Page 1

MAYFIELD® 2 Base Unit

(A3100, 3101, 3102)

EN – ENGLISH

Instruction Manual

EN – ENGLISH ...................................2

FR – FRANÇAIS ................................ 24

IT – ITALIANO ................................. 48

DE – DEUTSCH ................................ 72

ES – ESPAÑOL .................................96

NL – NEDERLANDS ........................... 120

1

Page 2

EN – ENGLISH

2

Page 3

0123

Symbols used on Labeling

EN – ENGLISH

CAUTION

Hazards which could result in equipment or property damage.

WARNING!

Hazards which could result in personal injury or death

EC REP

REF

Conforms to the European Medical Device Directive (MDD).

Authorized EC Representative in the European Community.

Attention, consult accompanying documents

Product catalog number

Manufacturer

Caution: Federal (USA) Law restricts this Device to sale by or on the order of a Licensed practitioner.

This device is not indicated for use in MR environment.

Indications For Use

The MAYFIELD® 2 Base Unit is intended to be used to support a patient during diagnostic examination and/or surgical

procedures where a rigid support between surgical table and headrest, or skull clamp is necessary, positional freedom is

required.

WARNING!

Failure to read and follow instructions and warnings furnished in this instruction manual and the instructions and warnings

included in the associated skull clamp instruction manual may result in skull pin slippage and serious patient injury, such as

scalp lacerations, skull fracture, or even death.

Failure to properly position patient and to fully tighten and secure all adjustable portions of this or any similar device may

result in skull pin slippage and serious patient injury, such as scalp laceration, skull fracture, or even death.

Monopolar electrosurgical equipment with operational voltages that exceed 3000 V may result in patient harm when this

system is used in conjunction with a skull clamp.

The user must make sure that any threaded connections are secure and starbursts have meshed (where applicable) after

adjustments are complete. Failure to do so may result in serious patient injury.

CAUTION!

Always make sure the base unit is properly secured to the operating table. The base unit must not be used if the device

appears to be damaged or functioning incorrectly.

Do not use any tools on this equipment to secure. Over-tightening any of the adjustment screws or knobs may result in

damage to the unit. If unit does not appear secure after hand-tightening, do not use the unit and contact your MAYFIELD

Representative or the MAYFIELD Service Team.

Over-extending or overloading the base unit may result in unintended movement, shortened product life and/or damage to the

unit.

Do not alter the construction of this device as it may result in serious patient injury.

Not all MAYFIELD products can be cleaned and decontaminated in the same manner as those labeled as MAYFIELD 2.

Consult the individual instructions for use (for each device) on the proper care and cleaning procedures.

2

Page 4

EN – ENGLISH

Description

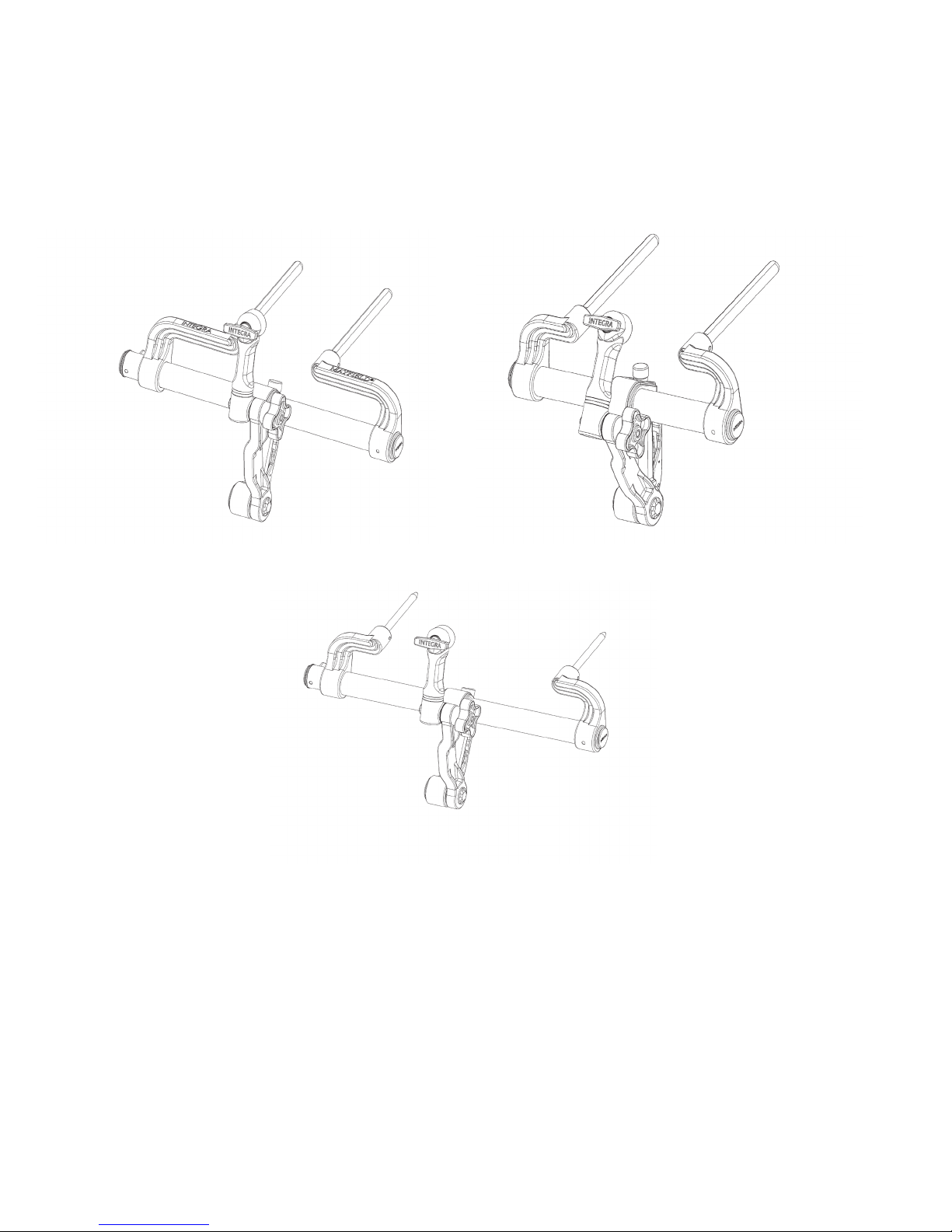

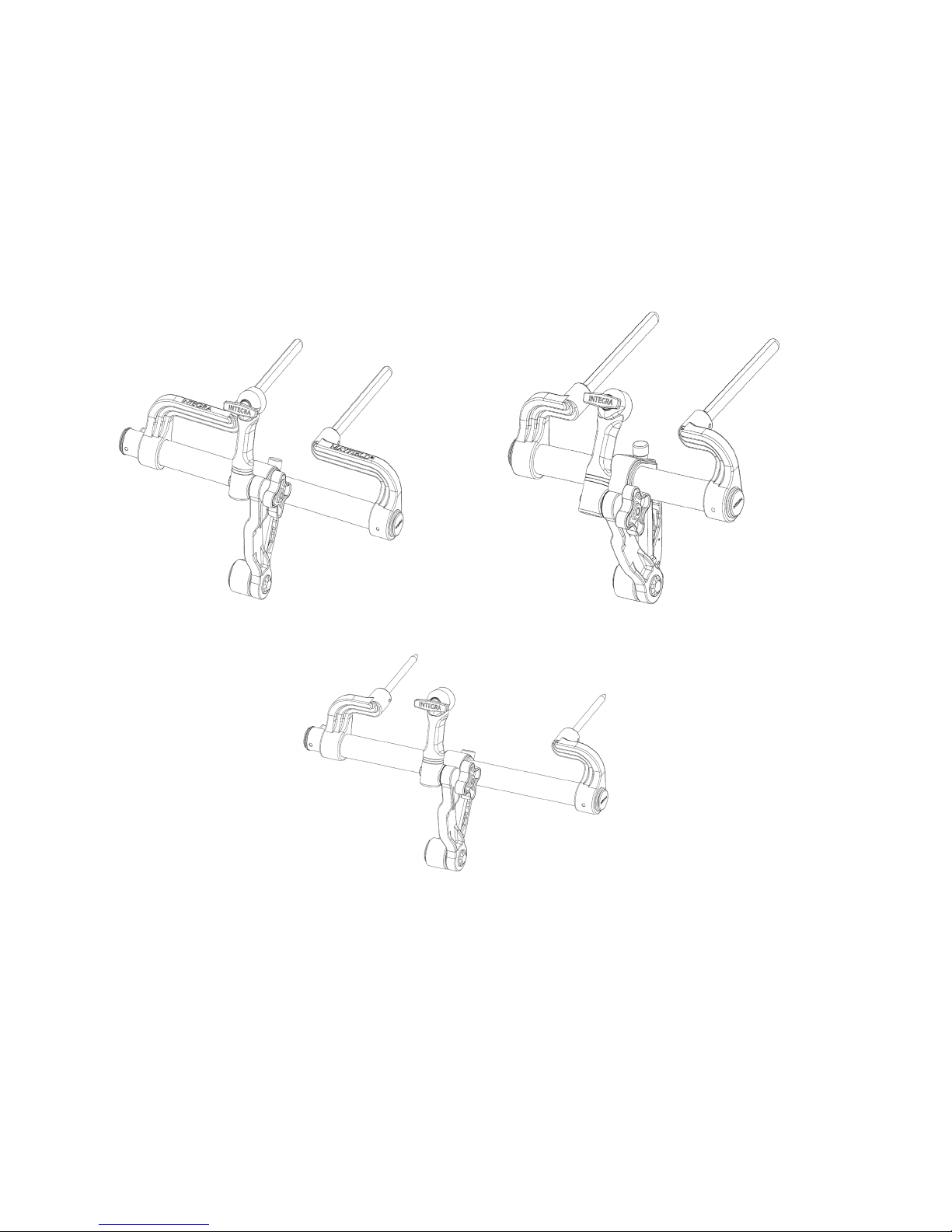

The MAYFIELD 2 Base Unit (REF A3101, A3102, A3100) is designed to provide attachment from the operating room table to

MAYFIELD Skull Clamps for rigid skeletal fixation or MAYFIELD Horseshoe Headrests for procedures where support only, and

not rigid fixation, is required. The MAYFIELD 2 Base Unit is designed for patient positioning in the prone, supine lateral or

park-bench and sitting positions. The Support Rod spacing may be readily adjusted to fit most operating room tables. No

tools are required. See Attachment to Operating Room Table for instructions to adjust the Support Rods.

MAYFIELD 2 Base Unit, Standard A3101

MAYFIELD 2 Base Unit, Narrow A3100

MAYFIELD 2 Base Unit, International A3102

Figure 1 MAYFIELD 2 Base Unit Catalog Numbers

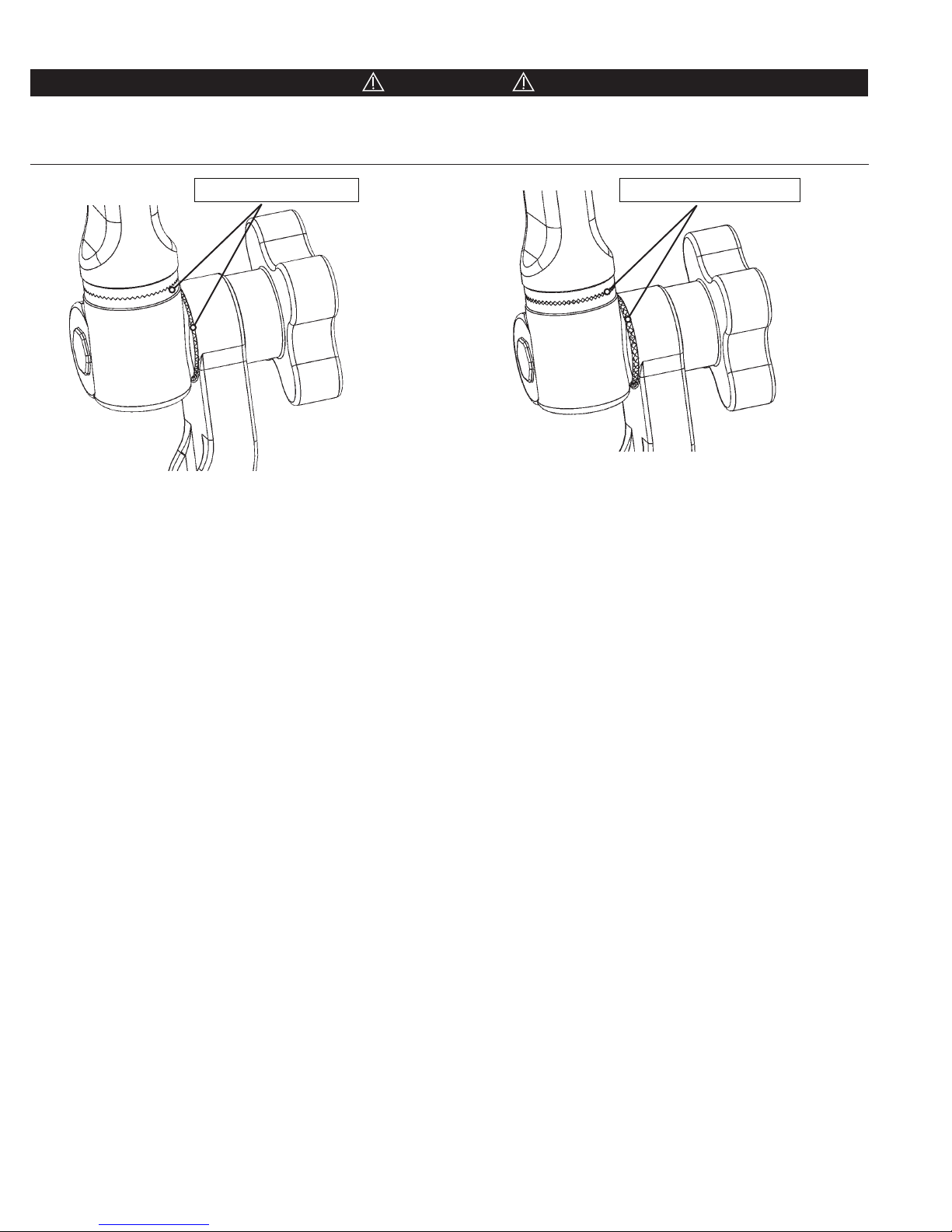

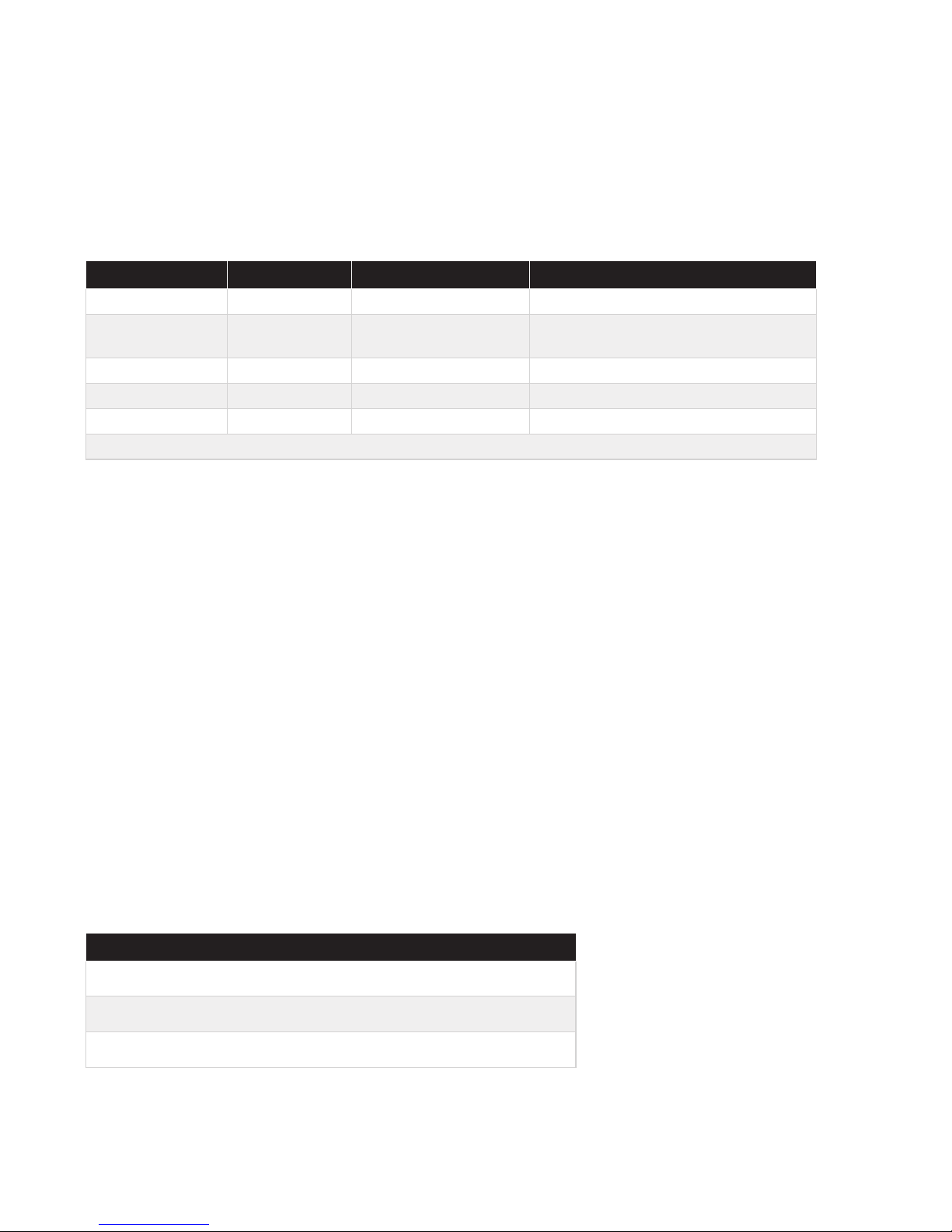

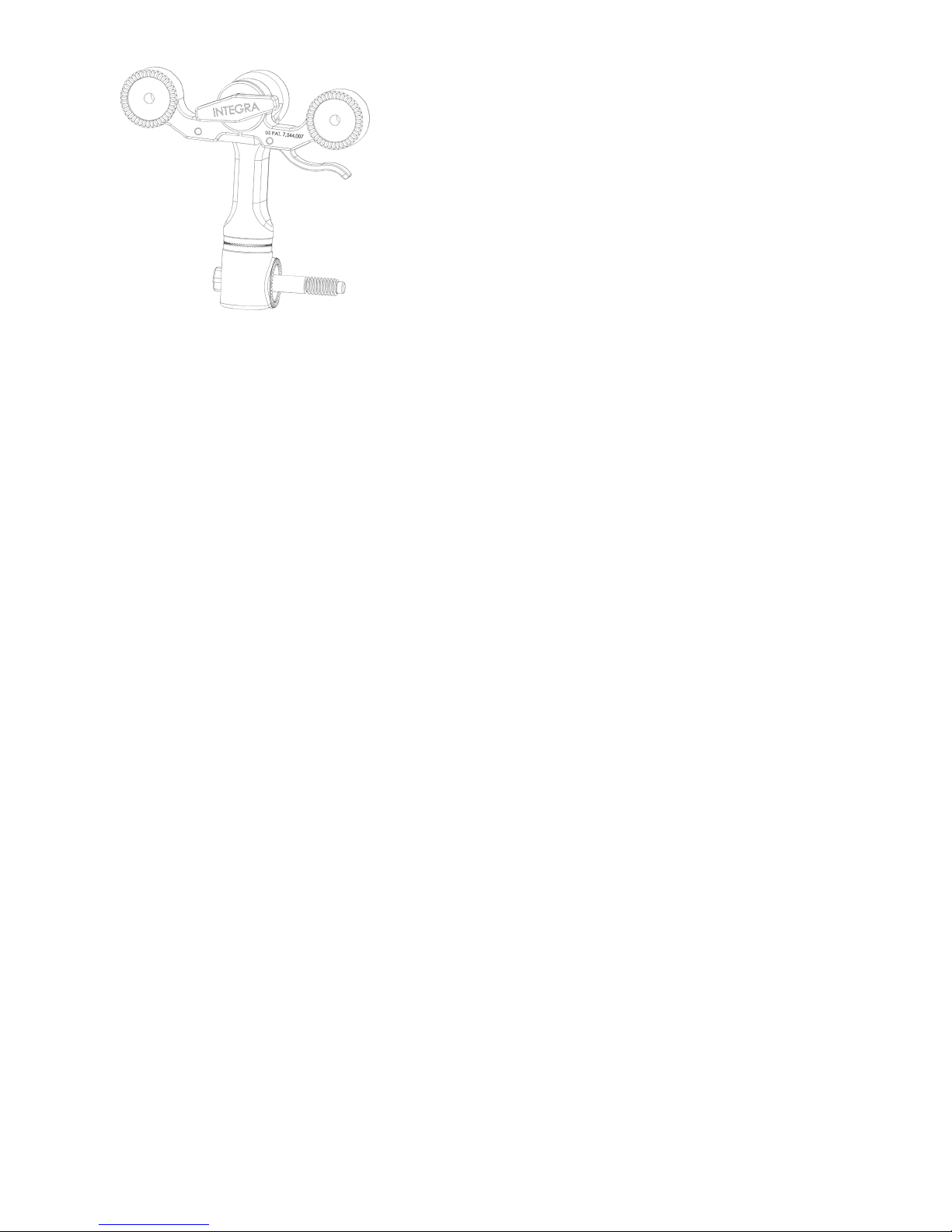

A Standard MAYFIELD 2 Swivel Adaptor (A3018) is an integral component of the Base Unit. A separate, optional MAYFIELD 2

Tri-Star Swivel Adaptor (A3008) is available as an accessory product when image-guided surgery (IGS) systems are used in the

procedures. The Tri-Star Swivel Adaptor provides two extra starbursts for attachment of the ancillary IGS equipment.

Each MAYFIELD 2 Base Unit purchased (A3100, A3101, or A3102) includes:

1- MAYFIELD 2 Base Unit

1- MAYFIELD 2 Swivel Adaptor (A3018)

OPTIONAL: MAYFIELD 2 Tri-Star Swivel Adaptor (A3008)

3

Page 5

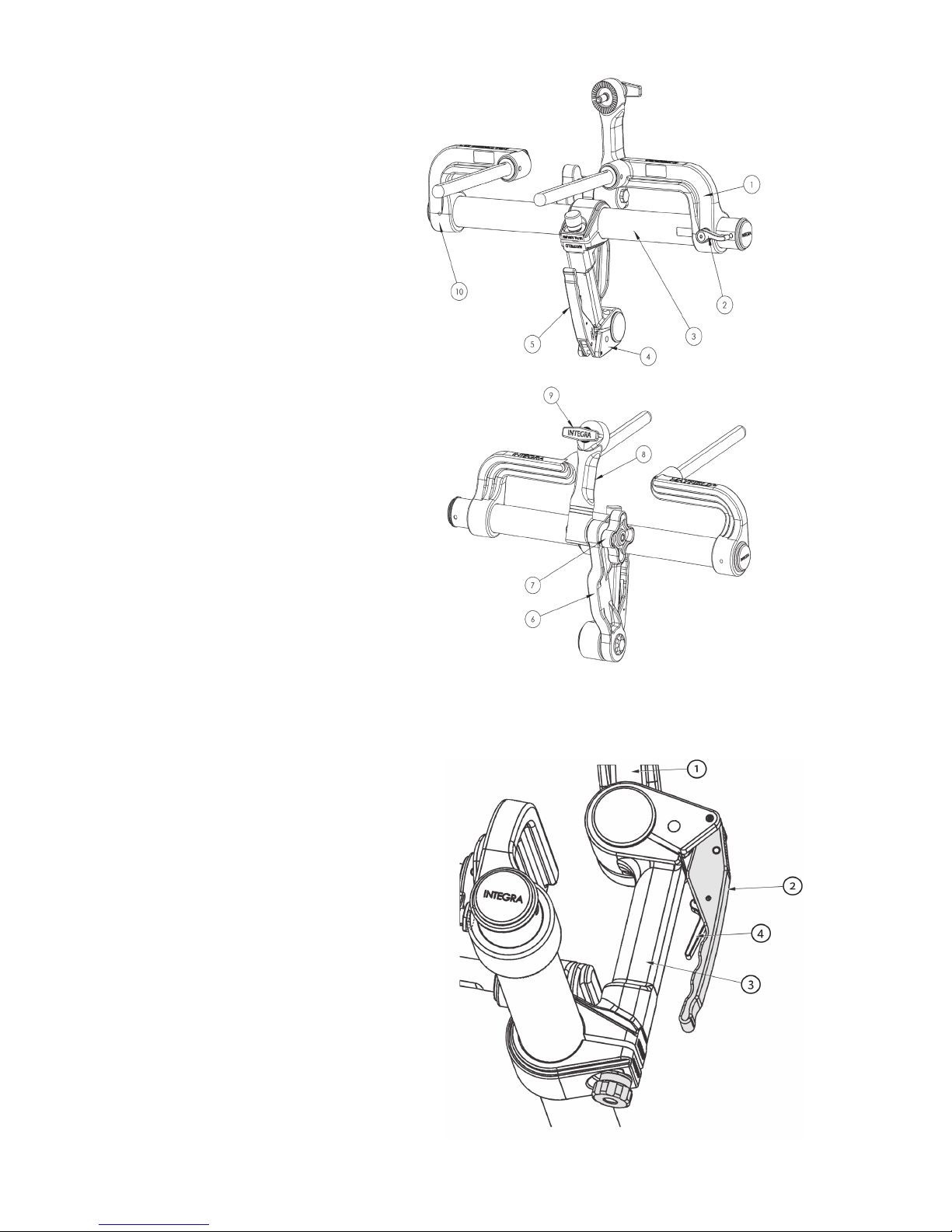

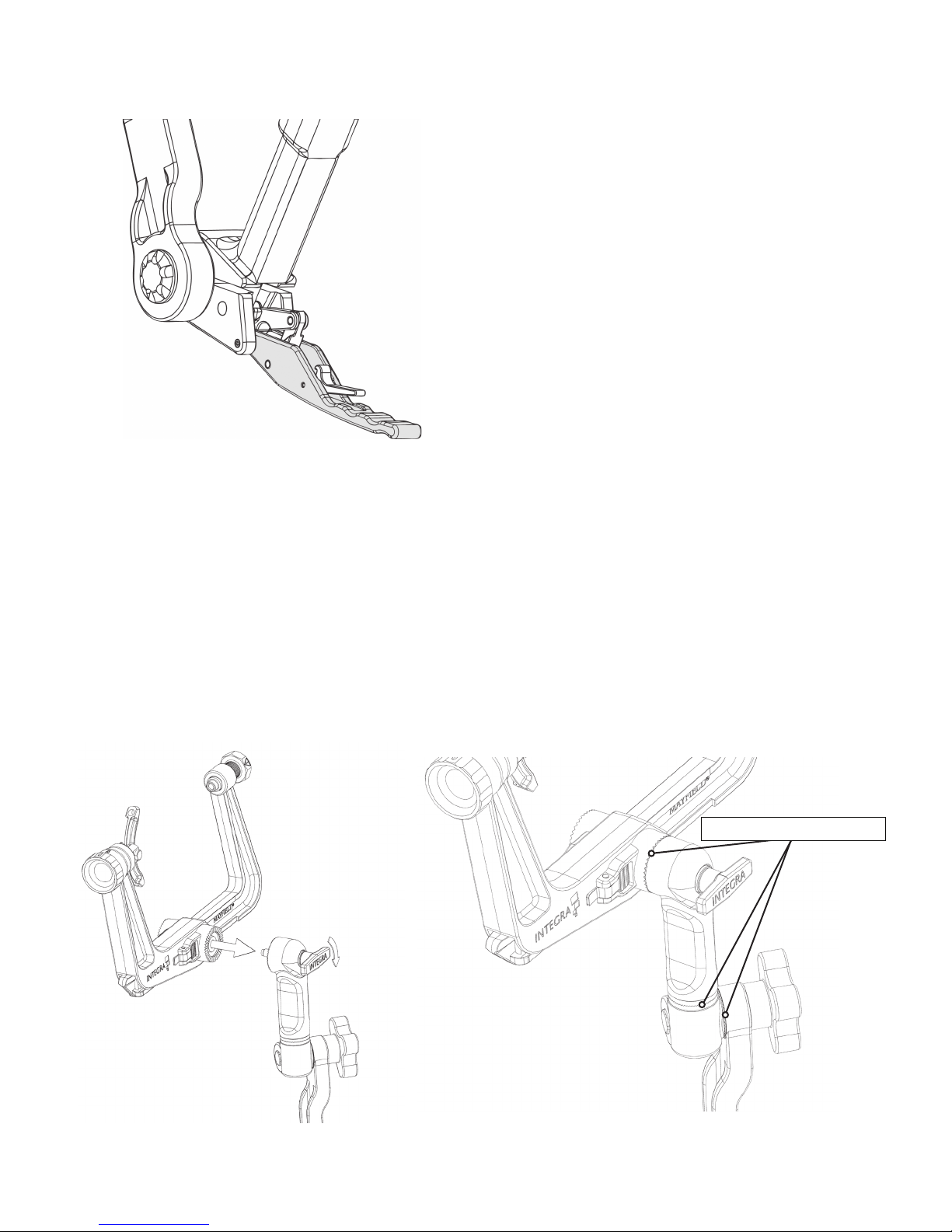

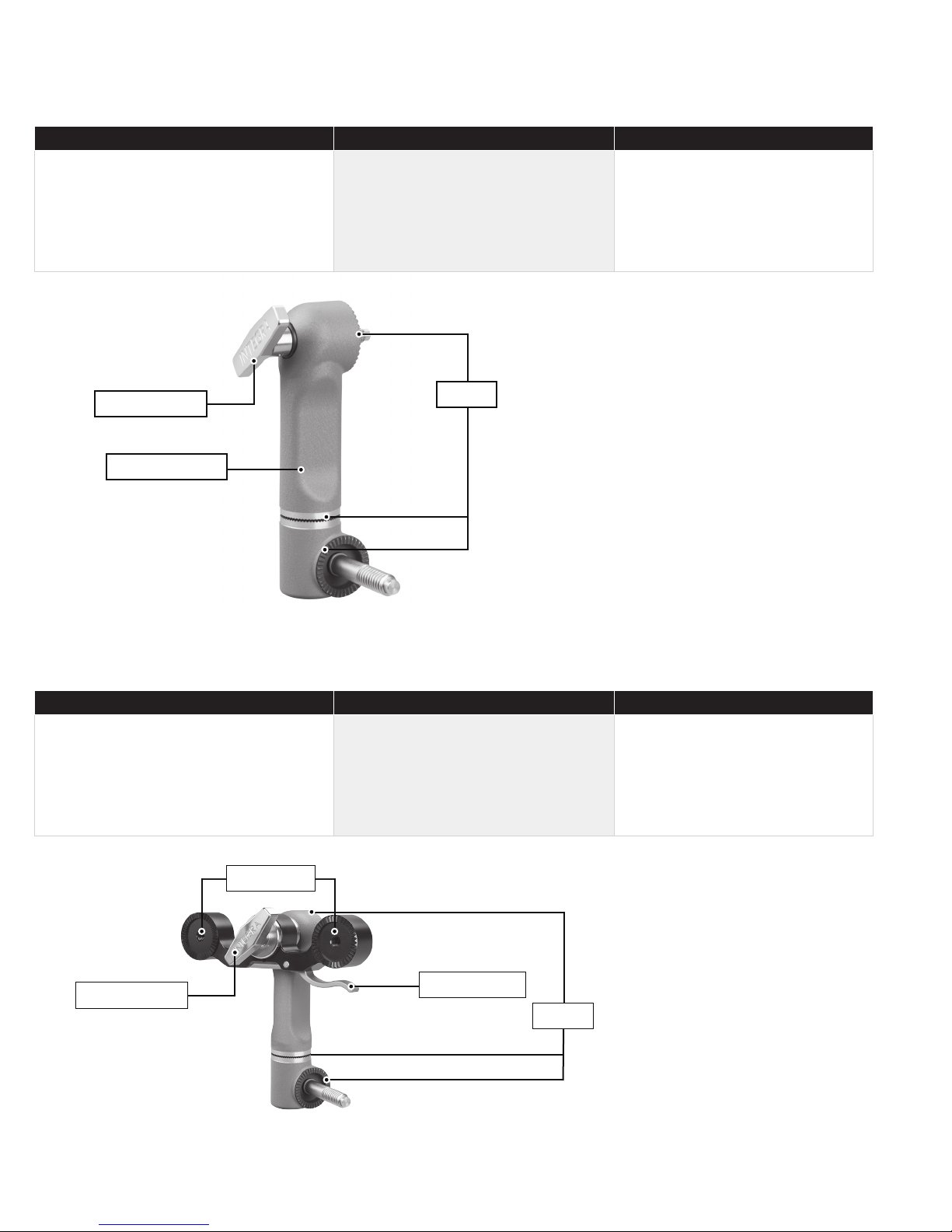

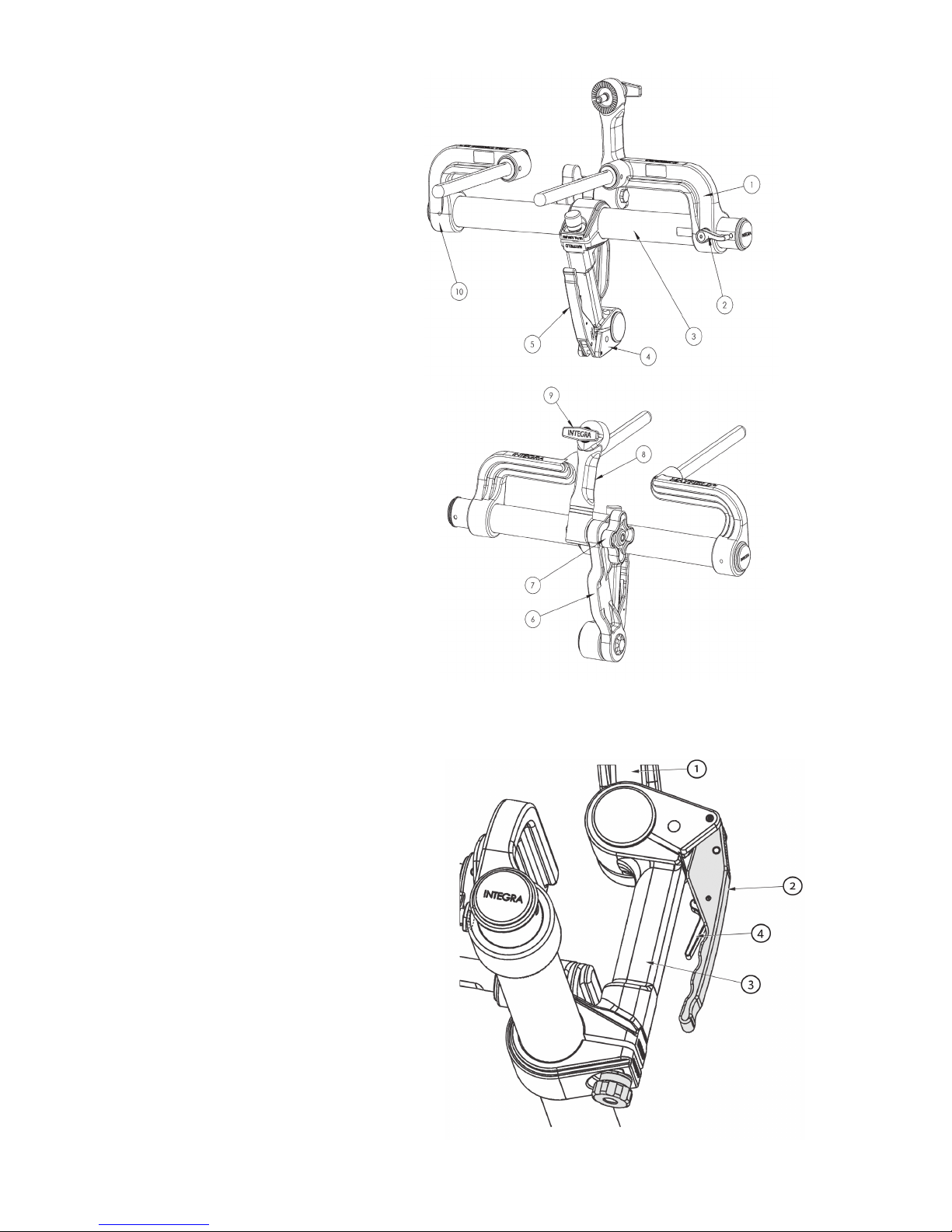

1. Left Bracket

2. Left Bracket Lock Knob

3. Connecting Tube

4. Base Handle Assembly

5. Locking Lever

6. Transitional

7. Swivel Lock Knob

8. Swvel Adaptor (A3018)

9. Headrest Lock Knob

10. Right Bracket

EN – ENGLISH

1. Transitional

2. Locking Lever

3. Latch

4. Base Handle Assembly

Figure 2A MAYFIELD 2 Base Unit Components

Figure 2B MAYFIELD 2 Base Handle Components

4

Page 6

EN – ENGLISH

Figure 3 OPTIONAL MAYFIELD 2 Tri-Star Swivel Adaptor (A3008)

The MAYFIELD 2 Base Unit is designed for use with the following equipment:

A1008 MAYFIELD General Purpose Headrest

A1011 MAYFIELD Horseshoe Headrest*

A1012 MAYFIELD Adult Horseshoe Headrest

A1015 MAYFIELD Crossbar Adaptor**

A1031 MAYFIELD (A&B) NeuroGen Adaptor

A1051 MAYFIELD Pediatric Horseshoe Headrest*

A1059 Modified MAYFIELD Skull Clamp

A1073 Posterior Cervical Support

A1108 MAYFIELD Triad Skull Clamp

A1109 MAYFIELD Horseshoe Conversion Adaptor

A1112 MAYFIELD Infinity Support System

A1113 NeuroGen Adaptor

A1114 MAYFIELD Infinity Skull Clamp

A1114A MAYFIELD Infinity Skull Clamp

A2000 MAYFIELD 2000 Skull Clamp

A3059 MAYFIELD 2 Skull Clamp

*A1109 MAYFIELD Headrest Conversion Adaptor is required for use

**A1060 Universal Side Rail Fittings is required for use

Note: Use of MAYFIELD products and accessories in conjunction with other manufacturer’s stabilization equipment is not

recommended.

5

Page 7

EN – ENGLISH

Inspection

Always inspect MAYFIELD equipment before and aer use. If a component appears damaged and/or does not seem to

function properly, do not use the device and immediately send the instrument to an authorized Integra repair center for

evaluation, repair or replacement.

Care and Maintenance

Your Integra representative will regularly perform a comprehensive inspection of your MAYFIELD equipment. In addition,

to ensure that factory-set calibrations remain in good working order, a Preventative Maintenance is required yearly at the

Integra authorized Service & Repair Center. Integra will do its best to provide comparable Service loaner equipment while

your MAYFIELD undergoes this required yearly maintenance.

To ensure proper function and to extend the life and performance of the equipment, Integra LifeSciences requires the

following:

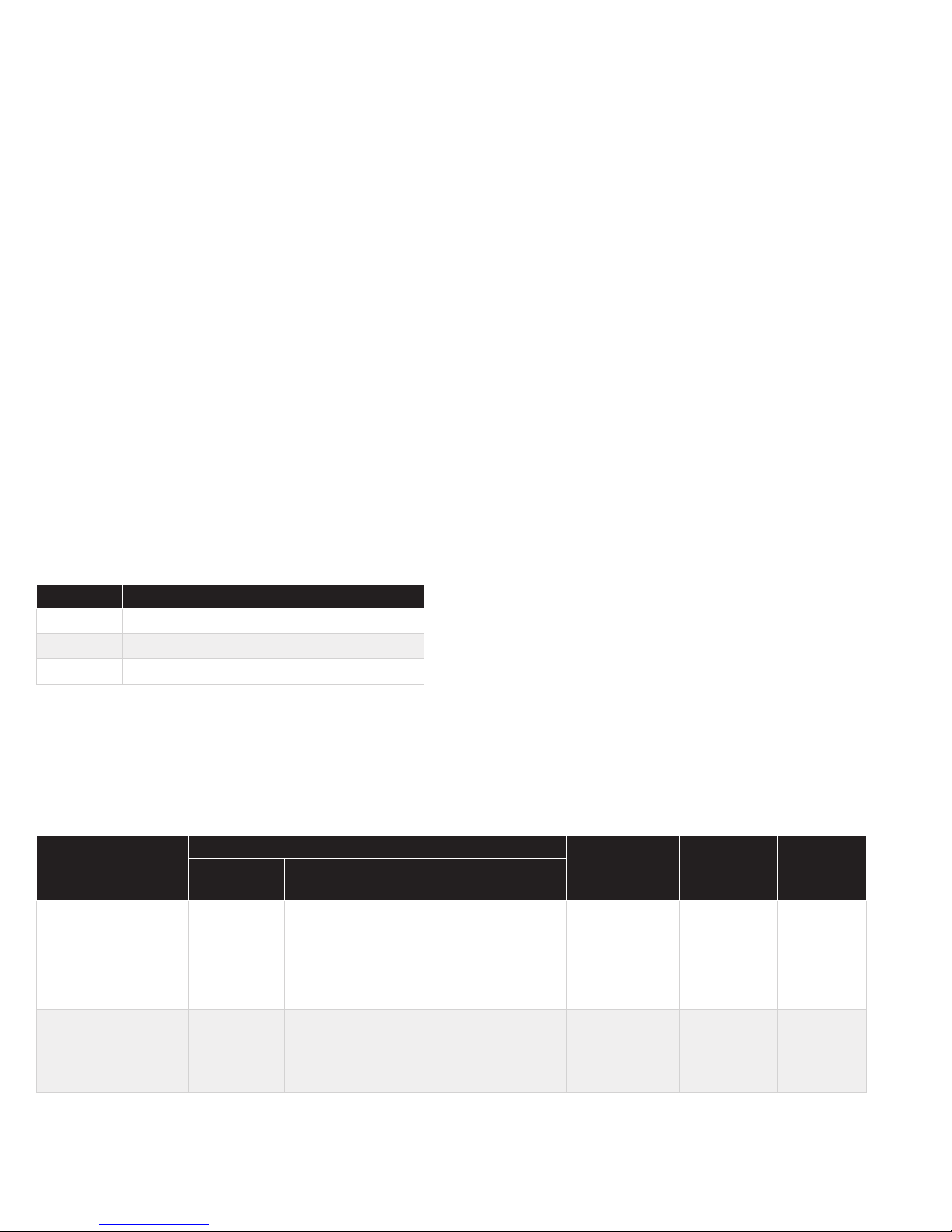

Required Action Required Frequency

Return the device to the Integra LifeSciences Repairs department for detailed inspection

and servicing.

Request that Integra NeuroSpecialists perform routine inspections of the device

In the absence of proper care and servicing of the device, negative effects may be seen after repeated processing over time

which may lead to reduced performance.

Contact information: See the Service and Repair section for contact information on how to return your device for periodic

servicing and to request periodic inspections.

Once / year

Twice / year

Device Disposal

NOTE: Follow hospital procedures for disposal of this device.

CAUTION!

If unit is dropped or mishandled, it should be inspected for damage. (REF Inspection section of this Instruction manual). If

damage occurs, do NOT use; return the complete device immediately to Integra for inspection.

6

Page 8

EN – ENGLISH

Directions for Use

Attachment of the Base Unit to Operating Room Table:

MAYFIELD 2 Base Unit (3100) Le Bracket may be adjusted along the Connecting Tube to allow the Support Rod to

accommodate table receptacles spaced 4-1/2” to 8-1/4” (114mm to 209.5mm) apart.

MAYFIELD 2 Base Unit (3101) Le Bracket may be adjusted along the Connecting Tube to allow the Support Rod to

accommodate table receptacles spaced 5-1/8” to 8-1/4” (130mm to 209.5mm) apart.

MAYFIELD 2 Base Unit (3102) Le Bracket may be adjusted along the Connecting Tube to allow the Support Rod to

accommodate table receptacles spaced 6-5/8” to 15-3/4” (168mm to 400mm) apart.

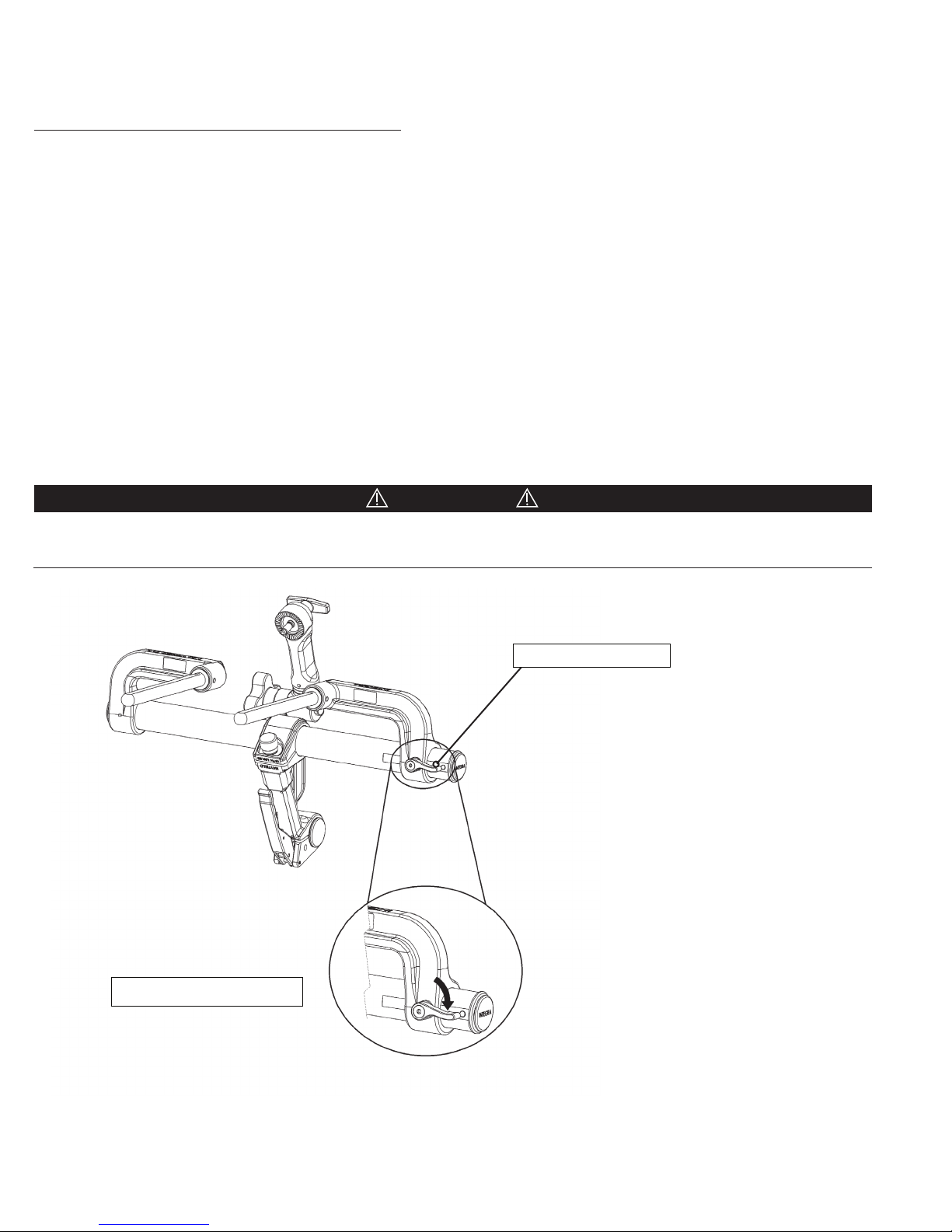

1. Locate and loosen the Left Bracket Lock Knob on the backside (See Figure 4) of the Left Bracket and slide the Left Bracket

smoothly along the the Connecting Tube until the desired width between the Support Rods is achieved.

2. Mount the Base Unit to the operating room table by aligning the two Support Rods with receptacles at the head end of

the Operating Room table, or, in the NeuroGen Adaptor or Crossbar Adaptor.

3. Tighten the Left Bracket Lock Knob to secure the Left Bracket into position.

CAUTION!

Do NOT use any tools to tighten any knobs on this device. All knobs should be hand tightened only. Use caution not to overtighten. Over-tightening may damage the device.

Le bracket lock knob

Clockwise rotation to tighten

Figure 4 Le Bracket Lock Knob

4. Secure the Base Unit Support Rods to the table by tightening the table lock knobs or the knobs on the NeuroGen

Adaptor or Crossbar Adaptor.

7

Page 9

EN – ENGLISH

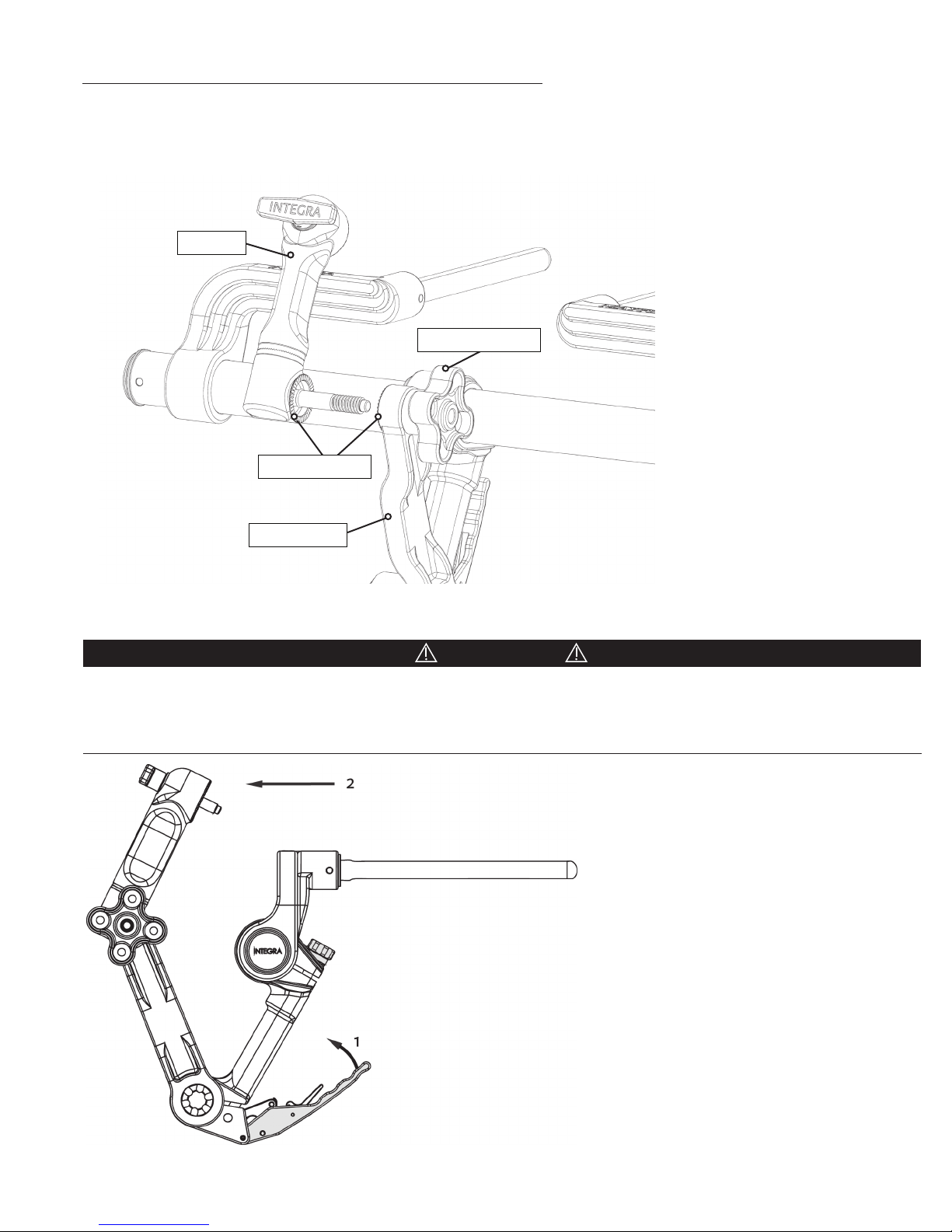

Attachment of the Swivel Adaptor (A3018 or A3008) to the Base Unit

Insert screw of Swivel Adaptor into clover-shaped Swivel Lock Knob at the end of the transitional arm. Tighten by turning

Swivel Lock Knob clockwise and ensure that all starburst teeth are meshed. Do not over-tighten. No tools should be used to

attach or remove the Swivel Adaptor from the Base Unit.

Swivel

Swivel Lock Knob

Starburst Teeth

Transitional

Figure 5 Aachment of Swivel Adaptor

CAUTION!

Confirm the Base Unit stability by positioning (connected to operating table) the components as shown in Figure 6. Exert

moderate force against the Swivel Adaptor in the indicated direction shown by arrow 2 in Figure 6. No movement should be

observed at any of the joints. If movement is observed, do not use product and contact your MAYFIELD Representative or the

MAYFIELD Service Team.

Figure 6 Stability Check

8

Page 10

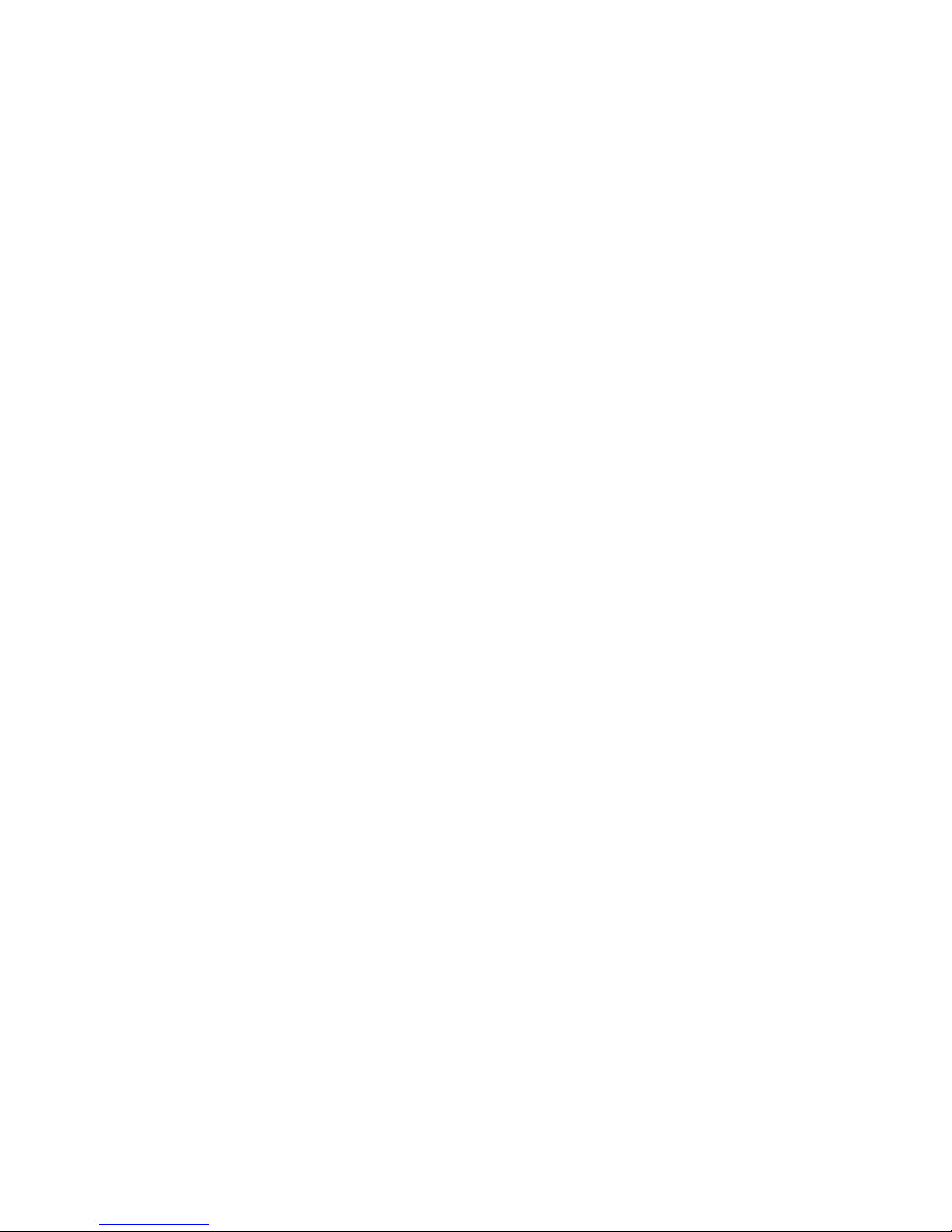

EN – ENGLISH

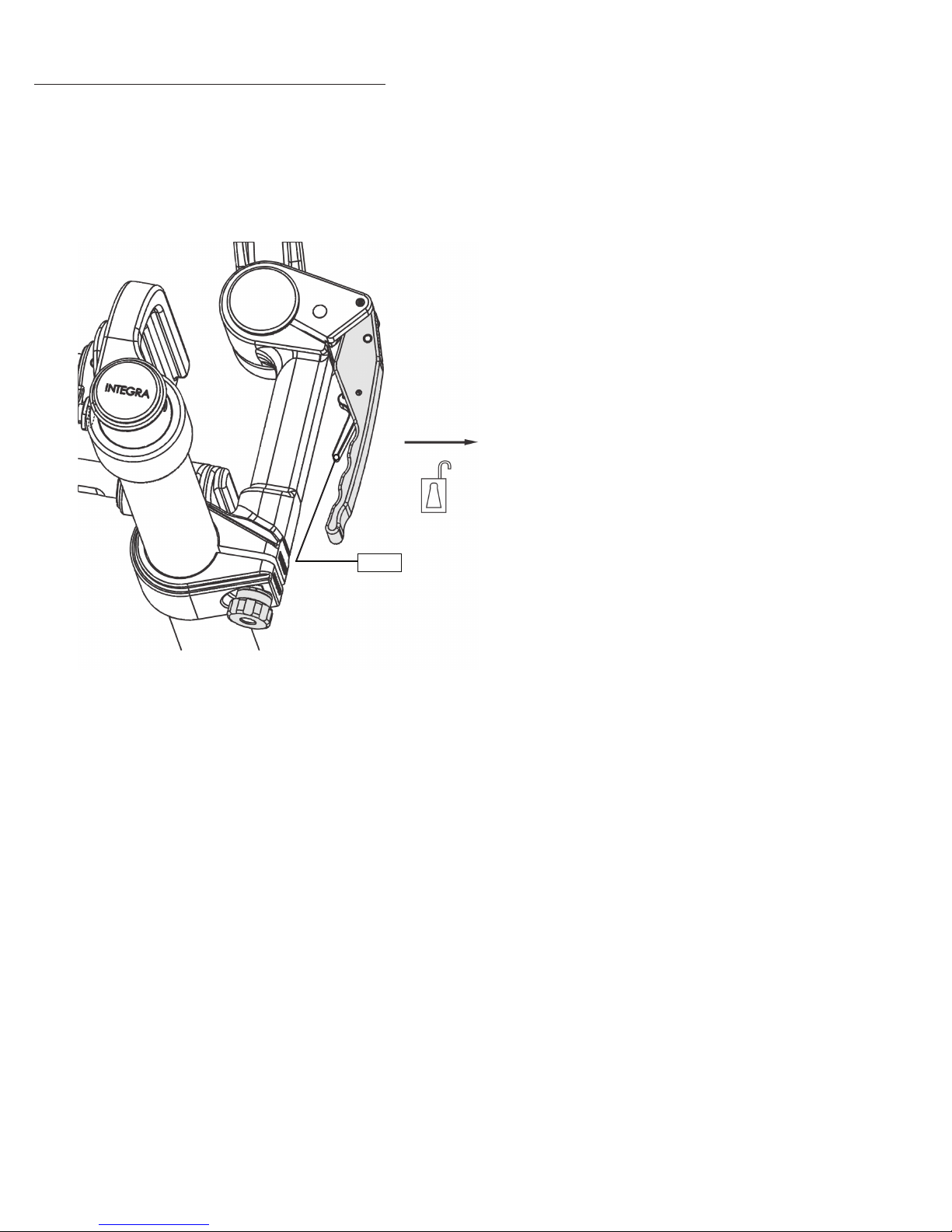

Positioning the Transitional Arm and Swivel Adaptor

The handle is equipped with a self-latching feature. To free the Locking Lever, press the latch into the Locking Lever, the

lever will move away from its closed position.

Latch

Figure 7 Handle Self-Latching Feature

9

Page 11

EN – ENGLISH

1. Open the Locking Lever to position the Transitional Arm as desired. The Locking Lever must be in the fully opened

position to perform free movement of the Transitional Arm.

Figure 8 Open Locking Lever

2. Once the Skull Clamp is applied to the patient’s skull, the surgeon will maneuver the patient to the surgical position

that is required for the procedure. With the patient in this position, the surgeon will hold the patient’s head and the

Skull Clamp and request that the Transitional Arm be brought up to the proper height for attachment of the Skull

Clamp to the Swivel Adaptor.

a) Once the Transitional Arm is at the proper height for attachment to the Skull Clamp, the mounting screw of the

large starburst on the Swivel Adaptor should be inserted into the large starburst of the Skull Clamp and turned

clockwise

and tightened. Care should be taken to maintain the position of the patient’s head as requested by the surgeon.

b) Ensure that the Skull Clamp is securely attached to the Swivel Adaptor by turning the mounting screw on the top

of the Swivel Adaptor clockwise to tighten (Figure 9A). Close the Locking Lever. Make certain that all starburst

teeth are fully meshed (where applicable) on all joints of the Base Unit after adjustments are complete.

(See Figure 9B)

Proper Meshing of Teeth (3x)

Figure 9B Proper meshing of Starburst TeethFigure 9A Attachment of Skull Clamp

10

Page 12

EN – ENGLISH

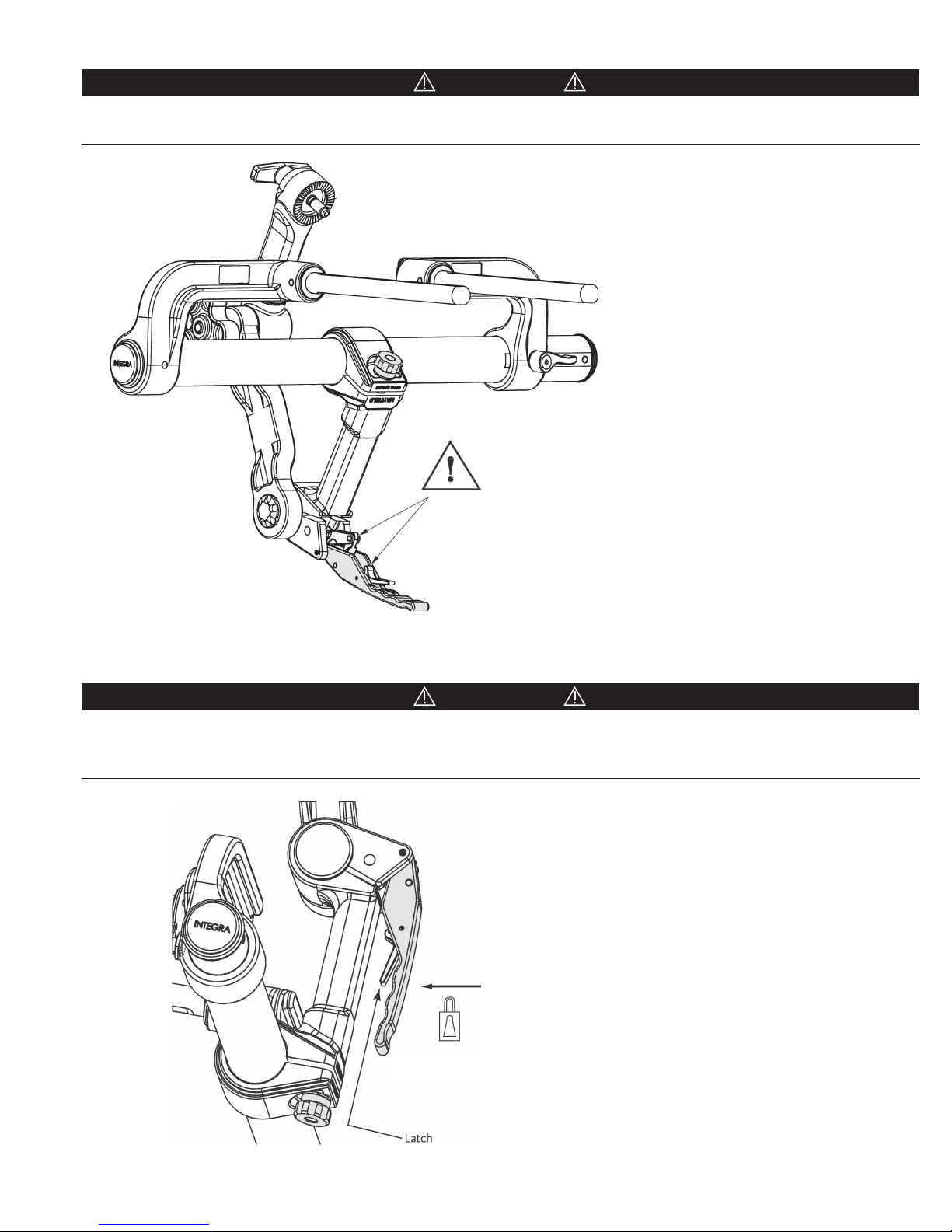

CAUTION!

Before fully tightening, always be certain that the starburst teeth of the Swivel Adaptor and other starburst fittings are the

same size and properly mesh. Failure to do so may damage fittings and/or allow unwanted movement of the patient. Figure

10 shows a typical starburst connection and proper meshing of teeth. (See Figures 10A and 10B)

Proper Meshing of Teeth

Figure 10A Proper Meshing of Teeth

Figure 10B Improper Meshing of Teeth

Improper Meshing of Teeth

(If aaching a Horseshoe Headrest, bring the Transitional Arm to the proper height. The mounting screw of the large

starburst on the Swivel Adaptor should be inserted into the large starburst of either the Horseshoe Headrest or the

Conversion Adaptor if used. Turn mounting screw on the top of the Swivel Adaptor clockwise to tighten.)

11

Page 13

EN – ENGLISH

CAUTION!

Keep fingers clear of hinge points when closing the Base Unit Locking Lever. See Figure 11 below. It is recommended that the

levers be closed using the palm of the hand.

Figure 11 Locking Mechanism

CAUTION!

Always be sure the locking mechanisms are secure after completing table adjustments. Verify that the Transitional Arm is

secured in place by confirming that the Locking Lever is engaged. Lift up on the Locking Lever WITHOUT depressing the

Latch. The Locking Lever should not be free to open.

Figure 12 Securing Locking Lever

12

Page 14

EN – ENGLISH

Cleaning of the MAYFIELD 2 Base Unit

These instructions are the recommendation of the manufacturer to ensure proper function and to extend the life and

performance of the equipment. As the equipment is reprocessed over time, many factors, including water quality used,

frequency of inspections and servicing, and method of reprocessing may impact the long term performance of the

equipment. Manual cleaning has been shown to exhibit the least amount of degradation of device performance over time,

and is therefore the recommended method of reprocessing to extend the long term performance of the equipment. The

equipment may also be reprocessed by automated cleaning and disinfection per the instructions contained in this section.

No degradation of product performance is anticipated given the device is properly cared for as recommended by the

manufacturer. This care includes inspections and periodic servicing, and avoidance of hard water where recommended. In

the absence of proper care and servicing, negative effects may be seen after repeated processing over time which may lead to

reduced performance.

Considerations:

• Follow the instructions exactly as listed in this Instruction Manual and your Hospitals procedures for

decontamination, cleaning and to reprocess medical instruments safely.

• It is important to know what method of cleaning/decontamination is needed based on what type of debris exposure

the equipment has received. This is especially important when there is the possibility of exposure to Highly

Infectious Diseases.

• This protocol has been validated for cleaning effectiveness only.

• Refer to the User Manual to disassemble the product before cleaning .

• Refer to the User Manual for further details on product use and set-up.

• The user should comply with hospital procedures and local laws and ordinances regarding reprocessing

requirements.

• Hospitals are responsible for decontaminating and packaging all loaner and demo equipment before returning to

Integra.

• Integra does not make any claims regarding the effectiveness of the decontamination processes listed in

deactivating pathogens, but rather, we are indicating that the device can withstand these procedures with minimal

loss of function.

• Please clean product using these guidelines prior to first use.

Warnings:

• Take all necessary precautions in wearing the appropriate protective equipment (eye/face, protection, gloves as

specified in the instructions provided by the cleaning agent. Clean device immediately aer each use.

• The use of highly alkaline agents may cause some components to tarnish and/or corrode. While this does not affect

the performance of the device we recommend that you use an acidic neutralizing agent immediately aer each use

to avoid the occurrence of cosmetic changes.

• Follow all instructions of the detergent, equipment washer, and autoclave manufacturer.

• Follow the detergent concentration, temperature, exposure time, material compatibility specifications, and disposal

directions of the cleaning agent as recommended by the manufacturer.

• Use only the cleaning tools mentioned in this manual. Never use metal brushes.

• Failure to follow the instructions of this document could result in damage to the equipment.

13

Page 15

MAYFIELD 2 Base Unit - A3101 (Including A3018 Swivel Adaptor)

Preparation for Cleaning and Reassembly

1. Remove skull clamp from the base unit.

2. Remove base unit from the operating room table.

Disassembly Inspecting for cleanliness Reassembly

1– Remove swivel adaptor (1) from the base

unit (2).

2– Keep base unit (2) in the UNLOCKED

position before cleaning.

3– Do not attempt to disassamble further.

Pay close attention to:

1– Area around the locking mechanism

(3).

2– Teeth of the starburst (both sides)

(4) .

EN – ENGLISH

1– Tighten swivel adaptor (1) to the

base unit (2).

2– Store the base unit (2) with the

locking handle (5) in the closed

position.

(1) swivel adaptor

(3) locking mechanism

(4) teeth

(2) base unit

(5) locking handle

14

Page 16

EN – ENGLISH

MAYFIELD 2 Standard Swivel Adaptor - A3018

Disassembly Inspecting for cleanliness Reassembly

1– Remove swivel adaptor (1) from the base

unit (2).

2– Do not attempt to disassamble further.

Pay close attention to:

1– Teeth of the starbursts (3).

2– Area around the locking screw (2).

3– The base of the swivel adaptor for

organic debris.

N/A

(2) locking screw

(1) swivel adaptor

TriStar Swivel Adaptor - A3008

Disassembly Inspecting for cleanliness Reassembly

1– Completely remove swivel adaptor from

any components.

2– Unlock the TriStar bar (1), remove

Locking screw (2) and TriStar bar (1).

(3) teeth

Pay close attention to:

1– Teeth of the starbursts (3).

2– Area around the locking screw (2).

3– The base of the swivel adaptor for

organic debris.

1– Re-install the dual TriStar bar (1).

2– Engage the locking lever (4) on

the TriStar bar (1).

3– Insert and firmly press the torque

screw (2) in place.

(1) TriStar bar

(2) locking screw

15

(4) locking lever

(3) teeth

Page 17

EN – ENGLISH

Step 1: Decontamination after Exposure to highly infectious diseases*

When the MAYFIELD 2 System has been exposed to pathogens that resist normal disinfection methods, the product should

be handled more carefully. The following steps are recommended in accordance with the World Health Organization (WHO)

Protocol for decontamination of highly infectious diseases**:

• Keep soiled areas of the device moist. Do not apply gluteraldehyde, alcohol or formalin to the device until the

decontamination process is complete.

NOTE: Do not subject the base unit & skull clamp to automated cleaning processes until after the decontamination

procedure.

1. Remove gross debris and soil from the device components using soft cloth or paper towels. Minimize formation of

aerosols or droplets during the initial preparation of the product for decontamination.

2. Place parts in a shallow pan and add enough chlorine solution to cover the device completely.

concentration is 20,000 ppm available chlorine. See Bleach Dilution section-Appendix A.

• Allow to soak for 60 minutes.

3. Remove the devices from the bleach solution and rinse components completely with water.

• The devices may then be autoclaved at 134°C for 18 minutes to one hour.

• The devices have been verified through testing to withstand this process up to 15 times without loss of

performance.

Note: Recommended

*Highly infectious diseases including but not limited to transmissible spongiform encephalopathies (TSEs) and Creutzfeldt-Jakob disease (CJD), also known as prion diseases (reference WHO/CDS/CSR/APH/2000.3,

“WHO Infection Control Guidelines for Transmissible Spongiform Encephalopathies”, (Switzerland, March 1999) Section 1). ** Integra makes no claims that the following protocol is effective in neutralizing any specific

pathogens. The protocol is a recommendation from the World Health Organization (WHO) based on the best available evidence at the time of publication. As stated in the World Health Organization (WHO) Protocol

for Decontamination of highly infectious diseases. “Immerse [instrument] in sodium hypochlorite for 1 hour; remove and rinse with water, then transfer to open pan and heat in a gravity displacement autoclave at

(121° C) or porous load (134°C) for 1 hour.”(Reference WHO/CDS/CSR/APH/2000.3, “WHO Infection Control Guidelines for Transmissible Spongiform Encephalopathies”, (Switzerland, March 1999) pp 29).

16

Page 18

EN – ENGLISH

Step 2: Cleaning

The instrument can withstand detergents having pH values between 3 and 11. Manufacturer's instructions of the selected

detergent must be followed for this device.

NOTE: The use of highly alkaline agents can tarnish and / or corrode some components. While this does not affect the

performance of the device, we recommend using an acid neutralizing agent immediately aer each use to keep a device

looking new.

2 Cleanings are available:

• Manual Cleaning

• Automatic cleaning

Manual Cleaning

Following these steps is recommended:

1. Remove Base Unit from operating table.

2. Remove Swivel Adaptor from Base Unit.

3. The Base Unit should be thoroughly cleaned after each use. Scrub each component with a soft brush. The Base Unit

can withstand detergents that fall within pH ranges of 3-11. Clean thoroughly to remove any traces of blood and/or

debris and to prevent such blood or debris from interfering with function or movement. Rinse thoroughly with clean

water to remove all traces of detergent.

4. Dry all components with a soft dry towel.

5. After components are totally dry, inspect the unit for cleanliness.

6. Inspect all components to ensure that there is no visible organic debris or residue from cleaning agent. Repeat

process if any visible debris or residue is detected.

17

Page 19

Automatic cleaning (including thermal disinfection)

Note: The washing machine used must comply with the NF EN ISO 15883-1.

1. Disassemble devices (Refer to PREPARATION FOR CLEANING & REASSEMBLY)

2. Rinse components under warm tap water prior to placing in washer.

3. Position the device so as to prevent contact between the elements.

4. Select the cycle for instruments and perform the proper programming for the following cycle:

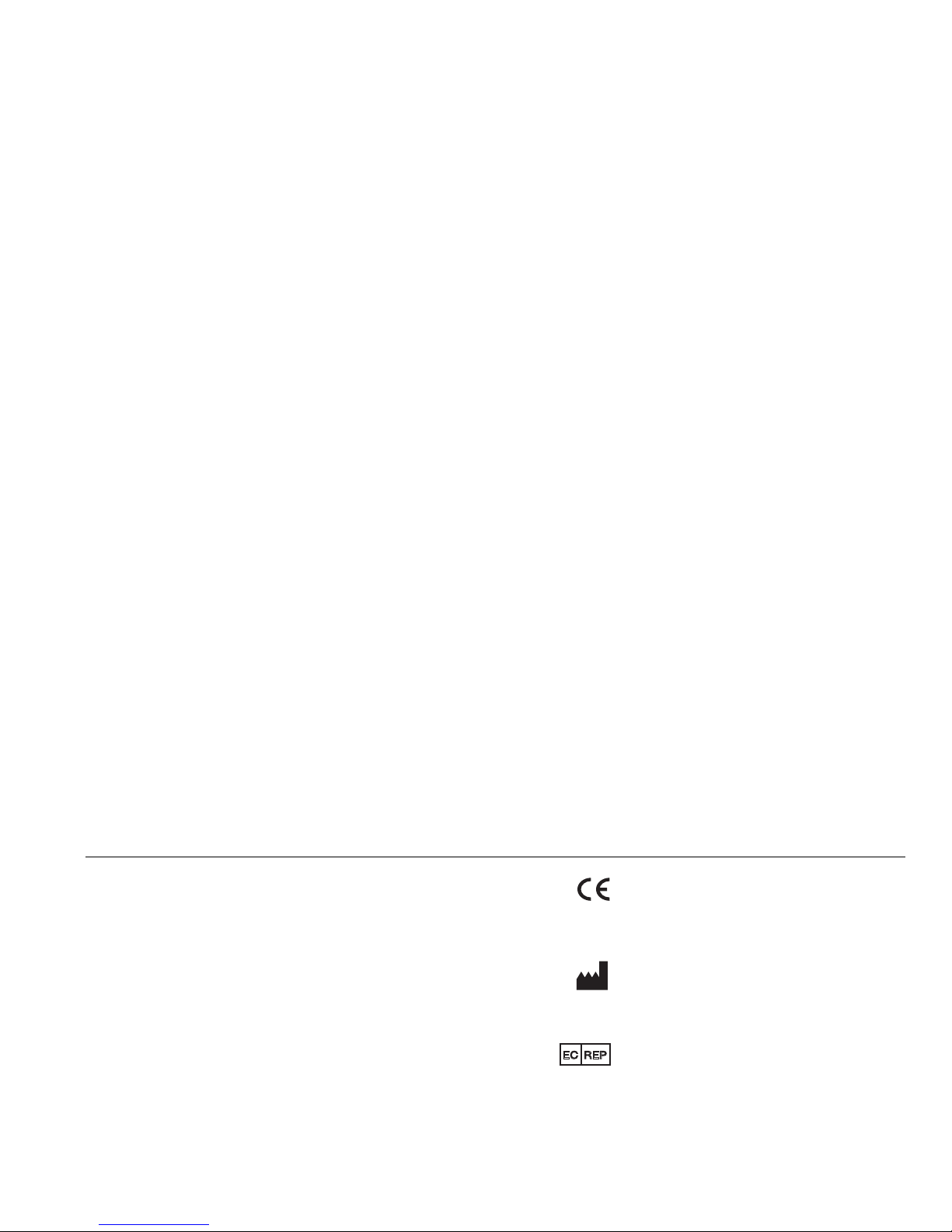

Phases Time (min) Water Temperature Detergent type and concentration

EN – ENGLISH

Pre-wash 1

Enzyme wash 04:00 Hot tap H2O*

04:00 Cold tap H2O N/A

Multi-tiered enzymatic

detergent with A.P.A

Wash 1

Rinse 1

Thermal rinse**

10:00 60°C Concentrated neutral pH cleaner

00:30 Hot tap H2O* N/A

02:00 82.2°C N/A

Table 1 Instrument Cycle

Step 3: Disinfection

The MAYFIELD 2 Base Unit must be thoroughly cleaned after each use. Where possible, keep the soiled areas moist until the

disinfection process can be initiated.

IMPORTANT: If the product has been exposed to persistent pathogens, do not apply gluteraldehyde, alcohol or formalin

to the device until the decontamination process is complete. After decontamination, normal cleaning processes can be

employed (see Decontamination section).

Disinfection of device components following normal usage may be achieved using the following methods:

Method 1: Thermal Rinse

• A Thermal Disinfection rinse may be added after the first rinse cycle as indicated in Table 1.

Method 2: Chemical

• Prepare a fresh solution for general disinfection (See below guidelines for bleach solution).

• With the device disassembled, place parts in a shallow pan and add enough general disinfection solution to

cover the device completely.

• Allow the parts to soak for 15 minutes.

• Rinse thoroughly with clean water.

For General Disinfection

Verify concentration of base hypochlorite is 4.5% or more

Mix 1/2 unit of bleach into 10 units of water

Table 2 Hypochlorite Bleach Mixing Guidelines

* No limit on tap water temperature

** Optional phase for disinfection of components – minimum water temperature as indicated or per washer manufacturer specifications for the thermal rinse cycle

1. Persistent pathogens are resistant to deactivation by normal disinfection procedures and may require more aggressive treatment to achieve disinfection. See guidelines in Decontamination

for recommended procedures.

section

18

Page 20

EN – ENGLISH

Disinfection (continued)

Method 3: Autoclave

• With device cleaned and disassembled, wrap components to keep clean.

• Time and temperature parameters vary widely according to the type of autoclave and packaging material. Follow

manufacturer’s instructions for loading and operating the autoclave.

• Make sure direct steam exposure to all surfaces is possible.

• Pre cycle vacuum (2psia / 14kPa) then steam disinfect at 132°C to 134°C for 4 minutes.

• Once device is removed from the autoclave, allow components to reach room temperature before reassembly,

handling, storage or use.

• Following the disinfection procedure, subject to routine cleaning (see Cleaning section).

5. Remove from the washing machine and ensure that all instruments are dried. If necessary, complete drying with a

sterile absorbent, lint-free towel.

6. Check all components to ensure they do not contain organic debris or residue of the cleaning agent. Repeat the

process if a soil is still visible. (For additionally validated cleaning cycles, refer to Appendix B)

Appendix A : Bleach Dilution

Bleach solutions produce chlorine gas. Prepare in a well-ventilated area.

NOTE: Hypochlorite potency decreases as bleach ages. Use only recently purchased bleach to prepare decontamination

solutions. Do not use pre-diluted bleach. Prepare a fresh batch for each application. Hypochlorite bleach mixing guidelines to

obtain 20,000 ppm solution:

Bleach Preparation Instructions

4.5%

5%

6%

For 4 units bleach into 5 units of water

For 2 units bleach into 3 units of water

For 1 unit bleach into 2 units of water

NOTE: The use of highly alkaline agents may cause some components to tarnish and/or corrode. While this does not affect

the performance of the device we recommend that you use an acidic neutralizing agent immediately aer each use as this

will help keep your device looking like new.

Appendix B: Additionally Validated Cleaning Cycles

Pre- Wash

Cold water from

building supply

(less than 110°or

43°C)/4min

Temperature

93°C

Hold

Time

1 or more

min.

Wash

Detergent Treatment

Alkaline

(e.g. neodisher®

SeptoClean)

Rinsing

Hot water

from building

supply/2 min

Thermal

Disinfection

Optional

(Drying

Optional)

90°C/2o

min.

50°C/7min

19

90°C

1 or more

min.

Neutral Enzymatic

(e.g. Enzol per

manufacturer's

instructions)

Hot water

from building

supply/ 2 min.

Optional

90°C/2o

min.

Page 21

EN – ENGLISH

Inspection of Components

A routine inspection of the components of the MAYFIELD 2 Base Unit should be made before each and every procedure to

assist in keeping it in good functional condition and to avoid problems the day of surgery. This check should include the

following:

1. Check to see that all the components of the base unit are available for assembly. Use the Inspection section of this

Instruction Manual for a complete list of components. ALL components must be available and ready for assembly or

the Base Unit should not be used.

2. Check the adjustment of the base locking handles by following these steps.

a. Attach the Base Unit to an OR table and lock in place as shown earlier in this manual.

b. Confirm that the handle is holding as it should.

c. If the handle is not holding under pressure, use the following directions to adjust the handle.

3. Test the operation of the handle after adjustment. Follow the same instructions as outlined earlier in this manual to

verify that the handle is going to hold when force is exerted against it.

4. Check the other components of the Base Unit for function.

a. Check that the Locking Handle assembly will slide easily from one side of the Horizontal Bar to the other.

b. Verify that the Left Bracket is securely fastened and does not move.

c. Fully engage the Locking Knob on the Swivel to make sure that it completely engages the starburst teeth and does

not swivel or move in either direction.

d. With the Locking Lever locked and the Swivel Knob tightened, the total Base Unit should be locked in place and no

movement should be seen.

e. If any movement is observed, re-tighten the knob and adjust the Locking Lever.

5. Perform visual check of all components (Start at on side of the Base Unit and systematically review each component as

you make your way to the other side to assure that you do not miss a component).

a. Check all connections to be free of debris that might impair the function of that component or the one that

connects to that component.

b. Examine all components for cracks on all surfaces.

20

Page 22

EN – ENGLISH

Integra Standard Warranty

INTEGRA warrants to the original purchaser only that each new MAYFIELD product is free from manufacturing defects in

material and workmanship under normal use and service for a period of one year (except as otherwise expressly provided as

to accessory items) from the date of delivery by INTEGRA to the first purchaser, but in no event beyond the expiration date

stated on any product labeling.

• Surgical instruments are guaranteed to be free from defects in material and workmanship when maintained

and cleaned properly and used normally for their intended purpose.

• Any covered product that is placed by INTEGRA under a lease, rental or installment purchase agreement and that

requires repair service during the term of such placement agreement shall be repaired in accordance with the terms

of such agreement.

If any covered defect occurs during the warranty period or term of such placement agreement, the purchaser should

communicate directly with INTEGRA’s home office. If purchaser seeks to invoke the terms of this warranty, the product must

be returned to INTEGRA at its home office. The defective product should be returned promptly, properly

packaged and postage prepaid. Loss or damage in return shipment to INTEGRA shall be at CUSTOMER’s risk.

INTEGRA’s sole responsibility under this warranty shall be repair or replacement, at INTEGRA’s sole discretion

at INTEGRA’s expense, subject to the terms of this warranty and applicable agreements.

IN NO EVENT SHALL INTEGRA BE LIABLE FOR ANY INCIDENTAL, INDIRECT, CONSEQUENTIAL OR PUNITIVE DAMAGES

IN CONNECTION WITH THE ACQUISITION OR USE OF ANY INTEGRA PRODUCT. Further, this warranty shall not apply to,

and INTEGRA shall not be responsible for, any loss arising in connection with the purchase or use of any INTEGRA product

that has been repaired by anyone other than an authorized INTEGRA service representative or altered in any way so as, in

INTEGRA’s judgment, to affect its stability or reliability, or which has been subject to misuse, negligence or accident, or

which has been used otherwise than in accordance with the instructions furnished by INTEGRA. THIS LIMITED WARRANTY

IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, AND OF ALL OTHER OBLIGATIONS OR

LIABILITIES ON INTEGRA’S PART, AND INTEGRA NEITHER ASSUMES NOR AUTHORIZES ANY REPRESENTATIVE OR OTHER

PERSON TO ASSUME FOR IT ANY OTHER LIABILITY IN CONNECTION WITH INTEGRA’S

PRODUCTS.

INTEGRA DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED INCLUDING ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE OR APPLICATION OR WARRANTY OF QUALITY AS

WELL AS ANY EXPRESS OR IMPLIED WARRANTY TO PATIENTS. No warranty or guarantee may be created by any act

or statement nor may this Standard Warranty be modified in any way, except as a result of a writing signed by an officer

of INTEGRA. These limitations on the creation or modification of this warranty may not be waived or modified orally

or by any conduct.

Service and Repair

For service and repairs outside the United States, contact your local authorized Integra representative.

Within the United States, send all instruments for service or repair to:

Integra

4900 Charlemar Drive, Building A

Cincinnati, Ohio 45227

(Always include the purchase order number or RMA number and a written description of the problem)

Or phone: 877-444-1114

21

Page 23

EN – ENGLISH

0086

Availability of these products might vary from a given country or region to another, as a result of specific local regulatory approval or clearance requirements for sale in such country or region.

n

Always refer to the appropriate instructions for use for complete clinical instructions.

n

Non contractual document. The manufacturer reserves the right, without prior notice, to modify the products in order to improve their quality.

n

Warning: Applicable laws restrict these products to sale by or on the order of a physician.

Additional information for EMEA Customers only:

Produc ts mentione d in this document are CE class I, IIa, IIb or III dev ices. Contac t Integra should you need any additional info rmation on devices clas sification. All the medical device s

mentioned on this document are CE mar ked according to European council directive 93/42/EEC on me dical devices an d its relatives, unles s specific ally identified as “NOT C E MARKED”.

For more information or to place an order, please contact:

United States, Canada, Asia, Pacific, Latin America

USA 800-654-2873

International +1 609-936-5400

integralife.com/contact

Europe, Middle-East, Africa

International +33 (0)4 37 47 59 50

Benelux +32 (0)2 257 4130

France +33 (0)4 37 47 59 10

Switzerland +41 (0)22 721 23 00

United Kingdom +44 (0)1 264 345 781

integralife.eu/contact

U.S. Patents 7,552,492; 8, 683, 630

Integra and the Integra logo are registered trademarks of Integra Life Sciences Corporation in the United States and/or other countr ies. MAYFIELD is a regis tered trademark of SM USA Inc

and is used by Integr a Lifescience s Corporation under license. Neodisher is a trademark of Chemische Fabrik Dr. Weiger t GHBH & Co. KB Enzol is a trademark of Johnson & Johnson.

©2017 Integra LifeSciences Corporation. All rights reser ved. 451A3100 Rev. H 01/17 0649598-1

n 888-980-7742 fax

n +1 609-750-4259 fax

n +33 (0)4 37 47 59 25 fax

n +32 (0)2 253 2466 fax

n +33 (0)4 37 47 59 29 fax

n +41 (0)22 721 23 99 fax

n +44 (0)1 264 363 782 fax

Manufacturer:

Integra LifeSciences Corporation

4900 Charlemar Drive, Bldg. A

Cincinnati, Ohio 45227

EC REP

Integra LifeSciences Services (France) SAS

Immeuble Séquoia 2

Parc technologique de la Porte des Alpes

69800 Saint Priest

n

USA

n

97 allée Alexandre Borodine

n

FRANCE

22

Page 24

FR – FRANÇAIS

23

Page 25

Unité de base MAYFIELD® 2

(A3100, 3101, 3102)

FR – FRANÇAIS

Mode d’emploi

24

Page 26

FR – FRANÇAIS

2525

Page 27

0123

Symboles indiqués sur les étiquees

Dangers risquant de produire des dégâts matériels.

Dangers risquant de produire des blessures corporelles ou le décès.

FR – FRANÇAIS

ATTENTION

AVERTISSEMENT

EC REP

REF

Conforme à la directive européenne relative aux dispositifs médicaux (DM).

Mandataire établi dans la Communauté européenne.

Attention, consulter la documentation jointe.

Numéro de référence produit

Fabricant

Attention : Selon la loi fédérale américaine, ce dispositif ne peut être vendu que par un praticien autorisé ou sur son

ordonnance.

Ce dispositif n’est pas indiqué pour être utilisé dans un environnement IRM.

Indications

L’unité de base MAYFIELD® 2 est prévue pour soutenir le patient au cours d’examens de diagnostic et/ou d’interventions

chirurgicales, lorsqu’un support rigide entre la table d'opération et une têtière ou un clameau crânien est nécessaire, et que la

souplesse du positionnement est requise.

AVERTISSEMENT

Tout manquement à lire et à observer les instructions et avertissements donnés dans ce mode d’emploi ainsi que les instructions et

avertissements donnés dans le mode d’emploi du clameau crânien associé, risque d’entraîner le glissement des pointes crâniennes

et des lésions graves chez le patient, notamment des lacérations du cuir chevelu, une fracture du crâne ou même le décès.

Tout manquement à positionner correctement le patient et à serrer et fixer complètement toutes les parties ajustables de ce

dispositif ou des dispositifs similaires risque d’entraîner le glissement des pointes crâniennes et des lésions graves chez le

patient, notamment des lacérations du cuir chevelu, une fracture du crâne ou même le décès.

Le matériel électrochirurgical monopolaire dont la tension de fonctionnement est supérieure à 3 000 V risque de nuire au

patient quand ce système est utilisé avec un clameau crânien.

L’utilisateur doit vérifier que les raccords filetés sont bien serrés et que les dentures radiales sont engagées (si applicable) après

avoir terminé les réglages. Tout manquement à observer cet avertissement risque d’entraîner des lésions graves chez le patient.

ATTENTION

Toujours vérifier que l’unité de base est solidement fixée à la table d’opération. Ne pas utiliser l’unité de base si elle est

endommagée ou ne fonctionne pas correctement.

N’utiliser aucun outil pour la fixation de ce matériel. Un serrage excessif des vis ou molettes de réglage risque d’endommager

l’unité. Si l’unité ne paraît pas solidement fixée après le serrage manuel, ne pas l’utiliser et contacter le représentant

MAYFIELD ou l’équipe de service après-vente MAYFIELD.

La surextension ou la surcharge de l’unité de base risque d’entraîner des déplacements involontaires, d’écourter la durée de

vie du produit et/ou d’endommager l’unité.

Ne pas modifier la construction de ce dispositif sous risque d’entraîner des lésions graves chez le patient.

26

Page 28

FR – FRANÇAIS

Tous les produits MAYFIELD ne peuvent pas nécessairement tous être nettoyés et décontaminés de la même façon que

les produits MAYFIELD 2. Consulter le modes d’emploi individuel (pour chaque dispositif) quant aux procédures correctes

d’entretien et de nettoyage.

Description

L’unité de base MAYFIELD 2 (REF A3101, A3102, A3100) est conçue assurer pour la fixation entre la table d’opération et les

clameaux crâniens MAYFIELD (pour une fixation squelettique rigide) ou les têtières fer à cheval MAYFIELD (pour les interventions

nécessitant uniquement un support et non une fixation rigide). L’unité de base MAYFIELD 2 est conçue pour le positionnement

du patient en décubitus ventral, en décubitus latéral ou en position Park Bench ou assise. L’espacement de la tige de support

peut être facilement réglée pour s’adapter à la plupart des tables d’opération. Aucun outil n’est requis. Consulter la section

« Fixation de l’unité de base à la table d’opération » pour des directives sur le réglage des tiges de support.

Unité de base MAYFIELD 2, Standard A3101

Unité de base MAYFIELD 2, étroite A3100

Unité de base MAYFIELD 2, internationale A3101

Figure 1 Unité de base MAYFIELD 2 – Numéros de référence

Un adaptateur pivotant MAYFIELD 2 standard (A3018) est un composant intégral de l’unité de base. Un adaptateur pivotant

Tri-Star MAYFIELD 2 (A3008) séparé, en option, est disponible en tant qu’accessoire quand des systèmes de chirurgie

assistée par ordinateur (CAO) sont utilisés lors des interventions. L’adaptateur pivotant Tri-Star offre deux dentures radiales

supplémentaires pour la fixation du matériel de CAO auxiliaire.

Chaque unité de base MAYFIELD 2 achetée (A3100, A3101 ou A3102) comprend :

1- Unité de base MAYFIELD 2

1- Adaptateur pivotant MAYFIELD 2 (A3018)

EN OPTION : Adaptateur pivotant Tri-Star MAYFIELD 2 (A3008)

27

Page 29

1. Support de gauche

2. Bouton de verrouillage du support de gauche

3. Tube connecteur

4. Ensemble de poignée de la base

5. Levier de blocage

6. Bras de transition

7. Molette de verrouillage du pivot

8. Adaptateur pivotant (A3018)

9. Bouton de verrouillage de la têtière

10. Support de droite

FR – FRANÇAIS

1. Bras de transition

2. Levier de blocage

3. Loquet

4. Ensemble de poignée de la base

Figure 2A Composants de l’unité de base MAYFIELD 2

Figure 2B Composants de la poignée de la base MAYFIELD 2

28

Page 30

FR – FRANÇAIS

Figure 3 Adaptateur pivotant Tri-Star MAYFIELD 2 (A3008) EN OPTION

L’unité de base MAYFIELD 2 est conçue pour être utilisée avec le matériel suivant :

Têtière à usage général MAYFIELD A1008

Têtière fer à cheval MAYFIELD A1011*

Têtière fer à cheval adulte MAYFIELD A1012

Adaptateur de barre transversale MAYFIELD A1015**

Adaptateur NeuroGen MAYFIELD A1031 (A et B)

Têtière fer à cheval pédiatrique MAYFIELD A1051*

Clameau crânien MAYFIELD modifié A1059

Support cervical postérieur MAYFIELD A1073

Clameau crânien MAYFIELD Triad A1108

Adaptateur de conversion pour fer à cheval MAYFIELD A1109

Système de support MAYFIELD Infinity A1112

Adaptateur NeuroGen A1113

Clameau crânien MAYFIELD Infinity A1114

Clameau crânien MAYFIELD Infinity A1114A

Clameau crânien 2000 MAYFIELD A2000

Clameau crânien MAYFIELD 2 A3059

*Adaptateur de conversion pour fer à cheval MAYFIELD A1109 requis.

**Raccords pour rail latéral universel A1060 requis.

Remarque : L’utilisation des produits et accessoires MAYFIELD avec le matériel de stabilisation d’autres fabricants n’est pas

recommandée.

29

Page 31

FR – FRANÇAIS

Inspection

Toujours inspecter le matériel MAYFIELD avant et après l’utilisation. Si un composant est endommagé et/ou ne fonctionne

pas correctement, ne pas utiliser le dispositif et le renvoyer immédiatement à un centre de réparation Integra agréé pour

évaluation, réparation ou remplacement.

Soins et entretien

Votre représentant Integra procède à l’inspection compréhensive régulière de votre matériel MAYFIELD. De plus, pour assurer

le bon fonctionnement des étalonnages réglés en usine, un service de maintenance préventive annuelle est requis dans un

centre de service après-vente et de réparation Integra agréé. Integra s’efforce d’assurer le prêt de matériel de remplacement

pendant le service après-vente annuel requis de votre matériel MAYFIELD.

Pour garantir le bon fonctionnement et prolonger la durée de vie et les performances du matériel, Integra LifeSciences exige

les mesures de maintenance suivantes :

Action requise Fréquence requise

Retour du dispositif au service Integra LifeSciences Repairs pour l’inspection détaillée et

l’entretien.

Inspection routinière du dispositif par le personnel Integra NeuroSpecialist

Si l’entretien et la maintenance du dispositif ne sont pas assurés, des effets délétères risquent d’être constatés à la longue

après des traitements répétés, ce qui peut conduire à la réduction des performances.

Informations de contact : Consulter la section « Service après-vente et réparation » pour obtenir les coordonnées à utiliser

pour le retour du dispositif dans le cadre du service après-vente périodique et de la demande d’inspections périodiques.

Une fois par an

Deux fois par an

Élimination du dispositif

REMARQUE : Observer le protocole hospitalier pour l’élimination de ce dispositif.

ATTENTION

Si le dispositif fait l’objet d’une chute ou d’une manipulation abusive, l’inspecter pour s’assurer qu’il n’a pas été endommagé.

(Consulter la section « Inspection » de ce manuel.) En présence d’endommagement, ne PAS utiliser le dispositif ; retourner

immédiatement le dispositif au complet à Integra pour inspection.

30

Page 32

FR – FRANÇAIS

Instructions d’utilisation

Fixation de l’unité de base à la table d’opération :

Le support de gauche de l’unité de base MAYFIELD 2 (3100) peut être réglé le long du tube connecteur pour permere à la

tige de support d’accueillir des logements de table espacés de 114 mm à 209,5 mm.

Le support de gauche de l’unité de base MAYFIELD 2 (3101) peut être réglé le long du tube connecteur pour permere à la tige

de support d’accueillir des logements de table espacés de 130 mm à 209,5 mm.

Le support de gauche de l’unité de base MAYFIELD 2 (3102) peut être réglé le long du tube connecteur pour permere à la

tige de support d’accueillir des logements de table espacés de 168 mm à 400 mm.

1. Situer et desserrer le bouton de verrouillage du support de gauche, qui se trouve au dos (voir Figure 4) du support de

gauche, et glisser doucement le support de gauche le long du tube connecteur jusqu’à ce que la largeur voulue soit

obtenue entre les tiges de support.

2. Monter l’unité de base sur la table d’opération en alignant les deux tiges de support avec les logements du côté tête de

la table d’opération, ou dans l’adaptateur NeuroGen ou l’adaptateur de barre transversale.

3. Serrer le bouton de verrouillage du support de gauche pour fixer le support de gauche en position.

ATTENTION

NE PAS utiliser d’outils pour serrer les boutons sur ce dispositif. Tous les boutons doivent être serrés uniquement à la main.

Veiller à ne pas serrer excessivement. Un serrage excessif risque d’endommager le dispositif.

Bouton de verrouillage du support de gauche

Tourner dans le sens

horaire pour serrer

Figure 4 Bouton de verrouillage du support de gauche

4. Fixer les tiges de support de l’unité de base à la table en serrant les boutons de verrouillage de la table ou les boutons de

l’adaptateur NeuroGen ou de l’adaptateur de barre transversale.

31

Page 33

FR – FRANÇAIS

Fixation de l’adaptateur pivotant (A3018 ou A3008) à l’unité de base

Insérer la vis de l’adaptateur pivotant dans la molette de verrouillage du pivot, en forme de trèfle, située à l’extrémité du bras

de transition. Serrer en tournant la molette de verrouillage du pivot dans le sens horaire et s’assurer que toutes les dentures

radiales sont engagées les unes dans les autres. Ne pas trop serrer. N’utiliser aucun outil pour fixer ou retirer l’adaptateur

pivotant de l’unité de base.

Pivot

Molee de

verrouillage du pivot

Dentures radiales

Bras de transition

Figure 5 Fixation de l’adaptateur pivotant

ATTENTION

Confirmer la stabilité de l’unité de base en positionnant les composants (connectés à la table d’opération) comme illustré à

la Figure 6. Exercer une force modérée contre l’adaptateur pivotant, dans le sens indiqué par la flèche 2 à la Figure 6. Aucun

mouvement ne doit être observé au niveau des articulations. Si un mouvement est observé, ne pas utiliser le produit et

contacter le représentant MAYFIELD ou l’équipe de service après-vente MAYFIELD.

Figure 6 Contrôle de la stabilité

32

Page 34

FR – FRANÇAIS

Positionnement du bras de transition et de l’adaptateur pivotant

La poignée est dotée d’un mécanisme autobloquant. Pour dégager le levier de verrouillage, enfoncer le loquet dans le

levier de verrouillage ; le levier se déplacera de sa position fermée.

Loquet

Figure 7 Mécanisme autobloquant de la poignée

33

Page 35

FR – FRANÇAIS

1. Ouvrir le levier de verrouillage afin de positionner le bras de transition de la façon voulue. Le levier de verrouillage doit

être complètement ouvert pour que le bras de transition puisse se déplacer librement.

Figure 8 Ouvrir le levier de verrouillage

2. Une fois que le serre-crâne est placé sur le crâne du patient, le chirurgien placera le patient dans la position

chirurgicale requise pour la procédure. Avec le patient dans cette position, le chirurgien maintient la tête du patient

et le clameau crânien, et demande à ce que le bras de transition soit ramené à la hauteur requise pour fixer le clameau

crânien à l’adaptateur pivotant.

a) Une fois que le bras de transition est à la bonne hauteur pour la fixation au clameau crânien, la vis de montage

de la grande denture radiale sur l’adaptateur pivotant doit être insérée dans la grande denture radiale du clameau

crânien, puis tournée dans le sens horaire et serrée. Veiller à maintenir la position de la tête du patient requise

par le chirurgien.

b) S’assurer que le clameau crânien est solidement fixé à l’adaptateur pivotant en tournant la vis de montage en

haut de l’adaptateur pivotant dans le sens horaire pour serrer (voir Figure 9A). Fermer le levier de verrouillage.

Quand tous les réglages sont terminés, s’assurer que toutes les dentures radiales sont complètement engagées

les unes dans les autres (si applicable) au niveau de toutes les articulations de l’unité de base.

(Voir Figure 9B)

Engagement correct

des dentures (3x)

Figure 9B Engagement correct des dentures radialesFigure 9A Fixation du clameau crânien

34

Page 36

FR – FRANÇAIS

ATTENTION

Avant se serrer complètement, toujours vérifier que les dentures radiales de l’adaptateur pivotant et des autres composants

sont de la même taille et correctement engagées. Le non respect de cette consigne risque d’endommager les raccords et/ou

de permettre un mouvement involontaire du patient. La Figure 10 montre un raccordement radial typique et l’engagement

correct des dentures. (Voir Figures 10A et 10B)

Engagement correct des dentures

Figure 10A Engagement correct des dentures

Figure 10B Engagement incorrect des dentures

Engagement incorrect des dentures

(Pour fixer la têtière fer à cheval, ramener le bras de transition à la hauteur voulue. La vis de montage de la grande denture

radiale sur l’adaptateur pivotant doit être insérée dans la grande denture radiale de la têtière fer à cheval ou de l’adaptateur de

conversion, le cas échéant. Tourner la vis de montage en haut de l’adaptateur pivotant dans le sens horaire pour serrer.)

35

Page 37

FR – FRANÇAIS

ATTENTION

Éloigner les doigts des charnières en fermant le levier de verrouillage de l’unité de base. Voir la Figure 11 ci-dessous. Il est

conseillé de fermer les leviers en utilisant la paume de la main.

Figure 11 Mécanisme de verrouillage

ATTENTION

Toujours s’assurer que les mécanismes de verrouillage sont fixés après avoir terminé les réglages de la table. Vérifier que le

bras de transition est fixé en place en confirmant que le levier de verrouillage est engagé. Soulever le levier de verrouillage

SANS enfoncer le loquet. Le levier de verrouillage ne doit pas pouvoir s’ouvrir.

Figure 12 Fixation du levier de verrouillage

Loquet

36

Page 38

FR – FRANÇAIS

Neoyage de l’unité de base MAYFIELD 2

Ces directives sont la recommandation du fabricant pour garantir le bon fonctionnement et prolonger la durée de vie et

les performances du matériel. À la longue après des retraitements répétés, plusieurs facteurs, y compris la qualité de l’eau

utilisée, la fréquence des inspections et de l’entretien, et la méthode de retraitement, peuvent impacter les performances

à long terme du matériel. Il a été prouvé que le nettoyage manuel présente la plus faible dégradation des performances

du dispositif dans le temps, et celui-ci constitue donc la méthode de retraitement recommandée pour prolonger les

performances à long terme du matériel. Le matériel peut également être retraité par nettoyage et désinfection automatisés,

conformément aux directives dans cette section. Aucune dégradation des performances du produit n’est anticipée si le

dispositif est correctement entretenu conformément aux recommandations du fabricant. Cet entretien inclut des inspections

et une maintenance périodiques, et l’évitement d’eau calcaire quand cela est conseillé. Si l’entretien et la maintenance ne

sont pas assurés, des effets délétères risquent d’être constatés à la longue après des traitements répétés, ce qui peut conduire

à une réduction des performances.

Considérations :

• Suivre les directives exactement comme indiqué dans ce mode d’emploi ainsi que vos procédures hospitalières pour

la décontamination, le nettoyage et le retraitement en toute sécurité des instruments médicaux.

• Il est important de savoir quelle méthode de nettoyage/décontamination est nécessaire en fonction du type

d'exposition aux débris auquel l'équipement a été soumis. Ceci est particulièrement important lorsqu’il existe un

risque d'exposition à des maladies très infectieuses.

• Ce protocole a uniquement été validé pour l'efficacité du nettoyage.

• Consulter le manuel d’utilisation pour le démontage du produit avant de le nettoyer.

• Consulter le manuel d’utilisation pour obtenir plus de détails sur l'utilisation et l’installation du produit.

• L'utilisateur doit se conformer aux procédures de l'établissement hospitalier et à la réglementation locale

concernant les obligations en matière de reconditionnement.

• Les hôpitaux doivent s'assurer de la décontamination et du conditionnement de tous les articles en prêt ou de

démonstration avant de les renvoyer à Integra.

• Integra ne fait aucune revendication quant à l'efficacité des procédés de décontamination cités pour la

désactivation des agents pathogènes, mais indique plutôt que le dispositif est capable de subir ces procédés avec

une perte minimale de la fonction.

• Nettoyer le produit en suivant ces directives avant la première utilisation.

Avertissements :

• Prendre toutes les précautions nécessaires pour porter l'équipement de protection approprié (protection des yeux/

du visage, gants) comme spécifié dans les instructions fournies avec le produit nettoyant. Nettoyer le dispositif

immédiatement après chaque utilisation.

• L'utilisation de produits fortement alcalins peut provoquer l’oxydation et/ou la corrosion de certains composants.

Bien que cela n’affecte pas les performances du dispositif, il est recommandé d'utiliser un produit qui neutralise

l’acide immédiatement après chaque utilisation pour éviter toute altération cosmétique.

• Suivre toutes les instructions des fabricants du détergent, du laveur de matériel et de l’autoclave.

• Suivre les spécifications du fabricant relatives à la concentration de détergent, la température, le temps

d'exposition, la compatibilité des matériaux et les directives d'élimination du produit de nettoyage.

• Utiliser uniquement les outils de nettoyage mentionnés dans ce manuel. Ne jamais utiliser de brosses métalliques.

• Le non respect des consignes données dans ce document peut entraîner l’endommagement du matériel.

37

Page 39

Unité de base MAYFIELD 2 - A3101 (avec l’adaptateur pivotant A3018)

Préparation avant le neoyage et le remontage

1. Retirer le clameau crânien de l'unité de base.

2. Retirer l'unité de base de la table d'opération.

Démontage Vérification de la propreté Remontage

1– Retirer l’adaptateur pivotant (1) de

l'unité de base (2).

2– Conserver l’unité de base (2) dans la

position DÉVERROUILLÉE

avant le nettoyage.

3– Ne pas essayer de démonter davantage

les composants.

Veiller en particulier aux points suivants :

1– Zone autour du mécanisme de

verrouillage (3).

2– Dentures radiales (des deux côtés)

(4).

FR – FRANÇAIS

1– Serrer l’adaptateur pivotant (1) sur

l'unité de base (2).

2– Ranger l'unité de base (2) avec le

levier de verrouillage (5) dans la

position fermée.

(1) adaptateur pivotant

(3) mécanisme de verrouillage

(4) dentures

(2) unité de base

(5) levier de verrouillage

38

Page 40

FR – FRANÇAIS

Adaptateur pivotant standard MAYFIELD 2 - A3018

Démontage Vérification de la propreté Remontage

1– Retirer l’adaptateur pivotant (1) de

l'unité de base (2).

2– Ne pas essayer de démonter davantage

les composants.

Veiller en particulier aux points suivants :

1– Dentures radiales (3).

2– Zone autour de la vis de blocage (2).

3– Base de l'adaptateur pivotant pour

la présence de débris organiques.

S.O.

(2) vis de blocage

(1) adaptateur pivotant

(3) dentures

Adaptateur pivotant Tri-Star - A3008

Étape 1 : Décontamination après exposition à des maladies hautement infectieuses*

Démontage Vérification de la propreté Remontage

1– Retirer complètement l’adaptateur

pivotant de tous les composants.

2– Déverrouiller la barre de l’adaptateur

Tri-Star (1), retirer la vis de blocage (2)

et la barre de l’adaptateur Tri-Star (1).

Veiller en particulier aux points suivants :

1– Dentures radiales (3).

2– Zone autour de la vis de blocage (2).

3– Base de l'adaptateur pivotant pour la

présence de débris organiques.

1– Réinstaller la barre double de

l’adaptateur Tri-Star (1).

2– Base de l'adaptateur pivotant

pour la présence de débris

organiques.

3– Insérer et enfoncer fermement en

place la vis de couple (2).

(1) barre de l'adaptateur Tri-Star

(2) vis de blocage

39

(4) levier de verrouillage

(3) dentures

Page 41

FR – FRANÇAIS

Étape 1 : Décontamination après exposition à des maladies hautement infectieuses*

Lorsque le système MAYFIELD 2 a été exposé à des agents pathogènes qui résistent aux méthodes de désinfection standard,

le produit doit être manipulé avec plus de soin. Les étapes suivantes sont recommandées conformément au protocole de

l'Organisation mondiale de la Santé (OMS) pour la décontamination des maladies hautement infectieuses** :

• Conserver les zones souillées du dispositif à l’état humide. Ne pas appliquer de glutaraldéhyde, d'alcool ou de

formol sur le dispositif avant que le procédé de décontamination ne soit terminé.

REMARQUE : Ne soumettre l'unité de base et le clameau crânien à des procédés de nettoyage automatisés qu'après le

procédé de décontamination.

1. Éliminer les débris et souillures visibles des composants du dispositif à l'aide d’un linge doux ou de serviettes en

papier. Réduire au minimum la formation d'aérosols ou de gouttelettes lors de la préparation initiale du produit avant

la décontamination.

2. Placer les pièces dans un bac peu profond et ajouter suffisamment de solution de chlore pour couvrir complètement

le dispositif. Remarque : La concentration recommandée est de 20 000 ppm de chlore disponible. Voir la section

« Dilution de l’eau de Javel », Annexe A

• Laisser tremper pendant 60 minutes.

3. Retirer les dispositifs de la solution d'eau de Javel et rincer complètement les composants avec de l'eau.

• Les dispositifs peuvent alors être passés à l'autoclave à 134 °C pendant une durée de 18 minutes à une heure.

• Les dispositifs ont été validés, par des tests, pour résister à ce procédé jusqu'à 15 fois sans perte de performances.

.

*Maladies hautement infectieuses, y compris mais sans s'y limiter les encéphalopathies spongiformes transmissibles (EST) et la maladie de Creutzfeldt-Jakob (MCJ), aussi connues comme les maladies à prions (référence OMS :

WHO/CDS/CSR/APH/2000.3, « WHO Infection Control Guidelines for Transmissible Spongiform Encephalopathies », (Suisse, mars 1999) Section 1). **Integra ne fait aucune revendication quant à l’efficacité du protocole suivant

pour neutraliser des agents pathogènes spécifiques. Le protocole est une recommandation de l'Organisation mondiale de la Santé (OMS) fondée sur les meilleures données disponibles au moment de la publication. Tel que stipulé

dans le protocole de l'Organisation mondiale de la Santé (OMS) pour la décontamination des maladies hautement infectieuses. « Immerger [l’instrument] dans de l'hypochlorite de sodium pendant 1 heure ; le retirer et le rincer à

l'eau, puis le transférer dans un bac ouvert et le chauffer dans un autoclave à déplacement par gravité à (121 °C) ou charge poreuse (134 °C) pendant 1 heure. » (Référence OMS : WHO/CDS/CSR/APH/2000.3, « WHO Infection Control

Guidelines for Transmissible Spongiform Encephalopathies », (Suisse, mars 1999) pp 29).

40

Page 42

FR – FRANÇAIS

Étape 2 : Nettoyage

L'instrument peut résister à des détergents dont les valeurs de pH se situent entre 3 et 11. Les instructions du fabricant du

détergent choisi doivent être respectées pour ce dispositif.

REMARQUE : L'utilisation de produits fortement alcalins peut oxyder et/ou corroder certains composants. Bien que cela

n’affecte pas les performances du dispositif, il est recommandé d'utiliser un produit qui neutralise l’acide immédiatement

après chaque utilisation pour conserver l’aspect neuf du dispositif.

2 méthodes de nettoyage sont disponibles :

• Nettoyage manuel

• Nettoyage automatique

Nettoyage manuel

Les étapes suivantes sont recommandées :

1. Retirer l'unité de base de la table d'opération.

2. Retirer l’adaptateur pivotant de l'unité de base.

3. L’unité de base doit être soigneusement nettoyée après chaque utilisation. Frotter chaque composant à l’aide

d’une brosse à poils souples. L'unité de base peut résister aux détergents dont la gamme de pH se situe entre 3

et 11. Nettoyer à fond pour éliminer toute trace de sang et/ou de débris et pour empêcher au sang ou aux débris

d'interférer avec le fonctionnement ou le mouvement. Rincer soigneusement avec de l’eau propre pour éliminer

toute trace de détergent.

4. Sécher tous les éléments avec un linge sec et doux.

5. Lorsque les composants sont complètement secs, inspecter l'unité pour en assurer la propreté.

6. Inspecter tous les composants pour assurer l’absence de débris organiques visibles ou de résidus de produit de

nettoyage. Répéter le procédé si des débris visibles ou résidus sont détectés.

41

Page 43

Nettoyage automatique (y compris la désinfection thermique)

Remarque : Le laveur automatique utilisé doit être conforme à la norme NF EN ISO 15883-1.

1. Démonter les dispositifs (consulter « Préparation avant le nettoyage et le remontage »).

2. Rincer les éléments à l’eau chaude du robinet avant de les placer dans le laveur automatique.

3. Positionner le dispositif de manière à empêcher tout contact entre les éléments.

4. Sélectionner le cycle pour les instruments et programmer le cycle suivant :

Phases Durée (min) Température de l’eau Type et concentration du détergent

FR – FRANÇAIS

Prélavage 1

Lavage

enzymatique

Lavage 1

Rinçage 1

Rinçage

thermique**

4 min 00 Eau froide du robinet S.O.

4 min 00 Eau chaude du robinet*

Détergent enzymatique

multi-usages avec APA

10 min 00 60 °C Produit neoyant concentré à pH neutre

0 min 30 Eau chaude du robinet* S.O.

2 min 00 82,2 °C S.O.

Tableau 1 Cycle pour instruments

Étape 3 : Désinfection

L’unité de base MAYFIELD 2 doit être soigneusement nettoyée après chaque utilisation. Lorsque cela est possible, conserver

les zones souillées à l’état humide jusqu'à ce que le procédé de désinfection puisse être démarré.

1

IMPORTANT : Si le produit a été exposé à des pathogènes persistants

formol sur le dispositif avant que le procédé de décontamination ne soit terminé. Après la décontamination, les procédés de

nettoyage standard peuvent être utilisés (voir la section « Décontamination »).

La désinfection des composants du dispositif après l’usage normal peut être réalisée en utilisant les méthodes suivantes :

Méthode 1: Rinçage thermique

• Un rinçage thermique de désinfection peut être ajouté après le premier cycle de rinçage, comme indiqué dans le tableau 1.

, ne pas appliquer de glutaraldéhyde, d'alcool ou de

Méthode 2: Chimique

• Préparer une nouvelle solution pour la désinfection générale (voir les directives ci-dessous pour l'eau de Javel).

• Avec le dispositif démonté, placer les pièces dans un bac peu profond et ajouter suffisamment de solution de

désinfection générale pour couvrir complètement le dispositif.

• Laisser tremper les pièces pendant 15 minutes.

• Bien rincer avec de l’eau claire.

Pour la désinfection générale

Vérifier que la concentration de base

d'hypochlorite est de 4,5 % au minimum

Mélanger 1/2 part d’eau Javel à 10 parts d'eau

Tableau 2 Directives de mélange pour l’hypochlorite de sodium

* *Aucune limite pour la température de l'eau du robinet

**Phase facultative pour la désinfection des composants - température minimale de l'eau indiquée, ou selon les spécifications du fabricant pour le cycle de rinçage thermique

1. Les pathogènes persistants sont résistants à la désactivation par les procédés de désinfection standard, et peuvent nécessiter un traitement plus

agressif pour assurer la désinfection. Voir les directives de la section « Décontamination » pour les procédures recommandées.

42

Page 44

FR – FRANÇAIS

Désinfection (suite)

Méthode 3: Autoclave

• Avec le dispositif nettoyé et démonté, envelopper les composants à nettoyer.

• Les paramètres de durée et de température varient considérablement selon le type d'autoclave et les matériaux

d'emballage. Suivre les instructions du fabricant pour le chargement et le fonctionnement de l'autoclave.

• S’assurer que l'exposition directe à la vapeur de toutes les surfaces est possible.

• Pré-vide (2 psia/14 kPa), puis désinfection à la vapeur de 132 °C à 134 °C pendant 4 minutes.

• Une fois le dispositif retiré de l'autoclave, laisser les composants revenir à la température ambiante avant de les

remonter, les manipuler, les ranger ou les utiliser.

• Après le procédé de désinfection, procéder au nettoyage de routine (voir la section « Nettoyage »).

5. Retirer du laveur automatique et s’assurer que tous les instruments sont secs. Si nécessaire, sécher complètement à

l’aide d’un linge non pelucheux absorbant stérile.

6. Contrôler tous les composants pour s’assurer qu'ils sont exempts de débris organiques ou résidus du produit de

nettoyage. Répéter le processus si des souillures sont encore visibles. (Pour les autres cycles de nettoyage validés,

consulter l'Annexe B).

Annexe A : Dilution de l’eau de Javel

Les solutions d’eau de Javel produisent du gaz de chlore. Veiller à les préparer dans un lieu bien ventilé.

REMARQUE : L'utilisation de produits fortement alcalins peut oxyder et/ou corroder certains composants. Bien que cela

n’affecte pas les performances du dispositif, il est recommandé d'utiliser un produit qui neutralise l’acide immédiatement

après chaque utilisation pour conserver l’aspect neuf du dispositif:

Eau de Javel Directives de préparation

4,5 %

5%

6%

4 parts d’eau de Javel dans 5 parts d’eau

2 parts d’eau de Javel dans 3 parts d’eau

1 part d’eau de Javel dans 2 parts d’eau

REMARQUE : La puissance de l’hypochlorite de sodium diminue avec l’âge. Utiliser uniquement de l'eau de Javel achetée

récemment pour préparer les solutions de décontamination. Ne pas utiliser de l'eau de Javel pré-diluée. Préparer un nouveau

lot pour chaque application. Directives de mélange pour l’hypochlorite de sodium pour obtenir une solution à 20 000 ppm :.

Annexe B : Autres cycles de nettoyage validés

Prélavage

Eau froide de

l'approvisionnement

en eau de

l’immeuble (moins

de 43 °C)/4 min

Température

Durée

d’exposition

93 °C 1 min. ou plus

Lavage

Traitement détergent

Alcalin (p. ex.,

neodisher®

SeptoClean)

Rinçage

Eau chaude de

l'approvisionne-

ment en eau de

l’immeuble/2 min

Désinfection

thermique

Facultatif

(Séchage,

facultatif)

90 °C/20

min.

50 °C/7 min

43

90 °C 1 min. ou plus

Neutre

enzymatique

(p. ex., Enzol selon

les directives

du fabricant)

Eau chaude de

l'approvisionne-

ment en eau de

l’immeuble/2 min

Facultatif

90 °C/20

min.

Page 45

FR – FRANÇAIS

Inspection des composants

Procéder à une inspection de routine des composants de l'unité de base MAYFIELD 2 avant chaque intervention pour

maintenir le bon état fonctionnel du matériel et éviter des problèmes le jour de la chirurgie. Cette vérification doit inclure les

points suivants :

1. Vérifier que tous les composants de l’unité de base sont disponibles pour l’assemblage. Utiliser la section

« Inspection » de ce manuel pour une liste complète des composants. TOUS les composants doivent être disponibles

et prêts pour le montage, sans quoi l'unité de base ne doit pas être utilisée..

2. Contrôler le réglage du levier de verrouillage de la base, en suivant ces étapes :

a. Fixer l'unité de base à une table d’opération et verrouiller en place, comme indiqué précédemment dans ce manuel.

b. Confirmer que le levier assure le maintien voulu.

c. Si le levier ne tient pas sous pression, utiliser les indications suivantes pour régler le levier.

3. Tester l'actionnement du levier après le réglage. Suivre les mêmes directives que celles indiquées précédemment dans

ce manuel pour vérifier que le levier tiendra en présence de force.

4. Contrôler le fonctionnement des autres composants de l'unité de base.

a. Vérifier que l'ensemble de levier de verrouillage glisse facilement d'un côté de la barre horizontale à l'autre.

b. Vérifier que le support de gauche est solidement fixé et ne bouge pas.

c. Engager pleinement la molette de verrouillage du pivot pour s’assurer qu'elle engage complètement les dentures

radiales et ne pivote pas ni ne se déplace dans un sens ou dans l’autre.

d. Avec le levier de verrouillage verrouillé et la molette du pivot serrée, l’ensemble de l'unité de base doit être

verrouillé en place et aucun mouvement ne doit être observé.

e. Si un mouvement est observé, resserrer la molette et régler le levier de verrouillage.

5. Procéder à la vérification visuelle de tous les composants (commencer par le côté de l'unité de base et examiner

systématiquement chaque composant en progressant de l'autre côté pour s’assurer de n’omettre aucun composant)..

a. Vérifier que toutes les connexions sont exemptes de débris susceptibles d’entraver le fonctionnement du

composant en question ou d’un composant connecté à ce composant.

b. Examiner tous les composants pour la présence de fissures sur toutes les surfaces.

44

Page 46

FR – FRANÇAIS

Garantie standard d’Integra

INTEGRA garantit à l’acheteur d’origine uniquement que tout nouveau produit MAYFIELD sera exempt de défauts

matériels et de fabrication, sous réserve d’une utilisation et d’un entretien normaux, pendant une durée d’un an

(sauf stipulation contraire expresse ayant trait aux accessoires) à compter de la date de livraison par INTEGRA

à l’acheteur initial, mais en aucun cas au-delà de la date d’expiration indiquée sur l’étiquette du produit.

• Les instruments chirurgicaux sont garantis exempts de défauts matériels et de fabrication, sous réserve d’un

entretien et d’un nettoyage corrects et d’une utilisation normale dans le cadre de leur usage prescrit.

• Tout produit couvert par cette garantie et concédé par INTEGRA au titre d’un contrat de crédit-bail, de location ou

de paiement échelonné, et qui requiert des services de réparation pendant la durée d’un tel contrat, sera réparé

conformément aux termes dudit contrat.

Si un défaut couvert survient pendant la période de garantie ou pendant la durée d’un tel contrat, l’acheteur est tenu de

communiquer directement avec le siège social d’INTEGRA. Si l’acheteur souhaite invoquer les termes de cette garantie, le

produit doit être renvoyé au siège social d’INTEGRA. Le produit défectueux doit être renvoyé rapidement, dans un emballage

adéquat et en port payé. Le CLIENT reconnaît assumer tout risque de perte ou de dommage lié au renvoi du produit à

INTEGRA. L’unique responsabilité d’INTEGRA au titre de cette garantie sera la réparation ou le remplacement, à la seule

discrétion d’INTEGRA, à la charge d’INTEGRA et en application des termes de la présente garantie ainsi que des contrats

applicables.

INTEGRA NE POURRA EN AUCUN CAS ÊTRE TENUE POUR RESPONSABLE DE TOUT DOMMAGE ACCESSOIRE, INCIDENT,

INDIRECT OU PUNITIF LIÉ À L’ACQUISITION OU À L’UTILISATION DE TOUT PRODUIT D’INTEGRA. En outre, la présente

garantie ne s’applique pas à, et INTEGRA ne peut être tenue pour responsable de toute perte résultant de l’achat ou de

l’utilisation d’un quelconque produit INTEGRA ayant fait l’objet de réparations effectuées par des personnes autres qu’un

technicien agréé INTEGRA ; ayant été modifié d’une manière qui, selon l’avis d’INTEGRA, pourrait entraver sa stabilité ou sa

fiabilité ; ayant été soumis à un usage abusif, négligent ou à un accident ; ou ayant été utilisé de toute autre manière non

conforme aux instructions fournies par INTEGRA. CETTE GARANTIE LIMITÉE EST EXCLUSIVE ET REMPLACE TOUTES LES

AUTRES GARANTIES EXPRESSES OU IMPLICITES, ET TOUTES LES AUTRES OBLIGATIONS OU RESPONSABILITÉS DE LA PART

D’INTEGRA, ET INTEGRA N’ASSUME NI N’AUTORISE AUCUN REPRÉSENTANT NI AUCUNE AUTRE PERSONNE À ASSUMER EN

SON NOM TOUTE AUTRE RESPONSABILITÉ EN LIEN AVEC LES PRODUITS INTEGRA.

INTEGRA EXCLUT TOUTE AUTRE GARANTIE, EXPRESSE OU IMPLICITE, NOTAMMENT TOUTE GARANTIE IMPLICITE DE

QUALITÉ MARCHANDE OU D’ADÉQUATION À UN USAGE OU À UNE APPLICATION PARTICULIÈRE, ET TOUTE GARANTIE

DE QUALITÉ AINSI QUE TOUTE GARANTIE EXPRESSE OU IMPLICITE FAITE AUX PATIENTS. Aucune garantie ne peut être

invoquée au titre d’un acte ou d’une déclaration et la présente garantie standard ne peut recevoir aucune modification, à

moins que celle-ci n’ait été rédigée et signée par un représentant d’INTEGRA. Ces limites sur l’invocation ou la modification

de cette garantie ne peuvent être ni renoncées ni modifiées verbalement ou par une conduite quelconque.

Service après-vente et réparation

Pour le service après-vente et les réparations en dehors des États-Unis, contacter un représentant Integra agréé. Pour le

service après-vente et les réparations aux États-Unis, renvoyer les instruments à :

Integra

4900 Charlemar Drive, Building A, Cincinnati, Ohio 45227 États-Unis

(Toujours inclure le numéro de commande et une description du problème par écrit)

Ou téléphone : 877-444-1114

45

Page 47

FR – FRANÇAIS

0086