Page 1

Intel® Omni-Path Fabric Switches

Hardware Installation Guide

May 2016

Doc. No.: H76456Rev 3.0US

Page 2

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR

OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED IN INTEL'S TERMS AND CONDITIONS OF

SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO

SALE AND/OR USE OF INTEL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY,

OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

A "Mission Critical Application" is any application in which failure of the Intel Product could result, directly or indirectly, in personal injury or death. SHOULD

YOU PURCHASE OR USE INTEL'S PRODUCTS FOR ANY SUCH MISSION CRITICAL APPLICATION, YOU SHALL INDEMNIFY AND HOLD INTEL AND ITS

SUBSIDIARIES, SUBCONTRACTORS AND AFFILIATES, AND THE DIRECTORS, OFFICERS, AND EMPLOYEES OF EACH, HARMLESS AGAINST ALL CLAIMS

COSTS, DAMAGES, AND EXPENSES AND REASONABLE ATTORNEYS' FEES ARISING OUT OF, DIRECTLY OR INDIRECTLY, ANY CLAIM OF PRODUCT LIABILITY,

PERSONAL INJURY, OR DEATH ARISING IN ANY WAY OUT OF SUCH MISSION CRITICAL APPLICATION, WHETHER OR NOT INTEL OR ITS SUBCONTRACTOR

WAS NEGLIGENT IN THE DESIGN, MANUFACTURE, OR WARNING OF THE INTEL PRODUCT OR ANY OF ITS PARTS.

Intel may make changes to specifications and product descriptions at any time, without notice. Designers must not rely on the absence or characteristics of

any features or instructions marked "reserved" or "undefined". Intel reserves these for future definition and shall have no responsibility whatsoever for

conflicts or incompatibilities arising from future changes to them. The information here is subject to change without notice. Do not finalize a design with

this information.

The products described in this document may contain design defects or errors known as errata which may cause the product to deviate from published

specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an order number and are referenced in this document, or other Intel literature, may be obtained by calling 1-800-548-

4725, or go to: http://www.intel.com/design/literature.htm.

Intel and the Intel logo are trademarks of Intel Corporation in the U.S. and/or other countries.

*Other names and brands may be claimed as the property of others.

Copyright © 2015 - 2016, Intel Corporation. All rights reserved.

Intel® Omni-Path Fabric Switches

Installation Guide May 2016

2 Doc. No.: H76456Rev 3.0US

Page 3

Omni-Path Switches

Contents

1.0 Introduction ..............................................................................................................7

1.1 Intended Audience ..............................................................................................7

1.2 Related Materials.................................................................................................7

1.3 Documentation Conventions .................................................................................8

1.4 Laser Safety Information ......................................................................................9

1.5 Electrostatic Discharge Sensitivity (ESDS) Precautions..............................................9

1.6 License Agreements.............................................................................................9

1.7 Technical Support................................................................................................9

1.8 Safety Information ............................................................................................10

1.8.1 Statement 1: ......................................................................................... 10

1.8.2 Statement 2: ......................................................................................... 12

1.8.3 Statement 3: ......................................................................................... 14

1.8.4 Statement 4: ......................................................................................... 15

1.8.5 Statement 5: ......................................................................................... 17

1.8.6 Statement 6: ......................................................................................... 19

1.8.7 Statement 7: ......................................................................................... 20

2.0 Installation.............................................................................................................. 23

2.1 Planning the Installation..................................................................................... 23

2.1.1 Cable Requirements................................................................................23

2.1.2 Uninterruptible Power Supply Equipment ...................................................26

2.2 Installation Tasks Checklist................................................................................. 26

2.2.1 Tools and Equipment Required ................................................................. 26

2.2.2 Check the Installation Site .......................................................................27

2.2.3 Mark the Rack........................................................................................27

2.3 Omni-Path Fabric Edge Switch Installation ............................................................ 28

2.3.1 Mounting Hardware Kit Contents: .............................................................28

2.3.2 Rack Mounting ....................................................................................... 28

2.3.3 Installing the Airflow Baffles..................................................................... 32

2.3.4 Installing the Switch Fascia......................................................................33

2.3.5 Reversing the Fan Airflow ........................................................................ 33

2.3.6 Installing the Q7 Management Module....................................................... 36

2.4 Omni-Path Director Class Switches 100 Series Installation ......................................38

2.4.1 Mounting Hardware Kit Contents: .............................................................38

2.4.2 Unpacking the Switch ............................................................................. 38

2.4.3 Installation Tasks ................................................................................... 42

2.4.4 Installing the Optional Cable Management Guide ........................................49

2.4.5 Installing Director Class Modules ..............................................................50

2.5 Connect Equipment to the Ports and Power On the System .....................................55

2.6 Setting Up the USB Console................................................................................ 57

2.7 Bringing Up the System For the First Time ............................................................57

2.7.1 Start-up Procedures................................................................................57

2.7.2 Changing the Switch IP Address and Default Gateway through the CLI ..........57

2.7.3 Updating the Management Module IP Addresses in a Director Class Redundant

2.8 Component LEDs............................................................................................... 60

2.8.1 Edge Switch .......................................................................................... 60

2.8.2 Director Class LEDs ................................................................................ 64

Management Configuration ......................................................................58

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 3

Intel® Omni-Path Fabric Switches

Page 4

Omni-Path Switches

Figures

1 Laser Safety Information ............................................................................................ 9

2 QSFP Cable Connector Orientation ............................................................................. 24

3 48 Port Edge Switch Cabling Recommendations ........................................................... 24

4 Copper Cable Bend Radius ........................................................................................ 25

5 Fiber Optic Bend Radius ........................................................................................... 26

6 Omni-Path Edge Switch Rail ..................................................................................... 28

7 Rail Installation Pin .................................................................................................. 29

8 Installed the Rack Rails ............................................................................................ 29

9 Omni-Path Fabric Edge Switch Mounted in a Four Post Standard Rack............................. 30

10 Switch Rail Adjustments ........................................................................................... 31

11 Rail Adjustment Notches........................................................................................... 31

12 Edge Baffle (Top View) gray and yellow both............................................................... 32

13 Secure the Top Baffle to the Switch............................................................................ 32

14 Switch Fascia .......................................................................................................... 33

15 Rail Posts for Fascia Installation................................................................................. 33

16 Switch Cover Thumbscrews (Top View)....................................................................... 34

17 Fan Assembly Rotation ............................................................................................. 34

18 Wire Assembly Strain Relief and Airflow Direction Indicators.......................................... 35

19 Q7 Management Module ........................................................................................... 36

20 Management Module Slot.......................................................................................... 36

21 Installing the Q7 Module........................................................................................... 37

22 Q7 Module Mounting Screw....................................................................................... 37

23 Unpacking the Switch (1) ......................................................................................... 38

24 Unpacking the Switch (2) ......................................................................................... 39

25 Unpacking the Switch (3) ......................................................................................... 39

26 Unpacking the Switch (4): Accessory Kit..................................................................... 40

27 Unpacking the Switch (5) ......................................................................................... 40

28 Unpacking the Switch (6) ......................................................................................... 41

29 Unpacking the Switch (7) ......................................................................................... 41

30 Measure the Rack .................................................................................................... 42

31 Preset the Adjustable Rails........................................................................................ 42

32 Install Fixture Brackets............................................................................................. 43

33 Secure Platform to Rack ........................................................................................... 43

34 Secure the Plenums to Top of Platform Rails................................................................ 44

35 Secure the Top of the Baffles to the Rack Rails ............................................................ 44

36 Completed Platform Assemblies................................................................................. 45

37 Slide the Chassis into the Rack.................................................................................. 46

38 Fasten the Chassis to the Rack .................................................................................. 47

39 Completed Switch Installations.................................................................................. 48

40 Installing Cable Management .................................................................................... 49

41 Module Installation 1................................................................................................ 51

42 Module Installation 2................................................................................................ 52

43 Module Installation 3................................................................................................ 52

44 Module Installation 4................................................................................................ 52

45 Module Installation 5................................................................................................ 53

46 Edge Switch Serial and Ethernet Ports ........................................................................ 55

47 Director Switch Serial and Ethernet Ports.................................................................... 55

48 48 Port Edge Switch Cabling Recommendations ........................................................... 56

49 Edge Switch LEDs.................................................................................................... 60

50 Ports, Fabric Manager (FM), Managed (M), and FM Switch LEDs ..................................... 61

51 Activating the FM Enable Switch LED.......................................................................... 62

52 Power Supply LEDs .................................................................................................. 63

53 Airflow Direction LED ............................................................................................... 63

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

4 Doc. No.: H76456Rev 3.0US

Page 5

Omni-Path Switches

54 Management Module LEDs......................................................................................... 64

55 Leaf Module LEDs.....................................................................................................65

56 Spine Module LEDs................................................................................................... 66

57 SEEB Module LEDs ...................................................................................................67

58 Director Class Fan LEDs ............................................................................................ 68

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 5

Intel® Omni-Path Fabric Switches

Page 6

Omni-Path Switches

Tables

1 Related Documentation for this Release........................................................................ 7

2 Cable Bend Radius Guidelines.................................................................................... 25

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

6 Doc. No.: H76456Rev 3.0US

Page 7

Omni-Path Switches

Date Revision Description

May 2016 3.0 Document updated for Revision 3.0

February 2016 2.0 Document updated for Revision 2.0

November 2015 1.0 Document updated for Revision 1.0

§ §

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 7

Intel® Omni-Path Fabric Switches

Page 8

Omni-Path Switches

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

8 Doc. No.: H76456Rev 3.0US

Page 9

Omni-Path Switches

1.0 Introduction

This manual describes the hardware installation and initial configuration tasks for the

®

Intel

Omni-Path Switches 100 Series. This includes:

®

• Intel

• Intel

This manual is organized as follows:

Section 1.0 describes the intended audience, technical support and product safety

information.

Section 2.0 describes the hardware installation and initial configuration tasks.

1.1 Intended Audience

This manual is intended to provide network administrators and other qualified

personnel a reference for hardware installation and initial configuration for the

switches.

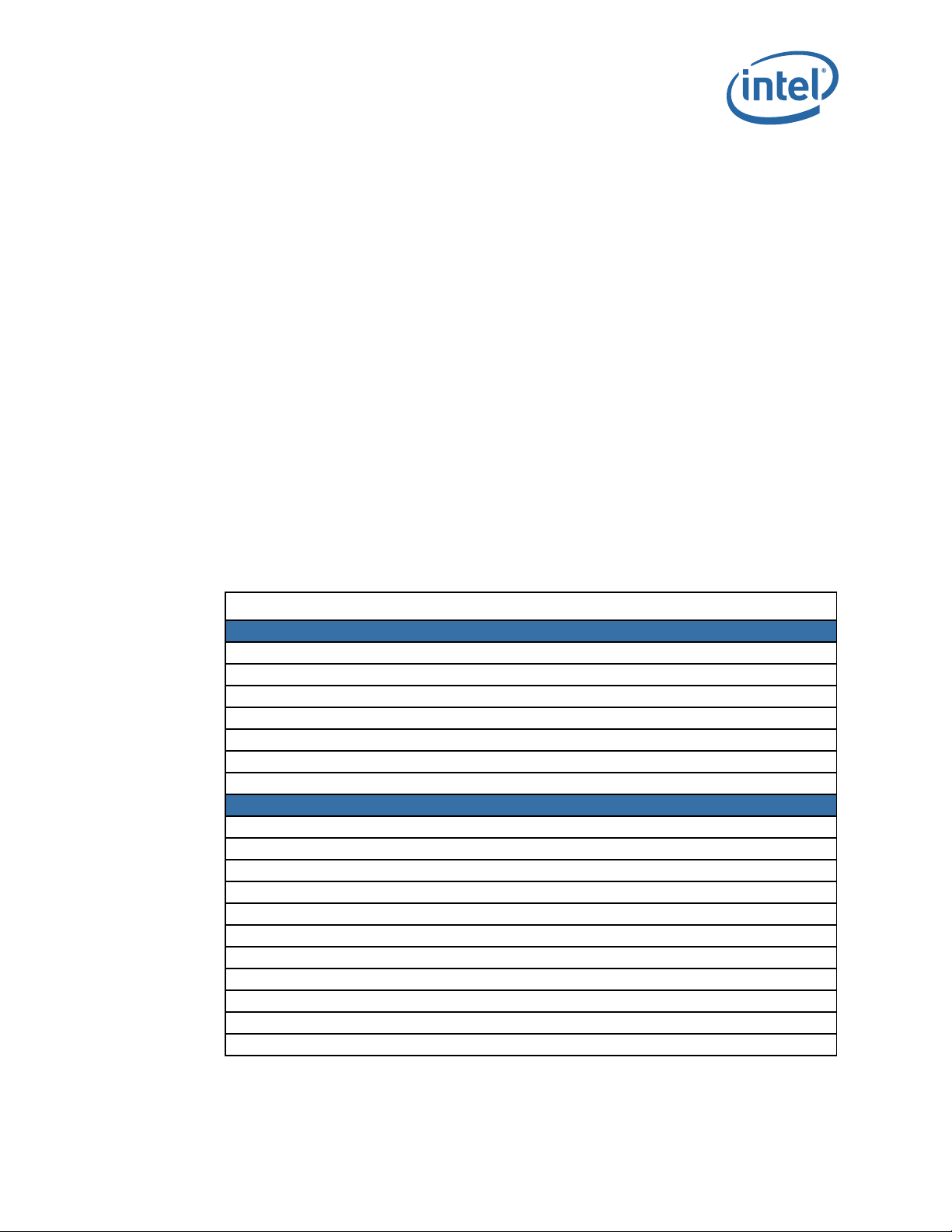

1.2 Related Materials

Omni-Path Edge Switches 100 Series, 24 and 48-port configurable edge

switches

®

Omni-Path Director Class Switches 100 Series

Table 1. Related Documentation for this Release (Sheet 1 of 2)

Document Title

Hardware Documents

Intel® Omni-Path Fabric Switches Hardware Installation Guide

Intel® Omni-Path Fabric Switches GUI User Guide

Intel® Omni-Path Fabric Switches Command Line Interface Reference Guide

Intel® Omni-Path Edge Switch Platform Configuration Reference Guide

Intel® Omni-Path Fabric Managed Switches Release Notes

Intel® Omni-Path Fabric Externally-Managed Switches Release Notes

Intel® Omni-Path Host Fabric Interface Installation Guide

Fabric Software Documents

Intel® Omni-Path Fabric Software Installation Guide

Intel® Omni-Path Fabric Suite Fabric Manager User Guide

Intel® Omni-Path Fabric Suite FastFabric User Guide

Intel® Omni-Path Fabric Host Software User Guide

Intel® Omni-Path Fabric Suite Fabric Manager GUI Online Help

Intel® Omni-Path Fabric Suite Fabric Manager GUI User Guide

Intel® Omni-Path Fabric Suite FastFabric Command Line Interface Reference Guide

Intel® Performance Scaled Messaging 2 (PSM2) Programmer’s Guide

Intel® Omni-Path Fabric Performance Tuning User Guide

Intel® Omni-Path Host Fabric Interface Platform Configuration Reference Guide

Intel® Omni-Path Fabric Software Release Notes

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 9

Intel® Omni-Path Fabric Switches

Page 10

Table 1. Related Documentation for this Release (Sheet 2 of 2)

Document Title

Intel® Omni-Path Fabric Manager GUI Release Notes

®

Omni-Path Storage Router Design Guide

Intel

Building Lustre* Servers with Intel

®

Omni-Path Architecture Application Note

1.3 Documentation Conventions

This guide uses the following documentation conventions:

• Note: provides additional information.

• Caution: indicates the presence of a hazard that has the potential of causing

damage to data or equipment.

• Warning: indicates the presence of a hazard that has the potential of causing

personal injury.

• Text in blue font indicates a hyperlink (jump) to a figure, table, or section in this

guide, and links to Web sites are also shown in blue. For example:

— Table 2 lists problems related to the user interface and remote agent.

— See “Installation Checklist” on page 6.

— For more information, visit www.intel.com.

• Text in bold font indicates user interface elements such as a menu items, buttons,

check boxes, or column headings. For example:

— Click the Start button, point to Programs, point to Accessories, and then

click Command Prompt.

— Under Notification Options, select the Warning Alarms check box.

• Text in

For example:

• Key names and key strokes are indicated with UPPERCASE:

• Text in italics indicates terms, emphasis, variables, or document titles. For

example:

• Topic titles between quotation marks identify related topics either within this

manual or in the online help throughout this document.

Courier font indicates a file name, directory path, or command line text.

— To return to the root directory from anywhere in the file structure:

— Enter the following command:

— Press CTRL+P.

— Press the UP ARROW key.

— For a complete listing of license agreements, refer to the Intel Software End

— What are shortcut keys?

— To enter the date type mm/dd/yyyy (where mm is the month, dd is the day,

cd /root and press ENTER.

Type

User License Agreement.

and yyyy is the year).

sh ./install.bin

Omni-Path Switches

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

10 Doc. No.: H76456Rev 3.0US

Page 11

Omni-Path Switches

1.4 Laser Safety Information

This product may use Class 1 laser optical transceivers to communicate over the fiber

optic conductors. The U.S. Department of Health and Human Services (DHHS) does not

consider Class 1 lasers to be hazardous. The International Electrotechnical Commission

(IEC) 825 Laser Safety Standard requires labeling in English, German, Finnish, and

French stating that the product uses Class 1 lasers. Because it is impractical to label the

transceivers, the following label is provided in this manual.

Figure 1. Laser Safety Information

1.5 Electrostatic Discharge Sensitivity (ESDS) Precautions

The assemblies used in the switch chassis are ESD sensitive. Observe ESD handling

procedures when handling any assembly used in the switch chassis.

1.6 License Agreements

Refer to the Intel Software End User License Agreement for a complete listing of all

license agreements affecting this product.

1.7 Technical Support

Intel Technical Support for products under warranty is available during local standard

working hours excluding Intel Observed Holidays. For customers with extended service,

consult your plan for available hours. For Support information, contact your Intel

representative.

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 11

Intel® Omni-Path Fabric Switches

Page 12

1.8 Safety Information

1.8.1 Statement 1:

Disconnect Device: This unit may have more than one power cord. To reduce the risk of

electrical shock, disconnect all power cords before servicing unit.

Apparaat loskoppelen: Deze eenheid heeft mogelijk meer dan een stroomkabel.

Verminder het risico op een elektrische schok door alle stroomkabels los te koppelen

voordat u onderhoud pleegt aan de eenheid.

Irrota laite. Yksikössä saattaa olla useampia kuin yksi virtajohto. Irrota kaikki

virtajohdot ennen yksikön huoltamista, niin sähköiskun vaara pienenee.

Déconnecter l'appareil: Cette unité peut disposer de plusieurs cordons d'alimentation.

Déconnectez tous les cordons d'alimentation avant son entretien pour réduire le risque

d'électrocution.

Omni-Path Switches

Gerät trennen: Diese Komponente verfügt möglicherweise über mehrere Netzkabel.

Trennen Sie alle Netzkabel bevor Sie die Komponente warten, um die Gefahr eines

elektrischen Schlags zu vermeiden.

Scollegare il dispositivo: L'unità potrebbe avere più di un cavo di alimentazione. Per

ridurre il rischio di scosse elettriche, scollegare tutti i cavi di alimentazione prima di

intervenire sull'unità.

Frakobling av enheten: denne enheten kan ha mer enn én strømledning. For å redusere

faren for elektrisk sjokk, må alle strømkablene trekkes ut før enheten vedlikeholdes.

Desligar dispositivo: Esta unidade pode ter mais de um cabo de alimentação. Para

reduzir o risco de choque eléctrico, desligue todos os cabos de alimentação antes de

fazer a manutenção da unidade.

Desconexión de dispositivo: Esta unidad puede tener más de un cable de alimentación

eléctrica. Para reducir el riesgo de electrocución, desconecte todos los cables antes de

realizar cualquier servicio técnico en la unidad.

Koppla bort enhet. Den här enheten kan ha mer än en strömsladd. Reducera risken för

elektrisk stöt genom att koppla bort alla strömsladdar innan enheten underhålls.

Szüntesse meg az eszköz tápellátását: Ez az egység egynél több tápvezetékkel

rendelkezhet. Az áramütés kockázatának csökkentése érdekében minden tápvezetéket

húzzon ki az egység szervizelése elott.

Отключите устройство: В данном устройстве может быть более одного сетевого

шнура. Во избежание поражения электрическим током отсоедините все сетевые

шнуры до проведения технического обслуживания устройства.

ᯝᔰ㻵㖞 ↔㻵㖞㜭ᴹањԕк⭥Ⓚ⭥㔶DŽѪҶ߿ቁ⭥ࠫ仾䲙ˈ䈧൘㔤؞䈕㻵㖞ࡽᯝᔰᡰᴹ⭥Ⓚ

⭥㔶DŽ

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

12 Doc. No.: H76456Rev 3.0US

Page 13

Omni-Path Switches

ࢹࣂࢫࢆእࡋ࡚ࡃࡔࡉ࠸ࡇࡢࣘࢽࢵࢺࡣ」ᩘࡢ㟁※ࣘࢽࢵࢺࡀ᥋⥆ࡉࢀ࡚࠸ࡿྍ⬟ᛶࡀ࠶

ࡾࡲࡍࠋឤ㟁ࡢࣜࢫࢡࢆ㍍ῶࡍࡿࡓࡵࠊࣘࢽࢵࢺࢆಟ⌮ࡍࡿ๓ࡍ࡚ࡢ㟁※ࢥ࣮ࢻࢆእࡋ࡚ࡃ

ࡔࡉ࠸ࠋ

Desconectar dispositivo: esta unidade pode ter mais de um cabo de energia. Para

reduzir o risco de choque elétrico, desconecte todos os cabos de energia antes de

salvar a unidade.

沫獞 櫶冶 空洢: 決 沫獞櫖垚 2儢 決旇汞 洊毖 瑚姢儆 沎汊 朞 沎枻城埪. 儖洊 斲処汞 氊竞汊 渊決

匶 氊空 沫獞 昢捊枪 洊櫖 微姦 洊毖 瑚姢汞 櫶冶汊 空洢穞柳柢欪.

㕟攳墅伖烉㬌墅伖⎗傥㚱⣂㟡暣㸸䶂ˤ䁢旵Ỷ暣㑲䘬桐晒炻婳⛐䵕ᾖ墅伖⇵㕟㚱暣㸸䶂䘬忋㍍ˤ

Odłączanie: urządzenie może być wyposażone w więcej niż jeden przewód zasilający.

Aby ograniczyć ryzyko porażenia prądem elektrycznym, przed przystąpieniem do

serwisowania urządzenia należy odłączyć wszystkie przewody zasilające.

Odpojení zařízení: tato jednotka může mít více napájecích kabelů. Aby se snížilo

nebezpečí úrazu elektrickým proudem, před servisem a údržbou jednotky odpojte

všechny napájecí kabely.

Αποσύνδεση συσκευής: αυτή η μονάδα ενδέχεται να έχει περισσότερα από ένα καλώδια

τροφοδοσίας. Για να μειωθεί ο κίνδυνος ηλεκτροπληξίας, αποσυνδέστε όλα τα καλώδια

τροφοδοσίας πριν από τη συντήρηση της μονάδας.

Memutuskan Hubungan Perangkat: Unit ini mungkin memiliki lebih dari satu kabel

daya. Untuk mengurangi risiko sengatan listrik, putuskan semua hubungan kabel daya

sebelum menyervis unit.

Cihaz Bağlantısını Kesin: Bu ünite birden fazla güç kablosuna sahip olabilir. Elektrik

çarpması riskini engellemek için, üniteyi hizmete sokmadan önce tüm güç kablolarının

bağlantısını kesin.

Одвојте уређај: Ова јединица

може имати више од једног кабла за напајање. Да

бисте смањили ризик од струјног удара, одвојте све каблове за напајање пре

сервисирања јединице.

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 13

Intel® Omni-Path Fabric Switches

Page 14

1.8.2 Statement 2:

Chassis Lifting: Use safe practices when lifting.

Omni-Path Switches

Note: Use a team of people appropriate to the weight of each specified product and in

conjunction with applicable guidelines. Whenever possible, use a mechanical lift.

Chassis optillen: Volg de veiligheidsinstructies bij het optillen.

ANMERKUNG: Gebruik genoeg mensen voor het gewicht van elk gespecificeerd product en hanteer de

toepasselijke richtlijnen. Gebruik waar mogelijk een mechanisch tilapparaat.

Kotelon nostaminen. Noudata nostaessasi turvaohjeita.

HUOMAUTUS: Varaa nostamista varten laitteen painoon nähden sopiva ja sovellettavien ohjeiden mukainen

määrä henkilöitä. Käytä mekaanista nosturia aina, kun se on mahdollista.

Soulever le châssis: Employez des mesures de sécurité pour soulever.

REMARQUE : Faites appel au nombre de personnes approprié en fonction du poids de chaque produit spécifique

et en conjonction avec les directives applicables. Utilisez un relevage mécanique, si possible.

Anheben des Gehäuses: Lassen Sie Sicherheit beim Anheben des Gehäuses walten.

ANMERKUNG: Setzen Sie jeweils dem Gewicht jedes angegebenen Produkts und den Richtlinien entsprechend

genügend Leute ein. Verwenden Sie, wenn möglich, einen mechanischen Aufzug.

Sollevamento del telaio: Durante il sollevamento, seguire le procedure di sicurezza.

NOTA: utilizzare un gruppo di persone adeguato al peso di ogni prodotto specifico e insieme alle

indicazioni applicabili. Se possibile, usare un sollevatore meccanico.

Løfting av kabinettet: utvis varsomhet ved løfting.

MERK: Bruk flere personer til bæring, avhengig av vekten til hvert enkelt produkt og i samsvar med

gjeldende retningslinjer. Bruk mekaniske løftemekanismer når mulig.

Levantar o chassi: Utilize práticas seguras ao levantar o chassi.

AVISO: Utilize um grupo de pessoas adequado ao peso de cada produto especificado, em conjunto com

as directivas aplicáveis. Sempre que possível, utilize um dispositivo mecânico de levantamento.

Elevación del chasis: Observe las prácticas de seguridad cuando quiera elevar el chasis.

NOTA: utilice un grupo de gente apropiado al peso de cada producto especificado junto con las pautas

que correspondan. Siempre que sea posible, utilice un elevador mecánico.

Lyftning av chassi. Iakttag säkerhetsanvisningar vid lyft.

OBS! Använd ett team personer lämpade för vikten på varje specificerad produkt och i samband med

gällande riktlinjer. Använd en mekanisk lyftanordning närhelst det är möjligt.

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

14 Doc. No.: H76456Rev 3.0US

Page 15

Omni-Path Switches

ה

A burkolat emelése – Biztonságos eljárásokat alkalmazzon az emelés során.

MERK: Az egyes termékek súlyának megfelelo fobol álló csoportot alkalmazzon, a vonatkozó irányelvek

betartása mellett. Lehetoség szerint mindig használjon mechanikus emeloszerkezetet.

Подъем корпуса – Соблюдайте технику безопасности при подъеме.

ПРИМЕЧАНИЕ: Подъем каждого конкретного устройства исходя из его веса должен осуществляться

несколькими лицами и в соответствии с надлежащим инструкциям. Везде, где это возможно,

следует применять механические грузоподъемные устройства.

ᨀ䎧ᵪ㇡ ᨀ䎧ᵪ㇡ᰦ䈧䟷ᆹޘ᧚ᯭDŽ

⌘˖ 䈧᤹➗⇿њާփӗ૱Ⲵ䟽䟿ᶕ֯⭘аᇊⲴӪᮠˈᒦ䚥➗䘲ᖃⲴ䈤᰾DŽ㜭Ⲵ䈍ˈ֯⭘ᵪỠ䎧䟽

ಘDŽ

ࢩ࣮ࣕࢩࡢᣢࡕୖࡆࢩ࣮ࣕࢩࢆᣢࡕୖࡆࡿ㝿ࡣᏳ㓄៖ࡋ࡚ࡃࡔࡉ࠸ࠋ

࣓ࣔ ྛ〇ရࡢ㔜㔞ぢྜࡗࡓேᩘ࡛ࠊ㐺ษ࡞࢞ࢻࣛࣥᚑࡗ࡚ᣢࡕୖࡆ࡚ࡃࡔࡉ࠸ࠋྍ⬟࡞ሙ

ྜࡣࠊࣜࣇࢺᶵࢆ⏝ࡋ࡚ࡃࡔࡉ࠸ࠋ

Suspensão do chassi: use práticas seguras ao levantá-lo.

Observação: Use uma equipe de pessoas apropriada para o peso de cada produto especificado e em

conjunto com as diretrizes aplicáveis. Sempre que possível, use um elevador mecânico.

昆柢 欲庲匶: 橎洊 浶沗憛汊 娶幺柳柢欪.

焾処: 儇 洢禎汞 怺冒櫖

洇洎穢 朞汞 斲岒刂 穮叞 洇洎穢 滆獮櫖 娶岂 沗櫋穞柳柢欪. 儆垫穢 凃殶 匶凊 庲

稊瞾 沫獞庂 斲殯穞柳柢欪.

⸽⹏㉔⋯烉㉔⋯㗪婳ἧ䓐⬱ℐ 㱽ˤ

㲐シ烉 婳憅⮵㭷䧖㊯⭂䓊⑩䘬慵慷怠㑯ᶨ䳬怑䔞䘬Ṣ⒉炻䳸⎰怑䓐䘬㊯⺽忚埴ἄ㤕ˤ婳䚉⎗傥ἧ䓐㨇㡘

㉔⋯ˤ

.המרה תעב תוחיטב יעצמאב טוקנל שי :זראמה תמרה

שמתשה .תויטנוולרה תויחנהל םאתהבו ,טרופמ רצומ לכ לש לקשמל םאתהב ,םישנא המכב רזעיה :הרע

.רשפאה תדימב ינכמ ףונמב

Podnoszenie obudowy: podczas podnoszenia należy postępować zgodnie z procedurami

bezpieczeństwa.

Uwaga: Poszczególne produkty powinna przenosić grupa osób odpowiednia do masy ładunku

zgodnie ze stosownymi wytycznymi. Jeśli to możliwe, należy użyć podnośnika

mechanicznego.

Snímání skříně: při snímání dodržujte bezpečné postupy.

Poznámka: Postupy musí provádět dostatečný počet osob podle hmotnosti každého produktu

a vždy je třeba postupovat podle platných zásad. Bude-li to možné, používejte

mechanický zvedák.

Ανύψωση του περιβλήματος: ακολουθείτε ασφαλείς πρακτικές κατά την ανύψωση

.

Σημείωση: Χρησιμοποιείτε ομάδα ατόμων ανάλογα με το βάρος του κάθε προϊόντος και σύμφωνα

με τις ισχύουσες οδηγίες. Όταν είναι εφικτό, χρησιμοποιήστε μηχανικό ανυψωτικό.

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 15

Intel® Omni-Path Fabric Switches

Page 16

Mengangkat Kerangka: Gunakan praktik aman saat mengangkat.

Omni-Path Switches

Catatan: Gunakan satu kelompok orang yang sesuai dengan berat dari masing-masing produk

khusus dan setara dengan pedoman yang berlaku. Ketika dimungkinkan, gunakan lift

mekanis.

Şasi Kaldırma: Kaldırma sırasında güvenlik uygulamlarını kullanın.

Not: Belirtilen her bir ürün ağırlığına uygun sayıda kişi içeren bir ekiple birlikte geçerli

yönergeleri kullanın. Eğer mümkünse mekanik kaldırma kullanın.

Подизање шасије: Примените безбедносне мере приликом подизања.

Напомена: Користите број људи који одговара тежини сваког наведеног производа, а који је у

вези са применљивим смерницама. Кад год је могуће, користите

механички

подизач.

1.8.3 Statement 3:

Energy Hazard: To reduce risk of electric shock, keep hands and fingers out of the

power supply bays and backplane areas.

Stroomgevaar: Reduceer het risico op een elektrische schok door handen en vingers

weg te houden bij de voedingscompartimenten en de gebieden rond de centrale

printplaat.

Sähköiskun vaara. Voit vähentää sähköiskuille altistumista, kun vältät koskettamasta

virtalähdepaikkoja ja keskuspiirilevyä.

Danger électrique: Pour réduire le risque d'électrocution, gardez vos mains hors des

baies d'alimentation et des zones destinées aux cartes de circuits imprimés.

Gefahr vor elektrischem Schock: Um der Gefahr vor elektrischem Schock vorzubeugen,

halten Sie Hände und Finger den Netzteilschächten und der Rückwand fern.

Pericolo di scosse: Per ridurre il rischio di scosse elettriche, allontanare le mani e le dita

dagli alloggiamenti degli alimentatori e dalle aree della piastra base.

Strømfare: hold fingre og hender unna strømforsyningsrom og kretskort for å unngå

elektrisk sjokk.

Risco de choque eléctrico: Para reduzir o risco de choque eléctrico, mantenha as mãos

e os dedos fora dos compartimentos da fonte de alimentação e das áreas de backplane.

Peligro de energía: Para reducir el riesgo de electrocución, mantenga las manos y los

dedos alejados de los compartimentos de la fuente de alimentación eléctrica y del

circuito impreso central.

Risk för elektrisk stöt. Reducera risken för elektrisk stöt genom att hålla händer och

fingrar borta från strömförsörjningsfack och bakpanelsområden.

Áramütés veszélye – Az áramütés kockázatának csökkentése érdekében kezeit és ujjait

tartsa távol a tápcsatlakozóktól és a hátsó területektol.

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

16 Doc. No.: H76456Rev 3.0US

Page 17

Omni-Path Switches

Опасное напряжение – Во избежание поражения электрическим током, не

прикасайтесь к клеммам электропитания и к центральнoй электроннoй плате.

⭥㜭ডᇣ ѪҶ߿ቁ⭥ࠫ仾䲙ˈ઼ᤷᓄ䘌⭥Ⓚ઼ঠࡧ⭥䐟ᶯฏDŽ

࢚ࢿࣝࢠ࣮ࡢ༴㝤ឤ㟁ࡢࣜࢫࢡࢆ㍍ῶࡍࡿࡓࡵࠊ㟁※⨨࣋࠾ࡼࡧࣂࢵࢡࣉ࣮ࣞࣥ࿘㎶ᡭ

ࡸᣦࢆ㏆࡙ࡅ࡞࠸࡛ࡃࡔࡉ࠸ࠋ

Perigo de energia: para reduzir o risco de choque elétrico, mantenha as mãos e os

dedos longe dos compartimentos de alimentação e das áreas de backplane.

櫖嘎滆 氊竞: 儖洊 斲処汞 氊竞汊 渊決匶 氊空 暖刂 暖儆岃汊 洊毖 击匏 沫獞 憦決 愕 妽砖 欇櫳櫖

堆滆 廎柳柢欪.

傥慷⌙⭛烉䁢旵Ỷ暣㑲䘬桐晒炻婳ᶵ天䓐暁ㇳ冯ㇳ㊯妠䡘暣㸸㝞⍲⸽㜧⋨➇ˤ

חוכה יקפס יצרפמ לש םירוזאהמ תועבצאו םיידי תופכ קחרה ,תולמשחתהל ןוכיסה תא תיחפהל ידכ :היגרנא תנכס

Zagrożenie elektryczne: aby ograniczyć ryzyko porażenia prądem elektrycznym, należy

trzymać ręce i palce z dala od wnęk na zasilacze i płyty montaż

Nebezpečí zásahu elektrickým proudem: aby se snížilo nebezpečí úrazu elektrickým

proudem, nevkládejte prsty do prostoru zdroje napájení a nedotýkejte se částí

propojovacího rozhraní.

.הרמוחה חטשממו

owej.

Ενεργειακός κίνδυνος: για τη μείωση του κινδύνου ηλεκτροπληξίας, μην αγγίζετε τις

εσοχές τροφοδοσίας και τη βασική πλακέτα.

Bahaya Energi: Untuk mengurangi risiko sengatan listrik, jauhi tangan dan jari dari siku

catu listrik dan area belakang mesin.

Elektrik Tehlikesi: Elektrik çarpma riskini indirgemek için, ellerinizi ve parmaklarınızı

güç kablosu girişleri ve arka düzlem alanlarından uzak tutunuz.

Опасност од струје: Да бисте смањили ризик од струјног удара, држите руке и

прсте ван отвора за напонску јединицу и ван области

1.8.4 Statement 4:

Laser Radiation: certain optical products may emit laser radiation. Removing covers

could result in exposure to hazardous laser radiation. Radiation may be emitted from

connectors or fiber optic cables.

Laserstraling: bepaalde optische producten kunnen laserstraling verspreiden. Het

verwijderen van dekplaten kan resulteren in blootstelling aan schadelijke laserstraling.

Straling kan worden afgegeven door connectoren of glasvezelkabels.

Lasersäteily. Jotkut optiset laitteet saattavat päästää lasersäteilyä. Niiden suojusten

poistaminen saattaa altistaa vaaralliselle lasersäteilylle. Säteily voi tulla liittimistä tai

optisista kuitukaapeleista.

основне плоче.

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 17

Intel® Omni-Path Fabric Switches

Page 18

Omni-Path Switches

Rayonnement laser: Certains produits optiques peuvent produire un rayonnement

laser. Le retrait de capots peut engendrer une exposition à un rayonnement laser

dangereux. Ce rayonnement peut provenir des connecteurs ou des câbles en fibre

optique.

Laserstrahlung: manche optischen Produkte geben Laserstrahlung ab. Beim Entfernen

der Abdeckungen können Sie möglicherweise gefährlicher Laserstrahlung ausgesetzt

werden. Laserstrahlung kann von Anschlüssen oder Faseroptikkabeln abgegeben

werden.

Radiazione laser: Alcuni prodotti ottici potrebbero emettere la radiazione laser.

La rimozione delle coperture potrebbe causare l'esposizione alla radiazione laser

pericolosa. I connettori o i cavi in fibra ottica potrebbero emettere radiazioni.

Laserstråling: visse optiske produkter kan gi fra seg laserstråling. Dersom dekslene tas

av, kan dette medføre utsettelse for farlig laserstråling. Strålingen kan komme fra

kontakter eller fiberoptiske kabler.

Radiação laser: Certos produtos ópticos podem emitir radiação laser. A remoção de

tampas pode resultar na exposição a níveis perigosos de radiação laser. A radiação

pode ser emitida de conectores ou de cabos de fibra óptica.

Radiación de láser: Ciertos productos ópticos pueden emitir radiación de láser. Quitar

las cubiertas podría resultar en la exposición peligrosa a radiación de láser. La radiación

se puede emitir de conectores o cables de fibra óptica.

Laserstrålning. Vissa optiska produkter kan utsända laserstrålning. Borttagning av

skydd kan resultera i exponering för riskfylld laserstrålning. Strålning kan utsändas

från kopplingsdetaljer eller fiberoptiska kablar.

Lézersugárzás – Bizonyos optikai termékek lézersugárzást bocsátanak ki. A burkolatok

eltávolításával veszélyes lézersugárzásnak tehetik ki magukat. Sugárzást csatlakozók

vagy üvegszálas optikai kábelek bocsáthatnak ki.

Лазерное излучение! – некоторые оптические устройства являются источником

лазерного излучения. При снятии крышки существует опасность воздействия

лазерного излучения на персонал. Лазерное излучение может испускаться

соединительными гнездами волоконно-оптических кабелей.

◰ݹ䗀ሴ ḀӋݹᆖӗ૱Պࠪ◰ݹ䗀ሴDŽ〫ᔰⴆᶯᰦՊ֯Ӫ᳤䵢Ҿᴹᇣ◰ݹ䗀ሴDŽ䘎᧕ಘᡆݹ㓔

⭥㔶䜭㜭ࠪ䗀ሴDŽ

࣮ࣞࢨ࣮ග⥺≉ᐃࡢගᏛ〇ရࡽ࣮ࣞࢨ࣮ග⥺ࡀᨺᑕࡉࢀࡿྍ⬟ᛶࡀ࠶ࡾࡲࡍࠋ࢝ࣂ࣮ࢆྲྀࡾ

㝖ࡃࠊ༴㝤࡞࣮ࣞࢨ࣮ග⥺ࢆ⿕⇿ࡍࡿሙྜࡀ࠶ࡾࡲࡍࠋග⥺ࡣࢥࢿࢡࢱࡲࡓࡣගࣇࣂ࣮

ࢣ࣮ࣈࣝࡽᨺᑕࡉࢀࡿࡇࡀ࠶ࡾࡲࡍࠋ

Radiação a laser: certos produtos óticos podem emitir radiação a laser. A remoção dos

revestimentos pode resultar em exposição à radiação a laser. A radiação pode ser

emitida de conectores para cabos de fibra óptica.

崎決洆 愯斲: 瞿洛 列穟 洢禎櫖昢垚 崎決洆 愯斲儆 愯犢夦 朞 沎枻城埪. 塴儢庂

洢其穞彺 氊竞穢

崎決洆 愯斲櫖 噾犢夦 朞 沎枻城埪. 愯斲垚 珪嘫瘶喞 列昲氦 理決挚櫖昢 愯犢夦 朞 沎枻城埪.

暟⮬廣⮬烉㝸ṃ⬠䓊⑩⎗傥㚫㔋䘤暟⮬廣⮬ˤ䦣昌味㜧⎗傥㚫ἧぐ㙜曚⛐⌙晒䘬暟⮬廣⮬ˤ忋

㍍☐ㆾ㗗举乄䶂悥⎗傥㚫㔋䘤廣⮬ˤ

תנירקל הפישחל ליבוהל הלולע םייוסיכ תרסה .רזייל תנירק טולפל םייושע םימיוסמ םייטפוא םירצומ :רזייל תנירק

.םייטפוא םיביס ילבכמ וא םירבחממ טלפיהל היושע הנירק .תנכוסמ רזייל

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

18 Doc. No.: H76456Rev 3.0US

Page 19

Omni-Path Switches

Promieniowanie laserowe: niektóre produkty optyczne mogą emitować promienie

lasera. Zdjęcie osłon może grozić wystawieniem się na niebezpieczne promieniowanie

laserowe. Złącza i kable światłowodowe mogą emitować promieniowanie.

Laserové záření: jistá optická zařízení mohou vyzařovat laserové záření. Po odstranění

krytů proto můžete být vystaveni nebezpečnému laserovému záření. Záření může

vycházet z konektorů nebo optických kabelů.

Ακτινοβολία λέιζερ: ορισμένα οπτικά προϊόντα ενδέχεται να εκπέμπουν ακτινοβολία

λέιζερ. Η αφαίρεση των καλυμμάτων ενδέχεται να προκαλέσει έκθεση σε επικίνδυνη

ακτινοβολία λέιζερ. Η

οπτικών ινών.

Radiasi Laser: produk optik tertentu mungkin menghasilkan radiasi laser. Melepas

penutup mungkin menyebabkan terpaparnya radiasi laser yang berbahaya. Radiasi

mungkin dipancarkan dari konektor atau kabel optik fiber.

Lazer Radyasyon: belirli optik ürünler lazer radyasyon yayabilir. Kapakların çıkarılması

tehlikeli lazer radyasyonuna maruz kalmaya neden olabilir. Radyasyon, konektörler

veya fiber optik kablolardan yayılabilir.

Ласерско зрачење: Неки оптички производи могу емитовати ласерско зрачење.

Уклањање поклопаца може довести до излагања опасном ласерском зрачењу.

Зрачење се може емитовати са конектора или каблова са оптичким влакнима.

ακτινοβολία ενδέχεται να εκπέμπεται από συνδέσμους ή καλώδια

1.8.5 Statement 5:

No user-serviceable parts: Hazardous energy levels may be present inside power

supplies and circuit card modules. Do not remove covers.

Onderdelen die niet door de gebruiker mogen worden onderhouden: Er kunnen

gevaarlijke energieniveaus aanwezig zijn binnen voedingen en printplaten. Verwijder in

geen geval dekplaten.

Ei osia, jotka käyttäjä voisi vaihtaa. Virtalähteiden ja piirikorttimoduulien sisällä saattaa

olla vaarallisen suuri virta tai jännite. Älä poista niiden suojuksia.

Pièces non entretenues par l'utilisateur: Des niveaux d'électricité dangereux peuvent

résider à l'intérieur des sources d'alimentation et des modules de carte de circuits

imprimés. Ne retirez pas les capots.

Wartung nur durch Fachmann möglich: Gefährlich hohe Stromstärken sind in Netzteilen

und in den Modulen der Busleiterplatte vorhanden. Entfernen Sie die Abdeckungen

nicht.

Non sono presenti componenti riparabili dall'utente: Livelli pericolosi di energia

potrebbero essere presenti all'interno degli alimentatori e dei moduli delle schede dei

circuiti. Non rimuovere le coperture.

Ingen deler som kan vedlikeholdes av brukeren: farlig strømmengde kan finnes inni

strømforsynings- og kretskortmoduler. Fjern ikke dekslene.

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 19

Intel® Omni-Path Fabric Switches

Page 20

Omni-Path Switches

Não há peças a serem consertadas pelo utilizador: Níveis perigosos de energia podem

estar presentes em fontes de alimentação e em módulos de placas de circuito. Não

remova as tampas.

No hay piezas técnicas: Niveles peligrosos de energía pueden hacerse presentes en las

fuentes de alimentación eléctrica. No quite las cubiertas.

Inga delar kan underhållas av användaren. Farliga energinivåer kan finnas i

strömförsörjningsenheter kretskortmoduler. Ta inte bort skydd.

A berendezés nem tartalmaz felhasználó által javítható alkatrészeket – Veszélyes

energiaszint lehet a tápegységeken és az áramköri kártyamodulokon belül. Ne távolítsa

el a burkolatokat.

Устройство не содержит деталей, предназначенных для обслуживания

пользователем – Блоки питания и электрические платы устройства являются

источником опасного электрического напряжения. Снимать крышки запрещено.

⾱→⭘ᡧ㔤؞䜘Ԧ ⭥Ⓚ઼⭥䐟⁑ඇ䜘㜭ᆈ൘аᇊ≤ᒣⲴᴹᇣ㜭DŽ࠷〫䲔ⴆᶯDŽ

࣮ࣘࢨ࣮ಟ⌮ྍ⬟㒊ရ࡞ࡋ㟁※⨨࠾ࡼࡧᅇ㊰࣮࢝ࢻࣔࢪ࣮ࣗࣝෆࡢ࢚ࢿࣝࢠ࣮ࡀ༴㝤࡞ࣞ࣋

ࣝ㐩ࡋ࡚࠸ࡿሙྜࡀ࠶ࡾࡲࡍࠋ࢝ࣂ࣮ࢆእࡉ࡞࠸࡛ࡃࡔࡉ࠸ࠋ

Não é nenhuma peça que possa ser reparada pelo usuário, não é? Os níveis de energia

perigosos podem estar presentes dentro de fontes de alimentação e em módulos de

cartões de circuito. Não remova os revestimentos.

斲殯沖 剖熺 儆垫 抆禎 櫌汒: 洊毖 击匏 沫獞 愕 箒嵢 獺姢 微姎 喺櫖垚 氊竞穢 櫖嘎滆 朞渆決 浺沲

穦 朞 沎枻城埪. 塴儢庂 洢其穞滆 廎柳柢欪

.

朆ἧ䓐侭⎗䵕ᾖ暞ẞ烉暣㸸⍲暣嶗⌉㧉䳬ℏ⎗傥⬀⛐⌙⭛傥慷ỵ㸾ˤ婳ᶵ天䦣昌味㜧ˤ

חוכ יקפס ךותב אצמיהל תולולע תונכוסמ היגרנא תומר :שמתשמה ידי לע לופיטל םינתינה םיקלח ליכמ וניא רצומה

.םייוסיכ ריסהל ןיא .םילגעמה יסיטרכ ילודומו

Brak części serwisowanych przez użytkownika: wewnątrz zasilaczy i modułów kart

może występować niebezpieczny poziom energii. Nie zdejmować osłon.

Zařízení neobsahuje žádné součásti, jejichž údržbu by mohl provádět sám uživatel:

uvnitř zdrojů napájení a modulů s kartami s tištěnými spoji se může nacházet

nebezpečné napětí. Neodstraňujte kryty.

Δεν υπάρχουν εξαρτήματα με δυνατότητα επισκευής από το χρήστη: ενδέχεται να

υφίστανται επικίνδυνα επίπεδα ενέργειας εντός μονάδων τροφοδοτικού και μονάδων

κάρτας κυκλώματος. Μην αφαιρείτε τα καλύμματα.

Tidak ada bagian yang dapat diservis pelanggan: Tingkat energi berbahaya mungkin

terjadi di dalam catu daya dan modul kartu sirkuit. Jangan melepaskan penutup.

Kullanıcı tarafından kullanılamaz parçalar: Güç kaynakları ve devre kart modülleri

içinde tehlikeli seviyede elektrik mevcut olabilir. Kapakları çıkarmayın.

Делови које корисници не могу сервисирати: Опасни нивои напона могу бити

присутни унутар напонских јединица и модула штампаних картица. Немојте

уклањати поклопце.

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

20 Doc. No.: H76456Rev 3.0US

Page 21

Omni-Path Switches

1.8.6 Statement 6:

Equipment Installation: Only qualified personnel should be allowed to install, remove or

replace chassis or modules.

Installatie apparatuur: Voor het installeren, verwijderen of vervangen van chassis of

modules mag alleen gekwalificeerd personeel worden gebruikt.

Laitteiston asentaminen. Vain pätevä asentaja saa asentaa, poistaa ja vaihtaa koteloita

tai moduuleja.

Installation de l'équipement: Seul un personnel qualifié est autorisé à installer, retirer

ou remplacer des châssis ou modules.

Geräteinstallation: Die Installation, Entfernung oder Erneuerung von Gehäuse und

Modulen sollte nur durch Fachpersonal erfolgen.

Installazione dell'apparecchiatura: Solo il personale qualificato è autorizzato ad

installare, rimuovere o ricollocare il telaio o i moduli.

Utstyrsinstallasjon: kun kvalifisert personell kan installere, fjerne eller skifte ut

kabinetter eller moduler.

Instalação do equipamento: A instalação, troca ou remoção de chassis ou módulos só

deve ser feita por técnicos qualificados.

Instalación del equipo: Solamente se permite personal cualificado para realizar la

instalación, quitar o sustituir módulos o chasis.

Installation av utrustning. Enbart kvalificerad personal får installera, ta bort eller byta

ut chassin eller moduler.

Berendezés telepítése – Kizárólag szakképzett személyzet számára megengedett a

burkolat vagy a modulok telepítése, eltávolítása vagy cseréje.

Установка оборудования – Установка, удаление и замена корпуса или модулей

устройства должна производиться только квалифицированным техническим

персоналом.

䇮༷ᆹ㻵 ᴹᴹ䍴ṬⲴᢰᵟӪઈݱ䇨ᆹ㻵ǃনлᡆ㻵എᵪ㇡ᡆ⁑ඇDŽ

⨨ࡢྲྀࡾࡅࢩ࣮ࣕࢩࡲࡓࡣࣔࢪ࣮ࣗࣝࡢྲྀࡾࡅࠊྲྀࡾእࡋࡲࡓࡣྲྀ᭰࠼ࡣࠊ᭷㈨᱁⪅ࡢ

ࡳࡀ⾜࠺ࡼ࠺ࡋ࡚ࡃࡔࡉ࠸ࠋ

Instalação de equipamento: somente funcionários qualificados devem ter permissão

para instalar, remover ou substituir chassi ou módulos.

沫獞 昪獞: 沖冯決 沎垚 汾毖廒 昆柢 嬖垚 微姎汊 昪獞, 洢其 嬖垚 剖熺穦 朞 沎枻城埪.

姕⁁⬱墅烉⎒㚱䫎⎰屯㟤䘬Ṣ⒉ㇵ姙⬱墅ˣ䦣昌ㆾ㚜㎃⸽⹏ㆾ㧉䳬ˤ

.םילודומ וא זראמ ףילחהל וא ריסהל ,ןיקתהל דבלב םינמוימ םידבועל רשפאל שי :דויצה תנקתה

Montaż sprzętu: tylko wykwalifikowany personel może być upoważniony do montaż

u,

demontażu lub wymiany obudowy i modułów.

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 21

Intel® Omni-Path Fabric Switches

Page 22

Instalace vybavení: instalaci, odinstalování nebo výměnu skříně či modulů smí

provádět pouze kvalifikovaní pracovníci.

Τοποθέτηση εξοπλισμού: η τοποθέτηση, αφαίρεση ή αντικατάσταση περιβλημάτων ή

μονάδων πρέπει να επιτρέπεται μόνο σε εξειδικευμένο προσωπικό.

Instalasi Peralatan: Hanya staf berpengalaman yang boleh memasang, melepaskan,

atau mengganti kerangka atau modul.

Ekipman Kurulumu: Şasi ve modüllerin yalnızca nitelikli personel tarafından

kurulumuna, çıkarılmasına veya değiştirilmesine izin verilir.

Инсталирање опреме: Само квалификованом особљу треба дозволити да

инсталира, уклања или замењује шасију или модуле.

1.8.7 Statement 7:

Adding or Replacing Modules: These modules are intended only for installation in Intel®

Omni-Path Fabric base units. Always install blanks when removing an active module.

They prevent exposure to energy hazards inside the unit, contain EMI, and maintain

cooling air balance in the chassis.

Omni-Path Switches

Toevoegen of vervangen van modules: deze modules zijn alleen bedoeld voor installatie

in basiseenheden uit de Intel

®

Omni-Path-reeks. Installeer altijd plaatshouders

wanneer u een actieve module verwijdert. Deze voorkomen blootstelling aan

energierisico's binnen de eenheid, bevatten EMI en handhaven de koelluchtbalans in

het chassis.

Moduulien lisääminen ja vaihtaminen. Moduulit on tarkoitettu asennettavaksi vain

®

Intel

Omni-Path -sarjan perusyksikköihin. Kun olet poistanut aktiivisen moduulin,

muista aina asentaa tyhjä kappale sen paikalle. Ne estävät sähköiskuille altistumista

yksikön sisällä, hillitsevät sähkömagneettisia häiriöitä (EMI) ja pitävät yllä

jäähdytysilman tasaista jakautumista koteloon.

Ajouter ou remplacer des modules: Ces modules sont conçus exclusivement pour une

installation avec des unités de base Intel

®

Omni-Path series. Installez toujours des

caches de protection lors du retrait d'un module actif. Ils protègent contre les dangers

électriques à l'intérieur de l'unité, limitent l'interférence électromagnétique et

maintiennent un volume d’air refroidissant approprié au sein du châssis.

Hinzufügen oder Austauschen von Modulen: Diese Module sind für die Installation in

Grundeinheiten der Intel

®

Omni-Path Serie vorgesehen. Installieren Sie stets leere

Module, wenn Sie ein aktives Modul entfernen. Diese verhindern, dass Stromgefahr im

Innern der Einheit entsteht, enthalten Störstrahlung und sorgen für den

Kühlungsausgleich im Gehäuse.

Aggiunta o sostituzione dei moduli: I moduli sono concepiti solo per l'installazione nelle

unità di base Intel

®

Omni-Path Serie. Quando si rimuove un modulo attivo, installare

sempre le protezioni, poiché impediscono l'esposizione ai pericoli di scosse all'interno

dell'unità, contengono le IEM e mantengono un equilibrio dell'aria di raffreddamento nel

telaio.

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

22 Doc. No.: H76456Rev 3.0US

Page 23

Omni-Path Switches

Tillegging eller utskifting av moduler: disse modulene skal kun installeres i

baseenhetene på Intel

®

Omni-Path-serien. Installer alltid tomme enheter når en aktiv

modul fjernes. De forhindrer utsettelse for strømfare inni enheten, inneholder EMI og

opprettholder kjølebalansen i kabinettet.

Adição ou troca de módulos: Estes módulos foram projectados para serem instalados

apenas nas unidades de base Intel

®

Omni-Path série. Instale sempre módulos de

preenchimento ("blanks") ao remover módulos activos. Eles diminuem os riscos de

choque eléctrico no interior da unidade, contêm dispositivos de protecção contra

interferência eletromagnética e mantêm o equilíbrio de resfriamento por ar no interior

do chassi.

Agregar o sustituir módulos: Estos módulos solamente se pueden instalar en unidades

de base de la serie Intel

®

Omni-Path. Siempre instale protectores al retirar un módulo

activo. Los protectores previenen la exposición a peligros de energía dentro de la

unidad, contienen EMI y mantienen el balance de enfriamiento de aire en el chasis.

Lägga till eller byta ut moduler. De här modulerna är enbart avsedda för installation i

®

Intel

Omni-Path-seriens basenheter. Installera alltid tomenheter vid borttagning av en

aktiv modul. De förhindrar exponering för energirisker på enhetens insida, hindrar EMI

och upprätthåller kylluftbalansen i chassin.

Modulok hozzáadása vagy cseréje – Ezek a modulok kizárólag Intel

®

Omni-Path-es

sorozatú bázisegységekbe építhetoek be. Aktív modul cseréjekor mindig szereljen be

üres helyeket. Ezek megakadályozzák az egységen belüli energiaveszélyek

kialakulását, tartalmaznak EMI-t, és fenntartják a hutolevego egyensúlyát a borításon

belül.

Установка и замена модулей – Модули предназначены только для установки внутрь

базовых блоков Intel

®

серии Omni-Path. После замены действующих модулей

следует всегда устанавливать заглушки с крышками. Это обеспечивает защиту от

опасного напряжения, электромагнитного излучения и надлежащий тепловой

баланс внутри корпуса.

࣐ᡆ㻵എ⁑ඇ 䘉Ӌ⁑ඇӵ⭘Ҿᆹ㻵൘ Intel

®

2PQL3DWK6HULHVสᓗ㻵㖞DŽ䈧൘〫䲔⍫ࣘ⁑ඇ

ᰦᆹ㻵オⲭⲴDŽᆳԜ㜭亴䱢㻵㖞䜘Ⲵᴹᇣ㜭Ⲵ᳤䵢ˈ(0,ᒦ൘ᵪ㇡؍ᤱߧতオ≄ᒣ㺑DŽ

ࣔࢪ࣮ࣗࣝࡢ㏣ຍࡲࡓࡣྲྀ᭰࠼ࡇࢀࡽࡢࣔࢪ࣮ࣗࣝࡣ Intel

®

2PQL3DWKࢩ࣮ࣜࢬ03)'࣮࣋

ࢫࣘࢽࢵࢺࡢྲྀࡾࡅᑓ⏝࡛ࡍࠋࢡࢸࣈ࡞ࣔࢪ࣮ࣗࣝࢆྲྀࡾ㝖ࡃ㝿ࡣࠊᖖࢲ࣑࣮ࢆྲྀࡾ

ࡅ࡚ࡃࡔࡉ࠸ࠋࡇࢀࡣࣘࢽࢵࢺෆࡢ༴㝤࡞࢚ࢿࣝࢠ࣮ࡢ㟢ฟࢆ㜵Ṇࡋࠊ(0, ࢆ㜼Ṇࠊ࠾ࡼࡧ

ࢩ࣮ࣕࢩෆࡢ✵෭ࣂࣛࣥࢫࢆ⥔ᣢࡋࡲࡍࠋ

Adicionando ou substituindo módulos: estes módulos destinam-se a instalação

somente leitura nas unidades base do Intel® Omni-Path Fabric. Sempre instale vazios

ao remover um módulo ativo. Eles impedem a exposição aos níveis perigosos de

energia dentro da unidade, contêm EMI e mantêm a o balanço de ar refrigerado.

微姎 犚儆 嬖垚 剖熺: 決峲穢 微姎汆 Intel

®

Omni-Path Fabric 匶愞 沫獞櫖廒 昪獞夦 朞 沎枻城

埪. 筢昷 微姎 洢其 柢 穳旇 挚岳畲庂 沫焯空檂 穯城埪. 挚岳畲垚 沫獞 喺抆汞 氊竞穢 櫖嘎滆儆 噾

犢夞垚 冉汊 愯滆穞彶 EMI庂 焮磖穞処 昆柢汞 嗏儇 击匶 愾島枪庂 氦滆穯城埪.

㕘⡆ㆾ㚜㎃㧉䳬烉忁ṃ㧉䳬ὃ⬱墅㕤 Intel

®

Omni-Path 㝞㥳➢㛔墅伖ˤ䦣昌䎦埴㧉䳬⼴炻婳

⥳䳪⬱墅䨢㧉䳬ˤ⬫Ᾱ⎗旣㬊墅伖ℏ䘬傥慷⌙⭛⢾㳑ˣ㈹⇞ EMI炻ᾅ㊩⸽⹏䘬⅟⌣䨢㯋⸛堉ˤ

.דבלב Intel® Omni-Path Fabric גוסמ סיסב תודיחיב הנקתהל ודעונ הלא םילודומ :םילודומ לש הפלחה וא הפסוה

ךותב היגרנא תונכסל הפישח םיענומ םיקיר םילודומ .םיקיר םילודומ דימת ןיקתהל שי ,ליעפ לודומ לש הרסה תעב

.זראמה ךותב ןוניצה ריווא ןוזיא לע םירמושו תויטנגמ-ורטקלא תוערפה םימסוח ,הדיחיה

Dodawanie i wymiana modułów: moduły są przeznaczone do montażu tylko w

urządzeniach podstawowych Intel

®

Omni-Path Fabric. Przy wyjmowaniu aktywnego

modułu należy zamontować pusty moduł zastępczy (wypełniacz). Moduły takie

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 23

Intel® Omni-Path Fabric Switches

Page 24

Omni-Path Switches

zapobiegają zagrożeniom elektrycznym wewnątrz urządzenia, ograniczają ilość

zakłóceń elektromagnetycznych, a także ułatwiają utrzymanie odpowiedniej ilości

powietrza chłodzącego w obudowie.

Přidávání nebo výměna modulů: tyto moduly jsou určeny pouze pro instalaci do

základnových jednotek Intel

®

Omni-Path Fabric. Po vyjmutí aktivního modulu vždy

nainstalujte rezervní výplně. Tyto výplně zabraňují kontaktu s nebezpečným napětím

uvnitř jednotky, obsahují EMI a udržují rovnováhu vzduchového chlazení ve skříni.

Προσθήκη ή αντικατάσταση μονάδων: αυτές οι μονάδες προορίζονται μόνο για

τοποθέτηση σε βασικές μονάδες Intel

®

Omni-Path Fabric. Τοποθετείτε πάντοτε

καλύμματα, όταν αφαιρείτε μια ενεργή μονάδα. Αυτά εμποδίζουν την έκθεση σε

ενεργειακούς κινδύνους εντός της μονάδας, περιορίζουν τις ηλεκτρομαγνητικές

παρεμβολές και διατηρούν την ισορροπία στον αέρα ψύξης εντός του περιβλήματος.

Menambah atau Mengganti Modul: Modul-modul ini ditujukan untuk instalasi dalam

unit dasar Intel

®

Omni-Path Fabric. Selalu pasang modul kosong saat mengeluarkan

modul aktif. Modul kosong akan mencegah terpaparnya energi berbahaya di dalam

unit, termasuk EMI, dan memelihara keseimbangan udara penyejuk di dalam kerangka.

Modüllerin Takılması veya Değiştirilmesi: Bu modüller yalnızca Intel

®

Omni-Path Fabric

sistem biriminde kullanım içindir. Aktif modülleri çıkarırken daima boşluk modüllerini

kurunuz. Bu boşluk modülleri, ünite içindeki elektrik tehlikelerine maruz kalmayı

önlerler, EMI içerirler ve şasi içindeki hava balans soğutmasını korurlar.

Додавање или замена модула: Ови модули су предвиђени само за инсталацију у

®

Intel

Omni-Path Fabric основне јединице. Увек инсталирајте празне модуле када

уклањате неки активни модул. То спречава излагање опасности од струје, садржи

EMI и одржава равнотежу расхлађеног ваздуха у шасији.

§ §

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

24 Doc. No.: H76456Rev 3.0US

Page 25

Omni-Path Switches

2.0 Installation

This section describes how to install and configure for first-time use:

®

• The Intel

2.1 Planning the Installation

The Omni-Path switches are designed for installation in standard 19-inch equipment

racks.

Racks should conform to conventional standards. Use the American National Standards

Institute (ANSI)/Electronic Industries Association (EIA) standard ANSI/EIA-310-D-92

and International Electrotechnical Commission (IEC) 297

Racks should meet the following mechanical recommendations:

• Four-post, 19" rack to facilitate easy maintenance

• Universal mounting rail hole pattern identified in IEC Standard 297

• Mounting holes flush with the rails to accommodate the chassis

Note: Operation is subject to the following conditions:

Omni-Path Fabric Series switches in a network environment.

Note: Use a rack grounding kit and a ground conductor that is carried back to earth or to

Note: Provide enough room to work on the equipment. Clear the work site of any

another suitable building ground. Ground the equipment rack to earth ground.

unnecessary materials. Make sure the equipment will have enough clearance for front

and rear access.

2.1.1 Cable Requirements

2.1.1.1 Cable Distances

When planning the location of the switches, consider the distance limitations for

signaling, EMI, and connector compatibility. It is recommended that the user does not

exceed specified transmission rate and distance limits.

2.1.1.2 Cable Guidelines

Note: Building and electrical codes vary depending on the location. Comply with all code

specifications when planning the site and installing cable.

When running cable to the equipment, consider the following:

• Do not run cables where they can be stepped on or rolled over.

• Be sure cables are intact with no cuts, bends, or nicks.

• If the user is making a cable, ensure that the cable is properly crimped.

• Provide proper strain relief for cables.

• Support cables using a cable manager mounted above connectors to avoid

unnecessary weight on the cable bundles.

• Bundle cable using Velcro straps to avoid injuring cables.

• Keep all ports and connectors free of dust.

• Untwisted Pair (UTP) cables can build up Electrostatic Discharge (ESD) charges

when being placed into a new installation. Before installing category 5 UTP cables,

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 25

Intel® Omni-Path Fabric Switches

Page 26

discharge ESD from the cable by plugging it into a port on a system that is not

powered on.

• When required for safety and fire rating requirements, plenum-rated cable can be

used. Check the local building codes to determine when it is appropriate to use

plenum-rated cable, or refer to IEC standard 850.

• In order to create enough space, QSFP cables connectors may need to be rotated

when plugging into alternate rows of switch components.

Figure 2. QSFP Cable Connector Orientation

2.1.1.3 Cable Handling and Bend Radius

• Intel® Omni-Path Copper Cable 100 Series:

— Recommended minimum bend radius is >69mm

®

• Intel

Omni-Path Active Optical Cable 100 Series:

— Recommended minimum bend radius is >105 mm within 100 mm of either

cable end module, and >60 mm on the rest of the cable

Omni-Path Switches

Table 2. Cable Bend Radius Guidelines

Intel® Omni-Path Copper Cable 100 Series

American Wire Gauge (AWG) Size

Cable

26 >69mm

30 >66mm

®

Omni-Path Active Optical Cable 100 Series

Intel

Gauge Bend Radius

Optical

Bend Radius

>105 mm within 100 mm of either cable end module

>60 mm on the rest of the cable

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

26 Doc. No.: H76456Rev 3.0US

Page 27

Omni-Path Switches

Figure 3. Copper Cable Bend Radius

Figure 4. Fiber Optic Bend Radius

2.1.2 Uninterruptible Power Supply Equipment

Consider the following when selecting uninterruptible power supply (UPS) equipment:

• The minimum amperage requirements for a UPS:

— Calculate VA (volt-amps): Locate the voltage and amperage requirements for

each piece of equipment (usually located on a sticker on the back or bottom of

the equipment). Multiply the numbers together to get VA.

— Add the VA from each piece of equipment together to find the total VA

requirement. Then add 30% to determine the minimum amperage

requirements for the UPS.

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 27

Intel® Omni-Path Fabric Switches

Page 28

• Transition time (the time necessary for the UPS to transfer from utility power to

full-load battery power).

• The longest potential time period the UPS might be required to supply backup

power.

• Whether the UPS unit provides online protection.

2.2 Installation Tasks Checklist

To perform the actual switch installation, the site implementation engineer must

perform the following tasks, which are detailed in this section.

Omni-Path Switches

Caution: Be sure to review the safety information before starting the installation and during the

installation process (refer to “Safety Information” on page 12).

1. Check the installation site to verify the installation of cabinet power feeds, rails,

and grounding.

2. Unpack the equipment and inspect for any shipping damage. Any shipping damage

should be reported to the shipping company.

3. Verify that the equipment shipped matches the packing list.

4. Mark the rack and install the mounting rails.

5. Physically install the switch in the rack.

2.2.1 Tools and Equipment Required

• An ESD wrist strap

• A #0 and #2 Phillips screwdriver

• An M6 HEX nut wrench

®

• Lifting device (e.g., pallet jack) for the Intel

Omni-Path Director Class Switches

100 Series

2.2.2 Check the Installation Site

The switches are designed to be installed in an existing server cabinet (not a telco

cabinet), where it can be mounted in a standard equipment rack.

Be sure of the following:

• The cabinet has a full earth ground to provide reliable grounding.

• There is enough room to work on the equipment.

• The equipment will have enough clearance for front and rear access.

• The cables can be accessed easily.

• Water or moisture cannot enter the switch.

• The ambient temperature stays between 50°–113°F (5°–40° C).

• Cabinet doors do not interfere with front-to-back air flow.

The cabinet should have its own switchable power distribution. If the switch has two

power supplies, it is suggested that a cabinet with dual power distribution units is used.

It is recommended that cabinet anti-tip devices are used. This is especially true if

installing or removing a switch in the upper half of the cabinet when the lower half is

empty.

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

28 Doc. No.: H76456Rev 3.0US

Page 29

Omni-Path Switches

2.2.3 Mark the Rack

Allow enough vertical space in the rack for each specific switch installation.

1. Determine the location in the rack of the bottom of the switch.

2. Mark the upper (if applicable) and lower mounting positions on the vertical rails on

the front of the rack.

3. Mark the upper (if applicable) and lower mounting positions on the vertical rails on

the back of the rack.

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 29

Intel® Omni-Path Fabric Switches

Page 30

2.3 Omni-Path Fabric Edge Switch Installation

This section describes the rack mounting instructions for the 24 and 48 port Omni-Path

Fabric Edge Switches in a four-post standard-depth rack. The installation of either

switch is very similar; the majority of steps apply to both switches. Where applicable,

any specifics for either switch are called out.

In a standard-depth rack, the distance between the front and back mounting posts is

~28" (700mm). Mounting rails for the switch are adjustable to accommodate racks

with 26"– 32" between mounting posts.

2.3.1 Mounting Hardware Kit Contents:

• ESD wrist strap

• One pair of mounting rails adjustable for 26"– 32" installation range

• M6 hex head screws

• Front 1U perforated cover

2.3.2 Rack Mounting

Figure 5. Omni-Path Edge Switch Rail

Omni-Path Switches

1. Insert the rail installation pin in to the rack hole as shown in Figure 6. This holds

the rail in place so the user can install the fan side screws. Fasten the rail using two

(2) M6 screws. Torque screws to 30in-lb. Repeat this step for the second rail.

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

30 Doc. No.: H76456Rev 3.0US

Page 31

Omni-Path Switches

Figure 6. Rail Installation Pin

2. Fasten the port-side rails using four (4) M6 screws. Torque screws to 30in-lb. Note

the orientation of mounting rails in Figure 7. The rails are shown from the front side

of the rack.

Figure 7. Installed the Rack Rails

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 31

Intel® Omni-Path Fabric Switches

Page 32

Omni-Path Switches

Figure 8. Omni-Path Fabric Edge Switch Mounted in a Four Post Standard Rack

3. The rails are designed for different mounting positions, from flush mount to

recessed (in 1 inch increments) as shown in Figure 9.

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

32 Doc. No.: H76456Rev 3.0US

Page 33

Omni-Path Switches

Figure 9. Switch Rail Adjustments

4. To change the depth of the switch, insert your fingers into the rail adjustment

notches and pull away from the switch as shown in Figure 10. This disengages the

rail latches from the switch hat section.

Figure 10. Rail Adjustment Notches

5. Slide the switch to the desired depth in the rack. The switch is adjustable in

increments of 1 inch. When the switch is at the proper depth, push the rail

adjustment notches back to their original position to secure in place.

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 33

Intel® Omni-Path Fabric Switches

Page 34

2.3.3 Installing the Airflow Baffles

When necessary, the airflow baffles help control the flow of air on the top and bottom of

the edge switch. The baffles are installed whenever the top and/or bottom of the edge

is exposed to greater than 1U of space in a rack.

Figure 11. Edge Baffle (Top View) gray and yellow both

Omni-Path Switches

Note: Installation of the baffle(s) take place after the edge switch has been rack mounted.

1. Unlock the rail system by pulling the handles out.

2. Guide the baffle onto the rails, then slide the baffle into the rack until it stops

against the edge switch.

a. Top Baffle Only: Insert 4 screws (2 on each side) to secure the baffle extension

(shown in yellow below) to the main baffle. The location of the screws depends

upon the depth that the edge has been mounted.

Figure 12. Secure the Top Baffle to the Switch

3. After baffle is fully inserted, push the handles back until the rail locks in place.

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

34 Doc. No.: H76456Rev 3.0US

Page 35

Omni-Path Switches

2.3.4 Installing the Switch Fascia

The Edge switch fascia guards against ESD as well as accidental contact with the fans

and power supplies.

Figure 13. Switch Fascia

The fascia is installed by snapping it in place onto the switch rail posts.

Figure 14. Rail Posts for Fascia Installation

2.3.5 Reversing the Fan Airflow

This section details the procedure to reverse the airflow on the switch fan assembly

from the default port-side exhaust position.

2.3.5.1 Tools Required:

• ESD wrist strap

• #0 Phillips screwdriver

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 35

Intel® Omni-Path Fabric Switches

Page 36

Omni-Path Switches

2.3.5.2 Procedures

Note: Before removing the cover from the switch, first disconnect the power cord(s).

1. Loosen the 4 thumbscrews from the switch cover. There are 3 screws on the top,

and 5 screws on the back. Lift the cover on a 45-degree angle, then pull to remove.

Figure 15. Switch Cover Thumbscrews (Top View)

2. Holding the fan assembly on the sides lift straight up and rotate the fan assembly

180 degrees as shown in Figure 16.

Figure 16. Fan Assembly Rotation

3. Lower the fan assembly straight down. The airflow direction indicators should now

face towards the rear of the chassis as shown in Figure 17.

Note: Make certain to provide strain relief for the wire assembly.

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

36 Doc. No.: H76456Rev 3.0US

Page 37

Omni-Path Switches

Figure 17. Wire Assembly Strain Relief and Airflow Direction Indicators

4. Reattach the switch cover.

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 37

Intel® Omni-Path Fabric Switches

Page 38

2.3.6 Installing the Q7 Management Module

This section details the procedure to install the Q7 Management Module into an existing

unmanaged edge switch.

Figure 18. Q7 Management Module

Omni-Path Switches

2.3.6.1 Tools Required:

• ESD wrist strap

• #0 Phillips screwdriver

• Regular screwdriver

2.3.6.2 Procedures

1. Remove the switch cover as detailed in Section 2.3.5.2, Step 1. The Management

Module slot is displayed in Figure 19.

Figure 19. Management Module Slot

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

38 Doc. No.: H76456Rev 3.0US

Page 39

Omni-Path Switches

2. Holding the module at approximately a 45-degree angle, slide the connector into

module slot. Make certain to line up the notch on the module and the connector

(see Figure 20).

Figure 20. Installing the Q7 Module

3. Once the module is seated properly in the connector, secure screw to the chassis

using a regular screwdriver.

Figure 21. Q7 Module Mounting Screw

4. Reattach the switch cover.

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 39

Intel® Omni-Path Fabric Switches

Page 40

Omni-Path Switches

2.4 Omni-Path Director Class Switches 100 Series Installation

2.4.1 Mounting Hardware Kit Contents:

• Mounting Kit containing:

— Support Platform (1)

— Plenums (2)

— #10 Mounting screws

— #10 Mounting nuts

— M6 Mounting Screws

2.4.2 Unpacking the Switch

Note: Set aside packaging materials in the event that the switch requires return shipment.

The following images and descriptions give a high-level overview for unpacking a

Director Switch (24 slot model in this example).

Figure 22. Unpacking the Switch (1)

1. Remove the banding.

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

40 Doc. No.: H76456Rev 3.0US

Page 41

Omni-Path Switches

Figure 23. Unpacking the Switch (2)

2. Remove the lid.

Figure 24. Unpacking the Switch (3)

3. Remove the accessory kit box and white packing form. The accessory kit contains

required hardware, power cables, documentation, etc.

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 41

Intel® Omni-Path Fabric Switches

Page 42

Figure 25. Unpacking the Switch (4): Accessory Kit

Figure 26. Unpacking the Switch (5)

Omni-Path Switches

4. Lift the box up out of the base.

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

42 Doc. No.: H76456Rev 3.0US

Page 43

Omni-Path Switches

Figure 27. Unpacking the Switch (6)

5. Remove the plenum boxes.

Figure 28. Unpacking the Switch (7)

6. Remove the plastic bag, then remove the support shelf from the top of the switch.

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 43

Intel® Omni-Path Fabric Switches

Page 44

2.4.3 Installation Tasks

The following section details rack mounting instructions for the 6-slot and 24-slot

®

Intel

Omni-Path Director Class Switch 100 Series. The installations are very similar;

the majority of steps apply to both switches. Where applicable, any specifics for either

the 6-slot or 24-slot Director are called out.

2.4.3.1 Install the Support Platform

1. Measure the inside distance between the front and middle rails on the cabinet (27”

in the Figure 29 example).

Figure 29. Measure the Rack

Omni-Path Switches

2. Before installing into the cabinet, preset the adjustable rails on the plenum base,

leaving the screws loose to the dimension measured on the cabinet (27” in this

example). In order to be able to fit the plenum base into the cabinet, set the rails

to slightly less than the measured size (i.e., < 27”). See Figure 30.

Figure 30. Preset the Adjustable Rails

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

44 Doc. No.: H76456Rev 3.0US

Page 45

Omni-Path Switches

3. Install the fixture brackets to the cabinet at the desired height (Figure 31). The

brackets support and help locate the installation of the plenum base. Remove and

discard/recycle the brackets after plenum base has been installed.

Figure 31. Install Fixture Brackets

4. Secure the platform to the rack using M6 mounting screws, 3 per platform rail (1 in

the front and 2 in the back) as displayed in Figure 32. Torque screws to 30in-lb.

Figure 32. Secure Platform to Rack

5. Attach the plenums to the top of each platform rail using 10 mounting nuts, 5 per

platform rail as displayed in Figure 33. Torque nuts to 30in-lb.

Note: Make certain to tighten the adjustable rail screws (from Step 2) at this time.

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 45

Intel® Omni-Path Fabric Switches

Page 46

Figure 33. Secure the Plenums to Top of Platform Rails

Omni-Path Switches

6. Secure the top of the plenums to the rack rail as displayed in Figure 34:

a. 6 Slot Chassis: use 2 mounting nuts, 1 per rail.

b. 24 Slot Chassis: use the lower of the 2 openings, 1 mounting nut per rail.

Figure 34. Secure the Top of the Baffles to the Rack Rails

®

Omni-Path Fabric Switches

Intel

Installation Guide May 2016

46 Doc. No.: H76456Rev 3.0US

Page 47

Omni-Path Switches

7. The completed Platform assemblies for both the 6 and 24 slot switches are

displayed in Figure 35.

Figure 35. Completed Platform Assemblies

May 2016 Installation Guide

Doc. No.: H76456Rev 3.0US 47

Intel® Omni-Path Fabric Switches

Page 48

2.4.3.2 Installing the Director Switch Chassis

Omni-Path Switches

Warning: To avoid injury, do not lift a fully-loaded Director class switch manually. Use a

mechanized lift only.

1. Align the chassis with the rack.

2. Using a pallet jack, raise the unit until the bottom of the chassis is at (or slightly

higher than) the surface of the support shelf installed in Steps 1 through 6. Lock