Page 1

21555 PCI-to-PCI Bridge Evaluation Board

User’s Guide

November 2002

Order Number: 278359-002

Page 2

Information in this document is provided in connection with Intel® products. No license, express or implied, by estoppel or otherwise, to any

intellectual property rights is granted by this document. Except as provided in Intel's Terms and Conditions of Sale for such products, Intel assumes no

liability whatsoever, and Intel disclaims any express or implied warranty, relating to sale and/or use of Intel products including liability or warranties

relating to fitness for a particular purpose, merchantability, or infringement of any patent, copyright or other intellectual property right. Intel products are

not intended for use in medical, life saving, or life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked “reserved” or “undefined.” Intel reserves these for

future definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from future changes to them.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an ordering number and are referenced in this document, or other Intel literature may be obtained by calling 1-800-

548-4725 or by visiting Intel's website at http://www.intel.com.

Copyright © Intel Corporation, 2002

Intel is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and other countries.

*Third-party brands and names are the property of their respective owners.

21555 PCI-to-PCI Bridge Ev aluation Board User’s Guide

Page 3

Contents

1 Introduction.........................................................................................................................5

1.1 Overview ...............................................................................................................5

1.2 Features................................................................................................................5

1.3 Major Components.......................... ...... ...... ....... ...... ....... ...... ....... .........................6

1.3.1 Connectors...........................................................................................6

1.3.2 Switches and Jumper...........................................................................7

1.3.3 Devices.................................................................................................7

1.4 Switch Settings............ ....... ...... ....... ...... ....................................... ...... ....... ...... ......8

1.5 Stake-Pin Jumper..................................................................................................9

1.6 Resistor Jumpers ................................................................................................10

1.6.1 Clock Configuration ............................................................................11

1.6.2 Clamping Voltage...............................................................................11

1.7 Secondary Slot Numbering and IDSEL Mapping................................................12

1.8 Interrupt Routing..................................................................................................13

1.9 Typical Configurations.........................................................................................14

2 Operations and Installation...............................................................................................17

2.1 Specifications ......................................................................................................17

2.2 Hardware Requirements .....................................................................................17

2.3 Software Requirements.......................................................................................17

2.3.1 Programming the SROM ....................................................................18

2.3.2 Programming the Flash ROM.............................................................18

2.4 Installation Procedure..........................................................................................19

2.5 Interrupt Routing..................................................................................................20

3 Optional Configurations....................................................................................................21

3.1 PICMG Configuration ..........................................................................................21

3.2 Central Function and Arbiter Control...................................................................21

3.3 Asynchronous Clocking.......................................................................................22

Figures

1 Major Components.......................... ...... ...... ....... ...... ....... ...... ....... .........................6

2 Switches................................................................................................................8

3 Jumper Resistors ...............................................................................................10

4 Local PCI Slot Numbering...................................................................................12

5 DE1B55503 with One Local Bus Option Card.....................................................14

6 DE1B55503 with Two Local Bus Option Cards...................................................15

21555 PCI-to-PCI Bridge Evaluation Board User’s Guide iii

Page 4

Tables

1 DIP Switch Operation............................................................................................9

2 Stake-Pin Jumper .................................................................................................9

3 Clock Configuration Jumpers..............................................................................11

4 Voltage Clamp.....................................................................................................11

5 Slot and IDSEL Mapping.....................................................................................12

6 Interrupt ORing....................................................................................................13

7 Switch Operation for SROM programming..........................................................18

8 Switch Operation for FLASH programming.........................................................19

9 Interrupt ORing....................................................................................................20

10 J9 PICMG Switches .............................................. ...... ....... ...... ....... ...... ....... ...... .21

11 Clock Routing Zero Ohm Resistors.....................................................................21

12 External Arbiter Switch Option ............................................................................22

13 J21 Switch Operations for Central Function and Arbiter Control ........................22

14 Switch Operations for Synchronous or Asynchronous Clock Control .................22

iv 21555 PCI-to-PCI Bridge Ev aluation Board User’s Guide

Page 5

Introduction 1

This User’s Guide describes the 21555 PCI-to -PCI non transpar ent Bridge Evalu ation Board which

is referred to as the DE1B55503.

1.1 Overview

The DE1B55503 is a PCI expansion board that is used to evaluate the o peration of the 21 555 when

it is used as a gateway to an intelligent subsystem. The subsystem can use a variety of PCI devices

and local processors. The DE1B55503 can be used to:

• Develop initialization code to configure the 21555 and associated logic and devices on the

local PCI bus as an intelligent controller.

• Evaluate the operation of the 21555 with a variety of PCI devices configured in an intelligent

subsystem.

• Build and evaluate a system using synchronous and asynchronous clocking.

• Test features:

— Intelligent Input/Output (I2O) transactions.

— Power management features.

— Vital Product Data (VPD) support.

1.2 Features

The DE1B55503:

• Complies fully with the protocol and electrical standards of the PCI Local Bus Specification,

Revision 2.3.

• Includes a 21555 “nontransparent” PCI-to-PCI Bridge that provides bridging between two

processor domains.

• Includes a host PCI interface that plugs into any 5V PCI option card slot.

• Provides three local bus 5V PCI bus option card slots. Slot 1 (see Figure 1 on page 6) may be

used as a local processor or system slot.

• Includes support, products, and documentation.

21555 PCI-to-PCI Bridge Evaluation Board User’s Guide 5

Page 6

Introduction

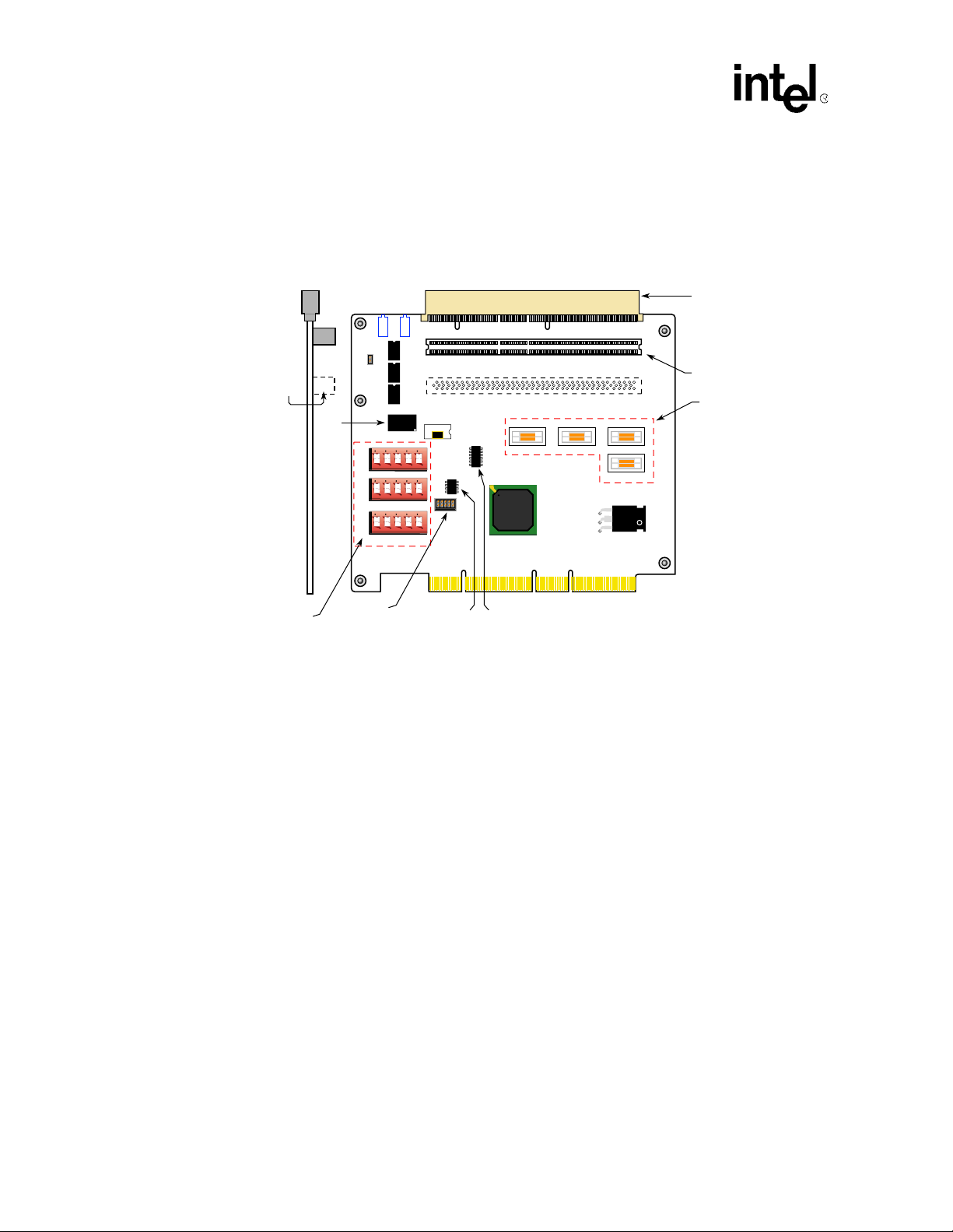

1.3 Major Components

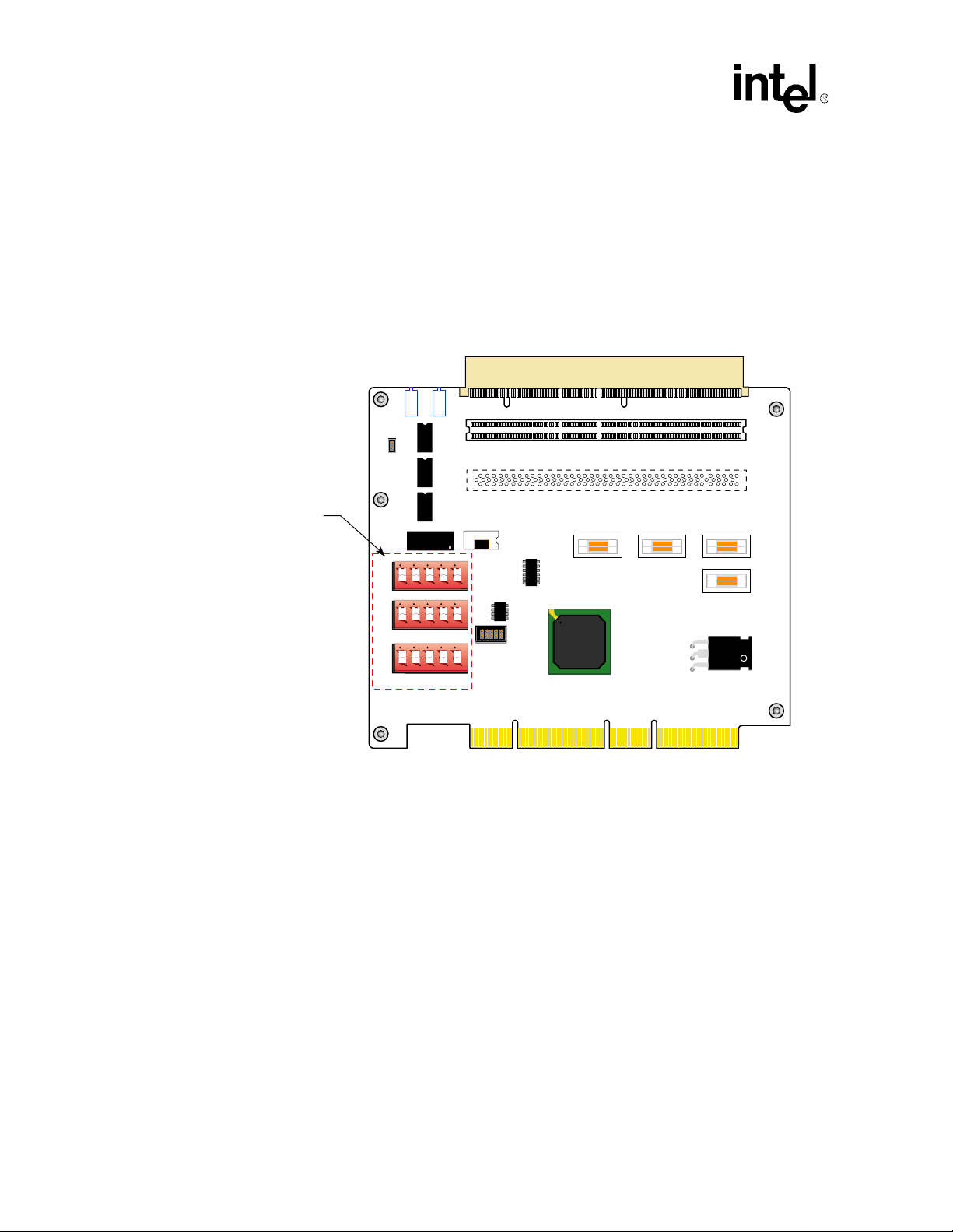

Figure 1 on page6 shows the major components on the DE1B55503.

Figure 1. Major Components

2

1

OPTIONAL

SLOT

Parallel

ROM

Initialization

Switches

1.3.1 Connectors

J8

J21

J20

J9

JTAG

Connector

L2

L1+

E9

E8

E7

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

SLOT 2

SLOT 1

Y1

E4

OPTIONAL SLOT

J4 J6 J2

E3

E2

21555

Clock Buffer

E5

J1

Serial

ROM

J7

J101

J102

J5

E1

PCI option and slot

PCI option and PICMG

slot

Mictor Connectors for

logic analyzers and

oscilloscopes

A8408-01

• J1 is the 10-pin JTAG connector. See Table A-5 on page 26.

• J7 and J101 (slot 2 and slot 1) are local (secondary bus) PCI option slots.

— J101 (slot 1) can be used for a local processor with the insertion of a PCI Indu strial

Computer Manufacturers Group

(PICMG) Single Board Computer. It is the PCI portion

of the PCI-ISA card edge connector. See Section 1.7 and Section 1.9.

• J102 (secondary bus) is the optional and connector-less slot. The optional slot is for a third

64-bit PCI connector. The through-holes are p rov id ed fo r ins talla ti on o f a local bus conn ect or.

The default build for this board is for two option cards on the local bus. 66MHz operation is

limited to two (2) loads on the PCI bus. All connectors are 64-bit.

• The J2 and J4 Mictor* (scope pod) connectors provide test points for the all the 64-bit S_AD

signals.

• The J5 and J6 Mictor connectors are for other PCI control signals, such as C/BE, REQ, and

GNT. J6 provides test points for parallel ROM data and address lines.

6 21555 PCI-to-PCI Bridge Ev aluation Board User’s Guide

Page 7

Note: See Table A-2 on page 24 for Mictor pinouts.

1.3.2 Switches and Jumper

The DE1B55503 uses a combination of DIP switch, stake-pin and zero ohm resistor jumpers to

control the various configuration options. See Section 1.4, Section 1.5, and Section 1.6 for

information.

• J8 is a single stake pin jumper. See Section 1.5 for information.

• J9, J20, and J21 are five-sw itch switch pack s. The du al-pole switch es are labeled S W1 through

SW5. They control the options at power up such as the d irection of the REQ# and GNT# lines,

the on-board parallel ROM functions, and the enabling of the asynchronous clock options for

the local bus. See Section 1.4 for informat ion.

• Figure 3 on page 10 identifies the location of each configuration jumper.

1.3.3 Devices

• E1 is the voltage regulator that produces the 3.3 and 5 V clamping signal. See Section 1.6.2.

• E2 is the 21555 PCI-to-PCI Bridge.

Introduction

• E3 is the clock buffer.

• E4 is the serial ROM (SROM).

• Y1 is a 33.333 MHz crystal oscillator that can be used for an independent local clock signal.

• E5 is the Parallel ROM. This device is nonvolatile EEPROM. See Section 2.3.2,

“Programming the Flash ROM” on page 18.

• E7, E8, and E9 are address latches.

• E6 (not shown) is the empty socket for attaching a ROM emulator.

• L1 is a LED that indicates the status of the LOO bit (LED On or Off bit) which is switched

through software. This LED can light if jumper J8 is installed.

• L2 is a LED that indicates DE1B55503 5Vdc power status.

21555 PCI-to-PCI Bridge Evaluation Board User’s Guide 7

Page 8

Introduction

1.4 Switch Settings

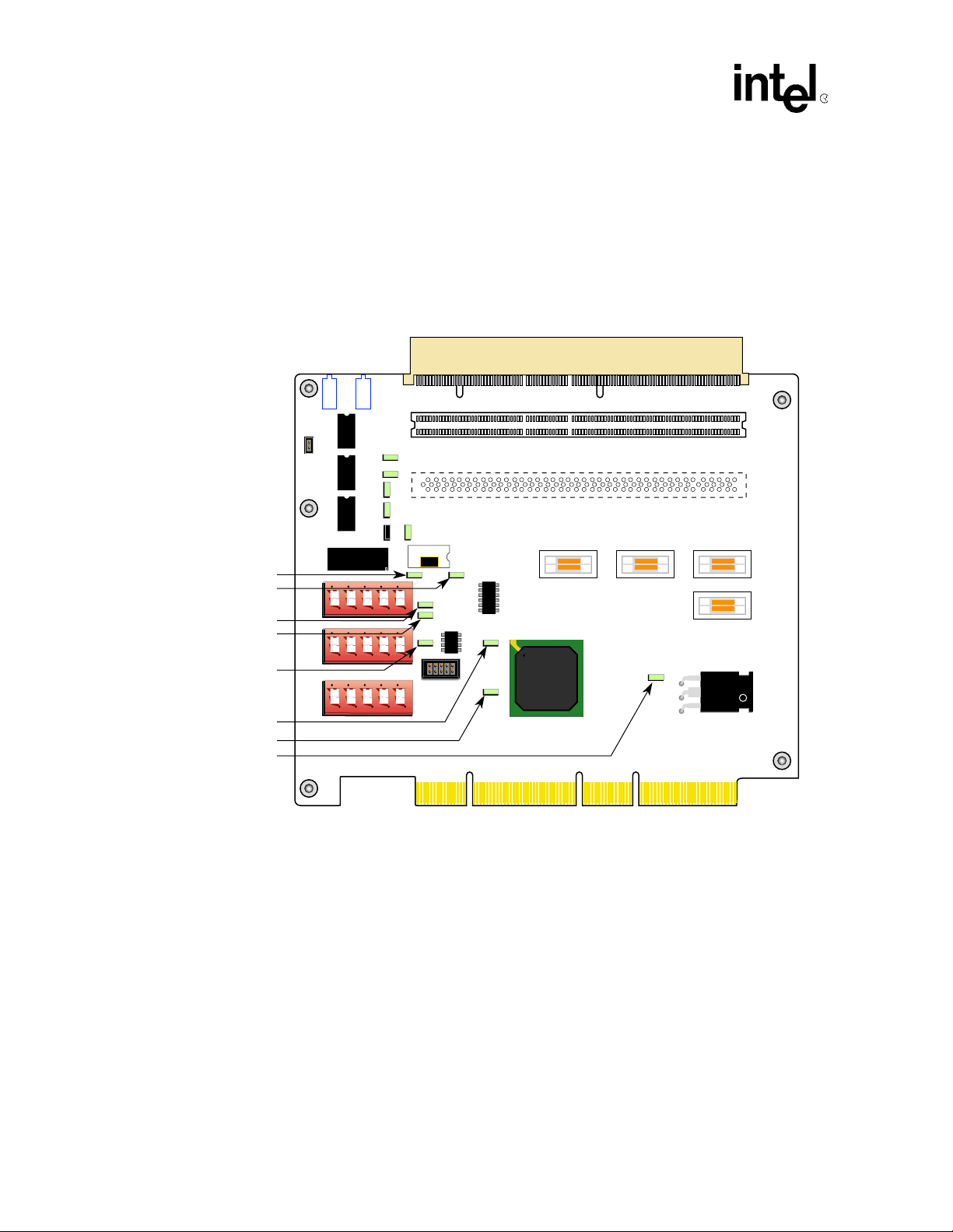

Figure 2 shows the th ree initialization switch packs, and Table 1 on page 9 gives a high-level

description of each switch. The switches are read at DE1B55503 power up. Further details on the

operation of these swi tches can b e found i n Chapter 3, “Optional Configurations”. Th e switches are

in dual-in-line (DIP) packs designated J9, J20, and J21. Each switch pack contains SW1 through

SW5.

Figure 2. Switches

Initialization

Switches

J8

J21

J20

J9

L2

L1+

E9

E8

E7

E5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

SLOT 2

J7

J101

SLOT 1

J102

OPTIONAL SLOT

Y1

E3

E2

E4

J1

J4 J6 J2

J5

21555

E1

A8409-01

8 21555 PCI-to-PCI Bridge Ev aluation Board User’s Guide

Page 9

T a ble 1. DIP Switch Operation

Introduction

Switch

Pack

Switch The Switch Controls Reference Information

SW1, 2, 3 PICMG configurations. (See Chapter 3). Table 10 on page 21

J9

SW4 PR_AD1 strapping option.

SW5 PR_CS to either Flash or optional ROM socket. Table 8 on page 19

SW1 PR_AD2 for SROM operation.

J20

SW2 PR-AD3 for lockout bit control.

SW3 PR_AD4 for synch ronous or async h ronous clock ing.

SW4 PR_AD5 for S_CLKO operation.

SW5 PR_AD6 for Central function selection. Table 12 on page 22

SW#

J21

(1,2,3,4,5)

The REQ/GNT lines for Arbiter control.

1.5 Stake-Pin Jumper

Table 2 shows the configuration and the function of the single stake-pin jumper. J8 enables the

DE1B55503 hot-swap functionality, controls operation of LED L1, and connects the l_stat signal

to a pullup resistor.

Table 2. Stake-Pin Jumper

a

21555 Non Transparent

PCI-to-PCI Bridge User’s

Manual

Table 7 on page 18

Table 14 on page 22

Table 12 on page 22

Table 13 on page 22

Jumper Function

• When removed, the hot-swap functionality is enabled, and L1 will light.

J8

a. No jumper is installed by the Factory default.

• When installed, hot-swap functionality is disabled and the L1 LED is

extinguished.

21555 PCI-to-PCI Bridge Evaluation Board User’s Guide 9

Page 10

Introduction

1.6 Resistor Jumpers

Figure 3 shows the lo cation of the zero (0) ohm resistor configuration jumpers. They control the

clock configuration and the clamping voltage. To alter the factory configuration of the

DE1B55503, the jumpers must be soldered on or off the DE1B55503 board. See Appendix A,

“Signal and Default Information”.

Figure 3. Jumper Resistors

R93

R100

R73

R66

R68

R65

R97

R95

J8

E5

J21

J20

J9

L2

L1+

E9

R72

E8

R69

E7

R91 R115

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

R116

R92

SLOT 2

J7

J101

SLOT 1

J102

OPTIONAL SLOT

Y1

E3

E2

E4

J1

J4 J6 J2

J5

21555

E1

A8410-01

10 21555 PCI-to-PCI Bridge Evaluation Boar d User’s Guide

Page 11

1.6.1 Clock Configuration

Table 3 describes the resistor jumpers to install that connect p_clk and s_clk_o to the Mictor

connectors. To improve signal integrity and minimize noise, these signals are not wired to the

Mictor connectors. Resistor jumpers also control the selection of clock signals. See Figure 3 on

page 10 for the resistor jumper locations. See Table A-3 on page 24 for Mictor pinouts.

Table 3. Clock Configuration Jumpers

Clock Source Installed Removed

Introduction

Use the s_clk_o signal from the 21555 as the local

clock.

Use the s_clk_i that is the output of the clock buffer

as the local clock.

Use the system slot to drive the 21555 s_clk_i. R68 R73

Use an oscillator as the asynchronous local clock. R93 R65, R68

Use the system slot to provide the local clock. R92, R116, R69 R91, R115, R72

Use the clock buffer to provide the local clock. R91, R115, R72 R92, R116, R69

1.6.2 Clamping Voltage

Table 4 gives the clamping voltage resistor jumper configurations. These jumper resistors

designate the DE1B55503 as a 3.3V or a 5V PCI devi ce. A mix of 3.3 and 5 V cards is no t allowed.

The E1 regulator provides the 3.3V or 5 V clamping voltage for the local bus. The resistor jumpers

connect s_vio to either 3.3V or 5V. Figure 4 on page 12 shows the location of the resistor jumpers.

Table 4. Voltage Clamp

Function Installed Removed

s_vio is 3.3V R95 R97

s_vio is 5V R97 R95

a. Only one jumper resistor (R95 or R97) may be installed at

a time. Installing both or no jumper resistors is not allowed.

R65, R73 R68, R93

R73 R68

a

21555 PCI-to-PCI Bridge Evaluation Board User’s Guide 11

Page 12

Introduction

1.7 Secondary Slot Numbering and IDSEL Mapping

Figure 4 gives the bus slot numbering. Table 5 shows how a Product Nam e numbers the Local

slots in response to a Type 0 or Type 1 configuration cycle. The local bus lines s_ad<24> and

s_ad<31:28> are used as local Initilization Device Select (IDSEL) lines.

Figure 4. Local PCI Slot Numbering

PCI option and slot

Device 20/Zero (0)

PCI option and PICMG

slot - Device 13/13

Device 8/8

Device None/17

OPTIONAL

SLOT

2

L2

L1+

E9

J8

1

E8

E7

E5

1 2 3 4 5

J21

1 2 3 4 5

J20

1 2 3 4 5

J9

Y1

E4

J1

SLOT 2

SLOT 1

OPTIONAL SLOT

E3

E2

21555

J7

J101

J102

J4 J6 J2

J5

E1

The 21555 cannot respond to Type 1 but does respond to Type 0 configuration cycles. During a

Type 0 configuration from a Local processor in the PICMG slot, the numbers change so that J7 is

counted one way but reflected as zero the other way.

Table 5. Slot and IDSEL Mapping

Physical Connector

Numbering

J7 (Slot 2) S_AD31 20 zero (0)

J102 (Opt. Slot) S_AD24 8 8

J101 (Slot 1) S_AD29 13 13

E2

(21555)

A8411-01

Device Configuration Numbering

IDSEL Lines Type 1 Type 0

S_AD28 (no response) 17

12 21555 PCI-to-PCI Bridge Evaluation Boar d User’s Guide

Page 13

1.8 Interrupt Routing

Table 6 shows the ORing of interrupts. 12 interrupts are connected to each of three secondary bus

PCI slots but four (4) interrupts are driven to the card edge. The 12 incoming interrupts must be

combined. Interrupt ORing is in accordan ce with the PCI-to-PCI Bridge Ar chitectur e Specification

revision 1.1.

Table 6. Interrupt ORing

Introduction

Device Number

5

(Optional slot J101)

6

(PICMG slot J101)

7

(Top slot J7)

Interrupt Pin on

Device

INTA#

INTB#

INTC#

INTD#

INTA#

INTB#

INTC#

INTD#

INTA#

INTB#

INTC#

INTD#

Interrupt Pin on Board

Connector

INTB#

INTC#

INTD#

INTA#

INTA#

INTB#

INTC#

INTD#

INTD#

INTA#

INTB#

INTC#

21555 PCI-to-PCI Bridge Evaluation Board User’s Guide 13

Page 14

Introduction

1.9 Typical Configurations

Figure 5 shows the DE1B55503 with one local bus option card. The option card can be either

32-bit or 64-bit.

Figure 5. DE1B55503 with One Local Bus Option Card

L2

L1+

J8

ADD-IN CARD

J7

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

21555

A8412-01

14 21555 PCI-to-PCI Bridge Evaluation Boar d User’s Guide

Page 15

Figure 6 shows the DE1B55503 with two local bus option cards.

Figure 6. DE1B55503 with Two Local Bus Option Cards

L2

L1+

Introduction

ADD-IN CARD

J7

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

21555

A8413-01

21555 PCI-to-PCI Bridge Evaluation Board User’s Guide 15

Page 16

Page 17

Operations and Installation 2

This chapter provides DE1B555 03 specificati ons and informati on about the hardwa re and software

requirements for using the DE1B55503. It also describes how to install the DE1B55503.

2.1 Specifications

This sections describes some overall specifications for the DE1B55503 board:

Physical dimensions:

• Height: 15.2 cm (6.0 in)

• Width: 17.8 cm (7.0 in)

Power requirements:

• DC amps @ 5 V: 2 A (maximum)

• On Board 3.3V regulator for S_VIO and Vdd 5A (Maximum)

2.2 Hardware Requirements

To operate the DE1B55503, the following equipment is needed:

• A computer system equipped with PCI option slots.

• A PCI expansion slot on the motherboard that is equipped for the 5V PCI environment.

• PCI option cards used to create the local subsystem.

• An optional local processor to control the subsystem. Install the local processor in any of the

three PCI slots. The top PCI slot is configurable as a PICMG (PCI Industrial Computer

Manufacturers Group) CPU slot.

2.3 Software Requirements

The DE1B55503 is shipped with the Serial ROM (SROM) and parallel ROM programmed. The

factory program prints a 21555 banner to the screen during system boot.

The DE1B55503 kit provides DOS utilities that can be used to configure the program in the SROM

and parallel ROM. The diskettes included in the DE1B55503 kit contain:

• PVIEW.EXE to read all PCI configuration space registers.

• CDEBUG, a version of DOS DEBUG that reads memory locations directly.

• DOS4GW.EXE is a DOS32 extender. It must be in the same directory when running the

utilities.

• DBFLASH.EXE an executable utility for erasing and updating the flash ROM memory.

21555 PCI-to-PCI Bridge Evaluation Board User’s Guide 17

Page 18

Operations and Installation

• MSKROM.EXE an executable utility for programming the SROM.

• The software diskettes are standard 3.5 inch floppy disks. Follow the installation procedure

printed on the inside of the shipping package. Be certain that the target system meets the

minimum system requirements.

2.3.1 Programming the SROM

To program the SROM on the DE1B55503, use the MKSROM.EXE utility. Use a text editor to

create an ASCII data file.

MSKSROM file.dat

Where: MSKROM Executes the MSKROM utility.

file.dat Specifies the file to load into the SROM.

To program a blank SROM:

1. Set SW1 and S W2 to “down” during initialization of the system.

2. After the system initializes, toggle SW1 to “up”.

3. Use the MKSROM.EXE utility. For example:

mksrom.exe sromfile.dat

4. Set SW2 to “up” position and reboot system .

Table 7 shows the two SROM enable and lockout switches.

Table 7. Switch Operation for SROM programming

Switch

Pack

J20

Switch

SW1

SW2

Switch

Down

SROM

Output

disabled

No lockout

(debug)

Switch Up Description

SROM

Output

enabled

Lockout

(normal

operation)

The initialization is read from the SROM on

pr_ad<2>:sr_do

Controls the primary lockout bit Reset Value on pr_ad<3>

2.3.2 Programming the Flash ROM

Dbflash.exe is an MSDOS based program that allows the flash ROM attached to the 21555 to be

erased and updated with new images. When dbflash.exe is run on a system that has a 21555

installed on the PCI bus, the program will scan all the PCI buses looking for the 21555 component.

When found, the program will identify the 21555’s PCI location and start the update process that

was selected on the command line.

18 21555 PCI-to-PCI Bridge Evaluation Boar d User’s Guide

Page 19

2.3.2.1 Board Setup

Table 8 gives the DE1B55503 switch configuration for using the DBFLASH.EXE utility.

Table 8. Switch Operation for FLASH programming

Operations and Installation

Switch

Pack

J9 SW5 ROM Socket pr_cs

a. Default configuration.

Switch Switch Down Switch Up

2.3.2.2 Running DbFlash.exe

Make sure that both DBFLASH.EXE and DOS4GW .EXE ar e in the same directory or environment

path. The user must specify the flash block to update and the new image to use. The following will

flash image ‘NewRomImage.bin’ into block zero (0) of the 21554 expansion ROM. During the

next boot of the PC, the BIOS will find this image in the ROM.

Dbflash /b0 NewRomImage.bin

If the BIOS has a PCI compliant Expansion ROM header, the image is loaded and executed by the

system BIOS during POST. For more information, read the PCI Local Bus Specification Revision

2.3.

Dbflash /bx image.bin

Where: Dbflash Runs the dbflash utility from the current directory.

/bx

image.bin

Specifies the starting block to write the program into.

If x=e then all blocks will be erased.

This is the name of the file to load. The file must be in the current directory or

folder. If image is larger than 1 block, the program will continue into the next

block until the entire image is loaded.

a

Program and access

memory using

DBFLASH.EXE.

Description

Enables DBFLASH access to the ROM

Socket or to the flash memory. See

Figure 1 on page 6.

Note: Any other application software is the responsibility of the user.

2.4 Installation Procedure

Figure 2 on page 8 shows the location of components referred to in this section. Follow these steps

to install the DE1B55503:

1. Power down the host system that will contain the DE1B55503.

2. Place the motherboard and the associated support devices on a work bench to allow testing of

the DE1B55503.

3. Before applying power, verify that the DIP switches are set to the desired positions. (The DIP

switch positions are only read during system power up.)

4. Insert the card edge of the DE1B55503 into a PCI slot.

5. Load up the DE1B55503 with the PCI option cards to be tested. Either the 5V or universal

type PCI cards can be installed but card types cannot be mixed. There are two (2) pro vided slot

21555 PCI-to-PCI Bridge Evaluation Board User’s Guide 19

Page 20

Operations and Installation

connectors and one (1) connector-less slot. Section 1.9, “Typical Configurations” on page 14

shows examples of typical PCI configurations.

6. Apply power to the system.

7. Verify the auto-configuration of the 21555 and other options.

a. If the on-board ROM is preloaded the 21555 banner displays.

b. Verify that system BIOS or firmware detects and configures the 21555.

c. To verify the loading of the SROM, run the MKSROM utility without an SROM file as an

input. See Section 2.3.1, “Programming the SROM” on page 18.

8. PCI bus data, address, and control signals are monitored by connecting a logic analyzer to

Mictor connectors J2, J4, J5, and J6. See Appendix A, “Signal and Default Inform atio n”

2.5 Interrupt Routing

Table 9 shows the ORing of interrupts. A total of 12 interrupts are connected to each of three

secondary bus PCI slots but fou r i nterru pt s are driven to t he card ed ge. The 12 incoming interrupts

must be combined. Interrupt ORing is in accordance with the PCI-to-PCI Bridge Architecture

Specification V2.x.

In accordance with the PCI Bridge Architecture Specification, the interrupts of the devices on the

secondary slots are wire ORed and routed to PCI fingers of the DE1B55503.

Table 9. Interrupt ORing

Device Number

5

(Optional Slot J101)

6

(PICMG slot J101)

7

(Top slot J7)

Interrupt Pin on

Device

INTA#

INTB#

INTC#

INTD#

INTA#

INTB#

INTC#

INTD#

INTA#

INTB#

INTC#

INTD#

Interrupt Pin on Board

Connector

INTB#

INTC#

INTD#

INTA#

INTA#

INTB#

INTC#

INTD#

INTD#

INTA#

INTB#

INTC#

20 21555 PCI-to-PCI Bridge Evaluation Boar d User’s Guide

Page 21

Optional Configurations 3

3.1 PICMG Configuration

This section describes how to configure the DE1B55503 to have a Single Board Computer (SBC)

with a PCI interface as defined in the PICMG PCI-ISA Interface Specification. See Section 1.3.1,

“Connectors” on page 6.

The DE1B55503 can have an intelligent subsystem installed that supports the local bus. The

intelligent subsystem is architecture independent. The 21555 can interface to any intelligent

subsystem that has a PCI interface. Connector J101 can accept an intelligent controller and operate

in the PICMG mode. See Figure 2 on page 8.

Table 10 gives the switch configuration to enable PICMG mode operation.

T able 10. J9 PICMG Switches

Switch

Pack

J9

a. J9 positions SW1, SW2, and SW3 must be down for normal PCI operation. The switches define where the RESET,

Switch Switch Down

SW1 PICMG slot DB66 Secondary reset originates

SW2

SW3 PICMG PCI (S_PME#)

ID-SEL, and PME originate.

PICMG

(becomes GNT2)

a

Switch Up Description

PCI

(S_AD24 becomes DSEL)

S_AD24 (IDSEL) originates

Table 11 identifies the zero ohm resistors to remove or install for the s yst em sl ot to act as the clock

source. See Figure 3 on page 10. To operate an SBC controller on the local bus, the clock s mus t be

routed accordingly.

Table 11. Clock Routing Zero Ohm Resistors

Function Installed Removed

System slot drives s_clk_i on the 21555 R68 R73, R65

System slot provides local clock R92, R116, R69 R91, R115, R72

3.2 Central Function and Arbiter Control

T able 12 on page 22 shows the configuration of the DE1B55503 for internal or external arbitratio n.

Arbiter control can be programmed on the evaluation board by switching SW1 J21.

• In one configuration, the internal arbitration logic of the 21555 is the central function.

21555 PCI-to-PCI Bridge Evaluation Board User’s Guide 21

Page 22

Optional Configurations

• In the other configuration, the central function is controlled by the intelligent subsys tem

through the J1 connector.

T a ble 12. External Arbiter Switch Option

Switch

Pack

J20 SW5

J21 SW1

Switch Switch Down Switch Up Description

Enable the 21555

as central arbiter

Disable the 21555

as central arbiter

System slot (J102) as

Central Function

System slot (J102) as

external arbiter.

Central Function Mode(pr_ad<6>)

Disable 21555 arbiter.

Table 13 shows how the req# and gnt # lines must be configured for PICMG operation.

Table 13. J21 Switch Operations for Central Function and Arbiter Control

Switch

Pack

J21

Switch

SW2 req#0 PICMG GNT becomes slot grant req=req

SW3 gnt#0 PICMG REQ becomes slot grant gnt=gnt

SW4 req#1 REQ1 from PICMG slot REQ1 from drawbridge

SW5 gnt#1 GNT1 from PICMG slot GNT1 from drawbridge

Request/

Grant

Switch Do wn

System slot (J102) as arbiter

3.3 Asynchronous Clocking

Table 14 shows how to configure the J20 switches for synchronous or asynchronous operations of

the local bus. If the PICMG slot is the source of the clocks, the resistor strapping options must be

followed as described in Section 3.1. In addition, J20 SW3 must be set for asynchronous clocking

and s_clk_o needs to be disabled from the 21555.

Switch Up

21555 as arbiter

Table 14. Switch Operations for Synchronous or Asynchronous Clock Control

Switch

Pack

J20

22 21555 PCI-to-PCI Bridge Evaluation Boar d User’s Guide

Switch Switch Down Switch Up Description

SW3

SW4 Disable 21555 (s_clk_o) Enable 21555 (s_clk_o)

Synchronous host and

local clock domains

Asynchronous host and

local clock domains

Selects synchronous or

asynchronous operation.

(pr_ad<4>)

s_clk_o

(pr_ad<5>)

Page 23

Signal and Default Information A

A.1 J2 J4, J5, and J6 Connector Pinouts

Table A-1 gives the Mictor connectors pin assignment and DE1B55503 schematic signal names.

See Figure 1 on p age 6 for the location of this connector.

Table A-1. J2 Connector Secondary AD Signals

Schematic

Signal Name

+5V 1 2 SCL

GND 3 4 SDA

S_CLK0_2

CLK

S_AD63 7 8 S_AD47

S_AD62 9 10 S_AD46

S_AD61 11 12 S_AD45

S_AD60 13 14 S_AD44

S_AD59 15 16 S_AD43

S_AD58 17 18 S_AD42

S_AD57 19 20 S_AD41

S_AD56 21 22 S_AD40

S_AD55 23 24 S_AD39

S_AD54 25 26 S_AD38

S_AD53 27 28 S_AD37

S_AD52 29 30 S_AD36

S_AD51 31 32 S_AD35

S_AD50 33 34 S_AD34

S_AD49 35 36 S_AD33

S_AD48 37 38 S_AD32

Mictor

Pin Number

56

Mictor

Pin Number

Schematic

Signal Name

S_CLK0_3

CLKB

21555 PCI-to-PCI Bridge Evaluation Board User’s Guide 23

Page 24

Signal and Default Information

Table A-2 gives the Mictor connectors pin assignment and DE1B55503 schematic signal names.

T able A-2. J4 Pin Assignments

Schematic

Signal Name

+5V 1 2 SCL

GND 3 4 SDA

S_CLK0_2

CLK

S_AD31 7 8 S_AD15

S_AD30 9 10 S_AD14

S_AD29 11 12 S_AD13

S_AD28 13 14 S_AD12

S_AD27 15 16 S_AD11

S_AD26 17 18 S_AD10

S_AD25 19 20 S_AD9

S_AD24 21 22 S_AD8

S_AD23 23 24 S_AD7

S_AD22 25 26 S_AD6

S_AD21 27 28 S_AD5

S_AD20 29 30 S_AD4

S_AD19 31 32 S_AD3

S_AD18 33 34 S_AD2

S_AD17 35 36 S_AD1

S_AD16 37 38 S_AD0

Mictor

Pin Number

56

Mictor

Pin Number

Schematic

Signal Name

S_CLK0_3

CLKB

Table A-3 gives the Mictor connectors pin assignment and DE1B55503 schematic signal names.

T able A-3. J5 CBE, REQ, and GNT

Schematic

Signal Name

+5V 1 2 SCL

GND 3 4 SDA

S_CLK0_2

CLK

S_CBE7

S_CBE6 910S_GNT8

S_CBE5 11 12 S_GNT7

S_CBE4 13 14 S_GNT6

S_CBE3 15 16 S_GNT5

S_CBE2 17 18 S_GNT4

S_CBE1 19 20 S_GNT3

S_CBE0 21 22 S_GNT2

24 21555 PCI-to-PCI Bridge Evaluation Boar d User’s Guide

Mictor

Pin Number

56

78S_REQ0

Mictor

Pin Number

Schematic

Signal Name

S_CLK0_3

CLKB

Page 25

Table A-3. J5 CBE, REQ, and GNT

Signal and Default Information

Schematic

Signal Name

S_REQ8 23 24 S_G NT1

S_REQ7 25 26 S_G NT0

S_REQ6 27 28 S_M 66ENA

S_REQ5

S_REQ4 31 32

S_REQ3

S_REQ2

S_REQ1

Mictor

Pin Number

29 30 S _PNE

33 34 S_CLKI

35 36 SCLK_O

37 38

Mictor

Pin Number

Schematic

Signal Name

Table A-4 gives the Mictor connectors pin assignment and DE1B55503 schematic signal names.

Table A-4. J6, Parallel ROM and Control

Schematic

Signal Name

+5V 1 2 SCL

GND 3 4 SDA

S_CLK0_2

CLK

PR_AD7 7 8 S_FRAME

PR_AD6 9 10 S_IRDY

PR_AD5 11 12 S_DEVSEL

PR_AD4 13 14 S_TRDY

PR_AD3 15 16 S_STOP

PR_AD2 17 18 S_PAR

PR_AD1 19 20 S_SERR

PR_AD0 21 22 S_PERR

DB_SAC5 23 24 S_REQ64

PR_CS 25 26 S_ACK64

PR_CLK 27 28 S_PAR54

PR_ALE 29 30

PR_RD

PR_WR 33 34 PICMG_RST

Mictor

Pin Number

56

31 32 S_RST

35 36 L_STAT

37 38 P_ENUM

Mictor

Pin Number

Schematic

Signal Name

S_CLK0_3

CLKB

21555 PCI-to-PCI Bridge Evaluation Board User’s Guide 25

Page 26

Signal and Default Information

A.2 JATAG Connector Pinout

Table A-5 gives the pin assignments between the DE1B55503 schematic and the ten-pin JTAG

connector. See Figure 1 on page 6 for the location of this connector.

T able A-5. J1 JATAG Connector

Schematic

Number

TRST

TDI 3 4 GND

TD0 5 6 GND

TMS 7 8 GND

TCK 9 10 GND

Mictor

Pin Number

12GND

Mictor

Pin Number

Schematic

Number

A.3 Factory Default Switch and Jumper Configuration

The DE1B55503 is configured at the factory for normal or typical operation.

• J8, the stake pin jumper, is not installed

• Table A-6 gives the factory configuration for the switch pack switches.

T able A-6. Switch Pack Factory Defaults

Switches on Are set at the Factory.

J9 all switches are in the up position.

J20

J21 all switches are in the up position.

SW1, SW2, and SW4 are n the up position

SW3 and SW5 are down.

a

a. The UP position leaves the switch lever pointing towards the

local option sockets.

• Table A-7 gives the configuration of the zero-ohm resistor jumpers.

Table A-7. Resistor Jumper Factory Defaults

Resistor

Jumper

R65 IN R92 OUT

R68 OUT R93 OUT

R69 OUT R95 OUT

R72 IN R97 IN

R73 IN R115 IN

R91 IN R116 OUT

26 21555 PCI-to-PCI Bridge Evaluation Boar d User’s Guide

In/Out

Resistor

Jumper

In/Out

Loading...

Loading...