Operating instructions

AMBUS®Net

Software versions 1.01.xx

VD 9-905e 02.2011

2

Table of contents

1

Introduction ................................................................................................................................................ 3

1.1 Applications ........................................................................................................................................... 3

2 Components ............................................................................................................................................... 4

2.1 Housing and power supply .................................................................................................................... 4

2.2 Processor .............................................................................................................................................. 4

2.3 Interfaces .............................................................................................................................................. 4

2.4 Technical data of interfaces .................................................................................................................. 5

2.5 Memory board and serial flash .............................................................................................................. 6

2.6 Multilingual feature with HTML tags ...................................................................................................... 6

2.7 Communication and security................................................................................................................. 7

2.8 Versions ................................................................................................................................................ 8

2.9 Open architecture ................................................................................................................................. 8

3 Commissioning .......................................................................................................................................... 9

3.1 Power supply and display ..................................................................................................................... 9

3.2 Basic setting of AMBUS® Net............................................................................................................... 9

3.3 Meter list, commissioning the M-Bus and automatic meter search .................................................... 11

3.4 Network (Windows) ............................................................................................................................. 13

3.5 Communication via modem ................................................................................................................ 16

3.6 Data logger / CF card .......................................................................................................................... 19

4 Operation .................................................................................................................................................. 20

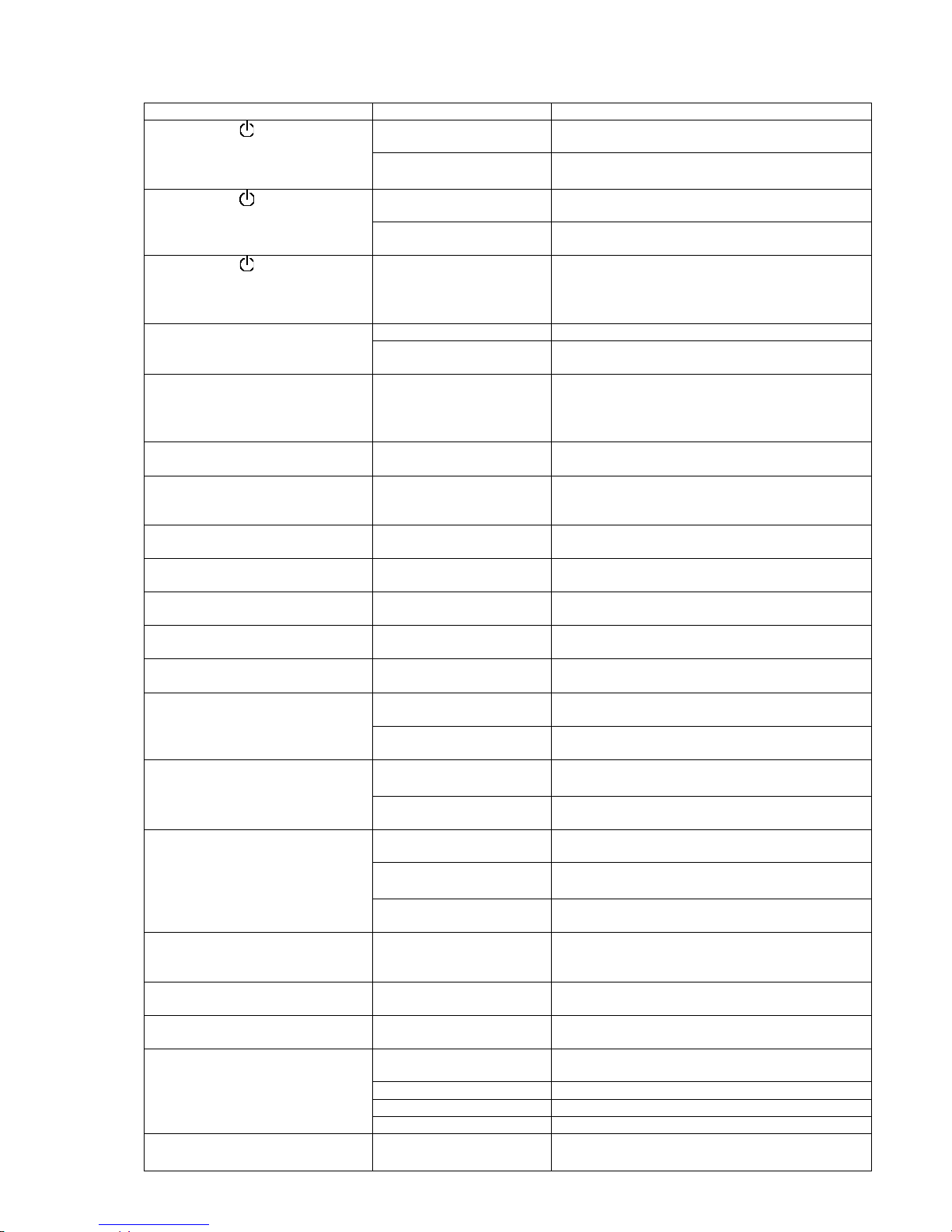

4.1 Summary of menu .............................................................................................................................. 20

4.2 Status message and general alarm .................................................................................................... 20

4.3 Reading the meter .............................................................................................................................. 21

4.4 The usage units .................................................................................................................................. 21

4.5 Monitoring the meters: the analysis usage unit ................................................................................... 23

4.6 Data logger (optional) ......................................................................................................................... 24

4.7 Meter list, manual meter readings ...................................................................................................... 26

5 Remote operation and system integration ............................................................................................ 29

5.1 SOAP: Creating a client with .Net ....................................................................................................... 29

5.2 Download protocol .............................................................................................................................. 32

6 Troubleshooting ...................................................................................................................................... 33

7 Appendix .................................................................................................................................................. 35

T

ABLE 1: SPECIFICATIONS OF HOUSING AND POWER SUPPLY .................................................................................. 4

TABLE 2: OVERVIEW OF INTERFACES ..................................................................................................................... 5

TABLE 3: COMMUNICATION AND SECURITY.............................................................................................................. 7

TABLE 4: SPECIFICATIONS FOR VERSIONS .............................................................................................................. 8

TABLE 5: SPECIFICATIONS FOR OPTIONS ................................................................................................................ 8

TABLE 6: TROUBLESHOOTING .............................................................................................................................. 34

TABLE 7: EXAMPLE OF METER PROTOCOL ............................................................................................................. 35

TABLE 8: EXAMPLE OF USAGE UNIT PROTOCOL .................................................................................................... 36

TABLE 9: EXAMPLE INSTALLATION PROTOCOL ....................................................................................................... 37

3

1 Introduction

AMBUS® Net is an integrated extension of AMBUS

®

ZS and enables intelligent M-Bus central units to be

configured, operated and monitored by M-Bus plants as complete systems with state-of-the-art technology

and customer-friendly operation.

The ¼ VGA touch screen display ensures easy-to-handle on-site operation without the need of a PC.

Because it contains a Web server, the instrument can also be remotely operated via either a direct telephone

link (analog, ISDN or GSM) or an Intranet/Internet network. It can be operated with every Java-supported

Web browser which reproduces the operating display of the instruments and allows protocol files to be downloaded (optional).

Existing plants can be updated very simply or else expanded as required, since AMBUS

®

Net is totally com-

patible with the earlier AMBUS

®

FA system and can also be updated to become an AMBUS® M-Bus central

device.

Features

• M-Bus central device with integrated Web server

• Capacity for up to 120 or 250 M-Bus meters

• 5.7“ LCD touch screen and plain text in various languages

• Data logger for optional plug-in data memory

• 10 MB Ethernet interface via RJ-45

• For integrating telephone modems (PSTN, ISDN, GSM) with RJ-45 / Antenna (optional)

• RS232 and RS485 interface

• 2 relay contacts for error handling and communication control

• Protocols: TCP/IP, ARP, ICMP, HTTP, HTML, PPP, LCP, IPCP, PAP, SOAP/XML, WSDL

1.1 Applications

The fields of applications of the AMBUS® Net range from analytical building management for invoicing services to facility management and domestic systems. It can be installed wherever a simple and cost-effective

solution is required for on-site operation or remote monitoring.

AMBUS

®

Net is an Internet-compatible M-Bus central device with state-of-the-art technology for the following

applications:

AMBUS® Net as a modern remote display

AMBUS® Net supplies on-site readings from all meters connected to an M-Bus (Meter-Bus) network. For the

first time an instrument of this class is able to offer a 5.7“ LCD touch screen with an easy, self-explanatory

procedure in your own particular language.

Readings require no PC, no special reading program and no interface cable.

Using the data logger option:

The data can also be optionally recorded on a compact flash memory board for later evaluation on a PC.

AMBUS® Net as M-Bus Internet gateway

With AMBUS® Net your data is now online. The AMBUS® Net links M-Bus and Web technologies in an ideal

combination. As an M-Bus/Internet gateway, the AMBUS

®

Net supplies M-Bus data in seconds to your work-

station from meters recording water, heat, gas and electricity.

Using a standard Java Internet browser and a direct modem connection, the AMBUS

®

Net can be remotely

operated or data can be downloaded as an Excel-compatible file and later exported to a billing system.

The data is also automatically read and processed using software with a SOAP (XML) interface.

4

2 Components

2.1 Housing and power supply

AMBUS® Net is protected by a rugged, red-lacquered aluminium pressure die-cast housing for wall or control

cabinet mounting. The power supply is a 230 VAC mains voltage.

For information on installation refer to the installation instructions AMBUS

®

Net

The power supply is a 230 VAC/50 Hz mains voltage only.

An LED indicates stand-by after the instrument is switched on. As soon as AMBUS

®

Net is connected to the

power supply, the device automatically runs through a start routine for initializing all integrated modules.

Display

5.7“ LCD touch screen, grey scale

Power supply voltage

230 VAC (+10, -15 %) / 50..60 Hz

Max. power consumption

2..110 VA (depending on the number of M-Bus devices installed)

Ambient temperature

5 ... 50 °C

Housing

Cast aluminium, red lacquered

Dimensions

B x H x D = 240 x 160 x 66 mm

Weight

Approx. 3.3 kg

Ingress Protection class

IP 20

Table 1: Specifications of housing and power supply

2.2 Processor

As an "embedded controller", AMBUS® Net is a high-performance device with a 32-bit RISC controller,

25 MHz, 380 KB of flash memory and 2 MB RAM. A certified, real-time operating system monitors the correct

functioning of the unit. AMBUS

®

Net is also equipped with a real-time clock and a buffer with a button cell

battery to secure data against power failure.

2.3 Interfaces

AMBUS® Net is composed of the ZS and the Net

module.

The ZS module has an M-Bus level converter, a

power supply for the M-Bus network with (2- or 4wire) auxiliary power supply and the M-Bus repeater. It has interfaces to the M-Bus, to any higher M-Bus master, one RS232 output,

one RS485 output and 2 relay outputs.

See also the installation instructions

for AMBUS® Net

The Net module consists of the display (touch

screen), the processor for evaluating the data and

slots for an optional modem and memory board.

Each is equipped with an Ethernet, telephone and

RS232 interface.

5

Ethernet network

AMBUS® Net is an Internet-supported device and can be connected to a network (LAN, Local Area Network)

via the Ethernet RJ-45 interface. It works at a speed of 10 Mbit/s.

Two LEDs on the pc board indicate if it is linked to the network (for diagnosis and only visible when the instrument is opened):

LED

Significance

LINK

Network correctly connected

LAN

Data being transmitted

Modem

AMBUS®Net is a modular system. It may be fitted with

the following modems: PSTN modem (analog), ISDN

modem and GSM modem.

The analog and ISDN modem can be connected to a

telephone network via the RJ 45 socket. For the antenna

of the GSM modem a screw connection comes from the

housing (type FME / quasi standard of cellular phones in

vehicles).

Analog modem

ISDN modem

GSM modem

Front and rear view of the

modem: The SIM board is

located on the back in the

SIM board reader

GSM modem antenna

The enclosed adhesive antenna with approx. 3 m cab

le is

suitable for mounting in a location with good radio reception (e.g. at a window).

2.4 Technical data of interfaces

M-Bus installation

2- or 4-wire system

Meter power supply (4-wire M-Bus)

15 VAC, ± 20 %

M-Bus data transmission rate

300, 2400, 9600 Baud; combination also possible

M-Bus repeater

yes, 1 M-Bus load

Ethernet

10 MB, RJ-45

Telephone modem

PSTN V.92, RJ-45 (analog modem), 56 kBit/s

ISDN, RJ-45, 64 kBit/s

GSM (dual band 900/1800 MHz) 9.6 kBit/s

Memory board

Compact flash card type 1 with 16 MB - 2 GB storage capacity

M-Bus direct connection

RS232, RS485

Service connection

RS232

Alarm and Busy relay

Semiconductor relay, potential-free, 50 V / 100 mA AC / DC

Table 2: Overview of interfaces

6

2.5 Memory board and serial flash

CF card

AMBUS® Net with the "data logger" option can record plant and meter data at periodical intervals. This requires e CF card being used as a removable data carrier between the AMBUS

®

Net and a PC.

The size of the CF memory card determines the extent of the memory available for

AMBUS® Net.

Max. number of files on the memory card

512

File system

FAT 16

Capacity

Max. 2 GB

All logger files are stored exclusively in CSV format (Microsoft Excel / ASCII-File /

*.CSV). The semicolon (;) is thus used for column formatting and the carriage return

(CR) for a new line.

A safety lock is supplied with the "data logger" option in order to prevent the CF card

from being removed.

CF card

Serial flash

AMBUS® Net stores all plant-specific parameters on a removable data carrier, or

serial flash. This is plugged onto the pc board attached to the front of the instrument.

The housing must be opened in order to replace it.

When changing the device, this means that all settings and parameters are adopted

in the new device.

The serial flash also contains the Java driver and language information.

Serial flash

2.6 Multili ngua l feature with HTML tags

With consistent use of World Wide W eb technology, AMBUS® Net supports the simple changeover to

various operating languages located on the serial flash. This means that any change requires another

language file in the serial flash.

Example 1 : Before start-up: Changing the language is relatively easy by simply ordering a new serial

flash and replacing the old one.

Example 2 : After start-up: Changing the language is more difficult as the plant data in the serial

flash should not be lost.

Please contact Aquametro Customer Service.

The following languages are at present available (other languages on request):

• German

• French

• English

7

2.7 Communication and security

Four versions of the AMBUS®Net are available: AMBUS® Net LCD120 and AMBUS® Net LCD250 have a

touch screen and are therefore to be used when a local display and on-site operation are required.

The gateway versions AMBUS® Net 120 and AMBUS® Net 250 do not have touch screens and are therefore

to be installed in plants where remote readout and operation are required and where a more rapid network

connection is available.

Channel

PC

AMBUS

®

Net No.

Connection

Access protection

A1Point-to-point connection with modem,

safe from unauthorized access.

•

Private telephone connection

• Access code

b2PC and AMBUS®Net are connected to

the Internet. The PC is protected by a

firewall. AMBUS®Net is operated us

ing a

dedicated IP ad

dress supplied by the

Internet provider.

•

IP address not openly known

• Access code

c3As , but within an Intranet protected by a

firewall.

•

Firewall

• Protected LAN connection

• Access code

b,c

1,2,3

Access to AMBUS®Net via an Internet

portal which has the following tasks:

• Monitoring access

• Communicating with AMBUS

®

Net via

configured channels (with modem, direct IP address or VPI agent, see dotted lines)

• Carrying out application-specific func-

tions, e.g. data conversion or data-

base-specific evaluations.

•

Access protection by portal

• Access code

b3VPI*)technology also provides secure

access to an AMBUS® Net

device within a

VPI-

protected network. The portal and VPI

agent in the DMZ

**)

ensure that only a

portal server has access.

•

Access protection by portal

• VPI

• Access code

Table 3: Communication and security

*)

VPI: Virtual Private Infrastructure ensure maximum access preotetion

**)

DMZ: Demilitarised Zone

8

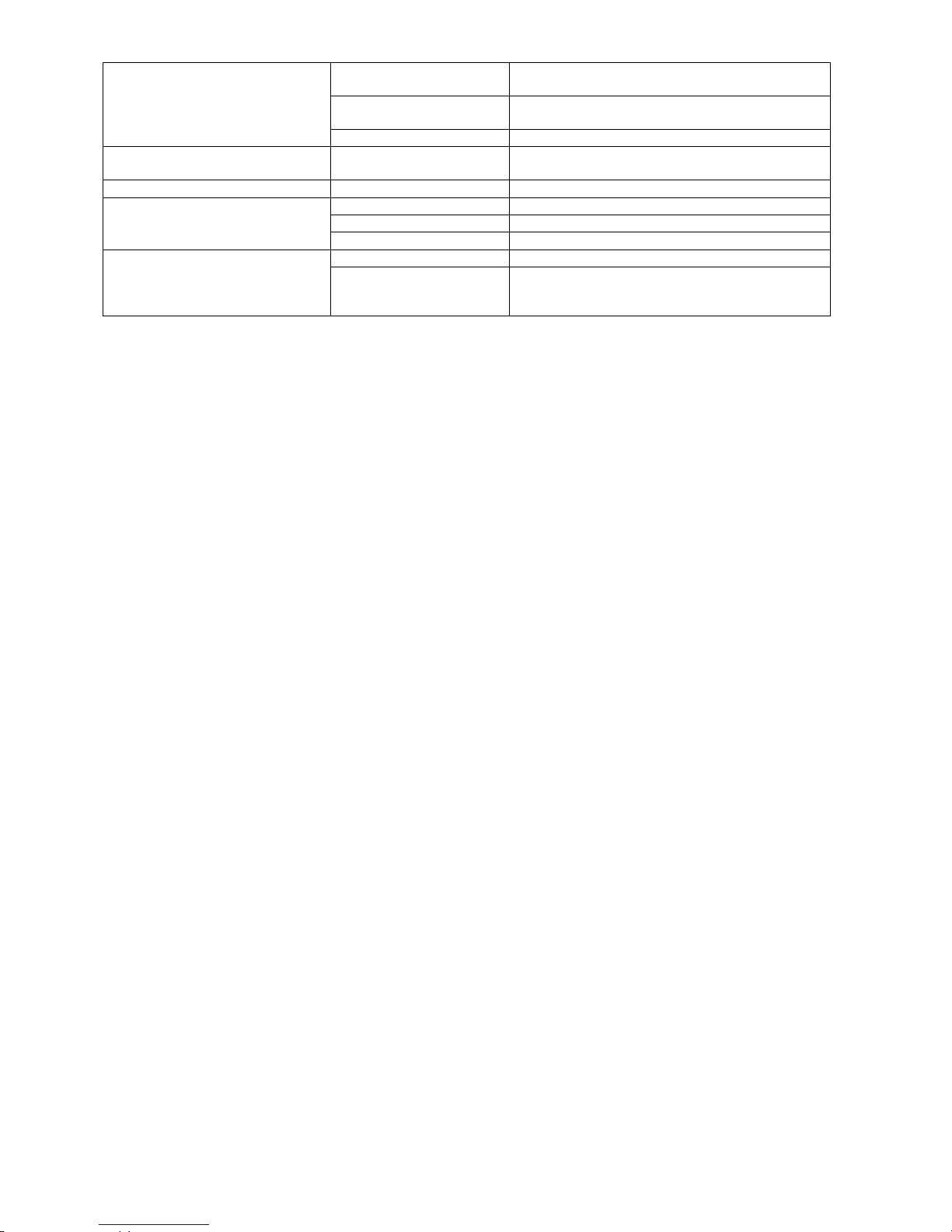

2.8 Versions

Four versions of the AMBUS® Net are available: AMBUS® Net LCD120 and AMBUS® Net LCD250 have a

touch screen and are therefore to be used when a local display and on-site operation are required.

The gateway versions AMBUS® Net 120 and AMBUS® Net 250 do not have touch screens and are therefore

to be installed in plants where remote readout and operation are required and where a more rapid network

connection is available.

Designation

Number

of M-Bus

units

LCD

Internet server

Ethernet RJ-45

Telephone

modem

Data logger

with CF

card

RS-232

&

RS-485

Art.

No.

AMBUS® Net LCD120

120

optional

optional

93178

AMBUS® Net LCD250

250

optional

optional

93179

AMBUS® Net 120

120

optional

optional

93180

AMBUS® Net 250

250

optional

optional

93181

Table 4: Specifications for versions

Options, accessories and services:

Designation

Description

Art.

No.

Data logger

Data logger with theft-proof and CF memory card

93182

PSTN modem (analog)

Integrated PSTN telephone modem (analog)

93183

ISDN modem

Integrated ISDN telephone modem

93184

GSM modem

Integrated GSM telephone modem

93185

CF Card

CF memory card

19879

Languages

Please state operating language when ordering. Languages available: German, French, English (others on request).

Table 5: Specifications for options

2.9 Open architecture

AMBUS® Net is based on an open architecture and is compatible with the following standards:

• HTTP Hypertext Transfer Protocol (transport medium)

• HTML Hypertext Markup Language (format)

• TCP/IP Transmission Control Protocol / Internet Protocol

• ARP Address Resolution Protocol (network command)

• PPP Point-to-Point Protocol (for communication via a modem)

• ICMP Internet Control Message Protocol (for transmitting the status of the protocols IP, TCP and

UDP between IP network nodes)

• LCP Link Control Protocol (connecting, configuring, testing and disconnecting a PPP connection)

• IPCP Internet Protocol Control Protocol (for IP-connections via PPP)

• PAP Point Authorization Protocol (authenticating method for the PPP protocol)

Communication with other applications is based on the following open standards:

• SOAP Simple Object Access Protocol (software interface with XML syntax)

• WSDL Web Services Description Language (describing the interfaces of the Web service)

9

3 Commissioning

3.1 Power supply and display

Connecting the power supply

Check that the power supply cable is connected to the correct terminals and switch on the power supply.

Refer to the installation instructions AMBUS® Net for connecting the power supply correctly

The display lights up. After 2 minutes of idle operation the background lighting is switched off. When touch-

ing the screen, backlighting is switched on again and the default page (see section 3.2) is displayed.

The operating lamp ("Power" / "Alarm") remains it.

• Installation and maintenance work may only be carried out when the device is not connected

to the power supply.

• The grounding cable must be connected to the ground terminal of the housing.

• Work on the 230 V power supply may only be carried out by authorized specialists in accord-

ance with all regulations currently in force.

• The power supply cable may only be connected to the terminals "L" and "N". Any other connections may endanger life and may also permanently damage all meters connected to the

bus system.

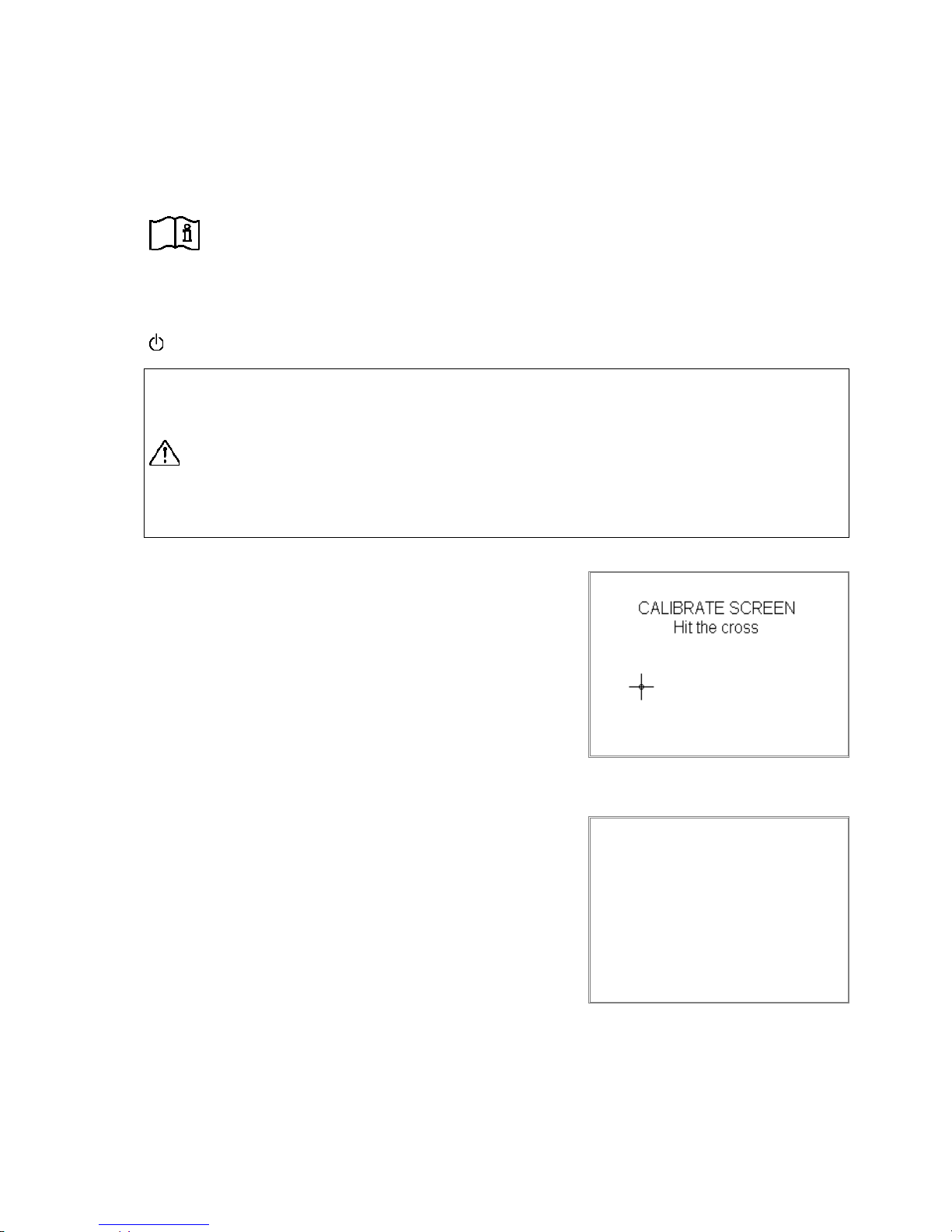

Calibrating the touch screen display

Once the device has been switched on, the IP address is first displayed then a prompt shown for approx. 10 seconds to calibrate the

display. This should only be done if operation is poor (that is, if the

sensitive fields do not align well with the displayed fields or if it is

necessary to press hard)

If calibration is necessary, then press the cross hairs with a blunt

object until the menu is shown in the default display.

3.2 Basic setting of AMBUS® Net

Default display

The menu is now in the default display. You see:

• At the bottom left, the maximum number of meters to be pro-

cessed, e.g. "AMBUS

®

Net 120"

• At the center top: the system designation (for programming see

3.2 System menu)

• At the center bottom: Status of the system (active only after

reading the connected meters)

10

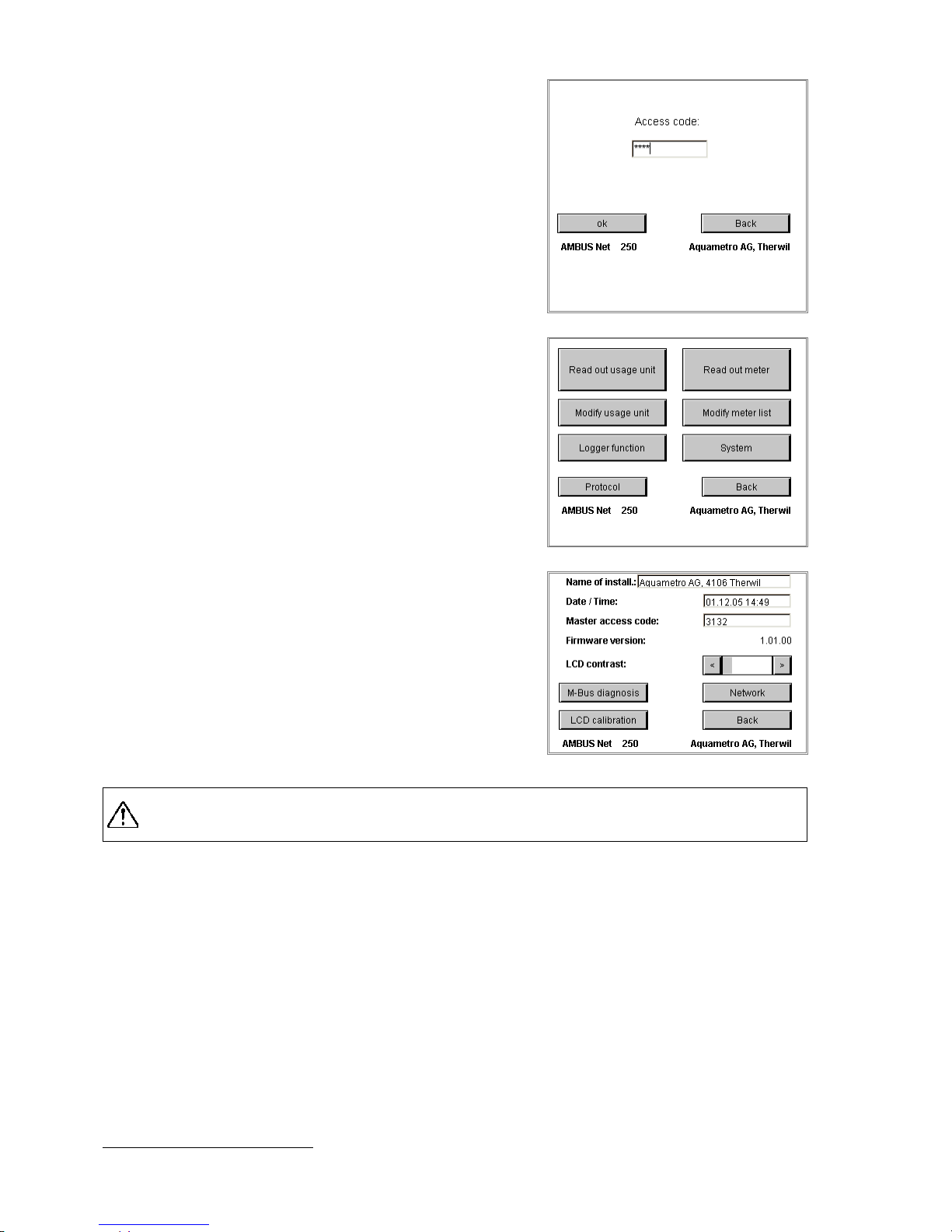

By pressing the display the following are called up:

Access code

AMBUS® Net differentiates between two access authorizations,

both of which are protected by a coded number.

1. System access code (shown on the right)

2. Usage unit access code (see sect. 4.4 The usage units)

When touching the field "Access-Code", a keyboard is displayed;

enter code “3132“(factory settings) and confirm with OK.

The main menu is displayed.

(The code must be re-entered if there is no operation after several

minutes.)

Main menu

Select "System" in the main menu for carrying out the basic settings of the device:

For other menu points see:

For read out meter / Modify meter list: see section 3.3 read

out meter

For Modify usage unit and Read out usage unit see section

4.4 The usage units

• For Logger function (option) see:

1.1 Fehler! Kein gültiges Resultat für Tabelle.

System menu

Check/correct the following basic settings:

• Name of the installation: Touch the field, a keyboard is

displayed; you can enter a name of max. 40 characters.

• Date and time: Setting the system time in the form of:

dd.mm.yy.hh.mm

• Access code: This can be a maximum of 8 characters

It is necessary to contact Aquametro Customer Service if the access code is lost!!

• Details of the current firmware version of the device

• LCD contrast

Adjust the contrast using the "<" and ">" keys so that there is sufficient contrast on the screen but

no shading.

*)

The calibration routine of the touch screen is done via the menu "LCD calibration" as described above.*)

*)

The LCD balance and contrast cannot be set over the remote control.

11

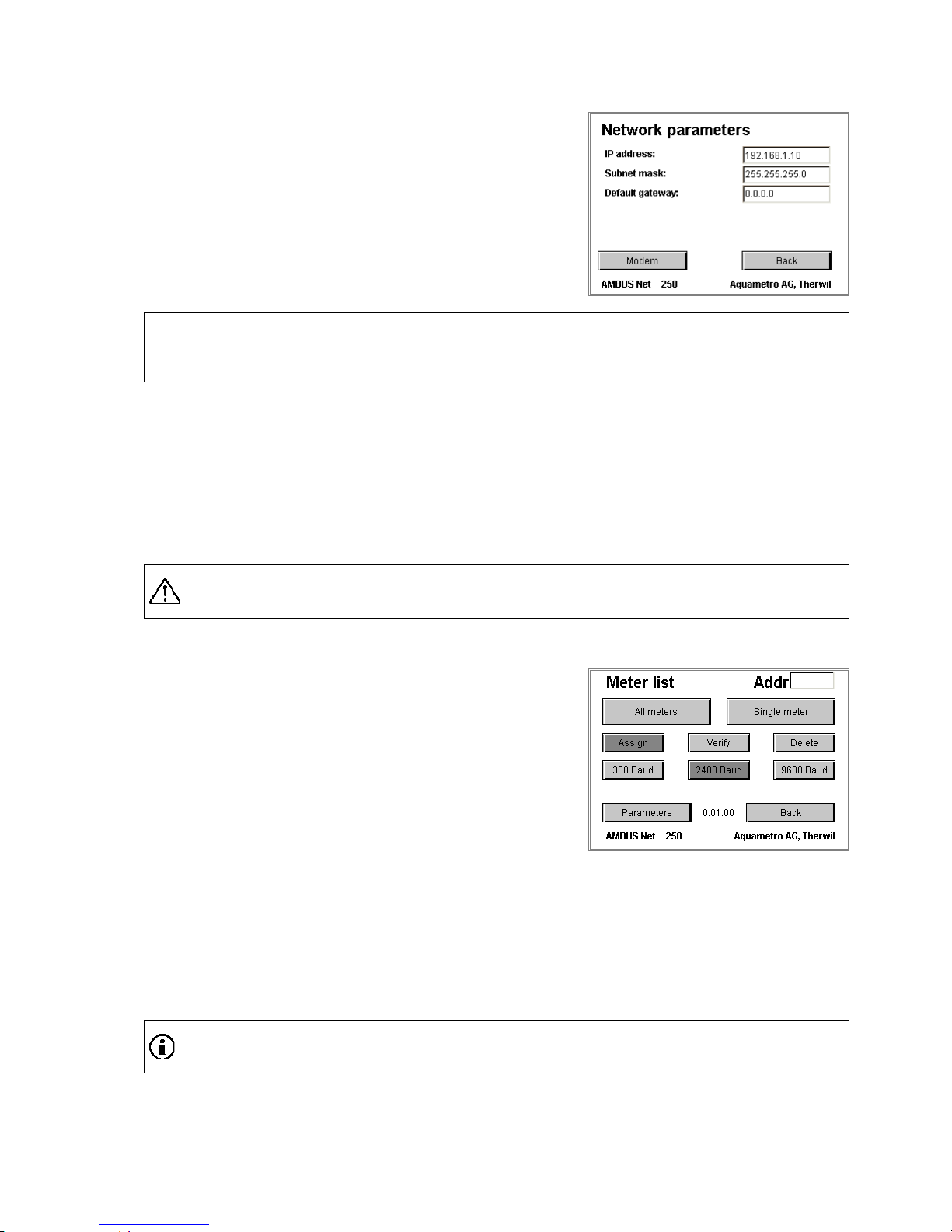

The communication parameters are checked and set via the menu "System / Network":

System / Network menu

Settings of the Ethernet interface:

• IP address, subnet mask and standard gateway are described

in greater detail in Section: 3.4 Network (Windows).

Entries are only required when using the network.

AMBUS® Net is now ready for operation!

Follow the instructions 3.3 Meter list, commissioning the M-Bus and automatic meter search.

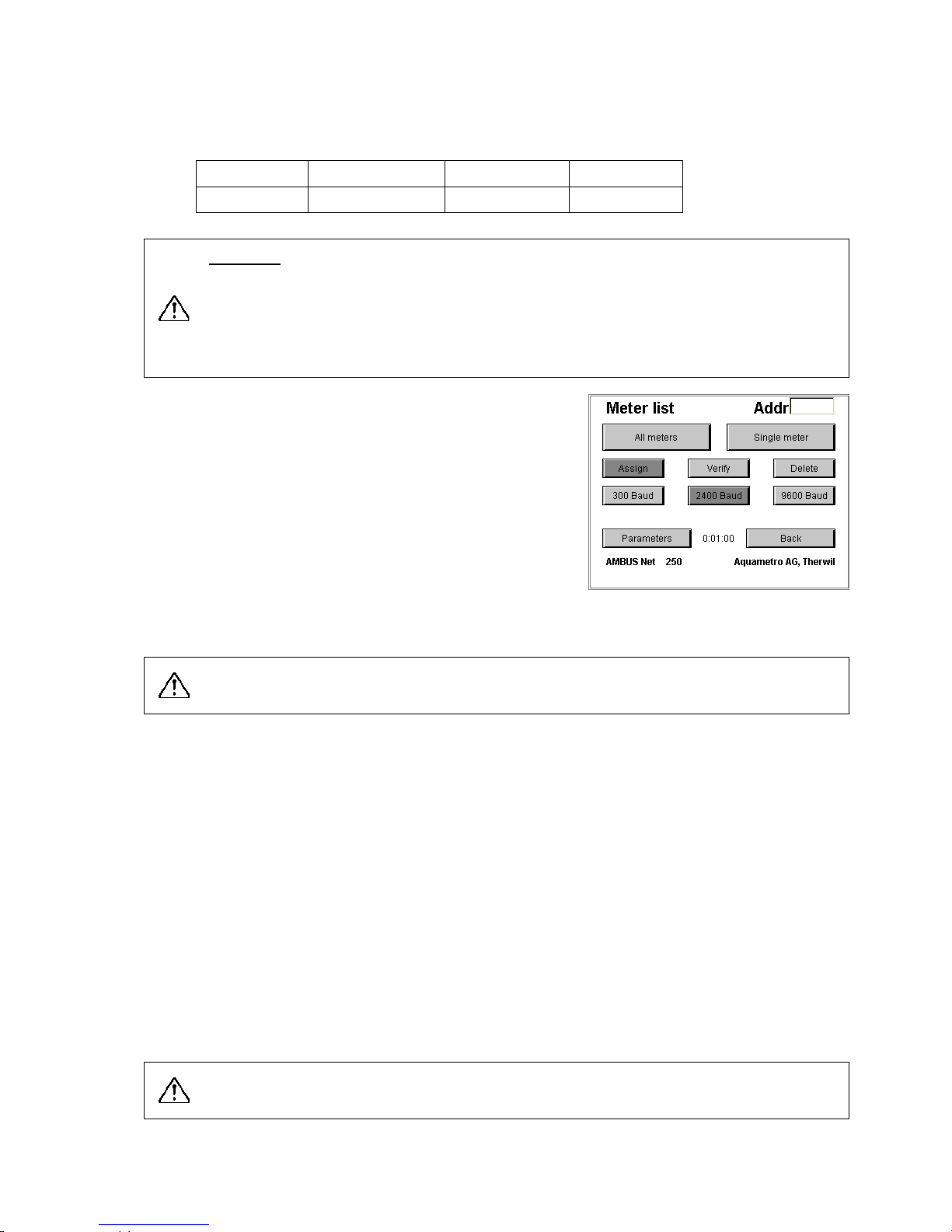

3.3 Meter list, commissioning the M-Bus and automatic meter search

System requirements

• All M-Bus meters to be processed by AMBUS® Net must be wired up correctly according to the installa-

tion instructions AMBUS

®

Net.

• All meters must have previously been assigned a unique primary address (M-Bus EN 1434-3).

(Please refer to the operating instructions of the meters used in the system.)

• Select addresses in the range 1...250.

Ensure that the same address is not assigned to different meters otherwise no communication to

those meters will be possible!

When in the main menu select:

Modify meter list

Use the automatic meter search function in order to enter meters in

the AMBUS

®

Net as follows:

• Select Delete – All meters if meters from a previous applica-

tion have been entered incorrectly

AMBUS

®

Net indicates: “All meters deleted“

Start with the highest baud rate to automatically differentiate between meters with different baud rates:

Assign – 9600 Baud – All meters

Assign – 2400 Baud –All meters

Assign – 300 Baud –All meters

After completing a search, the AMBUS

®

Net indicates the number of meters found e.g. “15 meters detect-

ed“

AMBUS

®

Net can administer plants with mixed baud rates!

12

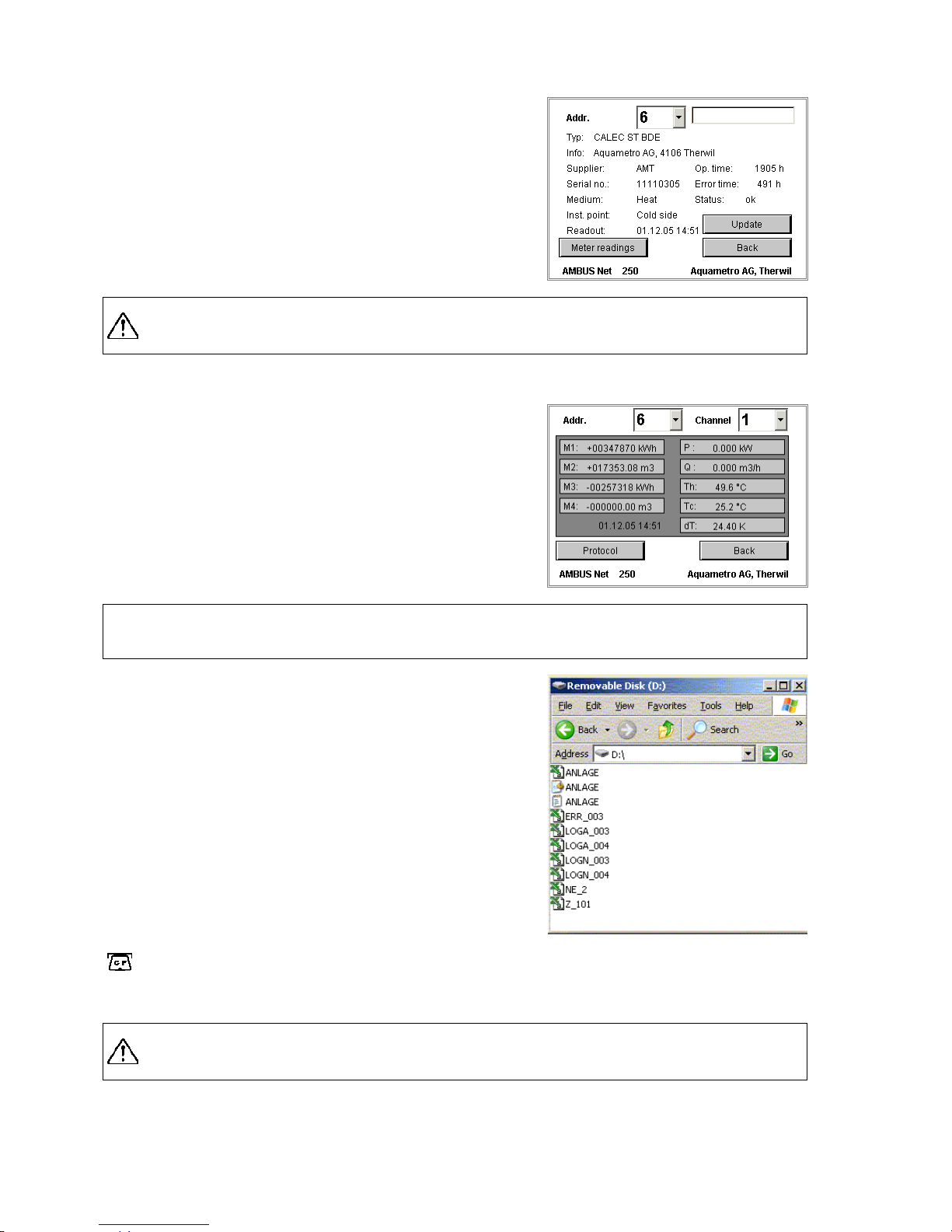

Select the meters to be read from the main menu:

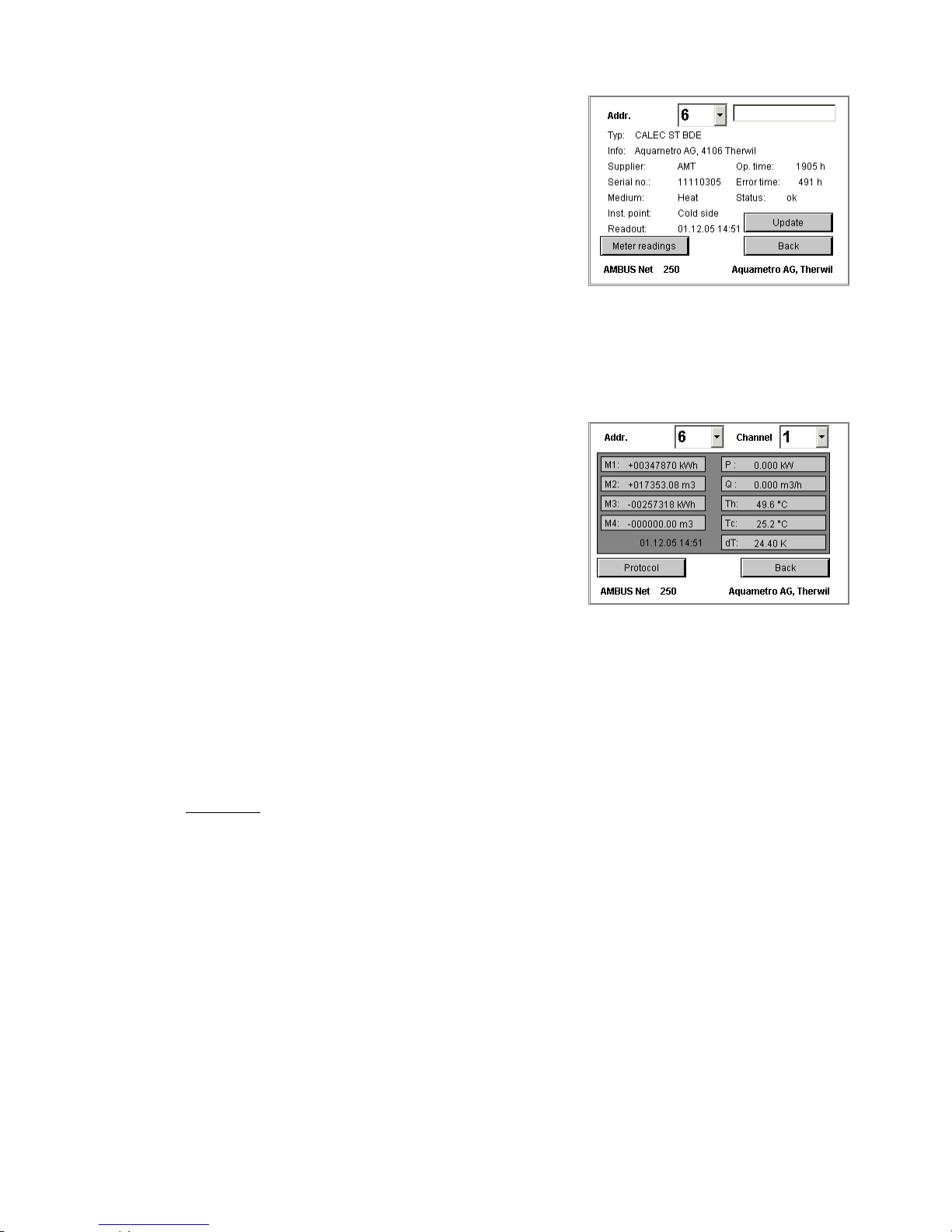

Read out meter

• Select the appropriate address in the drop-down list to read out

a specific meter

• An additional text field is available for more detailed identifi-

cation. More information is given in 4.3 Reading the meter

AMBUS® Net shows meter readings from an internal m

emory, i.e. at the time of the last reading. If

the meters are to be read again, then select update.

To read out the latest meter reading, select:

Read out meter / Meter readings:

• AMBUS® Net displays a maximum of 4 meter readings and 5

actual values per device (address) and channel.

• 3 channels are available.

• Tariffs are dealt with exactly like channels.

AMBUS

®

Net can now read out and administer the asigned M-Bus meters!

Protocolling meters

A meter protocol can be stored for every meter available using the

option "data logger" and the CF card (see also 3.6 Data logger /

CF card):

After selecting e.g. the meter with the primary address 123, press

Protocol

• AMBUS

®

Net creates the file Z_123.CSV (example)

Select Protocol in the main menu (see section 3.2) to protocol the

entire plant:

• AMBUS

®

Net creates ANLAGE.CSV

The indicator lamp lights up for at least 2 seconds every

time the CF card is accessed.

CF card read out via PC

Never remove the CF card during a write operation as data could be destroyed!

13

3.4 Network ( Windows)

For configuring the network, you require the following instrument

data that are found in the system / network:

Parameter

Factory settings

Subnet mask

255.255.255.0

Standard gateway

- Mac address

In range 00 0A FF F0 00 00 ...

00 0A FF F0 FF FF

Parameter

Factory settings

If AMBUS® Net is connected to the Internet via a gateway/router, the IP address for the standard gateway is

to be set here.

The AMBUS® Net can be uniquely identified in the network via the MAC address (Media Access Control, or

LAN address). If this is required by the network administrator, the particular instrument can be read out from

the network via a PC:

1. Response of the instrument, e.g. with : ping "IP address"

→ AMBUS

®

Net must respond

2. Listing the "Address Resolution Table" with: arp –a

→ Your PC displays the IP address list with the appropriate MAC address list

after the device has been successfully connected to the network. If this is not the case, then contact Aquametro Customer Service stating the serial number.

Start the device again after reprogramming the IP address, the subnet mask or the standard

gateway address!

If the network parameters of your network are correctly set according to your system and the device restarted, the

AMBUS

®

Net can be connected to your Ethernet network using a standard RJ 45 network cable.

The following settings must be made on the PC so that the network connection functions correctly:

Network setting on the PC

All components must be located in the same network group for a

communications link via the Ethernet.

AMBUS

®

Net requires a fixed IP address.

(Example shown in Windows XP)

• Select in:

Control Panel / Network c on nections

’LAN/Local Area connection’

• Select Properties of:

’Internet Protocol (TCP / IP)’

Request a permanent IP address for the AMBUS® Net

for your network or Internet operator as

this does not support DHCP (Dynamic Host Configuration Protocol).

14

Select an IP address that is located in the same group: (The first 3

bytes must be identical.)

• ’Use the following IP address:’

• IP address: 192.168.1.1

(AMBUS® Net is delivered with 192.168.1.10 as standard)

• Subnet mask: 255.255.255.0

If the AMBUS® Net is operated in a major network, then the

system administrator will assign a fixed IP address for operating the device. In this case network settings have not to

be changed on the PC!

The PC must again be started up if network settings are made on the PC!

Java settings on the PC

Java is a programming language that permits programs to be transmitted over the Internet which are then

carried out. This presents a risk since Java functions on most network PCs are deactivated as standard.

In order for the AMBUS

®

Net remote control to function correctly, these Java applications must be made

available to the particular device.

The following settings are thus required:

• In Control Panel:

Internet Options select the label "Security"

• Select Trusted Sites:

"Sites..."

• Insert the page (IP address) for the AMBUS® Net, without

requiring server verification (https: bottom left)

http://192.168.1.10

*)

• End with OK

• Click on custom level in the previous window:

and select in "Reset custom settings“: "low"

All settings on the PC have now been completed!

15

Start your Internet browser and select:

http://192.168.1.10

*)

The AMBUS

®

Net offers two options that can be selected:

• CF Device / (Access the files on the CF card)

• start.html (remote opera tion, start page)

If AMBUS® Net has been equipped with the option: "data logger",

then select:

• CF Device /

For direct access to the logger files of your CF card.

By clicking the particular file, you can:

• either open it

• or save it to a disk

To jump back to the start menu, select:

• Parent Directory

Select

• start.html

for direct remote operation of AMBUS

®

Net.

This starts a Java application, which must be uploaded by

AMBUS

®

Net.

Be patient as the time to load the application is strongly dependent on your network capability and

performance of the PC!

AMBUS

®

Net can now be remotely operated using Ethernet!

*)

Delivery address

16

3.5 Communication via modem

Modem settings on the AMBUS® Net

Communication between the PC and AMBUS® Net can also be made using a telephone connection.

Step Type of modem: Analog ISDN GSM

1 Plug in bridges for analog or ISDN modem any

2 Select type of modem Analog ISDN GSM

3 Set MSN No. -

-

4 Connect telephone cable (symbol for connector ->)

-

5 Secure and connect the GSM antenna

-

-

Step 1: Jumpers for analog or ISDN modem

Ensure that the position of both pin strips on the circuit board in the

cover of the AMBUS® Net correspond to the figure shown. For the pin

strips the jumpers are to be plugged in vertically.

• The figure shows the position of the jumpers for the analog

modem (marked ANALOG)

• The jumpers must connect the lower pin with the centre pin for

the ISDN modem (marked ISDN).

• The jumpers have no relevance for the GSM modem.

Step 2 – 3: Modem settings

The following entries are required for data transmission with the

AMBUS

®

Net:

Network settings – Modem settings

• Type of modem

• MSN No. (Multiple Subscriber Number) for ISDN modem only

With the ISDN connection, the relevant part of the telephone number (MSN) must also be entered on the

page system / network. The MSN No. is mostly the telephone number without the area code, please refer to

the instructions of your telephone switchboard.

An MSN (Multiple Subscriber Number) does not consist of the complete telephone number but

instead of as many integers as are required for differentiation. As a rule, this is the telephone

number without the area code.

17

Step 4: Connect the telephone cabl e

Connect the AMBUS® Net to the telephone connection using the modem cable supplied.

AMBUS® Net connection system modem / RJ-45

Step 5: Secure and connect the GSM antenna

Attach the stick-on antenna supplied to where the best possible GSM reception is obtained (check this out

beforehand using a cellular phone from the same provider). Connect the plug of the antenna to the socket

for the antenna on the top of the housing and screw tightly.

GSM-Modem

For activating the GSM modem, an SIM board with a contract for data communication is needed.

Aquametro recommends the contract: NATEL

®

data basic from Swisscom for Switzerland. This SIM board

enables data only to be transmitted. Speech (voice) over the cellular phone is not possible.

No other services are required.

The PIN code of the SIM board is not supported by AMBUS

®

Net. It must be deactivated when in

operation. (Deactivation is possible with most cellular phones).

Modem setting on the PC (data transmission net-

work)

A data transmission connection to the plant must be created for

communicating via a modem:

(An example is given in Windows XP)

• Create with:

Control Panel / Internet options

a new connection:

• Select: Dial-up to private network

• Enter the telephone number of the plant and the type of PC modem

• Enter a name for the connection (plant designation)

• The Wizard will now make the connection

The connection is now available as an icon with Control Panel /

Network Connections.

• Change the properties (right mouse button) and select with:

Security the Advanced Settings

18

Select with Data encryption:

• Optional encryption (connect even if no encryption)

• With Allow these protocols only:

Unencrypted password (PAP)

• End with OK

• Confirm the following security messages with Yes

Select the label Networking

• Select as Type of dial-up server:

PPP: Windows 95/98 NT4 2000, Internet

• and activate among the items used for this connection only

Internet Protocol (TCP / IP)

Under Settings deactivate all PPP-settings

The user name and password are requested when creating a link.

Select:

User name:

Password:

user

password

19

Geben Sie im Browser als URL die fixe IP address for Modem

• http://192.168.0.1

AMBUS

®

Net can now be remotely operated using a modem connection!

3.6 Data logger / CF card

AMBUS®Net can record the data in the network on a compact flash

card (type 1) data.

Compact flash cards can be read or deleted by any PC with a suitable disk drive / reader. They are displayed just like a disk drive.

The card can be formatted with a PC if it is already written on or is

full from another application.

Format CF cards with FAT / FAT16 only!

Only use cards for this between 16 MB and 2 GB!

http:192.168.0.1

20

4 Operation

The large touch screen display has made it possible to achieve a high degree of operating skill never previously found with an instrument of this class. The plain text in a language of your choice enables the device to be

easily operated. AMBUS

®

Net is the natural choice wherever operating procedures have to be quickly learnt.

The section 3 Commissioning has already explained the first steps to take in operating procedures. This section describes the individual functions in greater detail for specific tasks.

4.1 Summary of menu

4.2 Status message and general alarm

The default window opens with a status message after switching on

or if there has been no operation for a few minutes.

A message of the level "Alarm" or higher will be output to the alarm

relay (see installation instructions AMBUS®Net).

Status message (based on priority)

Alarm

Remark

Initialization of modem has failed !

Yes

On commissioning

Please insert memory card

Yes

CF board not present

Logger interval too short!

Yes

See sect.3.6

No answer

Yes

Meter does not reply

Error

Yes

Meter error

Alarm

Yes

Meter alarm

OkNoMessage: No fault

The standby light (“Power” / “Alarm”) flashes with continuous alarm.

An update of the status message is only possible once the specific meter has been read!

21

4.3 Reading the meter

The basic features for reading the meter are described in Section

3.3 Meter list, commissioning the M-Bus and automatic meter

search.

• Selecting the meter:

The meter is selected with a drop-down list, which lists all meters by their address.

• Meter data:

Values such as: Type, Info, Supplier, Serial No, Medium,

Installation point, Operating time, Error time and Status are

values that AMBUS

®

Net reads directly from the meter using

the M-Bus.

• Updating:

The date of the last readout is indicated by "Readout".

Press update to read the most current value.

• Designation:

A 10-character designation can also be assigned to each meter.

This designation is stored in the serial flash card.

The button Meter readings calls up the list of readings and instan-

taneous values which are sorted according to address and channel.

• The pages are sorted according to the meter address (0...250)

• 3 channels per address are possible (units and tariff as per M-

Bus)

• A maximum of 4 meter readings and 5 instantaneous values

are possible per address and channel. Sorting the values is according to the sequence in the M-Bus protocol.

See Section 3.3 for storing a meter protocol in the memory card or downloading a meter protocol via remote

control / Ethernet. For typical data, see section 7 Appendix.

4.4 The usage units

It is often useful to group readings from various meters. Creating usage units simplifies future invoicing when

invoicing refer to groups of meters

AMBUS® Net is able to group together any meter readings of similar or different meters. Such groups are

called usage units. Any meter reading assigned to a usage unit can be allocated a text for designation purposes.

22

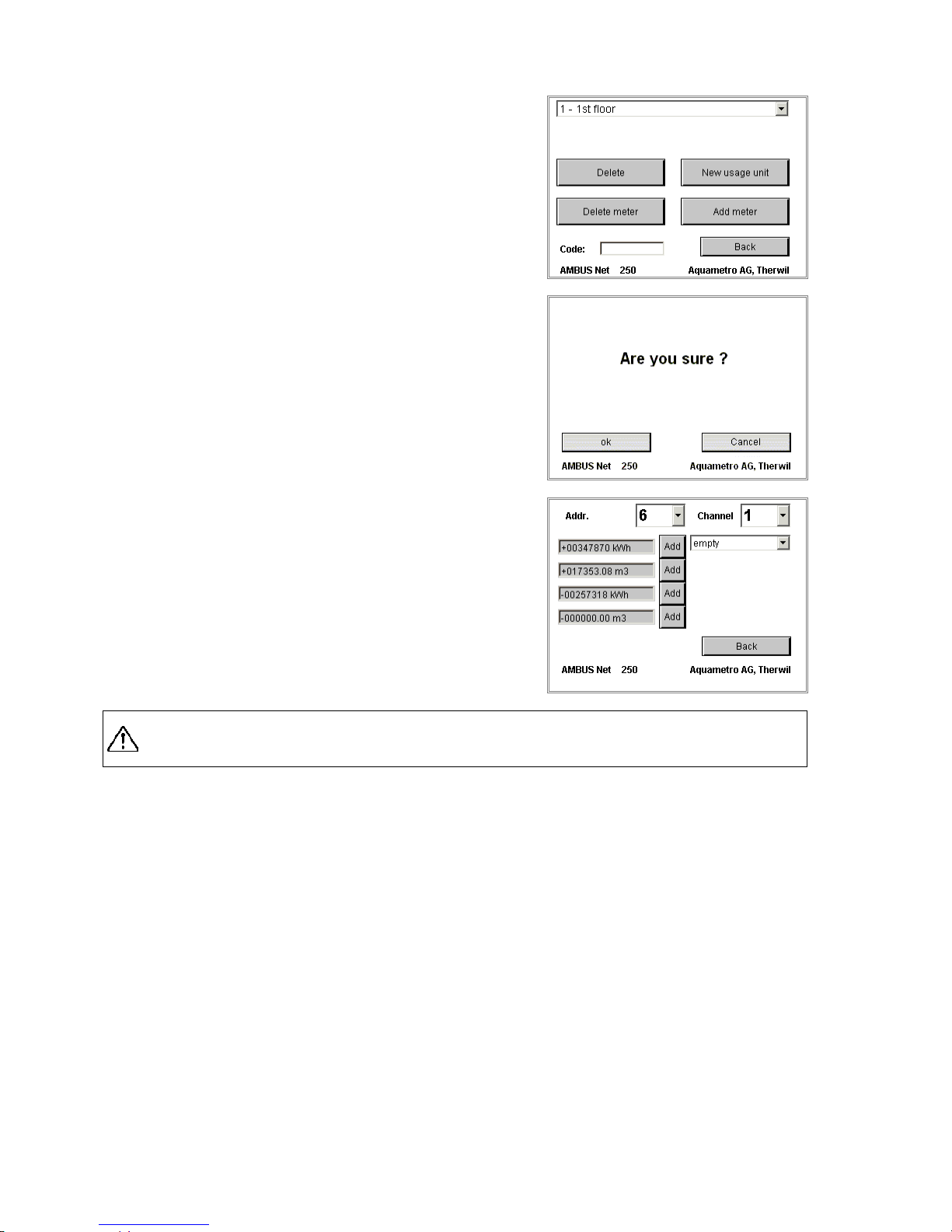

Select from the main menu to create a usage unit:

Modify usage unit

• With the button "New usage unit", the designation of a new

Usage Unit (UU) can be entered via the keypad which is then

displayed.

To the left, near the designation is the internal number of the

UU. This is important for protocols.

• The number of usage units available can be selected in the

scroll-down list.

Modify usage unit / Delete (security prompt)

• Usage units that are incorrectly entered or no longer required

can be deleted using the button "Delete". Since this process

cannot be reversed, the prompt requires confirmation

(ok / Cancel).

Modify usage unit / Add meter

• The button "Add meter" enables any meter readings be as-

signed to the selected usage units.

• Find the address of the particular meter to select (0…250). All

meter readings known to AMBUS

®

Net are available over the

additional channel selection (3 channels per address).

• A common media designation (heating, heat, hot water, cold

water, gas, electricity …) can be added to each meter reading

to be assigned using the drop-down list.

• Press "Add" to assign a meter reading: AMBUS® Net confirms:

“Meter ‚n’ added where n stands for meter reading 1...4.

The number of usage units and the number of assigned meters are limited.

Note: Number of UU times number of meters must be < 250.

23

Modify usage unit / Delete meter

Meter readings that are incorrectly entered or no longer required

can be removed from the usage unit.

• The button "Delete meter" calls up the delete menu:

• Select the meter reading to be deleted,

• And confirm with “Delete".

Access code for usage unit

• A separate 8 numerical character access code can be as-

signed at system level to each usage unit. Users with no system access have separate access to the usage unit by entering

the usage unit code.

• A user has access to several usage units by entering the same

code a number of times (authorization groups).

If a user is in the system having entered the usage unit code,

then only those usage units with the same code are visible.

Direct access to the meters or to the system settings is not

possible.

• Users with the usage unit code cannot alter the code.

All data concerning usage units are stored on the serial flash card.

Select from the main menu to read out a usage unit:

Read out usage unit

• The number of usage units available can be selected in the

scroll down list.

• Each line displays the medium, the meter reading, address and

serial number of the meter.

• Updating:

Updating the data is indicated by: "Readout:". Press "update" to

read the most current values.

o In addition, with the "Data logger" option it is possible to store a

protocol on the CF card or store it directly on the PC remotely.

Typical data are given in Section 7 Appendix.

4.5 Monitoring the m e t e rs: the analysis usage unit

It may be seen that, in the scroll-down list of usage units, there is one with the name "Analysis." One (optional) logger function is able to analyse one particular usage unit: The meters of the analysis usage unit are

protocolled in a fixed time raster for 15 minutes (see also section 1.1):

• The number of meters for which the analysis usage unit can be used is a maximum of 5.

• The analysis usage unit itself cannot be deleted.

24

4.6 Data logger (optional)

The optional data logger records event- or time-controlled data and stores these in the plug-in data memory (CF card).The time interval can be set to between 1 minute and

12 months. If the AMBUS® Net is not equipped with the logger function option, then the update rate is fixed at once per day. The reading is carried out shortly before 24.00.

The logger function (optional)

The keys on either side are used to determine:

1. Which data are to be recorded.

2. In which time interval the data are to be read and recorded.

3. the sequence of data by meters or usage units

4. Whether the data are partitioned according to size or time.

The following table describes the functions of the keys and the names of the logger

data:

Settings of the Logger format

Usage units protocol

Plant protocol

Settings of the

Logger function

Description

Max. size of data

(size-controlled)

Data per month/ data

per day (time-

controlled)

Max. size of data

(size-controlled)

Data per month/data

per day

(time-controlled)

Billing date 1,

Billing date protocols, readout is made at 23:30 on the given day

MEMN_nnn.CSV

MNyymmdd.CSV

MEMA_nnn*.CSV

MAyymmdd.CSV

Interval

Logger data, data recording within the preset time interval

LOGN_nnn.CSV

LNyymmdd.CSV

LOGA_nnn.CSV

Layymmdd.CSV

Fault

Error protocols. The following status messages from a meter are regarded

as faults: No answer, Error, Alarm

ERR_nnn.CSV

Eryymmdd.CSV

ERR_nnn.CSV

Eryymmdd.CSV

Analysis

Analysis data: 5 selected meters can be read in parallel to the logger

function in 15 minute intervals for a defined time period (see sect. 0

Monitoring the meters: the analysis usage unit.)

AN_nnn.CSV

ANyymmdd.CSV

AN_nnn.CSV

ANyymmdd.CSV

Logger format

Usage unit protocol

Meters are arranged according to usage units, meters not assigned to usage units are not shown.

Plant protocol

All meters are listed according to their address.

Max. fle size

Exceeding the file size causes the creation of a new data file (size-controlled)

Files per month

A new data file is created at the beginning of each month (time-controlled). For logger intervals typically between 1 hour and n days

Files per day

A new data file is created at the beginning of each day (time-controlled). For logger intervals typically between 1 minute and n hours

* ’nnn’ between 000 and 999 „…A…“ Plant protocol, i.e. meters are displayed according to their address

** ’yymmtt’ year, month, day, e.g. 061231 „…N…“ Usage units protocol, I.e. meters are di splayed according to the structured usage units

25

Setting the logger time interval

The logger time interval can be entered in the entry field on centre screen to the right. This value determines

the time intervals in which the meters are to be read. It can be set to the following ranges:

Minutes Hours Days Months

1 … 59 1 … 23 1 … 28 1 … 12

Important: Reading out an M-Bus plant can take from several seconds to over 1 hour depending

on the number of meters, the baud rate and the amount of data to be transmitted. The following

conditions must therefore be met:

Readout interval > M-Bus readout time

In cases of overflow the data can no longer be stored and the status message: Logger interval

too short! will appear in the default window

Measuring the M-Bus readout time

The time required for all M-Bus devices to be read out can be

measured as follows:

1. Select Meter list in the field

2. Press the Control button

3. Press the All meters button

AMBUS® Net now reads all meters and shows the time in the de-

fault window at the bottom of the field.:

Contents and format of the logger data are found in section 7 Appendix.

Note: Time-controlled data sizes are generally more advantageous because:

1. the time periods can be more easily limited,

2. an overflow of the memory board is automatically prevented (see below).

Logger: memory size, overflow

The size of the memory board limits the amount of data that can be stored.

Time-controlled logger data are a self-checking function and prevent the system creating an overflow since

the oldest data are automatically deleted.

Size-controlled logger data must be be prevented by the user by one of the following procedures otherwise

the data can no longer be stored in the memory:

• Select the size of the logger data so that:

the size of the memory board > 1000 x size of the data created periodi cally + other data

If the file index 999 is reached, the system then resets the index to 000 so that the oldest data are overwritten

• If this is not possible, the data must first be transferred to another data carrier and the data in the board

deleted.

Note the stipulation above in order to prevent an overflow of the memory board!

(Typical memory requirement in the logger file: 150 – 200 Bytes per meter and reading).

26

Checking the logger interval

To check the logger interval, first read all meters and proceed as

follows:

1 Activate the button "Check" in the field "Meter list"

2 Activate the button "All meters"

3 Wait until the reading time is shown in the field in the centre at

the bottom (example "0:00:25“)

4 Set the logger interval time to at least this time in the field

"Logger function"

Protocol files

The button "Data" shows a directory of all files stored on the

memory card.

If no memory card is available then the following error message is shown:

„Insert memory card please!“

4.7 Meter list, manual meter r eadings

Manual meter readings

Section 3.3 Meter list, commissioning the M-Bus and automatic

meter search described, how meters, e.g. are automatically looked

for and entered via:

Assign – 2400 Baud – all meters.

This search procedure checks the address range in the selected

baudrate from 1 to 250 and enters the addresses in the instru

ments

found.

Meters can also be entered manually, by which the appropriate address is entered in field: Adr.

and the search procedure is started with: Baud – assign – single meter

AMBUS® Net displays, e.g.: "0 meters detected" or "Meter detected"

Meters with an address from 0 to 250 can be entered manually.

27

Removing meters

To delete the entire list, select:

• Delete – all meters

If individual meters are to be removed, select:

• Delete – single meter (having first entered the address to be deleted in field "Adr")

• AMBUS

®

Net displays, e.g.: "all meters deleted or Meter deleted"

1.1.1.1 Checking meters

All meters entered, along with their baud rates, can be checked. Select:

• Verify – all meters

If individual meters are to be checked, select:

• Verify – single meter (having first entered the address to be checked in field "Adr")

This command enables all meters or individual meters to be read and thus checked.

• AMBUS

®

Net display, e.g. "All meters available" or for example "1 Meter not available!"

The time required to read the meters is shown in the display field in the centre at the bottom.

Modify meter list / Meter parameters

When recording, the AMBUS® Net tries to identify every meter

found and to set down the appropriate parameters of the meter

driver. These parameters are and stored in the serial flash card

structured by meters.

If the parameters found for a particular meter are to be checked or

changed, then select: Modify meter list / Meter parameters by

entering the address of the meter in the field: Adr.

The features of the meter are indicated by displaying the appropriate flags in a darker grey tone. By pressing the button, a feature

can be changed, if the meters allow to do so.

1.1.1.2 Baud rate

The 3 buttons at the bottom show the baud rate for which the meter was entered. If the meter can use another baud rates, this can be modified at this point.

1.1.1.3 Aquametro meters

The 3 buttons "AMTRON N“, “CALEC MB“, “Lock alarm“ activate special functions in these Aquametro me-

ters, e.g. reading the text field. The button Lock alarm suppresses an error message which the meters send

if the Lock level is not correctly set (to protect calibration parameters).

These flags are to be changed only by specialists with appropriate training or contact Aquametro

Customer Service for further information.

1.1.1.4 App-Reset (Application Reset)

When this button is activated, AMBUS® Net carries out an "Application reset" before a readout in the M-Bus

command procedure. This command initializes the meter protocol according to the M-Bus standard.

1.1.1.5 Snd_NKE (Send NKE)

When this button is activated, AMBUS® Net carries out a "Snd_NKE" command after every reading. This

command resets the address selection of the meter.

Not all meters respond correctly to the commands: "Application Reset" or "Snd_NKE'

". Check for

correct reading of the meters after a switchover!

1.1.1.6 Auto-Req

Certain meters inform the master with the command REQ_UD2 that more information is available than can

be called up by further read commands. When this button is activated, AMBUS

®

Net responds to this com-

mand by reading out all existing protocols.

28

This option can cause the readout to be considerably delayed. Select the "Auto-

Req" option only if

other important data are to be read!

1.1.1.7 Data in Mem(ory)

Parameters for meters which store the actual meter reading in memory 1 (e.g. EAM current meter).

1.1.1.8 Std-Sel (Standard Selection)

Activates the option Any VIF (alternative method for App Reset).

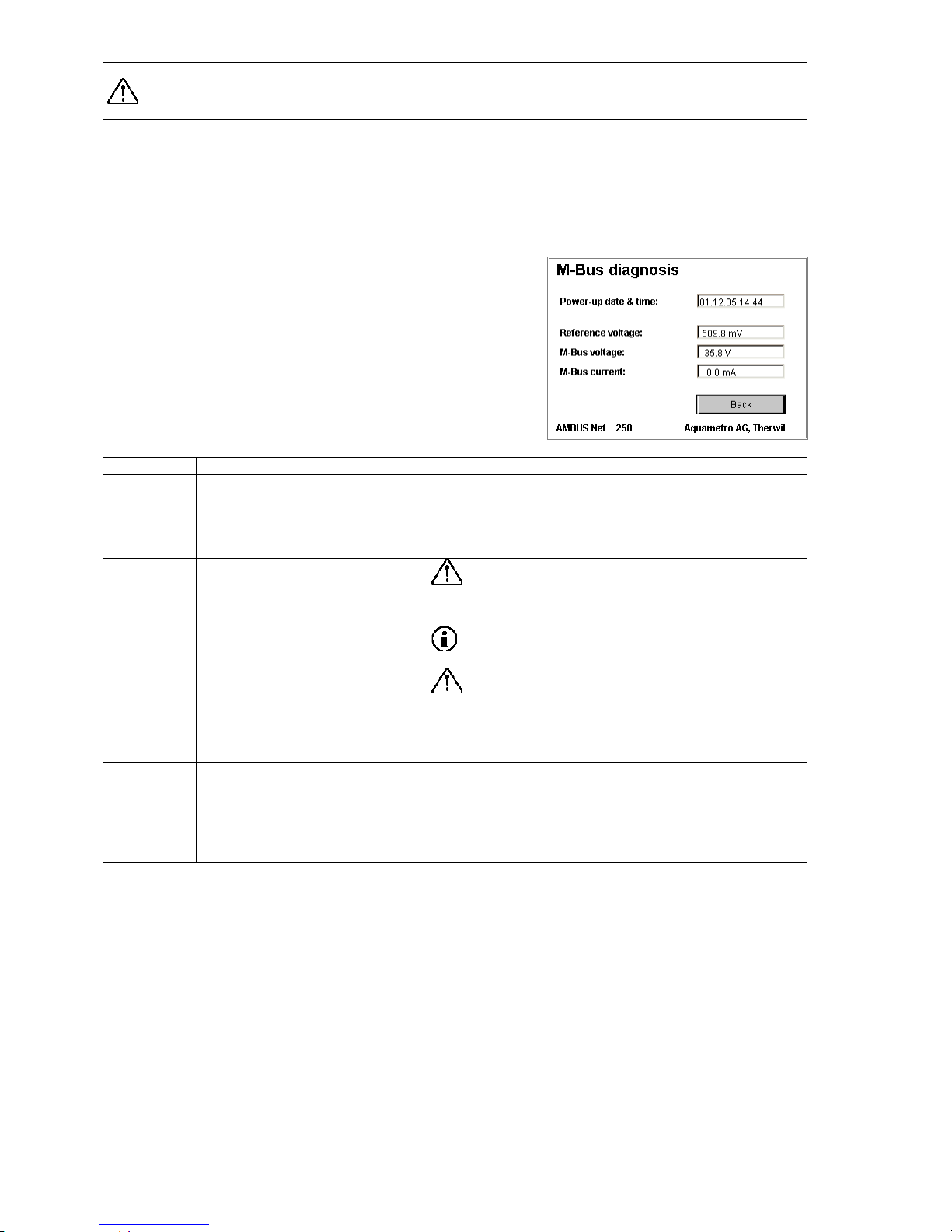

System / M-Bus diagnosis

The menu "M-Bus diagnosis" can be called up via the system me

nu

in order to show electric information about the M-Bus plant.

AMBUS® Net measures the system current, the M-Bus terminal

voltage and an internal reference voltage and then displays them.

Value

Description

Remark

Power-up

date

The date field shows when the

AMBUS® Net was last booted

up. Interruptions in voltage are

of fundamental importance when

monitoring plants.

Reference

voltage

Information on the reference

voltage is for function monitoring

of AMBUS

®

ZS modules. The

voltage is about 500mV.

Please contact Aquametro Customer Service is

the voltage varies by more than 30%!

M-Bus

voltage

The M-Bus voltage is the termi-

nal voltage of the M-Bus network

(terminals 26 / 27). The voltage

is just below 36V.

The voltage can vary slightly during communica-

tion.

• If the value is 24 V when measured over

several seconds, then there is an "Autobreak" error.

• If the value is near 0, then there is a short

circuit in the system.

Please contact Aquametro Customer Service!

M-Bus

current

The current of the M-Bus plant.

The value is proportional to the

number of M-Bus units connected. The theoretical value is

about 1.5mA per unit (1 M-Bus

load).

29

1.1.1.9

5 Remote operation and system integration

5.1 SOAP: Creating a client with .Net

SOAP is an XML-based interface that enables direct data connections to be created between clients over the

Internet, e.g. management software and servers (AMBUS

®

Net).

AMBUS

®

Net makes available data from meters and the usage units via a SOAP interface.

These instructions describe how to create a SOAP client for an AMBUS

®

Net plant.

The document does not claim to be an introduction into SOAP or .Net.

The code extracts are written in the programming language C#.

General description of the Web service

The Web service of AMBUS® Net provides two functions:

getMeter(PrimAddr As unsignedByte) As Meter

PrimAddr

The primary address of the meter

Returned value

The returned data are features of the meter with the primary address "Pri-

mAddr"

getUsageUnit(index As int) As UsageUnit

index

The index number of the usage unit

Returned value

The returned data are the features of the usage unit with the index number "in-

dex"

Features of a meter

If a meter is loaded with the function "getMeter(…)", then it is possible to use it like a local instance. A meter

has various features and is structured as follows:

Public class Meter

{

public byte primAddr;

public string deviceName;

public string desc;

public string type;

public string info;

public string supplier;

public string serial;

public string medium;

public string instPoint;

public string readout;

public string status;

public Display opTime;

public Display errorTime;

public Channel[] channel;

public Meter()

{

channel = new Channel[3];

// …

}

}

public class Channel

{

public Display P;

public Display Q;

public Display Th;

public Display Tc;

public Display dT;

public Display[] M;

public Channel()

{

M = new Display[4];

// …

}

}

public class Display

{

public string value;

public string unit;

public Display() { }

}

30

Features of a usage unit

If a usage unit is loaded with the function "getUsageUnit(…)", then it is possible to use it like a local instance.

A usage unit has various features and is structured as follows:

public class UsageUnit

{

public int index;

public string name;

public string readout;

public string deviceName;

public int size;

public Entry[] entries;

public UsageUnit() { }

}

public class Entry

{

public byte primAddr;

public byte channelNr;

public byte meterNr;

public string medium;

public Entry() { }

}

Linking the Web service to a network

The three steps below following describe how the Web service of AMBUS® Net is linked to a C# project.

1. The first step involves creating a new C#

Windows Application project in MS Visual

Studio .Net.

2. The next step involves creating a Web

Reference in the file AmbusNet.wsdl.

This file is in AMBUS® Net and describes

the Web service.

The following address is to be entered-

as a URL:

http://xxx.xxx.xxx.xxx/AmbusNet.wsdl.

where „xxx.xxx.xxx.xxx“ is the IP

address of the AMBUS

®

Net device. In

this example AMBUS

®

Net has the IP

address: “172.16.1.211“.

The name of the reference can be

freely selected but is still used in the

code.

31

3. The final step is to link the SOAP service to the code. In the example given, the Web reference is called

“NetService“. If another name is selected then this name must be used in the code. Note that a timeout of

approx. 100 ms should be set between two SOAP prompts. This pause guarantees that AMBUS

®

Net is

again ready for the next prompt and that no error occurs. However, if there is an error, then it might take

some minutes until the SOAP service is working correctly again in the AMBUS

®

Net device. The example

below shows how the Web service is linked up:

namespace AmbusNetClient

{

public class AmbusNet : System.Windows.Forms.Form

{

public AmbusNet()

{

InitializeComponent();

}

[STAThread]

static void Main()

{

Application.Run(new AmbusNet());

}

//...

// Function get single meter (m).

public void GetMeter(byte PrimAddress)

{

AmbusNetClient.NetService.Service1 ambus = new

AmbusNetClient.NetService.Service1();

ambus.Proxy = new System.Net.WebProxy(); // empty Proxy

ambus.Url = "http://172.16.1.211/";

AmbusNetClient.NetService.Meter m;

try

{

m = ambus.getMeter(PrimAddress); // remote call

if (m != null){

String deviceName = m.deviceName;

//...

}

}

catch (System.Exception ex)

{

// Error when loading the meter

}

}

// Function get one usuage unit (u).

public void GetUsageUnit (int UnitNr)

{

AmbusNetClient.NetService.Service1 ambus = new

AmbusNetClient.NetService.Service1();

ambus.Proxy = new System.Net.WebProxy(); // empty Proxy

ambus.Url = "http://172.16.1.211/";

AmbusNetClient.NetService.UsageUnit u;

try

{

u = ambus.getUsageUnit(UnitNr); // remote call

if (u != null){

String unitName = u.name;

//...

}

}

catch (System.Exception ex)

{

// Error when loading the usage unit

}

}

}

}

32

5.2 Download prot oc ol

Section 3.4 Network (Windows) explained

how all protocol files that AMBUS

®

Net stored

on the CF card

*)

can be saved to the PC

using a network.

By entering the address:

http://192.168.1.10/CF_Device/

**)

you get the file directory of the protocol files

from AMBUS

®

Net From which you can select.

*)

With data logger option only’

**)

Address when delivered

Click the individual file to:

• either open it

• or save it to a disk

The files can also be opened directly from the

application by entering the complete path with

the URL.

The figure to the right also shows an example

from the Office application: "Excel"

Open File / File name (example):

http://192.168.1.10/CF_Device/LOGA_003.CSV

33

6 Troubleshooting

Symptom

Cause

Remedy

Power symbol does not light

• No power supply

Check power supply including power isolating

terminal acc. to installation instructions

• Short-circuit in the

M-Bus

Check the M-Bus (4-wire) acc. to installation in-

structions AMBUS® Net.

Power symbol lights up but the

display cannot be operated or else

remains dark

• Display not connected

Display should be connected with three cables to

the electronics. Check the cables.

• Serial flash incorrectly

mounted or is defective

Check the seating and position of the serial flash

in its holder.

Power symbol flashes

• Error in M-Bus power

supply

The AMBUS® Net has identified an error in at

least one meter (sect.

4.2). Check the affected

meters (sect. 4.3

) and remove the error at the

meter itself.

No further operation after entering

the access code

• Incorrect access code

Enter the code acc. to sect. 3.2.

• Instruments incorrectly

operated

The code must be entered in the entry field and

confirmed on the access side with OK.

Status message “Initialization of

modem has failed !”

• Incorrect setting

• Modem not plugged in

correctly

• Modem faulty

Verify modem settings and restart device!

Verify telephone connection

Verify modem connection or exchange modem.

Status message "Please insert

memory card”

• Memory card not

plugged in (correctly)

Plug in memory card.

Status message “Logger interval

too short! “

• Logger interval shorter

than time required for

readout

Determine readout time (see section 1.1) and set

logger interval at a higher value.

Status message “No answer”

•

At least 1 meter does

not respond

Verify meter: power supply, M-Bus-connection,

temperature-sensor-connection…

Status message “Error”

• At least 1 meter detected an error

Verify meter: Meter display, temperature-sensorconnection.

Status message “Alarm”

• At least 1 meter detected an alarm

Verify meter: Meter display, temperature-sensorconnection.

Status message “Serial-Flash

not....“”

• Serial flash new or faulty

Verify position of serial flash in holder. Restart

device.

Status message “unlocked”

• AMBUS

®

IS was not

electronically locked

This is no error. The locking is optional.

Menu read meter cannot be se-

lected. The message "No meter

recorded" is displayed

• AMBUS® Net has not

identified meters

Proceed acc. to sect. 3.3.

• Serial flash new or defective

Check the seating and position of the serial flash

in its holder.

AMBUS® Net does not find any

meters

• No or incorrectly con-

nected meters

Check the M-Bus (4-wire) acc. to installation in-

structions AMBUS® Net.

• Incorrect baud rate selected

Check the selected baud rate when entering the

meter acc. to sect. 3.3.

AMBUS® Net does not find all

meters

• Addresses entered twice

Check the M-Bus network with a suitable M-Bus

tool for bus numbers entered twice.

• Poor M-Bus network

Check the M-Bus (4-wire) acc. to installation in-

structions AMBUS® Net.

• Meter with incorrect

baud rate

Check the baud rate of the meter or select a lower

baud rate, if possible.

AMBUS® Net does not find meters

with the address 0

• Address 0 is not auto-

matically supported.

Proceed acc. to sect. 4.7 Meter list, manual me-

ter readings Enter the meter manually or change

the address of the meter.

Menu logger function cannot be

selected.

• Data logger option missing

Logger functions are an option (sect. 2.8); please

contact Aquametro Customer Service.

Status message indicates:

“Serial Flash not....“

• Serial flash new or defective

Check the seating and position of the serial flash

in its holder and restart the instrument.

CF card remains empty

• Data logger option missing

Logger functions are an option (sect. 2.8); please

contact Aquametro Customer Service.

• Card wrongly formatted

Reformat the card acc. to sect. 3.6.

• Incorrect parameters

Check the card acc. to sect: 3.6

• CF card defective

Use a new CF card

Status message "unlocked"

• AMBUS®IS not locked No error: AMBUS® IS was not locked when using

the parameter setting software at start-up.

34

Modem does not function

• Modem incorrectly installed

Check the installation of the modem.

• Incorrect jumper position

on pc board

Check the rider position acc. to sect. 3.5

• RJ-45 cable incorrect

Check the cable and the power outlet.

Analog modem does not function

• MSN No. was erroneously entered

Do not enter a MSN No. with analog modem!

ISDN modem does not function

• MSN No. incorrect

Check the MSN No. acc. to sect. 3.5 .

GSM modem does not function

• Poor reception

Change the position of the adhesive antenna.

• Incorrect SIM card

Check Natel subscription acc. to sect. 3.5.

• PIN not deactivated

Deactivate PIN with Natel.

Ethernet connection does not func-

tion

• Incorrect cable

There are1:1 and crossed cable available!

• IP address / Subnet

mask is wrongly or else

not initialized

Check the network settings or ask your network

supervisor. See sect.: 3.4

Table 6: Troubleshooting

35

7 Appendix

Meter protocol

Meter protocol

Date of protocol:

30.09.2004 08:46

Installation:

Aquametro AG, 4106 Therwil

Type:

CALEC ST

Manufacturer:

AMT Designation:

Staircase 1

Comment:

Aquametro AG, 4106 Therwil

Primary address:

2

Nbr operating hours:

3942

h

Secondary address:

4313074

Nbr hours on alarm:

1 h Medium:

Heat

Status:

ok Installation side flow meter:

cold Side

Channel 1

Read out:

30.09.2004 08:42

Meter 1:

854033

kWh

Meter 2:

15288.9

m3

Meter 3:

Meter 4:

Power:

0

kW

Flow:

0

m3/h

Temperature hot side:

129.8

°C

Temperature cold side:

76.8

°C

Temperature difference:

52.99

K Channel 2

Read out:

30.09.2004 08:42

Meter 1:

0

HCA

Meter 2:

Meter 3:

Meter 4:

Power:

Flow:

Temperature hot side:

Temperature cold side:

Temperature difference:

Channel 3

Read out:

30.09.2004 08:42

Meter 1:

0

HCA

Meter 2:

Meter 3:

Meter 4:

Power:

Flow:

Temperature hot side:

Temperature cold side:

Temperature difference:

made out with AMBUS Net, Aquametro AG, Therwil

Table 7: Example of meter protocol

36

Usage unit protocol

Usage unit protocol

Date of protocol:

30.09.2004 08:58

Installation:

Aquametro AG, 4106 Therwil

Usage unit:

Primary address:

Serial Nr:

Designation:

Meter:

Channel

Medium:

Comment:

Status:

Read out:

Meter reading:

Power:

Appt 1st floor

2

4313074

Distributor 1

1 1 Heating

H-106

ok

30.09.2004 08:48

854033

kWh 0 kW

Appt 1st floor

7

22222222

Distributor 2

2 1 Hot water

W-170

ok

30.09.2004 08:48

1.014

m3 0 kW

Appt 1st floor

7

22222222

Distributor 2

4 1 Cold water

W-170

ok

30.09.2004 08:48

-4.432

m3 0 kW

Made out with AMBUS Net, Aquametro AG, Therwil

Flow: Temp. hot side:

Temp. cold side:

Temp. difference:

Nbr operating hours:

Nbr hours on alarm:

Type:

Manufacturer:

0

m3/h

129.8

°C

76.8

°C

52.99 K 3942 h 1 h CALEC ST

AMT 0 m3/h

30.9

°C

3.7

°C

27.23 K 5532 h 81 h CALEC ST BDE

AMT 0 m3/h

30.9

°C

3.7

°C

27.23 K 5532 h 81 h CALEC ST BDE

AMT

Table 8: Example of Usage unit protocol

37

Installation protocol

Installation protocol

Date protocol:

30.09.2004 08:48

Installation:

Aquametro AG, 4106 Therwil

Prim. address:

Serial Nr:

Chan.

Designation:

Comment:

Medium:

Status:

Read out:

Meter reading 1:

Meter reading 2:

Meter reading 3:

2

4313074

1

Device 1

Second. circuit

Heat

ok

30.09.2004 08:48

854033

kWh

15288.9

m3 2 4313074

2

Device 1

Second. circuit

Heat

ok

30.09.2004 08:48

0

HCA 2 4313074

3

Device 1

Second. circuit

Heat

ok

30.09.2004 08:48

0

HCA 7 22222222

1

Device 2

Main circuit

Heat

ok

30.09.2004 08:48

0.142

kWh

1.014

m3

-13.001

kWh 7 22222222

2

Device 2

Main circuit

Heat

ok

30.09.2004 08:48

0.204

kWh 7 22222222

3

Device 2

Main circuit

Heat

ok

30.09.2004 08:48

54321

HCA

Made out with AMBUS Net, Aquametro AG, Therwil

Meter reading 4:

Power:

Flow:

Temp. hot side:

Temp. cold side:

Temp. difference:

Nbr operating hours:

Nbr hours on alarm

Type:

Manufacturer

0

kW 0 m3/h

129.8

°C

76.8

°C

52.99 K 3942 h 1 h CALEC ST

AMT

3942 h 1 h CALEC ST

AMT

3942 h 1 h CALEC ST

AMT

-4.432

m3 0 kW 0 m3/h

30.9

°C

3.7

°C

27.23 K 5532 h 81 h CALEC ST BDE

AMT

5532 h 81 h CALEC ST BDE

AMT

5532 h 81 h CALEC ST BDE

AMT

Table 9: Example Installation protocol

38

39

Änderungen vorbehalten / Sous réserve de modifications / Modification rights reserved

Copyright © INTEGRA METERING AG, Switzerland

info@integra-metering.com

www.integra-metering.com

Art. Nr. 20275

Loading...

Loading...