Page 1

O

X

INFORMA

TION IS POWER

PRO-VISION

Temperature controller

User’s Manual

Current conditions

Set Point

Minim um ventilation

On/Off Settings

Inlets/Vents

Main Menu

Start flock / Egg

Light Programs

Alarms

History

Set-u p

M 890-00515 rev.07

MAIN

MENU

BACK

B

BOX

INFORMATION IS POWER

1

2

3

4

5

6

ENTER

360

DEL

7

8

9

+/-

0

AM/PM

REV.09

Page 2

PRO-VISION

WARNINGS

The warranty can be void if this product is used in a manner

not specified by the manufacturer.

Every effort has been made to ensure that this manual is

complete, accurate and up-to-date. The information contained in it is however subject to change without notice

due to further developments.

2

PRO-VISION rev.07

Page 3

PRO-VISION

TABLE OF CONTENTS

1. INTRODUCTION .................................................................................. 6

1.1. Precautions ................................................................................................. 6

1.2. Symbols of the Manual ................................................................................. 6

1.3. Controller’s Overview ................................................................................... 6

1.4. Main Features .............................................................................................. 7

2. MOUNTING INSTRUCTIONS ................................................................. 7

2.1. Installing the Controller on the Wall ................................................................ 7

2.2. Connections ................................................................................................ 7

2.2.1. Main Wiring ...........................................................................................7

2.2.2. Alarm Connection ...................................................................................8

2.2.3. Sensor Inputs .........................................................................................8

2.2.4. 0-10V Output Connection ........................................................................8

3. USER INTERFACE ................................................................................ 8

3.1. Location of the Controls ................................................................................ 8

3.2. Adjusting a Parameter ................................................................................... 8

4. INSTALLATION SETUP ......................................................................... 9

4.1. Setting the Time & Date ................................................................................ 9

4.2. Password ................................................................................................... 9

4.2.1. Entering a Password ...............................................................................9

4.2.2. Changing / Retrieving a Password .............................................................9

4.3. Controller Programs ................................................................................... 10

4.4. Set-up Menu .............................................................................................. 10

4.5. Sensor Assignment ..................................................................................... 14

4.5.1. Assigning the Sensors ...........................................................................14

4.5.2. Assigning the Digital Inputs ...................................................................14

4.5.3. Selecting the Attic Sensor .....................................................................15

4.5.4. Egg Room Sensors ................................................................................15

4.5.5. Main Breaker Sensor .............................................................................15

4.6. Calibrating the Inputs .................................................................................. 15

4.7. Relays ....................................................................................................... 16

4.7.1. Relay Assignment .................................................................................16

4.7.2. Relays with Current Sensors ..................................................................16

4.8. Non-Brood Zones & Clean Mode ................................................................... 17

4.9. Test Mode ................................................................................................. 18

4.10. Version ..................................................................................................... 18

5. SET POINTS .......................................................................................19

5.1. Temperature & RH Set Points ...................................................................... 19

5.2. Set Point Ramp .......................................................................................... 19

6. VENTILATION & COOLING ..................................................................20

6.1. Overview of the Ventilation Concepts ........................................................... 20

6.2. Minimum Ventilation .................................................................................. 21

6.2.1. Minimum Ventilation Timer ....................................................................21

6.2.2. Min Ventilation Timer Ramp ...................................................................22

PRO-VISION rev.07

3

Page 4

PRO-VISION

6.2.3. Minimum Ventilation Fans ......................................................................22

6.2.3.1. Fan Selection ...............................................................................22

6.2.3.2. Stir Fans in Minimum Ventilation .....................................................22

6.2.3.3. Fan Cycling ..................................................................................23

6.2.4. Air Intake in Min Ventilation ...................................................................23

6.3. Lateral Ventilation ...................................................................................... 25

6.3.1. Lateral Ventilation Fans ........................................................................25

6.3.2. Attic & Sidewall Vents based on Temperature ..........................................26

6.3.3. Attic & Sidewall Vents based on Static Pressure ......................................27

6.3.3.1. Compensation on Pressure Set Points ..............................................27

6.3.3.2. Settings .......................................................................................28

6.4. Natural Ventilation ...................................................................................... 29

6.5. Tunnel Ventilation ...................................................................................... 30

6.5.1. Principle of Operation ............................................................................30

6.5.2. Tunnel Ventilation in Standby .................................................................30

6.5.3. Tunnel Fans .........................................................................................31

6.5.4. Tunnel Inlets ........................................................................................32

6.5.4.1. Temperature-based Tunnel Inlet .....................................................32

6.5.4.2. Pressure-based Tunnel Inlets .........................................................33

6.6. Stir Fans ................................................................................................... 34

6.7. Cooling Output .......................................................................................... 35

6.8. Fogger Output ........................................................................................... 36

7. HEATING ...........................................................................................37

8. LIGHTS .............................................................................................38

8.1. Principle of Operation .................................................................................. 38

8.2. Settings .................................................................................................... 39

8.2.1. Light Program Settings ..........................................................................39

8.2.2. Light Peak Settings ...............................................................................39

9. TIME CLOCKS ..................................................................................40

9.1. Regular Time Clocks ................................................................................... 40

9.2. Time Clocks in a Breeder Facility .................................................................. 41

10. WATER LINE FLUSH ...........................................................................42

11. EGG ROOM OUTPUTS ........................................................................43

12. RELATIVE HUMIDITY (RH) COMPENSATION ..........................................44

12.1. High RH Comp.on the Min Vent. Timer ......................................................... 44

12.2. High RH Comp. with Heaters in Min Vent. ..................................................... 44

12.3. RH Comp. with Cooling & Foggers ............................................................... 45

4

PRO-VISION rev.07

Page 5

PRO-VISION

13. ALARMS ...........................................................................................46

13.1. Alarm Log ................................................................................................. 46

13.2. Temperature Alarms ................................................................................... 46

13.2.1. High/Low Temperature Alarms ...............................................................46

13.2.2. Temperature Alarms in Clean Mode ........................................................46

13.2.3. Outdoor Temperature Compensation .......................................................47

13.2.4. Temperature Alarm Settings ...................................................................47

13.2.5. Critical Temperature Ramp .....................................................................48

13.2.6. Static Pressure Alarms ..........................................................................48

13.2.7. Water Spill Alarms ................................................................................49

13.2.8. Feeder Alarms ......................................................................................49

13.2.9. Amperage Draw Alarms .......................................................................50

14. MONITORING FUNCTIONS ..................................................................51

14.1. Current Conditions ..................................................................................... 51

14.1.1. Current Condition Screen Saver ..............................................................51

14.1.2. Current Input/Output Status ...................................................................51

14.2. History Menus ........................................................................................... 52

14.3. Animal Age & Count ................................................................................... 52

14.4. Egg Count ................................................................................................. 53

14.5. Operation Costs & Current Consumption ....................................................... 53

15. UPDATE & BACKUP ............................................................................53

16. DIAGNOSTIC .....................................................................................54

17. TECHNICAL SPECIFICATIONS ..............................................................55

18. INDEX ...............................................................................................56

PRO-VISION rev.07

5

Page 6

PRO-VISION

1. INTRODUCTION

1.1. Precautions

WARNING: Read and save these instructions!

Safety may be jeopardized if the equipment is

used in a manner not specified by the manufacturer. Carefully read and keep the following

instructions for future reference.

We strongly recommend installing supplementary natural ventilation as well as a backup

thermostat on at least one cooling stage.

Although fuses at the input and outputs of

the controller protect its circuits in case of

an overload or over-voltage, we recommend

installing an additional protection device on

the controller’s supply circuit.

The room temperature where the controller

is located must always remain between 32°F

and 104°F (0°C to 40°C). Indoor use only!

To avoid exposing the controller to harmful

gases or excessive humidity, it is preferable

to install it in a corridor.

If the equipment is used in a manner not

specified by the manufacturer, the protection provided by the equipment may be

impaired.

1.2. Symbols of the Manual

Warning. Read the following text

carefully; it contains important

information which, if ignored, may

cause the controller to operate

improperly.

High Voltage. Hazard of electrical

shock. Read the message and follow

the instructions carefully.

Pay attention. The following text

contains very useful information.

Press on the proper menu selector.

Press the “Main Menu” push-button.

Both direct and alternating current

(AC/DC).

Direct current (DC).

Alternating current (AC).

Earth Ground Terminal

Primarily used for functional earth

terminals which are generally associated with test and measurement

circuits. These terminals are not

for safety earthing purposes but

provide an earth reference point.

1.3. Controller’s Overview

The PRO-VISION is an electronic device used

for environmental control in livestock buildings. It combines sidewall, natural and tunnel

ventilation into one powerful system.

OUTPUTS — The PRO-VISION can control

up to 128 relays located in external relay

panels. These relays can be used to control

the following outputs:

32 heaters;

16 hi-fire heaters;

5 lateral fans;

20 tunnel fans;

1 stir fan;

6 cooling outputs;

6 foggers

2 tunnel inlets;

8 natural ventilation curtains;

1 sidewall vent;

1 attic vent;

12 time clocks;

2 light outputs (0-10V);

8 water line flushing outputs;

1 egg room heater;

1 egg room cooling output;

1 egg room humidity output;

1 alarm output;

1 backup relay;

4 feeder cut-off relays.

Do not spray water on the controller! In

order to clean the control, wipe it with a

damp cloth.

Before servicing or cleaning unit, switch

power off at service panel and lock the

switch disconnecting means to prevent

power from being switched accidentally.

When the service disconnecting means

cannot be locked, securely fasten a

prominent warning device, such as a

tag, to the service panel.

6

PRO-VISION rev.07

For Customer Use: Enter below the serial

number located on the side of the alarm

system and keep this information for future

reference.

Model: PRO-VISION

Serial number:

Date installed:

BUILT-IN INPUTS:

32 inside temperature sensors (8 basic

temperature inputs & up to 24 additional

inputs with the expansion cards);

1 outside temperature sensor;

1 relative humidity sensor;

1 static pressure sensor;

1 NH3 sensor;

1 wind speed sensor;

6 digital inputs (water meters and/or feeder

monitoring inputs).

Refer to the end of this manual to connect the sensors and loads.

Page 7

PRO-VISION

1.4. Main Features

Easy-to-Use Controller — With its conve-

nient menu selectors and its large graphic

LCD screen, the PRO-VISION is certainly the

most easy-to-use temperature controller on

the market.

10 Controller Programs — The controller allows using 10 different programs to control

the room temperature. It is thus possible to

activate a specific program that uses particular temperature settings according to the

animal age for instance.

32 Indoor Temperature Sensors — Up to

32 temperature sensors can be connected

to the controller to obtain an accurate reading of the average room temperature and a

faster reaction time. The controller comes

with 8 basic temperature inputs and 24 additional inputs can be added with the optional

extension cards.

Minimum Ventilation Cycle — When ventilation is not required to reduce the room

temperature, fan outputs can run either continuously or intermittently to reduce humidity

levels and supply oxygen to the room.

Recuperation of the Warm Attic Air — In

order to make energy savings, the controller

can extract the warm air from the attic and

send it back into the room.

Natural Ventilation — This is a ventilation

mode that uses existing air currents and

natural convection to move and distribute air

through the building.

Humidity Control — The control offers many

ways to compensate for high or low humidity levels.

Control of the Air Inlet Movement — The

movement of the air inlets (sidewall vents

or tunnel inlets) can be coordinated with

the operation of the fans or according to

the pressure level. This allows the inlets to

be adjusted correctly, without the influence

of uncontrollable factors such as wind or air

from adjoining rooms.

Egg Room — In addition to controlling the

ambient temperature in the house, the PROVISION can control the temperature and

humidity conditions in an egg room. It can

also keeps a tally of the number of eggs

produced each day.

Operation Cost Monitoring — The controller can monitor the amperage draw of the

outputs and give you daily reports of the

operation costs.

History Menus — The history menus allow

monitoring the sensor readings and verify the

run time of some outputs. Below is a list of

all available histories menus:

Static pressure sensor ...............400 days

Heater run time ..........................400 days

Feeder run time .......................... 400 days

Water consumption .....................400 days

Mortality ................................... 400 days

Alarm Management — The controller provides

alarms for high-low temperatures, defective

sensors and other system failures. It keeps in

memory the 75 latest alarm conditions.

Password Protection — Different passwords

levels can be enabled to restrict access to

some menus of the controller.

Backup Battery — A backup battery allows

the unit to keep time in case of a power

failure.

USB Connector — Controller backups and

updates can be made easily with a standard

USB memory card.

Overload and Over-voltage Protection — Resettable fuses are provided at low-voltage

inputs of the controller to protect its circuitry

in the case of an overload or over-voltage.

Computer Control — The controller can be

connected to a computer, thus making it

possible to centralize the management of

information and diversify control strategies.

Tunnel Ventilation — When the room temperature rises, tunnel ventilation reduces

the actual temperature perceived by the

animals.

2. MOUNTING INSTRUCTIONS

2.1. Installing the Controller

on the Wall

Fasten the two metal brackets on the mounting holes located behind the controller using

four screws. Then, mount the enclosure on

the wall using four other screws. Leave a

clearance of at least 16” to the left of the

enclosure to allow the cover to be removed

for maintenance.

Minimum and maximum sensor readings:

Ambient temperature ................400 days

Inside temperature sensors ............7 days

Outside temperature sensor .......400 days

Relative humidity sensor ...........400 days

Test Mode — A test mode allows simulating temperature changes and verifying the

controller‘s performances.

2.2. Connections

2.2.1. Main Wiring

Refer to the wiring diagram enclosed with this

user’s manual to connect the controller. Drill

holes at the bottom of the enclosure to pass

the wires and install watertight connectors to

prevent water from entering in the enclosure.

Do not make any holes at the side and top of

the enclosure.

All wiring must be done by an authorized electrician and must comply with

applicable codes, laws and regulations.

Make sure power is off before doing any

wiring to avoid electrical shocks and

equipment damage.

PRO-VISION rev.07

7

Page 8

PRO-VISION

Do not install rigid conduit into electrical

knockouts. Only nylon cable glands are

permitted for cable or wire fastening.

The controller has no power-on switch.

An external switch or circuit breaker

shall be included in the building installation to interrupt power to L and N

electric power lines. It shall be in close

proximity to the equipment and within

easy reach of the operator. It shall be

marked as the disconnecting device for

the equipment.

2.2.2. Alarm Connection

There are two types of alarms on the market.

One type activates when current is cut off at its

input; the other type of alarm activates when

current is supplied at its input. For an alarm of

the first type, use the NC terminal as shown on

the wiring diagram. For an alarm of the second

type, use the NO terminal.

3. USER INTERFACE

3.1. Location of the Controls

Graphic LCD display — The large graphic

LCD screen is used to display the parameters

and menus.

Menu selectors — The menu selectors allow

selecting a tab on screen.

Home key — This short-cut key provides access to the main menu.

Back — The “Back” key is used to go back to

the previous menu.

Arrow keys — The arrow keys allow selecting a parameter on screen. The right and

left arrow keys can also be used to move

through the display by pages (left=page-up,

right=page-down).

Enter — The “Enter” key is used to change

the value of non-numerical parameters.

Pressing this key makes a drop-down choice

menu appear.

Adjustment buttons — The adjustment buttons allow increasing or decreasing the value

of a parameter.

2.2.3. Sensor Inputs

Sensors operate at low voltage and are

isolated from the supply. Make sure that

sensor cables remain isolated from all high

voltage sources. In particular, do not route

the sensor cables through the same electrical knockout as other cables. Do not connect

the shield from the sensor cable to a terminal

or a ground.

Extending a sensor: Each sensor can be extended up to 500 feet (150 meters).

To extend a sensor: Use a shielded cable of

outside diameter between 0.245 and 0.260 in

(6.22 and 6.60 mm) (the cable dimensions

should not be under 18 AWG) to ensure the

cable entry is liquid tight. Do not ground the

shielding.

It is preferable to solder the cable joint to

ensure a proper contact between the two

cables.

Delete — The delete key allows

clearing the last digit that has

been posted while editing a

Graphic

LCD

Display

numerical value.

+/- & AM/PM but ton — This

push-button allows entering

a negative value and allows

changing the AM/PM time indicator.

Digital keypad — The digital

keypad is used to modify the

value of numerical parameters.

Alarm Status LED — The alarm

LED turns red when an alarm

Menu

Selectors

Home

Key

Back

button

Arrow keys

(Right = Page-Down

Left = Page-Up)

situation is active or turns green

when there is no alarm.

3.2. Adjusting a Parameter

When a parameter is selected, the controller gives indications about the way it can

be modified at the bottom of the screen. A

parameter can either be modified with the

adjustment buttons, with the digital keypad or

by pressing the “Enter” key and then selecting

an item from a drop-down menu. Follow the

instructions on screen to modify the value

of a parameter.

Do not run sensor cables next to other

power cables. When crossing over other

cables, cross at 90°.

Defective sensors: An alarm is generated

when a defective sensor is detected. Defective sensors are identified in the “Alarm”

menu. Refer to chapter 13 fo r f ur the r

information on the alarms.

2.2.4. 0-10V Output Connection

It is recommended to use a 18 to 22 AWG

wire to connect the devices to the 0-10V

outputs. This type of output can be used to

connect various devices such as lights.

Alarm

AM/PM

Status

LED

3

6

9

+/-

+/-

AM/PM

Button

Delete

Main Menu

Current conditions

Set Point

Minimu m ventilation

On/Off Settings

Inlets/Vents

MAIN

MENU

BACK

ENTER

Start flock / Egg

Light Programs

Alarms

History

Set-up

Adjustment

Buttons

Digital Keypad

1

2

4

5

7

8

DEL

0

8

PRO-VISION rev.07

Page 9

PRO-VISION

4. INSTALLATION SETUP

4.1. Setting the Time & Date

1. Select:

Main menu

* Set-up

Time & Date

* A complete- access password may be required to

access this menu (see sec. 4.2.1).

Time & Date

Tue Jan 1 20XX

11:59:59 am

To modify use

Each of the following parameters must

be set in turn.

2. Press “En ter” to start editing the

month.

3. Use the navigation buttons to select the

current month from the scrolling list.

4. Press “En ter” to continue.

5. The day is now selected. Use the adjustment buttons or the numerical keypad

to change the current day.

6. Press “En ter” to continue.

7. The year is now selected. Use the +/push-buttons or the numerical keypad

to change the current year.

8. Press “En ter” to continue.

9. The time is now selected. Use the numerical keypad to set the time of day

and use the AM/PM key to change the

time indicator (if required).

4.2. Password

The controller can identify 6 users that are

having different privilege levels. Below is a list

of possible privileges:

History — This privilege provides access to all

read-only menus such as the “Current Condi-

tion s”, “A la rm ” & “His tory” menus.

Settings — This privilege provides access to

all menus except for the “Se t- up” menu.

All — This password provides complete access to all menus of the controller.

Using password security is optional. Refer to the Set-up menu to enable/disable

this protection (see section 4.4).

4.2.1. Entering a Password

If the password protection is used, the controller will prompt for a password each time a user

that does not have the proper privileges tries accessing a protected menu. Refer to section 4.4

to enable or disable the password protection.

Please enter password

****

1. Type in your 4-digit password.

The message “Wrong Password” is displayed either if the posted password is

incorrect or if the privileges associated

with it are not sufficient to access the

protected menu.

4.2.2. Changing / Retrieving a Password

A user that has complete access to the controller can view and modify the passwords

and privileges of all users.

1. Select:

Main menu

* Set-up

* * Password

* A complete-access password may be required to

access this menu (see sec. 4.2.1).

* * This menu is accessible if the password protection is enabled in the Set-up menu (see sec. 4.4).

Passwor ds

Sec urity

User 1

User 2

User 3

User 4

User 5

Maste r

To modify use

2. Set the following parameters:

Security — Select the level of privileges that

must be selected after 5 minutes of inactivity

(history, settings or all).

Cur. user — This is user currently logged in

(for information only).

User 1-5 — Set the password of each user.

Choose easy-to-remember passwords

and write them down in a safe place!

Master — Set the master password. This

user automatically has complete access to

all menus of the controller.

Histor y

1111

2222

3333

4444

5555

0610

Cur. user User 1

Level

Level

Level

Level

Level

Settings

Histor y

Histor y

Histor y

All

10. Press “E nte r” to validate the time and

date.

Level — Assign the desired level of privileges

to each user. *NB. T he Master user automatically

has complete access to all menus.

PRO-VISION rev.07

9

Page 10

PRO-VISION

4.3. Controller Programs

Program definition: A programs is an assem-

bly of settings (temperature settings, relay

assignment, sensor assignment, etc.) that

can be enabled at different moment of the

breeding process. In all, the controller can

use 10 different programs.

Refer to the Set-up menu to enable the desired number of programs (section 4.4).

Make sure the right program is selected

before adjusting any parameter.

1. Select:

Main menu

* Start Flock

* A password may be required to access this menu

(see section 4.2.1).

Start flock

Mortality

Loss (%)

Stat Flo ck

Age

Clean M ode

To modify use

2. Set the following parameters:

Program — Activate the desired controller

program. *Only the programs that are enabled in

the Set-up menu can be used (see section. 4.4).

0

0.00

No

10000

On

Remaining

Birds placed

Age

Program

New Mortality

Alarm low T°

-

10000

10000

Progra m 1

0

No

4.4. Set-up Menu

The following section shows how to customize the controller for your particular application. It shows how to enable and set the

inputs & outputs of your controller. Normally,

this setup needs to be done only once.

Hint: Use the right and left arrow keys

to scroll the display by pages (right =

page-down, left = page-up).

1. Select:

Main menu

* Set-up

* A complete-access password may be required to

access this menu (see sec. 4.2.1).

2. Set the following parameters:

Contrast — Adjust the contrast of the LCD

screen. Default = 50%.

Backlight intensity — Set the intensity of the

LCD screen backlight as required. This parameter ranges from 1 (darker) to 5 (brighter).

Default = 3.

Key beeper tone — Adjust the volume of the

keypad beeper.

Language — Select the desired language

(English or Spanish).

Hint! Press and hold the main menu

button for 5 seconds to switch from a

language to the other.

Controller used for — The controller can

either be used in a breeder, broiler, layer or

turkey production facility. The breeder facility

gives you access to additional parameters to

monitor an egg room; the breeder and turkey

options give you access to the natural ventilation mode (natural curtain).

Time mode— Select the desired time format

(AM/PM or 24 hours).

Pressure unit — Select the desired pressure

units (inches of water (“WC) or Pascal (Pa)).

* This parameter is accessible if the static pressure

sensor is enabled above.

Use min. vent ramping ? — Select “Yes” to

enable the ramping function on the Time ON

portion of the minimum ventilation timer.

Refer to section 6.2.2 for further information

on this feature.

Use relative humidity (RH) sensor ? — Select

“Ye s” if a humidity sensor is connected to the

controller. Note that if the controller operates

in a breeder facility, the RH sensor is used to

control the humidity level in the egg room; if

the controller is located in a broiler, layer or

in a turkey facility, the RH sensor is used to

control the humidity level in the house.

Use RH min vent compensation? — Select

“Ye s” for the controller to adjust On Time

portion of minimum ventilation cycles as a

function of the relative humidity level. Refer to section 12.1 for further information

about this RH compensation method. * This

parameter is accessible if the controller is used in a

broiler, layer or turkey facility and if the RH sensor

is enabled above.

Use outside T° sensor ? — Select “Yes” if an

outside temperature sensor is connected to

the controller.

Use critical alarm? — Select “Yes” to enable

the critical temperature alarm condition.

* This parameter is common to all programs of the

controller.

Number of programs — The controller can use

several programs to control the temperature.

Enable the desired number of programs (1 to

10 programs) * This parameter is common to all

programs of the controller.

Save current program to — This function

allows copying all parameter settings of a

program onto another program (it thus avoids

repeating the same programming sequence

several times). Select the program on which

the current program must be pasted. * This

parameter is accessible if more than 1 program is

enabled above.

10

PRO-VISION rev.07

Temperature unit — Select the desired temperature units (Celsius or Fahrenheit)

Use static pressure sensor ?— Select “Yes”

if a static pressure sensor is connected to

the controller.

The controller automatically selects the

newly pasted program after the saving

process.

Confirm — Select “Ye s” to start the copying

process. The message “Copy successful” will be

displayed after data transfer. *This parameter is

Page 11

PRO-VISION

accessible if the program selected above is different

from the program currently in use.

Number of water meters — Enable the desired

number of water meters and then refer to section 4.5.2 to assign them to the digital inputs

of the PRO-VISION. In all, the controller can

monitor 6 digital inputs (water meters and

feeder-monitoring inputs). *This parameter is

common to all programs of the controller.

Water meter unit — If a water meter is enabled above, select the desired unit of water

volume (gallons or liters). * This parameter is

common to all programs.

Number of temperature sensors — Select the

number of inside temperature sensors that

are connected to the controller. The controller initially comes with 8 temperature inputs

and 24 additional inputs can be used with

the expansion cards (total of 32 sensors).

* This parameter is common to all programs of the

controller.

Use wind speed? — Select “Ye s” if an anemometer is connected to the controller.

Use ammonia sensor? — Select “Yes” if an am-

monia sensor is connected to the controller.

Use water flush? — Select “Ye s” to use the

water line flush. Refer to chapter 10 for further information on this feature.

Number of water lines — Select the number

of water line outputs in used (1 to 8 outputs). Note that up to 2 water lines can be

connected to each output. * This parameter is

ac cessible if th e wa te r ush opti on i s enabled a bo ve .

Number of natural curtains — Enable the

desired number of natural ventilation curtains

(0 to 8 curtains). *This parameter is accessible if

the controller is used in a turkey or breeder facility

Use cur tain inlet? — It is possible to use one

natural curtain output in lateral and minimum

ventilation. When a curtain is used in one of

these ventilation mode, it follows the same

movements as the vent inlet. When the controller enters in natural ventilation, the curtain

output becomes a regular natural curtain

again Select the natural curtain output that

acts as a curtain inlet in lateral and minimum

ventilation or select “Non e” to disable this

function *This parameter is accessible if natural

ventilation curtains are enabled above.

Number of heaters — Enable the proper

number of heating outputs. If the controller is

used in a breeder, broiler or layer production

facility, the number of heaters ranges from 1

to 16 and can be doubled with the “Hi Fire”

option; if the controller is used in a turkey

production facility, the number of heaters

ranges from 1 to 32.

Use heater RH compensation ? — Select “Ye s”

for the controller to activate the heaters in

timer mode when the relative humidity level

is too high. Refer to section 12.2 for further

information about this RH compensation

method. * This parameter is accessible if the con-

troller is used in a broiler, layer or turkey facility

and if at least 1 heater and relative humidity sensor

are enabled above. It is also common to all programs

of the controller.

Use hi fire heaters ? — Select “Ye s” to enable

the hi fire option for the heating outputs.

This function allows doubling the number of

heating stages (refer to chapter 7 for further

information on this function). * This parameter

is common to all programs and is only accessible if

the controller is used in a breeder, broiler or layer

production.

Number of fans — Enable the proper number

of lateral fans: up to 5 fans can be used in a

breeder, broiler or turkey production and up to

20 fans can be used in a layer production. *If

tunnel fans are used in a layer facility, a maximum

of 5 lateral fans can be enabled; if tunnel fans are

not used, up to 20 lateral fans can then be enabled.

Number of tunnel fans — Enable the proper

number of tunnel fans (1 to 20 tunnel fans).

*If tunnel fans are used in a la yer facility, a maximum

of 5 lateral fans can be enabled; if tunnel fans are

not used, up to 20 lateral fans can then be enabled.

Number of coolings — Enable the proper

number of cooling outputs (0 to 6 outputs).

RH shutoff cooling ? — Select “Yes” for the

controller to disable the cooling outputs when

the humidity level gets too high. Refer to section 12. 3 for further information about this

RH compensation method. * This parameter is

accessible if the controller is used in a broiler, layer,

or turkey facility and if at least 1 cooling output and

relative humidity sensor are enabled above. It is also

common to all programs of the controller.

Activate cooling low RH ? — Select “Yes” for

the controller to activate the cooling outputs

when the humidity level gets too low. Refer to

List of parameters Value

Contrast 50%

Backlight intensity 3

Key beeper t one 100%

Language English

Controller used for Breeder

Time mo de AM/PM

Tempe rature Unit °F

Use static pressure sensor? Yes/No

Pressure Unit “WC

Use min. vent ram ping? Yes/No

Use relative humidity sensor? Yes/No

Use RH min ve nt. compe nsation? Yes/No

Use outside T° sensor? Yes/No

Use critical alarm? Yes/No

Num ber of program s 10

Save curre nt program to Progra m x

Co nfir m Yes/N o

Num ber of water meters 2

Water meter unit gal

Num ber of T° sensors 8

Use wind speed ? Yes/No

Use am monia sensor? Yes/No

Use water flush? Yes/No

Num ber of water lines 8

Num ber of natural curtains 8

Use curtain inlet? Yes/No

Num ber of heaters 32

Use heater RH com pensation? Yes/No

Use hi fire heaters Yes/No

Num ber of fans 5

Num ber of tunnel fans 20

Num ber of coolings 6

RH shutoff cooling ? Yes/No

Activate cooling on low RH? Yes/No

Use Weedon fog gers ? Yes/No

Num ber of fogger zones 2

Activate Foggers on low R H? Yes/No

Num ber of feeders 3

Num ber of time clocks 12

Cloc k mode Start /Stop

Feeder 1 Assigne d to clock Clk1

Feeder 2 Assigne d to clock Clk2

Feeder 3 Assigne d to clock None

Use stir fan? Yes/No

Stir fan base on T°

Use light? Yes/No

Num ber of light programs 9

Use sidewall vent? Yes/No

Use tunnel i nlet? Yes/No

Num ber of tunnel inlets 2

Tun nel inlet mode SP

Vent inlet mode T°

Vent inlet SP adjustment? Yes/No

Use attic vent? Yes/No

Use attic T° sensor Yes/No

Use attic min vent. compen s? Yes/No

Pre-opening m ode Auto

Use night set point? Yes/No

Use min vent. night on tim e? Yes/No

Day starts at 8:00A

Night starts at 6:00P

Monitor breaker te mperature? Yes/No

Breaker sensor Sensor 1

Use password s? Yes/No

Num ber of relays 3 RP32

Use current se nsors? Yes/No

Ap pr o x.o pe rat io n c ost 0.0 0$ /KW /H

Fan voltage 120 V

Tun fan v oltage 120 V

Com munication s peed High

Curre nt condition display All

(example only)

PRO-VISION rev.07

11

Page 12

PRO-VISION

section 12 .3 for further information about this

RH compensation method. * This parameter is

accessible if the controller is used in a broiler, layer

or turkey facility and if at least 1 cooling output and

relative humidity sensor are enabled above. It is also

common to all programs of the controller.

Use Weedon foggers ? — Select “Ye s” to use

the Weedon foggers.

Number of fogger zones — Enable the desired

number of fogger zones (1 to 6 zones). *This

parameter is accessible if the foggers are enabled

above.

Activate Foggers on low RH ? — Select “Ye s”

for the controller to activate the foggers when

the humidity level gets too low. Refer to section 12. 3 for further information about this

RH compensation method. * This parameter is

accessible if the foggers an d relative humidity sensor

are enabled above. It is also common to all programs

of the controller.

Number of feeders — Enable the desired number of feeder run time monitoring inputs and

then refer to section 4.5.2 to assign them to

the digital inputs of the PRO-VISION. In all,

the controller can monitor 6 digital inputs

(water meters and feeder-monitoring inputs).

*This parameter is common to all programs of the

controller.

Number of time clocks — Enable the proper

number of time clocks (0 to 12 outputs).

Use clock loop feeding? — This option allows defining a number of on/off cycles to

be performed within a given clock cycle (see

graph in section 9 .1). Select “Ye s” to enable

this operating mode or select “No” to use the

regular start/ stop mode. *This parameter is not

available in a breeder production.

Clock mode (Breeder mode only) — The clock

mode allows stopping a time clock at a specific time of the day (Start/Stop mode) or after

a certain run time (Start/Run mode). Select the

desired operating mode of the time clocks.

Note that the “S ta rt/Ru n” option allows stopping the outputs with a little more precision

since it allows stopping them by the seconds

(contrarily to the “Start/Stop” mode which allows stopping them by the minutes). * This

parameter is accessible in breeder mode if at least

1 time clock is enabled above.

Feeder #x Assigned to Clock — When a

feeder run time alarm occurs, the controller

can open the relay associated with the feeder

(see section 4.7.1) or stop a particular clock

output. Select the clock output that needs

to be stopped when a feeder run time alarm

occurs or select “None” if no clock output

needs to be stopped. *Refer to section “13.2.8.

Feeder Alarms” on page 49 to set the maximum run

time of the feeders or to restart a feeder after it has

been stopped.

Use stir fan? — Select “Yes” to enable the

stir fan output.

Stir fan base on — If the stir fan output is

enabled above, specify its operating mode:

select “ Tem p” if it operates within a certain

temperature range or select “MinV” if it only

operates in minimum ventilation (refer to

section 6.6 for further information on this

function).

Use light? — Select “ Yes” to enable the 0-10V

light output.

Number of light programs — If the light output

is enabled above, select the desired number

of light programs (1 to 9 programs).

Use sidewall vent ? — Select “Yes” to enable

the sidewall vent output. * This parameter is

accessible if the static pressure sensor is enabled

above.

Use tunnel inlet ? — Select “Yes” to use a

tunnel inlet.

Number of tunnel inlets — If the tunnel inlet

option is enabled above, select the number

of tunnel outputs in use (1 or 2 tunnel inlets).

Tunnel inlet mode — Tunnel inlets can either

move according to the level of static pressure

(S.P.) or according to the room temperature.

Select the desired operating mode. * This

parameter is accessible if at least 1 tunnel inlet is

enabled above.

Vent inlet mode — The position of vent inlets can either be defined according to the

static pressure level or in timer mode as a

function of temperature. Select “S .P.” if they

are regulated by the static pressure level or

“T°” if their opening is based on temperature

variations.

Vent inlet SP adjustment ? — The controller

can automatically adjust the static pressure

set points as a function of inside or outside

temperature. Select “Insi de T°” to define a

second group of static pressure set point

(this group starts being used when the room

temperature reaches a certain point); select

“Oustide T°” to define different pressure set

points for winter and summer or select “No”

to disable these functions. *This parameter

is accessible if the Vent Inlet Mode is set to “S.P.”

above.

Use attic vent? — Select “Ye s” to enable the

attic vent output.

Use attic T° sensor? — Select “Ye s” if a

temperature sensor is present in the attic.

* This parameter is accessible if the attic vent is

enabled above.

Use attic min vent. compens? — In order to

extract air from the attic, the controller can

increase the operating time of the fans, in

minimum ventilation, when temperature is

suitable in the attic. Select “Ye s” to enable

this compensation function (refer to section

6.5 for further information on this function).

* This parameter is accessible if the attic sensor is

enabled above. It is also common to all programs

of the controller.

Vents pre-opening mode — The pre-opening

delay is used to pre-open the vents (sidewall

& attic vents) before activating the fans at the

startup of each minimum ventilation cycle.

The controller can use a steady pre-opening

delay or can set this delay automatically. Select “Au to” to use an automatic pre-opening

delay or select “Ma n .” to set the delay yourself. * This parameter is accessible if the attic vent

or sidewall vent is enabled above.

Use Night Set Point? — Select “Ye s” to use a

different target temperature at night; select

“N o” to disable this function.

Use min. vent. night on time ? — The controller can use different minimum ventilation

timer at night. Select “Ye s” to use particular

night settings.

Day starts at — Set the time at which the day

timer starts being used in minimum ventilation. * This parameter is accessible if the “Night

min. vent. on time” option is enabled above.

12

PRO-VISION rev.07

Page 13

PRO-VISION

Night starts at — Set the time at which the

night timer starts being used in minimum

ventilation. * This parameter is accessible if the

“Night min. vent. on time” option is enabled above.

Monitor breaker temperature ? — Select “Yes”

if a temperature sensors is used to monitor

the temperature of the main breaker. The

controller will set off an alarm if the reading

of this input gets higher than acceptable

temperature limit. * This parameter is common

to all programs of the controller.

Breaker sensor — If the breaker monitoring

function is enabled above, specify which of

the temperature sensors is used for this purpose (sensor 1-8). * This parameter is common

to all programs of the controller.

Use password? — Select “Yes” to enable

the password protection or “N o” to disable

it. * This parameter is common to all programs of

the controller.

Number of relays — Select the proper relay

panel or combination of relay panels in use:

1 RP-32 / 1 RP-40 / 1 RP-40 & RP-16

2 RP-32 / 1 RP-32 & RP-40

2 RP-40 / 3 RP-32 / 3 RP-40 / 4 RP-32

* This parameter is common to all programs of the

controller.

your application only uses relay panels with

the “CS” technology or select “Low” if your

application contains 1 or more relay panels

that do not use this technology. *Refer to

chapter 16 to see the communication rate currently

being used by your controller.

Current condition display — Select what

information needs to be displayed on current

condition menu: select “Al l” for the controller

to display all possible pieces of information

or select “W/O heat” or “W/O Prb,Heat” to remove the heater run time and/or the reading

of individual temperature sensors from the

current condition display. * This parameter is

common to all programs of the controller.

Use current sensors ? —Select “Yes” if at least

1 output uses a current sensor.

Approximative operation cost — The controller can calculate the approximate operating

cost of the outputs that are using a current

sensor. Select the going rate per kilowatthour.* This parameter is accessible the current

sensor is enabled above. It is also common to all

programs of the controller.

Output voltage — Specify what voltage each

output uses: 120, 208 or 240 Volts.

Communication speed — The communication

speed provided by the controller depends on

the type of relay panels you are using. Using

the high-speed communication mode allows

connecting more relay panels and current

sensors without lowering the communication speed of the controller. Note that the

high-speed mode can only be used if your

application exclusively contains relay panels

with the “CS” technology (the letters “CS”

are written on the faceplate of a relay panel

that uses this technology). Select “High” if

PRO-VISION rev.07

13

Page 14

PRO-VISION

4.5. Sensor Assignment

The selection of sensors must be made

separately for each controller program

in use.

4.5.1. Assigning the Sensors

The controller outputs either run according to

the average reading of their own selection of

sensors or according to a pre-defined group of

sensors (such as the average temperature). The

table below gives a list of all outputs and tells

according to which selection of sensors each

one of them operates.

Outputs Selection of sensors

Heater 1-32

Heat 1-16 Hi Fire

Cooling 1-6

Fogger Zones 1-6

Natural curtains 1-2

Egg room heater

Egg room cooling

Fans 1-5

Stir Fan

Tunnel Fans 1-20

Non-brood zones: A non-brood zone is an

unused part of the house. This type of zone

is automatically created when a heater is only

being controlled by a selection of sensors that

are not used to measure the average room

temperature. Refer to section 4.8 for further

information about non-brood zones.

The selection of sensors

must be made separately

for each of these output.

In lateral ventilation,

these outputs operate

according to the “Aver-

age T°” sensor group. In

tunnel ventilation, they

operate according to the

sensors that are associated with the tunnel fan

output in use.

1. Select:

Main menu

* On / Off Settings

* A password may be required to access this menu

(see section 4.2.1).

2. A table showing all outputs in use is displayed. Select the desired output with the

arrow keys.

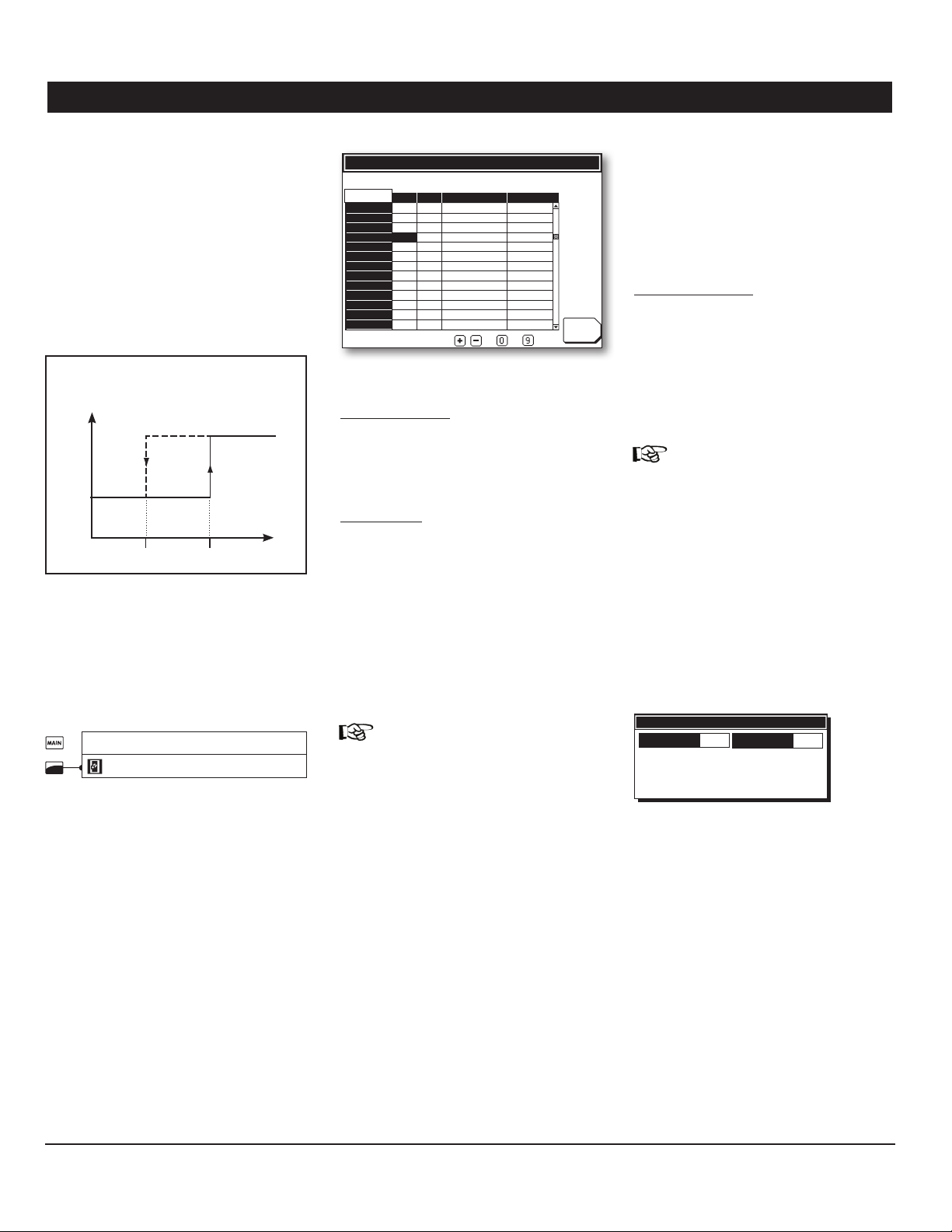

On/Off Settings

Ite ms

Tun 1

Tun 2

Tun 3

Tun 4

Tun 5

Cool 1

Fan 1

Fan 2

Fan 3

Fan 4

Heat 1

Heat 2

Heat 3

Set Point : 75.0

On Off Mode

60.0 63.5 Non brood

60.0 63.5

60.0 63.5

60.0 63.5

60.0 63.5 Ti me r

60.0 63.5 Sta rt si dew all

6 0.0 63. 5 Close attic

60.0 63.5 Start tunnel

6 0.0 63. 5 Close sidewall

60.0 63.5

60.0 63.5

60.0 63.5

60.0 63.5

To modify use

-

Htr /fan shut

Time

clock

Water

flush

Average

Sensor

When an output is selected, the controller

displays a sensor assignment tab at the right

hand side of the screen (the tab is associated with the chosen output). If the output

operates according to a group of sensors, the

tab leads to the sensor assignment menu of

the group; if it operates according to its own

selection of sensors, the tab leads to the sensor assignment menu of the chosen output.

3. Select the sensor assignment tab with the

menu selectors.

Average Sensor

1 2 3 4 5 6 7 8

--- --- --- ---

9 10 11 12 13 14 15 16

--- --- --- --- --- --- --- ---

17 18 19 20 21 22 23 24

--- --- --- --- --- --- --- ---

25 26 27 28 29 30 31 32

--- --- --- --- --- --- --- ---

To modify use

4. Use the +/- buttons to put a check mark in

the box of the temperature sensors that are

used to control the selected output (or that

forms the selected group of sensor).

4.5.2. Assigning the Digital Inputs

The controller has 6 digital inputs that can be

used to monitor a water meter or the run time

of a feeder. Enable these inputs in the Set-up

menu (section 4.4) and assign them to digital

inputs #1-6 of the controller.

1. Select:

Main menu

* Set-up

* * Digital Inputs

* A password may be required to access this menu

(see sec. 4.2.1).

* * This tab is accessible if at least 1 water meter

or feeder-monitoring input is enabled in the Set-up

menu (see sec. 4.4).

Digital Input Assig nment

1 2 3 4 5 6

Wtr1 Wtr2 Feed1 Feed2 Feed3 -

To modify use

2. Select the desired digital input and press

Enter to assign a function to this input.

14

PRO-VISION rev.07

Page 15

PRO-VISION

4.5.3. Selecting the Attic Sensor

If a temperature sensor is present in the attic,

please select which input number the attic

sensor uses.

1. Select:

Main menu

* Inlets / Vents

* * Attic Sensors

* This menu is accessible if at least 1 inlet is enabled

in the Set- up menu (see section 4.4). A password may

also be required to access it (see section 4.2.1).

* * This tab is accessible if the attic sensor input is

enabled in the Set-up menu (see section 4.4).

Attic Sensor

1 2 3 4 5 6 7 8

--- --- --- --- --- ---

9 10 11 12 13 14 15 16

--- --- --- --- --- --- --- ---

17 18 19 20 21 22 23 24

--- --- --- --- --- --- --- ---

25 26 27 28 29 30 31 32

--- --- --- --- --- --- --- ---

To modify use

---

2. Use the +/- buttons to put a check mark

in the box of the temperature sensor located

in the attic.

4.5.4. Egg Room Sensors

4.6. Calibrating the Inputs

This section shows how to calibrate the reading

of the sensor inputs in order to obtain accurate

and uniform readings from all sensors. It also

shows how to calibrate the flow rate of the

water meters.

1. Select:

Main menu

* Set-up

Sensor Calib.

* A complete-access password may be required to

access this menu (see sec. 4.2.1).

A table showing the calibration values of each

sensor input is displayed:

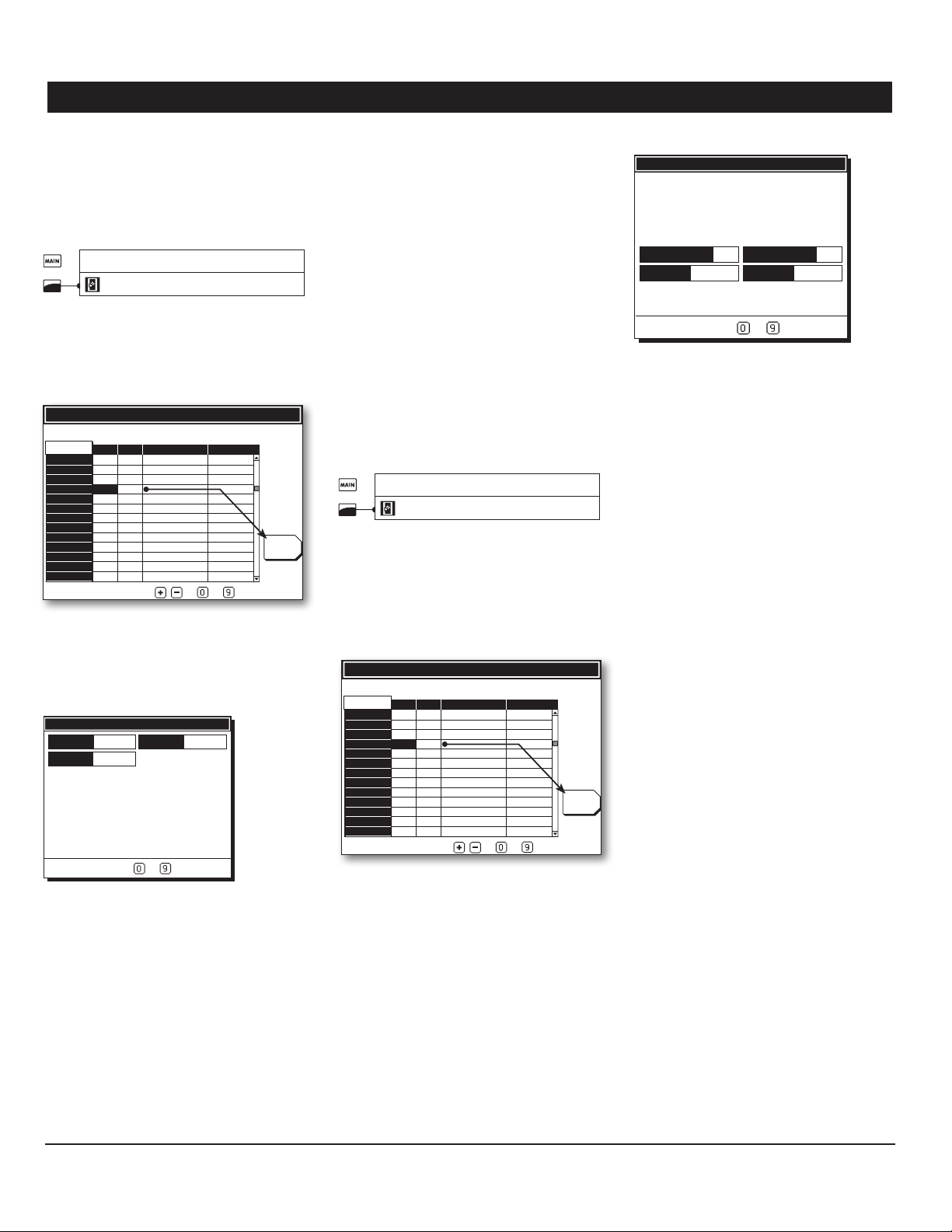

Sensor calibration

Temperatur e sensor 1

Temperatur e sensor 2

Temperatur e sensor 3

Outside tempe rature sensor

Static pressure sensor

Relative humidity sensor

Water meter 1

Water meter 2

Min am monia value

Max am monia value

To modify use

-

0.00

1.0g al /p

1.0g al /p

0 ppm

1000 ppm

0.0

0.0

0.0

0.0

0.0

2. If required, calibrate the reading of the

sensors. Note that the calibration settings

are common to all programs of the controller.

Use the +/- key to enter a negative offset.

Temperature (indoor & outdoor) — The reading

of the inside and outside temperature sensors

can be adjusted of ±10 °F (±5.6 °C).

Static pressure sensor — The reading of the

static pressure sensor can be adjusted of

±0.10 ” WC (±25 Pa). *This parameter is acces-

sible if the static pressure sensor is enabled in the

Set-up menu (see section 4.4).

Relative humidity sensor — The reading of

humidity sensor can be adjusted of ±10%.

*This parameter is accessible if the RH sensor is

enabled in the Set-up menu (see section 4.4).

Water meter calibration — Specify the flow

rate of each water meter. It ranges from 0.1

to 100.0 gallons (or liters) per pulse. *This

parameter is accessible if a water meter is enabled

in the Set-up menu (see section 4.4).

Min/max ammonia values— In order to use

the ammonia sensor, you must specify the

minimum and maximum ammonia levels that

can be detected by the sensor (in ppm). *This

parameter is accessible if the ammonia sensor is

enabled in the Set-up menu (see section 4.4).

If it is used in a breeder facility, the controller automatically enables an egg room and

controls up to 3 outputs in this room (heater,

cooling & humidity outputs). Each of these

outputs operates according to a specific temperature sensor. Please refer to chapter 11 of

this manual to specify which sensor is used

in the egg room.

4.5.5. Main Breaker Sensor

A temperature sensor can be used to monitor the temperature of the main breaker. The

controller will set off an alarm whenever the

reading of this temperature input gets too

high. Refer to the Set-up menu in section

4.4 to select the temperature sensors used

for this purpose (if applicable).

PRO-VISION rev.07

15

Page 16

PRO-VISION

4.7. Relays

4.7.1. Relay Assignment

The controller activates the loads by means

of external relay panels. In all, it can control

up to 128 relays. This section shows how to

specify the function of each relay. Please refer

to the wiring diagram enclosed with your relay

panel to connect the loads and to assign the

ID numbers of the panels.

A worksheet is available at the end of

this manual to write down the function

of each relay.

Relay Functions

Display Meaning

Htr Heater

Hi

#x; #xx Hi Fire heater #x or Heater #x

Fan Fan

Tun Tunnel fan

Feed Feeder

Cool Cooling output

Clk Time clock

Flu Water flush output

Stir Stir fan

Light On/Off light output

Bckup Backup device

2

SW-O

/SW-C2Sidewall vent open/close relay

2

AV-O

/ AV-C2Attic vent open/close relay

2

TN-O

/ TN-C2Tunnel inlet open/close relay

Eg.Htr Egg room heater

Eg.Cool Egg room cooling output

Eg.RH Egg room humidity output

Fogg Fogger zone

(depending if your controller uses the

hi-re option or if it uses 32 relays).

1

1. Select:

Main menu

* Set-up

Relay Assign

* A complete-access password may be required to

access this menu (see sec. 4.2.1).

The function of each relay is displayed.

Relay Assignm ent

1 2 3 4 5 6 7 8

Fan 1 Fan 2 Fan 2 Fan 3 Fan 4 Tun 1 Tun 2 T un 3

9 10 11 12 13 14 15 16

Heat HiFi1 Heat2 HiFi2 Heat3 HiFi3 Cool 1 Cool 2

17 18 19 20 21 22 23 24

Cool 3 Cool 4 Stir S V-O SV-C AV-O AV-C TN-O

25 26 27 28 29 30 31 32

TN-C Clk 1 Clk 2 Clk 3 - - - -

Select an item and press

2. Use the arrow keys to select the desired

relay number and then press “Enter” to change

its function. A table showing all possible

functions prompts on screen.

Relay 1 Assignm ent

Htr HiFi Fan Tun Fee d Cool

Clk Flu Stir Light Bcku p SW-O

SW-C TN-O TN-C AV-O AV-C Eg.Cool

Eg.Htr Eg.RH Fogg Off

Use the arrow keys to select the type of

output being controlled by the relay and then

press “Ent er”.

4.7.2. Relays with Current Sensors

The controller can monitor the current flow on

each of its outputs. The following procedure

shows how to identify the outputs that are

using a current sensor.

1. Select:

Main menu

* Set-up

* *Current sensors

* A complete-access password may be required to

access this menu (see sec. 4.2.1).

** This menu is accessible if a current sensor is

enabled in the Set-up menu (see section 4.4).

Relay current se nsor assignment

1 2 3 4 5 6 7 8

--- --- --- ---

9 10 11 12 13 14 15 16

--- --- --- --- --- --- --- ---

17 18 19 20 21 22 23 24

--- --- --- --- --- --- --- ---

25 26 27 28 29 30 31 32

--- --- --- --- --- --- --- ---

To modify use

2. Use the +/- buttons to put a check mark

in the box of the relays that are using a current sensor.

3. If the controller uses many outputs of the

same type, choose the output number from

the drop-down menu.

4. Proceed the same way

to assign a relay to each

output in use.

Htr

Htr 2

Htr 3

Htr 4

1. Feeder relays are used to stop the feeders when

a feeder run time alarm occurs. These relays are

normally closed (NC) relays which open when their

respective feeder exceeds a user-dened run time.

2. Some relays on the relay panels have specially

been designed to connect actuators (an actuator

relay has an “Open/Off/Close” marking instead

of an “On/Off” marking on the faceplate of the

panel). When actuators are connected to these

relays, their open and close relays can never be

activated at the same time.

16

PRO-VISION rev.07

Page 17

PRO-VISION

4.8. Non-Brood Zones & Clean Mode

Definition of a Non-Brood Zone: A non-brood

zone is an unused part of the house. This

type of zone is automatically created when

a heater exclusively uses temperature sensors that are not used to measure the average room temperature. Non-brood zones are

generally not ventilated and only have some

heaters to ensure minimum heat.

Heaters in Non- Brood Zones: The operating

temperatures of the heaters in non-brood zones

are related to the “Non-Brood temperature set

point” rather than on the regular temperature

set point. This means that if the non-brood

temperature set point changes, the operating

temperatures of non-brood heaters will be adjusted consequently. Refer to section 5.1 to set

the “Non-Brood temperature set point”.

Definition of the Clean Mode: The clean mode

is used to interrupt regular operations of the

controller when the whole house is empty.

When this mode is enabled, the controller

provides a minimum level of heat and ventilation (optional). In clean mode, the heaters

operate according to their non-brood settings.

Low Temperature Alarms in Clean Mode: The

controller can sound an alarm if the temperature

gets too low while it operates in clean mode (or

when the temperature gets too low in an empty

zone). Once it is enabled, refer to section 13. 2

to adjust the low temperature limit.

Figure: Heaters in Non-Brood Zones

Fans

Heaters

Temp.

Sensors

Heaters

Figure: Heaters in Clean Mode

Heaters

Temp.

Sensors

Heaters

Clean Mode

Unused Fans

Heater

Temp.

Sensors

Temp.

Heater

Temp.

Sensor

Sensor

Heater

Non-Brood ZoneBrood Zone

Unused Fans

Unused FansUnused Fans

Temp.

Sensors

Heater

Unused Fans

Unused Fans

1. Select:

Main menu

* Start Flock

* A password may be required to access this menu

(see section 4.2.1).

2. Set the following parameters:

Clean Mode — Select “On” to enable the clean

mode or select “Of f” to disable it.

Alarm low T° — Select “Yes” for the controller to set off an alarm when the average

temperature gets lower than the Non Brood

Set Point while the controller is in clean mode.

*This parameter is accessible if the clean mode is

enabled above or if an empty zone is used.

Use minimum ventilation? — Select “Yes” to

activate minimum ventilation cycles while the

clean mode is on.

Unused Fans

Mortality

Loss (%)

Stat Flo ck

Age

Clean M ode

Use min.vent?

To modify use -

PRO-VISION rev.07

Start flock

Remaining

0

Program

0.00

Age

Nb Birds

No

New Mortality

1

Alarm low T°?

Yes

Yes

10000

Progra m 1

10000

0

No

17

Page 18

PRO-VISION

4.9. Test Mode

The test mode is used to simulate changes in

the ambient temperature and relative humidity and verify the controller’s performance.

When the test is enabled, all outputs of the

controller operate according to the simulated

temperature. The test automatically ends after

15 minutes of inactivity or if the user deactivates it manually.

1. Select:

Main menu

* Set-up

Test Mode

* A complete-access password may be required to

access this menu (see sec. 4.2.1).

Test Mo de

Program

Progra m 1

Status

Hu mid ity

2. Set the following parameters:

Program # — This is the program that is currently used by the controller. It is displayed for

information only. *Refer to section 4.3 to change

the program in use.

S. P.

Tem peratur e

On

0

---

77. 8

4.10. Version

The version menu gives the version number

of the program used by the controller. This

piece of information is useful to get technical support.

1. Select:

Main menu

* Set-up

Version

* A complete-access password may be required to

access this menu (see sec. 4.2.1).

Pro -visio n

V X.X

Build no. XXXX

Released: Jan 1 200X

Stat. Pressure — This is the current level of

static pressure. It is displayed for information

only and cannot be modified manually. * This

parameter is accessible if the test mode is enabled

above and if a static pressure sensor is enabled in

the Set-up menu (see section 4.4).

Status — Select “On” to enable the test mode

or select “Off ” to disable it.

Temperature — Set the simulated room temperature to the desired value. * This parameter

is accessible if the test mode is enabled above.

Humidity — Set the simulated humidity level

to the desired value. * This parameter is acces-

sible if the test mode is enabled above and if the RH

sensor i s enabled in the Set-up menu (see section 4.4).

18

PRO-VISION rev.07

Page 19

PRO-VISION

5. SET POINTS

5.1. Temperature & RH Set Points

1. Select:

Main menu

* Set Point

* A password may be required to access this menu

(see section 4.2.1).

The current temperature & relative humidity (RH) set points are displayed along with

a graph of the temperature set point ramp.

Refer to section 5.2 for further information

about this ramp.

2. Set the following parameters:

Day set point — Set the temperature set point

that is used during the day (this set point is

used all day long if the night set point is not

enabled). The controller can also change the

day set point automatically over time by using a curve(see section 5.2). * This parameter

is common to all programs.

Night set point — A different temperature

set point can be used at night. The night set

point can be used to lower the target room

temperature for instance. The night set point

is relative to the day set point, which means

that it is automatically adjusted when the day

set point changes. Set the night set point to

the desired value. *Accessible if the night set point

is enabled (see section 4.4).

Non brood — Set the target temperature used

in the non-brood zones. *Refer to section 4.8 for

further information about non brood zones.

RH Set Point — The relative humidity (RH) set

point is the target level of relative humidity

in the room. It is only used if the controller is

used in a broiler, layer or turkey facility. If the

humidity level in the room gets higher than

this set point, the controller can enable different compensation functions to lower it down

(see chapter 12). Set the relative humidity set

point to the desired value. * This parameter is

accessible if the controller is used in a broiler, layer

or turkey facility and if a RH Compensation function is enabled in the Set-up menu (see section 4.4) .

Set Point

Day

Non brood

Temp erature

90.0

84.4

81.6

78.8

76.0

73.2

70.4

67.6

64.8

62.0

75.0

Night

RH Set Point

35.0

Ram ping

1 5 10 14 19 24 28 33 38 42 47 Age

To modify u se

-

77. 0

65

Ram ping

5.2. Set Point Ramp

The controller can automatically adjust the

temperature set point over time with a ramp.

The set point ramp is composed of 12 steps

and each step associates a temperature set

point with an animal age. Once the ramp is

enabled, the controller changes the temperature set point every hour in a linear fashion

between consecutive steps of the ramp.

When it reaches the last step, the controller

keeps using the last temperature set point

until the end of the flock.

Temperature

Tem peratu re

90.0

8 7.2

84.4

81.6

78.8

76.0

73.2

70.4

6 7.6

64.8

62.0

1 5 10 14 19 24 28 33 38 42 47 Age

Set Point Ramp

1. Select:

Main menu

* Set Point

Ramping

* A password may be required to access this menu

(see section 4.2.1).

2. Set the following parameters. * The parameters below are common to all programs.

Ramping Status — This is the status of the

set point ramp. Select “O n” to enable it or

select “Off” to disable it.

Age — Set the age at which each step starts.

This parameter ranges from -5 to 450 days

(negative values are used to prepare the

house before letting the animals in).

Temperature — Assign a temperature set

point with each step of the ramp. If you don’t

need 12 different steps, repeat the last temperature for each unnecessary step.

Rampin g Status: OFF

Age Set Point

1 90.0° F

7 85.0° F

10 8 0.0°F

15 78.0°F

21 7 2.0°F

25 70.0°F

28 6 8.0°F

32 6 6.0°F

36 64 .0°F

40 6 2.0°F

46 62 .0°F

47 62.0 °F

To modify u se

-

PRO-VISION rev.07

19

Page 20

PRO-VISION

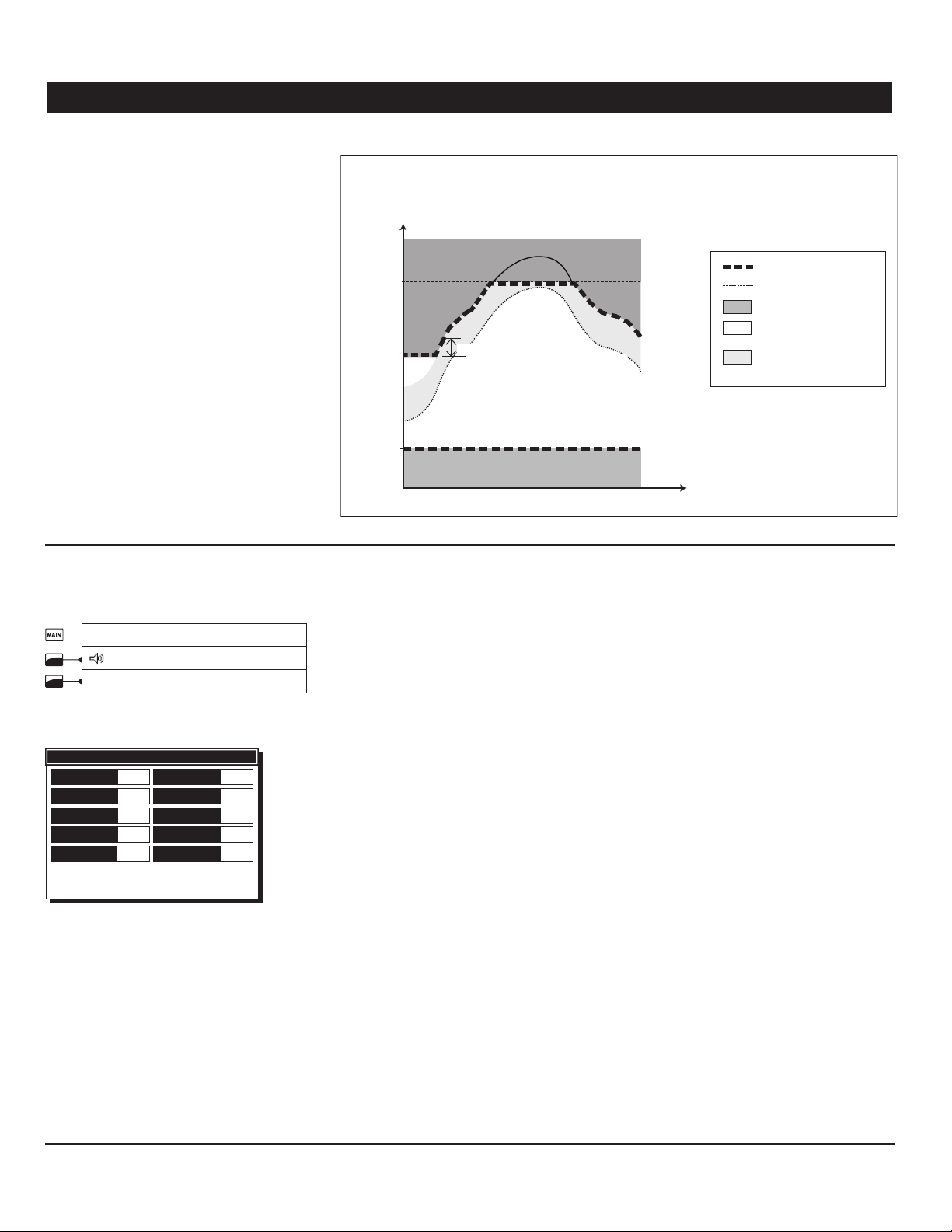

6. VENTILATION & COOLING

6.1. Overview of the Ventilation Concepts

Ventilation Concept in a Broiler or Layer Facility Ventilation Concept in a Turkey or Breeder Facility

In tunnel mode, ventilation is provided by

chosen tunnel fans and the air intake is

exclusively provided by the tunnel inlet (the

sidewall vents are closed). The controller

starts measuring the average temperature

according to the tunnel sensors and starts

using the tunnel inlet static pressure limits

and alarm limits.

In tunnel mode, ventilation is provided by

chosen tunnel fans and the air intake is

exclusively provided by the tunnel inlet (the

sidewall vents & natural curtains are closed).

The controller starts measuring the average

temperature according to the tunnel sensors

and starts using the tunnel inlet static pres-

sure limits and alarm limits. This ventilation

mode is optional in a turkey facility.

Startup of the

tunnel fan labeled

“Close sidewall”

(see sec. 6.5.3).

Startup of the

tunnel fan labeled

“S tar t Tunne l”

(see sec. 6.5.3).

“ON T°”

of the first

lateral fan

As the room temperature rises, the controller can start opening the tunnel inlet before

closing the sidewall vents in order to create

a smooth transition between lateral & tunnel

ventilation. This transition is optional.

In lateral mode, ventilation is provided by

chosen sidewall fans and the air intake is

provided by the sidewall and/or attic vents.

In minimum ventilation, the fans that are

used to ensure a minimum ventilation run in

timer mode and the vents (sidewall and/or

attic) slightly open prior to each activation

of the fans.

Minimum Vent. Lateral Mode Tunnel ModeTransition (opt.)

Startup of the

tunnel fan labeled

“S tar t Tunne l” (see

sec. 6.5.3).

Startup of the first

natural ventilation

curtain (see sec.

6.5.3).

“ON T°”

of the first

lateral fan

In natural ventilation, no fan is running and

the air intake is provided by the natural ventilation curtain and by the tunnel inlet (if a

tunnel inlet is used).

In lateral mode, ventilation is provided by

chosen sidewall fans and the air intake is pro-

vided by the sidewall and/or attic vents. This

ventilation mode is optional in a turkey facility.

In minimum ventilation, the fans that are

used to ensure a minimum ventilation run in

timer mode and the vents (sidewall and/or

attic) slightly open prior to each activation

of the fans. This ventilation mode is optional

in a turkey facility.

Minimum Vent. (opt.) Lateral Mode (opt.) Tunnel Mode (opt.)Natural Mode

20

PRO-VISION rev.07

Page 21

PRO-VISION

6.2. Minimum Ventilation

Minimum ventilation cycles are activated

when the room temperature is lower than the

start temperature of the first fan stage. Running the fans even though ventilation is not

required for reducing the room temperature