Page 1

RDA-7.1

SERVICE MANUAL

Ref. No. 3804

SERVICE MANUAL

SEVEN CHANNEL AMPLIFIER

MODEL RDA-7.1

Nov, 2004

120 V AC, 60HzADD

230-240 V AC, 50HzAPP

APA

230-240 V AC, 50Hz

220-230 V AC, 50/60HzAGT

AGK

220-230 V AC, 50/60Hz

SAFETY-RELATED COMPONENT

WARNING!!

COMPONENTS IDENTIFIED BY MARK ON THE

SCHEMATIC DIAGRAM AND IN THE PARTS LIST ARE

CRITICAL FOR RISK OF FIRE AND ELECTRIC SHOCK.

REPLACE THESE COMPONENTS WITH ONKYO

PARTS WHOSE PART NUMBERS APPEAR AS SHOWN

IN THIS MANUAL.

MAKE LEAKAGE-CURRENT OR RESISTANCE

MEASUREMENTS TO DETERMINE THAT EXPOSED

PARTS ARE ACCEPTABLY INSULATED FROM THE

SUPPLY CIRCUIT BEFORE RETURNING THE

APPLIANCE TO THE CUSTOMER.

Page 2

SPECIFICATIONS

AMPLIFIER SECTION

Number of channels :

Power :

Frequency response at -3 dB :

Input Impedance :

Input signal for max output power :

Input Sensitivity (Unbalanced) :

Input Sensitivity (Balanced) :

THD :

Damping Factor :

Power consumption

USA, Canada and some Asian model :

Other models :

Rated Speaker Impedance :

RDA-7.1

7

150 watts per channel min. RMS at 8 ohms, 2 channels

driven from 20 Hz to 20 kHz with no more than 0.1 % total

harmonic distortion (FTC).

300 watts per channel min. RMS at 4 ohms, 2 channels

driven at 1 kHz with no more than 0.1 % total harmonic

distortion (FTC).

350 W (EIAJ, 4 ohm, 1 kHz, 10 %)

300 W (DIN, 4 ohm, 1 kHz, 0.7 %)

3.5 Hz - 250 kHz

47 kohm each phase

1.2 V

100 mVrms

200 mV

0.03 % (20 Hz to 20 kHz)

40 at 8 ohm

15 A

10 A

4 ohms

GENERAL

Power Supply :

Dimensions (W x H x D) :

Weight :

Specifications and features are subject to change without notice.

Power supply and voltage vary depending on the area in which the unit is purchased.

AC 120 V, 60 Hz

AC 230 V, 50 Hz

AC 220 V, 50/60 Hz

450 x 197 x 602 mm

17-11/16" x 7-3/4" x 23-11/16"

52.5 kg, 115.7 lbs.

Page 3

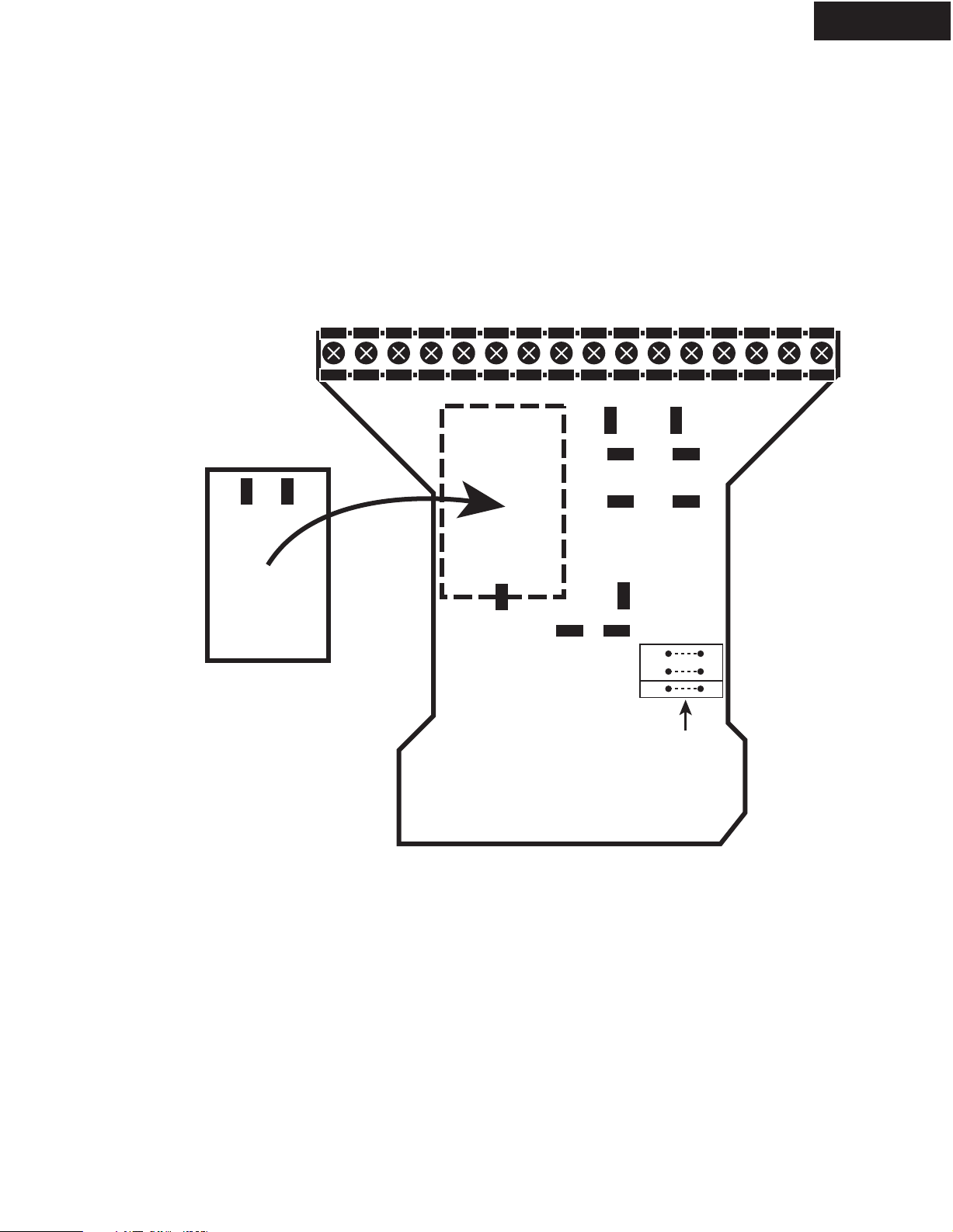

SERVICE PROCEDURE-1

PRIMARY CONNECTIONS FOR DIFFERENT VOLTAGES

AC Board Jumpers

For voltages in the 100V - 120V range, install the two jumpers marked L.

For voltages in the 200V - 240V range, install the single jumper marked H.

Main Transformer Jumpers

The following connections should be made for different line voltages.

RDA-7.1

100V :

K1-3 to TB1-4

P7 to TB1-3

P2 to TB1-2

K2-3 to TB1-12

P8 to TB1-11

P3 to TB1-10

110V :

K1-3 to TB1-6

P7 to TB1-5

P2 to TB1-2

K2-3 to TB1-14

P8 to TB1-13

P3 to TB1-10

120V :

K1-3 to TB1-8

P7 to TB1-7

P2 to TB1-2

K2-3 to TB1-16

P8 to TB1-15

P3 to TB1-10

200V :

K1-3 to TB1-4

TB1-2 to TB1-3

K2-3 to TB1-12

TB1-10 to TB1-11

220V :

K1-3 to TB1-6

TB1-2 to TB1-5

K2-3 to TB1-14

TB1-10 to TB1-13

230V :

K1-3 to TB1-6

TB1-2 to TB1-7

K2-3 to TB1-14

TB1-10 to TB1-15

240V :

K1-3 to TB1-8

TB1-2 to TB1-7

K2-3 to TB1-16

TB1-10 to TB1-15

Page 4

SERVICE PROCEDURE-2

PRIMARY CONNECTIONS FOR DIFFERENT VOLTAGES (Continued)

TB1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

RDA-7.1

P2

P3

Inrush Current Limiter Board

(RDA-7-030-A)

P7

P8

K1-3 K2-3

P4

P9P1P10

AC Board (RDA-7-020-B)

Low

Jumpers

K2-4K1-4

L

L

HHigh

Page 5

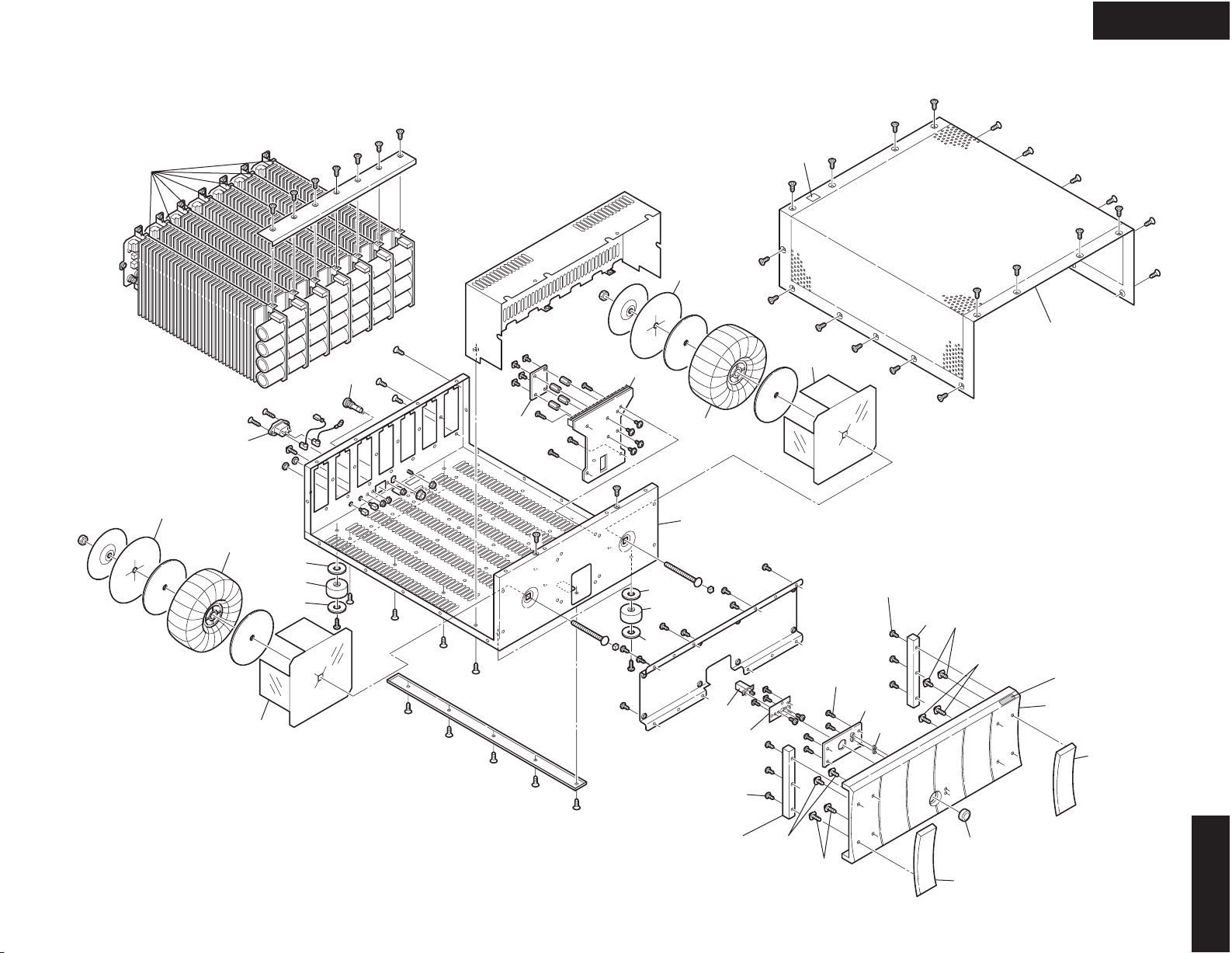

EXPLODED VIEWS-1

RDA-7.1

OVERALL

UN01

A35

B06

B03

A34

A52

A50

A51

B07

UN03

UN02

A52

A50

A51

A35

B02

B08

B05

B04

A635

A34

A22

x 4 pcs.

A21

B01

<Note>

A01 (Front panel ass'y) = A02 --- A08

A06

x 3 pcs.

A20

A05

A07

(10mm)

x 2 pcs.

A08

(14mm)

x 2 pcs.

A10

A02

A04

A06

x 3 pcs.

A05

A07

(10mm)

x 2 pcs.

A08

(14mm)

x 2 pcs.

A23

A03

RDA-7.1

Page 6

EXPLODED VIEWS-2

AMPLIFIER MODULE

RDA-7.1

B11

(Red)

A61

(Top)

B12

(Black)

A65

A62

(Bottom)

A60

(Base)

RDA-7.1

Page 7

EXPLODED VIEWS-3

SCREWS

RDA-7.1

A132 A131

A132 A131

A130

Cut

A132 A131

RDA-7.1

Page 8

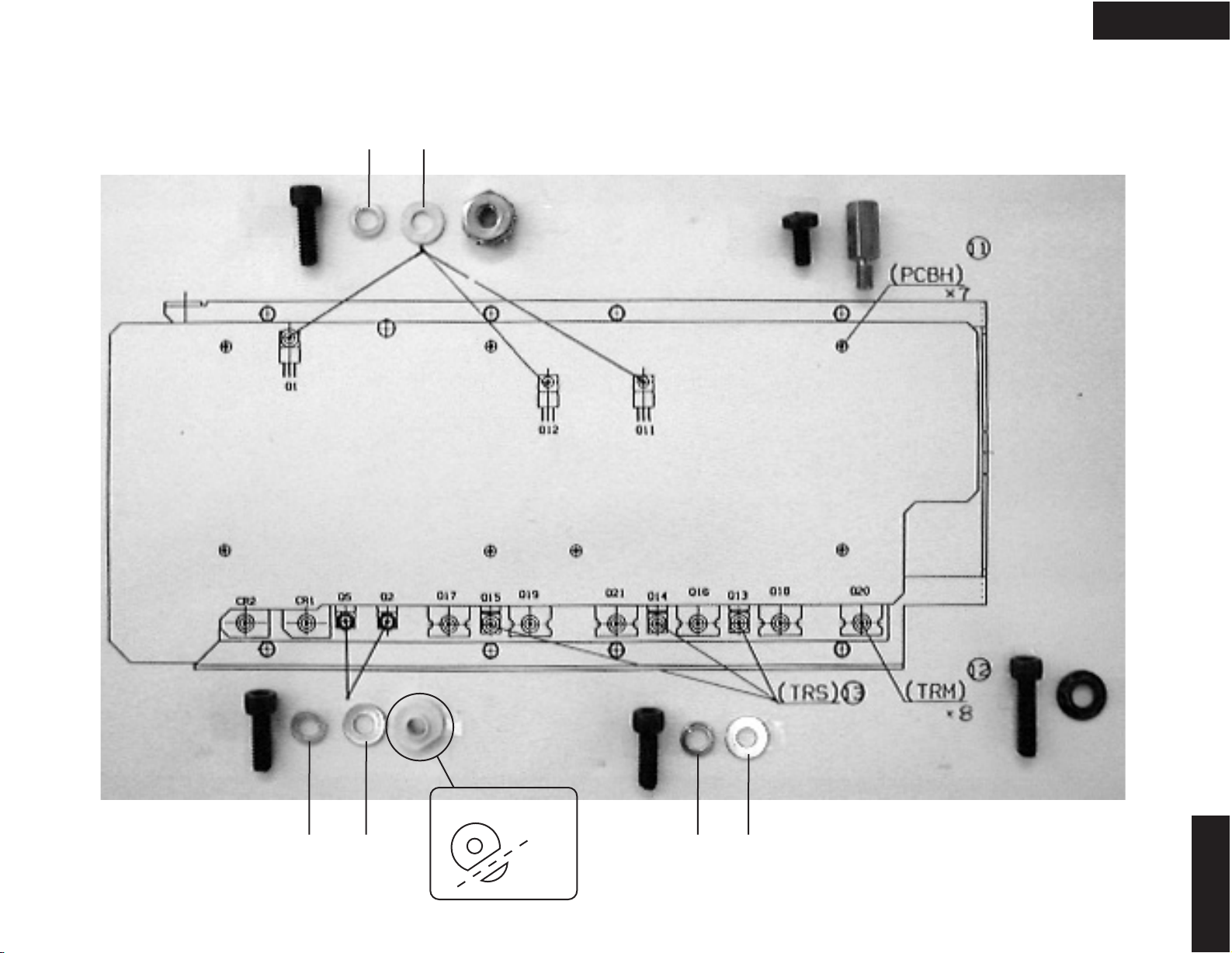

EXPLODED VIEWS-4

SCREWS

RDA-7.1

14

GROU

Page 9

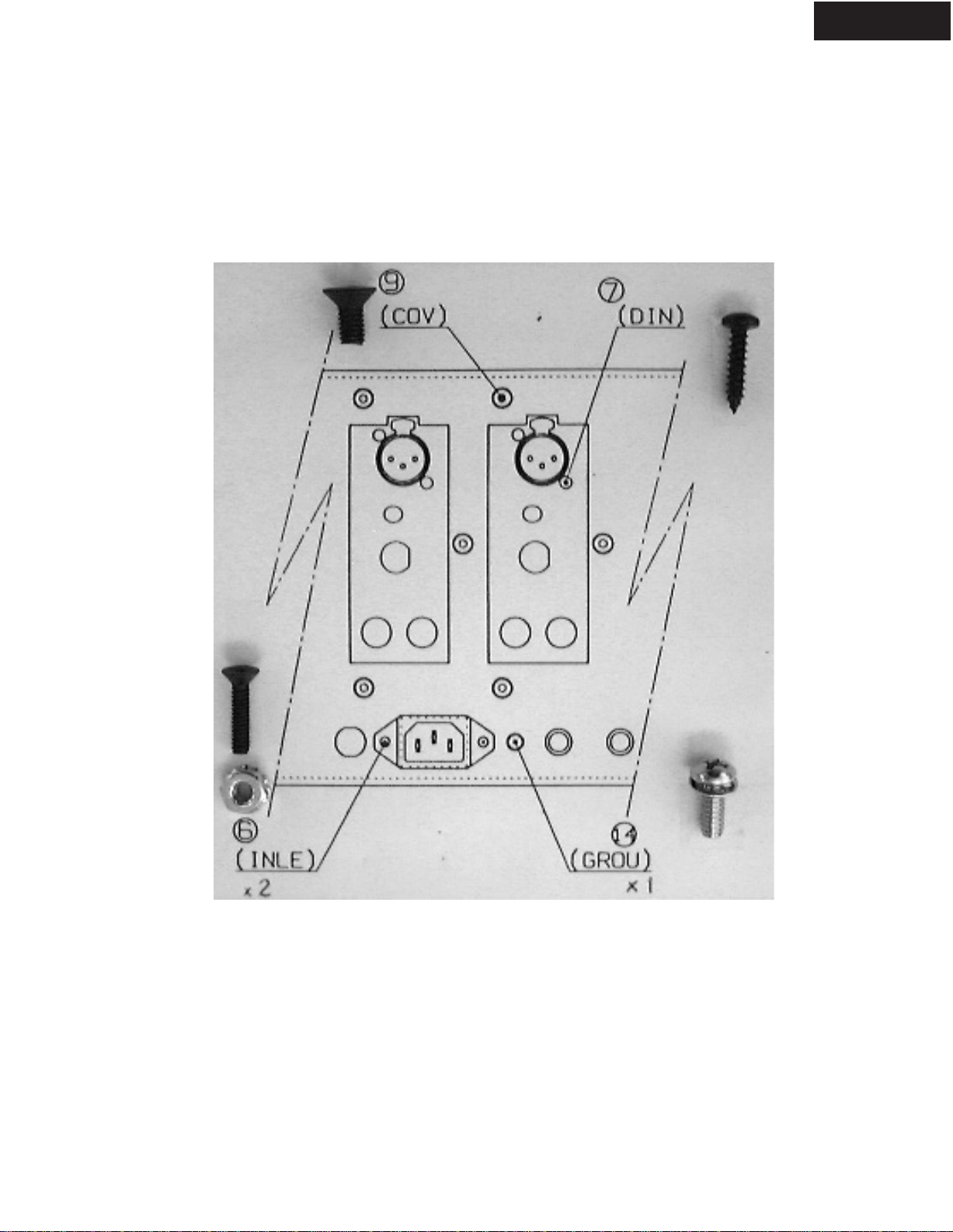

EXPLODED VIEWS-5

SCREWS

RDA-7.1

Page 10

RDA-7.1

A

SCHEMATIC DIAGRAMS-1

POWER SUPPLY

1

2

BCD

3

4

5

Page 11

RDA-7.1

A

SCHEMATIC DIAGRAMS-2

DRIVER CIRCUIT

1

2

BCD

3

4

C13 / C14

ROB C (For audio)

C13 / C14

5

C13a / C14a

C17 / C20

ROB C (For audio)

C17 / C20 C17a / C20a

Page 12

RDA-7.1

A

SCHEMATIC DIAGRAMS-3

OUTPUT STAGE AND PROTECTION

1

2

BCD

3

4

5

Page 13

RDA-7.1

A

SCHEMATIC DIAGRAMS-4

PROTECTION

1

2

BCD

3

4

5

Page 14

RDA-7.1

A

SCHEMATIC DIAGRAMS-5

AC BOARD

1

2

BCD

3

4

5

Page 15

RDA-7.1

A

SCHEMATIC DIAGRAMS-6

PROTECTION WIRING

1

2

BCD

3

4

5

Page 16

PRINTED CIRCUIT BOARD VIEWS-1

AMPLIFIER PC BOARD

RDA-7.1

A

1

2

3

4

5

BCDEFGH

AMPLIFIER PC BOARD (RDA-7-010-F)UN01

Side-A (Top)

Page 17

RDA-7.1

Page 18

RDA-7.1

PRINTED CIRCUIT BOARD VIEWS-1

AMPLIFIER PC BOARD

A

1

2

3

4

5

BCDEFGH

AMPLIFIER PC BOARD (RDA-7-010-F)UN01

Side-A (Top)

Page 19

PRINTED CIRCUIT BOARD VIEWS-2

AMPLIFIER PC BOARD

RDA-7.1

A

1

2

3

4

5

BCDEFGH

AMPLIFIER PC BOARD (RDA-7-010-F)UN01

Side-B (Bottom)

Page 20

RDA-7.1

Page 21

RDA-7.1

PRINTED CIRCUIT BOARD VIEWS-2

AMPLIFIER PC BOARD

A

1

2

3

4

5

BCDEFGH

AMPLIFIER PC BOARD (RDA-7-010-F)UN01

Side-B (Bottom)

Page 22

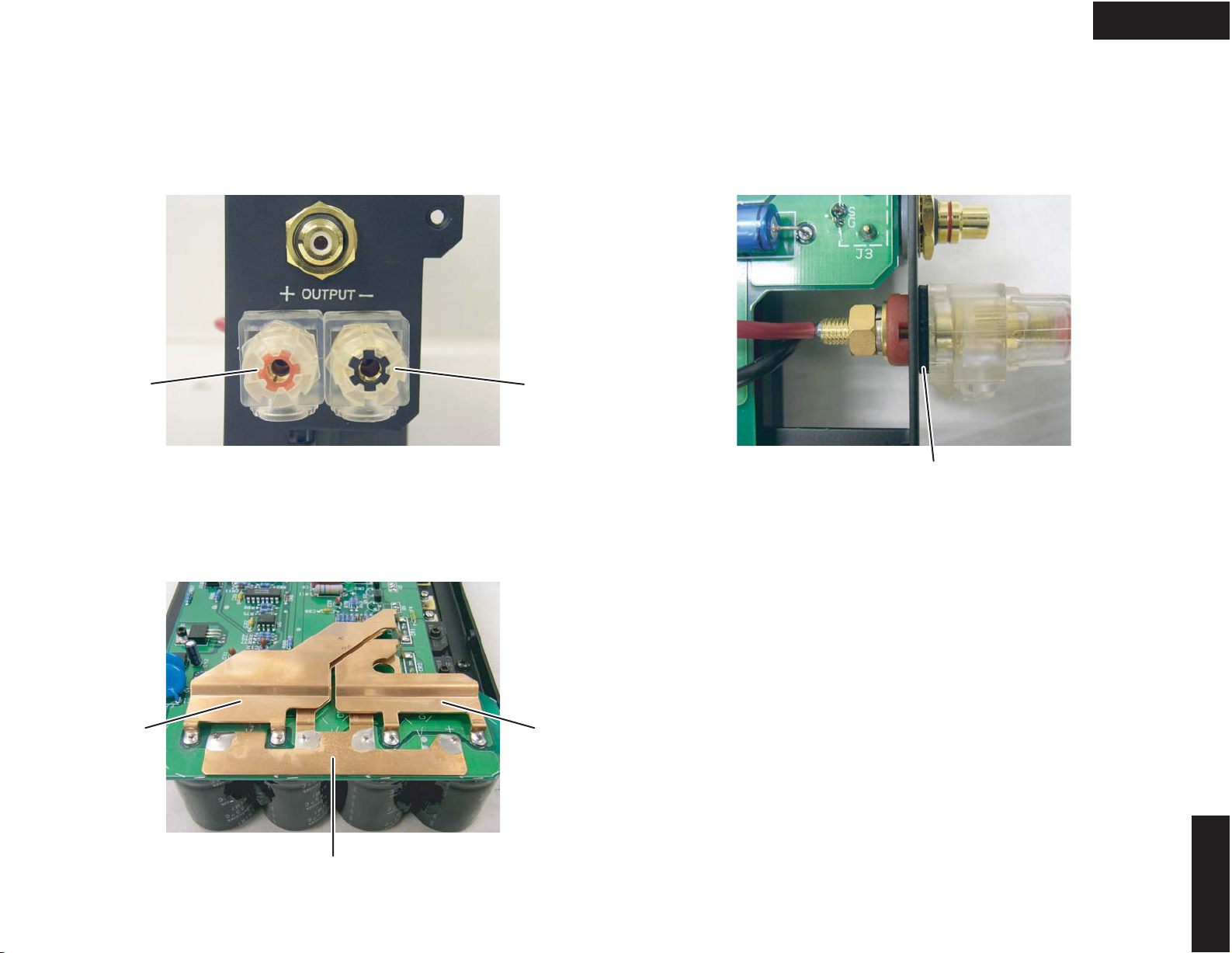

ADJUSTMENT PROCEDURE-1

BIAS & DC Offset Adjustment

Connect the assembled channel to the power transformer.

1.

Connect the power cord into an AC wall outlet.

2.

Turn ON the unit. After about 3 seconds the two green LED's should turn ON.

3.

Measure the following voltages and make sure they are within the specifications.

RDA-7.1

C7 (+)

C9 (-)

L1

Connect the DC voltmeter to the test points TP1 (-) and TP2 (+) and adjust the voltage to 4 mV using the R46 BIAS

4.

adjustment trimming resistor.

Allow the channel to warm up for 30 minutes, adjusting the bias currents every 10 minutes.

5.

Measure the output DC voltage and adjust it as close to zero as possible using the R24 trimming resistor.

6.

: 70 V +/- 3 V

: -70 V +/- 3 V

: 0 V +/- 0.1 V

Main Chassis Check

1.

Assemble the chassis / power supply.

2.

Connect the power cord into an AC wall outlet.

3.

Turn ON the unit. The blue ON LED should come ON.

4.

Turn OFF the unit and plug a remote control plug into the Remote IN jack.

5.

Turn ON the unit. The Red Standby LED should be ON.

6.

Apply 12V to the remote control plug. The unit should turn ON, the blue LED should be ON.

7.

Measure the secondary voltages on all power cables going to the channels. Each secondary should read 50 VAC

+/- 2 VAC.

Page 23

ADJUSTMENT PROCEDURE-2

Final Assembly Check

Check the screw which is the fixation of AMPLIFIER MODULE

when the electric conductivity between 1 and 2 is ruined.

RDA-7.1

Rear panel

FUSE

1

AC INLET

12V TRIGGER

IN OUT

2

Page 24

T

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

EXPLODED

1/4 PAGE

RDA-7.1

<Note>

Parts marked by "NSP" are generally unavailable because

they are not in our Master Spare Parts List.

NOTE : THE COMPONENTS IDENTIFIED BY THE MARK

! ARE CRITICAL FOR RISK OF FIRE AND

ELECTRIC SHOCK. REPLACE ONLY WITH PART

NUMBER SPECIFIED.

EXPLODED VIEWS PARTS LIS

REF. NO. PART NAME DESCRIPTION Q'TY PART NO. (SN) MARK

A01 F PANEL ASS'Y AS 1 27212607A

A02 F PANEL --- (1) 27212608A

A03 HANDLE (L) (1) 28158002

A04 HANDLE (R) (1) 28158004

A05 END CAP --- (2) 28125372

A06 SCREW 3P+6FN(BC) (6) 82143006

A07 SCREW 4TTC+10C(BC) (4) 830440109

A08 SCREW 4TTC+14C(BC) (4) 830440149

A10 BADGE (RESEARCH) 1 28135293

A20 FACET (1) 2 28198908

A21 GUIDE (POW) 1 27268013

A22 SCREW 3P+6FN(BC) 4 82143006

A23 KNOB (POW)AS 1 28325734

A34 SHLD PLT (PT) 2 27150462

A35 SHLD PLT --- 2 27150463

A50 LEG --- 4 27175402

A51 CUSHION --- 4 28141560

A52 CUSHION (LEG) 4 28141590

A60 RETAINER (BASE) 7 27141900

A61 RETAINER (T) 7 27141901

A62 RETAINER (B) 7 27141902

A65 RETAINER (S) 7 27141906

A635 LABEL LABEL(FLASH) 1 29360778

A130 BUSH (TOSHIBA AC331) 2 28170075

A131 WASHER W3 x 8F(BC) 8 87643008

A132 SP WASHER SW-3(SP-WASHER) 8 871130

B01 TOP COVER --- 1 14-ONK-0006

B02 TRANSFORMER 4ch 1 56-0041

B03 TRANSFORMER 3ch 1 56-0042

B04 SWITCH PLATE --- 1 14-ONK-0011

B05 POWER SWITCH TV-5, UL, VDE, SEMKO, 5A 1 51-0024

B06 AC INLET (UL APPROVED) 1 21-0091

B07 FUSE HOLDER (UL/CSA APPROVED) 1 43-0010

B08 CHASSIS (ADD, APP, APA, AGT, AGK, AJJ) 1 --- NSP

B11 SP TERMINAL (RED) 7 --- NSP

B12 SP TERMINAL (BLACK) 7 --- NSP

UN01 AMPLIFIER PC BOARD (RDA-7-010-F) 7 --- NSP

UN02 AC BOARD (RDA-7-020-B) 1 70-ONK-0002

UN03

INRUSH CURRENT LIMITER BOARD

(RDA-7-030-A) 1 --- NSP

!

!

!

!

!

Page 25

RDA-7.1

T

PRINTED CIRCUIT BOARD PARTS LIS

UN01 AMPLIFIER PC BOARD (RDA-7-010-F)

CIRCUIT NO. PART NAME DESCRIPTION Q'TY PART NO. (SN) MARK

PCB01

U1 IC LP2951CN (Voltage Regulator) 1 48-0097

PCB01

U2 IC LM317L (Voltage Regulator) 1 48-0098

PCB01

U3 IC LM317L (Voltage Regulator) 1 48-0098

PCB01

U4 IC LM385Z (Voltage Reference) 1 48-0099

PCB01

U5 PHT CP PS2502-1 1 24120092

PCB01

U6 IC TLC372CP (Dual Comparator) 1 48-0101

PCB01

U7 IC CD4013BCN (Dual D Flip-Flop) 1 48-0102

PCB01

U8 IC CD4025BCN (Triple 3 Input NOR) 1 48-0103

PCB01

U9 IC TLC555 8PIN DIP 1 48-0104

PCB01

U10 PHT CP PS2502-1 1 24120092

PCB01

Q1 TR MOS FET IRF620 or IRF621 1 48-0085

PCB01

Q2 TR IRF540 1 48-0087

PCB01

Q3 TR 2N5401 1 48-0088

PCB01

Q4 TR 2N5551 1 48-0089

PCB01

Q5 TR IRF5210 or IRF9540N 1 48-0086

PCB01

Q6 TR 2SC3381 1 48-0041

PCB01

Q7 TR 2SC3381 1 48-0041

PCB01

Q8 TR 2SA1349 1 48-0043

PCB01

Q9 TR 2N5550 1 48-0090

PCB01

Q10 TR 2N5400 1 48-0091

PCB01

Q11 TR 2SA1837 1 48-0092

PCB01

Q12 TR 2SC4793 1 48-0093

PCB01

Q13 TR MJF15030 1 48-0094

PCB01

Q14 TR MJF15030 1 48-0094

PCB01

Q15 TR MJF15031 1 48-0095

PCB01

Q16 TR 2SC5200-O 1 2202823

PCB01

Q17 TR 2SA1943-O 1 2202813

PCB01

Q18 TR 2SC5200-O 1 2202823

PCB01

Q19 TR 2SA1943-O 1 2202813

PCB01

Q20 TR 2SC5200-O 1 2202823

PCB01

Q21 TR 2SA1943-O 1 2202813

PCB01

Q23 TR MPS2222A 1 48-0096

PCB01

Q24 TR MPS2222A 1 48-0096

PCB01

CR1 DIODE RECTIFIER BRIDGE 10A 400V 1 48-0039

PCB01

CR2 DIODE RECTIFIER BRIDGE 10A 400V 1 48-0039

PCB01

CR6 DIODE SWITCHING 1N4150 1 48-0025

PCB01

CR7 DIODE SWITCHING 1N4150 1 48-0025

PCB01

CR8 DIODE SWITCHING 1N4150 1 48-0025

PCB01

CR10 DIODE SWITCHING 1N4150 1 48-0025

PCB01

CR11 DIODE SWITCHING 1N4150 1 48-0025

PCB01

CR12 DIODE SWITCHING 1N4150 1 48-0025

PCB01

CR13 DIODE DIP BRIDGE 1A 400V 4PIN 1 48-0011

PCB01

VR1 DIODE ZENER 30V 400mW 1N5256B 1 48-0015

PCB01

VR2 DIODE ZENER 24V 400mW 1N5252B 1 48-0036

PCB01

VR3 DIODE ZENER 24V 400mW 1N5252B 1 48-0036

2/4 PAGE

Page 26

PCB01

T

VR4 DIODE ZENER 24V 400mW 1N5252B 1 48-0036

PCB01

VR5 DIODE ZENER 24V 400mW 1N5252B 1 48-0036

PCB01

VR6 DIODE ZENER 12V 400mW 1N5242B 1 48-0084

PCB01

VR7 DIODE ZENER 12V 400mW 1N5242B 1 48-0084

PCB01

VR8 DIODE ZENER 24V 400mW 1N5252B 1 48-0036

PCB01

C3 ELECT C CE69W80V-10000M 1 3504395

PCB01

C4 ELECT C CE69W80V-10000M 1 3504395

PCB01

C5 ELECT C CE69W80V-10000M 1 3504395

PCB01

C6 ELECT C CE69W80V-10000M 1 3504395

PCB01

C7 ELECT C 100uF 100V 1 15-0104

PCB01

C9 ELECT C 100uF 100V 1 15-0104

PCB01

C13, C13a ROB C CE04W35V-100M(ROB) (For audio) 2 395861017

PCB01

C14, C14a ROB C CE04W35V-100M(ROB) (For audio) 2 395861017

PCB01

C17, C17a ROB C CE04W50V-22M(ROB) (For audio) 2 395882207

PCB01

C20, C20a ROB C CE04W50V-22M(ROB) (For audio) 2 395882207

PCB01

C40 ELECT C 100uF 100V 1 15-0104

PCB01

R24 TRIM R TRIMPOT 50 kohm (503) 1 46-0019

PCB01

R46 TRIM R TRIMPOT 25 Turn 500 ohm (501) 1 46-0020

PCB01

F3 FUSE LITTLE FUSE R251 015 F837-ND 1 43-0042

PCB01

F4 FUSE LITTLE FUSE R251 015 F837-ND 1 43-0042

PCB01

S1 SW NKKM2022S2A2G30 1 51-0035

PCB01

J2 JACK XLR NC3FAHL-2 1 21-0126

PCB01

J3 JACK RCA 1 21-0110

3/4 PAGE

UN02 AC BOARD (RDA-7-020-B)

CIRCUIT NO. PART NAME DESCRIPTION Q'TY PART NO. (SN) MARK

PCB02

U1 IC TLC555 8PIN DIP 1 48-0104

PCB02

Q1 TR MPS2222A 1 48-0096

PCB02

Q2 TR MPS2222A 1 48-0096

PCB02

CR1 DIODE DIP BRIDGE 1A 400V 4PIN 1 48-0011

PCB02

CR2 DIODE SWITCHING 1N4150 1 48-0025

PCB02

CR3 DIODE SWITCHING 1N4150 1 48-0025

PCB02

CR4 LED SEL2E10C (BLUE) 1 225374

PCB02

F2 FUSE LITTLE FUSE R251 001 F826-ND 1 43-0043

PCB02

T1 TRANSFORMER MICROTRAN MT3101 1 56-0168

PCB02

K1 RELAY 821-W-1A-C 12V DC 1 51-0009

PCB02

K2 RELAY 821-W-1A-C 12V DC 1 51-0009

RDA-7.1

PACKING PROCEDURE PARTS LIS

REF. NO. PART NAME DESCRIPTION Q'TY PART NO. (SN) MARK

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

01 INNER CARTON RDA-7.1 1 34-ONK-0001

02 PAD L & R 1 --- NSP

03 POLY BAG --- 1 34-0010

04 WARNING LABEL --- 1 --- NSP

05 LABEL (PE-LD) 1 29361573

06 TAPE (SEROHAN) NITTO NO.29 (1) 29110149

07 POLY BAG 350 x 250 2 29100097-1A

08 INS MANUAL E(RDA7.1) 1 29343637A <ADD>

08 INS MANUAL E(RDA7.1) 1 29343637A <APP>

!

!

Page 27

4/4 PAGE

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

PACKING

08 INS MANUAL E(RDA7.1) 1 29343637A <APA>

08 INS MANUAL E(RDA7.1) 1 29343637A <AGT>

08 INS MANUAL E(RDA7.1) 1 29343637A <AGK>

09 INS MANUAL U6(RDA-7.1) 1 29343638A <APP>

10 INS MANUAL T(RDA-7.1) 1 29343639A <AGT>

11 WRNTY CARD (RESEARCH) 1 29365091A <ADD>

12 AC CORD --- 1 --- NSP

13 PLUG CORD 3.5-MINI PLUG (RI) 1 2010200

14 OUTER CARTON RDA-7.1 1 34-ONK-0002

15 UPC LABEL --- (1) 29363591 <ADD>

15 EAN LABEL --- (1) 29363590 <APP>

15 EAN LABEL --- (1) 29363590 <APA>

15 EAN LABEL --- (1) 29363590 <AGT>

15 EAN LABEL --- (1) 29363590 <AGK>

16 PP TAPE W50 (1) 29110071 or

16 PP TAPE W48 OPP TAPE (1) 29110148 or

16 PP TAPE NITTO 3703 SUPER W50L100 (1) 29110176

17 DESTINATION LABEL --- (2) --- NSP

18 INST SHEET E(RDA-7.1) 1 29355513

Page 28

PACKING PROCEDURE-1

INNER CARTON

06

02

03

RDA-7.1

02

05

04

FRONT SIDE

01

Inner carton

08

18

09

11

10

12

Inner carton

13

07

07

06

06

Page 29

PACKING PROCEDURE-2

RDA-7.1

OUTER CARTON

15

RDA-7.1

R E S E A R C H

RDA-7.1

16

R E S E A

C H

R

RDA-7.1

Inner carton

15

RDA-7.1

14

Outer carton

16

RDA-7.1

RDA-7.1

17

16

Loading...

Loading...