Page 1

Intel® Astor II Server Chassis Subassembly Product Guide

A Guide for Technically Quali f i ed Assemblers of Intel® Identified Subassemblies/Products

Order Number: 722623-001

Page 2

If an FCC declaration of conformity marking is present on the board, the following statement applies:

FCC Declaration of Conformity

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

For questions related to the EMC performance of this product, contact:

Intel Corporation

5200 N.E. Elam Young Parkway

Hillsboro, OR 97124

1-800-628-8686

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and the receiver.

Connect the equipment to an outlet on a circuit other than the one to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Canadian Department of Communications Compliance Statement:

This digital apparatus does not exceed the Class B limits for radio noise emissions from digital apparatus set

out in the Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numerique német pas de bruits radioélectriques dépassant les limites applicables aux

appareils numériques de la classe B prescrites dans le Réglement sur le broullage radioélectrique édicté par

le ministére des Communications du Canada.

Disclaimer

Information in this document is provided in connection with Intel products. No license, express or implied, by

estoppel or otherwise, to any intellectual property rights is granted by this document. Except as provided in

Intel's Terms and Conditions of Sale for such products, Intel assumes no liability whatsoever, and Intel

disclaims any express or implied warranty, relating to sale and/or use of Intel products including liability or

warranties relating to fitness for a particular purpose, merchantability, or infringement of any patent, copyright

or other intellectual property right. Intel products are not designed, intended or authorized for use in any

medical, life saving, or life sustaining applications or for any other application in which the failure of the Intel

product could create a situation where personal injury or death may occur. Intel may make changes to

specifications and product descriptions at any time, without notice.

The Astor II Chassis may contain design defects or errors known as errata which may cause the product to

deviate from published specifications. Current characterized errata are available on request. Copies of

documents which have an ordering number and are referenced in this document, or other Intel literature, may

be obtained from:

Intel Corporation

P.O. Box 5937

Denver, CO 80217-9808

or call in North America 1-800-548-4725, Europe 44-0-1793-431-155, France 44-0-1793-421-777,

Germany 44-0-1793-421-333, other Countries 708-296-9333.

†

Third party brands and names are property of their respective owners.

Copyright Intel Corporation 1998.

Page 3

Contents

1 System Description

Kit Contents.......................................................................................................................... 7

Feature Summary ................................................................................................................ 7

Chassis Front Controls and Indicators......................................................................... 8

Chassis Back I/O Ports and Features.......................................................................... 9

Chassis Side View......................................................................................................10

Peripherals..........................................................................................................................11

External Bay for 5.25-inch Removable Media Devices ...............................................11

Internal Bay for 3.5-inch IDE Hard Drives...................................................................11

Hot-swap Bay.............................................................................................................11

Power Supply......................................................................................................................12

Checking the Power Cord...........................................................................................12

System Cooling...................................................................................................................12

System Security..................................................................................................................13

Mechanical Locks.......................................................................................................13

Monitoring...................................................................................................................13

2 Working Inside the System

Tools and Supplies Needed ................................................................................................15

Safety: Before You Remove the Side Cover.......................................................................15

Warnings and Cautions.......................................................................................................15

Removing the Side Cover....................................................................................................16

Installing Chassis Feet........................................................................................................17

Removing the Hot-swap Bay...............................................................................................18

Removing the IDE Drive Bay...............................................................................................19

Installing Server Board Clips and Bumpers.........................................................................21

I/O Shield............................................................................................................................22

Installing the Server Board..................................................................................................22

Installing a Chassis Intrusion Switch ...................................................................................24

Removing the Front Cover..................................................................................................25

Installing the Diskette Drive.................................................................................................26

Removing the Diskette Drive...............................................................................................26

Hard Drives.........................................................................................................................27

Drive Cabling Considerations .....................................................................................27

Installing a Hard Drive into the IDE Drive Bay.............................................................27

Removing a Hard Drive from the IDE Drive Bay.........................................................28

Installing the IDE drive bay.........................................................................................29

Installing a 5.25-inch Peripheral Device......................................................................30

Removing a 5.25-inch Peripheral Device....................................................................32

Installing the Front Cover....................................................................................................33

Installing the Hot-swap Bay.................................................................................................33

Installing an Add-in Board ...................................................................................................33

Removing an Add-in Board.................................................................................................34

iii

Page 4

Installing the Side Cover......................................................................................................35

Hot-swap Bay......................................................................................................................36

SCSI Hard Disk Drives ...............................................................................................36

Mounting a SCSI SCA2 Hard Disk Drive in a Plastic Carrier.......................................36

Installing a SCSI SCA2 Hard Disk Drive in the Hot-swap Bay ....................................37

Hot-swapping a SCSI SCA2 Hard Disk Drive .............................................................38

Fans ...................................................................................................................................39

Removing the Front Fan.............................................................................................39

Installing the Front Fan...............................................................................................40

Removing a Hot-swap Bay Fan..................................................................................41

Installing a Hot-swap Bay Fan....................................................................................41

Hot-swap Backplane ...........................................................................................................42

Removing the SCSI Backplane...................................................................................42

Installing the SCSI Backplane.....................................................................................43

Front Panel Board...............................................................................................................44

Removing the Front Panel Board................................................................................44

Installing the Front Panel Board..................................................................................44

3 Technical Reference

Power Supply Specifications...............................................................................................45

Input Voltages.............................................................................................................45

Output Voltages..........................................................................................................45

Environmental Specifications ..............................................................................................46

SCSI Hot-swap Backplane Connectors...............................................................................47

Ultra2/LVD SCSI 16-Bit Connector.............................................................................47

Ultra2/LVD SCA2 SCSI 16-Bit Connectors.................................................................48

Power Connectors......................................................................................................49

Backplane Fan Connector..........................................................................................49

Front Panel Cable Connector.....................................................................................50

4 Regulatory Information

Regulatory Compliance.......................................................................................................51

Safety Compliance......................................................................................................51

EMC Compliance........................................................................................................52

Regulatory Compliance Markings...............................................................................53

Electromagnetic Compatibility Notice (USA)........................................................................53

FCC Declaration of Conformity...................................................................................54

Electromagnetic Compatibility Notices (International)..........................................................54

Installation Safety Instructions....................................................................................55

Use Only for Intended Applications.............................................................................56

A Equipment Log and Worksheets

Equipment Log....................................................................................................................57

Current Usage.....................................................................................................................59

Calculating Power Usage............................................................................................59

iv Intel Astor II Server Chassis Subassembly Product Guide

Page 5

B Warnings

WARNING: English (US)....................................................................................................62

AVERTISSEMENT: Français..............................................................................................64

WARNUNG: Deutsch.........................................................................................................66

AVVERTENZA: Italiano......................................................................................................68

ADVERTENCIAS: Español.................................................................................................70

C Warranty

Limited Warranty for Intel® Server Chassis Subassembly Products....................................73

Extent of Limited Warranty..................................................................................................73

Warranty Limitations and Exclusions...................................................................................74

Limitations of Liability..................................................................................................74

How to Obtain Warranty Service.........................................................................................75

Telephone Support.....................................................................................................75

Returning a Defective Product....................................................................................76

Figures

1. Front Controls and Indicators ...................................................................................... 8

2. Back I/O Ports and Features....................................................................................... 9

3. Chassis Side View......................................................................................................10

4. System Security.........................................................................................................13

5. Removing the Side Cover...........................................................................................17

6. Removing the Hot-swap Bay......................................................................................18

7. Disconnect Cables and Remove Screws....................................................................19

8. IDE Hard Drive Bay....................................................................................................20

9. Rubber Bumper and Standoff Clip Placement ............................................................21

10. Installing the I/O Shield (typical shield shown)............................................................22

11. Installing the Server Board (typical board shown).......................................................23

12. Installing a Chassis Intrusion Switch...........................................................................24

13. Removing the Front Cover..........................................................................................25

14. Installing the Diskette Drive........................................................................................26

15. IDE Cable Dimensions................................................................................................27

16. IDE Hard Drive...........................................................................................................28

17. Disconnect Cables and Remove Screws....................................................................29

18. Remove Filler Panels and EMI Shields.......................................................................30

19. Snap-in Plastic Slide Rails..........................................................................................31

20. Installing a Removable Media Device.........................................................................32

21. Installing an Add-in Board...........................................................................................34

22. Hard Disk Drive and Plastic Carrier............................................................................37

23. Installing a Hard Disk Drive ........................................................................................38

24. Removing the Fan Bracket.........................................................................................39

25. Installing the Front Fan...............................................................................................40

26. Removing the Hot-swap Bay Fan Bracket..................................................................41

27. Removing the Plastic Shroud .....................................................................................42

28. Removing the SCSI Backplane...................................................................................43

29. Removing the Front Panel Board................................................................................44

Contents v

Page 6

Tables

1. Feature Summary........................................................................................................ 7

2. Fan Cable Connector Pinout ......................................................................................39

3. Power Supply Output Voltages...................................................................................45

4. Environmental Specifications......................................................................................46

5. Wide/Fast SCSI 16-Bit Connector Pinout ...................................................................47

6. Wide/Fast SCA2 SCSI 16-Bit Connector Pinout.........................................................48

7. Power Connector Pinout.............................................................................................49

8. Backplane Fan Connector Pinout...............................................................................49

9. Front Panel Connector Pinout ....................................................................................50

10. Power Usage Worksheet 1.........................................................................................59

11. Power Usage Worksheet 2.........................................................................................60

vi Intel Astor II Server Chassis Subassembly Product Guide

Page 7

1 System Description

Kit Contents

The Astor II chassis subassembly kit includes this Product Guide, a power cord, an I/O shield EMI

gasket, two chassis feet, and three hardware bags:

Server board installation bag: includes three rubber bumpers, 13 standoff clips, and 13

retention screws.

Chassis intrusion switch bag: includes one intrusion switch/cable assembly, one mounting

screw, and three wire tie clips.

Internal/external peripheral mounting bag: includes four 5.25-inch external drive rails and

mounting screws without washers (2 screws/rail x 4 + 2 for diskette = 10 total); mounting

screws with washers for SCA2 hard drive caddies (4 screws/drive x 5 + 1 spare = 21 total);

mounting screws with washers for chassis feet (2 screw/foot x 2 = 4 total); and gold colored

mounting screws for IDE drives (4 screws/drive x 2 = 8 total).

Feature Summary

Table 1. Feature Summary

Feature Description

Drive Bays One 3.5-inch diskette drive bay, accessible from front.

Two 5.25-inch wide bays that are externally accessible, designed to hold halfheight standard removable media devices; the bays can be converted into a

single full-height bay.

Hot-swap bay for 3.5-inch hard disk drives: space for up to five 1-inch high,

SCA2 hard drives.

Two 3.5-inch wide bays that are not externally accessible, designed to hold

half-height IDE drives.

Expansion slot covers Up to seven expansion slots can be used; every slot that does not have an

add-in board installed must have a slot cover installed.

Power supply 300 watt power factor correction (PFC) power supply, integrated cooling fan.

Detachable AC power cord.

Cooling Three system fans inside the chassis and one power supply fan provide

cooling and airflow.

7

Page 8

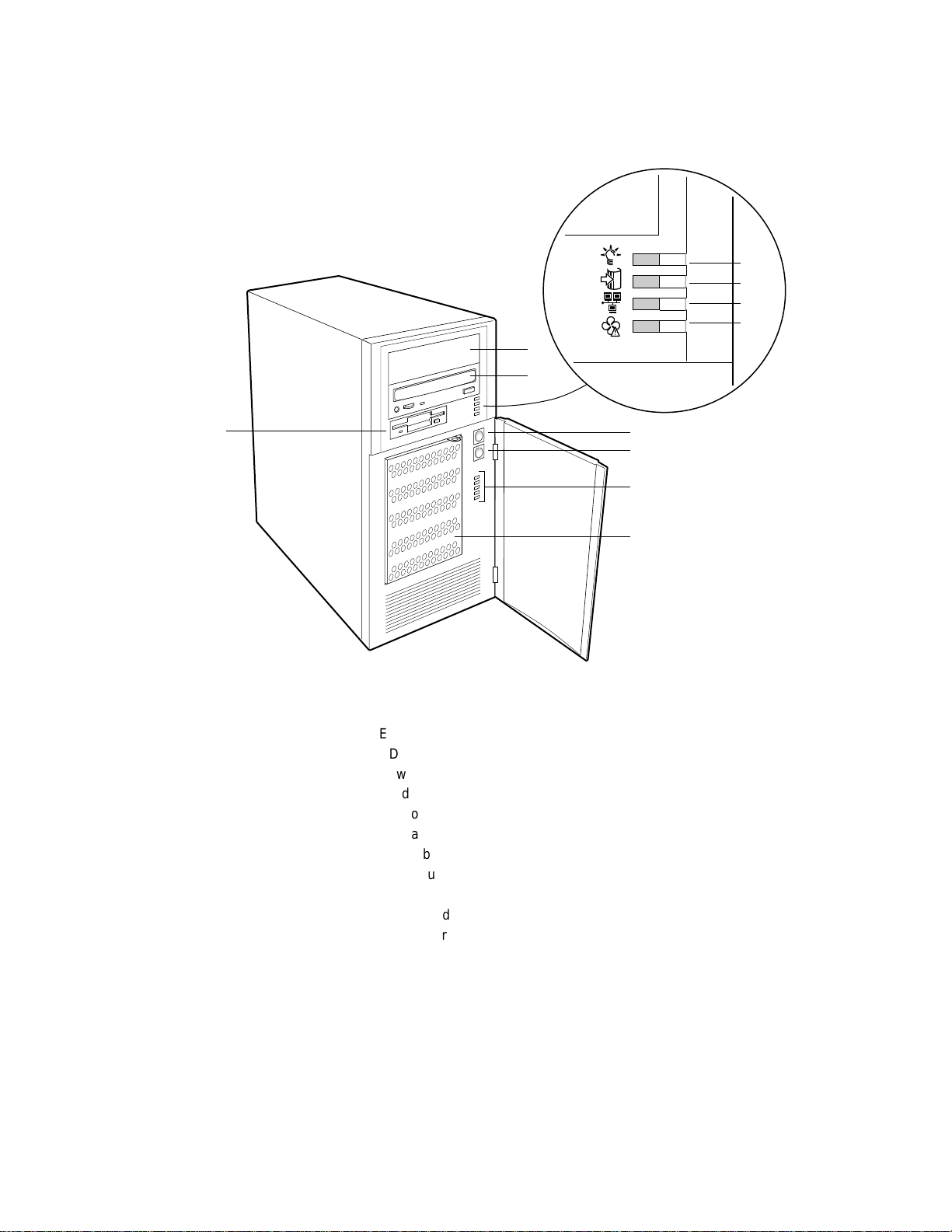

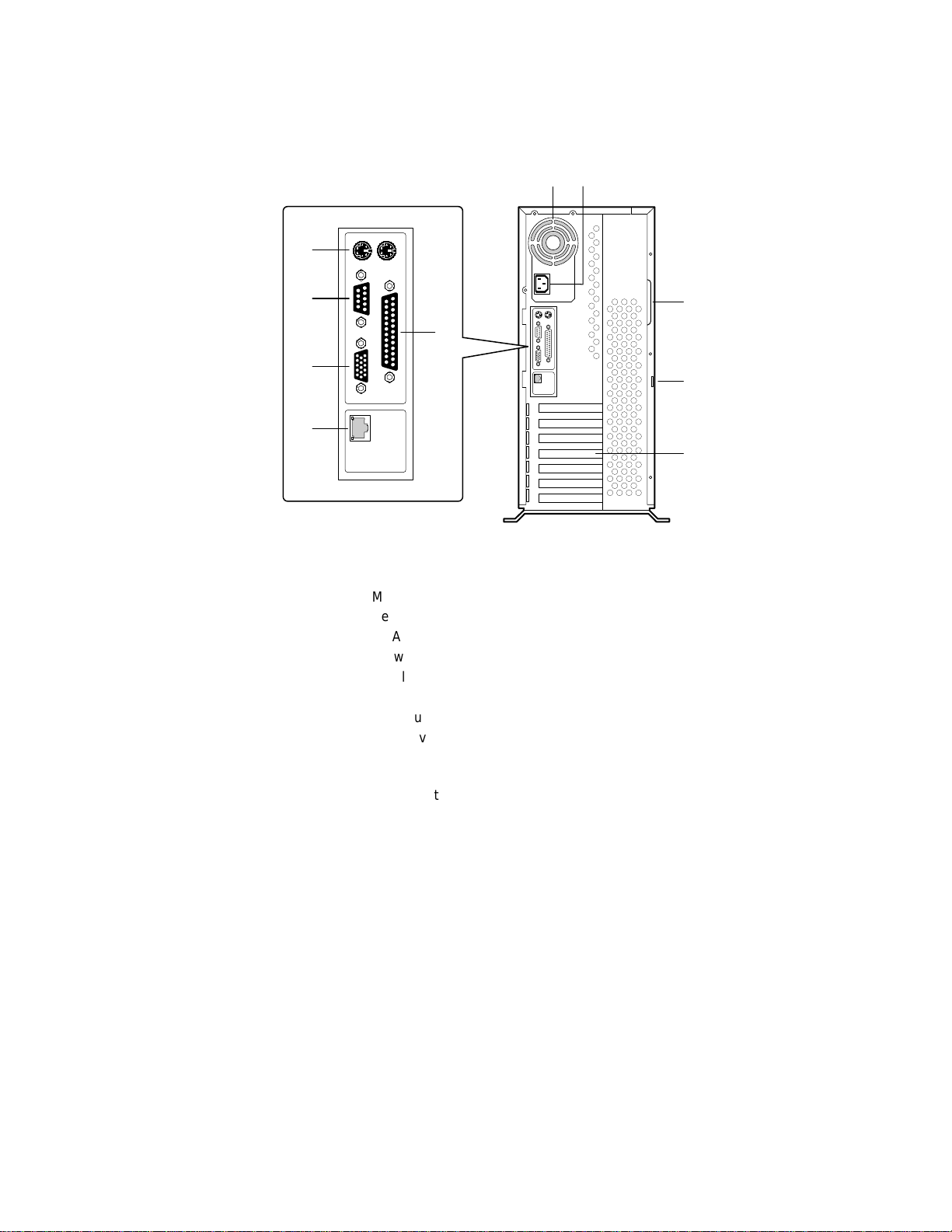

Chassis Front Controls and Indicators

C

D

E

F

A

B

K

G

H

I

J

OM07034

Figure 1. Front Controls and Indicators

A.Empty 5.25-inch drive bay

B.CD-ROM drive*

C.Power LED

D.Hard disk access LED

E.Network LED

F.Fan fault LED

G.Power button

H.Reset button

I.Hot-swap drive failure LEDs

J.Hot-swap drive bay

K.Diskette drive*

* Items shown may not be included in the chassis.

8 Intel Astor II Server Chassis Subassembly Product Guide

Page 9

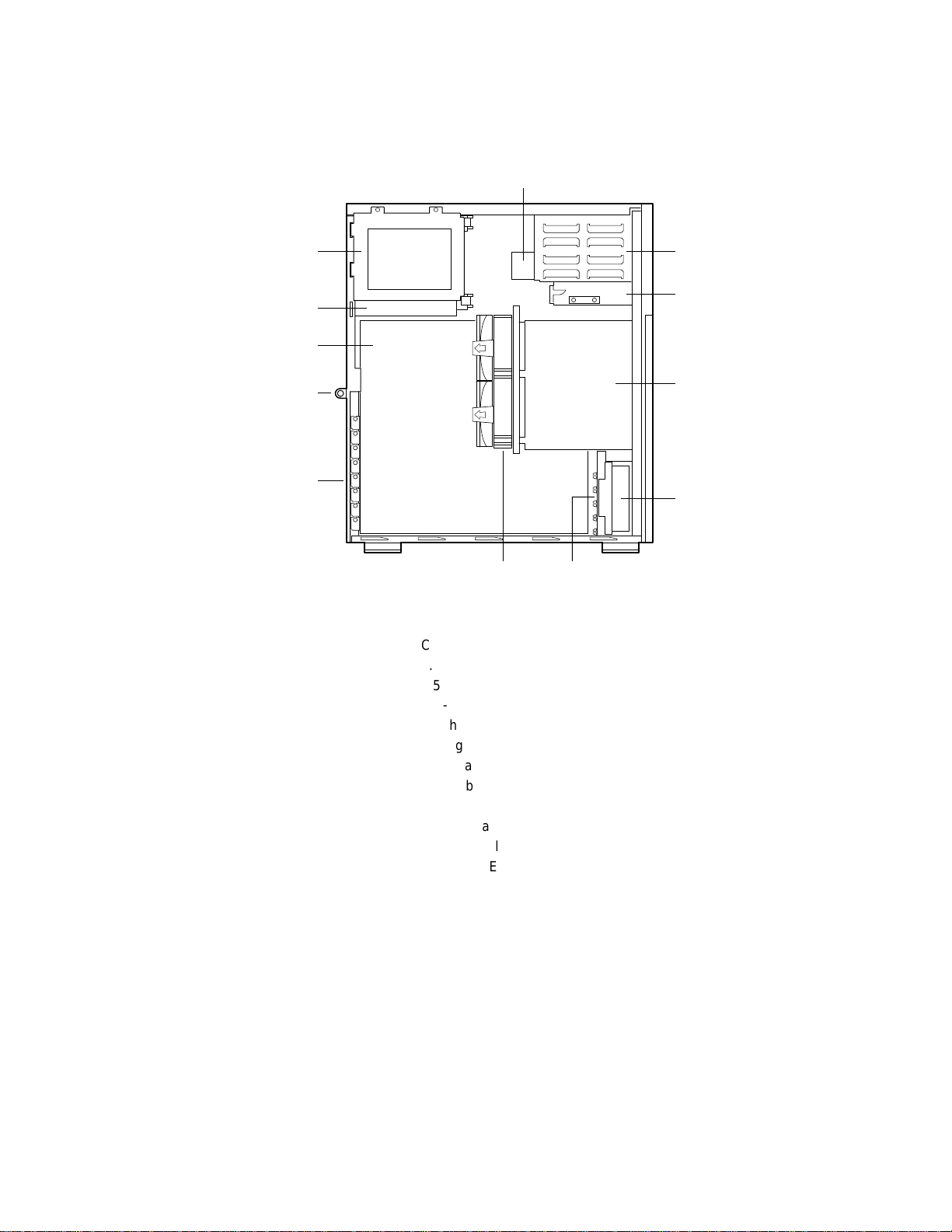

Chassis Back I/O Ports and Features

A

F G

B

E

C

D

Figure 2. Back I/O Ports and Features

A.Mouse and keyboard connectors*

B.Serial port A, COM1*

C.VGA monitor connector*

D.Network connector port*

E.Parallel port*

F.Power supply fan

G.AC input power connector

H.Side cover grip handle

I.Loop for padlock (padlock not supplied, see page 13

for padlock size)

J.Seven slot covers

* Typical baseboard I/O connectors shown.

H

I

J

OM07038

System Description 9

Page 10

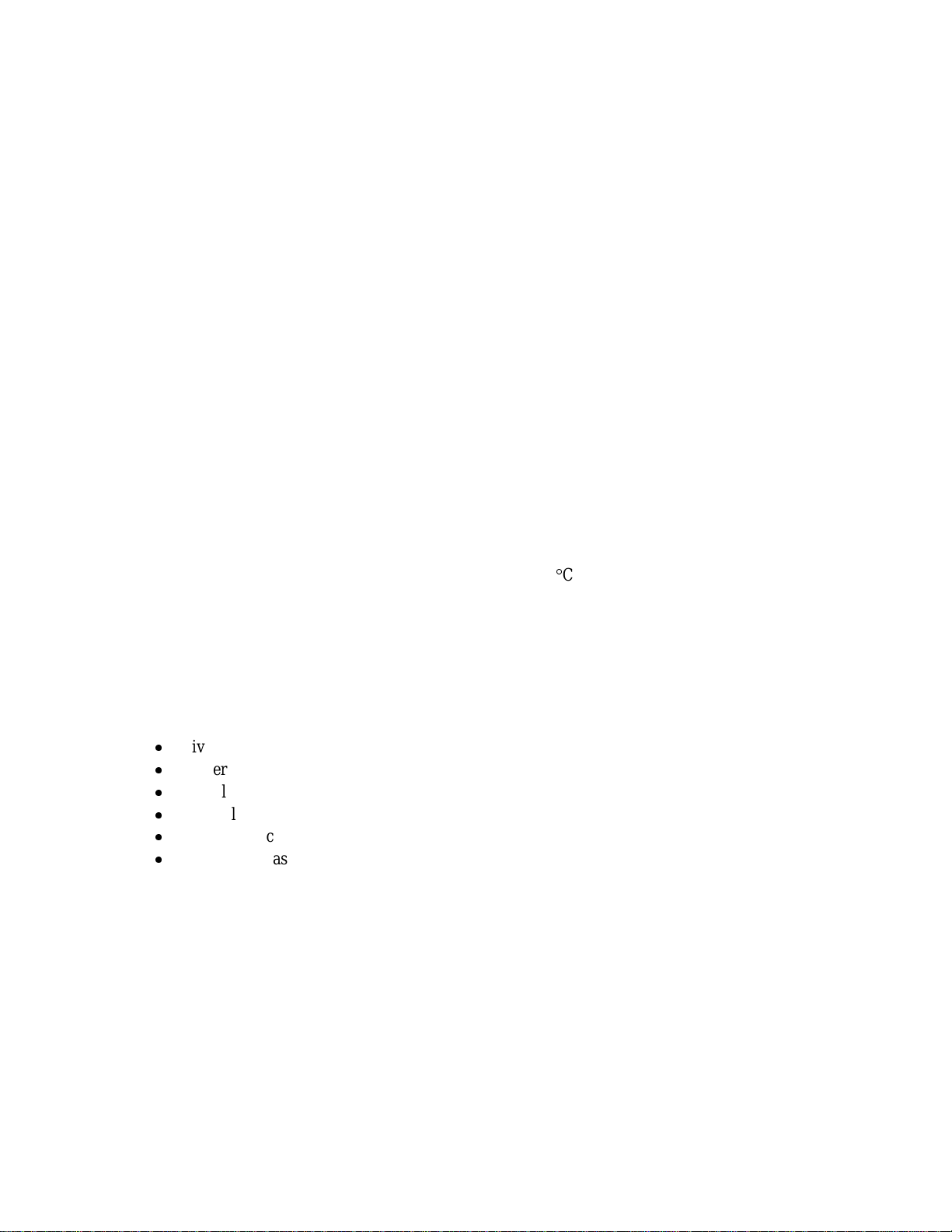

Chassis Side View

A

L

B

C

K

J

I

D

H

E

G F

OM07563

Figure 3. Chassis Side View

A.CD-ROM drive*

B.5.25-inch external bays

C.3.5-inch diskette drive*

D.Hot-swap drive bay

E.Fan housing

F.Card guide

G.Hot-swap fan shroud with two fans

H.Add-in board expansion slot covers

I.Security lock

J.Server board

K.Power supply

L.3.5-inch IDE drive bay

* Items shown may not be included in the chassis.

10 Intel Astor II Server Chassis Subassembly Product Guide

Page 11

Peripherals

External Bay for 5.25-inch Removable Media Devices

The chassis has a bay for two 5.25-inch half-height peripherals that is accessible from the front of

the system. This bay is intended to provide space for CD-ROM, tape backup or other removable

devices.

You can convert the 5.25-inch bays to a single full-height bay. We recommend that you do not use

this bay for hard disk drives, because they generate EMI, ESD susceptibility increases, and the

drive will not be adequately cooled.

Internal Bay for 3.5-inch IDE Hard Drives

The chassis has a 3.5-inch bay for two half-height or 1-inch high IDE hard drives. The bay is not

externally accessible.

Hot-swap Bay

A hot-swap bay is provided for five SCSI SCA2 hard drives that are 3.5 inches wide and 1 inch

high. The bay is designed for drives that consume up to 17 watts of power each. Drives must be

specified to run at a maximum ambient temperature of 50 C.

The system was designed to allow the user to install a Redundant Array of Independent Disks

(RAID). A software implementation with onboard SCSI or an add-in RAID controller card can be

used to set up RAID applications.

SCSI Hot-swap Backplane

The hot-swap backplane provides the following:

Five Single Connector Assembly (SCA2) connectors for SCA2-compatible SCSI drives

Power control for each drive, including automatic slot-power-down upon removing a drive

Signal for a fault indicator on the front panel for each drive

Internal IMB (Intelligent Management Bus)

Two +12 V connectors for a fan with tachometer

Local IMB-based temperature sensor

The SCSI hot-swap backplane provides control signals and power for five Ultra2/LVD 3.5-inch,

1-inch high, SCA2 SCSI hard disk drives. The backplane receives control signals from the SCSI

controller on the server board through a cable connected to the wide SCSI connector on the

backplane. The backplane is powered through cables connected to the two power connectors.

The drives get their control signals and power from the SCA2 connectors on the backplane.

The fault indicators on the front panel indicate failure status for each drive in the bay. These

indicators get their signals through a cable connected to the front panel connector on the

backplane.

System Description 11

Page 12

The temperature sensor on the backplane provides temperature information to the BMC (baseboard

management controller) on the server board through chassis service messages.

The backplane power control will power down a drive when a failure is detected and reported to

the SCSI bus. When a new drive is inserted, the power control waits a short time for the drive to

become fully seated and then applies power to the drive.

Power Supply

The 300 watt PFC (power factor correction) universal type power supply is designed to minimize

EMI. The supply operates within the following voltage ranges and is rated as follows:

100-120 V at 50/60 Hertz (Hz); 4.6 A maximum

200-240 V at 50/60 Hz; 2.3 A maximum

The DC output voltages of the power supply are +5 V, +12 V, +3.3 V, -5 V, -12 V, and

+5 V standby. Power to the server board is provided through the power cable to the 24-pin main

power connector.

Checking the Power Cord

WARNING

Do not attempt to modify or use a supplied AC power cord if it is not the

exact type required.

If a power cord supplied with the system is not compatible with the AC wall outlet in your region,

get one that meets the following criteria:

The cord must be rated for the available AC voltage and have a current rating that is at least

125% of the current rating of the system.

The connector that plugs into the wall outlet must be a grounding-type male plug designed

for use in your region. It must have certification marks showing certification by an agency

acceptable in your region.

The connector that plugs into the AC receptacle on the system power supply must be an IEC

320, sheet C13, type female connector.

In Europe, the cord must be less than 4.5 meters (14.76 feet) long, and it must be flexible

<HAR> (harmonized) or VDE certified cordage to comply with the system's safety

certifications.

System Cooling

The chassis includes four tachometer fans for cooling and airflow. One of these is the integrated

fan in the power supply.

NOTE

✏

The chassis side cover must be on the system for proper cooling.

12 Intel Astor II Server Chassis Subassembly Product Guide

Page 13

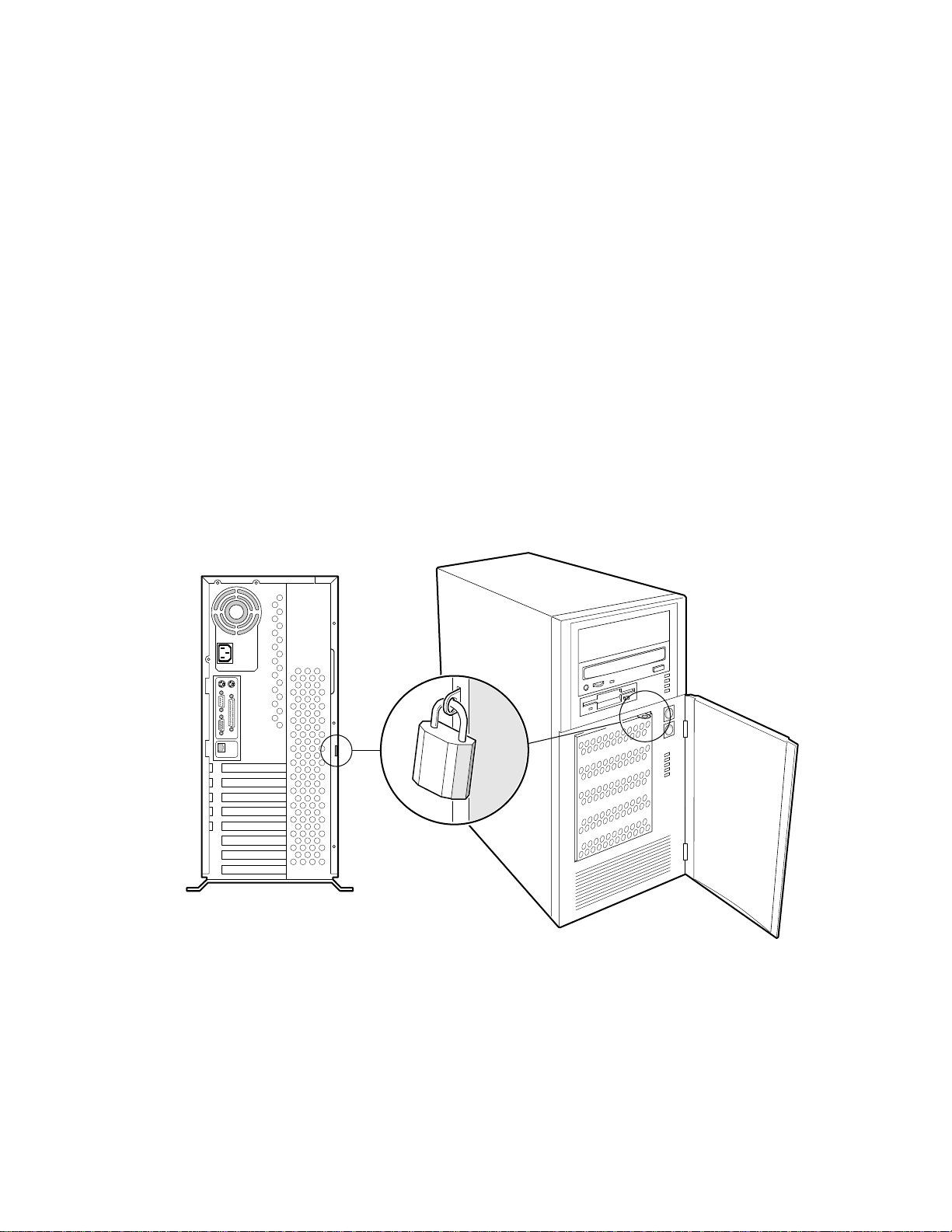

System Security

To help prevent unauthorized entry or use of the system, the chassis includes a chassis intrusion

switch that can be monitored by Server Management software and two padlock loops.

Mechanical Locks

A padlock loop on the rear of the system side cover can be used to prevent access to the

microprocessors, memory, and add-in cards. A variety of lock sizes can be accommodated by the

.300 diameter loop.

A padlock loop on the hard drive bay EMI door provides security for the hot swap hard drives.

†

The allotted space accommodates a MasterLock

.815” H x .830” W x .430” D. Pall diameter .145”

Monitoring

Install the chassis intrusion switch. When the side cover is removed, the switch transmits a signal

to the BMC on the server board. Server management software can be programmed to respond to

an intrusion by powering down or by locking the keyboard, for example.

model 120-D or equivalent lock. Dimensions:

OM07044

Figure 4. System Security

System Description 13

Page 14

14 Intel Astor II Server Chassis Subassembly Product Guide

Page 15

2 Working Inside the System

Tools and Supplies Needed

Phillips (cross head) screwdriver (#2 bit)

Antistatic wrist strap (recommended)

Needle-nosed pliers

Safety: Before You Remove the Side Cover

Before removing the system side cover for any reason, observe these safety guidelines.

1.Turn off all peripheral devices connected to the system.

2.Turn off the system by pressing the power button on the front of the system. Then unplug the

AC power cord from the system or wall outlet.

3.Label and disconnect all peripheral cables and all telecommunication lines connected to I/O

connectors or ports on the back of the system.

4.Provide some electrostatic discharge (ESD) protection by wearing an antistatic wrist strap

attached to chassis ground of the system—any unpainted metal surface—when handling

components.

Warnings and Cautions

These warnings and cautions apply whenever you remove the side cover of the system to access

components inside the system. Only a technically qualified person should integrate and configure

the system.

WARNINGS

The power button (a convex button) on the front panel DOES NOT turn

off the system AC power. To remove power from system, you must

unplug the AC power cord from the wall outlet or the system.

Hazardous electrical conditions may be present on power, telephone,

and communication cables. Turn off the system and disconnect the

power cords, telecommunications systems, networks, and modems

attached to the system before opening it. Otherwise, personal injury or

equipment damage can result.

Hazardous voltage, current, and energy levels are present inside the

power supply. There are no user-serviceable parts inside it; servicing

should be done by technically qualified personnel.

15

Page 16

CAUTIONS

ESD can damage disk drives, boards, and other parts. Perform all

procedures in this chapter only at an ESD workstation. If one is not

available, provide some ESD protection by wearing an antistatic wrist strap

attached to chassis groundany unpainted metal surfaceon your system

when handling parts.

Always handle boards carefully. They can be extremely sensitive to ESD.

Hold boards only by their edges. Do not touch the connector contacts. After

removing a board from its protective wrapper or from the system, place the

board component side up on a grounded, static free surface. If you place the

server board on a conductive surface, the battery leads may short out. If

they do, this will result in a loss of CMOS data and will drain the battery.

Use a conductive foam pad if available but not the board wrapper. Do not

slide board over any surface.

For proper cooling and airflow, always install the chassis side cover before

turning on the system. Operating it without the cover in place can damage

system parts.

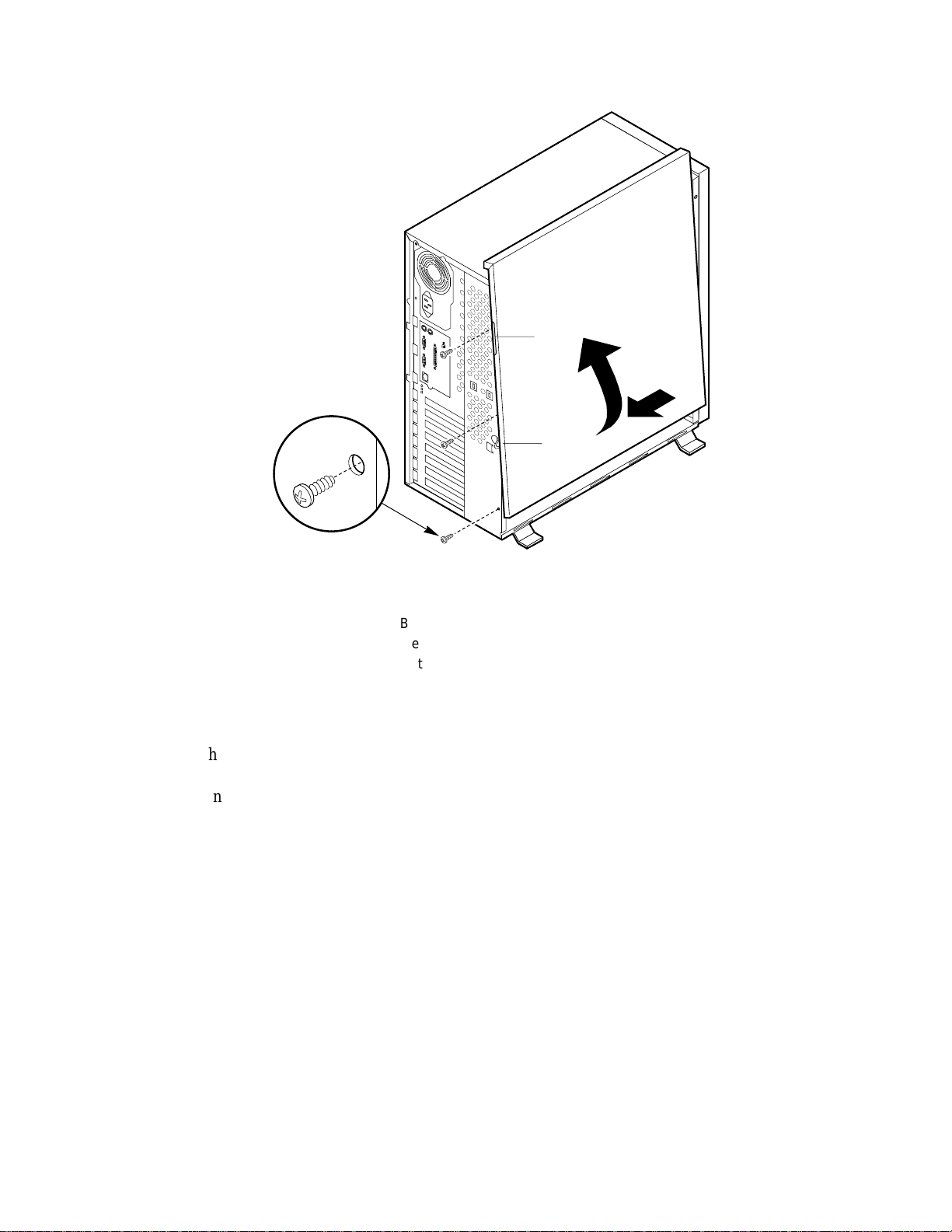

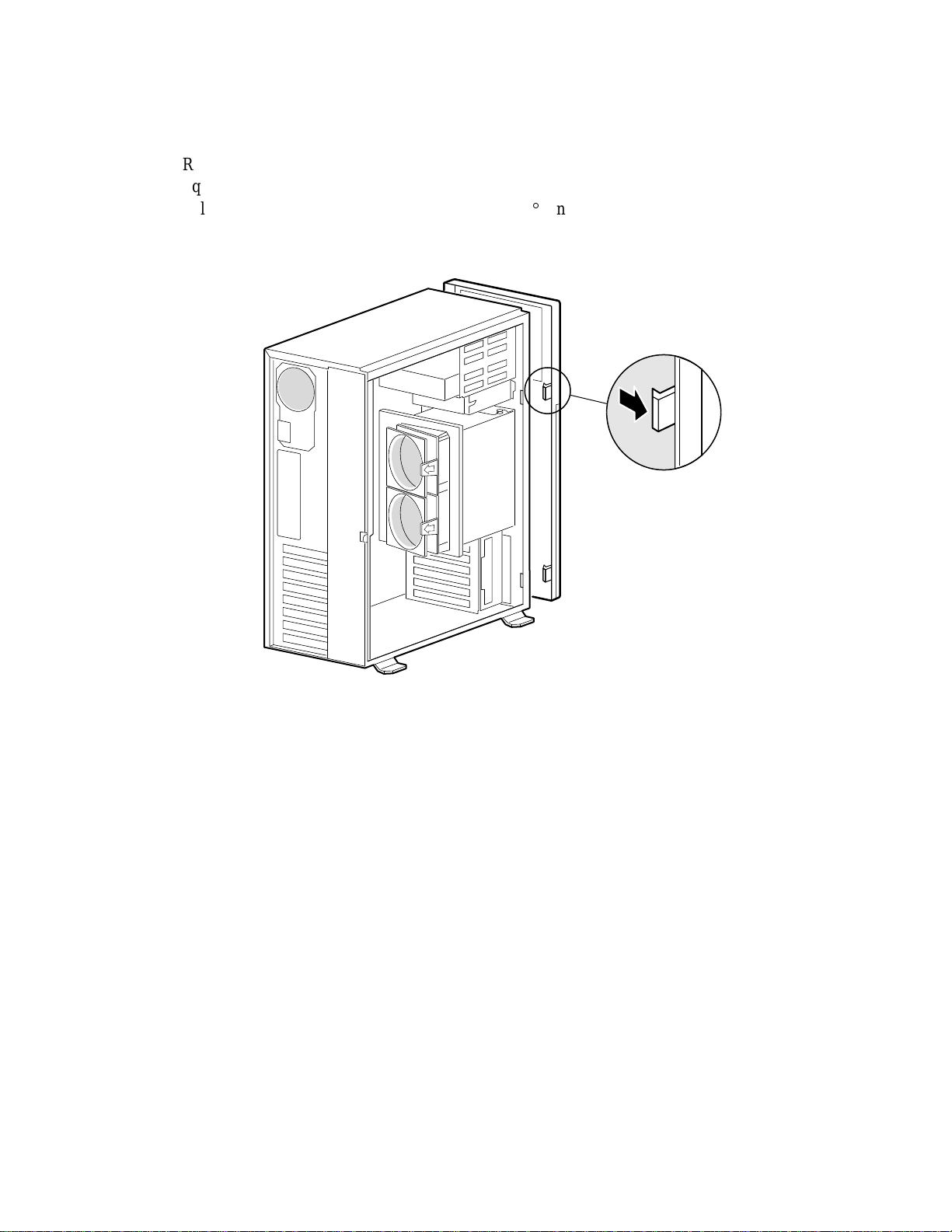

Removing the Side Cover

You need to remove the chassis side cover, and in some cases the front cover, to gain access to

components inside the system.

1.Observe the safety and ESD precautions at the beginning of this chapter.

2.Turn off all peripheral devices connected to the system.

3.Turn off the system by pressing the power button on the front panel, AND unplugging the AC

power cord.

4.Label and disconnect all peripheral cables attached to the I/O panel on the back of the system.

5.Remove and save the three screws from the side cover; you will need them later to reattach the

cover.

6.Place the fingertips of your left hand under the built in handle on the back of the cover.

7.Using an even pull, slide the cover backward, about an inch, until it stops.

8.Using your left hand, pull the back end of the cover toward you to disengage its bottom row of

tabs from the notches in the chassis.

9.Using both hands, lift the cover upward to disengage the top row of tabs from the notches in

the top edge of the chassis. Set the cover aside.

16 Intel Astor II Server Chassis Subassembly Product Guide

Page 17

A

B

C

OM06410

Figure 5. Removing the Side Cover

A.Built in handle

B.Metal loop (for padlock)

C.Retaining screws (3)

Installing Chassis Feet

1.Each chassis foot has two sets of holes. The larger holes fit over alignment features in the

chassis to assist positioning the feet.

2.Align the smaller holes with the corresponding screw holes on the chassis bottom, and attach

each foot with two screws (silver screws with washers are provided).

Working Inside the System 17

Page 18

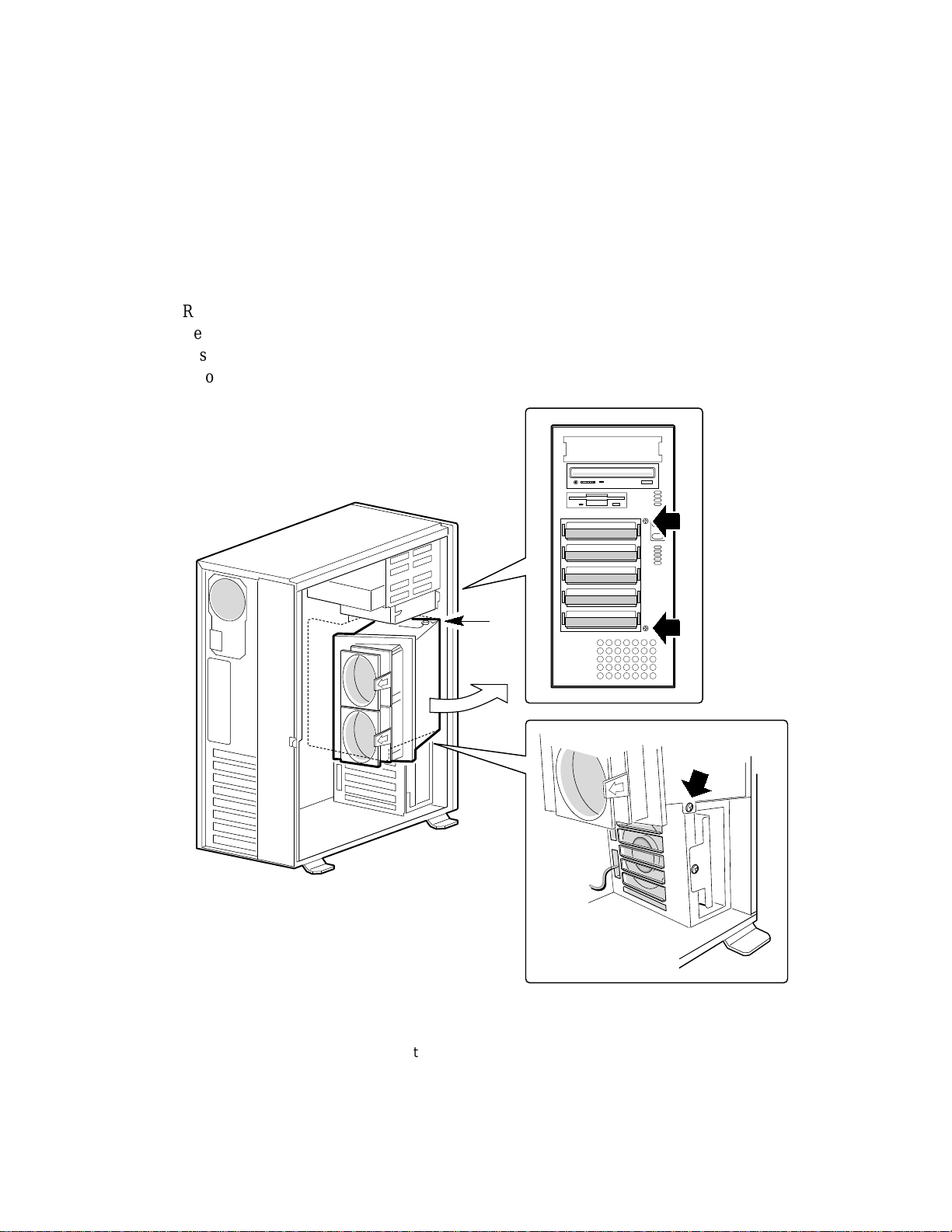

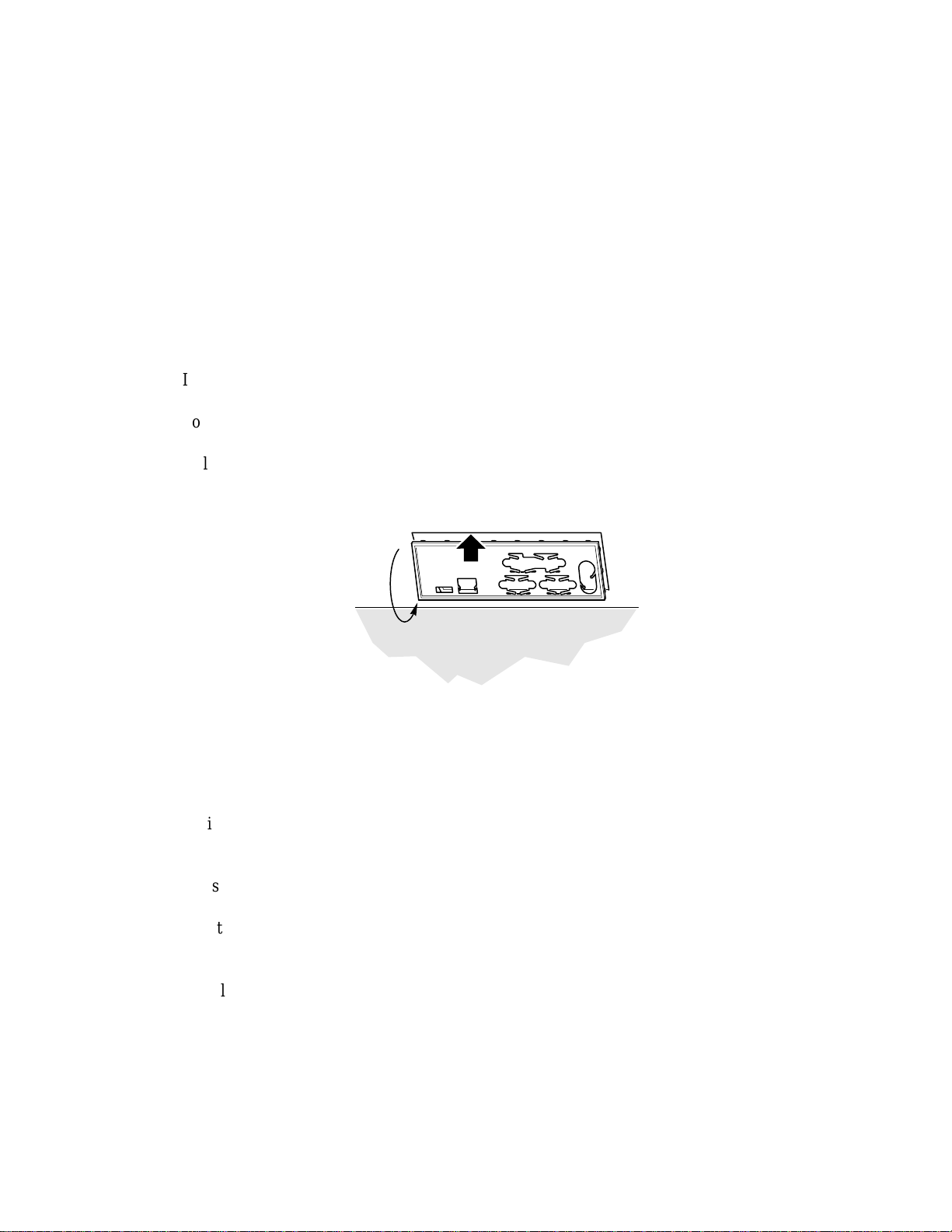

Removing the Hot-swap Bay

NOTE

✏

The hot-swap bay may be heavy if it is full of drives. It is not necessary to

remove the drives from the bay before removing the bay from the chassis.

However, we recommend you remove any drives in the bay before removing

the bay to minimize the risk of personal injury or property damage.

1.Remove the side cover. You do not need to remove the plastic front cover.

2.Remove the three screws holding the bay chassis.

3.Disconnect the power and data cables from the SCSI backplane.

4.Pivot the bay until it comes out of the chassis.

A

Figure 6. Removing the Hot-swap Bay

A.Pivot point

OM07043

18 Intel Astor II Server Chassis Subassembly Product Guide

Page 19

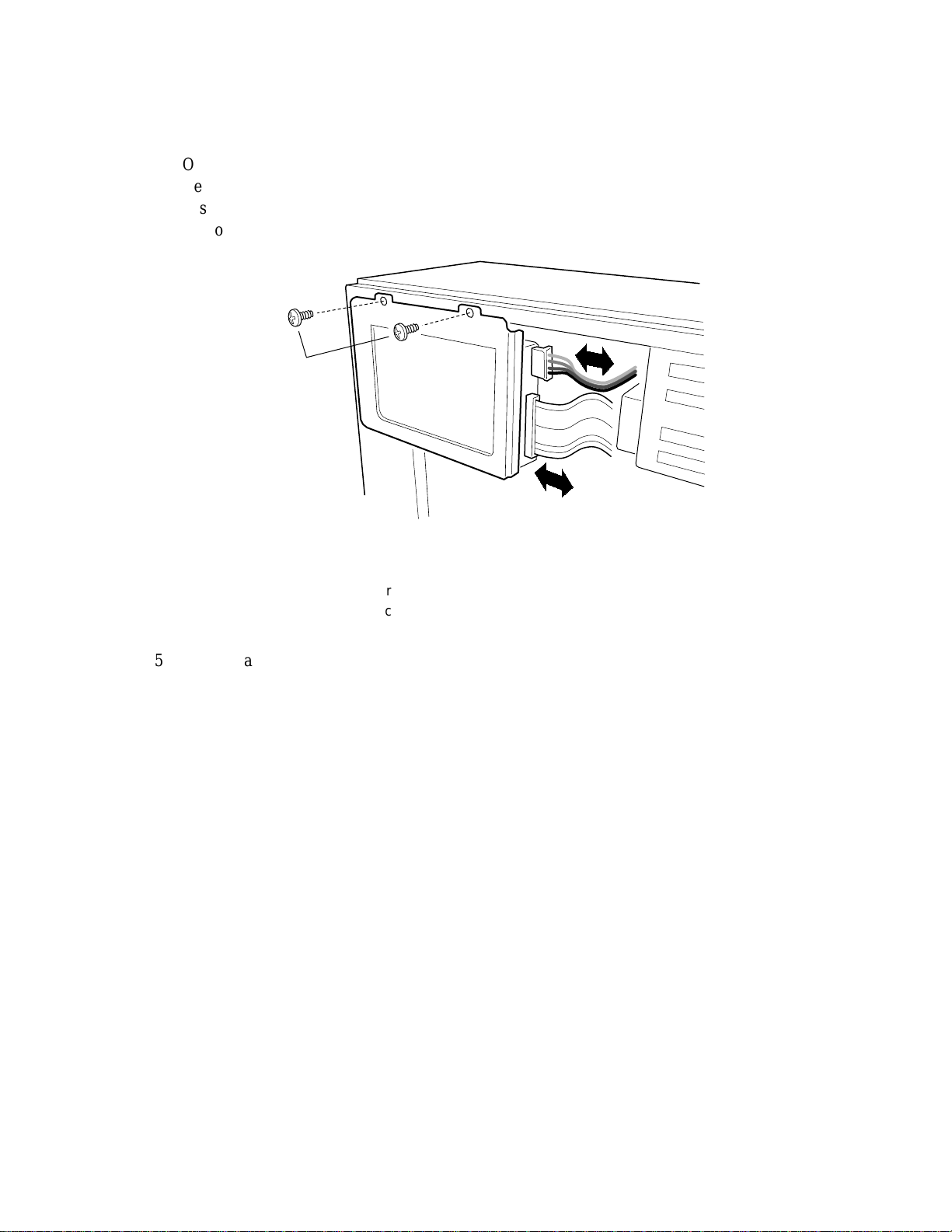

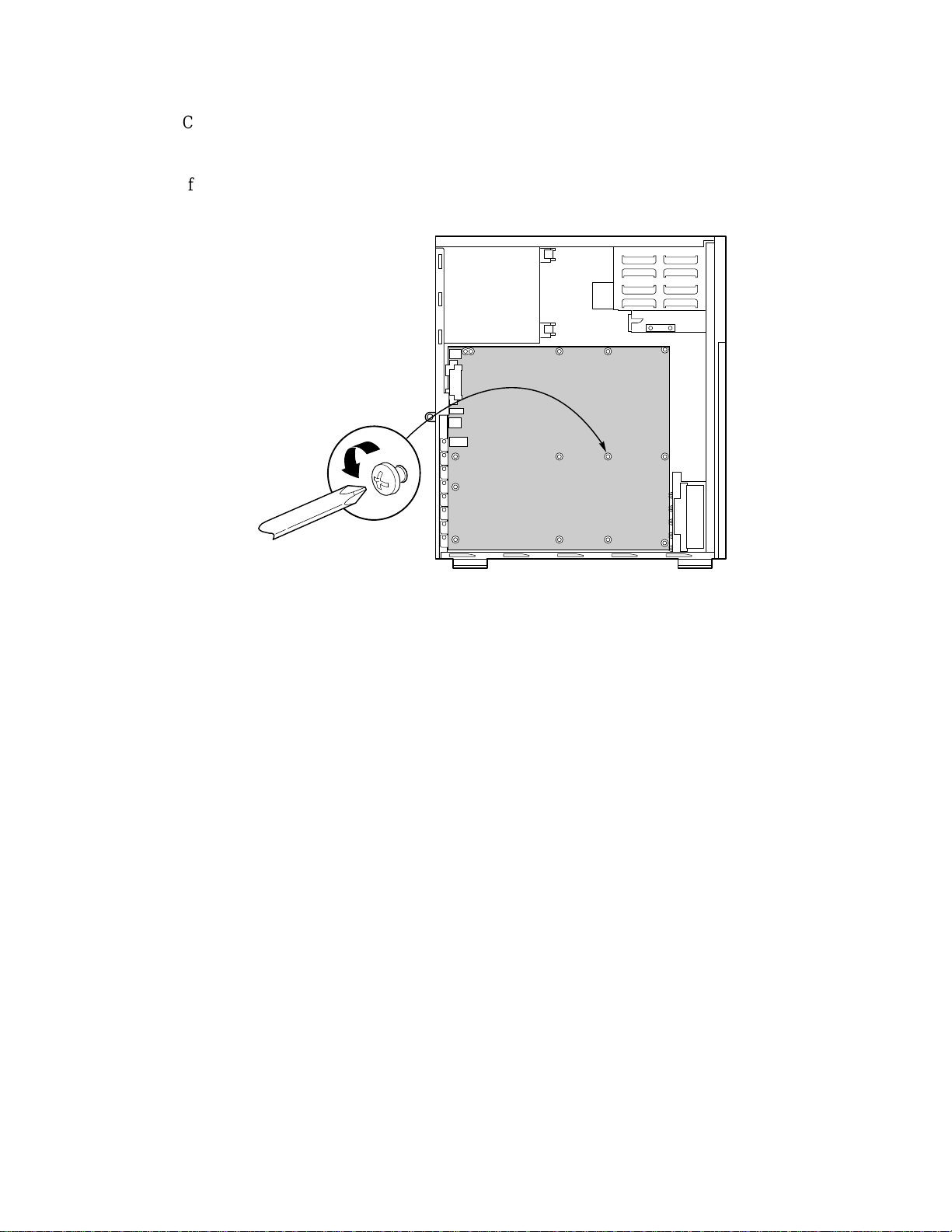

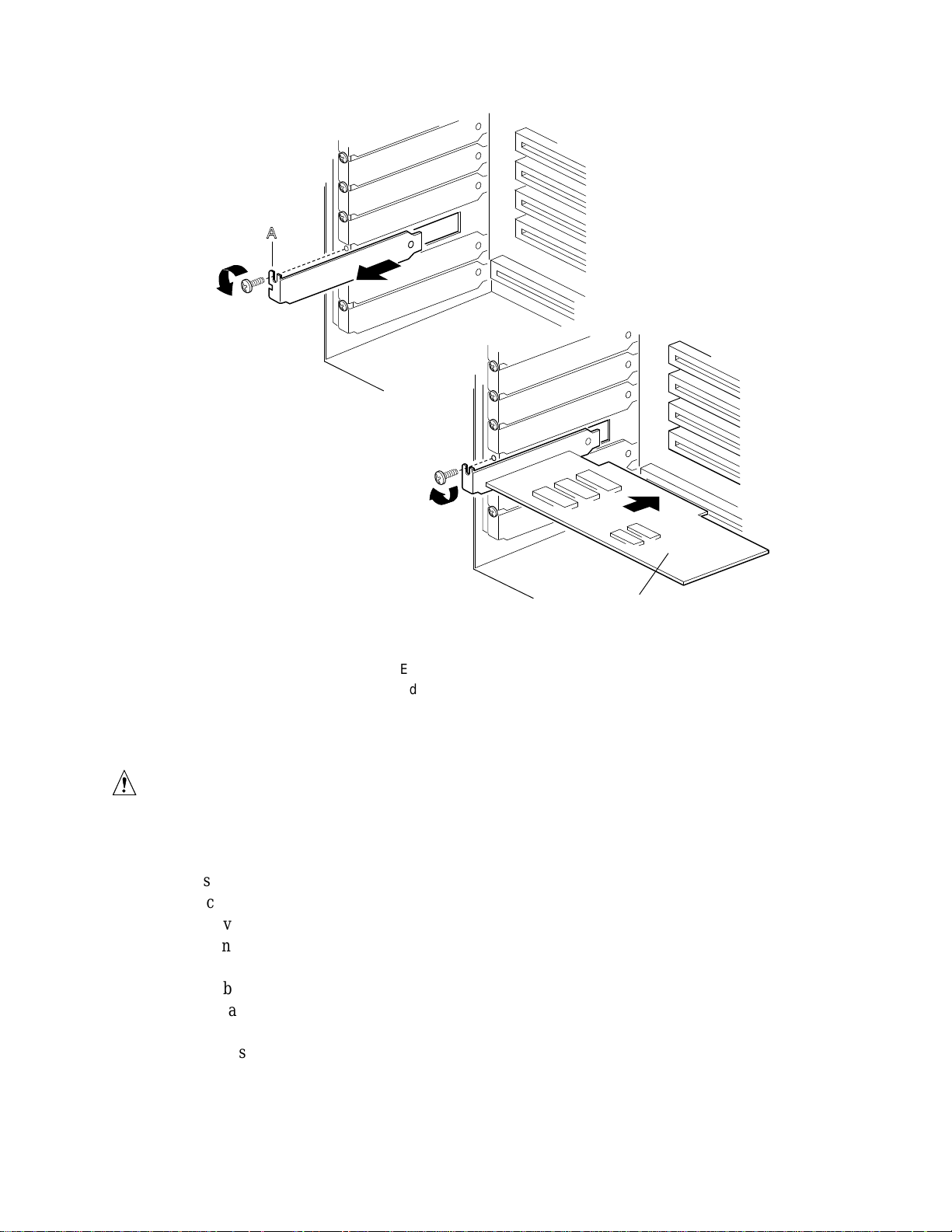

Removing the IDE Drive Bay

1.Observe the safety and ESD precautions at the beginning of this chapter.

2.Remove the side cover.

3.Disconnect the power and signal cables from any drives in the bay.

4.Remove and save the two screws at the top of the bay.

A

C

B

Figure 7. Disconnect Cables and Remove Screws

OM07560

A.Power cable

B.Data cable

C.Screws

5.Remove and save the screw in the flange at the bottom of the drive bay (see Figure 8, A).

6.Push the drive bay up and pull it out of the chassis. Do not swing it on its hinges, as the flange

may get caught in the fans mounted on the hot-swap bay.

Working Inside the System 19

Page 20

A.Screw

A

OM07561

Figure 8. IDE Hard Drive Bay

20 Intel Astor II Server Chassis Subassembly Product Guide

Page 21

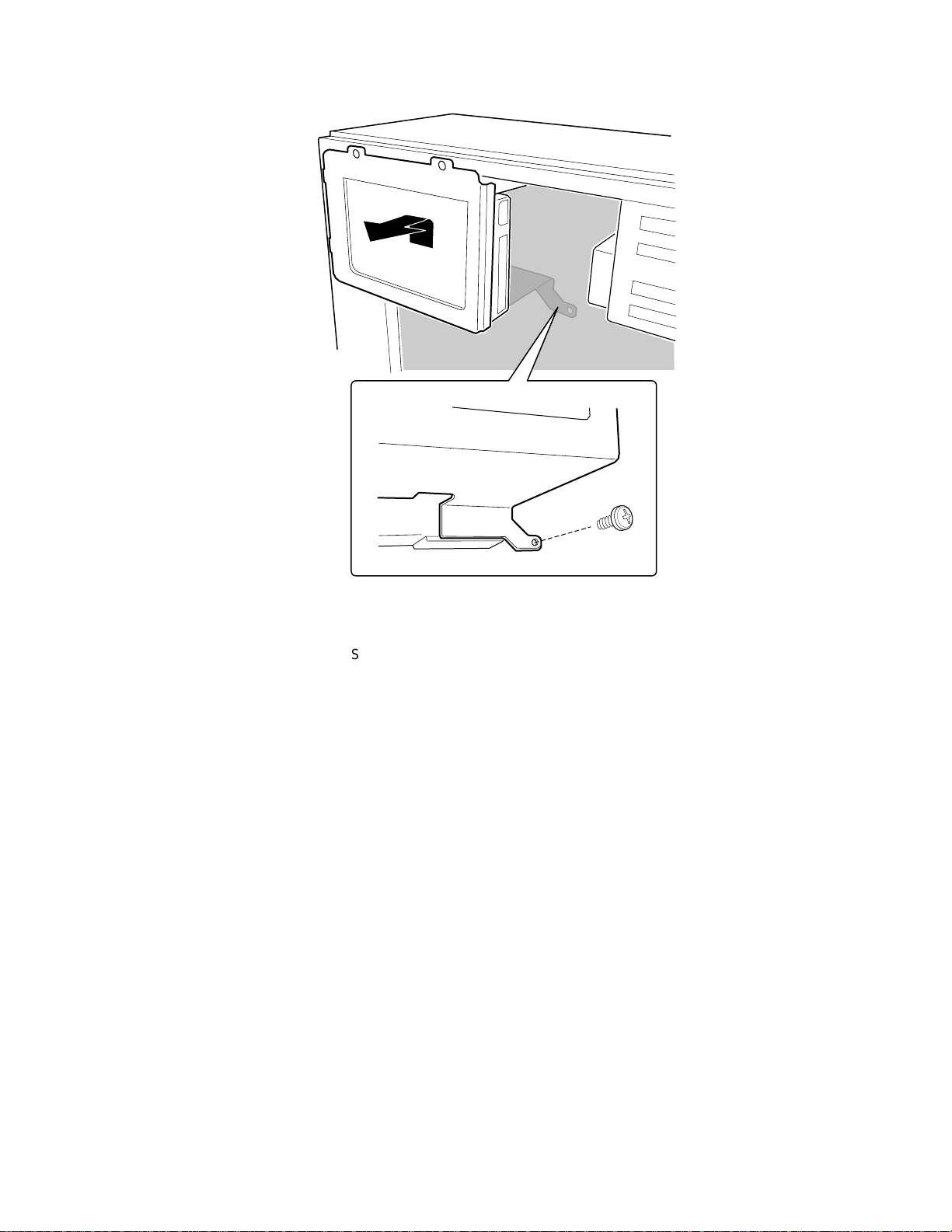

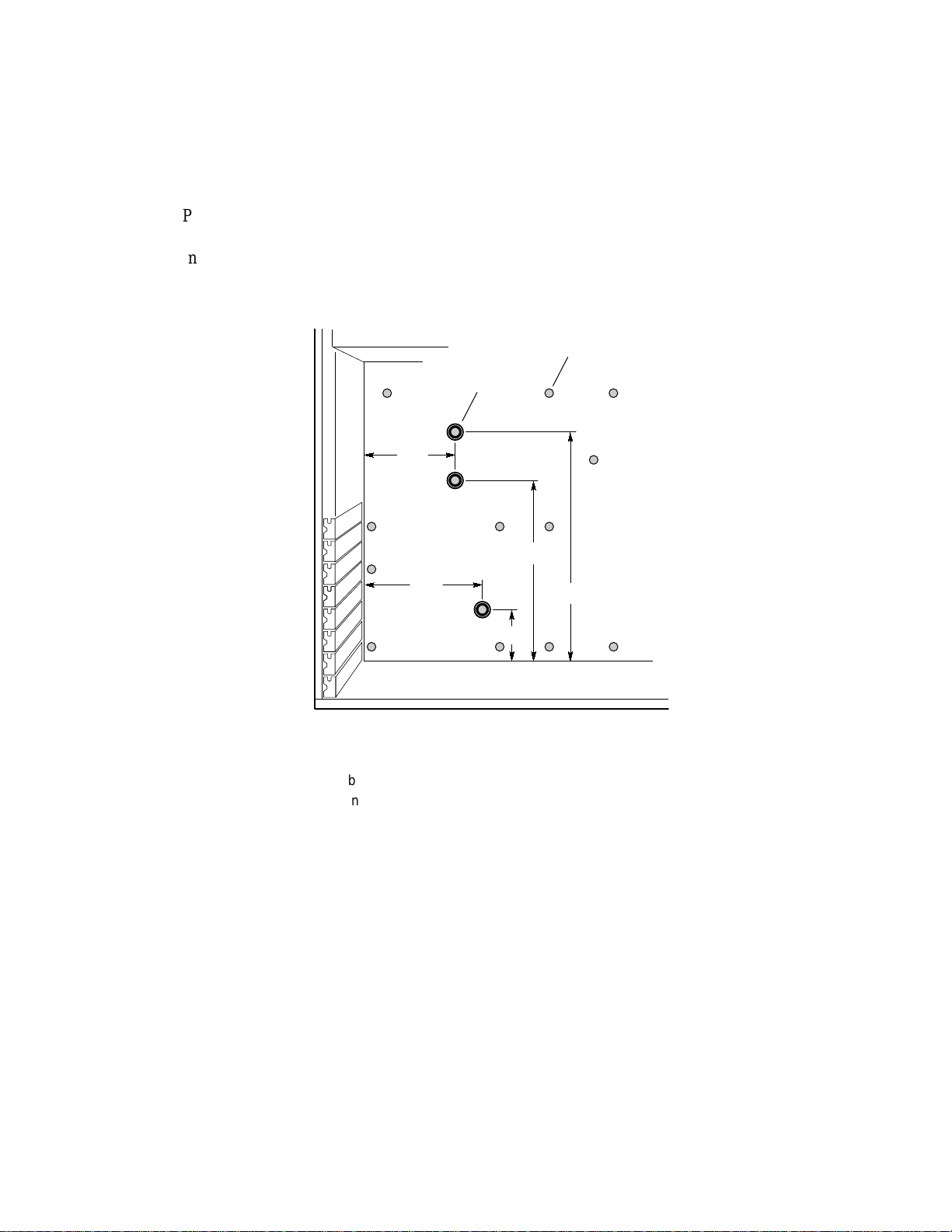

Installing Server Board Clips and Bumpers

To support the server board in the Astor II chassis, you must install three rubber bumpers and

eleven or twelve standoff clips (depending on the server board you are installing).

1.Peel the adhesive backing from three rubber bumpers; stick the bumpers to the chassis wall

(see Figure 9, A).

2.Install eleven or twelve standoff clips in the chassis wall (see Figure 9, B). Gently pinch the

open end of each clip with needle-nosed pliers, insert into a slot on the chassis wall, and

release. Pressure holds the clip in place.

B

A

4.5"

7.75"

6.0"

3.0"

Figure 9. Rubber Bumper and Standoff Clip Placement

B.Rubber bumper

C.Standoff clip location

10.0"

OM07019

Working Inside the System 21

Page 22

I/O Shield

NOTE

✏

An ATX 2.01-compliant I/O shield should be provided with your server

board. The shield is required by Electromagnetic Interference (EMI)

regulations. It minimizes EMI and ensures proper cooling of the server. If

the shield does not fit the chassis, obtain a properly sized shield from the

chassis supplier.

The shield fits the rectangular opening near the power supply in the back of the chassis. The shield

has cutouts that match the external I/O connectors (e.g., keyboard and mouse).

1.Install the shield from inside the chassis. Orient the shield so that the cutouts align with the

corresponding I/O connectors on the server board.

2.Position one edge so that the dotted groove (A) is outside the chassis wall, and the lip of the

shield rests on the inner chassis wall.

3.Hold the shield in place, and push it into the opening until it is seated (B). Pressure holds the

shield in place.

A

B

OM06332a

Figure 10. Installing the I/O Shield

(typical shield shown)

Installing the Server Board

4.Position the board over the snap in standoff and threaded standoffs inside the chassis, and slide

it carefully toward the rear of the system until the I/O connectors protrude through the back

panel.

5.Press the board onto the snap in standoff, and insert one screw through one of the mounting

holes of the board and into a threaded standoff. Do not tighten the screw until the next step.

6.Insert the remaining screws through the mounting holes and into the threaded standoffs. Make

sure the board is properly seated, and then tighten all the screws. Take care to not tighten the

screws more the 6 inch-pounds.

7.Install your processors and memory. See your server board manual for instructions.

8.Connect the power cable to the server board. See your server board manual for the location of

the main power connector. Once it is firmly connected to the server board, bend the wires

towards the front of the chassis. This will help when you install the hot-swap bay.

22 Intel Astor II Server Chassis Subassembly Product Guide

Page 23

9.Connect the Front Panel cable from the top of the front panel to the server board. See your

server board manual for the location of the front panel connector. The cable from the bottom

of the front panel goes to the hot-swap backplane.

10.If you are going to install a diskette drive or any hard drives, attach the appropriate cables to

the server board. See your server board manual for the locations of data cable connectors.

Figure 11. Installing the Server Board

OM07048

(typical board shown)

Working Inside the System 23

Page 24

Installing a Chassis Intrusion Switch

Your server board probably has a chassis intrusion connector on it. However, we recommend that

you attach the chassis intrusion switch to the front panel.

1.Remove the side cover.

2.Remove the IDE drive bay.

3.Remove the hot-swap bay.

4.Position the switch so the screw hole lines up with the hole in the chassis.

5.Insert and tighten the screw.

6.There are three small holes in the sheet metal, two on the back and one in the top. Attach two

of the plastic clips to the cable and route it along the back of the chassis. Insert the plastic

clips into the holes along the back of the chassis. Attach the third clip to the cable and route

the cable between the power supply and the IDE bay. Insert the third clip into the hole in the

top sheet metal. Route the cable behind the 5.25-inch drive bay.

7.Connect the chassis intrusion switch cable to the front panel.

OM08475

Figure 12. Installing a Chassis Intrusion Switch

24 Intel Astor II Server Chassis Subassembly Product Guide

Page 25

Removing the Front Cover

1.Remove side cover.

2.Squeeze the two plastic tabs inside the front cover, and push them through the chassis slots.

3.Pull the left side of the cover out slightly, about 15, until the cover clears the power and reset

buttons. Slide the cover to the right until the tabs disengage from the chassis slots. Set the

cover aside.

Figure 13. Removing the Front Cover

OM07097

Working Inside the System 25

Page 26

Installing the Diskette Drive

1.Observe the safety and ESD precautions at the beginning of this chapter.

2.Remove the new 3.5-inch diskette drive from its protective wrapper, and place it component

side up on an antistatic surface. Record the drive model and serial numbers in your equipment

log.

3.Set any jumpers or switches according to the drive manufacturer’s instructions.

4.Slide the drive into the chassis.

5.Secure the drive to the 5.25-inch bay with the screws you removed earlier; tighten the screws

firmly.

6.Connect the signal and power cables to the drive.

B

A

Figure 14. Installing the Diskette Drive

A.Power cable

B.Signal cable

C.Chassis screws

C

Removing the Diskette Drive

1.Observe the safety and ESD precautions at the beginning of this chapter.

2.Remove the side cover.

3.Remove the front cover.

4.Disconnect the power cable and signal cable from the diskette drive.

5.Remove and save the screws that secure the diskette drive to the 5.25-inch drive bay.

6.Slide the drive forward and out of the system and place it component side up on an antistatic

surface. If not reinstalling the same drive, place it in an antistatic protective wrapper.

OM07052

26 Intel Astor II Server Chassis Subassembly Product Guide

Page 27

Hard Drives

Drive Cabling Considera tions

The number of devices you can install depends on:

The number supported by the bus

The number of physical drive bays available

The combination of SCSI and IDE devices

You should route cables to minimize airflow disruption. Air flows from the front to the rear of the

chassis. You should route IDE and diskette drive cables behind the hot-swap bay.

IDE Requirements

An 18-inch long IDE cable that supports two drives is standard in the system.

For proper IDE operation, note the cable length specified in the following figure. If no drives are

present on an IDE channel, the cable must be removed. If only one drive is installed, it must be

connected at the end of the cable.

12" 6"

Baseboard Drive 1 Drive 0

18"

OM05093

Figure 15. IDE Cable Dimensions

SCSI Requirements

All SCSI devices must be unterminated except the peripheral at the end of the SCSI cable. Hard

drives usually provide an active termination, while CD-ROM drives do not. The SCSI controller

on the server board is actively terminated. The SCSI hot-swap backplane provides termination and

SCSI IDs for drives connected to it.

Installing a Hard Drive into the IDE drive bay

The IDE drive bay provides space for two 1-inch high hard drives.

1.Observe the safety and ESD precautions at the beginning of this chapter.

2.Remove the IDE drive bay from the chassis.

3.Remove the drive from its protective wrapper, and place it on an antistatic surface.

4.Record the drive model and serial numbers in your equipment log.

5.Set any jumpers and/or switches on the drive according to the drive manufacturer’s

instructions.

6.Slide the drive into the drive bay so the screw holes in the drive and the bay line up. For the

best cooling, the component side of the drive should face away from the plate of the drive bay.

Working Inside the System 27

Page 28

7.Insert and tighten four screws (gold colored screws with washers are provided).

8.Install the IDE drive bay into the chassis.

OM07562

Figure 16. IDE Hard Drive

Removing a Hard Drive from the IDE Drive Bay

1.Observe the safety and ESD precautions at the beginning of this chapter. Also see the cabling

considerations on page 27.

2.Remove the IDE drive bay from the chassis.

3.Remove the four screws holding the hard drive in the bay.

4.Slide the hard drive out of the bay.

5.Reinstall the hard drive bay.

28 Intel Astor II Server Chassis Subassembly Product Guide

Page 29

Installing the IDE Drive Bay

1.Observe the safety and ESD precautions at the beginning of this chapter.

2.Place the drive bay into the chassis so its hinges are in their slots.

3.Move the drive bay down until the screw holes in the bay and the chassis line up.

4.Replace the two screws on the top of the bay (see Figure 17, C).

A

C

B

Figure 17. Disconnect Cables and Remove Screws

OM07560

A.Power cable

B.Data cable

C.Screws

5.Replace the screw in the flange at the bottom of the drive bay (see Figure 8, A, on page 20).

6.Connect data and power cables to any drives in the bay.

Working Inside the System 29

Page 30

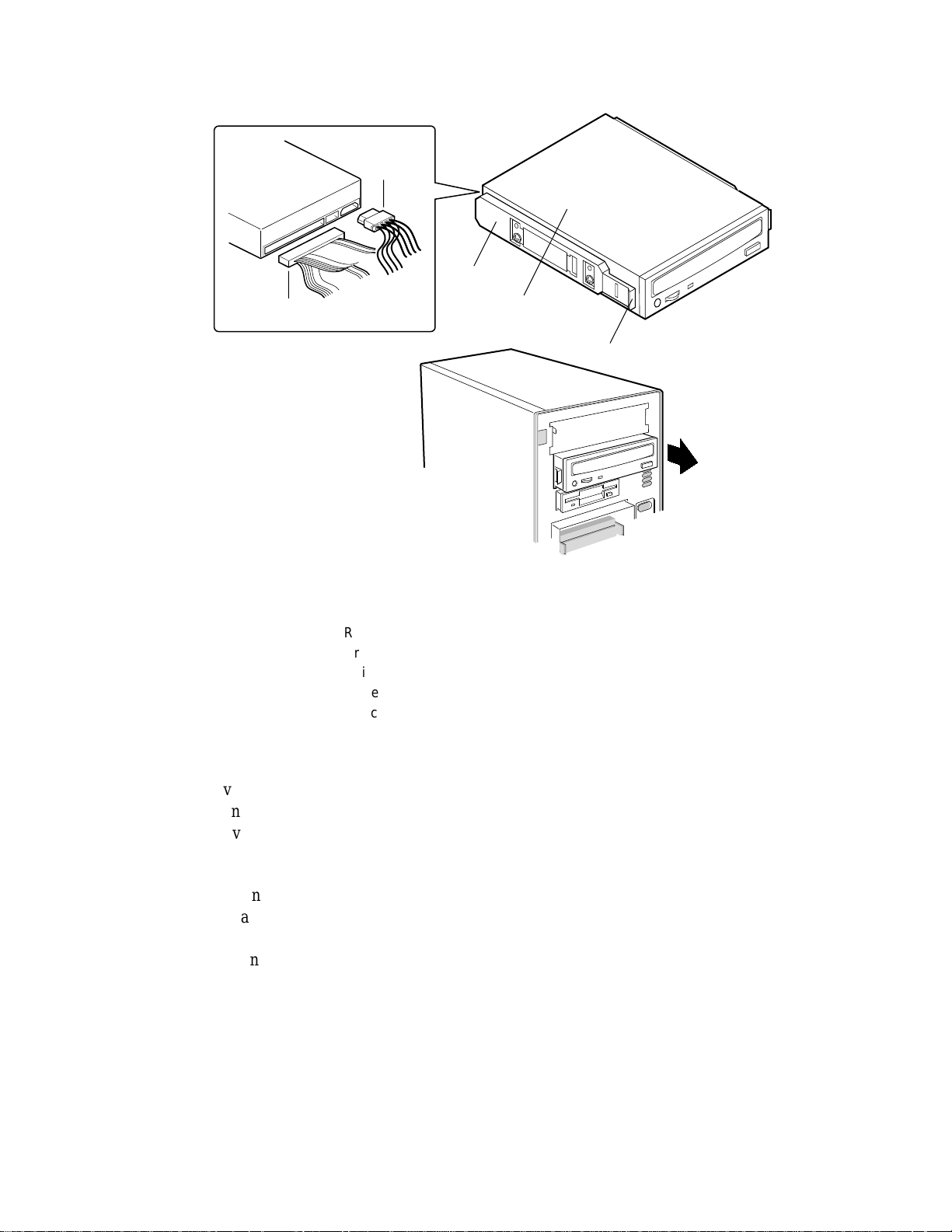

Installing a 5.25-inch Peripheral Device

Two 5.25-inch half-height bays provide space for tape backup, CD-ROM, or other removable

media drives.

CAUTION

For several reasons, we recommend that you do NOT install hard drives in

the 5.25-inch bays: the drives cannot be properly cooled in this location; a

hard drive generates EMI and is more susceptible to ESD in this location.

NOTES

✏

System EMI integrity and cooling are both protected by having drives

installed in the bays or filler panels and EMI shields covering the bays.

When you install a drive, save the panel and shield to reinstall in case you

should later remove the drive and not reinstall one in the same bay.

It is important that your cabling and connections meet the SCSI bus

specification. Otherwise, the bus could be unreliable and data corruption

could occur or devices may not work at all. The SCSI bus needs to be

terminated at the end of the cable, and this is usually provided by the last

SCSI device on the cable.

1.Observe the safety and ESD precautions at the beginning of this chapter.

2.Remove the side and front system covers. Place the front cover on a flat surface.

3.Remove filler panel from the bay and set it aside.

4.Push the tab on the left side of the EMI metal shield to the right to disengage it from the

chassis. Save the shield.

C

A

Figure 18. Remove Filler Panels and EMI Shields

A.EMI shield

B.Filler panel

C.Tab

B

OM07099

30 Intel Astor II Server Chassis Subassembly Product Guide

Page 31

5.Remove the drive from its protective wrapper, and place it on an antistatic surface.

6.Record the drive model and serial numbers in your equipment log.

7.Set any jumpers and/or switches on the drive according to the drive manufacturer’s

instructions.

8.Using two screws (silver screws without washers are provided), attach each plastic slide rail

with its metal grounding plate to the drive.

9.Position the drive so the plastic slide rails engage in the bay guide rails. Push the drive into the

bay until the slide rails lock in place.

D

B

C

Figure 19. Snap-in Plastic Slide Rails

A.CD-ROM or other removable media device

B.Tab on slide rail

C.Screws (4)

D.Slide rails (2)

10.Connect a power cable to the drive.

11.Connect a signal cable to the drive.

A

OM07046

Working Inside the System 31

Page 32

D

B

E

Figure 20. Installing a Removable Media Device

A.Removable media device

B.Drive rail

C.Rail tab

D.Power cable

E.Typical SCSI signal cable

A

C

OM07036

Removing a 5.25-inch Peripheral Device

1.Observe the safety and ESD precautions at the beginning of this chapter.

2.Disconnect the power and signal cables from the drive.

3.The drive has two protruding plastic, snap in rails attached. Squeeze the rail tabs toward each

other as you carefully slide the drive forward out of the bay, and place it on an antistatic

surface.

4.Remove and save the four screws and two slide rails.

5.If you leave the bay empty, install a stainless steel EMI shield on the bay and a filler panel on

the front cover for proper cooling and airflow.

6.If you do not replace the device with another SCSI device, and it was installed at the end of the

SCSI signal cable, modify the cable and termination arrangement so that a proper termination

exists at the end of the cable (it can be a termination device only, not necessarily a SCSI

peripheral).

32 Intel Astor II Server Chassis Subassembly Product Guide

Page 33

Installing the Front Cover

1.Insert the plastic tabs on the front cover into the slots on the right of the chassis. Squeeze the

front panel and chassis together along the left side until the plastic tabs snap into their slots.

Installing the Hot-swap Bay

1.Tilt the bay into the chassis.

2.Connect the power and data cables to the SCSI backplane.

3.Install and tighten the three screws holding the bay to the chassis.

4.Install the side cover.

Installing an Add-in Board

CAUTIONS

Do not overload the server board by installing add-in boards that draw

excessive current.

Add-in boards can be extremely sensitive to ESD and always require careful

handling. After removing the board from its protective wrapper or from the

server board, place it component side up on a grounded, static free surface or

conductive foam pad—if available. Do not slide the board over any surface.

1.Remove side cover.

2.Remove and save the expansion slot screw and cover.

3.Remove add-in board from its protective wrapper. Be careful not to touch the components or

gold edge connectors. Place board component side up on an antistatic surface.

4.Record the type and serial number of the add-in board in your equipment log.

5.Set jumpers or switches according to the manufacturer’s instructions.

6.Hold board by its top edge or upper corners. Firmly press it into an expansion slot on the

server board. The tapered foot of the board retaining bracket must fit into the mating slot in

the expansion slot frame.

Install an ISA board component side UP.

Install a PCI board component side DOWN.

7.Align the rounded notch in the retaining bracket with the threaded hole in the frame. The

bracket fits the space that was occupied by the slot cover.

8.Use the screw removed earlier. Insert it into the threaded hole, and push the rounded notch

against the screw. Tighten it firmly to prevent the bracket from interfering with adjacent

brackets. Attach cables if necessary.

9.Reinstall the side cover.

Working Inside the System 33

Page 34

A

B

OM06425

Figure 21. Installing an Add-in Board

A.Expansion slot cover and screw

B.Add-in board, use same screw

Removing an Add-in Board

CAUTION

Slot covers must be installed on all vacant expansion slots. This maintains

the electromagnetic emissions characteristics of the system and ensures

proper cooling of system components.

1.Observe the safety and ESD precautions at the beginning of this chapter.

2.Disconnect any cables attached to the board you are removing.

3.Remove and save the screw from the board retaining bracket.

4.Holding the board by its top edge or upper corners, carefully pull it out. Do not scrape the

board against other components.

5.Store board in an antistatic protective wrapper.

6.If you are not reinstalling a board in the same slot, install a slot cover over the vacant slot. The

tapered foot of the cover must fit into the mating slot in the expansion slot frame.

7.Use the screw removed earlier. Insert it into the threaded hole, and push the rounded notch

against screw. Tighten it firmly to prevent the bracket from interfering with adjacent brackets.

34 Intel Astor II Server Chassis Subassembly Product Guide

Page 35

Installing the Side Cover

CAUTION

When you install the side cover, do not damage the EMI gaskets mounted on

the cover. Replace any damaged strips, or your system may not meet EMI

requirements.

1.Before replacing a side cover, check that you have not left loose tools or parts inside the

system.

2.Check that cables, add-in boards, and other components are properly installed.

3.Position the cover over the chassis so that the top row of tabs aligns with slots in the top of the

chassis. Slide the cover toward the front of the system until the cover tabs firmly engage in the

chassis.

4.Attach the cover to the chassis with the three screws you removed earlier, and tighten them

firmly.

5.To prevent unauthorized access inside the system, insert and lock a padlock through the metal

loop protruding through the slot in the back of the side cover.

6.Connect all external cables and the power cord to the system.

Working Inside the System 35

Page 36

Hot-swap Bay

The plastic front door covers a removable metal EMI cover that is hinged at the bottom. Plastic

drive carriers for 3.5-inch wide by 1-inch high drives allow easy hot-swapping of drives without

shutting down the system.

The backplane uses industry-standard 80-pin SCA2 connectors to support up to five industrystandard Ultra2/LVD SCA2 SCSI hard disk drives. The bays accept peripherals that consume up

to 17 watts of power and run at a maximum ambient temperature of 50 °C.

SCSI Hard Disk Drives

The system supports a variety of single ended or LVD (low voltage differential) SCSI SCA2

devices. Visit the support website for your server board for a list of approved single ended SCSI

SCA2 devices. http://support.intel.com/support/motherboards\server\

WARNING

The Ultra2/LVD SCSI hot-swap backplane requires installing LVD or

single ended SCSI devices in your system. Installing high voltage

differential (HVD) SCSI drive types can result in electrical damage to

the server board and the peripherals.

CAUTION

ESD can damage disk drives, add-in boards, and other components. This

server can withstand normal levels of environmental ESD while SCSI hard

disk drives are being swapped. However, we recommend doing all

procedures in this manual only at an ESD workstation. If one is not

available, you can provide some ESD protection by wearing an antistatic

wrist strap attached to chassis ground of the server—any unpainted metal

surface—when handling components.

For proper air flow and hard drive cooling, make sure that the paper baffles

included with the chassis are installed in any drive carriers that do not

contain drives. Fold the ends of the paper baffle up along the dotted lines.

Mounting a SCSI SCA2 Hard Disk Drive in a Plastic Carrier

1.Record the drive model and serial number in your equipment log.

2.Orient the drive so the connector is near the top surface of the drive, and place it on an

antistatic surface.

3.Place the plastic carrier on top of the drive.

4.Using four screws (silver screws with washers are supplied), attach the carrier to the drive.

36 Intel Astor II Server Chassis Subassembly Product Guide

Page 37

OM07035

Figure 22. Hard Disk Drive and Plastic Carrier

Installing a SCSI SCA2 Hard Disk Drive in the Hot-swap Bay

1.Open the plastic front door.

2.If there is a padlock installed on the metal EMI cover, remove it.

3.Pull the top of the metal EMI cover away from the chassis.

4.Position the drive/carrier assembly, locking tab to the left, so it engages the hot-swap bay

guide rails.

5.Gently push the assembly into the bay until it docks with the backplane connector and snaps

into place.

6.Close the metal EMI cover.

7.Close the plastic front door.

Working Inside the System 37

Page 38

Figure 23. Installing a Hard Disk Drive

Hot-swapping a SCSI SCA2 Hard Disk Drive

A bank of five yellow LEDs on the front panel monitors the drive status of each drive in the hotswap bay. When a yellow LED is on continuously, it is okay to hot-swap (replace) a bad drive

with a good one. You do not need to shut the system down to hot-swap a drive.

1.Open the plastic front door of the system.

2.Pull the top of the metal EMI cover away from the chassis.

3.Check the bank of yellow LEDs on the front panel to determine which drive is bad. Grasp that

drive’s plastic drive carrier, squeeze the tab on the carrier, and carefully slide the bad drive out

of the bay. Place the drive on an antistatic surface.

4.Position the new plastic carrier and drive assembly so that it engages the bay guide rails.

5.Gently push the drive into the bay until it docks with the backplane connector and snaps into

place.

6.Close the metal door.

7.Close the plastic front door.

OM07049

38 Intel Astor II Server Chassis Subassembly Product Guide

Page 39

Fans

For cooling and airflow, the system contains three removable chassis fans to cool the boards and

removable media drives. The integrated power supply fan provides more cooling and airflow.

NOTE

✏

The fan has two connectors on its cable. One is labeled “N440BX” and

should only be connected a system fan connector on the Intel N440BX

Server Board. The other connector is label “ATX” and can be connected to

any ATX compliant board.

Table 2. Fan Cable Connector Pinout

Pin ATX signal N440BX Signal Wire Color

1 Ground Ground Black

2 +12V SPEED Yellow

3 Speed +12 V red

Removing the Front Fan

1.Observe the safety and ESD precautions at the beginning this chapter.

2.Remove the side cover.

3.Disconnect the fan power cable connector from the fan header on the server board.

4.Remove the screw holding the fan bracket to the chassis.

5.Pull the fan bracket out of the chassis.

A

B

OM07050

Figure 24. Removing the Fan Bracket

A.Fan power cable

B.Notched metal tabs

Working Inside the System 39

Page 40

Installing the Front Fan

NOTE

✏

The removable fan pulls air from in front of the chassis so that it flows

across the boards and out the back. Thus, the fan must be oriented for the

correct airflow direction. If you place the fan so the label faces the back of

the chassis, this should provide the correct orientation. You can confirm this

by checking the embossed arrows on the side of the fan as you place it in its

bracket:

Arrow points horizontally toward back of chassis

Arrow points vertically up

Replace a failed fan with the same type as the one removed, with a

tachometer signal, or an approved fan. For a list of approved fans, contact

your distributor or customer service representative.

OM07564

Figure 25. Installing the Front Fan

1.Attach the fan to the bracket with two snap rivets.

2.Feed the fan’s power cable through the hole in the card guide.

3.Slide the fan bracket into the chassis. Make sure that the bottom of the bracket is set into the

notches on the metal tab.

4.Install and tighten the screw that holds the bracket to the chassis.

40 Intel Astor II Server Chassis Subassembly Product Guide

Page 41

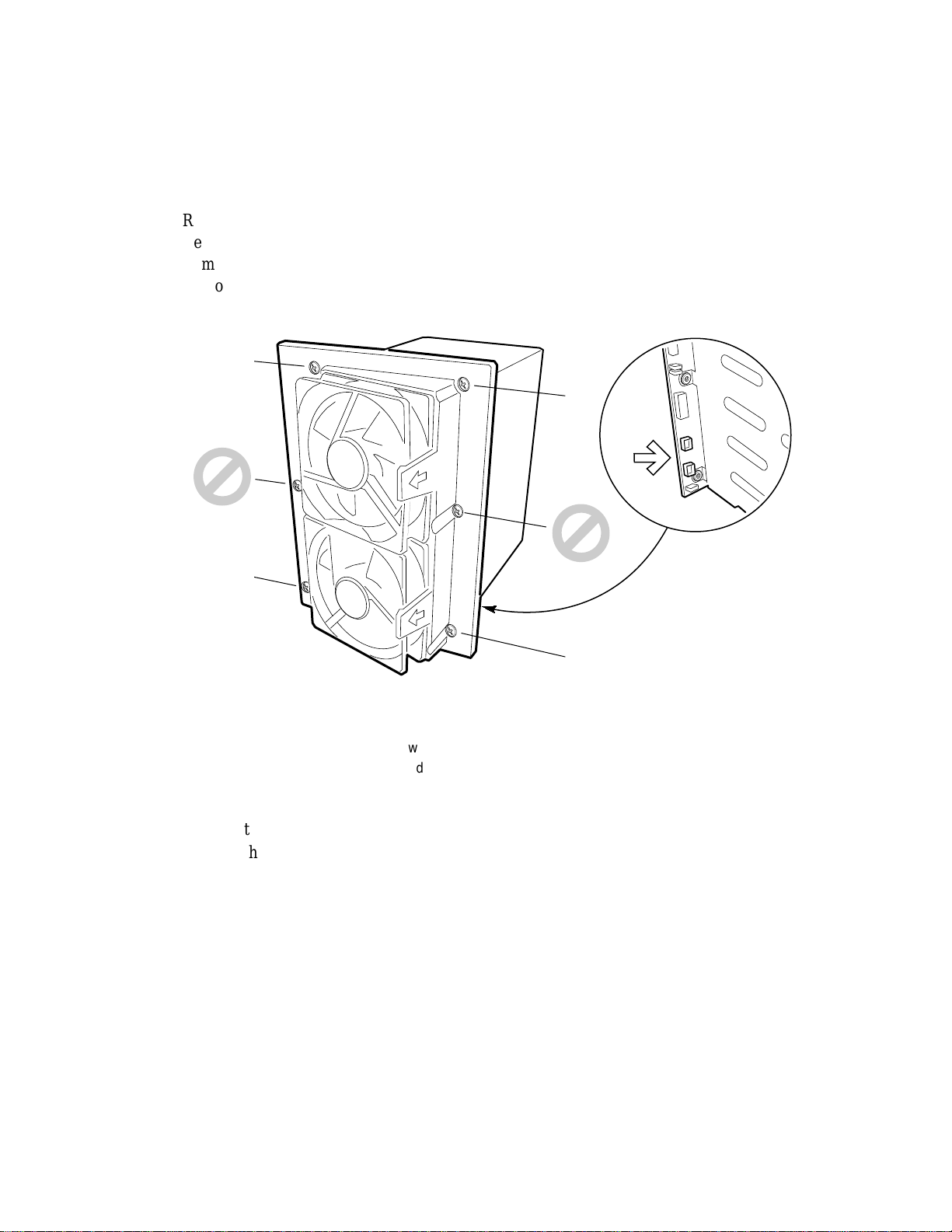

Removing a Hot-swap Bay Fan

Figure 26. Removing the Hot-swap Bay Fan Bracket

1.Observe the safety and ESD precautions at the beginning this chapter.

2.Remove the side cover.

3.Disconnect the fan’s power cable from the SCSI backplane.

4.Snap the fan out of the plastic shroud.

A

OM07042

Installing a Hot-swap Bay Fan

1.Position the fan, label side facing away from the hot-swap bay, and snap it into the shroud.

2.Connect the fan’s power cable to the SCSI backplane (a fan in the bottom of the shroud

connects to the Fan 1 header; a fan in the top of the shroud connects to Fan 0 header).

3.Reinstall the side cover.

Working Inside the System 41

Page 42

Hot-swap Backplane

Removing the SCSI Backplane

1.Remove any hard drives installed in the hot-swap bay.

2.Remove the hot-swap bay from the chassis.

3.Remove the hot-swap bay fans.

4.Remove the four corner screws holding the plastic shroud and SCSI backplane to the hot-swap

bay. Do not remove the two center screws.

A

A

B

A

A

OM07042A

Figure 27. Removing the Plastic Shroud

A.Screws

B.Threaded tabs on hot-swap bay

5.Remove the plastic shroud and set it aside.

6.Remove the two center screws holding the SCSI backplane to the hot-swap bay.

7.Remove the SCSI backplane, and place it component side up on a nonconductive, static free

surface or in an antistatic bag.

42 Intel Astor II Server Chassis Subassembly Product Guide

Page 43

A

A

OM07053

Figure 28. Removing the SCSI Backplane

A.Screws

Installing the SCSI Backplane

1.Place the SCSI backplane component side to the hot-swap bay.

2.Insert and tighten the two center screws that hold the backplane to the hot-swap bay.

3.Place the plastic shroud on the back of the backplane.

4.Insert and tighten the four corner screws holding the plastic shroud and SCSI backplane to the

hot-swap bay.

5.Install two hot-swap bay fans.

Working Inside the System 43

Page 44

Front Panel Board

Removing the Front Panel Board

The front panel board contains the system controls and indicators. The board is mounted on a snap

on standoff and a threaded standoff inside the chassis.

1.Observe the safety and ESD precautions at the beginning of this chapter.

2.Remove the side cover.

3.Remove the hot-swap bay.

4.Remove and save the snap rivets holding the front panel board to the chassis.

5.Disconnect the data cables from the front panel.

6.Remove the front panel board from the system, and place it on an antistatic foam pad or a

grounded workstation.

OM07098

Figure 29. Removing the Front Panel Board

Installing the Front Panel Board

1.Position the front panel board over the tabs inside the chassis.

2.Reconnect the data cables to the front panel board.

3.Insert the snap rivets from the bottom, through the tabs and the front panel.

4.Reinstall the hot-swap bay.

5.Reinstall the side cover.

44 Intel Astor II Server Chassis Subassembly Product Guide

Page 45

3 Technical Reference

Power Supply Specifications

Input Voltages

The 300 watt power supply, designed to minimize EMI, provides sufficient power for a maximum

configuration of the server. The input voltage ranges are:

100-120 V at 50/60 Hz; 4.6 A maximum current

200-240 V at 50/60 Hz; 2.3 A maximum current

If a system is integrated to a fully configured condition, checking the input current rating will

provide an indication of whether the system is overloaded or not. The input current rating should

not exceed 4.6 amperes (for 100-120Vac) or 2.3 amperes (for 200-240Vac).

Output Voltages

The table below lists the total watts available for each voltage. Adjust your loads so that the

combined total wattage for your system configuration is less than 300 watts. For information

about calculating the power usage for your system configuration, see page 59.

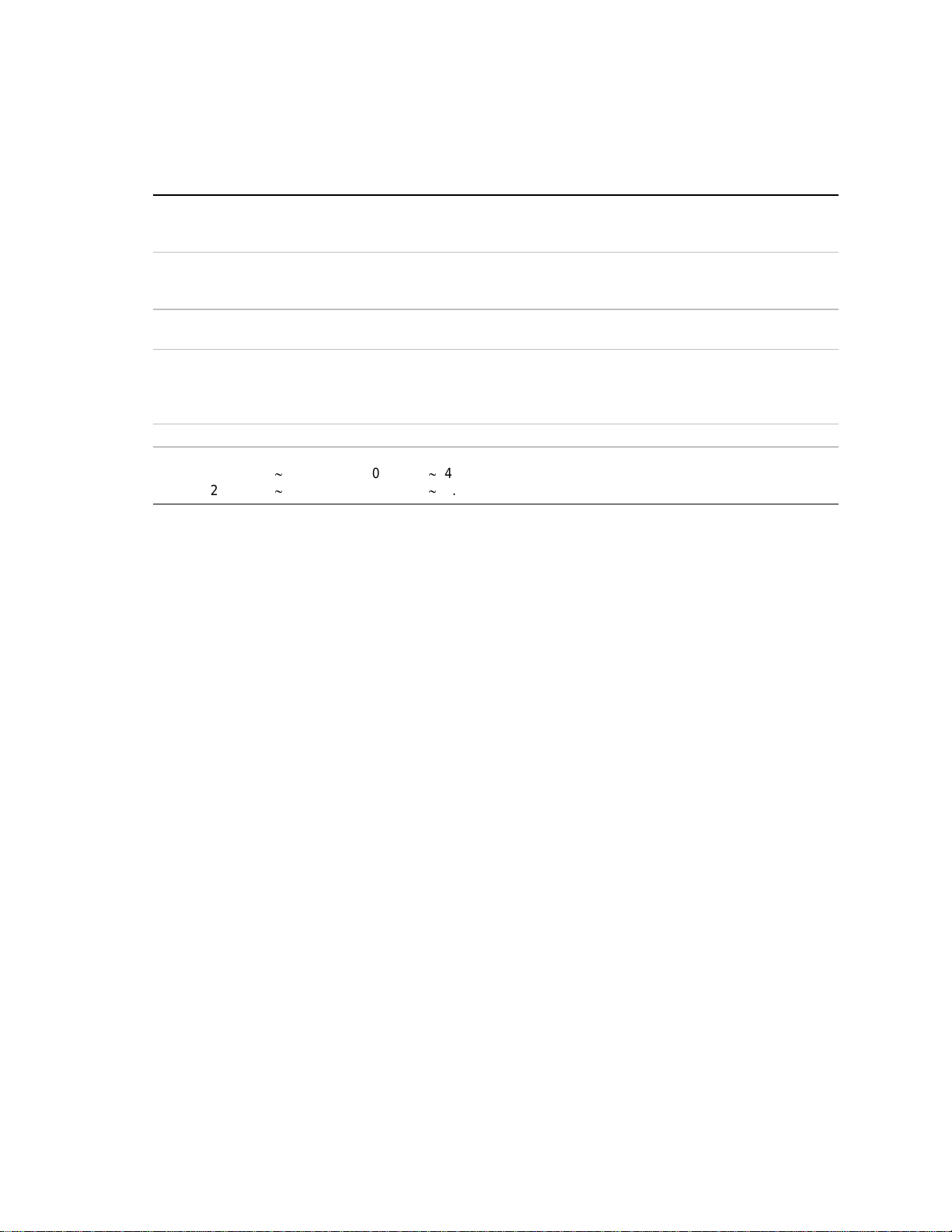

Table 3. Power Supply Output Voltages

Maximum

Voltage

+3.3 V 16.0 A 52.8 W

+5.0 V 26.0 A 130.0 W

–5.0 V 0.25 A 1.25 W

+5V Standby 0.8 A 4.0 W

+12.0 V 10.0 A 13.0 A 120.0 W

–12.0 V 0.5 A 6.0 W

Continuous Current Peak Current Watts

CAUTION

Do not exceed a combined power output of 167 watts for the +5 V and +3.3 V

outputs. Exceeding a combined 167 watts will overload the power supply and

may cause the power supply to overheat and malfunction.

The ISA slot(s) on the system board are rated at a maximum of 4.5 amperes per slot. The ISA

specification recommends supporting an average of 2.0 amperes per slot. The average current

usage should not exceed 3.0 amperes per slot; that is, 15 watts.

The PCI slots on the system board are rated at a maximum of 5 amperes per slot. The maximum

power allowed for each slot is 20 watts at +5 volts. The average current usage per slot should not

exceed 3.0 amperes per slot; that is, 15 watts.

45

Page 46

Environmental Specifications

Table 4. Environmental Specifications

Temperature

Nonoperating

Operating

Humidity

Nonoperating

Operating wet bulb

Shock

Operating 2.0 g, 11 msec, 1/2 sine

Acoustic noise Typically <45 dBA at 18° to 24 °C (65° to 75 °F) with five internal hard disk

Electrostatic discharge (ESD) Tested to 20 kilovolts (kV); no component damage

AC Input Power

100-120 V

200-240 V

–40° to 70 °C (–55° to 150 °F)

10° to 35 °C (41° to 95 °F); derated 0.5 °C for every 1000 ft (305 m)

95% relative humidity (noncondensing) at 30 °C (86 °F)

Not to exceed 33 °C (91.4 °F) (with diskette drive or hard disk drive)

drives (measured at 1 meter from the system with the peripherals idle). The

noise of the variable speed system fan will increase with temperature and

power load. Your selection of peripherals may change the noise level.

100-120 V, 4.6 A, 50/60 Hz

200-240 V, 2.3 A, 50/60 Hz

46 Astor II Chassis Subassembly Product Guide

Page 47

SCSI Hot-swap Backplane Connectors

OM03878

1

68

Ultra2/LVD SCSI 16-Bit Connector

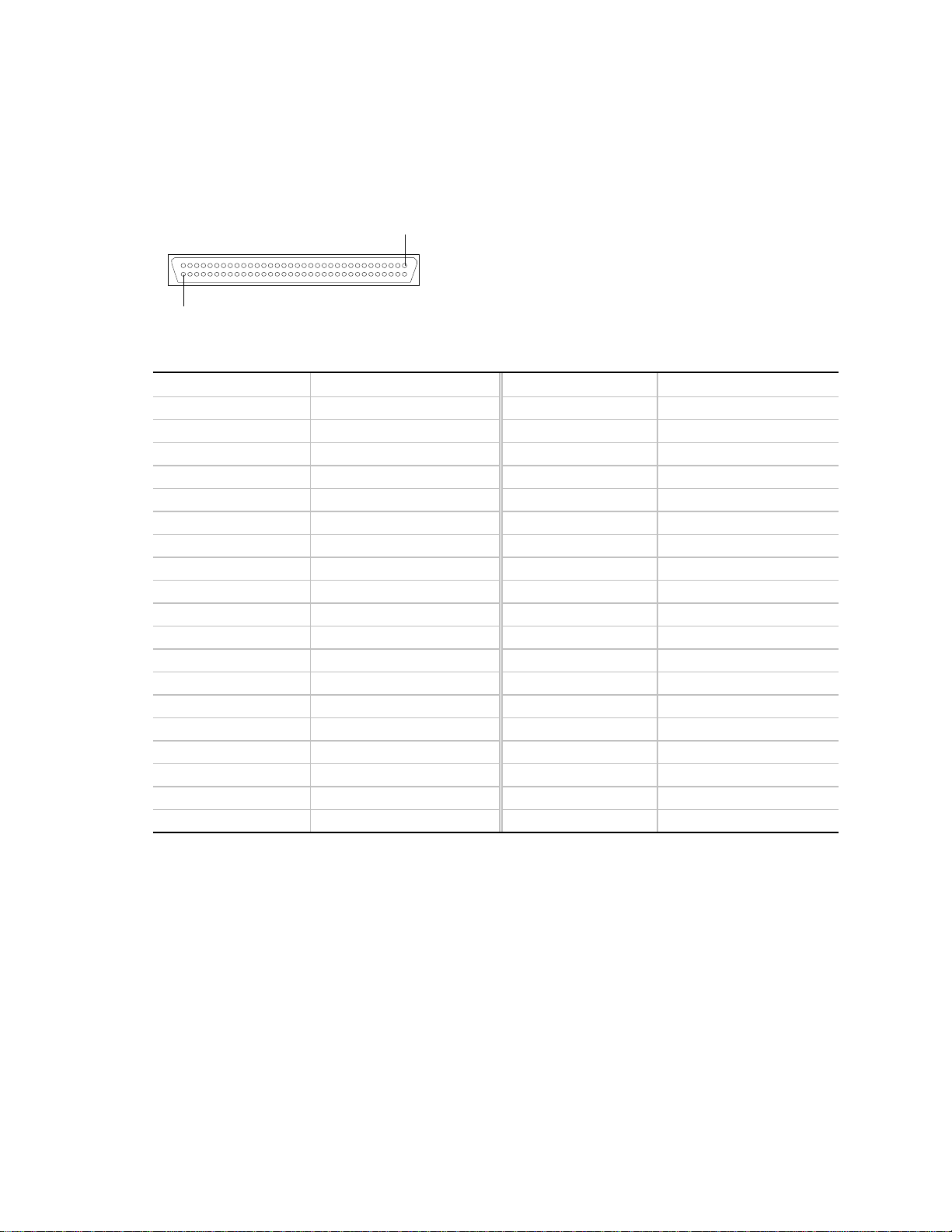

Table 5. Wide/Fast SCSI 16-Bit Connector Pinout

Pin Signal Pin Signal

1-16 GND (ground) 49-50 GND (ground)

17 TERMPWR 51 TERMPWR

18 TERMPWR 52 TERMPWR

19 RESERVED 53 RESERVED

20-34 GND (ground) 54 GND (ground)

35 DB12_L 55 ATN_L

36 DB13_L 56 GND (ground)

37 DB14_L 57 BSY_L

38 DB15_L 58 ACK_L

39 DBP1_L 59 RST_L

40 DB0_L 60 MSG_L

41 DB1_L 61 SEL_L

42 DB2_L 62 CD_L

43 DB3_L 63 REQ_L

44 DB4_L 64 I/O_L

45 DB5_L 65 DB8_L

46 DB6_L 66 DB9_L

47 DB7_L 67 DB10_L

48 DBP_L 68 DB11_L

Technical Reference 47

Page 48

Ultra2/LVD SCA2 SCSI 16-Bit Connectors

1

OM04855

Table 6. Wide/Fast SCA2 SCSI 16-Bit Connector Pinout

Pin Signal Pin Signal

1-4 +12 V 25 DB 3_L

56 NC 26 DB 2_L

7 DB 11_L 27 DB 1_L

8 DB 10_L 28 DB 0_L

9 DB 9_L 29 DB P_L

10 DB 8_L 30 DB 15_L

11 I/O_L 31 DB 14_L

12 REQ_L 32 DB 13_L

13 C/D_L 33 DB 12_L

14 SEL_L 34-36 +5 V

15 MSG_L 37 SYNC

16 RST_L 38 MTRON_L

17 ACK_L 39 ID0_L

18 BSY_L 40 ID2_L

19 ATN_L 41 DRV PRES_L

20 DB P_L 4276 GND

21 DB 7_L 77 LEDC, DRV ACT_L

22 DB 6_L 78 DLYDST_L

23 DB 5_L 79 ID1_L

24 DB 4_L 80 ID3_L

48 Astor II Chassis Subassembly Product Guide

Page 49

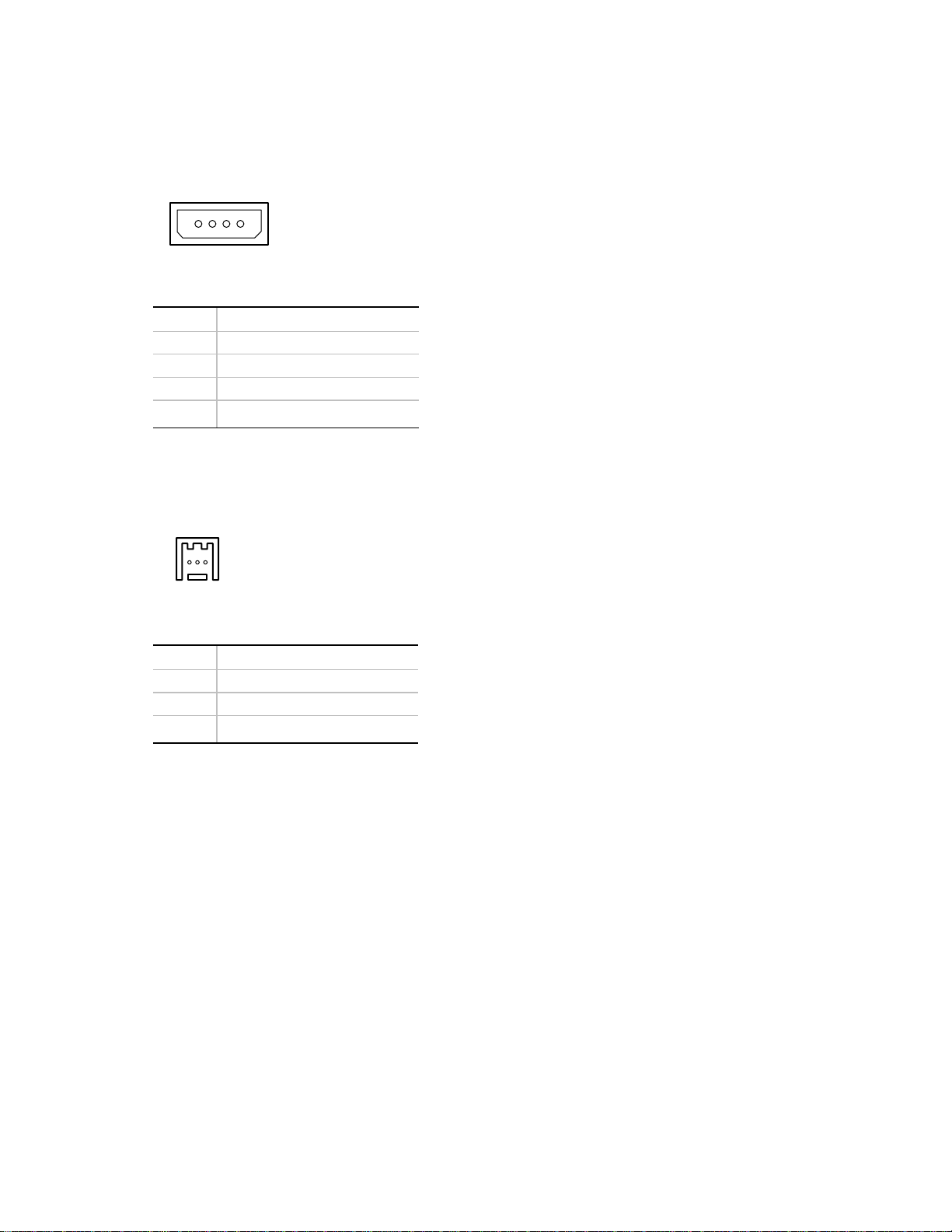

Power Connectors

The backplane power connectors are 4-pin shrouded plastic connectors with mechanical keying.

1234

OM04656

Table 7. Power Connector Pinout

Pin Signal

1 +12 V

2 Ground

3 Ground

4+5 V

Backplane Fan Connector

This connector provides power to the fan.

123

OM05211

Table 8. Backplane Fan Connector Pinout

Pin Signal

1 GND (ground)

2 SPEED

3 +12 V

Technical Reference 49

Page 50

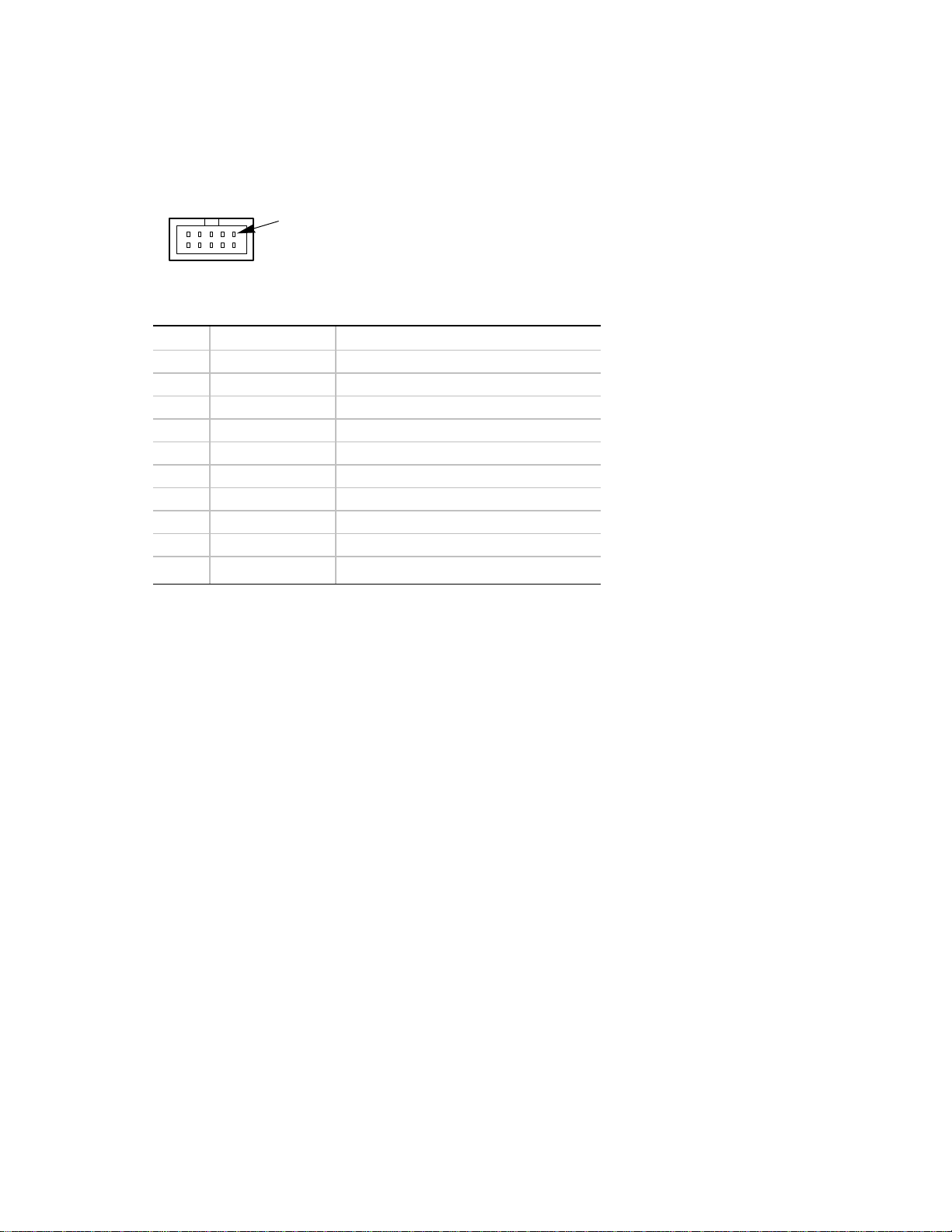

Front Panel Cable Connec tor

The front panel connector and cable provide the chassis wide IMB bus and the electrical path

between the drive fault indicators (LEDs) and the SCSI backplane that controls them.

1

OM04669

Table 9. Front Panel Connector Pinout

Pin Name Description

1 GND Electrical ground (0V)

2 I2C_SDA I2C SDA (Serial Data)

3 NC No Connect

4 I2C_SCL I2C Serial Clock

5 PRI_SEC_L Primary Secondary Backplane

6 FAULT1_L Fault signal for drive 1 (logical drive 0)

7 FAULT2_L Fault signal for drive 2 (logical drive 1)

8 FAULT3_L Fault signal for drive 3 (logical drive 2)

9 FAULT4_L Fault signal for drive 4 (logical drive 3)

10 FAULT5_L Fault signal for drive 5 (logical drive 4)

50 Astor II Chassis Subassembly Product Guide

Page 51

4 Regulatory Information

WARNING

You must adhere to the assembly instructions in this guide to ensure

and maintain compliance with existing product regulations. Use only

the described, regulated components specified in this guide. Use of

other products / components will void the UL listing of the product, will

most likely void other compliance markings provided, and may result in

noncompliance with product regulations in the region(s) in which the

product is sold.

Regulatory Compliance

This subassembly, when correctly integrated per this guide, complies with the following safety and

electromagnetic compatibility (EMC) regulations.

Safety Compliance

UL 1950 - CSA 950-95, 3rd Edition, July 28, 1995

The Standard for Safety of Information Technology Equipment including Electrical Business

Equipment. (USA and Canada). This product has been evaluated and complies to UL1950 – CSA

950-95 3

used, the system will be deemed to comply with UL 1950 2

rd

Edition. However, if a UL1950 2nd Edition modem telecommunications add-in card is

nd

Edition/CSA950-93.

EN 60 950, 2nd Edition, 1992 (with Amendments 1, 2, and 3)

The Standard for Safety of Information Technology Equipment including Electrical Business

Equipment. (European Union)

IEC60 950, 2nd edition, 1991 (with Amendments 1, 2, 3 and 4)

The Standard for Safety of Information Technology Equipment including Electrical Business

Equipment. (International)

EMKO-TSE (74-SEC) 207/94

Summary of Nordic deviations to EN 60 950. (Norway, Sweden, Denmark, and Finland)

51

Page 52

EMC Compliance

FCC Class B

Title 47 of the Code of Federal Regulations, Parts 2 and 15, Subpart B, pertaining to unintentional

radiators. (USA)

CISPR 22, 2nd Edition, 1993, Amendment 1, 1995

Limits and methods of measurement of Radio Interference Characteristics of Information

Technology Equipment. (International)

EN 55 022, 1995

Limits and methods of measurement of Radio Interference Characteristics of Information

Technology Equipment. (Europe)

EN 50 082-1, 1992

Generic Immunity Standard. Currently, compliance is determined via testing to IEC 801-2, -3

and -4. (Europe)

VCCI Class B (ITE)

Implementation Regulations for Voluntary Control of Radio Interference by Data Processing

Equipment and Electronic Office Machines. (Japan)

ICES-003, Issue 2

Interference Causing Equipment Standard, Digital Apparatus. (Canada)

Australian Communication Authority (ACA)

Australian C-tick mark, limits and methods of measurement radio interference characteristics of

information technology equipment to ASNZS 3548 (Australian requirements based on CISPR 22

requirements).

New Zealand Ministry of Commerce

Australian C-tick mark, limits and methods of measurement radio interference characteristics of

information technology equipment to ASNZS 3548 (New Zealand requirements based on

CISPR 22 requirements). New Zealand authorities accept ACA C-Tick Compliance Mark.

52 Intel Astor II Server Chassis Subassembly Product Guide

Page 53

Regulatory Compliance Markings

This Astor II chassis subassembly is provided with the following Product Certification Markings.

UL and cUL Listing Marks

CE Mark

Australian C-Tick Mark

German GS Mark

The CE marking on this product indicates that it is in compliance with the European

community’s EMC (89/336/EEC) and low voltage directives (73/23/EEC)

NEMKO Mark

FCC, Class B (Declaration of Conformity)

ICES-003 (Canada Compliance Marking)

VCCI Class B

Electromagnetic Compatibility Notice (USA)

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off

and on; the user is encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and the receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

Consult the dealer or an experienced radio/TV technician for help.

Any changes or modifications not expressly approved by the grantee of this device could void the

user’s authority to operate the equipment. The customer is responsible for ensuring compliance of

the modified product.

Only peripherals (computer input/output devices, terminals, printers, etc.) that comply with FCC

Class B limits may be attached to this computer product. Operation with noncompliant peripherals

is likely to result in interference to radio and TV reception.

All cables used to connect to peripherals must be shielded and grounded. Operation with cables,

connected to peripherals, that are not shielded and grounded may result in interference to radio and

TV reception.

Regulatory Information 53

Page 54

NOTE

✏

If a Class A device is installed within this system, then the system is to be

considered a Class A system. In this configuration, operation of this

equipment in a residential area is likely to cause harmful interference.

FCC Declaration of Conformity

Product Type: AST2

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: 1) This device may not cause harmful interference, and 2) this device must accept any

interference received, including interference that may cause undesired operation.

Intel Corporation

5200 N.E. Elam Young Parkway

Hillsboro, OR 97124-6497

Phone: 1-800-628-8686

Cet appareil numérique respecte les limites bruits radioélectriques applicables aux appareils

numériques de Classe B prescrites dans la norme sur le matériel brouilleur: “Appareils

Numériques”, NMB-003 édictée par le Ministre Canadian des Communications.

(English translation of the notice above) This digital apparatus does not exceed the Class B limits

for radio noise emissions from digital apparatus set out in the interference causing equipment

standard entitled “Digital Apparatus,” ICES-003 of the Canadian Department of Communications.

Electromagnetic Compatibility Notices (International)

(English translation of the notice above) This is a Class B product based on the standard of the

Voluntary Control Council For Interference (VCCI) from Information Technology Equipment. If

this is used near a radio or television receiver in a domestic environment, it may cause radio

interference. Install and use the equipment according to the instruction manual.

When used near a radio or TV receiver, it may become the cause of radio interference.

Read the instructions for correct handling.