Integrated Visual Data Technology Inc. ED3-Zebra SkidWeigh Plus Series, ED3 SkidWeigh Plus Series, ED4-Zebra SkidWeigh Plus Series Installation & Calibration Manual

!

Installation & Calibration Manual

ED3 SkidWeigh Plus Series

Lift Truck On-board Check Weighing System with

Mobile Zebra Label Printer QLn420

ED3-Zebra V1.25

Integrated Visual Data Technology Inc. 3439 Whilabout Terrace, Oakville, Ontario, Canada L6L 0A7 www.skidweigh.com

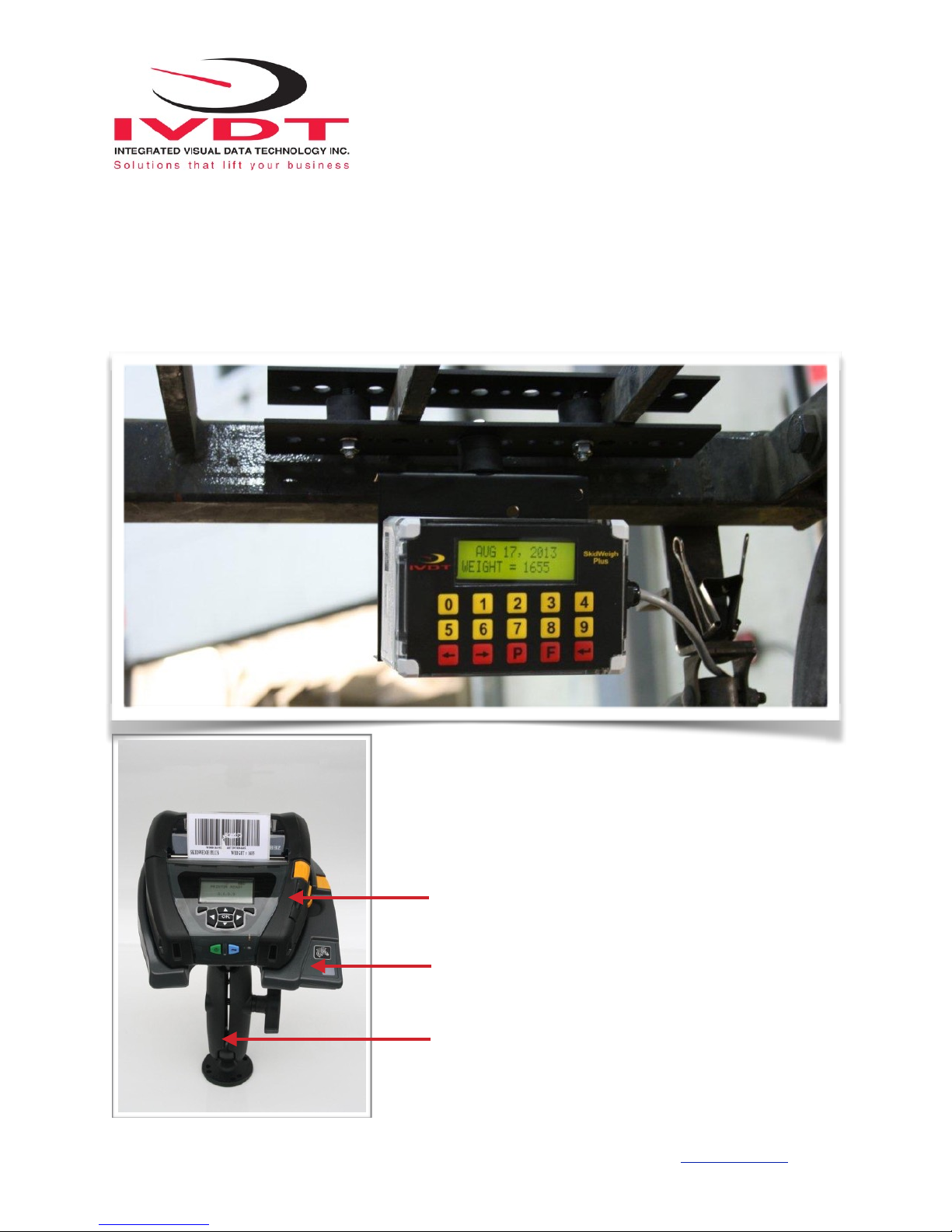

Mobile Label Printer

(Bluetooth interface with ED3 SkidWeigh Plus)

Forklift cradle

Optional Mounting

Arm

!

General Installation Guide

This ED3-Zebra SkidWeigh Plus V1.25 Series installation & calibration guide describes how to install, calibrate, test

and use your on-board check weighing unit. Following the instructions in the ADMINISTRATION MENU guide will

enable you to get the system time set up and weighing calibration function operating quickly. In the event that you require

additional assistance, please contact customer support via e-mail at support@skidweigh.com , visit www.skidweigh.com

or contact us at the address or contact number below:

Integrated Visual Data Technology Inc.

3439 Whilabout Terrace, Oakville, ON, Canada, L6L 0A7 Phone: 905-469-0985

Safety

Always disconnect the vehicle battery while installing SkidWeigh system or any other electronic product.

Make sure that unit, pressure transducer and any other associated cables are securely mounted and do not impede any

of the vehicle’s controls. Use care when routing the components cables. Route the cables where they will be protected.

Use commonly accepted install practices for after market industrial vehicle electronic devices.

The installation of the SkidWeigh systems should only be performed by an acknowledged lift truck dealer technician or

end user electro and hydraulic technical installer.

Here are two acceptable methods of making a wire connections:

* Soldering your connections (recommended)

* Crimp connectors ( with the use of the proper crimping tool)

Regardless of the method you choose, ensure that the connection is mechanically sound and properly insulated. Use

high quality electrical tape and shrink tubing where necessary. This product is connected directly to the vehicle’s ignition

switch, 12 to 55 VDC. There is no on-off switch on the unit.

Electro-Magnetic Compatibility

CE conformity to EC directive 89/336 (EMC) by application of harmonized standards: Interference stability EN 61000-6-2

and EN 61326-1 interference emit EN 61000-6-3, EN 61326-1 for the pressure transducer.

ED3-Zebra SkidWeigh Plus Series

Our policy is one of continuous improvement and the information in this document is subject to change without notice.

The software version is displayed on the LCD display once the power is turned on to the system.

Integrated Visual Data Technology Inc. 3439 Whilabout Terrace, Oakville, Ontario, Canada L6L 0A7 www.skidweigh.com

!

Overview of components

The standard ED3-Zebra SkidWeigh Plus check weighing system consist of two main components:

* Digital indicator, wiring harness, mounting bracket Option: (Zebra mobile printer QLn420 with mounting accessories)

* Hydraulic pressure transducer with 3 wires cable

* Installation & calibration manual and operator usage instruction

Operational principal

The ED3-Zebra SkidWeigh Plus series operational principal is based on the hydraulic pressure transducer mounted in

the vehicle lifting hydraulic circuit that will automatically activate the “weighing cycle / specific algorithm ” every time a

skid load is lifted just above the ground. The increase in pressure is converted in an electronic signal at the sample rate of

16000 readings which is converted into a load weight reading.

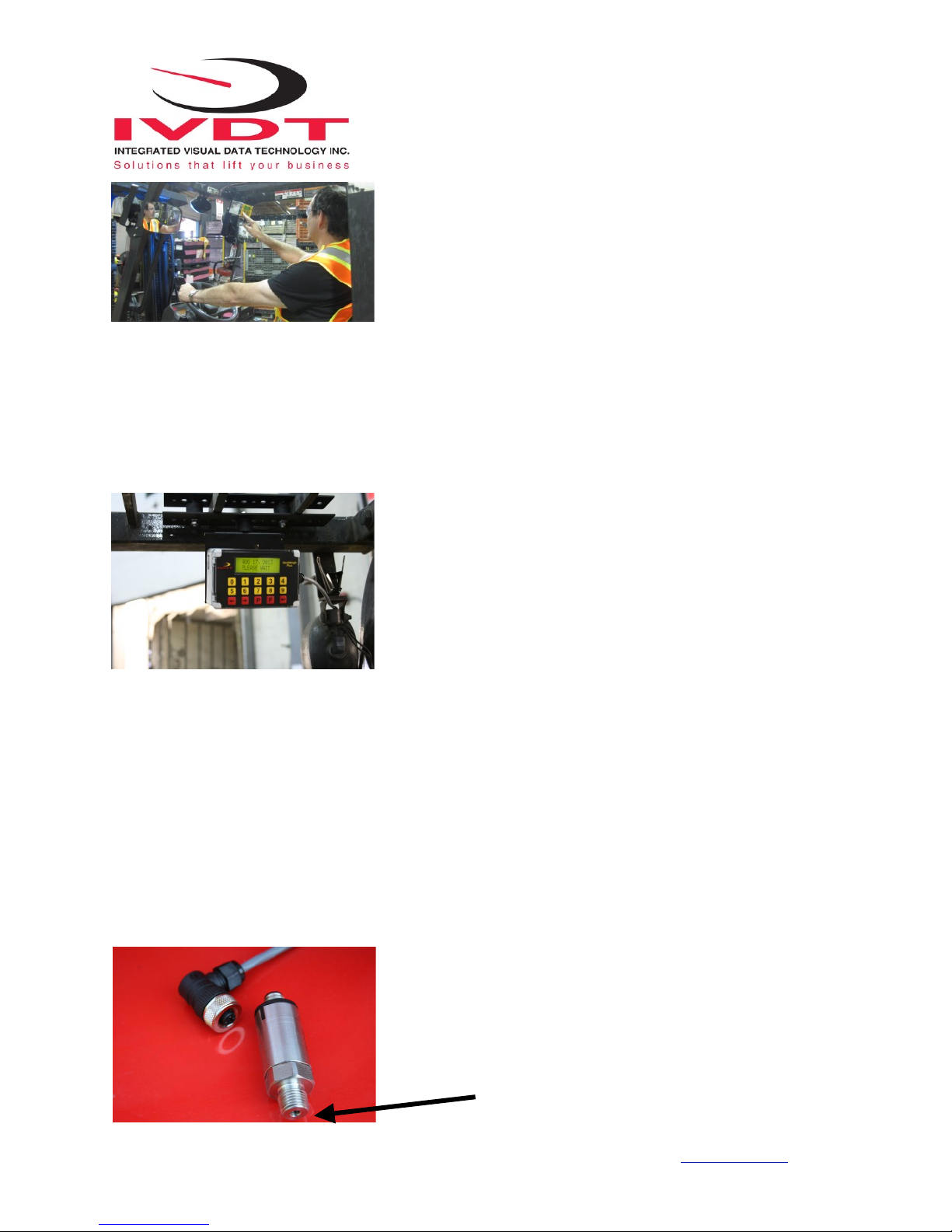

Pressure transducer installation

The pressure transducer must be installed in the lifting hydraulic line between the lift control valve and lift

cylinder(s). Mount a T-piece in hydraulic line. In some cases you can install the pressure transducer in the flow divider,

drilling and tapping for 1/4”-18 NPT male in spare plug (if only single or double

mast configuration) or in the body of the flow divider. Also, you can drill and

tap on any “larger elbow” that might be available in the hydraulic lifting circuit

found in vehicles with larger hoses to accommodate larger vehicle lifting

capacities.

Pressure transducer installation precautions

Before installation of the pressure transducer the hydraulic lift circuit must be

pressure free.

There are two ways to do that:

1. Place the forks on the ground in their lowest position and make the hydraulic system pressure free by tilting the mast

forward. The chain(s) should be slack.

2. Lift the forks and position them on the top of a supporting fixture. Start lowering the lifting cylinder into its lowest

position. Be sure that chain(s) are slack.

Make sure that that installed pressure transducer will not touch any moving parts or assembly of the vehicle while in

normal operation. Pressure transducer has 1/4”-18 NPT male thread. Use thread seal to ensure tight fit.

Selecting the mounting location for digital indicator

Use the mounting bracket with the anti vibration mount and fasten digital indicator on the vehicle dashboard, side railing

on the right hand side or preferably on the overhead guard. There are many examples of mounting locations that will

depend on the vehicle model. However, additional mounting items such as a flat brackets may be needed to help secure

the unit to upper right corner of the guard or side railing.

Integrated Visual Data Technology Inc. 3439 Whilabout Terrace, Oakville, Ontario, Canada L6L 0A7 www.skidweigh.com

!

Choose the correct location and make sure that:

- Indicator is visible and within reach of the operator

- Location so that operator has a clear unobstructed view of the working

environment

Compact size

All of the SkidWeigh systems are compact, housing dimension of only 120 x 80 x 55 mm is ideal for the installations to

material handling vehicles of all kinds.

Electrical connections

All SkidWeigh RFID equipped systems operate from 12 to 55 VDC.

Digital indicator with eight wires single cable

-

Orange Wire (+) Ignition switch On position

- Brown Wire (-) Battery negative

- Red Wire, connect to RED wire of the pressure transducer cable

- Black Wire, connect to BLACK wire of the pressure transducer

cable

- White Wire, connect to WHITE wire of the pressure transducer

cable

Vehicle Disable Function (Optional)

Internal relay SPDT dry contacts 1 A.

This relay will be activated and stay on once the valid operator ID# is inputed into the system.

To disable vehicle operation (connect two wires in series with seat switch, starting solenoid, etc.) either NO or NC

contacts. (In the majority of cases use BLUE and Green wires, N O contacts.

- Green Wire Common

- Yellow Wire N.C.

- Blue Wire N.O.

Pressure transducer cable

- White Wire, pressure transducer signal 0 to 2,5 V

- Black Wire, signal negative

- Red Wire, power supply + 11 VDC

Integrated Visual Data Technology Inc. 3439 Whilabout Terrace, Oakville, Ontario, Canada L6L 0A7 www.skidweigh.com

Male port 1/4”-18 NPT

Loading...

Loading...