Page 1

103950_V09

MEDIAJET Operating instructions

Page 2

Declaration of Conformity

INTEGRA Biosciences AG – 7205 Zizers, Switzerland

declares on its own responsibility that the devices

comply with:

EU Regulations

Standards for EU

Standards for Canada and USA:

Zizers, November 4, 2016

Description Models

MEDIAJET 103005, 103 006

MEDIAJET vario 113000, 113001, 113002

EU Directives (DoW: Date of Withdrawal) Before DoW DoW After DoW

Low Voltage Equipment 2006/95/EC 20.04.2016 2014/35/EU

Electromagnetic Compatibility 2004/108/EC 20.04.2016 2014/30/EU

Restriction of Hazardous Substances 2011/65/EU

Waste Electrical and Electronic Equipment 2012/19/EU

Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) 1907/2006

Safety requirements for electrical equipment for laboratory use EN 61010-1: 2010

Particular requirements for automatic and semi-automatic laboratory equipment for analysis and other purposes.

EN 61010-2-81: 2015

Electrical equipment for laboratory use - EMC requirements EN 61326-1: 2013

Safety requirements for electrical equipment for measurement,

control and laboratory use - General requirements

UL 61010-1

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including

interference that may cause undesired operation.

Part 15 of the

FCC Rules

Class A

Elmar Morscher

CEO

Thomas Neher

Quality Manager

Page 3

MEDIAJET – Operating instructions V09

3

www.integra-biosciences.com

Table of Contents

Chapter 1 Introduction

1.1 Intended Use.................................................................................. 5

1.2 General safety instructions............................................................. 5

1.3 Symbols used................................................................................. 6

Chapter 2 Description of the device

2.1 Scope of delivery............................................................................8

2.2 Overview of MEDIAJET ...............................................................11

2.3 Operating panel............................................................................ 12

2.4 MEDIAJET in detail...................................................................... 12

2.5 MEDIAJET vario in detail ............................................................. 13

2.6 Reverse side and interfaces.........................................................14

Chapter 3 Installation

3.1 Unpacking ................................................................................... 15

3.2 Preconditions ...............................................................................15

3.3 Removing and fitting the conversion set of MEDIAJET vario....... 17

3.4 Assembly...................................................................................... 19

3.5 Biplate option ............................................................................... 21

3.6 Turbo mode option....................................................................... 22

3.7 TUBEFILLER option.....................................................................23

Chapter 4 Operation

4.1 Overview MAIN MENU functions ................................................. 25

4.2 Adapt system parameter......................................

........................ 26

4.3 Loading Petri dishes.....................................................................28

4.4 Adapting a dish filling program..................................................... 30

4.5 Run dish filling program ............................................................... 34

4.6 Removing filled Petri dishes......................................................... 38

4.7 Process documentation................................................................ 39

4.8 Dosing function ............................................................................ 41

4.9 Mixing additives into the agar.......................................................42

4.10 TUBEFILLER option...................................................................44

Page 4

MEDIAJET – Operating instructions V09

4 INTEGRA Biosciences AG

Chapter 5 Maintenance

5.1 Cleaning .......................................................................................48

5.2 UV Lamp exchange......................................................................50

5.3 Leak test.......................................................................................51

5.4 Servicing.......................................................................................52

5.5 Fault notifications .........................................................................52

5.6 Disposal........................................................................................53

Chapter 6 Technical data

6.1 Specification of the device............................................................54

6.2 Petri dish specifications................................................................55

6.3 Configuration specifications .........................................................56

6.4 Test tube compatibility chart.........................................................57

Chapter 7 Optional functions and required accessories

7.1 General accessories.....................................................................58

7.2 Accessories for different Petri dish sizes......................................58

7.3 Consumables ...............................................................................60

7.4 Imprinting dishes ..........................................................................60

7.5 Turbo mode option .......................................................................61

7.6 Accessories for dosing function....................................................62

7.7 Driving a second pump.................................................................63

7.8 TUBEFILLER option.....................................................................64

Imprint ..........................................................................................................................66

Page 5

MEDIAJET – Operating instructions V09 Introduction

5

www.integra-biosciences.com

1 Introduction

This operating instructions contain all information required for installation,

operation and regular maintenance of MEDIAJET. It summarizes all important

technical data and provides an overview of available accessories and options.

Purpose This chapter informs you regarding the general safety instructions and the

symbols used in the operating instruction manual.

1.1 Intended Use

This is a general-purpose laboratory instrument. Any use of this instrument in a

medical or IVD setting is the sole responsibility of the user.

The MEDIAJET is used in laboratories to fill Petri dishes of various sizes, Petri

dishes with two compartments or test tubes of various diameters and length.

1.2 General safety instructions

The MEDIAJET conforms to the state of technology and the recognized safety

rules, and is operationally safe. Operate the MEDIAJET only when in a perfect

condition and observing this operating instruction manual.

Residual dangers can emanate from the device if it is used or operated

incorrectly by untrained personnel.

All persons entrusted with operation of the MEDIAJET must have read and

understood this operating instruction manual and, in particular, the safety

instructions, or must have been instructed by their superior such that they are

able to operate the device without danger.

Irrespective of the safety instructions set out here, applicable provisions and

regulations must be observed in addition; for example, GLP, GMP, FDA, of the

employer's liability insurance associations, of the health authorities and of the

trading standards authorities.

Please observe the danger references on the device.

Do not carry out any conversion work or alterations on the device.

Please visit our website www.integra-biosciences.com

on a regular basis for up

to date information regarding REACH classified chemicals contained in our

products.

Page 6

MEDIAJET – Operating instructions V09 Introduction

6 INTEGRA Biosciences AG

1.3 Symbols used

This operating instruction manual makes specific reference to residual dangers

using the symbols shown.

1.3.1 Safety alert symbol

1.3.2 Severity levels of hazards in these operating instructions

The signal word in the top panel designates the hazard severity level.

1.3.3 Work reference

SAFETY SIGN

This is the general warning sign. It is used to alert the user to potential personal

injury hazards. In addition, hazards for machinery, materials and the

environment are possible. All safety messages that follow this sign shall be

obeyed to avoid possible harm.

WARNING

Indicates a hazard with a medium level of risk, which, if not avoided, could

result in death or serious injury.

CAUTION

Indicates a hazard with a low level of risk, which, if not avoided, could result in

minor or moderate injury.

NOTICE

Means that material damage or data loss in a micro-processor control could

occur, if the corresponding precautionary measures are not taken.

ASSISTANCE

This symbol identifies important notes regarding the correct operation of the

device and labor-saving features.

Page 7

MEDIAJET – Operating instructions V09 Introduction

7

www.integra-biosciences.com

1.3.4 Warning labels on the device

DANGER UV LAMP

Do not directly stare into the UV lamp.

MOVING PARTS

Keep hands out of area of moving parts.

ROTATING COG WHEELS

Keep hands out of cog wheels, risk to squash your fingers.

BIOHAZARD

The instrument can be potentially biohazardous due to the use of

biozazardous substances by the operator.

Page 8

MEDIAJET – Operating instructions V09 Description of the device

8 INTEGRA Biosciences AG

2 Description of the device

MEDIAJET is a laboratory device designed for the filling of Petri dishes with agar

nutrient media. MEDIAJET is available in two different device versions. The

standard version is limited to the filling of 90/100 mm (nominal size) diameter

Petri dishes. The MEDIAJET vario version is convertible and provides the

possibility to fill Petri dishes of 35 mm, 60 mm and 90/100 mm diameter (nominal

size). The MEDIAJET vario with biplate option (Part No. 113 002) allows the

filling of Petri dishes with two compartments.

Purpose This chapter describes the most important components of the MEDIAJET and

introduces you to the specific terminology.

2.1 Scope of delivery

This section gives an overview of all required parts of an operable MEDIAJET

unit. Please also refer to packing list included in the shipment, as the total scope

of delivery is dependent on the respective device version and possible additional

accessories.

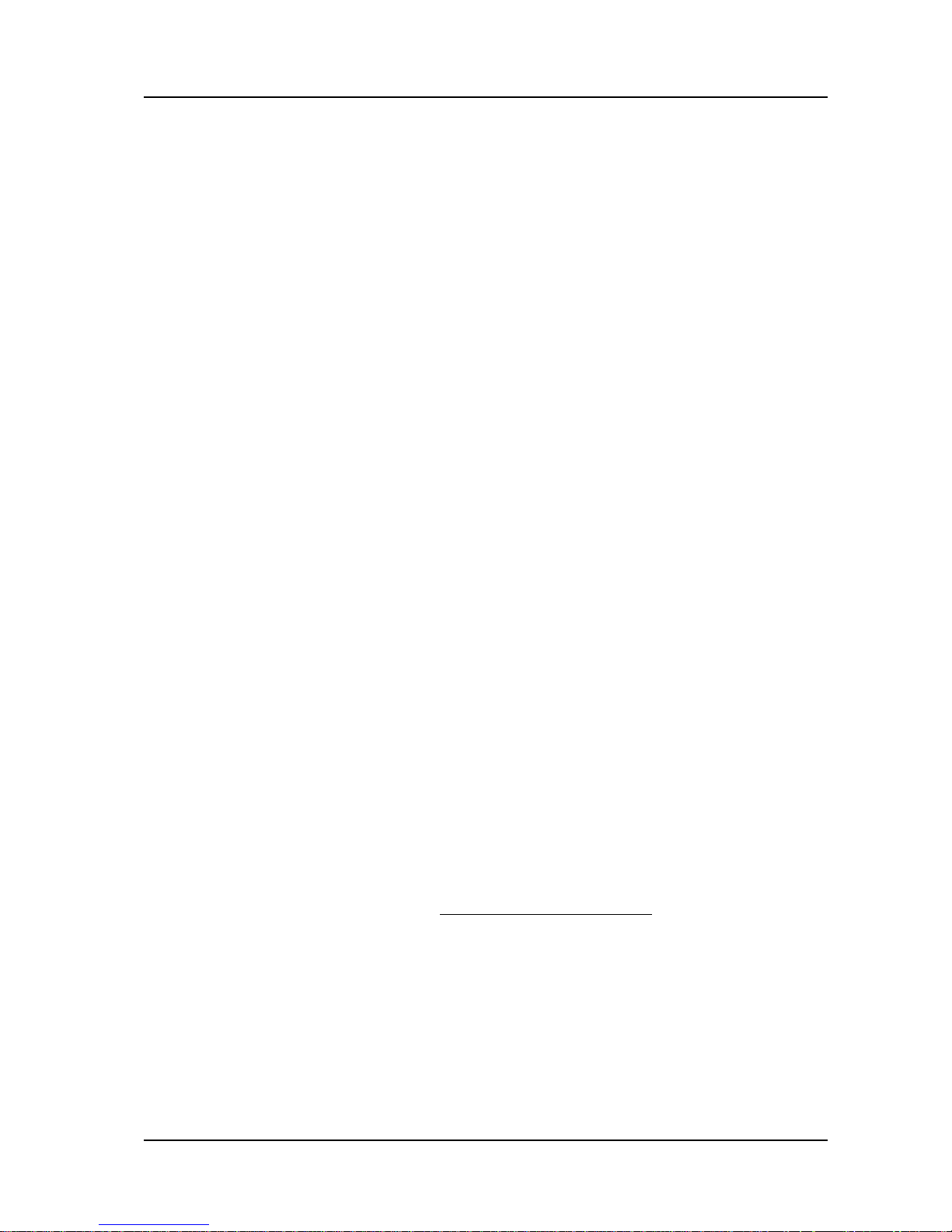

Basic device

(Part No. 103 005, 103 006, 113 000, 113 001

or 113 002)

Safety cover

(Part No.103 422) or

Biplate safety cover with reflector for alignment

sensor

(Part No. 113 801)

Rotor, different sizes possible

(Part No. 103 271, 103 272, 113 460, 113 271,

113 276 or 113 272) or

rotor for biplate option

(Part No. 113 806)

Page 9

MEDIAJET – Operating instructions V09 Description of the device

9

www.integra-biosciences.com

Base plate for filling nozzle holder for Petri

dishes with a height above 21 mm

(Part No. 103 212) or

Base plate for filling nozzle holder for Petri

dishes with a height above 21 mm

(MEDIAJET vario with biplate option only)

(Part No. 113 821)

Tubing set, including 1.5 m silicone tubing and

filling nozzle (two sets for MEDIAJET vario with

biplate option)

(Part No. 103 030 or 113 030)

Spirit level

(Part No. 103 095)

Line cord

Conversion set installed, applies to MEDIAJET

vario only,

(Part No. 113 051, 113 055, 113 052, 113 056

or 113 053)

Page 10

MEDIAJET – Operating instructions V09 Description of the device

10 INTEGRA Biosciences AG

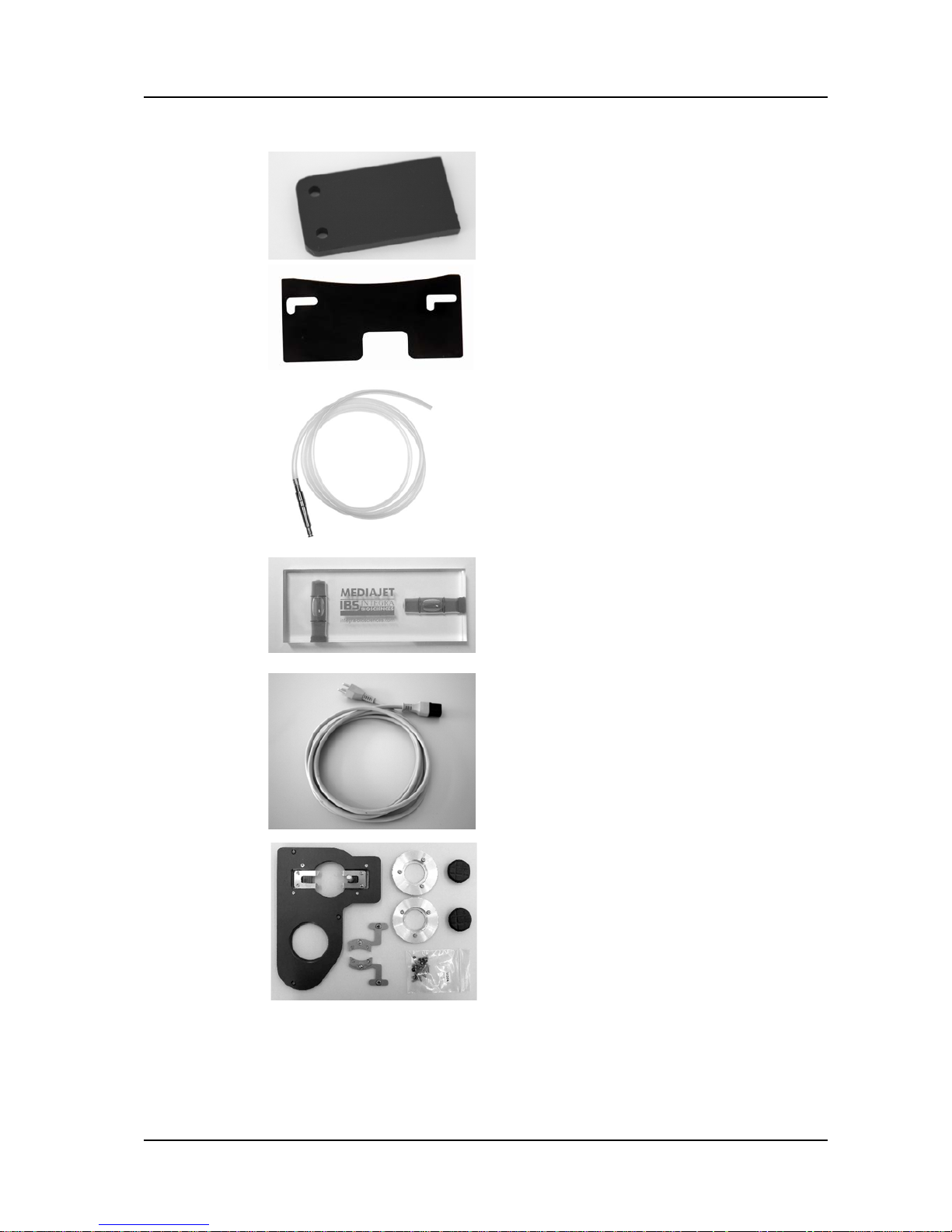

2.1.1 TUBEFILLER option

The TUBEFILLER option (Part No. 103 010) converts the MEDIAJET into a test

tube filler.

10 pack O-rings (MEDIAJET vario with biplate

option only)

(Part No. 113 822)

Carousel, in a separate box

(Part No. 103 020, 103 021, 113 022, 113 020

or 113 021)

Support plate, can accommodate 3 test tube

racks.

Filling arm, consisting of carrier piece (1), rod

(2) and radial arm (3).

Silicone tubing set, consisting of silicone tubing

3.0 mm ID, 2.5 m length, stainless steel

aspirating and dispensing tube, each of 10 cm

length.

3

2

1

Page 11

MEDIAJET – Operating instructions V09 Description of the device

11

www.integra-biosciences.com

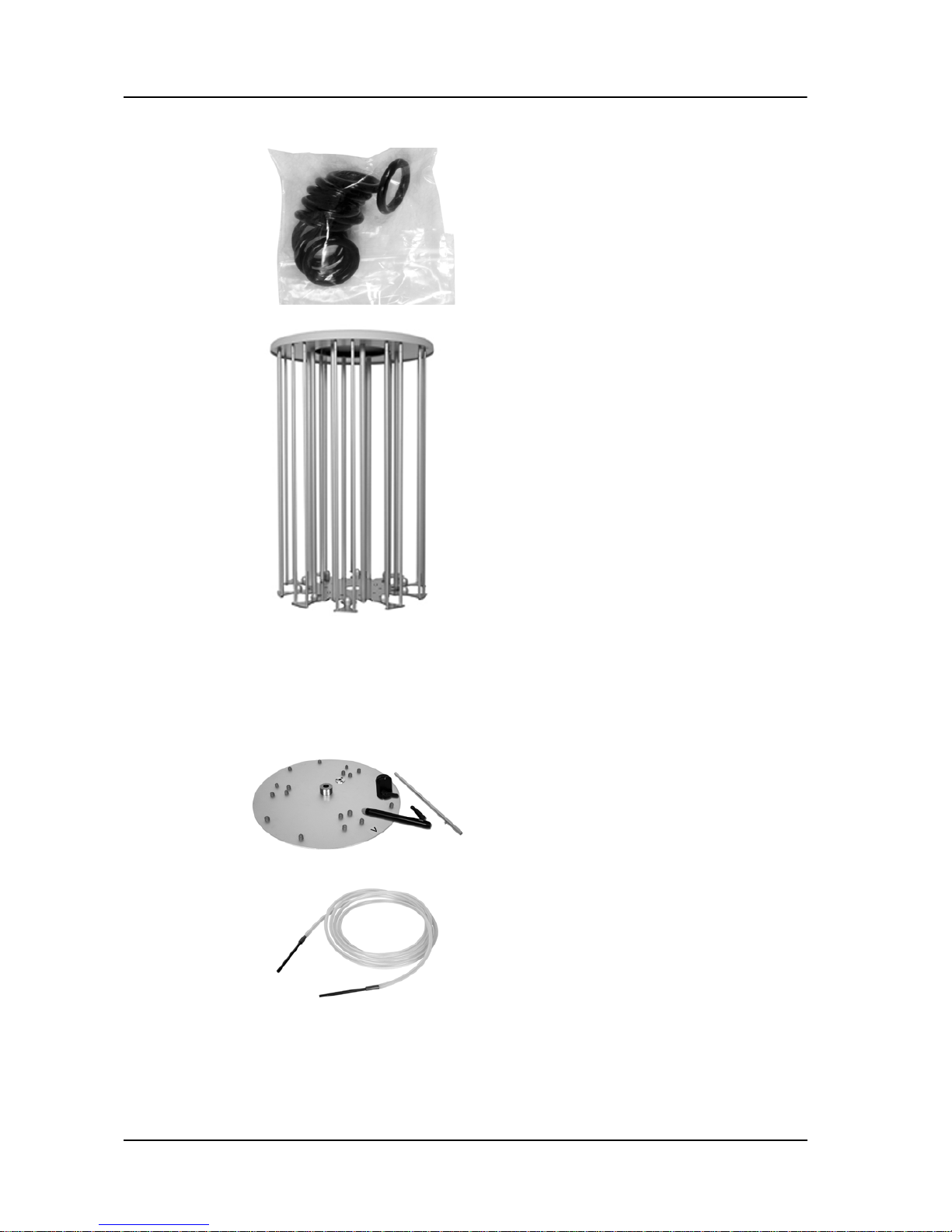

2.1.2 Turbo mode option

The turbo mode option accelerates the filling process by using a second pump

head installed. This option requires the turbo mode kit (Part No. 103 036)

including:

2.2 Overview of MEDIAJET

Extension pump head (Part No. 171 090)

Tubing set for Turbo mode (Part No. 103 035),

inner diameter 6 mm, length 2.0 m.

1 Carousel

A standard carousel can accommodate

360 Petri dishes divided up into nine

stacks of 40 dishes. One position in the

carousel must be kept free at all times to

enable perfect working of the device.

2 Safety cover

The safety cover from Plexiglas reduces

the penetration of germs from the ambient

air into the filling chamber and protects the

user against UV radiation.

3 Peristaltic pump

4 Operating panel

(see 2.3)

5 Main switch

1

5

4

3

2

Page 12

MEDIAJET – Operating instructions V09 Description of the device

12 INTEGRA Biosciences AG

2.3 Operating panel

2.4 MEDIAJET in detail

12 Cooling plate (factory option)

This cooling plate, which is available as a factory option built into the base

unit, accelerates the solidification of the agar medium in the Petri dish.

13 Rotor

The rotor separates the dish lid from the bottom, and transports the dishes

from the feeder position via the filling position to the stacker position.

14 Filling nozzle

The filling nozzle is part of the tubing set and establishes contact between

the MEDIAJET and the media preparator (MEDIACLAVE). It is positioned

correctly in the device by the filling nozzle holder.

6 Graphic user surface

7 Arrow keys

8 Function keys for operation of the

MEDIAJET

6

7

8

9 UV lamp

A UV lamp for decontamination of the

filling chamber is built in and switches off

automatically when the safety cover is

open.

10 Feeder position

At this position, the Petri dishes are

transferred from the carousel into the rotor

by the feeder piston.

11 Stacker position

At this position, the stacker piston transfers

the filled Petri dishes from the rotor back

into the carousel.

9

14 13 12

1110

Page 13

MEDIAJET – Operating instructions V09 Description of the device

13

www.integra-biosciences.com

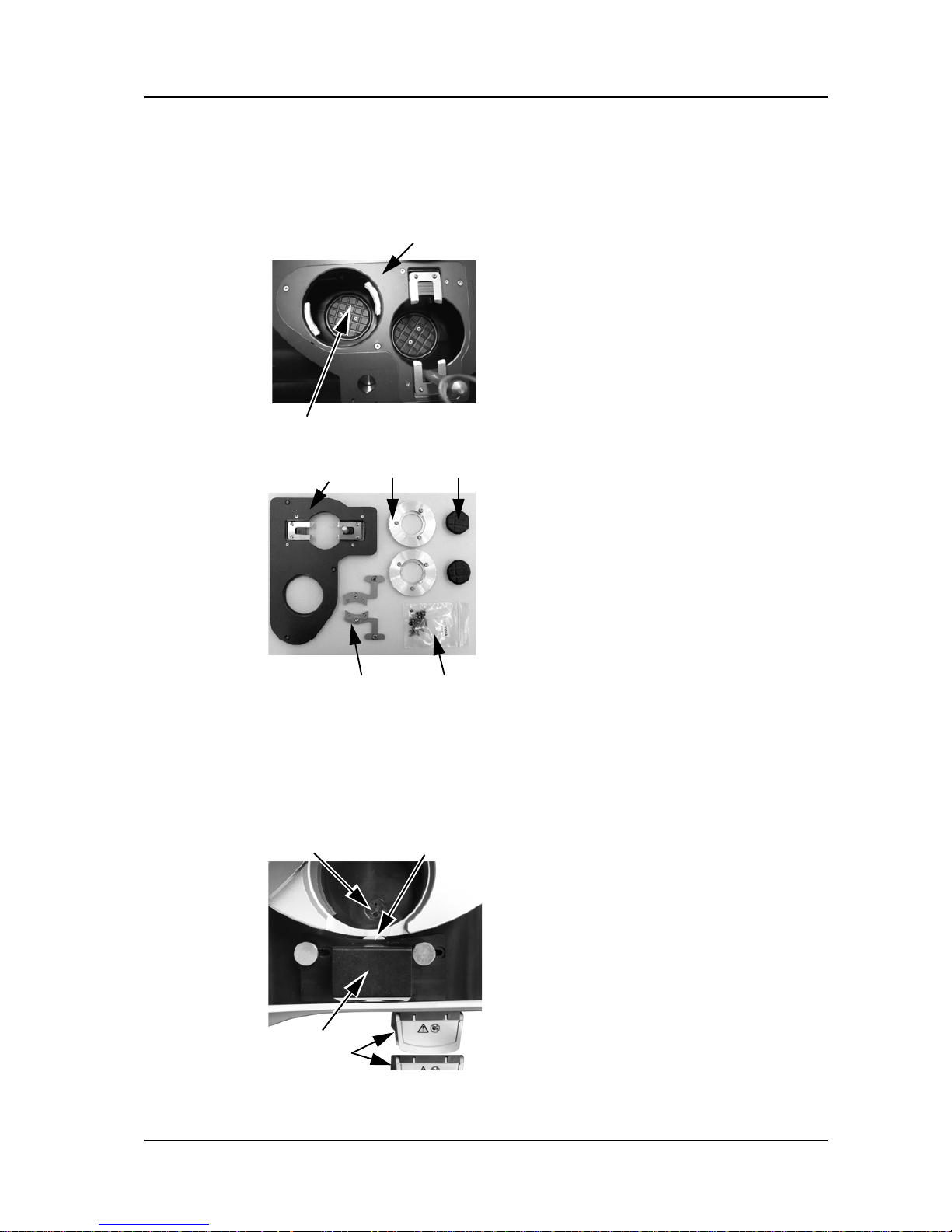

2.5 MEDIAJET vario in detail

MEDIAJET vario can be adapted to different diameters of Petri dishes, using a

conversion set.

The following parts of the conversion set can be exchanged:

The carousel, rotor and filling nozzle must also fit to the Petri dish size.

Description of MEDIAJET vario with biplate option:

The biplate option is used for filling Petri dishes with two compartments.

The following parts are specific for the biplate option.

The different parts of the conversion set are

already installed on the device.

15 Adaptation insert for Petri dishes of the

desired diameter.

16 Head plates for feeder and stacker piston

and flanges, laid underneath.

17 Adaptation insert with petri dish

guide pin.

18 Flanges for feeder and stacker.

19 Head plates for feeder a n d stacker

piston.

20 Extension gripper lever (applies

to conversion set for

35 and 60

mm Petri dishes only).

21 Set of spare screws and O-rings.

22 Alignment sensor at filling

position.

23 Drive wheel for rotating the Petri

dishes.

24 Filling nozzle holder with

integrated drive wheel.

25 Double pump head.

The Safety cover has a reflector,

needed for the alignment sensor.

15

16

17 18 19

20 21

22 23

24

25

Page 14

MEDIAJET – Operating instructions V09 Description of the device

14 INTEGRA Biosciences AG

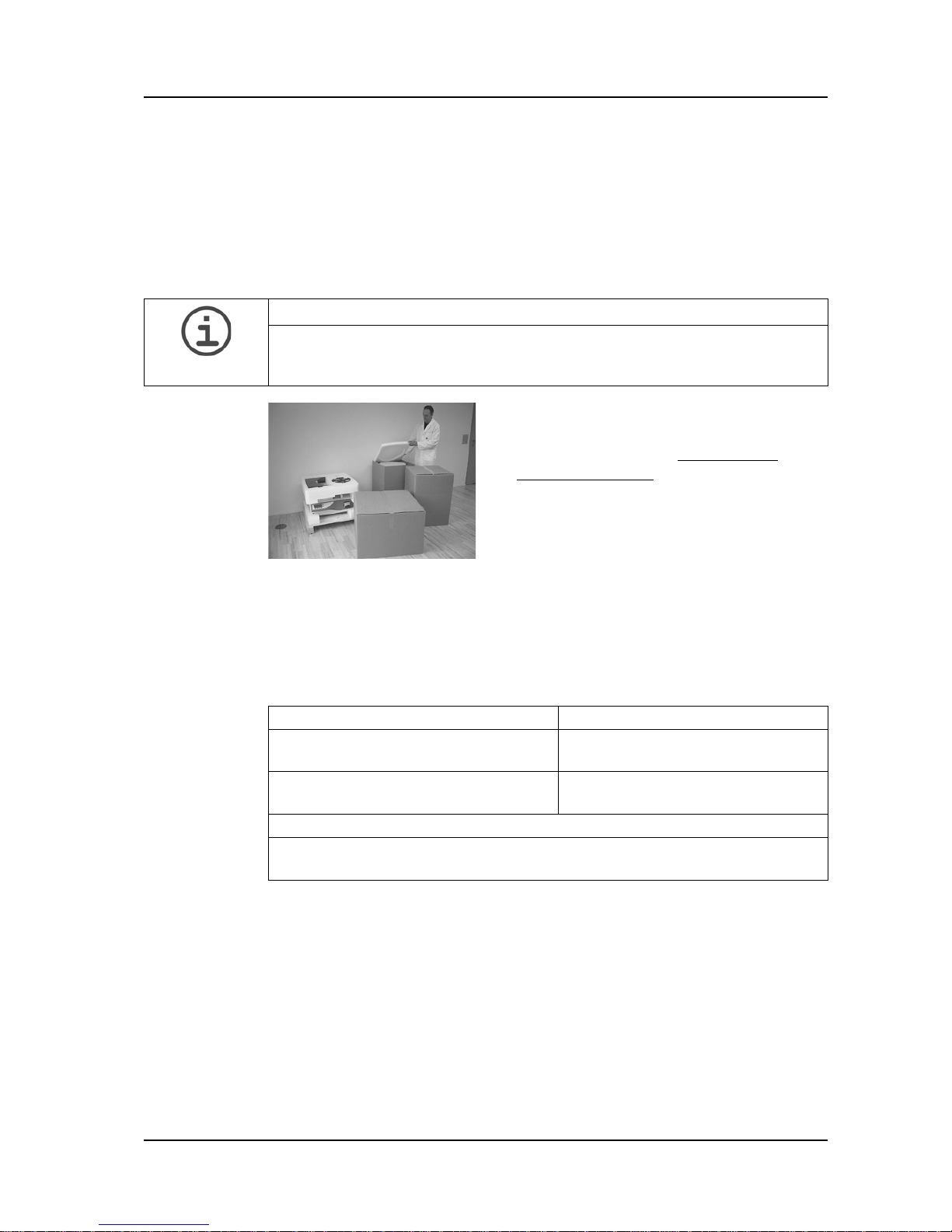

2.6 Reverse side and interfaces

Interface Function

26 FOOT-

SWITCH

Connection for the foot-switch

27 RS232(1) Service connection

28 RS232(2) Connection to an external protocol printer or to

MEDIACLAVE

29 INKJET Connection for an inkjet printer

30 PUMP Connection for controlling an additional peristaltic pump

31 AUX Potential-free connection for an external alarm system

32 SPARE Without function

26 27 28 29 30 31 32

Page 15

MEDIAJET – Operating instructions V09 Installation

15

www.integra-biosciences.com

3 Installation

Purpose This chapter shows the unpacking and installation of MEDIAJET.

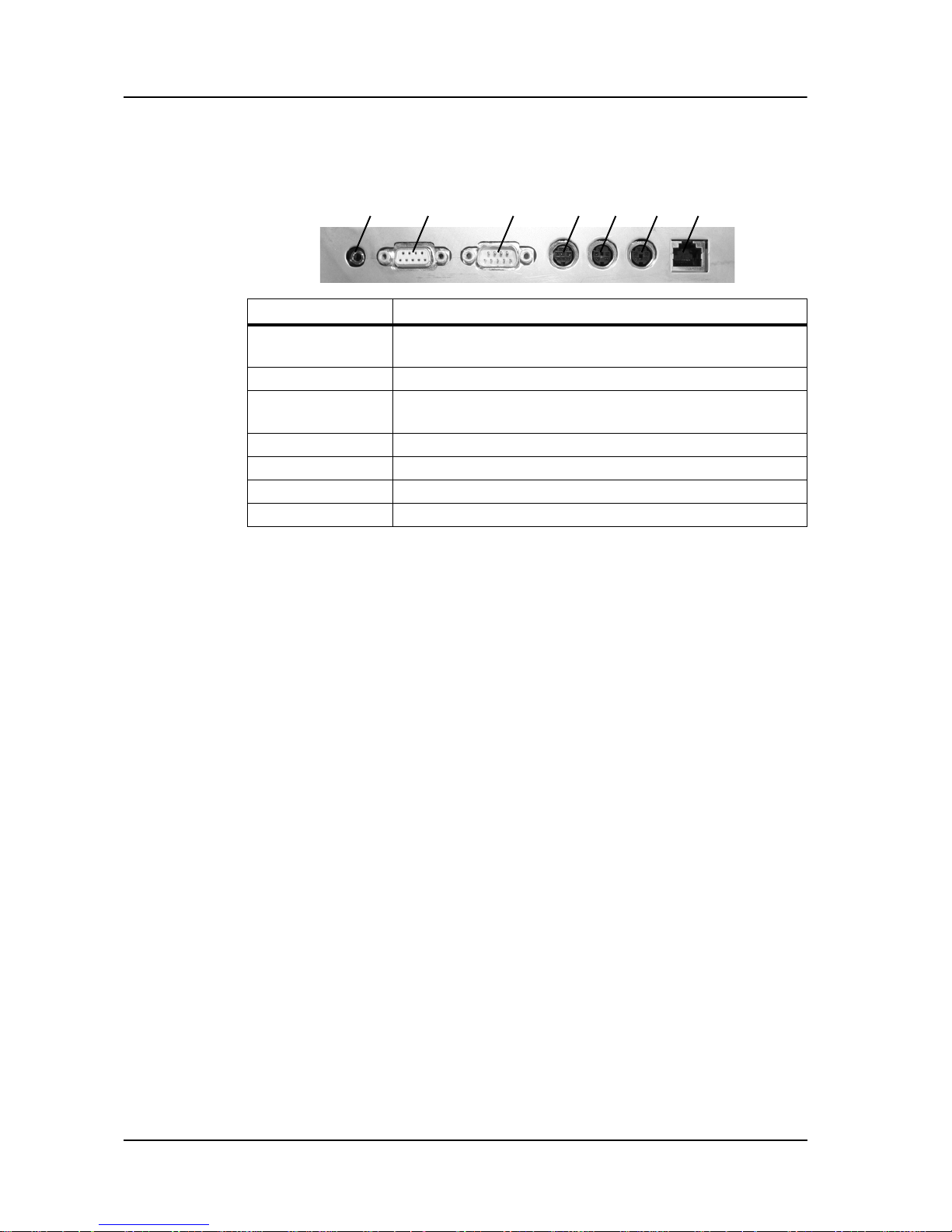

3.1 Unpacking

3.2 Preconditions

3.2.1 Operating environment

Generally inadmissible are locations with which there is a risk of spray water or

of contact with chemicals. The correct location satisfies the form of protection IP

21 and has a stable, horizontal base.

In the event of failure to observe the ambient conditions for the location, the

capacity to function and the safety cannot be guaranteed.

ASSISTANCE

Check the scope of delivery for any transport damage and notify your local

INTEGRA Biosciences AG representative (see last page of the operating

instructions).

Unpack the MEDIAJET and check the

scope of delivery (see “2.1 Scope of

delivery” on page 8).

Ambient temperature for operation 15-35°C

Maximum relative humidity Non-condensing, 30-80 % for up to

35 °C

Voltage fluctuations of the mains

supply

+/-10 % from the nominal value

Degree of contamination 2 as per IEC 60664-1

Ingress protection according to IEC 60529:

IP20 - Protection against objects >12.5 mm

Page 16

MEDIAJET – Operating instructions V09 Installation

16 INTEGRA Biosciences AG

3.2.2 Setting up

CAUTION

The basic device must only be set up on a cleaned, dry and perfectly

horizontal surface, capable of supporting a minimum weight of 80 kg.

ASSISTANCE

Leave sufficient space behind the device to allow easy connection of the

mains cable.

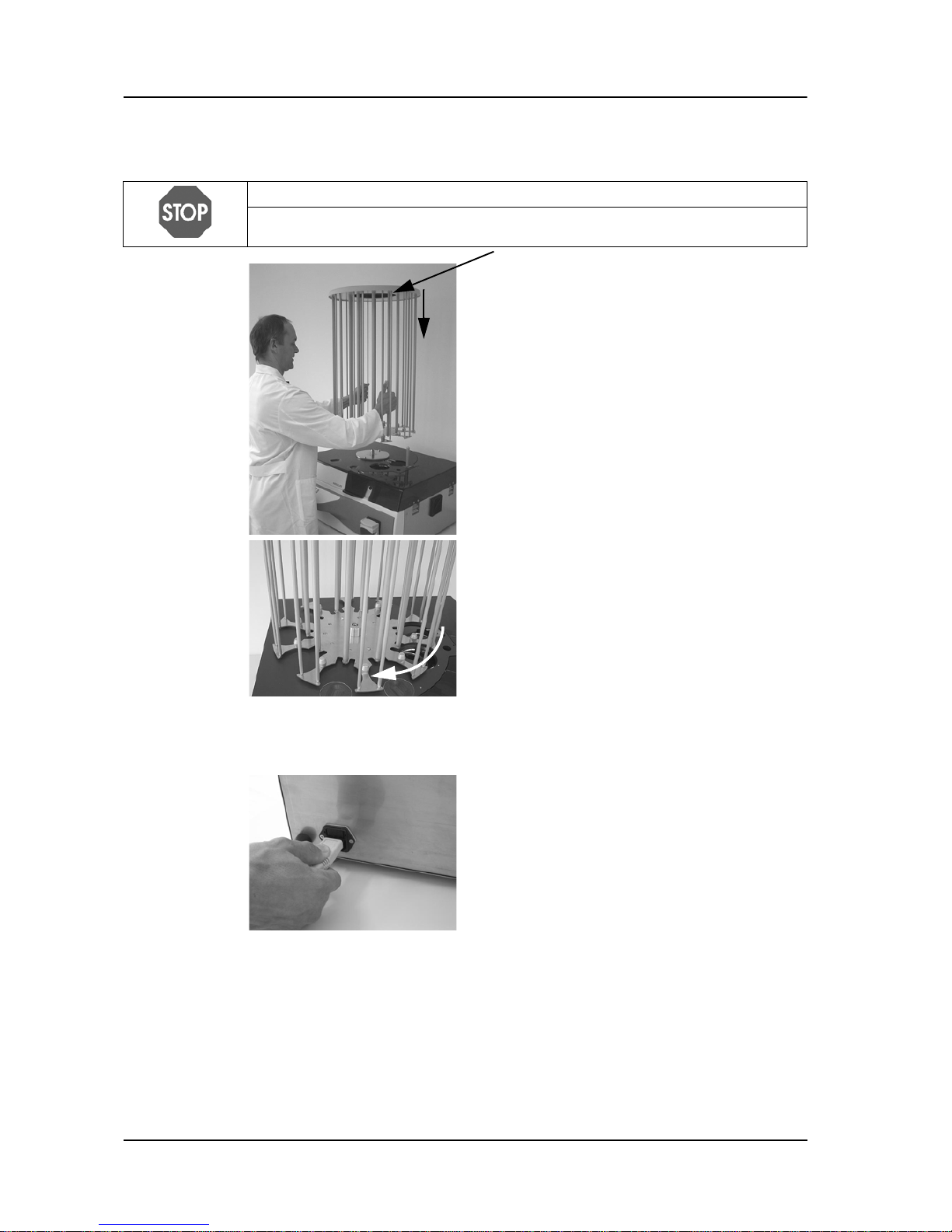

At least two persons are required to lift the

instrument. Lift the instrument holding it

steady and firmly at the base of both sides

beside the feet.

Set up the basic device on the bench. In

order to obtain a perfectly horizontal

alignment of the unit, use the included spirit

level and adjust the height of the equipment

feet with a 13 mm flat spanner.

Page 17

MEDIAJET – Operating instructions V09 Installation

17

www.integra-biosciences.com

3.3 Removing and fitting the conversion set of MEDIAJET vario

The MEDIAJET vario can handle different Petri dish sizes. To adapt the device

to the desired Petri dishes, the appropriate conversion set must be mounted.

3.3.1 Overview

3.3.2 Dismounting in detail

Removing the adaption insert

Conversion from

90 mm

to

35 or 60 mm Petri dish size

Conversion from

35 or 60 mm

to

90 mm Petri dish size

Removing the conversion set:

• Remove the adaption insert

• Unscrew the piston head plates

• Remove the flanges

Removing the conversion set:

• Remove the adaption insert

• Remove the extension gripper

lever

• Take off the piston head plates

• Remove the flanges

Inserting the conversion set for

35 or 60 mm Petri dishes:

• Insert the corresponding flanges

• Insert the corresponding head

plates tightly

• Mount the extension gripper lever

• Mount the adaption insert

Inserting the conversion set for

90 mm Petri dishes:

• Insert the corresponding flanges

• Mount the corresponding head

plates

• Mount the adaption insert

NOTICE

Make sure that the head plates of the

35 or 60 mm conversion set are tightly

inserted. Otherwise the Petri dishes may not be handled properly.

To exchange the conversion set, switch to the

CLEANING mode of the MAIN MENU.

Remove safety cover, carousel and rotor.

Unscrew the three countersink screws

M4x8 on the adaptation insert.

Remove the adaptation insert.

Page 18

MEDIAJET – Operating instructions V09 Installation

18 INTEGRA Biosciences AG

Removing or mounting the extension gripper lever

Removing the piston head plates

Removing the flanges

Applies to conversion set for

35 and 60 mm

Petri dishes only:

Unscrew the two sink screws M3x6 of the

right and left extension gripper lever for

small petri dishes.

Keep the STACKER or FEEDER keys of

the operating panel pressed and

consecutively move both pistons up to the

high of the carousel plate using the

ARROW KEYS.

If present, unscrew the four piston head

screws M3x6 of the head plates and remove

the plates.

Unscrew the six piston head screws M3x6

of the flanges.

To lift the flanges move feeder and stacker

all to the top.

Remove the two flanges.

NOTICE

For an error free performance of MEDIAJET vario with the desired Petri dish

size, make sure that the corresponding conversion set, including the

adaptation insert, extension gripper lever, head plates and flanges is

completely installed and that the correct rotor and carousel are mounted.

After every exchange of the conversion set perform the dish sensor teach-in

procedure, see “4.2.2

Dish sensor teach-in (teach-in sensors only)” on

page 27.

Page 19

MEDIAJET – Operating instructions V09 Installation

19

www.integra-biosciences.com

3.4 Assembly

3.4.1 Rotor

3.4.2 Safety cover

Slide the rotor under the black plate.

Turn the rotor until the anchor bolt locks into

position.

Hang the safety cover into the two hinges

on the right hand side of the device.

Page 20

MEDIAJET – Operating instructions V09 Installation

20 INTEGRA Biosciences AG

3.4.3 Carousel

3.4.4 Electricity supply

The device is now fully assembled.

Now switch on the device at the main switch.

Wait until the device has completed the automatic software initialization.

When the main menu with INTEGRA logo appears on the screen, the device

has been installed and is ready for use.

NOTICE

Always lift the carousel on the thick central rods, never on the outer, flexible

rods.

Keep the carousel vertical and place it on

the bolt in the center of the black carousel

base plate.

Turn the carousel until the anchor bolt locks

into position.

Plug the electricity cable into the socket on

the rear of the device.

Subsequently connect it to the electricity

mains.

Page 21

MEDIAJET – Operating instructions V09 Installation

21

www.integra-biosciences.com

3.4.5 Base plate for filling nozzle holder

For filling of Petri dishes with a height above 21 mm a base plate, used as a

spacer, must be mounted.

For MEDIAJET vario with biplate option, a special base plate must be mounted,

if Petri dishes with a height above 21 mm are filled:

3.5 Biplate option

The biplate option allows the filling of two Petri dish compartments in parallel by

two filling nozzles and a double pump head (available only with MEDIAJET vario

with biplate option, Part No. 113 002).

Remove the two screws below the caps on

the filling nozzle holder.

Place the base plate under the filling nozzle

holder and fix it with the long screws

supplied with the base plate.

Put the screw caps on the screws.

Remove the two screws of the filling nozzle

holder.

Place the base plate for biplate option under

the filling nozzle holder, so that the two Lshaped openings of the base plate are

stacked below those of the filling nozzle

holder.

Fix the stack with the screws of the filling

nozzle holder.

The filling nozzle holder must be adjusted,

see “4.2.3

Biplate (optional)” on page 27.

Enable the biplate alignment under program

configuration, see “4.2 Adapt system

parameter” on page 26.

Page 22

MEDIAJET – Operating instructions V09 Installation

22 INTEGRA Biosciences AG

3.6 Turbo mode option

The turbo mode option is used to accelerate the filling process. For this option

the turbo mode kit (Part No. 103 036) must be installed. For dish filling speeds

see “6.1 Specification of the device” on page 54

.

When placing the silicone tubing set (Part No. 103 035) into the double pump

head assembly, gently stretch the tubing so that inside the pump head the

tubing is taut (avoid loading the tubing in a loose, slackened way).

Finally, enable the turbo mode option under program configuration, see “4.2

Adapt system parameter” on page 26.

The turbo mode option is ready to start.

WARNING

Always switch off the MEDIAJET when assembling the double pump head.

Be aware of the sharp edges of the pump heads when assembling them and

when opening and closing the first pump head for tubing insertion.

Keep the lever on the right side of the

original pump head pressed and turn the

pump head to the left. Pull off the original

pump head and replace it by the extension

pump head. Turn the extension pump head

to the right and ensure that the lock

mechanism engages with an audible click.

Assemble the two pump heads by locking

the original pump head onto the extension

pump head in the same way. Turn the

original pump head to the right until it

audible locks in place.

Important: The rollers of the two pump

heads must be out of phase in order to avoid

excessive strain on the motor (torque limits)

and to obtain a reduction in flow pulsation.

Page 23

MEDIAJET – Operating instructions V09 Installation

23

www.integra-biosciences.com

3.7 TUBEFILLER option

ASSISTANCE

In order to install and use the TUBEFILLER option, MEDIAJET has to be

equipped with the software version 1.12 or higher. In case you need to

upgrade your MEDIAJET software version please contact your local INTEGRA

BIOSCIENCES dealer for support.

Place the support plate on the carousel axis

of MEDIAJET and turn it until the anchor

bolt locks into position.

Mount the filling arm carrier piece onto the

rotor axis inside the filling chamber.

Position the filling arm rod from the top into

the carrier piece.

Fix the carrier piece upright by tightening

the side lever.

Both levers (the one on the carrier plate and

the one on the filling arm) can be put into an

idle mode by pulling the lever outward on its

axis.

This helps to position the levers in a way

which allows to firmly tighten them.

ASSISTANCE

Check if the rod is mounted vertical in a 90° angle to the base unit in order to

guarantee a failure-free operation of the TUBEFILLER.

Page 24

MEDIAJET – Operating instructions V09 Installation

24 INTEGRA Biosciences AG

The TUBEFILLER is now installed.

Mount the radial arm onto the rod and

tighten it with the side lever in order to

prevent it from moving during the

dispensing phase.

NOTICE

To avoid contact of the side lever with the test-tubes during the filling process

make sure the lever is always on the right side of the rod.

Page 25

MEDIAJET – Operating instructions V09 Operation

25

www.integra-biosciences.com

4 Operation

Purpose This chapter describes how to adapt the general device settings and how to

program and carry out a petri dish filling process.

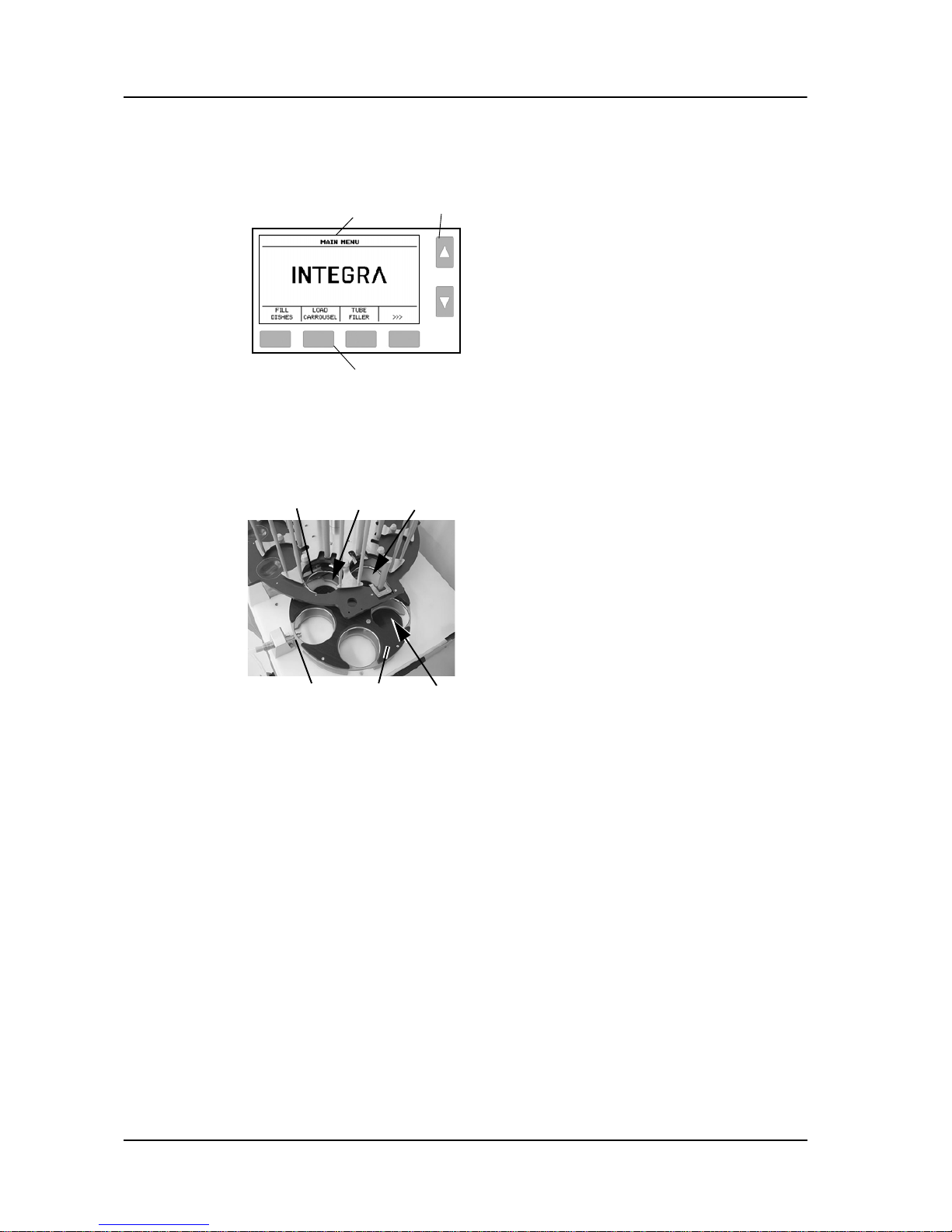

4.1 Overview MAIN MENU functions

The list below provides an overview of the selectable functions in the MAIN

MENU of the operating panel.

Press >>> in order to reach the second page of the MAIN MENU.

FILL DISHES: To adapt and store (see “4.4

Adapting a dish filling program” on

page 30), as well as execute (see “4.5 Run dish filling program” on page 34 and

“4.9

Mixing additives into the agar” on page 42) up to 19 individual Petri dish

filling programs.

LOAD CAROUSEL: This function supports the operator to load the carousel

with empty Petri dishes (see “4.3

Loading Petri dishes” on page 28) and remove

the filled agar plates after termination of the dispensing process (see “4.6

Removing filled Petri dishes” on page 38).

TUBE FILLER: Requires the optional available accessory TUBEFILLER, which

allows to automatically fill test-tube racks on MEDIAJET.

This function allows the operator to adapt, store and execute 19 individual testtube filling programs (see “4.10

TUBEFILLER option” on page 44 and “7.8

TUBEFILLER option” on page 64 for more information).

CLEANING: The piston of the feeder or stacker can be moved for cleaning by

this function (see “5.1

Cleaning” on page 48).

DOSING FUNCTION: Function for independent volumetric dosing applications

using the peristaltic pump of MEDIAJET (see “4.8

Dosing function” on page 41).

SYSTEM PARAMETER: To adapt the general device parameters (see “4.2

Adapt system parameter” on page 26).

Page 26

MEDIAJET – Operating instructions V09 Operation

26 INTEGRA Biosciences AG

4.2 Adapt system parameter

The following table gives an overview about the other parameters to be set

under the menu option SYSTEM PARAMETER, if required.

System

parameter

Description and function

Language

selection

Sets the desired language.

Time/date Sets the local time and date.

UV lamp Displays the operating hours of the UV-lamp.

Allows to switch the UV-lamp on or off and to reset the

operating-hour counter.

Display

contrast

Altering the display contrast.

Protocol

printing

Provides choice of printing the process data on an independent

external printer or on MEDIACLAVE and to execute a test print

(see more in “4.7

Process documentation” on page 39).

Program

configuration

Enabling/disabling functions in program parameters:

• Turbo mode: OFF

• Shaker level (Pour Plate): OFFBatch mode: OFF

• Power Stacker: OFF

(Allows handling stack weights that are at the upper limit of

the stacker force, e.g. filling Petri dishes with large volumes

of agar medium.)

• Pump Options: OFF

(Enabling this function allows pumping back the medium to

the source.)

• Biplate alignment (only MEDIAJET vario with biplate

option): OFF

Cooler

(optional)

Allows to switch off the cooling plate, in case the option is

installed.

Dish

sensor

teach-in

(optional)

Procedure to adjust the optical dish sensor, see “4.2.2

Dish

sensor teach-in (teach-in sensors only)” on page 27.

Biplate

(optional)

To fill Petri dishes with two compartments, see “4.2.3

Biplate

(optional)” on page 27.

Info General information on the device:

• Software and electronics version

• Series number

• Operating-hour and dish counter.

System

messages

Displays information on the status of the device (only shown, if

a message available).

Page 27

MEDIAJET – Operating instructions V09 Operation

27

www.integra-biosciences.com

4.2.1 Language selection

Press >>> in order to reach the second page of the MAIN MENU.

Select a language under SYSTEM PARAMETER / LANGUAGE

SELECTION.

4.2.2 Dish sensor teach-in (teach-in sensors only)

The dish sensor teach-in is a procedure to adjust the optical sensor to the used

type of Petri dishes. Whenever the type of Petri dishes is replaced (different

brand or size) the teach-in procedure should be carried out.

Select DISH SENSOR TEACH-IN under SYSTEM PARAMETER.

4.2.3 Biplate (optional)

This function supports the adjustment of the filling nozzle holder for dispensing

into two-compartment Petri dishes and tests the automatic alignment of the

dividing wall of the dishes. Before you perform a biplate filling program, follow

this procedure:

Select PROGRAM CONFIGURATION under SYSTEM PARAMETER and

enable the biplate alignment.

Press SAVE.

The screen will appear in the language

selected.

Follow the instructions on the screen. Press

START and later CONTINUE.

If “Teach-in successful” is displayed press

END.

Select BIPLATE under SYSTEM

PARAMETER.

Initialise the rotor by pressing INIT ROTOR.

Page 28

MEDIAJET – Operating instructions V09 Operation

28 INTEGRA Biosciences AG

.

Move the filling nozzle holder in the direction of the Petri dish, so that the drive

wheel pushes against the Petri dish without tilting it up. The drive wheel

should rotate the Petri dish easily.

Tighten the screws of the filling nozzle holder.

Press TEST to check the automatic alignment of the dividing wall of the Petri

dish.

The dividing wall is aligned at a right angle to the filling nozzle holder and

“Test: OK” is displayed.

4.3 Loading Petri dishes

Select LOAD CAROUSEL in the MAIN MENU and choose the mode of the

planned filling process:

I nse r t a Pet r i dis h into t he ro t or i n f ron t o f the

filling nozzle.

Unscrew the two screws of the filling nozzle

holder and move it to the leftmost position.

Press ON / OFF DRIVE to start the drive

unit for adjusting.

ASSISTANCE

If the biplate option is not required, move the filling nozzle holder to the

rightmost position and use the right filling nozzle.

Press NORMAL to prepare filling of all

dishes stack by stack or BATCH for filling

the dishes in the Batch mode, see “4.4

Adapting a dish filling program” on page 30.

MEDIAJET now carries out an automatic

self-calibration process.

ASSISTANCE

The two positions refer to the two locations situated directly in the front side of

the carousel towards the operator above the two cavities in the black cover

plate.

Page 29

MEDIAJET – Operating instructions V09 Operation

29

www.integra-biosciences.com

Press BACK and MAIN MENU in order to return to the MAIN MENU.

The MEDIAJET is now loaded with dishes.

Load sterile Petri dishes stack by stack from

top to bottom into the carousel at the

loading positions 2.

Only fill the loading positions as far as the

notch 1.

2

1

NOTICE

Under no circumstances load dishes above the marked notches, as a

sufficient space between the uppermost dish of the stack and the cover of the

carousel is fundamental for error-free functioning of the device.

CAUTION

Pay attention to your fingers. There is a risk of your fingers being squeezed

when you press ROTATE.

Press ROTATE.

The carousel turns two positions in a

clockwise direction.

Repeat the procedure described above until

nine of the ten positions (Batch mode: only

every second position) have been filled with

Petri dishes.

NOTICE

Fill only nine of the ten positions in the carousel with dishes to ensure perfect

functioning of the device. If using the Batch mode, only every second position

must be filled.

Page 30

MEDIAJET – Operating instructions V09 Operation

30 INTEGRA Biosciences AG

4.4 Adapting a dish filling program

Press FILL DISHES in the MAIN MENU in order to reach the stored

programs.

The following table gives an overview about the parameters to be set:

ASSISTANCE

If you are using the MEDIAJET for the first time, please adjust the program

parameters to your requirements before starting the filling process.

Select the desired program using the arrow

keys.

Press PROGRAM SETTINGS in order to

adjust the program.

Using the arrow keys, select a parameter

that you wish to change.

Press CHANGE.

Now follow the information on the screen.

ASSISTANCE

It is recommended to define a program name that easily identifies the program

mode, e. g. Standard, Turbo mode, Batch mode or Pour plate. Alternatively,

reserve a block of numbers for the particular program modes.

Program

parameter

Description Value

range

Basic

setting

Number of

dishes

Determines the number of

dishes to be filled in the

program.

0-9999 360

Dispensing

Volume (ml)

Defines the filling volume of a

Petri dish.

1-99.9 ml 18 ml

Pump speed (%) The setting 100 %

corresponds to a flow rate of

approx. 500 ml/min.

30-100 % 60 %

Anti-drip Prevents drop formation at the

end of a dosage.

ON

OFF

OFF

Pause time (s) Selectable pause time

between the filling of two Petri

dishes.

0-9.9 s 0 s

Page 31

MEDIAJET – Operating instructions V09 Operation

31

www.integra-biosciences.com

Dish height (mm) Stacking height of the Petri

dishes used (see below). To

use dishes with a height of

more than 21 mm, underlay

the filling nozzle holder with the

supplied base plate (see “3.4.5

Base plate for filling nozzle

holder” on page 21).

12-25 mm 16 mm

Rotor movement Sets of the speed of the rotor.

“Slow” is particularly well

suited for preventing

overflowing of the dishes with a

high filling volume.

“Spread” is used in order to

achieve homogenous

distribution of the agar with low

filling volumes.

Slow

Normal

Spread

Normal

Continuous

filling

Allows to switch the

continuous filling on or off.

“ON” continuously fills the

number of dishes specified in

the program. The process

does not stop when all dishes

in the carousel are filled.

“OFF” pauses the process

after all dishes in the carousel

are filled.

(For further information see

“4.4.2

Filling dishes

continuously or

discontinuously” on page 32.)

ON

OFF

OFF

Shaker level

(Pour plate)

Sets the shaking speed of the

rotor for pour plate applications

(has to be enabled in program

configuration, see “4.2

Adapt

system parameter” on

page 26).

1-5

OFF

OFF

Batch mode Allows highly planar agar

surfaces by filling a defined

number of dishes (i. e. a batch)

per carousel stack, see “4.4.3

Filling dishes in Batch mode”

on page 33 (has to be enabled

in program configuration, see

“4.2

Adapt system parameter”

on page 26).

1-20

dishes/

batch

OFF

OFF

Program

parameter

Description Value

range

Basic

setting

Page 32

MEDIAJET – Operating instructions V09 Operation

32 INTEGRA Biosciences AG

4.4.1 Adapt dish height parameter

Measure the height of a stack of 10 using a ruler.

4.4.2 Filling dishes continuously or discontinuously

The carousel has a capacity of 360 and 540 Petri dishes respectively. However,

the program parameter ‘Number of dishes’ can be set up to 9999 dishes to be

filled. If the number of Petri dishes programmed exceeding the capacity of the

carousel, the filled dishes must be removed and empty ones must be loaded

during the filling process. For this there are two possibilities: Continuous or

discontinuous filling.

Biplate

alignment

(option)

To fill Petri dishes with two

compartments (with automatic

alignment of the dividing wall,

has to be enabled in program

configuration, see “4.2

Adapt

system parameter” on

page 26).

ON

OFF

OFF

Turbo mode

(option)

To accelerate filling of Petri

dishes (has to be enabled in

program configuration, see

“4.2

Adapt system parameter”

on page 26).

ON

OFF

OFF

Program

parameter

Description Value

range

Basic

setting

ASSISTANCE

It is important to always adapt the program setting dish height to ensure perfect

functioning of MEDIAJET.

NOTICE

In case you are working with Petri dishes higher than 21 mm you need to

underlay the filling nozzle holder with the supplied Base plate.

Press PROGRAM SETTINGS, choose the

parameter dish height and press CHANGE.

Enter the measured value.

Press SAVE in order to save this value.

The program adjustment is now complete.

Page 33

MEDIAJET – Operating instructions V09 Operation

33

www.integra-biosciences.com

Continuous filling

If the program parameter continuous filling is switched on, the MEDIAJET fills

the total number of programmed plates without pause and the exchange of the

Petri dishes must be performed during the filling process.

Discontinuous filling

Alternatively, with the parameter continuous filling off, the filling process will be

paused automatically once all the dishes in the nine carousel positions have

been filled.

4.4.3 Filling dishes in Batch mode

The Batch mode can be used for applications where it is important to have a

highly planar agar surface, as for example automatic colony counting. In the

batch mode, only every second position of the carousel must be filled with empty

Petri dishes. These dish stacks are then processed by user-defined batches of

1-20 Petri dishes. This allows the agar of the filled batch to solidify before it gets

lifted by the next batch. That prevents that the uppermost dishes of the stack

become slightly tilted before the agar is solidified, resulting in very planar

surfaces. To enable this option, see “4.2

Adapt system parameter” on page 26.

The device will then offer you a possibility in

the dialogue FILLING PROCESS ON HOLD to

continue the filling process with the dishes on

the next two carousel positions.

MEDIAJET will request you to remove the filled

dishes from the loading positions.

Remove the filled dishes from the two

loading positions.

Fill both positions again with empty dishes.

Press CONTINUE in order to fill the two new

stacks.

Continue this process until the programmed

number of Petri dishes have been filled.

You stop the program with ABORT

PROCESS.

Page 34

MEDIAJET – Operating instructions V09 Operation

34 INTEGRA Biosciences AG

4.4.4 Shaker level (pour plate)

Total viable count determination is often carried out by using the pour plate

method. The built in shaker supports the mixing of the sample with the agar

medium.

To enable this option, see “4.2 Adapt system parameter” on page 26.

Press SAVE in order to save this value.

4.5 Run dish filling program

Select the desired program under FILL DISHES.

Press START PROGRAM.

4.5.1 Connecting the tubing set

Press PROGRAM SETTINGS and choose

the parameter shaker level.

Using the arrow keys, select the shaker

level according to your needs (depending

on the filling volume and viscosity of the

culture medium).

NOTICE

Please ensure that the filling nozzle holder is correctly installed and the sensor

in front of this holder is clean when running a program with Biplate alignment

ON.

The dialogue window PREPARE FOR

FILLING PROCESS appears.

An empty Petri dish is automatically placed

in the filling position of the rotor.

ASSISTANCE

The tubing set must be autoclaved prior to use, in order to avoid contamination

during the filling process. If PUMP OPTIONS in SYSTEM PARAMETER is

enabled, press first PUMP OPTIONS to prime or to calibrate.

CAUTION

Never press PRIME if the cover of the pump head is open. Risk to squash

your fingers.

Page 35

MEDIAJET – Operating instructions V09 Operation

35

www.integra-biosciences.com

The tubing set is now connected.

Open the cover of the pump head.

Turn the adjusting screws 1 on both sides of

the pump head as far to the right (anticlockwise) as possible.

The V-shaped tubing mountings 2 drop to

the lowest possible position.

Place the tubing set into the pump such that

the filling nozzle is lying on the left hand side

of the pump head.

For an optimum function of the pump, the

tubing needs to centered on the rollers leading

through the two V-shaped mountings.

You require approximately 30 cm of tubing 3

between the pump and the filling-nozzle

mountings.

Now close the pump cover and make sure

that the tubing leads correctly through the

V-shaped mountings.

Make sure that the filling nozzle is inserted

into the filling nozzle holder as far as

possible.

For programs with the parameter “Biplate

alignment ON” place a second tubing set

into the double pump head to allow the

filling of two compartments in parallel

(MEDIAJET vario with biplate option only).

1

2

3

Page 36

MEDIAJET – Operating instructions V09 Operation

36 INTEGRA Biosciences AG

4.5.2 Filling the tubing

The preparations for the filling are now complete.

4.5.3 Calibration of the pump before filling

Before you start the actual filling process, you have the option of carrying out a

calibration of the dosing volume. This is particularly important if you work with

tubing(s) not obtained from INTEGRA Biosciences, as the dosing quantity is

directly dependent on the diameter of the tubing.

Biplate option

The double head pump squeezes two tubings in parallel. To guarantee a correct

filling volume, identical tubing must be used. Connect both tubing sets, calibrate

the pumps as described above with two graduated cylinders and enter the mean

of the measured volumes.

Connect the tubing set(s) to the media

source.

Keep the PRIME key pressed until the

tubing or both tubings (biplate option) are

completely filled respectively.

The empty Petri dish in the filling position of the

rotor prevents accidental contamination of the

filling chamber.

Press CALIBRATE

The dialogue window PUMP

CALIBRATION opens.

Before you start the calibration, make sure

that the tubing is completely filled with

medium.

Hold the filling nozzle in a suitable

graduated cylinder and press START or

DELAYED START (dosing will start after 5

seconds).

Enter the volume measured and press

SAVE.

Following calibration, insert the filling nozzle

into the filling nozzle holder.

The pump is now calibrated.

Page 37

MEDIAJET – Operating instructions V09 Operation

37

www.integra-biosciences.com

4.5.4 Start the filling process

4.5.5 Calibration of the pump during the filling process (option)

This calibration routine is specifically suited for user which like to determine the

filling volume of the Petri dishes using weight measurement.

Following calibration, insert the filling nozzle into the filling nozzle holder.

The pump is now calibrated.

4.5.6 Altering program settings of the filling process

While a process is running, you can adjust the program parameters at any time.

CAUTION

While the MEDIAJET is in operation, pay attention to your fingers when

operating the carousel. Be particularly careful if your hands are in the

immediate vicinity of the loading positions.

Press START.

The screen always shows you how many

dishes you have already filled and how much

time there is remaining until the end of the

filling process.

Press PAUSE.

Press CALIBRATE.

Enter the volume measured and press

SAVE.

ASSISTANCE

If PUMP OPTIONS in SYSTEM PARAMETER is enabled, press first PUMP

OPTIONS and then CALIBRATE.

ASSISTANCE

Alterations to program parameters, carried out during the filling process, are

not automatically saved. Following ending of the filling process, you will be

asked whether you wish to save the alterations in the program.

Press PAUSE.

Press PROGRAM SETTINGS.

You can now alter the desired program

settings.

Page 38

MEDIAJET – Operating instructions V09 Operation

38 INTEGRA Biosciences AG

4.5.7 Automatical end of the filling process

Following ending of the filling process, the PRIME function enables you to clean

the tubing set with warm water.

With the BACK key you return to the MAIN MENU.

4.5.8 Stopping the filling process

The filling process can be ended manually at any time.

Press PAUSE and then press ABORT PROCESS in order to end the process

finally.

4.6 Removing filled Petri dishes

As soon as the desired number of dishes have

been filled, the MEDIAJET will stop

automatically and will show the dialogue

FILLING PROCESS TERMINATED on the

screen.

ASSISTANCE

If PUMP OPTIONS in SYSTEM PARAMETER is enabled, press first PUMP

OPTIONS and then PRIME.

Press LOAD CAROUSEL in the MAIN

MENU.

Press UNLOAD.

CAUTION

While the MEDIAJET is in operation, pay attention to your fingers when

operating the carousel. Be particularly careful if your hands are in the

immediate vicinity of the loading positions.

Page 39

MEDIAJET – Operating instructions V09 Operation

39

www.integra-biosciences.com

4.7 Process documentation

The MEDIAJET enables you to document all process-relevant data. You can

issue this data on a label printer with a serial interface by connecting this printer

to the RS232 (2) port on the back of the MEDIAJET.

Alternatively, it is possible to transfer the data onto the built in printer of

MEDIACLAVE. This requires a MEDIACLAVE (Part No. 135 0xx) equipped with

a software version 1.9.1 or higher and communication interface cable (see “7.1

General accessories” on page 58).

If using MEDIACLAVE 10 (Part No. 136 0xx) or MEDIACLAVE 30 (Part No.

136 05x) all process relevant data of the MEDIAJET will also shown up in the

MEDIACLAVE electronic log file.

Remove the filled dishes from the two

loading positions.

Press ROTATE.

The carousel will turn two positions in

counter-clockwise direction.

Repeat the procedure described until all

Petri dishes have been removed.

The dishes have now been removed.

Page 40

MEDIAJET – Operating instructions V09 Operation

40 INTEGRA Biosciences AG

The following data (example) is printed out:

In the SYSTEM PARAMETERs, the possibility exists of carrying out the

following test print:

The RS232(2) Interface settings are fixed as follows:

Following calibration When starting the filling

process

Following completion of the

filling process

========================

MEDIAJET (SN:12345678)

***Calibration done

Time: hh:mm

Date: dd.mm.yyyy

========================

========================

MEDIAJET (SN:12345678)

***Start Filling Process

Time: hh:mm

Date: dd.mm.yyyy

***Program Settings

Name: TEST

Number of dishes: 360

Volume: 18.0 ml

Pump speed: 60 %

Anti-drip: ON

Pause time: 0.0 s

Dish height: 15.7 mm

Rotor move: NORMAL

Cont. filling: OFF

Shaker level: OFF

Batch mode: OFF

Biplate: ON

***System Parameter

UV-Lamp: OFF

Cooler: OFF

========================

========================

MEDIAJET (SN:12345678)

***End Filling Process

Time: hh:mm

Date: dd.mm.yyyy

***Program Settings

Name: TEST

Dishes filled:

10 of 360

Volume: 18.0 ml

Pump speed: 60 %

Anti-drip: ON

Pause time: 0.0 s

Dish height: 15.7 mm

Rotor move: NORMAL

Cont. filling: OFF

Shaker level: OFF

Batch mode: OFF

Biplate: ON

Turbo mode: ON

========================

========================

MEDIAJET (SN:12345678)

***Test Printout

LEFT RIGHT

123456789012345678901234

========================

Transmission Speed 9600 bps

Databits 8 bits

Partity No

Stopbits 1

Handshake X ON / X OFF

Page 41

MEDIAJET – Operating instructions V09 Operation

41

www.integra-biosciences.com

4.8 Dosing function

This function uses the peristaltic pump of the MEDIAJET for volumetric dosing

with a 6 mm ID tubing. The dosing can be optionally controlled with a foot switch

(see available accessories in “7.6

Accessories for dosing function” on page 62).

Press DOSING FUNCTION in the MAIN MENU to reach the parameter for

volumetric dosing.

Here the parameters and the value ranges are listed:

Press PRIME to fill the tubing and DOSING to start the program.

Use the arrow keys to select a parameter to

be changed.

Press CHANGE, and enter the desired

value.

Program

parameter

Description Value

range

Basic

setting

Dosing

volume

Defines the dosing volume. 1-999.9 ml 10 ml

Pump speed The setting 100 % corresponds to

the maximum conveying amount

of the MEDIAJET pump of approx.

500 ml/min.

30-100% 60%

Anti-drip Prevents drop formation at the

end of a dosage.

ON

OFF

OFF

Pause time Enables adherence to a defined

waiting period between two dosing

steps. If set to manual, the dosing

is triggered by the push of the key

or by the foot switch.

0.1-9.9

manual

2 s

ASSISTANCE

If PUMP OPTIONS in SYSTEM PARAMETER is enabled, press DOSING PUMP OPTIONS - PRIME to fill the tubing and DOSING - START to start the

program.

Page 42

MEDIAJET – Operating instructions V09 Operation

42 INTEGRA Biosciences AG

4.9 Mixing additives into the agar

The MEDIAJET, in connection with the peristaltic pump DOSE IT, can mix

continuously an additive in the concentration of 3 to 10 % into the medium. This

setup is typically used for the preparation of blood agar. Please also refer to the

DOSE IT operating instructions.

4.9.1 Installation

Place the DOSE IT pump close to the right side of the MEDIAJET. Plug one

side of the electrical interface cable into the socket marked with “Pump” on

the back of the MEDIAJET and the other side to the foot switch socket on the

back side of the DOSE IT pump.

4.9.2 MEDIAJET Settings

Press FILL DISHES in the MAIN MENU for adapting a dish filling program.

Select the desired program and press PROGRAM SETTINGS in order to

adjust it (see also “4.4

Adapting a dish filling program” on page 30).

You need this value for the DOSE IT program parameters (see below).

4.9.3 Determine the dosing volume of the additive

Determine the volume of additive to be added per dishes to achieve the desired

percent mixture.

For example, if the total dispensing volume in the Petri dish is 18 ml and the final

concentration of additive is 5 %, the dosing volume of the additive is 0,9 ml

(18 ml × 0.05). You need to enter this value in the DOSE IT program parameter

(see next page).

When connecting a sterilized Tubing set for the

preparation of blood agar, the small diameter

tubing (2 x 5 mm) has to be entered into

DOSE IT pump head and the big diameter

tubing (6 x 9 mm) into the MEDIAJET pump

head. The glass T-piece needs to be located

ahead of the MEDIAJET pump head.

Set the desired total Dispensing volume

(agar and additive) to be filled into the Petri

dishes.

Select Pump speed and press CHANGE to

get the ‘Estimated dosing time’ displayed,

automatically calculated by the MEDIAJET.

Page 43

MEDIAJET – Operating instructions V09 Operation

43

www.integra-biosciences.com

4.9.4 DOSE IT settings

Switch on the DOSE IT, the APPLICATION window appears. Select one of the

programs listed and press PARAMETER to configure it. Use the arrow keys to

select the parameters and press CHANGE to set different values.

With these settings, an optimal mixing of additive and medium is reached.

Exit the program by pressing START.

In case you are connecting the DOSE IT and the MEDIAJET for the first time or

when working with a new Tubing set it is recommended to confirm the pump

settings again and to perform the calibration routine of the DOSE IT.

4.9.5 Operation of MEDIAJET in combination with DOSE IT

Once MEDIAJET and DOSE IT are connected and the settings are adjusted as

described above, the instruments are ready to start the dish filling process.

Consider the following important points:

Select the adjusted program in the APPLICATION window of the DOSE IT

and press START.

Then select the desired program of the MEDIAJET under FILL DISHES and

press START PROGRAM. Press PRIME until the big diameter tubing is

entirely filled with media up to the Filling nozzle.

Press START on the MEDIAJET to start the dish filling process.

Set the Type to “DISPENSE” and the

Tubing-ID to “2.0 mm”.

Enter the desired volume of the additive,

e.g. 0.9 ml.

Change the Flow rate with the arrow keys

so that the displayed ‘Dispensing time’ is

equal to or slightly shorter than the

‘Estimated dosing time’ shown in the

MEDIAJET program (see above).

Set Repetitions to ““ and Pause to

“manual”.

Press PRIME to fill the small diameter

tubing in the DOSE IT pump with the

additive up to the glass T-piece.

After priming press START. The DOSE IT is

now ready to get started by the MEDIAJET.

Page 44

MEDIAJET – Operating instructions V09 Operation

44 INTEGRA Biosciences AG

4.10 TUBEFILLER option

The TUBEFILLER option allows to automatically fill test-tube racks on

MEDIAJET. Please ensure that the option is correctly installed as described in

“3.7

TUBEFILLER option” on page 23.

4.10.1 Adapting a TUBEFILLER program

Press TUBE FILLER in the MAIN MENU to reach the individually stored

programs. Adjust the program with the function PROGRAM SETTINGS in th e

same way as described in “4.4

Adapting a dish filling program” on page 30.

The following table gives an overview about the parameters to be set:

Program

parameter

Description Value range Basic

setting

Program

name

Defines the desired name of

the individual programs.

PRG xx

Rack type Defines the type of racks

used in the program.

Choosing the right rack type

is crucial to ensure the right

filling pattern during the

dispensing process.

13mm 6x15

16mm 5x12

20mm 4x10

25mm 3x8

30mm 3x7

16 mm 5x12

Dispensing

Volume (ml)

Defines the filling volume of

the test tubes.

0.5-99.9 ml 5 ml

Number of

racks

Defines the number of racks

to be filled in the program.

1-99 3

Tubing

inner

diameter

(mm)

Defines the type of silicone

tubing used in the program.

Choose the right tubing to

influence both dosing

accuracy and dosing time.

2.0 mm

3.0 mm

4.0 mm

3.0 mm

Pump

speed (%)

The setting 100 %

corresponds to a maximal

flow rate of approx. 500 ml/

min.

30-100 % 60 %

Anti-drip Prevents drop formation at

the end of a dosage.

ON

OFF

OFF

Pause time

(s)

Selectable pause time

between the dosing of two

individual test tubes.

0-9.9 s 0 s

Continuous

filling

When switched on the

number of programmed racks

will be continuously filled.

When switched off the unit

automatically stops after 3

racks are filled.

ON

OFF

ON

Page 45

MEDIAJET – Operating instructions V09 Operation

45

www.integra-biosciences.com

4.10.2 Prepare tube filling process

Select the desired program in the TUBEFILLER menu using the arrow keys and

press START PROGRAM.

The dialogue window PREPARE FOR FILLING PROCESS appears.

Connect the tubing for the media source as described in “4.5.1 Connecting

the tubing set” on page 34. Especially consider the following important

points:

The dialogue window TUBE FILLING appears

again summarizing the most important settings

of the selected program.

Manually turn the support plate until the

arrow printed on the edge of the plate points

to the filling arm.

Close the safety cover.

Press START to execute the automatic

adjustment of the support plate.

The adjustment of the screws (1) on both sides

of the pump depends on the tubing type used:

For 2 mm ID tubing the 1.6 marking has to

be on a level with the 4.8 marking on the

pump head (2).

For 3 mm ID tubing the 1.6 marking has to

be on a level with the 6.4 marking on the

pump head (2).

For 4 mm ID tubing the 1.6 marking has to

be as low as possible (2).

Fix the dispensing tube, lying on the left

hand side of the pump, onto the front end of

the filling arm and firmly tighten the screw in

order to prevent the dispensing tube from

moving during the dosing process.

1

2

Page 46

MEDIAJET – Operating instructions V09 Operation

46 INTEGRA Biosciences AG

Connect the tubing set to the media source and hold the PRIME key pressed

to fill the entire tubing with media.

The preparations for the filling process are now completed.

Before starting the filling process, it is possible to calibrate the actual dosing

volume in the same way as described in “4.5.5

Calibration of the pump during

the filling process (option)” on page 37. Start the calibration in the dialog window

PREPARE FOR FILLING PROCESS.

4.10.3 Start the filling process

NOTICE

To avoid spillage during the filling process, only use test tubes with an outer

diameter matching the available racks from INTEGRA BIOSCIENCES. Find a

test tube compatibility chart in “6.4

Test tube compatibility chart” on page 57.

Place the test tube racks completely even

onto the support plate and neatly fitted into

the six surrounding green bolts.

NOTICE

To avoid spillage during the filling process, double-check that the test tube rack

on the TUBEFILLER is the same type specified in the program parameters.

Working with test tubes longer than 15 cm

requires the use of a rack specific centring

plate. This centring plate maintain the tubes

in a perpendicular position and thereby

ensure a error free dosing process. See

also test compatibility chart in “6.4

Test tube

compatibility chart” on page 57.

Page 47

MEDIAJET – Operating instructions V09 Operation

47

www.integra-biosciences.com

While the process is running, the program parameters can be adjusted at any

time by pressing the PAUSE button as described in “4.5.6

Altering program

settings of the filling process” on page 37.

4.10.4 End filling process

Manually move the filling arm to align the tip

of the dispensing needle with the first tube

all to the right in the rack position 1 on the

support plate. Make sure that the

dispensing needle is exactly centred over

the tube to ensure a smooth filling process.

Press START in the PREPARE FOR

FILLING PROCESS window.

The status of the filling process will

continuously be displayed.

ASSISTANCE

If PUMP OPTIONS in SYSTEM PARAMETER is enabled, press first PUMP

OPTIONS and then PRIME.

The filling process can be stopped manually at

any time by pressing PAUSE followed by

ABORT PROCESS.

As soon as the desired number of racks are

processed, MEDIAJET will automatically stop

and the dialogue FILLING PROCESS

TERMINATED will appear on the screen.

The PRIME function enables to empty or clean

the tubing.

With BACK you can return to the MAIN MENU.

Page 48

MEDIAJET – Operating instructions V09 Maintenance

48 INTEGRA Biosciences AG

5 Maintenance

Purpose This chapter describes the regularly required maintenance procedures of the

MEDIAJET.

5.1 Cleaning

Press CLEANING in the MAIN MENU.

Remove remaining Petri dishes from the carousel.

Hold the carousel on the central, thick rods and lift it vertically from the axis.

Remove the safety cover.

Lift the rotor from the axis and move it to the right out of the filling chamber.

-

MEDIAJET vario with biplate option: Thoroughly clean the glass plate of the

alignment sensor positioned in front of the filling nozzle holder.

Clean the base plate rotor and the base plate carousel. Remove any residual

(agar, petri dish abrasion) and soiling in the sensitive areas of the flap

bearing, UV-lamp and Feeding/Stacking pistons.

Clean the filling chamber, the rotor and the safety cover thoroughly.

WARNING

Before carrying out repair or maintenance work, the device must always be

switched off and disconnected from the electricity supply.

NOTICE

Do not clean the Plexiglas safety cover with organic solvent, Acetone or pure

alcohol.

ASSISTANCE

Regular cleaning of the MEDIAJET is important in order to maintain the device

in a good condition and thus ready for operation. We recommend carrying out

the cleaning protocol described below following each filling process.

Moisten a soft, fluff-free cloth with a mixture

of water and washing-up liquid.

Clean the glass window in front of the

reflection light sensors thoroughly (those

sensors are positioned above and below the

UV lamp). Make sure that the glass

windows are dry and free of soiling.

Page 49

MEDIAJET – Operating instructions V09 Maintenance

49

www.integra-biosciences.com

Remove the O-ring of the drive wheel by dismounting the filling nozzle holder

and wash it with water. Replace the O-ring if, if necessary (only MEDIAJET

vario with biplate option).

Subsequently disinfect the filling chamber using 70 % Ethanol.

Regularly apply a very thin coat of grease (Klüber Microlube GBU-Y131, Part

No. 200 150) to the anchor bolts of the rotor/carousel axis.

If necessary, the CLEANING dialogue also allows you to clean beneath the

feeder and stacker pistons.

The MEDIAJET is now clean and ready for another filling process.

The moving parts of the pumphead should

be checked from time to time for freedom of

movement.

Occasionally lightly grease the lever (1) and

the rollers with Teflon lubrication oil (see

image).

Keep STACKER or FEEDER pressed and

move the corresponding piston using the

ARROW KEYS.

Clean the lifter rod of feeder and stacker

(the rear side of the dish plate in particular).

Apply a very thin coat of grease (Klüber

Microlube GBU-Y131, Part No. 200 150) to

the feeder/stacker pistons above the

sealing. Place the feeder and stacker piston

back to the starting position.

Re-install rotor, safety cover and carousel.

1

Page 50

MEDIAJET – Operating instructions V09 Maintenance

50 INTEGRA Biosciences AG

5.2 UV Lamp exchange

The aim of the UV lamp is to reduce the risk of contamination during the plate

filling process.

The UV-C lamp has an average life of 8000 hours. UV light intensity stabilizes

at about 85 % of initial output after 4000 hours. Risk of failure during a run can

be minimized by changing the bulb after 1000 operating hours. When 1000

operating hours are achieved a message is displayed after switching on the

MEDIAJET. Proceed as follow to replace the UV Lamp:

Switch off the MEDIAJET.

Remove the safety cover.

Lift the rotor from the axis and move it to the right out of the filling chamber.

Slide out the UV lamp from the lamp holders.

Fit the new UV lamp in the lamp holders.

Completely pull up the red lever positioned on the left side of the lamp holder.

Switch on the MEDIAJET.

Access the UV-LAMP menu of the system parameter and press RESET to

set the counter back.

The MEDIAJET UV lamp is now ready to operate.

ASSISTANCE

To guarantee optimum germicidal effect of the UV lamp, we recommend

replacing it at the latest after 1000 operating hours.

Completely pull down the red lever

positioned on the left side of the lamp

holder.carousel

Page 51

MEDIAJET – Operating instructions V09 Maintenance

51

www.integra-biosciences.com

5.3 Leak test

It is recommended to perform a leak test about every 3 months or when dosing

errors occur. A leak test will reveal worn or defect tubing or pumphead.

Procedure:

1 Load a silicone tubing in the pumphead.

2 Position the dispensing end of the tubing below the pumphead height into a

container.

3 Put the aspiration tube in liquid and keep the PRIME key pressed to fill the

tubing completely without any bubbles.

4 Lift the aspirating end of the tubing as high as possible above the

pumphead. The system is tight, if the liquid level do not decrease and no

liquid flow out of the lower dispensing end.

If the system is leaking, you have to check whether the tubing or the pumphead

is worn:

Repeat the leak test with a new tubing (only use original INTEGRA tubings, see

“7.3

Consumables” on page 60).

• If system is tight, the tubing was worn and the problem is solved.

• If the system is still leaking, the pumphead is worn (e.g. lever loose,

mechanical play) and need to be replaced, see “7.1

General accessories” on

page 58.

ASSISTANCE

Work around until a new pumphead is available: Put a rubber band (5 to 8 mm

wide) around the pumphead to help holding it fully closed during operation.

Repeat the leak test to confirm that the work around works.

Page 52

MEDIAJET – Operating instructions V09 Maintenance

52 INTEGRA Biosciences AG

5.4 Servicing

We recommend that you have the MEDIAJET serviced once per year.

Servicing work and repairs must only be carried out by experts using original

replacement parts. For any service or repairs, please contact your local service

technician.

If the surface of the MEDIAJET has been in contact with biohazardous material,

it must be decontaminated in accordance to good laboratory practice. Do not

spray directly on the instrument but use a lint-free cloth, lightly soaked with a

disinfectant and wipe dry directly after decontamination. Never use acetone or

other solvents! Follow the instructions provided by the disinfectant

manufacturer.

5.5 Fault notifications

In the event of a fault an acoustic alarm sounds.

Switch off the active alarm tone by pressing the sign.

Now read the alarm text on the display and follow the instructions.

When the fault has been removed you can continue working.

ASSISTANCE

If the MEDIAJET is one year in operation since the last service, a service

reminder is displayed in the MAIN MENU and stored in SYSTEM

PARAMETER - SYSTEM MESSAGES, where it can be re-displayed.

WARNING

MEDIAJET needs to be cleaned before sending it to service and the

declaration on the absence of health hazards must be signed. This is

necessary to protect service personnel.

ASSISTANCE

There are various fault codes for quick and easy fault diagnosis. Some of them

are of relevance to you as user.

In case a TECHNICAL ERROR is displayed by MEDIAJET please contact the

local customer service department.

Page 53

MEDIAJET – Operating instructions V09 Maintenance

53

www.integra-biosciences.com

5.6 Disposal

The MEDIAJET is labelled with the “crossed-out bin” symbol to indicate that this

equipment must not be disposed of with unsorted municipal waste. Instead, it is

your responsibility to correctly dispose of your waste equipment by handing it

over to an authorised facility for separate collection and recycling.

It is also your responsibility to decontaminate the equipment in case of

biological, chemical, and/or radiological contamination so as to protect from

health hazards the persons involved in the disposal and recycling of equipment.

For more information about where you can drop off your waste equipment for

recycling, please contact your local dealer from whom you originally purchased

the product or your local council.

By doing so, you will help conserve natural resources and you will ensure that

your waste equipment is recycled in a manner that protects human health and

the environment. Thank you!

Page 54

MEDIAJET – Operating instructions V09 Technical data

54 INTEGRA Biosciences AG

6 Technical data

6.1 Specification of the device

Dimensions

Basic device (H x W x D) 330 mm x 655 mm x 634 mm

With 360 carousel (H) 1070 mm

With 540 carousel (H) 1405 mm

Maximal Petri dish stacking height

Carousel 360

683 mm

Carousel 540

1017 mm

Weight

Basic device 47.0 kg

360 carousel 6.8 kg

540 carousel 8.3 kg

Materials

Housing Polyurethane (PUR)

Safety cover Acrylic glas (PMMA)

Bare metal Stainless steel

Black carousel base plate Aluminium/PTFE

Rotor base plate (surface below

rotor)

Polyethylene (PE)

Electricity supply

Electricity consumption 200 W

Fuses T 2A (2x)

Input voltage 100-240 V 50/60 Hz

Connectors

Panel connector male (IEC C14)

For power cord with connector female (IEC C13)

Pump

Dosing range per dish 1–99.9 ml

Maximum dosing rate 500 ml/min

Maximum tube dosing rate 260 ml/min

Standard dish filling rate circa 900 dishes/hour (up to 15 ml)

Turbo dish filling rate circa 1100 dishes/hour (up to 24 ml)

Tube filling speed 1000 test tubes/hour (10 ml, 4 mm ID

tubing)

Dosing reproducibility circa 1% (at 15 ml)

Tube filling precision <1% (1–99 ml)

Page 55