Page 1

LOCOnTROLLER

Model LT 150 A

User Manual

Page 2

Page 3

Table of Contents

1. Introduction 5

What’s in the box? 5

1a. THE LT150A HANDSET 6

2. Handset - Before rst use 7

Inserting the rechargeable batteries into the handset. 7

Charging the handset batteries 7

Charger LED indicator codes: 8

Turning the handset on. 8

Turning the handset o. 8

3. System startup procedure 9

Startup: 9

4. System and Error Messages 10

User Induced E-STOP: 10

5. Control of your locomotive 11

Setting speed: 11

Changing direction: 11

Applying brakes: (With brake controller) 12

Stopping/slow down:(Without brake controller) 12

Locking brakes: (With brake controller) 13

Unlocking brakes: (With brake controller) 13

Checking locomotive battery voltages 13

Turning on the lights 14

Sounding the horn 14

Turning the bell on and o 14

Ditch lights 15

6. Setup Menu 15

Entering the Setup Menu: 15

Changing menu settings. 16

Description of functions: 17

Description of functions(continued): 18

Event System: 19

7. The LT150A (hardware setup) 20

Connections of the LT150A 20

Installing the radio Tranceiver 21

Installing the system connector 22

Installing the Light and Aux Connector 23

Locomotive Brake connector 24

Train brake connector 25

MU connector 26

Brake Controller types 27

Installing the speed sensor 28

9. Wiring Diagram 30

Integral Circuits Critter Control Model LT150A Manual

Document Version 1.0 ©2016 Integral Circuits,

Page 4

4

PRELIMINARY

Locomotive MAC Address and S/N

Handset MAC Address and S/N

The LT150A utilizes a matched pair of radios . the following two labels are the addresses and serial numbers of the locomotive unit and handset

If there is no label here , the same label/

information can be also found on the radio

tranceiver and the mounting side of the

Locomotive unit.

If there is no label here, the same information can be found on the back of the

handset.

Contains FCC ID: MCQ-PROS2B

The enclosed device complies with Part 15 of the FCC Rules.

Operation is subject to the following conditions:

(i.) this device may not cause harmful interference and

(ii.) this device must accept any interference received,

including interference that may cause undesired operation.

WARNING

Radio Transmitting Device

This handset contains a low power “spread spectrum”

radio transmitter. While the eective radiation of this

device is less than 200mW and though care has been

taken to design this handset such that the location of

the antenna minimizes human exposure to its 2.4GHz

energy, care should be taken to hold the handset per design to limit futher exposure and to improve operational

performance.

Page 5

5

PRELIMINARY

1. Introduction

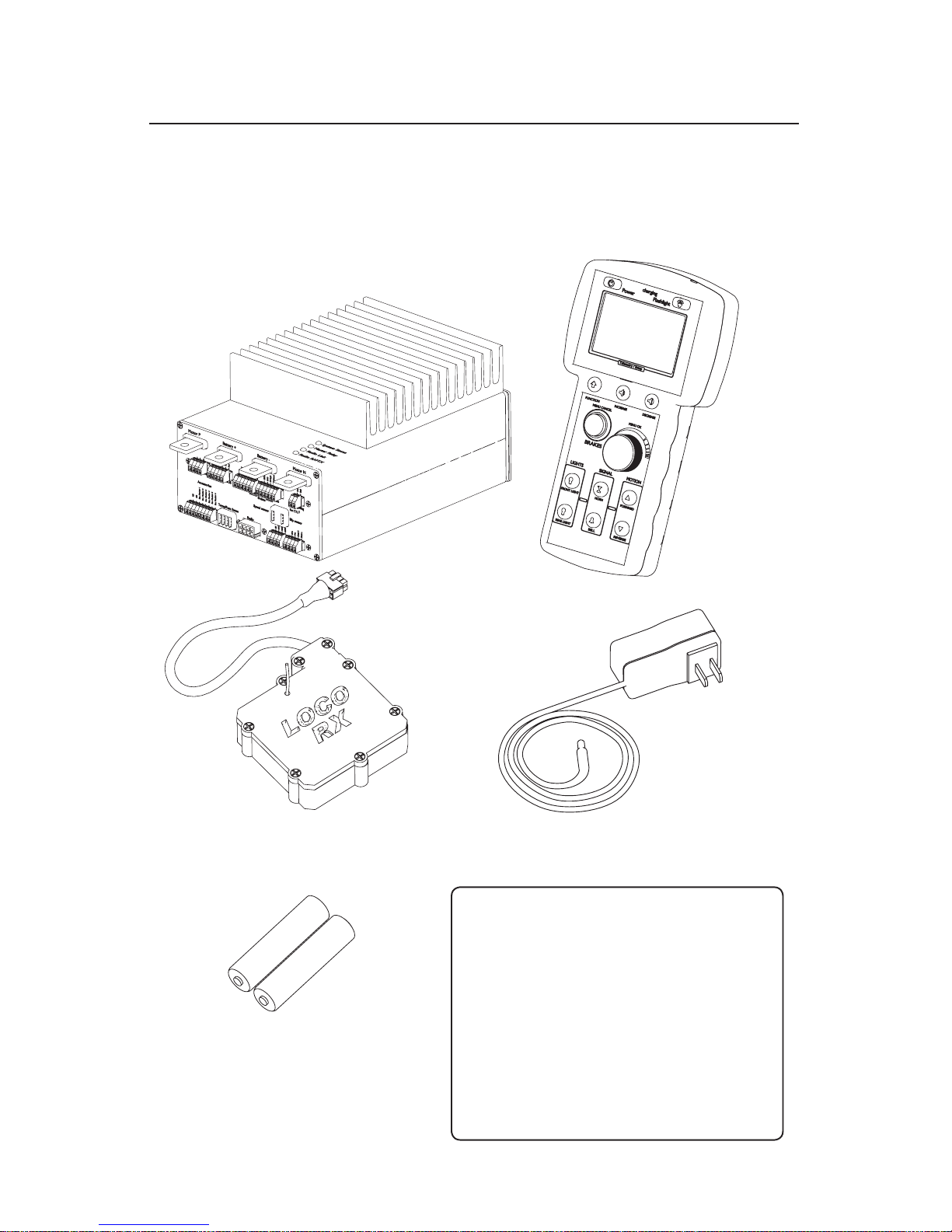

What’s in the box?

LT150A Locomotive control unit

LT150A Remote control Handset

LT150A Radio Tranceiver (picture might

dier, depending if the wire antenna or External

antenna version was ordered)

12V Charger for LT150A Handset With

MU Port Socket

Make sure your box contains everything listed below. If any pieces are missing, contact

the seller.

If this system got delivered pre-built into a locomotive, make sure that these items are

listed by your seller and nothing is missing.

Set of AA Rechargeable Batteries

Additional Items:

1. Bag of Phoenix connectors ( 1x 8pin, 2x

6pin, 1x 5pin, 3x 4pin, 1x 2 pin)

2. MU Rear Port Cable, for handset charging

3. This manual

4.(optional) Ballast resistors for LED lighting

5.(optional) Radio Tranceiver Extension Cord

Page 6

6

PRELIMINARY

D

U

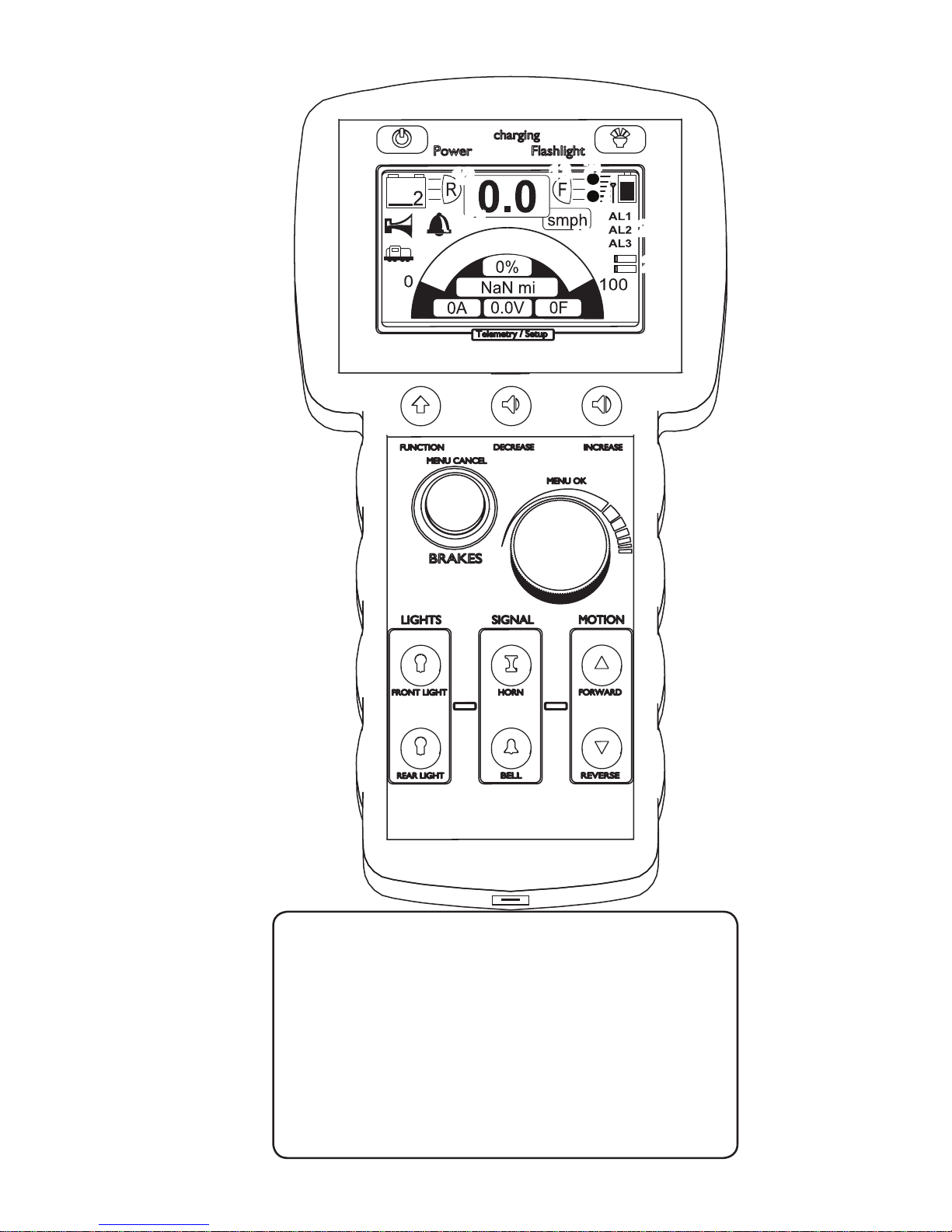

1a. THE LT150A HANDSET

1. Main Display

2. Power Button

3. Flashlight button

4. Light buttons

5. Horn button

6. Bell button

7. Forward button

8. Reverse button

9. Charging indicator

10. Locomotive Battery

Indicator

11. Remote Battery Indicator

12. Rear light Indicator

13. Front light indicator

14. Speed/PSI indicator

15. Speed format indicator

16. reverse indicator

17. forward indicator

18. brake button

19. control Knob

20. Charging port

21. Function button

22. Volume up

23. Volume down

24. Ditch Light Indicator

25. Signal Strength indicator

26. Data Load Meters

(Down and upstream)

27. Aux Panel

20

1.

2

3

4

5

6

7

8

9

10

11

12

14

15

16 17

18

19

21

22

23

13

25

26

24

27

Page 7

7

PRELIMINARY

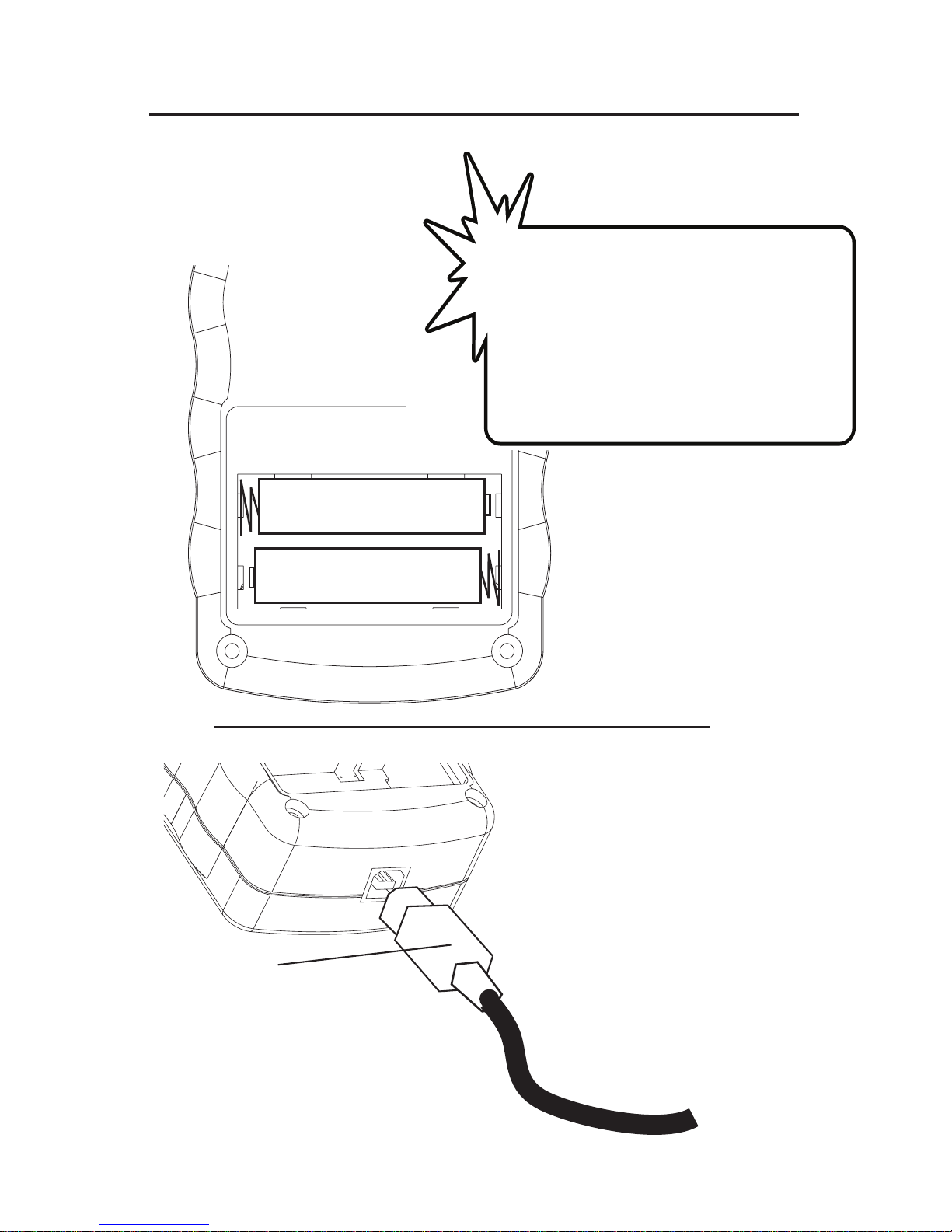

2. Handset - Before rst use

Inserting the rechargeable batteries into the handset.

!

Charging the handset batteries

The handset can also be operated

with 2 regular AA Alkaline batteries.

However, the internal charger will only

work with rechargeable batteries.

WARNING: Do not attempt to use

the charger with alkaline batteries

installed!

+

-

To charge the handset batteries, plug the

charger into the receptactle on the bottom

of the handset.

The LED on the front face of the handset

marked “charging” will indicate the charging mode and status. How the codes for

charging are read is described on page 8.

Charging

Cable

+

-

Page 8

8

PRELIMINARY

D

U

Press and hold the power button for a seconds.

You will see the splash-screen before the handset shows the main dashboard. The handset is

now ready to use

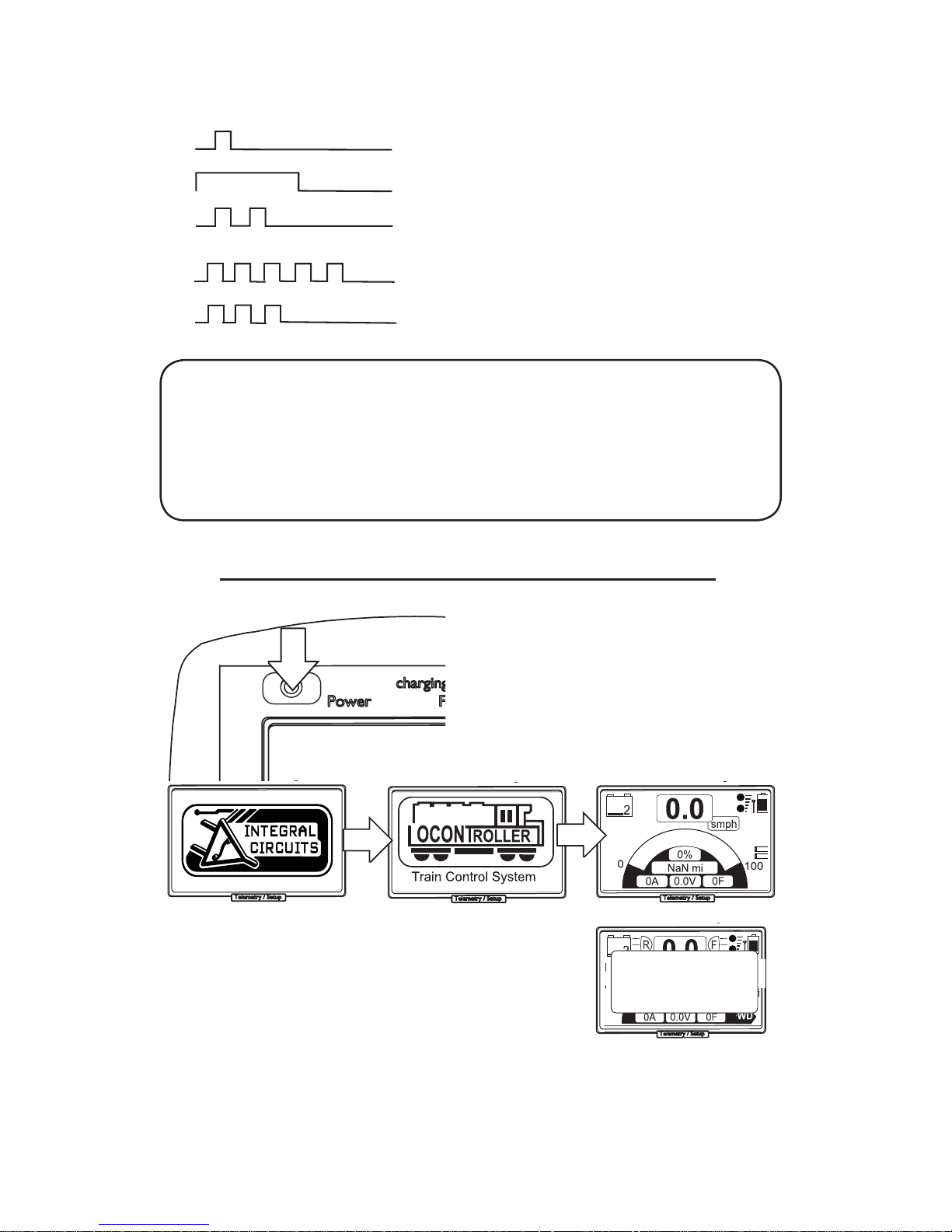

Turning the handset on.

Charger LED indicator codes:

Code:

Pre charge state - 1 short ash per second

Rapid Charge - led is equally on/o per sec

Post charge - led ashes short twice

No battery detected - 5 short pulses

Post charge constant voltage mode - 3

short ashes

During charging, if the battery is deeply discharged, the charger will indicate it is in a “pre-charge” state in which the battery voltage is brought up to

approximately .8V per cell before commencing rapid charge.

If the batterys are at .8V per cell or above, the charger will enter rapid

charge mode in which the batteries are charged at 500mA for a maximum

time of 5 hours

Please note: The charger will not start rapid charging the batteries if they are still more than 50% charged.

Turning the handset o.

To turn the handset o you have to press and hold the power button for another 2 - 3

seconds until it shows “info shutdown”

D

U

D

U

D

U

NO LOCO!

couldn’t nd loco

Turn on loco power!

When the locomotive is not turned on within 10

to 15 seconds the Handset will Time-out and

show that it can’t nd the locomotive.

Turn the locomotive on, and then press the

brake button once it is running. The message

will disappear and the system is ready.

No Link To locomotive.

Page 9

9

PRELIMINARY

3. System startup procedure

1. Turn on the handset by pressing the power button for 2

seconds

2. Turn the Key switch on your locomotive to ON. Position.

3. The LT150 A will go through a startup sequence.

4. When all system checks are done and turn out OK, it will start

ashing the system LED indicator while the Master Relay led will

become lit solid

4.a The Locomotive Link symbol (on left of screen) will show up

5. press the brake button on the handset until the system LED

lights up solid . System, Master Relay and Radio link should be

solid

Startup Error Messages:

These error messages appear if any of the system checks at startup return a

negative result.

The controller will check for battery voltage and motor drive/motor health, before

it unlocks the system for use

Low locomotive battery error:

Symptom: Solution:

Battery voltage shows 0 Check the wire and fuse for the battery monitors

Battery voltage is ~ 22V 24V sys Locomotive batteries need recharged.

Battery voltage is ~ 33V 36V sys Locomotive batteries need recharged.

Motor test failed error:

Symptom: Solution:

Motor short detected! Check the wiring of the motors for shorts.

Check the motors directly for shorts.

Startup:

1.

2.

3.

4.

5.

all initially o

press

D

U

LOCO BATTERY LOW

Low Battery Voltage: 0.02V

D

U

MOTOR TEST FAILED

Motor short detected!

D

U

D

U

0A

25.0V 78F

Dashboard lls with Telemetry.

Locomotive Link symbol appears(left)

3 Leds Solid

Page 10

10

PRELIMINARY

D

U

OVERHEAT!

Motor controller overheat!

turn o system for cooldown!

D

U

E-STOP

User E-STOP triggered

push brake to reset

4. System and Error Messages

User E-STOP:

This message shows when the power button is pressed while the

system is in operation.

It indicates that the locomotive entered the emergency stop state.

This can be cancelled with a push of the brake button.

Dropped handset E-STOP:

This message shows whenever the handset is dropped and been in

freefall for longer than the period specied in the setup menu. (“fall

time” page 17.)

Handset battery low warning:

This message shows whenever the batteries of the handset fall below

a charge voltage of 1.9v . This message is only shown for a short mo-

ment before the handset turns itself o. (safety shutdown)

Immediate recharging of the Handset batteries is adviced.

Overcurrent Warning:

The system triggers this message whenever the internal current limit of

approximately 175A is overstepped. This is a safety feature to prevent

damages to the motor or motor drive due to mechanical blockage or

overburdening of the locomotive.

Please note that the locomotive wont stop when this occurs, but the

internal safety will turn o the drive on a per PWM cycle basis, and

limiting the current.

To dismiss this message you need to rotate the knob of the handset a notch.

Overheat E-STOP:

The system triggers an Cycle STOP whenever the internal temperature

sensors measure a tamperature above the safe zone for the internal

components.

This message can not be dismissed until the locomotive and handset have been power cycled

System cool down before further use is adviced!

User Induced E-STOP:

If you press the power button at any given time

the locomotive will go into an User requested

E-Stop. To cancel this you need to push the

brake - button once.

D

U

E-STOP

User E-STOP triggered

push brake to reset

D

U

E-STOP

TX dropped!

push brake to reset

D

U

TX Battery Low!

shutting down handset..

D

U

Overcurrent!

Current above 175A

reduce speed to continue

D

U

LINK LOSS!

Link to locomotive lost

Check Locomotive power

LINK LOSS!:

The Remote is not receiving any telemetry or heart-beat signal from

the locomotive. This can be the result of a bad reception, out of signal

range or loss of power in the locomotive.

This message can be dismissed with the push of the brake-button.

However, it will come back until the link to the locomotive has

been re-established.

Page 11

11

PRELIMINARY

D

U

0A

25.0V 78F

10%

D

U

0A

25.0V 78F

80%

5. Control of your locomotive

Setting speed:

Make sure the brakes or brake lock are not active.

1. Turn the knob clockwise to increase speed.

2. turn the knob counter clockwise to decrease speed.

1.

2.

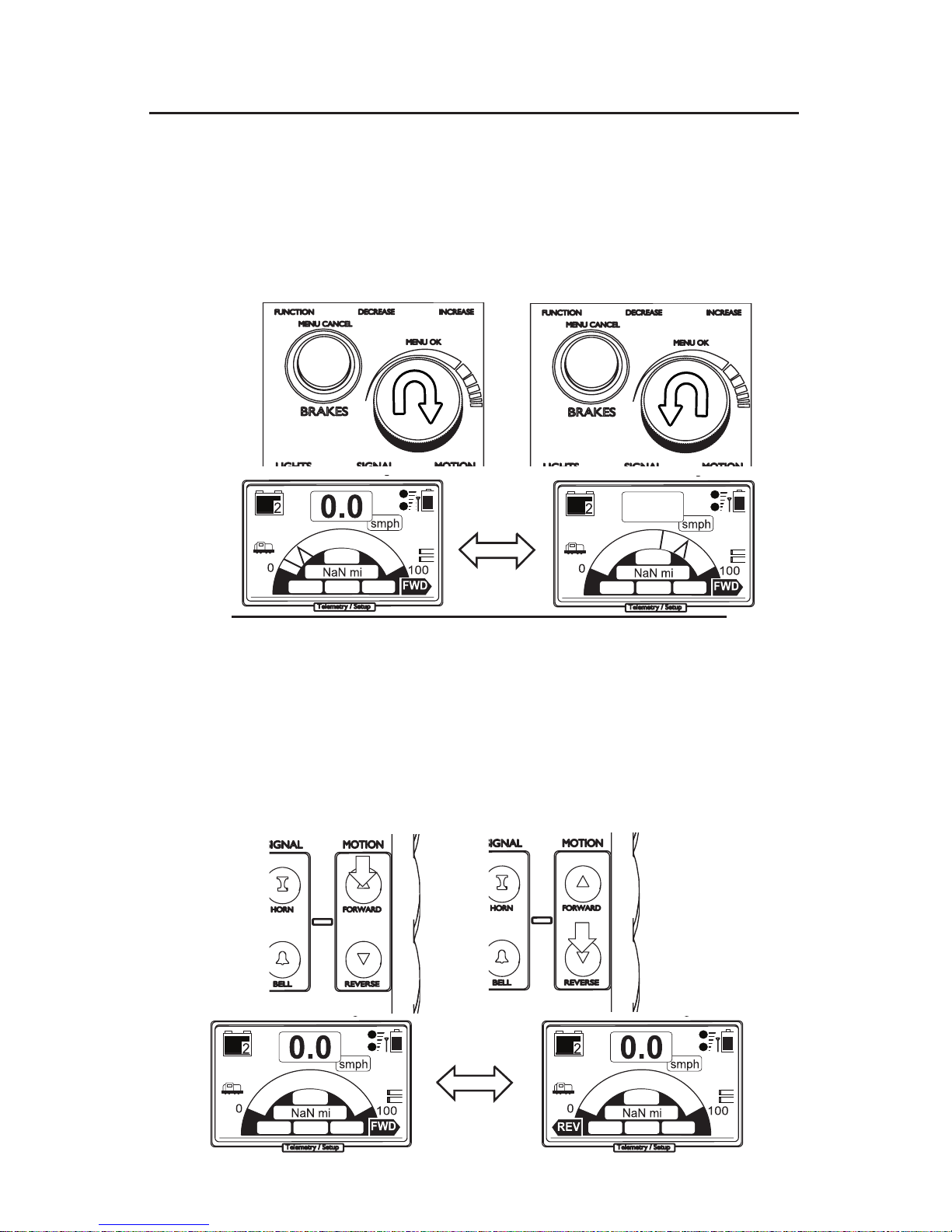

Changing direction:

1. press ‘forward’ to change the direction to forward

travel

2. press ‘reverse’ to change the direction to backward

travel.

Depending on the setting of reverse limit in the

Setup menu (page 18). you can change the direction

into the opposite way of travel while the locomotive

is throttled up. It will slow down and then reverse

into the opposite direction

1.

2.

7.8

D

U

0A

25.0V 78F

D

U

0A

25.0V 78F

0% 0%

Page 12

12

PRELIMINARY

Applying brakes: (With brake controller, or custom air-brakes installed)

1. Press and hold the brake button. Throttle will be automatically reduced to 0% and brake pressure applied

at the set value. (factory setting is 25psi)

2. Rotate the knob clockwise to increase pressure.

3. Rotate the knob counter clockwise to decrease pressure.

Stopping/slow down:(Without brake controller)

1. Press the Brake button. Throttle will be reduced to 0%.

The four quadrant motor drive of the LT150A will slow

down the locomotive to a stop on an even surface.

if you are on an inclined track piece , the locomotive

might continue to slowly creep forward or backward

down the track. You can prevent this by giving a little

bit of throttle in the opposite direction of travel

Warning! This method is

only useful for short stops.

DON’T

keep the locomotive

throttled up stationary on an

inclined track piece for too

long. It can cause heat damage to your motors!!

press

+

hold

1.

2.

3.

press

1.

!

D

U

D

U

15

15

D

U

D

U

27

26

Page 13

13

PRELIMINARY

Locking brakes: (With brake controller, or custom air-brakes installed)

1. Press and hold the Brake button.

2. Press knob.

3. Release both brake button and knob.

The brake button will light up, indicating that the brakelock mode is now active

Unlocking brakes: (With brake controller, or custom air-brakes installed)

1. Press and hold the Brake button.

2. Press knob.

3. Release both brake button and knob.

The brake button light will turn o, indicating that the

brake-lock mode is now inactive.

Note: Without brake - controller, this function does only maintain a

throttle value of 0. The locomotive might still creep on an inclined

track piece.

press

+

hold

1.

2.

3.

brake LED lights up

press

+

hold

1.

2.

3.

brake LED turns o

press

press

Checking locomotive battery voltages

This function does not work

in Brake Lock mode

1. Press the knob while not in brake-lock mode. The display switches from showing the regular dash to a screen

showing the voltages of the locomotive batteries.

1.

!

D

U

0A

24.4V 78F

0%

Page 14

14

PRELIMINARY

Turning on the front light

Sounding the horn

Turning the bell on and o

1. Press the front light button

2. Once the front light is on, you may dim it by pressing

the button again. It will toggle back and forth between

bright and dim setting.

3. To turn the front light o, press and hold the button

until the front light symbol on the LCD disappears and

the front-light turns o.

1. Press the “bell” button. This will turn the bell pulse

signal on and will repeat until you turn the bell o again.*

2. Press the button again to turn the bell signal o.*

1. Press the “horn” button, the horn should blow and

keep blowing as long as you keep the button pressed. It

will turn o as soon as you release the button*

Turning on the rear light

1. Press the rear light button

2. Once the rear light is on, you may dim it by pressing

the button again. It will toggle back and forth between

bright and dim setting.

3. To turn the rear light o, press and hold the button

until the rear light symbol on the LCD disappears and the

rear-light turns o.

* Please note that both functions (horn and bell) are

bound to the installed sound-module. And depending on

what module was used, there might be a slight lag of response (we use Econami,Tsunami or Loksound modules,

depending on customer order)

Page 15

15

PRELIMINARY

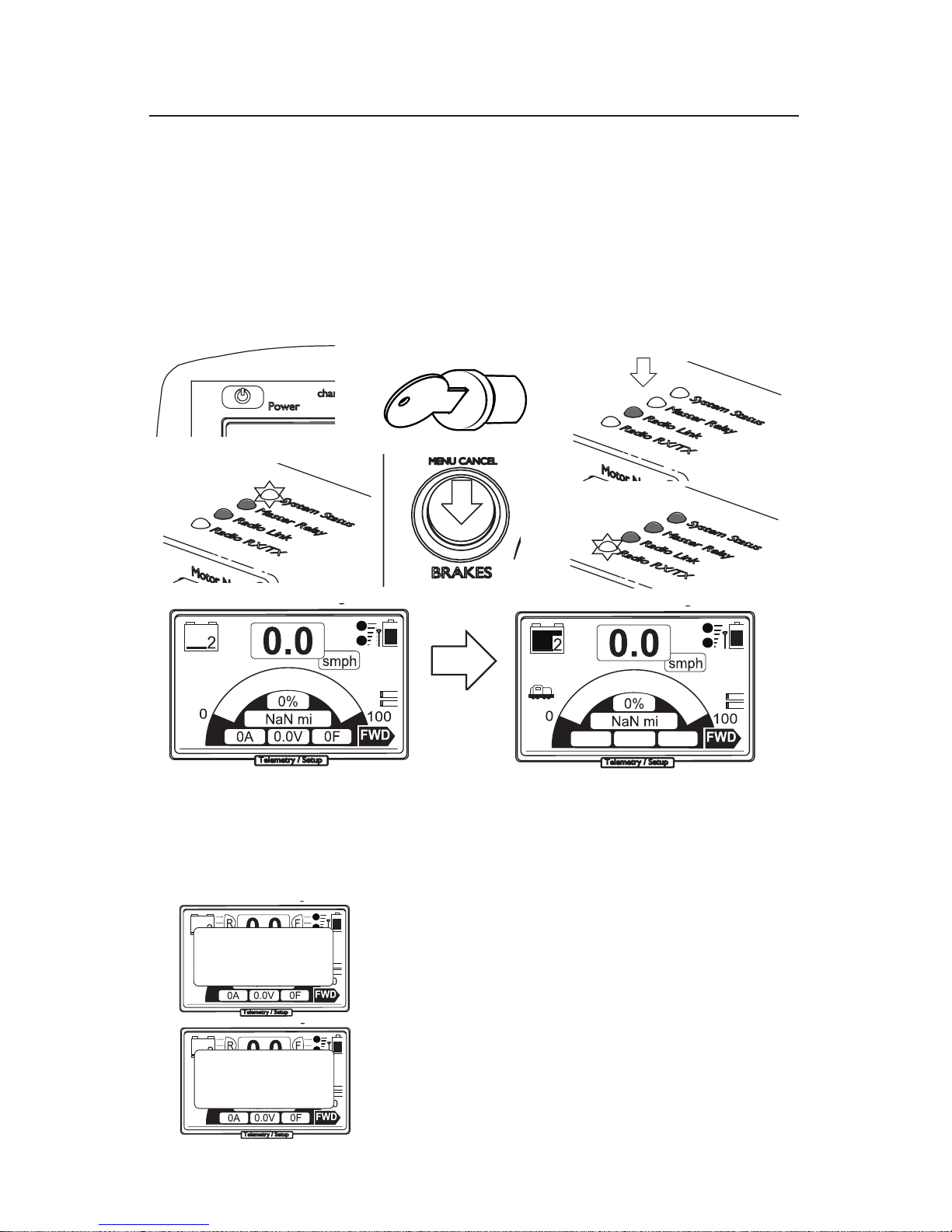

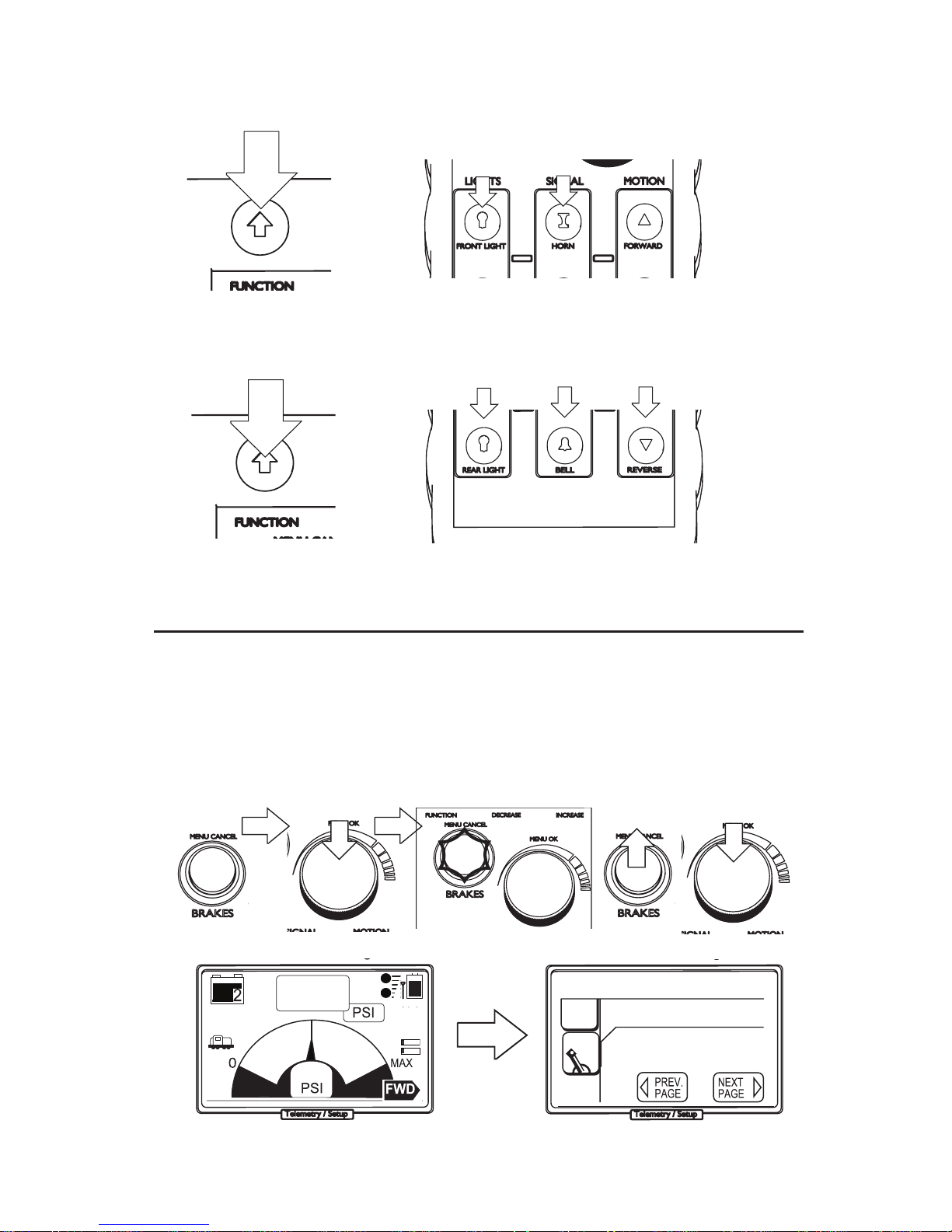

Entering the Setup Menu:

1. Press and hold the brake button.

2. With the brake button held, press the knob.

3. release both brake button and knob. The red LED on

the brake button will be lit (brake lock mode see page 9.)

4. Now press and hold the knob for a few seconds.

until the handset enters the setup menu.

6. Setup Menu

1.

2.

3.

brake LED lights up

press &

hold 3-4sec.

release

press

4.

5.

press

+

hold

D

U

D

U

15

15

D

U

D

U

Handset Setup 10

Throttle Resolution

25

clicks

1

2

4

5

3

Aux channel:

Press and hold press any of the Aux buttons

Aux1 Aux2 Aux3

Ditch Lights

Press and hold

Ditch On/o Ditch Flash

You can change the menu page via ‘increase’ and ‘decrease’ buttons

Page 16

16

PRELIMINARY

D

U

D

U

Handset Setup 10

Throttle Resolution

34

clicks

1

2

4

5

3

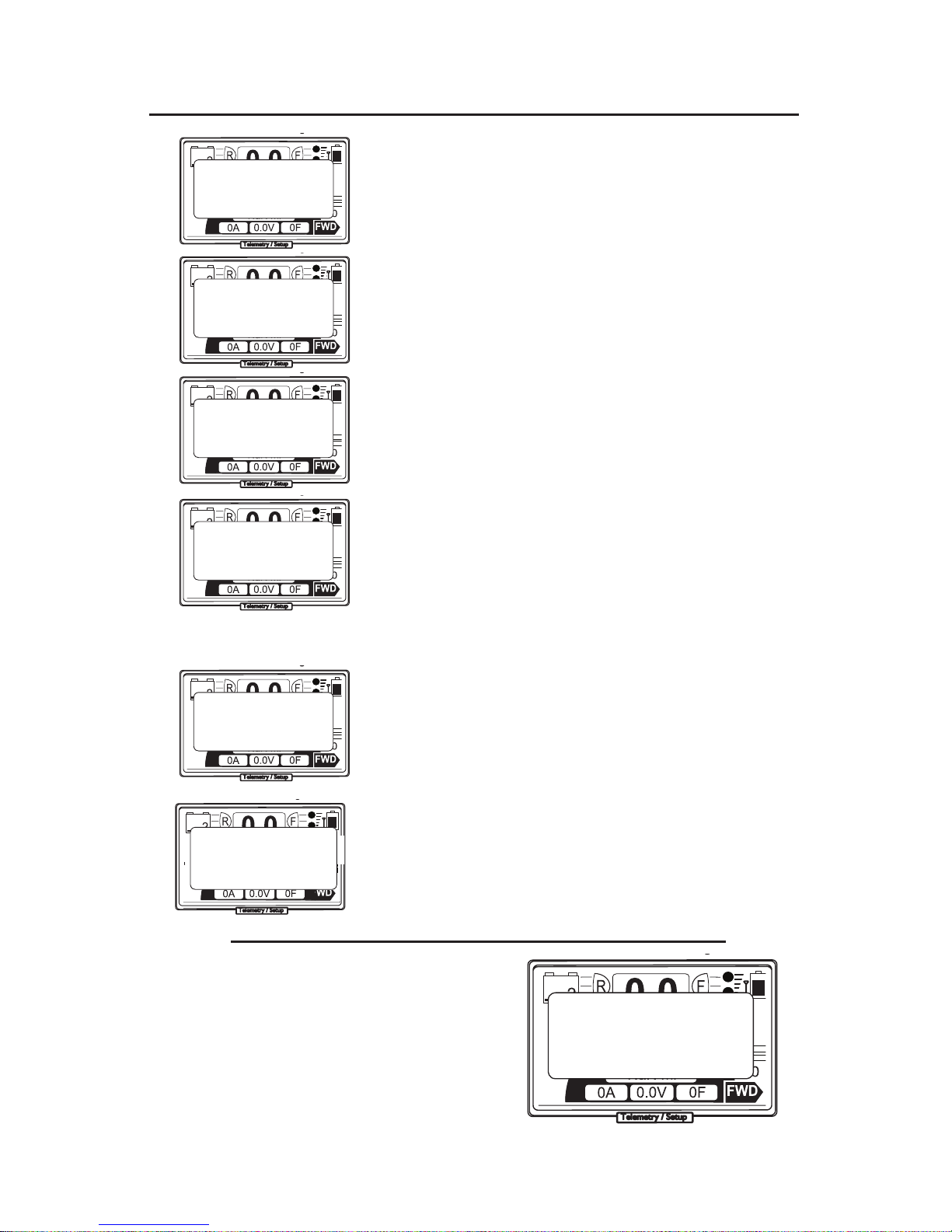

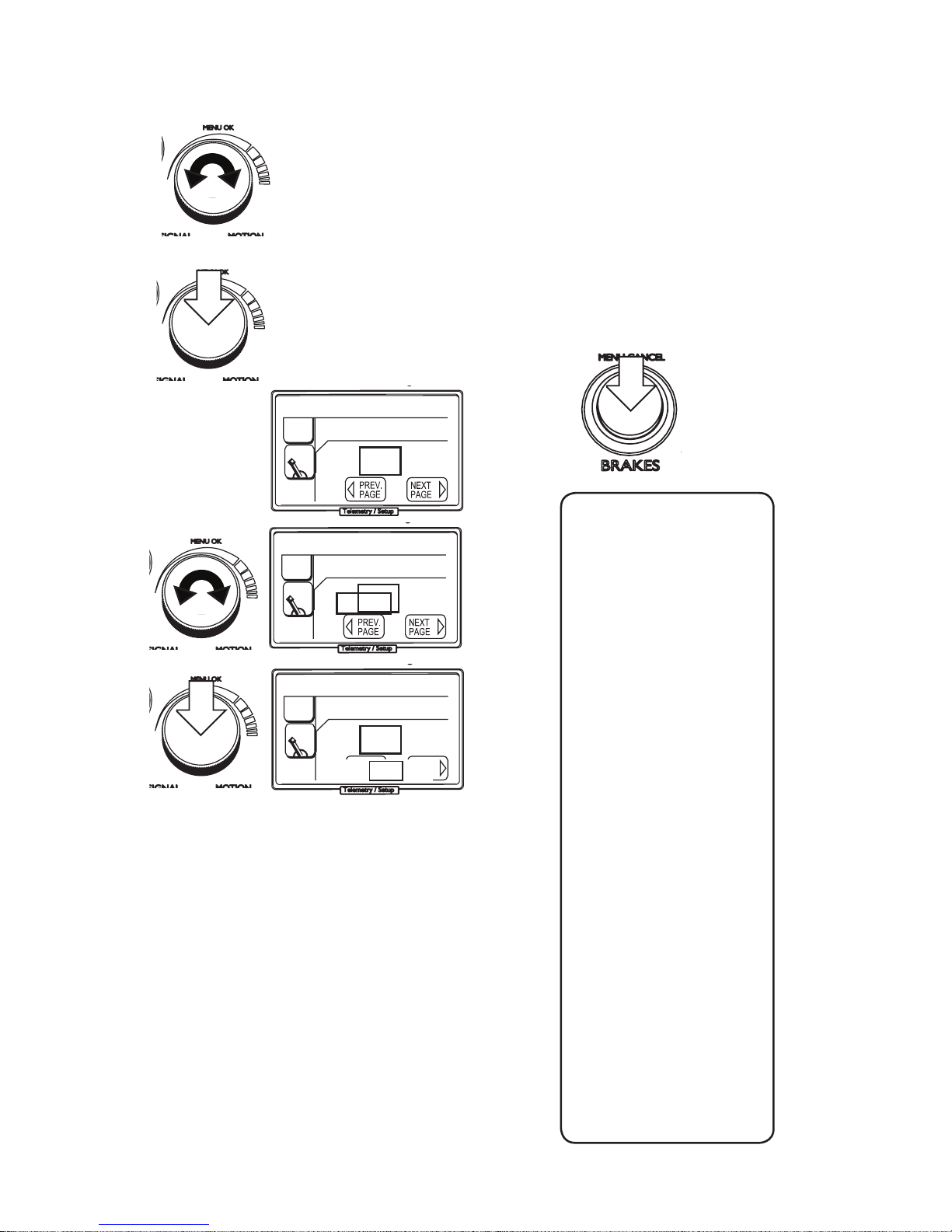

Changing menu settings.

1. Use the knob to choose which menu setting you want to

change.

2. Press the knob to change the currently selected setting.

3. A rectangle will appear around the value.

4. Now use the knob to change the value.

5. Press the knob again and the menu will ask you if you want

to save: Yes = save change. No = dismiss change.

6. Press the brake button (menu cancel) at any time and the

handset will return to the dash in brake-lock mode. You can

re-enter the menu by just holding down the knob again for a

moment.

List of available settings:

Throttle Resolution

Backlight on/off

Dead manTimeout

Speed Format

Drop Sensor

Autoreverse Limit

Maximum Speed

DefaultBrake PSI

Max Brake PSI

Acceleration

Deceleration

Wheel diameter

Electric or Gasoline

Battery Count

Load Current Gain

Sensor Input 1

Sensor Input 2

Sensor Input 3

Sensor Input 4

Front Light Level

Rear Light Level

Ditchlight time

Lighting System

EStop deceleration

EStop Brake Pressure

Front light Dim

Rear Light Dim

Brake Prsr. deadband

Brake Prsr. offset

Current gain

Current offset

ADC Calibration

Temp Calibration

Sound prole

Rung 1

Rung 2

Rung 3

Rung 4

Rung 5

Rung 6

Rung 7

Rung 8

press to exit

D

U

D

U

Handset Setup 10

Throttle Resolution

25

clicks

1

2

4

5

3

Save? YES NO

1.

2.

3.

4.

5.

6.

press

press

D

U

D

U

Handset Setup 10

Throttle Resolution

34

clicks

1

2

4

5

3

Page 17

17

PRELIMINARY

Sets the amount of clicks on the encoder it takes to get to full 100% of

throttle

Sets the backlight to either On (fade mode) or o (stays o)

Sets the time it takes for the deadman to stop the locomotive when no

input is received, in seconds

Sets the format the system shows speed and distance.

Sets the sensitivity of the accelerometer inside the handset. This is the

amount of time the handset has to be in free-fall before it E-stops

Sets the threshhold for the autoreverse limit. The locomotive can be

reversed, as long as it is not throttled up beyond this limit.

Sets the maximum available throttle that can be set. Limits the maximum

speed of the locomotive.

Sets the default brake pressure that is available upon system start. This is

also the setting the Emergency stop feature uses by default.

Sets the absolute maximum brake pressure the system can reach.

Sets the acceleration behavior of the locomotive (how fast or slow it accelerates) in percent per second . a higher value means a faster acceleration

Set the deceleration behavior of the locmotive (how fast or slow it decelerates) in percent per second. a higher value means a faster stop

Sets the wheel diameter of your locomotive. This is needed for correct

speed calculation via speed-sensor input. If you use the sensor on a ywheel (before a reduction occours) you need to divide your wheel diameter

by that reduction and set it accordingly. (5” wheel 1:2 reduction = 2.5”)

reserved setting. no function currently

Sets the amount of batteries in the system. This is needed to correctly

calculate voltages and battery levels.

Sets the gain for the sound module’s rung calculation. at high loads the

engine will sound more tasked.

Can be set either to fuse input (fuse detection) or Temperature sensor.

(This feature is currently only implemented but not enabled)

Sets the global brightness of the front lights. Dim will be calculated from

this too. (about half)

Sets the global brightness of the rear lights. Dim will be calculated from

this too (about half)

Determines how long the ditchlights keep ashing when triggered

Selects the type of lighting system and system voltage.

Incandescent 24 or 36V

1 LED per channel @ 24 or 36 v

2 LED per channel @ 24 or 36V

(continued on page 18)

Handset setup:

Throttle Resolution

(range 8-100)

Backlight on/off

(range on/off)

Deadman Timeout

(0-30 seconds)

Speed Format

(mph/smph/kph/skph)

Drop sensor

(5-100ms)

Auto-reverse Limit

(1-50%)

Locomotive setup:

Maximum Speed

(10-100%)

Default Brake Prsr.

(0-50psi)

Maximum Brake Prsr.

(10-80psi)

Acceleration

(1-50%/s)

Deceleration

(1-50%/s)

Wheel diameter

(1.000 to 8.000 inch)

Electric or Gasoline

Battery Count

(2-6 bat)

Load Current Gain

(1-20)

Sensor input 1 to 4

Front Light Level

(0-15)

Rear Light Level

(0-15)

Ditchlight time

Lighting System

Description of functions:

Page 18

18

PRELIMINARY

Description of functions (cont):

Sets the deceleration for the Emergency stop situation. This setting allows

for a rapid deceleration without stoping the locomotive too hard.

Sets the pressure that is used in an Emergency Stop.

Sets the Dim-level of the front light

Sets the Dim-level of the rear light

*These are Factory Calibrations that we set before shipping of the unit and

usually do not ned to be changed manually*

Sets the deadband of the brake pressure sensor. Default is 1PSI

Sets the voltage oset for the pressure sensor in use. The oset voltage

can be found in the datasheet of most pressure sensors.

by default this is set to a MPX5500 pressure sensor oset voltage

Sets the scale multiplier for the current gain

Sets the voltage oset of the current sensor in use.

Sets the multiplier for the Analog to Digital converter inside the Unit

Sets the Compensation value for the internal Temperature sensors

Sets dierent proles which distribute the rungs being send to the

sound module at dierent positions of the speed gauge. This is mainly

used to match the various dierent sound modules available.

Sets the amount of throttle where Rung 1 will be triggered

Sets the amount of throttle where Rung 2 will be triggered

Sets the amount of throttle where Rung 3 will be triggered

Sets the amount of throttle where Rung 4 will be triggered

Sets the amount of throttle where Rung 5 will be triggered

Sets the amount of throttle where Rung 6 will be triggered

Sets the amount of throttle where Rung 7 will be triggered

Sets the amount of throttle where Rung 8 will be triggered

Loco Setup(Cont):

EStop deceleration

EStop Brake PSI

Front light Dim

Rear Light Dim

Calibration Setup:

Brake Prsr.

deadband

Brake Prsr. offset

Current gain

Current offset

ADC Calibration

Temp Calibration

Sound Setup:

Prole

Rung 1

Rung 2

Rung 3

Rung 4

Rung 5

Rung 6

Rung 7

Rung 8

Page 19

19

PRELIMINARY

The Event System:

The event system gives the ability to assign functions of the

locomotive controller to certain events happening during

operation. At default the front and rear headlight are assigned

for dimming operation on direction change. The ditchlights are

assigned to the horn trigger.

Events

On Forward

On Reverse

On Brake

On B.Lock

On Horn

A1 A2 A3 FL RL DL

o = dim= on=

Selecting a Event:

1.

1. Use the knob to select the event on the grid you want to modify

2. press the knob

3. a menu will pop up that shows the dierent settings you can

choose.

4. select the setting and press the knob again. The event is now

assigned.

no action = nothing will happen, all functions remain as they

were

on = the selected channel will turn on with the event and o

again when the event is over.

o = the selected channel will be always on and only turns o

with the event happening, same as the on state but inverted.

dim = only used for the headlights, choose if the lights dim on

direction change or not.

2.

press

Events

On Forward

On Reverse

On Brake

On B.Lock

On Horn

A1 A2 A3 FL RL DL

o = dim= on=

no action

on

o

dim

3.

Page 20

20

PRELIMINARY

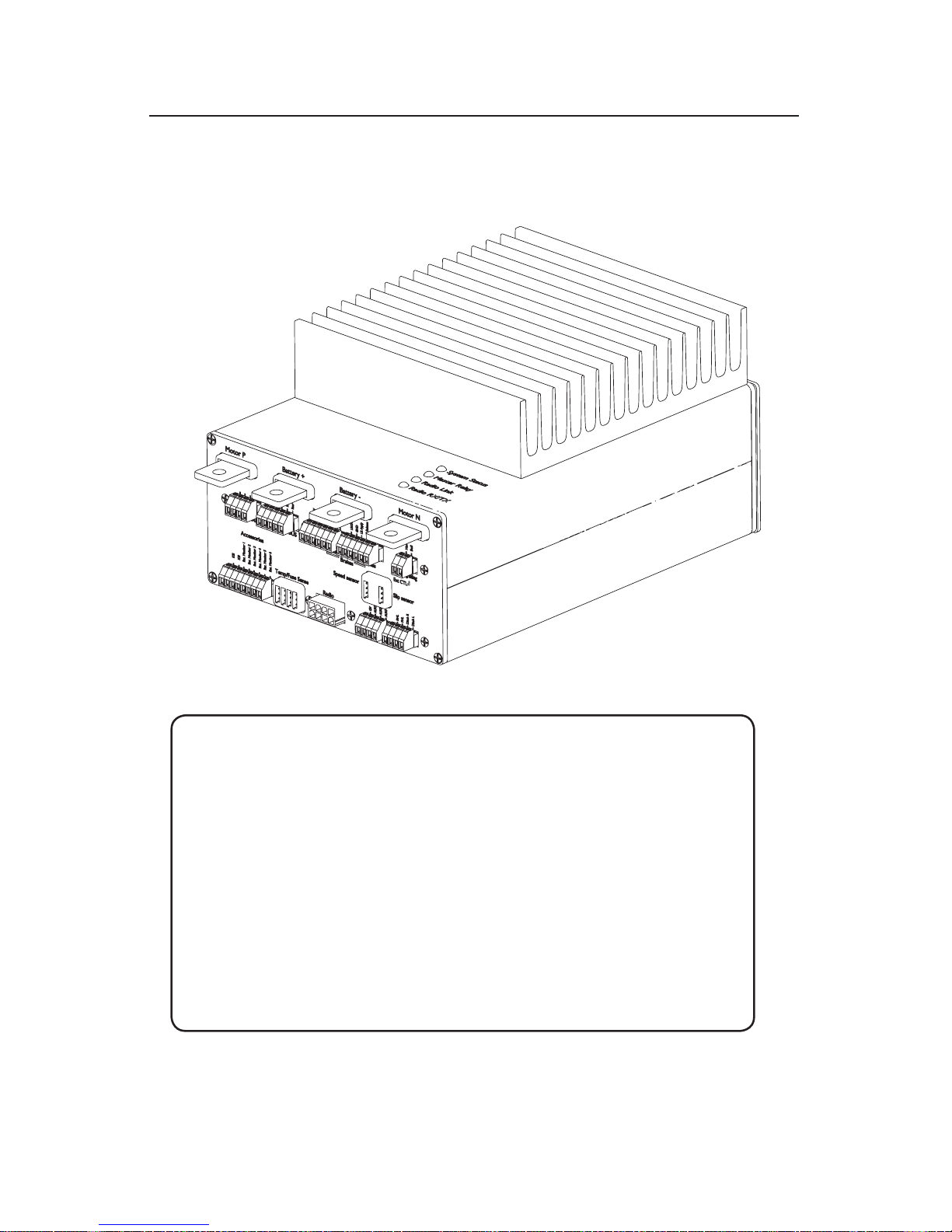

7. The LT150A (hardware setup)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1. System Connector

2. Lights / Aux Connectors

3. Radio Connector

4. Handset charge /

Mu connector

5. Loco Brakes connector

6. Train Brakes connector

7. Speed sensor input

8. Fuse sensor input

9. System LED panel

10. Positive Motor Lug

11. Negative Motor Lug

12. Positive Battery Lug

13. Negative Battery Lug(GND)

14. Heatsink

-

connector connections

Parts of the LT150A

Page 21

21

PRELIMINARY

7a. Front panel Pinout

Page 22

22

PRELIMINARY

Page 23

23

PRELIMINARY

Page 24

24

PRELIMINARY

Installing the radio Tranceiver

When you install the tranceiver you need to make

sure that the antenna is clear of any obstructions

1. 8pin radio tranceiver plug

2. Radio antenna

3. Activity / Connection LED (on backside)

!

Plug the radio tranceiver into the 8 pin receptacle on the frontpanel of the LT150A controller

1

2

3

Page 25

25

PRELIMINARY

Installing the system connector

Plug the 8 pin Phoenix plug into the system monitor receptacle

The pinout for this connector is as described here:

KSI and the battery monitors are absolutely mandatory for operation of the unit!

!

Key switch input (KSI)

This connection should be fused

with a 3A Fuse (minimum)

(mandatory connection)

Battery monitors

Bat Type: 6v 12v

Bat1 6v 12v

Bat2 12v 24v

Bat3 18v 36v

Bat4 24v

Bat5 30v

Bat6 36v

Battery Monitor connections

should be fused with a 0.5A

fuse (minimum)

Page 26

26

PRELIMINARY

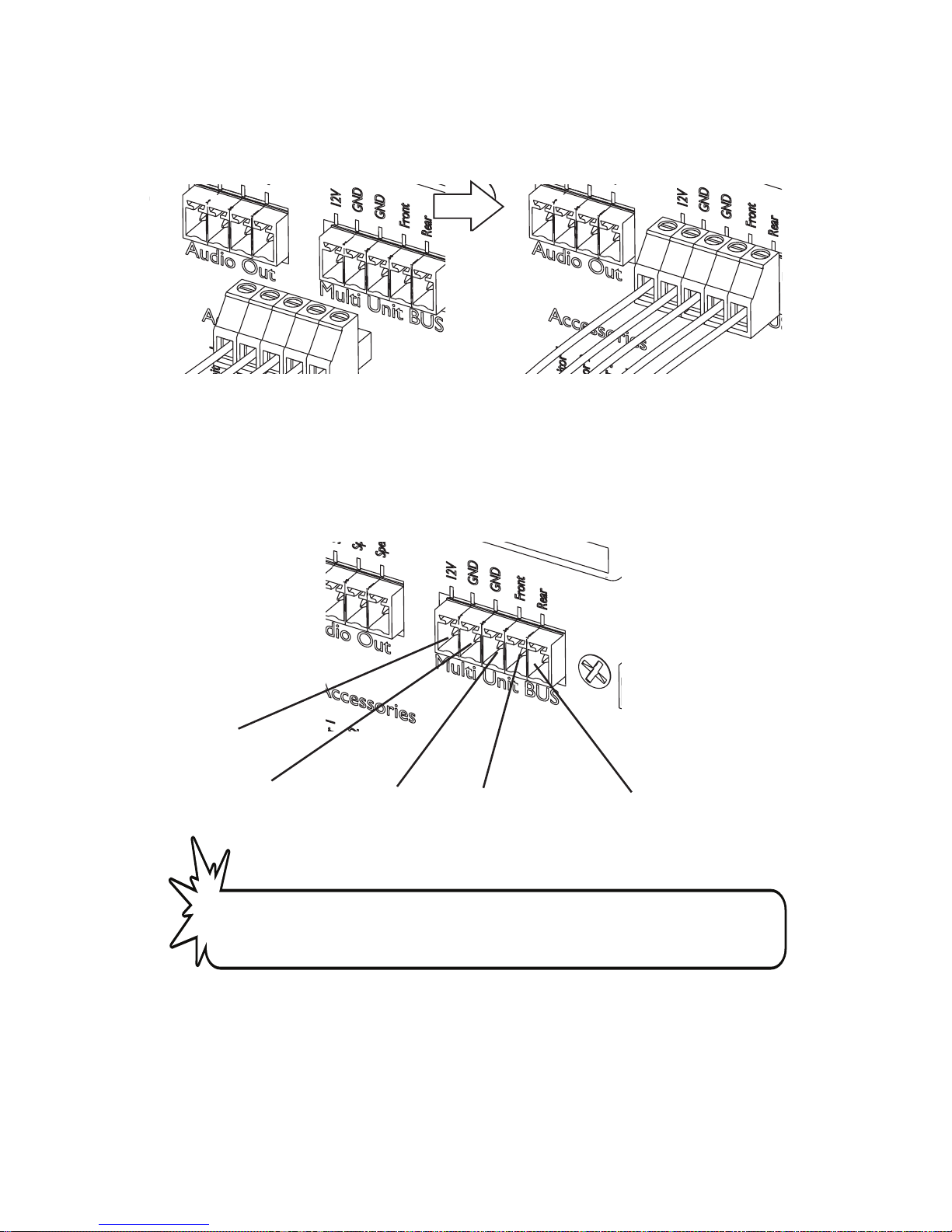

Make sure you do not mix the connection shemes up!

The Lighting pins can drive up to 4A (switched ground)

The Aux pins can drive up to _A (switched 12V)

The 12V Pin can drive up to _A

!

Installing the Lights and Aux Connector

Constant 12V

Aux 1 (12V)

Aux 2 (12V)

Aux 3 (12V)

Left Ditchlight

Right Ditchlight

Front Head Light

Rear Head Light

AUX/12V:

Lights:

VCC

LT150A

10/20w

3A Fuse

GND

LT150A

device

Page 27

27

PRELIMINARY

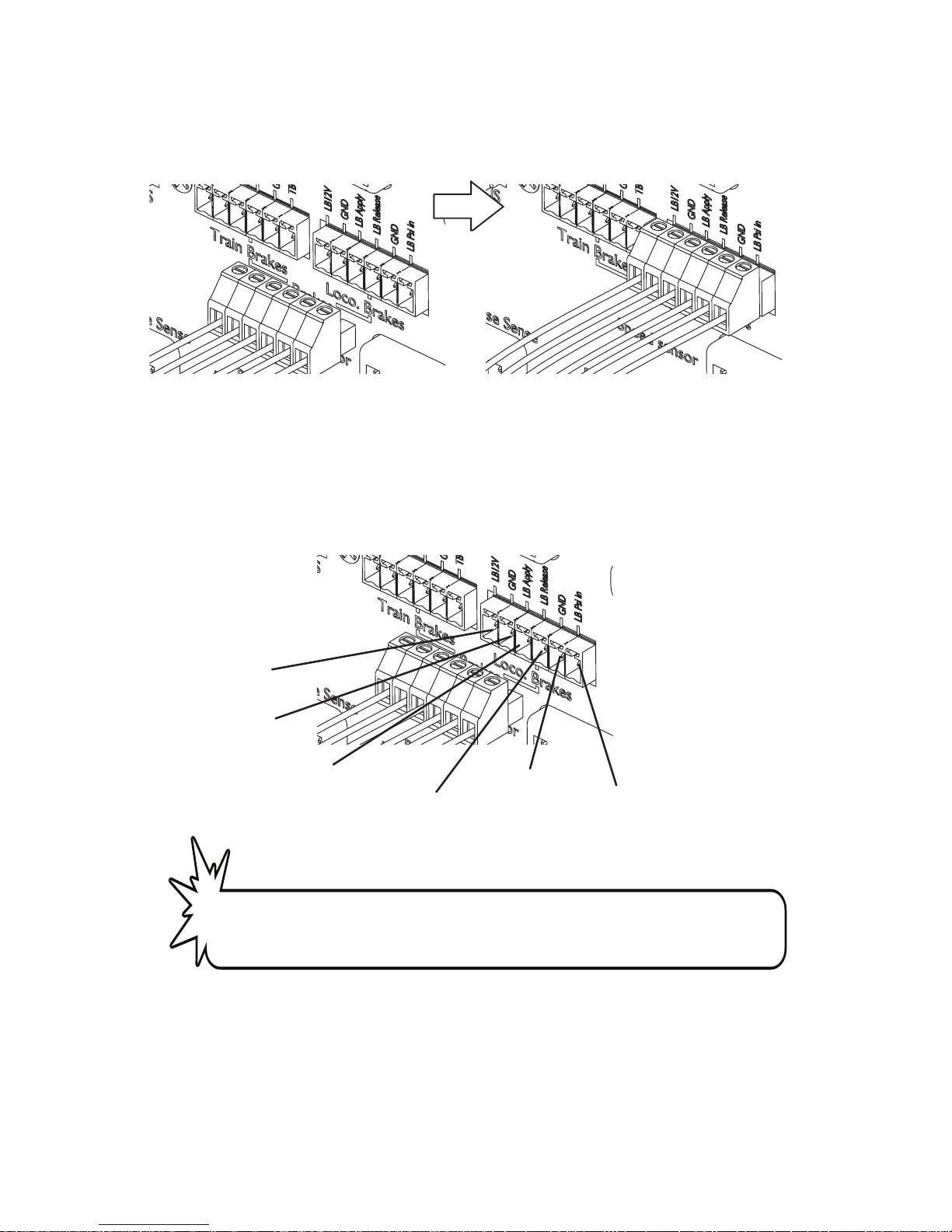

Integral circuits brake controllers come with a ready made control cable or an

attached cable, depending on the model.

Integral circuits brake controllers come with a

ready made control cable or attached cable depending on the model.

!

Installing the Loco brake connector

Plug the 6 pin brake phoenix connector into the Loco brake receptacle.

The pinout for this connector is as described here:

12V

GND

Apply

Release

GND

Pressure Sensor

Page 28

28

PRELIMINARY

Integral circuits brake controllers come with a ready made control cable or an

attached cable, depending on the model.

Integral circuits brake controllers come with a

ready made control cable or attached cable depending on the model.

!

Installing the Train brake connector

Plug the 6 pin brake phoenix connector into the Loco brake receptacle.

The pinout for this connector is as described here:

12V

GND

Apply

Release

GND

Pressure Sensor

Page 29

29

PRELIMINARY

Integral circuits brake controllers come with a ready made control cable or an

attached cable, depending on the model.

The LOCOnTROLLER comes with one pre-made

MU connector for installation in the Locomotive

body

!

Installing the Multi unit connector

Plug the 6 pin brake phoenix connector into the Loco brake receptacle.

The pinout for this connector is as described here:

12V

GND

GND

Front MU

Rear MU

Page 30

30

PRELIMINARY

Brake controller installation diagram (BC100)

Brake controller installation diagram (BC50)

LT150A

LT150A

Page 31

31

PRELIMINARY

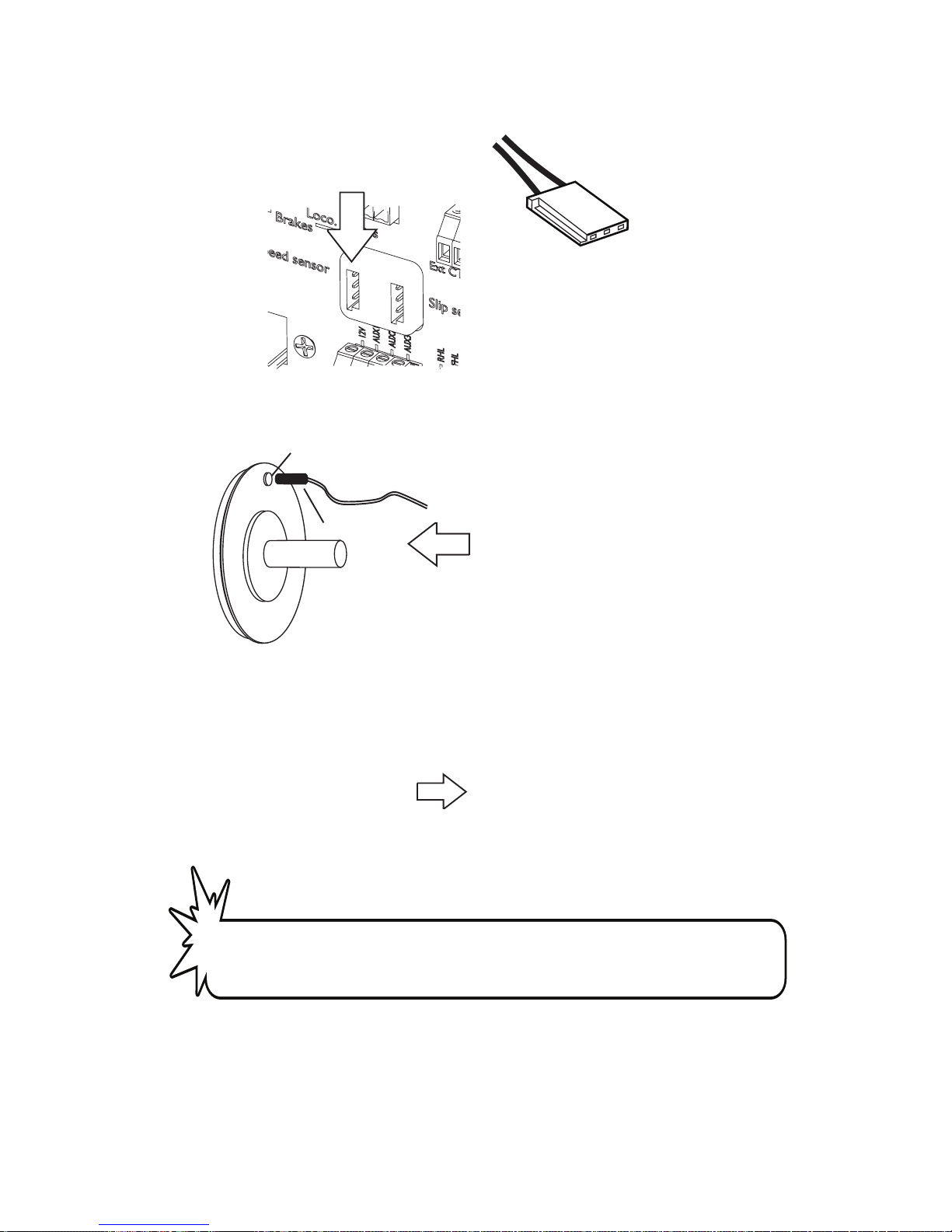

Installing the speed sensor

3 pin futaba servo connector

Sense

Ground

The LT150A needs a pulse signal to ground on

its speed input connection to measure speed.

A simple reed switch and one single magnet on

one of the wheels of the locomotive is sucient

for this.

Magnet

Sensor

Locomotive Wheel

The Handset will show the speed at the top of

the dashboard . The speed is shown in the format you have set in the setup menu “speed format” (mph, smph , kph, skph)

Like in the the example on the left where it shows

the locomotive traveling at 5.4 miles per hour.

Integral circuits brake controllers come with a ready made control cable or an

attached cable, depending on the model.

For this to work right, you need to set the according wheel diameter of your locomotive in the

Setup menu (page 17)

!

Page 32

32

PRELIMINARY

9. Wiring Diagram (provided Externally)

Page 33

33

PRELIMINARY

Page 34

34

PRELIMINARY

Notes

Page 35

Notes

Page 36

©2016 Integral Circuits, LLC.

Loading...

Loading...