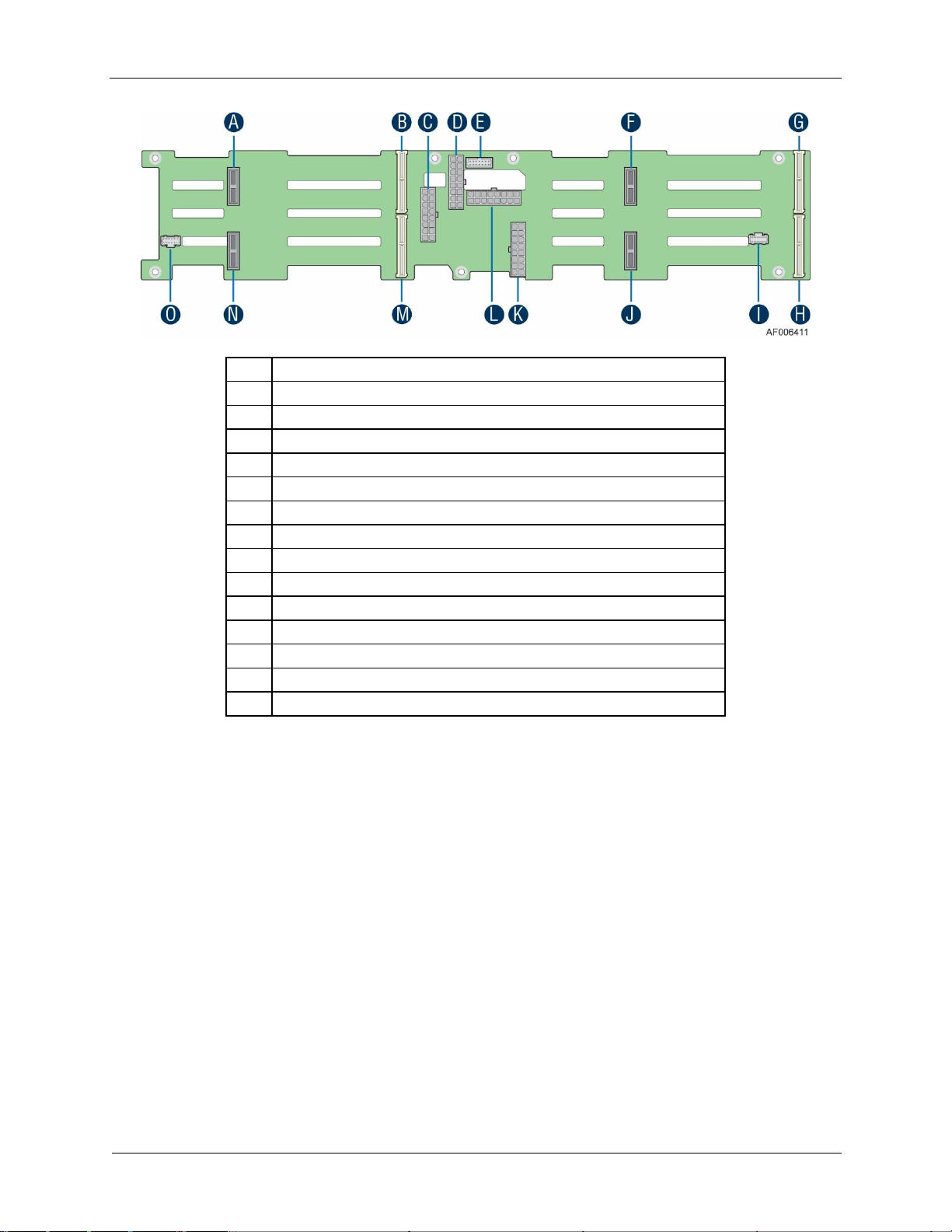

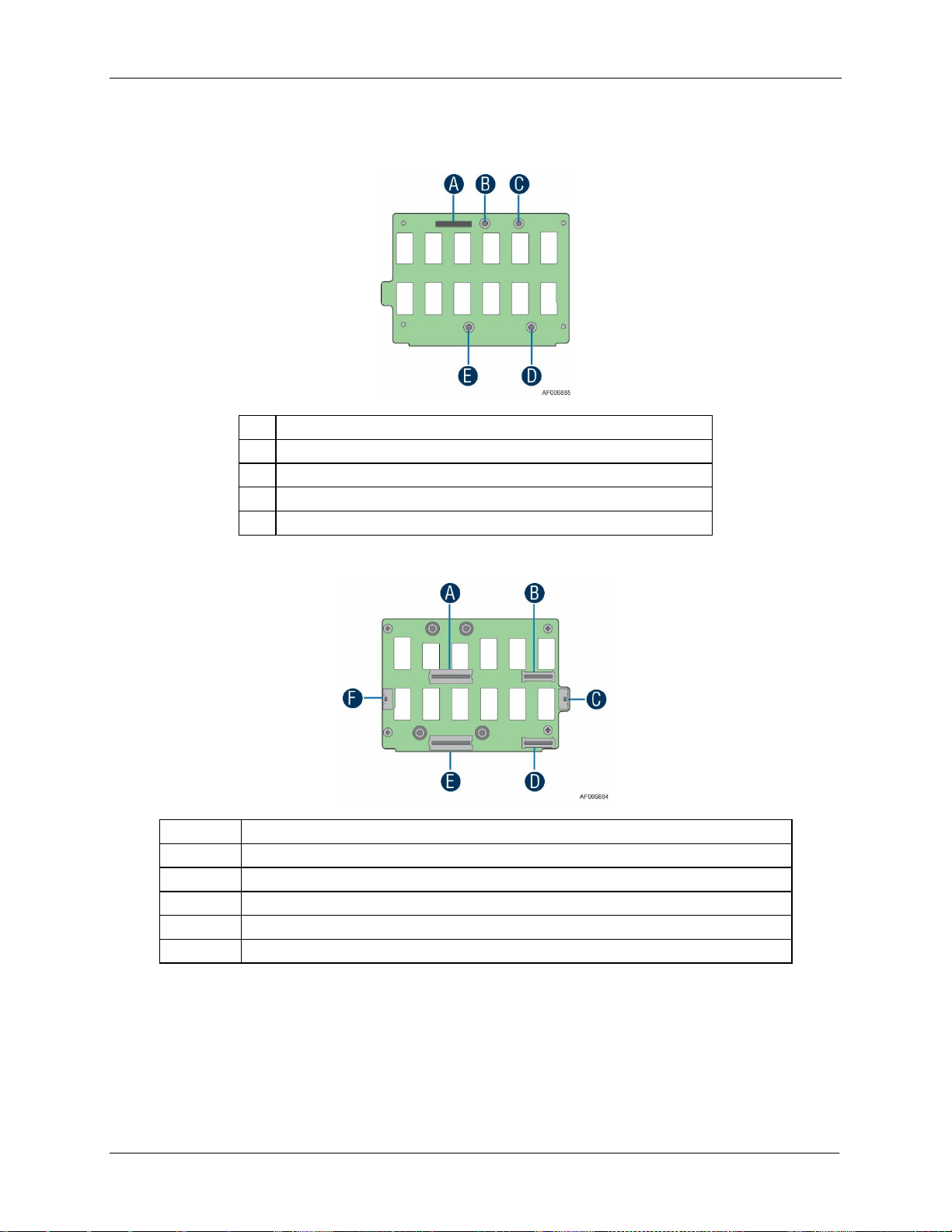

Figure 30. 3.5" Backplane Component and Connectors (Front View) ................................................... 43

Figure 31. 3.5" Backplane Component and Connectors (Back View) .................................................... 44

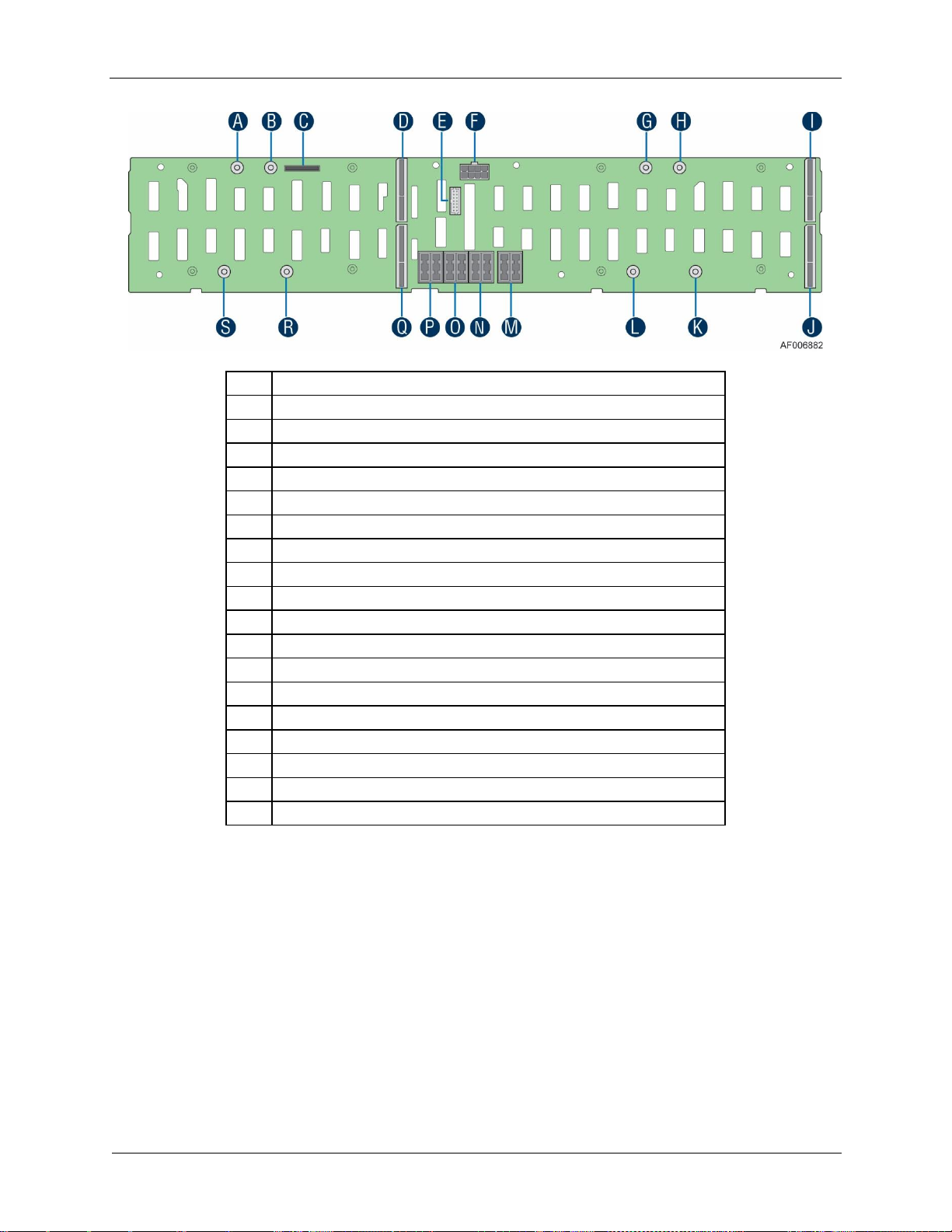

Figure 32. 2.5" Backplane Component and Connectors (Front View) ................................................... 45

Figure 33. 2.5" Backplane Component and Connectors (Back View) .................................................... 46

Figure 34. 24 x 2.5" Backplane Component and Connectors (Front View) ......................................... 47

Figure 35. 24 x 2.5" Backplane Component and Connectors (Back View) .......................................... 48

Revision 2.21

Page 8

List of Figures Intel® Server Chassis H2000G Product Family TPS

viii

Figure 36. Backplane Interposer Board Front View ...................................................................................... 49

Figure 37. Backplane Interposer Board Back View ....................................................................................... 49

Figure 38. Drive Tray LED Identification ............................................................................................................ 50

Figure 39. Front Control Panel .............................................................................................................................. 57

Revision 2.21

Page 9

Intel® Server Chassis H2000G Product Family TPS List of Tables

ix

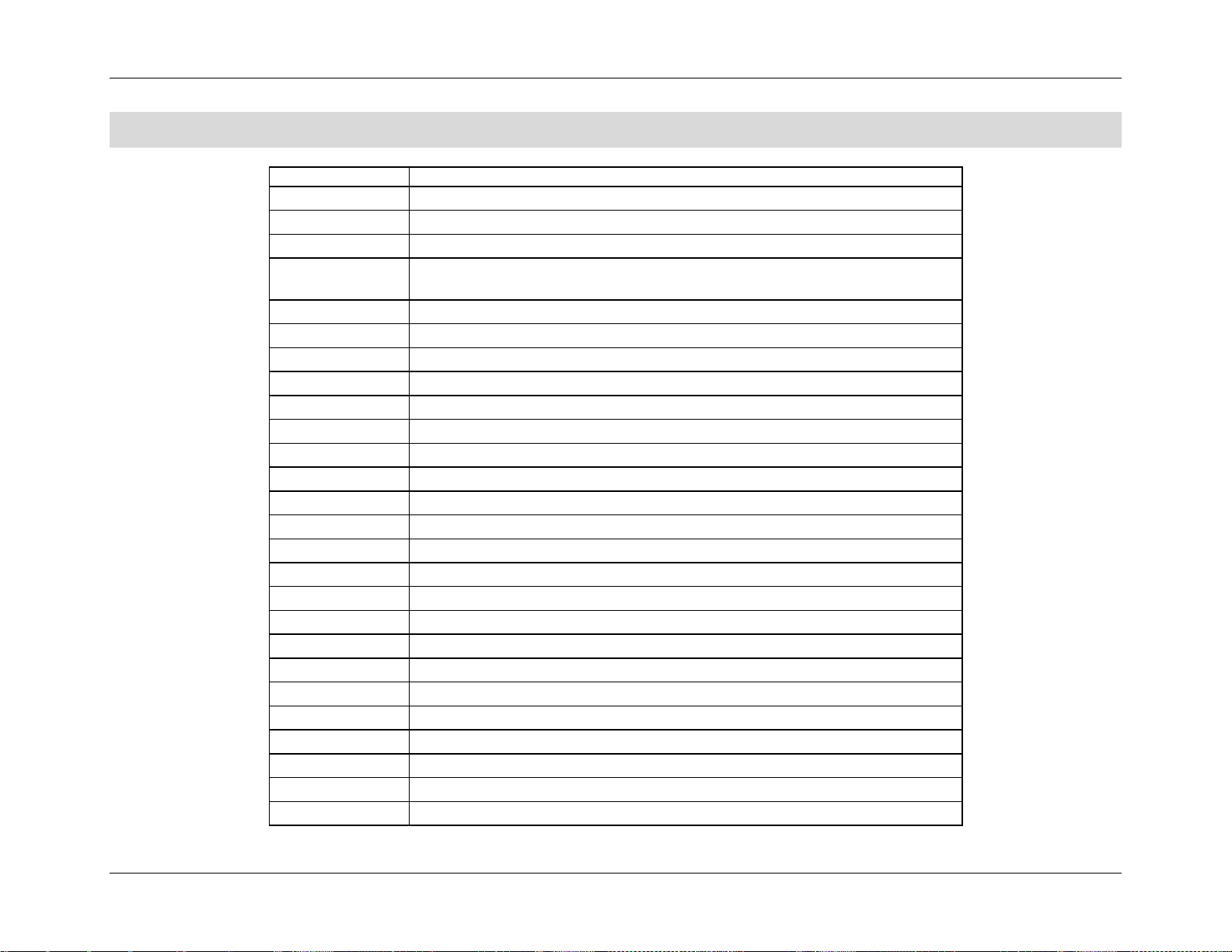

List of Tables

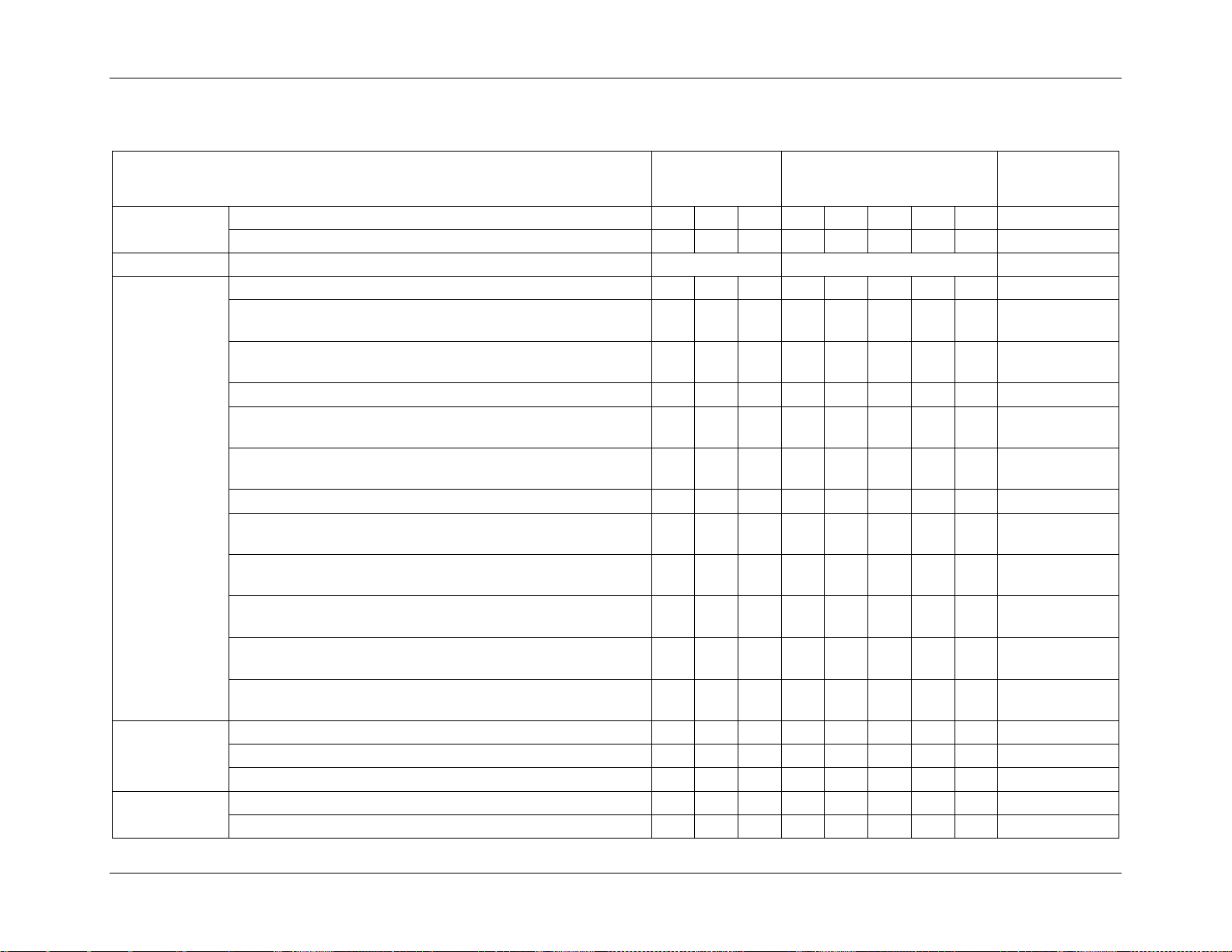

Table 1. Chassis Feature Set ...................................................................................................................................... 3

Table 2. System Environmental Limits Summary ............................................................................................. 7

Table 3. Specification Data for AC Power Supply Unit ................................................................................ 14

Table 4. AC Power Cord Specification ................................................................................................................ 14

Table 5. DC Output Power Connector ................................................................................................................ 15

Table 6. Power Supply Status LED ....................................................................................................................... 16

Table 7. Pin Assignment of Power Output Connector ................................................................................ 18

Table 8. Pin Assignment of Control Signal Connector ................................................................................ 18

Table 9. AC Input Rating ........................................................................................................................................... 19

Table 10. Typical Power Factor ............................................................................................................................. 19

Table 11. Platinum Efficiency Requirement ..................................................................................................... 19

Table 12. AC Power Holdup Requirement ........................................................................................................ 20

Table 13. Performance Criteria ............................................................................................................................. 21

Table 14. AC Line Sag Transient Performance ............................................................................................... 22

Table 15. AC Line Surge Transient Performance ........................................................................................... 22

Table 16. Load Ratings for Single 1600W Power Supply Unit................................................................. 24

Table 17. Voltage Regulation Limits ................................................................................................................... 24

Table 18. Transient Load Requirements ........................................................................................................... 25

Table 19. Capacitive Loading Conditions .......................................................................................................... 25

Table 20. Ripple and Noise ..................................................................................................................................... 25

Table 21. Timing Requirement .............................................................................................................................. 27

Table 22. 1600W CRPS Cold Redundancy Threshold................................................................................. 29

Table 23. 2130W CRPS Cold Redundancy Threshold................................................................................. 30

Table 24. PSON# Signal Characteristics ............................................................................................................ 30

Table 25. PWOK Signal Characteristics ............................................................................................................. 30

Table 26. SMBAlert# Signal Characteristics ..................................................................................................... 31

Table 27. Over Current Protection ....................................................................................................................... 32

Table 28. Over Voltage Protection (OVP) Limits ............................................................................................ 32

Table 29. PSU Addressing ....................................................................................................................................... 33

Table 30. PMBus Accuracy ...................................................................................................................................... 34

Table 31. Power Management Policy ................................................................................................................. 35

Table 32. Air Flow ....................................................................................................................................................... 36

Table 33. Drive Status LED States ........................................................................................................................ 50

Table 34. Drive Activity LED States ...................................................................................................................... 50

Table 35. Backplane Input Power Connector Pin-out ................................................................................. 51

Revision 2.21

Page 10

List of Tables Intel® Server Chassis H2000G Product Family TPS

x

Table 36. 2-Blade Compute Module Power Connector Pin-out ............................................................. 51

Table 37. 2x40 Pin Connector Pin-out for Compute Module Bridge Board....................................... 52

Table 38. Front Panel Connector Pin-out ......................................................................................................... 53

Table 39. Power Supply Control Connector Pin-out ................................................................................... 53

Table 40. 80 pin Misc. Signal Connector ........................................................................................................... 54

Table 41. 40 pin Misc. Signal Connector ........................................................................................................... 55

Table 42. BIB Power Edge Connector ................................................................................................................. 56

Table 43. Front Panel Connector ......................................................................................................................... 56

Table 44. Front Control Button Function .......................................................................................................... 57

Table 45. Front LED Indicator Functions ........................................................................................................... 58

Table 46. Power LED Operation ............................................................................................................................ 58

Table 47. Status LED State Definitions .............................................................................................................. 59

Table 48. ID LED .......................................................................................................................................................... 61

Table 49. Non-volatile Components List .......................................................................................................... 64

Table 50. Thermal Configuration Table – S2600KP Product Family, Normal Mode ...................... 66

Table 51. Thermal Configuration Table – S2600KP Product Family, Fan Fail Mode ..................... 67

Table 52. Thermal Configuration Table – S2600TP Product Family, Normal Mode ...................... 69

Table 53. Thermal Configuration Table – S2600TP Product Family, Fan Fail Mode...................... 71

Revision 2.21

Page 11

Intel® Server Chassis H2000G Product Family TPS List of Tables

xi

< This page intentionally left blank. >

Revision 2.21

Page 12

Page 13

Intel® Server Chassis H2000G Product Family TPS Introduction

1

1. Introduction

This Technical Product Specification (TPS) provides chassis specific information detailing the

features, functionality, and high-level architecture of the Intel® Server Chassis H2000G product

family. You should also reference the following product family TPS to obtain greater details of

functionality and architecture of the compute module to be integrated into this server chassis:

Intel® Server Board S2600KP Product Family

Intel® Compute Module HNS2600KP Product Family

Intel® Server Board S2600TP Product Family

Intel® Compute Module HNS2600TP Product Family

Intel® Server Board S7200AP Product Family

Intel® Compute Module HNS7200AP Product Family

In addition, you can obtain design-level information for specific subsystems by ordering the

External Product Specifications (EPS) or External Design Specifications (EDS) for a given

subsystem. EPS and EDS documents are not publicly available. They are only made available

under NDA with Intel and must be ordered through your local Intel representative. For a

complete list of available documents, refer to the Reference Documents section at the end of

this document.

The Intel® Server Chassis H2000G product family may contain design defects or errors known

as errata which may cause the product to deviate from published specifications. Refer to the

Intel® Server Board S2600KP Product Family Specification Update and Intel® Server Board

S2600TP Product Family and Intel® Server Board S7200AP Specification Update for published

errata.

1.1 Chapter Outline

This document is divided into the following chapters:

Chapter 1 – Introduction

Chapter 2 – Product Overview

Chapter 3 – Power Subsystem

Chapter 4 – Cooling Subsystem

Chapter 5 – Drive Support

Chapter 6 – Front Panel Control and Indicators

Appendix A – Integration and Usage Tips

Appendix B – Statement of Volatility

Appendix C – System Configuration Table for Thermal Compatibility

Glossary

Reference Documents

Revision 2.21

Page 14

Introduction Intel® Server Chassis H2000G Product Family TPS

2

1.2 Server Board Use Disclaimer

Intel Corporation server boards support add-in peripherals and contain a number of

high-density VLSI and power delivery components that need adequate airflow to cool. Intel

ensures through its own chassis development and testing that when Intel server building

blocks are used together, the fully integrated system will meet the intended thermal

requirements of these components. It is the responsibility of the system integrator who

chooses not to use Intel developed server building blocks to consult vendor datasheets and

operating parameters to determine the amount of air flow required for their specific

application and environmental conditions. Intel Corporation cannot be held responsible if

components fail or the server board does not operate correctly when used outside any of their

published operating or non-operating limits.

Revision 2.21

Page 15

Intel® Server Chassis H2000G Product Family TPS Product Overview

3

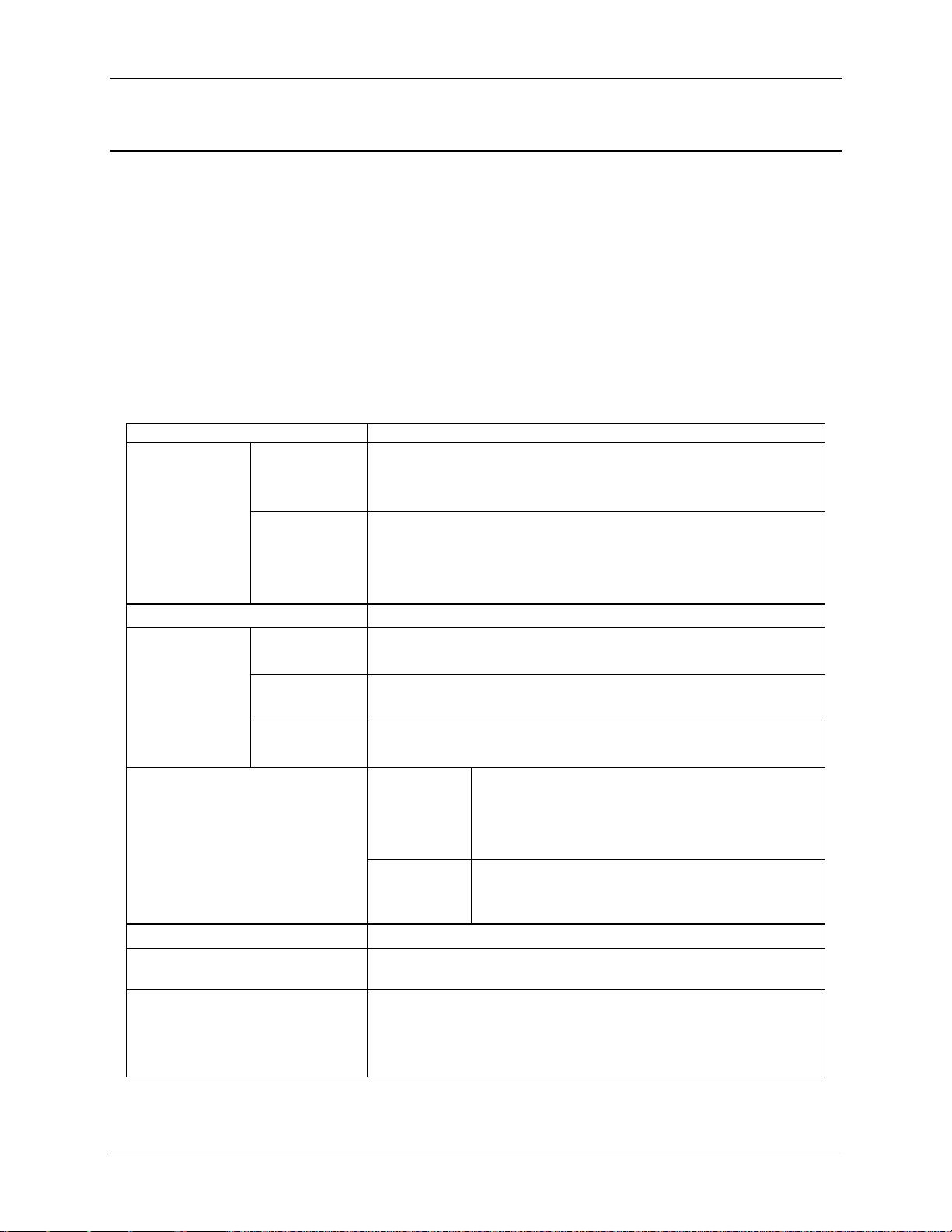

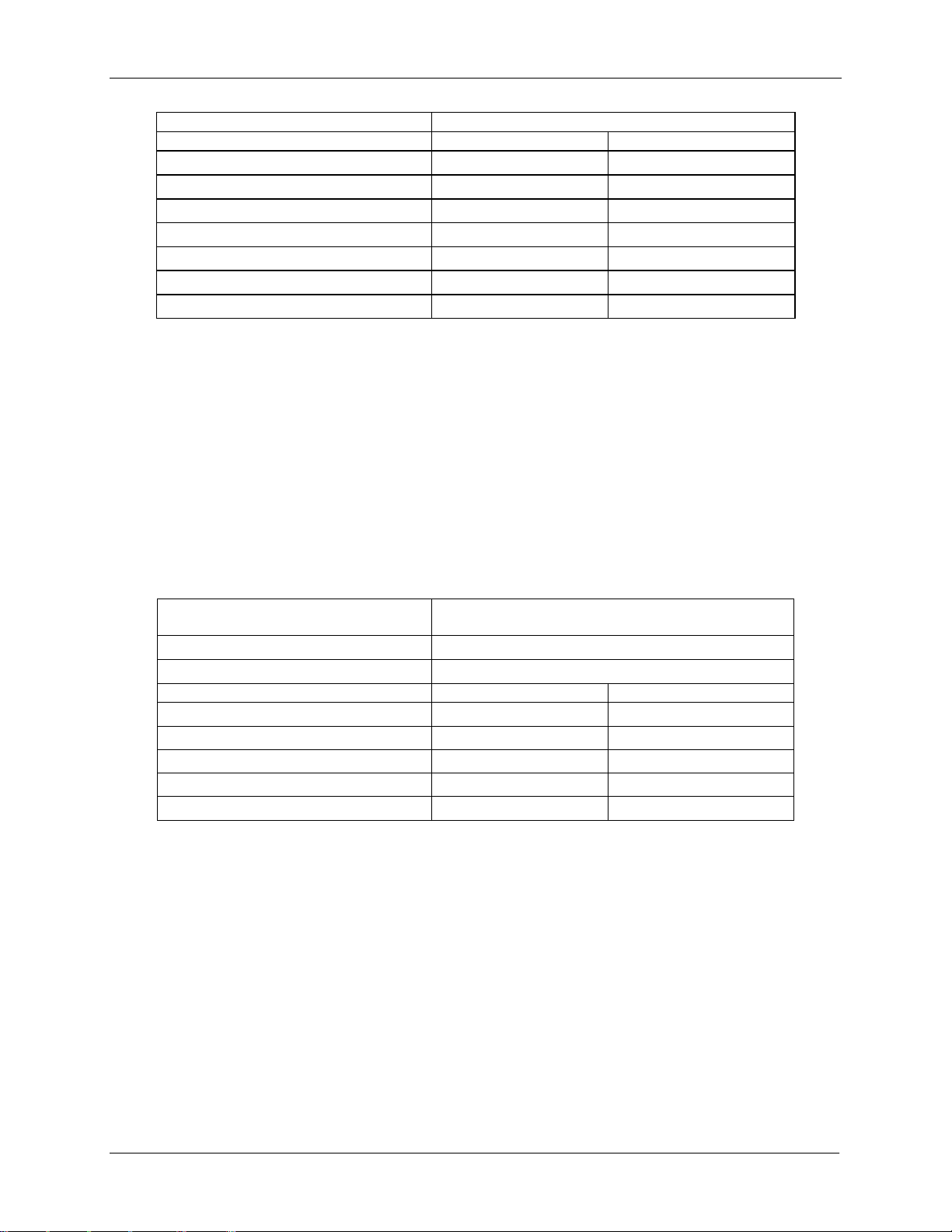

Feature

Description

Dimensions

H2312XXKR2

H2312XXLR2

3.42 inches (86.9 mm) high

17.24 inches (438 mm) wide

30.35 inches (771 mm) deep

H2216XXKR2

H2216XXLR2

H2224XXKR2

H2224XXLR2

3.42 inches (86.9 mm) high

17.24 inches (438 mm) wide

28.86 inches (733 mm) deep

Package Dimensions*

983X577X260 mm

Weight

H2312XXKR2

H2312XXLR2

Net weight 21.5kg, package weight 29.5kg

H2216XXKR2

H2216XXLR2

Net weight 20.5kg, package weight 28.4kg

H2224XXKR2

H2224XXLR2

Net weight 20.64 kg, package weight 28.86 kg

Compute Module Support

H2312XXKR2

H2312XXLR2

H2216XXKR2

H2216XXLR2

Intel® Compute Module HNS2600KP Product Family

Intel® Compute Module HNS2600TP Product Family

Intel® Compute Module HNS7200AP Product Family*

H2224XXKR2

H2224XXLR2

Intel® Compute Module HNS2600TP24 Product

Family

Intel® Compute Module HNS7200AP Product Family*

Fan

One internal power supply fan for each installed power supply unit

Power Supply Options

1600W or 2130W AC Common Redundant Power Supply (CRPS), 80

plus Platinum, supporting CRPS configuration

Storage Bay Options

12x 3.5-inch SATA/SAS drive bays – H2312XXKR2 and H2312XXLR2

16x 2.5-inch SATA/SAS drive bays – H2216XXKR2 and H2216XXKR2

24x 2.5-inch SAS drive bays (8 x PCIe* SFF) – H2224XXKR2 and

H2224XXLR2

2. Product Overview

The Intel® Server Chassis H2000G product family is rack mount 2U server chassis which can

support up to four compute modules, purpose-built for high-density and lowest total cost of

ownership in dense computing applications, such as HPC and IPDC. The chassis can be used

to integrate with four compute modules, supporting up to twelve 3.5" or sixteen 2.5" hot-swap

SAS or SATA drives, with 1600 Watts and 2130 Watts Common Redundant Power Supply

(CRPS) capability.

This chapter provides a high-level overview of the chassis features. The following chapters

provide greater detail for each major chassis component or feature.

Table 1. Chassis Feature Set

*The Intel® Compute Module HNS7200AP product family is only compatible with the Intel® Server

Chassis H2000XXLR2 product family

Revision 2.21

Page 16

Product Overview Intel® Server Chassis H2000G Product Family TPS

4

Note: The package dimensions are the outer dimensions of the package box out of the server

chassis.

The Intel® Server Chassis H2000G product family also supports different compute module

quantity in the same chassis. The compute module quantity can be at least 1, and up to 4 in

one chassis.

WARNING! Be protected before accessing the system from rear side since the temperature of

an operating system exit air could be over 70°C (158°F).

Caution: The chassis has limited support on mixed compute module configuration, for

example, compute modules based on different server board can be installed in the same

chassis for power-on only.

Revision 2.21

Page 17

Intel® Server Chassis H2000G Product Family TPS Product Overview

5

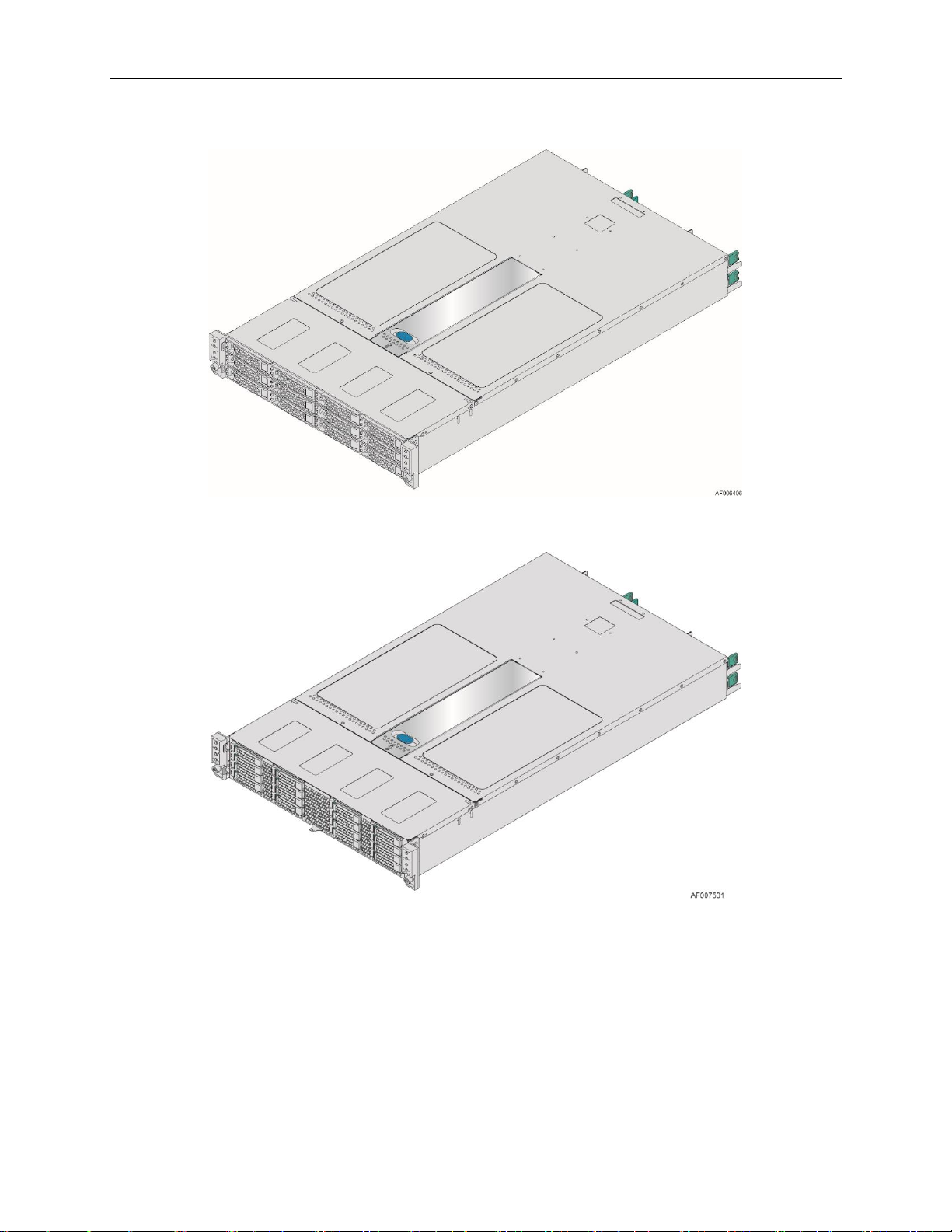

2.1 Chassis Views

Figure 1. Server Chassis Overview (12 x 3.5” drive bay)

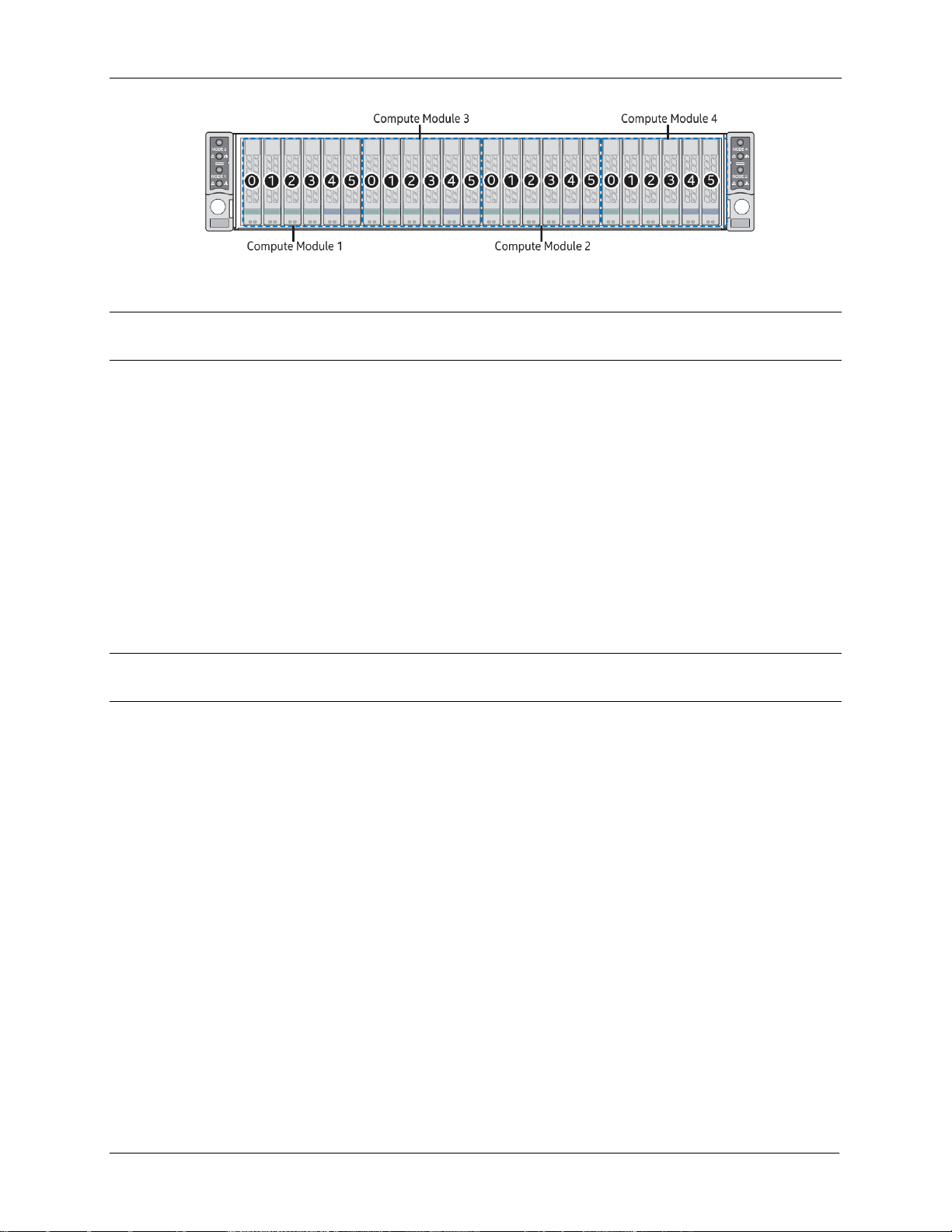

Figure 2. Server Chassis Overview (16 x 2.5” drive bay)

Revision 2.21

Page 18

Product Overview Intel® Server Chassis H2000G Product Family TPS

6

Figure 3. Server Chassis Overview (24 x 2.5” drive bay)

Figure 4. Server Chassis Rear View

Figure 5. Dummy Tray Cover

Revision 2.21

Page 19

Intel® Server Chassis H2000G Product Family TPS Product Overview

7

Parameter

Limits

Temperature

Operating

ASHRAE Class A2 – Continuous Operation. 10°C to 35°C (50°F to 95°F) with

the maximum rate of change not to exceed 10°C per hour

ASHRAE Class A3 – Includes operation up to 40°C for up to 900 hours per

ASHRAE Class A4 – Includes operation up to 45° for up to 90 hours per year

Non-Operating

-40°C to 70°C (-40°F to 158°F)

Altitude

Operating

Support for operation up to 3050m with ASHRAE class deratings.

Humidity

Non-Operating

50% to 90%, non-condensing with a maximum wet bulb of 28° C (at

temperatures from 25°C to 35°C)

Shock

Operating

Half sine, 2g, 11 mSec

Unpackaged

Trapezoidal, 25g, velocity change 175 inches/second

Packaged

ISTA (International Safe Transit Association) Test Procedure 3A

Vibration

Unpackaged

5 Hz to 500 Hz 2.20 g RMS random

Packaged

ISTA (International Safe Transit Association) Test Procedure 3A

AC-DC

Voltage

90 V to 132 V and 180 V to 264 V

Frequency

47 Hz to 63 Hz

Source Interrupt

No loss of data for power line drop-out of 12 mSec

Surge Non-

operating and

operating

Unidirectional

Line to earth Only

AC Leads 2.0 kV

I/O Leads 1.0 kV

ESD

Air Discharged

12.0 kV

Contact Discharge

8.0 kV

2.2 Environmental Limits

The following table defines the system level operating and non-operating environmental

limits.

Table 2. System Environmental Limits Summary

Disclaimer Note: Intel ensures the unpackaged server board and chassis meet the shock

requirement mentioned above through its own chassis development and configuration. It is the

responsibility of the system integrator to determine the proper shock level of the board and

chassis if the system integrator chooses different configuration or different chassis. Intel

Corporation cannot be held responsible, if components fail or the server board does not

operate correctly when used outside any of its published operating or non-operating limits.

Revision 2.21

Page 20

Product Overview Intel® Server Chassis H2000G Product Family TPS

8

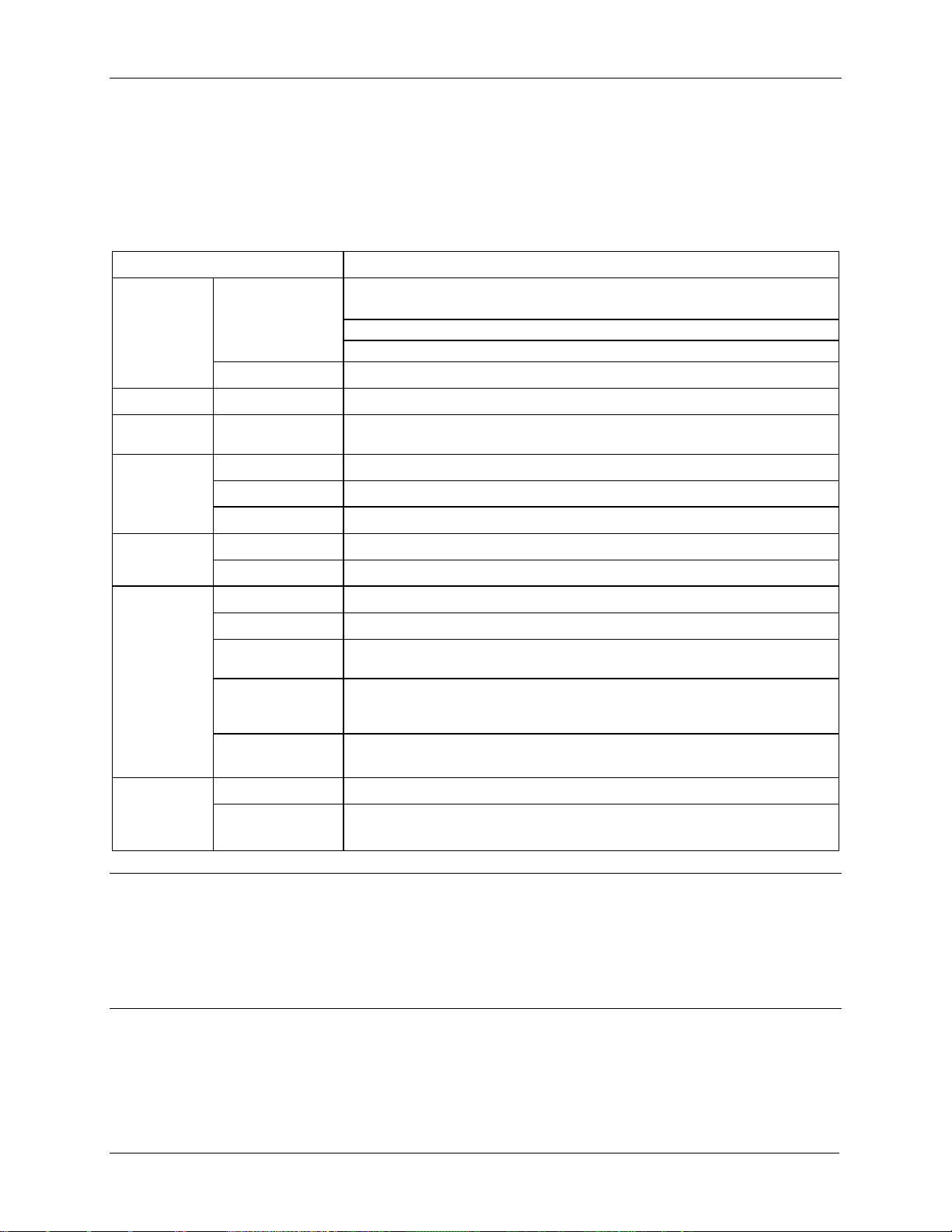

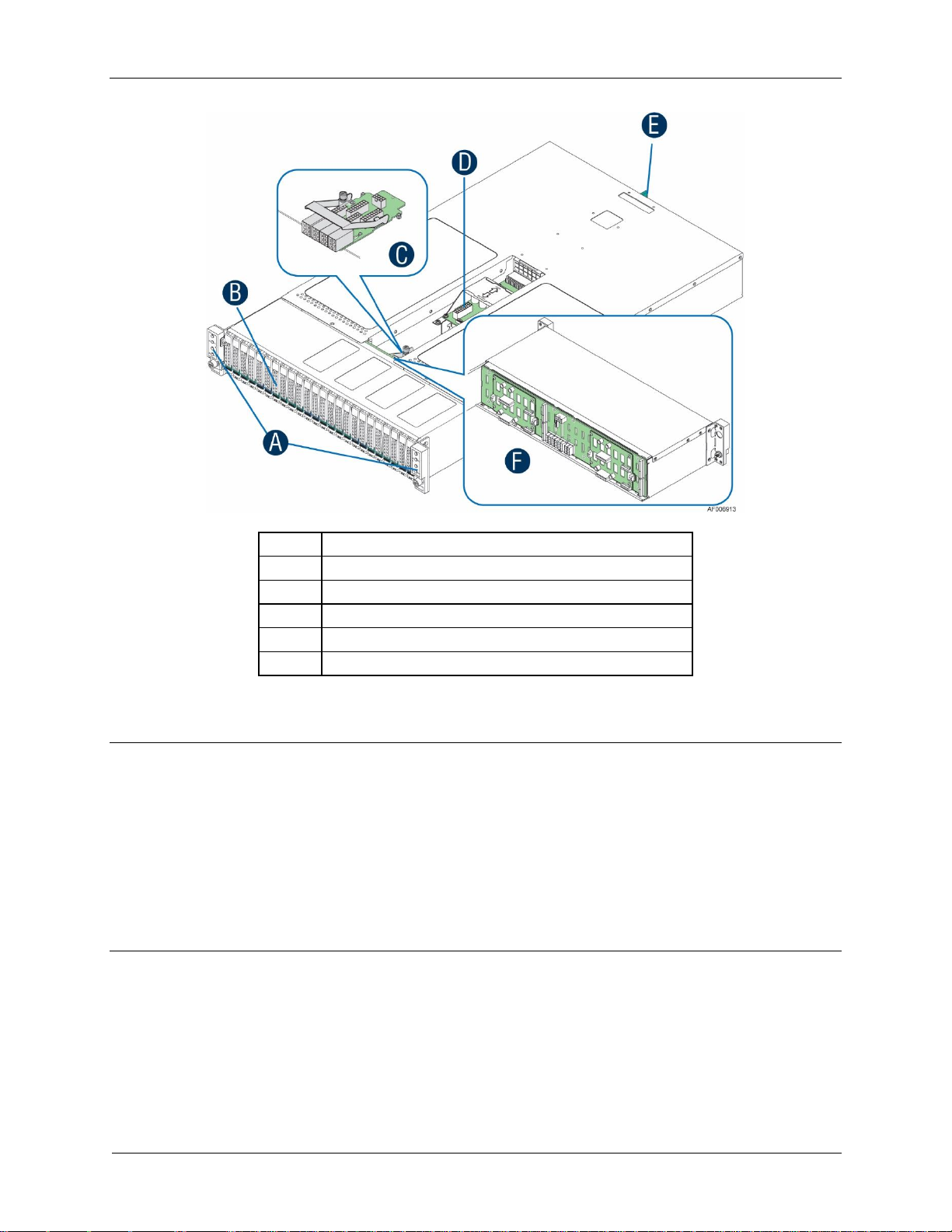

A

Front Control Panels

B

Drive bays

C

Power Distribution Module

D

Power Supply Modules

E

Hot Swap Back Plane (attached to the drive cage)

2.3 Chassis Parts

Note: Not shown – Rack slide rail and power distribution module cover

Figure 6. Major Server Chassis Parts (12 x 3.5” drive bay)

Revision 2.21

Page 21

Intel® Server Chassis H2000G Product Family TPS Product Overview

9

A

Front Control Panels

B

Drive bays

C

Power Distribution Module

D

Power Supply Modules

E

Hot Swap Back Plane (attached to the drive cage)

Note: Not shown – Rack slide rail and power distribution module cover

Figure 7. Major Server Chassis Parts (16 x 2.5” drive bay)

Revision 2.21

Page 22

Product Overview Intel® Server Chassis H2000G Product Family TPS

10

A

Front Control Panels

B

Drive bays

C

Power Interposer Board (24 x 2.5” drive chassis only)

D

Power Distribution Module

E

Power Supply Modules

F

Hot Swap Backplane (attached to the drive cage)

Note: Not shown – Rack slide rail and power distribution module cover

Figure 8. Major Server Chassis Parts (24 x 2.5” drive bay)

Notes:

1. The blank compute module bay must be covered by a dummy tray cover. When removed,

keep the dummy tray cover properly for future use.

2. The compute module bay in the chassis requires either a compute module being installed

and powered up or a dummy tray cover installed to maintain proper thermal environment

for the other running compute modules in the same chassis. In case of a compute module

failure, remove the failed compute module, and replace with a dummy tray cover until the

new compute module is installed.

Revision 2.21

Page 23

Intel® Server Chassis H2000G Product Family TPS Product Overview

11

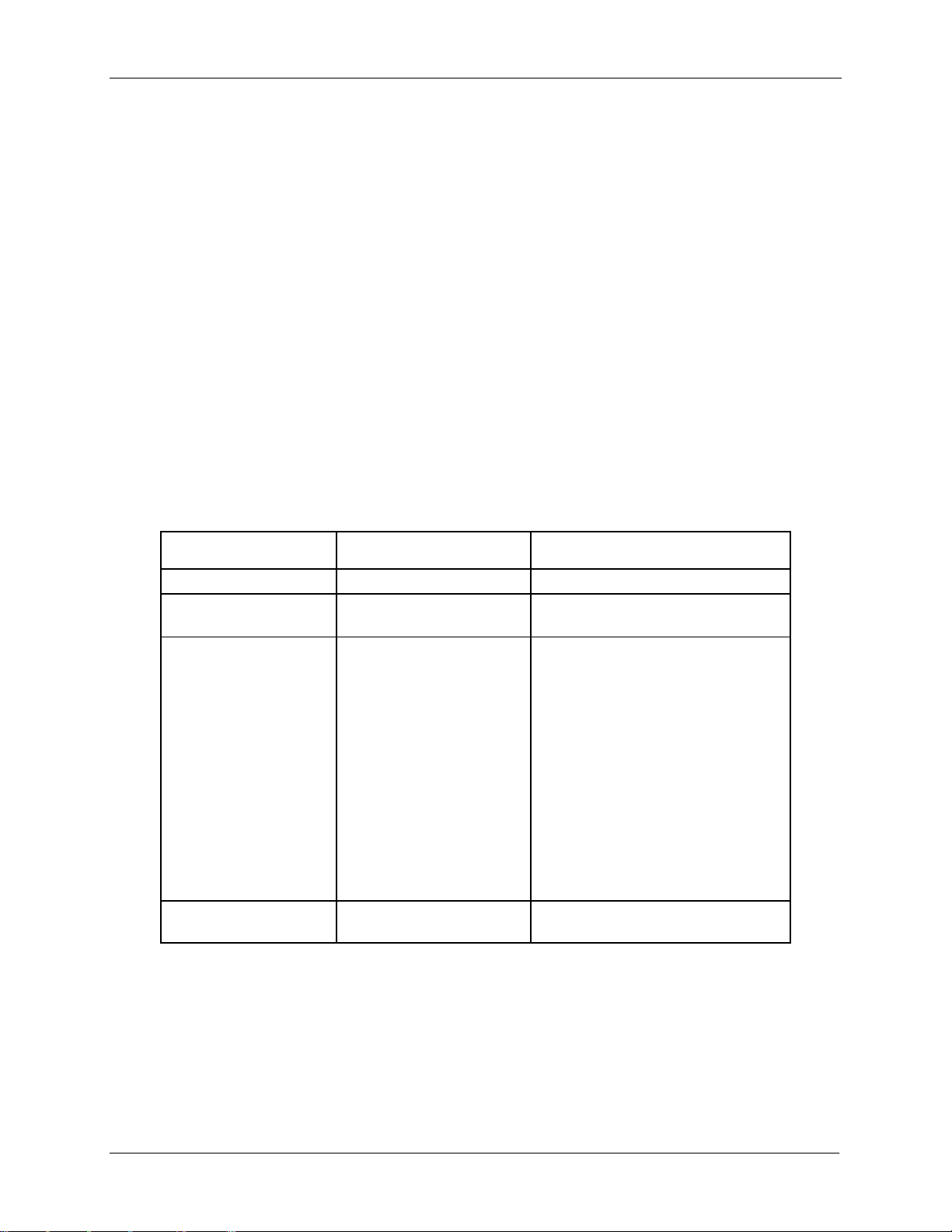

Intel® Server Chassis

H2312XXKR2, H2312XXLR2

Intel® Server Chassis

H2216XXKR2, H2216XXLR2

Intel® Server Chassis

H2224XXKR2, H2224XXLR2

SATA/SAS Drives (3.5-inch)

Up to 12

Not Supported

Not Supported

SATA/SAS Drives (2.5-inch)

Up to 12

Up to 16

Up to 24

(1)

PCIe* SFF Devices

Not Supported

Not Supported

Up to 8

(2)

2.4 Drive and Peripheral Bays

Note (1): Intel® SATA SSDs and 3rd party SAS drives were validated on the H2224XXKR2 and

H2224XXLR2 chassis.

Note (2): As the PCIe* SFF device (NVMe SSD) shares the drive slots with SAS drive, so when

support 8 NVMe SSD, SAS drive number will decrease from 24 to 16.

Figure 9. 12 x 3.5” Drive Chassis Front View

Figure 10. 16 x 2.5” Drive Chassis Front View

Figure 11. 24 x 2.5” Drive Chassis Front View

Revision 2.21

Page 24

Product Overview Intel® Server Chassis H2000G Product Family TPS

12

2.5 Front Bezel Support

The Intel® Server Chassis H2000G product family provides front panel bezel. The bezel

provides protection to chassis drive bays with a lock to the chassis. The front view of the bezel

is as below.

Figure 12. Front Bezel

2.6 Rack and Cabinet Mounting Options

The server chassis is designed to support 19 inches wide by up to 30 inches deep server

cabinets. The server chassis bundles with the following Intel® rack mount option:

The basic slide rail kit (Product order code – AXXELVRAIL) is designed to mount the

chassis into a standard (19 inches wide by up to 30 inches deep) EIA-310D compatible

server cabinet.

The premium quality rails (Product order code – AXXFULLRAIL) can support the travel

distance 780mm, full extension from rack.

Caution: THE MAXIMUM RECOMMENDED SERVER WEIGHT FOR THE RACK RAILS CAN BE

FOUND at http://www.intel.com/support/motherboards/server/sb/CS-033655.htm. EXCEEDING

THE MAXIMUM RECOMMENDED WEIGHT OR MISALIGNMENT OF THE SERVER MAY RESULT IN

FAILURE OF THE RACK RAILS HOLDING THE SERVER. Use of a mechanical assist to install and

align server into the rack rails is recommended.

Advisory Note: To support shipment of the server chassis while installed in a rack with the rack

mount rail kit, user should ensure the server cabinet and its package can support the shipment

under the actual transport conditions.

Revision 2.21

Page 25

Intel® Server Chassis H2000G Product Family TPS Power Subsystem

13

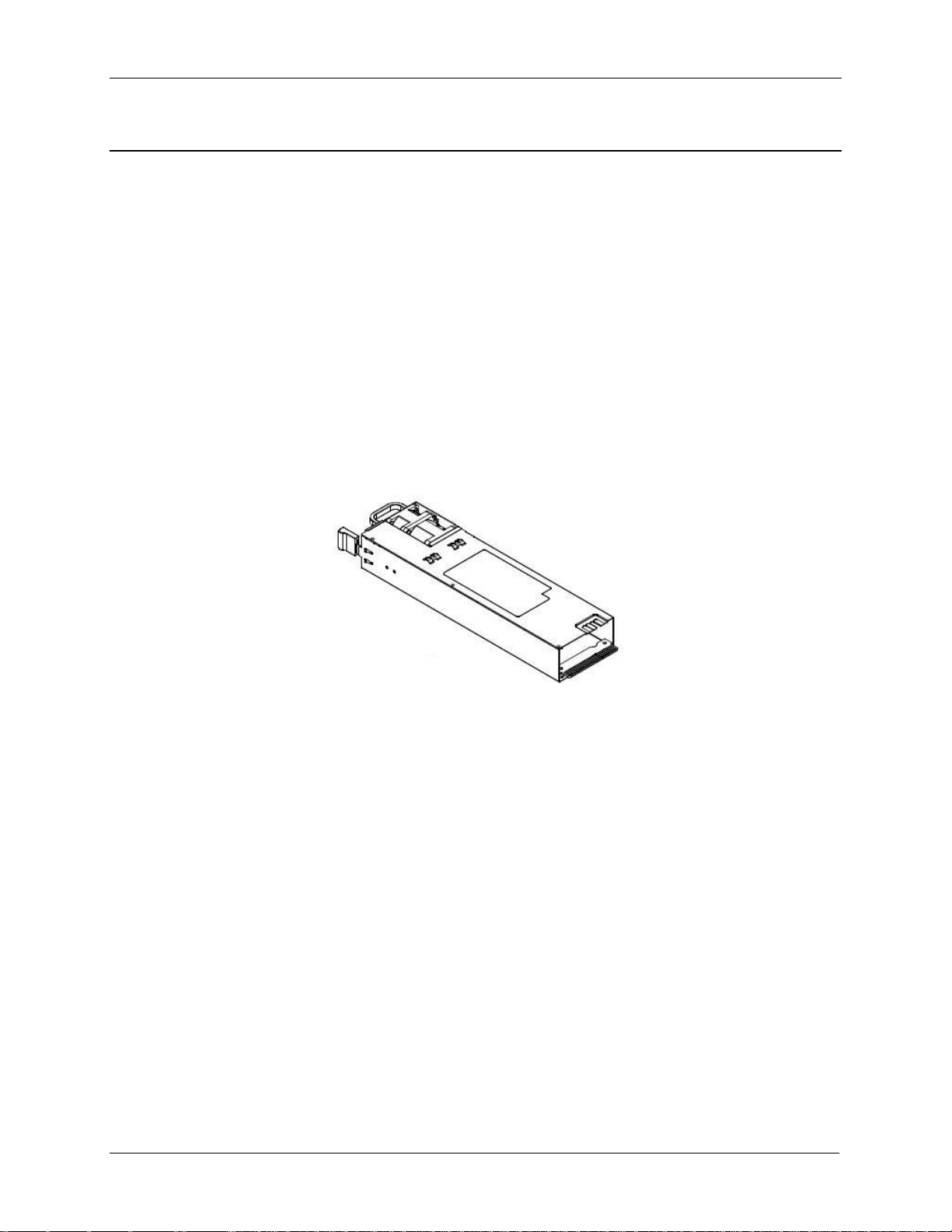

3. Power Subsystem

The server chassis supports 1600W and 2130W AC 1+1 hot-swap power supply module and

two power distribution boards which can support 2U rack high density server.

3.1 Power Supply Overview

The power supply module has a simple retention mechanism to retain the module self once it

is inserted. This mechanism withstands the specified mechanical shock and vibration

requirements. The power distribution board is fixed in the chassis with screws. Using existing

power supply module provided by vendor with updated PMBus* and custom-made power

connector board the server chassis supports four compute modules. The power supply has

two outputs: 12V and 12V standby. The input is auto ranging and power factor corrected. The

PMBus* features are requirements for AC silver rated box power supply for use in server

systems based on the Intel® Server Chassis H2000G product family. This specification is based

on the PMBus* Specifications part I and II, revision 1.1.

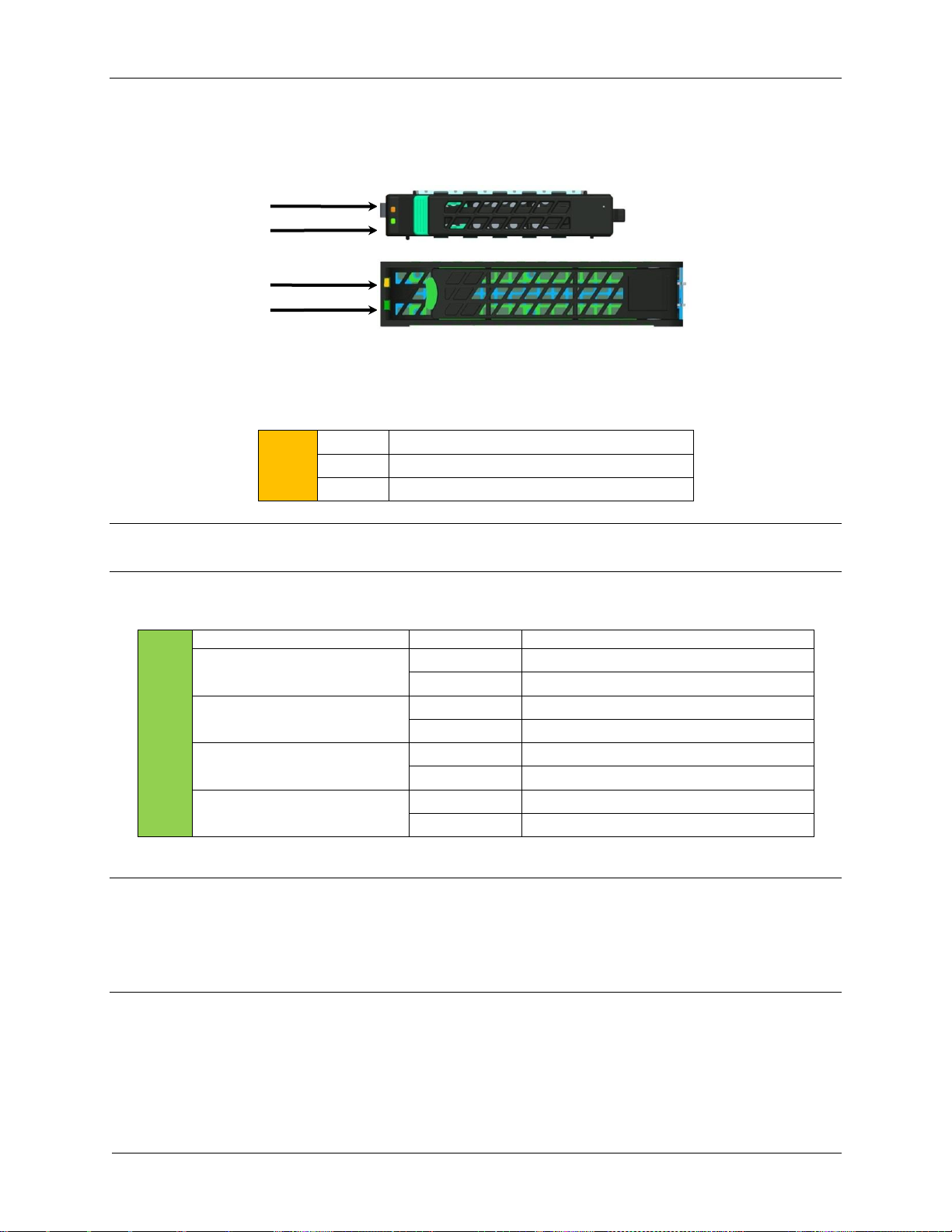

Figure 13. 1600W and 2130W AC Power Supply Module Overview

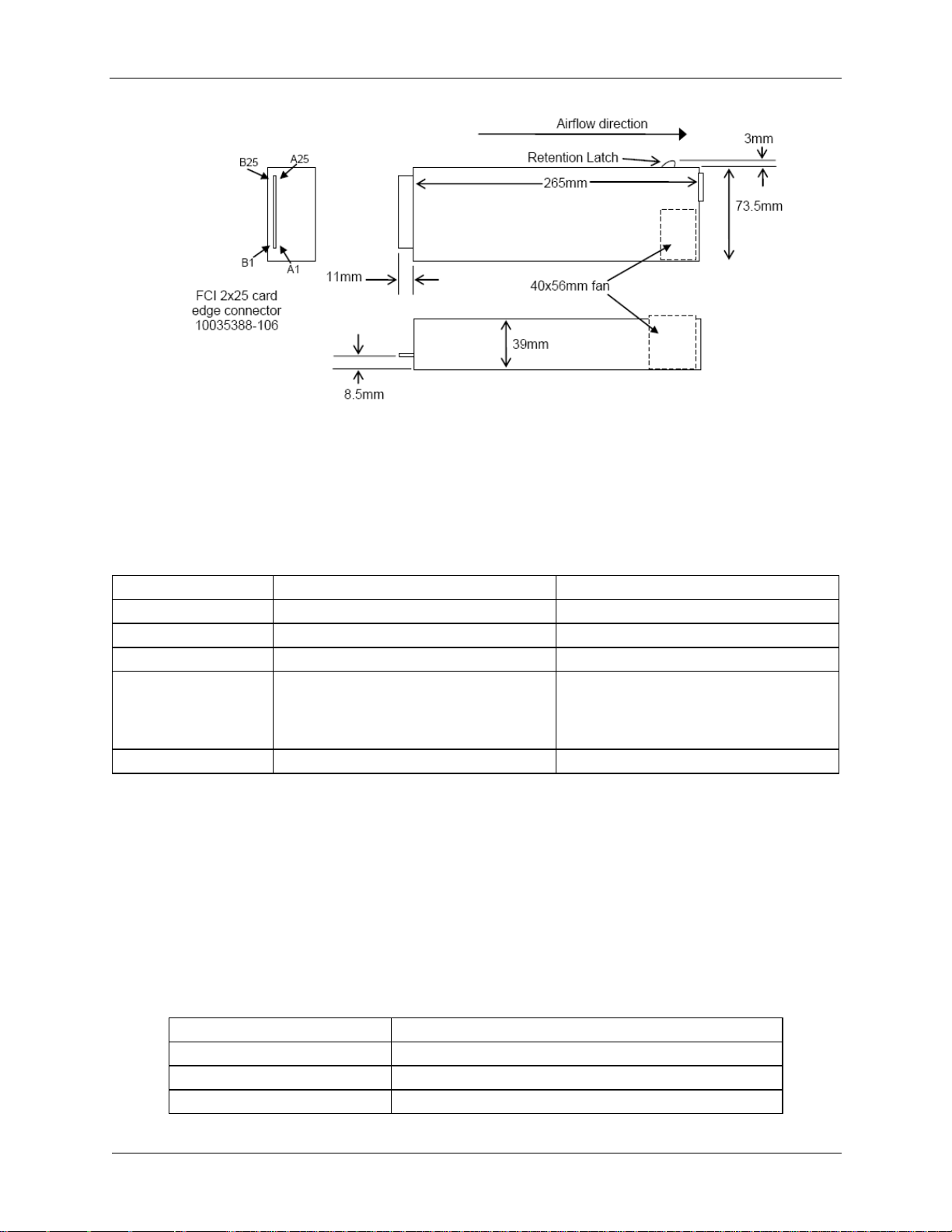

3.1.1 Power Supply Dimension

The physical size of the power supply enclosure is 39/40mm x 73.5mm x 265mm. The power

supply contains a single 40mm fan. The power supply has a card edge output that interfaces

with a 2x25 card edge connector in the chassis. The AC plugs directly into the external face of

the power supply.

Revision 2.21

Page 26

Power Subsystem Intel® Server Chassis H2000G Product Family TPS

14

1600W Power Supply

2130W Power Supply

Wattage

1600W (Energy Smart)

2130W (Energy Smart)

Voltage

90-264 VAC, auto-ranging, 47 Hz-63 Hz

90-264 VAC, auto-ranging, 47 Hz-63 Hz

Heat Dissipation

5459 BTU/hr

7268 BTU/hr

Maximum Inrush

Current

Under typical line conditions and over the

entire chassis ambient operating range,

the inrush current may reach 65 A per

power supply for 5 ms

Under typical line conditions and over the

entire chassis ambient operating range,

the inrush current may reach 65 A per

power supply for 5 ms

80 Plus rating

Platinum

Platinum

Cable Type

SJT

Wire Size

16 AWG

Temperature Rating

105º C

Amperage Rating

13A

Figure 14. AC Power Supply Unit Dimension Overview

3.1.2 AC Power Supply Unit General Data

Below is general specification data for AC power supply unit.

Table 3. Specification Data for AC Power Supply Unit

3.1.3 AC Input Connector

The power supply has an internal IEC320 C14 power inlet. The inlet is rated for a minimum of

10A at 250VAC.

3.1.4 AC Power Cord Specification Requirements

The AC power cord used meets the following specification requirements.

Table 4. AC Power Cord Specification

Revision 2.21

Page 27

Intel® Server Chassis H2000G Product Family TPS Power Subsystem

15

Cable Type

SJT

PSU Output Connector

A1

GND

B1

GND

A2

GND

B2

GND

A3

GND

B3

GND

A4

GND

B4

GND

A5

GND

B5

GND

A6

GND

B6

GND

A7

GND

B7

GND

A8

GND

B8

GND

A9

GND

B9

GND

A10

+12V

B10

+12V

A11

+12V

B11

+12V

A12

+12V

B12

+12V

A13

+12V

B13

+12V

A14

+12V

B14

+12V

A15

+12V

B15

+12V

A16

+12V

B16

+12V

A17

+12V

B17

+12V

A18

+12V

B18

+12V

A19

PMBus SDA*

B19

A0* (SMBus address)

A20

PMBus SCL*

B20

A1* (SMBus address)

A21

PSON

B21

12V STBY

A22

SMBAlert#

B22

Cold Redundancy Bus*

A23

Return Sense

B23

12V load share bus

A24

+12V Remote Sense

B24

No Connect

A25

PWOK

B25

CRPS Compatibility Check pin*

3.1.5 Power Supply Unit DC Output Connector

The DC output connector pin-out is defined as follows.

Table 5. DC Output Power Connector

3.1.6 Handle Retention

The power supply has a handle to assist extraction. The module is able to be inserted and

extracted without the assistance of tools. The power supply also has a latch which retains the

power supply into the chassis and prevents the power supply from being inserted or extracted

from the chassis when the AC power cord is pulled into the power supply.

The handle protects the operator from any burn hazard through the use of industrial designed

plastic handle or equivalent material.

Revision 2.21

* Refer to the spec of CRPS Common Requirements Specification.

Page 28

Power Subsystem Intel® Server Chassis H2000G Product Family TPS

16

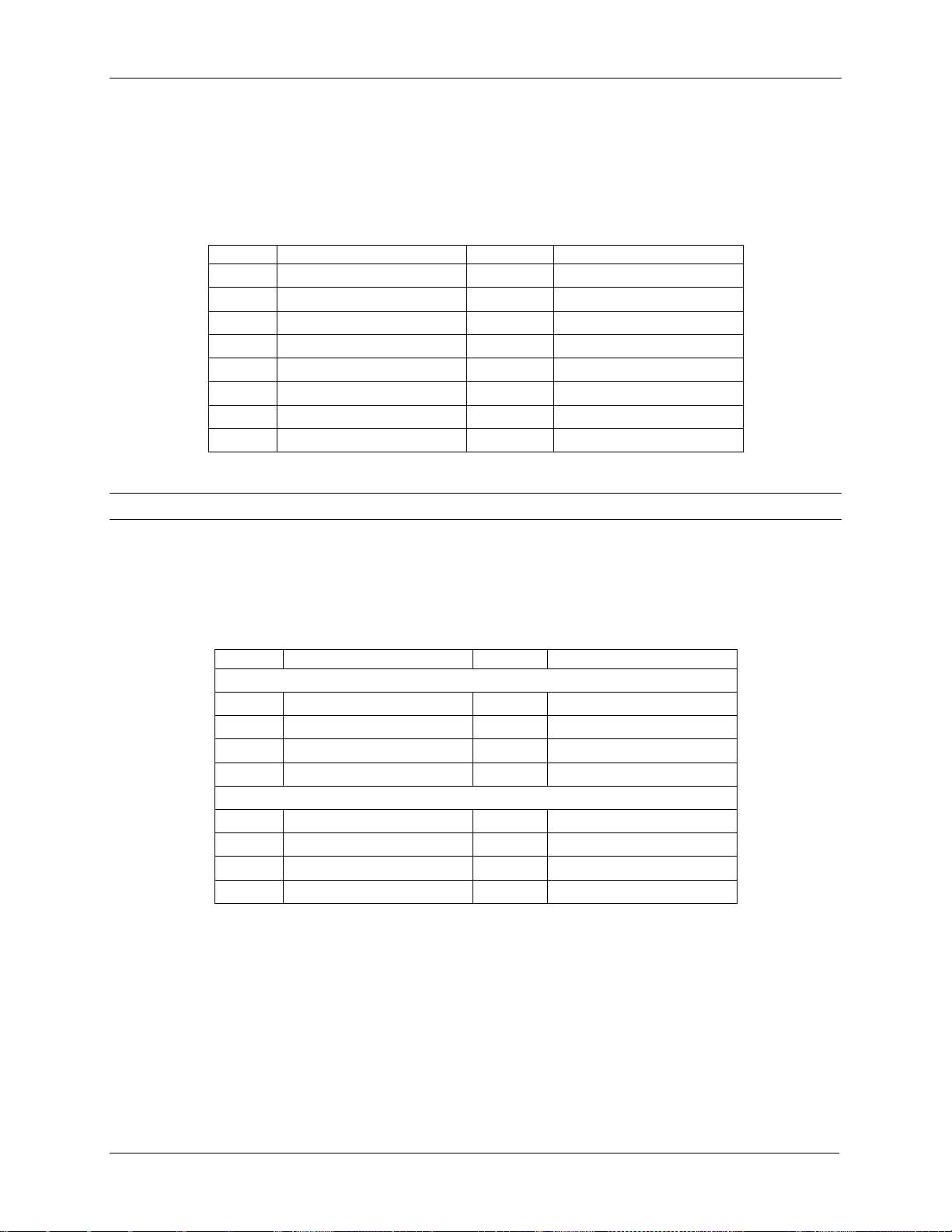

Power Supply Condition

LED State

Output ON and OK

Solid GREEN

No AC power to all power supplies

OFF

AC present/Only 12VSB on (PS off) or PS in Cold redundant state

1Hz Blink GREEN

AC cord unplugged or AC power lost; with a second power supply in parallel still with AC

input power.

Solid AMBER

Power supply warning events where the power supply continues to operate; high temp,

high power, high current, slow fan.

1Hz Blink Amber

Power supply critical event causing a shutdown; failure, OCP, OVP, Fan Fail

Solid AMBER

Power supply FW updating

2Hz Blink GREEN

A

Power Distribution Board 1

B

Power Distribution Board 2

C

Power Supply Unit #2 (upper) and #1 (lower)

D

PSU cage

3.1.7 LED Marking and Identification

The power supply is using a bi-color LED: Amber and Green for status indication. The

following table shows the LED states for each power supply operating state.

Table 6. Power Supply Status LED

3.1.8 Power Distribution Module

The power distribution module is at the middle of the chassis and consists of two Power

Distribution Boards (PDBs) to support Common Redundant Power Supplies (CRPS).

Following is the Power Distribution Module overview.

Figure 15. Power Cage Overview

Revision 2.21

Page 29

Intel® Server Chassis H2000G Product Family TPS Power Subsystem

17

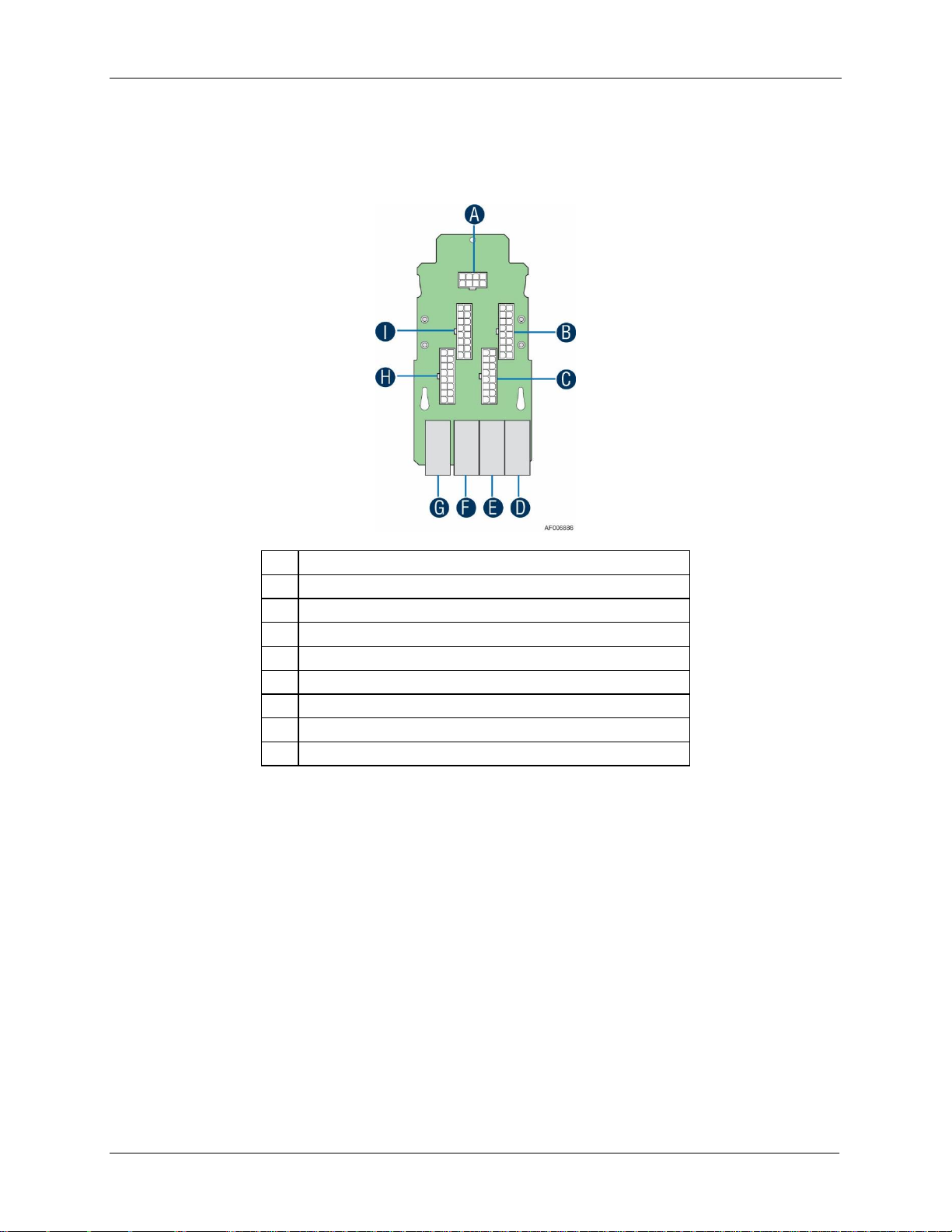

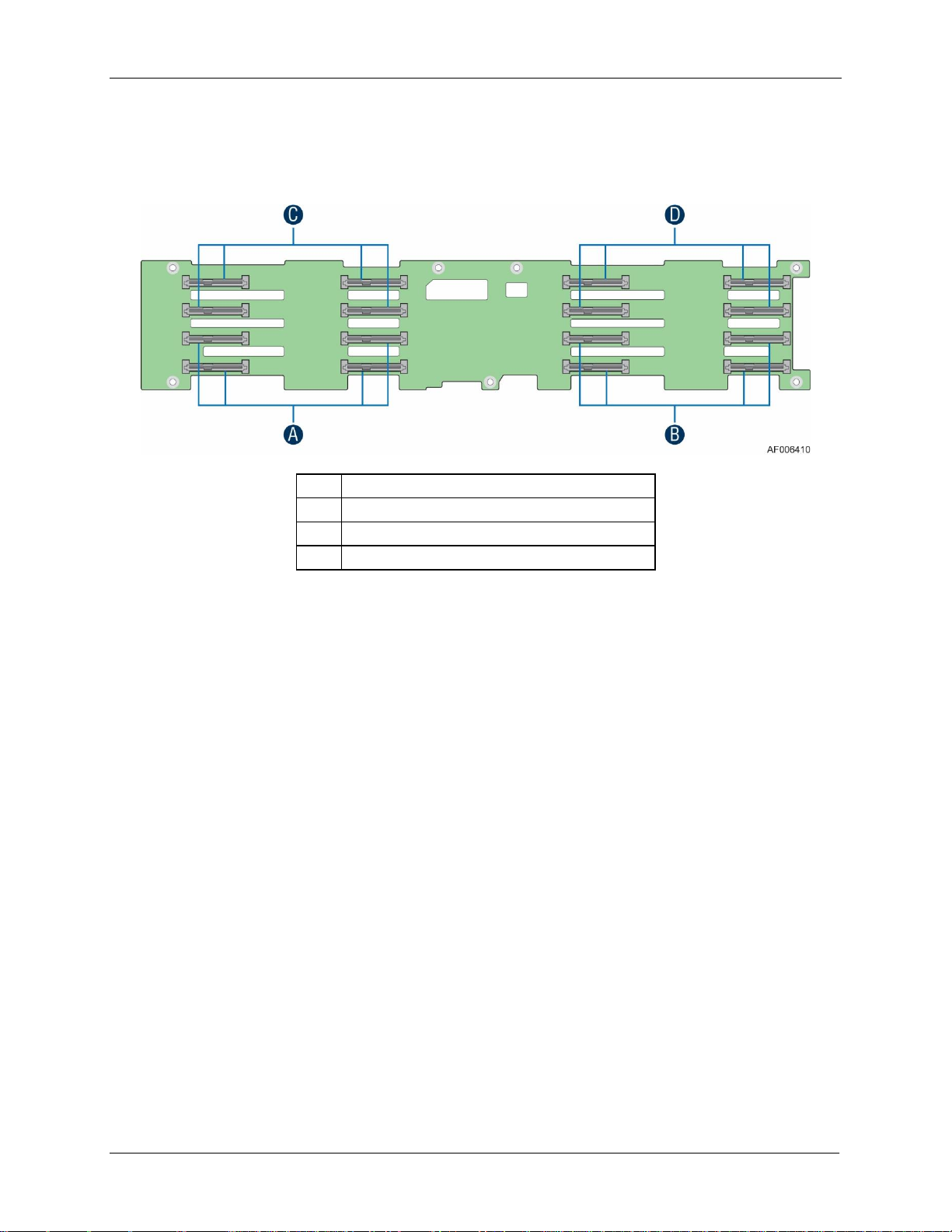

A

2x4 pin 5V Power Connector

B

2x8 pin 12V Power Connector (to PDB)

C

2x8 pin 12V Power Connector (to PDB)

D

12V Power Connector (to backplane)

E

12V Power Connector (to backplane)

F

12V Power Connector (to backplane)

G

12V Power Connector (to backplane)

H

2x8 pin 12V Power Connector (to PDB)

I

2x8 pin 12V Power Connector (to PDB)

3.1.9 Power Interposer Board

The power interposer board is only used in 24 x 2.5” drive chassis as the interposer between

power distribution board and the backplane.

Figure 16. Power Interposer Board Top View

Revision 2.21

Page 30

Power Subsystem Intel® Server Chassis H2000G Product Family TPS

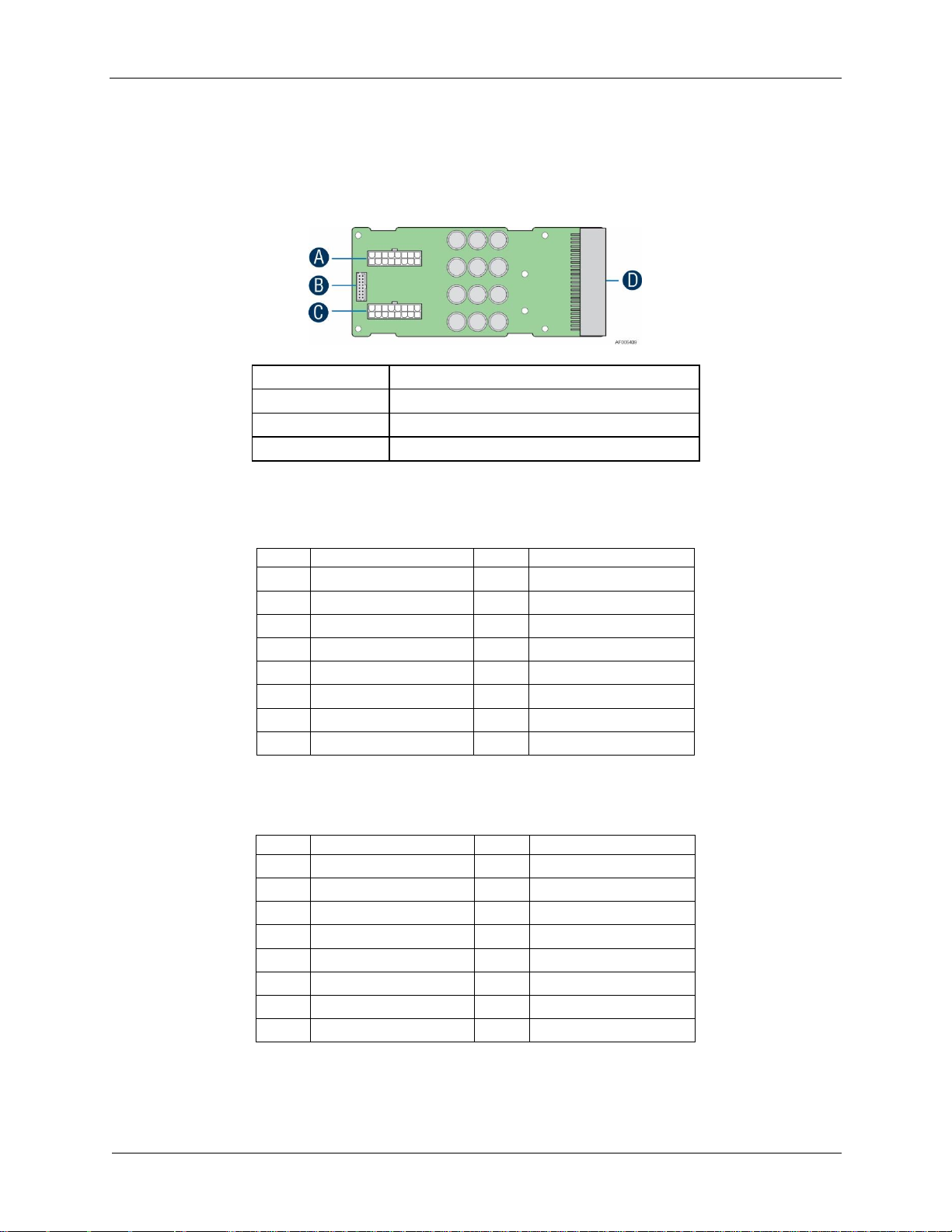

18

A

Main Power Output Connector

B

Control Signal Connector

C

Main Power Output Connector

D

Power Supply Unit Connector

Pin

Description

Pin

Description

1

GND

9

+12V

2

GND

10

+12V

3

GND

11

+12V

4

GND

12

+12V

5

GND

13

+12V

6

GND

14

+12V

7

GND

15

+12V

8

GND

16

+12V

Pin

Description

Pin

Description

1

PMBus SDA

2

For A0 addressing

3

PMBus SCL

4

PSON#

5

OCP_SHTDN#

6

12V Load Share Bus

7

SMBAlert#

8

Cold Redundancy Bus

9

Reserved

10

PWOK

11

Reserved

12

Compatibility Bus

13

Reserved

14

+12VSB

15

+12VSB

16

Key Pin (removed)

3.1.10 Power Cage Output Pin Assignment

The power cage provides +12V and +12V

output to the server chassis. Each PDB has two

STB

2x9 power output cable to chassis backplane, together with one 2x8 signal control cable for

power management. Refer to the following table for PDB pin assignment.

Figure 17. Power Distribution Board

Table 7. Pin Assignment of Power Output Connector

Revision 2.21

Table 8. Pin Assignment of Control Signal Connector

Page 31

Intel® Server Chassis H2000G Product Family TPS Power Subsystem

19

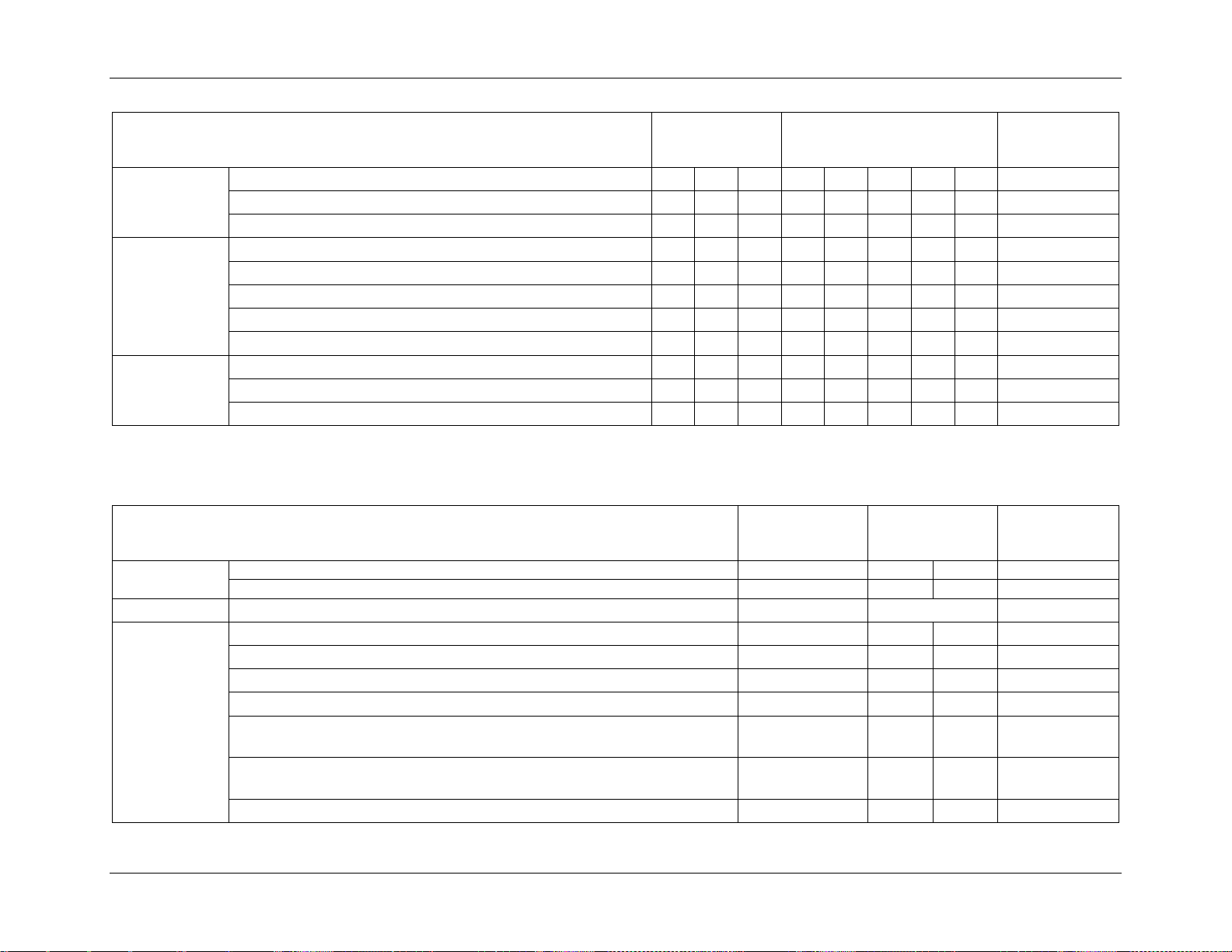

Parameter

Min

Rated

Max

Start-up VAC

Power-off VAC

110VAC

90 V

rms

100-127 V

rms

140 V

rms

85 VAC± 4VAC

70VAC±5VAC

220VAC

180 V

rms

200-240 V

rms

264 V

rms

85 VAC± 4VAC

70VAC±5VAC

Frequency

47 Hz

50/60 Hz

63 Hz

Output Power

10% Load

20% Load

50% Load

100% Load

Power factor

> 0.80

> 0.90

> 0.90

> 0.95

Loading

100% of Maximum

50% of Maximum

20% of Maximum

10% of Maximum

Minimum Efficiency

91%

94%

90%

82%

3.2 AC Input Specification

3.2.1 Input Voltage and Frequency

The power supply operates within all specified limits over the following input voltage range.

Table 9. AC Input Rating

Notes:

1. Maximum input current at low input voltage range is measured at 90VAC, at max load.

2. Maximum input current at high input voltage range is measured at 180VAC, at max load.

3. This requirement is not to be used for determining agency input current markings.

3.2.2 AC input Power Factor

The power supply meets the power factor requirements stated in the Energy Star* Program

Requirements for Computer Servers. These requirements are stated below.

Table 10. Typical Power Factor

3.2.3 Efficiency

The following table provides the required minimum efficiency level at various loading

conditions. These are provided at different load levels; 100%, 50%, 20%, and 10%. Output is

loaded according to the proportional loading method defined by 80 Plus in Generalized

Internal Power Supply Efficiency Testing Protocol, Rev 6.4.3.

Table 11. Platinum Efficiency Requirement

3.2.4 AC Line Fuse

The power supply has one line fused in the single line fuse on the line (Hot) wire of the AC

input. The line fusing is acceptable for all safety agency requirements. The input fuse is a slow

blow type. AC inrush current does not cause the AC line fuse to blow under any conditions. All

protection circuits in the power supply do not cause the AC fuse to blow unless a component

in the power supply has failed. This includes DC output load short conditions.

Revision 2.21

Page 32

Power Subsystem Intel® Server Chassis H2000G Product Family TPS

20

Loading

Holdup Time

70%

10.6msec

3.2.5 AC Line Inrush

AC line inrush current shall not exceed 65A peak, for up to one-quarter of the AC cycle, after

which, the input current should be no more than the specified maximum input current. The

peak inrush current shall be less than the ratings of its critical components (including input

fuse, bulk rectifiers, and surge limiting device).

The power supply meets the inrush requirements for any rated AC voltage, during turn on at

any phase of AC voltage, during a single cycle AC dropout condition as well as upon recovery

after AC dropout of any duration, and over the specified temperature range (Top).

3.2.6 AC Line Dropout/Holdup

An AC line dropout is defined to be when the AC input drops to 0VAC at any phase of the AC

line for any length of time. During an AC dropout the power supply meets dynamic voltage

regulation requirements. An AC line dropout of any duration shall not cause tripping of control

signals or protection circuits. If the AC dropout lasts longer than the holdup time, the power

supply should recover and meet all turn on requirements. The power supply shall meet the AC

dropout requirement over rated AC voltages and frequencies. A dropout of the AC line for any

duration shall not cause damage to the power supply.

Table 12. AC Power Holdup Requirement

The 12V

output voltage should stay in regulation under its full load (static or dynamic)

STB

during an AC dropout of 70ms min (=12VSB holdup time) whether the power supply is in ON

or OFF state (PSON asserted or de-asserted).

3.2.7 AC Line Fast Transient (EFT) Specification

The power supply meets the EN61000-4-5 directive and any additional requirements in

IEC1000-4-5: 1995 and the Level 3 requirements for surge-withstand capability, with the

following conditions and exceptions:

These input transients do not cause any out-of-regulation conditions, such as

overshoot and undershoot, nor do they cause any nuisance trips of any of the power

supply protection circuits.

The surge-withstand test does not produce damage to the power supply.

The supply meets surge-withstand test conditions under maximum and minimum DC-output

load conditions.

3.2.8 Hot Plug

The power supply is designed to allow connection into and removal from the chassis without

removing power to the chassis. During any phase of insertion, start-up, shutdown, or removal,

Revision 2.21

Page 33

Intel® Server Chassis H2000G Product Family TPS Power Subsystem

21

Level

Description

A

The apparatus shall continue to operate as intended. No degradation of performance.

B

The apparatus shall continue to operate as intended. No degradation of performance beyond

spec limits.

C

Temporary loss of function is allowed provided the function is self-recoverable or can be

restored by the operation of the controls.

the power supply does not cause any other like modules in the chassis to deviate outside of

their specifications. When AC power is applied, the auxiliary supply shall turn on providing

bias power internal to the supply and the 5VSB standby output.

3.2.9 Susceptibility Requirements

The power supply meets the following electrical immunity requirements when connected to a

cage with an external EMI filter, which meets the criteria, defined in the SSI document EPS

Power Supply Specification. For further information on customer standards, request a copy of

the customer Environmental Standards Handbook.

Table 13. Performance Criteria

3.2.10 Electrostatic Discharge Susceptibility

The power supply complies with the limits defined in EN 55024: 1998 using the IEC

61000-4-2:1995 test standard and performance criteria B defined in Annex B of CISPR 24.

3.2.11 Fast Transient/Burst

The power supply complies with the limits defined in EN 55024: 1998 using the IEC

61000-4-4:1995 test standard and performance criteria B defined in Annex B of CISPR 24.

3.2.12 Radiated Immunity

The power supply complies with the limits defined in EN 55024: 1998 using the IEC

61000-4-3:1995 test standard and performance criteria A defined in Annex B of CISPR 24.

3.2.13 Surge Immunity

The power supply is tested with the chassis for immunity to AC Ring wave and AC

Unidirectional wave, both up to 2kV, per EN 55024:1998, EN 61000-4-5:1995 and ANSI

C62.45: 1992.

The pass criteria include the following:

No unsafe operation is allowed under any condition

All power supply output voltage levels to stay within proper spec levels

No change in operating state or loss of data during and after the test profile

No component damage under any condition

Revision 2.21

Page 34

Power Subsystem Intel® Server Chassis H2000G Product Family TPS

22

AC Line Sag (10 sec interval between each sagging)

Duration

Sag

Operating AC Voltage

Line

Frequency

Performance Criteria.

0 to ½ AC

cycle

95%

Nominal AC Voltage

ranges

50/60Hz

No loss of function or performance.

> 1 AC cycle

>30%

Nominal AC Voltage

ranges

50/60Hz

Loss of function acceptable, selfrecoverable.

AC Line Surge

Duration

Surge

Operating AC Voltage

Line

Frequency

Performance Criteria

Continuous

10%

Nominal AC Voltages

50/60Hz

No loss of function or performance

0 to ½ AC

cycle

30%

Mid-point of nominal AC

Voltages

50/60Hz

No loss of function or performance

The power supply complies with the limits defined in EN 55024: 1998 using the IEC

61000-4-5:1995 test standard and performance criteria B defined in Annex B of CISPR 24.

3.2.14 AC Line Transient Specification

AC line transient conditions are defined as “sag” and “surge” conditions. “Sag” conditions are

also commonly referred to as “brownout”; these conditions are defined as the AC line voltage

dropping below nominal voltage conditions. “Surge” is defined to refer to conditions when the

AC line voltage rises above nominal voltage.

The power supply meets the requirements under the following AC line sag and surge

conditions.

Table 14. AC Line Sag Transient Performance

Table 15. AC Line Surge Transient Performance

3.2.15 Power Recovery

The power supply recovers automatically after an AC power failure. AC power failure is

defined to be any loss of AC power that exceeds the dropout criteria.

3.2.16 Voltage Interruptions

The power supply complies with the limits defined in EN 55024: 1998/A1: 2001/A2: 2003

using the IEC 61000-4-11: Second Edition: 2004-03 test standard and performance criteria C

defined in Annex B of CISPR 24.

3.2.17 AC Line Isolation

The power supply meets all safety agency requirements for dielectric strength. Transformers’

isolation between primary and secondary windings complies with the 3000Vac (4242Vdc)

dielectric strength criteria. If the working voltage between primary and secondary dictates a

Revision 2.21

Page 35

Intel® Server Chassis H2000G Product Family TPS Power Subsystem

23

Cable Type

SJT

Wire Size

16 AWG

Temperature Rating

105ºC

Amperage Rating

13 A

Voltage Rating

125 V

higher dielectric strength test voltage, the highest test voltage will be used. In addition the

insulation chassis complies with reinforced insulation per safety standard IEC 950. Separation

between the primary and secondary circuits, and primary to ground circuits, complies with the

IEC 950 spacing requirements.

3.2.18 AC Power Inlet

The AC input connector is an IEC 320 C-14 power inlet. This inlet is rated for 10A/250 VAC.

The AC power cord meets the following specification requirements.

Figure 18. AC Power Cord Specification

Revision 2.21

Page 36

Power Subsystem Intel® Server Chassis H2000G Product Family TPS

24

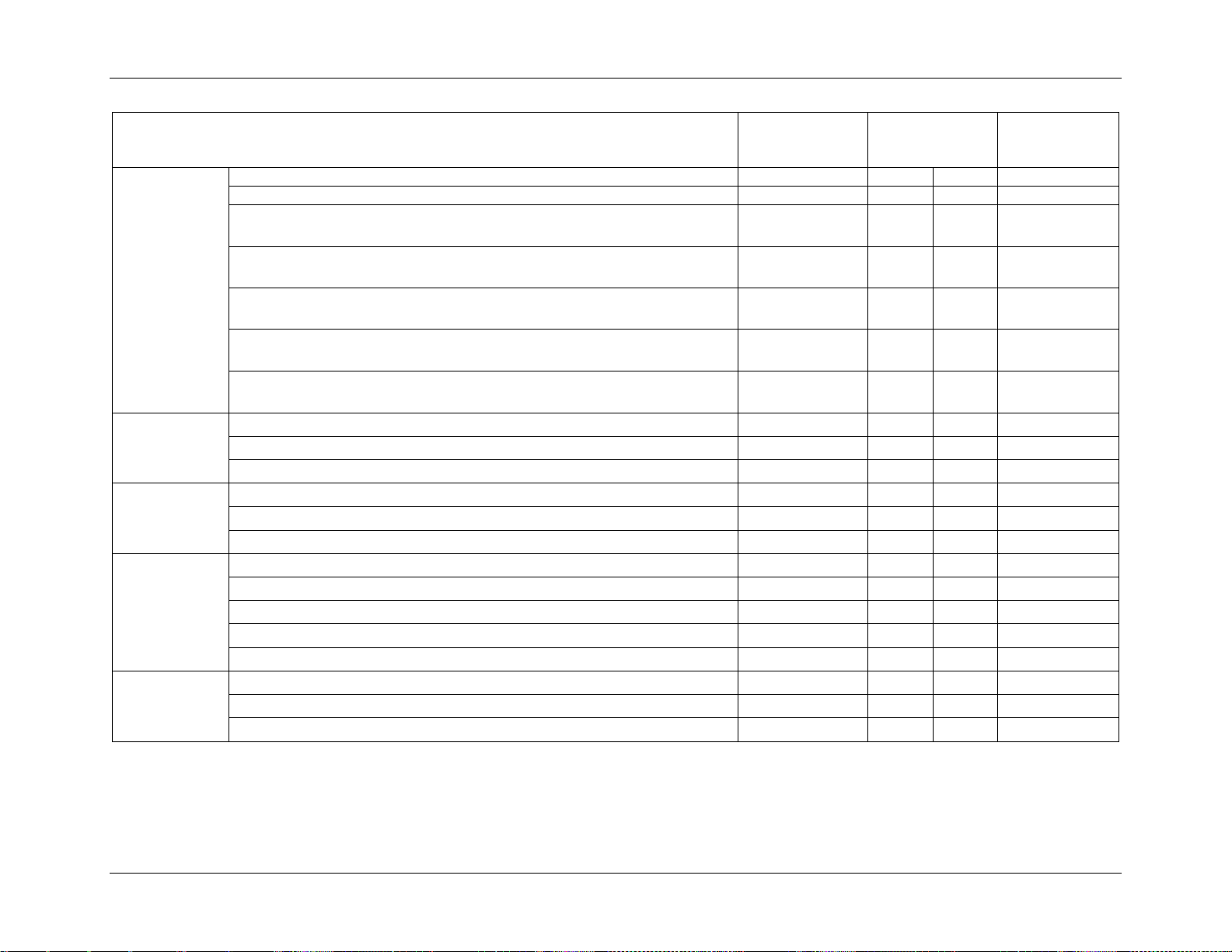

Parameter

Min

Max

Peak 2

Unit

+12V main (200-240VAC)

0.0

133

175 A +12VSTB 1

0.0

3.5

2.4

A

Vin

≥100VAC

≥110VAC

≥120VAC

P

o.max

1130W

1250W

1320W

Parameter

Min

Nom

Max

Unit

Tolerance

+12V

STB

+11.40V

+12.000V

+12.60V

Vrms

±5%

+12V

+11.40V

+12.000V

+12.60V

Vrms

±5%

3.3 DC Output Specification

3.3.1 Output Power/Currents

The following table defines the minimum power and current ratings. The power supply meets

both static and dynamic voltage regulation requirements for all conditions.

Table 16. Load Ratings for Single 1600W Power Supply Unit

Power rating for AC low line

Notes:

1. 12V

2. Length of time peak power can be supported based on thermal sensor and assertion of the SMBAlert#

3. The setting of I

4. The power supply must protect itself in case the system doesn't take any action based on SMBAlert/OCW

provides 4.0A peak load with single power supply. The power supply fan is allowed to run in

STB

standby mode for loads > 1.5A.

signal. Minimum peak power duration shall be 20 seconds without asserting the SMBAlert# signal.

< I

< I

needs to be followed to make the CLST work reasonably.

OCP

event.

Peak

OCW

3.3.2 Standby Output

The 12VSB output will be present when an AC input greater than the power supply turn on

voltage is applied.

3.3.3 Voltage Regulation

The power supply output voltages stay within the following voltage limits when operating at

steady state and dynamic loading conditions. These limits include the peak-peak ripple/noise.

These shall be measured at the output connectors.

Table 17. Voltage Regulation Limits

The combined output continuous power of all outputs does not exceed 3200W (1600W from

each 1600W power supply unit) or 4260W (2130W from each 2130W power supply unit).

Each output has a maximum and minimum current rating. The power supply meets both static

and dynamic voltage regulation requirements for the minimum dynamic loading conditions.

Revision 2.21

Page 37

Intel® Server Chassis H2000G Product Family TPS Power Subsystem

25

Output

Step Load Size

Load Slew Rate

Test Capacitive Load

+12V

STB

1.0A

0.25 A/sec

20 F

+12V

60% of max load

0.25 A/sec

2000 F

Output

Min

Max

Units

+12V

500

25,000

F

+12V

STB

20

3100

F

+12V

+12V

STB

120mVp-p

120mVp-p

The power supply meets only the static load voltage regulation requirements for the minimum

static load conditions.

3.3.4 Dynamic Loading

The output voltages remain within limits specified for the step loading and capacitive loading

specified in the table below. The load transient repetition rate is tested between 50Hz and

5kHz at duty cycles ranging from 10%-90%. The load transient repetition rate is only a test

specification. The step load may occur anywhere within the MIN load to the MAX load

conditions.

Table 18. Transient Load Requirements

Note: For dynamic condition +12V min loading is 1A.

3.3.5 Capacitive Loading

The power supply is stable and meets all requirements, with the following capacitive loading

conditions.

Table 19. Capacitive Loading Conditions

3.3.6 Ripple/Noise

The maximum allowed ripple/noise output of the power supply is defined in the table below.

This is measured over a bandwidth of 10Hz to 20MHz at the power supply output connectors.

A 10F tantalum capacitor in parallel with a 0.1F ceramic capacitor is placed at the point of

measurement.

Table 20. Ripple and Noise

3.3.7 Grounding

The output ground of the pins of the power supply provides the output power return path.

The output connector ground pins are connected to the safety ground (power supply

enclosure). This grounding is well designed to ensure passing the max allowed Common Mode

Noise levels.

Revision 2.21

Page 38

Power Subsystem Intel® Server Chassis H2000G Product Family TPS

26

The power supply is provided with a reliable protective earth ground. All secondary circuits

are connected to protective earth ground. Resistance of the ground returns to chassis does

not exceed 1.0 m. This path may be used to carry DC current.

3.3.8 Closed Loop Stability

The power supply is unconditionally stable under all line/load/transient load conditions

including capacitive load ranges specified in Section 3.3.5. A minimum of 45 degrees phase

margin and -10dB-gain margin is required. The power supply manufacturer shall provide

proof of the unit’s closed-loop stability with local sensing through the submission of Bode

plots. Closed-loop stability must be ensured at the maximum and minimum loads as

applicable.

3.3.9 Residual Voltage Immunity in Standby Mode

The power supply is immune to any residual voltage placed on its outputs (typically a leakage

voltage through the chassis from standby output) up to 500mV. There is no additional heat

generated, nor stressing of any internal components with this voltage applied to any

individual or all outputs simultaneously. It also does not trip the protection circuits during turn

on.

The residual voltage at the power supply outputs for no load condition will not exceed 100mV

when AC voltage is applied and the PSON# signal is de-asserted.

3.3.10 Common Mode Noise

The Common Mode noise on any output does not exceed 350mVp-p over the frequency band

of 10Hz to 20MHz.

The measurement is made across a 100Ω resistor between each of DC outputs,

including ground at the DC power connector and chassis ground (power subsystem

enclosure).

The test setup uses a FET probe such as Tektronix model P6046 or equivalent.

3.3.11 Soft Starting

The power supply contains control circuit which provides monotonic soft start for its outputs

without overstress of the AC line or any power supply components at any specified AC line or

load conditions.

3.3.12 Zero Load Stability Requirement

When the power subsystem operates in a no load condition, it does not need to meet the

output regulation specification, but it must operate without any tripping of over-voltage or

other fault circuitry. When the power subsystem is subsequently loaded, it must begin to

regulate and source current without fault.

Revision 2.21

Page 39

Intel® Server Chassis H2000G Product Family TPS Power Subsystem

27

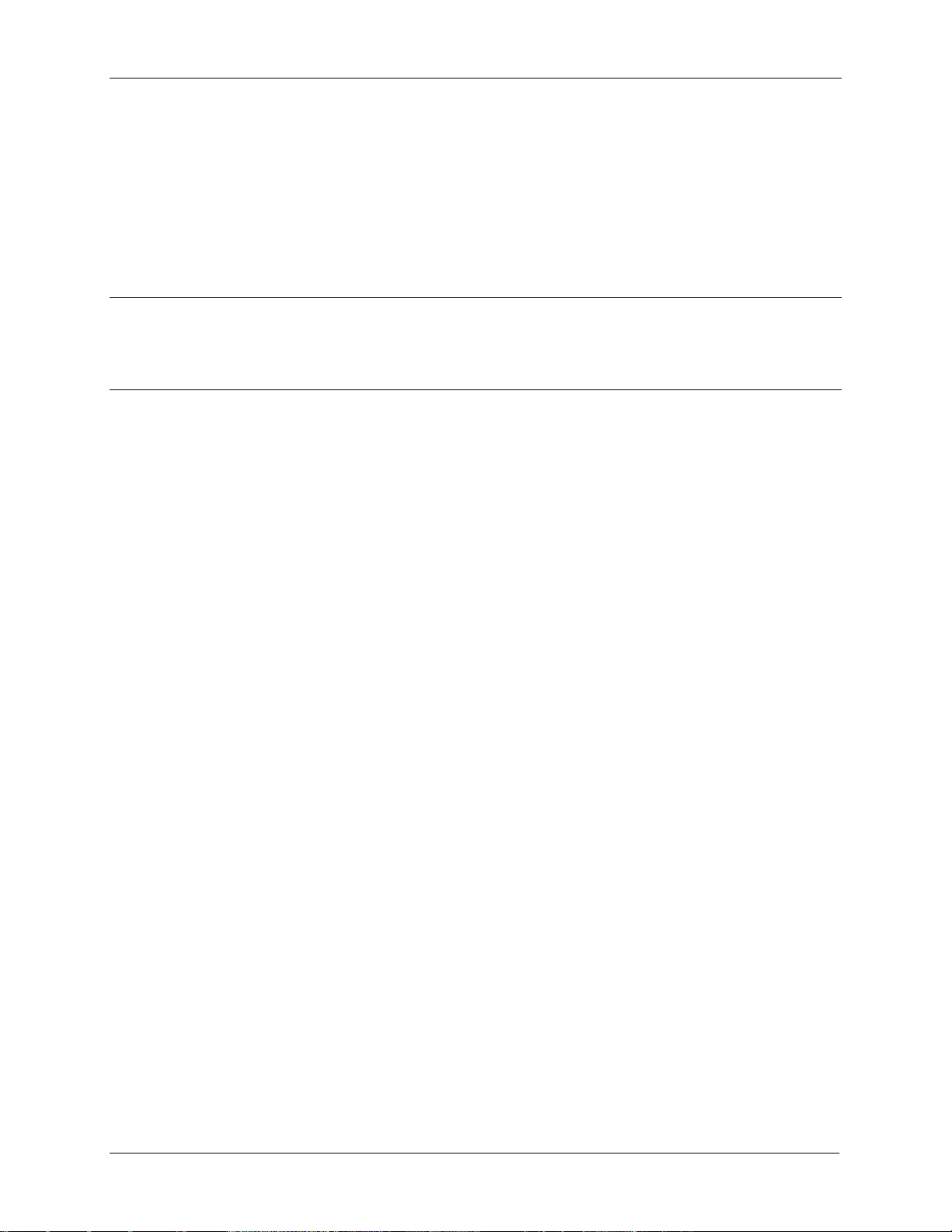

Item

Description

Min.

Max.

Units

T

vout_rise

Output voltage rise time

5.0 *

70 *

ms

T

sb_on_delay

Delay from AC being applied to 12VSBbeing within

regulation.

1500

ms

T

ac_on_delay

Delay from AC being applied to all output voltages being

within regulation.

3000

ms

T

vout_holdup

Time 12Vl output voltage stay within regulation after loss

of AC.

13 ms

T

pwok_holdup

Delay from loss of AC to de-assertion of PWOK

10.6

ms

T

pson_on_delay

Delay from PSON# active to output voltages within

regulation limits.

5

400

ms

T

pson_pwok

Delay from PSON# deactivate to PWOK being de-asserted.

5 ms

T

pwok_on

Delay from output voltages within regulation limits to

PWOK asserted at turn on.

100

500

ms

T

pwok_off

Delay from PWOK de-asserted to output voltages dropping

out of regulation limits.

1 ms

T

pwok_low

Duration of PWOK being in the de-asserted state during an

off/on cycle using AC or the PSON signal.

100 ms

T

sb_vout

Delay from 12VSBbeing in regulation to O/Ps being in

regulation at AC turn on.

50

1000

ms

3.3.13 Hot Swap Requirement

Hot swapping a power supply is the process of inserting and extracting a power supply from

an operating power system. During this process the output voltages remain within the limits

with the capacitive load specified. The hot swap test must be conducted when the system is

operating under static, dynamic, and zero loading conditions. The power supply will use a

latching mechanism to prevent insertion and extraction of the power supply when the AC

power cord is inserted into the power supply.

3.3.14 Forced Load Sharing

The +12V output has active load sharing. The output will share within 10% at full load. The

failure of a power supply will not affect the load sharing or output voltages of the other

supplies still operating. The supplies are able to load share in parallel and operate in a

hot-swap/redundant 1+1 configurations. The 12VSBoutput is not required to actively share

current between power supplies (passive sharing). The 12VSBoutput of the power supplies is

connected together in the system so that a failure or hot swap of a redundant power supply

does not cause these outputs to go out of regulation in the system.

3.3.15 Timing Requirement

These are the timing requirements for the power supply operation. The output voltages must

rise from 10% to within regulation limits (T

) within 5 to 70ms. For 12VSB, it is allowed to

vout_rise

rise from 1.0 to 25ms. All outputs must rise monotonically. The table below shows the timing

requirements for the power supply being turned on and off through the AC input, with PSON

held low and the PSON signal, with the AC input applied.

Table 21. Timing Requirement

Revision 2.21

Page 40

Power Subsystem Intel® Server Chassis H2000G Product Family TPS

28

T

12VSB_holdup

Time the 12VSBoutput voltage stays within regulation after

loss of AC.

70 ms

AC Input

Vout PWOK

12Vsb

PSON

T

sb_on_delay

T

AC_on_delay