Page 1

VIAFLO 96/384 Operating instructions

125950_V11

Page 2

Declaration of conformity

INTEGRA Biosciences AG – 7205 Zizers, Switzerland

declares on its own responsibility that the devices

Description Models

VIAFLO 96 6000, 6001

VIAFLO 384 6030, 6031

comply with:

EU Directives (DoW: Date of Withdrawal) Before DoW DoW After DoW

Low Voltage Equipment 2006/95/EC 20.04.2016 2014/35/EU

Electromagnetic Compatibility 2004/108/EC 20.04.2016 2014/30/EU

Restriction of Hazardous Substances 2011/65/EU

Waste Electrical and Electronic Equipment 2012/19/EU

EU Regulations

Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH)

Standards for EU

Safety requirements for electrical equipment for measurement,

EN 61010-1: 2010

control and laboratory use - General requirements.

Particular requirements for automatic and semi-automatic

EN 61010-2-81: 2015

laboratory equipment for analysis and other purposes.

Electrical equipment for measurement, control and laboratory use

EN 61326-1: 2013

- EMC requirements.

1907/2006

Standards for Canada and USA

Safety requirements for electrical equipment for measurement,

control and laboratory use - General requirements

Safety requirements for electrical equipment for measurement,

control and laboratory use - General requirements

Particular requirements for automatic and semi-automatic laboratory

equipment for analysis and other purposes

a

.

a

.

a

.

Operation is subject to the following two conditions: (1) this device may not

cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

a

NRTL certificate number (TÜV Süd): U8 17 05 42035 007

Zizers, June 19, 2017

Elmar Morscher

CEO

Thomas Neher

Quality Manager

CAN/CSA-C22.2

No. 61010-1

UL 61010-1

UL 61010-2-81

Part 15 of the

FCC Rules

Class A

Page 3

VIAFLO 96/384 – Operating instructions V11

Table of Contents

Chapter 1 Introduction

1.1 Symbols used...................................................................................7

1.2 Intended use.....................................................................................7

1.3 Safety notes .....................................................................................8

Chapter 2 Description of the device

2.1 Scope of delivery..............................................................................9

2.2 Overview of VIAFLO 96/384.............................................................9

2.2.1 VIAFLO 96/384 device..........................................................9

2.2.2 VIAFLO 96/384 control unit.................................................10

2.2.3 Display ................................................................................10

2.2.4 Touch wheel........................................................................11

2.2.5 Left and right arrow buttons ................................................11

2.2.6 PURGE button ....................................................................11

2.2.7 RUN key..............................................................................11

Chapter 3 Installation

3.1 Operating environment...................................................................12

3.2 Setting up and moving of the instrument........................................12

3.3 Getting started................................................................................13

3.4 Toolbox - adapt your VIAFLO 96/384.............................................14

3.4.1 Change head ......................................................................14

3.4.2 Storage of pipetting heads..................................................15

3.4.3 Position Settings .................................................................16

3.4.4 Preferences.........................................................................16

3.4.5 Calibration & Services.........................................................18

3.4.6 Communications .................................................................19

3.4.7 Device Information..............................................................19

3.4.8 Language............................................................................19

3.4.9 Write protect........................................................................20

www.integra-biosciences.com 3

Page 4

VIAFLO 96/384 – Operating instructions V11

Chapter 4 Operation

4.1 Turn on/off the device.....................................................................21

4.2 Attaching and removing GripTips ...................................................21

4.2.1 Loading tips from a complete box.......................................21

4.2.2 Partial tip loading ................................................................22

4.2.3 Ejecting used GripTips........................................................22

4.3 Start pipetting .................................................................................23

4.3.1 Pipetting..............................................................................23

4.3.2 Set Z-Position .....................................................................23

4.3.3 Blowout modes ...................................................................23

4.3.4 Recommendations for pipetting ..........................................24

4.4 Pipetting options and settings ........................................................25

4.4.1 Edit option...........................................................................25

4.4.2 Volume selection.................................................................25

4.4.3 Speed selection ..................................................................26

4.4.4 Custom................................................................................27

4.4.5 Pace....................................................................................27

4.4.6 Count, Mix Cycle and Rows................................................27

4.4.7 Pipetting between 96 and 384 well plates...........................28

4.4.8 Pipetting with the three position stage................................29

4.5 Troubleshooting/FAQ .....................................................................30

Chapter 5 Pipetting modes

5.1 Overview pipetting modes ..............................................................31

5.2 Detailed description of pipetting modes .........................................32

5.2.1 Pipet mode..........................................................................32

5.2.2 Repeat dispense mode.......................................................33

5.2.3 Sample dilute mode ............................................................34

5.2.4 Pipet/mix mode ...................................................................34

5.2.5 Manual pipet mode .............................................................35

5.2.6 Reverse pipet mode............................................................36

5.2.7 Variable dispense mode .....................................................37

5.2.8 Variable aspirate mode.......................................................38

5.2.9 Sample dilute/mix mode......................................................39

5.2.10 Serial dilution mode ..........................................................40

5.3 Custom step-based programming mode ........................................41

5.3.1 Manual custom program .....................................................42

5.3.2 Modify existing programs....................................................44

5.3.3 Automatic custom program.................................................44

5.4 VIALINK..........................................................................................46

4 INTEGRA Biosciences AG

Page 5

VIAFLO 96/384 – Operating instructions V11

Chapter 6 Maintenance

6.1 Cleaning and Decontamination ......................................................47

6.1.1 Base unit.............................................................................47

6.1.2 Pipetting heads ...................................................................47

6.2 Prolonged period of non-use..........................................................47

6.3 Leak test.........................................................................................48

6.4 Servicing.........................................................................................49

6.4.1 Blocked pipetting unit..........................................................49

6.4.2 Changing O-rings of tip fittings............................................50

6.5 Calibration ......................................................................................51

6.6 Equipment disposal ........................................................................51

Chapter 7 Technical Data

7.1 Environmental conditions ...............................................................52

7.2 Specification of the device..............................................................52

7.3 Intellectual Property........................................................................53

7.4 Pipetting specifications...................................................................54

Chapter 8 Accessories and consumables

8.1 Accessories....................................................................................55

8.2 Consumables .................................................................................56

www.integra-biosciences.com 5

Page 6

VIAFLO 96/384 – Operating instructions V11

Imprint

© 2017 INTEGRA Biosciences AG

All rights to this documentation are reserved. In particular the rights of reproduction,

processing, translation and the form of presentation lie with INTEGRA Biosciences AG.

Neither the complete documentation nor parts thereof may be reproduced in any way, or

stored and processed using electronic media or distributed in any other way without the

written consent of INTEGRA Biosciences AG.

This operating instruction manual has part number 125950, the version is V11. It applies

to software version as of (see Toolbox - Device information):

Control unit (FW) 3.10 or higher

Instrument base (HW) 3.20 or higher

until a newer revision is released.

Manufacturer

INTEGRA Biosciences AG

CH-7205 Zizers, Switzerland

T +41 81 286 95 30

F +41 81 286 95 33

INTEGRA Biosciences Corp.

Hudson, NH 03051, USA

T +1 603 578 5800

F +1 603 577 5529

info@integra-biosciences.com

www.integra-biosciences.com

Customer service

Please contact your local INTEGRA Biosciences AG representative.

To find out name and address of your local representative go to

www.integra-biosciences.com

Further information and operating instructions in other languages are available on

www.integra-biosciences.com

6 INTEGRA Biosciences AG

.

or on request info@integra-biosciences.com.

Page 7

VIAFLO 96/384 – Operating instructions V11 Introduction

1 Introduction

VIAFLO 96 and VIAFLO 384 are separate instruments. The abbreviation VIAFLO 96/384

is used if information is relevant to both instruments. These operating instructions contain

all the information required for installation, operation and maintenance of VIAFLO 96/384.

This chapter informs about the symbols used in these operating instructions, the intended

use of VIAFLO 96/384 and the general safety instructions.

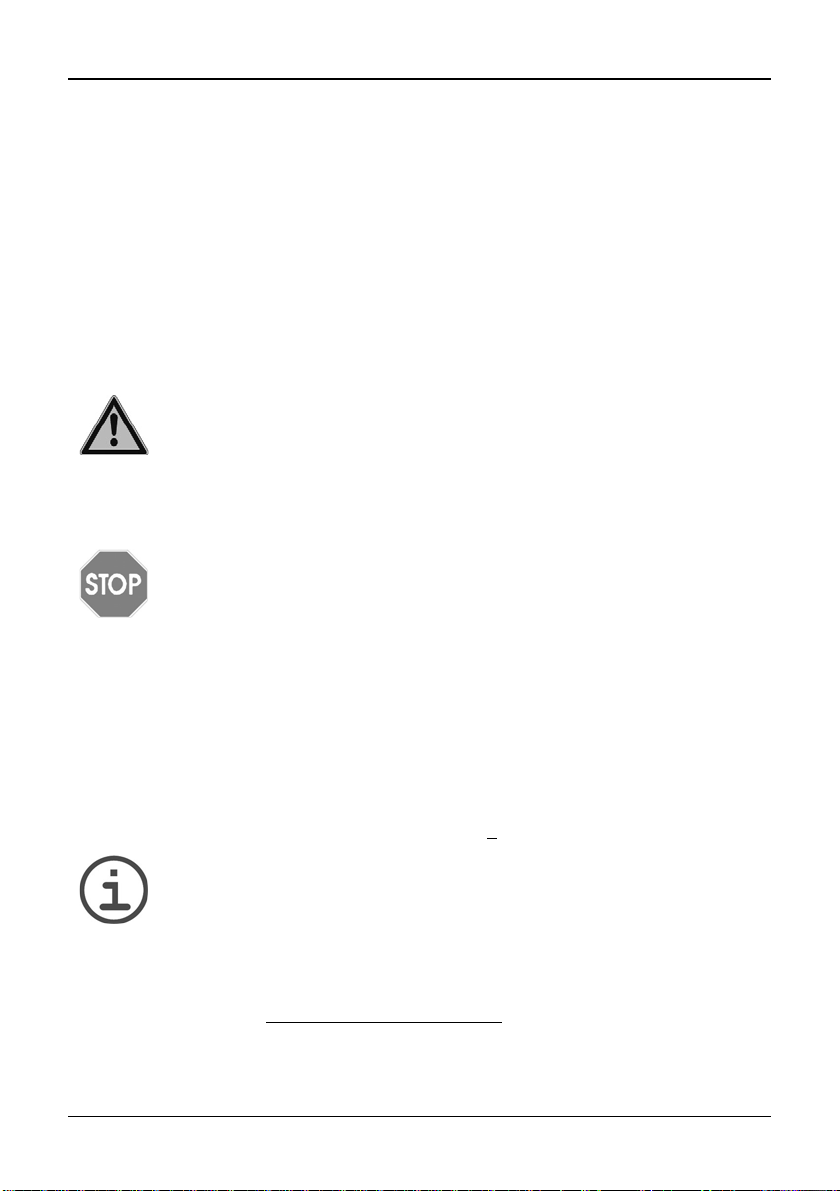

1.1 Symbols used

The operating instructions specifically advise of residual risks with the following symbols:

ARNING

W

This safety symbol warns against hazards that could result in injury. Italso

indicates hazards for machinery, materials and the environment.

It is essential that you follow the corresponding precautions.

AUTION

C

This symbol cautions against potential material damage or the loss of data in

a microprocessor controller. Follow the instructions.

NOTE

This symbol identifies important notes regardi ng the correct operation of the

device and labor-saving features.

The device is marked with the following symbols:

IOHAZARD

B

The instrument can be potentially biohazardous due to the use of

biozazardous substances by the operator.

UNPLUG

The power cable must be unplugged before the housing of the instrument is

opened by a service technician.

1.2 Intended use

This is general purpose laboratory instrument for use in research only. Any use of this

instrument in a medical or IVD setting is the responsibility of the user.

VIAFLO 96/384 is an electronic 96/384-channel hand held pipette designed for aspirating

and dispensing aqueous solutions in the volume range of 0.5 µl to 1250 µl using GripTip

pipette tips. VIAFLO 96/384 is used like a hand held pipette. The movement and

positioning of the 96-/384-channel pipette is supported by a servo assisted steering

mechanism which allows fast, precise and stress free multichannel pipetting. VIAFLO 96

can only be used with 96-channel pipetting heads, while VIAFLO 384 is compatible to both

96- and 384-channel pipetting heads.

www.integra-biosciences.com 7

Page 8

VIAFLO 96/384 – Operating instructions V11 Introduction

If VIAFLO 96/384 is used in a manner not specified by INTEGRA Biosciences, the

protection provided by the VIAFLO 96/384 may be impaired.

1.3 Safety notes

VIAFLO 96/384 complies to the recognized safety regulations and is safe to operate.

VIAFLO 96/384 can only be operated when in perfect condition and while observing these

operating instructions.

The device may be associated with residual risks if it is used or operated improperly by

untrained personnel. Any person operating the VIAFLO 96/384 must have read and

understood these operating instructions, and particularly, the safety notes, or must have

been instructed by supervisors so that safe operation of the device is guaranteed.

ARNING

W

Do not use the VIAFLO 96/384 near flammable material or in explosive

areas. Also, do not pipette highly flammable liquids such as acetone or ether.

When handling dangerous substances, comply with the material safety data

sheet (MSDS) and with all safety guidelines such as the use of protective

clothing and safety goggles.

AUTION

C

Do not immerse the pipetting head in liquid. The fluid can damage intern al

parts. Avoid pipetting of liquids whose vapors could attack the materials PA

(polyamide), POM (polyoxymethylene), FPM (fluor-rubber), NBR (nitrilerubber), CR (chloroprene), silicone. Corrosive vapors could also damage

metallic parts inside the device.

Do not open or modify VIAFLO 96/384 in any way . Th e sheet m eta l must not

be removed. Repairs may only be performed by INTEGRA Biosciences AG

or by an authorized after-sales service member.

Parts may be replaced with original INTEGRA Biosciences parts only.

Never insert the mains adapter of any INTEGRA electronic hand pipette into

the power connector of the control unit (5

NOTE

Prolonged exposure of the VIAFLO 96/384 to UV-light can cause

discoloration and/or yellowing of the control unit. However, this will not affect

the performance of the device in any way.

Regardless of the listed safety notes, additional applicable regulations and guidelines of

trade associations, health authorities, trade supervisory offices, etc. must be observed.

Please visit our website www.integra-biosciences.com

information regarding REACH classified chemicals contained in our products.

).

on a regular basis for up to date

8 INTEGRA Biosciences AG

Page 9

VIAFLO 96/384 – Operating instructions V11 Description of the device

4

5

8 A

8 B

10

6

1

2

9

3

7

2 Description of the device

2.1 Scope of delivery

• VIAFLO 96/384 device

• Power cable

• USB cable type A to B

• Operating instructions

AUTION

C

Verify the scope of delivery when unpacking the device and check for

potential transportation damage. Do not operate a device that is damaged,

instead contact your local dealer.

2.2 Overview of VIAFLO 96/384

2.2.1 VIAFLO 96/384 device

1 Base unit, to move left and right (X axis)

2 Carrying handle of base unit

3 Pipetting unit, to move up and down (Z axis)

4 Tip load button

5 Control unit, see 2.2.2

6 Knob of Side cover, covers the pipetting head

7 Instrument deck

8 Plate holders on position A and B

9 Plate slider, with front (384), zero (96) and back

(384) position to index 96 or 384 well plates (Y axis)

10 Main switch

www.integra-biosciences.com 9

Page 10

VIAFLO 96/384 – Operating instructions V11 Description of the device

11

12

15

13

14

19

Current mode

Active step

OK

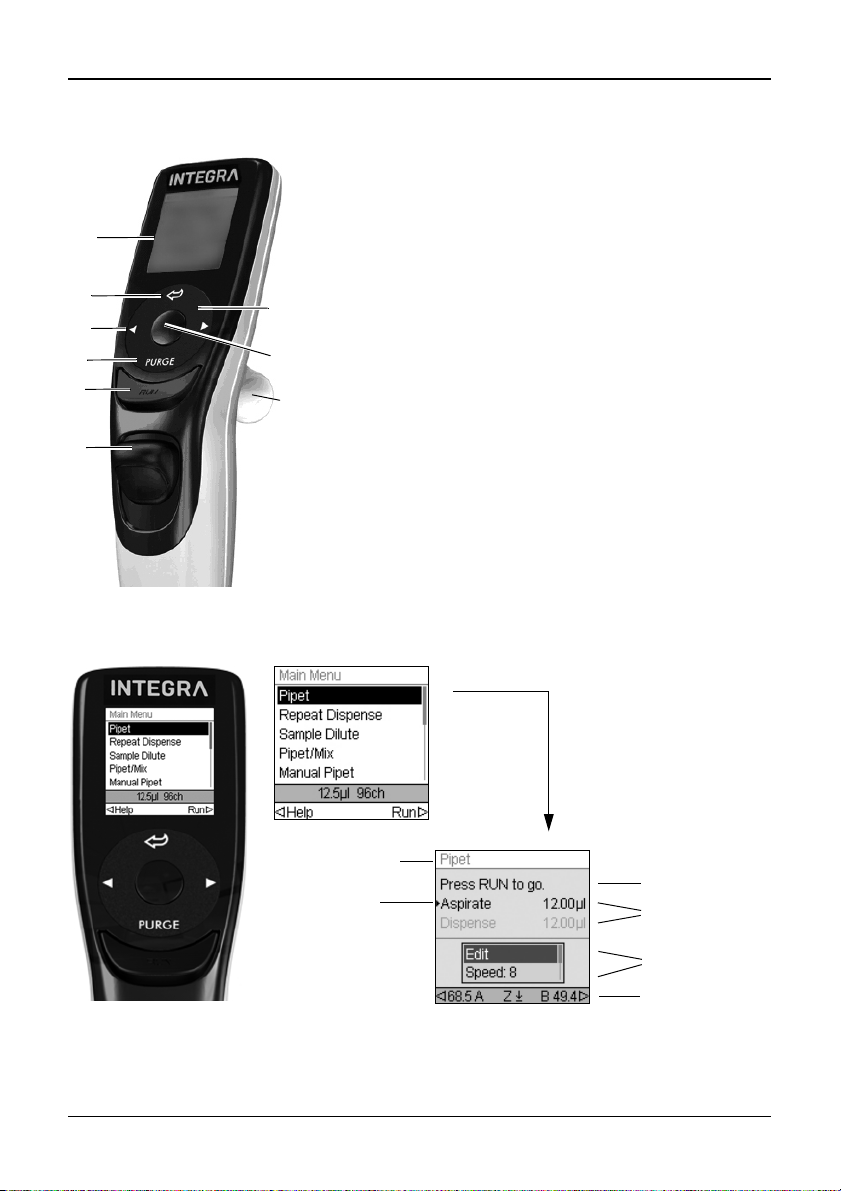

2.2.2 VIAFLO 96/384 control unit

11 Display

12 Back button, to navigate backward

13 Touch wheel, spin to scroll and move the cursor

14 OK button, to make a selection

15 Left and right arrow buttons, for selections

16 PURGE button, to empty tips

17 RUN key, to start operations

18 Tip ejector

19 Finger hook, facilitates easy operation

2.2.3 Display

The Display shows all pipetting options.

10 INTEGRA Biosciences AG

Instruction

Volumes

Options

Arrow buttons

to set Z height

Page 11

VIAFLO 96/384 – Operating instructions V11 Description of the device

2.2.4 Touch wheel

The Touch wheel is fully operational with only one hand. Rotational finger movements

translate into up and down cursor movement on the display. The Touch wheel is fully

functional with the use of latex gloves.

Move finger on the Touch wheel to choose (and

highlight) an option on the display. Press OK (14

make the selection.

When a setting dial is displayed, spin the Touch wheel

to change the value and press OK.

2.2.5 Left and right arrow buttons

At times, you will see and on a display screen. These buttons

are used to select options.

Press to select the option indicated with the left arrow (HELP, in

the example beside). Press to select the option indicated with the

right arrow (RUN, in the example).

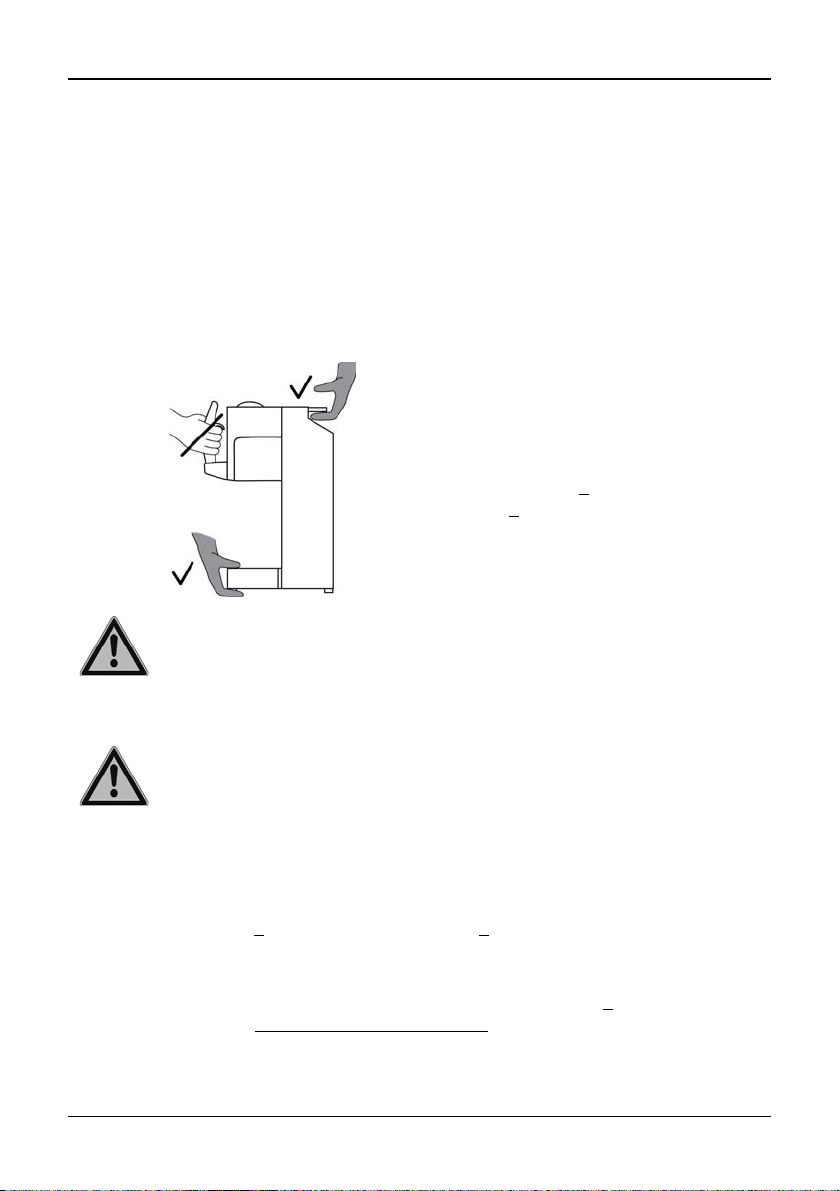

2.2.6 PURGE button

During pipetting, you can interrupt the current pipetting protocol and purge all remaining

liquid currently in the GripTips. To do so, press PURGE (16

).

) to

The pipette will display a prompt.

To proceed, press and release the RUN key (17

of the dispense, the first step in the current program will be

displayed.

2.2.7 RUN key

Press and release the RUN key (17

special pipetting operations.

During dispense, you can press and hold the RUN key to perform a two-step blowout, see

Blowout modes” on page 23.

“4.3.3

www.integra-biosciences.com 11

) to initiate aspiration, dispense, mix, purge, and

). Upon completion

Page 12

VIAFLO 96/384 – Operating instructions V11 Installation

2

7

3 Installation

3.1 Operating environment

VIAFLO 96/384 has been designed for use in a laboratory. It shall be operated in a dry and

dust-free location with a temperature of 5– 40 °C and a maximal (non-condensing) relative

humidity of 80 %.

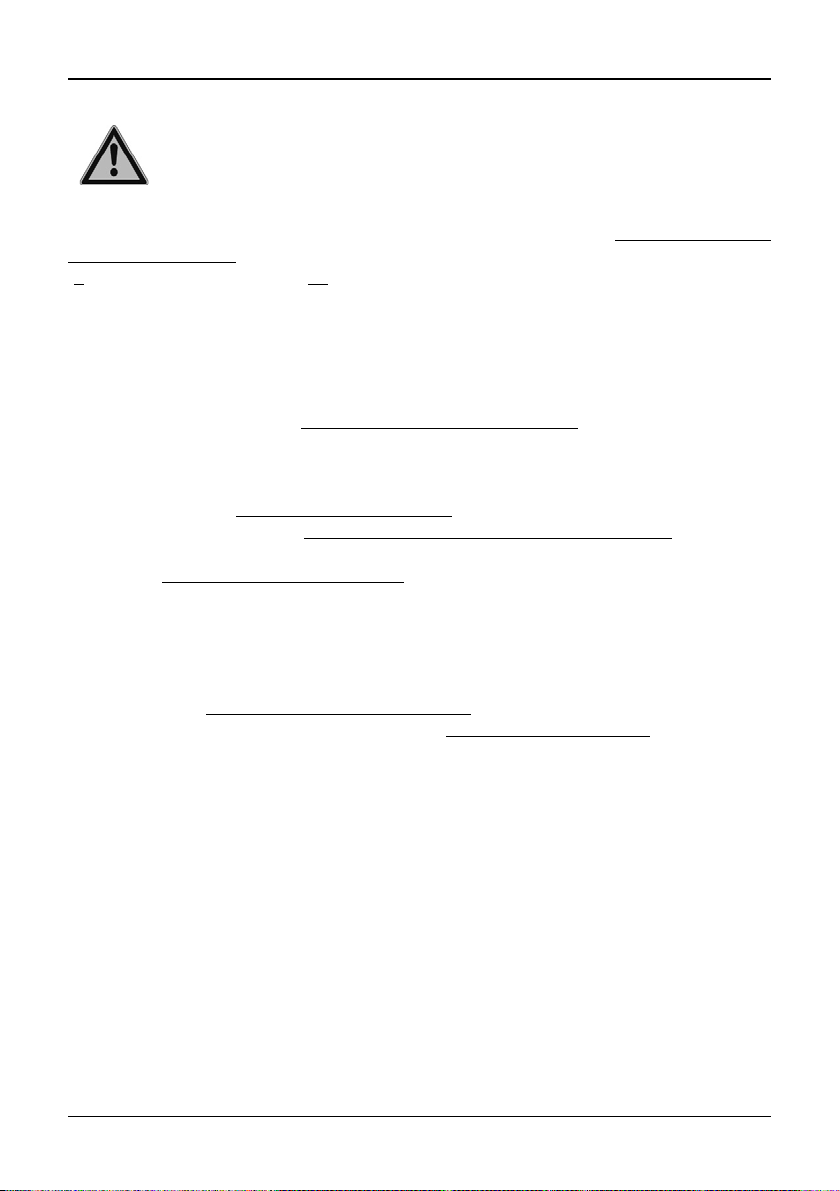

3.2 Setting up and moving of the instrument

The VIAFLO 96/384 must be set up on a cleaned, dry and horizontal surface.

.

Hold the Carrying handle (2

Instrument deck (7

) to lift VIAFLO 96/384.

) and the

WARNING

The device must not be carried on the control unit because it will be

damaged.

Leave at least 5 cm of free space on the back for air circulation and to allow easy

connection of the mains cable.

ARNING

W

It must always be possible to manually disconnect the plug of the VIAFLO 96/

384 from electricity supply. The corresponding socket shall be within easy

reach of the operator and be clearly labeled as the disconnecting device of

VIAFLO 96/384.

Only use a 3 core mains cable with protective earth to connect VIAFLO 96/384 with the

power source. The socket is located on the reverse side of the instrument deck.

Put the Plate holders (8

) on the Instrument deck (7) on Position A and/or B. They can

both be placed on either side. Move the Plate holder from left to right until the two bolts

click into the two holes.

Alternatively, put the three position stage on the Instrument deck (7

) until the bolts click

into the four holes, see “8.1 Accessories” on page 55).

12 INTEGRA Biosciences AG

Page 13

VIAFLO 96/384 – Operating instructions V11 Installation

WARNING

VIAFLO 96/384 must be secured with the “Park Head” function before

carrying.

Before VIAFLO 96/384 can be relocated, the pipetting and base unit must be fixed. Select

“Park Head” from “Calibration & Service” of the Toolbox menu, see “3.4.5 Calibration &

Services” on page 18. Make sure GripTips have been ejected, clear the Instrument deck

(7

) and press the RUN key (17) to start the park routine. The unit moves to the park

position and is anchored on the base with a bolt. Switch off VIAFLO 96/384 and

disconnect it from the electricity mains.

3.3 Getting started

Turn on VIAFLO 96/384 (see "Turn on/off the device" on page 21). To adapt the device to

the appropriate applications, select the following functions of the Toolbox menu in this

order:

• Change head: Select the toolbox menu “Change head” and insert the appropriate

pipetting head, see "

• Load 96/384 GripTips, see "Attaching and removing GripTips" on page 21

• Position settings - Head alignment: Define the center of the wells of a 96-or 384-well

plate, see "

• Position settings - Tip align: VIAFLO 96/384 base unit can be moved left and right

(X direction). Tip align locks onto the wells of a plate and helps to guide the tips into the

microplate wells.

• Z-Height: VIAFLO 96/384 pipetting unit can be moved up and down (Z direction). A

minimum height can be defined in every pipetting mode, e. g. to set optimal tip immersion depth, see “4.3.2

• Preferences: Define system parameters, see "Preferences" on page 16.

Position Settings" on page 16.

Change head" on page 14.

Set Z-Position” on page 23.

www.integra-biosciences.com 13

Page 14

VIAFLO 96/384 – Operating instructions V11 Installation

3.4 Toolbox - adapt your VIAFLO 96/384

The Toolbox provides options to adapt the device to appropriate applications, setting

personal preferences, calibration, computer connectivity and storing owner information.

Toolbox mode Description

Change Head Allows to change the pipetting head.

Position Settings Sets the tip alignment, head alignment and Z-height.

Preferences Customizes the system parameters.

Calibration & Service Sets calibration and service history options and parks the head.

Communications Enables communication between your VIAFLO 96/384 and a

PC.

Device Information View your pipette’s serial number, software version and set a

personal ID.

Language Sets display language.

Write Protect Protects programs or menu options from modification.

The Help information describes the modes and some settings, press to select the Help

option.

3.4.1 Change head

N

OTE

VIAFLO 96 can only be used with 96-channel pipetting heads, while VIAFLO

384 is compatible with both 96- and 384-channel pipetting heads.

The following pipetting heads are available:

Pipetting head Channels Volume range

12.5 µl 96 0.5–12.5 µl

50 µl 96 2–50 µl

125 µl 96 5–125 µl

300 µl 96 10–300 µl

1250 µl 96 50–1250 µl

12.5 µl 384 0.5–12.5 µl

50 µl 384 2–50 µl

125 µl 384 5–125 µl

14 INTEGRA Biosciences AG

Page 15

VIAFLO 96/384 – Operating instructions V11 Installation

a

a

b

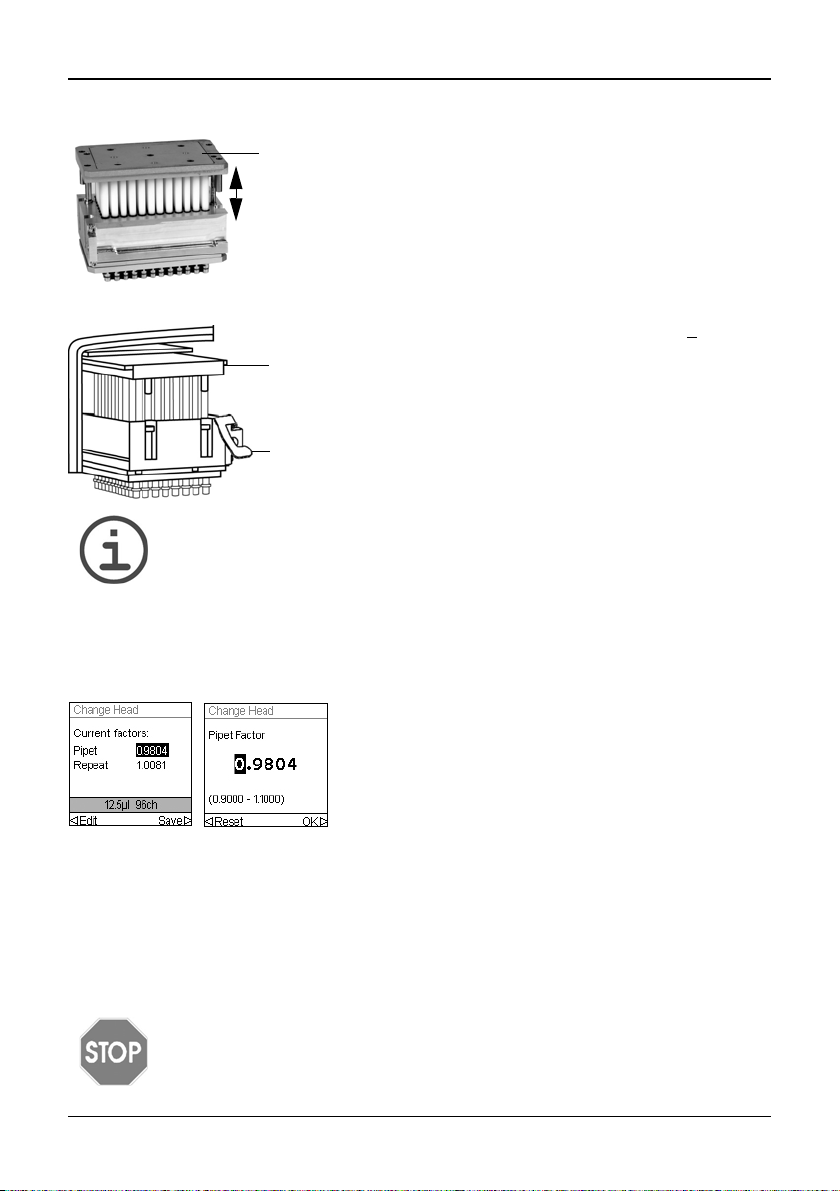

Remove the pipetting head from the case.

Make sure the pipetting head is in extended position (see

image to the left). If necessary, pull apart the Piston plate

(a) on the top as far as possible.

To install the appropriate pipetting head select the Toolbox option “Change Head”.

Loosen the knob and remove the Side cover (6

Remove the existing head, if installed.

Push the appropriate pipetting head into the slide block

and make sure the Piston plate (a) slides onto the

brazen rails.

Mount the Side cover, screw the knob tightly and press

OK to continue.

OTE

N

Pipetting heads with a serial number >50274 feature an ejection lever (b) to

facilitate the removal of the head. Pull up the lever to loosen the pipetting

head, then remove it from the instrument.

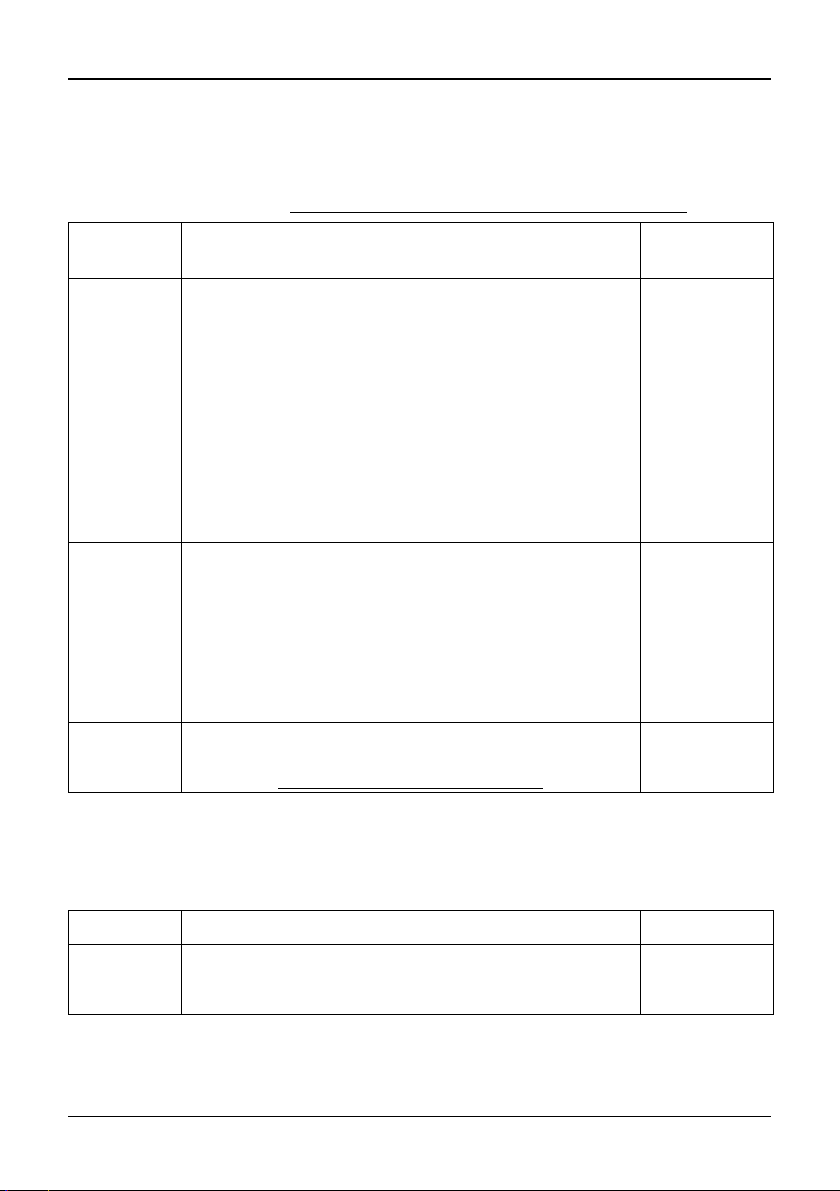

Check whether the Pipet factor on the display corresponds to the Pipet factor labeled on

the side of the head itself or indicated in the latest calibration certificate. Press OK if the

factors coincide. If they don't, click Edit.

).

With the factor “Pipet” selected click Edit to change

the Pipet factor accordingly. Using the Touch Wheel,

select the digit to be modified, then press OK and use

the Touch Wheel to select a number. Press OK to

confirm. Once finished, press Save to apply the

correct Pipet factor to the instrument.

Reset sets the factor to 1.0000. Changing the factor “Repeat” is only necessary under

special circumstances. Refer to the calibration document (PROTO_VIAFLO96_384_

calibration), available on request.

3.4.2 Storage of pipetting heads

Once a pipetting head is removed from VIAFLO 96/384 it must be stored in the appropriate

casing to protect it from dust and mechanical damage.

AUTION

C

Pipetting heads with 384-channels must always be stored in extended

position.

www.integra-biosciences.com 15

Page 16

VIAFLO 96/384 – Operating instructions V11 Installation

3.4.3 Position Settings

Position settings contain options that help to find correct pipetting positions. These

settings are globally stored and are valid for all pipetting heads. Perform these alignments

with GripTips attached, see “4.2 Attaching and removing GripTips” on page 21.

Position

settings

Tip Align Optimally aligns the tips to target the center of the wells

Head Alignment

Z Height Activate to enable overriding of the defined Z-height.

Description Range

on a 96-or 384-well plate.

•Select Position A or B and press OK to activate the tip

alignment.

• Highlight the Strength option and press OK. Set align-

ment support strength 1 (low) to 3 (high). Press OK.

• Column Detent activates column positions of a plate

on Position A or B, e. g. for serial dilutions. Press OK.

Press to save.

Use a 96 well plate for a 96-channel and a 384-well plate

for a 384-channel pipetting head to define the center of

the wells. This setting is required only once per pipetting

head. Move the unit to Position A or B until the selected

position, e.g. A, is displayed.

• Move the unit down and align the tips to the center of

the wells. Select Set to save this position.

• Repeat at position B.

Keep pushing down the control unit to overcome the Zheight, see “4.3.2

Set Z-Position” on page 23.

/

(On/Off)

1-3

(Off)

(A or B)

-

/

(On/Off)

3.4.4 Preferences

Preferences customizes your system parameters. Select an option and press OK to

access. After changing desired settings, press to Save.

Preferences

Deck Brightness

16 INTEGRA Biosciences AG

Description Range

Sets brightness of deck illumination.

• Use the Touch wheel to change the brightness:

off, 1 (weak) to 10 (bright). Press OK.

Off

1-10

Page 17

VIAFLO 96/384 – Operating instructions V11 Installation

Handle Sensitivity

Sound Select an option and press OK to change the status of

Display

Brightness

Main Menu Select a function to be hidden from the main menu (Off)

Touch

Wheel

Pipetting Select an option and press OK.

Sets the sensitivity of the control unit to move the

pipetting unit and base unit.

• Use the Touch wheel to set a sensitivity 1 (low) to 9

(high). Press OK.

the beep tone between On and Off:

• Step Complete: at the end of a program step

• Program Complete: at program completion

• Purge Key: when PURGE is pressed.

• Messages: when a message appears.

• Error Message: when an error message appears or

when illegal data entry is attempted.

• Touch Wheel: When spinning the Touch wheel.

• Last dispense: before the last dispense in Repeat

Dispense and Variable Dispense.

Sets brightness of the display. Use the Touch wheel to

change the brightness: 1 (dim) to 10 (bright). Press OK.

and press OK:

• Pipet, Repeat Dispense, Dilute, Pipet/Mix, etc.

• The Automatic mode is by default deactivated. To activate it, change the status to “” (On). See section 5.3.3

for a description of the Automatic mode.

Adjust your Touch wheel spin sensitivity. Low, Medium,

• Purge Key Speed: Choose the desired purge speed.

• Blowin Delay: Choose a timed delay between the

blowout and the blowin at the end of a dispense, if no

two step blowout is performed, see “4.3.3

modes” on page 23.

• Extend Volume (not available for 12.5 µl pipetting

head): For pipetting below the volume range specified:

50 μl pipette: (1.0)–2–50 μl

125 μl pipette: (2.0)–5–125 μl

300 μl pipette: (5.0)–10–300–(310) μl

1250 μl pipette: (25)–50–1250 μl

The volumes in brackets refer to extended volumes,

e.g. extend the minimal pipetting volume of a 125 μl

head from 5 μl to 2 μl.

NOTE

Extending the volume range is not recommended. Full functionality and

specified accuracy/precision cannot be guaranteed.

Blowout

1-9

/

(On/Off)

1-10

/

(On/Off)

High

1-10

None/

0.5-5.0 s

/

(On/Off)

www.integra-biosciences.com 17

Page 18

VIAFLO 96/384 – Operating instructions V11 Installation

3.4.5 Calibration & Services

These options enable you to set calibration features, review service history and move the

pipetting head into the parking position.

Calibration

& Services

Calibration Allows for re-calibration of VIAFLO 96/384 to restore

Calibration

Reminder

Service History

Park Head Fixes the pipetting and base unit for safe transportation.

After changing desired settings, press to Save.

Description Range

accuracy. The calibration factors for Pipet and Repeat

type are displayed.

To edit the calibration volumes, press .

• Target Volume: This is the volume you are interested

in using for the calibration.

• Actual Volume: This is the measured volume obtained

when dispensing the target volume.

• Current Factor: Displays the factor currently in use.

This factor should be the same as specified on the

head or the latest calibration certificate.

• Reset: Resets the correction factor back to the original factory setting. Press to apply the factory setting.

Sets a calibration reminder based on a number of

pipetting cycles. When the calibration reminder is

displayed, press any key to confirm. However, the

reminder will reappear every time the pipette is turned on

until you change the reminder time or use the reset

option.

• Reminder: Press OK to turn the reminder timer On or

Off.

• Cycles: Use the Touch wheel to set a reminder inter-

val for calibration (time in thousands of cycles). Press

to set the timer to the defined calibration interval.

• Remind in/Total Cycles: Displays the residual amount

of cycles before calibration is required.

• Reset: Resets the timer to the defined calibration

interval. Press to enable.

Press to save.

Displays notes of any service that took place on the

VIAFLO 96/384 listed newest entry first.

• Make sure GripTips are ejected, clear the deck and

press the RUN key to start the park routine. The

pipette moves to park position and can then be turned

off.

-

/

(On/Off)

1k - 240k

cycles

-

-

18 INTEGRA Biosciences AG

Page 19

VIAFLO 96/384 – Operating instructions V11 Installation

3.4.6 Communications

VIAFLO 96/384 can be programmed from a PC via USB communication cable (type A to

B).

Communications

VIALINK Connect the USB cable betweenVIAFLO 96/384 and a PC. Press OK to

3.4.7 Device Information

Device

Information

VIAFLO 96/

384

In addition, information about your VIAFLO 96/384, such as serial number, the firmware

(FW) and hardware (HW) version of the control unit and of the base unit are displayed.

3.4.8 Language

Language Description

Language You can choose the language in which all screens are displayed. Scroll to

Description

begin bi-directional communication. To exit the communications mode

turn off VIAFLO 96/384.

Description

Owner: Press to enter the user name for your pipette. Use the Touch

Wheel to highlight a character and press OK. You can press to Delete

the last character entered. After entering the desired text, press to

Save.

the desired language, press OK and to Save.

www.integra-biosciences.com 19

Page 20

VIAFLO 96/384 – Operating instructions V11 Installation

3.4.9 Write protect

Select this option to protect programs and menu options from inadvertent modification.

The pipetting programs can still be used.

Write

protect

Keep the password in a safe place. Should you lose your password, contact

INTEGRA Biosciences to retrieve your password.

Description Range

Select an option and press OK to switch protection on or

off:

• Standard Programs

• Custom Programs

• Calibration

• Too lbo x

• Password Protection: Protect the access to the write

protect menu by selecting “”.

• Edit Password, if password protect is switched on. To

enter a password use the Touch wheel to highlight a

character and press OK. Press to save the password. The password must be entered before you can

access the write protect menu.

/

(On/Off)

20 INTEGRA Biosciences AG

Page 21

VIAFLO 96/384 – Operating instructions V11 Operation

4 Operation

4.1 Turn on/off the device

Turn on:

AUTION

C

Remove hands from Control unit (5) at switch on and during homing.

When VIAFLO 96/384 is turned on by the Main switch (10), you are prompted to press

the RUN key (17

Press the RUN key again to home the pipetting unit. If filled tips are still on the device, put

a basin below the pipetting head. After homing the Main menu is displayed.

Turn off:

To turn off VIAFLO 96/384, press the Main switch (10

4.2 Attaching and removing GripTips

) to perform a vertical and horizontal homing routine.

).

NOTE

VIAFLO 96/384 automatically goes into stand-by after 30 minutes of

inactivity.

Press OK to continue.

CAUTION

To ensure optimal performance of your VIAFLO 96/384, use only GripTips

designated for use with VIAFLO 96/384, see “8 Accessories and

consumables” on page 55. To prevent contamination of VIAFLO 96/384

pipetting heads, it is recommended to use filtered GripTips only.

NOTE

When using 12.5 µl or 125 µl GripTips with a 96-channel pipetting head, put

the tip box on a Plate holder with slide function and move the Plate slider

) to a 384 position, see “4.4.7 Pipetting between 96 and 384 well plates” on

(9

page 28.

4.2.1 Loading tips from a complete box

Put a tip box either on the left or right Plate holder (8). Hold the Control unit (5) and lower

the pipetting head down onto the tip box until the Tip load button (4) flashes.

www.integra-biosciences.com 21

Page 22

VIAFLO 96/384 – Operating instructions V11 Operation

a

b

When prompted push the Tip load button (a) and at the

same time push down the Control unit (b).

When the tips are loaded, the Tip load button lights up.

) up until the light of the Tip

4.2.2 Partial tip loading

C

AUTION

If only one tip column should be loaded, reduced loading force is required.

Move the Pipetting unit (3

load button turns off.

Put a tip box either on the left or right Plate holder (8

). Hold the Control unit (5) and lower

the pipetting head down onto the tip box until the Tip load button (4) flashes.

When prompted to push the Tip load button, first press OK (14

) to switch to “low power”

loading mode. Then push Tip load button while pushing down the Control unit until the

Tip load button lights up.

Move the Pipetting unit (3

) up until the light of the Tip load button turns off.

4.2.3 Ejecting used GripTips

If liquid is in the tips, empty them by pressing the PURGE button (16

by pressing the Tip ejector (18

). Confirm ejection by pressing the Tip ejector a second

). Tips are ejected

time.

22 INTEGRA Biosciences AG

Page 23

VIAFLO 96/384 – Operating instructions V11 Operation

4.3 Start pipetting

4.3.1 Pipetting

Use the Touch wheel (13

Actions you are about to perform will be displayed on the Run screen.

) to scroll to your desired pipetting mode and press OK (14).

Insert the tips into the liquid to be transferred. Press

and release the RUN key (17) to aspirate the volume

selected in the first step of your protocol (shown on

the Run screen).

To execute subsequent steps, press the RUN key.

For a detailed description of all pipetting modes see “5.2

modes” on page 32. You can change the parameters of your pipetting mode at any time,

see the following sections.

4.3.2 Set Z-Position

To define the optimal tip immersion depth, press or to access the Z-position

screen.Then move the pipetting unit to the target position (A, B) until the actual Z-height

and the current setting are displayed.

• Move the unit down to the desired dispensing height, e.g. 31 mm.

Select Set to enter this position and save your setting.

• Repeat this procedure with position B.

4.3.3 Blowout modes

During the last dispense of a program, a blowout is performed automatically to ensure

efficient liquid delivery. Liquid may be aspirated back into the tips when the pistons move

back to the home position, a process called blowin. There are two ways to perform the

blowin:

• Automatic blowout: Pressing (and releasing) the RUN key starts the dispense with

automatic blowout and blowin. You can choose a timed delay between the blowout and

the blowin, see “Pipetting - Delayed blowin” under “3.4.4

• Two-step automatic blowout: Perform a two-step blowout to manually delay the

blowin:

- Press and hold

- Remove the tips from the target vessel.

- Release the RUN key to start blowin.

the RUN key to start dispense with blowout.

Detailed description of pipetting

Preferences” on page 16.

www.integra-biosciences.com 23

Page 24

VIAFLO 96/384 – Operating instructions V11 Operation

4.3.4 Recommendations for pipetting

INTEGRA Biosciences recommends the following techniques for enhancing pipetting

results. These techniques are consistent with ISO standard 8655-2.

• It is best to immerse the GripTips just enough in liquid to allow the desired volume to be

aspirated.

• Always pre-wet GripTips. After loading tips onto your pipette, aspirate and dispense the

full volume 2-3 times to coat the inside of pipet tips. Pre-wetting ensures that the liquid

and air inside the tips are at equal temperature and the dead air space is humidified.

• VIAFLO 96/384 is an air displacement pipette. It requires to touch the GripTips against

the side of the well or dip them into the liquid after a dispense. This process is referred

to as “touching off” or “tip touch” and prevents liquid from clinging to the pipette tips.

• In programs such as Repeat Dispense, a first and last dispense can be programmed.

These two dispenses are not used and are dispensed into the waste as they contain the

accumulated pipetting errors. Using a first and last dispense is recommended if

accuracy and precision are of high importance.

• Viscous samples should be aspirated and dispensed at the slowest speeds to ensure

accurate pipetting. In addition, the pipetting mode “Reverse pipet” can be used to

optimize pipetting results with viscous samples.

• For pipetting liquids with high vapor pressures (such as methanol or ethanol), use

relatively fast pipetting speeds and avoid prolonged pauses after aspiration.

• Calibrate based on fluid type. VIAFLO 96/384 is tested and calibrated at the factory for

use with distilled water at room temperature. It may be necessary to re-calibrate your

VIAFLO 96/384 if the liquid to be used has different physical properties (specific gravity

and vapor pressure) than water. Calibration mode can be accessed in the Toolbox

menu.

ARNING

W

Avoid pipetting for extended periods. To minimize the risk of repetitive strain

injury, include regular pauses of several minutes.

24 INTEGRA Biosciences AG

Page 25

VIAFLO 96/384 – Operating instructions V11 Operation

4.4 Pipetting options and settings

4.4.1 Edit option

The Edit option is available for each mode. It enables you to access the variables that you

can adjust for a pipetting mode. These variables include Speed, Volume, Pace, Count, Mix

Cycles, Rows and Direction. Additional steps include First Dispense, Last Dispense, Air

Gap, Aspirate Speed, Dispense Speed, etc..

Select a pipetting mode. Then, select Edit on the list

of options and press OK. A list of associated steps is

displayed. For example, if selecting Edit on the

Repeat Dispense screen, the modifiable steps

associated with Repeat Dispense are displayed.

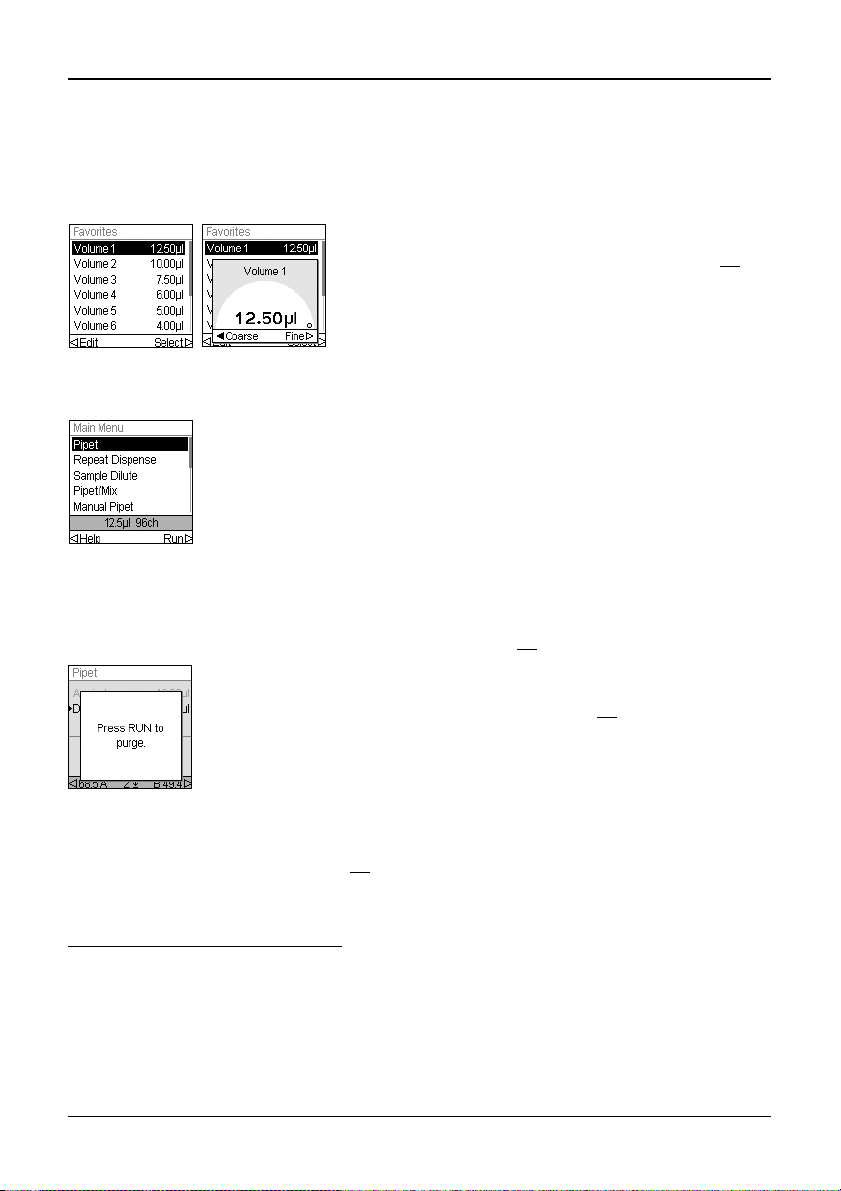

4.4.2 Volume selection

To change a volume select the Edit option and press OK. The adjustable volumes are

displayed.

Use the To u ch wheel to highlight the volume you

want to change (Aspirate, Dispense, Mix, or Air Gap).

Press OK and a Volume setting “dial” is displayed.

Use the Touch wheel to change the volume. Press

OK to confirm your volume selection and to save.

OTE

N

Use the arrow buttons to change the volume in coarse or fine incre ments.

Select Coarse to change the volu me in larger increments. Select F ine

to change the volume in smaller increments. The increment sizes vary based

on the pipetting head, as shown under “7.4

page 54.

www.integra-biosciences.com 25

Pipetting specifications” on

Page 26

VIAFLO 96/384 – Operating instructions V11 Operation

Define and select favorite volumes

You can define, save, and select up to ten favorite volumes for quick access. These

volumes can only be within the pipetting head volume range.

There are two ways to access and customize the list of favorite volumes:

• When in Pipet mode, use the Touch wheel to highlight Favorites and press OK.

• When in other modes, select the Edit option and press OK. The steps with volumes to

be adjusted are displayed. Use the Touch wheel to highlight the desired volume and

press Favorites to display the list of favorite volumes.

Use the Touch wheel to highlight the desired volume

and press Select. Alternatively, modify a volume

by pressing Edit.

Save your setting .

4.4.3 Speed selection

The speed option controls the speed at which liquid is aspirated, dispensed, or mixed in

each mode. Speed can be set as a value from 1 (slowest) to 10 (fastest).

When in any pipetting mode, use the Touch wheel to

highlight the Speed option and press OK. Select the

speed and press OK to save your setting.

Speed may be changed in most

Edit menus. Scroll to the Speed and

press OK. Choose the speed,

press OK, and press to save

your selection.

The speeds selected in each mode (i.e., Pipet, Repeat Dispense, etc.) are stored for that

mode only.

Speeds can be set independently for each operation (Aspirate, Dispense, Mix).

OTE

N

Viscous samples should be aspirated and dispensed at the slowest speeds

to ensure accurate pipetting.

To dispense liquids with low viscosity and high vapor pressure, such as

ethanol, use relative fast pipetting speeds and avoid prolonged pauses for

aspiration.

26 INTEGRA Biosciences AG

Page 27

VIAFLO 96/384 – Operating instructions V11 Operation

4.4.4 Custom

You can convert any predefined pipetting mode into a Custom program.

After setting up a pipetting mode with your

parameters, use the Touch wheel to select

Custom.

You are prompted to enter an name. Use the To uch

Wheel to select characters and press OK. Once

finished, press to save the name.

The program is now stored in the Custom program section.

4.4.5 Pace

The Pace option sets the time gap between dispenses in repeat pipetting. Pace is used in

the Repeat Dispense and Variable Dispense modes. While you press and hold the RUN

key, the pipette will dispense multiple programmed volumes with the selected pace.

Release the RUN key to stop the paced dispense. Press the RUN key to continue

dispensing.

Use the Touch wheel to select the desired Pace

option and press OK.

Select the pace, from None, 1 (slowest) to 9 (fastest).

Press OK to save your setting.

4.4.6 Count, Mix Cycle and Rows

The Count, Mix Cycle, and Rows steps are used in various modes, see “5.2

description of pipetting modes” on page 32. Each is accessed with the Edit option. Use

the Touch wheel to highlight the step and press OK.

Count sets the number of dispensing steps. Mix Cycle sets the number of mixes. In serial

dilution mode, Rows sets the number of rows. A row indicator will notify the number of

dilutions performed. Rows (first number) and Mix Cycles (second number) are tracked on

the display. Mix Cycles are shown in red when mixing. A green dot on the row number

indicates the active program step.

Select a desired value. Press OK and then press to save your setting(s).

www.integra-biosciences.com 27

Detailed

Page 28

VIAFLO 96/384 – Operating instructions V11 Operation

384

384

96

4.4.7 Pipetting between 96 and 384 well plates

For fast and simple reformatting between 96 and 384 well microplates and for loading of

12.5 or 125 µl GripTips with a 96-channel pipetting head, some Plate holders feature a

slide function to shift the microplate in Y-direction beneath the pipetting head. Put this

Plate holder, accommodating the 384 well plate, either on Position A or B (8). Move the

Plate slider (9

) to one of the following 3 positions:

The back position of the Plate slider is used to

accommodate the front positions of 384 well plates.

For pipetting the second columns move the pipetting

head one well to the right, or left respectively.

The front position of the Plate slider accommodates the

back positions of 384 well plates.

For pipetting the second columns move the pipetting

head one well to the right, or left respectively.

Set the Plate slider to the middle to pipet 96 well plates.

28 INTEGRA Biosciences AG

Page 29

VIAFLO 96/384 – Operating instructions V11 Operation

a

4.4.8 Pipetting with the three position stage

The three position stage (see “8.1

of three possible positions.

Use the Stage slider (a) to accommodate the positions of 384 or 96 well plates as

described in 4.4.7

.

Accessories” on page 55) supports the pipetting on two

Move the three position stage to

the right to pipette on position A

and AB.

Move the three position stage to

the left to pipette on position AB

and B.

www.integra-biosciences.com 29

Page 30

VIAFLO 96/384 – Operating instructions V11 Operation

4.5 Troubleshooting/FAQ

Problem Probable cause Remedy

Base unit is drifting

sidewards.

Touch wheel does

not work properly.

Menu options not

selectable (grayed

out).

Pipetting not possible.

Tips cannot be

loaded.

Tips are not centered in the wells,

although tip alignment is activated.

Droplets on the tips. Temperature of liquid differs

Obstruction error. Base unit moved in X direc-

Control unit was touched at

switch on.

Control unit was touched

during homing.

No pipetting head installed. Install a pipetting head.

Side cover missing or pipetting head not correctly

installed.

Z height defined too high

above the top of the box.

Head alignment was not performed yet.

from that of air inside the tips.

Liquid of low viscosity and

high vapor pressure.

Touch-off was not performed. Perform a touch-off (mandatory in

tion by hand.

Tips hit an obstacle during

X movement, e.g. box, container.

Guide rail soiled. Clean the guide rail for base unit.

Other causes. Switch the device off and on.

Do not touch the control unit when

switching on the VIAFLO 96/384.

Restart VIAFLO 96/384 to initiate

new homing routine.

Do not touch the control unit

during homing.

Restart VIAFLO 96/384 to initiate

new homing routine.

Ensure pipetting head is installed

correctly. Mount the side cover

and screw the knob tightly.

Exit the pipetting mode. Alternatively clear Z height setting on

position where tips are loaded.

Perform head alignment for every

pipetting head.

Pre-wet tips up to 3 times.

Pre-wet tips and increase dispensing speed.

Repeat Dispense and Variable

Dispense mode).

Always hold the control unit to

move the base unit sidewards.

Move the tips upwards to a height

that clears the tip rack out.

30 INTEGRA Biosciences AG

Page 31

VIAFLO 96/384 – Operating instructions V11 Pipetting modes

5 Pipetting modes

This chapter describes how to program the VIAFLO 96/384 in two ways:

• Function-based pipetting modes: You can select from ten predefined pipetting modes

that you can quickly and easily edit and execute. They are described in the

following sections.

• Custom step-based programming mode: You can create and store up to forty multistepped pipetting protocols on the pipette using the basic functions of

“Aspirate, Dispense, Mix, Purge, Prompt, Set Z Height, Tip Align and Loop” presented

in “5.2

Detailed description of pipetting modes” on page 32. The custom programming

mode is described in “5.3

5.1 Overview pipetting modes

The table below provides an overview of the selectable pipetting modes. All modes are

accessed from the Main Menu. Use the Touch wheel to scroll to your desired pipetting

mode.

Pipetting mode Description

Pipet Allows liquid transfers when aspirate and dispense volumes are

Repeat Dispense Allows dispensing multiple aliquots of the same volume without

Sample Dilute Allows aspirating of sample and diluent divided by a defined air

Pipet/Mix Transfers a defined volume and follows with a defined number of

Manual Pipet Allows the operator to manually control the aspiration and

Reverse Pipet Allows liquid transfers of viscous or high vapor pressure liquids

Variable Dispense Allows dispensing multiple aliquots of different volumes.

Variable Aspirate Allows aspirating multiple aliquots of different volumes.

Sample Dilute/Mix Allows aspirating two liquids separated by an air gap followed by

Serial Dilution Allows aspirating a transfer volume followed by a mix. Rows and

Custom Allows to create and store of up to 40 multi-stepped pipetting

Press the OK to access the pipetting mode and to start defining parameters. Press to

select the Help option.

Custom step-based programming mode” on page 41

equal.

refilling the tips after each dispense for fast microplate filling and

processing.

gap into one tip, followed by a complete dispense.

automatic mixing cycles.

dispensing up to the set volume.

by preventing introduction of any air into the sample. The

aspiration volume is higher than the volume to be dispensed.

a complete dispense and Mix step.

Mix Cycles are tracked on the display.

protocols.

www.integra-biosciences.com 31

Page 32

VIAFLO 96/384 – Operating instructions V11 Pipetting modes

5.2 Detailed description of pipetting modes

VIAFLO 96/384 offers ten predefined pipetting modes. Most liquid handling protocols can

be easily accommodated using one or more of these modes. The options and steps of the

different pipetting modes are described in the following subsections.

5.2.1 Pipet mode

Application: Use this mode for quick transfer of liquid to or from microplates.

Options Steps Description

Edit Aspirate Sets the aspiration volume that is equal to the dispense

volume.

Speed Sets speed for the current pipetting step (1 = low, 10 = fast).

Favorites Defines up to 10 favorite volumes

Custom Converts the predefined program into a custom program.

Operation:

• With the tip(s) in liquid, press and release the RUN key to aspirate.

• With the tip(s) in the destination plate, press and hold the RUN key to execute the

dispense and perform a two-step blowout, see “4.3.3

• When the tips are removed from the target plate, release the RUN key.

Blowout modes” on page 23.

32 INTEGRA Biosciences AG

Page 33

VIAFLO 96/384 – Operating instructions V11 Pipetting modes

5.2.2 Repeat dispense mode

Application: This mode can be used for fast reagent addition to microplates from one

source container. You can dispense a large aspirated volume of liquid in multiple aliquots

to multiple targets.

Options Steps Description

Edit Dispense Sets the volume for repetitive dispensing. The aspirated

volume is calculated automatically.

First

Dispense

Last Dispense A last-dispense volume can be selected independently to

Reuse Last

Disp.

Count The maximum number of dispenses possible (count) is

Asp. Speed Sets speed uniquely for aspirating (1 = slow, 10 = fast).

Disp. Speed Sets speed uniquely for dispensing (1 = slow, 10 = fast).

Speed Sets speed of the current pipetting step.

Pace Sets the time duration between dispenses in repeat pipetting,

Custom Converts the predefined program into a custom program.

Operation:

• With the tip(s) in liquid, press and release the RUN key to initiate the aspirate step.

• Press and release the RUN key for every dispense. Alternatively, press and hold Run

to execute paced dispenses. The dispense number is shown on the display.

• The pipette will stop paced dispenses when it reaches the Last Dispense. You can

choose to use this Last Dispense or discard it.

- If reuse of last dispense is not activated, press and hold the RUN key to purge the

Last Dispense volume with a two-step blowout.

- If reuse of last dispense is active, you can start the next repeat dispense cycle with

aspirating liquid to the last dispense in the tip. To finish the repeat dispense cycle,

press PURGE.

A pre-dispense volume can be selected independently to

improve accuracy and precision. The dispense is discarded.

improve accuracy and precision. The dispense is discarded.

By default (red ), the mode ends with dispensing of the last

dispense. This aliquot contains the accumulated error from all

prior dispenses.

If you want to reuse the last dispense, press OK (green ).

At the end of the program the last dispense remains in the tip,

while the pipette is ready to aspirate a new volume to start the

next repeat dispense run.

calculated automatically. This count may be reduced to the

desired number.

if keeping RUN key pressed (1 = long, 9 = short).

www.integra-biosciences.com 33

Page 34

VIAFLO 96/384 – Operating instructions V11 Pipetting modes

5.2.3 Sample dilute mode

Application: Accomplish accurate sample dilutions by using diluent to “chase” small

sample volumes from the pipet tips. An air gap keeps liquid separated in the tips and helps

to minimize carryover of diluent when aspirating the sample.

Options Steps Description

Edit Aspirate 1 Sets the volume of the diluent aspirated first in the tip.

Air Gap Sets the volume of the air gap to keep both liquids separated.

Aspirate 2 Sets the volume of the sample in the tip.

Asp. Speed Sets speed uniquely for aspirating (1 = slow, 10 = fast).

Disp. Speed Sets speed uniquely for dispensing (1 = slow, 10 = fast).

Speed Sets speed of the current pipetting step.

Custom Converts the predefined program into a custom program.

Operation:

• Press and release the RUN key to initiate each aspiration (remove tips from liquid for

air-gap aspiration).

• Press and hold the RUN key to perform a two-step blowout. The entire tip contents will

be dispensed together.

5.2.4 Pipet/mix mode

Application: Use this mode when mixing is required immediately after transfer of liquid.

This mode saves a programming step by incorporating the mix option after dispensing.

Options Steps Description

Edit Aspirate Sets the aspiration volume that is equal to the dispense

volume.

Mix Sets the mixing volume after dispensing.

Mix Cycles Sets the number of mix cycles.

Asp. Speed Sets speed uniquely for aspirating (1 = slow, 10 = fast).

Mix Speed Sets speed uniquely for mixing (1 = slow, 10 = fast).

Speed Sets speed of the current pipetting step.

Custom Converts the predefined program into a custom program.

Operation:

• Press and release the RUN key to initiate the aspiration.

• Press and release the RUN key to dispense. Mixing occurs automatically after the

dispense step.

• Upon completing the desired number of mixes, a blowout is initiated automatically

prompting you to remove the tip(s) from the liquid and press the RUN key to complete

the blowout.

34 INTEGRA Biosciences AG

Page 35

VIAFLO 96/384 – Operating instructions V11 Pipetting modes

5.2.5 Manual pipet mode

Application: This mode can be used when the aspiration volume is not defined or

unknown. You have control over the aspiration and dispense steps and can view the

display to confirm how much liquid has been aspirated or dispensed. Manual control over

the dispense steps is perfect for performing titrations or for controlling the loading of

samples in gel lanes.

Options Steps Description

Edit Aspirate Sets the aspiration or dispensing volume. Toggle between

Aspirate and Dispense using the Direction menu option.

Speed Sets speed of the current pipetting step (1 = slow, 10 = fast).

Direction Changes the direction of pipetting between aspiration ()

Favorites Defines up to 10 favorite volumes

Operation:

• When aspirating, the motor will stop when you release the RUN key or when the

programmed aspirate volume is reached.

• You can change pipetting direction at any time even if aspiration volume is not reached.

Change the direction of pipetting by pressing OK on the Direction option. The notation

on the display changes between (Aspirate) and (Dispense).

• The volume remaining in the tip(s) is displayed.

N

OTE

Use slower pipetting speeds (1-5) for better control and resolution.

and dispensing ().

www.integra-biosciences.com 35

Page 36

VIAFLO 96/384 – Operating instructions V11 Pipetting modes

5.2.6 Reverse pipet mode

Application: With this mode the aspiration volume is higher than the volume dispensed.

It is recommended for liquid transfers of viscous and high vapor pressure liquids. The

dispense method prevents introduction of air into the sample because no blowout is made.

Options Steps Description

Edit Dispense Sets the dispense volume.

Last Dispense Sets the volume to leave in the tip until final blowout.

Reuse Last

Disp.

Asp. Speed Sets speed uniquely for aspirating (1 = slow, 10 = fast).

Disp. Speed Sets speed uniquely for dispensing (1 = slow, 10 = fast).

Speed Sets speed of the current pipetting step.

Custom Converts the predefined program into a custom program.

Operation:

• Press and release the RUN key to initiate the aspiration. The total volume aspirated is

the sum of desired dispense volume and last dispense volume.

• Press and release the RUN key to dispense the programmed volume.

• If reuse of last dispense is not activated, press and hold the RUN key to purge the Last

Dispense volume with a two-step blowout.

• If reuse of last dispense is active, you can start the next reverse pipet cycle with

aspirating liquid to the last dispense in the tip. To finish the reverse pipet cycle, press

PURGE.

By (red ) default, the mode ends with dispensing of the last

dispense.

If you want to reuse the last dispense, press OK (green ).

At the end of the program the last dispense remains in the tip,

while the pipette is ready to aspirate a new volume to start the

next reverse pipet run.

36 INTEGRA Biosciences AG

Page 37

VIAFLO 96/384 – Operating instructions V11 Pipetting modes

5.2.7 Variable dispense mode

Application: Use this mode when differing dispense volumes are required. This mode

could be used to quickly set up a dilution series in plates or for feeding similar samples to

different assay plates where different sample volumes are needed.

Options Steps Description

Edit Count Sets the total number of dispensing steps.

Asp. Speed Sets speed uniquely for aspirating (1 = slow, 10 = fast).

Disp. Speed Sets speed uniquely for dispensing (1 = slow, 10 = fast).

Dispense

1...Count

Speed Sets speed of the current pipetting step.

Pace Sets the time interval between dispenses, if keeping RUN

Custom Converts the predefined program into a custom program.

Operation:

• Press and release the RUN key to initiate the aspiration of total volume.

• Press and release the RUN key to initiate each subsequent dispense. The pipette stops

and beeps when ready for the Last Dispense step, i.e. to purge the calculated waste

volume amount.

• Alternatively, press and hold the RUN key to execute paced dispenses. The pipette

stops paced dispensing when it reaches the Last Dispense. This aliquot contains the

accumulated error from all prior dispenses. You can choose to use this Last Dispense

or discard it.

• During the Last dispense, press and hold the RUN key to perform a two-step blowout.

Sets different volumes for repeated dispensing. Number of

dispenses and dispense volume cannot exceed nominal

volume of the pipetting head. The total volume is

automatically calculated.

key pressed (1 = long, 9 = short).

www.integra-biosciences.com 37

Page 38

VIAFLO 96/384 – Operating instructions V11 Pipetting modes

5.2.8 Variable aspirate mode

Application: This mode can be used for a variety of collection applications where the

aspiration volume is well known. This mode is also suited for supernatant collection in

microplates.

Options Steps Description

Edit Count Sets the total number of aspirating steps.

Asp. Speed Sets speed uniquely for aspirating (1 = slow, 10 = fast).

Disp. Speed Sets speed uniquely for dispensing (1 = slow, 10 = fast).

Aspirate

1...Count

Speed Sets speed of the current pipetting step.

Custom Converts the predefined program into a custom program.

Operation:

• With the tip(s) in liquid, press and release the RUN key to initiate the first aspiration

volume. Again in liquid, press and release the RUN key to initiate the second aspiration

volume, etc.

• Press and hold the RUN key to start Dispense and perform a two-step blowout.

Sets different volumes used for sequentially aspirating (in the

same tip) followed by a single dispense. Number of aspirates

and aspirate volume cannot exceed nominal volume of the

pipetting head.

38 INTEGRA Biosciences AG

Page 39

VIAFLO 96/384 – Operating instructions V11 Pipetting modes

5.2.9 Sample dilute/mix mode

Application: Use this mode to perform sample dilutions where mixing of sample and

diluent is required. This mode could also be used to introduce and mix diluent and sample

to the first column of a serial dilution plate.

Options Steps Description

Edit Aspirate 1 Sets the volume of the sample aspirated first in the tip.

Air Gap Sets the volume of the air gap to keep both liquids separated.

Aspirate 2 Sets the volume of the diluent in the tip.

Mix Sets the mixing volume after dispensing.

Mix Cycles Sets the number of mix cycles.

Asp. Speed Sets speed uniquely for aspirating (1 = slow, 10 = fast).

Mix Speed Sets speed uniquely for mixing (1 = slow, 10 = fast).

Speed Sets speed of the current pipetting step.

Custom Converts the predefined program into a custom program.

Operation:

• With the tip(s) in liquid, press and release the RUN key to initiate aspiration 1. With the

tip(s) out of the liquid, press and release the RUN key for the Air Gap. Again in liquid,

press and release the RUN key to initiate aspiration 2.

• Press and release the RUN key to dispense the entire tip contents and begin the mixing

routine. Upon completing the desired number of mixes, a blowout occurs automatically.

Remove tips from liquid and press and release the RUN key to complete the blowout.

www.integra-biosciences.com 39

Page 40

VIAFLO 96/384 – Operating instructions V11 Pipetting modes

5.2.10 Serial dilution mode

Application: Use this mode to perform serial dilutions. The Serial Dilution mode enables

aspiration of a specific volume followed by a mix sequence and ending with the original

aspiration volume in the tips.

Options Steps Description

Edit Aspirate Sets the aspiration volume that is identical to the dispense

volume.

Mix Sets the mixing volume after dispensing.

Mix Cycles Sets the number of mix cycles.

Rows Sets the number of rows. A row indicator will notify the

number of dilutions performed.

Asp. Speed Sets speed uniquely for aspirating (1 = slow, 10 = fast).

Mix Speed Sets speed uniquely for mixing (1 = slow, 10 = fast).

Disp. Speed Sets speed uniquely for dispensing (1 = slow, 10 = fast).

Speed Sets speed of the current pipetting step.

Custom Converts the predefined program into a custom program.

OTE

N

For serial dilutions it is helpful to switch Column Detent on, see “Tip Align”

under "

Position Settings" on page 16.

Operation:

• Attach 8/16 GripTips on the leftmost row by lowering the Pipetting unit onto the tips.

CAUTION

When prompted to push the Tip load button, first press OK (14) to switch to

“low power” loading mode. Then press the Tip load button and at the same

time push down the Control unit to load the tips with reduced forces.

• Replace the tip box with the microplate and put the reagent container on the other

position, e. g. position A. Press and release the RUN key to initiate the aspiration of the

reagent.

• Press and release the RUN key to start the dispense and mix sequence. Proceed with

the next rows.

• Rows (first number) and Mix Cycles (second number) are tracked on the display. Mix

Cycles are shown in red when mixing. A green dot on the column number indicates the

active program step.

40 INTEGRA Biosciences AG

Page 41

VIAFLO 96/384 – Operating instructions V11 Pipetting modes

5.3 Custom step-based programming mode

Application: Use the Custom program mode to create personalized pipetting protocols.

Up to forty programs can be stored.

Select “Custom” to create a personalized protocol. Programs can contain up to 98

individual steps based upon the following basic operations: Aspirate, Dispense, Mix,

Purge, Prompt, Set Z Height, Tip Align and Loop.

Press to create a new program. Select the

pipetting head and the type of the new custom

program, i. e. Manual or Automatic.

OTE

N

The program type can only be selected if “Automatic” is activated under

Toolbox - Preferences - Main Menu, see “3.4.4

We recommend creating automatic custom programs on a PC with the

VIALINK software, see also “5.4 VIALINK” on page 46.

Next, your are prompted to enter a name.

Use the Touch Wheel to select characters and press

OK. Once finished, press to save the name.

Preferences” on page 16.

The first step is highlighted, press OK.

Use the Touch Wheel to select the first step from the

menu, e. g. Aspirate. Press OK. Define the required

parameters and press OK to add the step.

After adding the first step, the selection should now be on the second line. Press OK again

to define the second step. Continue adding steps until your entire pipetting protocol is

defined.

www.integra-biosciences.com 41

Page 42

VIAFLO 96/384 – Operating instructions V11 Pipetting modes

5.3.1 Manual custom program

Manual custom programs can consist of the following steps:

Step Description

Aspirate Sets an aspiration volume and speed.

Dispense Sets a dispense volume and speed.

Mix Sets the mixing volume after dispensing.

Purge Purges all remaining liquid currently in the GripTips with the selected

Prompt A prompt is any message that is displayed during the program. Three

Z Height Sets the Z height on Position A or B.

Tip Align Within a custom program, you can switch the tip alignment on or off,

Loop A loop repeats the steps between the selected step and the loop

purge speed. A “Purge” step is automatically integrated at the end of

a program if the last programming step leaves liquid in the tips.

lines with a total of 30 characters are available. To continue the

program, press the RUN key.

if required.

Use the Touch wheel to select Tip Align and press OK.

„“ (

Select Position A or B and pr ess OK to toggle between

„“

(Off), see also “3.4.4 Preferences” on page 16.

The tip align setting applies to the subsequent steps of the custom

program.

command.

Chose to which step the loop directs and how many times the loop

should be performed.

The number of steps can often be shortened by adding a loop.

Note: Nested loops (loops inside loops) are not allowed.

On) and

When starting with an “Aspirate” step followed by a “Mix” step, the tips contain the aspirate

volume after completing the last mix cycle. When starting with a “Mix” step, the tips are

emptied upon completion of the last mixing cycle.

To save and store a Custom program, press Save.

42 INTEGRA Biosciences AG

Page 43

VIAFLO 96/384 – Operating instructions V11 Pipetting modes

Example of manual custom program

The task is to combine 2 different liquids in a 96 well plate for a kinetic assay and then

mixing it to achieve a homogeneous solution. The microplate should then be incubated for

5 minutes and the content is then distributed to a 384 well plate. The custom program

would be set up as followed:

Program step Action

1) Aspirate liquid 1: 160 µl (e.g. diluent) With tips in liquid 1 press RUN key.

2) Aspirate air: 20 µl Move tips out of liquid and press RUN key.

3) Aspirate liquid 2: 50 µl (e.g. reagent) With the tips in liquid 2 press RUN key.

4) Dispense: 230 µl Press and hold RUN key until liquid is

dispensed and tips are removed from the

liquid (two-step blowout).

5) Mix 3x: 200 µl Press RUN key.

6) Prompt: Incubate 5 min No action.

7) Aspirate: 210 µl With tips in the 96 well plate, press RUN key.

8) Dispense: 50 µl Move the Plate slider to the front and press

9) Dispense: 50 µl Move the pipetting head one well to the right

10) Dispense: 50 µl Move the Plate slider to the back and press

11) Dispense: 50 µl Move the pipetting head to the left and press

12) Purge Purge (does not need to be programmed).

RUN key to dispense the back positions of

the 384 well plate.

and press RUN key to dispense the second

columns.

RUN key to dispense the front positions of

the 384 well plate.

RUN key to dispense the first columns.

The residual liquid is dispensed into the

waste container. Press and hold RUN key

until liquid is purged and tips are removed

from the liquid (two-step blowout), see “4.3.3

Blowout modes” on page 23.

N

OTE

The program steps 8-11 can be shortened with the Loop step:

9) Loop to step 8, 4 times

10) Purge

www.integra-biosciences.com 43

Page 44

VIAFLO 96/384 – Operating instructions V11 Pipetting modes

5.3.2 Modify existing programs

At the Custom program display, use the Touch wheel to highlight an

existing program. Press Options, use the Touch wheel to select an

option (View/Edit, Delete, Copy, Rename) to modify the program and

press OK

OK

Press Back to return to the list of Custom programs. To run the program, press

5.3.3 Automatic custom program

The Automatic Mode performs automatically a defined series of liquid handling

operations. This mode is by default inactive and has to be manually enabled, see “3.4.4

Preferences” on page 16.

An automatic Program always starts with a Move X,Z step to define the starting position.

Step Description

Move X,Z Teach the unit by moving the pipetting unit to the desired position.

Current Setting is the position to be used by the program, X and Z

indicates the momentary position. Move the pipetting head to the

desired position and press Set to adapt the Current Setting to the

momentary position.

Move Z Move the pipetting head to the desired position and press OK to

adapt the Current Setting to the Actual Position.

The pipetting unit moves to the defined absolute Z height.

Move X This command travels the set distance in X-direction relative to the

actual position. Setting a negative value (mm) moves the unit to the

left, setting a positive value (mm) moves the unit to the right.

Use the Touch wheel to enter the desired value and press OK.

.

AUTION

C

Always ensure that the pipetting head is at a clear height for a movement to

the side.

44 INTEGRA Biosciences AG

Page 45

VIAFLO 96/384 – Operating instructions V11 Pipetting modes

Step Description

Blowout / Blowin In automatic mode, the blowout and blowin need to be programmed

after the last dispense.