Page 1

Mounting and operating instructions

VD 9-925 e 02.2017

AMBUS® Link

The intelligent M-Bus data central for configuration, operation and monitoring of M-Bus

installations as a total system. The integrated web server offers a modern administration

of consumption data.

Table of contents

1 Safety 2

1.1 Intended use 2

1.2 Notes on safety instructions and symbols 2

1.3 Safety instructions and precautionary measures 3

1.4 About the operation manual 3

2 Product description 4

2.1 Areas of application 4

2.2 Device design 4

2.3 Power supply 5

2.4 Interfaces 6

2.5 Memory card 7

3 Scope of delivery and accessories 7

4 Mounting 8

5 Installation 9

5.1 Connection scheme 10

5.2 M-Bus network (field level) 11

6 Commissioning 17

6.1 Switchig on the AMBUS® Link 17

6.2 Operation via AMBUS® Link 18

6.3 Operation via web server 20

6.4 Configuration meter via web server 24

6.5 Creating usage units via web server 29

6.6 Configuring a reporting date reading via web server 32

6.7 Driver configuration via web server 34

6.8 Configuring a logger via web server 37

6.9 Data management via w eb server 45

6.10 System integration via web server 47

7 Maintenance and repair 51

8 Malfunctions and error messages 52

9 Decommissioning, disassembly and disposal 55

9.1 Decommissioning 55

9.2 Disassembly 55

9.3 Disposal 56

10 Technical data 56

10.1 Dimensions 58

11 Appendix 59

11.1 CE declaration of conformity 59

11.2 Export file type csv standard 60

11.3 Export file type csv FULL-DB 65

Page 2

indicates an action or measure which, if performed incorrectly,

CAUTION indicates an action or measure which, if performed incorrectly,

NOTE

COMMENT

1 Safety

1.1 Intended use

The device AMBUS® Link is exclusively intended for the configuration, operation and

monitoring of M-Bus installations as a total system.

Any improper or inappropriate use might result in a state in which the operational safety

of the device cannot be guaranteed anymore. The manufacturer waives any liability for

resulting damages of persons and materials.

1.2 Notes on safety instructions and symbols

The devices have been designed to fulfil modern safety requirements. They have been

tested and delivered in a condition that ensures safe operation. However, improper or

non-intended use of the device may result in it becoming dangerous. Please always pay

attention to the safety instructions in this manual which are accompanied by the following

symbols:

WARNING

WARNING

can potentially cause life-threatening injuries and lead to a high safety risk.

ATTENTION

can cause minor to medium severe injuries.

NOTE indicates a dangerous situation which might lead to material damage,

if not prevented.

COMMENT provides helpful tips and recommendations as well as information for efficient and trouble-free operation.

AMBUS® Link 2

Page 3

in this manual are

This installation instruction is intended for qualified personnel and contains

1.3 Safety instructions and precautionary measures

The manufacturer takes over no responsibility if the following safety instructions and precautionary measures are disregarded:

1. Changes to the device, which are implemented without prior written approval of

the manufacturer, lead to the immediate termination of product liability and warranty.

2. Installation, operation, maintenance, repair and decommissioning of this device

must only be performed by specialists authorised by the manufacturer, operator or

owner of the device. The specialist needs to read and understand the entire installation and operation manual and is obliged to follow these instructions.

3. Control the supply voltage and information given on the type plate, before the device is installed.

4. Check all connections, settings and technical specifications of any available peripheral devices.

5. Open the housing or parts of the housing, which contain electrical or electronic

components, only if the electric energy is turned off.

6. Touch no electronic compo ne nts (ESD sensitivity).

7. Expose the system concerning the mechanical load (pressure, temperature, IP

protection etc.) maximally to the specified classification.

8. For works concerning mechanical components of the system, the pressure in the

pipe system has to be released or the temperature of the medium needs to be

brought to values harmless for humans.

9. No information stated her e or anywhere else releases planners, engineers, fitt er s

and operators from their personal careful and comprehensive evaluation of the respective system configuration in terms of functionality and operational safety.

10. The local working and safety standards and statutes need to be met.

1.4 About the operation manual

The manufacturer reserves the right to change the technical details without prior notice.

The newest information and versions of this operation manual are available at your local

subsidiary or representation as well as on the website.

WARNING

Any liability is waived if the instructions and procedures

not followed!

NOTE

thus no basic working steps. Before putting AMBUS® Link or the system into

operation, the installation and operation manual needs to be read and understood completely.

Keep this manual for later reference!

AMBUS® Link 3

Page 4

2 Product description

We congratulate you for purchasing this high-quality M-Bus data central.

The device AMBUS® Link makes the configuration, operation and monitoring of M-Bus

installations as a total system easier. The integrated web server serves for easy provision

of your consumption data on any terminal devices or subordinate control systems.

2.1 Areas of application

AMBUS® Link is designed for technical building management and also for building services and can be used as follows:

Data concentrator

As central function of your consumption data for analysis and documentation purposes of

all flow and energy meters. For easy administration the integrated web server supports

on all web-enabled terminal devices the user in recording, presentation and provision of

consumption data for utility cost billing or monitoring.

System integration component

With the versatile interfaces AMBUS® Link has to offer you can integrate your consumption data in the simplest way in subordinate building control systems.

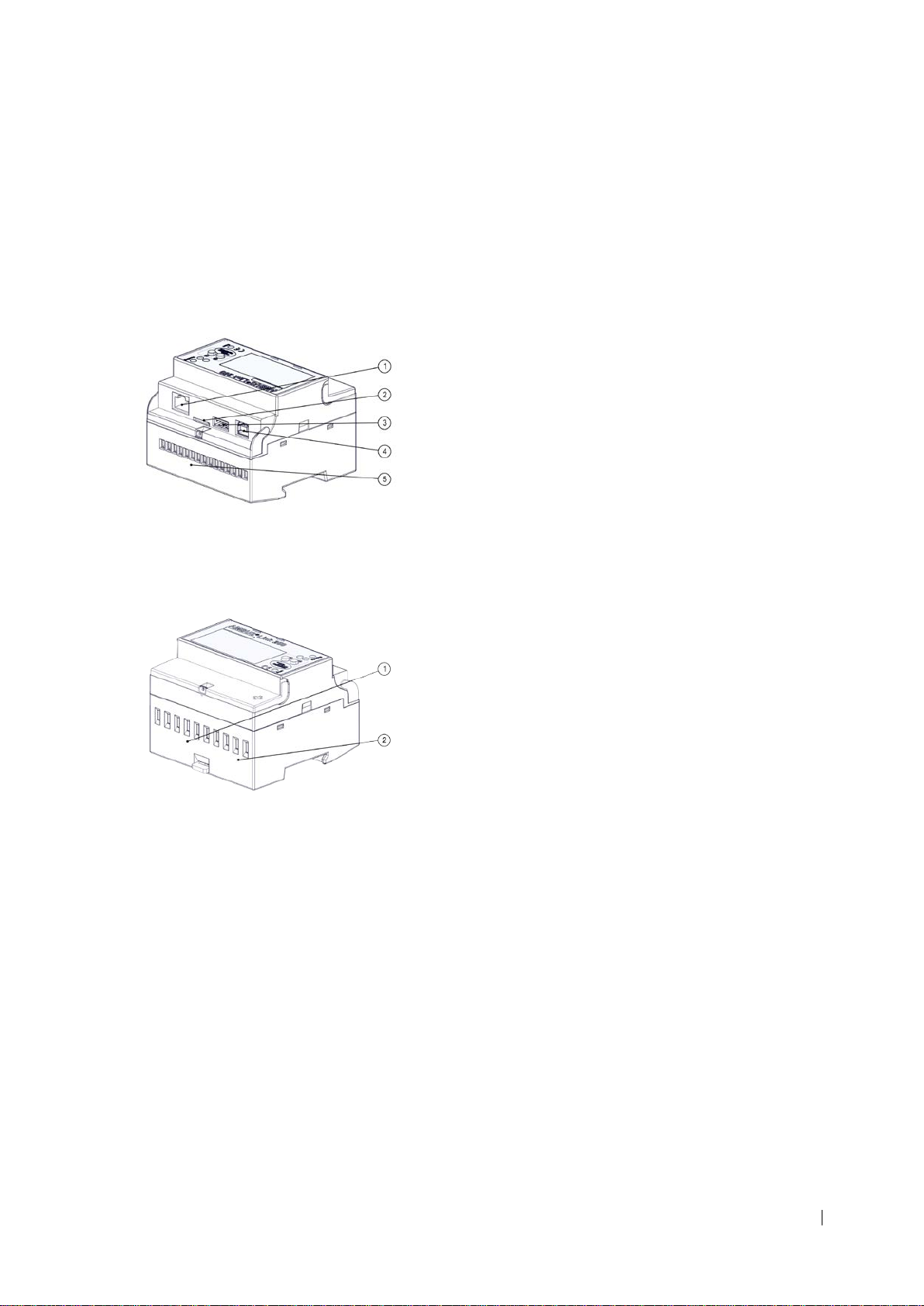

2.2 Device design

AMBUS® Link is intended for control cabinet installation. The device design is defined as

follows:

Optical signals/lights

LED reading and LED scanning

Operating elements

o Enter button

o Function button

AMBUS® Link 4

Page 5

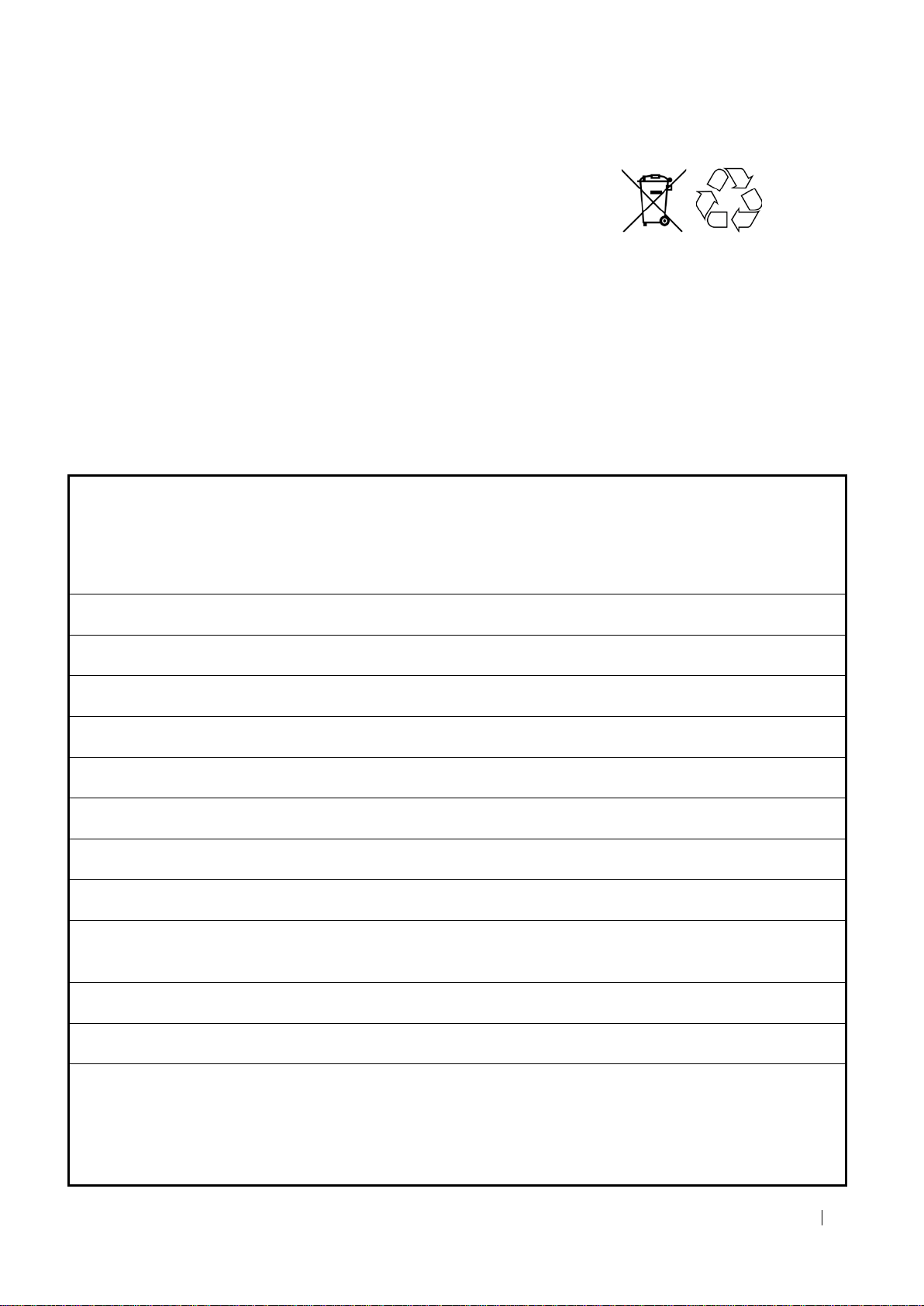

External

Manufacturer recommendations

Switching power supply UNO POWER

Dimensions W x H x D 55×90×84 mm

Protection covers

Mounting rail protection

Mounting rail guide

Status logger, operating status

M-Bus slaves

IP address

Subnet mask

Default gateway

Firmware version

2.3 Power supply

For using the product outside a control cabinet the power supply can be realised as follows.

• Output voltage 24 VDC

• Output power 4.2 A

• Capacity 100 W

AMBUS® Link 5

Page 6

2.4 Interfaces

The data central consists of a TCP/IP interface with integrated data logger and combines

the function of an M-Bus data logger and an M-Bus reading software. Thus the following

software and hardware interfaces are implemented.

2.4.1. Connections

RJ45 LAN connection

Micro SD card slot

USB type A

USB type B

Terminal connection 1-15

Pulse inputs terminals 1-8

Power supply terminals 9-10

AMBUS® Link 6

Page 7

Communication protoc ol s

Micro SD

microSDHC card Transcend Pr emium 400x

1x

AMBUS® Link

1x

microSDHC card

1x

brief instruction

3x

protective covers

2.4.2. Protocols

• Ethernet/LAN/WLAN

• BACnet/IP

• FTP/sFTP

• HTTP

• JSON

• CSV

• POP3

2.5 Memory card

The medium stores all system-specific parameters and contains parts of the operating

system. It is a requirement for op er ati ng the AM BU S® Link.

Options retrofittable via external

router

• LTE

• UMTS/HSPA

• GPRS/EDGE

• Storage capacity 32 GB

• Class 10

• Reading (max.) 60 MB/s

• Writing (max.) 25 MB/s

3 Scope of delivery and accessories

The scope of delivery is described on the delivery note and the content is displayed on

the packaging. Please check all components and delivered parts immediately after receiving the product. Transport damages need to be reported immediately!

AMBUS® Link 7

Page 8

ATTENTION

Control cabinet mounting

AMBUS

ing rail

Control cabinet removal

AMBUS

rail

4 Mounting

Material damage caused by neglected ambient conditions

Danger of malfunction or damag e!

• Assuring accessibility for installation, operation and maintenance

• Protected, dr y surroundings

• Avoid exposure to heat/sun

• Keep a safe distance to sources of electrical nois e

1. Place recesses of the device at the top

edge of the mounting rail

2. Press lightly on the AMBUS®Link

3. AMBUS®Link snaps onto the mounting

rail

®

Link is firmly connected to the mount-

1. Remove the piston

2. Lift AMBUS®Link up from the mounting

rail

®

Link is separated from the mounting

AMBUS® Link 8

Page 9

Life hazard due to electrical shock!

NOTE

5 Installation

Carefully read the following calls for action and warning information to assure a troublefree commissioning.

WARNING

Burns and paralysis resulting in death when touching or grabbing energised system parts.

• Perform installation and maintenance work only when the system is

off power

• W ork on and with voltage shall only be performed by authorised spe-

cialists under consideration of applicable regulations

Apply voltage only to the terminals intended

•

• Safeguarding by external protection elements to assure a safe

switch-off in case of an error

• Install a labelled disconnector (fuse) at an accessible location

• Use a separate fuse circuit for installation

Terminal connections cable cross section

• Terminal connections relay, temperature sensor and M-Bus

• Terminal connections S0 inputs and power supply

o Braid up to 2.5 mm2

o Torque 0.4 Nm

o Braid up to 6 mm2

o Torque 1.3 - 1.6 Nm

AMBUS® Link 9

Page 10

Terminals

Function

Rel 1 NO/Rel 1 C

Relay 1

Normally open

Rel 2 NO/Rel 2 C

Relay 2

Normally open

PT1000 1/PT1000 C

Temperature sensor

PT1000

PT1000 2/PT1000 C

Temperature sensor

PT1000

M-BUS1-/M-BUS1+

M-BUS output 1

Master

M-BUS2-/M-BUS2+

M-BUS output 2

Master

M-BUS3-/M-BUS3+

M-BUS output 3

Master

S0 1A/S0 1B

S0 pulse input 1

Active encoder signal

S0 2A/S0 2B

S0 pulse input 2

Active encoder signal

S0 3A/S0 3B

S0 pulse input 3

Active encoder signal

S0 4A/S0 4B

S0 pulse input 4

Active encoder signal

RJ45

Ethernet port

USB type A

USB interface of type A

WLAN and modems

Level converter and mainte-

5.1 Connection scheme

+24V/GND 24VDC supply voltage

USB type B USB interface of type B

AMBUS® Link 10

nance

Page 11

5.1.1. Power supply:

1. Assure that the power cable

AMBUS

5.1.2. Attach the protective covers

The interfaces are protected

ATTENTION

is voltage-free!

2. The disconnector needs to be switched

off!

3. Flip up the protective cover

4. Loosen the terminal connection

(terminal 9 (+24V DC) /10 (GND))

5. Connect the power supply to

terminal 9 (+24V DC) /10 (GND).

6. Tighten the terminal connection

7. Close the protective cover

®

Link is ready for use

1. Attach included protec t i on cover with

slight pressure

2. Attach included protec t i on cover with

slight pressure

3. Attach included protec t i on cover with

slight pressure

5.2 M-Bus network (field level)

In the following the installation of the M-Bus network with AMBUS® Link is described

Material damage caused by neglected installation conditions

Danger of malfunction or damag e!

• Generously dimension the main cable cross section and possibly

divide it into 3 terminal groups

Apply voltage only to the intended terminals

•

AMBUS® Link 11

Page 12

NOTE

Bus cables between data central and

5.2.1. Connect M-Bus meter

AMBUS

M

5.2.2. Connect the temperature sensor

The temperature sensor is connected

High voltage drops of 5 VAC on the Mterminal node need to be avoided.

• Divide the main strand into several part strands (largest strands)

• Increase cable cross section

• Apply star shape network topology instead of chained network

topology

• Apply no circular network topologies

1. Open the protective cover

2. Loosen the terminal connection

(terminals 10-15)

3. Connect M-Bus participant to terminal

10/11, 12/13 or 14/15

4. Tighten the terminal connection

5. Close the protective cover

®

Link is physically connected with the

-Bus participants

1. Open the protective cover

2. Loosen the terminal connection

(terminals 6-9)

3. Connect the temperature sensor with the

terminal 6/7 or 8/9

4. Tighten the terminal connection

5. Close the protective cover

AMBUS® Link 12

Page 13

COMMENT

5.2.3. Connect alarm relay 1

The relay output is connected

COMMENT

Operating principle alarm relay 1

• Operating principle as normally open

• The following signals appear

o Meter cannot be read out

o Parameter error flag

o M-Bus short circuit

1. Open the protective cover

2. Loosen the terminal connection

(terminals 1/2)

3. Connect the participant to terminal 1/2

4. Tighten the terminal connection

5. Close the protective cover

Operating principle alarm relay 2

• Operating principle as inverted normally open

• The following signals appear

o Meter cannot be read out

o Parameter error flag

o M-Bus short circuit

AMBUS® Link 13

Page 14

5.2.4. Connect alarm relay 2

The relay output is connected

5.2.5. Connect pulse inputs

The pulser is connected

5.2.6. Connect USB type A

The external USB device is

1. Open the protective cover

2. Loosen the terminal connection

(terminals 3/4)

3. Connect the participant to terminal 3/4

4. Tighten the terminal connection

5. Close the protective cover

1. Open the protective cover

2. Loosen the terminal connection

(terminals 1-8)

3. Connect pulser to terminal 1/2,

3/4, 5/6 or 7/8

4. Tighten the terminal connection

5. Close the protective cover

1. Plug the USB type A into the intended

port

connected.

AMBUS® Link 14

Page 15

5.2.7. Connect USB type B

The external USB device is connected.

5.2.8. Connect network cable RJ45

The network cable is connected

1. Plug the USB type B into the intended

port

1. Plug the RJ-45 connector into the intended port

AMBUS® Link 15

Page 16

5.2.9. I nserting a mini SD card

The microSD card is connected.

NOTE

In case of improper handling the microSD card falls into the housig between the

slot and the surface.

• Control the exact positioning of the microSD card before inserting it

Use a slotted screwdriver to insert it.

•

1. Insert the microSD card centred into the

intended port

2. Press the microSD card with slight pressure over the snap-in point

3. The microSD card snaps in the port

AMBUS® Link 16

Page 17

Life hazard due to electrical shock!

Switching AMBUS® Link on

AMBUS

6 Commissioning

AMBUS® Link can be commissioned in two ways, which are described in the following

chapter.

6.1 Switchig on the AMBUS® Link

WARNING

Burns and paralysis resulting in death when touching or grabbing energised system parts.

• Perform installation and maintenance work only when the system is

off power

• W ork on and with voltage shall only be performed by authorised spe-

cialists under consideration of applicable regulations

Apply voltage only to the intended terminals

•

• Protection by external protection elements to assure a safe switch-off

in case of an error

• Install a labelled disconnector (fuse) at an accessible location

Use a separate fuse circuit for installation

1. Start the supply via the disconnector

2. AMBUS® Link starts

3. The reading and scanning LEDs are

"slightly" glowing

4. The display is flashing after 30 sec.

®

Link is ready for use

AMBUS® Link 17

Page 18

COMMENT

COMMENT

6.2.1. Quick commissioning M-Bus network

All meters have been read in

COMMENT

6.2 Operation via AMBUS® Link

The delivery state of the network configuration ex works

• DHCP is activated, IP address is automatically obtained

Functionality of the secondary search

DHCP is deactivated by manual entry of the network parameters

•

Activating DHCP by entering zeros for all network parameters

o

• The search via secondary address is conducted as reverse search

1. Hold the button for more than 5 sec.

2. M-Bus meter search is started via

secondary address

3. The reading and scanning LEDs are glowing "brightly"

4. The operating mode reports SCAN

5. Scanned meters are shown on the

display (slaves)

Finalising the quick configuration of the network parameters

• The set parameters are activated after the configuration has been

finished

• The configur ati on is fi n i shed after de-selecting the last digit

AMBUS® Link 18

Page 19

6.2.2. Quick configuration network parameters

IP address, subnet

are set, the network is configured

6.2.3. Re s tar t AMBUS® Link

AMBUS

preserved

1. Hold the button for more than 2 sec.

first position at IP is selected and

configurable

2. When pressing the button the marked

digit increases by one (0-9)

3. The button confirms the set digit and

jumps to the next

mask and default gateway

1. Hold the button and button

together longer than 5 sec.

2. After releasing the buttons a restart is performed

®

Link restarts and the settings remain

AMBUS® Link 19

Page 20

COMMENT

COMMENT

not connected (connection failed)

COMMENT

COMMENT

6.3 Operation via web server

Operation

• Button for home screen view

• Automatic logout a fter 10 minutes without operation

Role rights

• The rights of each role are fixed and cannot be changed

Administrator «all rights»

•

Standard user «read rights» cannot make changes to the system

•

• In the delivery state a user is predefined

o Admin (administrator role)

Reachability of the web server concerning the firewall

• The communication takes place via TCP, HTTP and websocket

• Port 80 is the communication por t

Explanation of the connection indicator

connected (connection established)

connecting (connection in establishment)

AMBUS® Link 20

Page 21

6.3.1. Language settings

Language is loaded

COMMENT

6.3.2. Create a user profile

The user is created

1. Change language

• German

• English

• French

User administration, password

• Any number of users can be registered in the system

Username minimum length 3 characters

•

Password minimum length 3 characters

•

• Each logged in user can change their personal password

• The standard password for the «admin» user is 123

It is recommended to change the standard password!

1. Enter a username

2. Select role

3. Enter password

4. Enter password again

5. Press

AMBUS® Link 21

Page 22

COMMENT

6.3.3. Change a user profile

The settings are changed

COMMENT

User management as administrator

• A role change for other users is possible

• A password change for other users is possible

1. Select a user

2. Change role

3. Press for role change

4. Enter password

5. Enter password again

6. Press for password change

User management as administrator

• Deleting other users is possible

AMBUS® Link 22

Page 23

6.3.4. Deleting a user profile

The user is deleted

6.3.5. Changing the personal

The

6.3.6. Basic settings

Basic settings are defined and displayed in the

banner

1. Select a user

2. Press

3. Confirm the prompt

password

1. Enter current passwor d

2. Enter new password

3. Enter new password again

4. Press

password is changed

1. Enter name and location

2. Choose time zone

3. Press

AMBUS® Link 23

Page 24

6.3.7. Setting date and time

Date and time

footer

COMMENT

COMMENT

6.4 Configuration meter via web server

1. Set date and time

2. Press

are set and displayed in the

Registration procedure of M-Bus partic ipants

• Network search of connected M-Bus participants

o All meters in the M-Bus network can be registered

• Offline registration of M-Bus participants

o Configuration of the M-Bus network without M-Bus partici-

pants

o Registration of participants after installation in the M-Bus net-

work and first-time network reading

Restrictions of the address range

• When searching with the primary address the range can be freely

selected between 1-250

AMBUS® Link 24

Page 25

6.4.1. Search all meters

The meters in the M

6.4.2. Recording individual meters

The individual meter is saved

6.4.3. Check recorded meters

All meters are available

1. Choose Baud rate

2. Start scan or

-Bus network are registered

1. Choose recording or

2. Set Baud rate

3. Enter the primary and sec on dar y address

of the meter

4. Confirm

1. All registered meters are listed in a table

2. Check status

Found meters - successfully read

Existing meters - M-Bus alarm

Existing meters - Reading error

Missing meters - not yet read out

AMBUS® Link 25

Page 26

COMMENT

6.4.4. Configuring a global reading

All meters are cyclically read out

Definition of the global reading cycle

• The reading cycle is set with «15 min» as a standard

• The reading cycle can be set between 10 sec. - 48h

• The reading cycle is dependent on the entire M-Bus network

cycle

1. Choose reading cycle

2. Press

AMBUS® Link 26

Page 27

COMMENT

COMMENT

NOTE

Bus participants might lead to wrong consumption

M-Bus protocol-specific parameters

• M-Bus protocol-specific values can be overmodulated via

AMBUS® Link

o Meter type

o SND_NKE

o Application reset (including subcodes)

o Designation

o Unit

o Decimal place

o Phase (phase number for electricity meters)

o Tariff (tariff number for meters with several counting modules

for different tariffs)

o Mon. (Month number of a record date meter value)

Single meter configuration for Aquametro and third party meters

• Easy meter configuration for individual meters

• Individual configurations can be saved as templates and applied for

all identical meters

• As a standard for each M-Bus request an SND-NKE and an application reset with subcode «0» are set. The function can be deactivated

by using the checkbox

• Application reset subcodes can be entered into the field

• Meter-specific reading cycles overmodulate global reading cycles

Correct the deci mal pl aces for v alue units

• For decimal places to the left «factor 1000»

• For decimal places to the right «factor 0.001»

Parameter changes for Mdata

• In case of manipulated meters (M-Bus), the meter s need to be new l y

registered (registration)

AMBUS® Link 27

Page 28

6.4.5. Editing meter details

1. State name, location, cost centre and

The individual meter configuration is finished

6.4.6. Deleting a meter

All/individual meters are deleted

or

comment

2. choose meter

type

3. Choose recording or

4. Choose reading cycle

5. Choose Baud rate

6. Tick battery operation

7. Press

8. Confirm the designatio n

9. Mark the designation

10. Choose the unit

11. State phase, divisor, tariff

12. Press

1. Select all or individual meters

2. Press

3. The data is updated

AMBUS® Link 28

Page 29

COMMENT

6.5.1. Defining a usage units

The usage unit is created

6.5 Creating usage units via web server

In the following chapter the creation of user-defined, organisational units (usage units) for

administration of M-Bus participants is described

Administration of usage units

• Formation of organisational units

• User-specific meter gr oup al loc ati o n

1. Press to create a usage unit

1. Enter the name of the usage unit

2. Enter a description

3. Press

AMBUS® Link 29

Page 30

6.5.2. Deleting a usage unit

The usage unit is deleted

6.5.3. Allocating a meter to a usage

The meter

1. Select a usage unit

2. Press

unit

1. Select a usage unit

2. Press

1. Press

2. Select the meter for the usage unit

3. Press

is now allocated to a usage unit

AMBUS® Link 30

Page 31

6.5.4. Deleting a meter from a usage

The meters are now deleted from the

unit

6.5.5. Add a user for a usage unit

The user is now allocated to the usage unit

unit

1. Select a usage unit

2. Press

3. Select the meter of the usage unit

4. Press

usage

1. Select a usage unit

2. Press

3. Press

4. Select the user for the usage unit

5. Press

AMBUS® Link 31

Page 32

6.5.6. Delete a user from a usage

The user is now deleted from the usage unit

COMMENT

6.6.1. Creating a reporting date

The reporting date reading is set for the last day

of the month and the specified reporting date

unit

1. Select a usage unit

2. Press

3. Select the user for the usage unit

4. Press

6.6 Configuring a reporting date reading via web server

Configuration of reporting date reading

• Use numeric input for month, day and hour

o Month (1 -12)

• Report date data available in the export file

o Day (1-31)

o Hour (0 -23)

1. Press

2. Enter month, day and hour

3. Confirm the last day

4. Actively press

AMBUS® Link 32

Page 33

6.6.2. Deleting a reporting date

The reporting date reading is deleted

1. Mark the line

2. Press

AMBUS® Link 33

Page 34

COMMENT

COMMENT

NOTE

Bus participants might lead to wrong consumption

6.7 Driver configuration via web server

Driver configuration for Aquametro and third party meters

• Easy driver configuration for all meters

• M-Bus protocol-specific values can be overmodulated via AMBUS

Link

o Designation

o Unit

o Decimal place

o Phase (phase number for electricity meters)

o Tariff (tariff number for meters with several counting modules

for different tariffs)

• Templates are appl i ed on the bas i s of the following criteria

• Driver templates can be exported and sent to Aquametro

o Mon. (Month number of a record date meter value)

o Manufacturer code

o Version byte

o Number of data records

o Inclusion in third party meter library

o Export file in JSON format

o The exported file is saved in the download folder of the web

browser

®

Correct the decimal places for value units

• For decimal places to the left «factor 1000»

• For decimal places to the right «factor 0.001»

Parameter changes for Mdata

• In case of manipulated meters (M-Bus), the meter s need to be new l y

registered (registration)

AMBUS® Link 34

Page 35

6.7.1. Creating a driver template

The driver template for meters is created

6.7.2. Editing a driver template

1. Select a driver template

Update and save the driver template

1. Select a meter

2. Press

3. Press

2. Press

3. Enter the device designation

4. Choose the device designation from the

value definitions

5. Set the target unit

6. Enter the phase and div is or

(if required)

7. Mon. enter (if required)

8. Enter tariff (if required)

9. Press

AMBUS® Link 35

Page 36

6.7.3. Apply driver template to meter

All meters with the same manufacturer code are

configured

6.7.4. Export driver template

The meter driver template is exported

1. Select a driver template

2. Press

3. Press

according to the driver template

1. Select a driver template

2. Enter a file name

3. Press

4. Execute save file as

AMBUS® Link 36

Page 37

6.7.5. Import driver template

Import driver template

6.7.6. Delete driver template

The reporting date reading is deleted

COMMENT

1. Press

2. Press

3.

4. Press

6.8 Configuring a logger via web server

1. Select a driver template

2. Press

Correctly choose reading times

• Reading times depend on the circumstances and the dimensioning

of the M-Bus network

The reading cycle applies for the entire M-Bus network

•

For 100 or more meters at least 2 min per reading

•

For 250 meters at least 5 min per reading

•

AMBUS® Link 37

Page 38

COMMENT

COMMENT

6.8.2. Set up an NTP time server

The system time is synchronised with the defined server

6.8.1. Network settings

Established connection with AMBUS

Define network parameters via DHCP

• DHCP needs to be activated at the router

• Set that the IP address is automatically allocated from the DHCP

server

1. Enter IP address of the AMBUS® Link

2. Enter subnet mask

3. Enter the gateway of the router

4. Enter the DNS server address 1 and 2 on

demand

5. Activate on demand

6. Press

®

Link

Requirements for correct logging of consumption data

• The system time is correctly set (see basic settings)

• AMBUS® Link is working with UTC time

• The UTC time is calculated with the defined local time and time zone

The system time is defined via an NTP server

•

e.g. metasntp 11.admin.ch

o

AMBUS® Link 38

1. Define the NTP server

2. Press

Page 39

6.8.3. Logging the temperature sen-

The temperature

6.8.4. Logging the S0 inputs

S0 input is logged

COMMENT

sors

1. Mark the line

2. Activate

sensor is logged

1. Mark the line

2. Enter the starting value

3. Activate

Using the level converter

• Using the level converter via USB type B interface

• Setting «Default» complies with 2400 Baud

• When the level converter is activated the status changes

o to web server «Level converter RS232» is on

o to AMBUS® Link «[< - - >]» is on

• The logger function is deactivated in the level converter operation

AMBUS® Link 39

Page 40

6.8.5. Switching on the level con-

The level converter is activated

COMMENT

verter

1. Choose the Baud rate of the meter

2. Activate the level converter

3. Press

Filtering the status messages

• Status details

o 0 - After switching on the device, start process "logger"

o 1 - M-Bus overcurrent

o 2 - Start cloud upload

o 3 - Error cloud upload

o 4 - Cloud upload successfully completed

o 5 - Start FTP/sF TP upl oad

o 6 - Error FTP/sF TP upl oad

o 7 - FTP/sFTP upload successfully completed

o 8 - Meter (serial number), reading failed

o 9 - Email transmission failed

o 10 - Error on a meter

It is recommended to regularly delete the status messages to prevent

•

long updating times.

AMBUS® Link 40

Page 41

6.8.6. Status messages

Status information is displayed

6.8.7. Message type selection

Message type selected

1. Enter status number

2. The data is updated

3. Press for actualisation

1. Select a message

a. Error

b. Warning

c. Info

2. The data is updated

3. Press for actualisation

AMBUS® Link 41

Page 42

6.8.8. Delete status messages

All status messages are deleted

COMMENT

6.8.9. Sending alarms via email

1. Enter email server and port

Alarms have been sent via email

1. Press

Configuration email

• Several email addresses possible by using a semicolon as separator

• Sending of

o M-Bus alarm (warning)

o Reading error (error)

2. Enter name and email address o f the

sender

3. Enter email address of the recipient

4. Select connection type

• TCP

• SSL

• TLS

5. Select login

• Login

• Plain

6. Adjust timeouts

7. Enter username and password

8. Activate/deactivate function

9. Press

AMBUS® Link 42

Page 43

COMMENT

6.8.10. Export logger configuration

Data is exported

6.8.11. Import logger configuration

Logger configuration is imported

NOTE

Configuration logger

• Backup file

o Export file in JSON format

o The exported file is saved in the download folder of the w eb

browser

• Contains complete logger configuration

o Without meter

1. Press for saving the current

logger configuration

2. Data is downloaded

1. Press (format JSON)

2. Select file

3. File is

displayed

Failed firmware updates might lead to a loss of data

• Perform configuration logger «Backup» (6.8.10)

AMBUS® Link 43

4. Press

5. Backup is imported

Page 44

COMMENT

6.8.12. Firmware package update

Updates have been installed

COMMENT

Install firmware updat e s

• Updating individual functional units

o M-Bus logger

o BACnet/IP

o Connect

o Websocket

o Web server

• Package update as for mat «*.ipk»

• Multiple selection for package updates possible

• Fail-safe firmware update with intermediate storage

1. Press

2. Select file

3. Press

4. File is uploaded

5. Data is displayed in table

6. Repeat step 1-4 for ad dit ional fil es

7. Updates are installed

8. Execute firmware package overview

(see 6.8.13)

9. Press

Installed firmware pack ages

• View of all firmware packages with time stamp and status

• Control of successful installations with the time stamp

• The update process might take several minutes

AMBUS® Link 44

Page 45

6.8.13. Firmware package overview

The overview of installed updates is refreshed

6.9.1. Overview of meter statuses

The table with current meter statuses is displayed

COMMENT

1. Press

6.9 Data management via web server

The function "Update" reads the current data of the last reading process from a

database. No M-Bus reading is performed.

1. Select of a meter

AMBUS® Link 45

Page 46

6.9.2. Viewing meter statuses

Data of selected meters are shown

Meter statuses are

Comparison with the previous day, week,

month or year is displayed

6.9.3. Print/save charts

Charts are saved or printed

1. Selecting a meter

2. Press

1. Select for diagram view

2. Choose starting time

displayed from starting time.

1. Select for diagram view

2. Choose starting time

3. Press

4. Select Print or Save

AMBUS® Link 46

Page 47

COMMENT

6.10 System integration via web server

Data export

• Data can be exported manually or via FTP/sFTP

• For a larger time period the process takes several minutes

• Export type CSV

o Option «Standard» see chapter 11.2

o Option «Standard» see chapter 11.3

o Enter separator

• The exported fil es ar e saved in a compressed ZIP archive (DataExport.zip) in the download folder of the web browser.

• FTP files are saved after each reading cycle in the indicated directory (push process)

Integration of a cloud solution

• ISO 500001 certified energy management software solution

• Please contact your Aquametro contact person

Integration via BACnet/IP

• All registered M-Bus meters are also available as BACnet objects

• AMBUS® Link is BBMD-capable

• At maximum 16 BBMD servers can be set up

• The M-Bus can be permanently read out

o Permanent reading: It is not waited for the next reading cycle. As

soon as the reading is finished the next query is started

AMBUS® Link 47

Page 48

6.10.1. Export meter data

Export file is generated and saved in the ZIP

archive

6.10.2. Meter data upload via

1. Define information about FTP/sFTP

Data is pushed to the FTP/sFTP server

COMMENT

1. Select individual meters or all meters

2. Select a time period

3. Choose a medium (optional)

4. Select export type

5. Select options

6. Select a separator

7. Press

FTP upload File path

10-46110815-20161122102732

ID-Secondary address-YearMonthDayHourMinuteSecond

ID : Internal AMBUS Link identification number (configur ati on met er 6.4.5)

FTP /sFTP

server

• Server address

• Port

• Username

• Password

• Path

2. Activate/deactivate upload

AMBUS® Link 48

3. Activate/deactivate

4. Select export type

5. Select a separator

6. Select options

7. Select language

8. Press

9. Press (manual upload)

Page 49

6.10.3. Upload of meter data via cloud

1. Specify information about the cloud

Data is pushed in the cloud

6.10.4. Switch on BACnet/IP

1. Define BACnet settings

BACnet/IP is switched on

server

• Server address

• Port

• ID

2. Activate/deactivate upload

3. Press

4.

5. Press (manual upload)

6.

• D-Net number

• Port number

• Device inst ance nu mb er

2. Activate/deactivate

3. Activate/deactivate

4. Activate/deactivate

5. Press

AMBUS® Link 49

Page 50

6.10.5. Define a BACnet BBMD server

BACnet BBMD server has been defined

6.10.6. Delete BACnet BBMD server

BACnet BBMD server is deleted

1. Define BACnet BBMD settings

• IP address

• Subnet mask

• UDP port

2. Press

1. Select server

2. Press

AMBUS® Link 50

Page 51

WARNING

used.

7 Maintenance and repair

The product requires no maintenance. Cleaning shall only be performed with a moistened cloth. No solvents or other aggressive agents shall be applied.

Risk of death by electric shock from live cables and parts.

Risk of electric shock!

1. Perform installation and maintenance work only when the system is off

power.

2. Work on and with voltage shall only be performed by authorised specialists under consideration of applicable regulations.

3. For connections to the power supply only the intended terminals shall be

AMBUS® Link 51

Page 52

Symptom

Reason

Correction

LEDs are not glowing

• No supply available

Check power supply incl.

AMBUS®Link finds no me-

• No or wrongly installed

Check meter installations

• Wrong Baud rate select-

Check the selected Baud

AMBUS®Link finds not all

• Addresses have been

Control M-Bus network with

• Meter with wrong Baud

Control the Baud rate at the

The operating status shows

• No mini SD ca rd in the

• Disconnect AMBUS® Link

8 Malfunctions and error messages

supply isolation termi n al

according to installation

manual

ter

meters

«OFF» during startup and

«MMC Missing» appears

on the display

meters

ed

assigned twice

rate

slot.

rate according to chapter

6.4.1

a suitable M-Bus tool f or bus

numbers, which have been

assigned twice

meter, select a lower Baud

rate at the meter, if possible.

from the power supply

• Enter a microSD card in the

respective slot

Switch AMBUS® Link on

•

AMBUS® Link 52

Page 53

Login

• Wrong username or

• Enter correct username

Create a user profile

• The current password is

• Enter the password correct-

• The minimum length of 3

• Enter a password with at

• The details have not

• Repeat the registration and

password

not corresponding with

the repeated password

characters has not been

complied with

and password

ly again

least 3 characters

AMBUS® Link 53

been filled out completely.

fill out all details

Page 54

Changing the password

• The current password is

• Enter the password correct-

• The minimum length of 3

• Enter a password with at

Search all meters

• Primary address range

• Set the primary address

Define BACnet/IP BBMD server

• A BBMD server with an

• Select new, unique IP

not corresponding with

ly again

the repeatedly entered

password

characters has not been

least 3 characters

complied with

set too small

identical IP address already exists.

range generously

address

AMBUS® Link 54

Page 55

WARNING

used.

Control cabinet removal

9 Decommissioning, disassembly and disposal

Risk of death by electric shock from live cables and parts.

Risk of electric shock!

1. Perform installation and maintenance work only when the system is off

power.

2. Work on and with voltage shall only be performed by authorised specialists under consideration of applicable regulations.

3. For connections to the power supply only the intended terminals shall be

9.1 Decommissioning

1. Disconnect from all sources of energy

2. Remove all cables and

connections from the device

3. Remove the device from the

system

AMBUS® Link is out of service

9.2 Disassembly

1. Remove the piston

2. Lift AMBUS®Link up from the mounting

rail

AMBUS® Link 55

AMBUS®Link is separated from the

mounting rail

Page 56

Basic data

Power supply:

24 VDC

Power consumption

Max. 1A

Temperature range

0 - 55°C

Display

LCD display with background lighting (128x64 dots)

Weight

Approx. 400g

Installation

35mm DIN rail

Housing:

Polycarbonate, recyclable, non-flammable

Evaluation

Web server/diagram

Data export

As JSON or CSV file

Data memory

Micro SD card (needs to have more than 32 GB free

Firmware update

Yes, is possible

Configuration

Local and remote configuration with web browser

Inputs

3x M-Bus

9.3 Disposal

At the end of the life cycle this product must be recycled or disposed according to the

local provisions.

Remove batteries and accumulators and dispose them separately.

The separate collection and recycling of old devices helps to preserve natural resources

and assures that they are disposed in a way that the protection of the environment and

nature is assured.

10 Technical data

space available)

2x temperature PT1000 (-20°C to +100°C)

4x S0

AMBUS® Link 56

Page 57

M-Bus

Baud rates

300, 600, 1200, 2400, 4800, 9600

Compatibility

Heat, water, fas and electricity meter with M-Bus accord-

Level converter

Integrated

M-Bus closed current

Max. 375mA (250 x 1.5mA)

Number of M-Bus slaves

Max. 250 (see order information)

Galvanic separation

Yes

Short-circuit protection

Yes

Overload protection

Yes

BACnet/IP

Specifications

All M-Bus meters registered on AMBUS® Link are auto-

BBMD

Yes

Protocol Implementation Con-

The PICS document can be found on our website at:

Outputs

2 x relay

Interfaces

1x Ethernet 10/100 Base RJ45

1x USB type A

1x USB type B

ing to EN 13 757-2,-3 (former EN1434-3)

Transparently operatable via USB type B

matically translated into BACnet/IP objects.

formance Statement

www.aquametro.com/ambuslink

AMBUS® Link 57

Page 58

Approvals and norms

Safety

CE-declaration

EMC metering

EN 610000-6.2

Interference immunity

EN 61000-6-3

M-Bus norm

EN 13757-2,-3

Energy management

Suitable for ISO 50001

BACnet

Certified

10.1 Dimensions

AMBUS® Link 58

Page 59

11 Appendix

11.1 CE declaration of conformity

AMBUS® Link 59

Page 60

Date/Time(UTC) PrimaryAddress Serial ManufacturerId Version

26.01.2017 16:12 10 4800181 AMT 192

26.01.2017 16:27 10 4800181 AMT 192

26.01.2017 16:43 10

4800181 AMT 192

Medium Energy Energy_Einheit Volume

Volume_Einheit

Heat (outlet) 2709840000 Wh 43240.1 m^3

Heat (outlet) 2709870000 Wh 43240.5 m^3

Heat (outlet) 2709890000 Wh 43240.8 m^3

Units for H. C. A . Units for H. C. A._Einheit

Units for H. C. A . Units for H. C. A._Einheit

Power

0 0 86269.3

0 0 86212.8

0 0

86216.5

Power_Einheit Volume flow Volume flow_Einheit Flow temperature Flow temperature_Einheit

W

1.37621 m^3/h 131.759 Degree C

W 1.37584 m^3/h 131.766 Degree C

W 1.37555 m^3/h 131.759 Degree C

Return temperature Return temperature_Einheit Temperature difference Temperature difference_Einheit Energy (per kelvinliter)

76.9198 Degree C 54.8394 K 1.14265

76.9266 Degree C 54.8395 K 1.14264

76.9061 Degree C 54.8531 K 1.14264

Energy (per kelvinliter)_Einheit Mass (per liter) Mass (per liter)_Einheit On time On time_Einheit

Wh 0.974371 kg 45865 h

Wh 0.974366 kg 45866 h

Wh 0.974362 kg 45866 h

On time / V T =3 (Error) On time / VT=3 (Error)_Einheit Volume (per input pulse ch. 0) Volume (per input pulse ch. 0)_Einheit Units for H. C. A. (per input pulse ch. 0)

0 h 0.00101 m ^3 1

0 h 0.00101 m ^3 1

0 h 0.00101 m ^3 1

Units for H. C. A. (per input pulse ch. 0)_Einhe

Units for H. C. A. (per input pulse ch. 0)

Units for H. C. A. (per input pulse ch. 0)_Einh

Address Address_Einheit

1 10 None

1 10 None

1 10 None

11.2 Export file type csv standard

AMBUS® Link 60

Page 61

Date/time (UTC)

Coordinated world time

PrimaryAddress

Primary address

Serial

Secondary address/serial number

ManufacturedId

Manufacturer identification number according to M-Bus

Version

M-Bus version byte

Medium

Medium

Energy

Energy value

Energy unit

Unit of the energy value

Volume

Volume

Volume unit

Unit of the volume

Fabrication Fabrication_Einheit Timestamp (future value) / Monat 1 Timestamp (future value) / Monat 1_Einheit Timestamp (future value) / Monat 2

4800181 None 2024246144

UTC 2040143744

4800181 None 2024246144

UTC 2040143744

4800181 None 2024246144

UTC 2040143744

Timestamp (future value) / Monat 2_Einheit Customer Customer_Einheit Metrology (firmware) version Metrology (firmware) version_Einheit

UTC 0 None 10500 None

UTC 0

None 10500 None

UTC 0 None 10500 None

Hardware version Hardware version_Einheit

0 None

0 None

0 None

AMBUS® Link 61

Page 62

Units for H.C.A.

Heat Cost Allocator allocation formula

Units for H.C.A. Unit

No unit ("none")

Units for H.C.A.

Heat Cost Allocator allocation formula

Units for H.C.A. Unit

No unit ("none")

Power

Power

Power unit

Unit of the power

Volume flow

Flow value

Volume flow_unit

Unit of the flow

Flow temperature

Flow temperature

Flow temperature_unit

Unit of the flow temperature

Return temperature

Return temperature

Return temperature_unit

Unit of the return temperature

Temperature difference

Temperature difference

Temperature difference_unit

Unit of the temperature difference

Energy (per kelvin litre)

Correction factor

Energy (per kelvin litre)_unit

Unit of the correction factor

Mass (per litre)

Density

AMBUS® Link 62

Page 63

On time

Operating hours

On time_unit

Unit of the operating hours

On time/VT=3 (error)

Error hours

On time/VT=3 (error)_unit

Unit of the error hours

Volume (per input pulse ch. 0)

Pulse value

Volume (per input pulse ch. 0)_unit

Unit of the pulse value

Units for H.C.A. (per input pulse ch. 0)

Pulse value auxiliary meter 1

Units for H.C.A. (per input pulse ch.

No unit ("none")

Units for H.C.A. (per input pulse ch. 0)

Pulse value auxiliary meter 2

Units for H.C.A. (per input pulse ch.

No unit ("none")

Address

Primary address

Address_unit

No unit ("none")

Fabrication

Fabrication number

Fabrication_unit

No unit ("none")

Time stamp (future value)/month 1

Reporting date 1

Time stamp (future value)/month 1_unit

Unit of the reporting date

0)_unit

0)_unit

AMBUS® Link 63

Page 64

Time stamp (future value)/month 2

Reporting date 2

Time stamp (future value)/month 2_unit

Unit of the reporting date

Customer

Customer text field

Customer_unit

Text

Metrology (firmware) ve rsio n

Firmware version

Metrology (firmware) version_unit

No unit ("none")

Hardware version

Hardware version

Hardware version_unit

No unit ("none")

AMBUS® Link 64

Page 65

Device .ID

Internal AMBUS Link i dentification number (configuration meter)

AddressMode

Primary switch - secondary reading

PrimaryAddress

Primary address

ManufacturedId

Manufacturer identification number according to M-Bus

Serial

Secondary address/serial number

Version

M-Bus version byte

Device.Id AddressMode PrimaryAddress ManufacturerId Serial Version Medium Device.Active ReadoutCycle BaudRate

29 0 10 AMT 4800181 192 H eat (outlet) -1 0 2400

29 0 10 AMT 4800181 192 H eat (outlet) -1 0 2400

29 0 10 AMT 4800181 192 H eat (outlet) -1 0 2400

BACNetDevInstNumber

Name Site CostUnit CommentStr LoggerLastReadoutOk LoggerReadoutState LoggerReadoutCycle MediumGroup Battery

4194077 CALEC ST 1485440274 1 0 3 0

4194077 CALEC ST 1485440274 1 0 3 0

4194077 CALEC ST 1485440274 1 0 3 0

Position

DescriptionStr UnitStr ScalePower ScaleMantissa EncodeType ValueType StorageNum Tariff ValueDesc.Active

0 Energy Wh 0 0 0 0 0 0 -1

0 Energy Wh 0 0 0 0 0 0 -1

0 Energy Wh 0 0 0 0 0 0 -1

LoggerLastValue

CfgDescription CfgUnit CfgPhase CfgFactor CfgStorageNum CfgTariff TimeStamp Val1 ValueDesc.Id

2709680000 0 0 0 0 0 0 1485303093 2706390000 3438

2709680000 0 0 0 0 0 0 1485304020 2706420000 3438

2709680000 0 0 0 0 0 0 1485304945 2706440000 3438

11.3 Export file type csv FULL-DB

Explanation CSV export (FullDB)

AMBUS® Link 65

Page 66

Medium

Medium

Device.Active

Defines if a meter is logged during reading and transferred with the report. Value 1: Me-

ReadoutCycle

Meter-specific reading cycle (only configuration, without reading)

Baud rate

Baud rate

BACNetDevInstNumber

BACnet device instance number

Name

Name

Site

Location

CostUnit

Cost centre

CommentStr

Comment

LoggerLastReadoutOk

Last successfuly readout (UNIX time stamp)

LoggerReadoutState

Satus of readout

LoggerReadoutCycle

Individual reading cycle (position in dropdown)

ter is logged and transferred

Value 0: Meter is not transferred

Value -1: not configu r ed

Value 0: not defined

Value 1: OK

Value 2: Error

AMBUS® Link 66

Page 67

MediumGroup

Individual meter type (value from dropdown)

Battery

Battery flag

Position

N/A

DescriptionStr

M-Bus parameter name

UnitStr

M-Bus unit

ScalePower

Scale factor for the integrated reading value

ScaleMantissa

Scale factor (mantissa)

EncodeType

Encoding type of the meter in the M-Bus package (e.g.: INT8, INT32, BCD8 or

ValueType

Value MAXIMUM: Meter value is a maximum value over a timespan.

StorageNum

The storage number of the meter value defined by the meter.

VARIABLEDATA).

Within the logging integer-based meter values are listed as numbers, text-based meter

values as text and binary data as text-based hexadecimal characters.

Value MINIMUM: Meter value is a minimum value over a timespan.

Value ERRORSTATE: Meter value is in error status.

Value INSTANTANEOUS: Meter value is an instantaneous value.

Value 0 defines that the associated meter value for the current time has been recorded.

AMBUS® Link 67

A value unequal 0 defines that a meter value at a specific time (defined by the meter

manufacturer) has been recorded.

Page 68

An associated time stamp is also included in the CSV log (time stamp).

Tariff

Tariff

ValueDesc.Active

N/A

LoggerLastValue

Last value

CfgDescription

Designation (manual fr om template)

CfgUnit

Unit (manual from template)

CfgPhase

Phase (manual from template)

CfgFactor

Factor

CfgStorageNum

Storage number (transmitted by meter)

CfgTariff

Tariff (manual from template)

TimeStamp

Time stamp

Val1

Value

ValueDesc.Id

Value identification number

AMBUS® Link 68

Page 69

info@integra-metering.com

www.integra-metering.com

Änderungen vorbehalten / Sous réserve de modifications / Modification rights reserved

Copyright © INTEGRA METERING AG, Switzerland

Loading...

Loading...