Page 1

VACUSAFE Operating instructions

158340_V12

Page 2

Declaration of conformity

INTEGRA Biosciences AG –

7205 Zizers, Switzerland

declares on its own responsibility that the devices

comply with:

Zizers, November 4, 2016

Description Models

VACUSAFE 158300, 158310, 158320

EU Directives (DoW: Date of Withdrawal) Before DoW DoW After DoW

Low Voltage Equipment 2006/95/EC 20.04.2016 2014/35/EU

Electromagnetic Compatibility 2004/108/EC 20.04.2016 2014/30/EU

Restriction of Hazardous Substances 2011/65/EU

Waste Electrical and Electronic Equipment 2012/19/EU

EU Regulations

Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH)

1907/2006

Ecodesign - Power supplies 278/2009

Standards for EU

Safety requirements for electrical equipment for measurement,

control and laboratory use - General requirements.

EN 61010-1: 2010

Electrical equipment for measurement, control and laboratory use EMC requirements.

EN 61326-1: 2013

Standards for Canada and USA

Safety requirements for electrical equipment for measurement,

control and laboratory use - General requirements.

CAN/CSA-C22.2

No. 61010-1

Safety requirements for electrical equipment for measurement,

control and laboratory use - General requirements.

UL 61010-1

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including

interference that may cause undesired operation.

Part 15 of the

FCC Rules

Class A

Elmar Morscher

CEO

Thomas Neher

Quality Manager

Page 3

VACUSAFE – Operating instructions V12

www.integra-biosciences.com 3

English

Table of Contents

Introduction ......................................................................................................................4

Description of the device ..................................................................................................5

Installation ........................................................................................................................6

Operation .........................................................................................................................8

Maintenance ..................................................................................................................11

Technical data ...............................................................................................................12

Accessories and consumables ......................................................................................14

Imprint

© 2018 INTEGRA Biosciences AG

Manufacturer

Customer service

Please contact your local INTEGRA Biosciences AG representative, see

www.integra-biosciences.com

or contact info@integra-biosciences.com.

Further information and other languages are available on www.integra-biosciences.com

or on request (info@integra-biosciences.com).

INTEGRA Biosciences AG

CH-7205 Zizers, Switzerland

T +41 81 286 95 30

B +41 81 286 95 33

INTEGRA Biosciences Corp.

Hudson, NH 03051, USA

T +1 603 578 5800

F +1 603 577 5529

info@integra-biosciences.com

www.integra-biosciences.com

Page 4

VACUSAFE – Operating instructions V12 Introduction

4 INTEGRA Biosciences AG

English

1 Introduction

1.1 Intended use

This is a general-purpose laboratory instrument. Any use of this instrument in a medical

or IVD setting is under the sole responsibility of the user.

VACUSAFE is a vacuum-based system for aspiration of non explosive aqueous solutions,

such as biological buffers and media.

If the VACUSAFE is used in a manner not specified by INTEGRA Biosciences, the

protection provided by the VACUSAFE may be impaired.

1.2 Safety notes

WARNING

Read these operating instructions carefully before use and pay particular

attention to sections containing this symbol.

1) Do not carry out any conversions and alterations on the device.

2) Defective parts may only be replaced with original INTEGRA Biosciences spare parts

according to the INTEGRA Biosciences operating or service instructions.

3) Do not use VACUSAFE in an atmosphere with danger of explosion. Also, do not

aspirate highly flammable liquids such as acetone or ether.

4) When handling dangerous substances, comply with the material safety data sheet

(MSDS) and with all safety guidelines such as the use of protective clothing and safety

goggles.

5) Prolonged exposure of VACUSAFE to UV-light can cause discoloration and/or

yellowing of the plastic housing. However, this will not affect the performance of the

device in any way.

6) Excess spare parts, accessories and consumables (e.g. tubings, lids, plastic parts,

rubber products, O-rings, filter) should be stored in a light protected place at ambient

temperature to prevent premature material aging caused by prolonged exposure to UVlight.

Regardless of the listed safety notes, additionally applicable regulations and guidelines of

trade associations, health authorities, trade supervisory offices, etc. must be observed.

Please visit our website www.integra-biosciences.com

on a regular basis for up to date

information regarding REACH classified chemicals contained in our products.

Page 5

VACUSAFE – Operating instructions V12 Description of the device

www.integra-biosciences.com 5

English

2 Description of the device

Please determine which VACUSAFE model you have purchased as it will simplify the

reading of these operating instructions. Find the part number of your model on the main

packaging label and note it here: 158 .

2.1 Scope of delivery

• Base (housing with integrated bottle stand)

• Bottle

• Lid with openings for tubing

• Tubing and filter

• Cable for level sensor (models 158300, 158310)

• Mains adapter

• VACUBOY hand operator

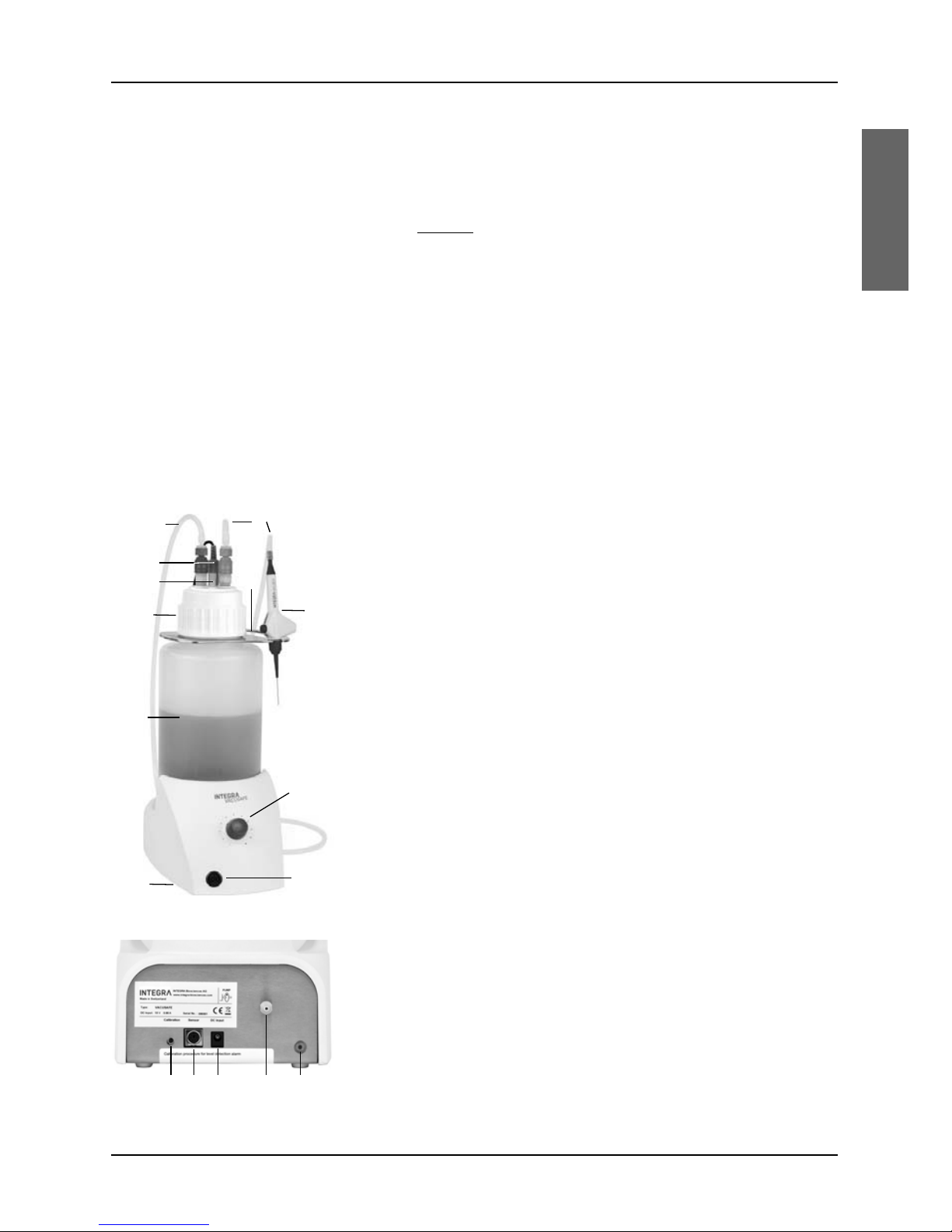

2.2 Overview of the VACUSAFE

1 Housing

2 Bottle for liquid collection

3 Lid with openings for tubing

4 Bottle handle (except model 158300)

5 VACUBOY hand operator

6 Tubing for connection of hand operator to bottle

7 Tubing for connection of base to bottle

8 On/off switch with indicator lamp

9 Knob for vacuum regulation

10 Level sensor (models 158300 and 158310)

11 Atmospheric pressure return valve

Rear view

12 Button for calibration of level sensor

13 Socket for level sensor cable

14 Mains connection socket

15 Filter port (air inlet)

16 Air outlet with screwed air outlet connector

1

2

3

4

5

6

7

10

9

8

11

12 13 14 15 16

Page 6

VACUSAFE – Operating instructions V12 Installation

6 INTEGRA Biosciences AG

English

3 Installation

3.1 Operating environment

The VACUSAFE has been designed for use in a laboratory. It shall be installed in a level,

dry and dust-free location with a temperature of 5– 40 °C and a maximal (non-condensing)

relative humidity of 80%.

3.2 Power supply

Insert the mains adapter cable into the VACUSAFE mains connection socket (14) and plug

it into the power source.

W

ARNING

Use an original INTEGRA Biosciences mains adapter only (see “6.1

Specifications” on page 12 for voltage requirements)

3.3 Set-up

3.3.1 Connecting the filter

WARNING

The VACUSAFE should never be used without a filter.

3.3.2 Connecting the tubing for the air outlet

Insert the hydrophobic filter into the filter port with the green

dot facing the instrument (see "

Rear view" on page 5) in

order to guarantee that the hydrophobic side of the filter is

facing the liquid collection bottle

1) If not installed, screw the air outlet connector (#158 427)

on the air outlet of the pump (16).

2) Fix the silicon tubing, ID 4 mm (e.g. #158332), on the

screwed air outlet connector.

Page 7

VACUSAFE – Operating instructions V12 Installation

www.integra-biosciences.com 7

English

3.3.3 Connection of the bottle and hand operator

1) Place the bottle without lid in the base of the instrument.

Insert the bottle handle into the neck of the bottle by

screwing it in place. Close the bottle with the lid fitted

with tubing openings and make sure that the lid is

screwed on tightly.

2) Connect one end of the blue tubing to the filter and the

other end either to the fitting on the lid marked “P

UMP”

(model 158 320) or to the blue tubing coupling (models

158300, 158 310).

3) Connect the long transparent tubing to the fitting on the

lid marked “H

AND” (model 158 320) or to the red tubing

coupling (models 158300, 158 310). Insert the

VACUBOY hand operator into the other end of the long

tubing.

1

23

Page 8

VACUSAFE – Operating instructions V12 Operation

8 INTEGRA Biosciences AG

English

3.3.4 Connection and calibration of the level sensor

In case of failed calibration (indicated by continuous beeping and blinking of the switch

indicator lamp), repeat the calibration after cleaning the sensor pins inside the lid and

checking that the level sensor cable is fully inserted in the lid and base.

4 Operation

4.1 Vacuum activation and notes on use

Switch on the VACUSAFE to start the vacuum pump (the switch indicator lamp lights).

Wait a few seconds until the air from the collection bottle is evacuated. To increase or

decrease aspiration speed, turn the knob for vacuum regulation to the right or left,

respectively (see “2.2

Overview of the VACUSAFE” on page 5).

Aspirate liquid by pressing the green button of the VACUBOY hand operator fitted with a

suitable tip. Check the level of liquid in the bottle frequently, especially when working

without level sensor, and make sure that there is enough space left for the liquid that needs

to be aspirated.

To open the bottle, first release the vacuum by opening the venting port on the lid (open

the sealing screw or remove the sealing cap). Alternatively you can aspirate air with the

VACUBOY. When closing the bottle for use, screw the lid on tightly. The seal in the lid

needs to be adequately compressed in order to function. Also make sure the venting port

is closed.

Prevent liquid or foam overflow from the collection bottle into the filter. In case the filter

gets accidentally wetted or soiled, exchange it immediately or otherwise the retention of

further liquid cannot be guaranteed. Note that the hydrophobic filter holds back aqueous

solutions, whereas retention of apolar liquids is limited. To prevent the build-up of foam,

we recommend the use of an anti-foaming agent (e.g. Antifoam A from Sigma).

1) Plug the level sensor cable into its socket at the back of

the instrument and connect it to the bottle lid (models

158300, 158310). Make sure that the sensor pins inside

the lid are dry and unsoiled.

2) Switch on the VACUSAFE. A double beep confirms

correct connection of the level sensor.

3) Press the “C

ALIBRATION” button on the back of the

VACUSAFE base until a short beep is emitted.

Page 9

VACUSAFE – Operating instructions V12 Operation

www.integra-biosciences.com 9

English

WARNING

When working with dangerous substances, you must comply with the

material safety data sheet (MSDS) and the additionally applicable

regulations of trade ass ociati ons, hea lth authorities , supervisory offices, etc.

In addition, when working with hazardous volatile substances or

biohazardous agents, either place the V ACUSAFE inside a biosafety cabinet

or connect the instrument's air outlet (16

) to a safety ventilation by means of

a tube and of a connector (Part No. 158427).

4.2 Use of the level sensor

When the VACUSAFE bottle is full, the level sensor prevents foam or liquid from

overflowing and accidentally soaking filter and instrument. As soon as foam or liquid is

detected, the pump switches off (models 158 300, 158 310) to avoid overfilling of the

bottle. Additionally, an audible alarm is activated and the switch indicator lamp starts

blinking.

It is possible to deactivate the level sensor by simply disconnecting the sensor cable

(confirmed by a double beep).

Instrument, sensor cable and bottle lid constitute an assembly and they must be calibrated

to match one another (see “3.3.4

Connection and calibration of the level sensor” on

page 8). If you have several lids, sensor cables and instruments and swap them, you have

to recalibrate the newly formed assemblies. Depending on the degree of soiling of the

sensor pins inside the lid, it may be necessary to clean them and to calibrate the level

sensor periodically.

Page 10

VACUSAFE – Operating instructions V12 Operation

10 INTEGRA Biosciences AG

English

4.3 Troubleshooting

Problem Probable cause Remedy

Device not

running.

Level sensor has

been activated.

Empty the bottle.

No electrical power. Plug the mains adapter in the power source and in

the device.

Device is switched

off.

Switch on the device (switch indicator lamp must

light).

Aspiration is

very low

and/or pump

never stops

running.

Aspiration speed is

set to minimum.

Turn the knob for vacuum control clockwise to

increase speed.

Leak in the vacuum system.

Close the venting port by closing the sealing screw

or sealing cap. Close the bottle lid tightly.

Check tubing and filter for leaks.

Reduce the residual flow of the VACUBOY hand

operator by closing the screw opposite the operator

button (see the VACUBOY operating instructions).

Liquid overflowed

thereby blocking filter.

Empty the bottle and exchange the filter

Tubing is blocked. Clean or exchange the tubing.

Level sensor activated

erroneously

(bottle is not

full).

Sensor cable is

connected incorrectly.

Fully insert the sensor cable with the correct orientation in the lid and base sockets.

Foam activates the

level sensor.

Use an anti-foaming agent (e.g. Antifoam A from

Sigma)

No or incorrect calibration.

Calibrate following the instructions (see “3.3.4

Connection and calibration of the level sensor” on

page 8).

Soiled sensor pins. Clean pins inside the lid and recalibrate.

Electromagnetic

interferences disturb level sensor.

Eliminate or inactivate the source of electromag-

netic interference.

Page 11

VACUSAFE – Operating instructions V12 Maintenance

www.integra-biosciences.com 11

English

5 Maintenance

5.1 Cleaning

WARNING

Always switch off the VACUSAFE and disconnect it from the mains when

carrying out maintenance work.

Clean the VACUSAFE housing with a lint-free cloth lightly soaked with mild soap solution

in distilled water or with a 70 % solution of isopropanol or ethanol. Never use bleach

(sodium hypochlorite) or other solvents.

It is recommended to change the hydrophobic filter regularly, at least once a year.

Exchange the filter immediately if liquid has entered.

When working with solvents and other hazardous materials always rinse the hand

operator and tubing with water followed by 70% ethanol.

5.2 Autoclaving and chemical sterilization

5.2.1 Autoclaving

All parts contacting the liquid can be autoclaved: waste collection bottle, lid with tube

fittings, silicone tubing and hand operator VACUBOY. When working with biohazardous

material, disinfect the VACUBOY with a 70 % solution of isopropanol or ethanol or a

suitable disinfectant before disassembling for autoclaving. For disassembly please refer

to the operating instructions VACUBOY. Recommendation regarding autoclaving:

polypropylene bottle for at least 60 min, glass bottle and disassembled VACUBOY for at

least 20 min at 121°C.

The bottle lid has to be always unscrewed and kept loosely on the bottle during

autoclaving. The tubing couplings made of PVDF have to be always disconnected during

autoclaving.

Silicone may become brittle after extensive autoclaving. Replace the tubings if they are

damaged.

W

ARNING

It is not recommended to autoclave the VACUBOY regularly as premature

material aging may occur.

The filter and the instrument itself cannot be autoclaved.

5.2.2 Chemical sterilization

Two methods for chemical inactivation of biohazardous agents are commonly used:

• A suitable disinfectant is added to the full collection bottle and left to react for the recommended time. Any disinfectant can be used, provided that it is compatible with the bottle

material (glass or polypropylene).

• The disinfectant is added to the empty bottle so that the aspirated liquid gets sterilized

as it accumulates in the bottle. Use disinfectants that are free of chlorine or other corrosive agents, especially when corrosive vapors are generated and aspirated.

Page 12

VACUSAFE – Operating instructions V12 Technical data

12 INTEGRA Biosciences AG

English

5.3 Equipment disposal

The VACUSAFE device must not be disposed of with unsorted municipal waste.

Dispose the VACUSAFE device in accordance with the laws and regulations in

your area governing disposal of devices.

6 Technical data

6.1 Specifications

6.2 Chemical compatibility

The table below lists VACUSAFE parts that come into contact with the aspirated liquid or

its aerosols and vapors, and rates the compatibility of these parts to a few of the chemicals

commonly used in laboratories. To determine the compatibility of a component to a

chemical not listed in the table, please consult one of the several tables available on the

internet.

Note that the rating refers to soaking in the concentrated chemical; however, more

relevant here is the attenuated effect resulting from indirect contact with the diluted

chemical. It is recommended to test the compatibility of relevant components to a specific

chemical prior to extensive use.

INTEGRA Biosciences AG does not warrant that the information in the table is accurate

or complete and that any material is suitable for any purpose.

Vacuum range -300 to -600 mbar, continuously adjustable

Flow rate Pump: 8 l/min (air); Aspiration: 17 ml/s (liquid, aspiration

pipette)

Dimensions

(H x W x D)

530 x 180 x 320 mm

Weight 3.4 kg

Electricity supply Mains adapter input: 100–240 VAC, 50/60 Hz

Device input: 17–19 VDC, 15 W

Degree of protection IP21

Ambient conditions Operation:

5 to 40°C, max. 80% RH (non-condensing)

Storage:

-10 to 40°C, max. 95% RH (non-condensing)

Page 13

English

www.integra-biosciences.com 13

VACUSAFE – Operating instructions V12 Technical data

Chemical compatibility chart

Compatibility ratings (N/A = info not available):

A = good, no or minor effects (discoloration or slight corrosion).

B = fair, moderate effects (softening, swelling and loss of

strength), not recommended for continuous use.

C = critical, not recommended.

JAVEL (e.g. NaClO)

Ethanol EtOH

Hydrochloric acid

HCl

Sodium hydroxide

NaOH

Acetone

Dimethyl sulfoxide

DMSO

Phenol PhOH

Acetic acid AcOH

Sodium carbonate

Na

2CO3

Parts Materials

VACUBOYPlastic parts POM CABAAABCA

O-rings FPM (Viton) AAACCBAAA

Valve spring Stainless steel B A C B A A A C A

Tubing Silicone A A C C C A C B A

Bottle 4 L Polypropylene AAAAAAAAA

3 L glass AAAAAAAAA

Lid Lid Polypropylene AAAAAAAAA

Lid seal TPE AAAAAAN/AN/AN/A

Quick couplings PVDF A A A C C C A B A

Coupling‘s o-ring FPM (Viton) AAACCBAAA

Level detection pinsStainless steel BACBAAAAA

Tubing Silicone A A C C C A C B A

Y-piece POM CABAAABCA

Filter Membrane PTFE AAAAAAAAA

Housing Polypropylene AAAAAAAAA

VACUSAFE

base

Pump head housing PPS A A C A A A A A N/A

Pump head membraneFPM (Viton) AAACCBAAA

Page 14

VACUSAFE – Operating instructions V12 Accessories and consumables

14 INTEGRA Biosciences AG

English

7 Accessories and consumables

Accessories Part No.

Bottle 4 liters, polypropylene 158370

3 liters, safety coated glass 158420

Lid for 4 L bottle with quick couplings (PVDF) + level detection 158401

with tubing fittings 158372

Lid for 3 L bottle with quick couplings (PVDF) + level detection 158418

4 L bottle and lid comprises part no. 158 370 and 158401 158431

comprises part no. 158370 and 158372 158 432

3 L bottle and lid comprises part no. 158 420 and 158418 158430

Level sensor cable 158403

Bottle handle for carrying polypropylene bottle

(see “2.2

Overview of the VACUSAFE” on page 5)

158625

Bottle stand for 4L polypropylene bottle 158630

Stand for PIPETBOY and VACUBOY 155065

Mains adapter 100 – 240 VAC, 50/60 Hz 158395

Y-connector for connection of second VACUBOY hand operator 158 354

Air outlet connector for connection of tubing to the air outlet of the pump 158427

Page 15

VACUSAFE – Operating instructions V12 Accessories and consumables

www.integra-biosciences.com 15

English

VACUBOY VACUBOY hand operator with:

• 1-channel stainless steel adapter 40 mm

• 1-channel adapter with ejector for disposable tips

(with locking)

• Rubber adapter for Pasteur pipettes

155510

VACUBOY set consists of:

• VACUBOY hand operator

• Stand for hand operator

• 1-channel stainless steel adapter 40 mm

• 1-channel adapter for disposable tips/GripTips

(with locking)

• 1-channel adapter with ejector for disposable tips

(with locking)

• Rubber adapter for Pasteur pipettes

• 8-channel stainless steel adapter 40 mm

• 8-channel adapter with ejector for disposable tips

(with locking)

155500

VACUBOY

aspiration adapters

Rubber adapter for Pasteur pipettes 155 505

1-channel stainless steel adapter 40 mm 155502

1-channel stainless steel adapter 150 mm 155522

1-channel stainless steel adapter 280 mm 155525

1-channel adapter for disposable tips/GripTips

(with locking)

155504

1-channel adapter for disposable tips/GripTips (pack of 5) 159 023

1-channel adapter with ejector for disposable tips

(with locking)

155526

1-channel adapter with ejector for disposable tips 159026

1-channel adapter with ejector for GripTips 159027

4-channel stainless steel adapter 40 mm 155524

8-channel stainless steel adapter 40 mm 155503

8-channel adapter with ejector for disposable tips

(with locking)

155520

8-channel adapter with ejector for disposable tips 159024

8-channel adapter with ejector for GripTips 159025

Stand for VACUBOY hand operator 155501

Accessories Part No.

Page 16

VACUSAFE – Operating instructions V12 Accessories and consumables

16 INTEGRA Biosciences AG

English

Consumables Part No.

Tubing for connection of hand operator to bottle, 1.8 m, silicone 158332

for connection of base to bottle, 0.7 m, silicone, blue 158331

Filter for protection of vacuum source, 0.45 m, hydrophobic 158015

Tubing set + filter comprises part no. 158 331, 158 332, 158 015 158342

Quick tubing couplings Material Part No.

Coupling plug

(linked to tubing)

self-closing, with barbed fitting, white/blue PVDF 158416

self-closing, with barbed fitting, white/red PVDF 158417

Coupling socket

(mounted on lid)

self-closing, with O-ring, white/blue PVDF 158423

self-closing, with O-ring, white/red PVDF 158424

Loading...

Loading...