Page 1

Rp

DO

=Falleylab.

Service

CUSA

Manual

EXcel""-8

System

Page 2

Preface

This

manual

medical

procedure

CUSA

Equipment

CUSA

professionals

to

EXcel

covered

EXcel™

handpieces.

The

CUSA

EXcel

{part 1 of

2)

schematics.

and

the

equipment

trained

be

performed.

ultrasonic

in

this

ultrasonic

"System

and a Schematics

surgical

manual

surgical

Service

it

describes

in

the

particular

It

is

intended

aspirator

aspirator

Manual

Supplement

are

for

technique

as

a

guide

only.

with

consists

(part 2 of

23

2),

use

only

for

servicing

kHz

and

of

two

which

by

qualified

and

surgical

36

kHz

parts—the

contains

the

text

the

Vatleytab

Effective

Trademark

CUSA

CEM™,

Ajax“

Comet“

Torgue

Manufactured

Part

Date

Number

October

945

2004

acknowledgements

EXcei™,

and

is a registered

TISSUE

Force

FX™

trademark

is a registered

Seal“

is a

registered

by

103

105

Select™,

are

trademarks

of

trademark

trademark

MacroTip™,

the

Colgate-Palmolive

of

Procter & Gamble.

MicroTip™,

of

Valleylab.

of

Organic

PrecisionTip™,

Company.

Products

Co.

Valleylab

a

division

Boulder,

©

2004

not

of

Colorado

Valleylab

be

reproduced

Tyco

Healthcare

80301-3299

All

rights

in

any

form

Group

LP

USA

reserved.

without

Contents

the

written

of

this

publication

permission

may

of

Valleylab.

Tyco

Healthcare

Gosport,

PO13

1-303-530-2300

C

€

Patent

Information

UK

OAS,

Made

Ltd.

UK

in

USA

Printed

in

USA

ii

0086

One

or

patents

4734964

4988334

5484398

more

cover

of

the

the

following

CUSA

4768496

5015227

5847046

EXcel

U.S.

patents and

corresponding

system:

4827911

5190517

6214817 6256859

4921476

5421829 5466020

CUSA

EXcel-8

4931047

6499858

System

foreign

Service

Manual

Page 3

About

The

aspirator.

handpieces,

-

Organization

We

and

for

specifications,

check

A

and

This

service

It

*

Descriptions

operation

*

Step-by-step

calibrate,

©

Step-by-step

e

Parts

lists,

have

organized

its

functions.

unpacking

out,

schematics

schematics.

Manual

manual

presents

and

accessories:

of

instructions

and

troubleshoot

instructions

board

After

the

system,

and

theory

maintain,

supplement

describes

the

the

system,

layouts,

this

troubleshoot,

CUSA

on

on

and

guide

safety

then

of

operation.

includes

the

and

CUSA

EXcel

as a system

its

functions,

how

to

the

system

how

to

schematics.

to

introduce

the

system,

describes

replace

printed

EXcel

ultrasonic

specifications,

unpack,

replace

its

The

install,

specific

the

safety

the

components,

next

sections

parts,

and

circuit

surgical

that

includes a console,

and

theory

maintain,

components

issues,

guide

calibrate

board

the

gives

instructions

technical

tell

you

the

(PCB)

layouts

of

system,

how

to

system.

CUSA

EXcel-8

System

Service

Manual

iii

Page 4

rr

m

D

important

Indicates

maintenance

an

operating

suggestion.

tip

or

Conventions

indicates a potentially

death

or

serious

indicates a hazardous

moderate

Notice

Indicates a hazard

A

Used

injury.

injury.

in

this

hazardous

situation

which

may

Guide

situation

which,

result

in

which,

if

not

avoided,

product

if

not

may

damage.

avoided,

result

could

in

minor

result

or

in

iv

CUSA

EXcel-8

System

Service

Manual

Page 5

Table

of

Contents

Preface

List

of

List

of

Section

Safety

Warnings,

ii

About

This

Manual

Organization

Conventions

Figures

Tables

Information

General

Introduction

Unpacking

Console

Technical Specifications

Checkout

Maintaining

Troubleshooting

Replacement

Calibration

Repair

Used

xiii

xvi

1.

Service

Cautions,

1-2

and

Components

Procedures

the

Procedures

Policy

iii

iii

in

this

Guide

Personnel

1-1

and

Notices

1-2

Installing

CUSA

1-5

1-5

the

1-2

1-3

EXcel

1-4

Safety

1-1

CUSA

1-2

System

1-4

iv

EXcel

1-3

System

1-2

Section

For

Overview

Fragmentation

Irrigation

Aspiration

Handpieces

Wide

Section

The

Unpacking

Preparing

2.

Introduction

Your

Information

2-2

Tip

Motion

Cooling

Variety

Responsibility

Tools

Unpacking Procedure

Replacing

2-2

2-3

(Suction)

2-5

of

Tips

3.

Unpacking

the

CUSA

You

Will

the

CUSA

the

2-1

2-2

2-2

2-4

2-5

of

the

Manufacturer

EXcel

Need

EXcel

Power

Connector

and

Installing

System

3-2

3-2

Console

for

3-2

Use

3-9

3-1

the

3-8

CUSA

EXcel

System

CUSA

EXcel-8

System

Service

Manual

Page 6

K

Replacing

Replacing a Control

installing

Section

For

Your

Console

LV,

Control

Arm

Housing

Console

Shelf

Casters

Control

Alerts

Lap

Displays

Status

Setpoint

Fuses

the

4.

Console

Information

Overview

Pole

Panel

and

Arm

for

Body

for

Suction

Panel

4-5

Mode,

Indicators

Adjustment

(lf

Necessary)

Panel

Reference

Components

4-1

and

Structural

4-3

4-3

Housing

Irrigation

4-3

4-4

Prime,

4-5

Pump

4-3

Canister

Test,

4-7

Buttons

Overlay

Card

Features

4-3

Head

and

Status

3-10

(Optional)

Set

and

4-3

Buttons

4-7

3-15

4-2

Suction

3-11

Pinch

4-5

Valve

4-3

Console

Console

Body

Handpiece

Suction

System

Irrigation

Contamination

Retaining

Body

Control

Rotation

Housing

LV.

Pole

1.V.

Pole

Arm

Arm

Cooling

Console

Body

Speaker

Volume

Footswitch

AC

Main

Fuses

Footswitch

Front

Connector

Pinch

Power

Pump

Bail for

Side

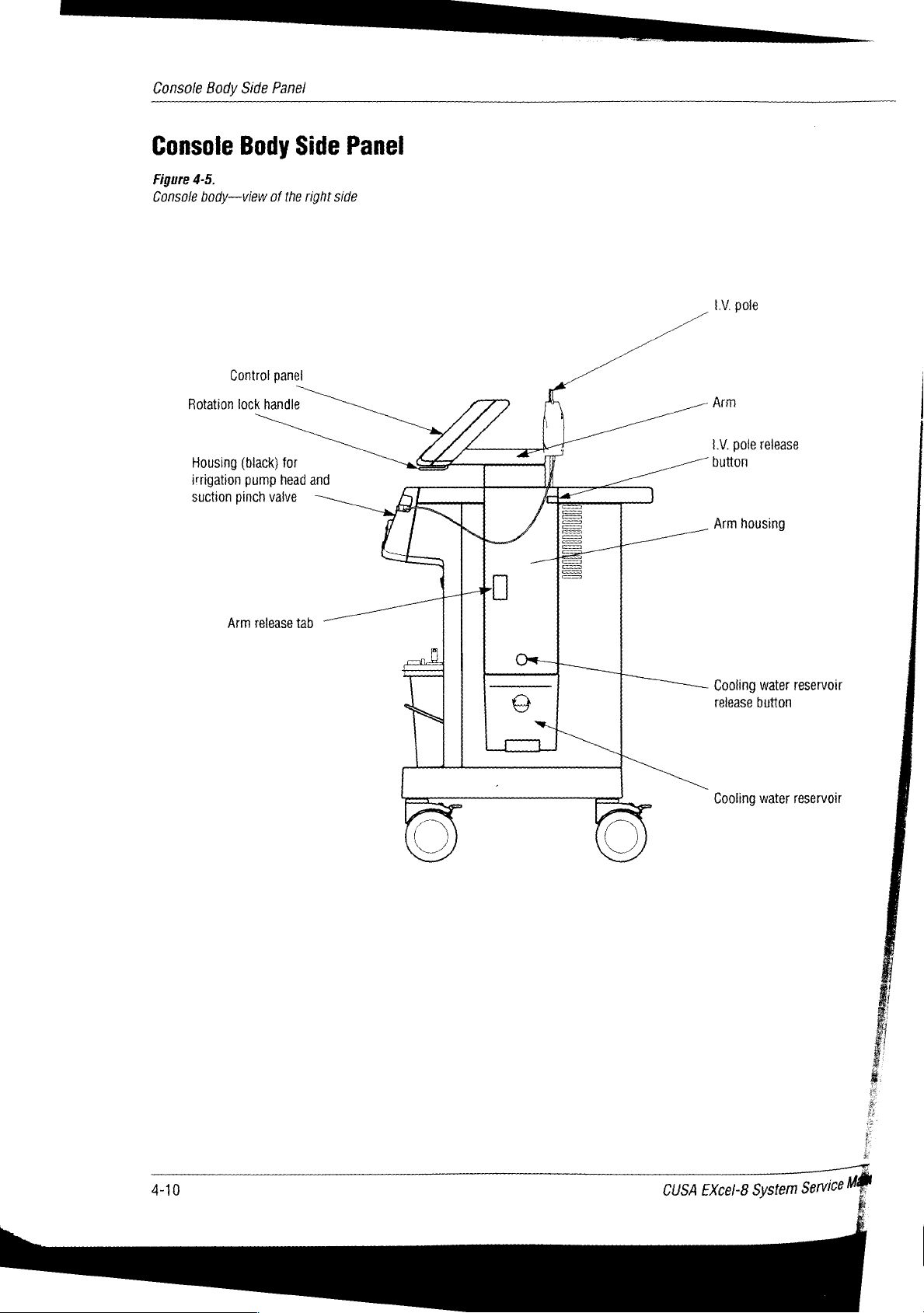

Panel

Lock

for

Release

and

Arm

Release

Water

Rear

Control

Connector

Switch

4-13

Panel

Receptacle

Valve

Switch

Head

Guard

Panel

4-9

Suction

4-11

Handle

Irrigation

4-11

Housing

Tab

4-13

Pump

Button

4-11

Reservoir

Panel

4-13

Receptacle

4-13

4-13

4-8

4-9

4-9

4-9

Canister

4-10

4-11

Head

4-11

4-11

4-11

4-12

4-8

and

4-13

4-9

Suction

Pinch

Valve = 4-11

vi

CUSA

EXcel-8

System

Service

Manual

Page 7

AC

PowerCord

Equipotential

Label

Cord

Storage

4-15

Wraps

Compartment

4-15

Grounding

4-15

Lug

4-15

4-15

Symbols

Other

Section

Console

Console

Electrical

on

the

Features

Filling

the

Cooling

Raising/Lowering

Rotating

Adjusting

Adjusting

CUSA

Footswitch

Ultrasonic

Fluidic

Input

Power

Low

Duty

the

the

the

5.

Technical

Dimensions

EXcel

Subsystems

System

Requirements

Power

Cords

Frequency

Cycle

Control

Panel

4-18

Water

the

Control

Tone

Volume

I.V.

Pole

Console

5-2

5-2

5-3

Source

5-3

Leakage

5-4

4-16

Reservoir

Arm

Panel

4-18

4-19

4-19

4-20

Specifications

5-2

5-2

5-2

5-3

5-3

5-4

4-18

CUSA

EXcel-8

System

Service

Manual

Environment

Standards

Handpieces

Tip

and

Class | Equipment

Type

BF

Applied

IPX - 8

(IEC

Electromagnetic

System

Pinch

Fuse

Footswitch

Voluntary

Statutory

EMC

Nominal

Dimensions

Specifications

Power

Point

Replacement

Compatibility

5-4

IEC

Classifications

(IEC

Part

Equipment

529,

UL

2601)

Interference

Off / Standby

in

the

Suction

Symbols

Standards

and

Regulatory

5-12

Frequencies

5-12

5-12

5-5

601-1)

(IEC

Footswitch

5-6

5-6

Pinch

Valve

5-6

5-6

5-7

Requirements

5-7

5-12

5-5

601-1)

5-5

5-5

5-6

5-7

vil

Page 8

K

23

36

kHz

kHz

5-13

5-14

Section

How

How

Section

For

Display

Machine

6.

Principles

the

Handpiece

Electromechanical

Fragmentation

Cooling

the

TISSUE

Inherent

increasing

TISSUE

Benefits

A

Common

Your

Board

General Description

Fundamentals

Detailed

Introduction

Irrigation

Suction

Cooling

Suction

Amplitude

Valve

Power

Valtage

interface

6-3

Tissue

Tissue

Select

of

TISSUE

Misunderstanding

7.

Circuit

Information

Circuit

Control

Pump

Pump

Pump

Valve

Control

Controls.

Control

Regulators

Connectors

Works

Operation

6-3

Select

Feature

Selectivity

Selectivity

Reduces

Select

Theory

741

7-2

of

Operation

Description

Board

7-4

7-4

7-5

7-6

7-6

7-7

Input

and

of

Operation

6-2

Works

Reserve

6-8

7-2

7-4

7-6

Output

7-8

7-8

6-2

6-5

6-5

Power

of

the

72

7-3

Signals

5-4

tothe

Tip

Amplitude

7-7

6-6

Setting

6-9

viii

Ultrasonics

Ultrasonics

Board-Ultrasonic

Fundamentals

The

Main

Bandpass

AGC/Error

Phase

Compensator

Driver

Stage

Feedback

Bias

Circuitry

Frequency

Board-Other

of

Operation

Frequency

Filter

(BPF)

Amplifier

7-11

Signal

7-12

Selection

Generator

Loop

7-9

Circuit

7-11

7-12

Circuitry

Circuits

7-8

7-9

7-19

7-13

7-12

7-8

CUSA

EXcel-8

System

Service

Manual

Page 9

:

Audible

Valve

Power

Dual

Section

Inspections

Footswitch

Power

Power

Handpiece

Section

For

Your

Recommended

Clean

Clean

Maintain

Clean

Lubricate

Replace

Recalibrate

Alert

Drivers

and

24 V Power

8.

Cord

On

Verification

Test

9.

Information

the

CUSA

the

Sterilizer

the

Handpiece

the

the

and

Operation

7-13

Other

Signal

Connections

Supply

Checkout

8-1

(Optional)

Maintaining

Maintenance

EXcel

Handpiece

the

Handpiece

the

Board

Procedures

8-1

8-2

8-2

9-1

Console

Case

Handpiece

Handpiece

9-3

9-3

Connector

8-2

the

Schedule

9-4

Connector

Indicator

7-13

CUSA

9-3

O-Rings

O-Rings

9-5

7-13

7-13

EXcel

9-2

System

9-5

9-5

Maintain

Store

Section

For

Troubleshooting

User

Engineer

the

Tip

Torquing

Clean

the Tip

Torquing

Check

the

Torque

the

CUSA

EXcel

CUSA

Console

Handpiece

Footswitch

CEM

Nosecone

10.

Troubleshooting

Your

Information

Safety

Troubleshooting

Responding

General

Troubleshooting

Guidelines

Flowcharts

No

Power

Handpiece

to

Troubleshooting

Alarm

on

System

9-7

9-7

9-7

9-7

Alerts

10-15

10-15

10-16

Set

Set

the Tip

and

10-1

10-2

10-2

10-3

10-15

10-17

9-6

9-6

Torquing

Accessories

10-6

Wrench

9-6

9-7

|

CUSA

EXcel-8

System

Service

Manual

*

Page 10

K

-

Footswitch

Cooling

Low

Suction

Low

irrigation

Vibration

Section

For

Console

Dual

Ultrasonics

11.

Your

Information

Cavers

Open

the

Open

the

Open

the

Re-install

Re-install

Re-install

24

Volt

Remove

Install

the

Remove

install

the

Remove

Remove

Install

the

install

the

Alarm

Water

Alarm

10-20

10-22

Alarm

Replacement

11-3

Left

Cover

Right

Cover

Rear

Cover

the

Left

Cover

the

Right

the

Rear

Power

Supply

the

Dual

24

Dual

24

Volt

and

Machine

the

Ultrasonics

Ultrasonics

the

Control

the

Machine

Machine

Control

Panel

10-18

10-19

10-23

11-2

11-4

11-4

11-4

Cover

Cover

Volt

Power

Power

Control

PCB

PCB

Panel

Control

Control

Assembly

Procedures

11-5

11-5

11-5

11-6

Supply

Supply

Printed

Assembly

PCB

11-8

11-11

PCB

Circuit

11-14

11-14

11-6

11-13

11-15

11-6

Boards

11-8

x

Control

Suction

Suction

Head

Remove

Remove

Remove

Remove

install

Install

install

Install

Remove

Install

Remove

Install

Ready

Remove

Components

the

the

the

the

the

Display

the

Control

the

Machine

the

Control

Control

Pump

the

the

Suction

and

the

the

Suction

for

Suction

the

Valve

Control

Machine

Control

Display

Suction

Suction

Suction

Panel

Control

Panel

PCB

PCB

Panel

Control

Panel

11-21

Control

Control

Controller

Pump

Pump — 11-34

Pump

Pump

11-15

Assembly

PCB

Overlay

11-18

11-19

Overlay

PCB o 11-20

Assembly

Valve

Valve

Card

Controller

11-29

11-29

Card

Controller

11-17

11-18

11-18

11-20

11-20

11-21

11-27

Replacement

Card

CUSA

11-36

EXcel-8

System

11-35

Service

Manual

Page 11

Install

the

Suction

Pump

Controller

Card

11-37

Suction

Irrigation

Handpiece

Cooling

Pinch

Remove

Remove

Install

the

Instali

the

Pump

Remove

Remove

Install

the

Remove

Install

the

Replace

Flow

Remove

Install

the

Water

Tools

and

Remove

Install

Tubing

Valve

the

Irrigation

the

Suction

Suction

Irrigation

Head

and

the

Irrigation

the

Irrigation

Irrigation

the

Irrigation

Irrigation

the

Irrigation

Sensor

the

Handpiece

Handpiece

Pump

Tubing

Materials

the

Cooling

and

11-38

Pump

Bezel

Pinch

Valve

Pinch Valve

Pump

Bezel

Gear

Motor

Pump

Bezel

Pump

Head

Pump

Head

Pump

Gear

Pump

Gear

Pump

Bezel

11-46

Flow

Sensor

Flow

Sensor

11-49

11-49

Water

Pump

Re-Assemble

11-38

11-40

11-40

11-41

11-42

Motor

Motor

Head

the

Cooling

11-38

11-41

11-42

11-45

11-45

11-46

11-48

11-49

11-43

Water

Pump

Head

11-50

Cooling

Fuses

Section

For

Tools/Equipment

DC

Suction

Motor

Section

Return

Water

Reservoir

O-Rings

Your

Bias

Set

Procedure

Obtaining a Return

Returning

Returning

Returning

Ordering

on

the

11-52

12.

Calibration

Information

Power

Supply

Pump

for

the

Cooling

Up

123

13.

Repair

Equipment

the

the

Circuit

Replacement

Needed

O-Rings

Cooling

12-3

12-4

12-1

for

12-2

Water

Water

Pump

Policy

for

Service

Authorization

Console

Handpiece

Boards

Parts

11-51

Reservoir

Calibrations

12-3

13-2

Number

13-2

13-9

13-9

13-9

Connectors

12-2

13-2

11-51

i

CUSA

EXcel-8

System

Service

Manual

Valleylab

Service

Centers

13-10

*

Page 12

Section

Ordering

Replacement

Electronic

Appendix

Schematics

14.

Replacement

Parts

Handpiece

Irrigation

Miscellaneous

Power

Suction

Parts

Ultrasonics

A.

Service

Cooling

14-2

14-4

14-4

PCB

Warranty

Supplement.

Parts

14-2

14-3

14-4

Parts

Parts

14-2

14-5

Lists

14-1

Assembly

Drawings

and

Schematics

xii

CUSA

EXcel-8

System

Service

Manue

Page 13

List

of

Figures

Figure

2-1.

Figure

2-2.

Figure

3-1.

Figure

3-2.

Figure

3-3.

Figure

3-4. _ Installing

Figure

3-5.

Figure

4-1.

Figure

4-2.

Figure

4-3.

Figure

4-4.

Figure

4-5.

Figure

4-6.

Figure

4-7.

The

pre-aspiration

The

three

handpieces

Replacing

Disconnecting

Removing

Installing

Console

Control

Control

Console

Console

Console—rear

Console—rear

fuses

control

the

control

the

control

the

reference

structural

panel

features

panel

features

body—front

body—view

view

view

holes

and

in

the

3-10

panel

panel

panel

overlay

cards

features

4-4

(continued)

view

4-8

of

the right

4-12

(continued)

threads

CUSA

EXcel

assembly

overlay

3-14

3-15

4-2

4-6

side

4-14

on

tips

system

cables

3-12

4-10

2-3

2-5

3-11

Figure

Figure

Figure

Figure

6-3.

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

4-8.

6-1.

6-2.

7-1.

9-1.

9-2.

11-1.

11-2.

11-3.

11-4.

11-5.

11-6.

11-7.

11-8.

Control

The

Reserve

Reserve

The

Cleaning

Replacing

Right

The

Cables

The

Plugging

connector

Disconnecting

Removing

11-14

The

panel

symbols

handpiece

display

and

wiring

on

ultrasonics

layers

components

power

vs.

power

vs.

organization

the

handpiece

the

handpiece connector

left

sides

harness

the

ultrasonics

the

adapter

at

J6

control

the

Machine

of

control

TISSUE

amplitude

of

the

on

the

PCB

fan

for

on the

ultrasonics

panel

Control

head

4-16

6-2

Select settings

setting

on

the

control

with a soft

console

dual 24

PCB

assembly

the

components

cloth

o-rings

11-3

volt

assembly

connections

syphon

assembly

PCB

valve

PBC

from

6-7

6-9

panel

9-4

power

11-9

cable

11-11

cables

the

control

11-16

7-3

9-5

supply

11-10

assembly

11-13

11-7

panel

into

the

assembly

|

CUSA

EXcel-8

System

Service

Manual

Figure

Figure

Figure

Figure

11-9.

11-10.

11-11.

11-12.

Disconnecting

Disconnecting

Control

Removing

Removing

PCB

the

the

control

the

11-19

Display

ends

panel

cables

50-pin ribbon

PCB

from

from

the

suction

11-17

cable

the

control

pump

and

removing

head

assembly

chamber

the

Machine

11-23

11-19

xiii

Page 14

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

11-13.

11-14.

11-15.

11-16.

11-17.

11-18.

11-19.

11-20.

11-21.

11-22.

11-23.

11-24.

Removing

Disconnecting

elbow

Disconnecting

control

Pulling

Removing

Removing

Removing

11-27

Removing

Pulling

Disconnecting

controller

Removing

pump

Removing

11-24

valve

the

the

card

and

the

suction

the

the

11-24

strain

the

manifold

the

suction

the

suction

the

suction

split

cables

the

suction

its

wires

the

suction

pump

suction

suction

relief

bushing

bracket

control

hose

tube

bushing

from

11-31

tube

11-33

pump

enclosure

tube

tube

valve

and

and

away

the

and

from

at

the

from

the

away

from

from

from

clamp

clamp

from

the

suction

strain

its

from

the

console

contamination

left

end

of

the

the

manifold

the

console

the

from

the

from

manifold

pump

relief

bushing

bracket

11-25

manifold

suction

the

“T”

fitting

bracket

to

the

suction

from

mount

11-23

guard

90°

suction

bracket

bracket

control

11-30

11-30

pump

the

suction

11-33

11-25

11-26

valve

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

11-25.

11-26.

11-27.

11-28.

11-29.

11-30.

11-31.

11-32.

11-33.

11-34.

11-35.

Attaching

sure

Removing

controller

Removing

Removing

Removing

Removing

Disconnecting

11-43

Replacing

shaft

Replacing

Removing

11-50

O-rings

to

center

11-44

on

the

suction

the

card

the

the

the

the

the

the

the

cooling

pump

the

pump

on

cable

clamps

11-36

irrigation

suction

irrigation

irrigation

the

gear

handpiece

end

pump

pinch

pump

pump

irrigation

motor/pump

flow

bell

and

water

motor

the

bracket

and

screws

bezel

valve

bezel

head

pump

gear

head

sensor

tubing

from

reservoir

to

its

mounting

11-34

from

11-39

11-39

11-41

11-42

motor

coupler

11-47

the

cooling

connectors

the

from

on

the

11-51

suction

water

bracket,

the

pump

control

motor

making

drive

pump

e

tema

rs

card

head

CUSA

EXcel-8

System

Service

Manu

Page 15

Schematics

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

Schematic

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

Supplement

The

console

Console

Console

Console

Subsystems

Arm

and

Interconnect

interconnect

Display

Display

Display

shown)

Display

Display

Display

Display

Machine

Machine

Machine

Machine

Machine

Machine

Machine

Ultrasonics

Ultrasonics

Ultrasonics

shown)

Ultrasonics

Ultrasonics board

Ultrasonics

Ultrasonics

Ultrasonics board

rear

covers

interior, rear

miscellaneous

relating

control

diagram,

diagram,

board

board

board

S-11

board

board

board

board

control

control

control

control

control

control

control

board

board

board

5-25

board

board

board

and

left

side

and

panels

and

left

subsystems

to

suction

panel

assembly

sheet 1 of 2 S-7

sheet 2 of 2 5-0

layout,

sheet 1 of 2 S-9

layout,

sheet 2 of 2 S-10

schematic,

schematic,

schematic,

schematic,

schematic,

board

board

board

board

board

board

board

sheet 2 of 6 (sheet 1 blank,

sheet 3 of 6 S-12

sheet 4 of 6 5-13

sheet 5 of 6 5-14

sheet 6 of 6 5-15

layout,

schematic,

schematic,

schematic,

schematic,

schematic,

schematic,

layout,

sheet 1 of 2 5-23

layout,

sheet 2 of 2 S-24

schematic,

schematic,

schematic,

schematic,

schematic,

schematic,

9-1

$-2

side

S-3

S-4

and

irrigation

S-6

sheet 1 of 1 S-16

sheet 1 0f6

sheet 2 of 6 5-18

sheet 3 of 6 S-19

sheet 4 of 6 5-20

sheet 5 of 6 S-21

sheet 6 of 6 5-22

sheet 2 of 7 (sheet 1 blank,

sheet 3 of 7 9-26

sheet 4 of 7 5-27

sheet 5 of 7 9-58

sheet 6 of 7 S-29

sheet 7 of 7 $-30

5-5

thus

S-17

not

thus

not

GUSA

=

EXcel-8

System

Service

Manual

XV

Page 16

List

of

Tables

Table

3-1.

Table

3-2.

Table

5-1.

Table

5-2.

Table

6-1.

Table

6-2.

Table

7-1.

Table

7-2.

Table

7-3.

Table

7-4.

Table

9-1.

Table

9-2.

Table

11-1.

Table

11-2.

Table

11-3. | Cable

Table

11-4.

Table

11-5.

Table

11-6.

Table

11-7.

Table

11-8.

Table

11-9.

Table

14-1.

Table

14-2.

Table

14-3.

Table

14-4.

Table

14-5.

Table

14-6.

Table

14-7.

Table

14-8.

Table

14-9.

Table

14-10.

Table

14-11.

Table

14-12.

Wire

colors

Fuse

values

Tip

Specifications—23

Tip

Specifications—36

On-off

Fragmentation

Irrigation

Suction

Cooling

Handpiece

Routine

Torque

Cable

Ultrasonics

3-9

3-10

intervals

for

performance

pump

voltage

pump

voltage

pump

voltage

amplitude

maintenance

values

for

connections

PCB

fan

connections

Procedures

Suction

The suction

Suction

Irrigation

Fuse

Handpiece

Irrigation

Miscellaneous

Power

Suction

Printed

Ultrasonics

Ultrasonics

Ultrasonics

Ultrasonics

Ultrasonics

Ultrasonics

to

access

pump

cable

pump

pump

cable

pump

values

11-52

cooling

replacement

replacement

replacement

replacement

circuit

board

board

board

board

board

board

board

control

kHz

5-13

kHz

5-14

TISSUE

the

on

on

controller

replacement

parts

parts—resistors

parts—-diodes

parts 一 FETs

parts—integrated

parts—connectors

Select

vs.

TISSUE

steps

7-4

steps

7-5

steps

7-6

control

tasks

assembly

connections

voltages

9-2

torque

wrench

the

ultrasonics

connectors

the

ultrasonics

control

panel

card

to

cable

connections

card

connections

parts

parts

14-2

parts

14-4

parts

14-4

spares

14-4

14-6

6-6

Select

7-6

9-7

PCB

PCB

components

the

controller

to

11-37

14-2

14-3

14-5

14-5

circuits

14-7

parts—miscellaneous

settings

11-8

11-10

11-12

11-16

card

the

ultrasonics

11-45

14-6

14-8

6-8

11-31

PCB

11-36

xvi

CUSA

EXcel-8

System

Service

Man

Page 17

Service

Personnel

In

this

section:

*

Safety

e

Warnings,

Safety

information

Cautions,

and

Notices,

organized

by

section.

Safety

Warnings,

Information

Cautions,

The

safe

to a large

There

important

with

this

and

Notices

Before

that

you

cautions,

understand,

install,

and

effective

degree

is

no

substitute

that

ultrasonic

servicing

read,

understand,

and

notices

and

test,

adjust,

servicing

on factors solely

for a properly

you

read,

understand,

equipment.

the

CUSA

EXcel

and

supplied

follow

or

repair

the

instructions

the

of

ultrasonic

under

trained

console

follow

with

it.

CUSA

surgical

the

control

and

and

follow

or

handpieces,

the

instructions

It

is

also

for

any

EXcel

system.

equipment

of

the

vigilant

the

procedures

it

and

important

other

equipment

service

service

is

important

the

warnings,

that

you

depends

person.

staff.

It

is

supplied

read,

used

to

CUSA

EXcel-8

System

Service

Manual

Page 18

Warnings,

Cautions,

and

Notices

General

SM

Federal

(USA)

Notice

Operating

to

the

power

Introduction

Read

all

warnings,

CUSA

EXcel

Read

the

CUSA

EXcel

To

avoid

injury

valve.

1

law

restricts

the

console

supply.

outside

cautions,

system

instructions,

before

warnings,

handpieces

to

surgical

Så

this

device

the

notices

servicing

before

personnel,

RR

ai

to

sale

specified

and

instructions

it.

cautions,

servicing

keep

by

voltage

and

notices

them.

fingers

or

on

ranges

away

the

order

may

provided

provided

from

the

of a physician.

cause

damage

with

the

with

the

suction

pinch

BE

Unpacking

To

prevent

the

Notice

To

avoid

power

+

220

¢

95

Console

To

avoid

valve.

Technical

the

up

position

product

supply:

to

240 V —

to

120 V ~T10A,

Components

injury

Specifications

and

Installing

ramp

from

while

cutting

damage,

T5A,

to

surgical

falling

the

be

Time

Delay

Time

Delay

personnel,

the

CUSA

and

causing

corrugated

sure

to

insert

(default)

keep

EXcel

injury,

tab

that

fuses

that

fingers

System

be

sure

secures

are

appropriate

away

from

to

it

the

hold

to

the

suction

the

ramp

carton.

to

the

pinch

in

Explosion

flammable

Hazard

Do

anesthetics

not

or

use

the

any

potentially

CUSA

EXcel

system

explosive

CUSA

in

the

or

flammable

EXcel-8

System

presence

atmosphere.

Service

of

Man

Page 19

To

avoid

valve

injury

while

to

surgical

powering

personnel,

the

unit

on

or

off,

keep

fingers

activating

Warnings,

away

from

vibration,

or

Cautions,

the

using

and

suction

fast

Notices

pinch

flush.

291A18S

Checkout

Do

not

Contact

Notice

To

avoid

the

Maintaining

0

«“«ὕ“όὃἃ«ᾱἃὃἃἝἃἝὃἝἃᾱἝἃ“ςἝ«ἄἃἄναυυαυυ

Electric

Notice

Do

not

abrasive

scratch

discoloration.

Do

not

allow

may

product

torque

Shock

rub,

cleaning

the

allow

Procedures

the

handpiece

result

in

patient

damage,

wrench

the

Hazard

press,

or

or

panels.

fluids

to

tighten

CUSA

Always

touch

disinfectant

Do

not

to

enter

tip

to

contact

injury,

NEVER

or

loosen

EXcel

unplug

any

panels

compounds;

use a betadine-based

the

chassis.

anyone

user

injury,

hold

the

the

tip.

System

the

CUSA

with

or

handpiece

system

solvents;

or

or

anything

handpiece

in

before

caustic,

other

materials

solution;

during

tip

damage.

your

hand

cleaning.

corrosive,

that

it

will

cause

tip

activation.

while

using

or

could

|8UU0SJ84

э/е

№

I

E

|

6

CUSAEXcel-8

System

Service

Manual

Do

¢

+

*

*

Tip

*

e

*

*

not

clean

Product

handpiece:

Product

damage

Do

not

Do

not

Do

not

Do

not

damage

Torquing

Do

not

Do

not

Do

not

Do

not

the

sterilizer

will

immerse

use

ultrasonic

use

chlorinated

clean

the

will

Set.

use

ultrasonic

autoclave.

use

chlorinated

clean

with

case

result

if

the

handpiece

or

automated

substances

handpiece

result

if

or

automatic

substances

abrasives

with

you

with

you

such

abrasives.

do

not

follow

cable

electrical

cleaners.

such

abrasives

do

not

follow

washers.

such

as

Ajax,

Product

these

as

bleach

such

these

as

bleach

Comet,

damage

notices

connector

solution.

as

Ajax,

notices

solution.

or

steel

will

when

in

liquid.

Comet,

when

wool.

result.

cleaning

or

steel

cleaning

the

wool.

the

Page 20

Warnings,

Cautions,

and

Notices

Troubleshooting

Electric

while

when

Electric

tools

or

cleaner.

effects

components.

Shock

Hazard

the

system

working

Shock

Hazard

and

equipment;

troubleshooting

Do

not

activate

Tip

damage,

may

occur.

Notice

Electrostatic

Sensitive

When

on

Wear a grounding

Handle

for

circuit

transport

boards

of

electrostatic

Replacement

Electric

Shock

authorized

Hazard

to

service

Do

not

is

disassembled

an

energized

Take

appropriate

use

of

the

the

system.

vibration

or

user

the

injury,

Devices

repairing

strap

when

by

their

sensitive

Procedures

Only

trained

the

CUSA

touch

any

exposed

and

energized.

system.

precautions

“one

hand

CEM

handswitching

electrical

This

unit

contains

the

system,

handling

work

electrostatic

nonconductive

components

biomedical

EXcel

system.

wiring

Never

rule,”

etc.)

shock,

or

electrostatic

at a static

edges.

engineers

or

conductive

wear a grounding

(such

as

the

when

taking

nosecone

any

combination

control

sensitive

Use

an

antistatic

and

circuit

and

surface

use

of

isolated

measurements

while

using

of

these

sensitive

workstation.

components.

container

boards.

technicians

strap

the

are

tip

Electric

Shock

Hazard

while

the

CUSA

grounding

Electric

tools

or

troubleshooting

High

CUSA

deliver

strap

Shock

and

equipment;

Current

EXcel

very

Hazard

Hazard

system

high

Do

EXcel

system

when

working

Take

use

the

CUSA

Do

is

energized.

current,

not

touch

is

on an

appropriate

of

the

“one

EXcel

not

touch

resulting

any

exposed

disassembled

energized

precautions

hand

rule,”

system.

the

ultrasonics

The

heat

sink

in

injury.

wiring

and

energized.

CUSA

(such

etc.)

when

PCB

is

isolated

or

conductive

system.

as

the

taking

heat

sink

from

surface

Never

wear

use

of

isolated

measurements

while

the

ground,

and

a

can

CUSA

EXcel-8

System

Service

>

Manual

Page 21

Notice

If

you

plan

to

available

damage

to

to

supply

the

connect

tip

the

cooling

and/or

handpiece

irrigation

handpiece

for

activation,

solution

may

result.

Warnings,

to

the

ensure

handpiece

Cautions,

that

an

I.V.

tip.

Otherwise,

and

set

Notices

is

99IAJ9S

Electrostatic

components.

Wear a grounding

Handle

for

transport

When

from

the

To

avoid

To

avoid

to

the

To

avoid

turn

the

speed

Sensitive

When

strap

circuit

boards

of

electrostatic

installing a new

previous

product

product

Machine

product

three

(R12),

power

damage,

damage,

Control

damage,

white

and

min

Devices

repairing

by

power

adjustment

speed

This

the

when

handling

their

nonconductive

sensitive

supply,

supply. A too-long

do

not

remove

PCB.

when

handling

dials

(R11).

unit

contains

system,

electrostatic

components

use

remove

the

ESD

designated

work

the

screw

the

wrist

the

same

electrostatic

at a static

sensitive

edges.

Use

and

screws

will

damage

jumper

cabie

strap

suction

pump

as

current

sensitive

control

components.

an

antistatic

circuit

boards.

and

or

the

before

connecting

controller

limit

workstation.

container

washers

the

(R13),

removed

power

connector

card,

max

supply.

at

J4.

cables

do

not

|l9uu0sJ9d

Ajayes

Calibration

High

Current

Hazard

CUSA

EXcel

system

deliver

very

high

Repair

To

the

Policy

prevent

up

position

the

Do

current,

ramp

from

while

not

touch

is

energized.

resulting

falling

stapling

the

The

and

the

corrugated

ultrasonics

heat

in

injury.

causing

sink

is

injury,

tab

that

PCB

heat

isolated

be

sure

secures

sink

from

to

hold

it

while

ground,

the

to

the

the

and

ramp

crate.

can

in

GUSA

EXcel-8

System

Service

Manual

>

Page 22

Introduction

In

this

e

Overview

e

Fragmentation

e

Irrigation

¢

Aspiration

*

Handpieces

e

Wide

section:

(Suction)

variety

of

tips.

For

Your

0054

EXcel-8

Information

System

Service

Manual

Read

EXcel

Read

EXcel

This

is,

what

all

warnings,

system

the

instructions,

handpieces

section

presents

it

does,

cautions,

before

before

and

notices,

servicing

warnings,

the

(generally)

it.

cautions,

servicing

CUSA

and

them.

EXcel

how

instructions

and

notices

system

it

general

works.

provided

provided

with

information;

with

the

the

CUSA

CUSA

what

it

A

Page 23

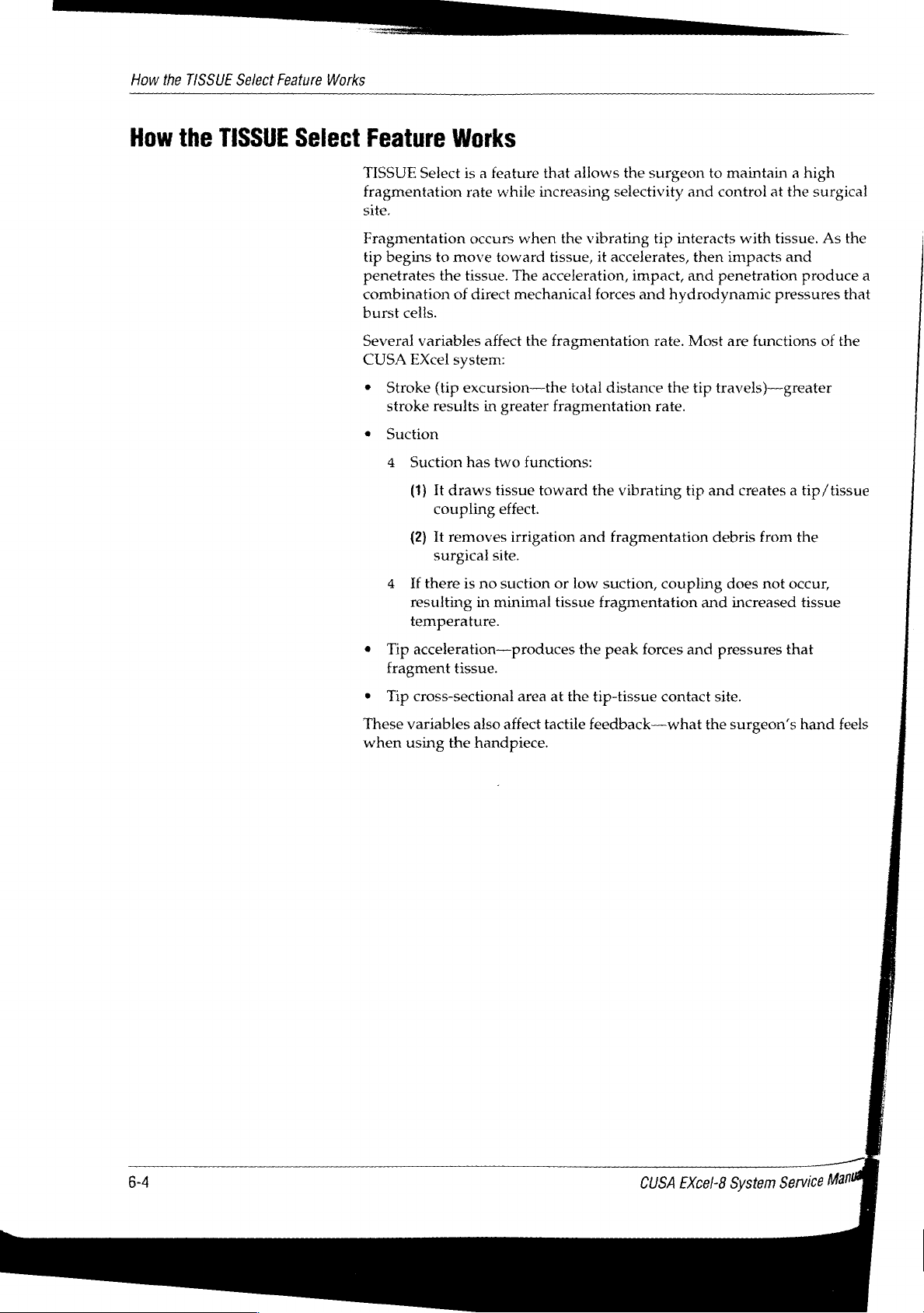

Overview

Overview

The

CUSA

surgeon

body.

*

+

*

All

The

+

e

e

to

It

performs

Fragmentation

Irrigation

Aspiration

three

functions

CUSA

The

console:

4

The console

make

4

The

The

handpiece

the

patient.

Accessories

large

selection

sterilizer

EXcel

system

remove

Excel

control

tissue—selectively

three

(suction).

may

system

body

the

system

panel

is

the

include a variety

of

tips, a tip

case.

is

an

ultrasonic

functions:

occur

at

the

includes

houses

work.

allows

handheld

the

electronics,

the

of

torquing

surgical

and

with

same

time.

following

user

to

control

surgical

items;

for

base

aspirator

precise

components:

pumps,

device

example, manifold

and torque

control—from

and

other

the

system.

that

actually

wrench,

that

allows

parts

that

touches

tubing,

and

a

the

a

a

Fragmentation

Tip

Motion

Fragmentation

tip

begins

penetrates

combination

burst

For

Principles

cells.

more

to

move

the

of

information

of

Operation,

Cooling

The

high

frequency

CUSA

EXcel

system

This

system

the

handpiece

the

handpiece

35

to

50

As

it

passes

handpiece

pulls

cc/min.

through

temperature,

occurs

tissue.

direct

cable,

cable

when

toward

The

acceleration,

mechanical

on

how

in

this

vibration

includes a closed,

water

from a cooling

through

to

the

the

handpiece,

in

the

vibrating

tissue,

cooling

sustained

it

forces

the

handpiece

manual.

generates

the

handpiece,

water

tip

interacts

accelerates,

impact,

and

heat.

recirculating

water

reservoir.

the

water

heavy

impacts

and

hydrodynamic

works,

To

reduce

reservoir,

and

removes

use,

remains

with

tissue.

the

tissue,

penetration

refer

the

cooling

through a tube

through a return

Cooling

heat.Normal

produce

pressures

to

Section

heat,

water

water

at

about

the

flows

40°

As

the

then

a

that

6,

system.

in

tube

in

at

C.

CUSA

EXcel-8

System

Service

Manuál

Page 24

Irrigation

Use

distilled

contain

present

problems

natural

in

water

minerals,

tap

water.

within

for

the

the

cooling

chemical

Any

of

cooling

these

water

water

system

additives,

impurities

system.

because

or

organic

in

tap

materials

water

it

can

does

cause

Irrigation

not

that

are

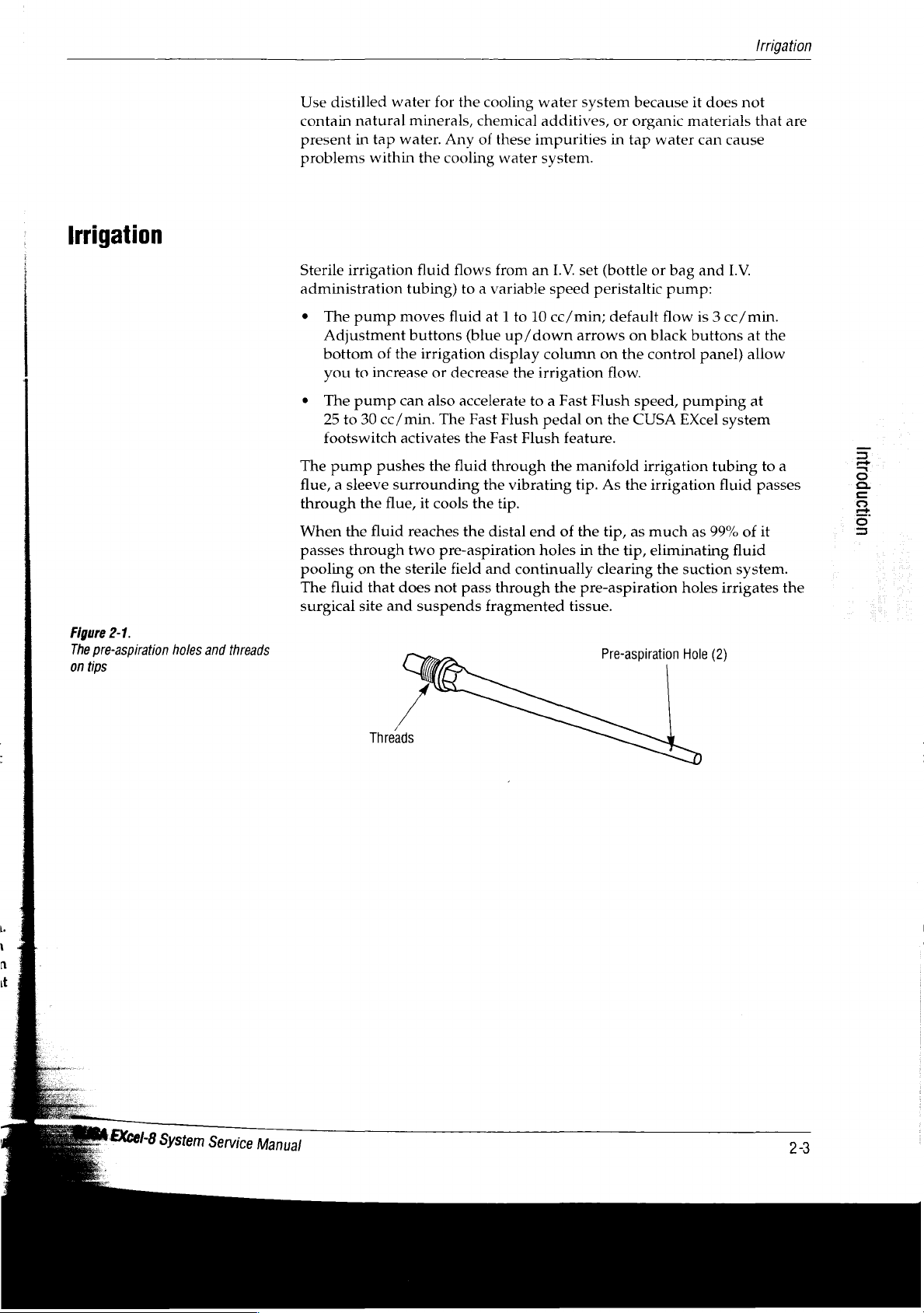

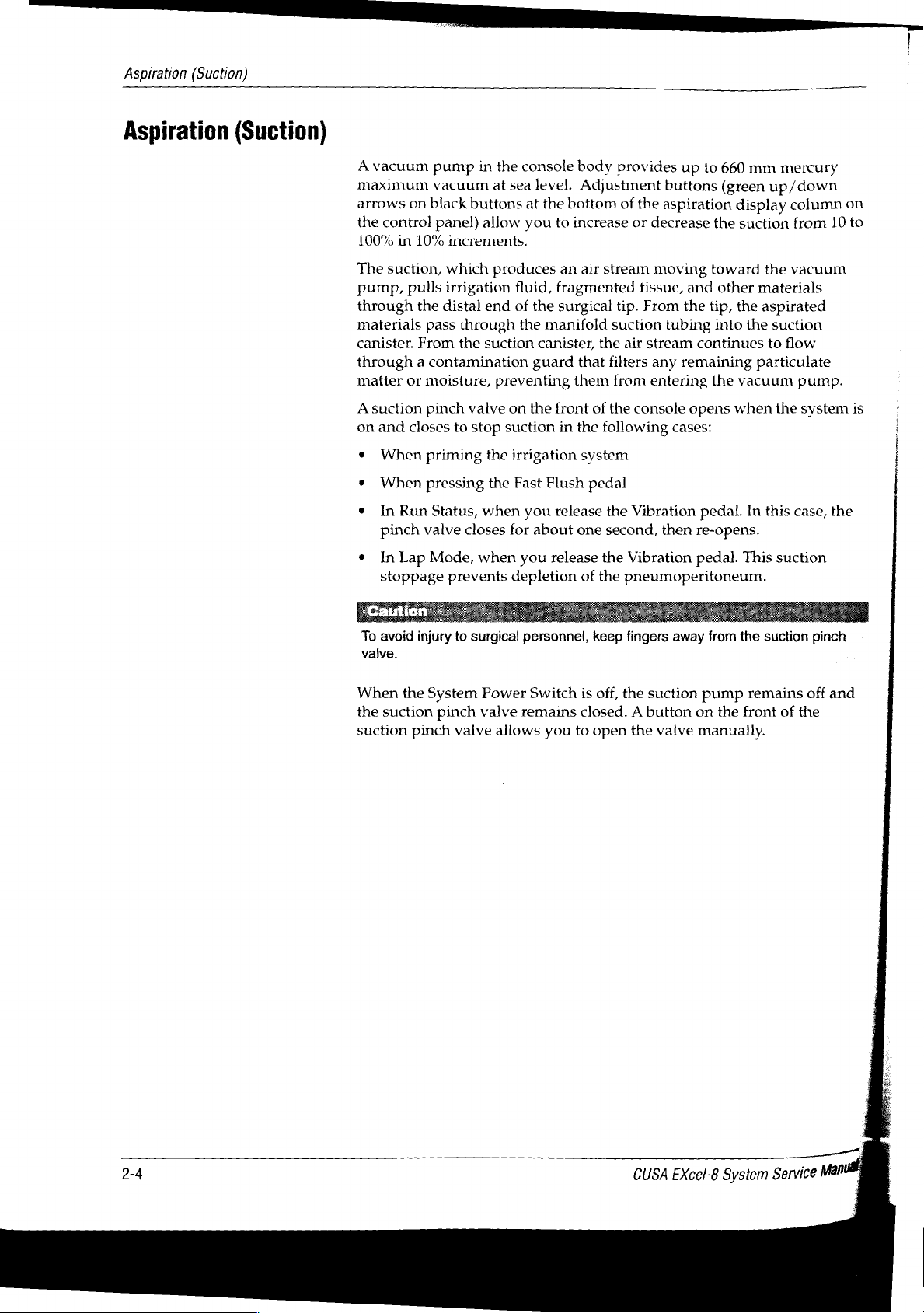

Figure

The

pre-aspiration

on

tips

2-1.

holes

and

threads

Sterile

administration

e

e

The

flue, a sleeve

through

When

passes

pooling

The

surgical

irrigation

The

pump

Adjustment

bottom

you

The

25

footswitch

to

pump

to

30

pump

the

the

through

on

fluid

site

of

the

increase

cc/min.

pushes

surrounding

flue,

fluid

the

that

and

moves

can

activates

does

fluid

flows

tubing)

buttons

reaches

two

sterile

to a variable

fluid

(blue

irrigation

or

decrease

also

accelerate

The

Fast

the

the

fluid

it

cools

the

the

pre-aspiration

field

not

pass

suspends

from

an

speed

at 1 to

10

cc/min;

up/down

display

Fast

through

the

distal

and

through

fragmented

column

the

irrigation

to a Fast

Flush

pedal

Flush

the

vibrating

tip.

end

holes

continually

LV.

set

(bottle

peristaltic

default

arrows

feature.

manifold

tip.

of

the

in

the

pre-aspiration

tissue.

on

on

the

flow.

Flush

on

the

As

the

tip,

as

the

tip,

clearing

Pre-aspiration

or

bag

pump:

flow

black

buttons

control

speed,

CUSA

pumping

Excel

irrigation

irrigation

much

as

eliminating

the

suction

holes

Hole

and

1.V.

is 3 cc/min.

at

panel)

allow

at

system

tubing

fluid

passes

99%

of

it

fluid

system.

irrigates

(2)

the

to

a

lOH9nDOJUI

the

Threads

Page 25

Aspiration

(Suction)

Aspiration

(Suction)

A

vacuum

maximum

arrows

the

control

100%

The

pump,

through

materials

canister.

through a contamination

matter

A

suction

on

and

e

When

+

When

e

In

pinch

*

In

stoppage

pump

vacuum

on

black

panel)

in

10%

suction,

pulls

the

distal

pass

From

or

moisture,

pinch

closes

priming

pressing

Run

Status,

valve

Lap

Mode,

in

the

at

sea

buttons

allow

increments.

which

produces

irrigation

through

the

valve

to

closes

prevents

end

suction

preventing

on

stop

suction

the

irrigation

the

when

for

when

depletion

fluid,

of

the

Fast

you

console

level.

at

the

bottom

you

to

an

fragmented

the

surgical

manifold

canister,

guard

the

front

in

Flush

you

release

about

release

body

provides

Adjustment

of

the

increase

air

that

them

the

system

one

of

or

stream

tissue,

tip.

suction

the

air

filters

from

of

the

console

following

pedal

the

Vibration

second,

the

Vibration

the

pneumoperitoneum.

up

buttons

aspiration

decrease

moving

and

From

the

tubing

stream

any

remaining

entering

opens

cases:

then

to

660

mm

(green

display

the

suction

toward

other

tip,

the

into

the

continues

the

vacuum

when

pedal.

re-opens.

pedal.

In

This

mercury

up/down

column

from

10

the

vacuum

materials

aspirated

suction

to

flow

particulate

pump.

the

system

this

case,

the

suction

on

to

is

To

avoid

valve.

When

the

suction

suction

injury

the

pinch

to

System

pinch

valve

surgical

Power

valve

allows

personnel,

Switch

remains

is

closed. A button

you

to

keep

off,

open

fingers

the

suction

the

valve

away

from

pump

on

manually.

the

the

suction

remains

front

of

pinch

off

the

and

24

EXcel-8

CUSA

System

Service

Mam”

Page 26

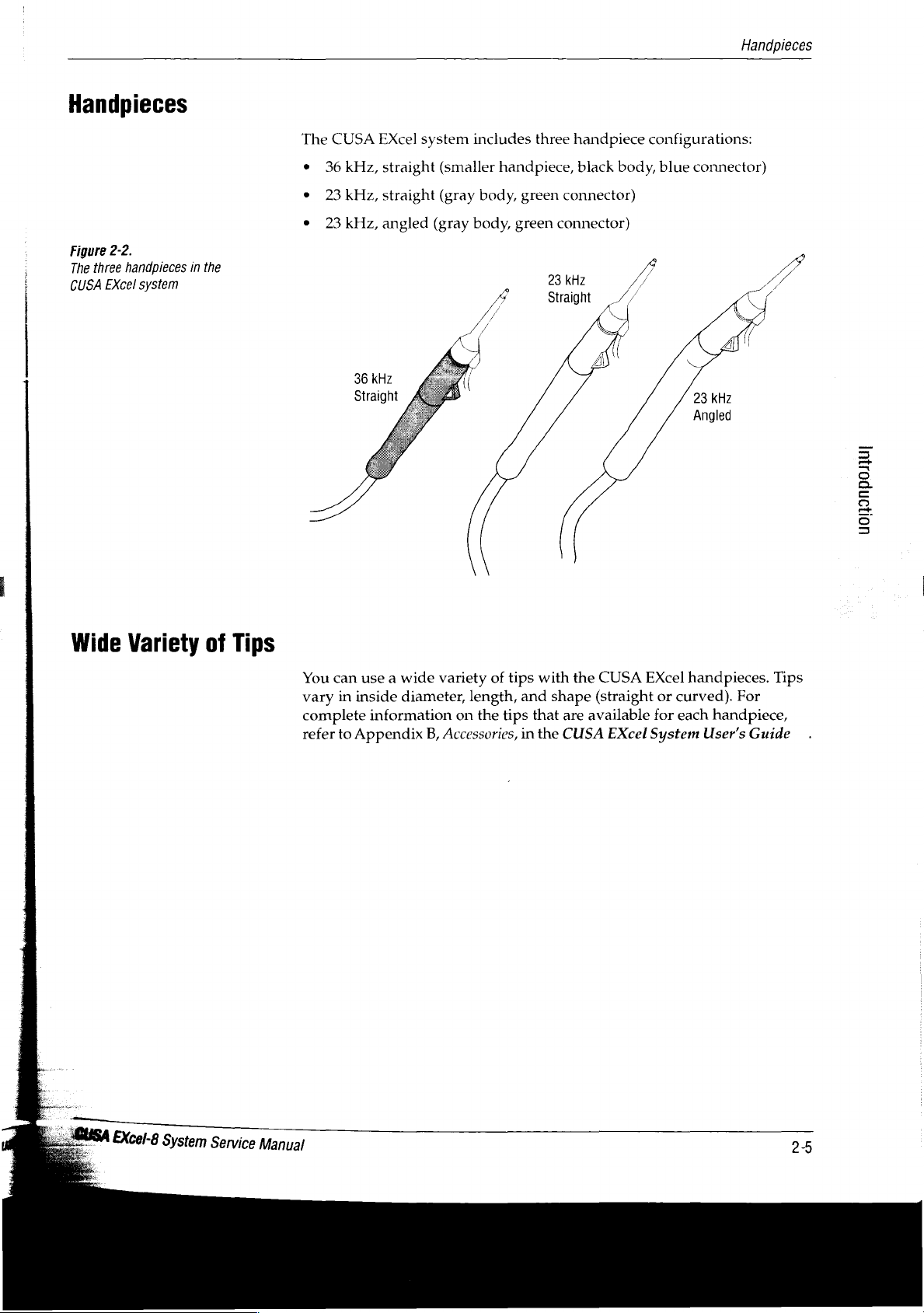

Handpieces

Figure

2-2.

handpieces

three

The

system

EXcel

CUSA

in

the

The

CUSA

e

36

e

23

。

23

EXcel

kHz,

straight

kHz,

straight

kHz,

angled

36

kHz

Straight

system

(smaller

(gray

(gray

includes

handpiece,

body,

green

body,

green

three

handpiece

black

connector)

connector)

kHz

23

Straight

configurations:

body,

blue

connector)

и

Handpieces

^

Wide

Variety

of

Tips

You

can

vary

in

inside

complete

refer

to

Appendix

use a wide

diameter,

information

B,

variety

Accessories,

of

length,

on

the

tips

and

tips

in

with

shape

that

the

the

CUSA

(straight

are

available

CUSA

EXcel

EXcel

or

curved).

for

each

System

handpieces.

For

handpiece,

User's

Guide

UOH9nDOJiUI

Tips

EXcel-8

System

Service

Manual

>

Page 27

Unpacking

and

Installing

the

The

CUSA

Responsibility

EXcel

of

System

In

this

section:

e

The

responsibility

e

Unpacking

¢

Preparing

4

4

4

4

the

Manufacturer

the

the

Replacing

Replacing

Replacing a Control

Installing

of

CUSA

CUSA

the

power

fuses

the

reference

the

manufacturer

EXcel

system

EXcel

console

connector

(if

necessary)

Panel

card

for

use:

overlay

(optional)

set.

LUSA

EXcel-

8

System

Service

Manual

Valleylab

CUSA

EXcel

*

The

person

and

setup

+

Authorized

modifications,

*

The

electrical

codes

*

You

use

for

use.

For

warranty

is

responsible

system

unpacking

procedures

persons

or

installation

and

regulatory

the

equipment

information,

for

the

only

under

and

in

this

perform

repairs.

of

requirements.

in

accordance

refer

safety,

reliability,

the

following

installing

manual.

assembly

the

to

the

relevant

with

the

Preface

and

performance

circumstances:

unit

follows

operations,

room

complies

the

Valleylab

section

of

of

the

the

installation

re-adjustments,

with

local

instructions

this

manual.

3-1

Page 28

Unpacking

the

CUSA

EXcel

System

Unpacking

the

CUSA

EXcel

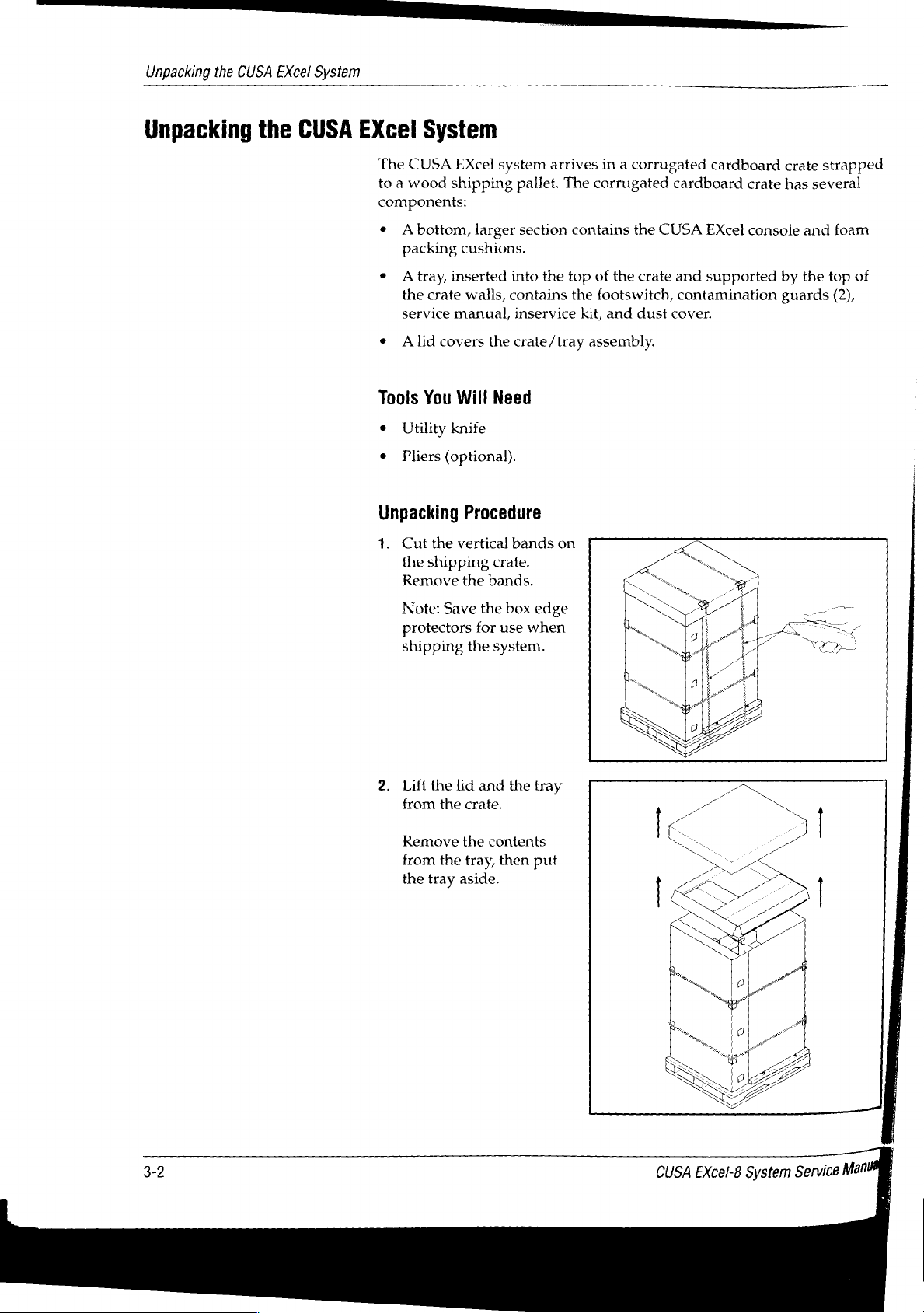

The

CUSA

to a wood

components:

*

Abottom,

packing

+ A tray,

the

service

e

Alid

Tools

e

Utility

+

Pliers

Unpacking

1.

Cut

the

Remove

System

EXcel

shipping

larger

cushions.

inserted

crate

walls,

manual,

covers

You

the

shipping

the

Will

knife

(optional).

Procedure

vertical

the

bands.

system

pallet.

section

into

the

contains

inservice

crate/tray

Need

bands

crate.

arrives

The

corrugated

contains

top

of

the

footswitch,

kit,

assembly.

on

in a corrugated

cardboard

the

CUSA

the

crate

and

contamination

and

dust

cover.

cardboard

crate

EXcel

console

supported

crate

has

several

and

by

the

guards

strapped

foam

top

of

(2),

Note:

protectors

shipping

2.

Lift

from

Remove

from

the

tray

Save

the

the

the

the

for

the

system.

lid

and

crate.

the

contents

tray,

aside.

box

use

the

then

edge

when

tray

put

一

3-2

EXcel-8

CUSA

System

Service

Man

Page 29

Unpacking

the

CUSA

EXcel

System

|

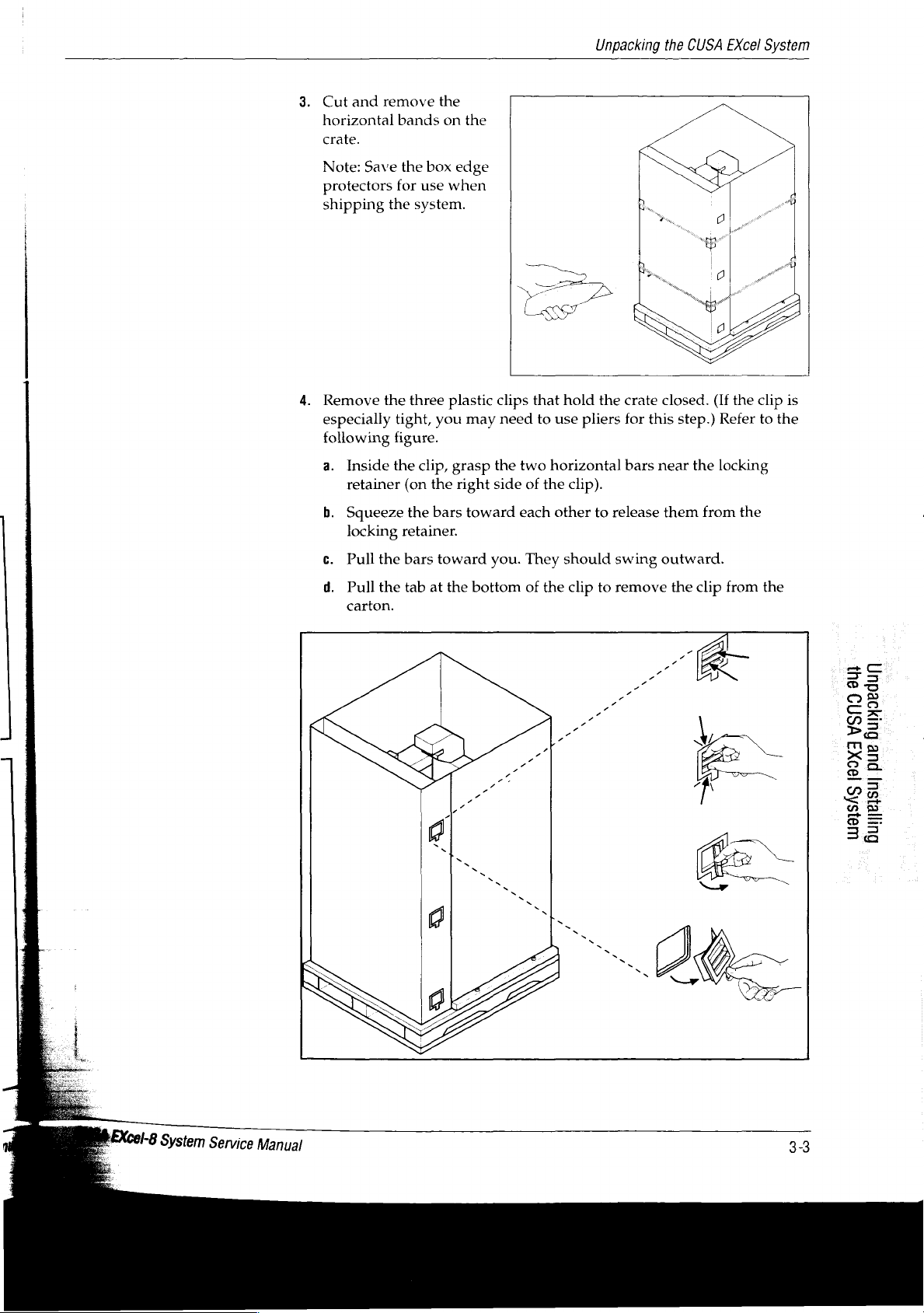

3.

Cut

horizontal

crate.

Note:

protectors

shipping

4.

Remove

especially

following

a.

Inside

retainer

b.

Squeeze

locking

c.

Pull

and

Save

remove

bands

the

for

use

the

system.

the

three

tight,

figure.

the

clip,

(on

the

retainer.

the

bars

the

on

box

edge

when

plastic

you

grasp

the

right

bars

toward

the

clips

that

may

need

to

the

two

horizontal

side

of

the

toward

each

you.

They should

hold

use

pliers

clip).

other

the

crate

for

bars

to

release

swing

closed.

this

step.)

near

the

them

outward.

(If

the

Refer

locking

from

clip

the

to

is

the

d.

Pull

the

carton.

tab

at

the

bottom

of

the

clip

to

remove

the

clip

from

the

SU)

VSNO

Bupjoedur)

pue

[99XI

UIBISÁS

Gurexsu]

Page 30

Unpacking

the

CUSA

EXcel

System

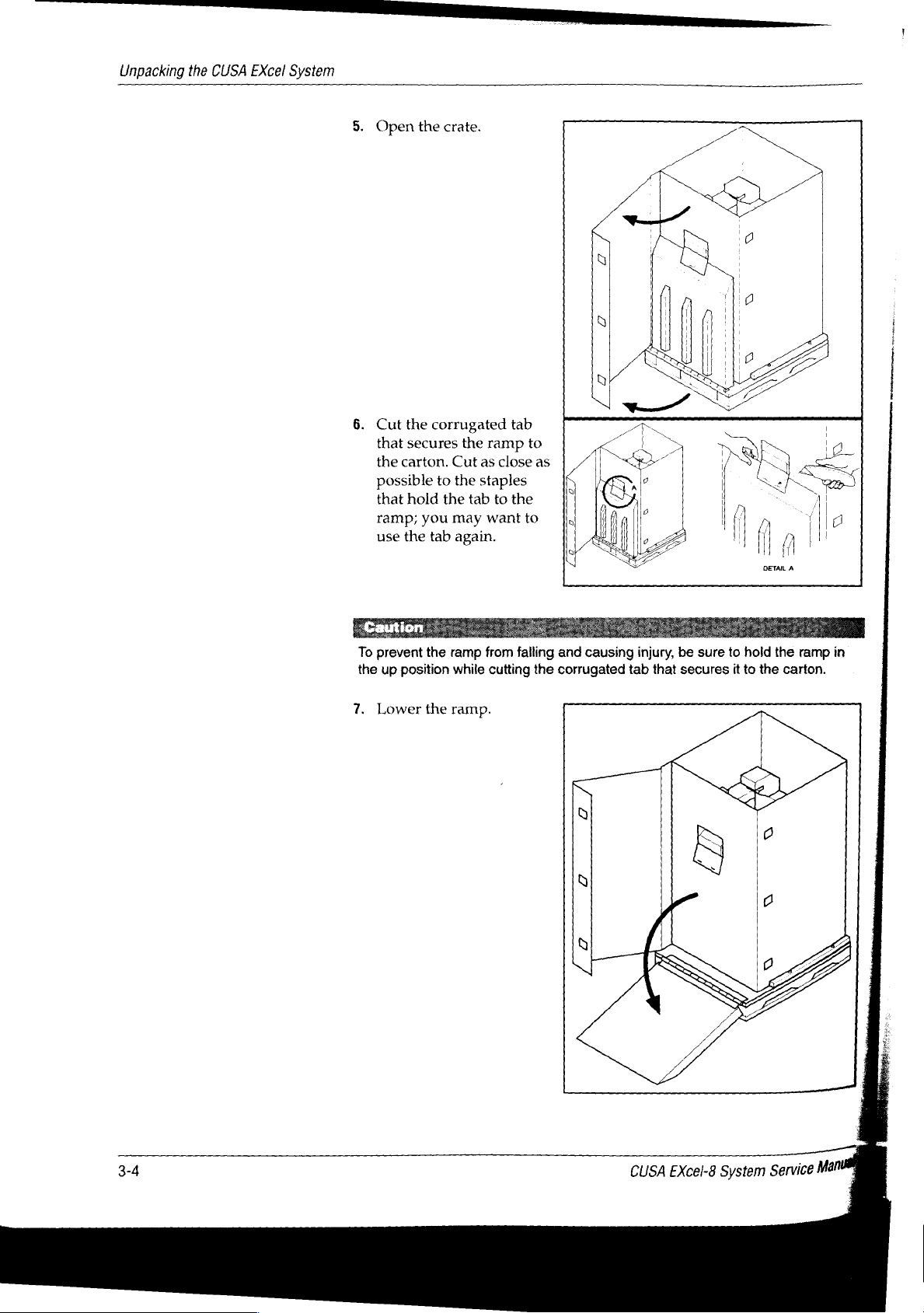

5.

Open

6.

Cut

that

the

possible

that

ramp;

use

the

crate.

the

corrugated

secures

carton.

the

hold

you

tab

Cut

to

the

may

the

ramp

as

the

staples

tab

to

want

again.

tab

to

close

the

to

as

To

the

7.

prevent

up

position

Lower

the

the

ramp

from

while

ramp.

falling

cutting

and

causing

the

corrugated

injury,

tab

that

be

sure

secures

to

it

hold

to

the

the

ramp

carton.

in

CUSA

EXcel-8

System

Mani

Service

Page 31

Unpacking

the

CUSA

EXcel

System

8.

9.

Lift

the

walls

off

Remove

around

Remove

corrugated

the

pallet.

the

four

interlocking

the

console

the

right

and

carton

(refer

left

foam

to

the

following

foam

cushions

pieces

from

from

the

figure).

the

console.

foam

cushion

À

EXcel-8

System

Service

Manual

9

VSNI

Gumoedun

pue

[99XI

LUB]SÁS

furesu]

Page 32

Unpacking

the

CUSA

EXcel

System

10.

Cut

the

remove

console.

the

vertical

clear

the

band

plastic

bag

bag,

from

on

then

the

11.

The

rear

one

direction;

prevent

a.

Unlock

b.

Check

console

casters

the

the

wheels

the

front

the

rear

to

roll

have

front

from

casters

casters

toward

direction

casters

have

rolling

by

lifting

to

be

the

ramp.

locks

brake

(vefer

sure

that

to

the

that,

keep

locks

the

following

lock

lever

if

locked,

the

that,

wheels

when

figure).

upward.

they

will

rolling

in

locked,

allow

the

CUSA

EXcel-8

System

Mani

Service

Page 33

Unpacking

the

CUSA

EXcel

System

12.

Roll

ramp.

are

you

console

of

13.

Unlock

release

the

cushion

control

the

console

If

the

unlocked,

do

not

to

the

ramp.

the

tab,

U-shaped

from

panel.

down

rear

be

allow

roll

off

control

then

foam

under

the

casters

sure

that

the

the

side

arm

remove

the

.

a

;

|

>

7

-i

Put

the

box

plastic

if

that

ship

packing

the

information

Policy,

Inspect

If

repair

arrange

If

Valleylab

bag

you

need

you

the

console.

procedures

console,

in

all

any

damage

or

repair

you

have

for

use

this

contents

replacement

Service

edge

protectors

storage.

to

return

the

proper

If,

you

may

on

packing

guide.

has

occurred,

or

replacement,

any

questions

Center

and

Save

all

the

console

materials

in

Valleylab's

or

if

you

void

the

the

console

for

damage

notify

of

damaged

about

nearest

all

foam

shipping

to

Valleylab.

and

judgement,

use

improper

warranty

for

:

that

may

Valleylab

parts.

refer

to

the

contents

you,

packing

components.

In

the

proper

you

packaging

on

this

shipping,

have

immediately

For

more

Section

of

or

your

Valleylab

materials

You

fact,

it

packing

fail

to

materials

system.

refer

to

occurred

information

13,

Repair

these

cartons,

into the

will

is

very

procedures

use

the

For

more

Section

during

to

Policy.

representative.

clear

need

them

important

proper

to

return

13,

Repair

shipping.

arrange

on

how

contact

to

to

the

041

YSNO

Buryoedun

pue

|99X

91SAS

Guyjesu]

Cel-8

System

Service

Manual

Page 34

Preparing

the

CUSA

EXcel

Console

for

Use

Preparing

the

CUSA

EXcel

Valleylab

contains

*

Console

ο

Footswitch

e

In-service

*

Contamination

e

Service

e

Dust

The

small

e

User's

e

Reference

e

Instructions

panel

+

Tip

On

the

e

Common

Console

ships

the

the

following

kit

manual

cover.

box

contains

guides

card

for

card.

CUSA

Excel

European

for

Use

CUSA

guard

set

EXcel

items:

several

installing

console,

power

system

other

items:

reference

Valleylab

connector

in

two

boxes.

card

set

provides

in

the

the

following

The

large

console

box

control

items:

e

220

to

240V,

e

International

Before

set.

If

power,

If

international

your

+

Replace

e

Change

your

shipping,

facility

you

need

the

the

facility

control

T5A,

time

delay

(symbols

Valleylab

uses a different

to

make

power

fuses.

has

ordered

only)

includes,

power

the

appropriate

connector.

an

English

panel overlay

fuses

control

but

connector

language

and

panel

overlay ~ installed.

does

not

install, a reference

or

receives

changes

reference

to

kit,

replace

card

the

system:

set.

95

the

to

120

card

V

3-8

EXcel-8

CUSA

System

Service

Ma

Page 35

Preparing

the

CUSA

EXcel

Console

for

Use

Table

3-1.

Wire

colors

D

important

Ensure

comply

regulatory

that

all

electrical

with

local

codes

requirements.

installations

and

Replacing

If

your

connector

connector

Tools

Slotted

Procedure:

1.

Remove

2.

Attach

Wire

green

brown

light

The

power

defeat