Page 1

Revision 1.5

Intel

®

Server Chassis H2000 Family

Technical Product Specification

Intel order number: G59059-006

April, 2015

Enterprise Platforms and Services Division

Page 2

Revision History Intel® Server Chassis H2000 Family TPS

Date

Revision Number

Modifications

Updated link to Rail Specification.

Updated warning message on PSU configuration.

July, 2013

1.4

Updated chassis usage model.

Revision History

February, 2012 1.0 Initial release .

July, 2012 1.1 Updated safety notice for rail kit.

August, 2012 1.2 Updated power redundancy mode.

November, 2012 1.3

April, 2015 1.5 Updated LAN (i350 Dual NIC) LED behavior.

ii

Revision 1.5

Intel order number: G59059-006

Page 3

Intel® Server Chassis H2000 Family TPS Disclaimers

Disclaimers

INFORMATION IN THIS DOCUMENT I S PRO VIDED IN CONNECTION WITH INTEL®

PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE, TO

ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS

PROVIDED IN INTEL

INTEL

®

ASSUMES NO LIABILITY WHATSOEVER AND INTEL® DISCLAIMS ANY EXPRESS

OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL

INCLUDING LIABILITY OR W ARRANTIES RELAT I NG TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRI GHT OR

OTHER INTELLECTUAL PROPERTY RIGHT.

A "Mission Critical Application" is any application in which failure of the Intel

result, directly or indirectly, in personal injury or death. SHOULD YOU PURCHASE OR USE

INTEL

®

'S PRODUCTS FOR ANY SUCH MISSION CRITICA L AP PLICATION, YOU SHALL

INDEMNIFY AND HOLD INTEL

AFFILIATES, AND THE DIRECTORS, OFFICERS, AND EMPLOYEES OF EACH, HARMLESS

AGAINST ALL CLAIMS COSTS, DAMAGES, AND EXPENSES AND REASONABLE

ATTORNEYS' FEES ARISING OUT OF, DIRECTLY OR INDIRECTLY, ANY CLAIM OF

PRODUCT LIABILITY, PERSONAL INJURY, OR DEATH ARISING IN ANY WAY OUT OF

SUCH MISSION CRITICAL APPLICATIO N, W HET HER OR NOT INTEL

SUBCONTRACTOR WAS NEGLIGENT IN THE DESIGN, MANUFACTURE, OR WARNING OF

THE INTEL

®

PRODUCT OR ANY OF ITS PARTS.

®

Intel

may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked

"reserved" or "undefined". Intel

responsibility whatsoever for conflicts or incompatibilities arising from future changes to them.

The information here is subject to change without notice. Do not finalize a design with this

information.

The products described in this document may contain design defects or errors known as errata

which may cause the product to deviate from published specifications. Current characterized

errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and

before placing your product order.

Copies of documents which have an order number and are referenced in this document, or

other Intel

®

literature, may be obtained by calling 1-800-548-4725, or go to:

http://www.intel.com/design/literature

®

'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS,

®

PRODUCTS

®

Product could

®

AND ITS SUBSIDIARIES, SUBCONTRACT O RS AND

®

OR ITS

®

reserves these for future definition and shall have no

.

Revision 1.5

Intel order number: G59059-006

iii

Page 4

Table of Contents Intel® Server Chassis H2000 Family TPS

Table of Contents

1. Introduction ........................................................................................................................ 1

1.1 Chapter Outline ...................................................................................................... 1

1.2 Server Board Use Disclaimer ................................................................................. 2

2. Product Overview ............................................................................................................... 3

2.1 Chassis Views ........................................................................................................ 4

2.2 Chassis Dimensions ............................................................................................... 5

2.3 System Level Environmental Limits ........................................................................ 5

2.4 Chassis Parts ......................................................................................................... 6

2.5 Hard Drive and Peripheral Bays ............................................................................. 7

2.6 Front Bezel Support ............................................................................................... 8

2.7 Rack and Cabinet Mounting Options ...................................................................... 8

3. Power Sub-System ........................................................................................................... 10

3.1 Mechanical Overview ........................................................................................... 10

3.1.1 AC Power Supply Unit Dimension Overview ........................................................ 10

3.1.2 AC Power Supply Unit General Data .................................................................... 11

3.1.3 AC input connector ............................................................................................... 11

3.1.4 AC Power Cord Specification Requirements ........................................................ 11

3.1.5 Power Supply Unit DC Output Connector ............................................................. 11

3.1.6 Handle Retention ................................................................................................. 12

3.1.7 LED Marking and Identification ............................................................................. 12

3.1.8 Power Cage with Power Distribution Board .......................................................... 13

3.1.9 Power Cage Output Pin Assignment .................................................................... 14

3.2 AC Input Specification .......................................................................................... 16

3.2.1 Input Voltage And Frequency ............................................................................... 16

3.2.2 AC input Power Factor ......................................................................................... 16

3.2.3 Efficiency .............................................................................................................. 17

3.2.4 AC Line Fuse ....................................................................................................... 17

3.2.5 AC Line Inrush ..................................................................................................... 17

3.2.6 AC Line Dropout/Holdup ...................................................................................... 18

3.2.7 AC Line Fast Transient (EFT) Specification .......................................................... 18

3.2.8 Hot Plug ............................................................................................................... 18

3.2.9 Susceptability Requirements ................................................................................ 18

3.2.10 Electrostatic Discharge Susceptibility ................................................................... 19

3.2.11 Fast Transient/Burst ............................................................................................. 19

3.2.12 Radiated Immunity ............................................................................................... 19

3.2.13 Surge Immunity .................................................................................................... 19

3.2.14 AC Line Transient Specification ........................................................................... 19

3.2.15 Power Recovery ................................................................................................... 20

iv

Revision 1.5

Intel order number: G59059-006

Page 5

Intel® Server Chassis H2000 Family TPS Table of Contents

3.2.16 Voltage Interruptions ............................................................................................ 20

3.2.17 AC Line Isolation .................................................................................................. 20

3.2.18 AC Power Inlet ..................................................................................................... 21

3.3 DC Ouput Specification ........................................................................................ 21

3.3.1 Output Power/Currents ......................................................................................... 21

3.3.2 Standby Output .................................................................................................... 22

3.3.3 Voltage Regulation ............................................................................................... 22

3.3.4 Dynamic Loading ................................................................................................. 22

3.3.5 Capacitive Loading ............................................................................................... 23

3.3.6 Ripple/Noise ......................................................................................................... 23

3.3.7 Grounding ............................................................................................................ 23

3.3.8 Closed Loop Stability ............................................................................................ 24

3.3.9 Residual Voltage Immunity in Standby Mode ....................................................... 24

3.3.10 Common Mode Noise ........................................................................................... 24

3.3.11 Soft Starting ......................................................................................................... 24

3.3.12 Zero Load Stability Requirement .......................................................................... 24

3.3.13 Hot Swap Requirement ........................................................................................ 24

3.3.14 Forced Load Sharing ............................................................................................ 25

3.3.15 Timing Requirement ............................................................................................. 25

3.4 Power Supply Cold Redundancy Support ............................................................. 26

3.4.1 1200W CRPS Cold Redundancy .......................................................................... 27

3.4.2 1600W CRPS Cold Redundancy .......................................................................... 28

3.5 Control And Indicator Functions ........................................................................... 28

3.5.1 PSON# Input Signal ............................................................................................. 28

3.5.2 PWOK(power good) Output Signal ....................................................................... 28

3.5.3 SMBAlert# Signal ................................................................................................. 29

3.6 Protection circuits ................................................................................................. 30

3.6.1 Curren t Limit (OCP).............................................................................................. 30

3.6.2 Over Voltage Protection (OVP) ............................................................................ 30

3.6.3 Over Thermal protection ....................................................................................... 30

3.7 PMBus* ................................................................................................................ 31

3.7.1 PSU Address Lines A0 ......................................................................................... 31

3.7.2 Accuracy .............................................................................................................. 32

3.8 Power Management Policy ................................................................................... 33

4. Cooling Sub-System......................................................................................................... 35

4.1 Power Supply Fan ................................................................................................ 35

4.2 Drive Bay Population Requirement ....................................................................... 35

5. Hard Disk Drive Support .................................................................................................. 36

5.1 Hard Disk Drive Bays Scheme ............................................................................. 36

5.2 Hard Drive Carrier ................................................................................................ 37

5.3 Hot-Swap Hard Drive Support .............................................................................. 37

Revision 1.5

Intel order number: G59059-006

v

Page 6

Table of Contents Intel® Server Chassis H2000 Family TPS

5.3.1 Backplane Feature set: ........................................................................................ 38

5.3.2 Backplane Block Diagram .................................................................................... 38

5.3.3 3.5" Hot Swap Backplane Connector scheme ...................................................... 39

5.3.4 2.5" Hot Swap Backplane Connector scheme ...................................................... 40

5.3.5 Backplane LED Support ....................................................................................... 42

5.3.6 Backplane Connector Definition ........................................................................... 43

6. Front Panel Control and Indicators ................................................................................. 48

6.1 Control Panel Button ............................................................................................ 49

6.2 Control Panel LED Indicators ............................................................................... 49

6.2.1 Power/Sleep LED ................................................................................................. 50

6.2.2 System Status LED .............................................................................................. 50

6.2.3 System Status LED – BMC Initialization ............................................................... 52

Appendix A: Integration and Usage Tips .............................................................................. 53

Glossary .................................................................................................................................. 54

Reference Documents ............................................................................................................ 57

vi

Revision 1.5

Intel order number: G59059-006

Page 7

Intel® Server Chassis H2000 Family TPS List of Figures

List of Figures

Figure 1. Chassis Overview (H2312xx SKU) ............................................................................... 4

Figure 2. Power Supply Scheme (Rear View) ............................................................................. 4

Figure 3. Dummy Tray Cover ...................................................................................................... 4

Figure 4. Major Chassis Parts ..................................................................................................... 7

®

Figure 5. Intel

Figure 6. Intel

Figure 7. Chassis Bezel Front View ............................................................................................ 8

Figure 8. AC Power Supply Unit Dimension Overview .............................................................. 10

Figure 9. Power Cage Overview ............................................................................................... 14

Figure 10. Power distribution board ........................................................................................... 15

Figure 11. AC Power Cord Specification ................................................................................... 21

Figure 12. Turn On/Off Timing (Power Supply Signals) ............................................................. 26

Server Chassis H2312xx Drive Bay Front View .................................................. 8

®

Server Chassis H2216xx Drive Bay Front View .................................................. 8

Figure 13. Power Supply Device Address ................................................................................. 31

Figure 14. PMBus Monitoring Accuracy .................................................................................... 33

Figure 15. HDD Scheme for H2312xx ....................................................................................... 36

Figure 16. HDD Scheme for H2216xx ....................................................................................... 36

Figure 17. 3.5" HDD Assembly Overview .................................................................................. 37

Figure 18. 2.5" HDD Assembly Overview .................................................................................. 37

Figure 19. Passive Backplane Block Diagram (for one node) .................................................... 39

Figure 20. 3.5" Backplane Component and Connectors (Front View) ........................................ 39

Figure 21. 3.5" Backplane Component and Connectors (Back View) ........................................ 40

Figure 22. 2.5" Backplane Component and Connectors (Front View) ........................................ 41

Figure 23. 2.5" Backplane Component and Connectors (Back View) ........................................ 41

Figure 24. Hard Drive Carrier LED ............................................................................................ 42

Figure 25. Front Control Panel .................................................................................................. 49

Revision 1.5

Intel order number: G59059-006

vii

Page 8

List of Tables Intel® Server Chassis H2000 Family TPS

List of Tables

Table 1. Chassis Feature Set ...................................................................................................... 3

Table 2. Chassis SKU Matrix ...................................................................................................... 3

Table 3. Chassis Dimension (SKU: H2312xxJR/KR) ................................................................... 5

Table 4. Chassis Dimension (SKU: H2216xxJR/KR) ................................................................... 5

Table 5. System Environmental Limits Summary ........................................................................ 5

Table 6. Specification Data for AC Power Supply Unit .............................................................. 11

Table 7. AC power cord specification ........................................................................................ 11

Table 8. DC Output Power Connector ....................................................................................... 11

Table 9. Power Supply Status LED ........................................................................................... 13

Table 10. Pin assignment of power ouput connector ................................................................. 15

Table 11. Pin assignment of control signal connector................................................................ 16

Table 12. AC input rating .......................................................................................................... 16

Table 13. Typical power factor .................................................................................................. 17

Table 14. Platinum Efficiency Requirement ............................................................................... 17

Table 15. AC Power Holdup Reuqirement ................................................................................. 18

Table 16. Performance Criteria ................................................................................................. 19

Table 17. AC Line Sag Transient Performance ......................................................................... 20

Table 18. AC Line Surge Transient Performance ...................................................................... 20

Table 19. Load Ratings for single power supply unit ................................................................. 21

Table 20. Voltage Regulation Limits .......................................................................................... 22

Table 21. Transient Load Requirements ................................................................................... 22

Table 22. Capacitive Loading Conditions .................................................................................. 23

Table 23. Ripple and Noise ....................................................................................................... 23

Table 24. Timing Requirement .................................................................................................. 25

Table 25. 1200W CRPS Cold Redundancy Threshold. ............................................................. 27

Table 26. 1600W CRPS Cold Redundancy Threshold. ............................................................. 28

Table 27. PSON# Signal Characteristics. .................................................................................. 28

Table 28. PWOK Signal Characteristics .................................................................................... 29

Table 29. SMBAlert# Signal Characteristics .............................................................................. 29

Table 30. Over Current Protection............................................................................................. 30

Table 31. Over Voltage Protection (OVP) Limits ....................................................................... 30

Table 32. PSU addressing ........................................................................................................ 32

Table 33. PMBus Accuracy ....................................................................................................... 32

Table 34. Power Management Policy ........................................................................................ 33

viii

Revision 1.5

Intel order number: G59059-006

Page 9

Intel® Server Chassis H2000 Family TPS List of Tables

Table 35. Hard Drive Carrier Status LED Functions .................................................................. 42

Table 36. Hard Drive Carrier Activity LED Functions ................................................................. 42

Table 37. Backplane Input Power Connector Pin-out ................................................................ 43

Table 38. 2-Blade Compute Node Power Connector Pin-out..................................................... 43

Table 39. 2x40 Pin Connector Pin-out for Node Bridge Board ................................................... 44

Table 40. Front Panel Connector Pin-out .................................................................................. 46

Table 41. Power Supply Control Connector Pin-out .................................................................. 47

Table 42. Front Control Button Function.................................................................................... 49

Table 43. Front LED Indicator Functions ................................................................................... 49

Table 44. Power LED Operation ............................................................................................... 50

Table 45. System Status LED Operation ................................................................................... 50

Revision 1.5

Intel order number: G59059-006

ix

Page 10

List of Tables Intel® Server Chassis H2000 Family TPS

<This page is intentionally left blank.>

x

Revision 1.5

Intel order number: G59059-006

Page 11

Intel® Server Chassis H2000 Family TPS Introduction

1.1

Chapter Outline

1. Introduction

This Technical Product Specification (TPS) provides system specific information detailing the

features, functionality, and high-level architecture of the Intel

You should also reference the Intel

®

Server System H2000JF, H2000WP, H2000LP Family

®

Server Chassis H2000 family.

Technical Product Specification to obtain greater detail of functionality and archit ecture of the

server board integrated in this server system.

In addition, you can obtain design-level information for specific sub-systems by ordering the

External Product Specifications (EPS) or External Design Specifications (EDS) for a given subsystem. EPS and EDS documents are not publicly available. They are only made available

under NDA with Intel

®

and must be ordered through your local Intel® representative. For a

complete list of available documents, refer to the Reference Documents section at the end of

this document.

The Intel

may cause the product to deviate from published specifications. Refer to the Intel

S2600JF/Intel

®

Server Chassis H2000 may contain design defects or errors known as errata which

®

Server System H2000JF Specification Update for published errata.

®

Server Board

This document is divided into the following chapters:

Chapter 1 – Introduction

Chapter 2 – Product Overview

Chapter 3 – Power Sub-System

Chapter 4 – Cooling Sub-System

Chapter 5 – Hard Disk Drive Support

Chapter 6 – Front Panel Control and Indicators

Appendix A – Integration and Usage Tips

Glossary

Reference Documents

Revision 1.5

Intel order number: G59059-006

1

Page 12

Introduction Intel® Server Chassis H2000 Family TPS

1.2

Server Board Use Disclaimer

Intel Corporation server boards support add-in peripherals and contain a number of high-density

VLSI and power delivery components that need adequate airflow to cool. Intel

its own chassis development and testing that when Intel

®

server building blocks are used

®

ensures through

together, the fully integrated system will meet the intended thermal requirements of these

components. It is the responsibility of the system integrator who chooses not to use Intel

®

developed server building blocks to consult vendor datasheets and operating parameters to

determine the amount of air flow required for their specific application and environmental

conditions. Intel Corporation cannot be held responsible if components fail or the server board

does not operate correctly when used outside any of their published operating or

non-operating limits.

2

Revision 1.5

Intel order number: G59059-006

Page 13

Intel® Server Chassis H2000 Family TPS Product Overview

Feature

Description

Hard Disk Drive

12x 3.5-inch SATA/SAS HDD bays or 16x 2.5-inch SATA/SAS HDD bays.

System Power

1200w AC Common Redundant Power Supply (CRPS), 80 plus Platinum with PFC, supporting

Chassis SKU

3.5" HDD support

2.5" HDD support

1200W CRPS

H2312xxJR

H2216xxJR

1600W CRPS

H2312xxKR

H2216xxKR

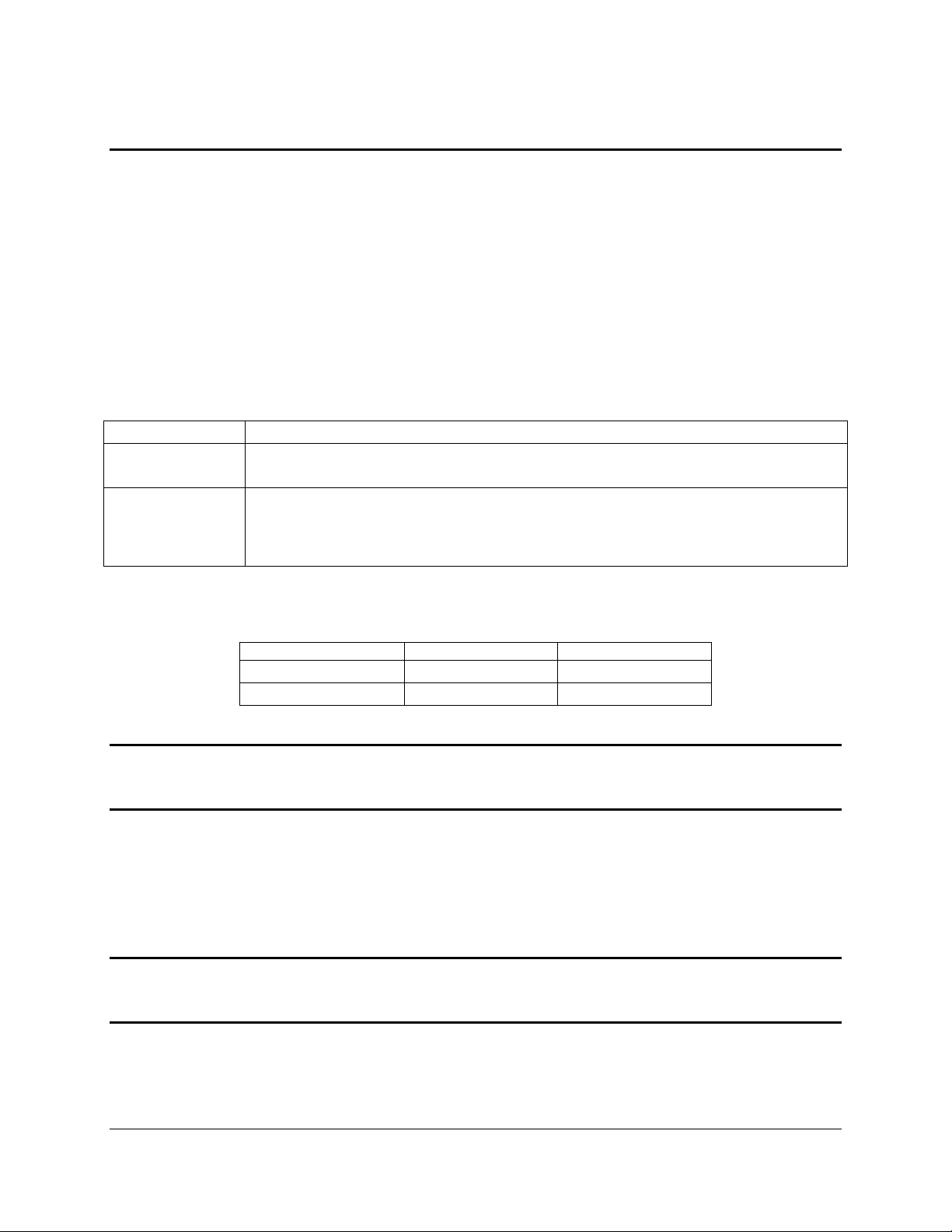

2. Product Overview

The Intel® Server Chassis H2000 family includes two major SKUs: H2312xxJR/KR and

H2216xxJR/KR, which are supporting rack mount 2U 4-node server systems, purpose-built for

high-density and lowest total cost of ownership in dense computing applications, such as HPC

and IPDC. The chassis can be used to integrate with four units of node trays which are built with

®

Intel

Server Board S2600JF, S2600WP or S2400LP, supports up to twelve 3.5" or sixteen 2.5"

hot-swap SAS or SATA hard drives, with 1200 Watts or 1600 Watts Common Redundant Power

Supply(CRPS) capability .

This chapter provides a high-level overview of the chassis features. The following chapters

provide greater detail for each major chassis component or feature.

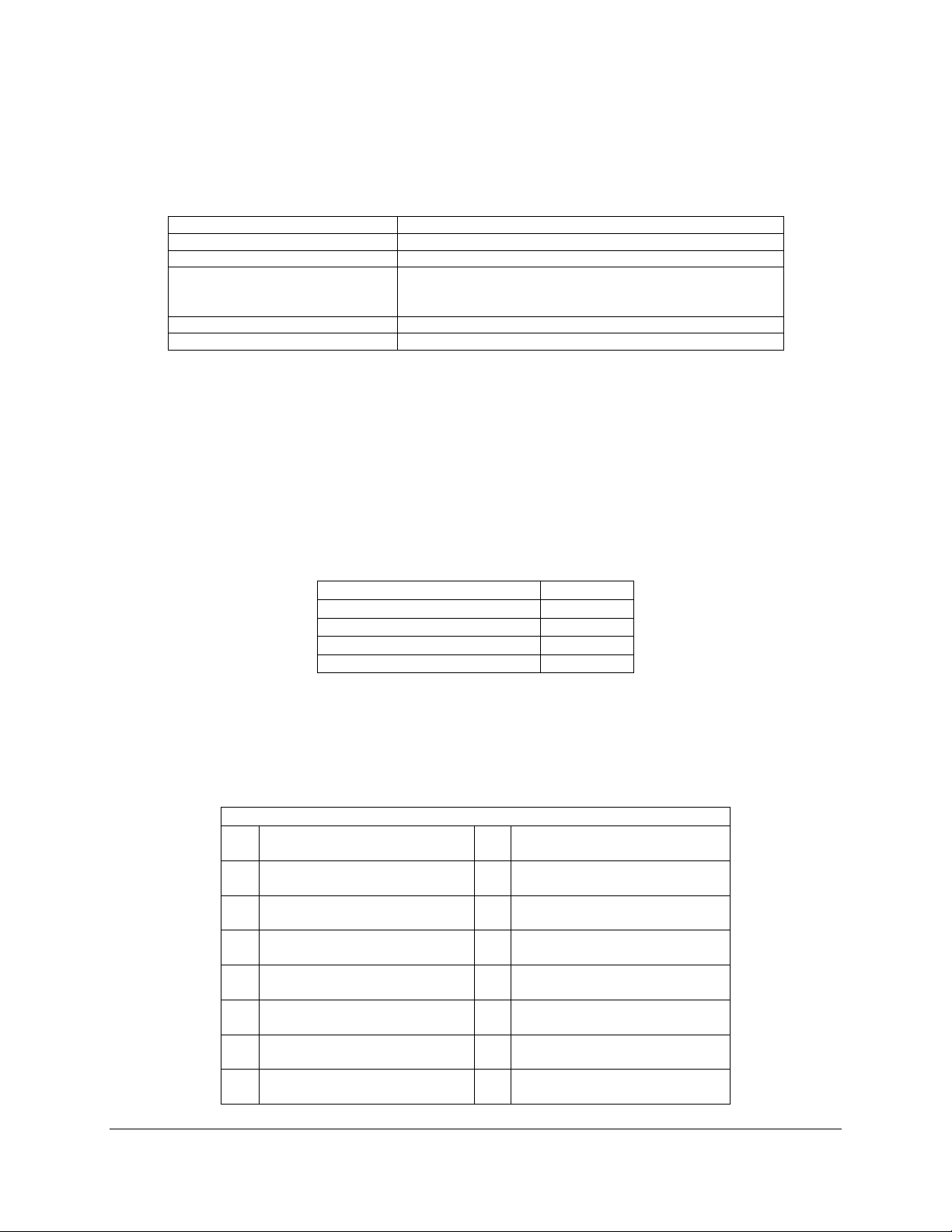

Table 1. Chassis Featu re Set

Supported

CRPS configuration, or

1600w AC Common Redundant Power Supply (CRPS), 80 plus Platinum with PFC, supporting

CRPS configuration. Chassis.

Table 2. Chassis SKU Matrix

Caution: Installing two Power Supply Units with different wattage ratings on a system is not

supported. This will not provide Power Supply Redundancy and causes the system to log

multiple errors.

The Intel® Server Chassis H2000 family supports node trays which are built with Intel® Server

Board S2600JF, S2600WP, or S2400LP.

The Intel

®

Server Chassis H2000 family also supports different node quantity in the same

chassis. The compute node quantity can be at least 1, and up to 4 in one chassis.

Caution: The chassis doesn’t support mixed node configuration, for example, compute nodes

based on different Intel® Server Board S2600JF, S2600WP, or S2400LP cannot be installed in

the same chassis.

Revision 1.5 3

Intel order number: G59059-006

Page 14

Product Overview Intel® Server Chassis H2000 Family TPS

2.1

Chassis Views

Figure 1. Chassis Overview (H2312xx SKU)

Figure 2. Power Supply Scheme (Rear View)

Figure 3. Dummy Tray Cover

4

Revision 1.5

Intel order number: G59059-006

Page 15

Intel® Server Chassis H2000 Family TPS Product Overview

2.2

Chassis Dimensions

Height

87.9 mm

3.46"

Width

438 mm

17.24"

Depth

771 mm

30.35"

Height

87.9 mm

3.46"

Width

438 mm

17.24"

Depth

733 mm

28.86"

2.3

System Level Environmental Limits

Parameter

Limits

Table 3. Chassis Dimension (SKU: H2312xxJR/KR)

Table 4. Chassis Dimension (SKU: H2216xxJR/KR)

The following table defines the system level operating and non-operatin g environmental limits.

Table 5. System Environmental Limits Summary

Temperature

Operating 10ºC to 35ºC (50ºF to 95ºF) with the maximum rate of change not to exceed 10°C

per hour

Non-Operating -40º C to 70º C (-40º F to 149º F)

Humidity

Non-Operating 50% to 90%, non-condensing with a maximum wet bulb of 28° C (at temperatures

from 25°C to 35°C)

Shock

Operating Half sine, 2g, 11 mSec

Unpackaged Trapezoidal, 25g, velocity change is based on packaged weight

Packaged Product Weight: ≥ 40 to < 80

Non-palletized Free Fall Height = 18 inches

Palletized (single product) Free Fall Height = NA

Vibration

Unpackaged 5 Hz to 500 Hz 2.20 g RMS random

Packaged 5 Hz to 500 Hz 1.09 g RMS random

AC-DC

Voltage 90 V to 132 V and 180 V to 264 V

Frequency 47 Hz to 63 Hz

Source

Interrupt

No loss of data for power line drop-out of 12 mSec

Revision 1.5 5

Intel order number: G59059-006

Page 16

Product Overview Intel® Server Chassis H2000 Family TPS

Parameter

Limits

-16 to 3048 m (-50 to 10,000 ft.) Note: For altitudes above 2950 feet, the

2.4

Chassis Parts

Surge Non-

operating and

operating

Line to earth

Only

ESD

Air Discharged 12.0 kV

Contact

Discharge

Altitude

Operating

Storage -16 to 10,600 m (-50 to 35,000 ft.)

Unidirectional

AC Leads 2.0 kV

I/O Leads 1.0 kV

DC Leads 0.5 kV

8.0 kV

maximum operating temperature is de-rated 1°F/550 ft.

Disclaimer Note: Intel® ensures the unpackaged server board and system meet the shock

requirement mentioned above through its own chassis development and system configuration. It

is the responsibility of the system integrator to determine the proper shock level of the board

and system if the system integrator chooses different system configuration or different chassis.

Intel Corporation cannot be held responsible, if components fail or the server board does not

operate correctly when used outside any of its published operating or non-operating limits.

6

Revision 1.5

Intel order number: G59059-006

Page 17

Intel® Server Chassis H2000 Family TPS Product Overview

2.5

Hard Drive and Peripheral Bays

Intel® Server System H2312xx

Intel® Server System H2216xx

Slim-line SATA Optical Drive

Not Supported

Not Supported

Internal USB Floppy Drive

Not Supported

Not Supported

SATA/SAS Hard Disk Drives (3.5-inch)

Up to Twelve

Not Supported

SATA/SAS Hard Disk Drives (2.5-inch)

Not Supported

Up to Sixteen

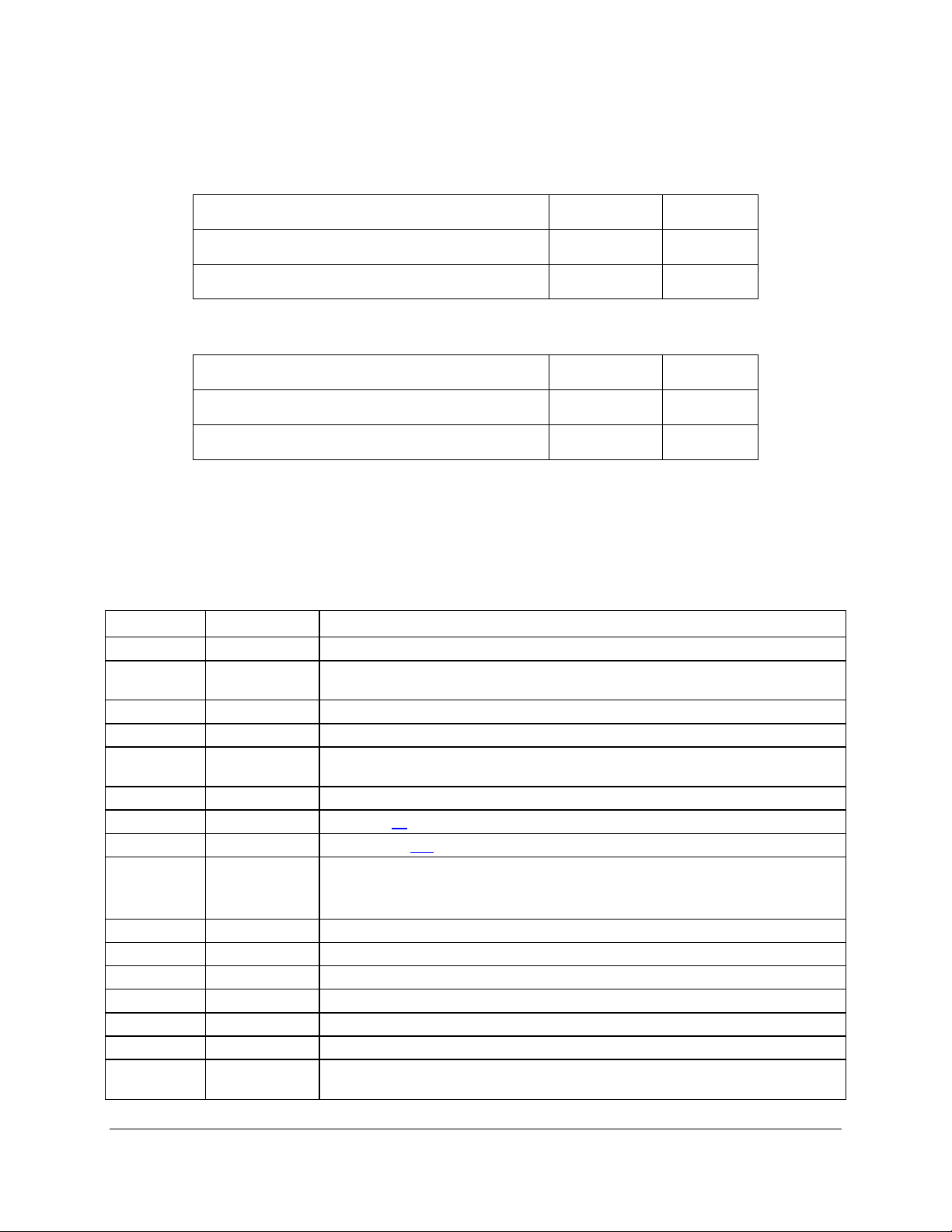

A Front Control Panel

B HDD bays

C Upper and Lower Power Distribution Boards

D Common Redundant Power Supply

E Hot Swap Back Plane

Note: Not shown - Rack slide rail, and top cover.

Figure 4. Major Chassis Parts

Revision 1.5 7

Intel order number: G59059-006

Page 18

Product Overview Intel® Server Chassis H2000 Family TPS

2.6

Front Bezel Support

2.7

Rack and Cabinet Mounting Options

®

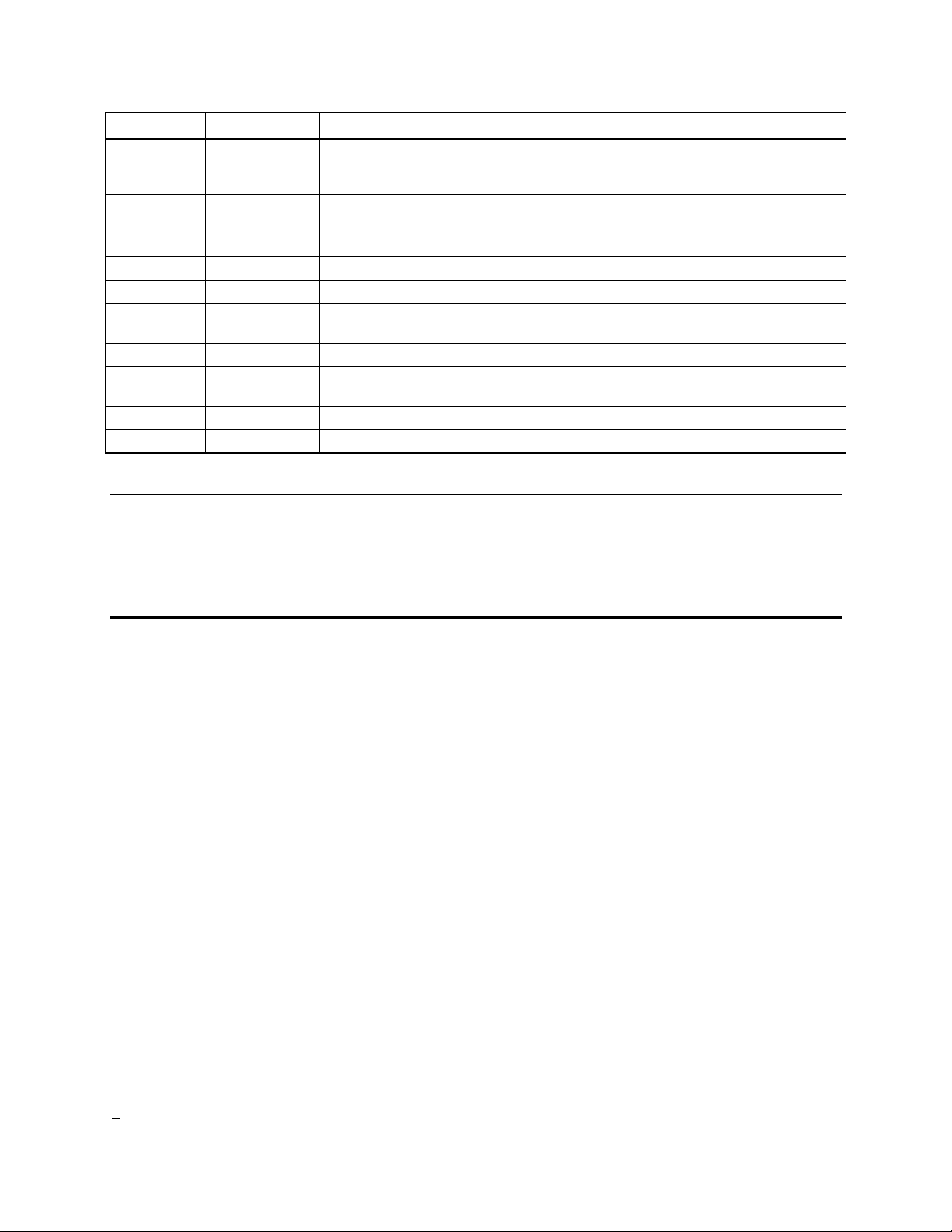

Figure 5. Intel

Figure 6. Intel® Server Chassis H2216xx Drive Bay Front View

Server Chassis H2312xx Drive Bay Front View

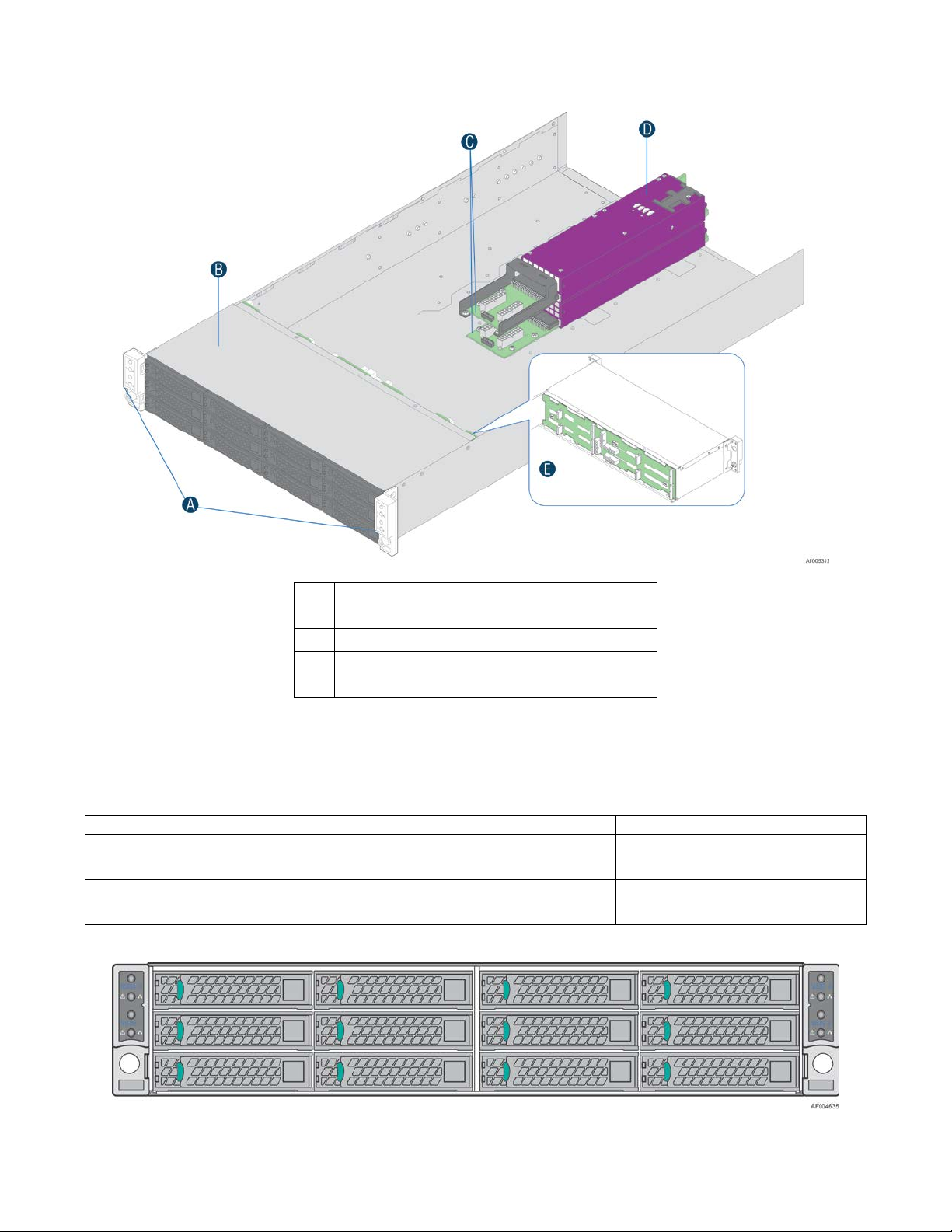

Intel® Server Chassis H2000 family provides front panel bezel. The bezel provides protection to

system HDD bays with a lock to chassis. The front view of the bezel is as below.

Figure 7. Chassis Bezel Front View

The chassis was designed to support 19 inches wide by up to 30 inches deep server cabinets.

The system bundles with the following Intel

®

rack mount option:

A basic slide rail kit (Product order code – AXXELVRAIL) is designed to mount the

chassis into a standard (19 inches by up to 30 inches deep) EIA-310D compatible

server cabinet.

Caution: THE MAXIMUM RECOMMENDED SERVER W EIGHT FOR THE RACK RAILS CAN

BE FOUND at http://www.intel.com/support/motherboards/server/sb/CS-033655.htm.

EXCEEDING THE MAXIMUM RECOMMENDED WEIGHT OR MISALIGNMENT OF THE

SERVER MAY RESULT IN FAILURE OF THE RACK RAILS HOLDING THE SERVER. Us e of a

8

Revision 1.5

Intel order number: G59059-006

Page 19

Intel® Server Chassis H2000 Family TPS Product Overview

mechanical assist to install and align server into the rack rails is recommended.

Advisory Note: The AXXELVRAIL value rack mount rail kit is not designed to support shipment

of the server system while installed in a rack.

Revision 1.5 9

Intel order number: G59059-006

Page 20

Power Sub-System Intel® Server Chassis H2000 Family TPS

3.1

Mechanical Overview

3.1.1

AC Power Supply Unit Dimension Overview

3. Power Sub-System

The system supports AC 1+1 hot swap power supply module and two power distribution board

which can support 2U rack high density server system. Two different power supply units are

supported: 1200W and 1600W. The single power supply module has Platinum level energy

efficiency, dem onstr ating climat e saver with silver rating.

The power supply module has a simple retention mechanism to retain the module self once it is

inserted. This mechanism shall withstand the specified mechanical shock and vibration

requirements. The power distribution board will be fixed in the chassis with screws. This

specification defines a 1+1 hot swap redundancy power supply that supports 2U server system.

Using existing power supply module provided by vendor with updated PMBus* and custommade power connector board to support four computing nodes. The power supply shall have

two outputs: 12V and 12VSB. The input shall be auto ranging and power factor corrected. The

PMBus* features included in this specification are requirements for AC silver rated box power

supply for use in server systems based on Intel

specification is based on the PMBus* Specifications part I and II, revision 1.1.

®

Server Chassis H2000 Family. This

The casing dimension is W 73.5mm x L 265.0mm x H 39/40mm. The power supply contains a

single 40mm fan. The power supply has a card edge output that interfaces with a 2x25 card

edge connector in the system. The AC plugs directly into the external face of the power supply.

Figure 8. AC Power Supply Unit Dimension Overview

10

Revision 1.5

Intel order number: G59059-006

Page 21

Intel® Server Chassis H2000 Family TPS Power Sub-System

3.1.2

AC Power Supply Unit General Data

Wattage

1200W/1600W (Energy Smart)

Voltage

90 – 264 VAC, auto-ranging, 47 Hz-63 Hz

Heat Dissipation

2560 BTU/hr

Maximum Inrush Current

Under typical line conditions and over the entire system

A per power supply for 5 ms

80 Plus rating

Platinum

Climate Saver (CS) rating

Platinum

3.1.3

AC input connector

3.1.4

AC Power Cord Specification Requirements

Cable Type

SJT

Wire Size

16 AWG

Temperature Rating

105º C

Amperage Rating

13A

Cable Type

SJT

3.1.5

Power Supply Unit DC Output Connector

PSU Output Connector

A1

GND

B1

GND

A2

GND

B2

GND

A3

GND

B3

GND

A4

GND

B4

GND

A5

GND

B5

GND

A6

GND

B6

GND

A7

GND

B7

GND

A8

GND

B8

GND

Below is general specification data for AC Power Supply Unit.

Table 6. Specification Data for AC Power Supply Unit

ambient operating range, the inrush current may reach 65

The power supply has an internal IEC320 C14 power inlet. The inlet is rated for a minimum of

10A at 250VAC.

The AC power cord used must meet the following specification requirements:

Table 7. AC power cord specification

The DC output connector pin-out is defined as follows:

Table 8. DC Output Power Connector

Revision 1.5 11

Intel order number: G59059-006

Page 22

Power Sub-System Intel® Server Chassis H2000 Family TPS

PSU Output Connector

A9

GND

B9

GND

A10

+12V

B10

+12V

A11

+12V

B11

+12V

A12

+12V

B12

+12V

A13

+12V

B13

+12V

A14

+12V

B14

+12V

A15

+12V

B15

+12V

A16

+12V

B16

+12V

A17

+12V

B17

+12V

A18

+12V

B18

+12V

A19

PMBus SDA*

B19

A0* (SMBus address)

A20

PMBus SCL*

B20

A1* (SMBus address)

A21

PSON

B21

12V STBY

A22

SMBAlert#

B22

Cold Redundancy Bus*

A23

Return Sense

B23

12V load share bus

A24

+12V Remote Sense

B24

No Connect

A25

PWOK

B25

CRPS Compatibility Check pin*

3.1.6

Handle Retention

3.1.7

LED Marking and Identification

The power supply has a handle to assist extraction. The module is able to be inserted and

extracted without the assistance of tools. The power supply also has a latch which retains the

power supply into the system and prevents the power supply from being inserted or extracted

from the system when the AC power cord is pulled into the power supply.

The handle protects the operator from any burn hazard through the use of industrial designed

plastic handle or equivalent material.

The power supply is using a bi-color LED: Amber and Green for status indication. Below are

table showing the LED states for each power supply operating state.

12

Revision 1.5

*: Refer to the spec of CRPS Common Requirements Specification.

Intel order number: G59059-006

Page 23

Intel® Server Chassis H2000 Family TPS Power Sub-System

Power Supply Condition

LED State

Output ON and OK

Solid GREEN

No AC power to all power supplies

OFF

AC present/Only 12VSB on (PS off) or PS in Cold

1Hz Blink GREEN

AC cord unplugged or AC power lost; with a second

Solid AMBER

Power supply warning events where the power supply

Power supply critical event causing a shutdown; failure,

Solid AMBER

Power supply FW updating

2Hz Blink GREEN

3.1.8

Power Cage with Power Distribution Board

Table 9. Power Supply Status LED

redundant state

power supply in parallel still with AC input power.

continues to operate; high temp, high power, high

current, slow fan.

OCP, OVP, Fan Fail

1Hz Blink Amber

The power cage is at the middle of the chassis, consists of two Power Distribution Boards (PDB)

to support Common Redundant Power Supplies (CRPS).

Caution: Installing two Power Supply Units with different wattage ratings on a system is not

supported. This will not provide Power Supply Redundancy and causes the system to log

multiple errors.

Following is the power system overview:

Revision 1.5 13

Intel order number: G59059-006

Page 24

Power Sub-System Intel® Server Chassis H2000 Family TPS

A

Power Distribution Board 1

B

Power Distribution Board 2

C

Power Supply Unit #2(upper) and #1(lower)

3.1.9

Power Cage Output Pin Assignment

Figure 9. Power Cage Overview

The power cage provides +12V and +12V

output to the system. Each PDB has two 2x9

STB

power output cable to system backplane, together with one 2x8 signal control cable for power

management. Refer to below table for PDB pin assignment.

14

Revision 1.5

Intel order number: G59059-006

Page 25

Intel® Server Chassis H2000 Family TPS Power Sub-System

A

Main Power Output Connector P1

B

Power Supply Unit Connector

C

Control Signal Connector

D

Main Power Output Connector P2

Pin

Description

Pin

Description

1

GND

2

+12V

3

GND

4

+12V

5

GND

6

+12V

7

GND

8

+12V

9

GND

10

+12V

11

GND

12

+12V

13

GND

14

+12V

15

GND

16

+12V

17

GND

18

+12V

Figure 10. Power distribution board

Table 10. Pin assignment of power ouput connector

Revision 1.5 15

Intel order number: G59059-006

Page 26

Power Sub-System Intel® Server Chassis H2000 Family TPS

Pin

Description

Pin

Description

1

PMBus SDA

2

A0 (SMBus Address)

3

PMBus SCL

4

A1 (SMBus Address)

5

PSON#

6

12V Load Share Bus

7

SMBAlert#

8

Cold Redundancy Bus

9

Return Sense

10

PWOK

11

+12V Remote Sense

12

Compatibility Bus

13

Reserved

14

+12VSB

15

+12VSB

16

Key Pin (removed)

3.2

AC Input Specification

3.2.1

Input Voltage And Frequency

Parameter

Min Rated

Max

Start up VAC

Power Off VAC

110VAC

90 V

100-127 V

140 V

85 VAC± 4VAC

70VAC±5VAC

220VAC

180 V

200-240 V

264 V

Frequency

47 Hz

50/60 Hz

63 Hz

3.2.2

AC input Power Factor

Table 11. Pin assignment of control signal connector

The power supply must operate within all specified limits over the following input voltage range.

Harmonic distortion of up to 10% THD must not cause the power supply to go out of specific

limits. The power supply shall be capable of start-up (power-on) with full rated power load, at

line voltage as low as 90VAC.

Table 12. AC input rating

rms

rms

Note:

1. Maximum input current at low input voltage range shall be measured at 90VAC, at max load.

2. Maximum input current at high input voltage range shall be measured at 180VAC, at max load.

rms

rms

rms

rms

3. This requirement is not to be used for determining agency input current markings.

16

Revision 1.5

Intel order number: G59059-006

Page 27

Intel® Server Chassis H2000 Family TPS Power Sub-System

Output power

10% load

20% load

50% load

100% load

Power factor

> 0.80

> 0.90

> 0.90

> 0.95

3.2.3

Efficiency

Loading

Minimum Efficiency

3.2.4

AC Line Fuse

3.2.5

AC Line Inrush

The power supply must meet the power factor requirements stated in the Energy Star® Program

Requirements for Computer Servers. These requirements are stated below.

Table 13. Typical power factor

Note: Tested at 230Vac, 50Hz and 60Hz and 115VAC, 60Hz. Tested according to Generalized

Internal Power Supply Efficiency Testing Protocol, Rev 6.4.3. This is posted at

http://efficientpowersupplies.epri.com/methods.asp.

The following table provides the required minimum efficiency level at various loading conditions.

These are provided at three different load levels; 100%, 50%, 20%, and 10%. Output shall be

load according to the proportional loading method defined by 80 Plus in Generalized Internal

Power Supply Efficiency Testing Protocol, Rev 6.4.3. This is posted at:

http://efficientpowersupplies.epri.com/methods.asp

.

Table 14. Platinum Efficiency Requirement

100% of maximum 50% of maximum 20% of maximum 10% of maximum

91% 94% 90% 82%

The power supply must pass with enough margins to make sure in production all power supplies

meet these efficiency requirements.

The power supply shall have one line fused in the single line fuse on the line (Hot) wire of the

AC input. The line fusing shall be acceptable for all safety agency requirements. The input fuse

shall be a slow blow type. AC inrush current shall not cause the AC line fuse to blow under any

conditions. All protection circuits in the power supply shall not cause the AC fuse to blow unless

a component in the power supply has failed. This includes DC output load short conditions.

AC line inrush current shall not exceed 65A peak, for up to on e-quarter of the AC cycle, after

which, the input current should be no more than the specified maximum input current. The peak

inrush current shall be less than the ratings of its critical components (including input fuse, bulk

rectifiers, and surge limiting device).

Revision 1.5 17

Intel order number: G59059-006

Page 28

Power Sub-System Intel® Server Chassis H2000 Family TPS

3.2.6

AC Line Dropout/Holdup

Loading

Holdup time

70%

10.6msec

3.2.7

AC Line Fast Transient (EFT) Specification

3.2.8

Hot Plug

3.2.9

Susceptability Requirements

The power supply must meet the inrush requirements for any rated AC voltage, during turn on at

any phase of AC voltage, during a single cycle AC dropout condition as well as upon recovery

after AC dropout of any duration, and over the specified temperature range (T

).

op

An AC line dropout is defined to be when the AC input drops to 0VAC at any phase of the AC

line for any length of time. During an AC dropout the power supply must meet dynamic voltage

regulation requirements. An AC line dropout of any duration shall not cause tripping of control

signals or protection circuits. If the AC dropout lasts longer than the holdup time the power

supply should recover and meet all turn on requirements. The power supply shall meet the AC

dropout requirement over rated AC voltages and frequencies. A dropout of the AC line for any

duration shall not cause damage to the power supply.

Table 15. AC Power Holdup Reuqirement

The 12V

output voltage should stay in regulation under its full load (static or dynamic) during

STB

an AC dropout of 70ms min (=12VSB holdup time) whether the power supply is in ON or OFF

state (PSON asserted or de-asserted).

The power supply shall meet the EN61000-4-5 directive and any additional requirements in

IEC1000-4-5: 1995 and the Level 3 requirements for surge-withstand capability, with the

following conditions and exceptions:

These input transients must not cause any out-of-regulation conditions, such as

overshoot and undershoot, nor must it cause any nuisance trips of any of the power

supply protection circuits.

The surge-withstand test must not produce damage to the power supply.

The supply must meet surge-withstand test conditions under maximum and minimum DC-output

load conditions.

Power supply shall be designed to allow connection into and removal from the system without

removing power to the system. During any phase of insertion, start-up, shutdown, or removal,

the power supply shall not cause any other like modules in the system to deviate outside of their

specifications. When AC power is applied, the auxiliary supply shall turn on providing bias

power internal to the supply and the 5VSB standby output.

The power supply shall meet the following electrical immunity requirements when connected to

18

Revision 1.5

Intel order number: G59059-006

Page 29

Intel® Server Chassis H2000 Family TPS Power Sub-System

Level

Description

A

The apparatus shall continue to operate as intended. No degradation of performance.

B

The apparatus shall continue to operate as intended. No degradation of performance beyond

C

Temporary loss of function is allowed provided the function is self-r ec ov erable or can be restored

3.2.10

Electrostatic Discharge Susceptibility

3.2.11

Fast Transient/Burst

3.2.12

Radiated Immunity

3.2.13

Surge Immunity

3.2.14

AC Line Transient Specification

a cage with an external EMI filter, which meets the criteria, defined in the SSI document EPS

Power Supply Specification. For further information on customer standards please request a

copy of the customer Environmental Standards Handbook.

Table 16. Performance Criteria

spec limits.

by the operation of the controls.

The power supply shall comply with the limits defined in EN 55024: 1998 using the IEC 610004-2:1995 test standard and performance criteria B defined in Annex B of CISPR 24.

The power supply shall comply with the limits defined in EN55024: 1998 using the IEC 61000-44:1995 test standard and performance criteria B defined in Annex B of CISPR 24.

The power supply shall comply with the limits defined in EN55024: 1998 using the IEC 61000-43:1995 test standard and performance criteria A defined in Annex B of CISPR 24.

The power supply shall be tested with the system for immunity to AC Ring wave and AC

Unidirectional wave, both up to 2kV, per EN 55024:1998, EN 61000-4-5:1995 and ANSI C62.45:

1992.

The pass criteria include the following:

1. No unsafe operation is allowed under any condition

2. All power supply output voltage levels to stay within proper spec levels

3. No change in operating state or loss of data during and after the test profile

4. No component damage under any condition

The power supply shall comply with the limits defined in EN55024: 1998 using the IEC 61000-45:1995 test standard and performance criteria B defined in Annex B of CISPR 24.

AC line transient conditions shall be defined as “sag” and “surge” conditions. “Sag” conditions

are also commonly referred to as “brownout”; these conditions will be defined as the AC line

Revision 1.5 19

Intel order number: G59059-006

Page 30

Power Sub-System Intel® Server Chassis H2000 Family TPS

AC Line Sag (10 sec interval between each sagging)

Duration

Sag

Operating AC Voltage

Line

Frequency

Performance Criteria.

0 to ½ AC

Nominal AC Voltage

Nominal AC Voltage

Loss of function acceptable, self-

3.2.15

Power Recovery

3.2.16

Voltage Interruptions

3.2.17

AC Line Isolation

AC Line Surge

Duration

Surge

Operating AC Voltage

Line Frequency

Performance Criteria

No loss of function or

0 to ½ AC

Mid-point of nominal AC

No loss of function or

voltage dropping below nominal voltage conditions. “Surge” will be defined to refer to conditions

when the AC line voltage rises above nominal voltage.

The power supply shall meet the requirements under the following AC line sag and surge

conditions.

Table 17. AC Line Sag Transient Performance

cycle

> 1 AC cycle >30%

Continuous 10% Nominal AC Voltages 50/60Hz

cycle

95%

30%

ranges

ranges

Table 18. AC Line Surge Transient Performance

Voltages

50/60Hz No loss of function or performance.

50/60Hz

50/60Hz

recoverable.

performance

performance

The power supply shall recover automatically after an AC power failure. AC power failure is

defined to be any loss of AC power that exceeds the dropout criteria.

The power supply shall comply with the limits defined in EN55024: 1998/A1: 2001/A2: 2003

using the IEC 61000-4-11: Second Edition: 2004-03 test standard and performance criteria C

defined in Annex B of CISPR 24.

The power supply shall meet all safety agency requirements for dielectric strength.

Transformers’ isolation between primary and secondary windings must comply with the

3000Vac (4242Vdc) dielectric strength criteria. If the working voltage between primary and

secondary dictates a higher dielectric strength test voltage the highest test voltage should be

20

Revision 1.5

Intel order number: G59059-006

Page 31

Intel® Server Chassis H2000 Family TPS Power Sub-System

3.2.18

AC Power Inlet

Cable Type

SJT

Wire Size

16 AWG

Temperature Rating

105º C

Amperage Rating

13 A

Voltage Rating

125 V

3.3

DC Ouput Specification

3.3.1

Output Power/Currents

Parameter

Min

Max

Peak

2,3

Unit

PSU SKU

1200W

1600W

1200W

1600W

+12V main (100-127VAC)

0.0

83

83

110

110

A

used. In addition the insulation system must comply with reinforced insulation per safety

standard IEC 950. Separation between the primary and secondary circuits, and primary to

ground circuits, must comply with the IEC 950 spacing requirements.

The AC input connector should be an IEC 320 C-14 power inlet. This inlet is rated for

10A/250 VAC.

The AC power cord must meet the following specification requirements:

Figure 11. AC Power Cord Specifica tion

The following table defines the minimum power and current ratings. The power supply must

meet both static and dynamic voltage regulation requirements for all conditions.

Table 19. Load Ratings for single power supply unit

+12V main (200-240VAC) 0.0 100 133 133 175 A

+12V

Notes:

Revision 1.5 21

1

0.0 3.0 3.5 3.5 2.4 A

STB

Intel order number: G59059-006

Page 32

Power Sub-System Intel® Server Chassis H2000 Family TPS

3.3.2

Standby Output

3.3.3

Voltage Regulation

Parameter

Min

Nom

Max

Unit

Tolerance

+12V

+11.40V

+12.000V

+12.60V

Vrms

±5%

+12V

+11.40V

+12.000V

+12.60V

Vrms

±5%

3.3.4

Dynamic Loading

Output

∆ Step Load Size

Load Slew Rate

Test capacitive Load

+12V

1.0A

0.25 A/µsec

20 µF

+12V

60% of max load

0.25 A/µsec

2000 µF

1. 12V

2. Peak combined power for all outputs shall not ex ceed 160 0 W (for 1200W PSU) and 2100W (for 1600W PSU)

3. Length of time peak power can be supported is based on thermal sensor and assertion of the SMBAlert#

must provide 4.0A with two power supplies in parallel. The power supply fan is allowed to run in

STB

standby mode for loads > 1.5A.

signal. Minimum peak power duration shall be 20 seconds without asserting the SMBAlert# signal.

The 12VSB output shall be present when an AC input greater than the power supply turn on

voltage is applied.

The power supply output voltages must stay within the following voltage limits when operating at

steady state and dynamic loading conditions. These limits include the peak-peak ripple/noise.

These shall be measured at the output connectors.

Table 20. Voltage Regulation Limits

STB

The combined output continuous power of all outputs shall not exceed 3200W (1600W from

each power supply unit). Each output has a maximum and minimum current rating shown in

below table. The power supply shall meet both static and dynamic voltage regulation

requirements for the minimum dynamic loading conditions. The power supply shall meet only

the static load voltage regulation requirements for the minimum static load conditions.

The output voltages shall remain within limits specified for the step loading and capacitive

loading specified in the table below. The load transient repetition rate shall be tested between

50Hz and 5kHz at duty cycles ranging from 10%-90%. The load transient repetition rate is only

a test specification. The ∆ step load may occur anywhere within the MIN load to the MAX

load conditions.

Table 21. Transient Load Requirements

STB

22

Revision 1.5

Intel order number: G59059-006

Page 33

Intel® Server Chassis H2000 Family TPS Power Sub-System

3.3.5

Capacitive Loading

Output

Min

Max

Units

+12V

500

25,000

µF

+12V

20

3100

µF

3.3.6

Ripple/Noise

+12V

+12V

STB

120mVp-p

120mVp-p

3.3.7

Grounding

Note: For dynamic condition +12V min loading is 1A.

The power supply must be stable and meet all requirements, with the following capacitive

loading conditions.

Table 22. Capacitive Loading Conditions

STB

The maximum allowed ripple/noise output of the power supply is defined in below table. This is

measured over a bandwidth of 10Hz to 20MHz at the power supply output connectors. A 10µF

tantalum capacitor in parallel with a 0.1µF ceramic capacitor is placed at the point

of measurement.

Table 23. Ripple and Noise

The output ground of the pins of the power supply provides the output power return path. The

output connector ground pins shall be connected to the safety ground (power supply enclosure).

This grounding should be well designed to ensure passing the max allowed Common Mode

Noise levels.

The power supply shall be provided with a reliable protective earth ground. All secondary

circuits shall be connected to protective earth ground. Resistance of the ground returns to

chassis shall not exceed 1.0 mΩ. This path may be used to carry DC current.

Revision 1.5 23

Intel order number: G59059-006

Page 34

Power Sub-System Intel® Server Chassis H2000 Family TPS

3.3.8

Closed Loop Stability

3.3.9

Residual Voltage Immunity in Standby Mode

3.3.10

Common Mode Noise

3.3.11

Soft Starting

3.3.12

Zero Load Stability Requirement

3.3.13

Hot Swap Requirement

The power supply shall be unconditionally stable under all line/load/transient load conditions

including capacitive load ranges specified in section 3.3.5. A minimum of: 45 degrees phase

margin and -10dB-gain margin is required. The power supply manufacturer shall provide proof

of the unit’s closed-loop stability with local sensing through the submission of Bode plots.

Closed-loop stability must be ensured at the maximum and minimum loads as applicable.

The power supply should be immune to any residual voltage placed on its outputs (typically a

leakage voltage through the system from standby output) up to 500mV. There shall be no

additional heat generated, nor stressing of any internal components with this voltage applied to

any individual or all outputs simultaneously. It also should not trip the protection circuits during

turn on.

The residual voltage at the power supply outputs for no load condition shall not exceed 100mV

when AC voltage is applied and the PSON# signal is de-asserted.

The Common Mode noise on any output shall not exceed 350mVp-p over the frequency band

of 10Hz to 20MHz.

The Power Supply shall contain control circuit which provides monotonic soft start for its outputs

without overstress of the AC line or any power supply components at any specified AC line or

load conditions.

When the power subsystem operates in a no load condition, it does not need to meet the output

regulation specification, but it must operate without any tripping of over-voltage or other fault

circuitry. When the power subsystem is subsequently loaded, it must begin to regulate and

source current without fault.

1. The measurement shall be made across a 100Ω resistor between each of DC outputs,

including ground at the DC power connector and chassis ground (power subsystem

enclosure).

2. The test set-up shall use a FET probe such as Tektronix model P6046 or equivalent.

Hot swapping a power supply is the process of inserting and extracting a power supply from an

operating power system. During this process the output voltages shall remain within the limits

with the capacitive load specified. The hot swap test must be conducted when the system is

operating under static, dynamic, and zero loading conditions. The power supply shall use a

24

Revision 1.5

Intel order number: G59059-006

Page 35

Intel® Server Chassis H2000 Family TPS Power Sub-System

3.3.14

Forced Load Sharing

3.3.15

Timing Requirement

Item

Description

Min.

Max.

Units

T

5.0 *

70 *

ms

T

1500

ms

T

3000

ms

T

13

ms

T

10.6

ms

T

Delay from PSON# active to output voltages within regulation

5

400

ms

T

5

ms

T

100

500

ms

latching mechanism to prevent insertion and extraction of the power supply when the AC power

cord is inserted into the power supply.

The +12V output will have active load sharing. The output will share within 10% at full load. The

failure of a power supply should not affect the load sharing or output voltages of the other

supplies still operating. The supplies must be able to load share in parallel and operate in a hotswap/redundant 1+1 configurations. The 12VSBoutput is not required to actively share current

between power supplies (passive sharing). The 12VSBoutput of the power supplies are

connected together in the system so that a failure or hot swap of a redundant power supply

does not cause these outputs to go out of regulation in the system.

These are the timing requirements for the power supply operation. The output voltages must

rise from 10% to within regulation limits (T

) within 5 to 70ms. For 12VSB, it is allowed to

vout_rise

rise from 1.0 to 25ms. All outputs must rise monotonically. Table below shows the timing

requirements for the power supply being turned on and off through the AC input, with PSON

held low and the PSON signal, with the AC input applied.

vout_rise

sb_on_delay

ac_on_delay

vout_holdup

pwok_holdup

pson_on_delay

pson_pwok

pwok_on

Table 24. Timing Requirement

Output voltage rise time

Delay from AC being applied to 12VSBbeing within regulation.

Delay from AC being applied to all output voltages being within

regulation.

Time 12Vl output voltage stay within regulation after loss of

AC.

Delay from loss of AC to de-assertion of PWOK

limits.

Delay from PSON# deactivate to PWOK being de-asserted.

Delay from output voltages within regulation limits to PWOK

asserted at turn on.

Revision 1.5 25

Intel order number: G59059-006

Page 36

Power Sub-System Intel® Server Chassis H2000 Family TPS

Item

Description

Min.

Max.

Units

T

Delay from PWOK de-asserted to output voltages dropping out

1

ms

T

Duration of PWOK being in the de-asserted state during an

100

ms

T

Delay from 12VSBbeing in regulation to O/Ps being in

50

1000

ms

T

70

ms

AC Input

Vout

PWOK

12Vsb

PSON

T

sb_on_delay

T

AC_on_delay

T

pwok_on

T

vout_holdup

T

pwok_holdup

T

pson_on_delay

T

sb_on_delay

T

pwok_on

T

pwok_off

T

pwok_off

T

pson_pwok

T

pwok_low

T

sb_vout

AC turn on/off cycle

PSON turn on/off cycle

T

5Vsb_holdup

3.4

Power Supply Cold Redundancy Support

pwok_off

of regulation limits.

pwok_low

off/on cycle using AC or the PSON signal.

sb_vout

regulation at AC turn on.

Time the 12VSBoutput voltage stays within regulation after loss

12VSB_holdup

of AC.

Note: * The 12V

output voltage rise time shall be from 1.0ms to 25ms.

STB

Figure 12. Turn On/Off Timing (Power Supply Signals)

Power supplies that support cold redundancy can be enabled to go into a low-power state (that

is, cold redundant state) in order to provide increased power usage efficiency when system

loads are such that both power supplies are not needed. When the power subsystem is in Cold

Redundant mode, only the needed power supply to support the best power delivery efficiency is

ON. Any additional power supplies; including the redundant power supply, is in Cold

26

Revision 1.5

Intel order number: G59059-006

Page 37

Intel® Server Chassis H2000 Family TPS Power Sub-System

3.4.1

1200W CRPS Cold Redundancy

Enable (V)

percent

power (W)

Disable (V)

percent

power (W)

Cold

3.2

40.00%

480(±5%)

1.44

18.00%

432(±5%)

Standby state.

Each power supply has an additional signal that is dedicated to supporting Cold Redundancy;

CR_BUS. This signal is a common bus between all power supplies in the system. CR_BUS is

asserted when there is a fault in any power supply OR the power supplies output voltage falls

below the Vfault threshold. Asserting the CR_BUS signal causes all power supplies in Cold

Standby state to power ON.

Enabling power supplies to maintain best efficiency is achieved by looking at the Load Share

bus voltage and comparing it to a programmed voltage level through a PMBus command.

Whenever there is no active power supply on the Cold Redundancy bus driving a HIGH level on

the bus all power supplies are ON no matter their defined Cold Redundant roll (active or Cold

Standby). This guarantees that incorrect programming of the Cold Redundancy states of the

power supply will never cause the power subsystem to shut down or become over loaded. The

default state of the power subsystem is all power supplies ON. There needs to be at least one

power supply in Cold Redundant Active state or Standard Redundant state to allow the Cold

Standby state power supplies to go into Cold Standby state.

Caution: Installing two Power Supply Units with different wattage ratings on a system is not

supported. This will not provide Power Supply Redundancy and causes the system to log

multiple errors.

If the output power is less than 480W (40%). the Cold redundant function will be enable. Thus

you will see one PSU working normal. The second PSU will be CR mode. The Power Supply

LED is green blinking.

Table 25. 1200W CRPS Cold Redundancy Threshold.

Standby 1

(02h)

Revision 1.5 27

Intel order number: G59059-006

Page 38

Power Sub-System Intel® Server Chassis H2000 Family TPS

3.4.2

1600W CRPS Cold Redundancy

Enable (V)

percent

power (W)

Disable (V)

percent

power (W)

Cold

3.2

40.00%

640(±5%)

1.44

18.00%

576(±5%)

3.5

Control And Indicator Functions

3.5.1

PSON# Input Signal

Signal Type

Accepts an open collector/drain input from the system. Pull-up

to VSB located in power supply.

PSON# = Low

ON

PSON# = High or Open

OFF

MIN

MAX

Logic level low (power supply ON)

0V

1.0V

Logic level high (power supply OFF)

2.0V

3.46V

Source current, Vpson = low

4mA

Power up delay: T

5msec

400msec

PWOK delay: T

50msec

3.5.2

PWOK(power good) Output Signal

If the output power is less than 640W (40%). the Cold redundant function will be enable. Thus

you will see one PSU working normal. The second PSU will be CR mode. The Power Supply

LED is green blinking.

Table 26. 1600W CRPS Cold Redundancy Threshold.

Standby 1

(02h)

The following sections define the input and output signals from the power supply.

Signals that can be defined as low true use the following convention: Signal

#

= low true.

The PSON# signal is required to remotely turn on/off the power supply. PSON# is an active low

signal that turns on the +12V power rail. When this signal is not pulled low by the system, or left

open, the outputs (except the +12VSB) turn off. This signal is pulled to a standby voltage by a

pull-up resistor internal to the power supply. Refer to below table for the timing diagram.

Table 27. PSON# Signal Characteristics.

pson_on_delay

pson_pwok

PWOK is a power OK signal and will be pulled HIGH by the power supply to indicate that all the

outputs are within the regulation limits of the power supply. When any output voltage falls below

regulation limits or when AC power has been removed for a time sufficiently long so that power

supply operation is no longer guaranteed, PWOK will be de-asserted to a LOW state. See the

table below for a representation of the timing characteristics of PWOK. The start of the PWOK

28

Revision 1.5

Intel order number: G59059-006

Page 39

Intel® Server Chassis H2000 Family TPS Power Sub-System

Signal Type

PWOK = High

Power OK

PWOK = Low

Power Not OK

MIN

MAX

Logic level low voltage, Isink=400uA

0V

0.4V

Logic level high voltage, Isource=200µA

2.4V

3.46V

Sink current, PWOK = low

400uA

Source current, PWOK = high

2mA

PWOK delay: Tpwok_on

100ms

1000ms

PWOK rise and fall time

100µsec

Power down delay: T pwok_off

1ms

200msec

3.5.3

SMBAlert# Signal

Signal Type (Active Low)

Open collector/drain output from power supply. Pull-

up to VSB located in system.

Alert# = High

OK

Alert# = Low

Power Alert to system

MIN

MAX

Logic level low voltage, Isink=4 mA

0 V

0.4 V

Logic level high voltage, Isink=50 µA

3.46 V

delay time shall inhibited as long as any power supply output is in current limit.

Table 28. PWOK Signal C haracteristics

This signal indicates that the power supply is experiencing a problem that the user should

investigate. This shall be asserted due to Critical events or Warning events. The signal shall

activate in the case of critical component temperature reached a warning threshold, general

failure, over-current, over-voltage, under-voltage, failed fan. This signal may also indicate the

power supply is reaching its end of life or is operating in an environment exceeding the

specified limits.

This signal is to be asserted in parallel with LED turning solid Amber or blink Amber.

Table 29. SMB Alert# Si gnal Characteristics

Revision 1.5 29

Intel order number: G59059-006

Page 40

Power Sub-System Intel® Server Chassis H2000 Family TPS

Sink current, Alert# = low

4 mA

Sink current, Alert# = high

50 µA

Alert# rise and fall time

100 µs

3.6

Protection circuits

3.6.1

Current Limit (OCP)

Output VOLTAGE

Input voltage range

OVER CURRENT LIMITS

PSU SKU 1200W

1600W

+12V

90 – 264VAC

140A min; 170A max

180A min; 200A max

+12V

90 – 264VAC

2.5A min; 3A max

2.5A min; 3A max

3.6.2

Over Voltage Protection (OVP)

Output Voltage

MIN (V)

MAX (V)

+12V

13.3

14.5

+12VSB

13.3

14.5

3.6.3

Over Thermal protection

Protection circuits inside the power supply shall cause only the power supply’s main outputs to

shut down. If the power supply latches off due to a protection circuit tripping, an AC cycle OFF

for 15sec and a PSON

#

cycle HIGH for 1sec shall be able to reset the power supply.

The power supply shall have current limit to prevent the outputs from exceeding the values

shown in table below. If the current limits are exceeded the power supply shall shutdown and

latch off. The latch will be cleared by toggling the PSON

#

signal or by an AC power interruption.

The power supply shall not be damaged from repeated power cycling in this condition. 12VSB

will be auto-recovered after removing OCP limit.

Table 30. Over Current Protection

STB

The power supply over voltage protection shall be locally sensed. The power supply shall

shutdown and latch off after an over voltage condition occurs. This latch shall be cleared by

toggling the PSON

#

signal or by an AC power interruption. The values are measured at the

output of the power supply’s connectors. The voltage shall never exceed the maximum levels

when measured at the power connectors of the power supply connector during any single point

of fail. The voltage shall never trip any lower than the minimum levels when measured at the

power connector. 12VSBwill be auto-recovered after removing OVP limit.

Table 31. Over Voltage Protection (OVP) Limits

The power supply will be protected against over temperature conditions caused by loss of fan

30

Revision 1.5

Intel order number: G59059-006

Page 41

Intel® Server Chassis H2000 Family TPS Power Sub-System

3.7 PMBus*

3.7.1

PSU Address Lines A0

cooling or excessive ambient temperature. In an OTP condition the PSU will shut down. When

the power supply temperature drops to within specified limits, the power supply shall restore

power automatically, while the 12VSB remains always on. The OTP circuit must have built in

margin such that the power supply will not oscillate on and off due to temperature recovering

condition. The OTP trip level shall have a minimum of 4°C of ambient temperature margin.