Page 1

Intel® Server Board S2600ST

Product Family

Technical Product Specification

An overview of product features, functions, architecture, and support specifications.

Rev 1.03

March 2018

Intel® Server Products and Solutions

Page 2

<This page is left intentionally blank>

Page 3

Intel® Server Board S2600ST Product Family Technical Product Specification

Date

Revision

Changes

June 2017

1.0

Production release.

August 2017

1.01

Added Design and Environmental Specifications Section

Corrected post codes on Appendix B (Tables: 40, 41 and 42)

Added a note on section 4.6.2

Fixed a part on section 5.3.1 where DIMM population suggested was not accurate

Added Information to Appendix E

February 2018 1.02

Document Revision History

Corrected thermal Configuration Tables on Appendix E (Tables: 49, 50, 51 and 52)

Corrected the Maximum TDP from 165W to 205W

Added section 10.5.4 Chassis Intrusion header Pin-out

Added reference to the Chassis Intrusion Header on Figure 2

March 2018 1.03

Added documents to the Reference documents table

3

Page 4

Intel® Server Board S2600ST Product Family Technical Product Specification

Disclaimers

Intel technologies’ features and benefits depend on system configuration and may require enabled

hardware, software or service activation. Learn more at Intel.com, or from the OEM or retailer.

You may not use or facilitate the use of this document in connection with any infringement or other legal

analysis concerning Intel products described herein. You agree to grant Intel a non-exclusive, royalty-free

license to any patent claim thereafter drafted which includes subject matter disclosed herein.

No license (express or implied, by estoppel or otherwise) to any intellectual property rights is granted by this

document.

The products described may contain design defects or errors known as errata which may cause the product

to deviate from published specifications. Current characterized errata are available on request.

Intel disclaims all express and implied warranties, including without limitation, the implied warranties of

merchantability, fitness for a particular purpose, and non-infringement, as well as any warranty arising from

course of performance, course of dealing, or usage in trade.

Intel, the Intel logo, Xeon, and Xeon Phi are trademarks of Intel Corporation in the U.S. and/or other

countries.

*Other names and brands may be claimed as the property of others.

© Intel Corporation. All Rights Reserved.

4

Page 5

Intel® Server Board S2600ST Product Family Technical Product Specification

Table of Contents

1. Introduction ............................................................................................................................................................... 13

1.1 Chapter Outline ............................................................................................................................................................... 14

1.2 Intel® Server Board Use Disclaimer......................................................................................................................... 14

2. Server Board Family Overview .............................................................................................................................. 15

2.1 Server Board Feature Set ............................................................................................................................................ 16

2.2 Server Board Component / Feature Identification ........................................................................................... 17

2.3 Server Board Mechanical Drawings ........................................................................................................................ 21

2.4 Product Architecture Overview ................................................................................................................................ 28

2.5 System Software Stack ................................................................................................................................................ 28

2.5.1 Hot Keys Supported During Power-On Self-Test (POST) ............................................................................. 29

2.5.2 BIOS Update Capability ............................................................................................................................................... 30

2.5.3 BIOS Recovery ................................................................................................................................................................. 30

2.5.4 Field Replaceable Unit (FRU) and Sensor Data Record (SDR) Data ........................................................... 31

3. Processor Support .................................................................................................................................................... 32

3.1 Processor Heat Sink Module (PHM) and Processor Socket Assembly .................................................... 32

3.2 Processor Thermal Design Power (TDP) Support ............................................................................................ 34

3.3 Intel® Xeon® Processor Scalable Family Overview ........................................................................................... 35

3.3.1 Intel® 64 Instruction Set Architecture (ISA) ......................................................................................................... 36

3.3.2 Intel® Hyper-Threading Technology ...................................................................................................................... 36

3.3.3 Enhanced Intel SpeedStep® Technology ............................................................................................................. 36

3.3.4 Intel® Turbo Boost Technology 2.0 ........................................................................................................................ 36

3.3.5 Intel® Virtualization Technology for IA-32, Intel® 64 and Intel® Architecture (Intel® VT-x) ............. 36

3.3.6 Intel® Virtualization Technology for Directed I/O (Intel® VT-d) .................................................................. 36

3.3.7 Execute Disable Bit ........................................................................................................................................................ 36

3.3.8 Intel® Trusted Execution Technology (Intel® TXT) for Servers .................................................................... 37

3.3.9 Intel® Adavanced Vector Extension 512 (Intel® AVX-512) ............................................................................ 37

3.3.10 Intel® Advanced Encryption Standard New Instructions (Intel® AES-NI) ................................................ 37

3.3.11 Intel® Node Manager (Intel® NM) 4.0 ...................................................................................................................... 37

3.4 Processor Population Rules ....................................................................................................................................... 38

3.5 Processor Initialization Error Summary ................................................................................................................ 38

4. PCI Express* (PCIe*) Support ................................................................................................................................. 41

4.1.1 PCIe* Enumeration and Allocation ......................................................................................................................... 41

4.1.2 Non-Transparent Bridge ............................................................................................................................................. 41

5. Memory Support ....................................................................................................................................................... 43

5.1 Memory Sub-system Architecture Overview ...................................................................................................... 43

5.2 Supported Memory ....................................................................................................................................................... 44

5.3 Memory Slot Identification and Population Rules ........................................................................................... 44

5.3.1 DIMM Population Guidelines for Best Performance ........................................................................................ 46

5.4 Memory RAS Features .................................................................................................................................................. 47

5.4.1 DIMM Populations Rules and BIOS Setup for Memory RAS ........................................................................ 48

5

Page 6

Intel® Server Board S2600ST Product Family Technical Product Specification

6. System I/O ................................................................................................................................................................. 49

6.1 Intel® QuickAssist Technology Support ................................................................................................................ 49

6.2 PCIe* Add-in Card Support ........................................................................................................................................ 50

6.2.1 Riser Card Support ........................................................................................................................................................ 51

6.3 Onboard Storage Subsystem .................................................................................................................................... 51

6.3.1 M.2 Storage Device Support ...................................................................................................................................... 52

6.3.2 Onboard PCIe* OCuLink Connectors ..................................................................................................................... 53

6.3.3 Intel® Volume Management Device (Intel® VMD) for NVMe* SSDs ............................................................ 53

6.3.4 Intel® Virtual RAID on Chip (Intel® VROC) for NVMe* ...................................................................................... 56

6.3.5 Onboard SATA Support .............................................................................................................................................. 57

6.3.6 Embedded Software RAID Support ........................................................................................................................ 59

6.4 Network Interface ........................................................................................................................................................... 61

6.4.1 Onboard Ethernet Ports .............................................................................................................................................. 61

6.4.2 SFP+ LAN Riser Option ................................................................................................................................................ 62

7. System Security ........................................................................................................................................................ 64

7.1 BIOS Setup Utility Security Option Configuration ............................................................................................ 64

7.2 BIOS Password Protection ......................................................................................................................................... 64

7.3 Trusted Platform Module (TPM) Support ............................................................................................................ 65

7.3.1 TPM Security BIOS ......................................................................................................................................................... 66

7.3.2 Physical Presence .......................................................................................................................................................... 67

7.3.3 TPM Security Setup Options ..................................................................................................................................... 67

7.4 Intel® Trusted Execution Technology .................................................................................................................... 68

8. Platform Management ............................................................................................................................................. 69

8.1 Management Feature Set Overview ....................................................................................................................... 69

8.1.1 IPMI 2.0 Features Overview ....................................................................................................................................... 69

8.1.2 Non-IPMI Features Overview .................................................................................................................................... 70

8.2 Platform Management Features and Functions ................................................................................................ 71

8.2.1 Power Subsystem .......................................................................................................................................................... 71

8.2.2 Advanced Configuration and Power Interface (ACPI) ..................................................................................... 71

8.2.3 Watchdog Timer ............................................................................................................................................................. 72

8.2.4 System Event Log (SEL) ............................................................................................................................................... 72

8.3 Sensor Monitoring ......................................................................................................................................................... 73

8.3.1 Sensor Re-arm Behavior ............................................................................................................................................. 73

8.3.2 Thermal Monitoring ...................................................................................................................................................... 73

8.4 Standard Fan Management ........................................................................................................................................ 74

8.4.1 Hot-Swap Fans ................................................................................................................................................................ 74

8.4.2 Fan Domains ..................................................................................................................................................................... 75

8.4.3 Thermal and Acoustic Management ...................................................................................................................... 75

8.4.4 Thermal Sensor Input to Fan Speed Control ..................................................................................................... 75

8.5 Memory Thermal Management ................................................................................................................................ 76

8.6 Power Management Bus (PMBus*) .......................................................................................................................... 77

8.6.1 Component Fault LED Control ................................................................................................................................. 77

6

Page 7

Intel® Server Board S2600ST Product Family Technical Product Specification

9. Standard and Advanced Server Management Features .................................................................................. 79

9.1 Dedicated Management Port .................................................................................................................................... 80

9.2 Embedded Web Server ................................................................................................................................................ 81

9.3 Advanced Management Feature Support (Intel® RMM4 Lite) ...................................................................... 82

9.3.1 Keyboard, Video, and Mouse (KVM) Redirection .............................................................................................. 82

9.3.2 Media Redirection .......................................................................................................................................................... 83

9.3.3 Remote Console ............................................................................................................................................................. 84

9.3.4 Performance ..................................................................................................................................................................... 85

10. On-board Connector/Header Overview .............................................................................................................. 86

10.1 Power Connectors ......................................................................................................................................................... 86

10.1.1 Main Power ....................................................................................................................................................................... 86

10.1.2 CPU Power Connectors ............................................................................................................................................... 86

10.1.3 Supplemental 12-V Power-In Connector ............................................................................................................ 88

10.2 Front Panel Headers and Connectors ................................................................................................................... 88

10.2.1 Front Panel Header ....................................................................................................................................................... 88

10.2.2 Front Panel USB Connector ....................................................................................................................................... 89

10.3 Onboard Storage Connectors ................................................................................................................................... 89

10.3.1 SATA 6 Gbps Connectors ........................................................................................................................................... 89

10.3.2 M.2 Connectors ............................................................................................................................................................... 91

10.4 Fan Connectors ............................................................................................................................................................... 92

10.4.1 System Fan Connectors ............................................................................................................................................... 92

10.4.2 CPU Fan Connectors ..................................................................................................................................................... 92

10.5 Other Headers and Connectors ............................................................................................................................... 92

10.5.1 HSBP Inter-Integrated Circuit (I

2

C) Headers ....................................................................................................... 93

10.5.2 Serial Port Connector ................................................................................................................................................... 93

10.5.3 PMBUS Connector ......................................................................................................................................................... 93

10.5.4 Chassis Intrusion Header ............................................................................................................................................ 93

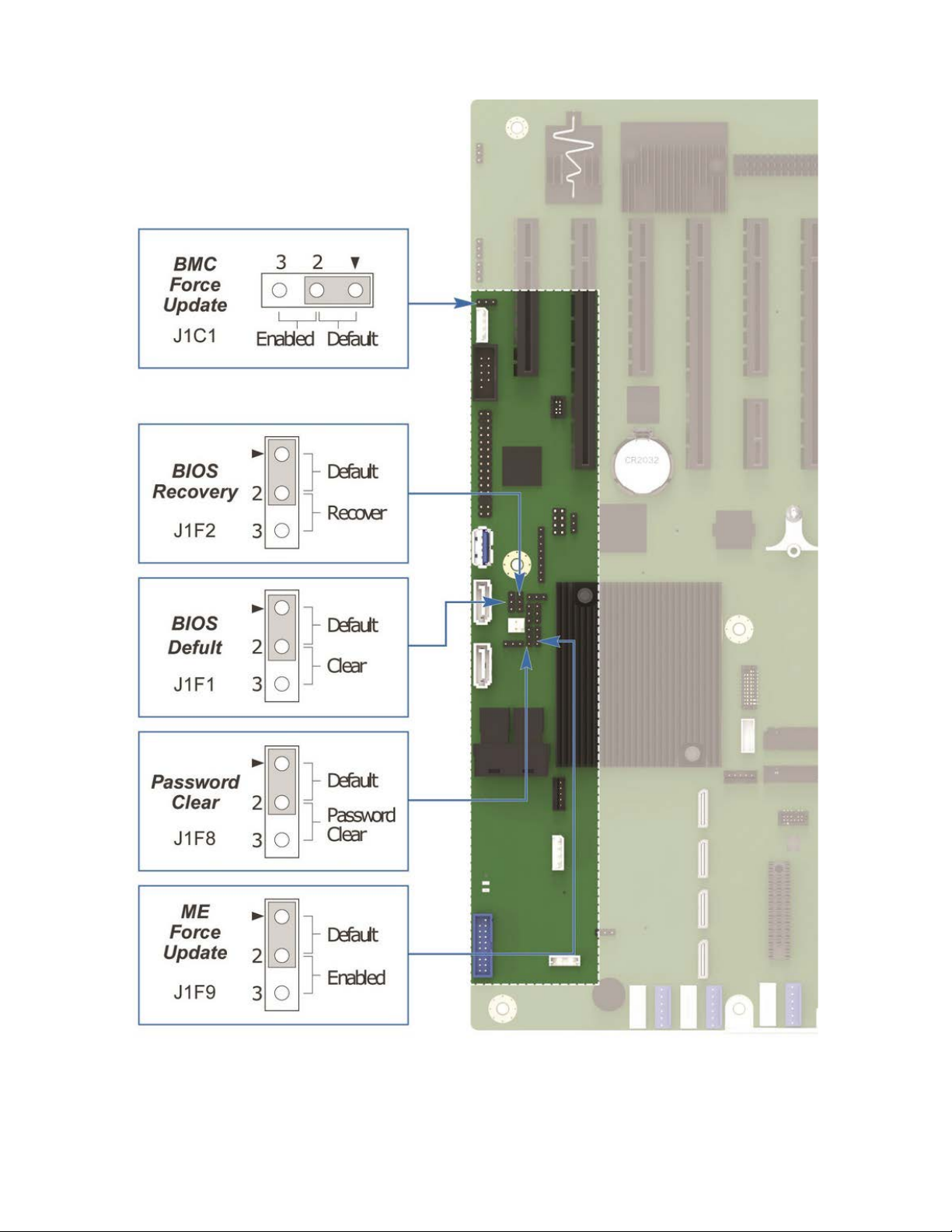

11. Reset and Recovery Jumpers ................................................................................................................................. 94

11.1 BIOS Default Jumper Block ....................................................................................................................................... 95

11.2 Password Clear Jumper Block .................................................................................................................................. 95

11.3 Management Engine (ME) Firmware Force Update Jumper Block ............................................................ 96

11.4 BMC Force Update Jumper Block ........................................................................................................................... 96

11.5 BIOS Recovery Jumper Block ................................................................................................................................... 97

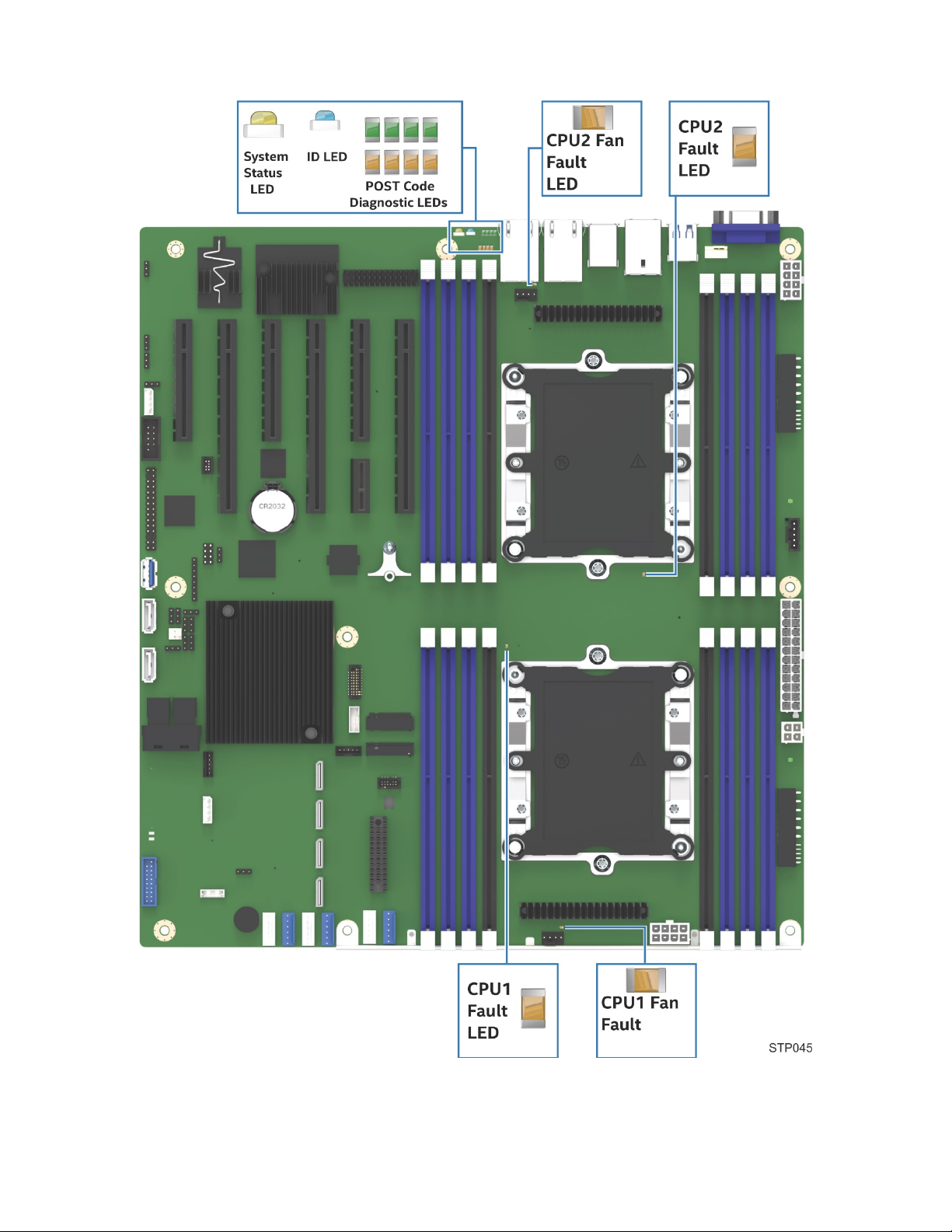

12. Light Guided Diagnostics ........................................................................................................................................ 99

12.1 DIMM Fault LEDs ............................................................................................................................................................ 99

12.2 System LEDs .................................................................................................................................................................. 100

12.2.1 System ID LED .............................................................................................................................................................. 100

12.2.2 System Status LED ...................................................................................................................................................... 100

12.3 Post Code Diagnostic LEDs ..................................................................................................................................... 101

12.4 CPU Fault LEDs ............................................................................................................................................................. 102

12.5 BMC Boot/Reset Status LED Indicators ............................................................................................................. 102

13. Design and Environmental Specifications ........................................................................................................ 103

7

Page 8

Intel® Server Board S2600ST Product Family Technical Product Specification

13.1 Intel® Server Board S2600ST Design Specifications..................................................................................... 103

Appendix A. Integration and Usage Tips .............................................................................................................. 104

Appendix B. POST Code Diagnostic LED Decoder ............................................................................................. 105

B.1. Early POST Memory Initialization MRC Diagnostic Codes ......................................................................... 106

B.2. BIOS POST Progress Codes .................................................................................................................................... 108

Appendix C. POST Code Errors .............................................................................................................................. 115

C.1. POST Error Beep Codes ........................................................................................................................................... 121

Appendix D. Statement of Volatility...................................................................................................................... 123

Appendix E. Supported Intel Server Chassis ...................................................................................................... 125

E.1. Hot-Swap Backplane (Optional) ............................................................................................................................ 128

E.2. System Level Environmental Limits .................................................................................................................... 129

E.3. Thermal Configuration Tables ............................................................................................................................... 130

Appendix F. Glossary ............................................................................................................................................... 141

8

Page 9

Intel® Server Board S2600ST Product Family Technical Product Specification

List of Figures

Figure 1. Intel® Server Board S2600STB ......................................................................................................................................... 15

Figure 2. Server board component / feature identification ..................................................................................................... 17

Figure 3. Intel® Server Board S2600ST product family external I/O connector layout ............................................... 18

Figure 4. Intel® Light Guided Diagnostics - DIMM fault LEDs .................................................................................................. 18

Figure 5. Intel® Light Guided Diagnostics – LED identification ............................................................................................... 19

Figure 6. Jumper block identification ............................................................................................................................................... 20

Figure 7. Primary side keep out zone and component height restrictions ....................................................................... 21

Figure 8. Secondary side keep out zone ......................................................................................................................................... 22

Figure 9. Mounting holes ....................................................................................................................................................................... 23

Figure 10. Mounting holes continued ............................................................................................................................................... 24

Figure 11. Major components and connectors (1 of 3) ............................................................................................................. 25

Figure 12. Major components and connectors (2 of 3) ............................................................................................................. 26

Figure 13. Major components and connectors (3 of 3) ............................................................................................................. 27

Figure 14. Intel® Server Board S2600ST product family block diagram ............................................................................ 28

Figure 15. Processor socket assembly ............................................................................................................................................. 32

Figure 16. Processor socket assembly and protective dust cover ....................................................................................... 32

Figure 17. Processor heat sink module (PHM) components and processor socket reference diagram ............... 33

Figure 18. Processor heat sink module (PHM) sub-assembly ................................................................................................ 33

Figure 19. Fully assembled processor heat sink module (PHM) ........................................................................................... 34

Figure 20. Two systems connected through PCIe* Non-Transparent Bridge (NTB) ..................................................... 42

Figure 21. Memory sub-system architecture ................................................................................................................................. 43

Figure 22. Intel® Server Board S2600ST product family memory slot layout ................................................................. 45

Figure 23. Optional Intel® QuickAssist Technology bridge cable installed ...................................................................... 50

Figure 24. Intel® QuickAssist Technology bridge cable – iPC AXXSTCBLQAT ................................................................ 50

Figure 25. PCIe* slots ............................................................................................................................................................................... 51

Figure 26. M.2 connectors ..................................................................................................................................................................... 52

Figure 27. Onboard OCuLink connectors ....................................................................................................................................... 53

Figure 28. Intel® Volume Management Device (Intel® VMD) for NVMe* SSDs ................................................................. 53

Figure 29. VMD support disabled in BIOS setup .......................................................................................................................... 55

Figure 30. VMD support enabled in BIOS setup .......................................................................................................................... 55

Figure 31. Intel® VROC basic architecture overview ................................................................................................................... 56

Figure 32. Intel® VROC upgrade key .................................................................................................................................................. 56

Figure 33. SATA RAID 5 upgrade key ................................................................................................................................................ 61

Figure 34. Network interface connectors ........................................................................................................................................ 61

Figure 35. External RJ45 network interface controller (NIC) port LED definition .......................................................... 62

Figure 36. SFP+ LAN Riser Option...................................................................................................................................................... 62

Figure 37. SFP+ LAN Riser Option Support ................................................................................................................................... 63

Figure 38. BIOS setup security options ............................................................................................................................................ 64

Figure 39. Onboard TPM Connector ................................................................................................................................................. 66

Figure 40. High-level fan speed control process ......................................................................................................................... 76

9

Page 10

Intel® Server Board S2600ST Product Family Technical Product Specification

Figure 41. Intel® RMM4 Lite placement ............................................................................................................................................ 80

Figure 42. Dedicated Management Port .......................................................................................................................................... 80

Figure 43. Jumper block locations and pins .................................................................................................................................. 94

Figure 44. DIMM fault LEDs ................................................................................................................................................................... 99

Figure 45. System status LED and ID LED identification ....................................................................................................... 100

Figure 46. POST diagnostic LED location and definition ....................................................................................................... 105

Figure 47. Intel® Server Chassis P4304XXMFEN2 feature overview ................................................................................ 125

Figure 48. Intel® Server Chassis P4304XXMUXX feature overview .................................................................................. 126

Figure 49. Chassis-only building block (no front drive bay configuration) .................................................................... 126

Figure 50. Intel® Server Chassis P4304XXMFEN2/P4304XXMUXX front panel .......................................................... 127

Figure 51. P4304XXMFEN2 back panel ........................................................................................................................................ 127

Figure 52. Intel® Server Chassis P4304XXMUXX back panel .............................................................................................. 127

Figure 53. Drive tray LED identification ........................................................................................................................................ 128

10

Page 11

Intel® Server Board S2600ST Product Family Technical Product Specification

List of Tables

Table 1. Reference Documents ........................................................................................................................................................... 13

Table 2. Intel® Server Board S2600ST product family common feature set ................................................................... 16

Table 3. POST hot keys .......................................................................................................................................................................... 29

Table 4. Intel® Xeon® Processor Scalable Family Feature Comparison .............................................................................. 35

Table 5. Mixed processor configurations error summary ........................................................................................................ 39

Table 6. CPU – PCIe* port routing ...................................................................................................................................................... 41

Table 7. DDR4 RDIMM and LRDIMM support ................................................................................................................................ 44

Table 8. Memory RAS Features ........................................................................................................................................................... 47

Table 9. Intel® VROC upgrade key options ..................................................................................................................................... 57

Table 10. SATA and sSATA Controller Feature Support .......................................................................................................... 57

Table 11. SATA and sSATA controller BIOS utility setup options ........................................................................................ 58

Table 12. Onboard Network interface controller (NIC) LED Definition .............................................................................. 62

Table 13. SFP+ LAN Riser LED Definition ........................................................................................................................................ 63

Table 14. BIOS security configuration TPM states ...................................................................................................................... 67

Table 15. BIOS security configuration TPM administrative controls .................................................................................. 68

Table 16. Power control sources ........................................................................................................................................................ 71

Table 17. ACPI power states ................................................................................................................................................................. 71

Table 18. Component fault LEDs ........................................................................................................................................................ 78

Table 19. Intel® Remote Management Module 4 (Intel® RMM4) options ........................................................................... 79

Table 20. Standard and advanced server management features ......................................................................................... 79

Table 21. Main Power Connector Pin-out (“MAIN_PWR_CONN”) ......................................................................................... 86

Table 22. CPU1 Power Connector Pin-out (“CPU_1_PWR”) ................................................................................................... 87

Table 23. CPU2 Power Connector Pin-out (“CPU_2_PWR”) ................................................................................................... 88

Table 24. Auxiliary Power-in Connector Pin-out ("AUX_PWR_IN”) ...................................................................................... 88

Table 25. Front Panel Header Pin-out .............................................................................................................................................. 88

Table 26. Front Panel USB 3.0 Connector Pin-out ..................................................................................................................... 89

Table 27. SATA 6 Gbps Connector Pin-out .................................................................................................................................... 89

Table 28. Mini-SAS HD Connectors for SATA 6 Gbps Pin-out ............................................................................................... 90

Table 29. M.2 Connector Pin-outs (for SATA & PCIe* modules) ........................................................................................... 91

Table 30. 6-Pin System Fan Connector Pin-out ........................................................................................................................... 92

Table 31. 4-pin System Fan Connector Pin-out ........................................................................................................................... 92

Table 32. CPU Fan Connector Pin-out ............................................................................................................................................. 92

Table 33. I

Table 34. Serial Port A Connector Pin-out ..................................................................................................................................... 93

Table 35. PMBUS Connector Pin-out ............................................................................................................................................... 93

Table 36. Chassis Intrusion Header Pin-out .................................................................................................................................. 93

Table 37. System status LED state detail ..................................................................................................................................... 101

Table 38. BMC Boot/Reset Status LED Indicators .................................................................................................................... 102

Table 39.Server Board Environmental Limits ......................................................................................................................... 103

Table 40. POST progress code LED example ............................................................................................................................. 105

11

2

C Header B Pin-out (“HSBP_I2C_B”) ........................................................................................................................... 93

Page 12

Intel® Server Board S2600ST Product Family Technical Product Specification

Table 41. MRC progress codes ......................................................................................................................................................... 106

Table 42. MRC Fatal Error Codes ..................................................................................................................................................... 107

Table 43. POST progress codes ....................................................................................................................................................... 108

Table 44. POST error codes and messages ................................................................................................................................ 116

Table 45. POST error beep codes ................................................................................................................................................... 121

Table 46. Integrated BMC beep codes .......................................................................................................................................... 122

Table 47. Volatile and non-volatile components on the Intel® Server Board S2600ST product family ........... 123

Table 48. Volatile and non-volatile components on the LAN riser ................................................................................... 123

Table 49. Drive status LED states .................................................................................................................................................... 128

Table 50. Drive activity LED states .................................................................................................................................................. 128

Table 51. PCIe* SSD drive status LED states .............................................................................................................................. 128

Table 52. Environmental Limits ....................................................................................................................................................... 129

Table 53. System in “Normal” Operating Mode for Systems with Fan Redundancy ................................................. 131

Table 51. System in “Fan Fail” Operating Mode for Systems with Fan Redundancy ................................................ 134

Table 52. System in “Normal” Operating Mode for Systems without Fan Redundancy .......................................... 137

Table 53. System in “Throttling” Operating Mode for Systems with Fan Redundancy ............................................ 140

12

Page 13

Intel® Server Board S2600ST Product Family Technical Product Specification

Document

Classification

Intel® Server System BMC Firmware External Product Specification for Intel® Xeon®

processor Scalable family

Intel® Server System BIOS External Product Specification for Intel® Xeon® processor

Scalable family

Intel® C620 Series Chipset Platform Controller Hub External Design Specification

Intel Confidential

Intel® Xeon® processor Scalable Family Server Processor External Design Specification

Volume 1, Volume 2 Part A, Volume 2 Part B, Volume 3

Advanced Configuration and Power Interface Specification. Revision 3.0 (2004)

http://www.acpi.info/

Intelligent Platform Management Interface Specification, v2.0 (2004)

Public

Intelligent Platform Management Bus Communications Protocol Specification, v1.0

(1998)

Platform Support for Serial-over-LAN (SOL), TMode, and Terminal Mode External

Architecture Specification, Version 1.1 (2002)

Intel® Remote Management Module User Guide

Public

Alert Standard Format (ASF) Specification, Version 2.0 (2003), ©2000-2003,

Distributed Management Task Force, Inc., http://www.dmtf.org

SmaRT & CLST Architecture on Intel Systems and Power Supplies Specification

Public

Intel® Remote Management Module 4 Technical Product Specification

Public

Intel® Remote Management Module 4 and Integrated BMC Web Console User Guide

Public

1. Introduction

This Technical Product Specification (TPS) provides a high level overview of the features, functions, and

architecture of the Intel® Server Board S2600ST product family.

For more in-depth technical information, refer to the documents listed in Table 1.

Note: Some of the documents listed in the following table are classified as “Intel Confidential”. These

documents are made available under a Non-Disclosure Agreement (NDA) with Intel and must be ordered

through your local Intel representative.

Table 1. Reference Documents

Document Title

Intel Confidential

Intel Confidential

Intel Confidential

Public

Public

Public

Public

13

Page 14

Intel® Server Board S2600ST Product Family Technical Product Specification

1.1 Chapter Outline

This document is divided into the following chapters:

• Chapter 1 – Introduction

• Chapter 2 – Server Board Overview

• Chapter 3 – Processor Support

• Chapter 4 – PCI Express* (PCIe*) Support

• Chapter 5 – Memory Support

• Chapter 6 – System I/O

• Chapter 7 – System Security

• Chapter 8 – Platform Management

• Chapter 9 – Standard and Advanced Server Management Features

• Chapter 10 – On-Board Connector and Header Overview

• Chapter 11 – Reset and Recovery Jumpers

• Chapter 12 – Light-Guided Diagnostics

• Chapter 13 – Design and Environmental Specifications

• Appendix A – Integration and Usage Tips

• Appendix B – Post Code Diagnostic LED Decoder

• Appendix C – Post Code Errors

• Appendix D – Statement of Volatility

• Appendix E – Supported Intel Server Chassis

• Appendix F – Glossary

1.2 Intel® Server Board Use Disclaimer

Intel® Server Boards support add-in peripherals and contain a number of high-density very large scale

integration (VLSI) and power delivery components that need adequate airflow to cool. Intel ensures through

its own chassis development and testing that when Intel server building blocks are used together, the fully

integrated system will meet the intended thermal requirements of these components. It is the responsibility

of the system integrator who chooses not to use Intel developed server building blocks to consult vendor

datasheets and operating parameters to determine the amount of airflow required for their specific

application and environmental conditions. Intel Corporation cannot be held responsible if components fail

or the server board does not operate correctly when used outside any of its published operating or nonoperating limits.

14

Page 15

Intel® Server Board S2600ST Product Family Technical Product Specification

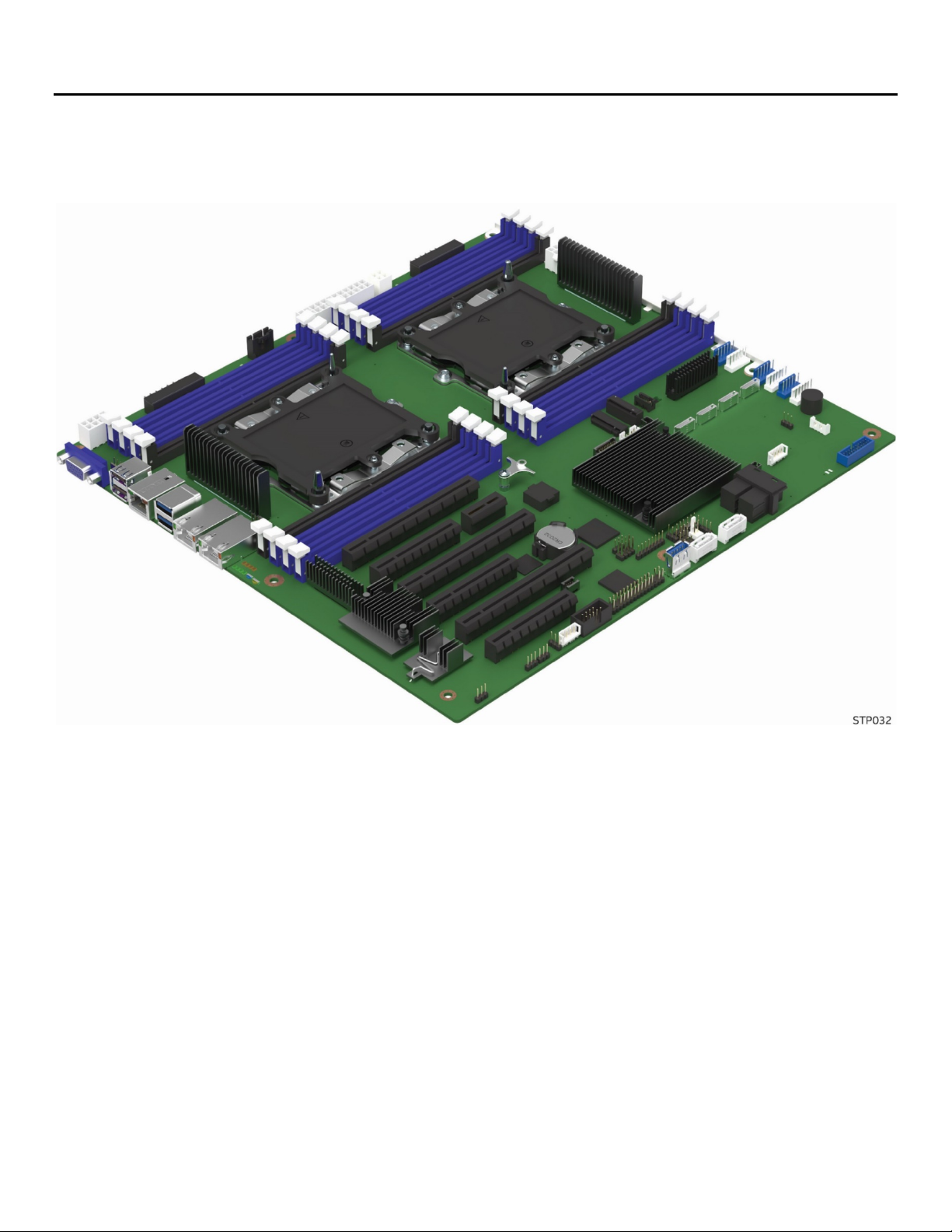

2. Server Board Family Overview

The Intel® Server Board S2600ST product family is a monolithic printed circuit board assembly with features

that are intended for flexibility in scalable performance environments. This server board is designed to

support the Intel® Xeon® processor Scalable family. Previous generation Intel® Xeon® processors are not

supported.

Figure 1. Intel® Server Board S2600STB

15

Page 16

Intel® Server Board S2600ST Product Family Technical Product Specification

Intel® Server Board Feature

iPC – S2600STB

iPC –S2600STQ

Processor

2 – LGA3647-0 (Socket P) processor sockets

Note: Previous generation Intel® Xeon® processors are not supported.

Memory

16 total DIMM slots

DDR4 standard voltage of 1.2 V

Intel® C62x Series Chipset

Intel® C624 Chipset

Intel® C628 Chipset

Intel® QuickAssist Technology

No

Yes

Local Area Network (LAN)

Dual port RJ45 10 GbE on board

Optional riser aligned to Slot 5 with two 10 Gb SFP+ connectors

Onboard PCIe* NVMe*

• (4) – OCuLink connectors

(accessory option)

• (2) – OCuLink connectors

option)

Onboard SATA

12 x SATA 6 Gbps ports (6 Gb/s, 3 Gb/s and 1.5 Gb/s transfer rates are supported)

PCIe* Add-in Card Slots

• Slot 1: PCIe* 3.0 x8 slot (x8 electrical) handled by CPU2

• Slot 6: PCIe* 3.0 x16 slot (x16 electrical) handled by CPU1 (riser capable)

Video

• Integrated 2D video controller

(1) – DB-15 external connector

USB

• (2) – external USB 2.0 ports

(1) – 2x10 pin connector providing front panel support for (2) USB 2.0 / 3.0 ports

Serial Port

(1) – internal DH-10 serial port A connector

Server Management

• Integrated baseboard management controller, IPMI 2.0 compliant

• Advanced server management via Intel® RMM4 Lite (accessory option)

Security

Trusted platform module 2.0 (Rest of World) – iPC- AXXTPMENC8 (accessory option)

Trusted platform module 2.0 (China Version) – iPC- AXXTPME8 (accessory option)

System Fan Support

• (2) – 4-pin processor fan headers

• (1) – 4-pin rear system fan header

2.1 Server Board Feature Set

Table 2. Intel® Server Board S2600ST product family common feature set

Supports (1) or (2) Intel® Xeon® processor Scalable family with maximum TDP of 205 W.

2 UPI* links between processors

8 DIMM slots across 6 memory channels per processor

• 1 DIMM slot per memory channel on 4 channels

• 2 DIMM slots per memory channel on 2 channels

Supported memory: Registered DDR4 (RDIMM), Load Reduced DDR4 (LRDIMM)

Memory data transfer rate up to 2666 MT/s (processor SKU dependent)

• Intel® VMD support

• Intel® RSTe VROC support

• (2) – single port 7-pin SATA connectors

• (2) – M.2 connectors – SATA / PCIe*

• (2) – 4-port mini- SAS high density (HD) (SFF-8643) connectors

Embedded SATA software RAID

• Intel® RSTe 5.0

• Intel® Embedded Server RAID Technology 2 1.60 with optional RAID 5 key support (see

section 6.3.6 for details)

• Slot 2: PCIe* 3.0 x16 slot (x16 electrical) handled by CPU2 (riser capable)

• Slot 3: PCIe* 3.0 x8 slot (x8 electrical) handled by CPU2

• Slot 4: PCIe* 3.0 x16 slot (x16 electrical) handled by CPU2

• Slot 5: PCIe* 3.0 x8 slot (x8 electrical) handled by CPU1

• 16 MB of DDR4 video memory

•

• (2) – external USB 3.0 ports

• (1) – internal USB 3.0 type A connector

•

• Intel® VMD support

• Intel® RSTe VROC support (accessory

• Support for Intel® Server Management software

• Dedicated onboard RJ45 management port

16

• (6) – 6-pin front system fan headers

Page 17

Intel® Server Board S2600ST Product Family Technical Product Specification

2.2 Server Board Component / Feature Identification

Figure 2. Server board component / feature identification

17

Page 18

Intel® Server Board S2600ST Product Family Technical Product Specification

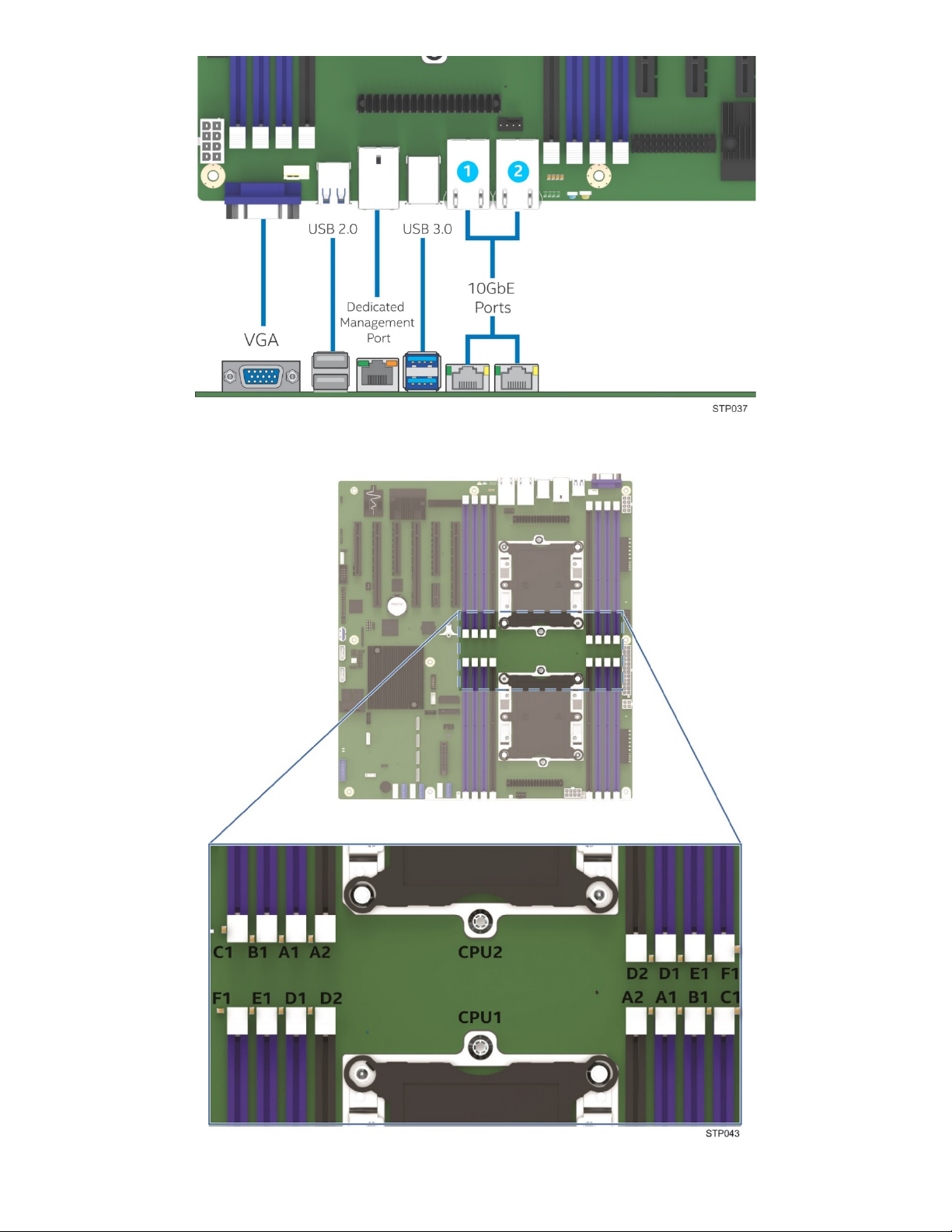

Figure 3. Intel® Server Board S2600ST product family external I/O connector layout

Figure 4. Intel® Light Guided Diagnostics - DIMM fault LEDs

18

Page 19

Intel® Server Board S2600ST Product Family Technical Product Specification

Figure 5. Intel® Light Guided Diagnostics – LED identification

19

Page 20

Intel® Server Board S2600ST Product Family Technical Product Specification

Figure 6. Jumper block identification

See Chapter 11 for additional details on reset and recovery jumpers.

20

Page 21

Intel® Server Board S2600ST Product Family Technical Product Specification

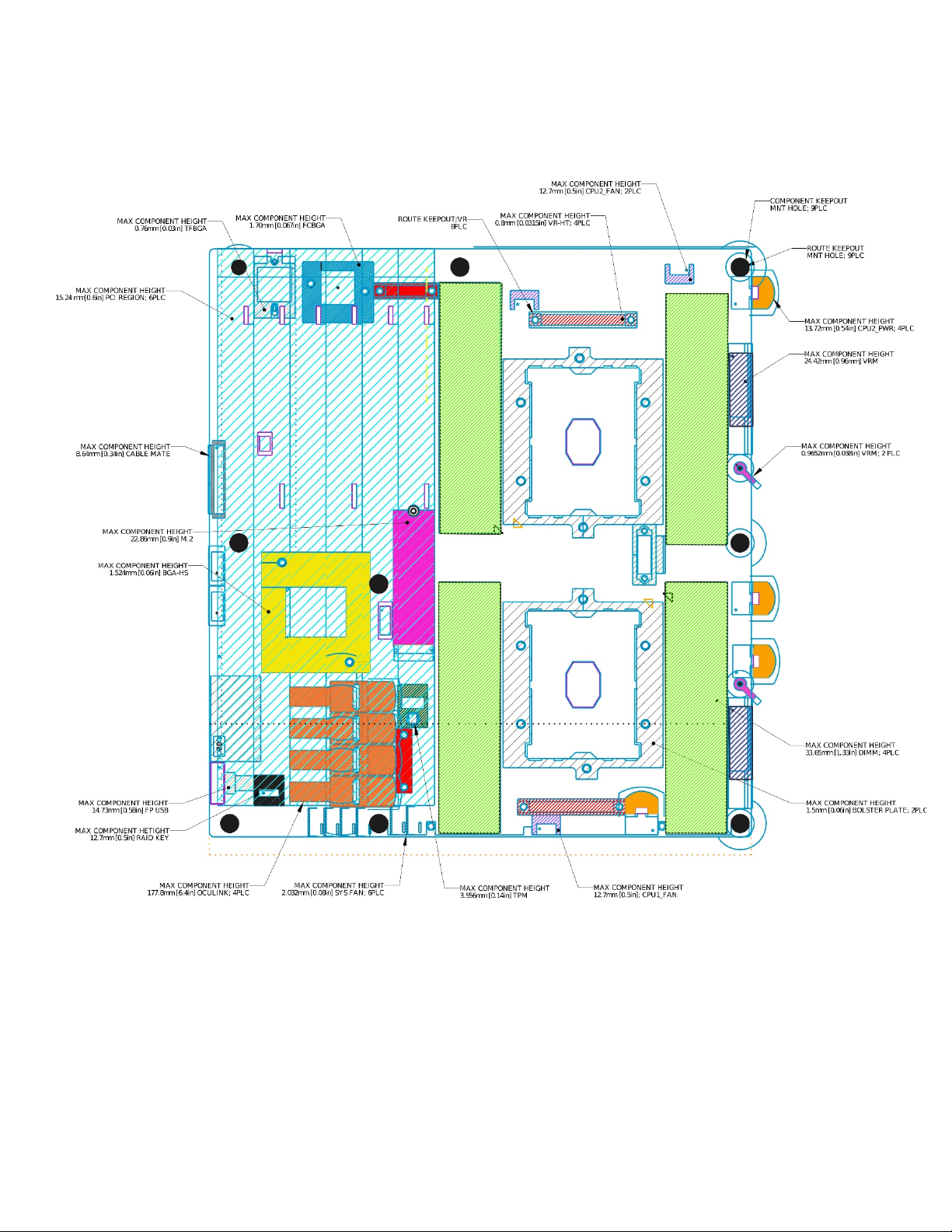

2.3 Server Board Mechanical Drawings

Figure 7. Primary side keep out zone and component height restrictions

21

Page 22

Intel® Server Board S2600ST Product Family Technical Product Specification

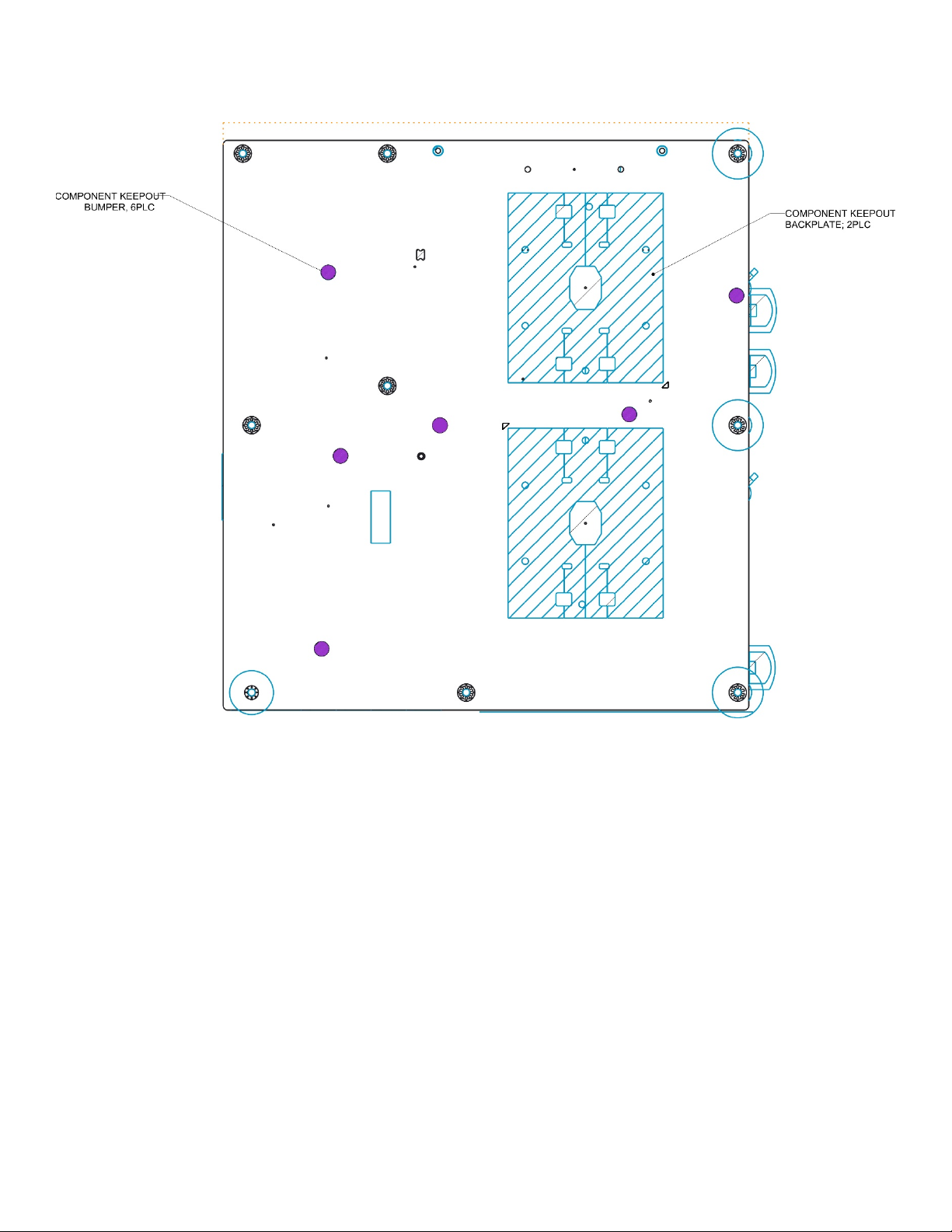

Figure 8. Secondary side keep out zone

22

Page 23

Intel® Server Board S2600ST Product Family Technical Product Specification

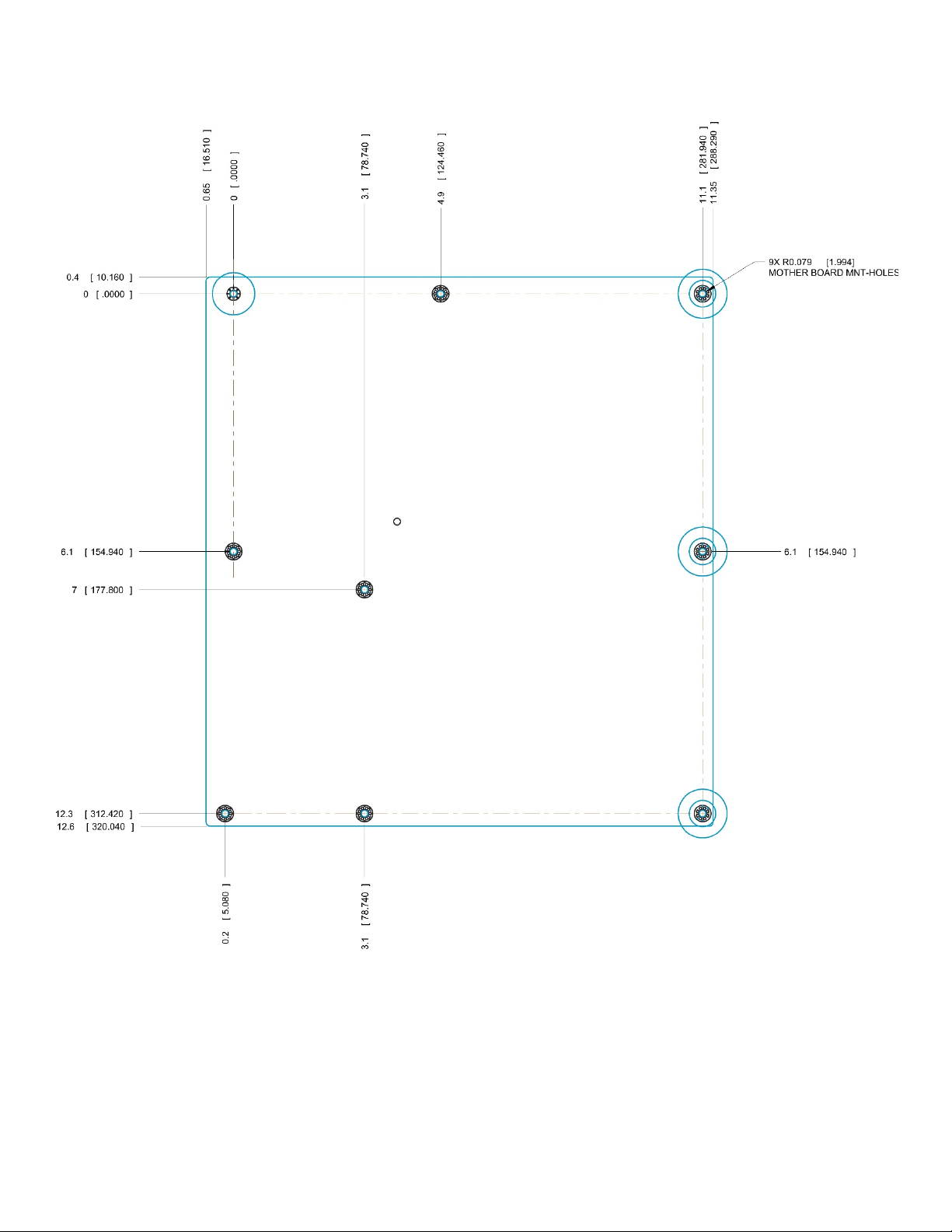

Figure 9. Mounting holes

23

Page 24

Intel® Server Board S2600ST Product Family Technical Product Specification

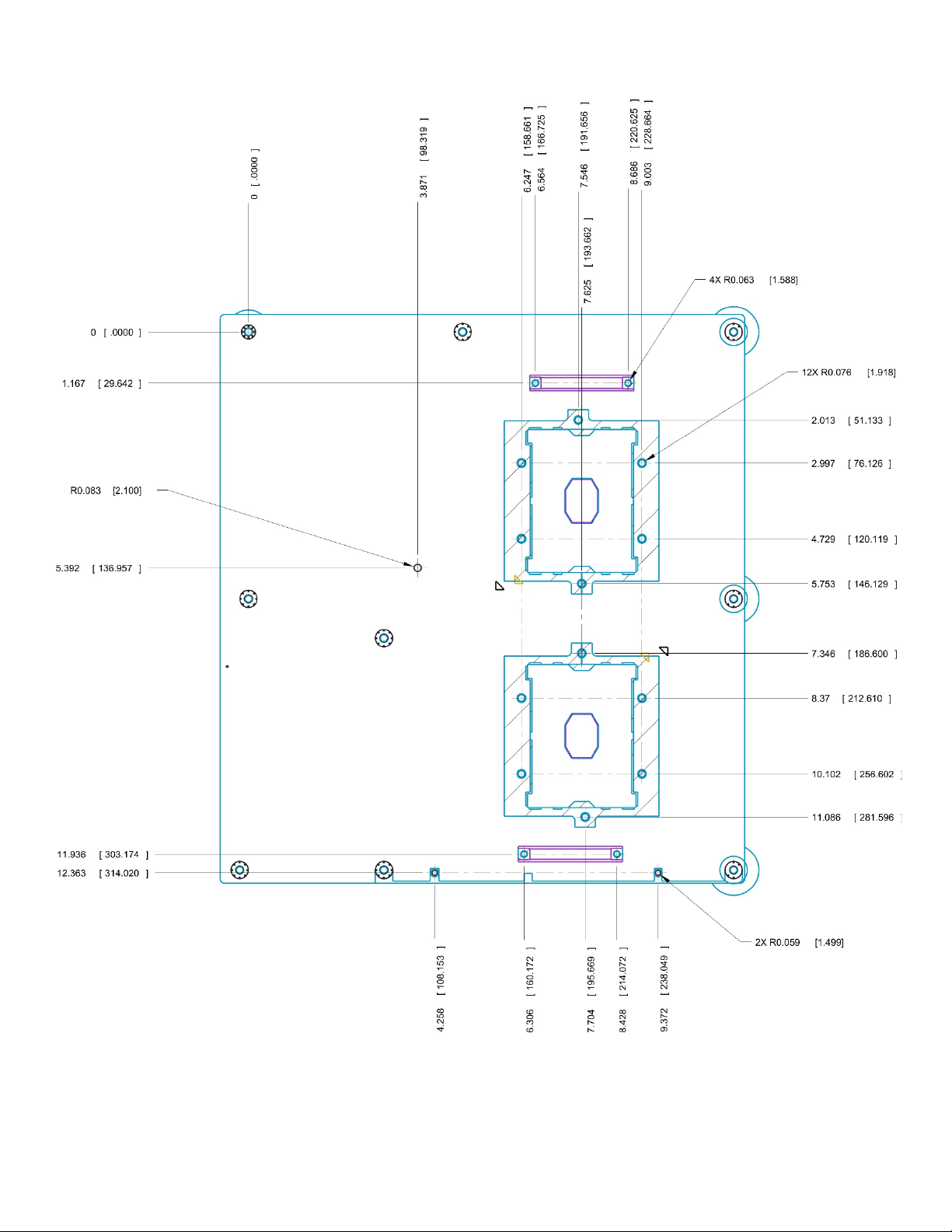

Figure 10. Mounting holes continued

24

Page 25

Intel® Server Board S2600ST Product Family Technical Product Specification

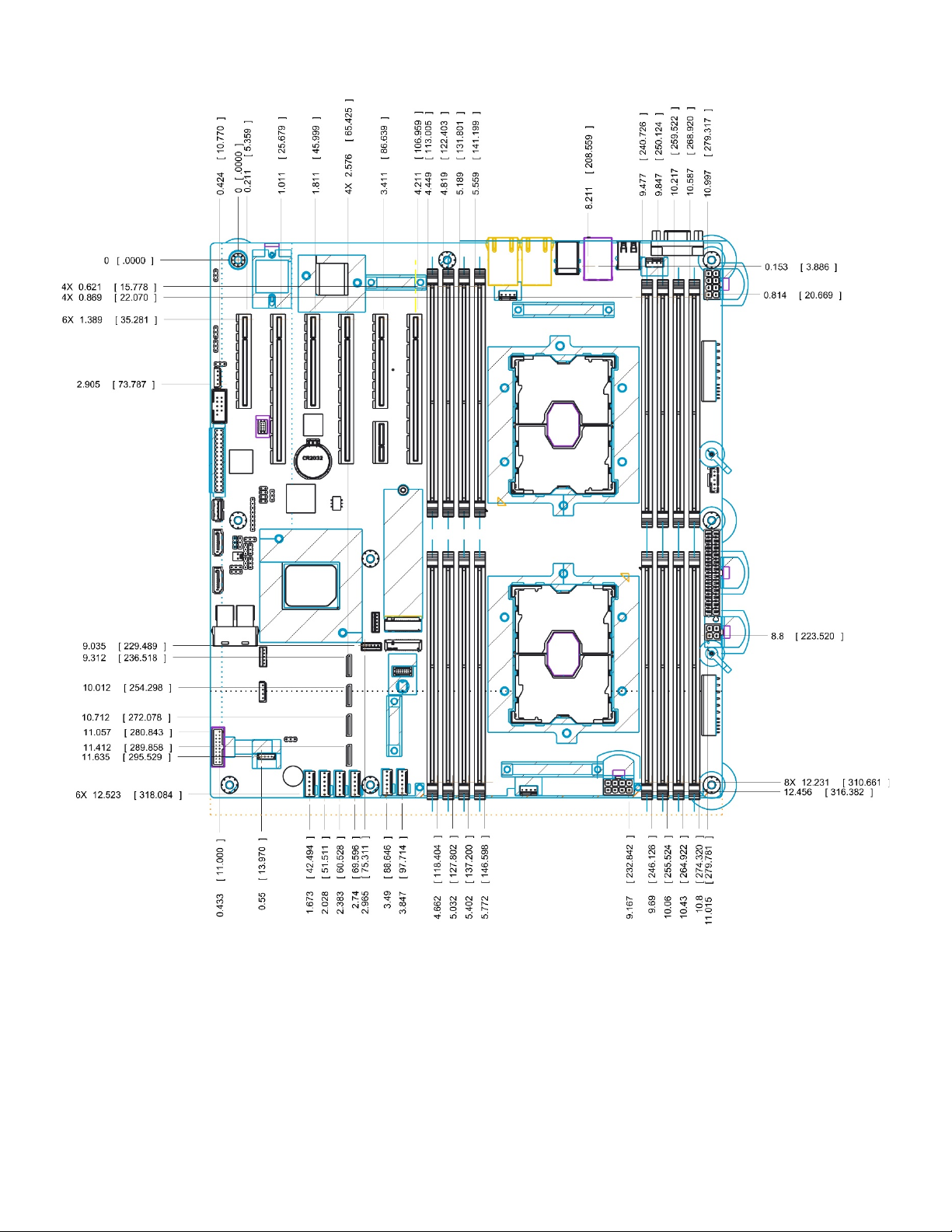

Figure 11. Major components and connectors (1 of 3)

25

Page 26

Intel® Server Board S2600ST Product Family Technical Product Specification

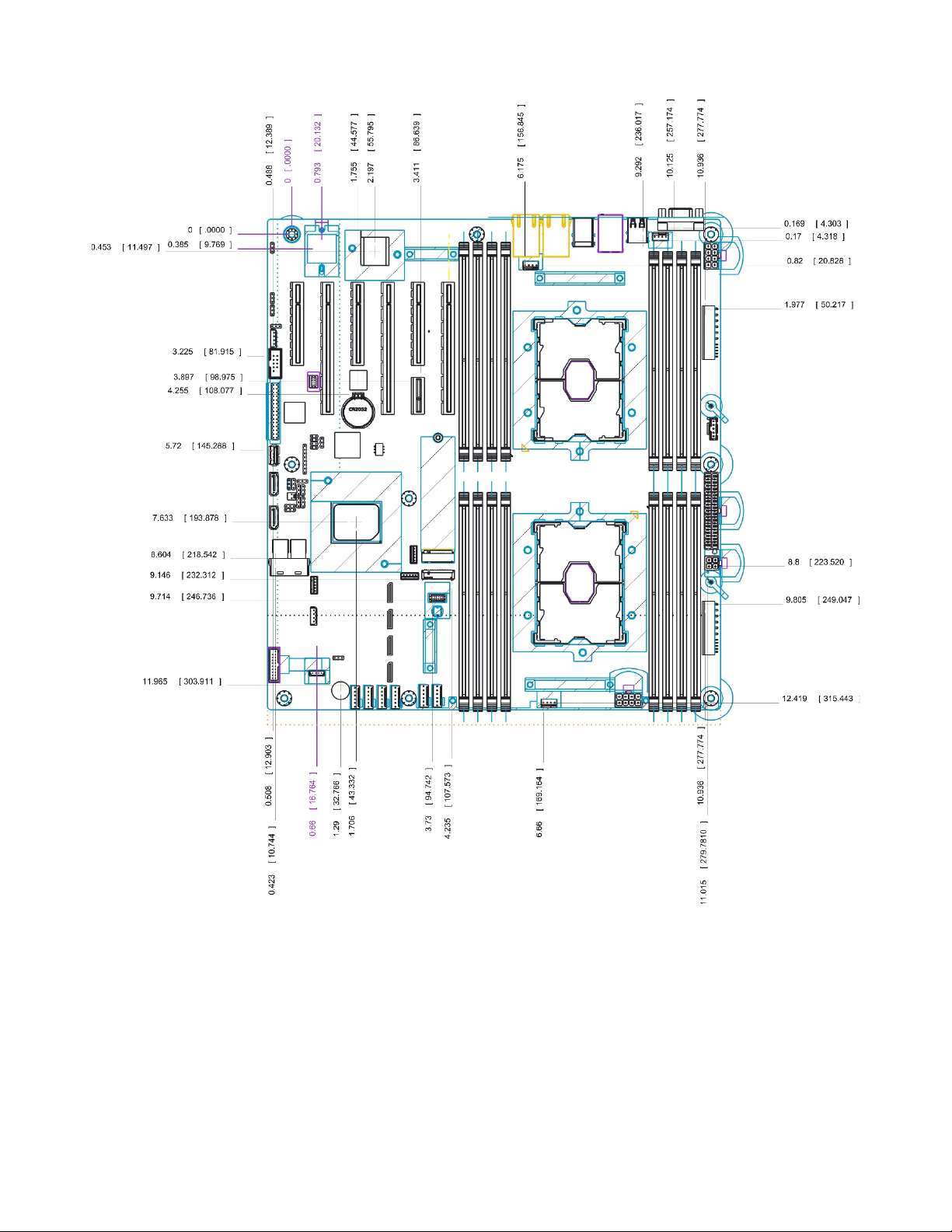

Figure 12. Major components and connectors (2 of 3)

26

Page 27

Intel® Server Board S2600ST Product Family Technical Product Specification

Figure 13. Major components and connectors (3 of 3)

27

Page 28

Intel® Server Board S2600ST Product Family Technical Product Specification

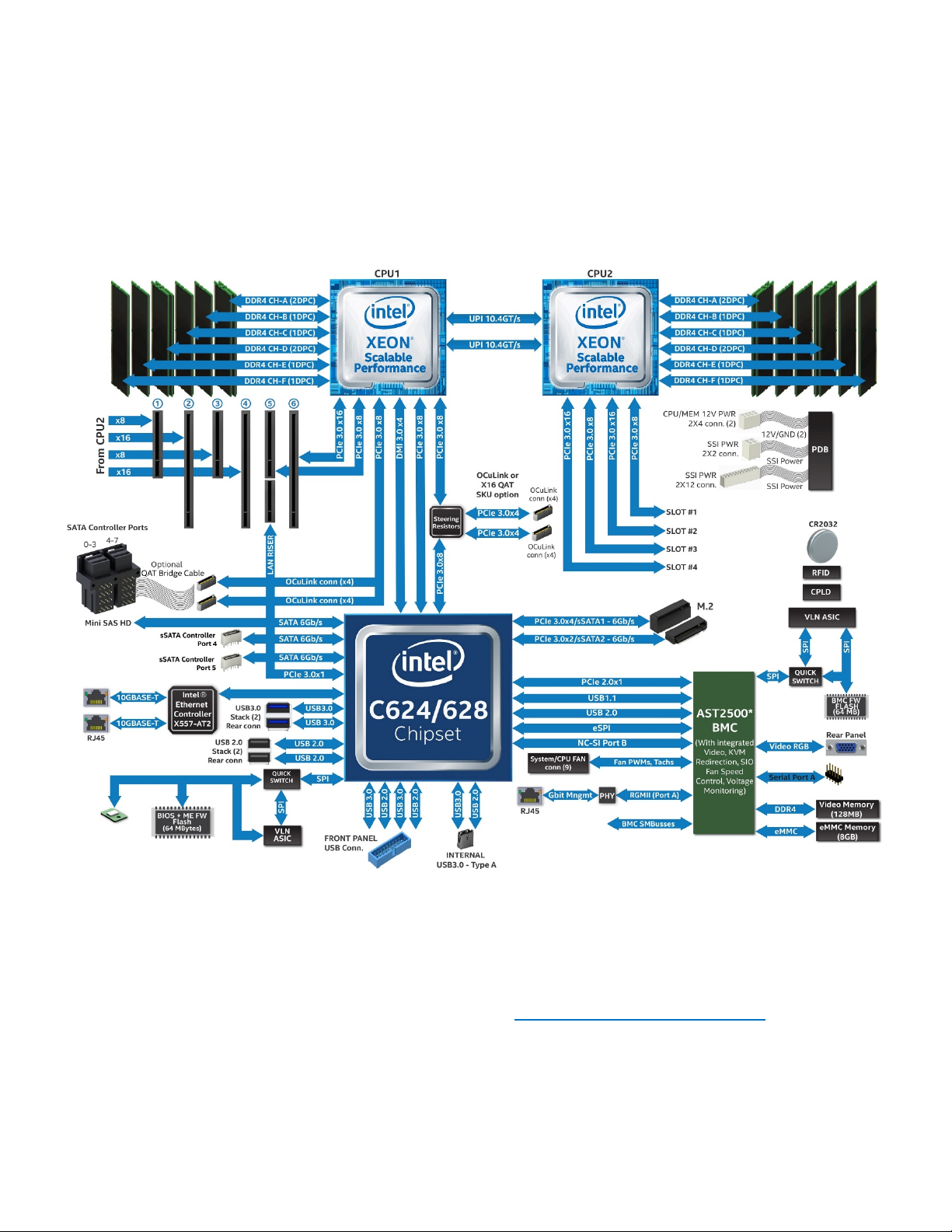

2.4 Product Architecture Overview

The architecture of the Intel® Server Board S2600ST product family is developed around the integrated

features and functions of the Intel® Xeon® processor Scalable family, the Intel® C624 and C628 chipsets, and

the Aspeed* AST2500 Baseboard Management Controller (BMC).

The following diagram provides an overview of the server board architecture, showing the features and

interconnects of each of the major sub-system components.

Figure 14. Intel® Server Board S2600ST product family block diagram

2.5 System Software Stack

System software is pre-programmed by Intel on the server board during the board assembly process,

making the server board functional at first power on after system integration. However, to ensure the most

reliable system operation, it is highly recommended to visit http://downloadcenter.intel.com

available system updates.

System updates can be performed in a number of operating environments, including the embedded Unified

Extensible Firmware Interface (UEFI) shell using the UEFI only System Update Package (SUP), or under Intel

supported operating systems using the Intel® One Boot Flash Update (Intel® OFU) utility.

28

for the latest

Page 29

Intel® Server Board S2600ST Product Family Technical Product Specification

Hot Key

Function

<F2>

Enter the BIOS setup utility

<F6>

Pop-up BIOS boot menu

<F12>

Network boot

<Esc>

Switch from logo screen to diagnostic screen

<Pause>

Stop POST temporarily

As part of the initial system integration process, system integrators must program system configuration data

onto the server board using the Field Replaceable Unit / Sensor Data Record (FRUSDR) utility to ensure the

embedded platform management subsystem is able to provide the best performance and cooling for the

final system configuration. The FRUSDR utility is included in the uEFI SUP and Intel OFU packages.

Refer to the following Intel documents for more in-depth information about the system software stack and

their functions:

• Intel® Server System BMC Firmware External Product Specification for Intel® Xeon® Processor Scalable

Family – Intel NDA Required

• Intel® Server System BIOS External Product Specification for Intel® Xeon® processor Scalable family –

Intel NDA Required

2.5.1 Hot Keys Supported During Power-On Self-Test (POST)

Certain hot keys are recognized during power-on self-test (POST). A hot key is a key or key combination that

is recognized as an unprompted command input by the system operator. In most cases, hot keys are

recognized even while other processing is in progress.

The Basic Input/Output System (BIOS) supported hot keys are only recognized by the BIOS during the

system boot time POST process. BIOS supported hot keys are no longer recognized once the POST process

has completed and the operating system boot process has begun.

Table 3 provides a list of BIOS supported hot keys.

Table 3. POST hot keys

2.5.1.1 POST Logo and Diagnostic Screens

With the BIOS Setup Utility set to Quiet Boot (default), the BIOS will display a splash screen to the display

monitor during the POST process. Pressing the <ESC> key will close the splash screen and open a POST

Diagnostic / Information screen in its place.

The factory default splash screen is that of an Intel Logo. A custom OEM splash screen can be installed to a

designated flash memory location to over-ride the factory default.

If a splash screen is not present in the BIOS flash memory space, or if Quiet Boot is disabled in BIOS Setup,

the POST diagnostic screen is displayed during POST with a summary of the system configuration

information. The POST diagnostic screen is purely a text mode screen, as opposed to the graphics mode

logo screen.

If console redirection is enabled in the BIOS setup utility, the quiet boot setting is disregarded and the text

mode diagnostic screen is displayed unconditionally. This is due to the limitations of console redirection,

which transfers data in a mode that is not graphics-compatible.

29

Page 30

Intel® Server Board S2600ST Product Family Technical Product Specification

2.5.1.2 BIOS Boot Pop-Up Menu

The BIOS Boot Specification (BBS) provides a boot pop-up menu that can be invoked by pressing the <F6>

key during POST. The BBS pop-up menu displays all available boot devices. The boot order in the pop-up

menu is not the same as the boot order in the BIOS setup utility. The pop-up menu simply lists all of the

available devices from which the system can be booted, and allows a manual selection of the desired boot

device.

When an Administrator password is installed in the BIOS setup utility, the Administrator password is

required to access the boot pop-up menu. If a User password is entered, the user is taken directly to the boot

manager in the BIOS setup utility only allowing the system to boot in the order previously defined by the

administrator.

2.5.1.3 Entering BIOS Setup

To enter the BIOS setup utility using a keyboard (or emulated keyboard), press the <F2> function key during

boot time when the OEM or Intel logo screen or the POST diagnostic screen is displayed.

The following instructional message is displayed on the diagnostic screen or under the quiet boot logo

screen:

Press <F2> to enter setup, <F6> Boot Menu, <F12> Network Boot

Note: With a USB keyboard, it is important to wait until the BIOS discovers the keyboard and beeps; until the

USB controller has been initialized and the keyboard activated, key presses are not read by the system.

When the BIOS setup utility is entered, the main screen is displayed initially. However, if a serious error

occurs during POST, the system enters the BIOS setup utility and displays the error manager screen instead

of the main screen.

Refer to the following Intel document for additional BIOS setup utility information:

• Intel® Server System BIOS External Product Specification for Intel® Xeon® processor Scalable family –

Intel NDA Required

2.5.2 BIOS Update Capability

To bring BIOS fixes or new features into the system, it is necessary to replace the current installed BIOS

image with an updated one. The BIOS image can be updated using a standalone IFLASH32 utility in the UEFI

shell or using the OFU utility program under a supported operating system. Full BIOS update instructions are

provided with update packages downloaded from the Intel website.

2.5.3 BIOS Recovery

If a system is unable to boot successfully to an OS, hangs during POST, or even hangs and fails to start

executing POST, it may be necessary to perform a BIOS recovery procedure to replace a defective copy of

the primary BIOS

The BIOS provides three mechanisms to start the BIOS recovery process, which is called recovery mode:

• The recovery mode jumper causes the BIOS to boot in recovery mode. See Figure 6 for jumper

location.

• At power on, if the BIOS boot block detects a partial BIOS update was performed, the BIOS

automatically boots in recovery mode.

• The baseboard management controller (BMC) asserts the recovery mode general purpose

input/output (GPIO) in case of partial BIOS update and FRB2 timeout.

30

Page 31

Intel® Server Board S2600ST Product Family Technical Product Specification

The BIOS recovery takes place without any external media or mass storage device as it uses a backup BIOS

image inside the BIOS flash in recovery mode.

Note: The recovery procedure is included here for general reference. However, if in conflict, the instructions

in the BIOS release notes are the definitive version.

When the BIOS recovery jumper is set, the BIOS begins by logging a recovery start event to the System Event

Log (SEL). It then loads and boots with a backup BIOS image residing in the BIOS flash device. This process

takes place before any video or console is available. The system boots to the embedded UEFI shell, and a

recovery complete event is logged to the SEL. From the UEFI shell, the BIOS can then be updated using a

standard BIOS update procedure defined in update instructions provided with the system update package

downloaded from the Intel website. Once the update has completed, switch the recovery jumper back to its

default position and power cycle the system.

If the BIOS detects a partial BIOS update or the BMC asserts recovery mode GPIO, the BIOS boots in recovery

mode. The difference is that the BIOS boots up to the error manager page in the BIOS setup utility. In the

BIOS Setup utility, a boot device, shell or Linux for example, could be selected to perform the BIOS update

procedure under shell or OS environment.

Note: Prior to performing a recovery boot, be sure to check the BIOS release notes and verify the recovery

procedure shown in the release notes. This process needs to be followed step by step to ensure the stability

of the system once it is completed.

2.5.4 Field Replaceable Unit (FRU) and Sensor Data Record (SDR) Data

As part of the initial system integration process, the server board/system must have the proper Field

Replaceable Unit (FRU) and Sensor Data Record (SDR) data loaded. This ensures that the embedded platform

management system is able to monitor the appropriate sensor data and operate the system with best

cooling and performance. The BMC supports automatic configuration of the manageability subsystem after

changes have been made to the system’s hardware configuration. Once the system integrator has performed

an initial FRU/SDR package update, subsequent auto-configuration occurs without the need to perform

additional SDR updates or provide other user input to the system when any of the following components are

added or removed.

• Processors

• Intel Add-in cards / modules

• Power supplies

• Fans

• Fan options (for example, upgrade from non-redundant cooling to redundant cooling)

• Intel® Xeon Phi™ coprocessor cards

• Hot swap backplane

• Front panel

Note: The system may not operate with best performance or best/appropriate cooling if the proper FRU and

SDR data is not installed. The system fans may operate at full speed 100% all the time if the FRUSDR utility

is not run after the initial board integration and system configuration.

The FRU and SDR data can be updated using a standalone FRUSDR utility in the UEFI shell, or can be done

using the OFU utility program under a supported operating system. Full FRU and SDR update instructions are

provided with the appropriate system update package (SUP) or OFU utility which can be downloaded from

the Intel website.

31

Page 32

Intel® Server Board S2600ST Product Family Technical Product Specification

3. Processor Support

The server board includes two Socket-P0 LGA3647-0 processor sockets compatible with the Intel® Xeon®

processor Scalable family with a maximum Thermal Design Power (TDP) of 205 W. Visit http://ark.intel.com/

for a complete list of supported processors.

Note: Previous generation Intel® Xeon® processors are not supported on the Intel® Server Boards described

in this document.

3.1 Processor Heat Sink Module (PHM) and Processor Socket Assembly

Each processor socket of the server board is pre-assembled and includes a back plate, LGA3647-0 processor

socket, and a bolster plate assembly. The illustration in Figure 15 identifies each sub-assembly component.

Figure 15. Processor socket assembly

Server boards with no processors installed have a plastic protective dust cover installed over each processor

socket assembly. The protective covers must be carefully removed before processor installation, as shown in

Figure 16.

Figure 16. Processor socket assembly and protective dust cover

32

Page 33

Intel® Server Board S2600ST Product Family Technical Product Specification

This generation server board introduces the concept of the Processor Heat Sink Module (PHM) shown in

Figure 17, Figure 18, and Figure 19.

Processor installation requires that the processor be attached to the processor heat sink prior to

installation onto the server board.

Figure 17. Processor heat sink module (PHM) components and processor socket reference diagram

Figure 18. Processor heat sink module (PHM) sub-assembly

33

Page 34

Intel® Server Board S2600ST Product Family Technical Product Specification

Figure 19. Fully assembled processor heat sink module (PHM)

3.2 Processor Thermal Design Power (TDP) Support

To allow for optimal operation and provide for best long-term reliability of Intel processor-based systems,

the processor must remain within the defined minimum and maximum case temperature (TCASE)

specifications. Thermal solutions not designed to provide sufficient thermal capability may affect the longterm reliability of the processor and system. The server board described in this document is designed to

support the Intel® Xeon® processor Scalable family TDP guidelines up to and including 205 W.

Disclaimer Note: Intel® Server Boards contain a number of high-density very large scale integration (VLSI)

and power delivery components that need adequate airflow to cool. Intel ensures, through its own chassis

development and testing, that when Intel server building blocks are used together, the fully integrated

system meets the intended thermal requirements of these components. It is the responsibility of system

integrators who choose not to use Intel developed server building blocks to consult vendor datasheets and

operating parameters to determine the amount of airflow required for their specific applications and

environmental conditions. Intel Corporation cannot be held responsible if components fail or the server

board does not operate correctly when used outside any of its published operating or non-operating limits.

34

Page 35

Intel® Server Board S2600ST Product Family Technical Product Specification

Feature

Platinum 81xx

Gold 61xx

Gold 51xx

Silver 41xx

Bronze 31xx

# of Intel® UPI Links

3 3 2

2

2

Intel UPI Speed

10.4 GT/s

10.4 GT/s

10.4 GT/s

9.6 GT/s

9.6 GT/s

2S-2UPI

8S- 3UPI

Node Controller Support

Yes

Yes

No

No

No

# of Memory Channels

6 6 6

6

6

Max DDR4 Speed

2666

2666

2400

2400

2133

768GB

1.5TB (select SKUs)

768GB

1.5TB (select SKUs)

768GB

1.5TB (select SKUs)

RAS Capability

Advanced

Advanced

Advanced

Standard

Standard

Intel® Turbo Boost

Technology

Intel® HT Technology

Yes

Yes

Yes

Yes

No

Intel® AVX-512 ISA Support

Yes

Yes

Yes

Yes

Yes

Intel® AVX-512 - # of 512b

FMA Units

# of PCIe* Lanes

48

48

48

48

48

3.3 Intel® Xeon® Processor Scalable Family Overview

The Intel® Server Board S2600ST product family has support for the Intel® Xeon® processor Scalable family:

• Intel® Xeon® Bronze XXXX processor,

• Intel® Xeon® Silver XXXX processor,

• Intel® Xeon® Gold XXXX processor, and

• Intel® Xeon® Platinum XXXX processor,

where XXXX is the Intel defined processor SKU.

Table 4. Intel® Xeon® Processor Scalable Family Feature Comparison

2S-2UPI

2S-3UPI

4S-2UPI

4S-3UPI

2S-2UPI

4S-2UPI

2S-2UPI 2S-2UPI

768 GB 768 GB

Supported Topologies

Memory Capacity

2S-3UPI

4S-2UPI

4S-3UPI

Yes Yes Yes Yes No

2 2 1 1 1

The Intel® Xeon® processor Scalable family combines several key system components into a single processor

package, including the CPU cores, Integrated Memory Controller (IMC), and Integrated IO Module (IIO). The

processor includes many core and uncore features and technologies described in the following sections.

Core features:

• Intel® Ultra Path Interconnect (Intel® UPI) – up to 10.4 GT/s

• Intel® Speed Shift Technology

• Intel® 64 architecture

• Enhanced Intel SpeedStep® Technology

• Intel® Turbo Boost Technology 2.0

• Intel® Hyper-Threading Technology (Intel® HT Technology)

• Intel® Virtualization Technology for IA-32, Intel® 64 and Intel® Architecture (Intel® VT-x)

• Intel® Virtualization Technology for Directed I/O (Intel® VT-d)

• Execute Disable Bit

• Intel® Trusted Execution Technology (Intel® TXT)

• Intel® Advanced Vector Extensions 512 (Intel® AVX-512)

• Intel® Advanced Encryption Standard New Instructions (Intel® AES-NI)

Uncore features:

35

Page 36

Intel® Server Board S2600ST Product Family Technical Product Specification

• Up to 48 PCIe* lanes 3.0 lanes per CPU – 79GB/s bi-directional pipeline

• Six channels DDR4 memory support per CPU

• DMI3/PCIe 3.0 interface with a peak transfer rate of 8.0 GT/s.

• Non-Transparent Bridge (NTB) enhancements – three full duplex NTBs and 32 MSI-X vectors

• Intel® Volume Management Device (Intel® VMD) – manages CPU attached NVM Express* (NVMe*) solid

state drives (SSDs)

• Intel® Quick Data Technology

• Support for Intel® Node Manager 4.0

3.3.1 Intel® 64 Instruction Set Architecture (ISA)

Intel® 64 architecture is a 64-bit memory extension to the IA-32 architecture. Further details on Intel 64

architecture and programming model can be found at http://developer.intel.com/technology/intel64/.

3.3.2 Intel® Hyper-Threading Technology

The processor supports Intel® Hyper-Threading Technology (Intel® HT Technology), which allows an

execution core to function as two logical processors. While some execution resources such as caches,

execution units, and buses are shared, each logical processor has its own architectural state with its own set

of general-purpose registers and control registers. This feature must be enabled via the BIOS and requires

operating system support.

3.3.3 Enhanced Intel SpeedStep® Technology

Processors in the fifth generation Intel® Core™ processor family support Enhanced Intel SpeedStep®

Technology. The processors support multiple performance states, which allows the system to dynamically

adjust processor voltage and core frequency as needed to enable decreased power consumption and

decreased heat production. All controls for transitioning between states are centralized within the processor,

allowing for an increased frequency of transitions for more effective operation.

The Enhanced Intel SpeedStep Technology feature may be enabled and disabled by an option on the

processor configuration setup screen. By default Enhanced Intel SpeedStep Technology is enabled. If

disabled, the processor speed is set to the processor’s max TDP core frequency (nominal rated frequency).

3.3.4 Intel® Turbo Boost Technology 2.0

Intel® Turbo Boost Technology is featured on all processors in the fifth generation Intel® Core™ processor

family. Intel Turbo Boost Technology opportunistically and automatically allows the processor to run faster

than the marked frequency if the processor is operating below power, temperature, and current limits. This

results in increased performance for both multi-threaded and single-threaded workloads.

3.3.5 Intel® Virtualization Technology for IA-32, Intel® 64 and Intel® Architecture (Intel® VT-x)

Intel® Virtualization Technology for IA-32, Intel® 64 and Intel® Architecture (Intel® VT-x) provides hardware

support in the core to improve performance and robustness for virtualization. Intel VT-x specifications and

functional descriptions are included in the Intel® 64 and IA-32 Architectures Software Developer’s Manual.

3.3.6 Intel® Virtualization Technology for Directed I/O (Intel® VT-d)

Intel® Virtualization Technology for Directed I/O (Intel® VT-d) provides hardware support in the core and

uncore implementations to support and improve I/O virtualization performance and robustness.

3.3.7 Execute Disable Bit

Intel's Execute Disable Bit functionality can help prevent certain classes of malicious buffer overflow attacks

when combined with a supporting operating system. This allows the processor to classify areas in memory

by where application code can execute and where it cannot. When malicious code attempts to insert code in

the buffer, the processor disables code execution, preventing damage and further propagation.

36

Page 37

Intel® Server Board S2600ST Product Family Technical Product Specification

3.3.8 Intel® Trusted Execution Technology (Intel® TXT) for Servers

Intel® Trusted Execution Technology (Intel® TXT) defines platform-level enhancements that provide the

building blocks for creating trusted platforms. The Intel TXT platform helps to provide the authenticity of the

controlling environment such that those wishing to rely on the platform can make an appropriate trust

decision. The Intel TXT platform determines the identity of the controlling environment by accurately

measuring and verifying the controlling software.

3.3.9 Intel® Adavanced Vector Extension 512 (Intel® AVX-512)

The base of the 512-bit SIMD instruction extensions are referred to as Intel® Advanced Vector Extension 512

(Intel® AVX-512) foundation instructions. They include extensions of the Intel AVX family of SIMD

instructions but are encoded using a new encoding scheme with support for 512-bit vector registers, up to

32 vector registers in 64-bit mode, and conditional processing using opmask registers.

3.3.10 Intel® Advanced Encryption Standard New Instructions (Intel® AES-NI)

Intel® Advanced Encryption Standard New Instructions (Intel® AES-NI) is a set of instructions implemented in

all processors in the fifth generation Intel® Core™ processor family. This feature adds instructions to

accelerate encryption and decryption operations used in the Advanced Encryption Standard (AES). The Intel

AES-NI feature includes six additional Single Instruction Multiple Data (SIMD) instructions in the Intel®

Streaming SIMD Extensions instruction set.

The BIOS is responsible in POST to detect whether the processor has the Intel AES-NI instructions available.

Some processors may be manufactured without Intel AES-NI instructions.

The Intel AES-NI instructions may be enabled or disabled by the BIOS. Intel AES-NI instructions are in an

enabled state unless the BIOS has explicitly disabled them.

3.3.11 Intel® Node Manager (Intel® NM) 4.0