Installation and operating instructions

CALEC ® energy master

The benchmark for energy

Short version

Firmw

are Version 1.00

measurement technology

VD 3-135 e, 05.2019

1 Contents

1

Contents 2

2 Information and references 3

2.1 Information 3

2.2 Documents 3

3 Safety notices 4

3.1 Symbols used 4

3.2 Intended use 4

3.3 Inappropriate use 4

3.4 Installation guidelines 5

4 View of device with protective housing 6

5 View of device without protective housing

(Mod) 7

6 Mounting the device with protective

housing (Prot) 8

6.1 Scope of supply, tools and mounting

material (Prot) 8

6.2 Installation (Prot) 8

7 Mounting the device without protective

housing (Mod) 12

7.1.1 Rail mounting 12

7.1.2 Connecting to mains power supply

230 VAC 12

7.1.3 Connecting to low voltage supply 24

VDC 13

7.1.4 Connecting signal cables 13

9 Operation 16

9.1 PC-Software AMBUS Win II 16

9.2 Display 16

9.2.1 Key functions 17

9.3 Right of access, security levels 17

10 Menu overview 18

10.1 Main display and main menu 18

10.2 Submenus 19

11 Use under operating conditions 21

11.1 The main display 21

11.2 The measured values submenu 22

11.2.1 Measured values 22

11.2.2 Meter readings 22

11.2.3 Current values 22

11.2.4 Billing date values 22

11.2.5 Logger values 22

12 Dimensional drawings and technical

specifications 23

12.1 Drawings of device with protective

housing (Prot) 23

12.2 Drawings of device without protective

housing (Mod) 23

12.3 Technical specifications 13

Declaration of conformity

25

28

8 Electrical connections 14

8.1 Connection instructions 14

8.2 Wiring diagram, module and signal

numbers 14

8.3 Numbering rules 15

CALEC® energy master installation and operating instructions 2

2 Information and references

2.1 Information

These installation and operating instructions describe the installation and commissioning of a standard device. The chapters describe the topics and tasks in the sequence in which they are needed

during commissioning.

•

Safety instructions

• Information about the device

• Installation

• Electrical connections

• Operation

• Fault

• Technical data

clearan

ce

Always co

mply with the safety instructions.

2.2 Documents

The installation and operating instructions VD 3-135 vary in scope, depending on the version and

items covered by the delivery. The information required for ancillary modules and optional functions

is described in additional document extracts (VD 3-136).

Parameterisation software AMBUS Win II

The parameterisation software AMBUS Win II is available for setting the parameters. It can be

downloaded free of charge (see below).

Downloads

The current documents and AMBUS Win II are available as free downloads at

www.aquametro.com /downloads.

CALEC® energy master installation and operating instructions 3

3 Safety notices

3.1 Symbols used

Important information

Non-observance can le

General warning

Non-observance can le

Warning of dangerous electric voltage

Non-observance can le

ad to malfunction.

ad to damage or malfunction.

ad to physical injury!

3.2 Intended use

The device is used as an energy calculator for heating, cooling and air conditioning applications in

district heating or cooling, in building management services and in industrial energy metering.

It is part of a combined heating/cooling or air conditioning meter, consisting of a calculator, a pair of

temperature sensors and a flow meter, or as a transducer for a flow meter.

The environmental conditions described in the technical specifications, as well as the installation and

operating instructions must be complied with.

3.3 Inappropriate use

The device must not be used:

In explosion-risk zone

•

• In a wet environment (condensing, splashing or dripping water)

•

Outdoors, without suitable protection

• In environmental conditions (temperature, humidity, vibrations, electromagnetic interference etc.) that do not comply with the technical specifications

• In all other instances that do not conform to its intended use

The device can be dangerous if it is not used as intended, or not in accordance with the installation

and operating instructions. In order to avoid this, it is essential that the safety instructions, operating

conditions (see technical specifications) and the relevant chapters of these instructions are strictly

adhered to.

The manufacturer accepts no liability for damage arising from inappropriate use.

s (no ex-risk protection!)

4 CALEC® energy master installation and operating

3.4 Installation guidelines

The installation should be performed by authorised, skilled p

the regulations in force (EN1434 part 6 Regulations and recommendations for installation

and operation) and the recommendations of the industry-specific associations (e.g. the

AGFW series of leaflets on district heating supplies).

The skilled personnel must have read and understood these instructions

ments in the instructions and the applicable regulations on electrical installations must always be observed.

Work on electrical circu

carried out by authorised, skilled people, in compliance with the locally applicable regulations!

its with hazardous voltages (> 24 VAC or >42 VDC) may only be

ersonnel, in compliance with

. The require-

CALEC® energy master installation and operating instructions 5

4 View of device with protective housing

Device with closed protective housin

1 Housing cover

2 Operating keys

3 Dot-matrix LCD

4 Type plate with CE marking

5 IR interface on display module

(EN13757-2 / -3 M-Bus)

IrDA interface on CPU module

6 Housing screws, covered by security sealing

caps

Device with opened protective housing

Operating keys

2

3 Display, LCD dot matrix

5

IR interface (EN13757-2 / -3 M-Bus)

IrDA interface

7 Display module

8a Upper terminals, plug-in

8b Lower terminals, plug-in

9 Clip-on holder for modules

10 3 Fastening holes for wall mounting

11 Clip-on holder for rail mounting

12 Strain relief

13 Cover hinges

g

The wiring diagram is on the inside of the housing cover.

View of the protective housing from below

Clip for rail

11

14 Cable duct supply 14 mm

15

Cable ducts 10 mm

16 Cable ducts 14 mm

6 CALEC® energy master installation and operating

5 View of device without protective housing (Mod)

The following diagram shows the device without protective housing.

2 Operating keys

3 Display, LCD dot matrix

IR interface (EN13757-2 / -3 M-Bus)

5

IrDA interface

7 Display module

8a Upper terminals, plug-in

8b Lower terminals, plug-in

9 Clip-on holder for modules

The Display can be installed at a remote location e.g. in a control panel by using the two

Remote Display Adapters:

11

12

13

11

Remote Dis

RDA/CPU

12 Remote Display Adapter

RDA/Display

13 Network cable

p

lay Adapter

CALEC® energy master installation and operating instructions 7

6 Mounting the device with protective housing (Prot)

6.1 Scope of supply, tools and mounting material (Prot)

Warning! Precision measuring devices! Protect against heat, humidity, dirt and vibra-

tion. Only unpack the d

age or malfunction.

evice when ready to install. Non-observance can result in dam-

• One Installation and Operating Instructions manual

1) Support rail optional

6.2 Installation (Prot)

Opening the housing

8 CALEC® energy master installation and operating

Mounting on support rail (DIN-EN 50222)

Choose the location for installation

• which is protected against humidity, heat, direct sunlight and damage

• with easy access for reading, operation and installation

• with sufficient distance from sources of electromagnetic interference

1. Drill holes

2. Screw on support rail

3. Clip device onto support

rail

Wall mounting

Remove clip-on holder

to get a stable support.

Only mount device on a

flat surface!

CALEC® energy master installation and operating instructions 9

Wiring diagram

The wiring diagram is on the

inside of the housing cover.

Connecting to mains power supply 100 - 240 VAC

The mains supply must be connected via a two-pole separator and be adequately protected

against unauthorised interruption.

The mains supply 100 - 240 VAC

may only be connected to the following terminals:

The device must be protected by a 10 AT external fuse.

The device is fully isolated and requires no grounding connections.

Connection to other terminals is extremely dangerous and can permanently dam-

age the instrument!

Connecting to low volt

age supply 24 VDC

Terminals L, N (supply module)

Terminals 110, 115 (relay module 2

VAC)

x240

10 CALEC® energy master installation and operating

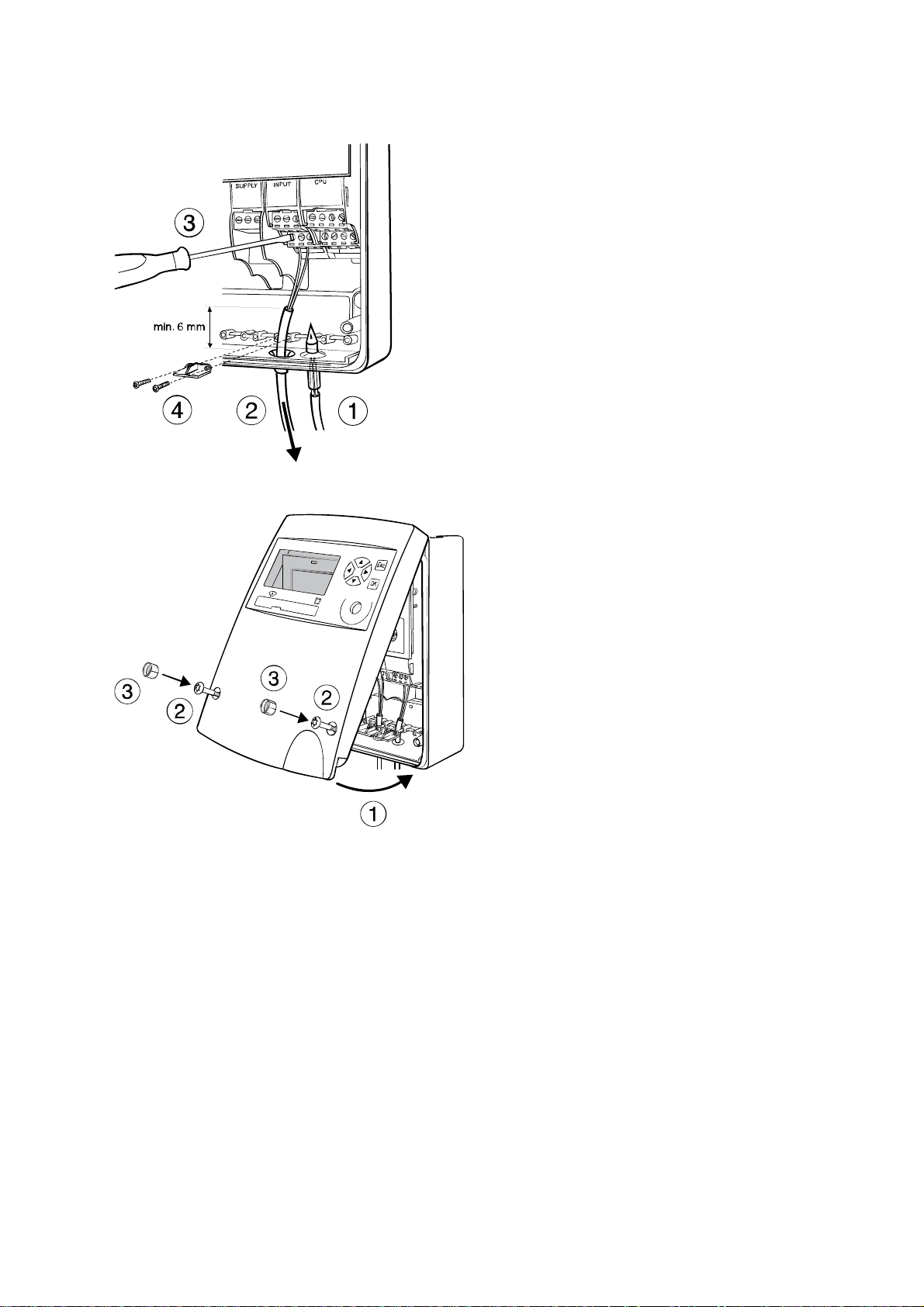

Connecting signal cables

Closing housing

1.

Pierce sealing membra

ne with en-

closed awl

2. Insert

cable

3. Attach cable to terminal screws

according to wiring diagram on the

inside cove

4.

Affix strain relief clamp

r

1. Insert the cover into the hinge from

above and turn to close

2. Tighten the two fixing screws

3. Engage the security sealing caps

with the smooth side on the outside.

Once the caps e

have been fitted,

any unauthorised opening of the device can be detected.

Removing the caps:

Insert a pointed tool and lever out.

The cap is damaged as a result and

must be replaced.

CALEC® energy master installation and operating instructions 11

7 Mounting the device without protective housing (Mod)

7.1.1 Rail mounting

1. Drill fastening holes

2. Screw on support rail

3. Clip modules onto support

rail

7.1.2 Connecting to mains power supply 230 VAC

Refer to the wiring diagram before starting wiring!

The mains supply may only be connected to terminals L and N!

The device is fully isolated and requires no grounding connections.

All other terminals are only for low voltage (<50 V) and measuring signals. Connection

to these terminals is extremely dangerous and can permanently damage the instrument!

1. Strip the power cable as

shown in drawing.

2. Connect power cable to

supply module (see enclosed wiring diagram)

12 CALEC® energy master installation and operating

7.1.3 Connecting to low voltage supply 24 VDC

7.1.4 Connecting signal cables

1. Strip cable as shown in

drawing

2.

Attach cable to the connect module (see enclosed wirin

1. Attach signal cables to

terminal screws according to enclosed wiring

diagram

g diagram)

2. The terminal blocks can

be plugged in.

CALEC® energy master installation and operating instructions 13

8 Electrical connections

8.1 Connection instructions

Devices with 100 - 240 VAC connections must have a safety fuse with a max. 10 AT, and

must be capable of being made voltage-free by means of an isolating element!

The device must be connected to the same electric circuit and the same fusing, switching

and isolating elements as the corresponding heating or cooling system.

If the device is additionally connected via fusing, switching and isolating elements, then

these must be protected against unauthorised access (e.g. by security seals), so that the

device cannot be put out of operation by unauthorised persons.

8.2 Wiring diagram, module and signal numbers

Below are two examples of wiring diagrams in which the module numbers and signal numbers or signal designations are shown:

Basic unit with 3 modules (right

to left): M-101-Prot-AC[I]-CT

• CPU module 2 x Pt100

• Input module for flow sig-

nal

• Mains power supply (supply module)

• Designation:

• Module numbers

• Signal designation accord-

ing to standard diagram of

the application

Input

Qv, Qv1

Qv2, STA

CPU

Modul 1Modul 2

Th

Tc

Fully assembled unit with 7 modules (right to left):

EM-101-Prot-AC[MMOOI]-CT

• CPU module 2 x Pt100

• Input module for flow signal

• 2 output modules for 4 analogue output signals, e.g. for a

building services management system

• 2 M-Bus modules for data reading with 2 M-Bus master units

• Mains power supply (supply module)

• Designation:

• Signal numbers, without signal designation

• Signal designation according to the standard diagram of the

application

M-Bus M-Bus Output Output Input CPU

Modul 1Modul 2Modul 3Modul 4Modul 5Modul 6

Schnittst.1Schnittst.2

Ausgang 3

Ausgang 4

Ausgang 1

Ausgang 2

Eingang 1

Eingang 2

Pt100 1

Pt100 2

Note on input module: Left-hand pair of terminals: Power via calculator

Right-hand pair of terminals: External supply

14 CALEC® energy master installation and operating

8.3 Numbering rules

Basic rule: The signals are numbered from right to left and f

rom the top down.

This table shows the elements that have a number, and their maximum number.

Element Display/number Explanation

Module Mod-No.1… 6 (Prot) *

Mod-No.1…15 (Mod) *

Input Input 1…8 Pulse, current or frequency signal

Pt100 input Pt100 No.1…6 Pt100 inputs for temperature measurement

Output Output 1…8 (Prot) *

Output 1…12 (Mod)

Terminals Trm.No. 82-10-11 See terminal marking

Tariff register R1 … R4 4 tariff registers per active calculator

Interfaces Interface 1 … 5 1 Internal bus between the modules

Numbers according to assembly from right to left

No. 1 is the CPU module

The module for power supply has no number

Output 1 …8, (short designation e.g. A1)

Output 9 …12 can be used virtually

Display example: R 1 A2+

Tariff register 1 is active when output 2 is switched on.

2 Optical M-Bus interface in the display module

3 IrDA interface in the CPU module

4 M-Bus module 1

5 M-Bus module 2

*: Prot: Device version with protective housing

Mod: Device version without protective housing

CALEC® energy master installation and operating instructions 15

9 Operation

9.1 PC-Software AMBUS Win II

The parameters of the device can be set both via keys and display and via one of the data interfaces

with the PC parameterising software AMBUS Win II.

With AMBUS Win II, the meter reading data can be saved, and parameter settings that have to be

executed repeatedly can be stored as macros, which can then be reloaded and run. AMBUS Win II

and the associated operating instructions can be downloaded free of charge at www.aquametro.com.

The use of AMBUS Win II offers advantages if:

• large data records have to be read,

• several devices require identical or similar parameter settings,

• complex applications with inputs/outputs are to be parameterized.

AMBUS Win II and instructions are available as free downloads at www.aquametro.com.

9.2 Display

3

1

1 Operating keys

see section 9.2.1 Key functions.

IR interface, M-Bus

2

4

3 LCD display, dot matrix 128 x 64

(see section 18.3)

5

4 Title for display window

5 Display field, up to 4 values with

6

2

Symbols on t

, , no lock

he status bar

identification and units

6 Status bar

Currently available keys

A flow signal is being

Edit mode active, input possible

Protection level (see section 0)

user, service, programming mode

detected

16 CALEC® energy master installation and operating

9.2.1 Key functions

Keys Function in display mode Function in edit mode

Move line/image up or down

Setting of figures and/or characters

Selection from a preset list

No function in the main menu

Change channel / input / output

Change billing date / logger period

Keys Short ( < 0.5 s ) Long ( > 0.5 s ) Key operation

Confirm

Back to a pre

abort process

vious level,

Activate/deactivate the 3 additional decimal points in the

meter settings

Back to the standard display Abort input / selection

Select setting position in the edit window

Change list inside a double-list

Accept set value

Accept selected value

Finish edit mode

In double list: finish process

9.3 Right of access, security levels

The parameters for the device can be set entirely via the keys or via the interfaces. The security level

(lock level) determines which parameters can be altered. At the time of delivery, the devices are in

user mode.

Symbol Security level Settings Code At delivery

User mode Only operating language

All values that are not relevant for calibration,

e.g. initial parameter settings, date/time, measuring point designation etc.

All parameters can be set, e.g. initial settings,

resetting/synchronising of meter readings etc.

S-Code 1111

P-Code 3132

no lock

Service mode

Programming

mode

The codes can be chang

In EU-compliant devices, activating p

ed in the Basic setting/System submenu.

rogramme mode will result in the invalidation of the

calibration! The date and time will be recorded in the calibration log and the device displays an error.

Warning: If you change a code, make sure that you keep it in a safe place. If the code

ist lost

CALEC® energy master installation and operating instructions 17

, reprogramming is necessary by a service technician on site or in the factory.

10 Menu overview

10.1 Main display and main menu

The content and sequence of the main display may vary.

The diagram shows, by way of example, the status of a heat meter on delivery.

The content and sequence of the main display may vary.

The diagram shows, by way of example, the status of a heat meter on delivery.

18 CALEC® energy master installation and operating

10.2 Submenus

p

g

mode

eratin

Overview Submenu Measured values

CALEC® energy master installation and operating instructions 19

Overview Submenu O

g

These parameters are only displayed if they are relevant for the selected function

Overview Submenu Basic settin

20 CALEC® energy master installation and operating

Overview Submenu Diagnosis

11 Use under operating conditions

11.1 The main display

Start

Main display

ImpVal 1.00000 L

Side Q cold side

C.-Dat. 21.04.09

Valid 31.12.13

After switching on the device, the page

marked ‘start’ of the main display appears.

The arrow keys can be used to move

between a maximum of 4 pages of the

main display:

1: Calibration-relevant data

2: Meter readings and designation

3: Current values

4: other values, if configured

Segment test (display test)

Error display

Main menu

The segment test shows a chequerboard pattern to test the display.

In the error message window, an error

message is displayed if an error occurs

In the main menu, the submenus can

be selected and displayed to show or

set further values.

If no operation is carried out for

Submenus

approx. 5 min., the device will display

the main menu page marked ‘Start’.

Notes:

The content of the main display depends on the device version. The main display can contain up to

four pages with up to four values (i.e. up to 16 values). In standard CALEC

®

energy master devices,

only three pages are displayed with the values shown above.

The display values of the main display are predefined at delivery. These values and their sequence

can be altered in a non-CE conformity assessed device using the software AMBUS Win II.

CALEC® energy master installation and operating instructions 21

11.2 The measured values submenu

11.2.1 Measured values

Measured values

Meter readings Meter readings for energy, volume (mass)

Current values Current values: temperatures, volume/mass flow rates, power

Billing date 1 values Meter readings on the set billing dates

Billing date 2 values

Logger values Meter readin gs per calculator at the set times

11.2.2 Meter readings

Meter Display calc1, calc2 and 3 Explanation

Energy E E 2: E

2: EVolume V, V- 2: V, 2: V- 3: V, 3: V- Volume meter reading, E, E- respectively

Mass M, M- 2: M, 2: M- 3: M, 3: M- Mass meter reading E, E- respectively

11.2.3 Current values

Current value Display Explanation

Power P Thermal power

Volume flow Qv Volume flow rate

Mass flow Qm Mass flow rate

Temperatures Th, Tc Temperature of the heat transfer medium hot / cold side

Temp. difference dT Temperature difference: dT = Th - Tc

Density Den Density of the heat transfer medium (Den: Density)

K-factor K-F Heat coefficient

Enthalpy Hh, Hc Enthalpy of the heat transfer medium hot / cold side

Current values of calc2 and 3, or with a negative prefix, are displayed similarly ( 2: P or P- ).

If a current value exceeds 999 999 (6 digits), Overflow is displayed

3: E

3: E-

Energy meter reading, positive

Energy meter reading negative, in options BDE / BDV

11.2.4 Billing date values

Shows the meter readings saved on the two set billing dates. The billing dates can be set under

Operating settings/time settings/Billing and Billing2. The meter readings are saved at 23:59 each

time.

11.2.5 Logger values

In version 1.0, only the meter readings can be recorded.

Logger values 1 1. Logger value, select with keys

Date/T 01.05.08

E 24.567 MWh Energy meter reading at this time

V 1000.12 m3 Volume meter reading at this time

M 982.1 t Mass meter reading at this time

M 982.1 t Mass meter reading at the displayed time

22 CALEC® energy master installation and operating

Date/time when the value was chosen

The time interval for the logger

function can be set under

Operating settings/

Time settings/Logger

.

12 Dimensional drawings and technical specifications

12.1 Drawings of device with protective housing (Prot)

12.2 Drawings of device without protective housing (Mod)

CALEC® energy master installation and operating instructions 23

Dimensional drawings of modules with low voltage

Massbilder Module mit Netzspannung

In supply module 100-240 VAC and output module 2 x relays 240 VAC, the terminals are protected

against accidental contact by two lateral partition walls.

Dimensional drawing of display module

The dimensions in the diagram refer to the size

of the section.

Dimensions of the module are:

W x H x D: 132 x 72 x 7.8 mm

24 CALEC® energy master installation and operating

12.3 Technical specifications

Standards

CE Directives

Standards EN 1434, EN 61000-6-2, EN 61000-6-3, EN 60950

EC comformity assessment Module B, DE-07-MI004-PTB029

2014/32/EU (MID) Measuring Instruments Directive

2014/130/EU (EMC) Electromagnetic compatibility

2014/35/EU (LVD) Low voltage directive

Housing, modules With protecti

Mounting On support rail or wall On support rail

Protective housing size W x H x D 140 x 202 x 83 mm

Module housing size W x H x D 3 poles: 17.5 x 117.4 x 63.5 mm

Type of ingress protection according to EN60529

Maximum number of modules

Environmental conditions

Ambient temperature during operation

Storage temperature 0 °C … 60 °C

Humidity Max. 95% rel. humidity, without producing condensation

Cable cross-sections

Power supply 0.8 …2.5 mm2

Pulses, frequency, analogue 0.35 …2.5 mm2

Pt100 0.8 … 2.5 mm2 (preferably large)

IP54 IP20

6 – 7, including 1 CPU

and 1 supply module,

max. 2 communications

modules

+ 5… +55 °C, EN 1434 class C

ve housing Without protective housing

3 poles: 240 V: 17.5 x 129.5 x 63.5 mm

4 poles: 22.5 x 117.4 x 63.5 mm

16, including 1 CPU and 1 supply

module,

max. 2 communications modules

Power supply Supply module 100-240VAC

Nominal voltage 100 … 240 VAC, 50 … 60 Hz

Operating voltage 86 … 265 VAC, 47 … 63 Hz

Current input Max. 300 mA

Protection class II

Isolat.-voltage primary/secondary 3000 VAC

additional approvals UL 60950, EN 60950 (via CSA-NRTL/C)

CPU module 2*Pt100

Accuracy of energy calculation Energy error in % Ec <= 20 mK / ∆T (mK)

Significantly below EN 1434-1: Ec <= 0.5% + (∆T/∆Tmin)

∆T [K] Ec CALEC energy master Ec EN 1434-1

3 0.7% 1.5%

6 0.3% 1%

20 0.07% 0.65%

100 0.02% 0.53%

CALEC® energy master installation and operating instructions 25

CPU module 2*Pt100

Data backup in case of

EEPROM > 10 years

power failure

Backup battery (button cell) Lithium 3 V, 48 mAh, Type CR1225, soldered

Life of backup battery Typically >10 years in normal operation (T < 45 °C)

Typically > 6 years without mains supply

Data logger 100 values of all meter readings with time stamp in the ring memory

Logger interval: 15 min.., 30 min., 1 hr., 1 day, 15 days, 1 month

Billing dates 2 billing dates, dates adjustable

Optical interface IrDA V1.0 with 57600 baud and M-Bus protocol, max. distance 70 m

Measuring and calculating cycle 1 second

Temperature measurement CPU-module 2*Pt100 and Input-module 2*Pt100

Temperature range

Temperature deviation

Temperature differential range

Deviation ∆T ( Ta = 5 … 55°C )

-50 … +550 °C according to MID/EN1434: 1 … 200 °C

< ± 10 mK

0 … 550 K according to MID/EN1434: 3 … 198 K

< ± 15 mK

Temperature sensor type Pt 100 (IEC751, paired according to EN1434 ), 2-, 3- or 4-wire cable

Resolution ADC 24 Bit

Display module

Dimensions W x H x D 132 x 72 x 7.8 mm

Dimension of cut-out W x H 128 x 68 mm

Display Alphanumeric LCD, 128 x 64 pixel

Backlight White, flashes red when fault occurs

Display Title bar, 4 lines each of 21 characters, status line

Language Settable: German, English, French, Italian

Keys 6 keys: 4 arrow keys for navigation, OK, Esc

Detachable display module Max 100 m with Remote Display Adapters (RDA)

Optical interface

IEC 870-5, 300, 2400 or 9600 baud, M-Bus protocol

( Display module)

Input-Module 2*Pulse/frequency/analogue

Number of inputs 2

Pulse input Pulse input: 0.003 … 12.5 kHz

Min. pulse width 40 µs

Types settable according to EN 1434, see below

Frequency input Frequency input 0 … 10 kHz (PFM)

Measuring error: typ. < 0.1%

Analogue input Measuring range 0 or 4 … 20 mA

absolute measuring range 0 … 22 mA

Accuracy 0.025% full scale, drift 15ppm / K

Load

50 Ω

Measuring transducer power supply 24V

26 CALEC® energy master installation and operating

Input-Module 2*Pulse/frequency/analogue

Measuring transducer

6, 8 or 24 VDC, settable, max. 25 mA, short-circuit proof

power supply

Error detection Short circuit and interruption (settable)

Pulse input ty

pe according to EN 1434

Max. pulse fr

eq. Pulse length Input resistance Ri

Meas. transducer

power supply

Class IB 5Hz ≥ 100 ms 100 kΩ 6 V

Class IC 200 Hz ≥ 2 ms 100 kΩ 6 V

Class ID 200 Hz ≥ 2 ms 1 kΩ 8 V

Class IE 12.5 kHz ≥ 0.04 ms 1 kΩ 8 V

PFM 12.5 kHz ≥ 0.04 ms 150 Ω 24 V

Switching level: low < 1.5 V, high > 2.1 V, 0.6 V Hysteresis

Output module 2*relays 24V, analogue

Number of outputs Two

Output type settable Relay functions: Pulse / status / limit value / limit value 2

Analogue functions: 0 … 20 mA / 4 … 20 mA

Test functions: Relay test / analogue test

Relay output (solid state relay) Max. contact voltage: 24 VDC

Max. current: 100 mA

Frequency: max. 50 Hz at *

* Pulse width: 10 ms, 50 ms, 250 ms, 1 s, settable

Duty cycle: 50%

Normal state: Contact closed or open, settable

Leak current: < 30 µA corresp. to > 800 kOhm at 24 VDC

Analogue output Current range 0 … 20 mA or 4 … 20 mA

Accuracy 0.1% full scale, drift 50 ppm / K

Max. load R = (Uext - 4V) / 22 mA

Galvanic isolation 50 V

Measuring transducer power sup-

24 VDC, max. 25 mA, short-circuit proof

ply

M-Bus module M-Bus interface EN1434-3, 2007

Transmission rate 300, 2400, 9600 Baud

Current requirements 1.5 mA (1 M-Bus load)

Addressing Point-to-point, primary address, secondary address

One address per active calculator (max. 3)

Galvanic isolation Max. 50 V

CALEC® energy master installation and operating instructions 27

13 Declaration of conformity

28 CALEC® e

nergy master installation and operating

info@integra-metering.com

www.integra-metering.com

Änderungen vorbehalten / Sous réserve de modifications / Modification rights reserved

Copyright © INTEGRA METERING AG, Switzerland

Art.Nr. 20765

Loading...

Loading...